Method for degumming soybean oil by phospholipase catalysis

A degumming method and phospholipase technology, applied in the field of vegetable oil degumming, can solve the problems of low gum removal rate, inability to be popularized on a large scale, and long time consumption, and achieve the effect of improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

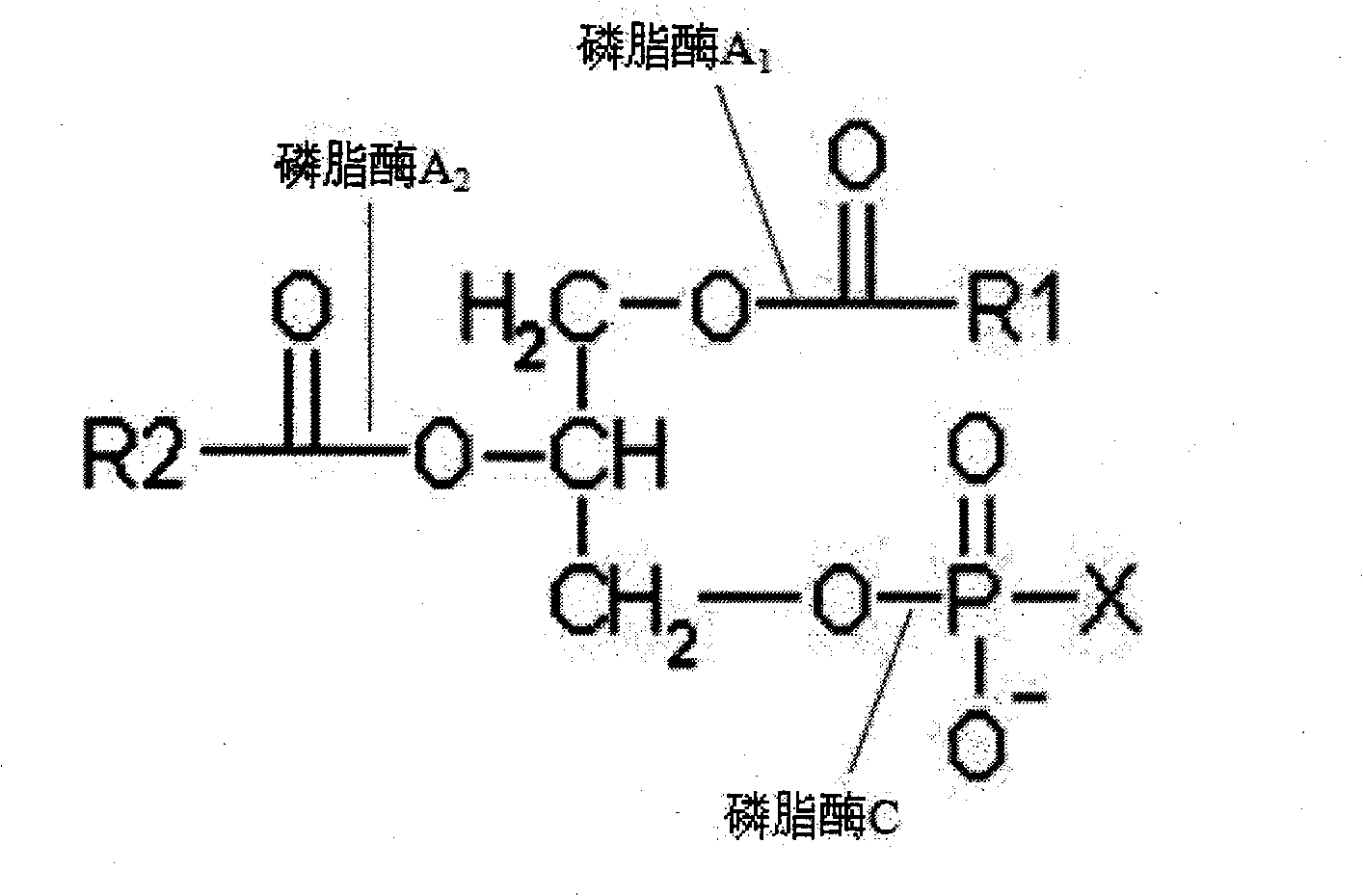

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment 1: Heat soybean oil to 70°C, add a citric acid solution with a mass concentration of 45% and a mass of 0.5% soybean oil, and carry out acid pretreatment for 20 minutes under stirring conditions of 500r / min; after acid treatment Cool the oil-water mixture to 47℃, add 4% NaOH solution by mass concentration, adjust the pH to 5, add 2% distilled water by oil weight, add phospholipase C at the ratio of 1000U / g oil, and mix well; set the stirring speed at Enzyme reaction is carried out at 300r / min, and the time is controlled at 1h; the reaction system is heated to above 90℃ to inactivate the enzyme for at least 10min, and centrifuged at above 8000r / min for at least 10min, to complete the phospholipase C catalyzed soybean oil.

[0011] After degumming in this embodiment, the phosphorus content of the degummed soybean oil is 23 mg / kg, the phosphorus content is reduced by about 87% compared to before degumming, and the glycolic acid content in soybean oil is incr...

specific Embodiment approach 2

[0012] Specific embodiment two: heating the hydrated degummed soybean oil to 80°C, adding a citric acid solution with a mass concentration of 50% and a mass of 0.5% soybean oil, and performing acid pretreatment for 20 minutes under stirring conditions of 500r / min; Cool the acid-treated oil-water mixture to 50°C, add 4% NaOH solution by mass concentration to adjust the pH to 5.2, add 4% oil weight distilled water, add phospholipase C according to the ratio of 1200U / g oil, mix well; The enzyme reaction is carried out at a speed of 400r / min and the time is controlled at 2h; the reaction system is heated to above 90°C to inactivate the enzyme for at least 10 minutes, and centrifuged above 8000r / min for at least 10 minutes to complete the degumming process of phospholipase C catalyzed soybean oil.

[0013] After degumming in this embodiment, the phosphorus content of the degummed soybean oil is 20 mg / kg, the phosphorus content is about 64% lower than that before degumming, and the glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com