Patents

Literature

33results about How to "High degumming rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly silk degumming method

InactiveCN107268092AQuality improvementImprove the lubrication effectDe-gumming silkAlkaline proteaseWax

The invention mainly relates to the technical field of silk processing, and discloses an environment-friendly silk degumming method, which includes immersion, enzymolysis, fermentation and washing. The method is simple, conditions are mild, high temperature and high pressure are not needed, energy is saved, the method is suitable for batch processing, the degumming rate can reach 89.3 percent, obtain silk is fine and smooth, the color is bright and white-yellow, and economic income can be increased by 12.7 percent. pH of immersed silk is regulated to be alkaline, lipase is added to decompose grease and wax components in the silk, high-temperature cooking is avoided, so that energy is saved, pH is then regulated to be acidic, bromelain is added, and enzymic preparations with different pHs are sequentially used for enzymolysis. The conventional joint use of alkaline protease and surfactant is changed, the environment is protected, soluble impurities under different pHs are sufficiently removed, sericin and remaining fat are decomposed, and the silk degumming rate is increased.

Owner:HEFEI JUFENG THROWING

Tuna coarse oil refining method

The invention provides a tuna coarse oil refining method. The method comprises the steps as follows: firstly, degumming; secondly, deacidification; thirdly, decoloration; fourthly, deodorization. According to the method, the degumming rate can reach as high as 5.35%, the degummed tuna oil is better in transparency, light in color, and has tinny fishy taste, and convenient for storage, and moreover, the technology required in the method is simple and convenient to realize, and has high practicability.

Owner:应夏英

Degumming method for biological diesel oil

InactiveCN101058770AHigh degumming rateProcessing speedBiofuelsFatty-oils/fats refiningBiodieselCentrifugal force

The invention discloses a degumming method of biological diesel in the grease, which comprises the following steps: utilizing hydrophilicity of peptizing purity of phosphatide; adding certain quantity of water or dilute electrolyte solution into rough oil to blend; bulking the gel after adsorbing water; coagulating; forming the hydrate with large oil density; centrifuging in the separator; combining the degelling and centrifuging; improving the degumming efficiency and processing speed.

Owner:FANGXIA ENTERPRISE INFORMATION CONSULTING WUJIANG

Preparing method for mulberry fibers

InactiveCN105154997AHigh degumming rateAvoid damageFibre treatment to obtain bast fibreCardingPulp and paper industry

The invention discloses a preparing method for mulberry fibers. The preparing method includes the steps of impurity removing, bundling, cage loading, chemical preprocessing, supercritical carbon dioxide fluid degumming processing, bio-enzyme degumming processing, washing, dewatering, oil feeding, carding and drying, wherein the chemical preprocessing method includes the steps of pickling processing and alkali-oxygen processing. The mulberry fibers obtained with the preparing method are high in degumming rate, small in damage and high in performance, and meet the modern environment-friendly requirement.

Owner:耿云花

Preparation method of mulberry bark fibers

ActiveCN104032380AHigh degumming rateAvoid damageFibre treatment to obtain bast fibreCardingPulp and paper industry

A preparation method of mulberry bark fibers includes the steps of roguing, binding, caging, chemical pretreatment, supercritical carbon dioxide fluid degumming treatment and biological enzyme degumming treatment, washing, dehydration, oil feed, carding and drying, wherein the chemical pretreatment method includes pickling treatment and alkali oxygen treatment. The mulberry bark fibers prepared through the preparation method are high in degumming rate, low in damage, high in performance and capable of meeting the requirement for modern environment friendliness.

Owner:山东银鹰化纤有限公司

Method for extracting plant pectin from hemp skin

The invention discloses a method for extracting plant pectin from hemp skin. According to the method, the pectin is extracted from the hemp skin, the raw material source is wide, the content of pectinin the hemp skin is high, the amount of the pectin extracted by virtue of the method is 10.46% of the weight of the hemp skin, and the process for extracting the pectin is simple and easy in operation. Ammonium oxalate is weak-acid and weak-base salt, the degumming rate of a solution of ammonium oxalate to the hemp skin is high, the treatment conditions are mild, and the strong damage of jute fibers is small; and meanwhile, oxalate ions can be cheated with calcium ions of calcium pectate to generate soluble ammonium salt, most pectin of the hemp skin is extracted in the solution, and the ethanol precipitation of pectin is further facilitated. Therefore, ammonium oxalate is a degumming agent and a pectin extracting agent, the jute fibers are acquired through the degumming of the hemp skin,and meanwhile, colloid in hemp degumming liquid is adequately utilized, so that the waste is turned into wealth, the economic utilization value of the hemp skin is increased, and sewage discharge isreduced.

Owner:TIANJIN POLYTECHNIC UNIV

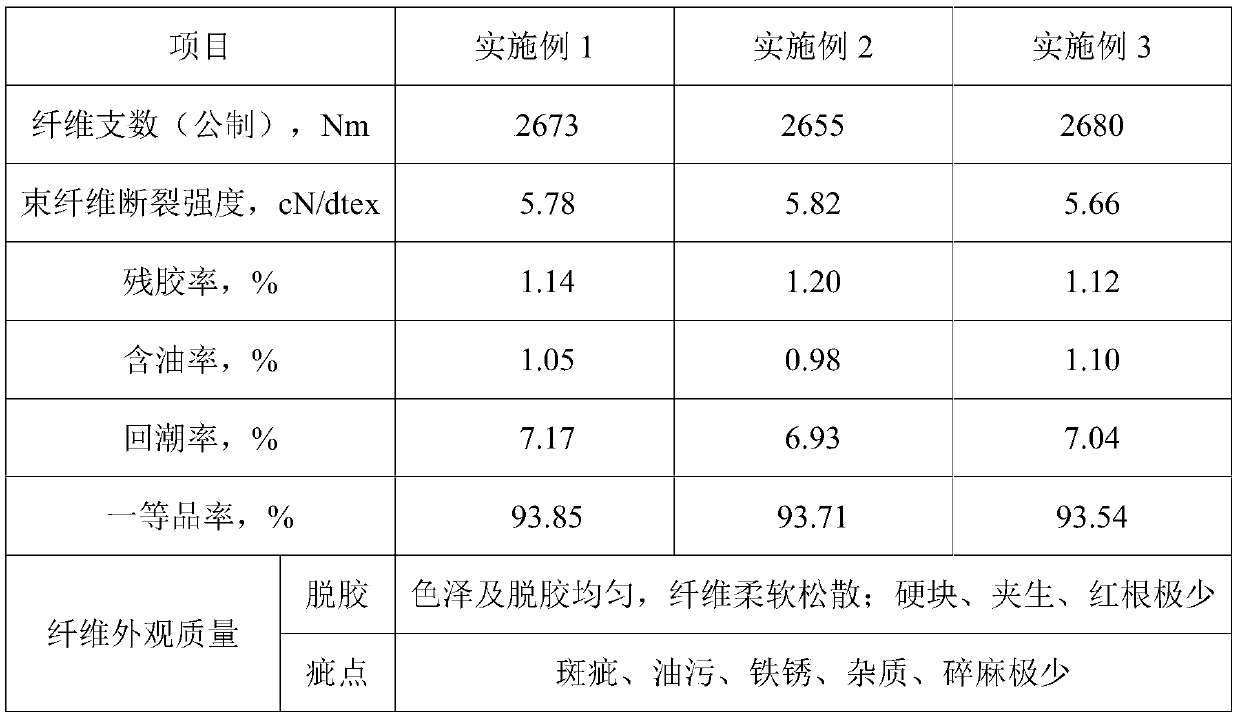

Preparation method of ramie fibers for high-count textile fabric

InactiveCN110453294ALess residual glueHigh degumming rateFibre treatment to obtain bast fibreChemistrySodium silicate

The invention relates to a preparation method of ramie fibers for a high-count textile fabric. The preparation method comprises the steps of 1) preimpregnation, wherein raw ramie is immersed in a presoak containing sodium hydroxide for preimpregnation, taken out and dehydrated to obtain a preimpregnated material; 2) steam explosion, wherein the obtained preimpregnated material is subjected to steam explosion to obtain a steam explosion material; 3) boiling off, wherein the obtained steam explosion material is placed in a degumming solution for heat preservation and boiling off to obtain a boiling-off material; the degumming solution comprises water and the following components of sodium hydroxide, sodium sulfite, sodium metasilicate, sodium tripolyphosphate and sodium dodecyl benzene sulfonate; 4) ultrasonic ramie washing, wherein the obtained boiling-off material is placed in water for ultrasonic immersion washing to obtain a water washing material; 5) aftertreatment. The residual gumratio of the obtained ramie fibers reaches 1.2% or below, residual gum is less, and the degumming rate is high; the fiber count is high and reaches 2655 Nm or above, and fibrils of the high-count rawramie are fully released; the loss of strength is less; the first-grade product rate reaches 93.54% or above, the quality is high, and the ramie fibers are fluffy and soft, and suitable for producingthe high-count light ramie textile fabric.

Owner:北京知淘科技有限责任公司

Processing method of silk

InactiveCN107653496AHigh degumming rateShort degumming timeDe-gumming silkAlkaline proteaseHydrolysis

The invention belongs to the technical field of silk processing, and particularly relates to a processing method of silk. The method comprises the following steps of (1) silk drying; (2) degumming: adding 1.0 to 2.0 mol / L of urea solution into a degumming groove; performing heating to 50 to 60 DEG C; starting ultrasonic waves; soaking the silk dried in the step (1) into water in the degumming groove; adding alkaline protease into the urea solution according to the proportion of 0.6 / 100 mL to 1.2g / 100 mL to be subjected to hydrolysis for 1h to 2h; then, adding lipase according to the proportionof 0.3 / 100 mL to 0.6g / 100 mL to be subjected to hydrolysis for 1h to 2h; preparing coarse degumming silk; (3) water washing; (4) washing: adding a functional detergent for washing for 50 to 60min; then, preparing the degumming silk after cleaning by clean water. The method has the advantages that the silk degumming efficiency is high; the degumming time is short; the color quality of raw silk isbetter; no pollution exists; green and environment-friendly effects are achieved.

Owner:河池市宜州区壮之都丝绸家纺有限公司

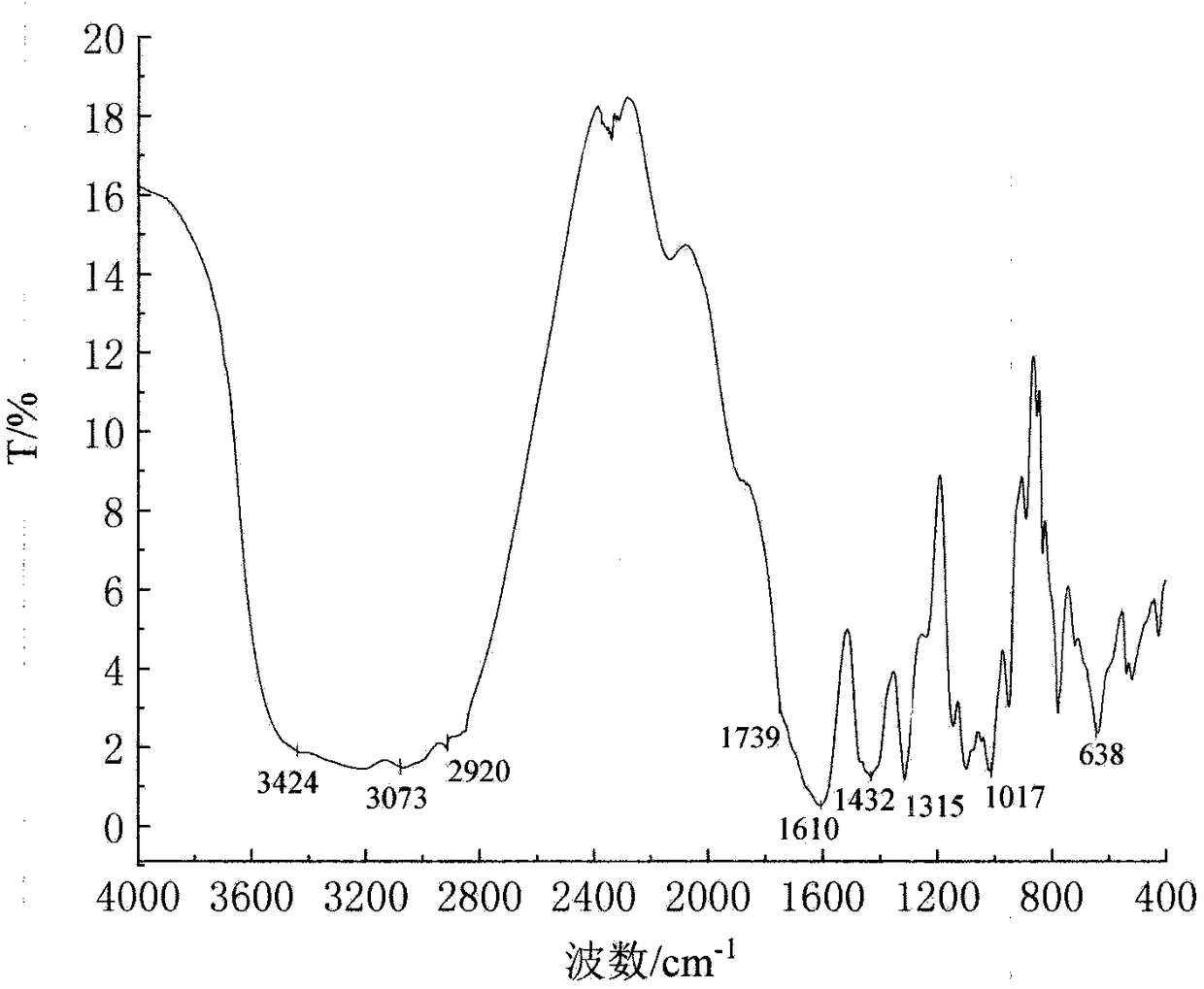

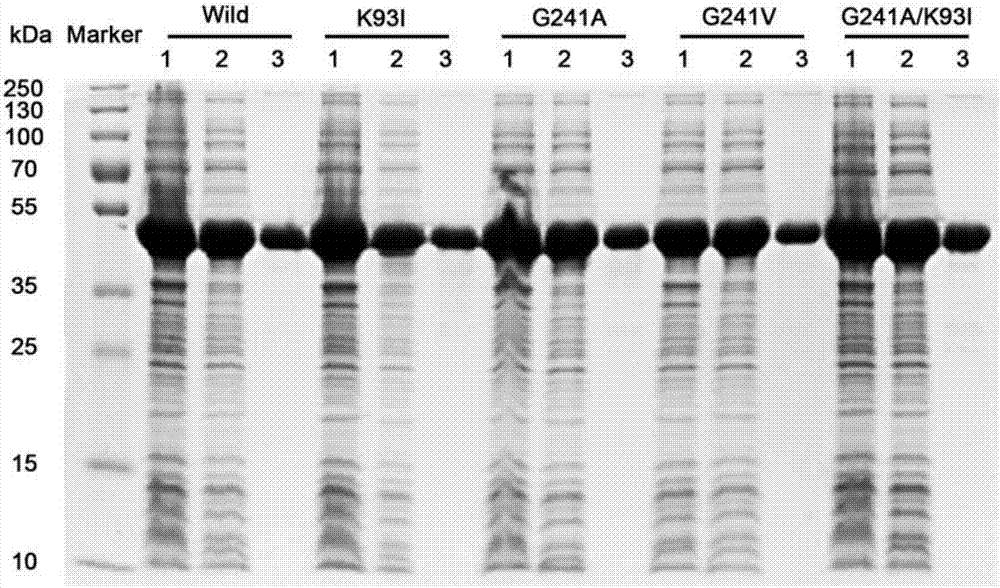

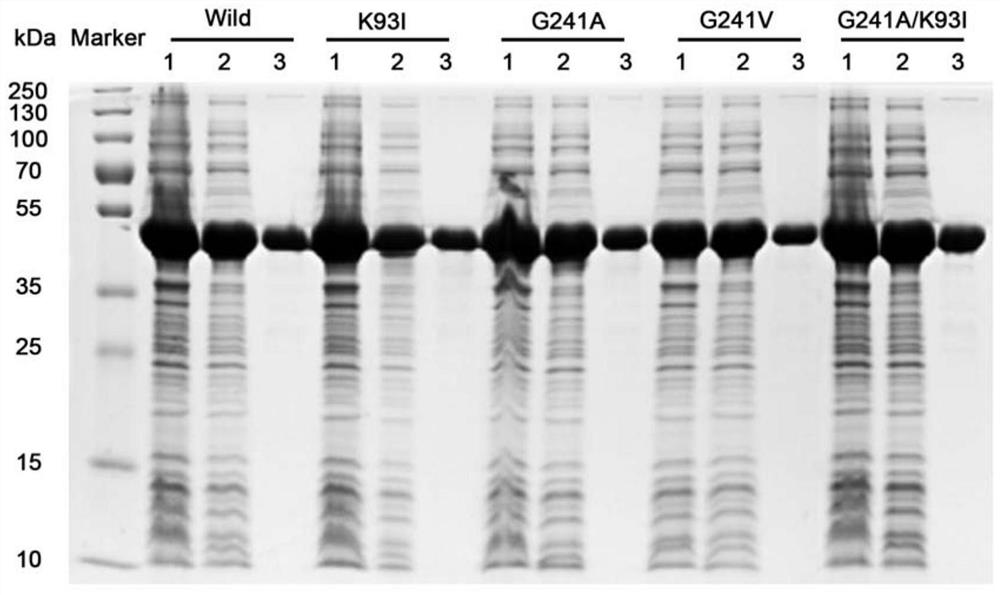

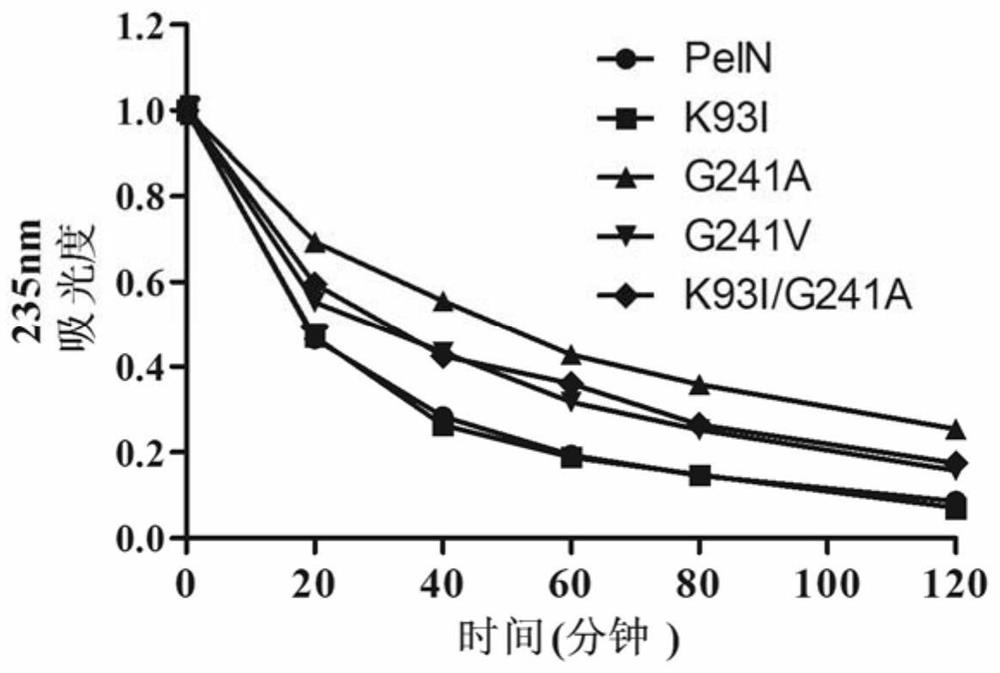

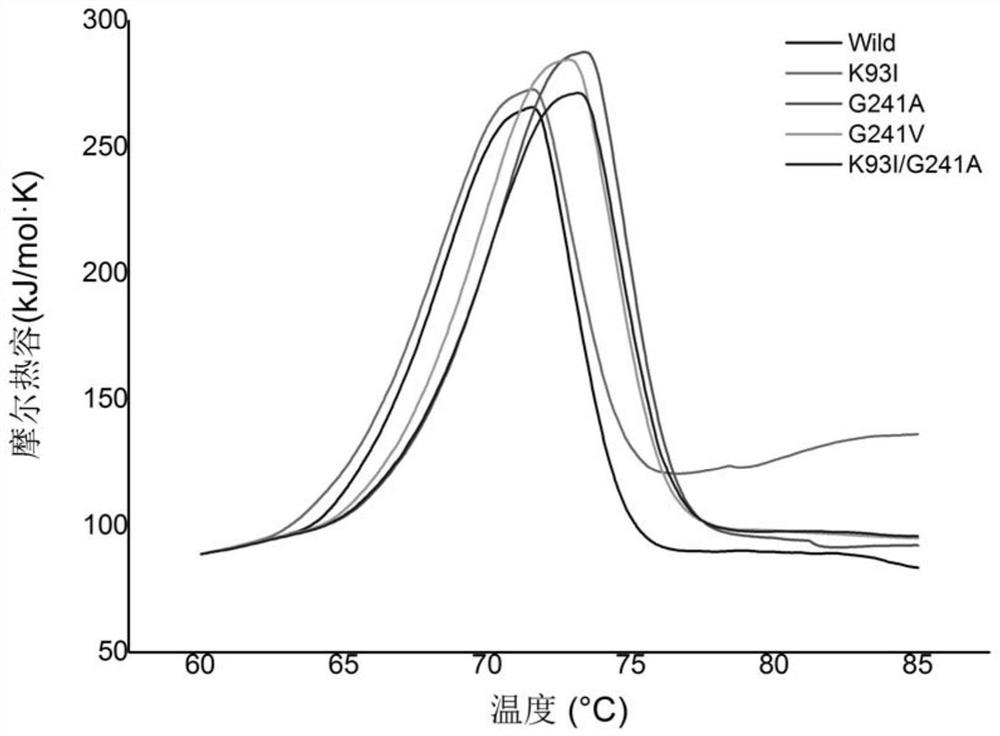

Alkaline pectinase mutant with improved heat stability as well as encoding gene and application of alkaline pectinase mutant

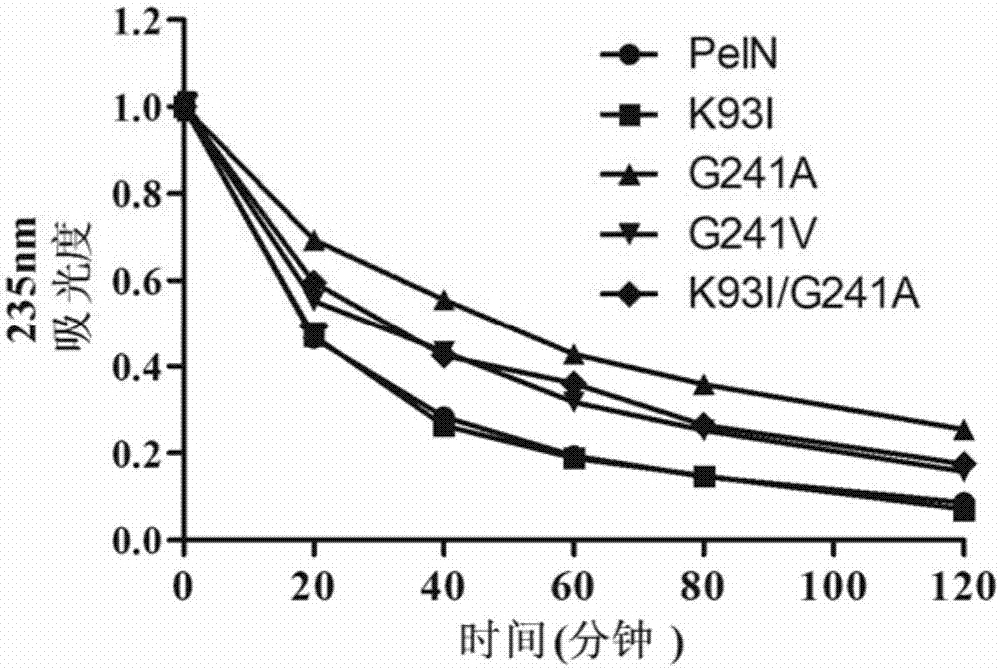

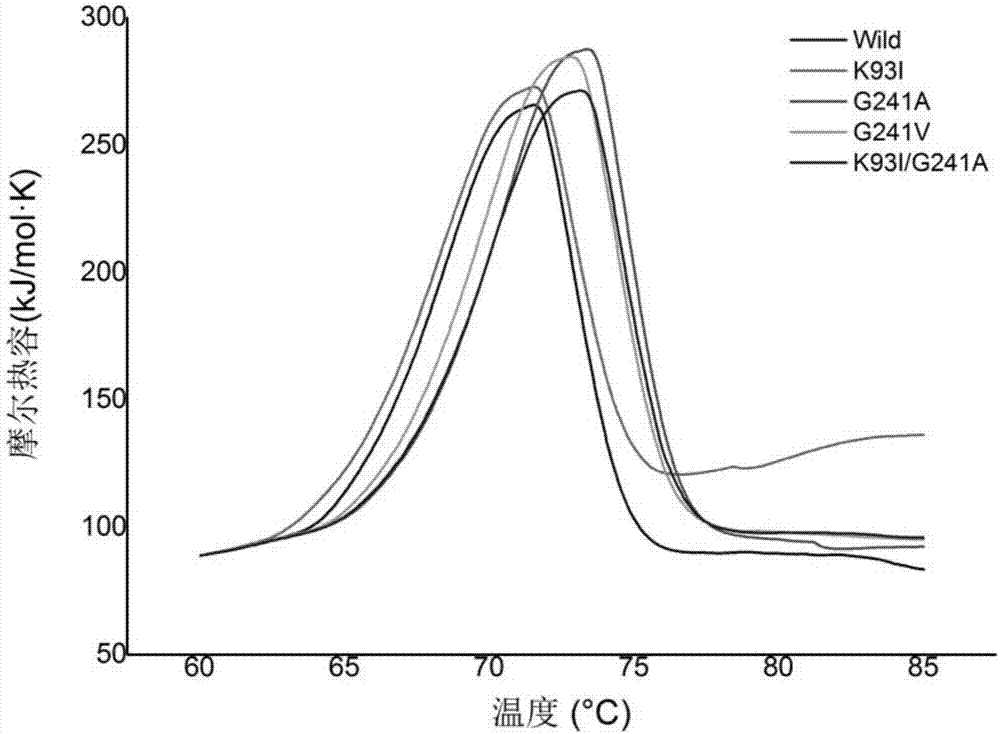

ActiveCN107460185AImprove thermal stabilityHigh catalytic efficiencyFermentationVector-based foreign material introductionPectinaseHalf-life

The invention discloses an alkaline pectinase mutant with improved heat stability as well as an encoding gene and application of the alkaline pectinase mutant. By carrying out site-specific mutagenesis at two sites of wild alkaline pectinase, the alkaline pectinase mutant with the improved enzyme activity and heat stability and the decreased optimal action temperature is obtained; the optimal enzyme activity temperature of a double mutant pelN-K93I / G241A is decreased by 5 DEG C than that before mutation, Tm is increased by 1.671 DEG C, the half-life period is prolonged by 15.86 minutes at 60 DEG C, Km is decreased from 2.59 g / L to 1.1 g / L, and the optimal enzyme activity temperature is decreased from 67.5 DEG C to 60 DEG C. The alkaline pectinase mutant has relatively high heat stability and relatively high ramie degumming rate, so that the alkaline pectinase mutant is more suitable for degumming processes and has relatively good application potentials in the textile industry.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

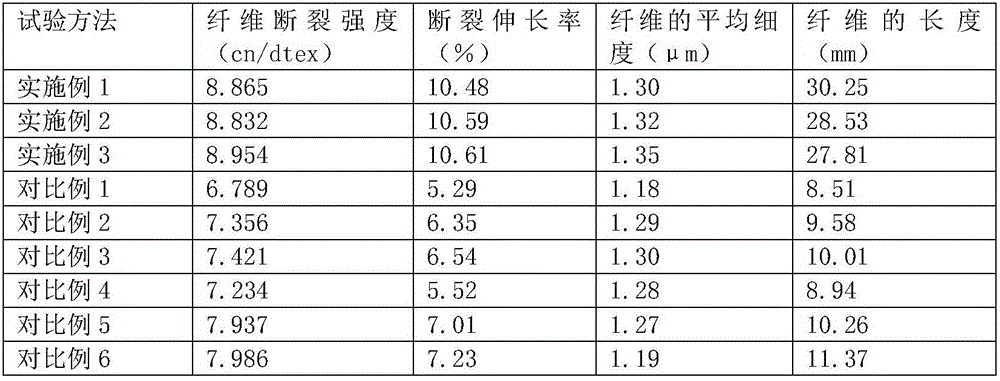

Method for preparing garlic bolt leaf fibers

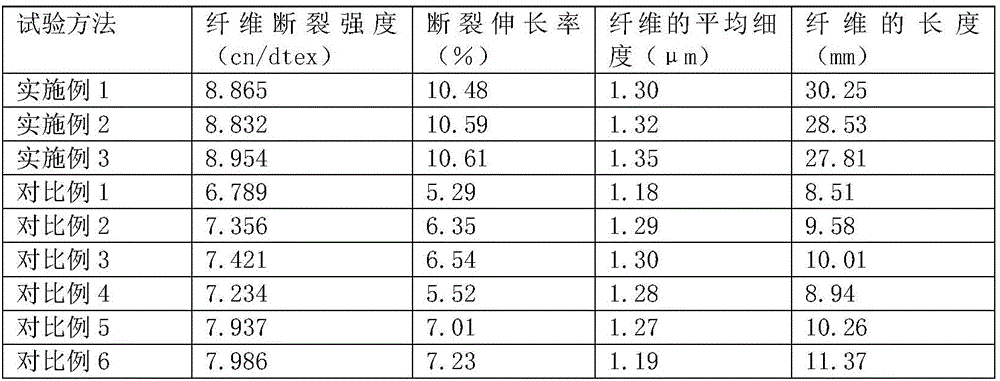

ActiveCN105908263AHigh degumming rateShort degumming timeVegetable materialMechanical fibre separationFiberMicrowave

The invention provides a method for preparing garlic bolt leaf fibers. The method comprises the steps of compound acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soap washing, dewatering, shaking to be loose, oil feeding and drying. According to the method for preparing the garlic bolt leaf fibers, fiber degumming time can be shortened, attachments on the surfaces of the garlic bolt leaf fibers can be reduced, spinnability can be improved, and the garlic bolt leaf fibers prepared through the method for preparing the garlic bolt leaf fibers have high strength and elongation at break and large length.

Owner:南通隆特家纺有限公司

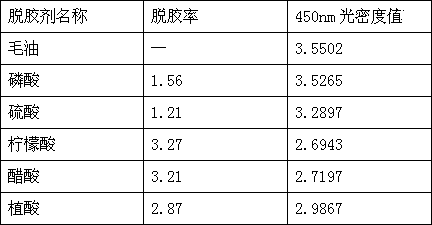

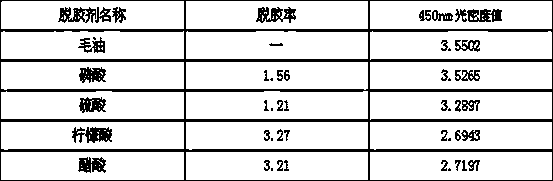

Method for removing colloidal matters in tuna raw oil

InactiveCN104232306AImprove degumming effectHigh degumming rateFatty-oils/fats refiningEdible oils/fatsAcetic acidPhosphoric acid

The invention relates to a method for removing colloidal matters in tuna raw oil, belonging to the field of food processing. The method aims to solve the problems of poor phosphoric acid colloid removal effect, and low transparency and deep color of the tuna oil subjected to colloid removal. The method comprises the following steps: compounding citric acid, acetic acid and phytic acid in a ratio of 2:1:3-1:1:1 (v / v), adding into tuna raw oil, stirring at 40-60 DEG C for at least 20 minutes, and centrifuging at the rate of at least 5000 r / min for at least 10 minutes, wherein the total mass of the citric acid, acetic acid and phytic acid at least accounts for 1.5% of the oil. The compounding ratio of the citric acid, acetic acid and phytic acid is preferably 1.5:1:2 (v / v), the addition amount is preferably 1.5 wt% of the crude tuna oil, the stirring temperature is preferably 60 DEG C, and the colloid removal time is preferably 30 minutes. By using the method, the colloid removal ratio is up to 4.63%; and the obtained tuna oil has the advantages of favorable transparency, lighter color than the crude oil, less fishiness than the crude oil, and better phosphoric acid colloid removal effect than the prior art.

Owner:ZHEJIANG OCEAN UNIV

Preparation technique of sisal fiber

InactiveCN106868605AHigh degumming rateLow residual glue rateVegetable materialMechanical fibre separationCorona dischargeSisal fiber

The invention belongs to the technical field of textile processing, and particularly relates to a preparation technique of a sisal fiber. The degumming technique comprises the following steps: pretreatment, corona discharge treatment, ultrasonic oscillation, degradation by bacteria, impurity removal, secondary ultrasonic treatment, water washing, pressing, oil supply, forming and drying. By performing the corona discharge treatment, ultrasonic treatment, degradation by bacteria and secondary ultrasonic treatment on the sisal fiber, the degumming technique of sisal has better effects than the traditional single chemical degumming process or mechanical degumming process, has the advantages of lower gum residue rate and lower lignin content, and satisfies the sisal deep processing technique demands. In addition, no chemical reagent is adopted expect the acetic acid and a small amount of sodium hydroxide, so the polluted wastewater discharge is low, and thus, the technique is a green environment-friendly technological process.

Owner:GUANGXI XIUMEI ZHUANGXIANG ENERGY ENVIRONMENTAL PROTECTION CO LTD

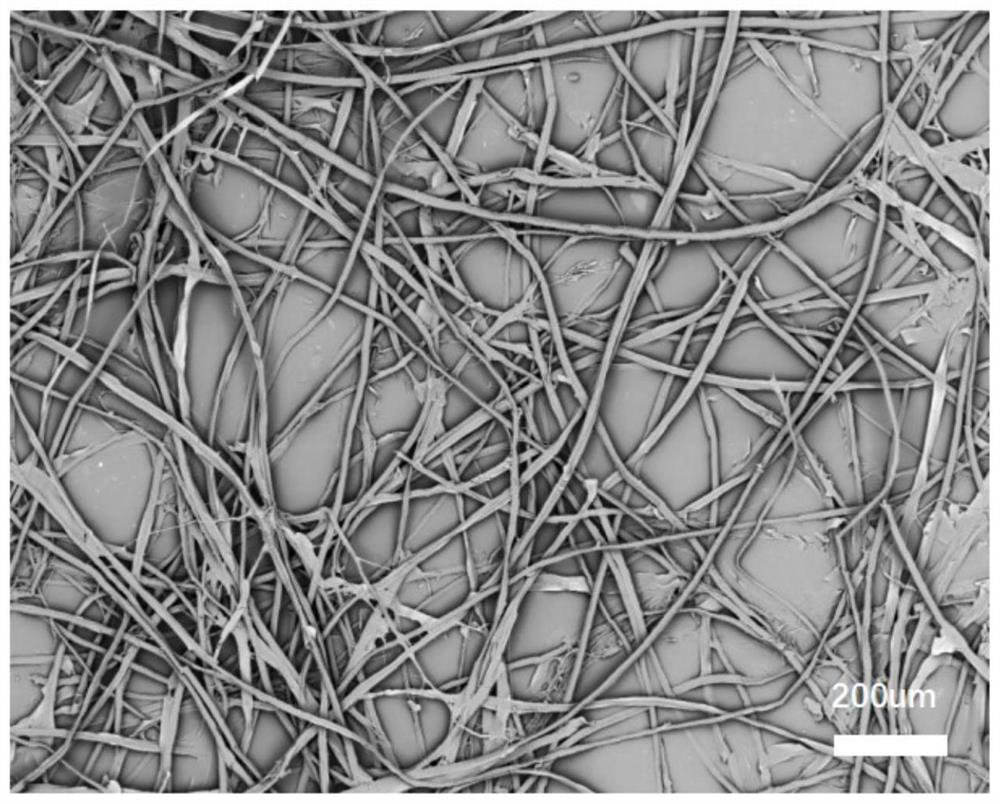

Method for improving mechanical property of lotus fiber

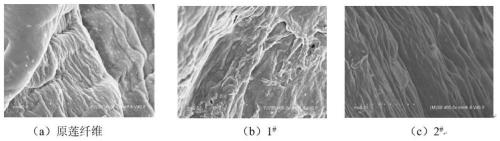

ActiveCN111575806AImprove mechanical propertiesHigh degumming rateMechanical fibre separationFibre treatment to obtain bast fibreCelluloseFiber

One or more embodiments of the invention provide a method for improving the mechanical property of a lotus fiber, and belong to the technical field of lotus fiber modification. The modification methodcomprises the steps that the lotus fibers are placed in a sulfuric acid solution for soaking; a mixed solution of a 1-ethyl-3-methylimidazolium chloride solution, sodium carboxymethyl cellulose and wheat bran is added, and microwave treatment is carried out; the lotus fibers are boiled with sodium hydroxide solution; soaking is carried out in a sulfuric acid solution; and finally, baking is carried out at 90-110 DEG C for 80-120 min to obtain the treated lotus fibers. The modified lotus fiber not only has excellent chemical properties such as moisture absorption and moisture release performance, but also has high medicinal value, and can be used for making close-fitting clothes and articles. Thus, the method for improving the performance of the lotus fiber has a great market prospect, andhas a wide application prospect in the future.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

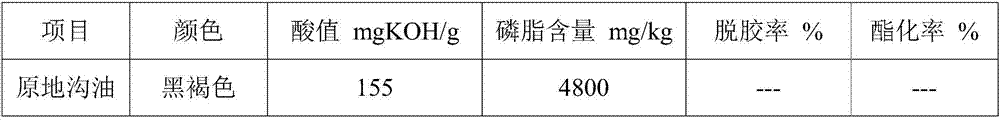

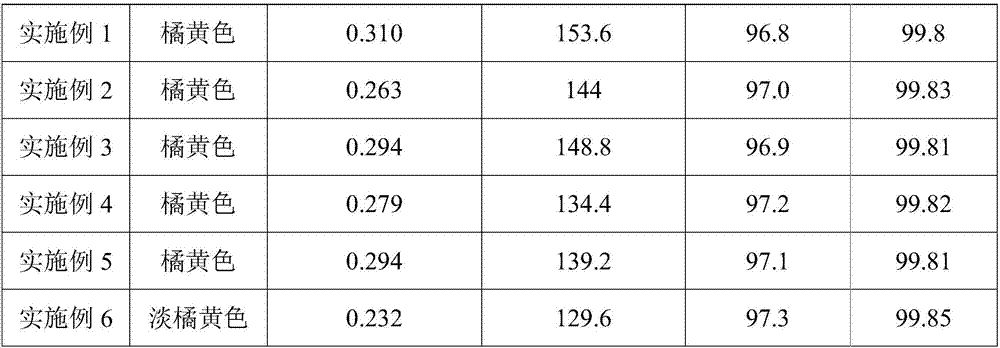

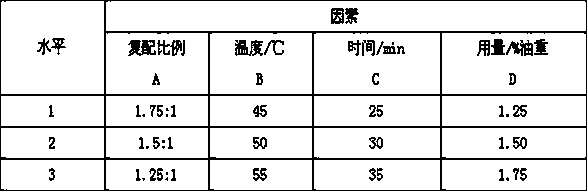

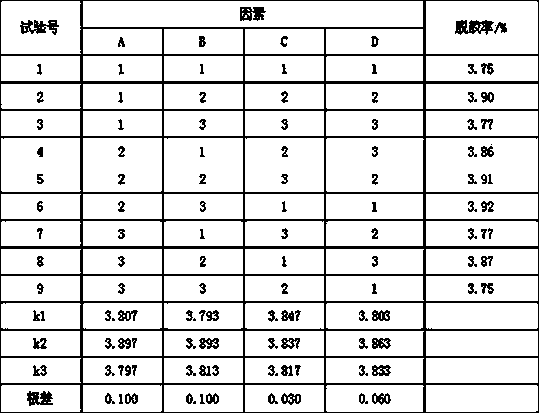

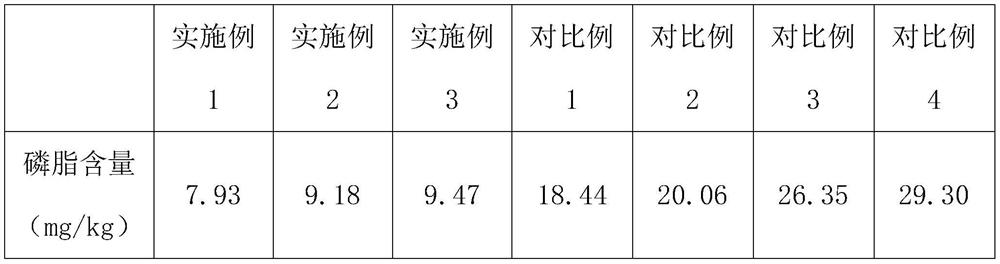

Refining method for recovered gutter oil

InactiveCN107418726AImprove qualityHigh degumming rateFatty oils/acids recovery from wasteFatty-oils/fats refiningActivated carbonGutter oil

The invention discloses a refining method for recovered gutter oil. The refining method comprises steps as follows: S1, gutter oil is taken, solid dregs are removed from the gutter oil, the gutter oil is centrifuged and filtered, and clear oil is obtained; S2, the clear oil obtained in S1 is taken, pH is regulated, the clear oil is heated, phospholipase A2 is added, the mixture is subjected to heat-insulation stirring, heated and centrifuged, an upper oil phase is taken, and degummed oil is obtained; S3, a chemical decolorizing agent is added to the degummed oil obtained in S2, heating and heat-insulation stirring are performed, then diatomite and activated carbon are added, heating and heat-insulation stirring are performed, a mixture is filtered, and a filtrate is obtained; S4, glycerin is added to the filtrate obtained in S3, heating and heat-insulation stirring are performed, and refined gutter oil is obtained. The refining method adopts a simple process and is high in degumming rate, good in decolorization and high in esterification rate, and prepared gutter oil has light color and is low in acid value and low in phospholipid content.

Owner:安庆华威油脂科技有限公司

Degumming method for skipjack crude oil

InactiveCN104232305AHigh transparencyHigh degumming rateFatty-oils/fats refiningAcetic acidPhosphoric acid

The invention discloses a degumming method for skipjack crude oil, and belongs to the field of food processing. The degumming method is used for solving the problems that the phosphoric acid degumming effect is poor and the degummed skipjack oil is low in transparency and dark in color. The degumming method for the skipjack crude oil comprises the following steps: compounding and adding citric acid and acetic acid in a ratio of (2:1) to (1:1) into the skipjack crude oil, and stirring at 40-60 DEG C for at least 20 minutes; and then, centrifuging at a speed of 5000r / min for at least 10 minutes, wherein the mass of the added citric acid and acetic acid is 1.5% of that of the oil. The compounding proportion of the citric acid to the acetic acid is preferably 1.5:1, the mass of the added citric acid and the acetic acid is preferably 1.5% of that of the skipjack crude oil, the stirring temperature is preferably 50 DEG C and the degumming time is preferably 25 minutes. According to the technical scheme adopted in the invention, gum in the skipjack oil is removed, so that the degumming efficiency is as high as 3.93%; and the obtained degummed skipjack oil is good in transparency, lighter in color than the crude oil, lighter in fishlike smell than the crude oil, and better in phosphoric acid degumming effect in comparison with that in the prior art.

Owner:ZHEJIANG OCEAN UNIV

Alkaline pectinase mutant with improved thermostability and its coding gene and application

ActiveCN107460185BImprove thermal stabilityHigh catalytic efficiencyFermentationVector-based foreign material introductionPectinaseSite-directed mutagenesis

The invention discloses an alkaline pectinase mutant with improved heat stability as well as an encoding gene and application of the alkaline pectinase mutant. By carrying out site-specific mutagenesis at two sites of wild alkaline pectinase, the alkaline pectinase mutant with the improved enzyme activity and heat stability and the decreased optimal action temperature is obtained; the optimal enzyme activity temperature of a double mutant pelN-K93I / G241A is decreased by 5 DEG C than that before mutation, Tm is increased by 1.671 DEG C, the half-life period is prolonged by 15.86 minutes at 60 DEG C, Km is decreased from 2.59 g / L to 1.1 g / L, and the optimal enzyme activity temperature is decreased from 67.5 DEG C to 60 DEG C. The alkaline pectinase mutant has relatively high heat stability and relatively high ramie degumming rate, so that the alkaline pectinase mutant is more suitable for degumming processes and has relatively good application potentials in the textile industry.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Garlic sprout leaf fiber

ActiveCN105839417AHigh degumming rateShort degumming timeUltrasonic/sonic fibre treatmentBiochemical treatment with enzymes/microorganismsEnzymeMicrowave

The invention provides garlic sprout leaf fiber with the fracture intensity being 8.5 to 9cn / dtex, the fracture elongation rate being 10 to 11 percent and the fiber length being 20 to 40mm. Preparation steps of the garlic sprout leaf fiber include composite acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soaping, dewatering, fluffing, oiling and drying. The preparation method has the advantages that the fiber degumming time can be shortened; garlic sprout leaf surface attachments can be reduced; the spinning performance can be improved.

Owner:朱兰英

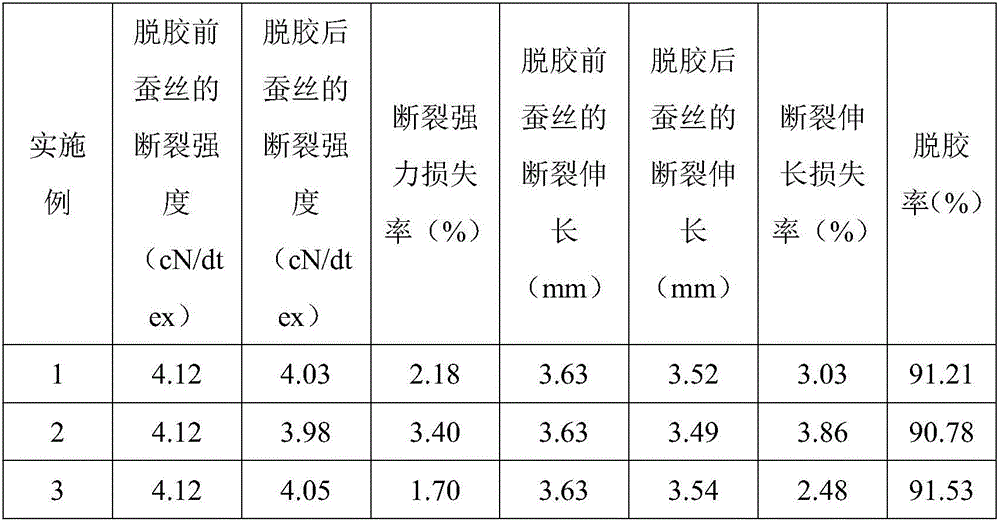

Method for increasing silk degumming rate

The invention discloses a method for increasing the silk degumming rate and belongs to the technical field of degumming. The method for increasing the silk degumming rate comprises steps as follows: S1: to-be-treated silk is immersed into a silk degumming agent, heated under the airtight condition, stirred under the ultrasonic wave action and filtered, and silk is obtained; S2: the silk obtained through filtration in S1 is added to an ethanol-tartaric acid mixed solution and cooled to the room temperature after being heated and stirred; S3: the silk treated in S2 is added to a potassium carbonate solution and cooled to the room temperature after being heated and stirred; S4: the silk treated in S3 is washed clean with deionized water, and gum protein is removed; S5: the silk obtained in S4 is dried, and degummed silk is obtained. The silk treated with the silk degumming method has lower silk breakage strength loss and breaking elongation loss, silk gum in the silk before degumming is basically removed, and the whiteness, the glossiness and the dyeing property of the silk are effectively improved.

Owner:广西立盛茧丝绸有限公司

Preparation method of mulberry fibers

PendingCN114775067AAvoid damageHigh degumming rateVegetable materialBacteriological rettingBiotechnologyPectinase

The invention discloses a mulberry fiber preparation method which is simple and easy to operate, high in product economic benefit and suitable for large-scale production and processing. Before fiber extraction, mulberry bark is subjected to pretreatment such as beating and soaping, and the problem that microorganism-enzyme combined degumming is not thorough can be effectively solved. In the microbial fermentation process, bacteria take colloids as nutrient substances, macromolecular structures of the colloids in the mulberry bark are damaged, gaps among macromolecules are enlarged, fiber aggregates become loose, and enzyme secreted by microorganisms can conduct preliminary degumming on the mulberry bark. And performing biological enzyme degumming through combined treatment of cellulase, alkaline pectinase and neutral protease to obtain mulberry fibers. And further separating the fibers by using the vibration effect of an ultrasonic cell crusher to obtain micron-sized mulberry fibers. The prepared mulberry bark fiber is smooth in surface, high in degumming rate and small in fiber damage, chemical reagents are not used in the whole process, and the requirement for environmental protection is met.

Owner:SUZHOU UNIV

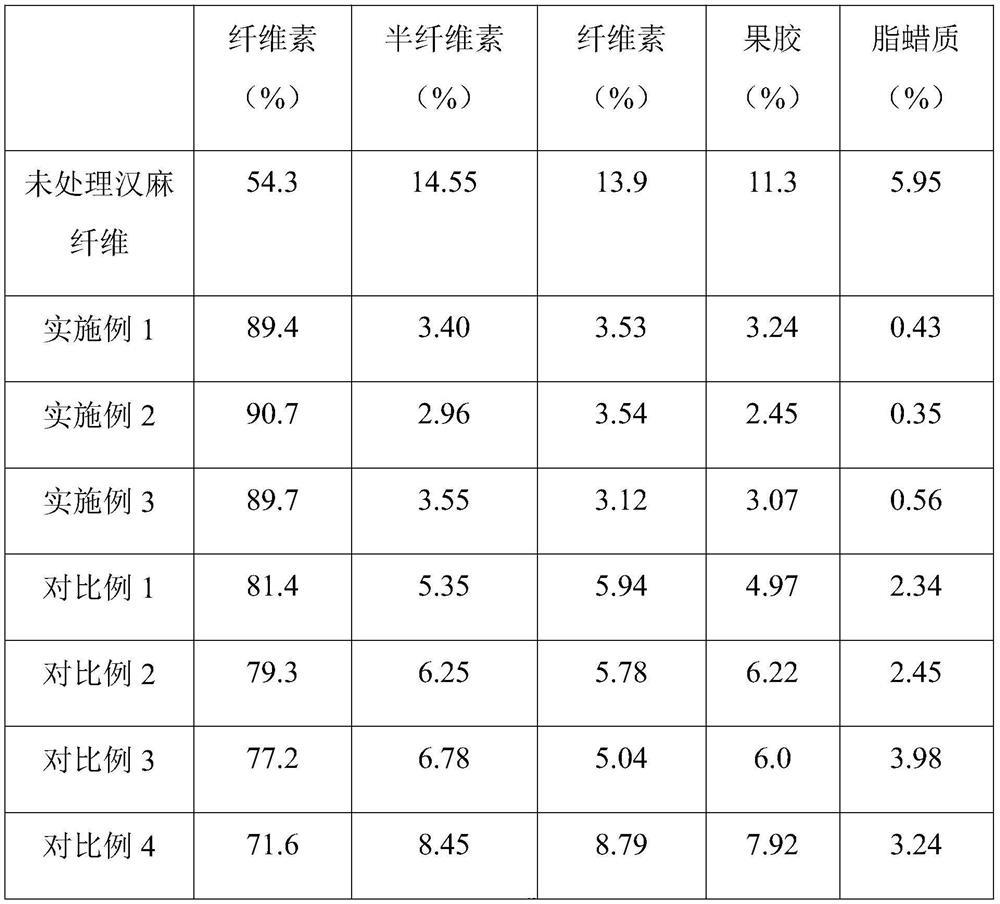

Environment-friendly novel hemp fiber degumming technology

PendingCN114381810AFully moistenedImprove solubilityFibre treatment to obtain bast fibreEngineeringAqueous solubility

The invention discloses an environment-friendly novel hemp fiber degumming technology, and relates to the technical field of textile processing. When the hemp fiber degumming technology is carried out, firstly, the hemp fibers are subjected to ultrasonic pretreatment, and then sulfydryl chitosan treatment, irradiation treatment and steam explosion compound enzyme treatment are carried out; colloid is crushed through ultrasonic pretreatment, part of water-soluble impurities are removed, degumming is facilitated, sulfydryl chitosan and calcium ions in calcium pectate are chelated to generate soluble ammonium salt, and the solubility of pectin is increased; a gelatinous layer on the surface of the fiber is damaged through irradiation, and tiny cracks are generated on the surface; the steam flash explosion compound enzyme treatment overcomes the defect of long time consumption of enzyme degumming treatment, so that the colloid in the hemp fibers is completely separated, and the degumming rate is increased.

Owner:TUNGGA LINENANDCOTTON CO LTD

New bast fiber pectin degumming processing method

InactiveCN105506754AReduce processing technologyIncrease productivityFibre treatment to obtain bast fibrePectinFiber

The invention discloses a new bast fiber pectin degumming processing method. The new bast fiber pectin degumming processing method comprises the following steps: placing original hemp in water, adding dilute sulphuric acid, heating to 35 to 45 DEG C and soaking for 40 to 50 minutes; taking out the original hemp which is soaked with acid and rinsing twice; heating water to 80 to 90 DEG C in a steamer, placing the original hemp in the water, adding a pre-degumming solution at 150 DEG C, continuing heating for 60 minutes, and cooling to 95 DEG C; heating to 135 DEG C and steaming for 10 minutes; heating to 110 DEG C and steaming for 25 minutes; rinsing the pre-degummed original hemp twice; heating water to 70 to 80 DEG C in the other steamer, placing the pre-degummed original hemp in the steamer, adding a degumming solution at 120 DEG C, heating the water for 50 minutes, and finally cooling to 90 DEG C; heating to 115 DEG C and steaming for 10 minutes; heating to 110 DEG C and steaming for 20 minutes; and cooling to room temperature and rinsing the original hemp three times. According to the method disclosed by the invention, the processed fibers are complete; pectin is removed completely; the damage to the fibers is low; the process time is greatly shortened; and the production efficiency is remarkably improved.

Owner:宿州学院

A kind of preparation method of corn bran fiber and corn bran fiber obtained by the method

A method for preparing corn husk fiber, the method comprising (1) screening corn husks free of mildew, soaking them in water overnight, and then performing ultrasonic treatment for 10-20 minutes in an aqueous solution with a bath ratio of 1:15-20; (2 ) Soak corn bran fibers in hydrogen peroxide for pretreatment; (3) Degumming corn bran with biological enzymes; (4) Further degumming corn bran with chemical methods; (5) Finishing. The cornhusk fiber obtained by the preparation method of the invention has low residual glue rate, good fiber fineness and high strength.

Owner:青岛晟任现代农业发展有限公司

Gutter oil degumming and metal salt removing process

PendingCN111718800AEvenly dispersedReduce moisture contentFatty oils/acids recovery from wasteFatty substance recoveryDemulsifierGutter oil

The invention discloses a gutter oil degumming and metal salt removing process. The process comprises the following steps: colloid components in the illegal cooking oil are gathered and separated through acidifying and hydrating, and then the gutter oil is subjected to electric desalting treatment to separate the water phase in which the metal salt is dissolved from the oil phase and thus metal salt components and water components in the gutter oil are removed; specifically, the gutter oil is subjected to degumming and metal salt removal through a gutter oil degumming and metal salt removal device, wherein the mixing cavity is used for processing, the deionized water, the demulsifier and the acid can be uniformly dispersed in the gutter oil, acidification and hydration are facilitated, liquid drops are polymerized in the electric desalting process and thus the degumming rate is improved and the moisture content in the gutter oil is reduced; meanwhile, due to the integrated arrangement,the occupied area can be reduced, the integration degree of the device is improved, the power output device, the output adjusting device and the mixing cavity are arranged in a scattered mode, the convenience during overhauling is improved, meanwhile, the working efficiency is improved through continuous production, and the modern industrial production requirement is met.

Owner:YANGZHOU JIANYUAN BIOLOGICAL TECH CO LTD

Preparation method of cotton stalk bark fibers

ActiveCN104047064AReduce damageHigh whitenessFibre treatment to obtain bast fibreFiberSupercritical carbon dioxide

The invention relates to a preparation method of cotton stalk bark fibers. The method comprises the following steps: removing impurities, bundling, caging, conducting chemical pretreatment, conducting supercritical carbon dioxide fluid degumming treatment, washing, dewatering, feeding oil, combing, and drying, wherein the chemical pretreatment method comprises acid soaking-ultrasonic treatment, and boiling off. The obtained fibers are high in degumming efficiency, low in fiber damage, and high in fiber performance, thus meeting the modern and environment-friendly requirement.

Owner:重庆新锐科技服务有限公司

A kind of preparation method of cotton stalk fiber

ActiveCN104047064BShort timeHigh degumming rateFibre treatment to obtain bast fibreFiberSupercritical carbon dioxide

A method for preparing cotton stalk fiber, wherein the method includes removing impurities, binding, caged, chemical pretreatment, supercritical carbon dioxide fluid degumming treatment, washing, dehydrating, oiling, carding, and drying, wherein the The chemical pretreatment methods include pickling - ultrasonic treatment, scouring. The obtained fiber has high degumming rate, small fiber damage and high fiber performance, which meets the requirements of modern green environmental protection.

Owner:重庆新锐科技服务有限公司

Degumming method of rice bran oil

ActiveCN111793523AHigh degumming rateLow residual phosphorusFatty-oils/fats refiningFatty substance recoveryCelluloseCarboxymethyl cellulose

The invention discloses a degumming method of rice bran oil. The method comprises the following steps: S1, mixing an acid solution of carboxymethyl cellulose and rice bran crude oil, heating to a temperature of 65-80 DEG C, and carrying out thermal insulation stirring for 20-30 min; and S2, heating an aqueous solution of hydroxypropyl guar gum to 65-80 DEG C, then adding the heated aqueous solution of hydroxypropyl guar gum into the material obtained in step S1, carrying out ultrasonic treatment for 4-8 min, then carrying out heat preservation and stirring for 20-30 min, carrying out centrifugal separation, and taking upper-layer grease, so as to obtain the rice bran oil after degumming treatment. The degumming method disclosed by the invention has the advantage of low residual phosphoruscontent of the degummed rice bran oil, can greatly improve the degumming efficiency of the rice bran oil degumming process, is beneficial to subsequent decolorization and refining treatment, and is simple in process, low in cost and convenient to popularize and apply.

Owner:BENGBU QIONGHUAI GRAIN & OIL

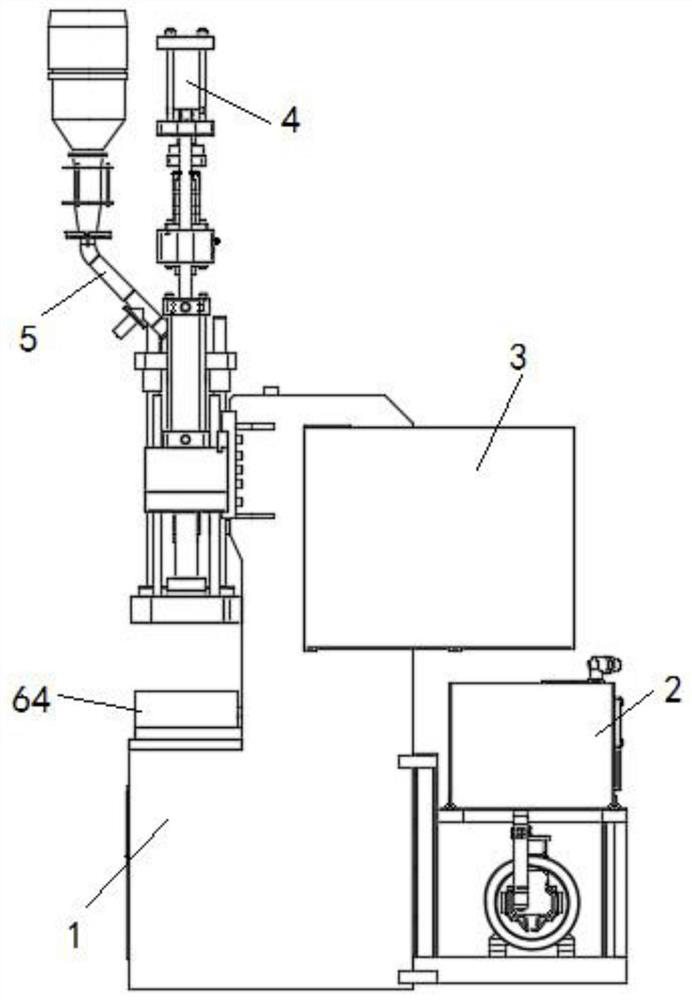

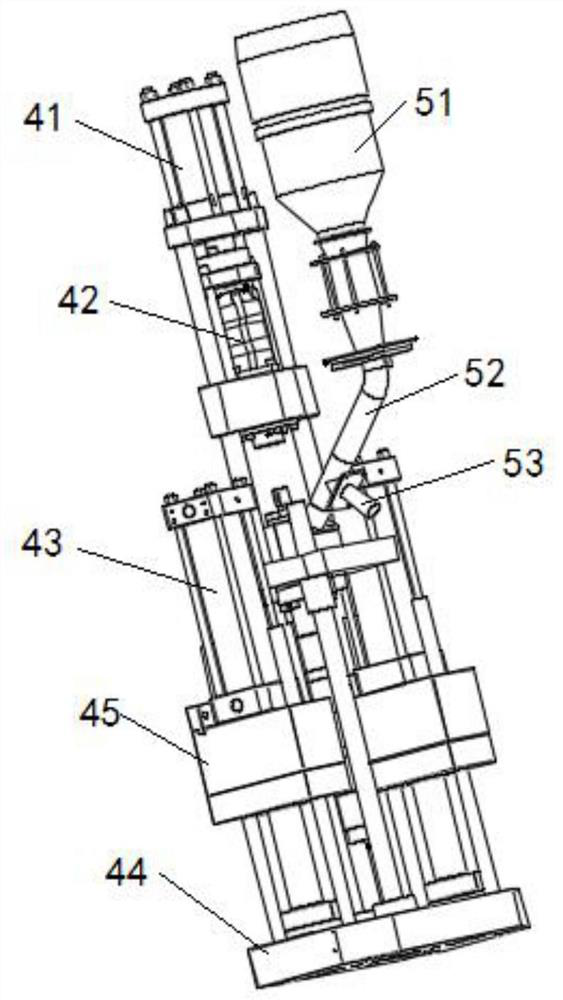

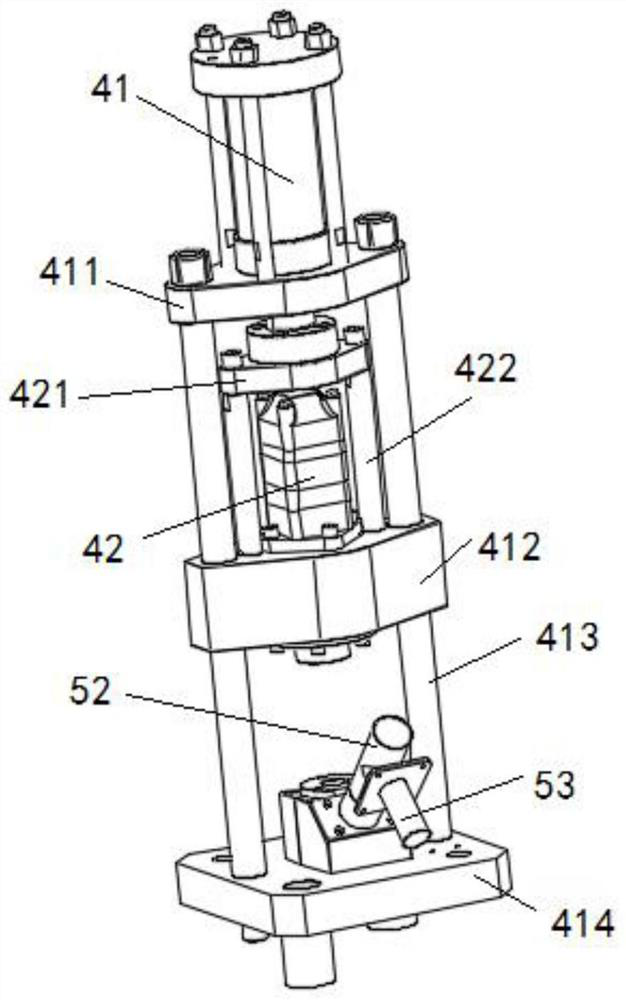

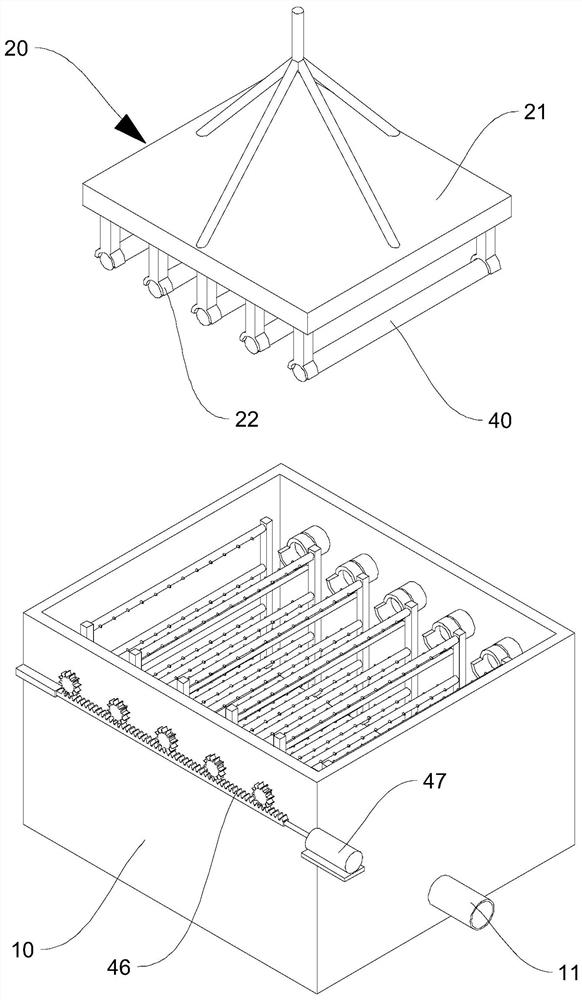

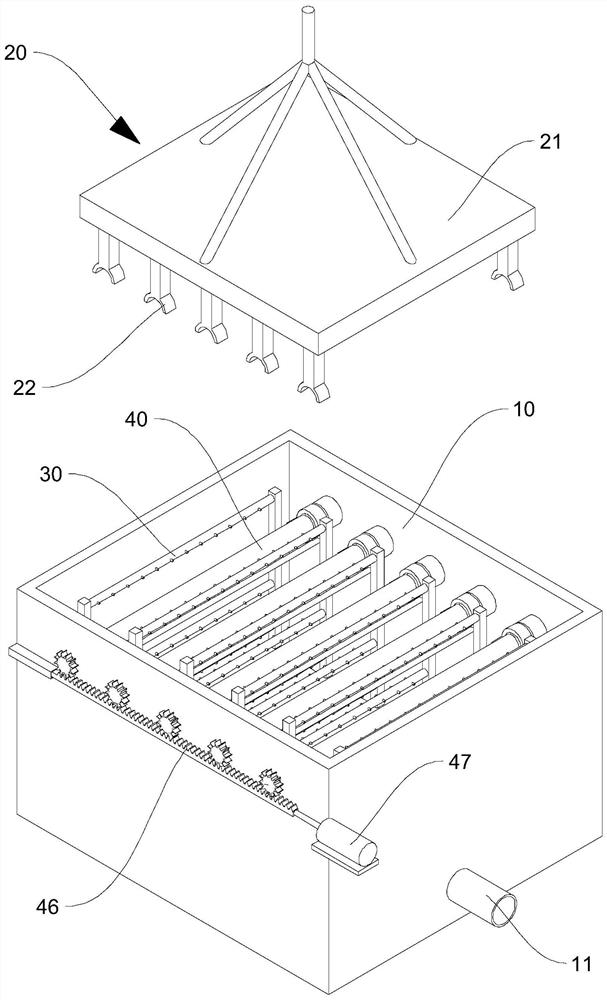

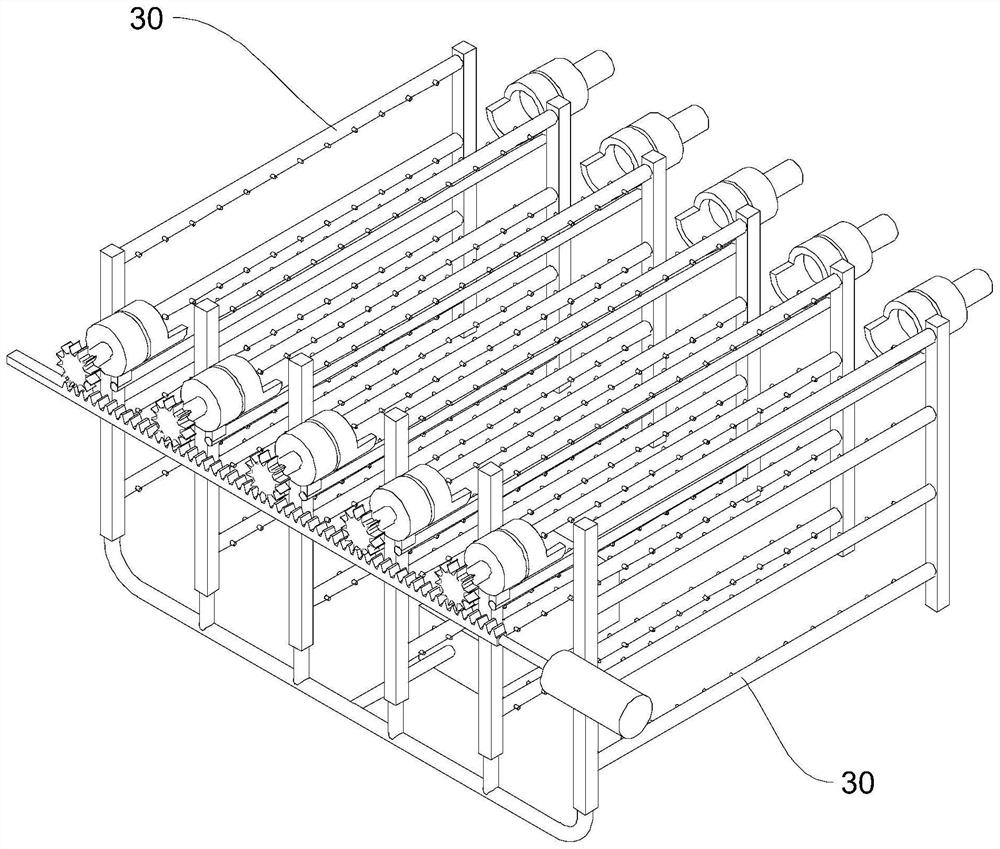

Ramie degumming device and degumming method

ActiveCN113235168AConvenient follow-upImprove qualityFibre treatment to obtain bast fibreProcess engineeringMechanical engineering

The invention provides a ramie degumming device. The ramie degumming device comprises a plurality of box bodies with openings in the upper ends, guide rails arranged above the box bodies, and a plurality of grabbing devices arranged above the box bodies; the multiple box bodies are evenly distributed in the conveying direction of the guide rails; the guide rails are used for conveying the grabbing devices; a spraying device, a suspension device and a plurality of suspension rods are arranged in each box body; the suspension devices are used for supporting suspension rods; the grabbing devices are used for grabbing the suspension rods; and the suspension rods are used for suspending ramie strips. The ramie degumming device can efficiently and automatically complete degumming operation. The invention further provides a degumming method used in cooperation with the degumming device. By alternately using biological degumming and chemical degumming, degumming can be more efficient.

Owner:SICHUAN ZITONG LINJIANG RAMIE TEXTILE

A kind of garlic leaf fiber, reed viscose fiber and milk fiber blended fabric

ActiveCN105926268BHigh degumming rateShort degumming timeRadio/micro wave fibre treatmentUltrasonic/sonic fibre treatmentViscoseMoisture absorption

The invention provides a garlic sprout leaf fiber, reed viscose fiber and milk fiber blended fabric. The weight ratio of garlic sprout leaf fibers, reed viscose fibers and milk fibers is 15-45:20-50:30-40. Preparation steps of the garlic sprout leaf fibers include composite acid preprocessing, low-temperature plasma processing, microwave irradiation and alternate complex enzyme processing, washing, soaping, dehydrating, fluffing, oil feeding and drying. The blended fabric has the advantages that the blended fabric has fragrance of milk fibers and excellent moisture absorption and moisture conduction performances and healthcare performance.

Owner:常熟市德美针纺织有限公司

Method for efficiently preparing fatty acid from recycled illegal cooking oil

InactiveCN107299000AHigh degumming rateImprove qualityFatty substance recovery/refiningFatty acids production/refiningHydrogenFiltration

The invention discloses a method for efficiently preparing fatty acid from recycled illegal cooking oil. The method comprises the following steps: S1, taking illegal cooking oil, carrying out primary filtration, adding phosphoric acid, heating, carrying out heat preservation and stirring, then adding water, continuously carrying out heat preservation and stirring, centrifuging and taking an oil phase, and carrying out secondary filtration, so that clear oil liquid is obtained; S2, adding water into the clear oil liquid obtained in the S1, uniformly mixing, then adding a catalyst and an adsorbent, heating, carrying out heat preservation and stirring, introducing hydrogen, continuously carrying out heat preservation and stirring, carrying out reduced pressure evaporation, and collecting evaporated gas, so that the fatty acid is obtained. The method disclosed by the invention has the advantages that an appropriate catalyst and adsorbent are selected, and an appropriate preparation technology is combined, so that yield of the fatty acid is greatly increased, preparation period is shortened, and preparation efficiency is improved.

Owner:安庆华威油脂科技有限公司

A kind of preparation method of garlic leaf fiber

ActiveCN105908263BHigh degumming rateShort degumming timeVegetable materialMechanical fibre separationFiberMicrowave

The invention provides a method for preparing garlic bolt leaf fibers. The method comprises the steps of compound acid pretreatment, low-temperature plasma treatment, microwave radiation and complex enzyme alternate treatment, water washing, soap washing, dewatering, shaking to be loose, oil feeding and drying. According to the method for preparing the garlic bolt leaf fibers, fiber degumming time can be shortened, attachments on the surfaces of the garlic bolt leaf fibers can be reduced, spinnability can be improved, and the garlic bolt leaf fibers prepared through the method for preparing the garlic bolt leaf fibers have high strength and elongation at break and large length.

Owner:南通隆特家纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com