Lead and conductor connection device of strain gauge

A technology of wire connection and strain gauge, which is applied in the direction of flexible lead devices, measuring devices, clamping/spring connections, etc., can solve the problems of short circuit, disconnection of wires and terminals, unfavorable economic and environmental protection, etc., to prevent short circuit Phenomenon, prevent mutual crossing, avoid the effect of short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

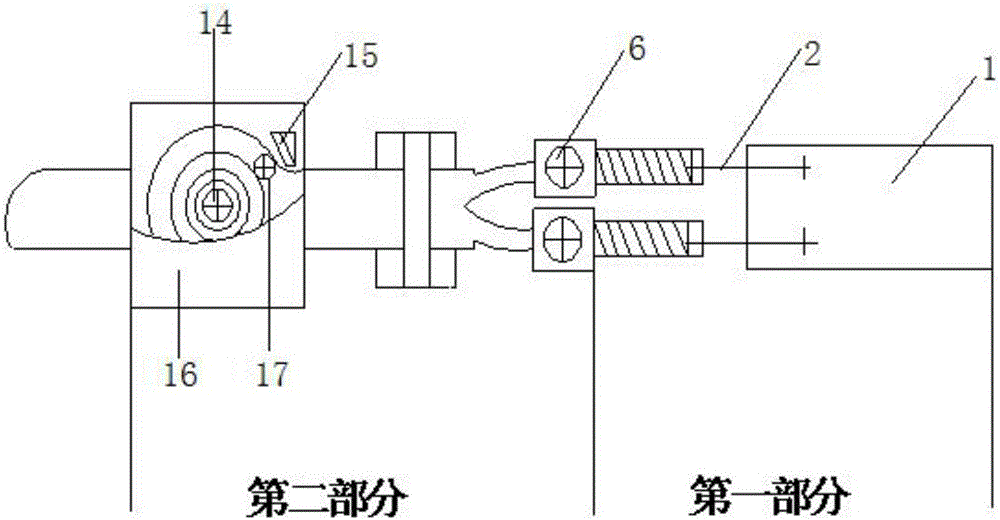

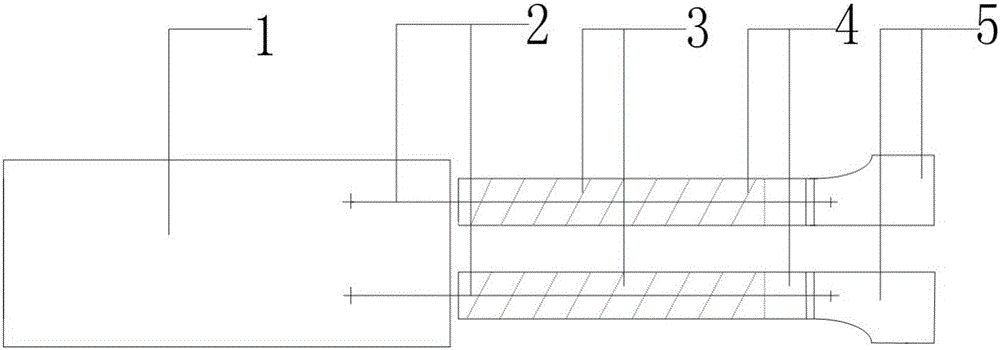

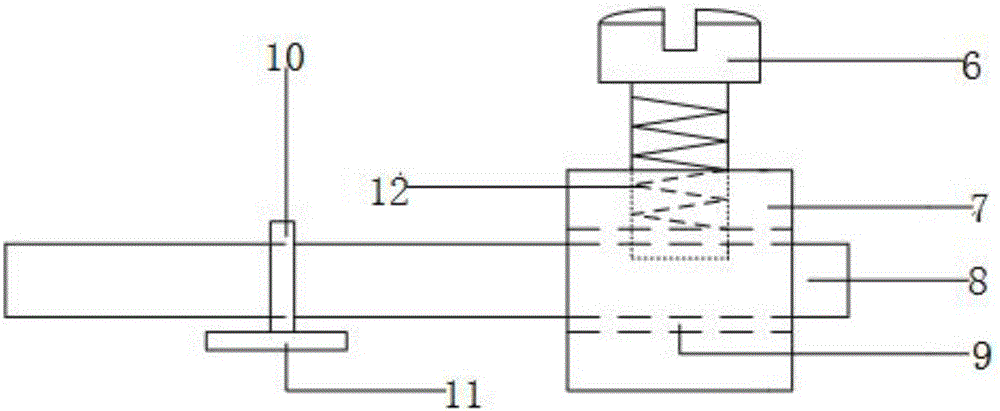

[0017] The main structure of this embodiment is composed of a strain gauge lead device (the first part) and a strain gauge lead and wire connection device (the second part). The strain gauge lead device includes a strain gauge 1, a lead 2, a translucent rectangular parallelepiped colloid 3, Double-sided tape 4, arc welding piece 5, strain gauge lead and wire connection device including half-round head cross bolt 6, fastening block 7, wire 8, wire through hole 9, fastening tape 10, adhesive sheet 11, threaded hole 12. Clockwork sheet 13, clockwork pin 14, lock 15, housing 16, and stop shaft 17; strain gauge 1 and two leads 2 are connected by two solder points on the upper surface of strain gauge 1; two leads 2 are connected by Two translucent rectangular parallelepiped colloids 3 are wrapped. The translucent rectangular parallelepiped colloid 3 has a certain degree of hardness (toughness) (cannot be broken at one time); the ends of the two leads 2 pass through a series of solder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com