Preparation method of super-strong breathable moisture-absorbing cool-feeling silk fabric

A breathable, moisture-absorbing, cool-feeling, fabric technology, applied in the field of fabrics, can solve problems such as poor coolness, unfavorable breathability and perspiration, and poor sweat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

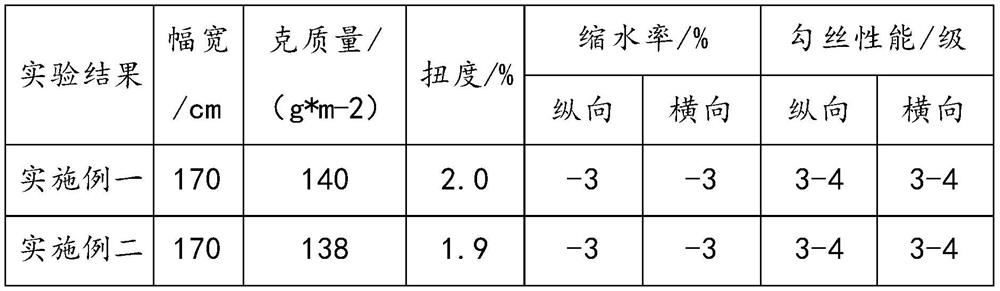

Embodiment 1

[0028] This implementation provides a super-breathable, moisture-absorbing and cool-feeling silk fabric, which is made of ultra-fine breathable polyester filaments, cool-feeling silk, and polyester imitation cotton yarns. The yarn weight ratio of polyester imitation cotton yarn is 34.6%: 15.4%: 50%. The special-shaped cross-section cool silk fiber, ultra-fine breathable polyester filament fiber and polyester imitation cotton yarn fiber are woven by double-sided large circular machine. Distance: 26G: size 28; blank weight: 150g / m2.

[0029] Specifically adopt the following method to prepare:

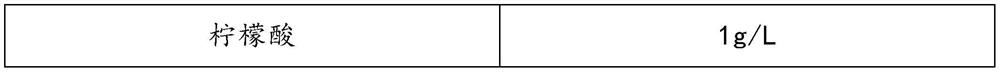

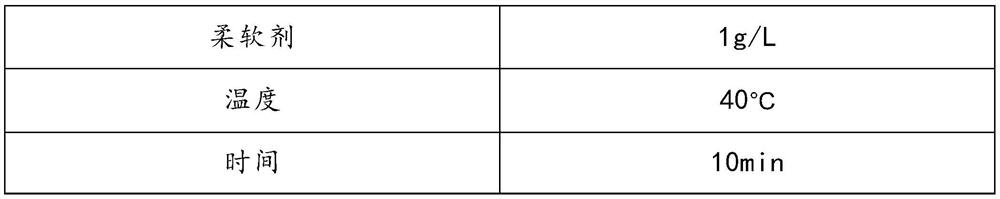

[0030] Step 1: Pretreatment: add 1g / L Na2CO3, 0.8g / L SEM-35N scouring emulsifier and 1g / L C-180 oil-removing yarn agent at room temperature, and heat up at a heating rate of 4°C / min , when it reaches 100°C, keep it warm for 20 minutes, and then carry out the cooling water drainage treatment and pickling process. The formulations and conditions adopted in the pickling process are shown i...

Embodiment 2

[0041] This implementation provides a super-breathable, moisture-absorbing and cool-feeling silk fabric, which is made of ultra-fine breathable polyester filaments, cool-feeling silk, and polyester imitation cotton yarns. The yarn weight ratio of polyester imitation cotton yarn is 34.6%: 15.4%: 50%. The special-shaped cross-section cool silk fiber, ultra-fine breathable polyester filament fiber and polyester imitation cotton yarn fiber are woven by double-sided large circular machine. Distance: 26G: size 28; blank weight: 150g / m2.

[0042] Specifically adopt the following method to prepare:

[0043] Step 1: Pretreatment: add 1g / L Na2CO3, 0.8g / L SEM-35N scouring emulsifier and 1g / L C-180 oil-removing yarn agent at room temperature, and heat up at a heating rate of 4°C / min , when it reaches 100°C, keep it warm for 20 minutes, and then carry out the cooling water drainage treatment and pickling process. The formulations and conditions adopted in the pickling process are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com