Spray covering process of solid pollution sources

A pollution source and solid technology, applied in the field of pollution source control, can solve the problems of polluted soil, groundwater, polluted atmosphere and ecological environment, a large amount of deodorization operation cost, etc., and achieves saving operation cost, excellent environmental friendliness, and good deodorization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

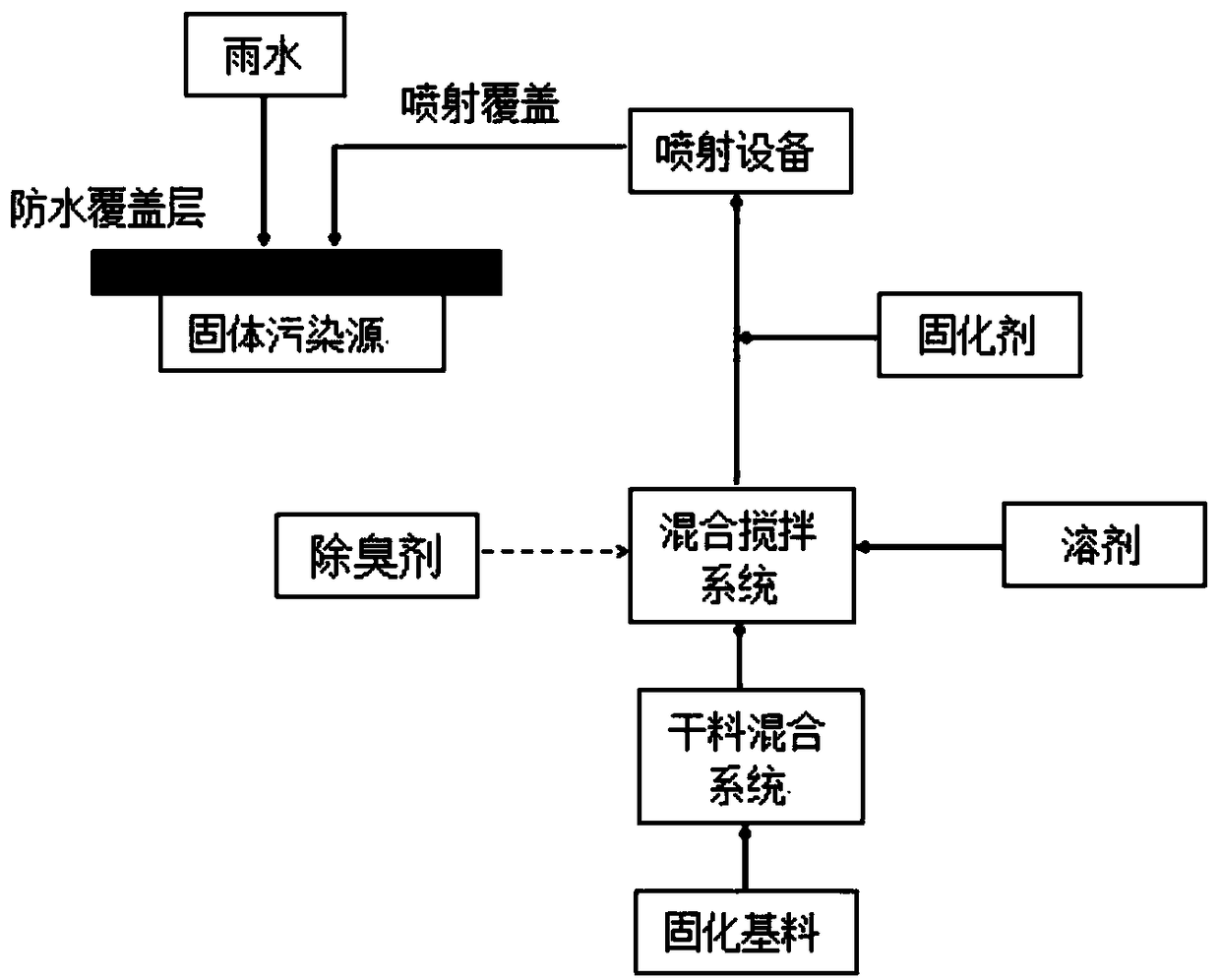

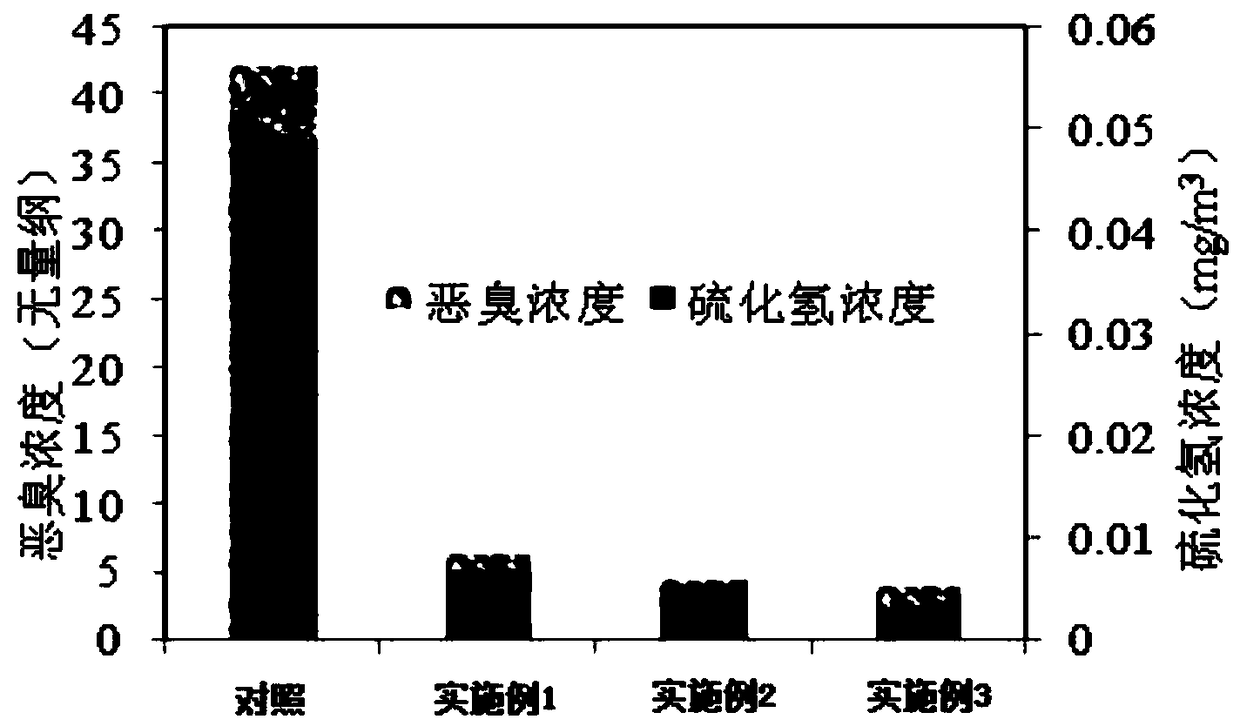

[0042] refer to figure 1 , a spray covering process for solid pollution sources, the solid pollution source is a sludge storage site, the surface moisture content of the sludge storage site is 70% to 80%, and the volume of the test pile is about 1m 3 .

[0043] Specifically include the following steps:

[0044] (1) Put the solidified base material A into the dry material mixing system for mechanical mixing, and mix it for 4 minutes at normal temperature and pressure to form the solidified base material A; the solidified base material A is made of cement, fly ash and diatoms Soil composition; the quality added by curing base material A accounts for 82% of the total mass of curing base material A, curing agent A and deodorant, wherein the quality added by cement, fly ash and diatomite accounts for respectively curing base material A, curing agent A and deodorant. 55%, 15%, 12% of the total mass of curing agent A and deodorant;

[0045] (2) Mix and stir the curing base compoun...

Embodiment 2

[0054] A spray covering process for solid pollution sources, the solid pollution source is a sludge storage site, the surface moisture content of the sludge storage site is 70% to 80%, and the volume of the test pile is about 1m 3 .

[0055] Specifically include the following steps:

[0056] (1) Put the solidified base material A into the dry material mixing system for mechanical mixing, and mix for 4 minutes at normal temperature and pressure to form the solidified base material A; the solidified base material A is composed of cement, fly ash and bentonite The added quality of curing base material A accounts for 85% of the total mass of curing base material A, curing agent A and deodorant, wherein the quality added by cement, fly ash and bentonite accounts for respectively curing base material A, curing agent A and deodorant 60%, 10%, 15% of the total mass of deodorant;

[0057] (2) Mix and stir the curing base compound A, curing agent A and solvent evenly, and the solvent ...

Embodiment 3

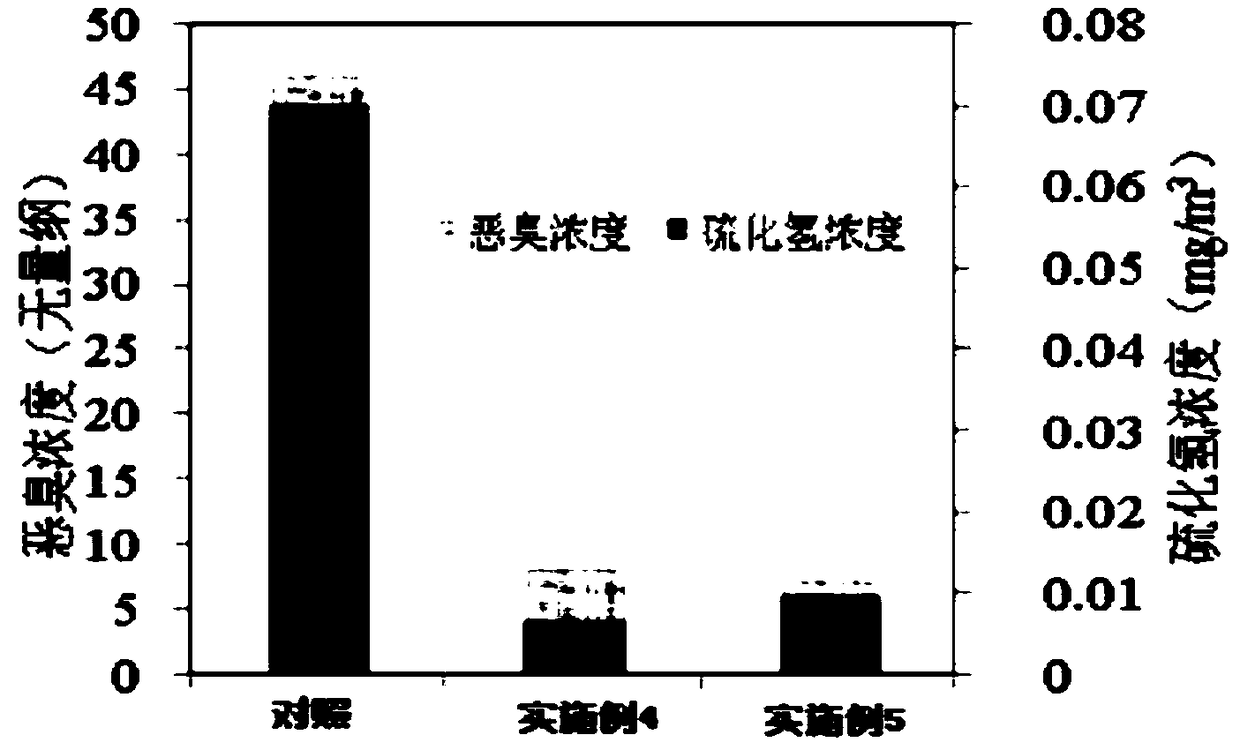

[0066] A spray covering process for solid pollution sources, the solid pollution sources are sludge piles in sludge storage sites, the moisture content of sludge is 70% to 80%, and the volume of each test pile is about 1m 3 .

[0067] Specifically include the following steps:

[0068] (1) Put the solidified base material A into the dry material mixing system for mechanical mixing, and mix for 4 minutes at normal temperature and pressure to form the solidified base material A; the solidified base material A is composed of cement, fly ash and bentonite The added quality of curing base material A accounts for 85% of the total mass of curing base material A, curing agent A and deodorant, wherein the quality added by cement, fly ash and bentonite accounts for respectively curing base material A, curing agent A and deodorant 65%, 5%, 15% of the total mass of deodorant;

[0069] (2) Mix and stir the curing base compound A, curing agent A and solvent evenly, and the solvent is clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com