Adhesive tape sticking machine with pull-apart mechanism

A technology of gluing machines and rubber wheels, which is applied in labeling machines, labels, packaging, etc., can solve problems such as low efficiency, and achieve the effects of improving firmness, preventing mutual interference, and not easy to slip off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

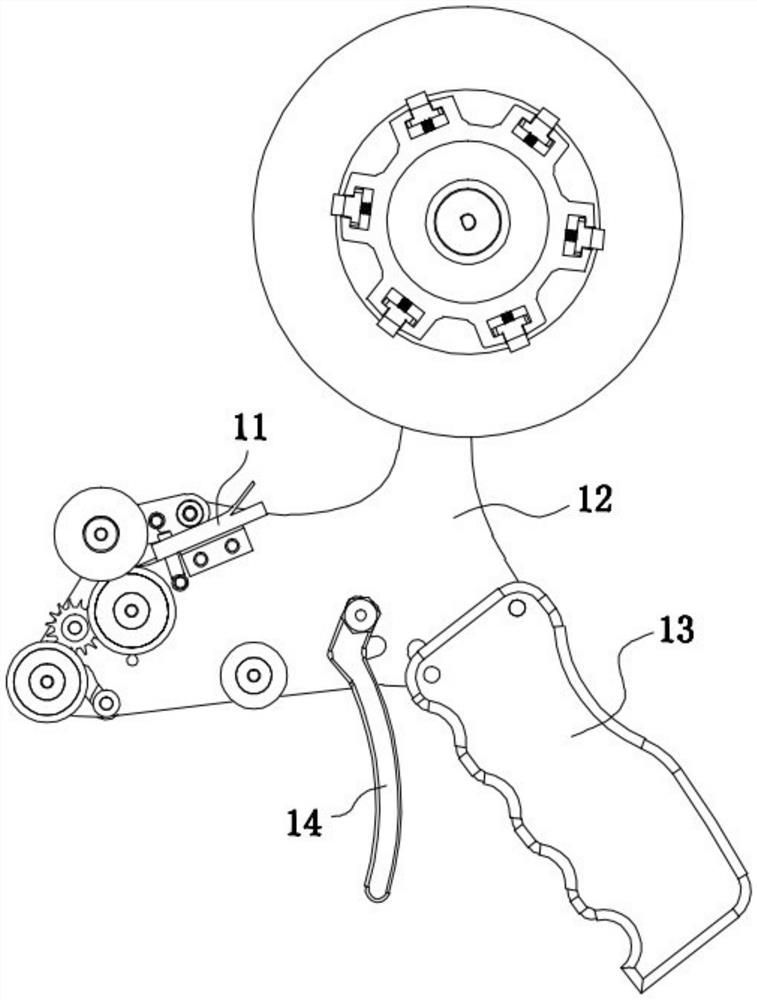

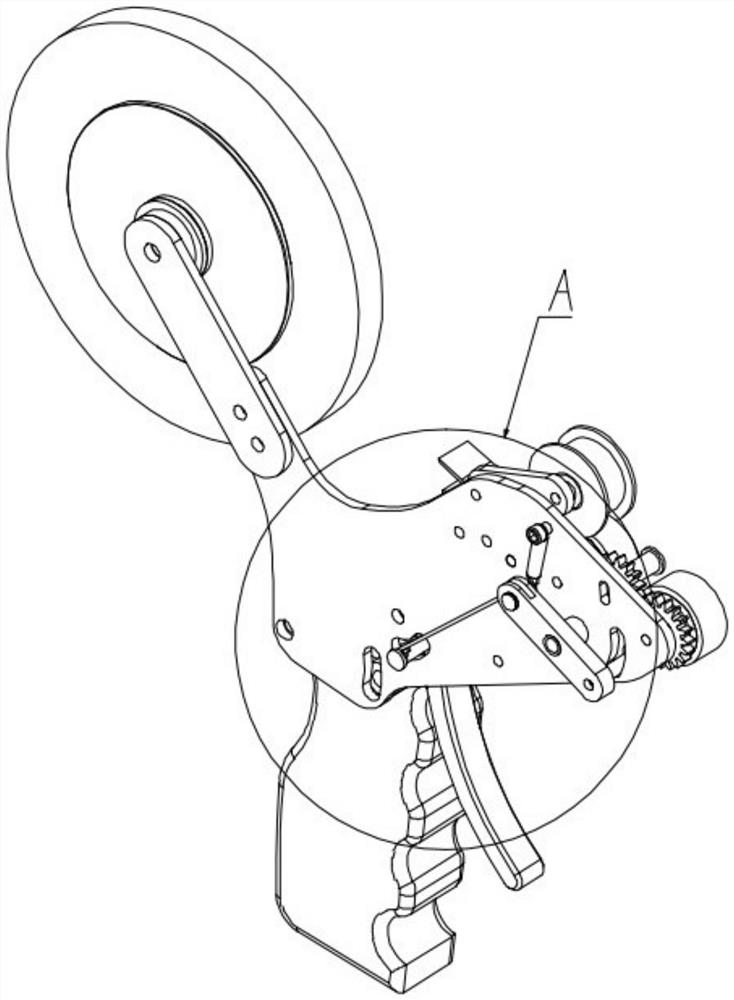

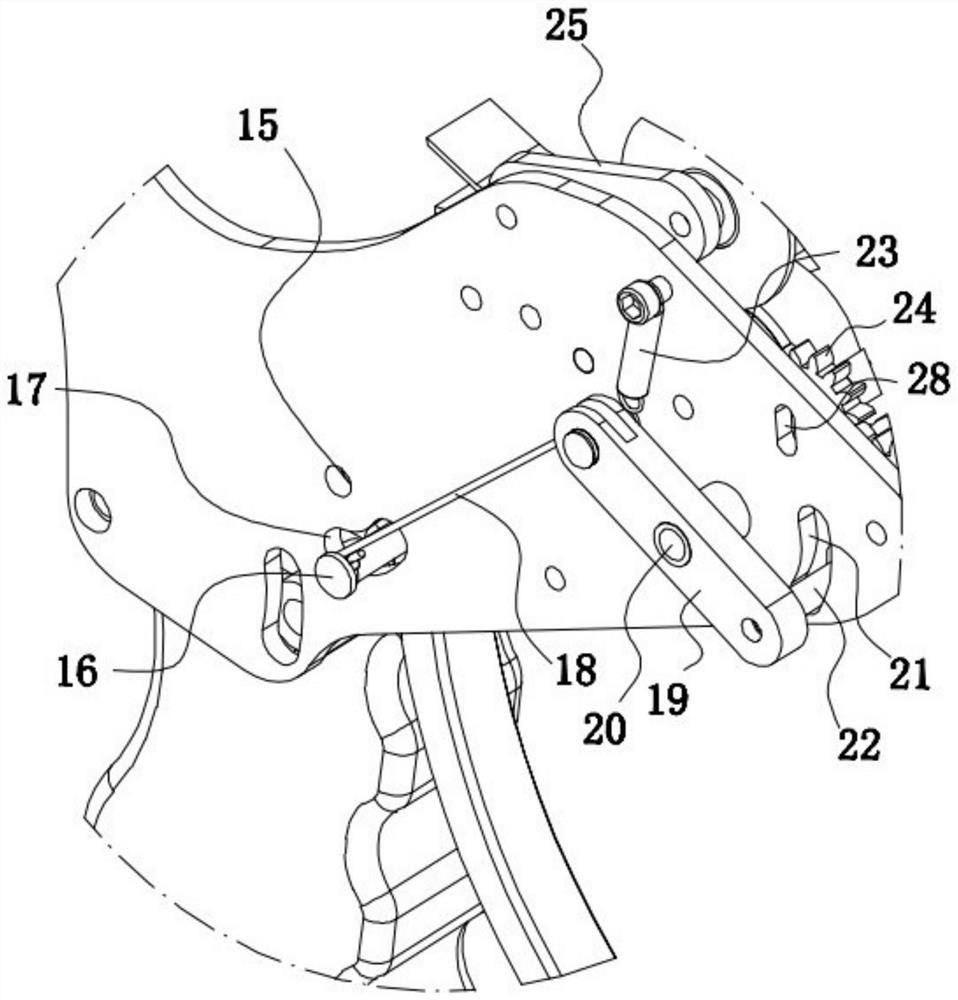

[0035] In order to achieve the purpose of the present invention, a glue applicator with a tear-off mechanism includes: a storage wheel 4, which stores an adhesive tape 1 in a coiled state; a glue wheel 7, the adhesive tape 1 on the storage wheel 4 is drawn out and In contact with the gluing wheel 7, the gluing wheel 7 rolls and attaches the adhesive tape 1. The adhesive tape 1 is composed of a release paper 3 and a double-sided adhesive 2 that are attached to each other. After passing through the gluing wheel 7, the double-sided adhesive 2 1. The release paper 3 is conveyed and separated in different directions; the movable wheel 6 is arranged in parallel with the gluing wheel 7, along the transmission path of the adhesive tape 1, the movable wheel 6 is arranged between the gluing wheel 7 and the storage wheel 4, and the movable The wheel 6 and the glue whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com