Process of making moisture-proof health wooden floor board with self-cleaning function

A wood floor and floor technology, applied in the direction of manufacturing tools, metal processing equipment, wood processing utensils, etc., to achieve good deodorization function, prevent moisture infiltration, and enhance disease resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

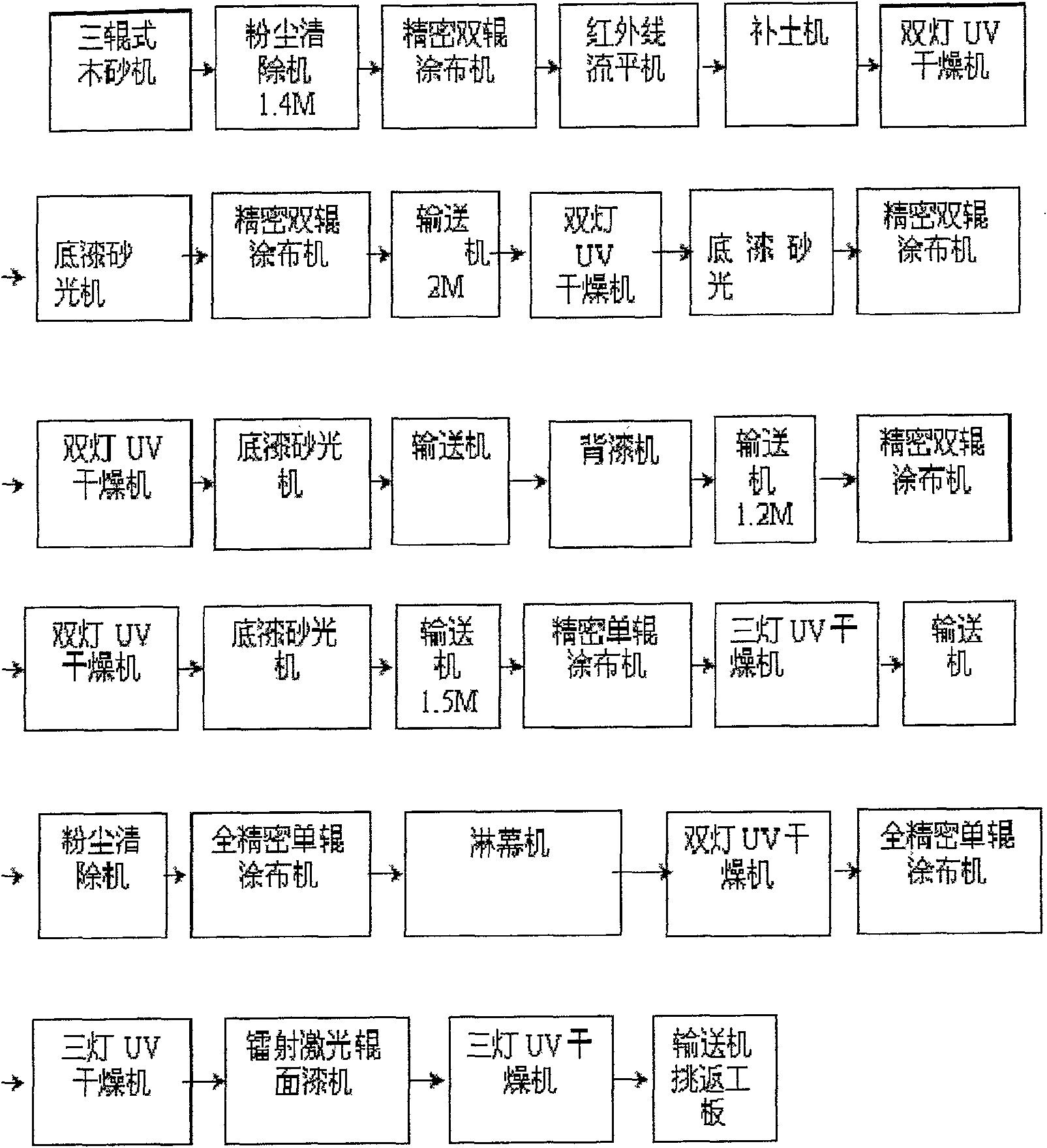

[0016] Embodiments of the present invention: raw materials used in the present invention: nanometer waterproof sealant: commercially available; negative ion photocatalyst: TiO 2 Negative ion photocatalyst, commercially available; antibacterial layer material: TiO 2 Powerful photocatalyst, commercially available. Epoxy paint: commercially available. The technological process that the present invention implements is as follows:

[0017] First, waterproof the wooden floor production process:

[0018] Double-layer protection and 6-sided three-dimensional sealing process are adopted. The first layer is sealed with a nano-sized waterproof sealant made of nano-modified resin materials. After sealing, it is carried out at room temperature for 12 to 30 hours (preferably 24 hours) ) until the nano-waterproofing agent penetrates into the board at 1.3-2.5 mm, usually at 2 mm to form a seamless bond with the board, thereby blocking the contact between the substrate fiber and the outside...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com