Shielding film and pasting method therefor

A technology of shielding film and film layer, applied in the bonding method of surface pretreatment, magnetic field/electric field shielding, electrical components, etc., can solve the problems of waste generation, waste of raw materials, etc., to reduce waste, improve paste efficiency, save The effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

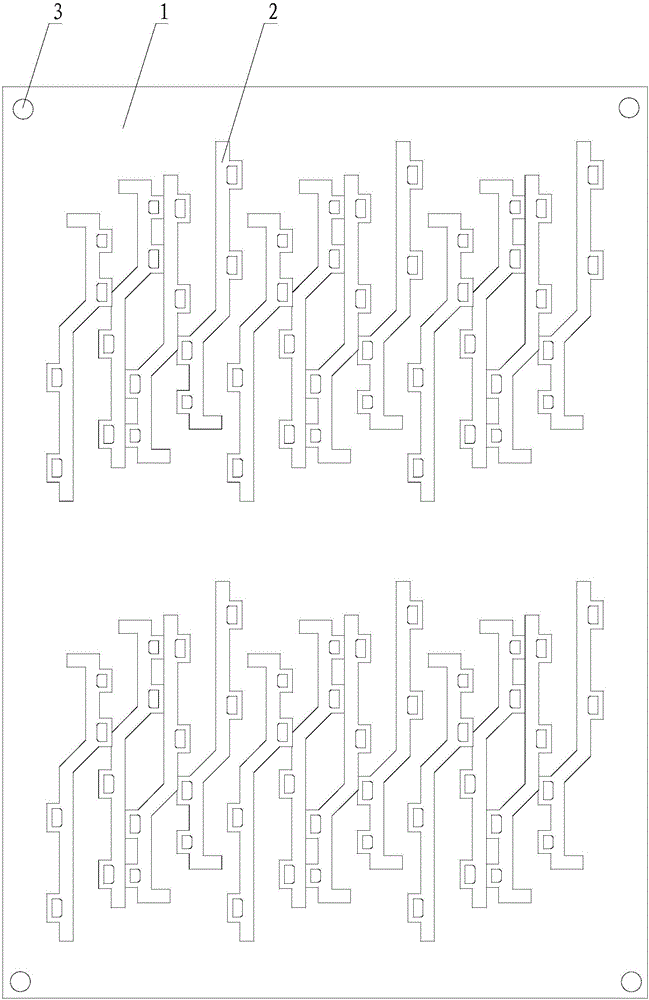

[0030] Please refer to figure 1 , Embodiment 1 of the present invention is:

[0031] A method for pasting a shielding film. The adhesive film 1 is punched. The adhesive film 1 includes a film layer and an adhesive layer, the adhesive layer is arranged on the film layer, and the adhesive layer is silica gel. The through hole 3 obtained after the adhesive film 1 is punched can be used as a mark and a positioning reference, and the viscosity of the adhesive film 1 is 0.5kgF / cm; the protective film on the shielding film is surface treated to increase the roughness of the protective film surface , so that the adhesive film 1 is closely connected with the protective film on the shielding film, it is convenient to remove the protective film on the shielding film when the adhesive film 1 is removed. The surface roughness Ra of the protective film is 1-3um, and Rz is 3 -5um.

[0032] The shielding film is punched to form a shielding film unit 2, the number of the shielding film unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com