Ramie degumming device and degumming method

The technology of a degumming device and a degumming method is applied in the direction of producing bast fibers by chemical method, which can solve the problems of affecting the production efficiency of cellulose quality in ramie, low ramie degumming rate, etc., and achieve convenient subsequent finishing, good degumming effect, and fiber quality. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

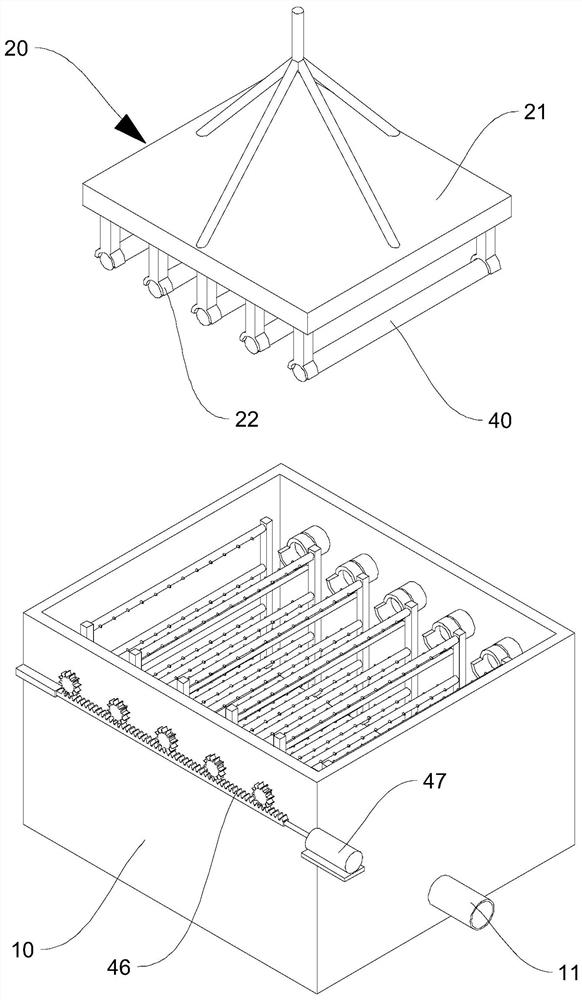

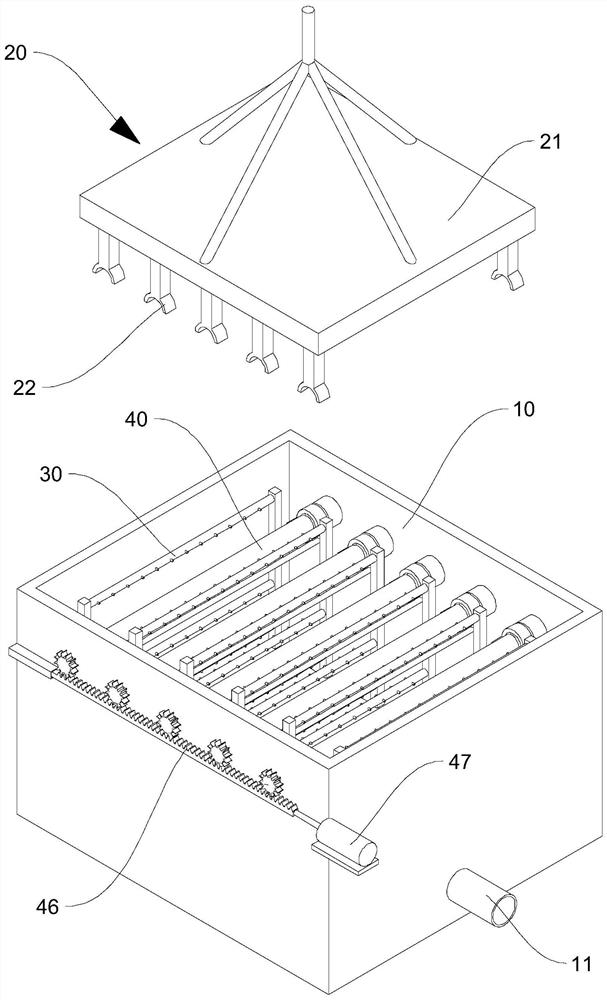

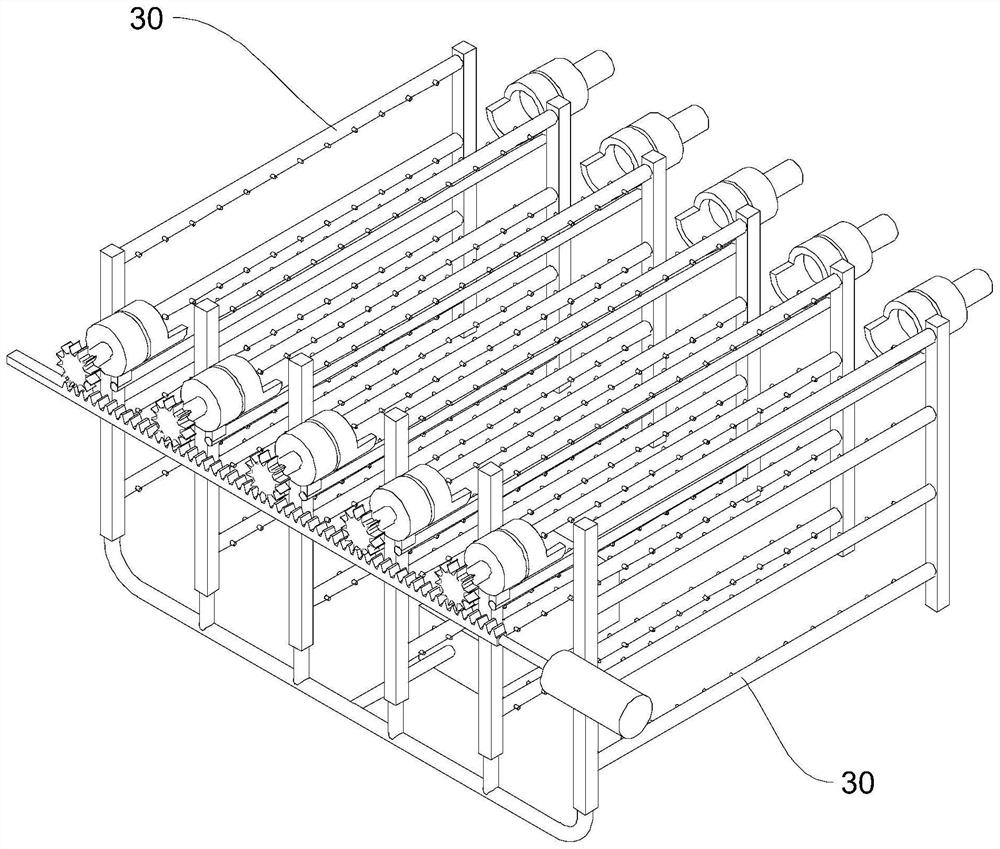

[0043] Below in conjunction with specific embodiment the degumming device of ramie of the present invention is further described, as attached figure 1 - attached Figure 8 Shown, the degumming device of the ramie in the present embodiment comprises the box body 10 of upper end opening of many pieces, is located at the guide rail above box body 10, and a plurality of grasping devices 20 that is located at box body 10 tops; The body 10 is evenly distributed along the transport direction of the guide rail; the guide rail is used to transport the grabbing device 20; the inside of the box body 10 is provided with a spraying device, a suspension device and a plurality of suspension rods 40; the suspension device is used to support the suspension rod 40; the grabbing device 20 is used for grabbing suspension bar 40; Suspension bar 40 is used for hanging ramie strip. Specifically, hang the ramie strips on the suspension rod 40, and use the grabbing device 20 to automatically grab the...

Embodiment 2

[0051] Use the degumming device in embodiment 1 to carry out degumming to ramie strip. The main operation steps are:

[0052] (1) pretreatment, stripping fresh ramie to obtain ramie strips with a large amount of fibers therein; using an extrusion device to fully compress the ramie strips, and hanging the ramie strips evenly on the suspension rod; using multiple grabbing devices At the same time, grab the suspension rod, wherein the liquids sprayed by the spray devices in the multiple boxes along the transport direction of the guide rail are biological degumming liquid, flushing liquid, chemical degumming liquid and flushing liquid in sequence, and repeat the arrangement in sequence;

[0053] (2) Biological degumming, the grabbing device grabs the suspension rod on which the ramie strips are suspended, and places it in the suspension device in the box, so that the ramie strips are fully washed by the biological degumming liquid in the box, wherein the biological degumming The ...

Embodiment 3

[0060] Use the degumming device among the embodiment 1 and the degumming method among the embodiment 2 to process 100kg through the ramie after stripping the hemp.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com