Anti-bacterial cool-feel yarn and fabric with the same

A cool-feeling fabric and cool-feeling technology, applied in the field of textile fabrics, can solve problems such as poor moisture absorption and perspiration, skin allergies, and damage to human health, and achieve the effect of satisfying wearing performance, enhancing coolness, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

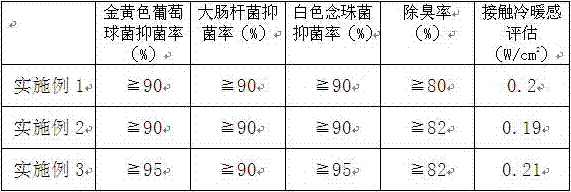

Embodiment 1

[0019] An antibacterial cool-feeling yarn is made of fibers through the steps of blowing, carding, drawing, roving and spun yarn. The antibacterial cool-feeling yarn is made of blended icy fiber, aloe fiber, cool-feeling fiber and Aviary fiber , icy fiber accounts for 45% of the total mass of antibacterial cool-feeling yarn, aloe fiber accounts for 25% of the total mass of antibacterial cool-feeling yarn, and cool-feeling fiber accounts for 5% of the total mass of antibacterial cool-feeling yarn. Fiber accounts for 25% of the total mass of antibacterial cool yarn.

[0020] The cooling fiber is selected from one of polyester cooling fibers and cellulose cooling fibers.

[0021] An antibacterial cool-feeling fabric, antibacterial cool-feeling yarns undergo warping, sizing, drawing-in and weaving steps to complete the weaving of the antibacterial cool-feeling fabric; the specific steps are as follows:

[0022] (1) Warping: Warp the antibacterial cool yarn in batches, wind it int...

Embodiment 2

[0027] An antibacterial cool-feeling yarn is made of fibers through the steps of blowing, carding, drawing, roving and spun yarn. The antibacterial cool-feeling yarn is made of blended icy fiber, aloe fiber, cool-feeling fiber and Aviary fiber , icy fiber accounts for 60% of the total mass of antibacterial cool-feeling yarn, aloe fiber accounts for 20% of the total mass of antibacterial cool-feeling yarn, and cool-feeling fiber accounts for 8% of the total mass of antibacterial cool-feeling yarn. Fiber accounts for 12% of the total mass of antibacterial cool yarn.

[0028] The cooling fiber is selected from one of polyester cooling fibers and cellulose cooling fibers.

[0029] An antibacterial cool-feeling fabric, antibacterial cool-feeling yarns undergo warping, sizing, drawing-in and weaving steps to complete the weaving of the antibacterial cool-feeling fabric; the specific steps are as follows:

[0030] (1) Warping: Warp the antibacterial cool yarn in batches, wind it int...

Embodiment 3

[0035] An antibacterial cool-feeling yarn is made of fibers through the steps of blowing, carding, drawing, roving and spun yarn. The antibacterial cool-feeling yarn is made of blended icy fiber, aloe fiber, cool-feeling fiber and Aviary fiber , icy fiber accounts for 55% of the total mass of antibacterial cool-feeling yarn, aloe fiber accounts for 22% of the total mass of antibacterial cool-feeling yarn, cool-feeling fiber accounts for 8% of the total mass of antibacterial cool-feeling yarn, Ivy Fiber accounts for 15% of the total mass of antibacterial cool yarn.

[0036] The cooling fiber is selected from one of polyester cooling fibers and cellulose cooling fibers.

[0037] An antibacterial cool-feeling fabric, antibacterial cool-feeling yarns undergo warping, sizing, drawing-in and weaving steps to complete the weaving of the antibacterial cool-feeling fabric; the specific steps are as follows:

[0038] (1) Warping: Warp the antibacterial cool yarn in batches, wind it int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com