Patents

Literature

799 results about "Diglyceride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

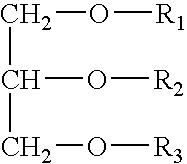

A diglyceride, or diacylglycerol (DAG), is a glyceride consisting of two fatty acid chains covalently bonded to a glycerol molecule through ester linkages. Two possible forms exist, 1,2-diacylglycerols and 1,3-diacylglycerols. DAGs can act as surfactants and are commonly used as emulsifiers in processed foods. DAG-enriched oil (particularly 1,3-DAG) has been investigated extensively as a fat substitute due to its ability to suppress the accumulation of body fat; with total annual sales of approximately USD 200 million in Japan since its introduction in the late 1990s till 2009.

Glyceride compositions and methods of making and using same

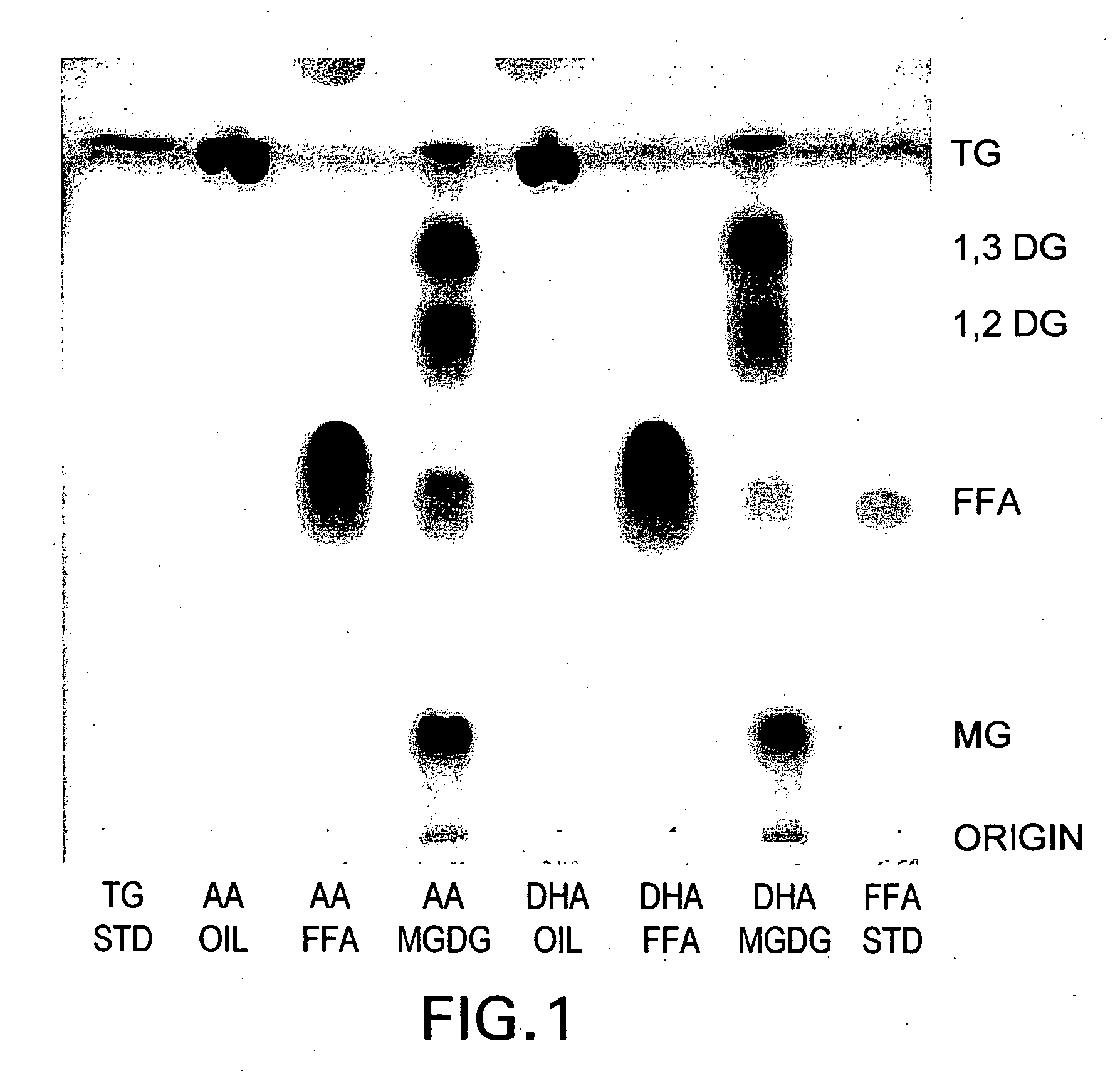

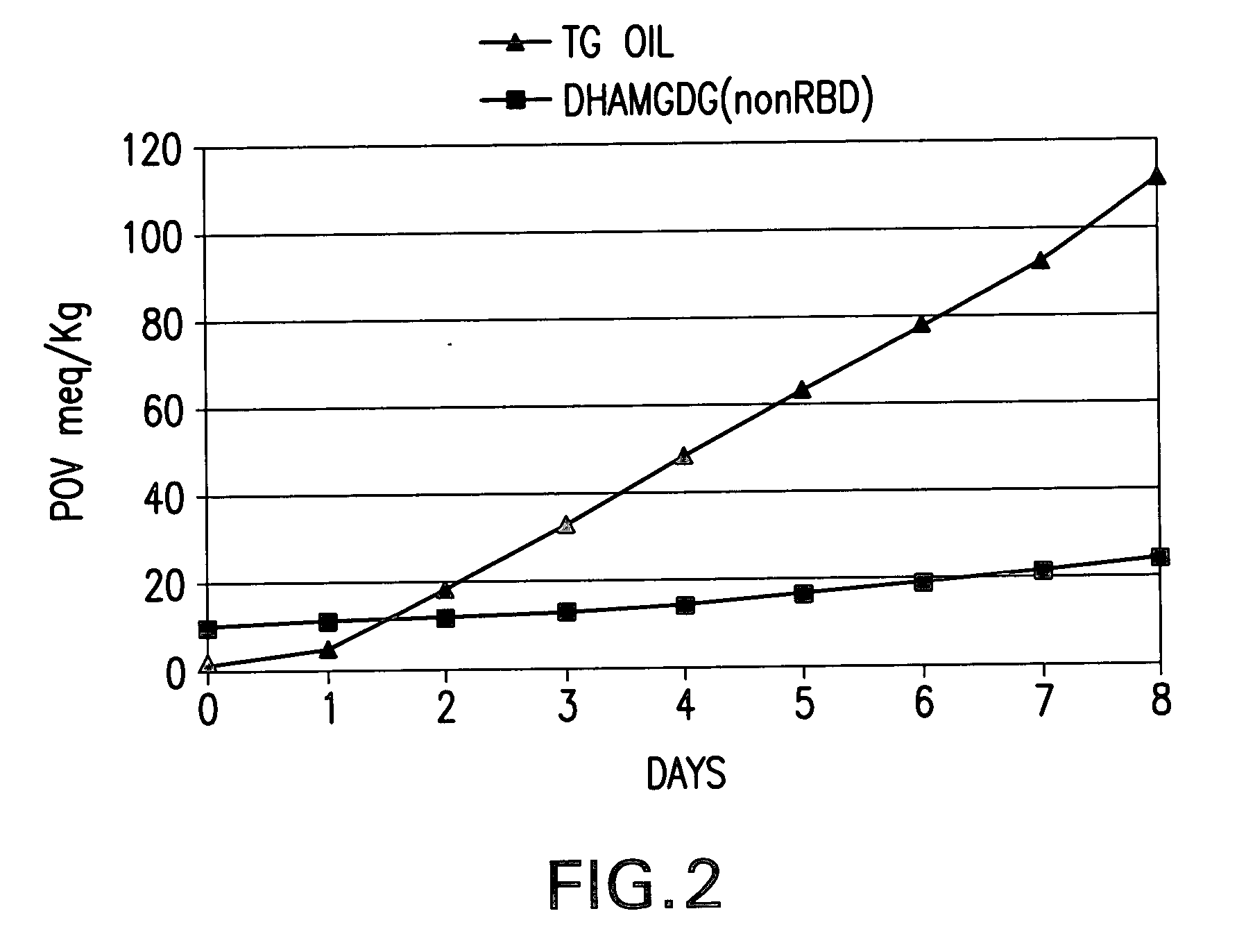

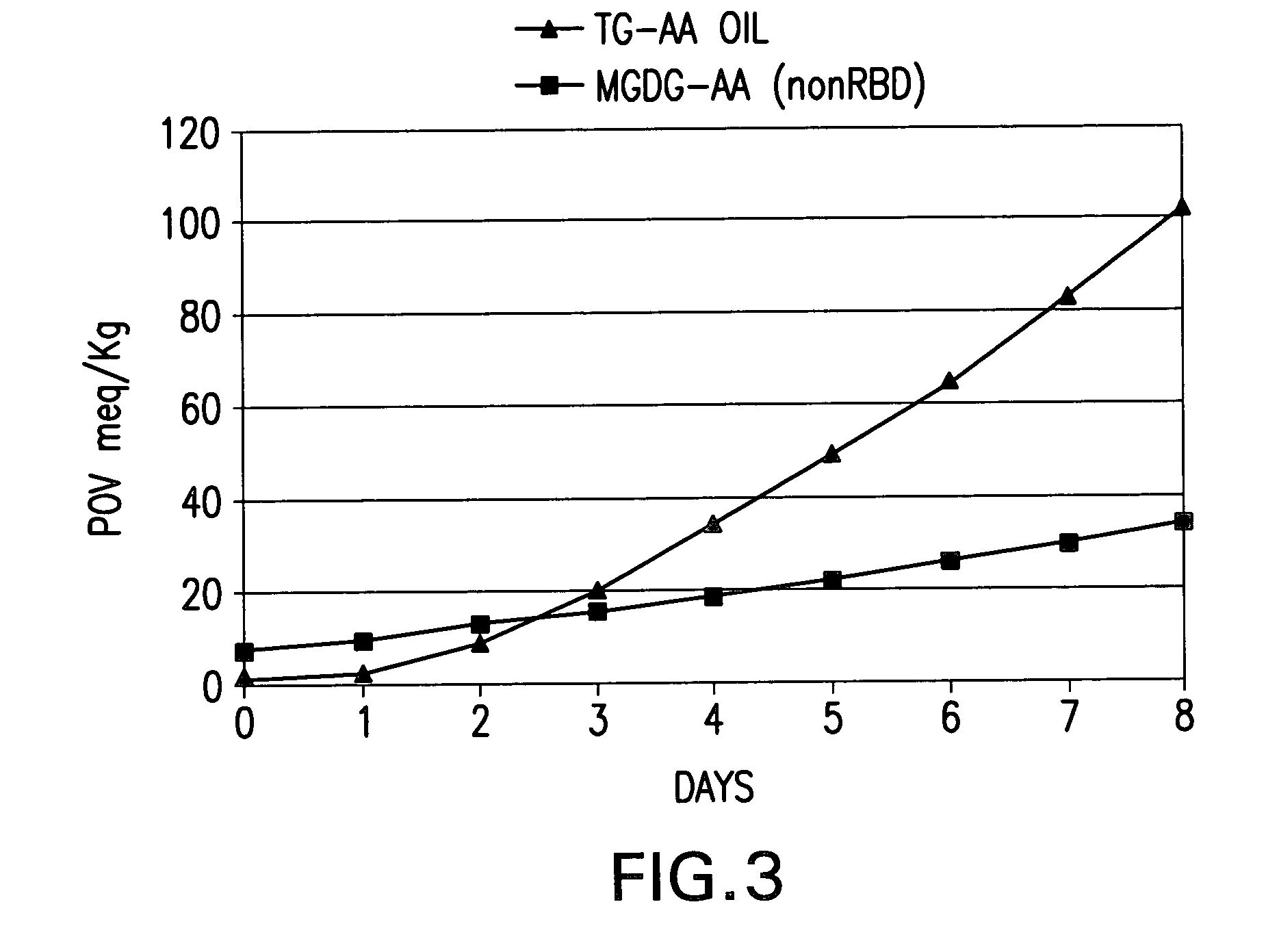

InactiveUS20040209953A1Fast absorptionImprove stabilityOrganic active ingredientsBiocideMonoglycerideDiglyceride

Disclosed are glyceride compositions, methods of making the glyceride compositions, and nutritional formulations containing the glyceride compositions. The glyceride compositions contain predominantly monoglycerides and diglycerides carrying one or more long chain polyunsaturated fatty acids. Also disclosed are methods of using the glyceride compositions and nutritional formulations.

Owner:ABBOTT LAB INC

Ophthalmic devices for delivery of hydrophobic comfort agents

ActiveUS20100140114A1Easy to understandPackage sterilisationPharmaceutical delivery mechanismLipid formationMonoglyceride

The invention relates to a soft hydrogel contact lens, especially a silicone hydrogel contact lens, which has a capability of delivering a hydrophobic comfort agent into the eye of a wearer. The hydrophobic comfort agent includes without limitation a monoglyceride, a diglyceride, a triglyceride, a glycolipid, a glyceroglycolipid, a sphingolipid, a sphingo-glycolipid, a phospholipid, a fatty acid, a fatty alcohol, a hydrocarbon having a C12-C28 chain in length, a mineral oil, a silicone oil, or a mixture thereof. It can be released from the soft hydrogel contact lens into the eye of a wearer when being worn so as to strengthen and stabilize the tear film lipid layer and alleviate the dryness of the eye.

Owner:ALCON INC

Oil/fat powder

InactiveUS20050123667A1Good dispersibilityGood storage stabilitySugar food ingredientsDough treatmentMonoglycerideGlycerol

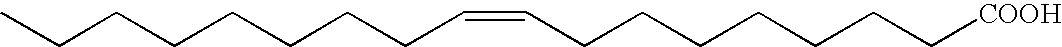

Provided is an oil / fat powder comprising the following Components (A), (B) and (C): (A) 15 to 79.9 wt. % of a glyceride mixture containing 5 to 84.9 wt. % of triglycerides, 0.1 to 5 wt. % of monoglycerides and 15 to 94.9 wt. % of diglycerides, and having, as at least 50 wt. % of all the constitutive fatty acids, unsaturated fatty acids; (B) 20 to 84.9 wt. % of one or at least two powder forming bases selected from carbohydrates, proteins and peptides; (C) 0.1 to 5 wt. % of water. The diglyceride-containing oil / fat powder according to the present invention exhibits good taste, and excellent dispersibility in water and storage stability. Moreover, owing to good handling use and workability when it is added to food, it can be used readily for various forms of foods. Foods containing this oil / fat powder taste good and have good storage stability.

Owner:KAO CORP

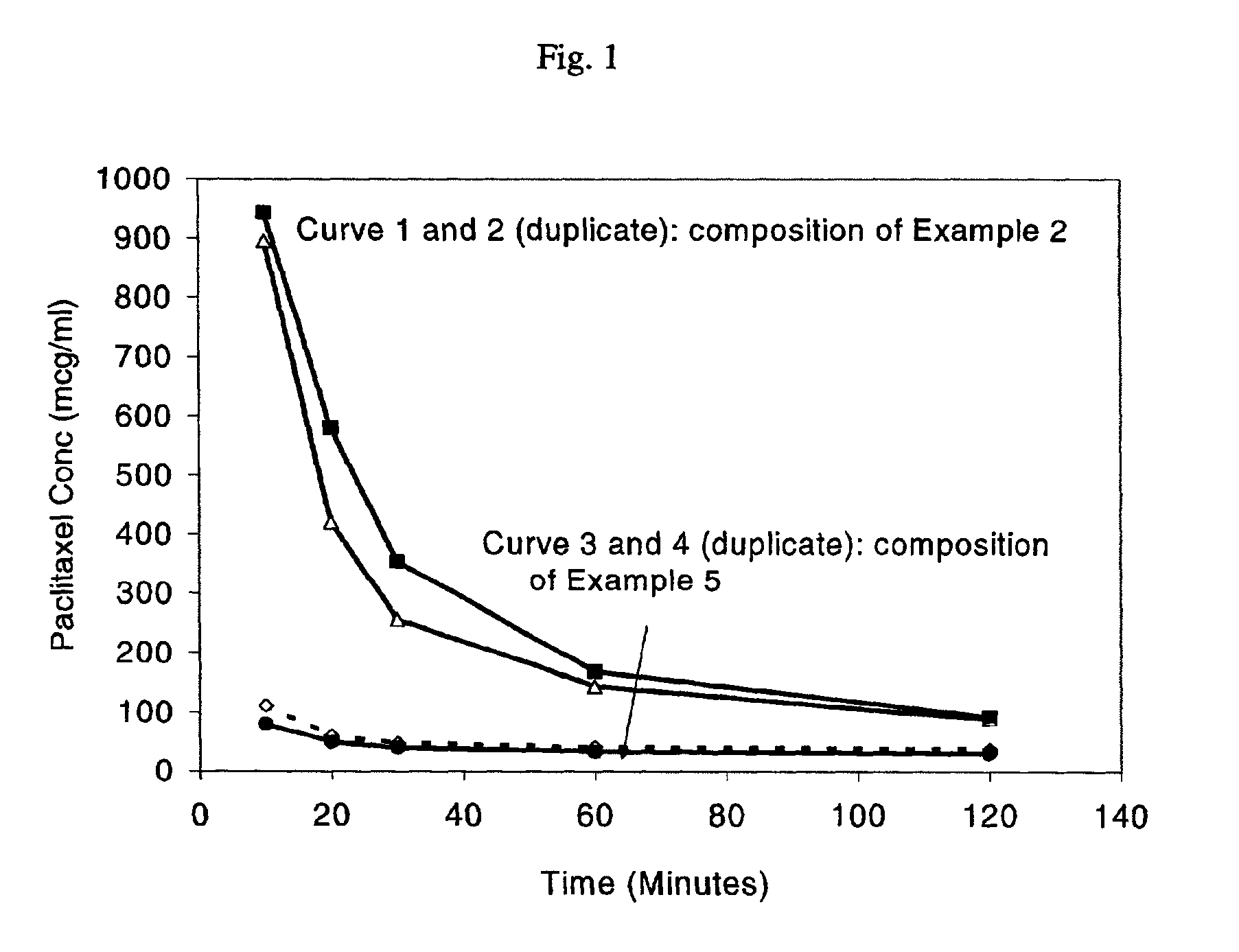

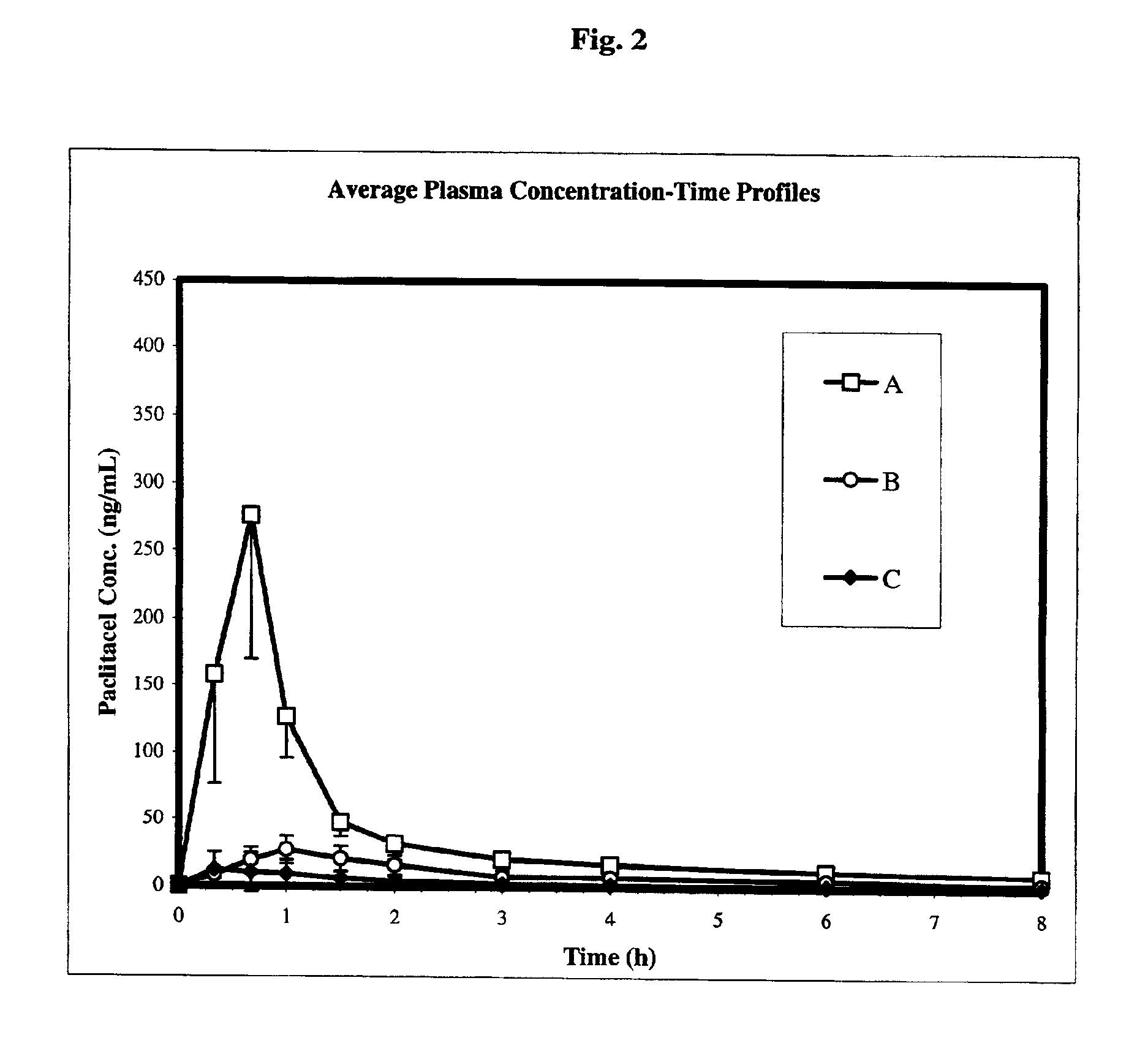

Chemotherapeutic microemulsion compositions of paclitaxel with improved oral bioavailability

InactiveUS7115565B2Rapid and efficient absorptionImprove bioavailabilityBiocideNervous disorderMonoglycerideSolvent

Pharmaceutical compositions suitable for oral administration comprising paclitaxel, a solvent, a surfactant, a substituted cellulosic polymer, and optionally but preferably a P-glycoprotein inhibitor. The composition may further comprise a diglyceride or mixture of diglyceride and monoglyceride. The composition generates a supersaturated paclitaxel microemulsion upon contact with water resulting in improved oral bioavailability of paclitaxel.

Owner:PHARMACIA & UPJOHN CO

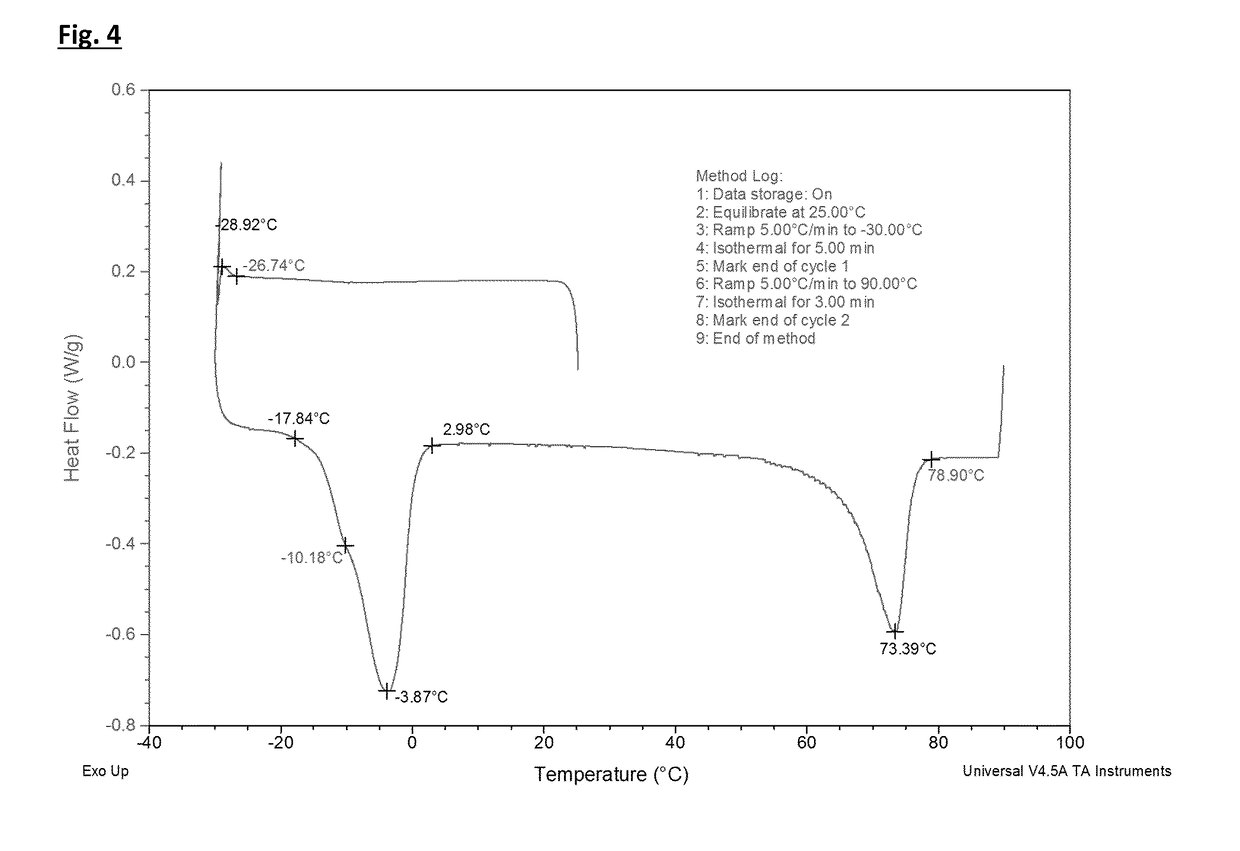

Zero-trans fatty acid non-dairy creamer and preparation method thereof

The invention relates to a zero-trans fatty acid non-dairy creamer and a preparation method thereof, and belongs to the technical field of non-dairy creamers. The zero-trans fatty acid non-dairy creamer consists of the following components in percentage by weight: 22 to 32 percent of vegetable oil and fat, 2.2 to 3.5 percent of sodium caseinate, 0.8 to 1.5 percent of mono-and diglycerides, 0.5 to 1 percent of stearoyl sodium lactate, 1.2 to 1.5 percent of dipotassium phosphate, 0.25 to 0.5 percent of silicon dioxide and the balance of glucose syrup. The preparation method comprises the following steps of: heating, dissolving, mixing, shearing at high temperature, homogenizing, spray-drying and packaging to obtain the zero-trans fatty acid non-dairy creamer. The preparation process is simple and easy to operate; and the obtained non-dairy creamer is high in nutritional performance, good in mouthfeel, fragrant and smooth, does not contain trans fatty acid, meets the consumption demand of health and nutrition at present, and is particularly suitable to be drunk by old people, overweight people, patients who suffer from diabetes and consumers. The zero-trans fatty acid non-dairy creamer can be used as coffee creamers to be mixed with coffee, fruit juice, tea and the like respectively for drinking and also can be used as instant drinks independently for drinking.

Owner:杭州博多工贸有限公司

Process for the production of monoglyceride based on the glycerolysis of methyl ester

InactiveUS6127561AAvoid pollutionFatty acid chemical modificationPreparation by ester-hydroxy reactionMonoglycerideDistillation

The invention discloses a process for the production of monoglycerides by glycerolysis of methyl ester derived from animal or vegetable fat and oils which includes mixing a surplus of 0.1 to 3 moles of glycerols in relation to methyl ester, subjecting the reaction mixture to a reaction temperature between 130 to 160 at a vacuum of 200 to 400 mbar, adding of alkaline catalysts, stopping the reaction by fast cooling of the reaction mixture and the destruction of the alkaline catalyst when the quantity of glycerides has reached a concentration of mono and diglyceride of 40 to 60%, leaving the catalyst in the reaction mixture to catalyse the reaction downstream in a reactor, separating the surplus methyl ester and glycerol by distillation and stopping the reaction by fast cooling of the reaction mixture with reactor and the destruction of the alkaline catalyst when the quantity of glycerides has reached a concentration of 40 to 60% and the ratio of concentrations of mono and diglyceride lies between 3 to 10.

Owner:GLOBAL PALM PROD

Method

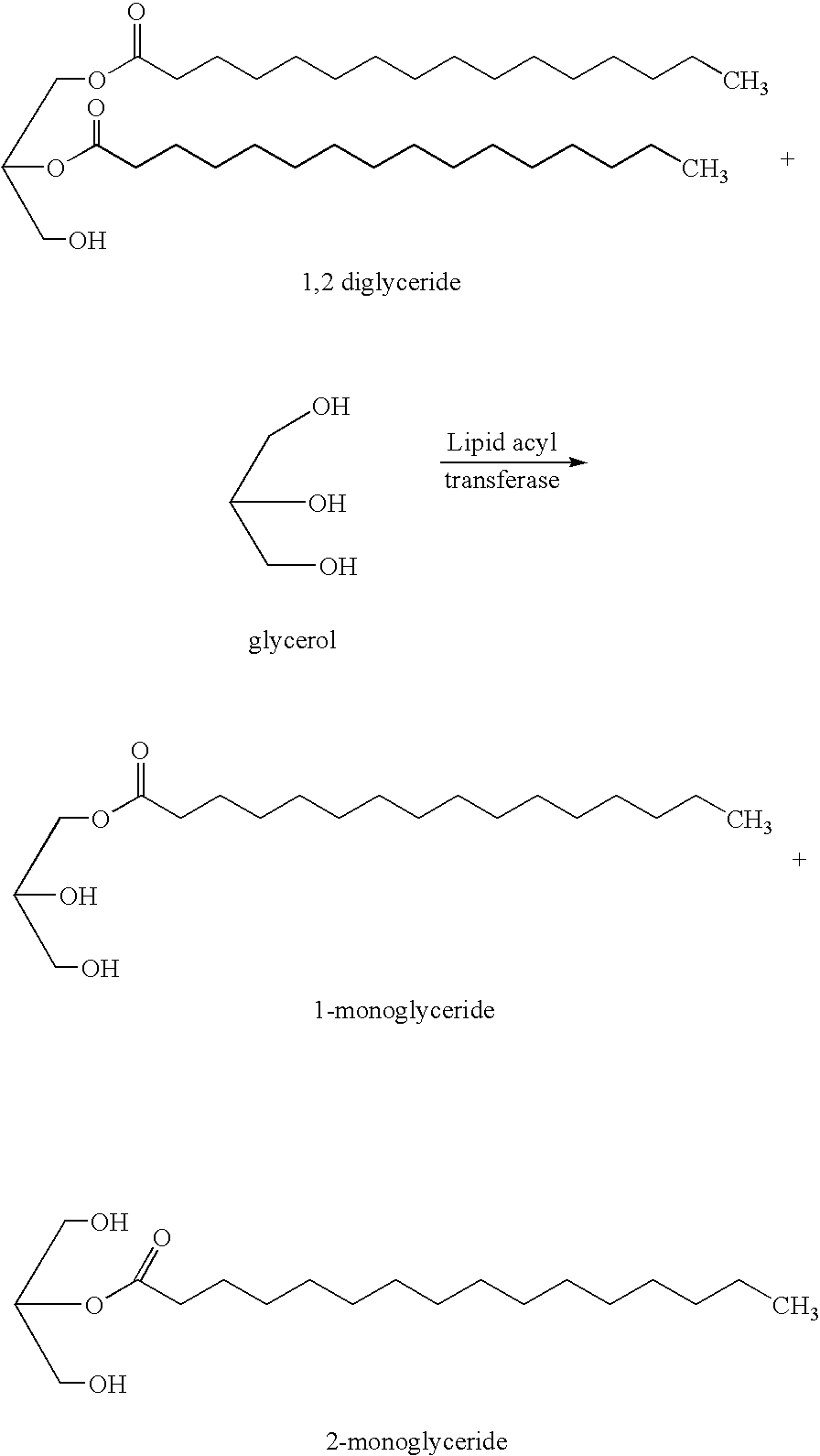

InactiveUS20080063783A1Accumulation is reduced and eliminatedIncreased amount of free fatty acidMilk preparationDough treatmentMonoglycerideGlycerol

A method for the in situ production of an emulsifier in a foodstuff, wherein a lipid acyltransferase is added to the foodstuff. Preferably the emulsifier is produced without an increase or without a substantial increase in the free fatty acid content of the foodstuff. Preferably, the lipid acyltransferase is one which is capable of transferring an acyl group from a lipid to one or more of the following acyl acceptors: a sterol, a stanol, a carbohydrate, a protein or a sub-unit thereof, glycerol. Preferably, in addition to an emulsifier one or more of a stanol ester or a stanol ester or a protein ester or a carbohydrate ester or a diglyceride or a monoglyceride may be produced. One or more of these may function as an additional emulsifier.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Oil or fat composition

ActiveUS20050129830A1Edible oils/fats with fatty acid estersAnimal feeding stuffMonoglycerideEicosapentaenoic acid

The present invention relates to an oil or fat composition containing the following components (A) and (B): (A) from 80 to 99.9 wt. % of a monoglyceride containing 20 to 75 wt. % of docosahexaenoic acid (DHA) and 0.1 to 25 wt. % of icosapentaenoic acid (IPA), as the constituent fatty acids thereof, wherein the weight ratio of DHA / IPA being 2 or more; and (B) from 0.1 to 20 wt. % of a diglyceride.

Owner:KAO CORP

Process for producing paraffinic hydrocarbons

ActiveUS20100076236A1Carry-outIncrease temperatureFatty acid chemical modificationBiofuelsAlkaneMonoglyceride

Process for producing paraffinic hydrocarbons, the process comprising the following steps: (a) contacting hydrogen and a feedstock comprising triglycerides, diglycerides, monoglycerides and / or fatty acids with a hydrogenation catalyst under hydro-deoxygenation conditions; and (b) contacting the whole effluent of step (a) with a hydroprocessing catalyst comprising sulphided Ni and sulphided W or Mo as hydrogenation components on a carrier comprising amorphous silica-alumina and / or a zeolitic compound under hydro-isomerisation conditions.

Owner:SHELL USA INC

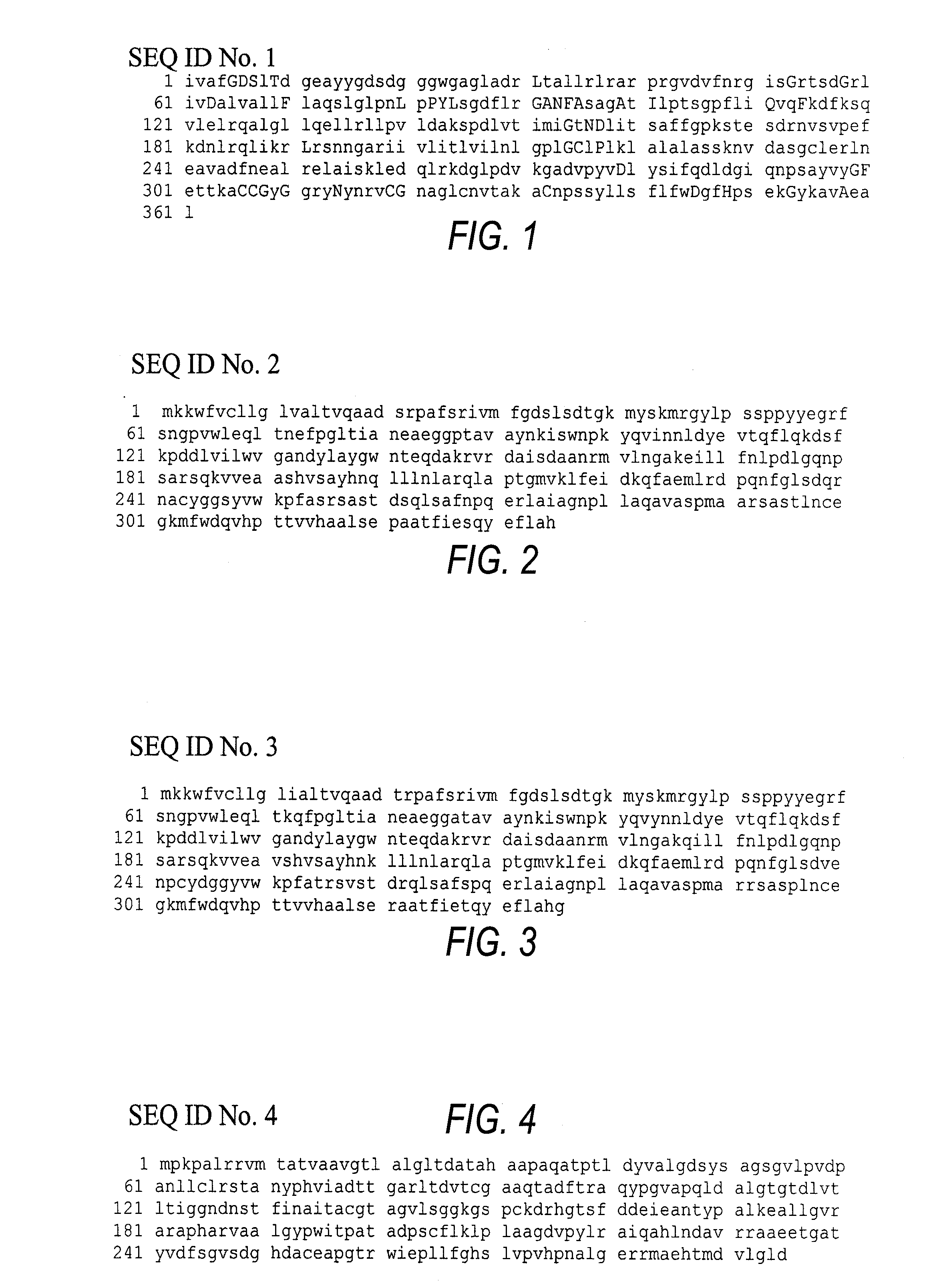

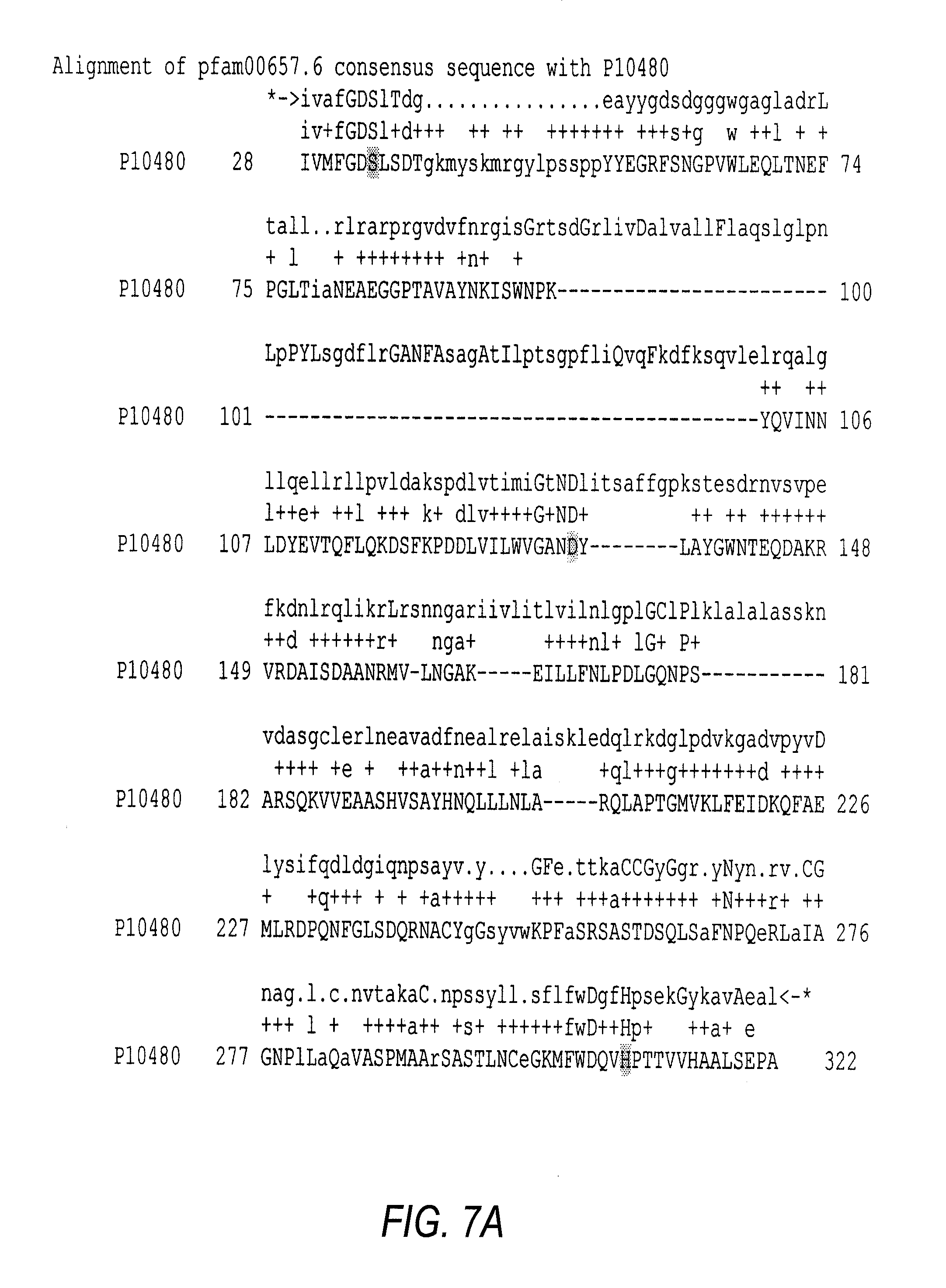

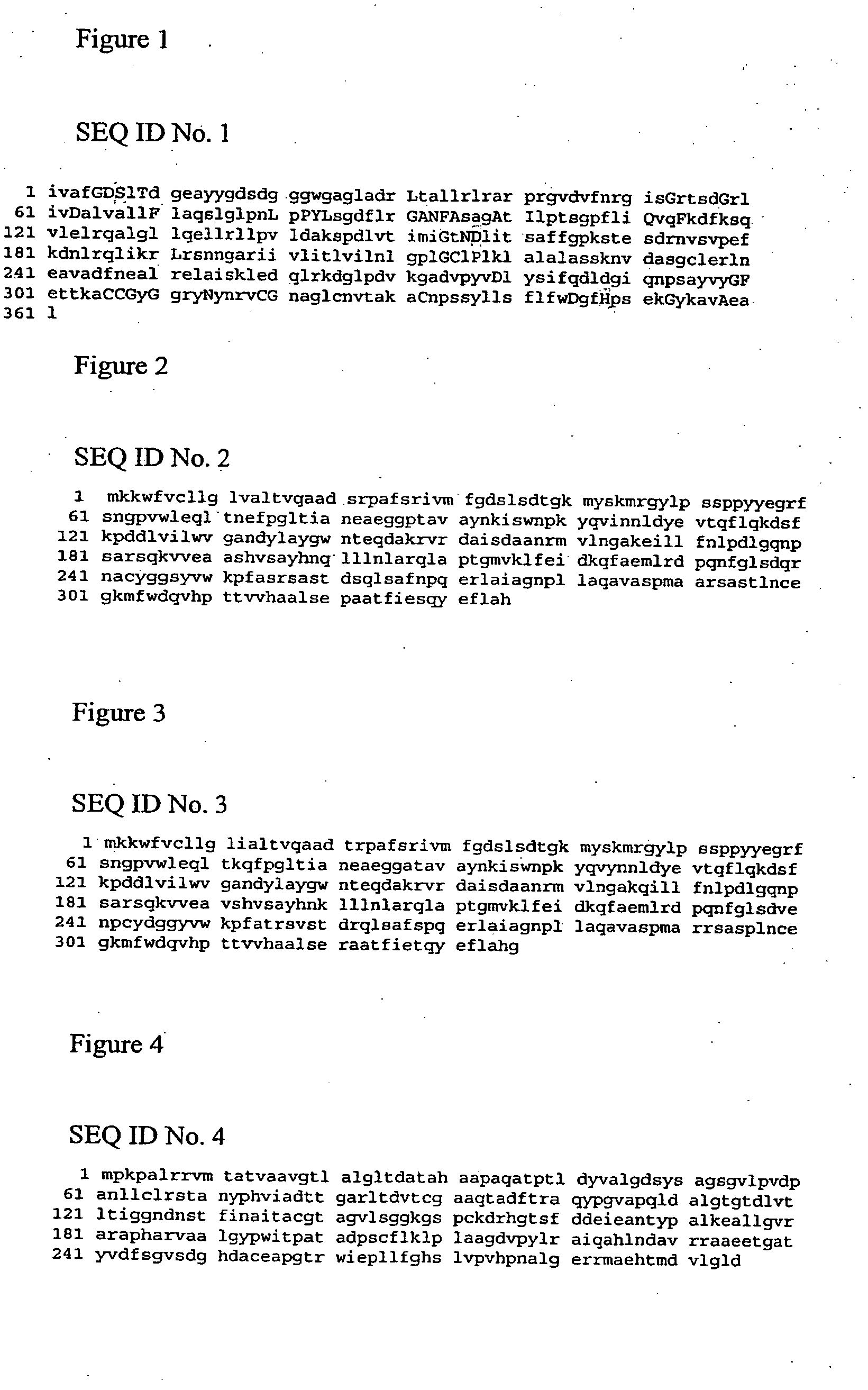

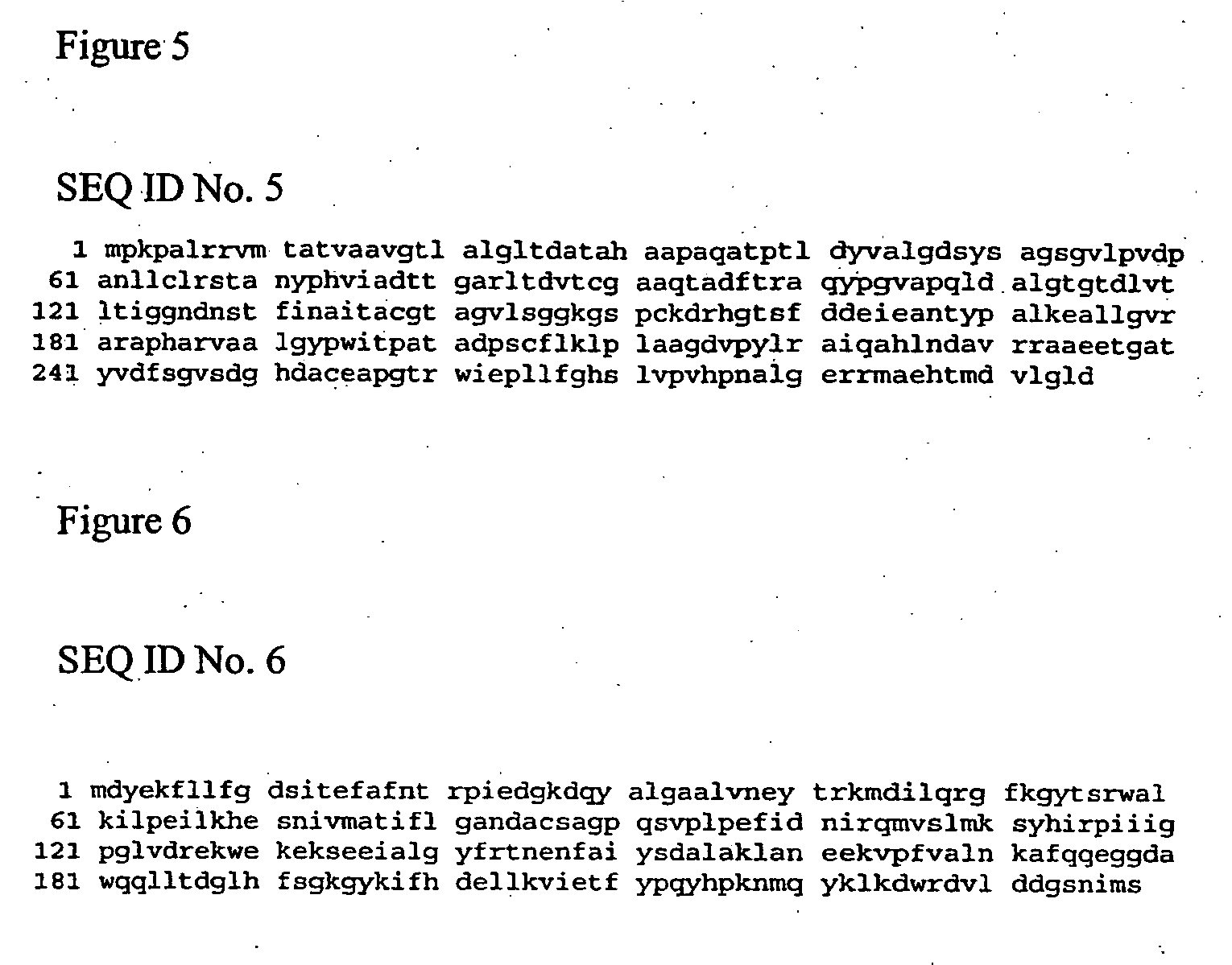

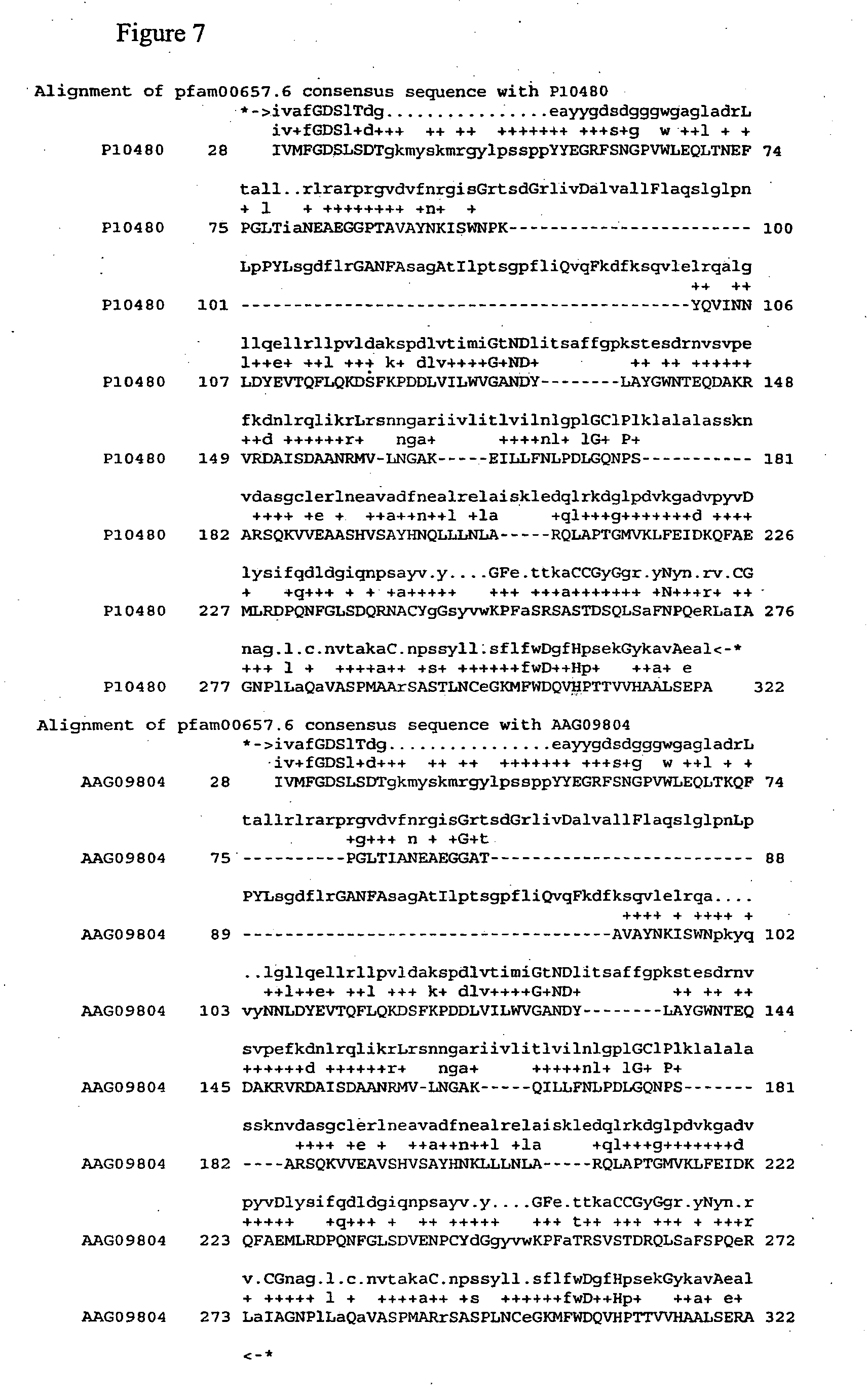

Method

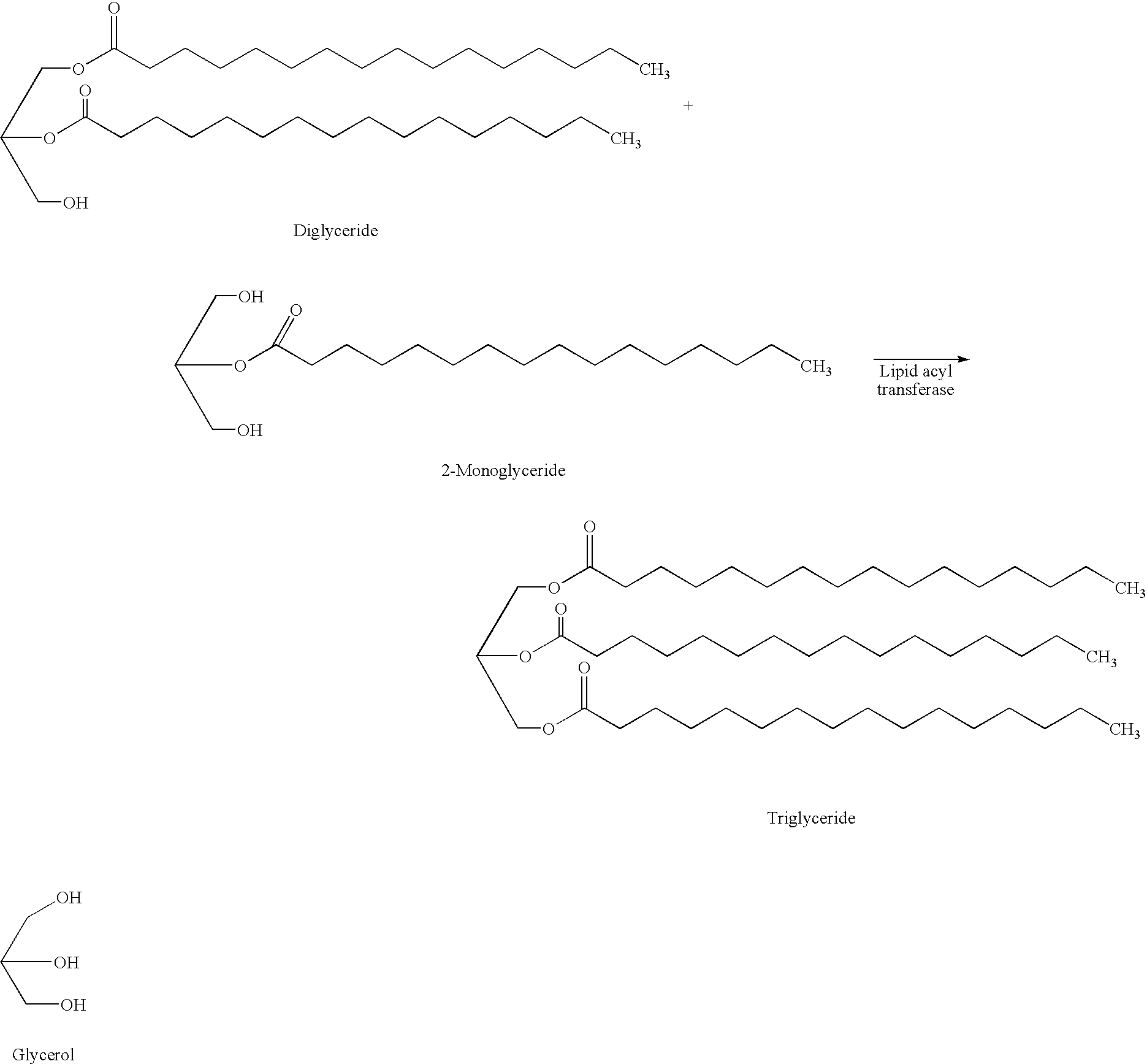

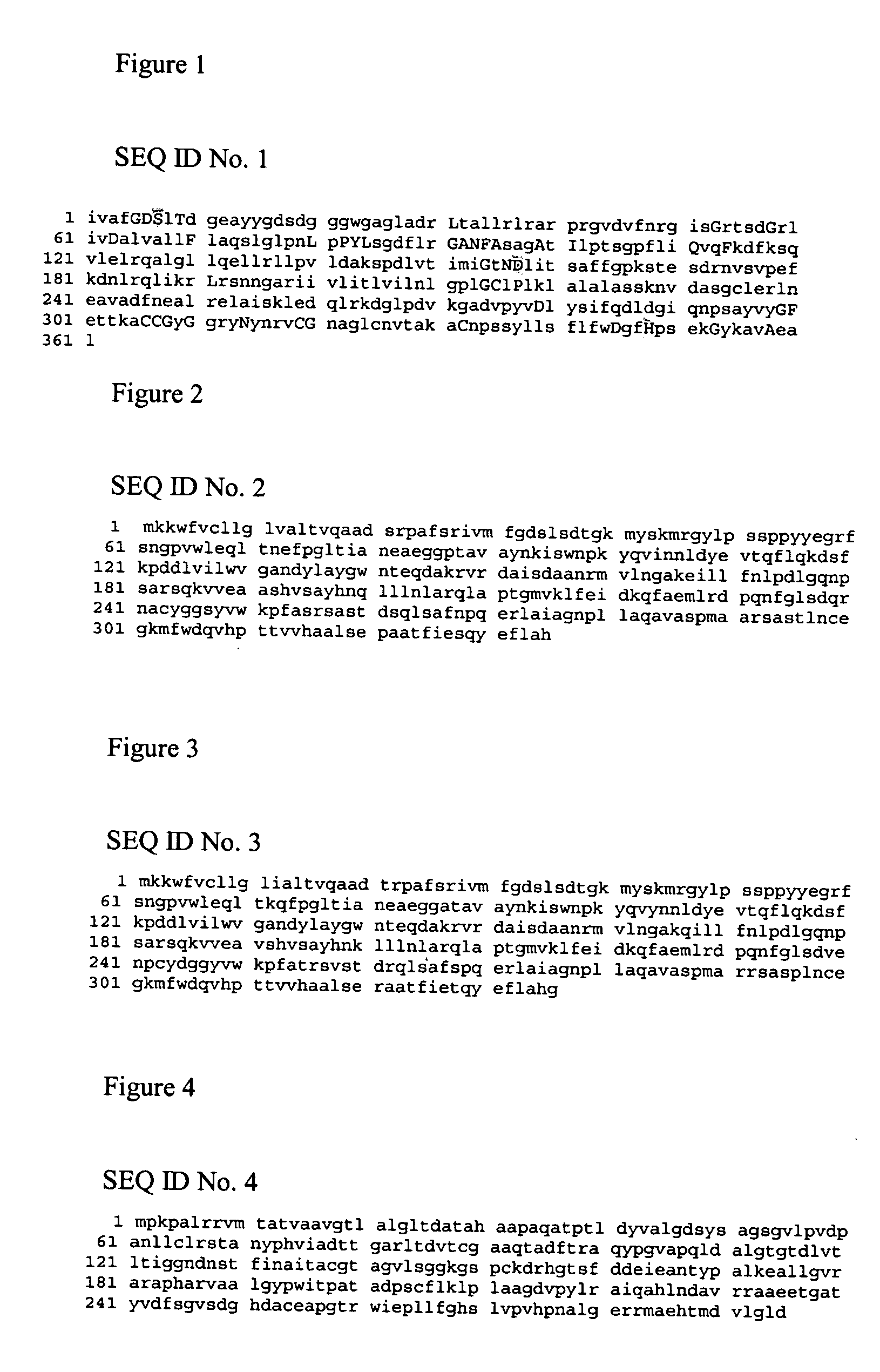

The present invention relates to a method of reducing and / or removing diglyceride from an edible oil, comprising a) admixing an edible oil with an acyl acceptor substrate and a diglyceride:glycerol acyltransferase, wherein the diglyceride:glycerol acyltransferase is characterized as an enzyme which in an edible oil is capable of transferring an acyl group from a diglyceride to glycerol. Preferably, the diglyceride:glycerol acyltransferase comprises the amino acid sequence motif GDSX, wherein X is one or more of the following amino acid residues L, A, V, I, F, Y, H, Q, T, N, M or S. Furthermore the present invention relates to the use of a diglyceride:glycerol acyltransferase characterized as an enzyme which in an edible oil is capable of transferring an acyl group from a diglyceride to glycerol, in the manufacture of an edible oil, for reducing and / or removing (preferably selectively reducing and / or removing) diglyceride from said edible oil and to the use of said enzyme in the manufacture of a foodstuff comprising an edible oil for improving the crystallization properties of said foodstuff.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Shortening composition

ActiveUS20050214436A1Improve stabilityImprove the organoleptic and physical propertiesDough treatmentBakery productsBiotechnologyVegetable oil

The present invention relates to a shortening system, for use as dough fat or filling fat; for instance, a shortening system containing, consisting essentially of, or consisting of, unhydrogenated or non-hydrogenated vegetable oil, such as a highly unsaturated, non-hydrogenated or unhydrogenated vegetable oil, e.g., soybean oil, sunflower oil, corn oil, ricebran oil, or cottonseed oil and a minimum or minor amount (e.g., by weight about 3-10%, advantageously about 3-7%, more advantageously about 3-6% or about 3-5% or less than about 6% or less than about 8%) of an emulsifier composition comprising a monoglyceride and / or diglyceride, an alpha tending emulsifier and an ionic emulsifier as well as to methods for making and using such a shortening system and products from the use of such a shortening system.

Owner:DUPONT NUTRITION BIOSCIENCES APS

Aerated confectionery material

ActiveUS20180064127A1Assemble firmlyResisting bubble shrinkageFrozen sweetsConfectioneryPorosityMonoglyceride

The present invention relates generally to the field of aerated fat-based confectionery material. One aspect of the invention provides an aerated fat-based confectionery material having a continuous lipid phase and a porosity of between 1 and 80%, wherein, at a temperature at which the lipid phase has a solid lipid content between 0.1 and 80, the fat-based confectionery material comprises gas bubbles having at least 50% of their surface occupied by crystals, the crystals comprising a glyceride selected from the group consisting of monoglycerides, diglycerides, triglycerides, esters of monoglycerides, esters of diglycerides and combinations of these. Further aspects of the invention are a confectionery product comprising an aerated fat-based confectionery material and a process for forming an aerated fat-based confectionery material.

Owner:SOC DES PROD NESTLE SA

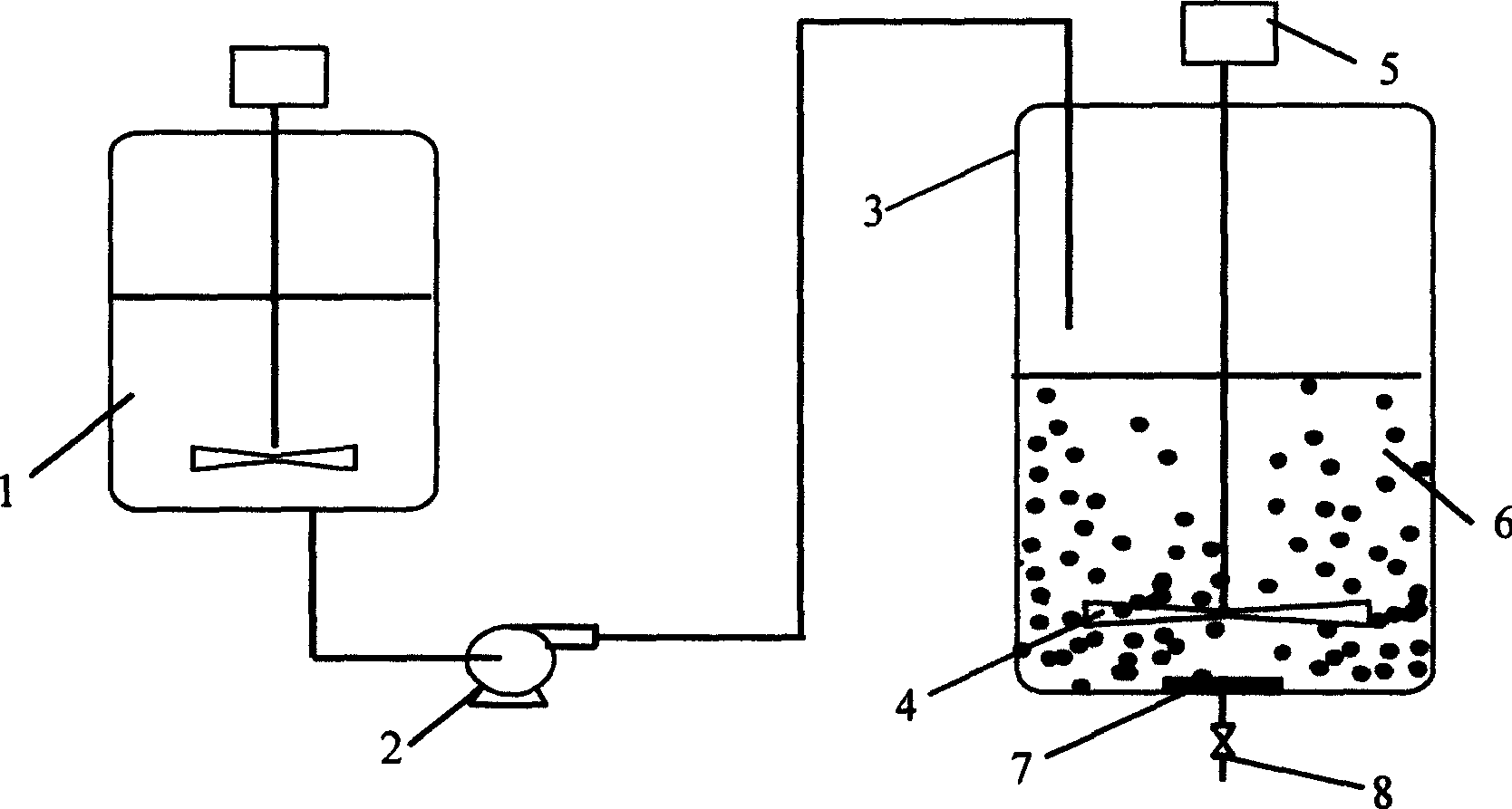

Process for the production of diglyceride using holoenzyme

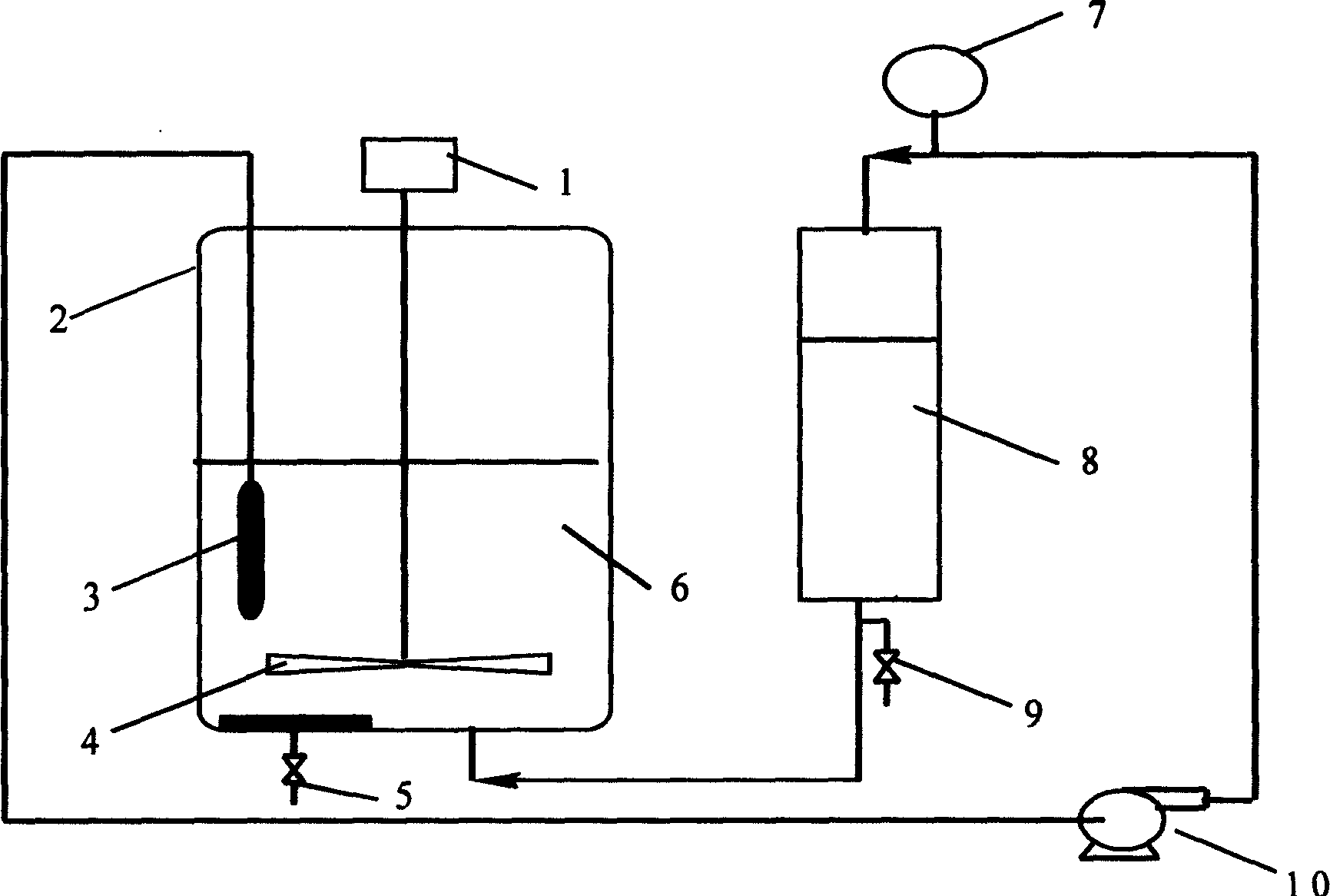

InactiveCN1884564AFlexible adjustment of distillation temperaturePromote generationMicroorganism based processesFermentationMonoglycerideEnzymatic hydrolysis

This invention is associated with the producing method of diglyceride with enzyme. The steps include: hydrolyze fat or oil using 1, 3 special lipase, the hydrolysis degree is 20 - 55%. After molecular distillation or short path distillation the obtained hydrolysis products can generate the high temperature fractions with the main contents of diglyceride and triglyceride as well as the low temperature fractions with the main contents of fatty acid and monoglycerides. This invention gets the fat or oil catalyzed by specific lipase, and then appropriately hydrolyzes it. The hydrolyzed products contain a lot of diglycerides, but the contents of by-product monoglycerides are very low. This invention also combined the enzymatic hydrolysis and enzymatic deacidification so to increase the output of diglyceride.

Owner:广东润隆再生资源股份有限公司

Compositions for enhanced epithelial permeation of peptide yy for treating obesity

InactiveUS20070275893A1Promote absorptionImprove bioavailabilityBiocideOrganic active ingredientsPYY PeptidePYY receptors

Pharmaceutical compositions comprising PYY(3-36), a cyclodextrin, and a compound selected from phosphatidylcholine or diglyceride, wherein the PYY(3-36) is present in an amount effective to alleviate one or more symptom(s) of obesity in a subject, and the cyclodextrin and the compound selected from phosphatidylcholine or diglyceride are present in an amount sufficient to enhance epithelial permeation.

Owner:NASTECH PHARMA

Oil or fat composition

InactiveUS7060316B2Stable against thermal oxidationStable hydrolysisFatty acid esterificationFatty substance preservation using additivesOil and greaseCarboxylic acid

An oil or fat composition containing 15 wt % or more of diglyceride (component (A)) and 70 ppm or more, on the basis of the diglyceride, of an organic carboxylic acid (Component (B)).

Owner:KAO CORP

Method

InactiveUS20060078648A1Accumulation is reduced and eliminatedIncreased amount of free fatty acidFatty acid esterificationHydrolasesMonoglycerideGlycerol

A method for the in situ production of an emulsifier in a foodstuff, wherein a lipid acyltransferase is added to the foodstuff. Preferably the emulsifier is produced without an increase or without a substantial increase in the free fatty acid content of the foodstuff. Preferably, the lipid acyltransferase is one which is capable of transferring an acyl group from a lipid to one or more of the following acyl acceptors: a sterol, a stanol, a carbohydrate, a protein or a sub-unit thereof, glycerol. Preferably, in addition to an emulsifier one or more of a stanol ester or a stanol ester or a protein ester or a carbohydrate ester or a diglyceride or a monoglyceride may be produced. One or more of these may function as an addition emulsifier.

Owner:DUPONT NUTRITION BIOSCIENCES APS

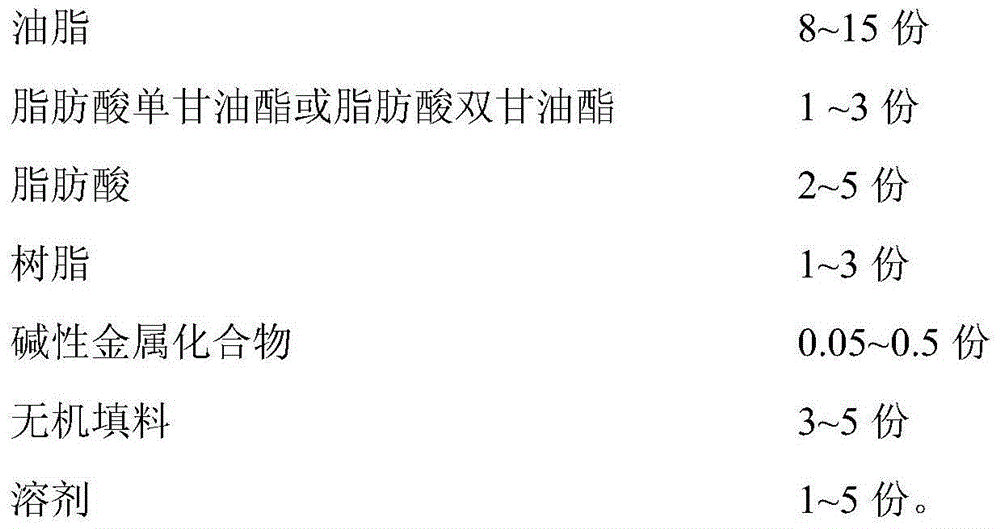

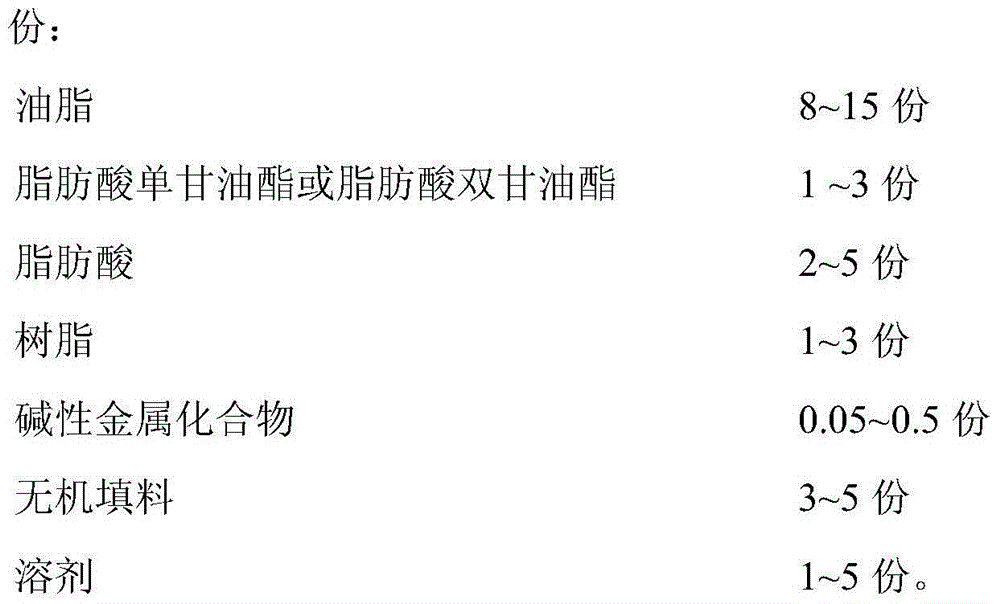

Concrete releasing agent for aluminum alloy template of building

InactiveCN104629885ABlock penetration throughAvoid destructionCeramic shaping apparatusLubricant compositionMonoglycerideDiglyceride

The invention provides a concrete releasing agent for an aluminum alloy template of a building. The releasing agent comprises the following components in parts by weight: 8-15 parts of grease, 1-3 parts of fatty acid monoglyceride or fatty acid diglyceride, 2-5 parts of fatty acid, 1-3 parts of resin, 0.05-0.5 parts of basic metal compound, 3-5 parts of inorganic filler and 1-5 parts of solvent. The releasing agent coats the aluminum alloy template of the building and is used in the concrete pouring technology, the concrete releasing quality is good without obvious blister, and the releasing agent residue surface matter is easily removed and the releasing agent is suitable for use for single or multiple times, and the service life of the template is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

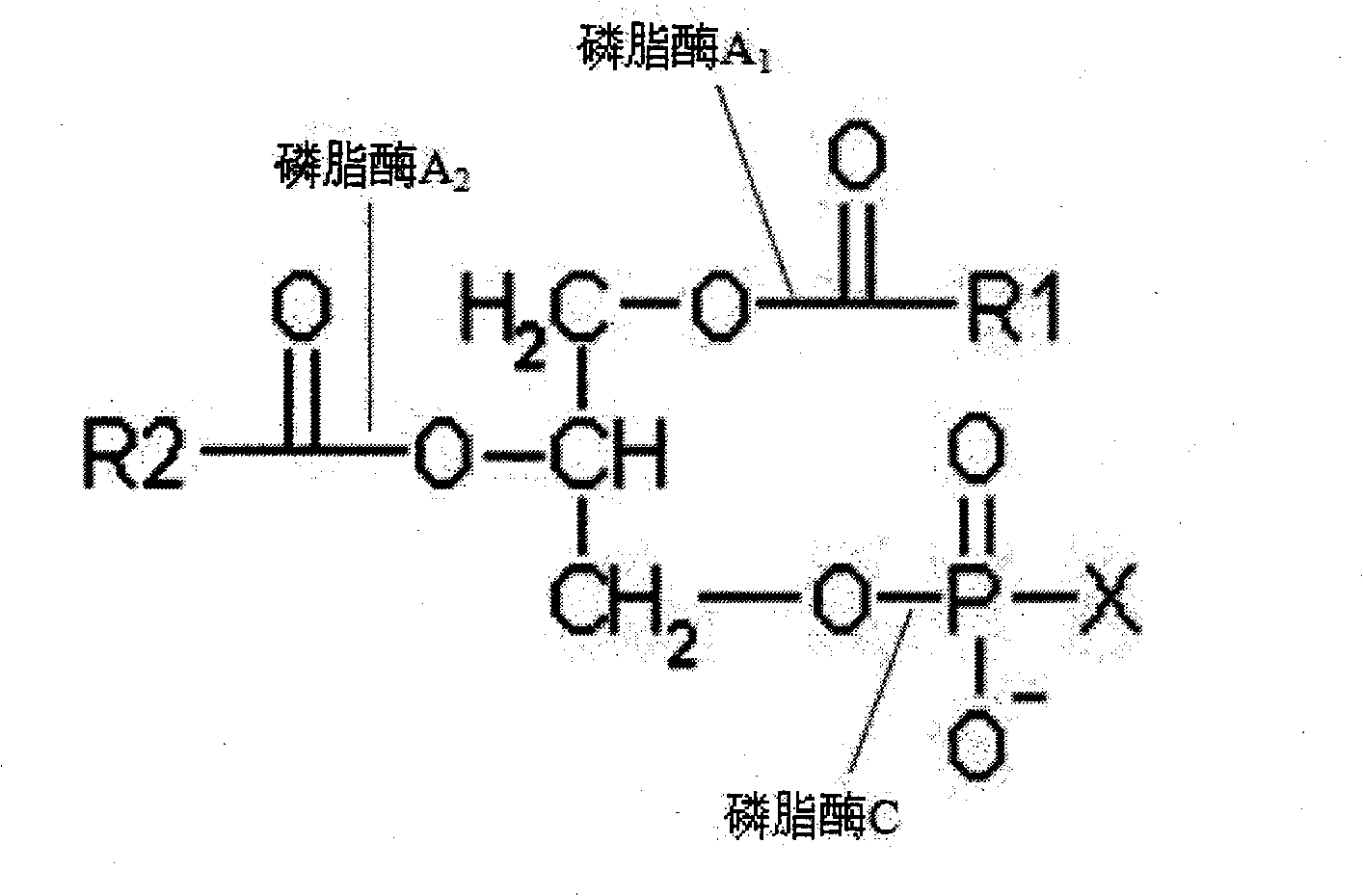

Method for degumming soybean oil by phospholipase catalysis

InactiveCN102634411AIncreased diglyceride contentShort degumming timeFatty-oils/fats refiningEdible oils/fatsVegetable oilOil production

The invention discloses a method for degumming soybean oil by phospholipase catalysis, which belongs to the field of vegetable oil degumming and includes the steps of preheating, adjusting pH, adding enzyme prior to mixing, allowing for enzymolysis, deactivating the enzyme and separating. The method is technically characterized by including: using phospholipase C as the phospholipase for catalysis, and preheating crude soybean oil prior to acid treatment; cooling oil-water mixture subjected to acid treatment to 37-60 DEG C, adding NaOH solution to adjust pH to 3-8, adding distilled water accounting for 1%-5% of the weight of the oil, adding the phospholipase C according to an oil proportion of 100-2000U / g, and mixing well; setting the mixing speed at 100-600r / min, and allowing for enzyme reaction for 0.5-2 hours; and deactivating the enzyme at high temperature for a reaction system, and performing high-speed centrifugal separation to complete degumming. The degumming time of the method is shortened by 1-2 times as compared with that of using phospholipase A1, phosphorus content is reduced, diglyceride content of the oil is increased slightly, and economic benefit is increased for oil production industries.

Owner:JIANGNAN UNIV

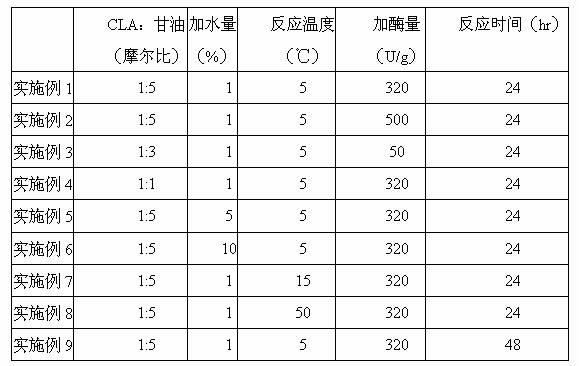

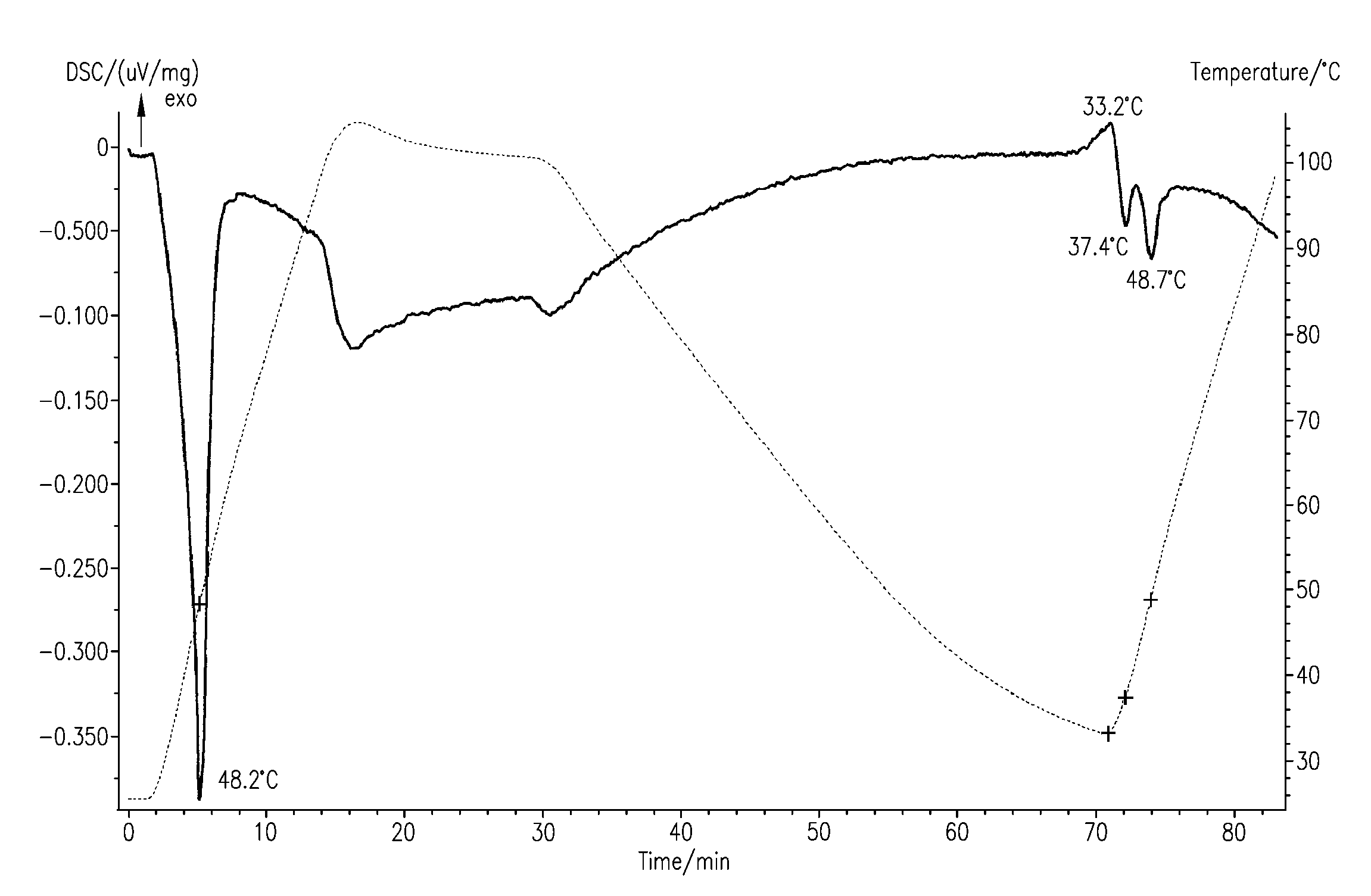

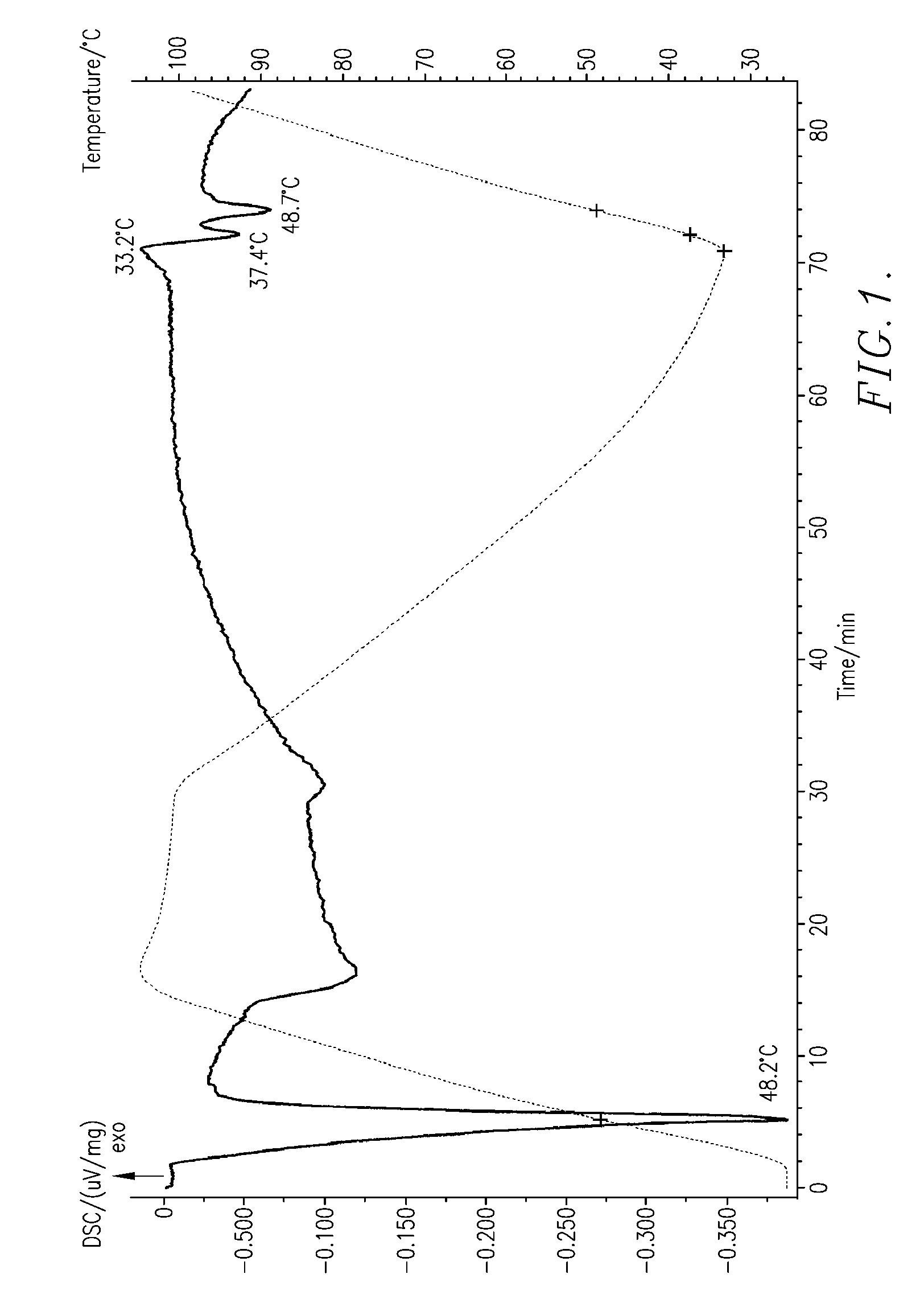

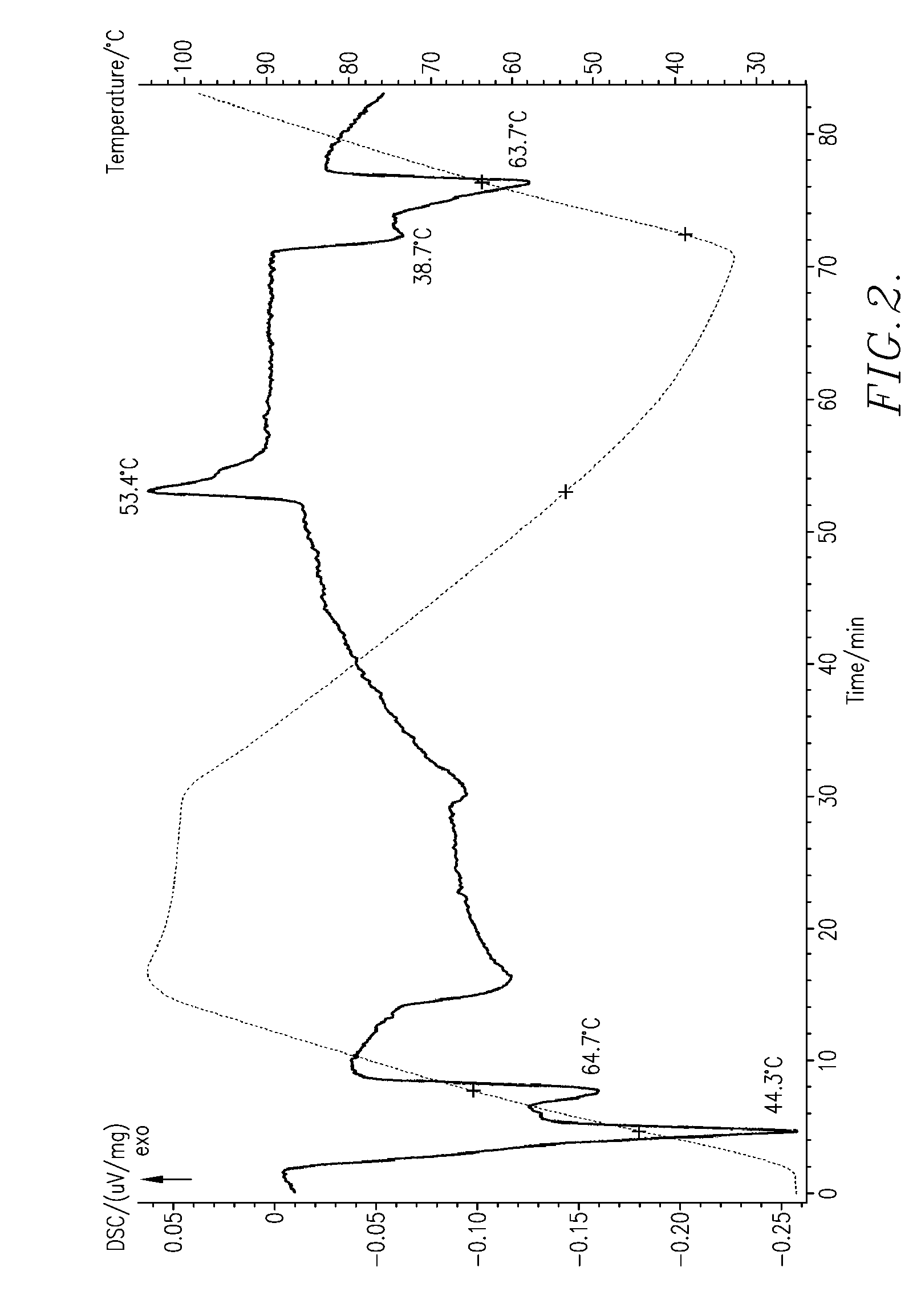

Diglyceride lipin production method

InactiveCN1544412AThe problem of controlling the darkening of the colorGlycerolysis reactionOrganic chemistryFatty acid esterificationGlycerolTG - Triglyceride

The invention relates to a process for preparing diglyceride grease comprising the steps of, (1) adsorbing the glycerine onto adsorption material, (2) mixing the adsorption material obtained in step (1) and glycerine with triglyceride, using immobilization lipolytic enzyme as catalyst for catalyzing the reaction between triglyceride and glycerine at 20-90 deg. C, (3) separation by removing immobilization lipolytic enzyme and glycerine adsorption material from the outcome yield of (2), separating aliphatic acid to obtain diglyceride grease.

Owner:广东润隆再生资源股份有限公司

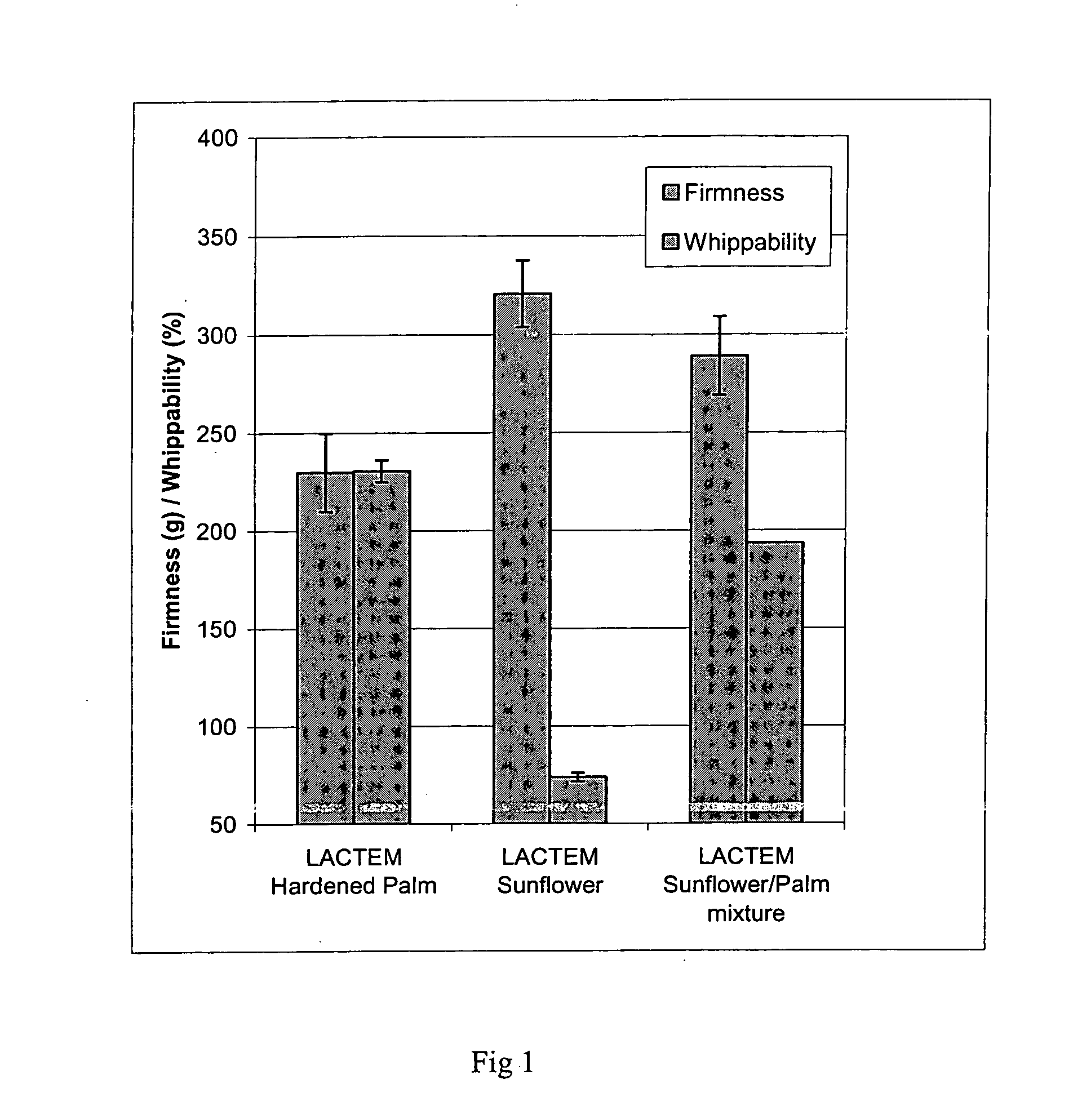

Composition comprising lactic acid esters of mono-and diglycerides of fatty acids, an emulsifier containing the same and its use

InactiveUS20050026999A1Improve firmnessIncrease volumeBiocideOrganic active ingredientsMono- and diglycerides of fatty acidsDiglyceride

The invention relates to compositions comprising lactic acid esters of mono- and diglycerides of fatty acids i.e. LACTEM compositions. The invention relates especially to novel LACTEM, which include 5 to 95% by weight unsaturated fatty acid(s), as well as to emulsifiers containing LACTEM with unsaturated fatty acids. The use of unsaturated fatty acids in LACTEM improves firmness, volume and / or texture of food and non-food products produced with said LACTEM.

Owner:AS DE DANSKE SUKKERFABRIKKER

Production method for coproducing unsaturated monoglyceride by using diglyceride enzyme method

ActiveCN103361387ASolve the acid value problemEasy to operateFermentationGeneration rateMonoglyceride

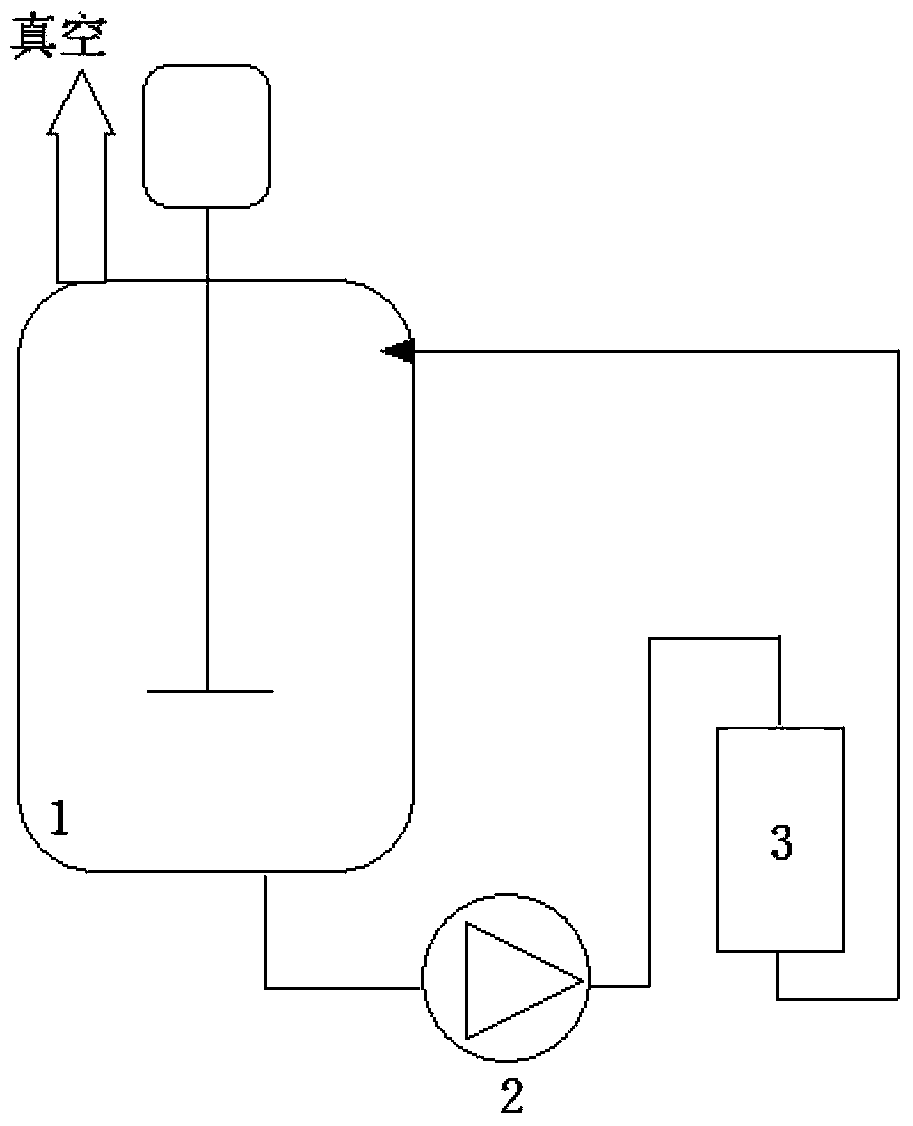

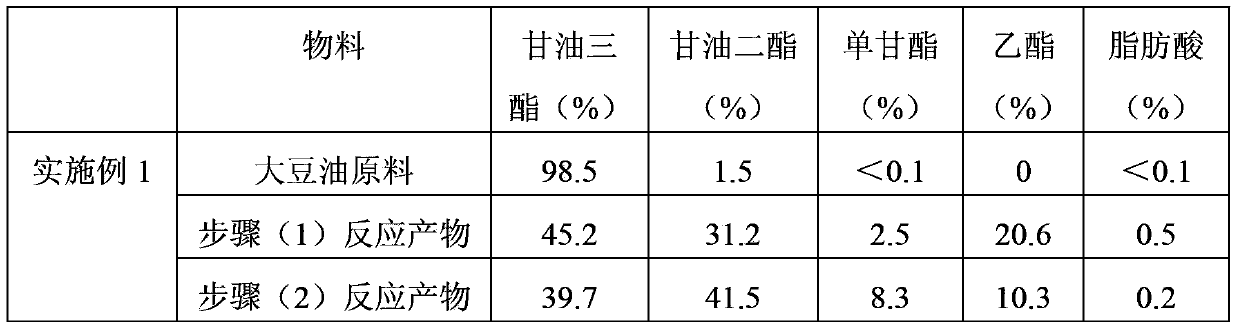

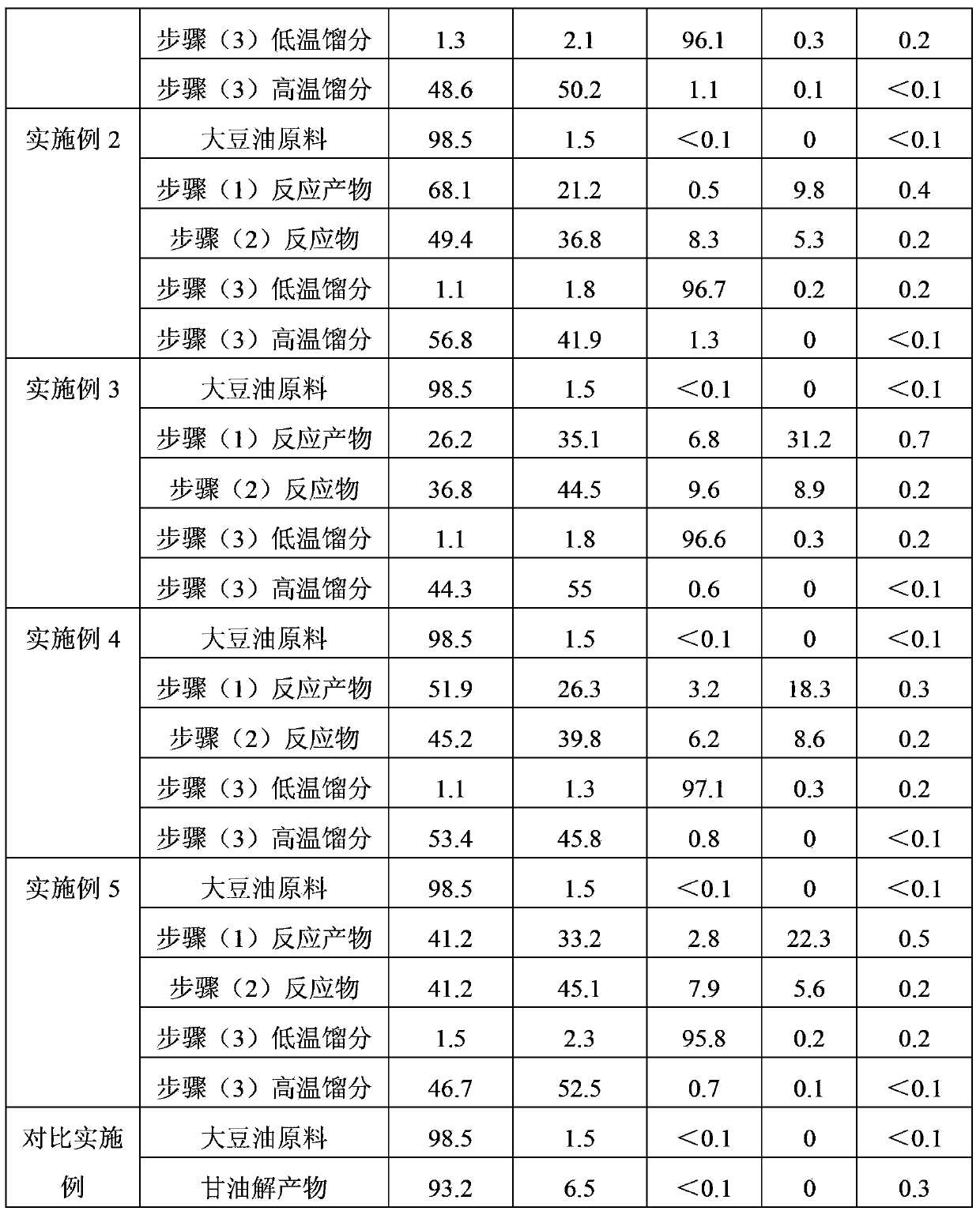

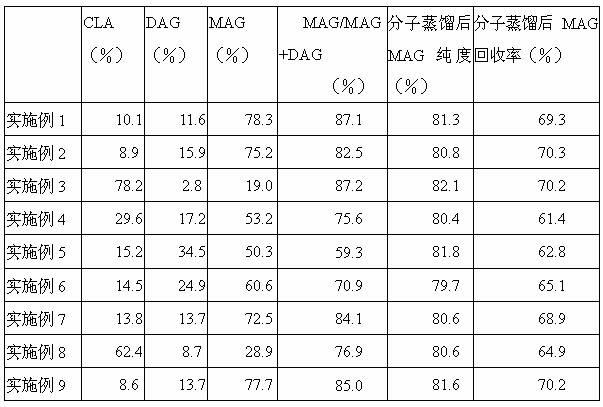

The invention discloses a production method for coproducing unsaturated monoglyceride by using a diglyceride enzyme method. The method comprises: (1)adding absolute ethyl alcohol into a natural grease, carrying out an alcoholysis reaction under catalysis of immobilized lipase, making the generation rate of fatty acid ethyl ester to be 5-40%w / w, and removing the residual alcohol to obtain an alcoholysis product; (2) adding 5-15%w / w of glycerin into the alcoholysis product of step (1), then reacting the above mixed substrates in a packed-bed enzyme reactor filled with immobilized lipase under a vacuum condition; and (3) performing molecular distillation on the reaction product of step (2), and separating to obtain a high-temperature fraction which is a diglyceride-containing product and a low-temperature fraction which mainly comprises monoglyceride. The reaction system of the invention needs no water, therefore the problem of product acid value is solved, and then coproduction of monoglyceride is realized; and the glycerin does not need preadsorption processing, and therefore the production operation is simplified.

Owner:YHSN TECH LTD

Method for producing diglyceride

InactiveCN1438308ASolve the problem of excessive viscosityGood compatibilityFatty acid esterificationPreparation by ester-hydroxy reactionMicrobial oilAlcohol

The invention refers to a method of producing diglyceride, mixing lower alcohol and triglyceride to react under fixed lipase, separating reaction product to get the diglyceride, and at the same time getting the by-product, fatty acid lower alcohol ester; the lower alcohol is monobasic alcohol, C number less than 3, the triglyceride is refined animal oil, or vegetable oil, or microbial oil or their mixture, and the fixed liphase is fixed on carrier by physical adsorption, and covalent cross-linking.

Owner:广东润隆再生资源股份有限公司

Low-trans fats for confectionery and bakery fat compositions

ActiveUS20050163909A1Promote meltingImprove crystallization speedFatty acid hydrogenationDough treatmentGlycerolTriglyceride

The present invention relates to a process for the production of a fat composition for confectionery or baking applications. According to this process, a starting fat composition containing palm oil or a palm oil fraction and having the following composition: (1) a glyceride composition with—a S2U content between 47 and 75 wt. %,—a SU2+U3 content <40 wt %. %,—a S3 content between 1 and 15 wt. %,—a diglyceride content of 3 to 12 wt. %, the glyceride contents being expressed as wt. % with respect to the total amnount of di- and triglycerides in which S means a saturated fatty acid with A hydrocarbon chain length of 14-24 carbon atoms and U means unsaturated fatty acid with a hydrocarbon chain length of 14-24 carbon atoms and (2) a total content of unsaturated fatty acids of less than 55 wt. %, preferably less than 50 wt. %, more preferably less than 48 wt. %, is subjected to a catalytic hydrogenation so as to obtain a first fat with a trans fatty acid content <wt. %, preferably <10 wt. %, most preferably <5 wt. % and an increase of C18-0 of less than 1 wt. %, preferably less than 0.7 wt. %, more preferably less than 0.4 wt. %. This first fat is incorporated in the fat composition.

Owner:FUJI OIL CO LTD

Environmental protection remover

InactiveCN101126052AAccelerated disengagementImprove decomposition abilityAnionic-cationic-non-ionic surface-active compoundsDetergent compounding agentsSorbitanFatty alcohol

The invention relates to an environment-friendly ablution used in washing, sterilizing and removing smell to protect clothing, plastic, rubber, office articles, household appliances, auto-inner ornament and toilet in daily life. In order to solve the problems in the prior art, biosurfactant, promoter enzyme, etc. are adopted to be remixed with relative organic reagent. The invention comprises n-acyl glutamate, pineapple enzymic, dodecyl dimethyl benzyl ammonium bromide, fatty alcohol polyoxyethylene ether, ester succinate sulfonate, boric acid diglyceride, linear alkyl benzene sulphonate, sorbitan fatty acid, fatty acid diethanol amide, sunscreen, carbamide, sodium hypochlorite, odor component water. The invention has six functions of 1.laundry washing, decontaminating, sterilizing; 2.plastic and rubber cleaning; 3.office articles and hoursehold appliances renewing; 4.sleeping mat cleaning, decontaminating, sterilizing and acarus killing;5.auto-inner ornament cleaning, sterilizing and smell removing; 4 toilet cleaning, sterilizing, mildew and abnormal smell removing; 6.wall cleaning and stain removing as well as innocuity, no pollution and environment protective.

Owner:王锦容

Method for co-producing biodiesel, phytosterol and tocopherol by using grease deodorized distillate

The invention discloses a method for co-producing biodiesel, phytosterol and tocopherol by using grease deodorized distillate. Aiming at the characteristics of high acid value and complex components of the grease deodorized distillate, fatty acid and glyceride in the deodorized distillate are reacted with methanol to generate fatty acid methyl ester (biodiesel) by adopting p-toluenesulphonic acid as a catalyst. The method comprises the following steps of: adding a small amount of sterol powder serving as crystal seeds into a reaction mixture after methyl esterification reaction, then promoting the sterol in the reaction system to form crystals through a temperature program consisting of three steps in turn, and primarily separating the sterol by methods of centrifuging, filtering and the like; and separating fatty acid methyl ester (light phase) from the reaction mixture after the primary separation of the sterol by adopting primary molecular distillation, removing triglyceride, diglyceride and glycerol (heavy phase) from the reclaimed heavy phase through molecular distillation again, performing sterol crystallization and separation on the reclaimed light phase again, and reclaiming the tocopherol from the mixture after the sterol is re-separated through anion exchange chromatography. The method has the characteristics of high extraction efficiency, mild conditions and the like.

Owner:JIANGNAN UNIV

Modified coconut oils with broad antimicrobial spectrum

InactiveUS20100016430A1Improve antibacterial propertiesAntibacterial agentsBiocideEscherichia coliCandida famata

Owner:MALAYSIAN AGRI RES & DEV INST MARDI

Oil/fat powder

InactiveUS7141265B2Good dispersibilityImprove stabilitySugar food ingredientsDough treatmentOil and greaseMonoglyceride

Provided is an oil / fat powder comprising the following Components (A), (B) and (C): (A) 15 to 79.9 wt. % of a glyceride mixture containing 5 to 84.9 wt. % of triglycerides, 0.1 to 5 wt. % of monoglycerides and 15 to 94.9 wt. % of diglycerides, and having, as at least 50 wt. % of all the constitutive fatty acids, unsaturated fatty acids; (B) 20 to 84.9 wt. % of one or at least two powder forming bases selected from carbohydrates, proteins and peptides; (C) 0.1 to 5 wt. % of water. The diglyceride-containing oil / fat powder according to the present invention exhibits good taste, and excellent dispersibility in water and storage stability. Moreover, owing to good handling use and workability when it is added to food, it can be used readily for various forms of foods. Foods containing this oil / fat powder taste good and have good storage stability.

Owner:KAO CORP

Application of lipase SMG1 in preparation of fatty acid monoglyceride

InactiveCN102676592AStrong esterification abilityEasy to separateHydrolasesGenetic engineeringMonoglycerideGlycerol

The invention relates to application of lipase SMG1 in preparation of fatty acid monoglyceride, which comprises the following steps of: (1) preparing glycerol and fatty acid donor, adopting partial glyceride hydrolase SMG1 from Malasseziaglobosa as catalyst, and adding 1%-5% of water to catalyze reaction of the glycerol and fatty acid donor at 5-15 DEG C; and (2) separating, and removing lipase and glycerol from the product obtained from the step (1), separating and removing diglyceride and fatty acid to obtain the fatty acid monoglyceride. The glycerol and fatty acid donor can be used as a raw material in the invention, and esterification of the glycerol and fatty acid donor is catalyzed through lipase SMG1 at low temperature so as to generate the fatty acid monoglyceride. The prepared product has few by-products, light color and high yield.

Owner:SOUTH CHINA UNIV OF TECH

Non-hydrogenated vegetable oil based margarine for puff pastry containing an elevated diglyceride emulsifier

ActiveUS20070148313A1Sufficient structureHigh than usual level of diglycerides functionDough treatmentFatty acid esterificationGreek letter betaGlycerol

A mono-, di-, and triglyceride emulsifier is provided that is obtained by the interesterification or glycerolysis of triglycerides with glycerol. The diglyceride portion w / w is at least about 65% to about 80%, and most preferably from about 70% to about 80%. The high diglyceride emulsifier is useful in preparing a margarine from a selected quantity a non-hydrogenated vegetable oil and from an amount of saturated fat for use in puff pastry products. The puff pastry is trans fat free and a less than usual percentage of saturated fats. A preferred structured puffpastry margarine is prepared by mixing on a weight to weight basis about 14 parts of the high diglyceride emulsifier that is in predominantly stable beta crystal form, from about 14 to 27 parts of a non-hydrogenated vegetable oil, and from about 40 to about 52 parts of a saturated fat.

Owner:CARAVAN INGREDIENTS

Sprayable cookware release composition with fractionated oil and method of preparing food item

A sprayable cookware release composition includes a cookware release agent, a fractionated oil, such as a fractionated palm oil or a fractionated coconut oil, and a propellant. A combination of fractionated oils or a combination of a fractionated oil and a non-fractionated oil can also be utilized. The cookware release agent and the fractionated palm oil are mixed, and the mixture is dispensed from the aerosol container by the propellant. Suitable fractionated oils include fractionated coconut oil and fractionated palm oil, such as palm olein and palm super olein. Suitable cookware release agents include phospholipids, including phosphorus-containing glycerides, such as lecithin, lyso-phospholipids, phosphated monoglycerides, phosphated diglycerides, and mixtures thereof. Suitable propellants include pressurized gases, such as nitrous oxide, liquefied hydrocarbons, or mixtures thereof.

Owner:CONAGRA GROCERY PROD CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com