Antibacterial sock

A technology for socks and antibacterial masterbatch, applied in the field of textile products, can solve the problems of unsuitability for ordinary people, poor wear resistance, high cost of socks, and achieve excellent effectiveness and long-term effect, excellent wear resistance, and health care. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

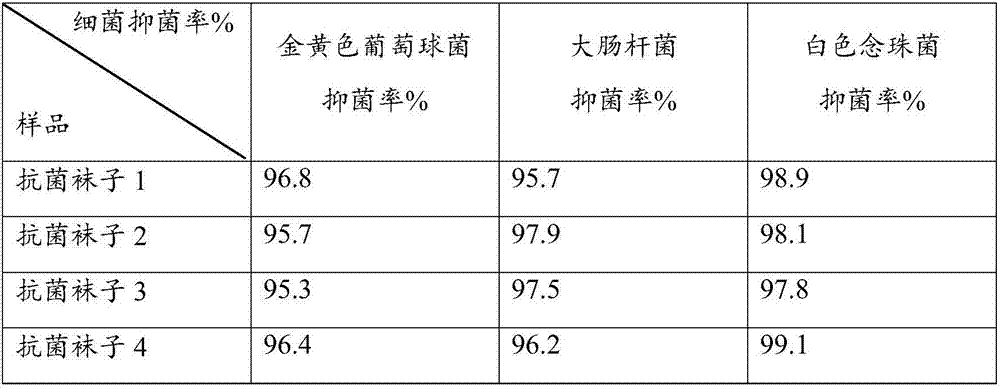

Examples

Embodiment 1

[0022] The concentration is 5% nano-silver solution, joins in diatomite, the ratio of the mass of solute in diatomite and nano-silver is 9:1 (mass ratio), dry after slowly absorbing, the primary product that obtains is carried out Granulate, control the granulation temperature to 62°C, and make antibacterial fiber masterbatch with a particle size of 1-20 μm. The obtained antibacterial masterbatch is blended with cotton fiber, polyester fiber and seaweed fiber, wherein the mass ratio of antibacterial masterbatch, cotton fiber and polyester fiber is 1:2:5, and seaweed fiber accounts for 2% of the total weight to obtain antibacterial socks 1.

Embodiment 2

[0024] The concentration is 8% nano-silver solution, joins in diatomite, the ratio of the mass of solute in diatomite and nano-silver is 19:1 (mass ratio), dry after slowly absorbing, the primary product that obtains is carried out Granulate, control the granulation temperature to 84°C, and make antibacterial fiber masterbatch with a particle size of 1-20 μm. The obtained antibacterial masterbatch is blended with cotton fiber, polyester fiber and seaweed fiber, wherein the mass ratio of antibacterial masterbatch, cotton fiber and polyester fiber is 1:5:8, and seaweed fiber accounts for 5% of the total weight to obtain antibacterial socks 2.

Embodiment 3

[0026] The concentration is 4% nano-silver solution, joins in diatomite, the ratio of the mass of solute in diatomite and nano-silver is 15:1 (mass ratio), dry after slowly absorbing, the primary product that obtains is carried out Granulation, control the granulation temperature to 73°C to make antibacterial fiber masterbatch with a particle size of 1-20 μm. The obtained antibacterial masterbatch is blended with cotton fiber, polyester fiber and seaweed fiber, wherein the mass ratio of antibacterial masterbatch, cotton fiber and polyester fiber is 1:3:6, and seaweed fiber accounts for 3.5% of the total weight to obtain antibacterial socks 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com