Patents

Literature

1713results about "Rapid change measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

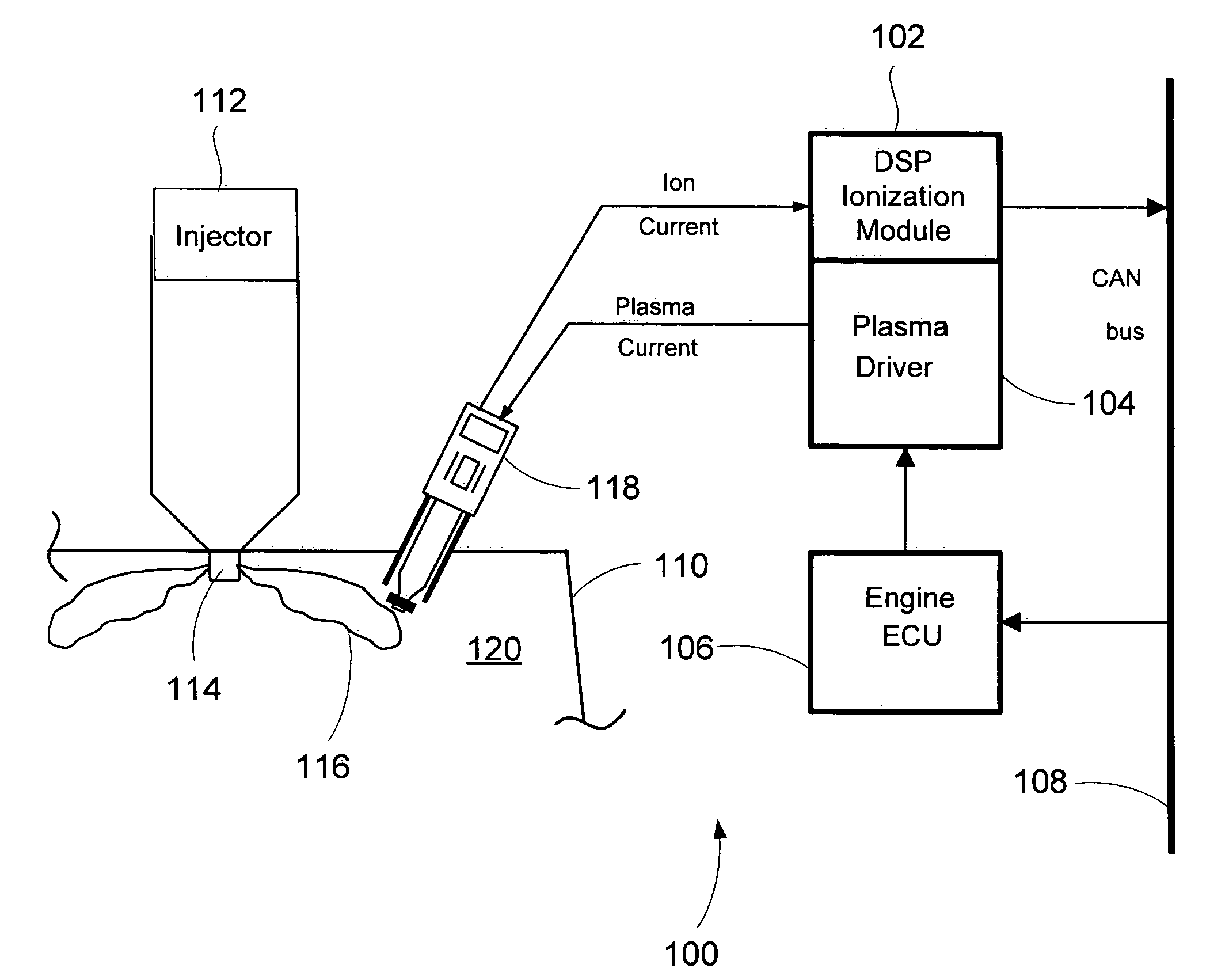

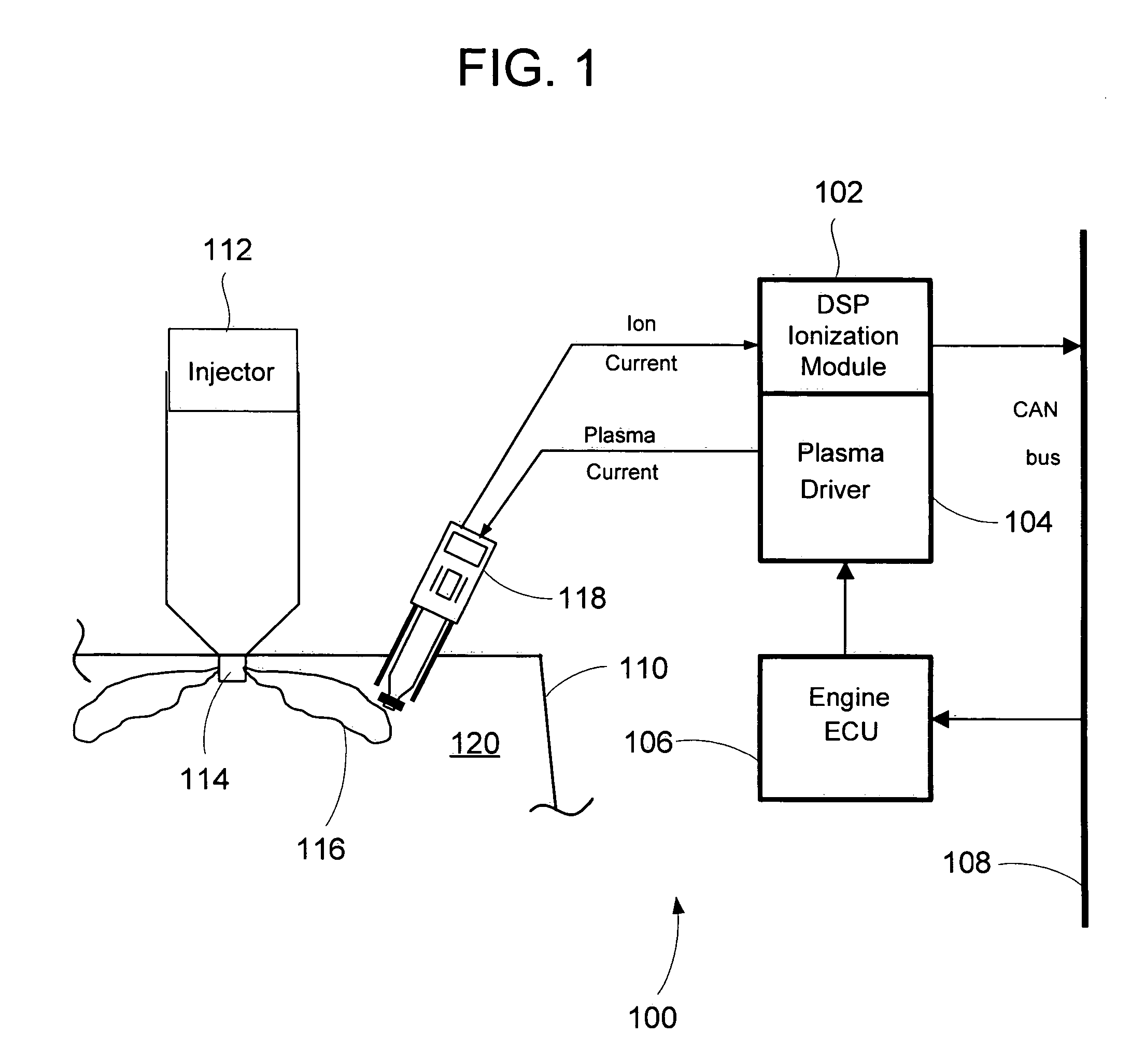

Method and apparatus for detecting ionization signal in diesel and dual mode engines with plasma discharge system

Owner:WOODWARD GOVERNOR CO

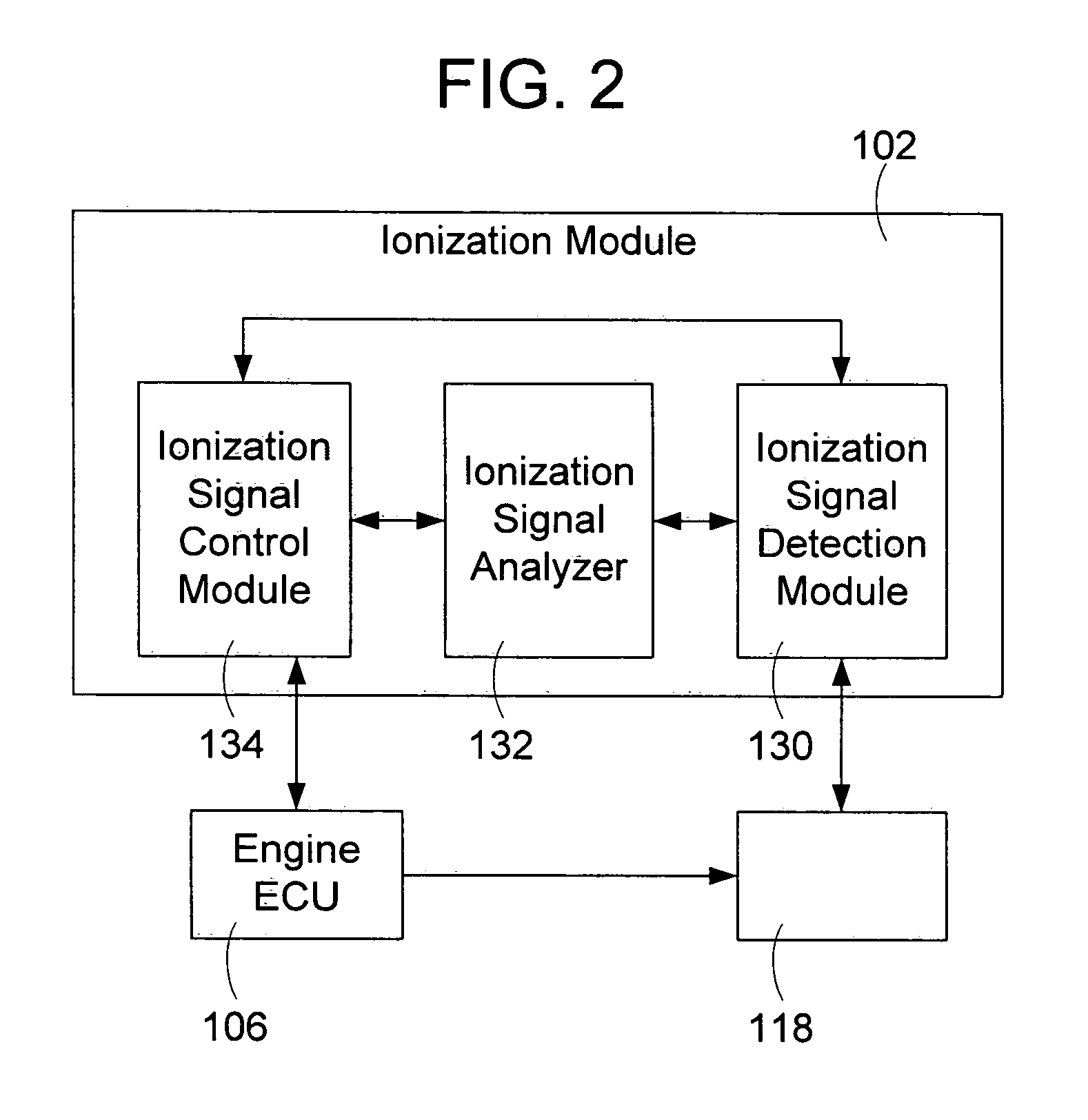

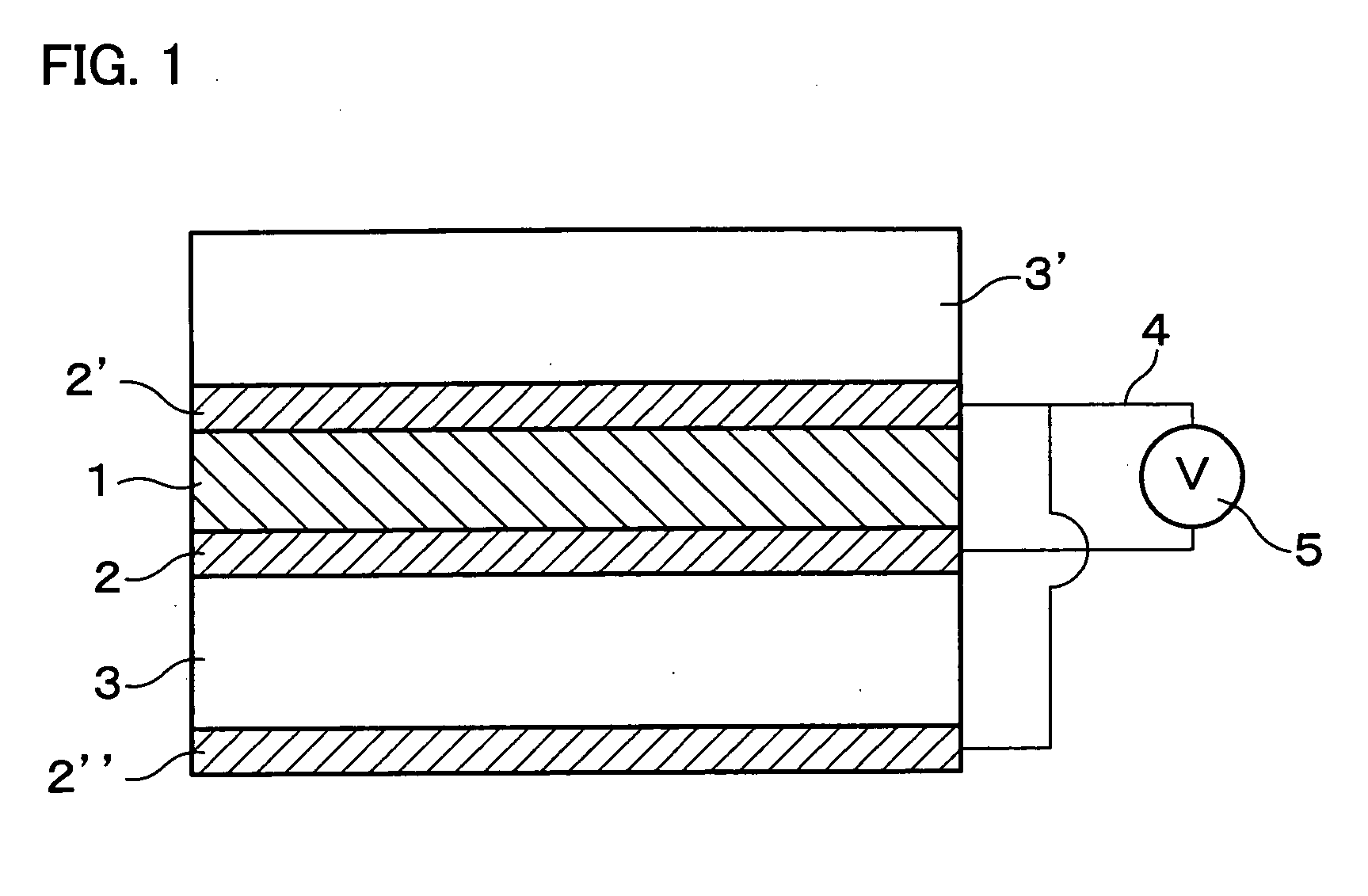

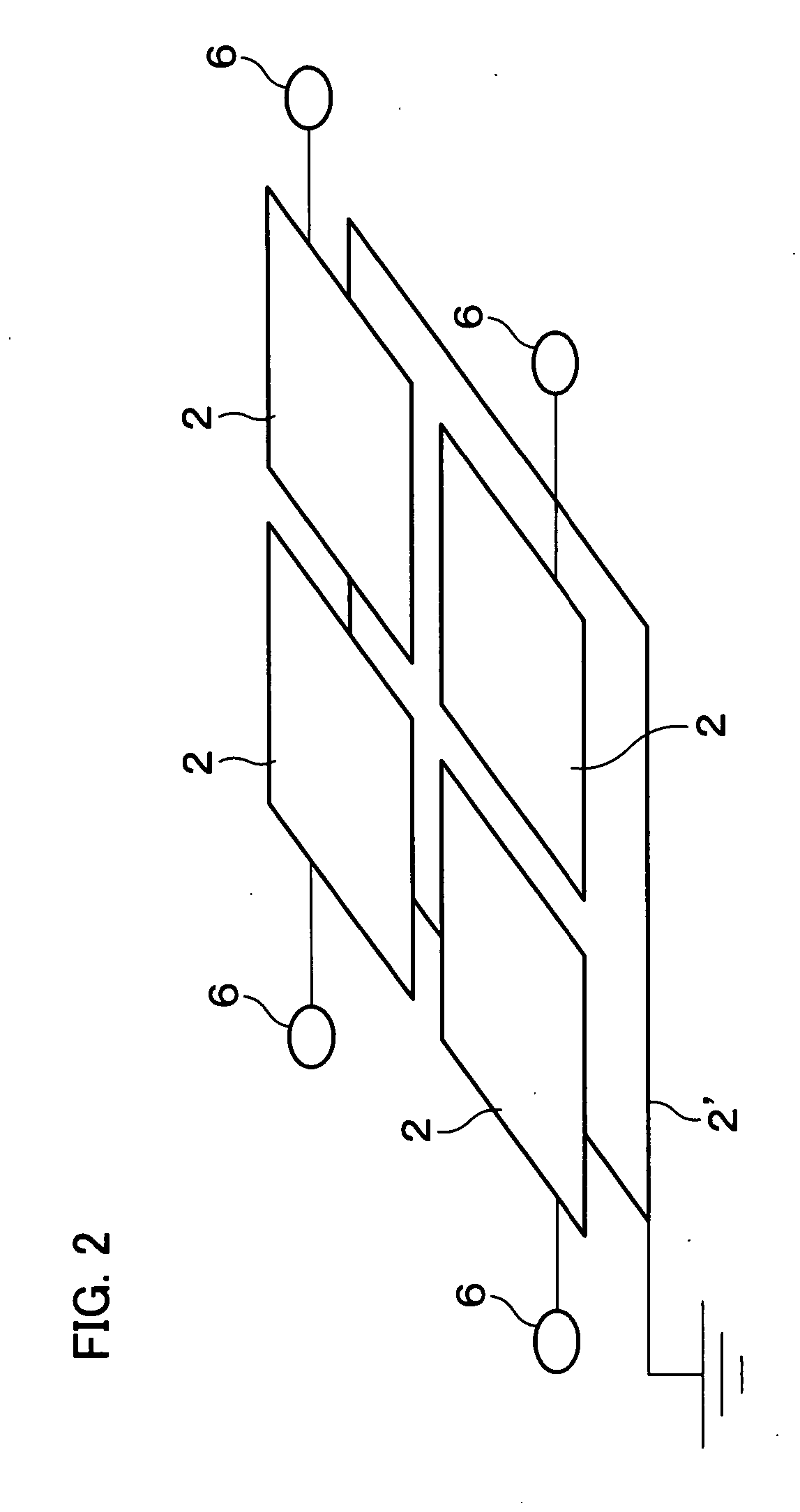

Piezoelectric sensor and input device comprising same

InactiveUS20060144154A1Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

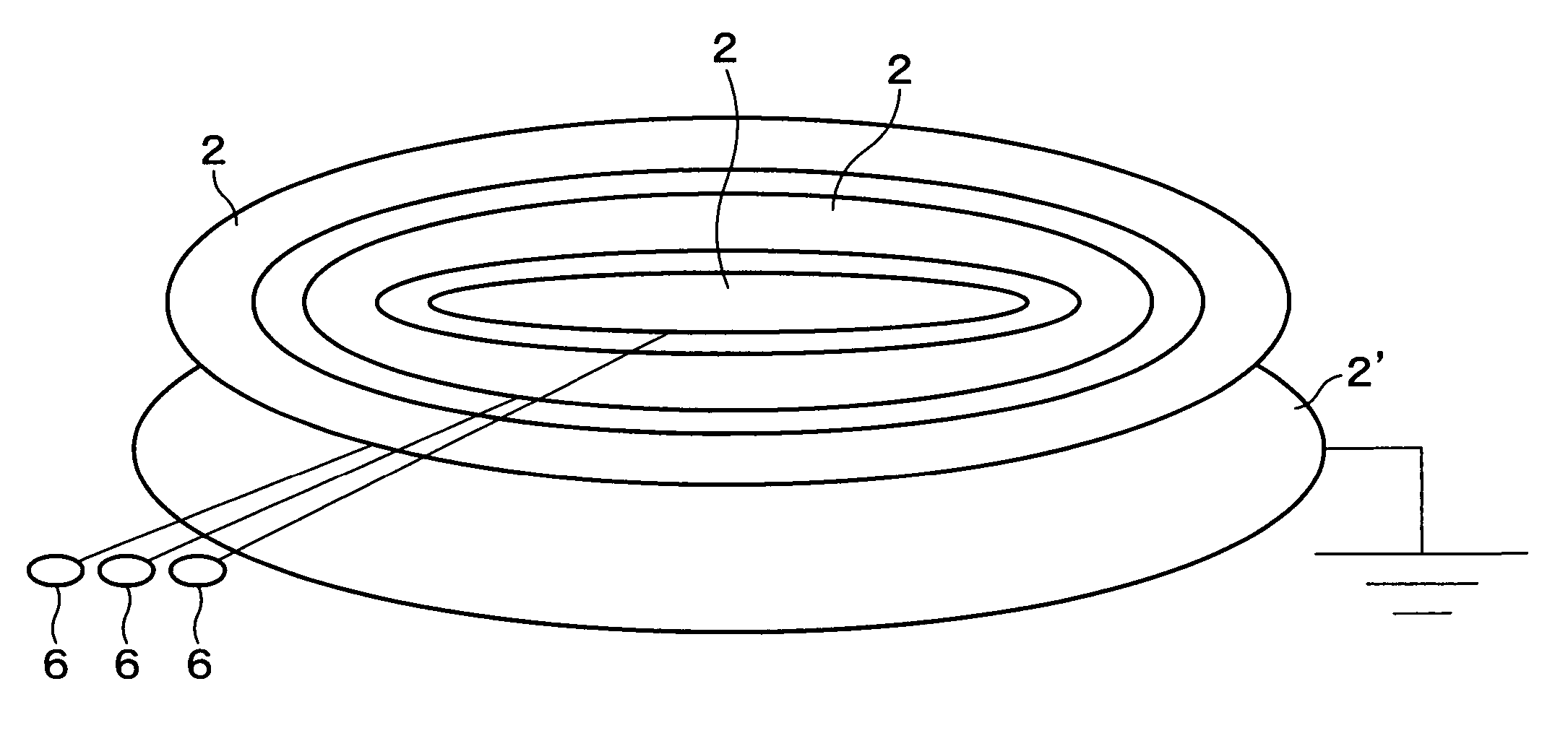

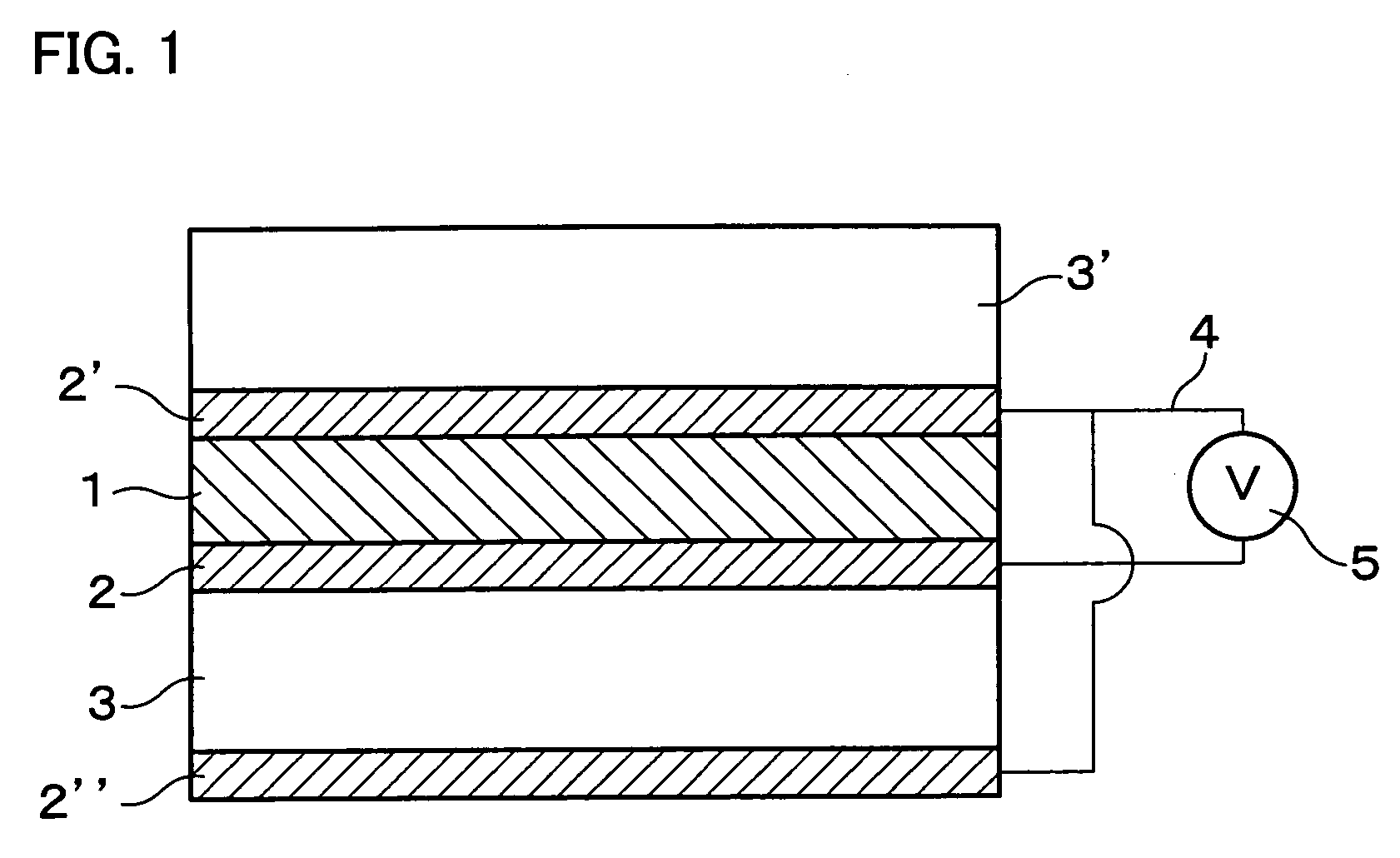

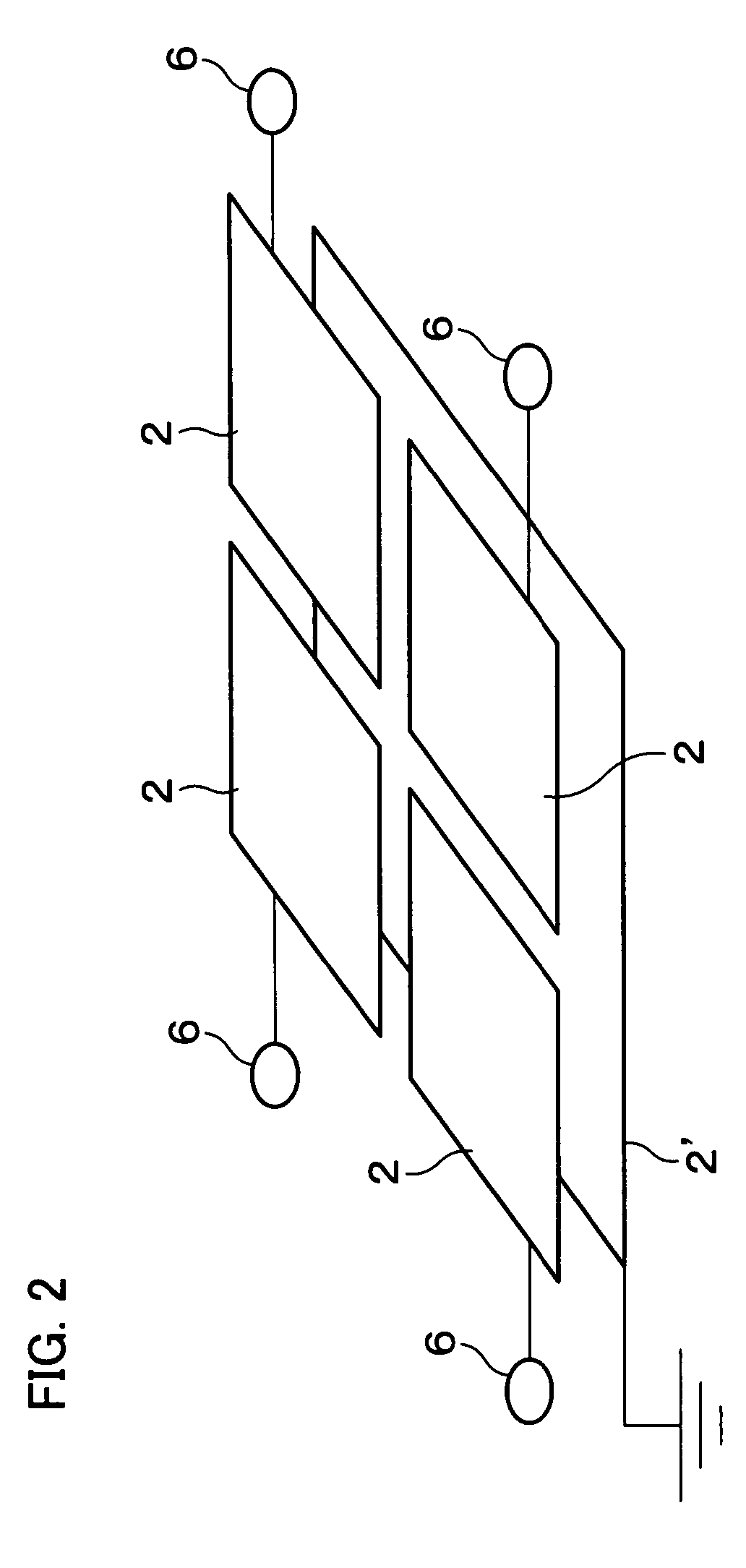

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

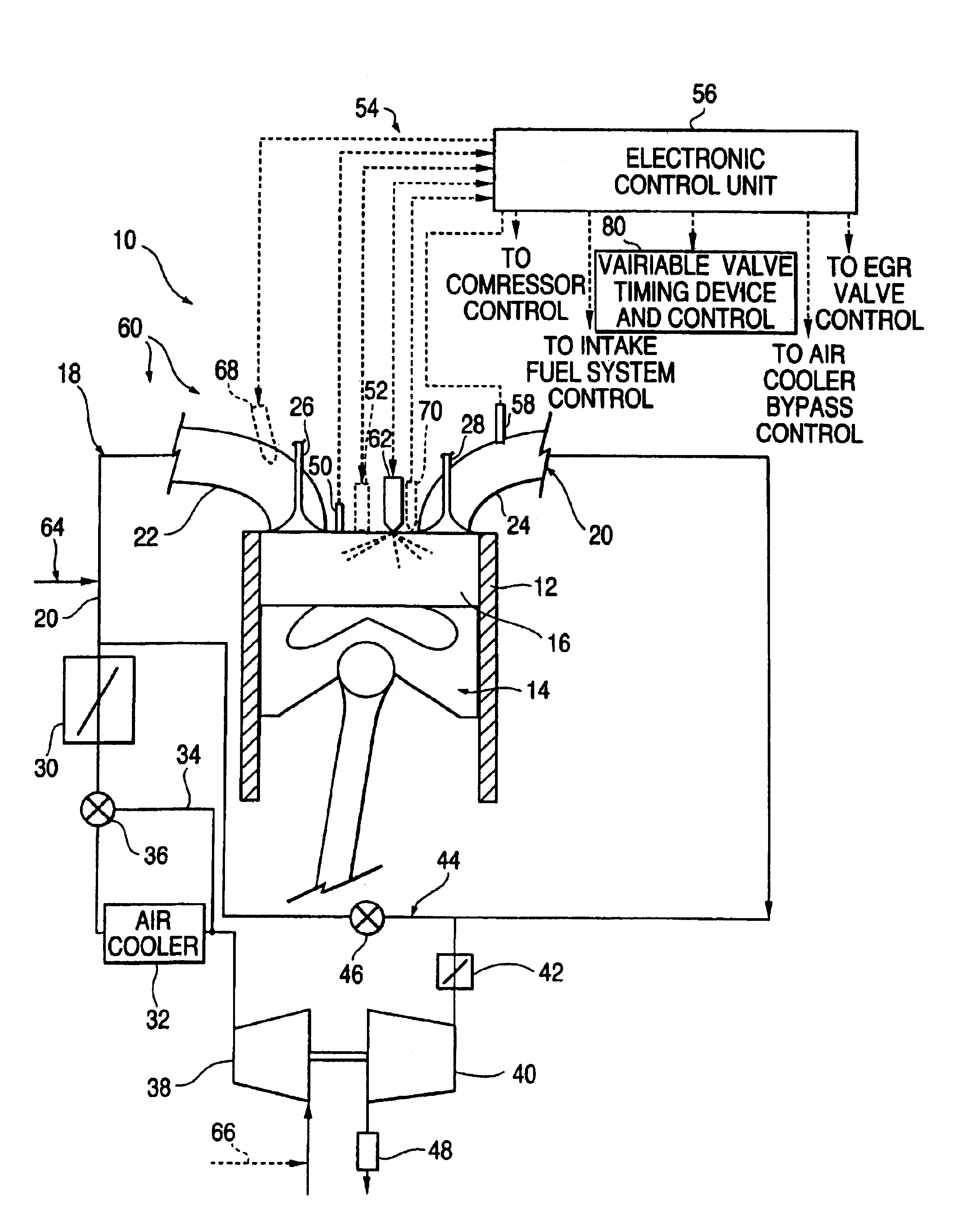

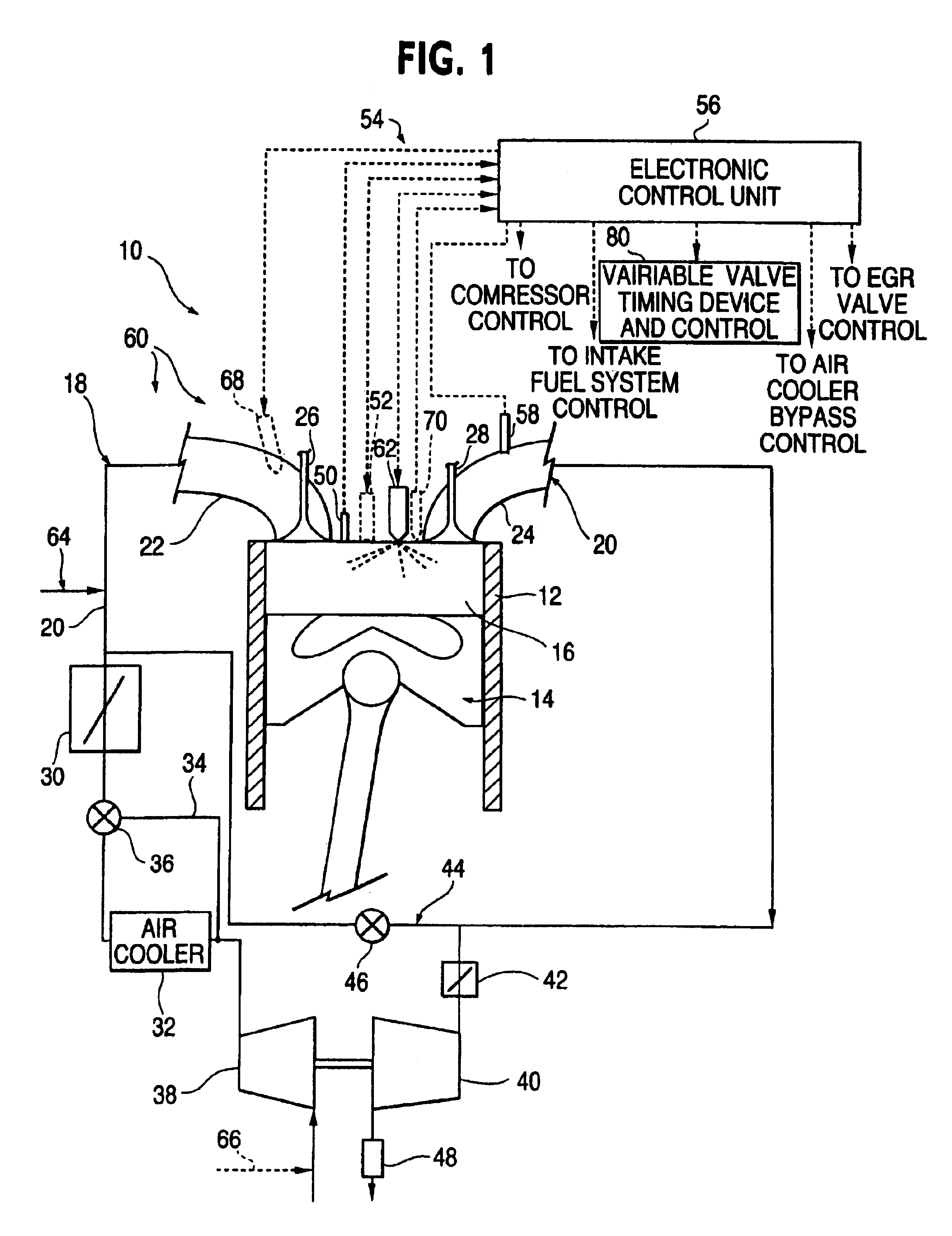

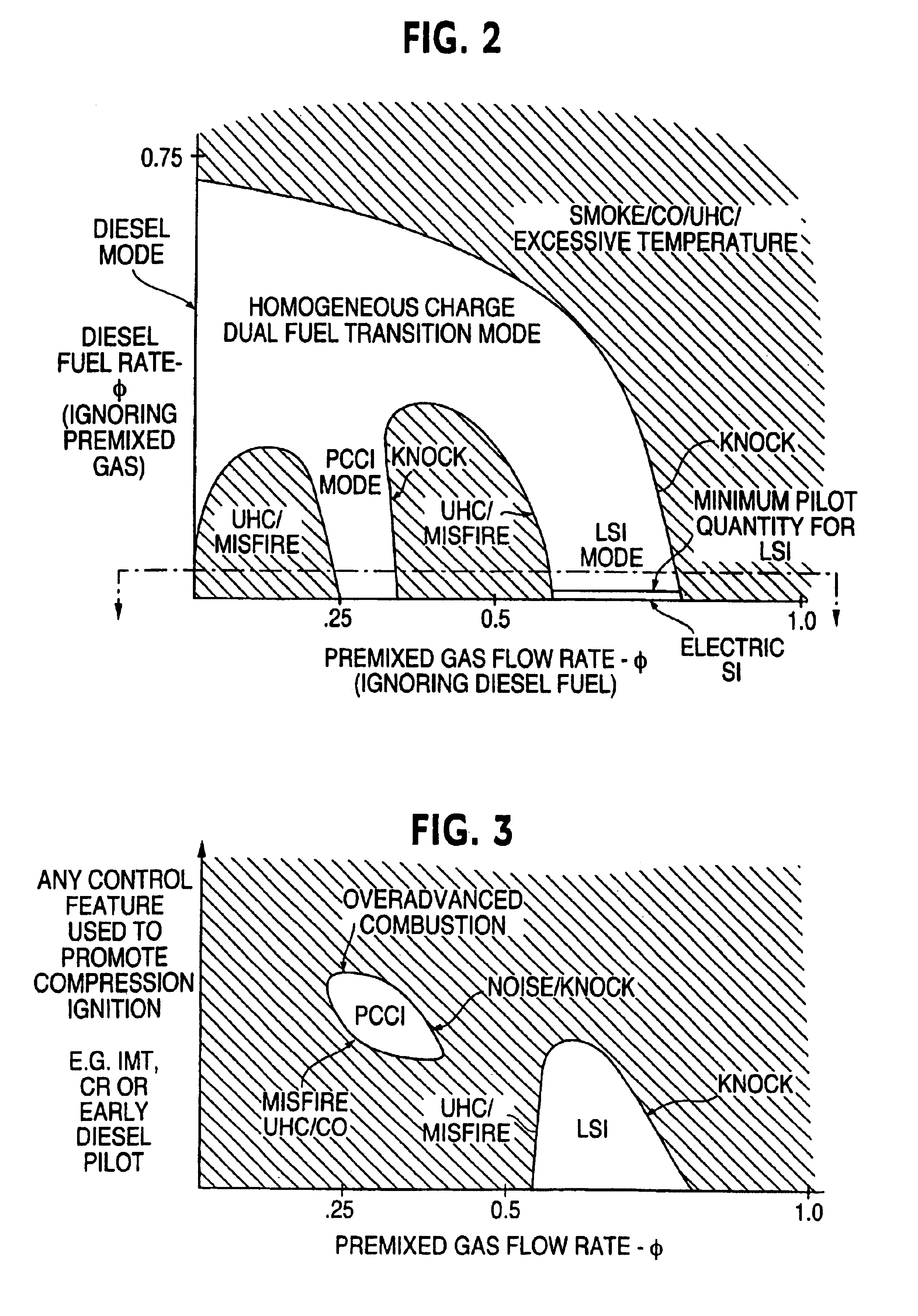

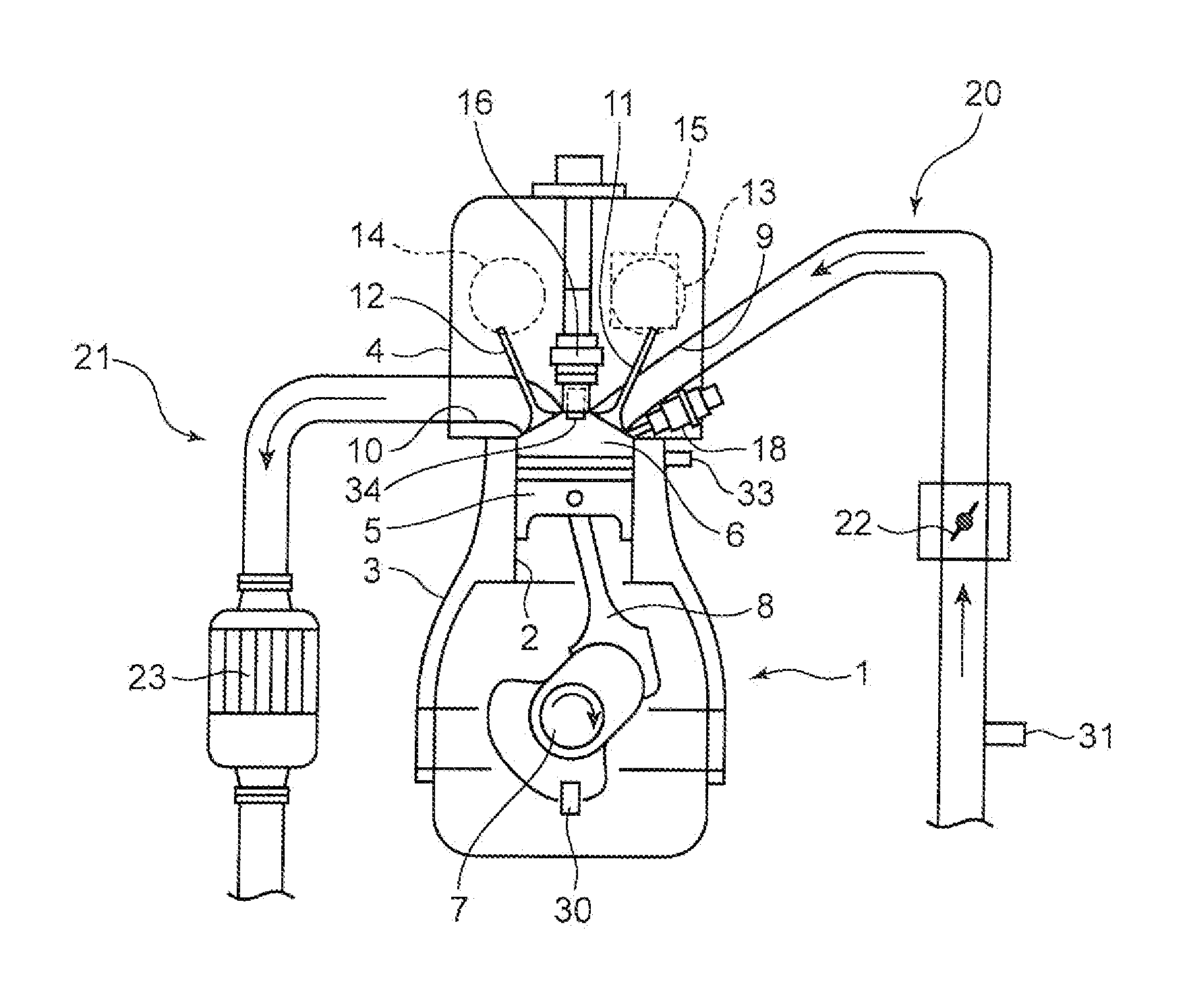

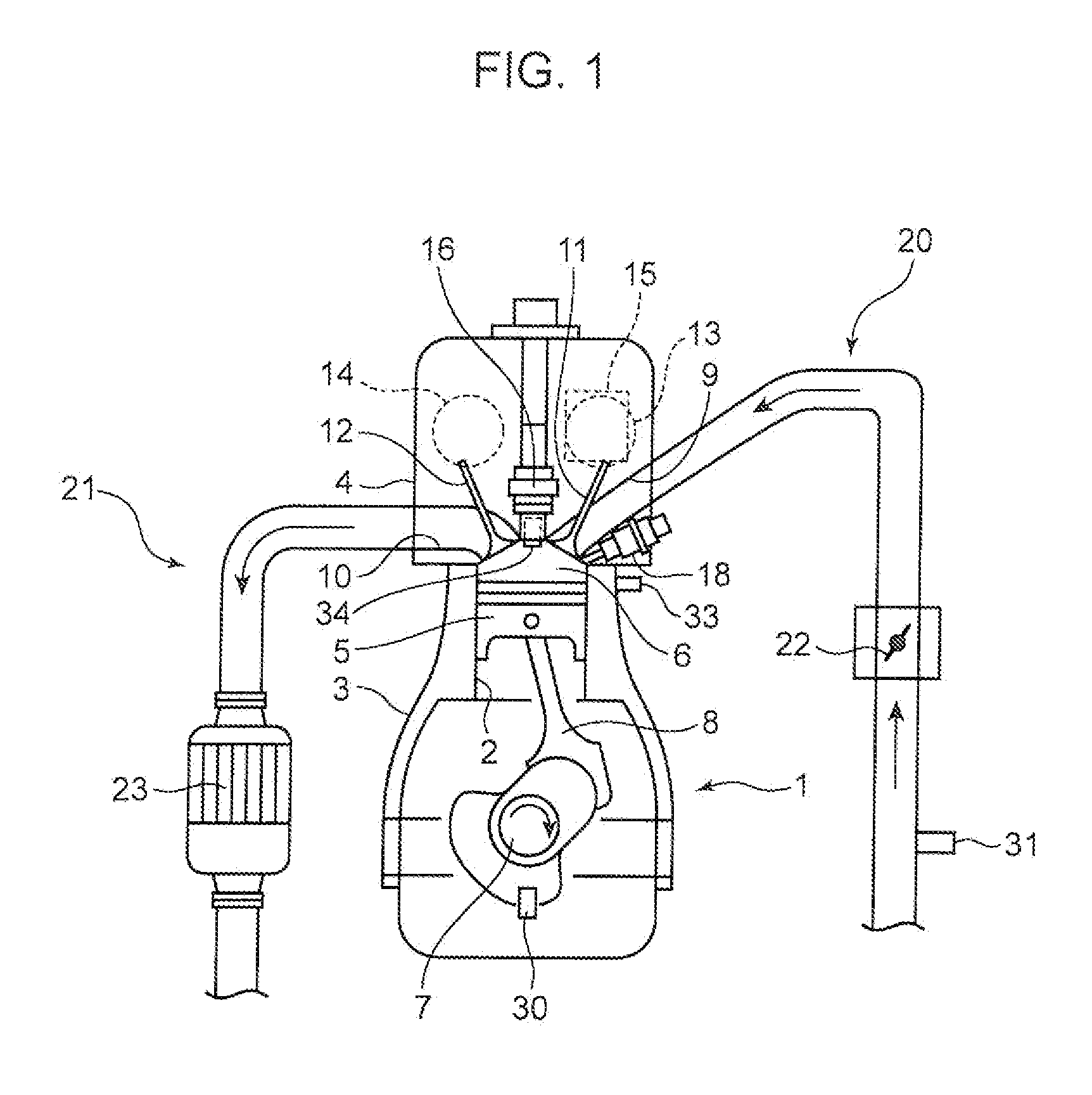

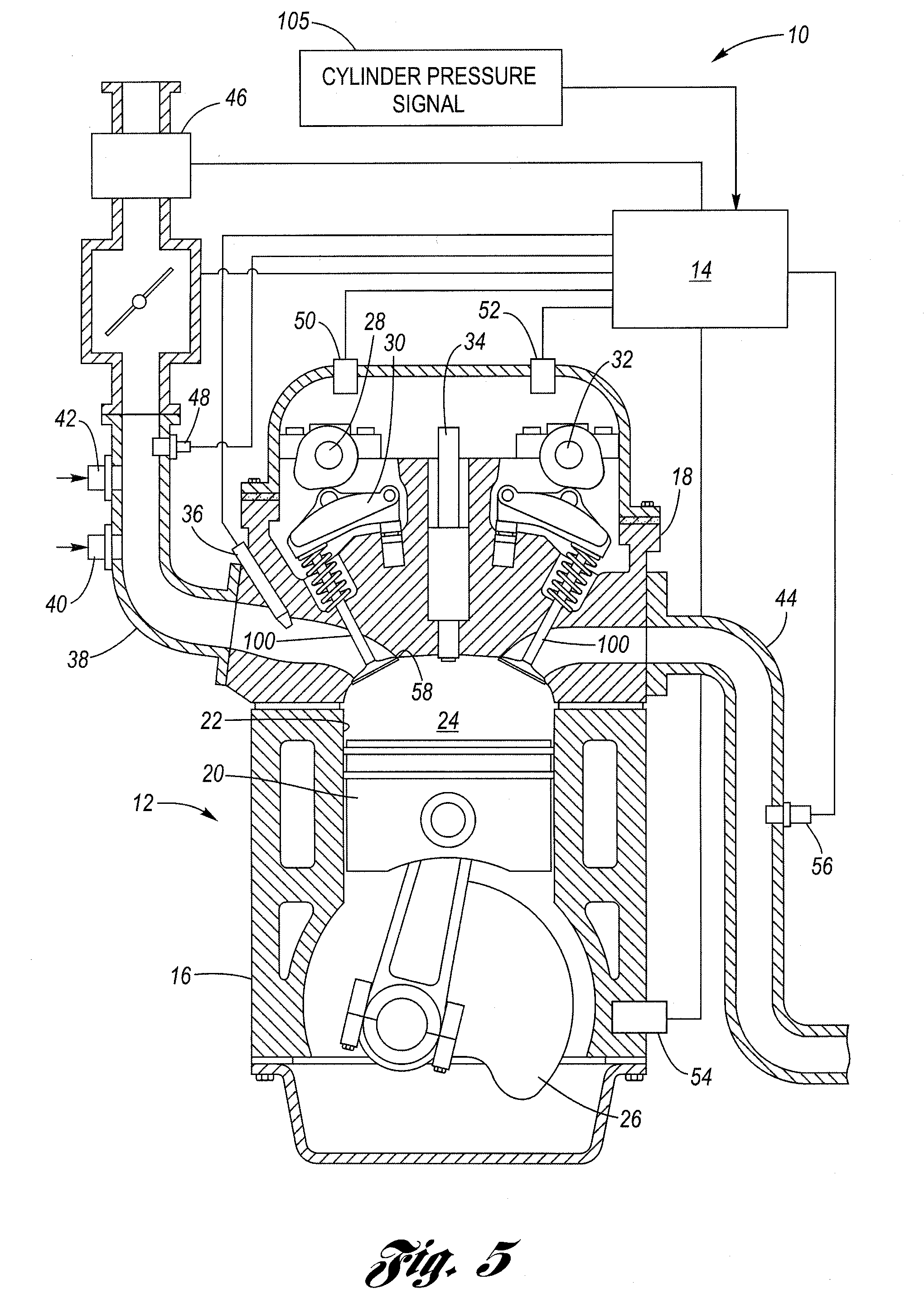

Multiple operating mode engine and method of operation

InactiveUS6907870B2Easy to operateOvercome deficienciesValve arrangementsElectrical controlControl systemFuel efficiency

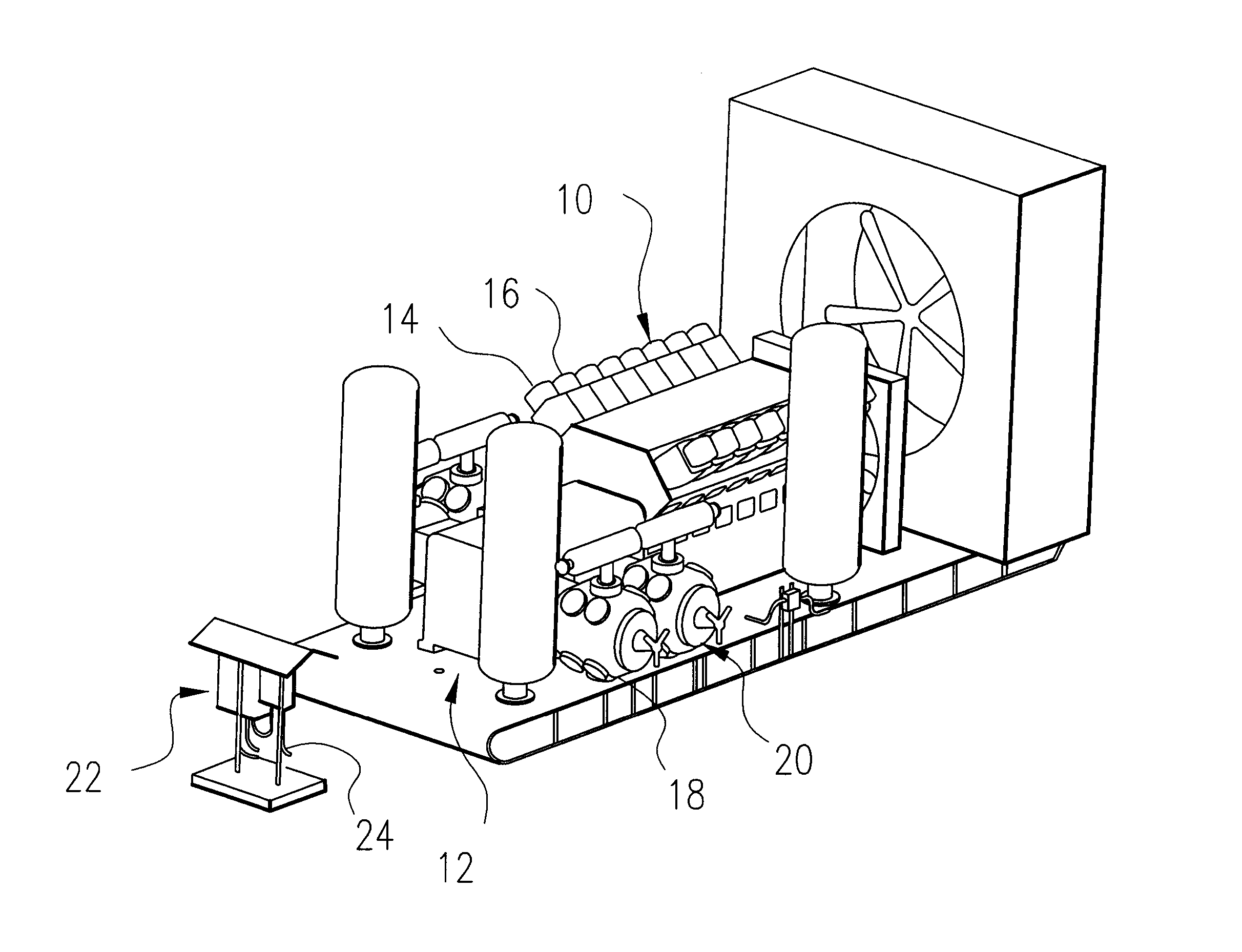

A multi-mode internal combustion engine and method of operating the engine is provided which is capable of operating in a variety of modes based on engine operating conditions to enhance fuel efficiency and reduce emissions. The multi-mode engine include a fuel delivery system and control system for permitting the engine to operate in a diesel mode, a homogeneous charge dual fuel transition mode, a spark ignition or liquid spark ignition mode and / or a premixed charge compression ignition mode. The control system and method permits the engine operation to transfer between the various modes in an effective and efficient manner by controlling one or more fuel delivery devices or other engine components so as to move along a continuous transfer path while maintaining engine torque at a substantially constant level.

Owner:CUMMINS INC

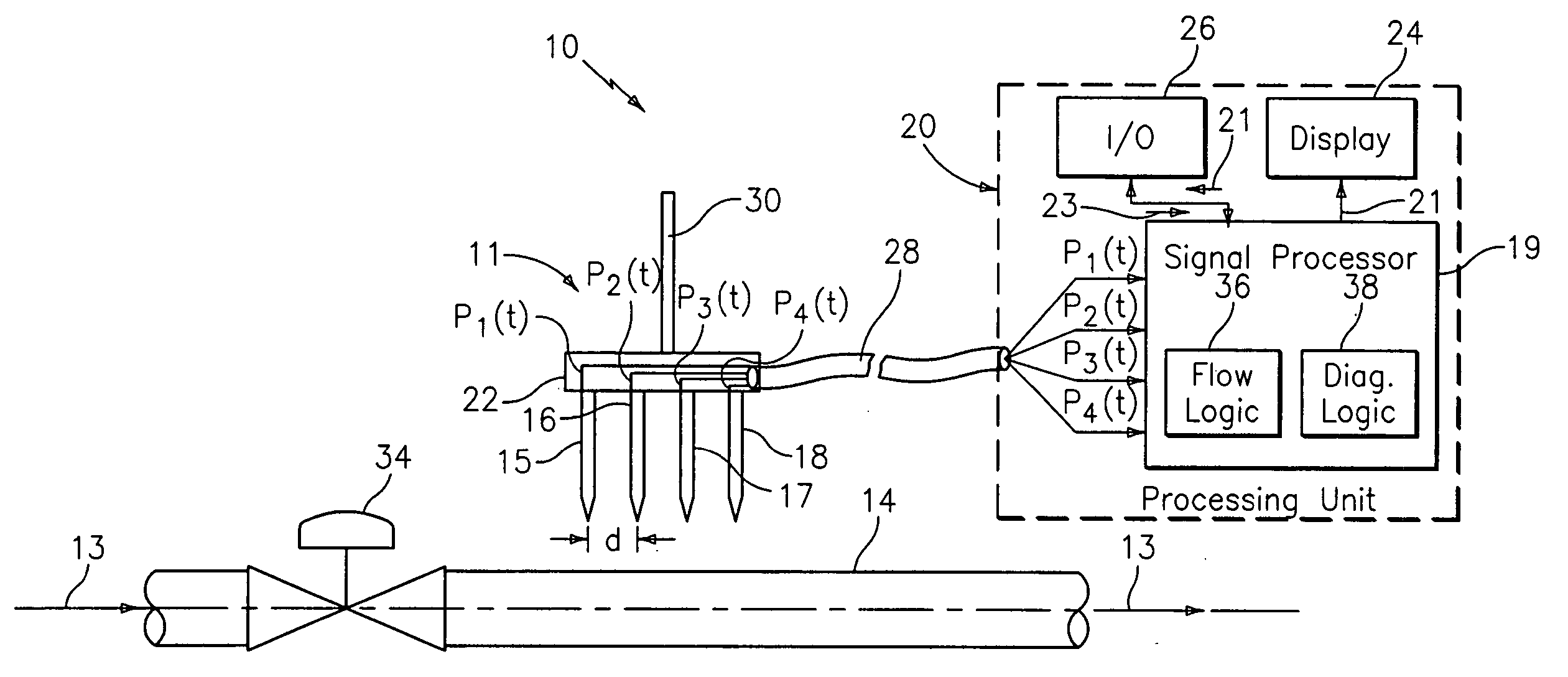

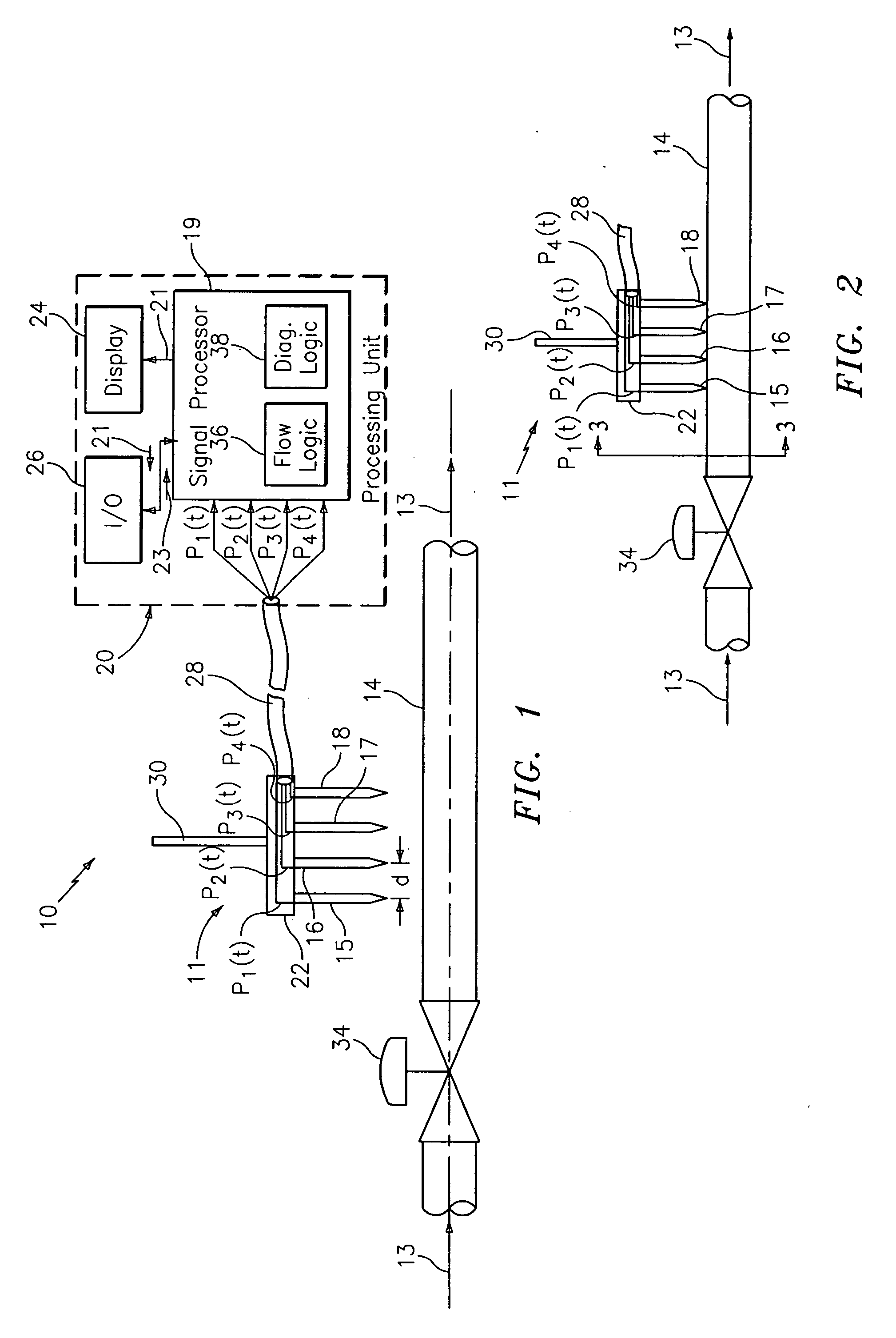

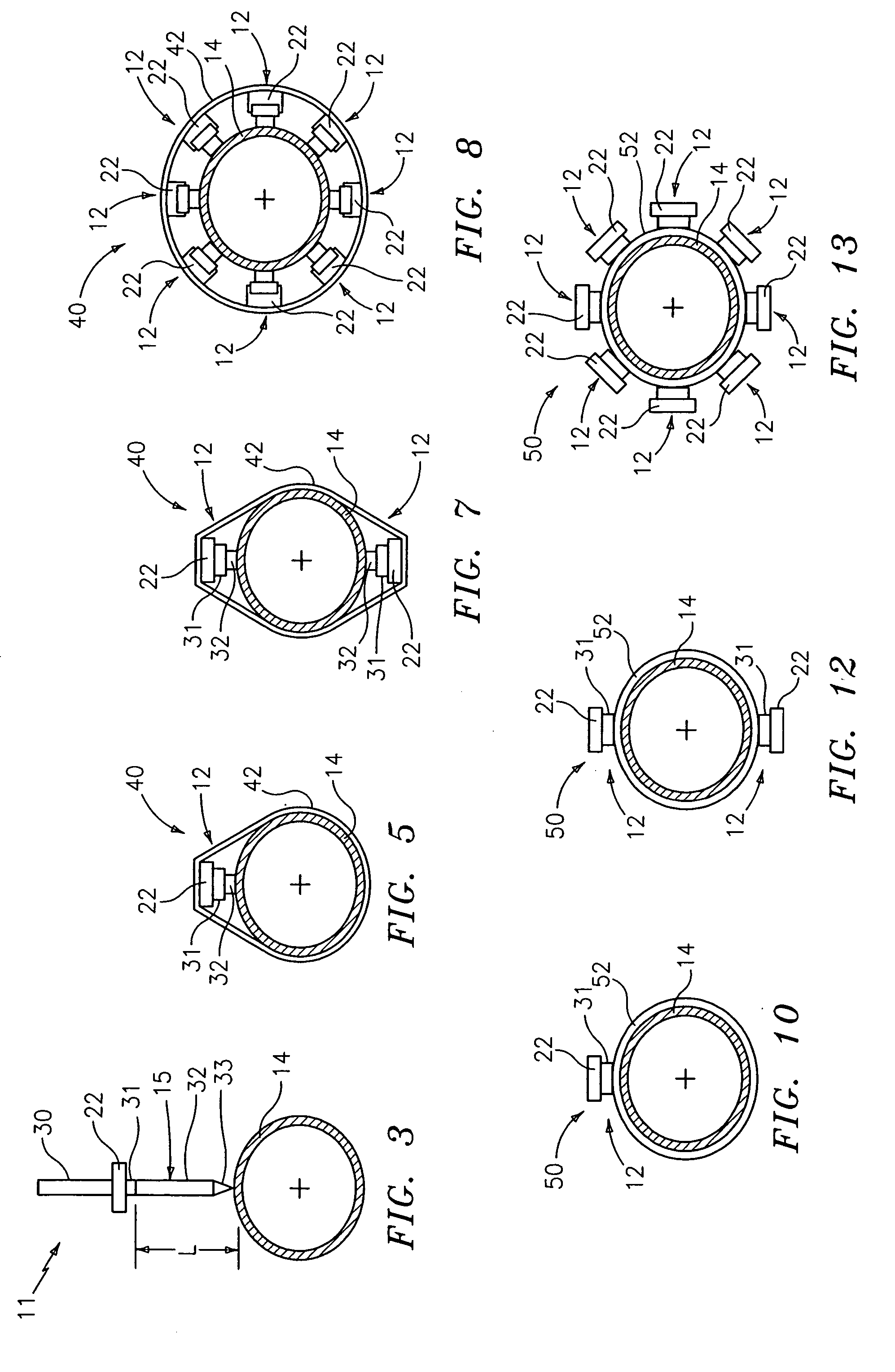

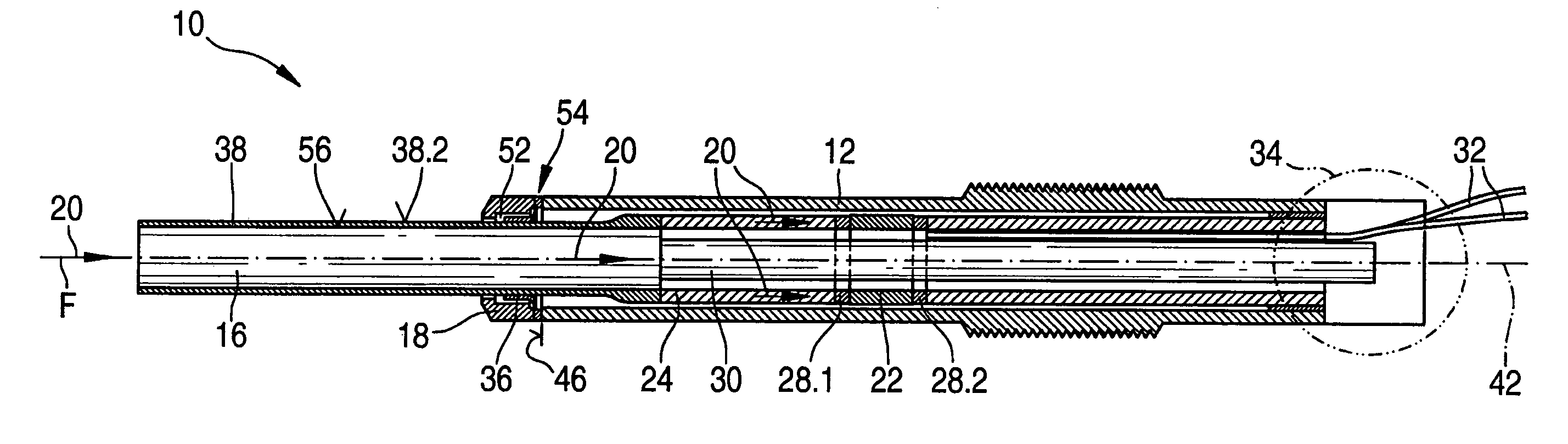

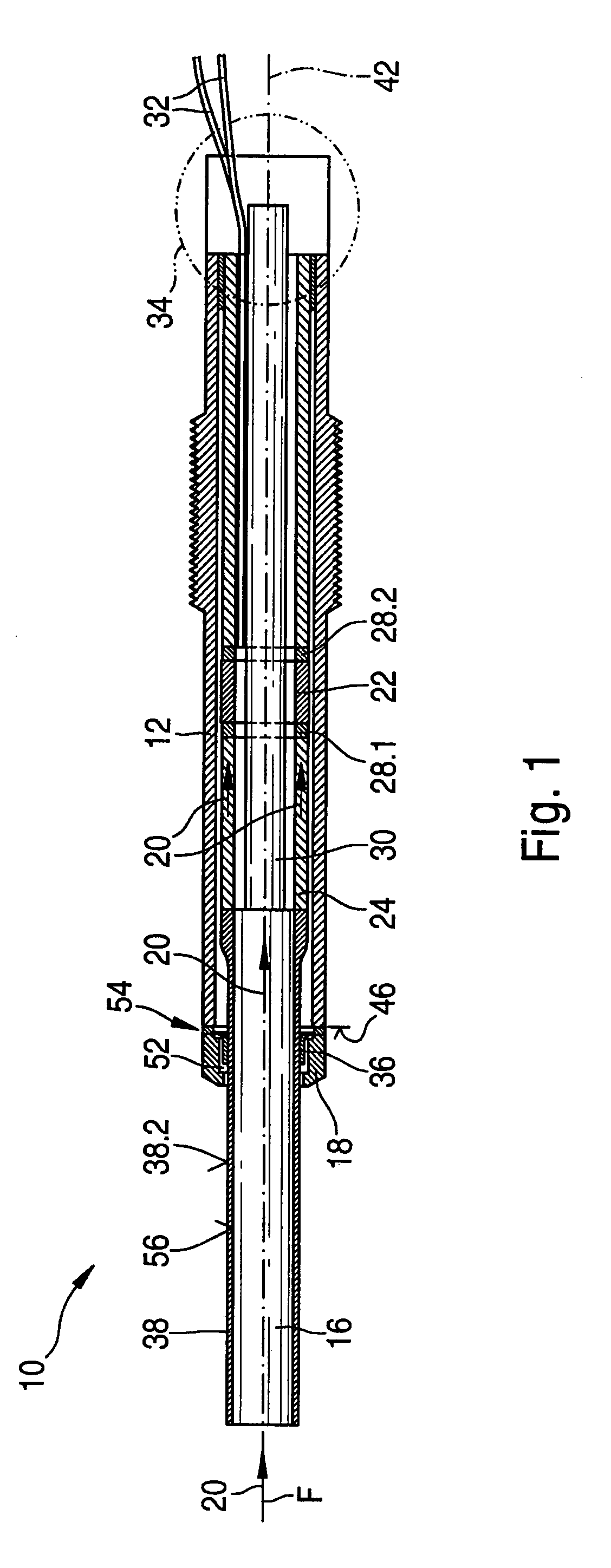

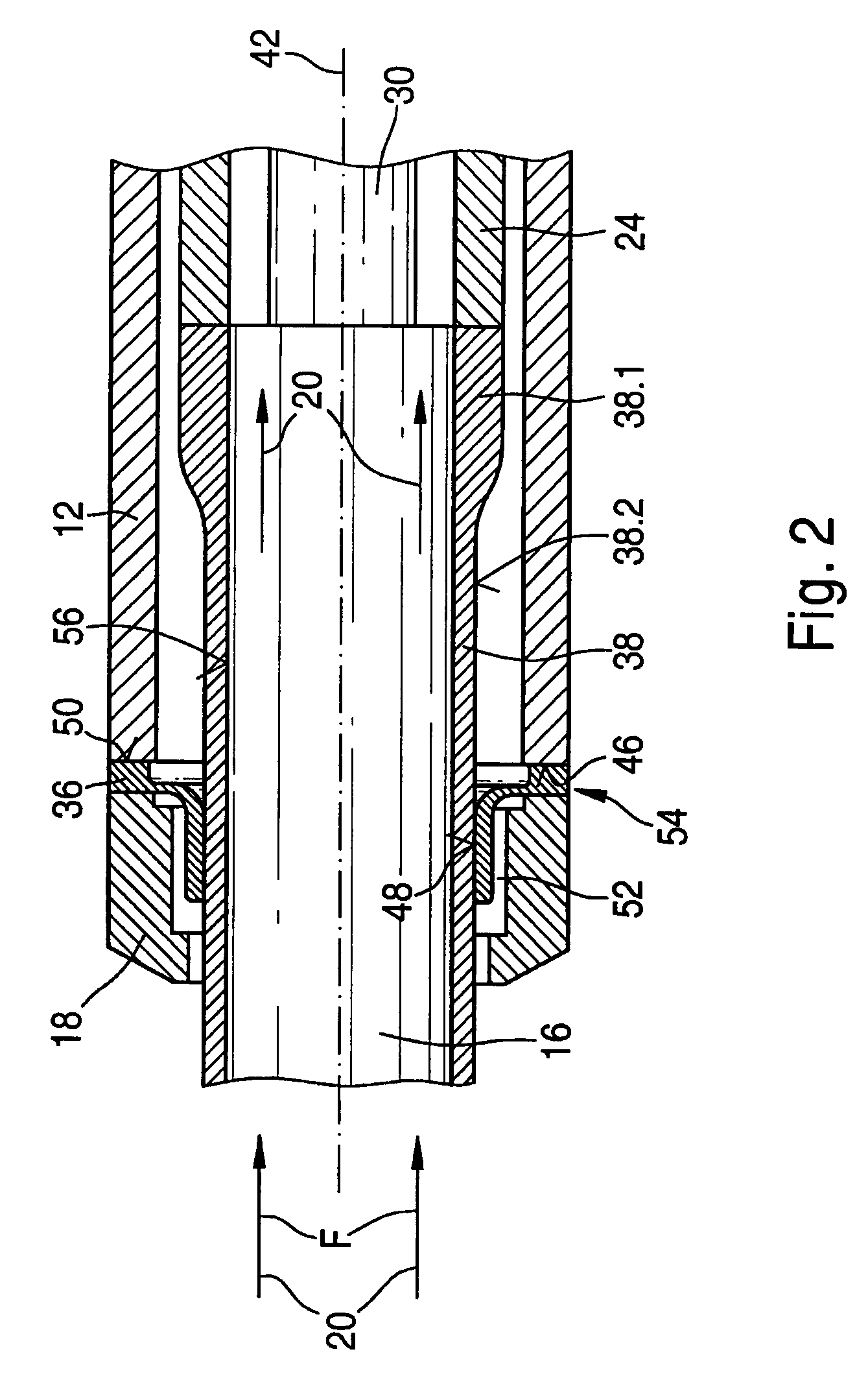

Contact-based transducers for characterizing unsteady pressures in pipes

InactiveUS20050050956A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsTransducerEngineering

A sensor head characterizes unsteady pressures in a fluid flowing within a pipe, as may be caused by one or both of acoustic waves propagating through the fluid within the pipe and / or pressure disturbances that convect with the fluid flowing in the pipe. The sensor head comprises a rigid support structure and at least one transducer attached to the rigid support structure. The rigid support structure holds the transducer in contact with an outer surface of the pipe. The at least one transducer senses relative movement between the outer surface of the pipe and the support structure and provides a signal indicative of unsteady pressures within the fluid at a corresponding axial position of the pipe in response to the relative movement. The support structure may be attached to each transducer in an array of transducers, and may include a handle secured thereto for manipulating the sensor head into contact with the pipe. Output signals from the transducers are provided to a processing unit, which processes the output signals to provide a signal indicative of at least one parameter of the flow process.

Owner:CIDRA

Piezoelectric sensor and input device including same

InactiveUS7152482B2Increased durabilityFlaw can be preventedFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesElectrical conductorPressure transmission

A piezoelectric sensor arranged so as to includes: a transparent piezoelectric element having a piezoelectric property; and a pair of transparent conductor film layers opposed to each other with the piezoelectric element therebetween, the transparent piezoelectric element and the transparent conductor film layers are formed between a pair of transparent substrates, opposed to each other, which serve as pressure transmission means. Consequently, the transparent piezoelectric sensor has an excellent durability. A piezoelectric sensor comprises a piezoelectric element with a piezoelectric property which is made of a piezoelectric material having no Curie point and has a dipole orientation degree of not less than 75%. Consequently, the piezoelectric sensor having an excellent durability and a simple structure is provided at low cost.

Owner:NAT INST OF ADVANCED IND SCI & TECH

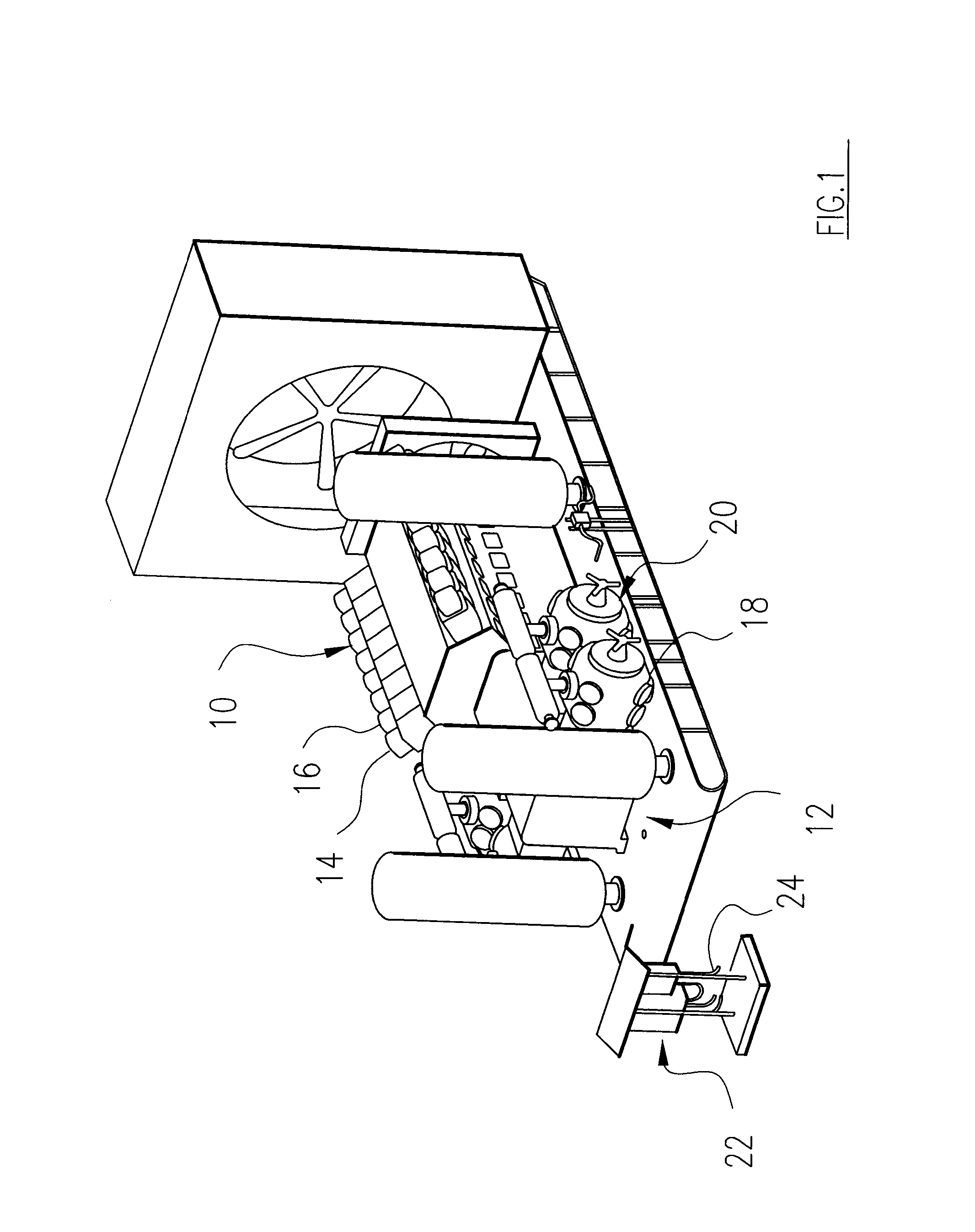

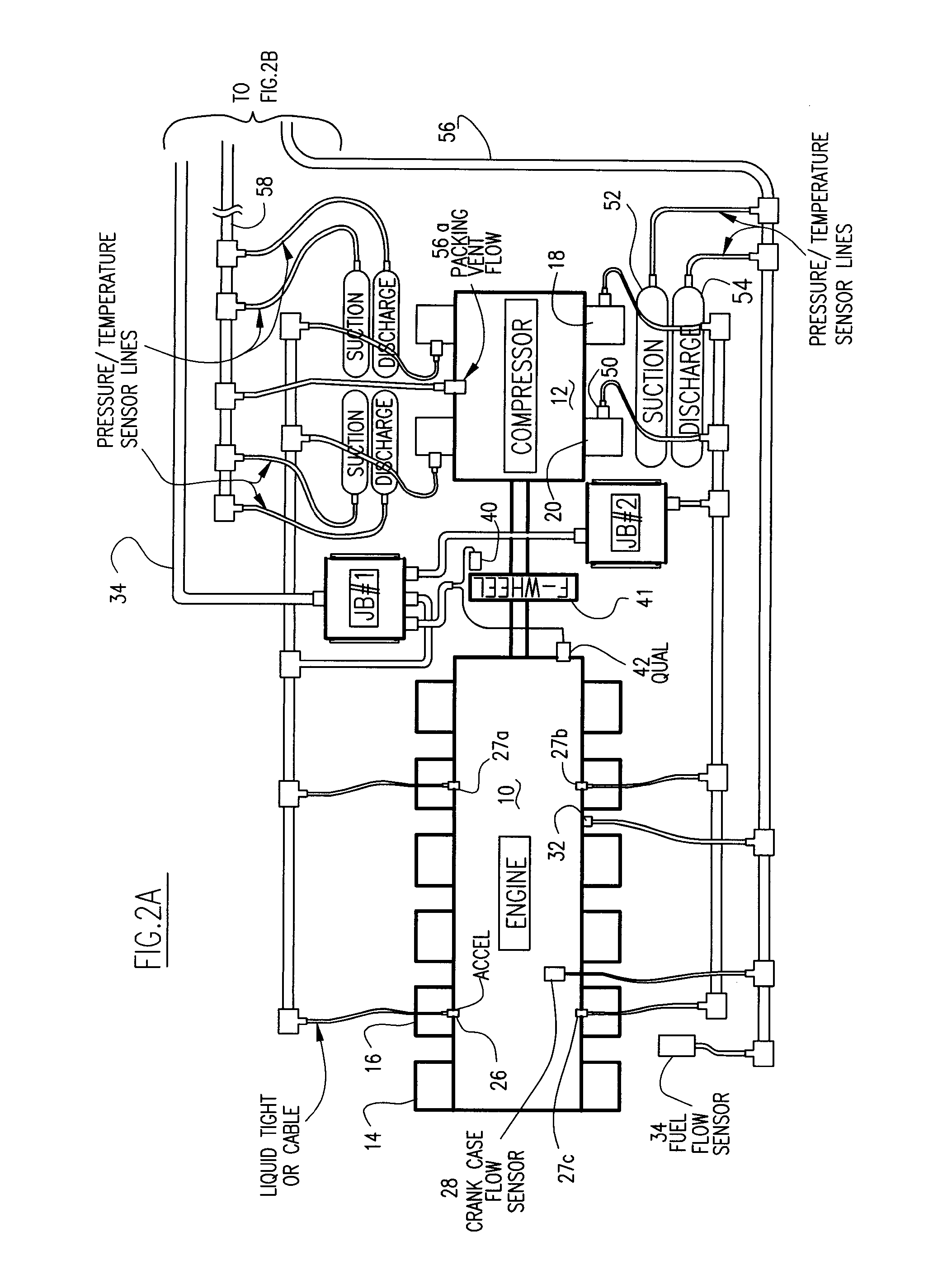

Automated fault diagnosis method and system for engine-compressor sets

InactiveUS7403850B1Improve economic performanceIncrease fuel consumptionInternal-combustion engine testingAutomatic initiationsBaseline dataData acquisition

The automated fault diagnostic system operates on engine-compressor sets with one vibration sensor per sub-group of engine cylinders and one sensor per compressor cylinder. Vibration signals linked to crankshaft phase angle windows (“VT”) mark various engine events and compressor events. In data-acquisition-learning mode, VT is stored for each engine and compressor event per operating load condition, statistical process control (SPC) theory identifies alarm threshold bands. Operator input-overrides are permitted. If no baseline data is stored, the system automatically enters the learn mode. To monitor, current VT are obtained and current load condition is matched to the earlier load set and alarms issue linking predetermined engine or compressor event to the over-under VT. Baseline data, SPC analysis, alarms and monitoring are set for crankcase flow, engine cylinder exhaust temperatures, ignition system diagnostic messages. Compressor performance alarms use suction and discharge temperatures and pressures.

Owner:WINDROCK

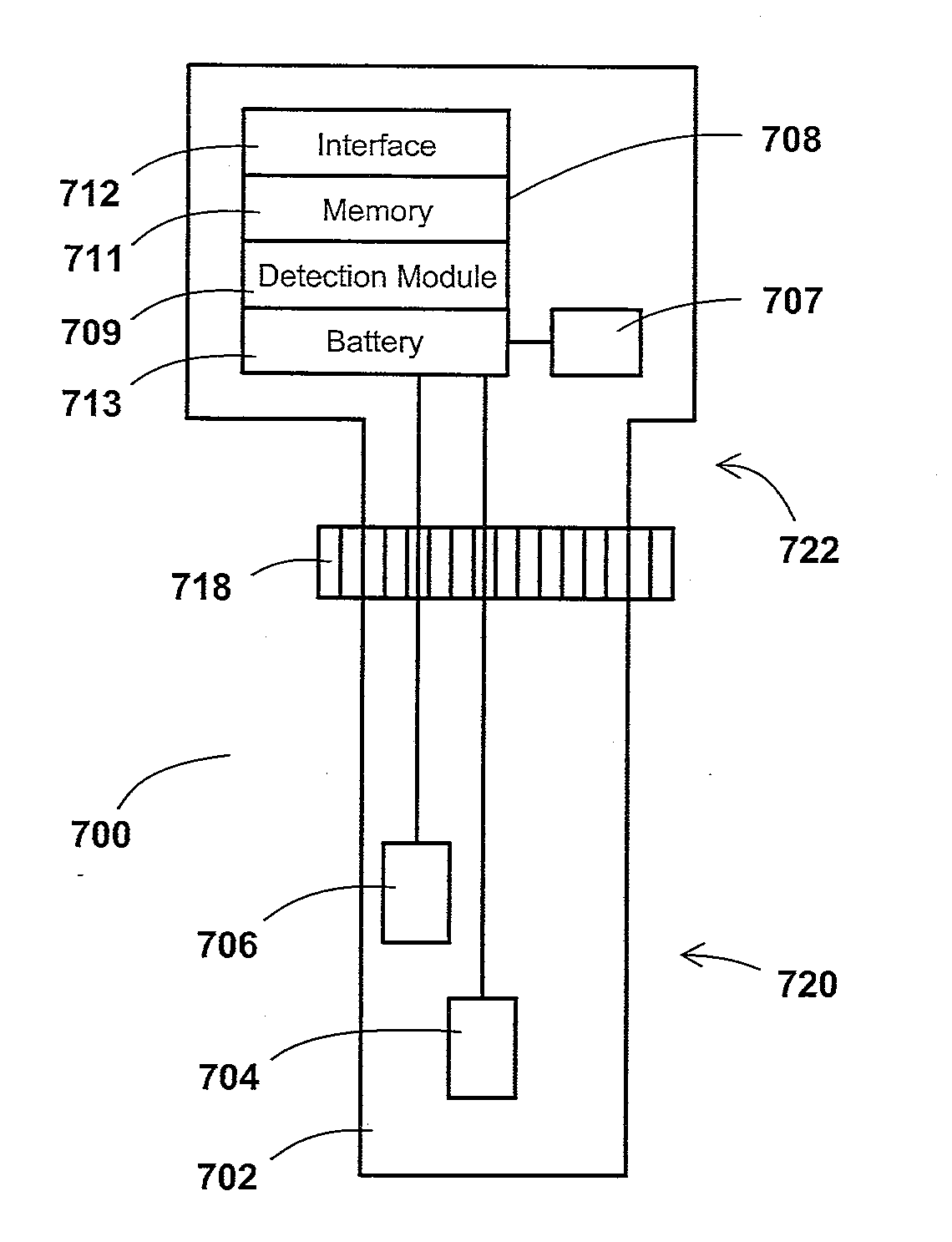

Measurement probe with heat cycle event counter

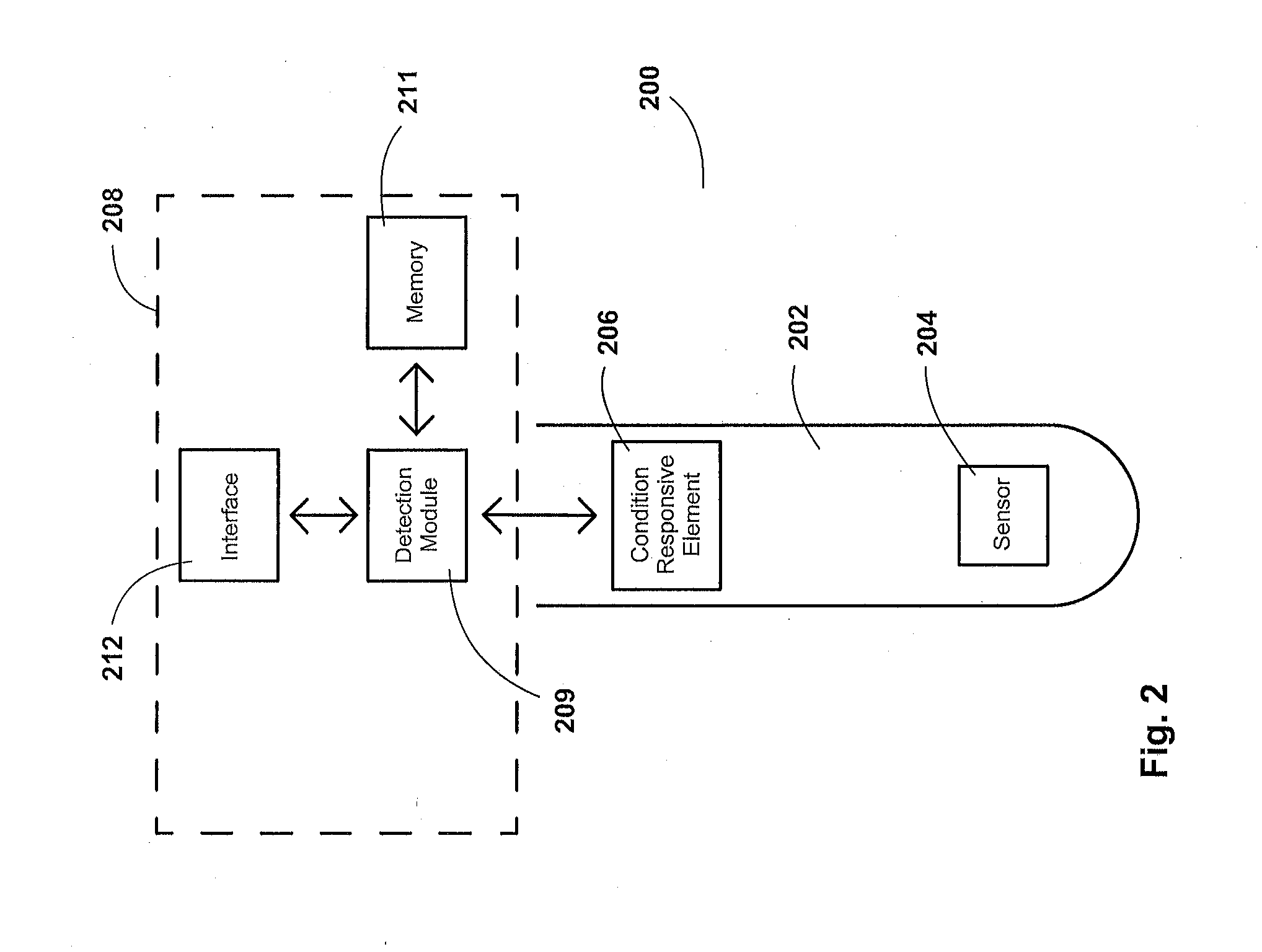

ActiveUS20160004956A1Protect the circuitSave powerBatteries circuit arrangementsRegistering/indicating working of machinesMeasurement deviceComputer module

A system comprising a measurement device and a handheld device is disclosed, the system adapted to withstand, detect, record, and display heat cycle event counts. The measurement device comprises a sensor for measuring and a heat cycle detection unit. The heat cycle detection unit comprises a temperature or pressure responsive element, a detection module, data interface, and data memory. The handheld device comprises a screen, a button, a communication circuit, and a processing system. The communication circuit is configured to communicate with the measurement device and a computing device and the processing system is configured to receive non-measurement information from the measurement device, display the received information on the screen, and cycle the received information displayed on the screen based on an actuation of the button, wherein the handheld device is used to display a heat sterilization cycle count of the measurement device.

Owner:BROADLEY JAMES

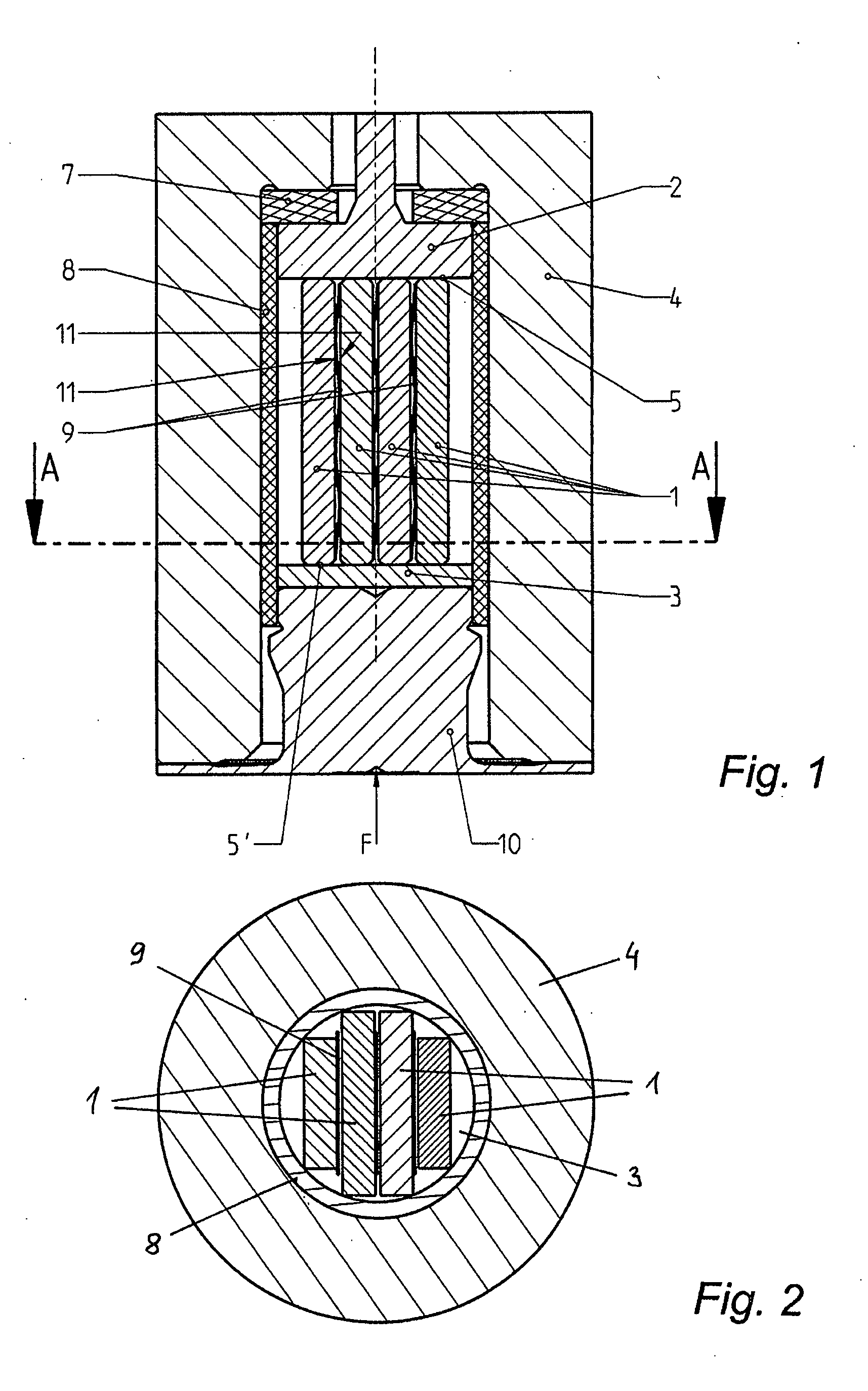

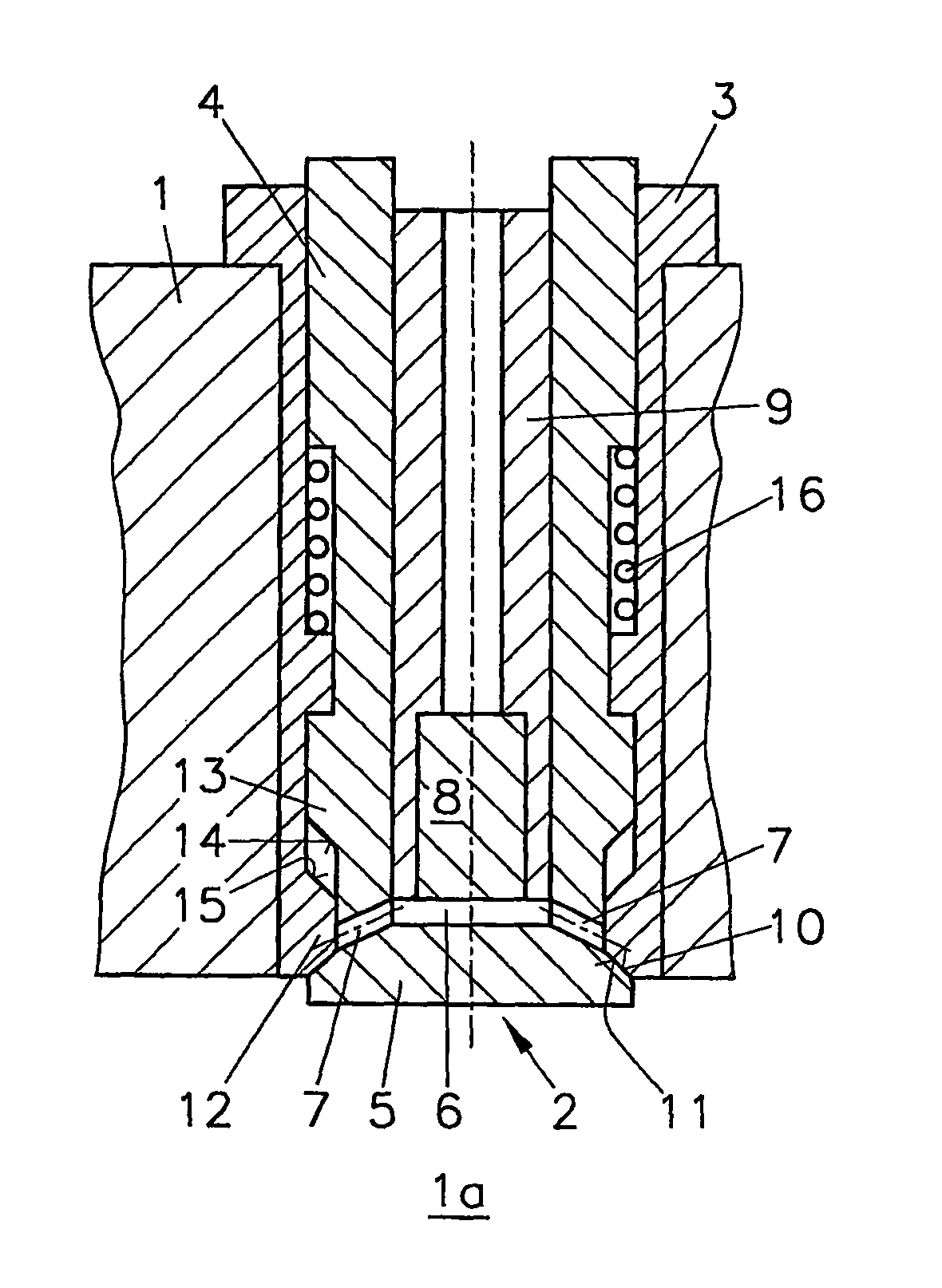

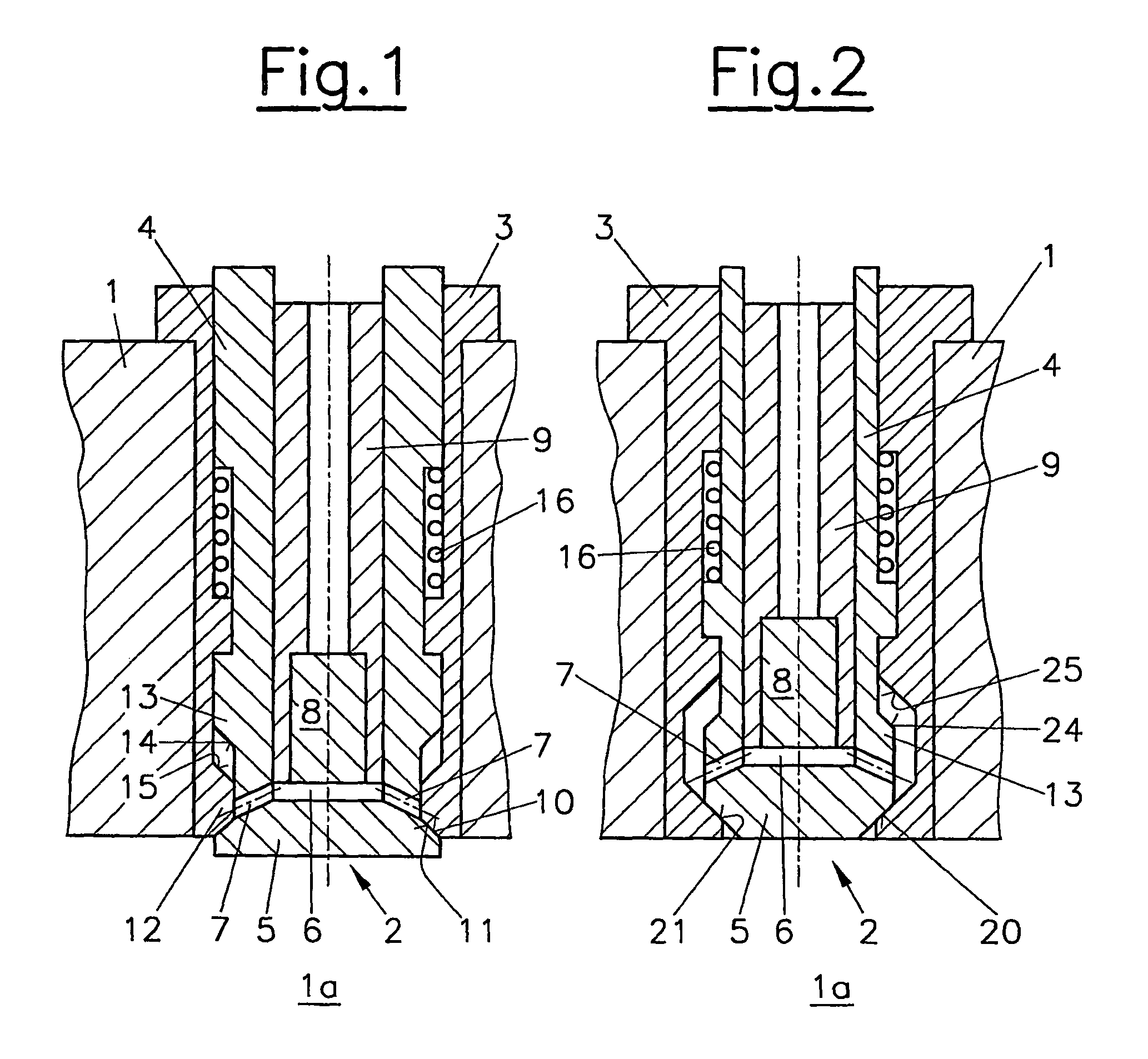

Pressure glow plug for a diesel engine

ActiveUS20050061063A1Increase powerReduce or optimize emission values, consumption valuesIncandescent ignitionEngine testingGlowplugDiesel engine

A pressure glow plug for a diesel engine has a glow plug body 2 for being inserted into a cylinder of the diesel engine, a heating rod 1 that is arranged in the glow plug body 2 and a pressure sensor 9 that is arranged between the heating rod 1 and the glow plug body 2 in such a way that the pressure in the combustion chamber of the cylinder that is transmitted by the heating rod 1 influences the pressure sensor 9. The heating rod 1 is arranged in the glow plug body 2 such that it can be displaced in an axially sliding fashion, namely by a corresponding sliding element, for example, a membrane 7 or seals 3.

Owner:SENSATA TECH HOLLAND +1

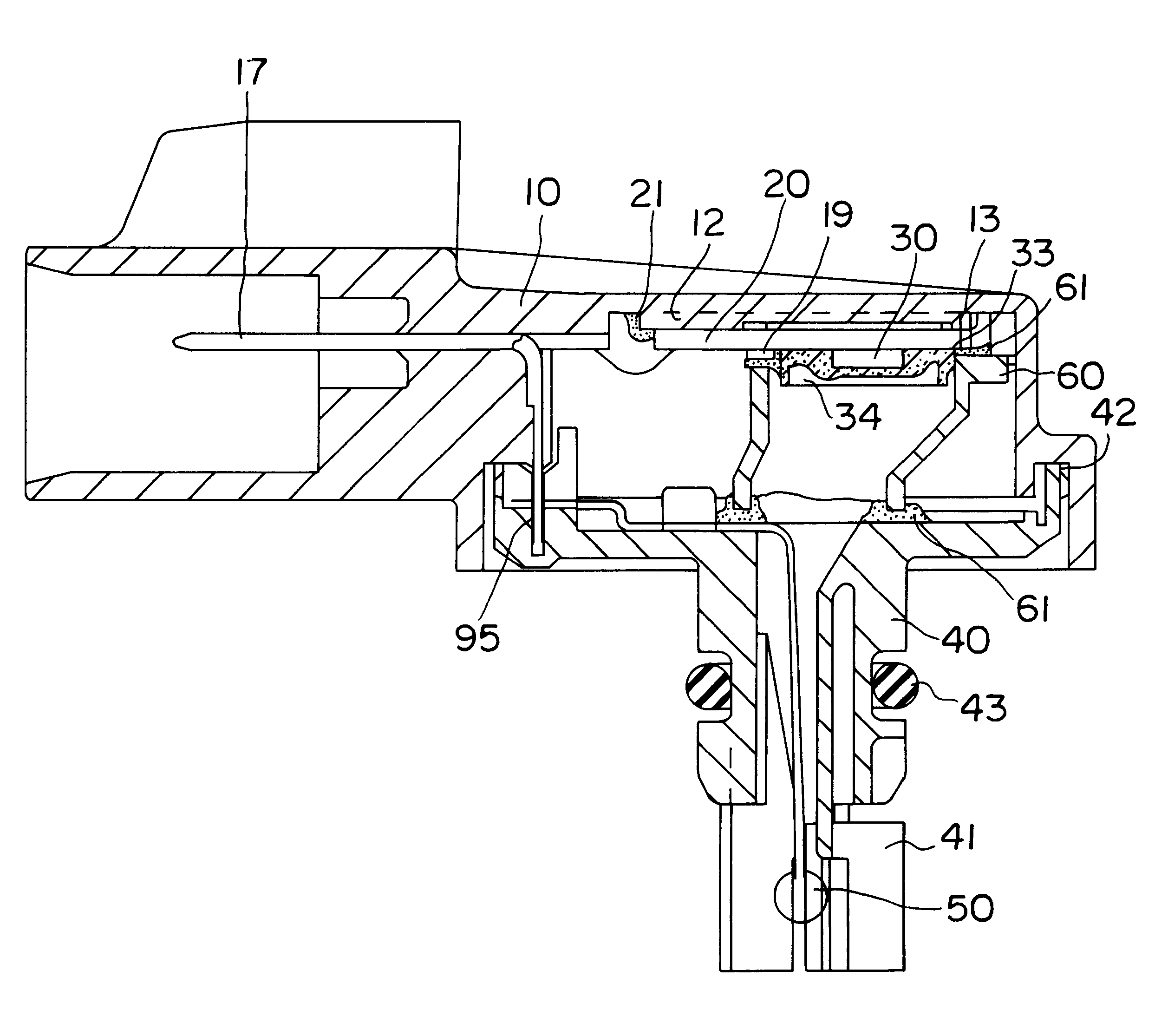

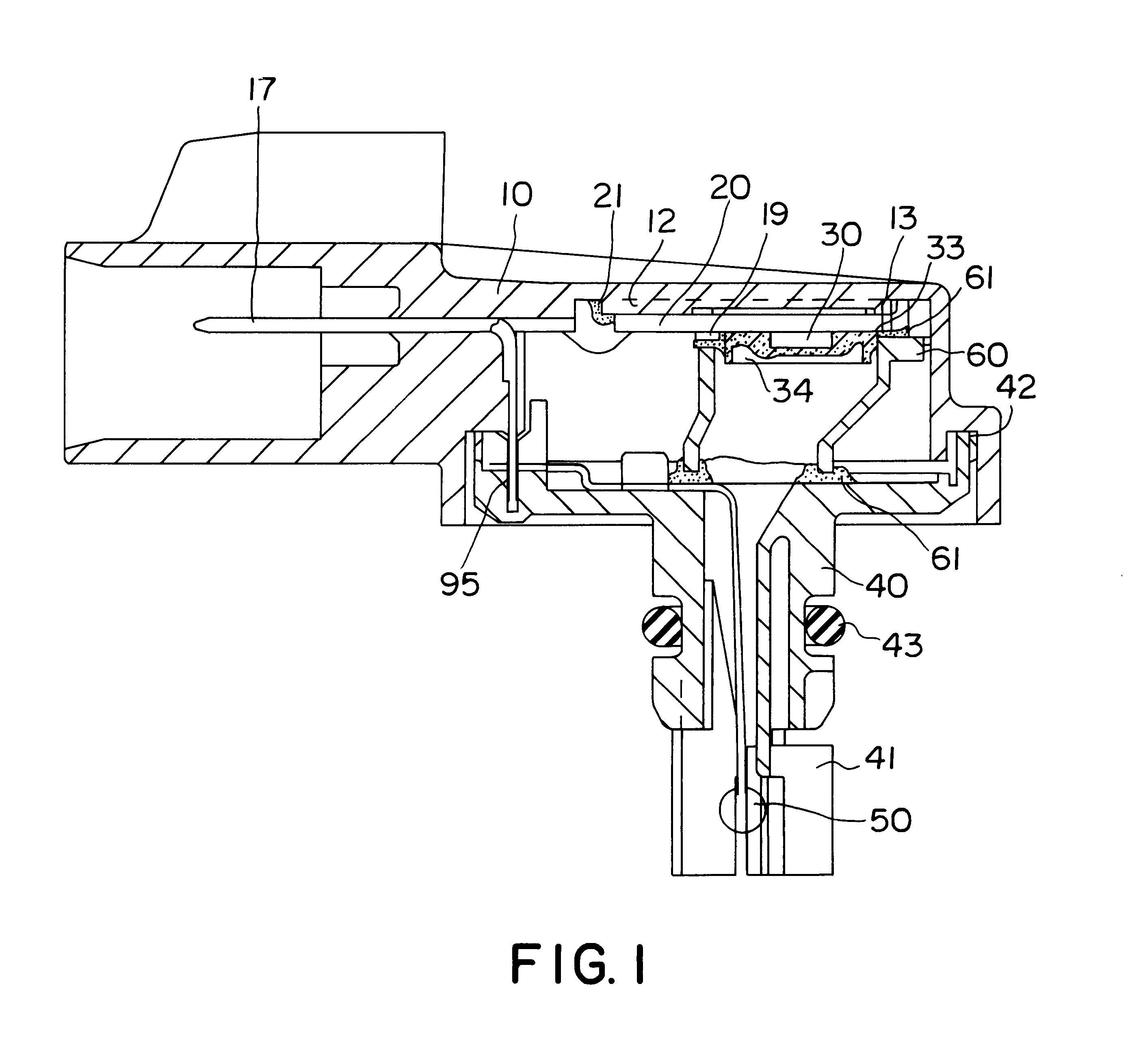

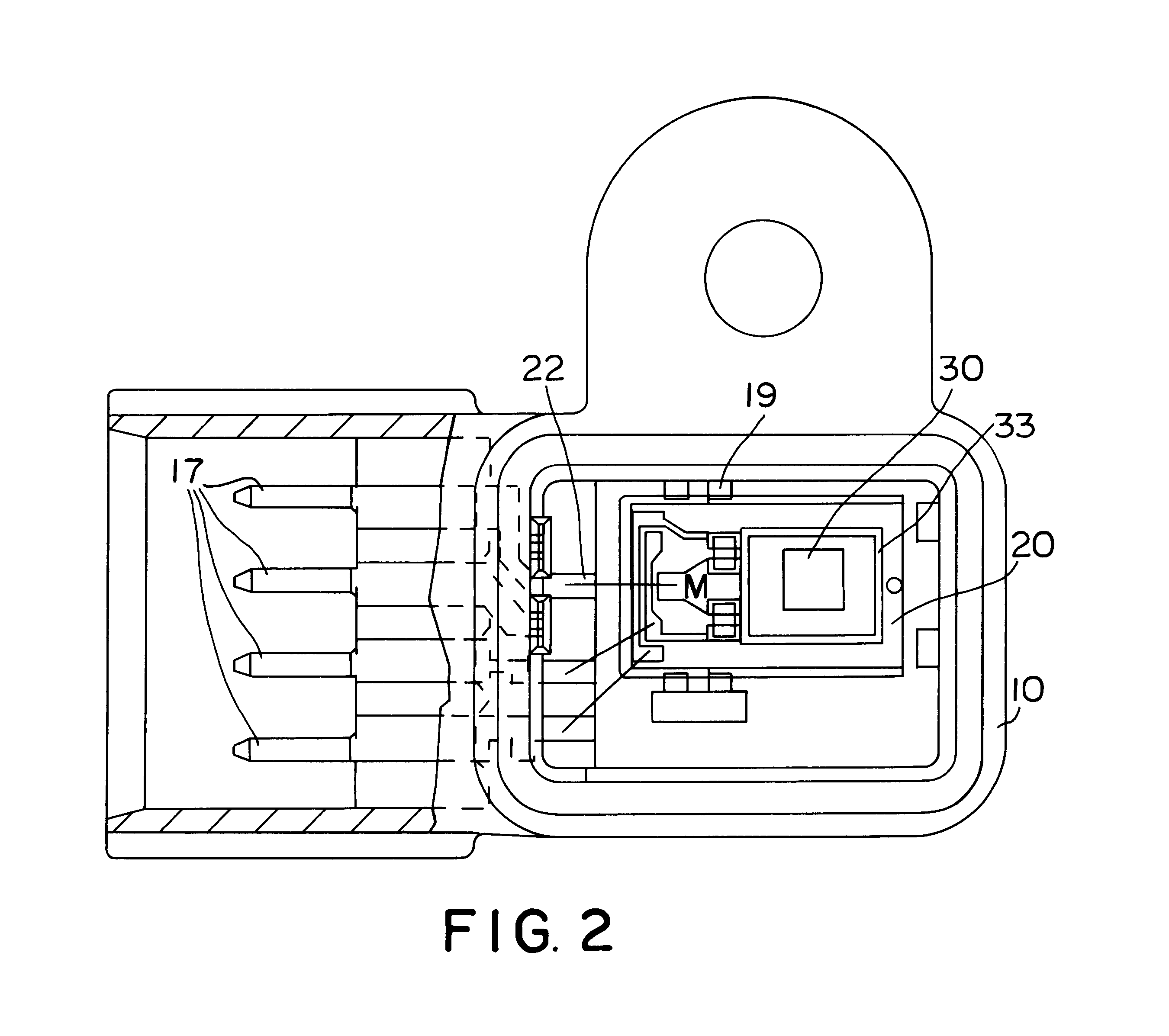

Apparatus for detecting the pressure and temperature in the intake tube of an internal combustion engine, and method for producing it

An apparatus for detecting the pressure and temperature in the intake tube of an internal combustion engine. A temperature sensor and a pressure sensor are secured to a carrier together with an evaluation circuit in a common housing with as little strain as possible. The housing includes at least two chambers separate from one another, one of which forms a pressure chamber that communicates with the intake tube via a stub and is sealed off from the environment in which the pressure sensor is secured. The other chamber serves to secure the temperature sensor therein by use of connection elements, and sealing adhesive connections that decouple mechanical strains for securing the carrier and sealing off the pressure sensor.

Owner:ROBERT BOSCH GMBH

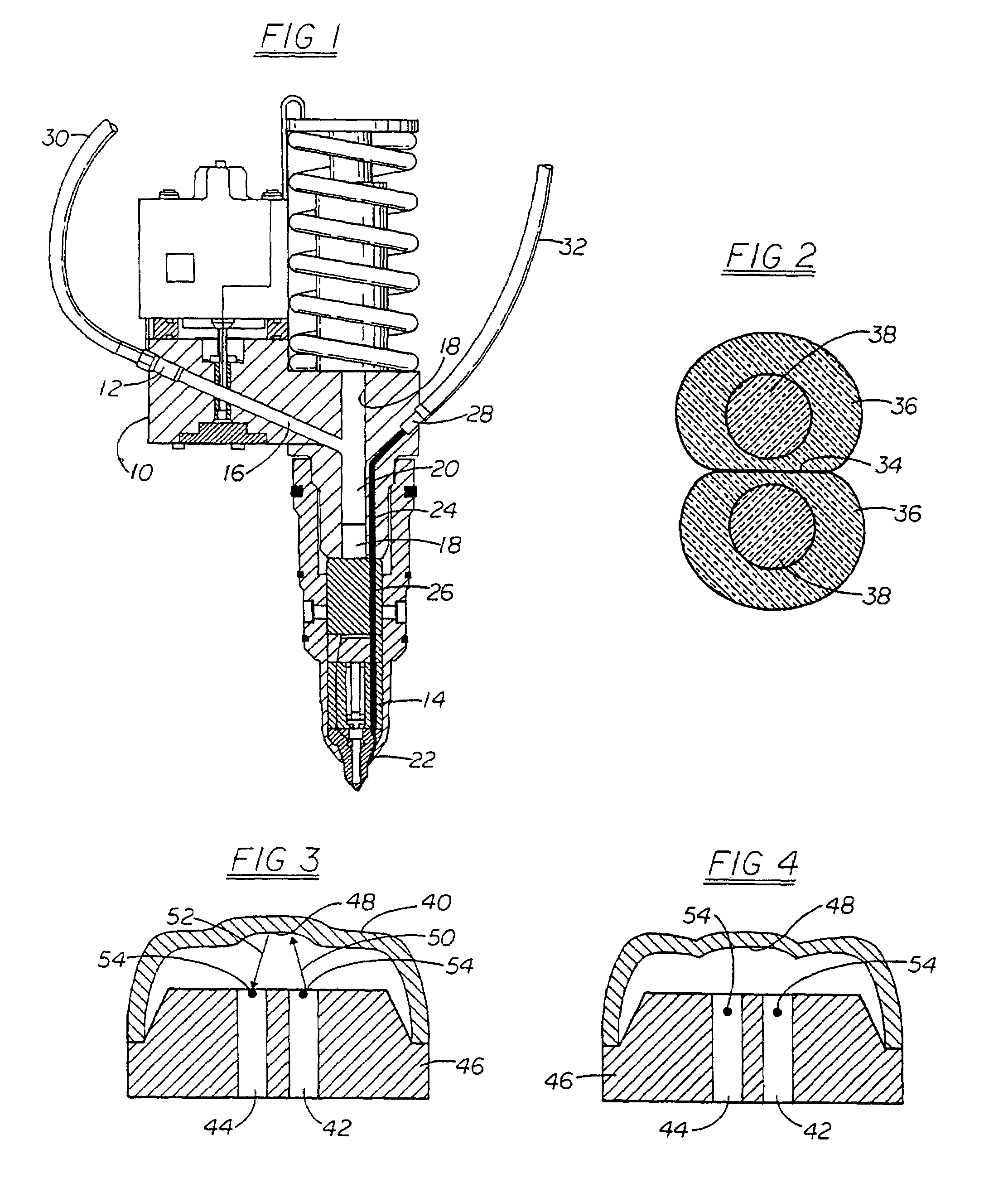

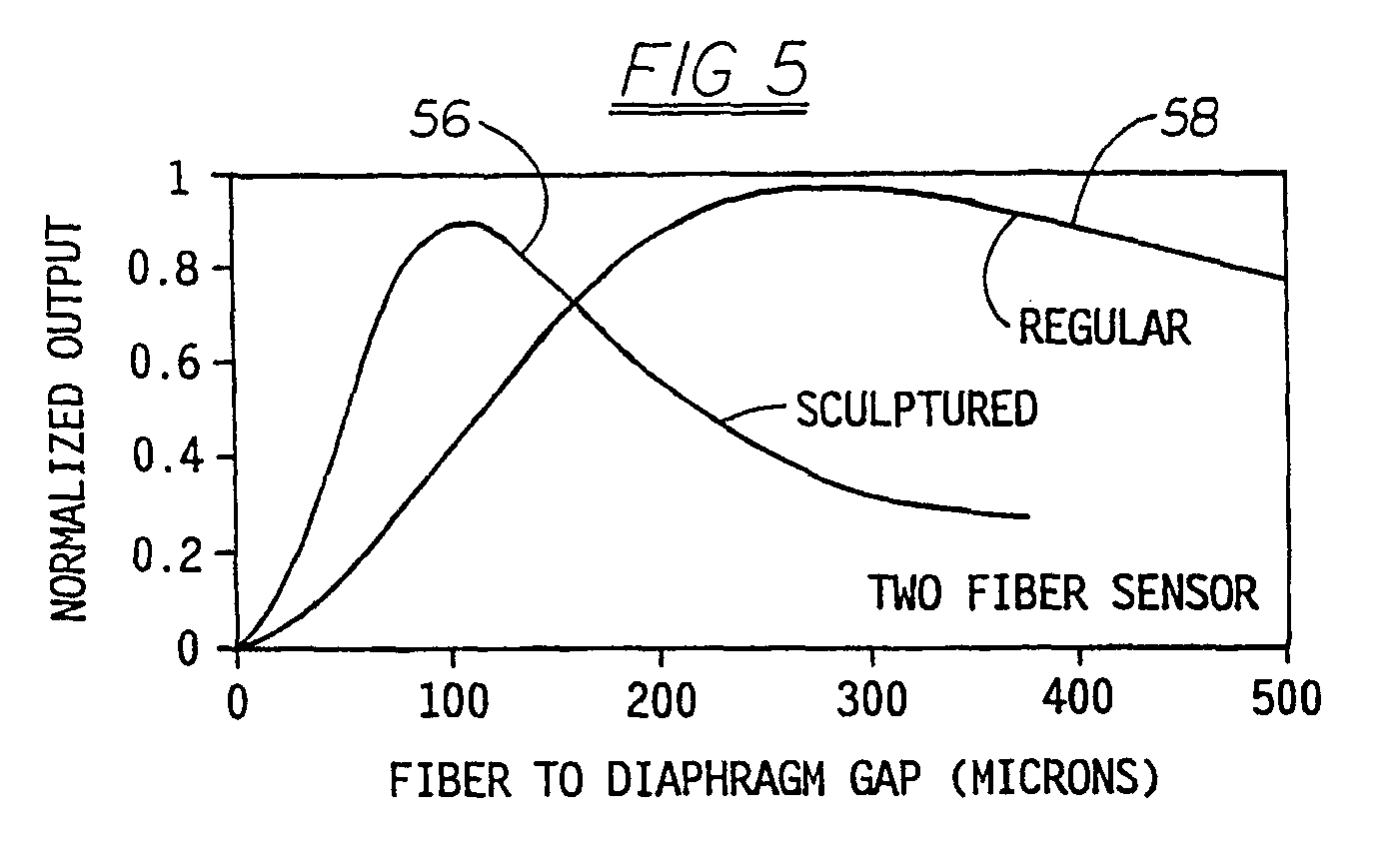

Fuel injectors with integral fiber optic pressure sensors and associated compensation and status monitoring devices

InactiveUS7340118B2Cost-effective and accurateAccurate and repeatable spray patternsTemperature measurement in motorsElectrical controlFiberCombustion chamber

Owner:WLODARCZYK MAREK T +1

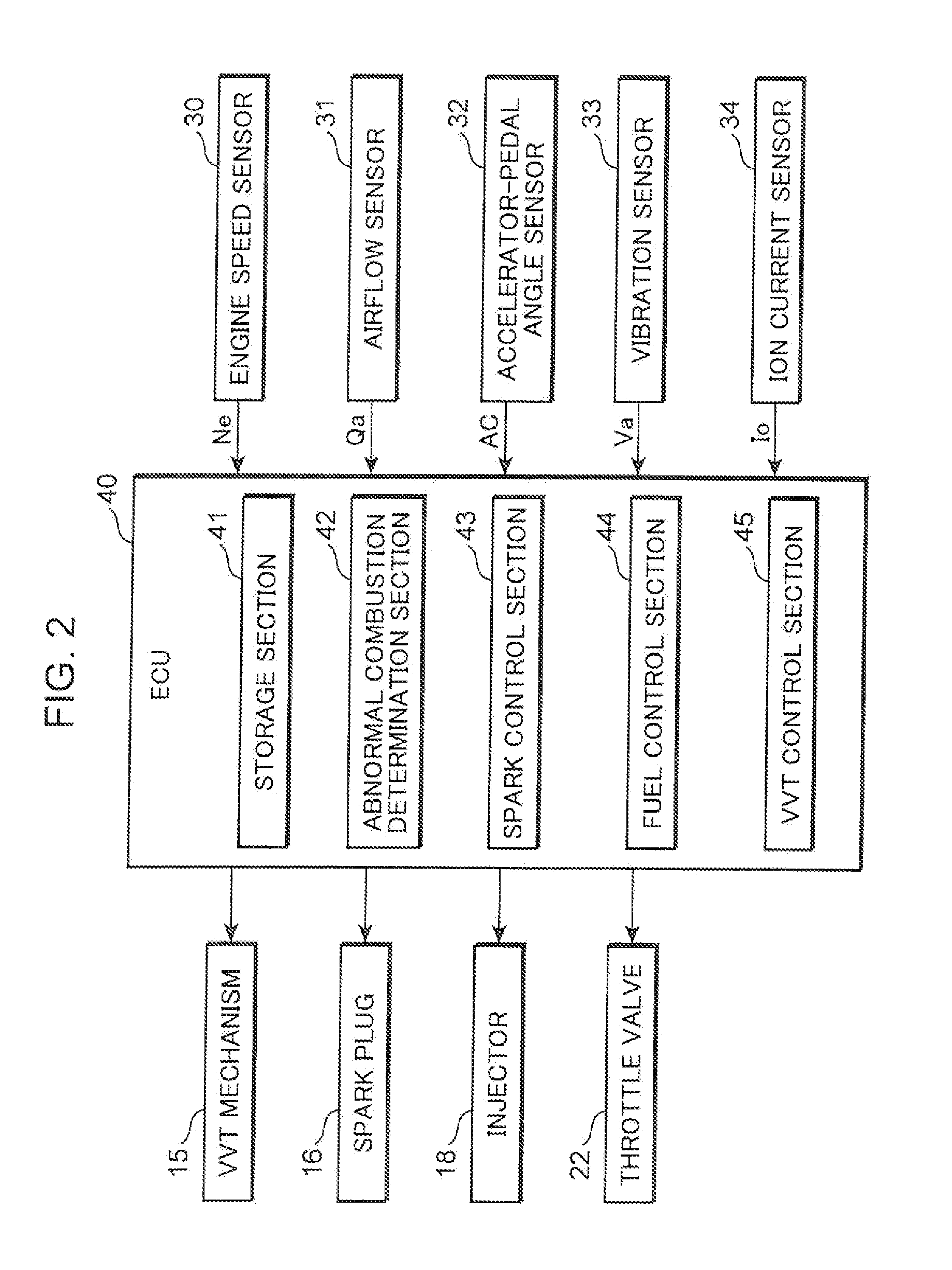

Abnormal combustion detection method for spark-ignition engine, and spark-ignition engine

ActiveUS20110246049A1Enough can be detectedInternal-combustion engine testingAnalogue computers for vehiclesTop dead centerEngineering

When a maximum value of vibration intensity (maximum vibration intensity) (Vmax) acquired from a vibration sensor (33) in a low engine speed / high engine load (operating region (R)) is equal to or greater than a given threshold value (X), a spark timing of a spark plug (16) is shifted from a point set in a normal state on a retard side with respect to a compression top dead center, farther toward the retard side. Then, when a maximum vibration intensity (Vmax2) acquired after the spark timing retard is greater than a maximum vibration intensity (Vmax1) acquired before the spark timing retard, it is determined that preignition occurs. This technique makes it possible to reliably detect preignition using the vibration sensor, while distinguishing the preignition from knocking. An in-cylinder pressure sensor for detecting an in-cylinder pressure of an engine may be used to determine the presence or absence of the preignition, in the same manner.

Owner:MAZDA MOTOR CORP

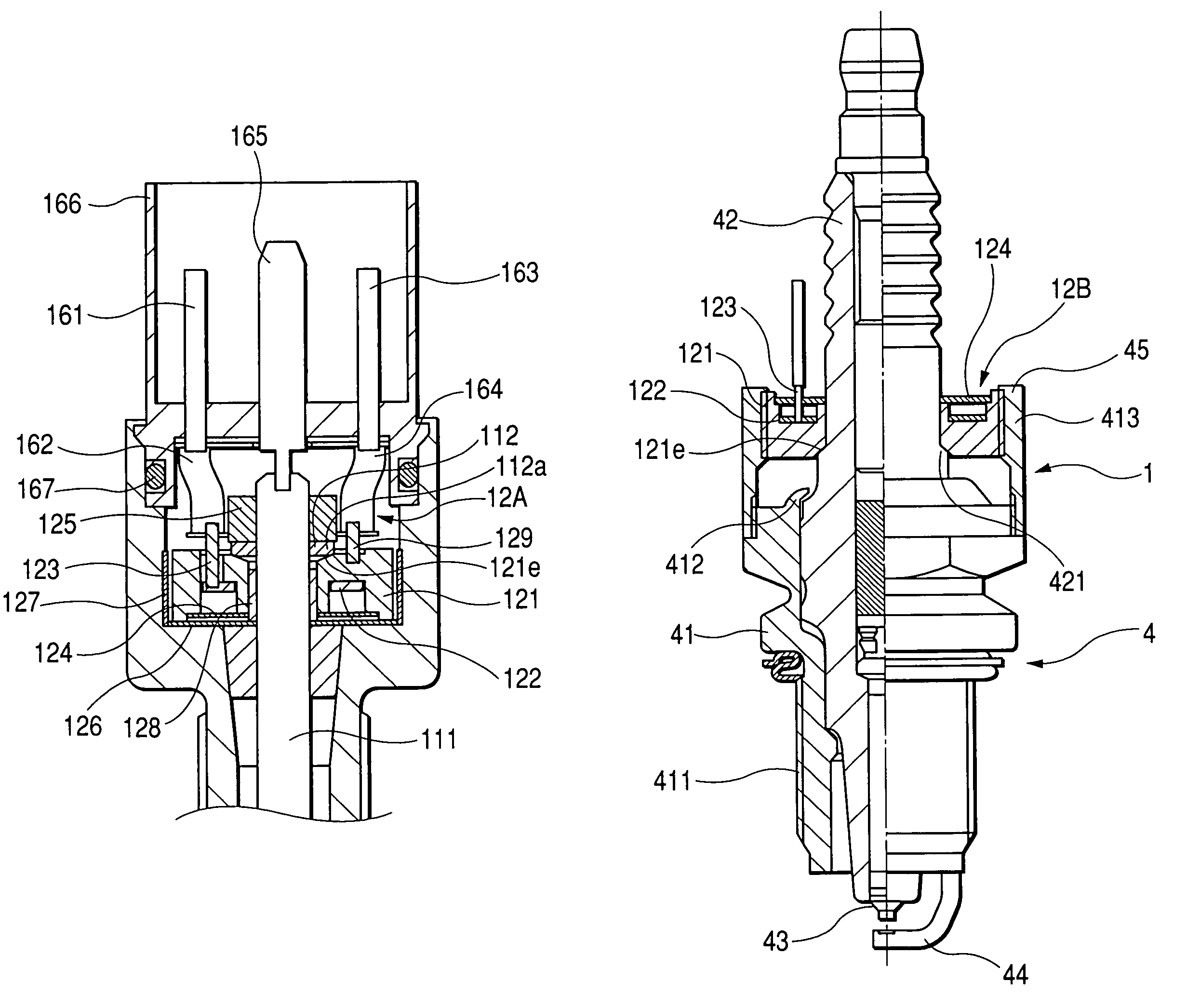

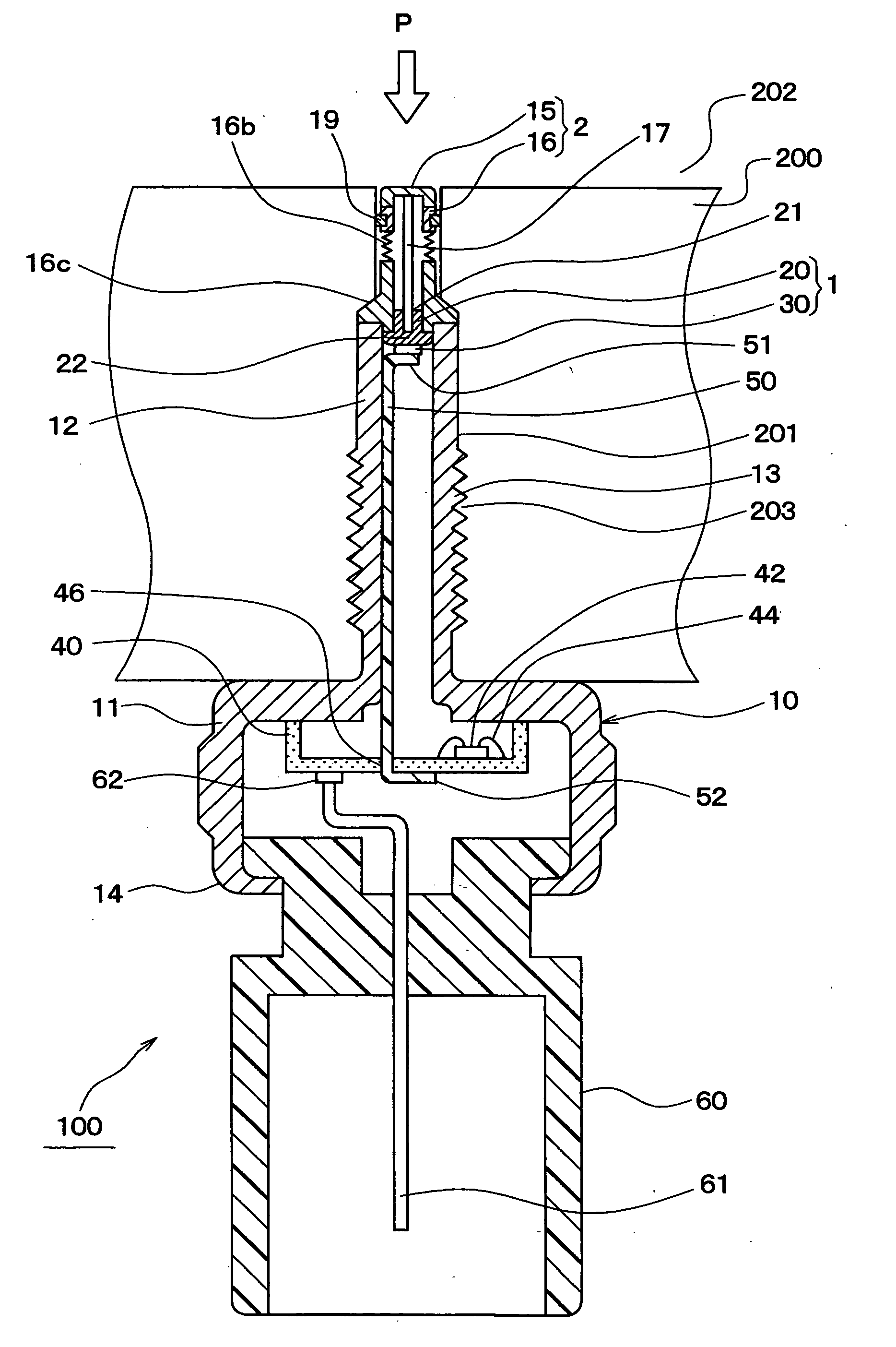

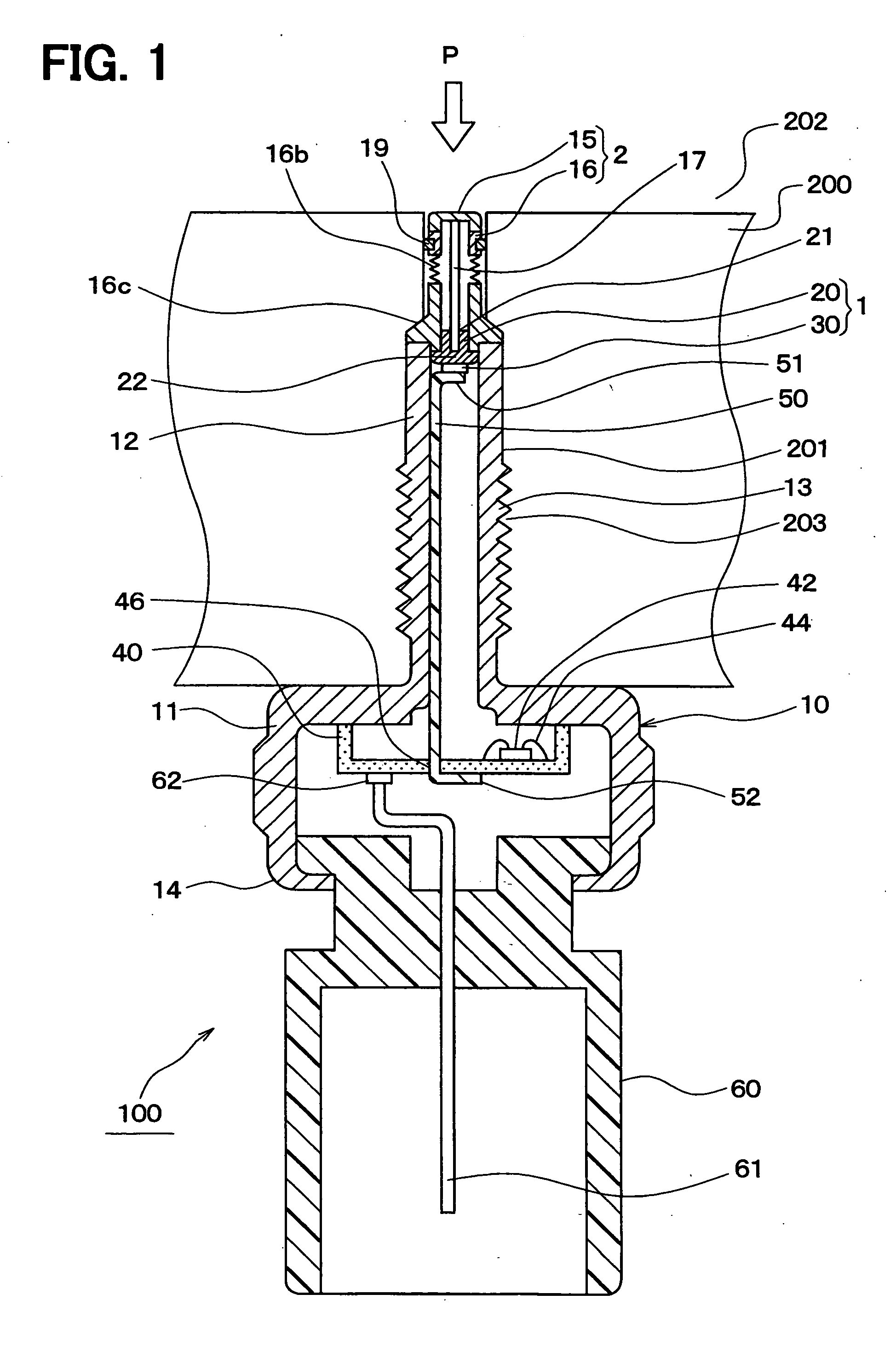

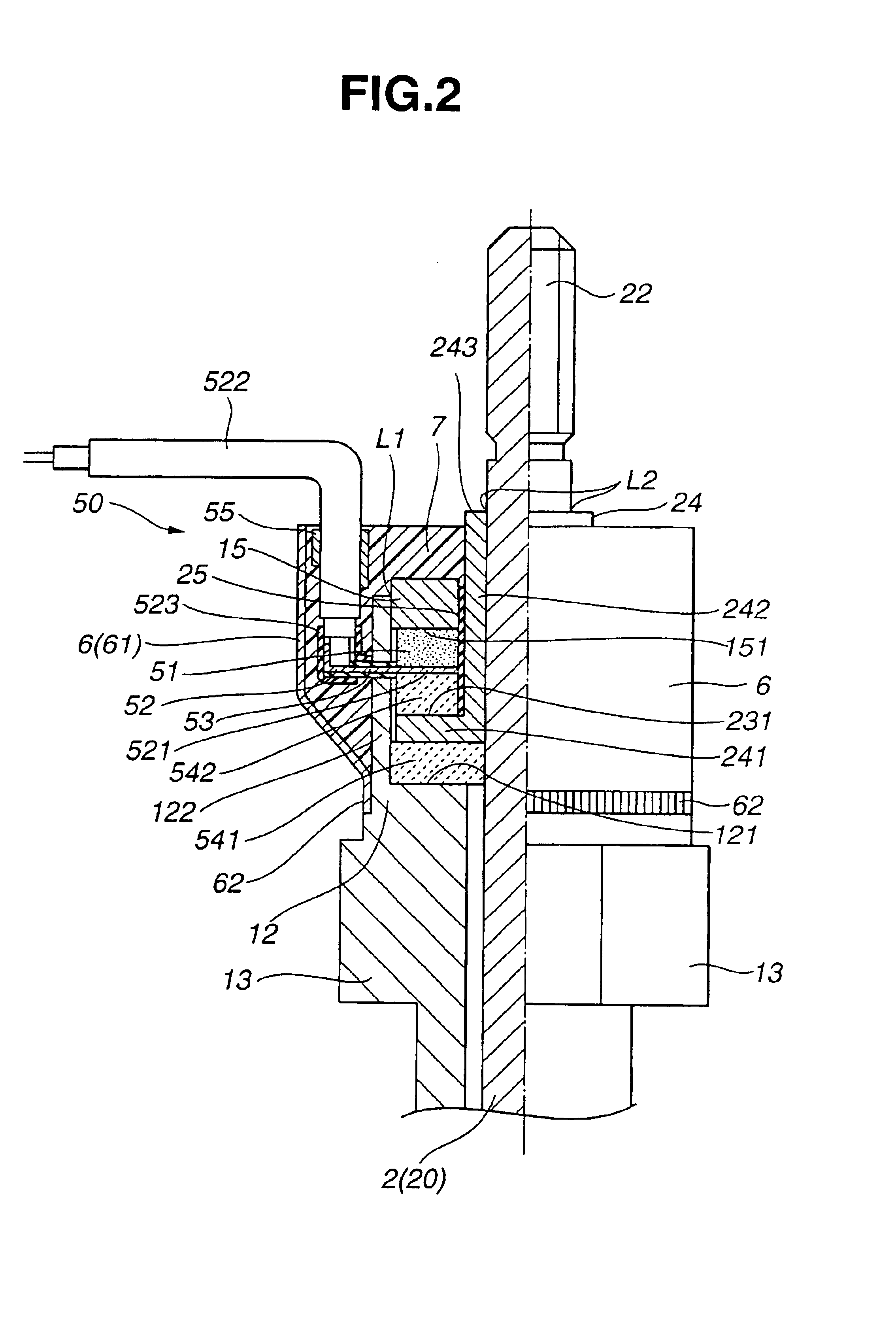

Combustion pressure sensor designed to ensure stability of output characteristic and sensitivity

ActiveUS6973820B2Minimize unit-to-unit variation in sensitivityEnsure output stabilityIncandescent ignitionFluid pressure measurementElectricityCombustion

A combustion pressure sensor for an internal combustion engine is provided. The sensor includes a sensing element such as a piezoelectric device sensitive to a physical load applied thereto to produce an electric signal indicative thereof and a bendable member. The bendable member is bent upon application of the combustion pressure in the engine to apply the physical load to the sensing element. Specifically, the physical load is applied to the sensing element which arises from the bend deformation of the bendable member, thus eliminating the need for a complete surface-to-surface contact between the sensing element and the bendable member. This results in a decreased unit-to-unit variation in sensitivity of combustion pressure sensors and ensures the stability of output characteristics of the combustion pressure sensor.

Owner:DENSO CORP

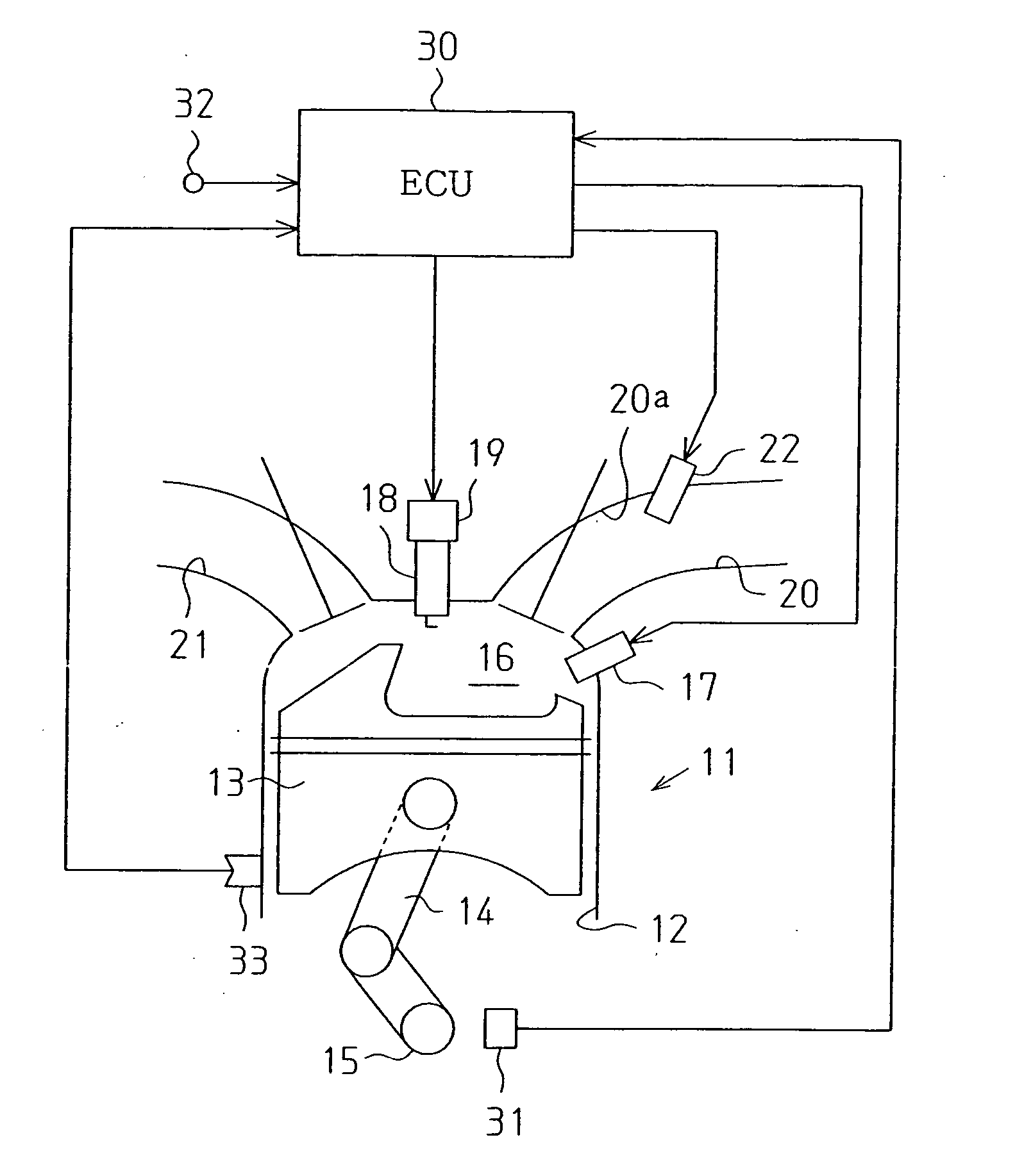

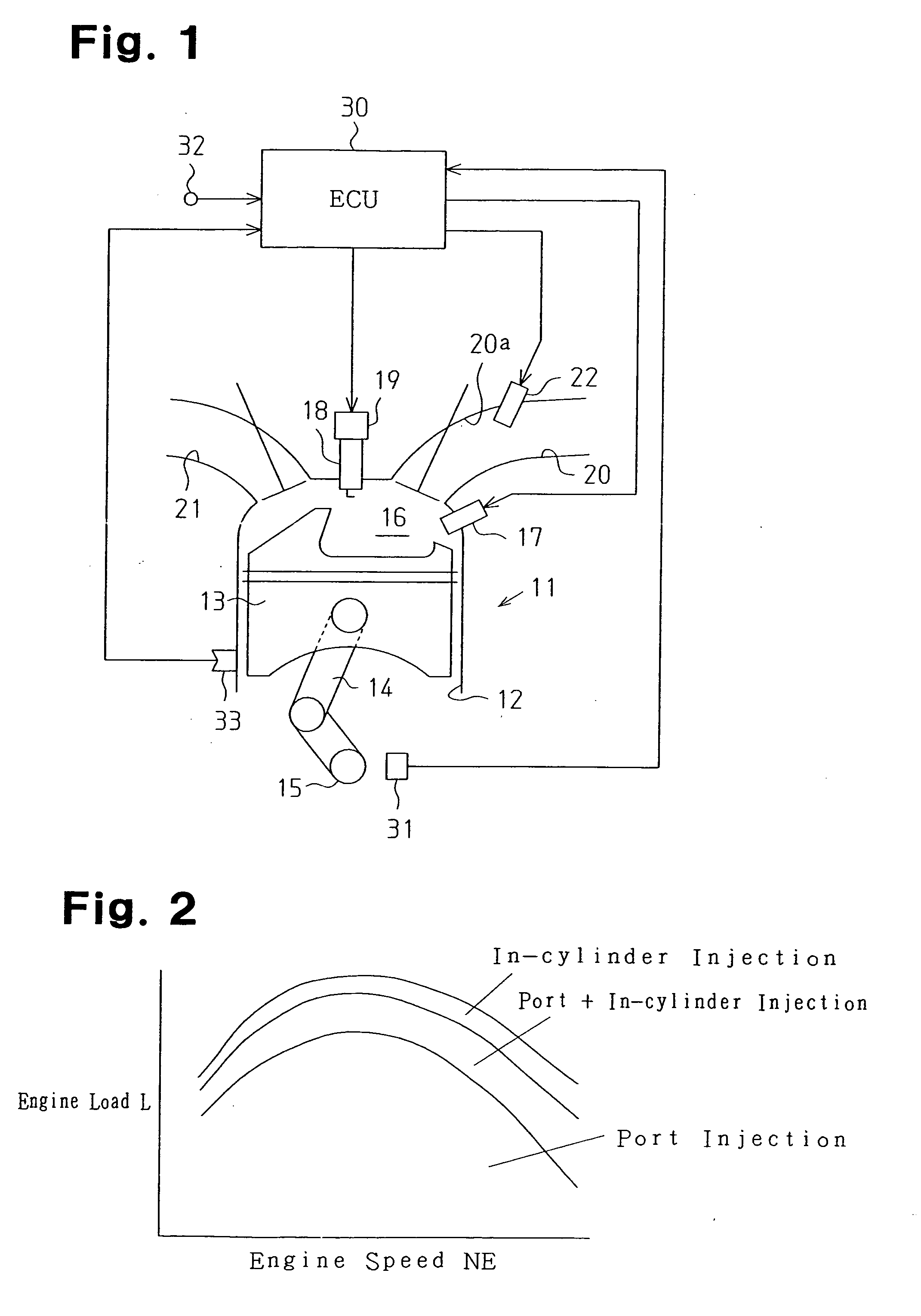

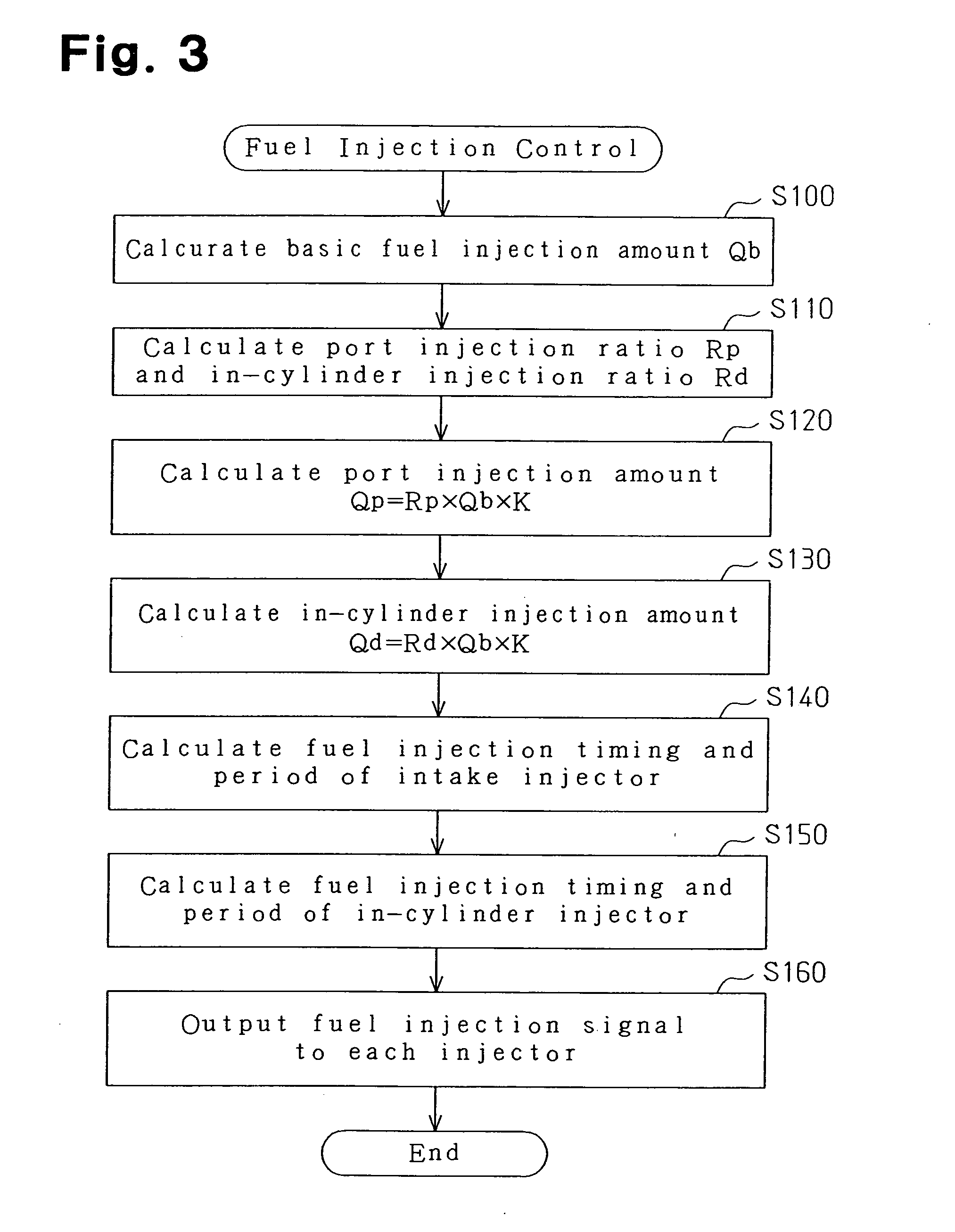

Knocking determination apparatus for internal combustion engine

InactiveUS20050098156A1Avoid knockingElectrical controlInternal combustion piston enginesCombustion chamberEngineering

An electronic control for determining knocking in an internal combustion engine having an intake injector for injecting fuel into an air intake port and an in-cylinder injector for directly injecting fuel into a combustion chamber. Knocking is determined based on an output signal from a knock sensor during a knock determination period. The electronic control unit alters the knock determination period in accordance with the ratio of the amount of fuel injected by the two injectors.

Owner:TOYOTA JIDOSHA KK

Method of mounting an accelerometer on an internal combustion engine and increasing signal-to-noise ratio

ActiveUS20080035108A1Increases signal output 's signal-to-noise ratioRaise the ratioAnalogue computers for vehiclesInternal-combustion engine testingSignal-to-noise ratio (imaging)Accelerometer

A method of mounting an accelerometer to an internal combustion engine comprises securing the accelerometer to a mating surface on an engine component external to a combustion chamber where the accelerometer can generate a signal output that is characteristic of engine knock, when it occurs, and at least one other combustion behavior inside the combustion chamber during a combustion event. The method further comprises connecting a signal wire at one end to the accelerometer and at an opposite end to a signal processor, and increasing the signal output's signal-to-noise ratio.

Owner:WESTPORT FUEL SYST CANADA INC

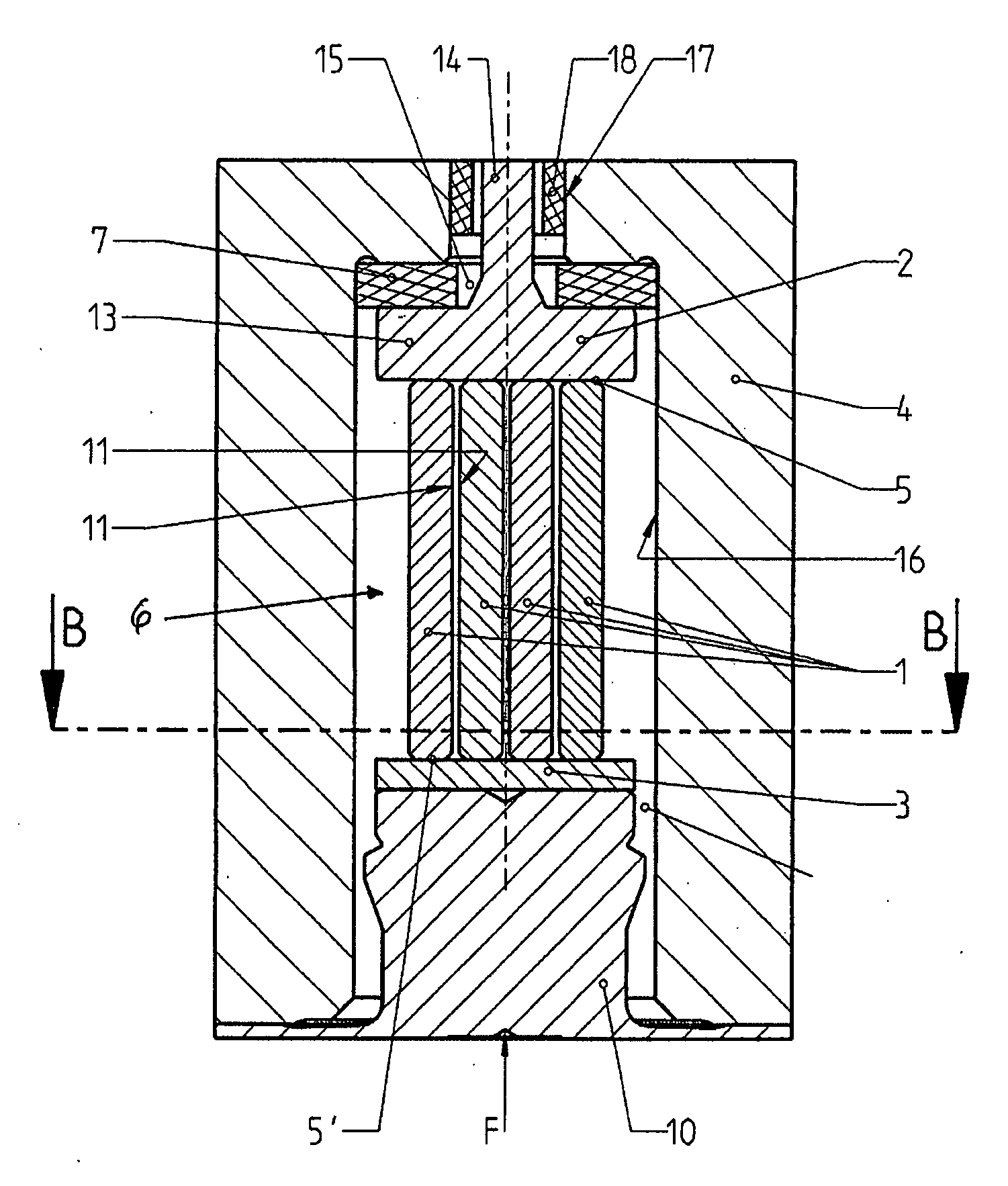

Pressure sensor for measurement of gas pressure in a cylinder of a combustion engine

InactiveUS6561036B1Minimize impactChange effectEngine testingFluid pressure measurement by electric/magnetic elementsCombustionEngineering

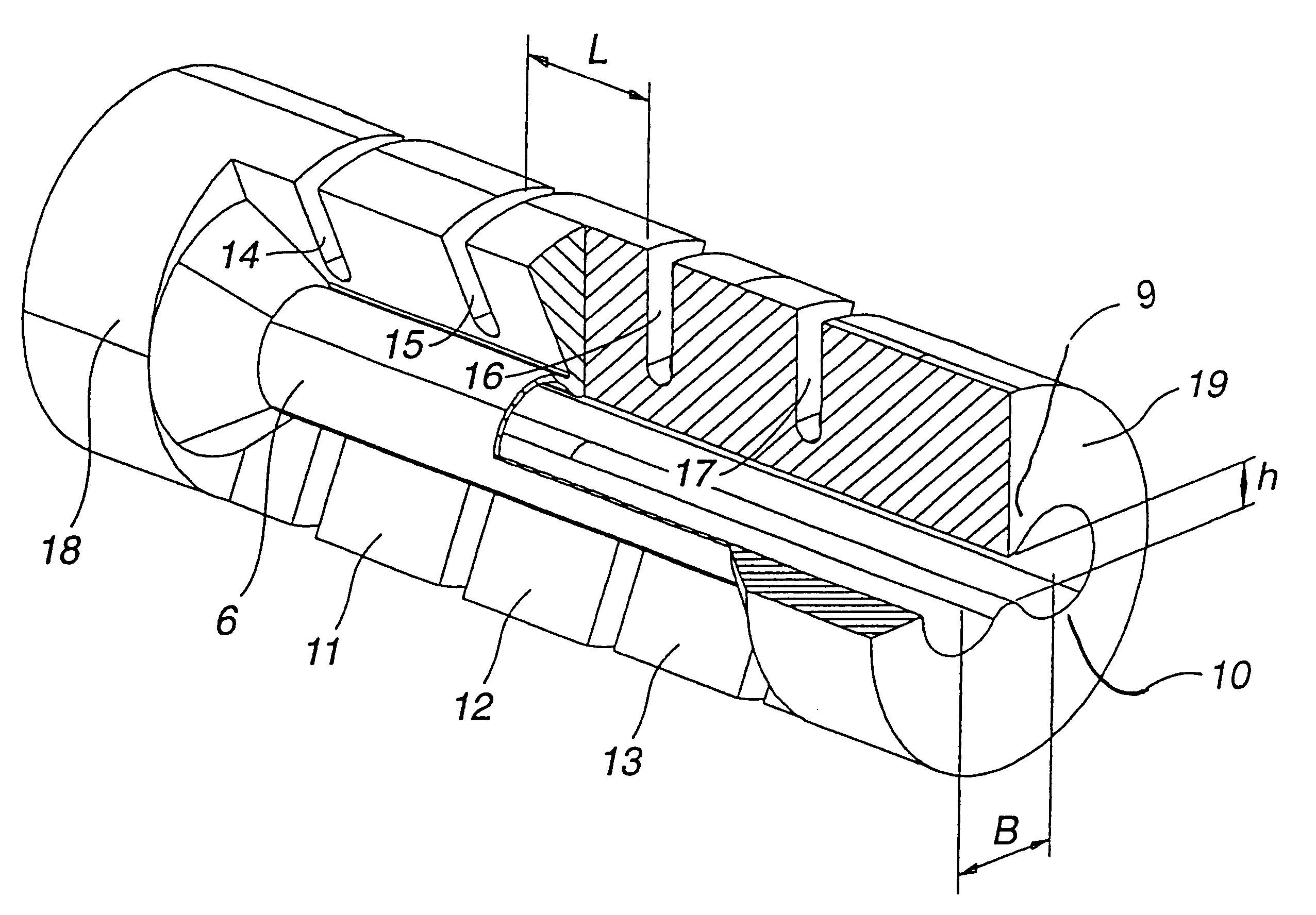

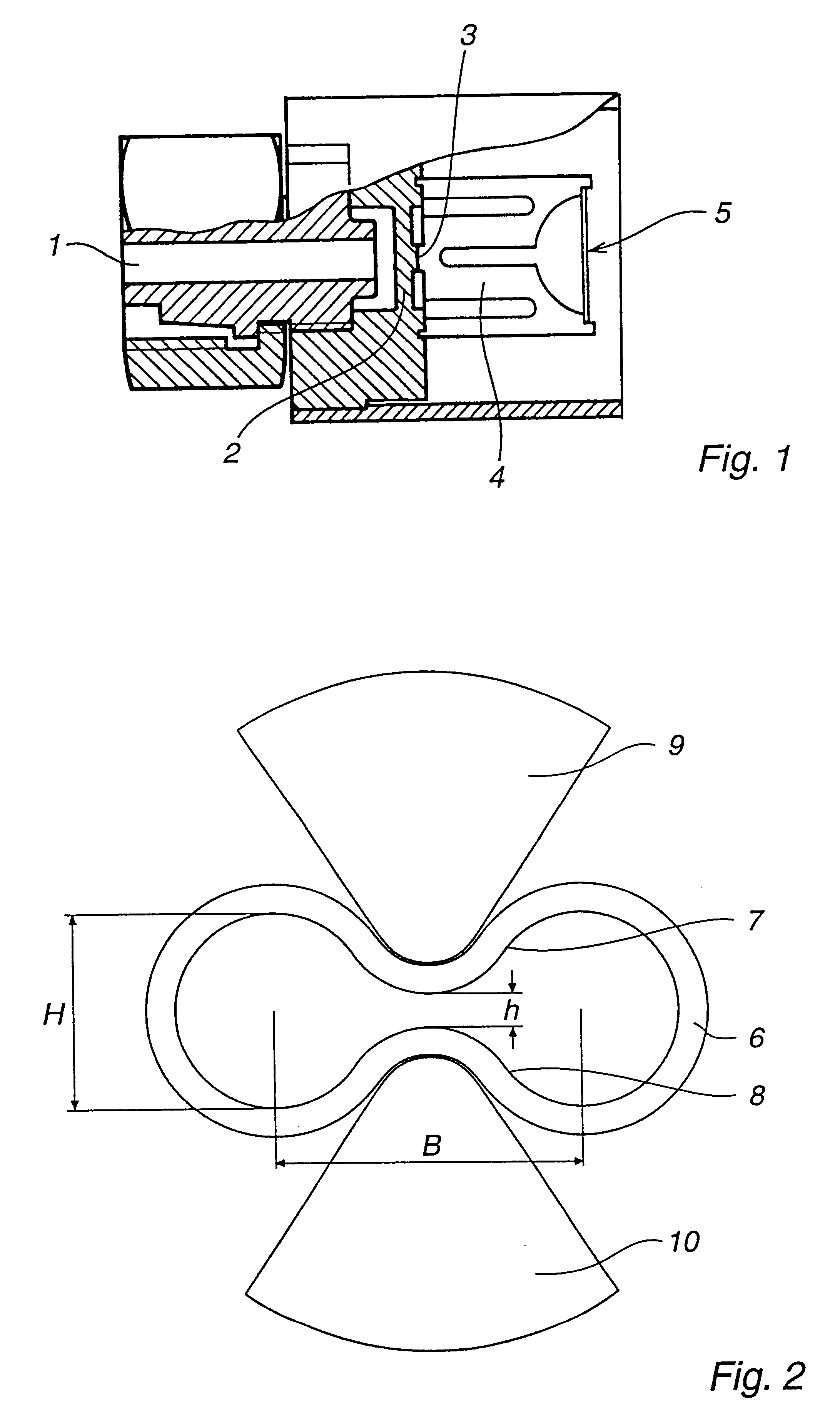

Pressure sensor for measurement of gas pressure in a cylinder of a combustion engine, including a tube shaped in cross section as an hourglass. In the axial direction the tube consists in part of a section connected to the cylinder and open to the cylinder, in part of a measuring section and in part of a final section the end of which is closed. The measuring section of the tube is shaped so that in the tubes axial direction two parallel measuring surfaces are established against which are two beams connected to force transferring yokes arranged to influence force measuring organs for the determination of the force with which the gas pressure influences the parallel measuring surfaces of the tube. In this pressure sensor and other embodiments the influences of temperature fluctuations and any shunting effects of the material of the measuring tube are reduced to a minimum.

Owner:ABB (SCHWEIZ) AG

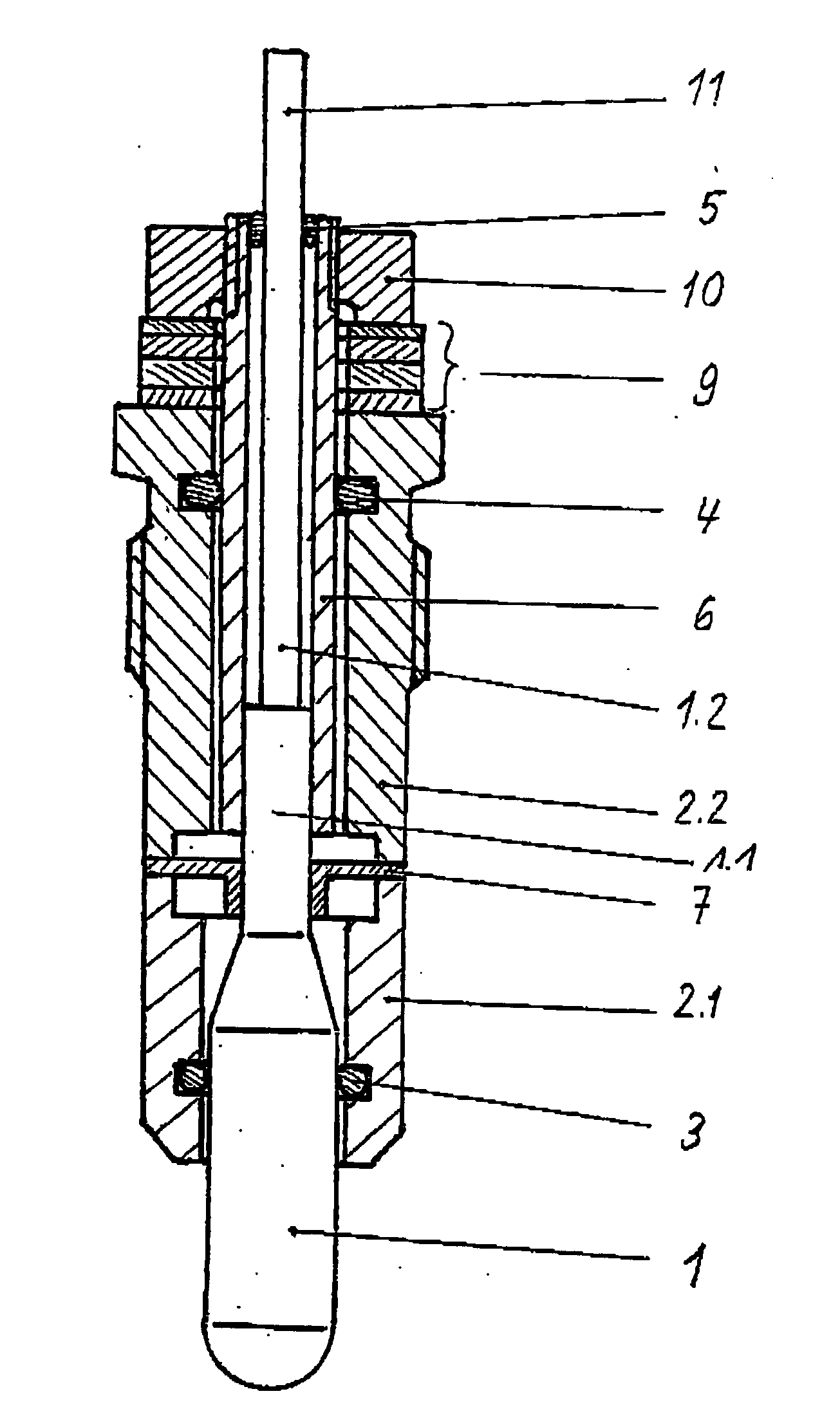

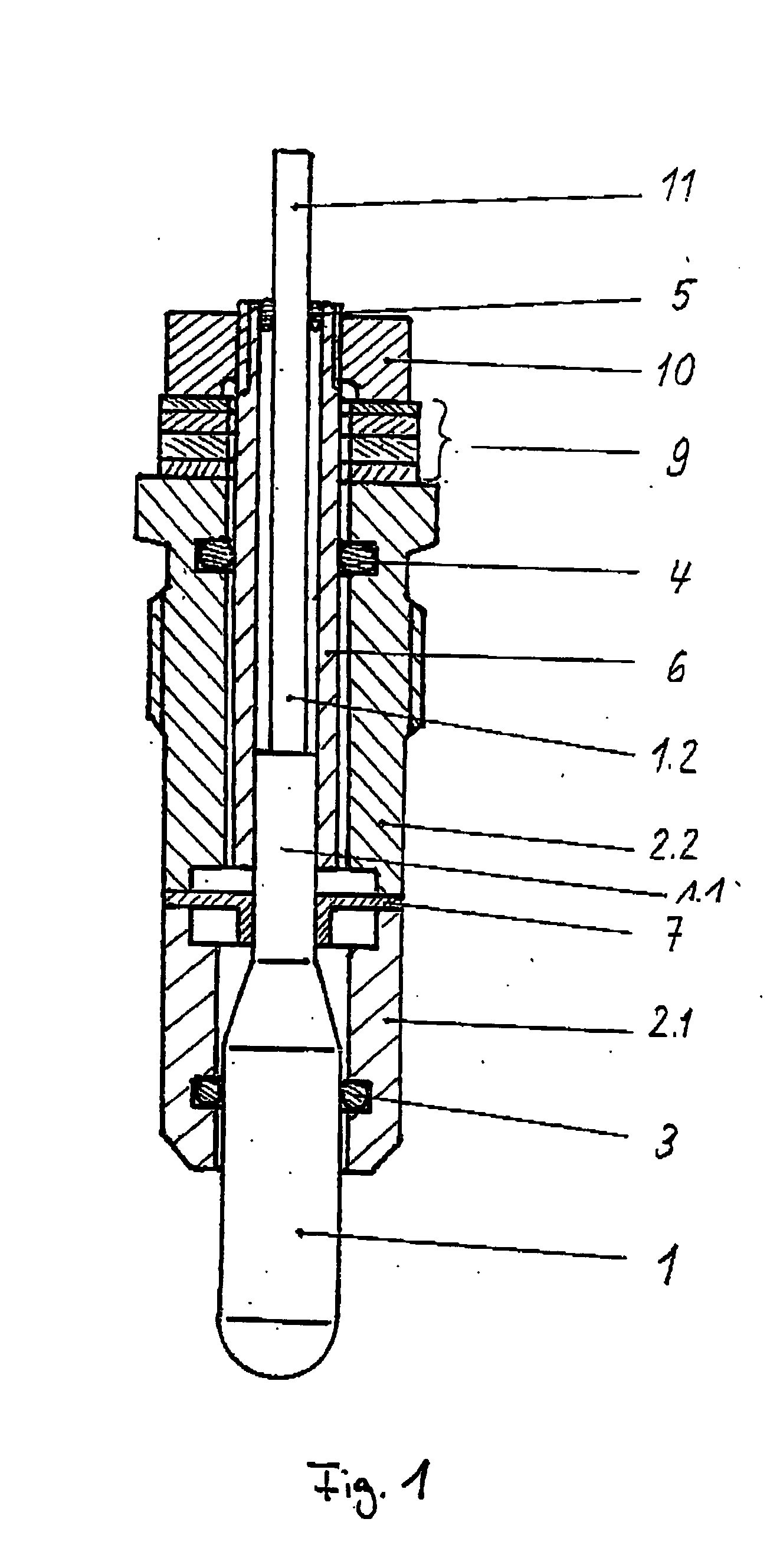

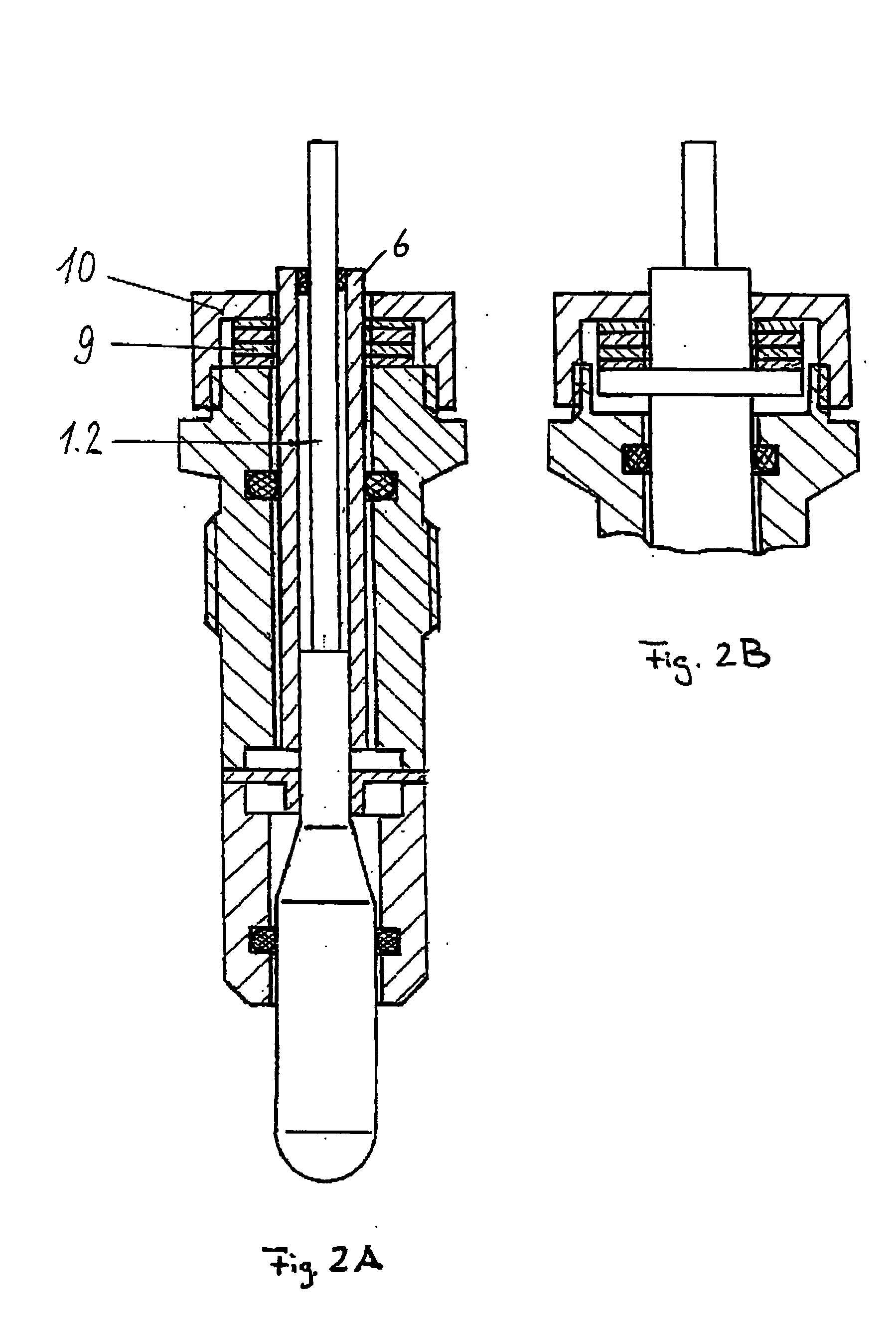

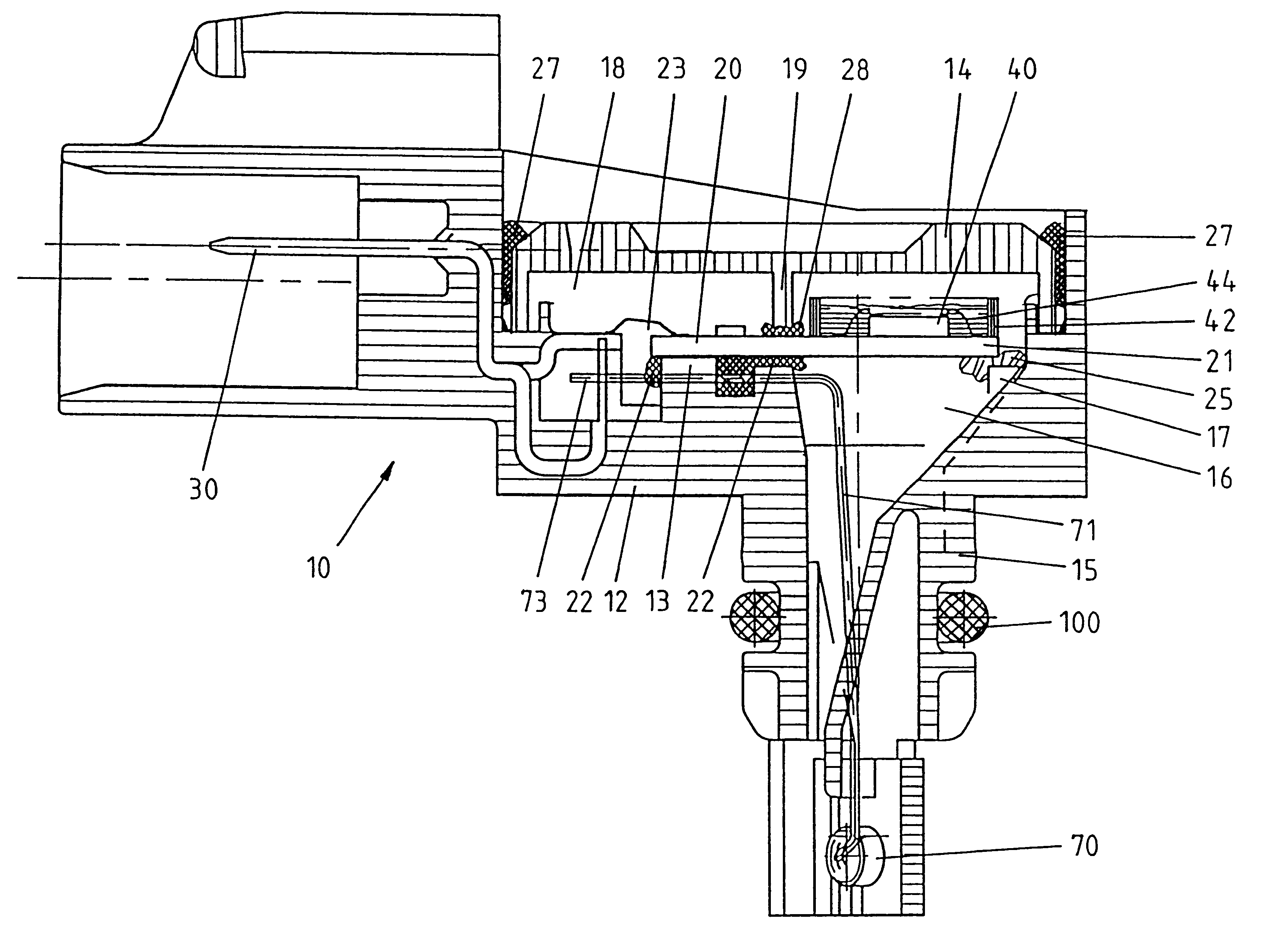

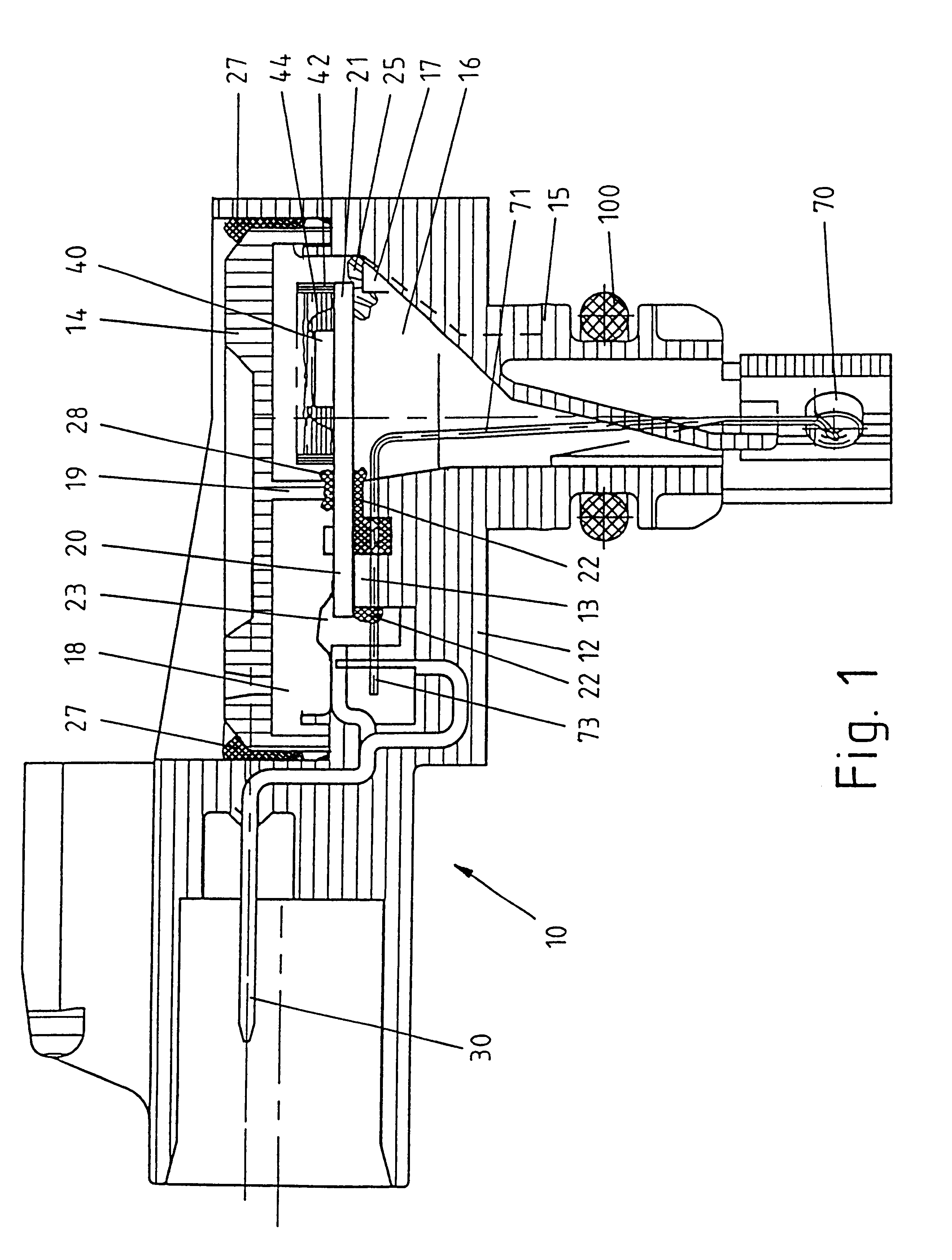

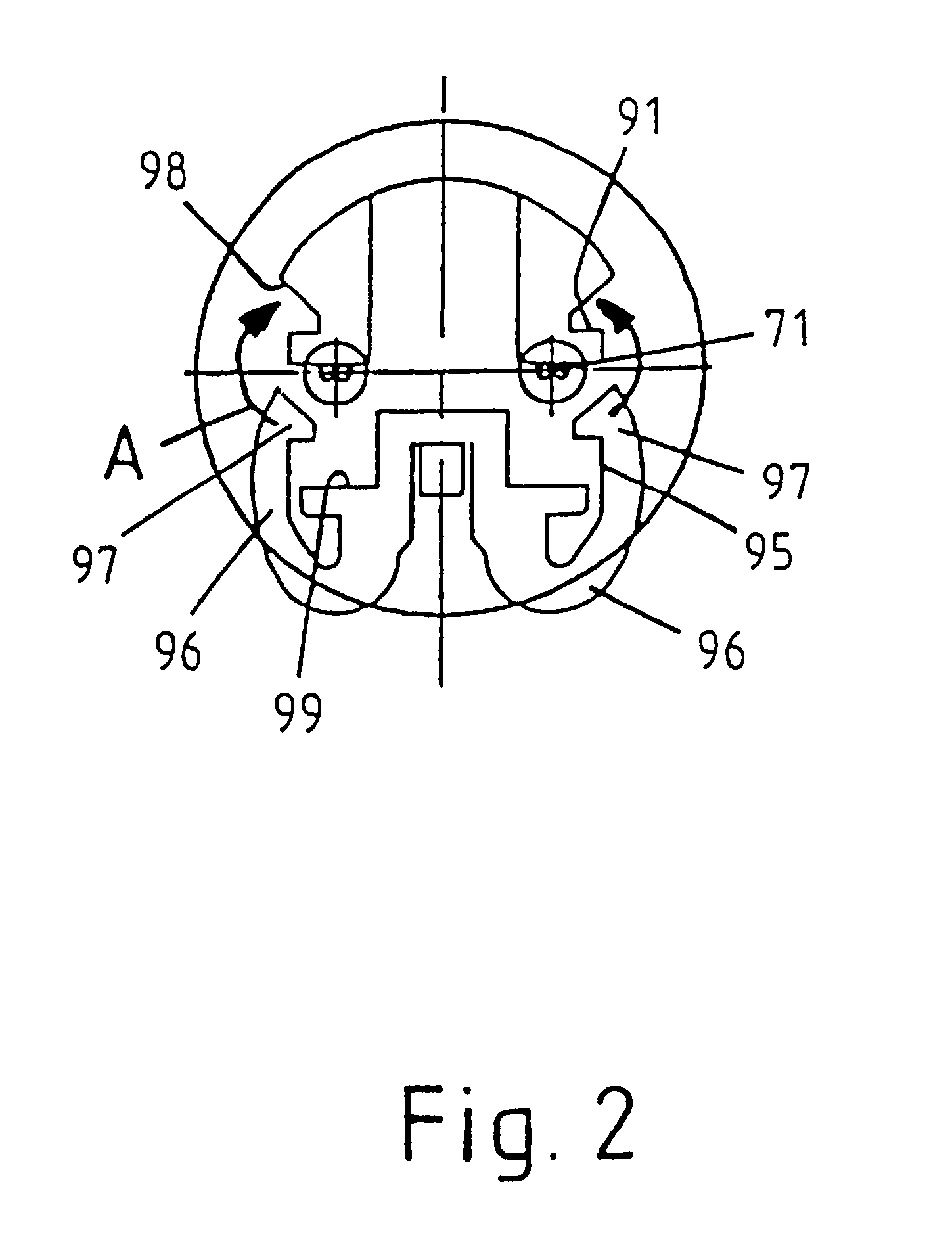

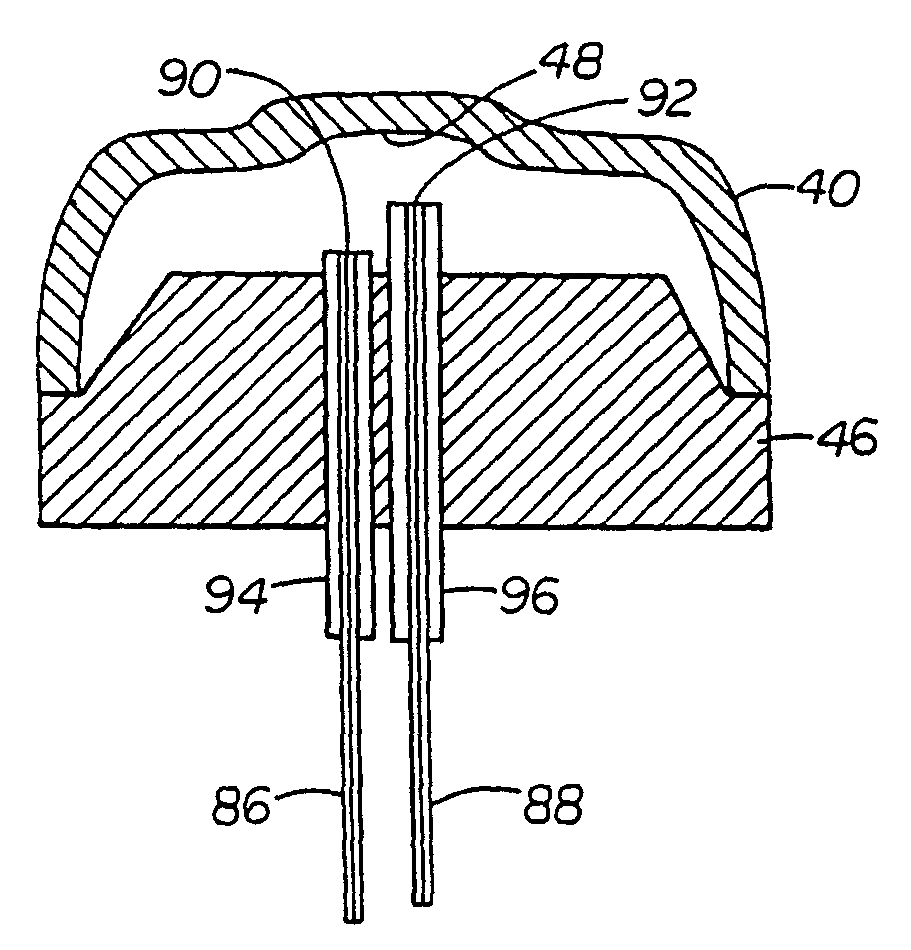

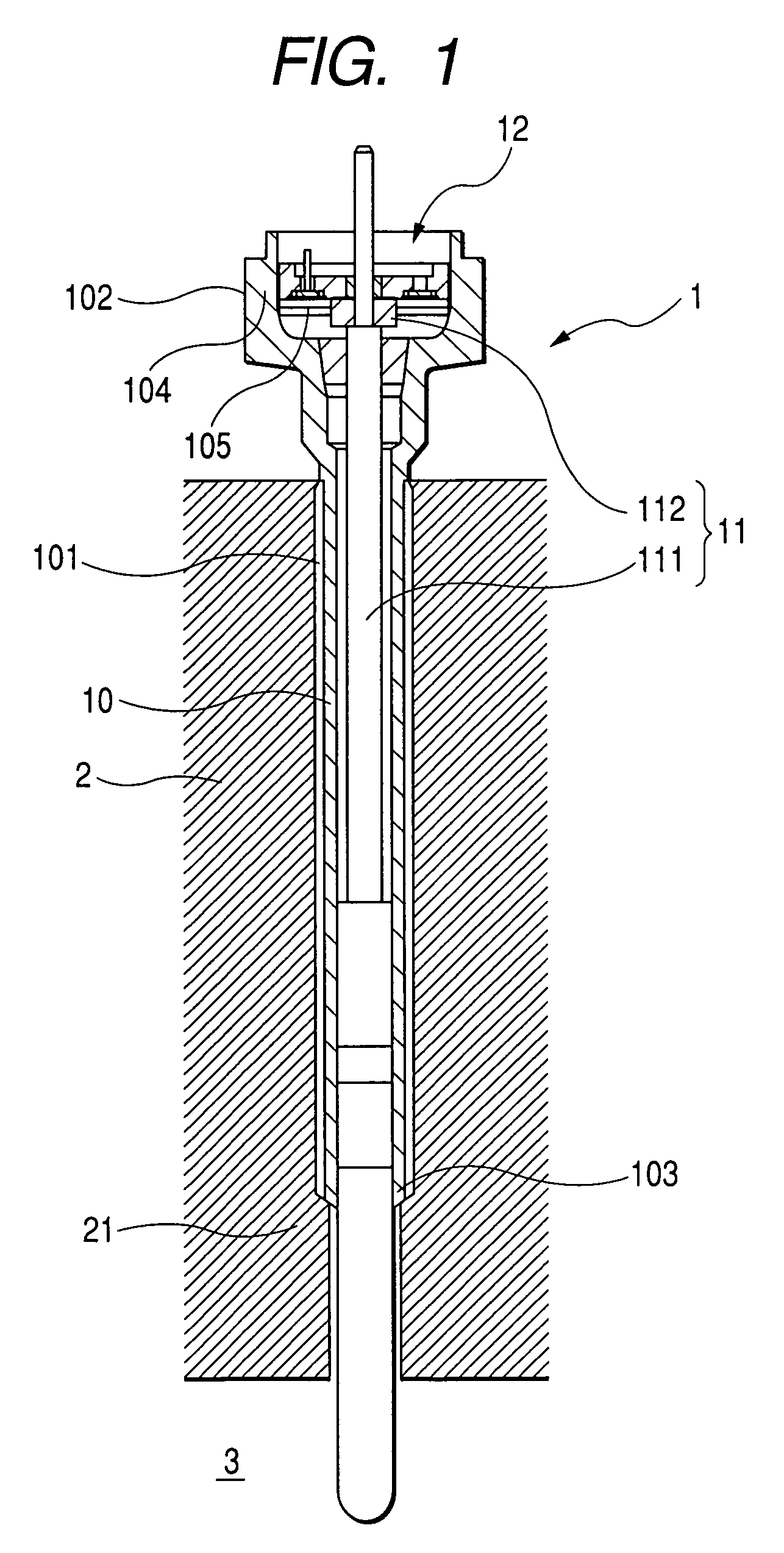

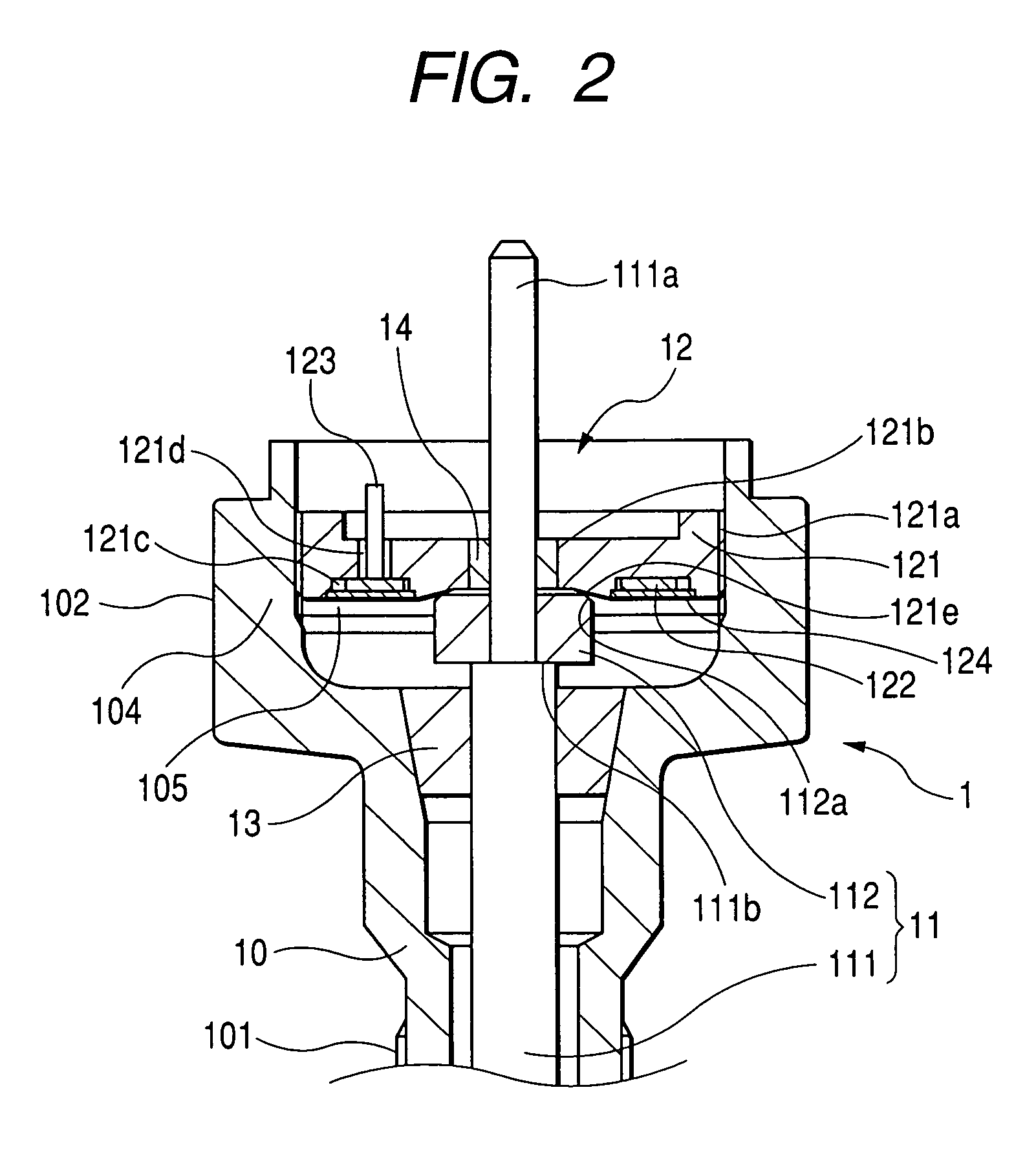

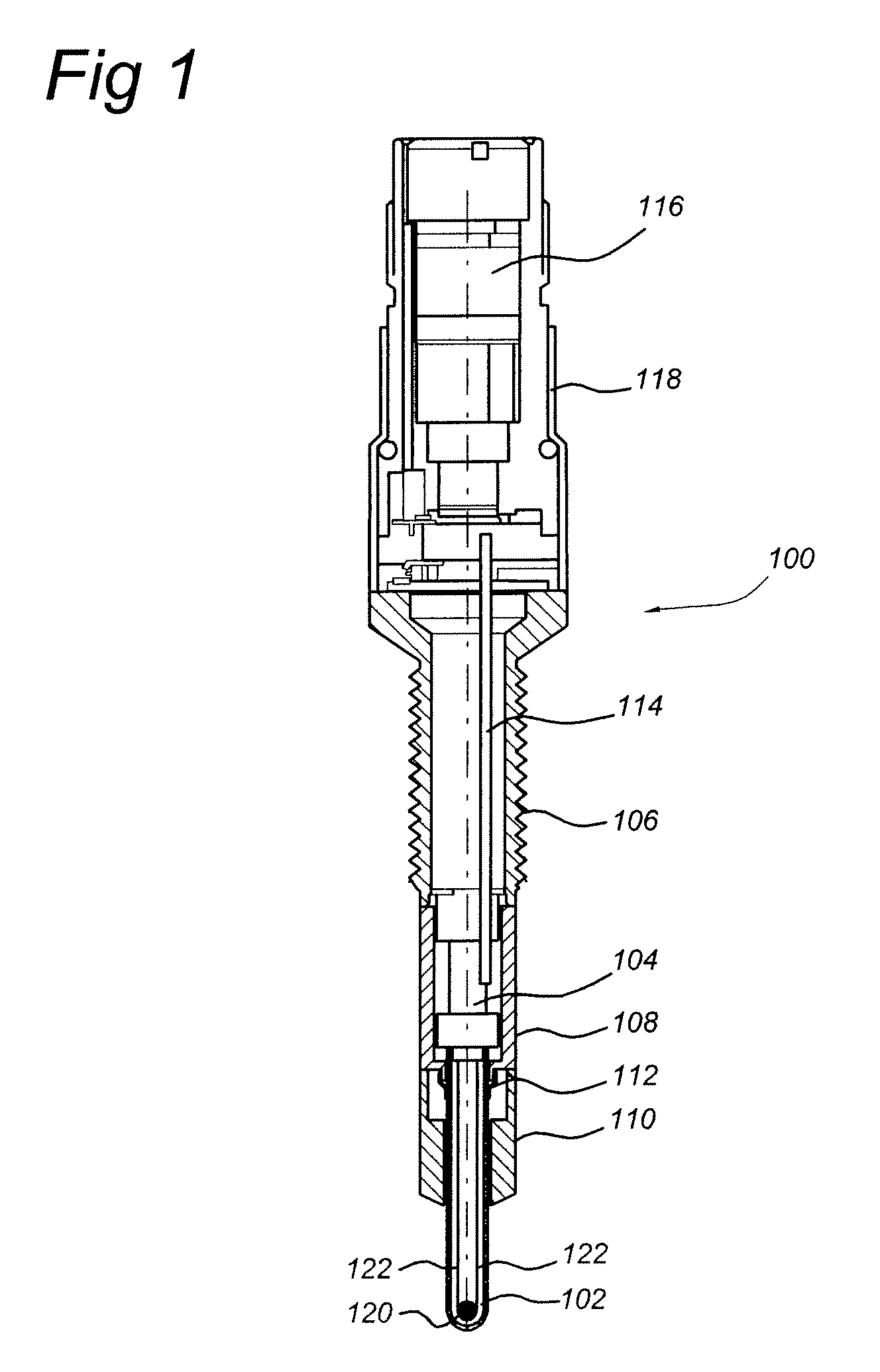

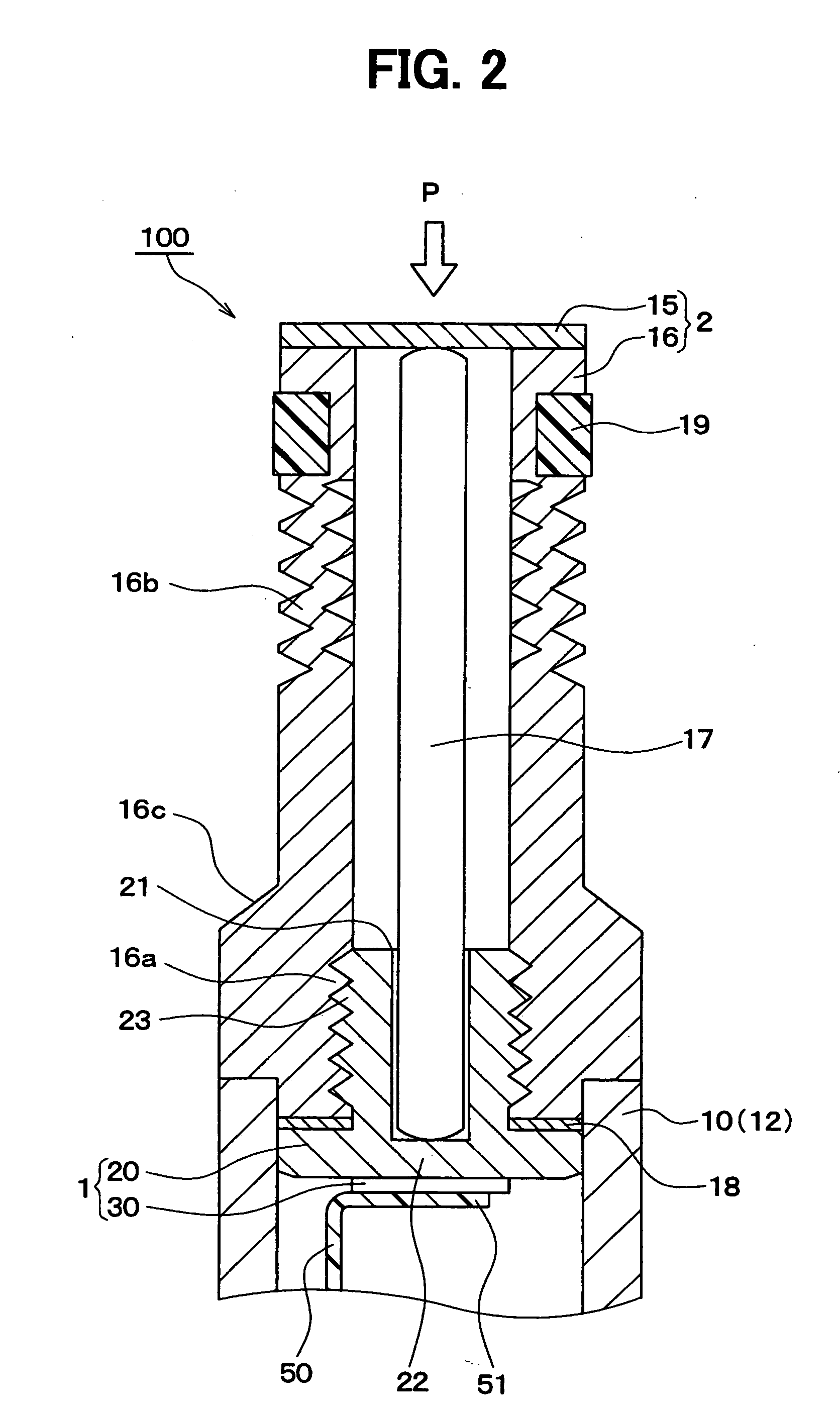

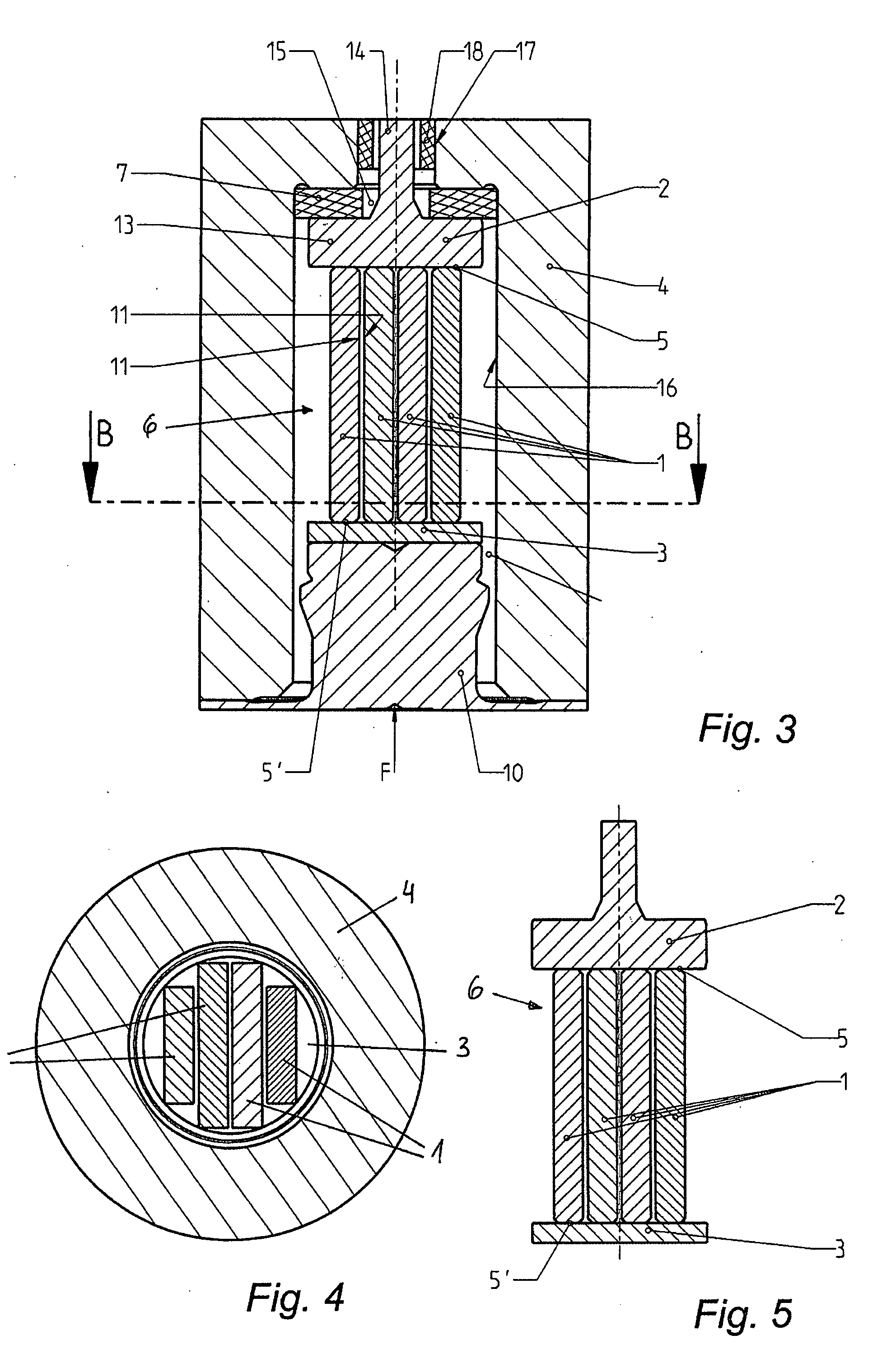

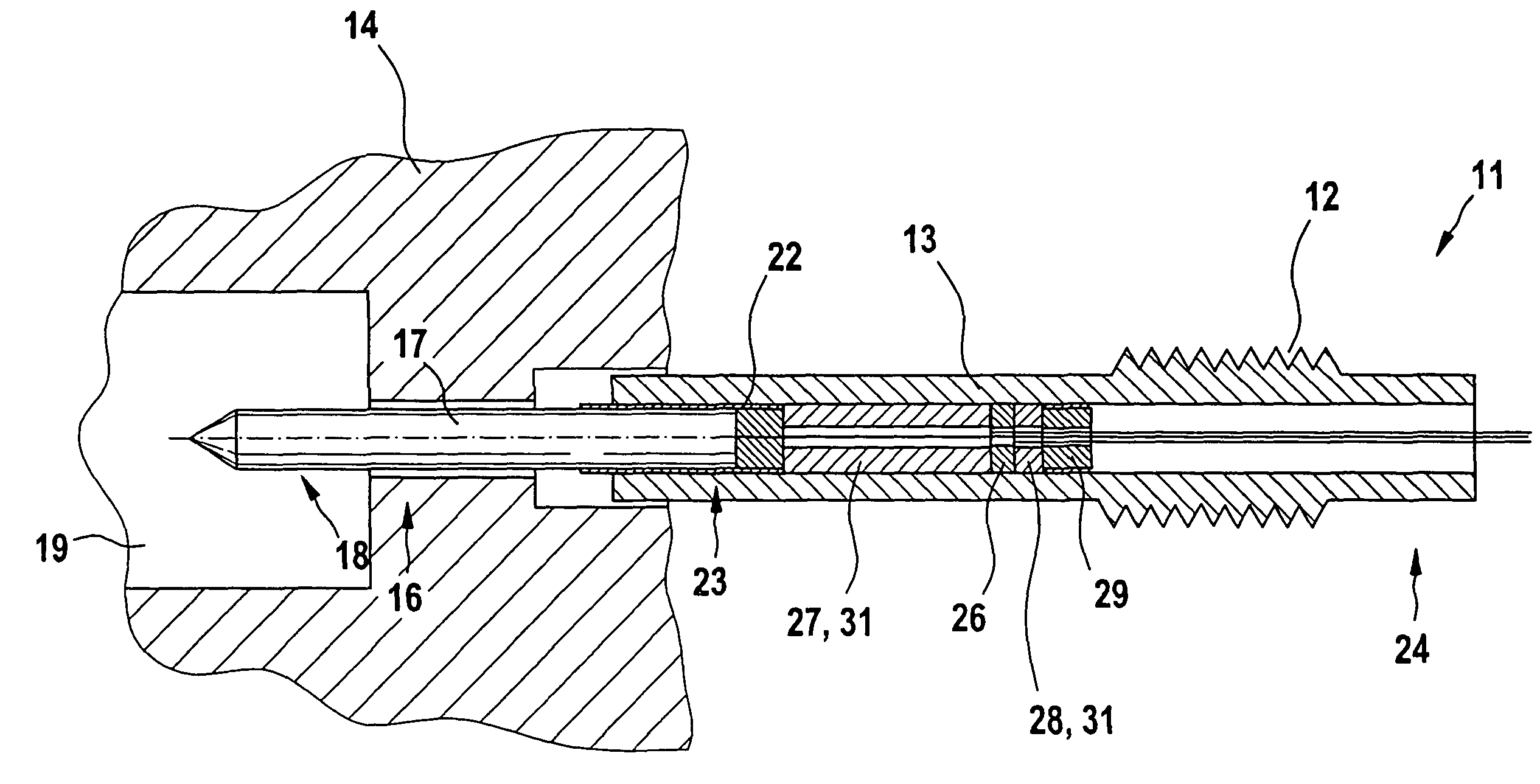

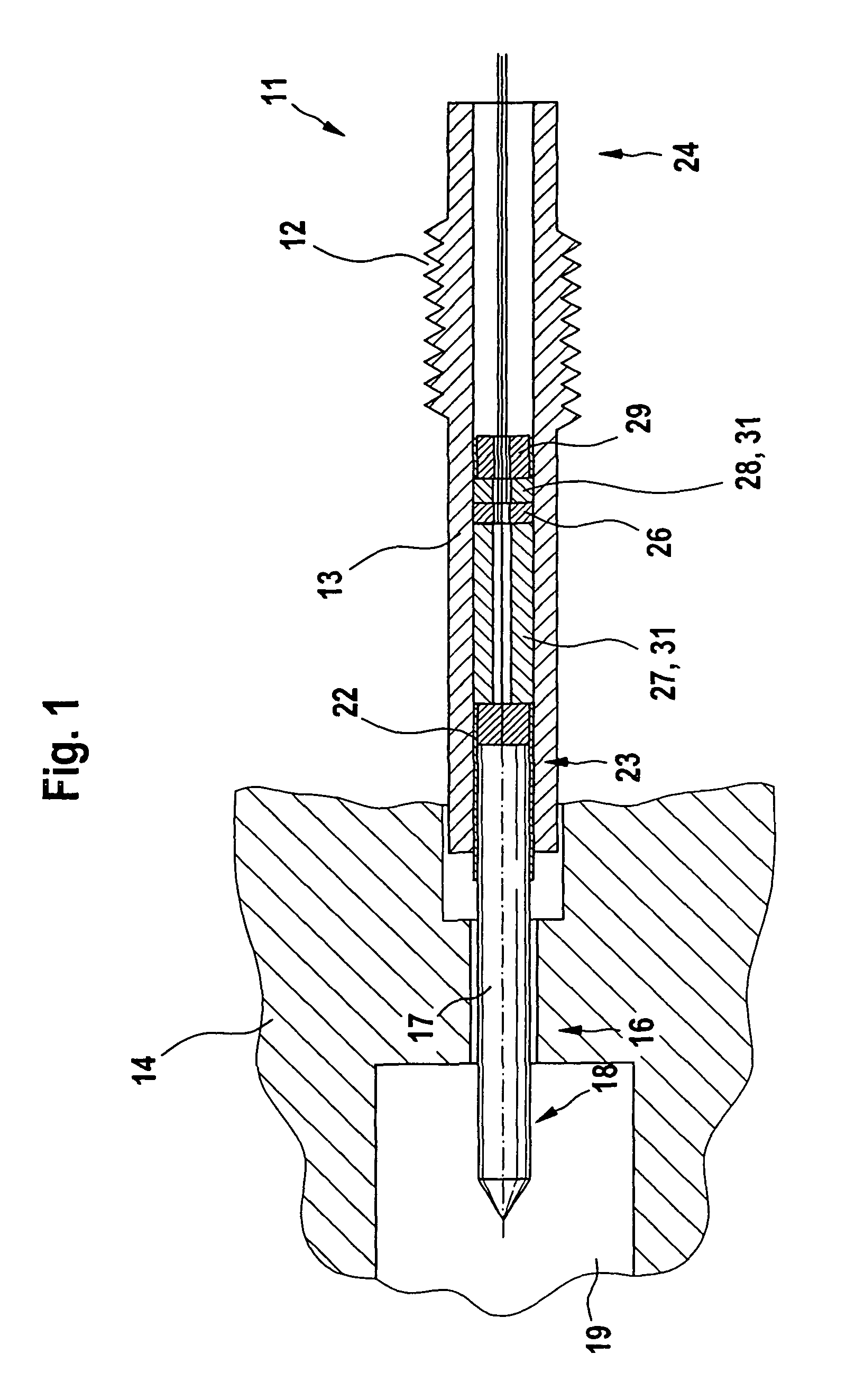

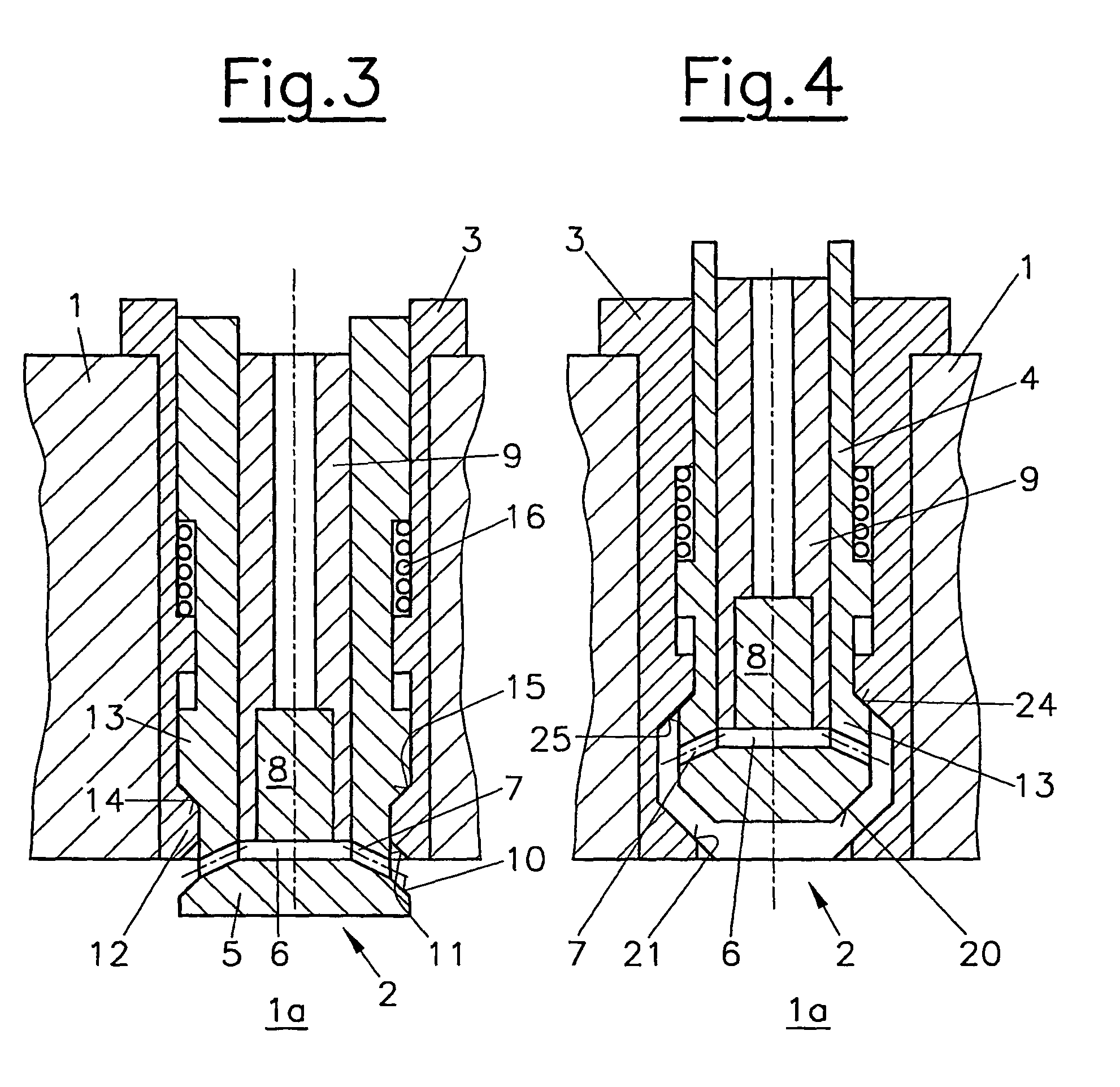

Pencil-type glow plug having an integrated combustion chamber pressure sensor

InactiveUS7581520B2Improve fatigue strengthAvoid failureIncandescent ignitionLamp incadescent bodiesCombustion chamberDiaphragm seal

A pencil-type glow plug for a self-igniting internal combustion engine is described. The pencil-type glow plug includes a plug body in which a combustion chamber pressure sensor is integrated, and a bar-shaped heating element that protrudes out from the plug body at one end, into the combustion chamber of the internal combustion engine. A force-measuring element of the combustion chamber pressure sensor is accommodated behind the heating element, which moves axially under the influence of force. The force-measuring element is sealed against combustion chamber gases by a steel diaphragm made of a stainless precipitation-hardened maraging steel.

Owner:ROBERT BOSCH GMBH

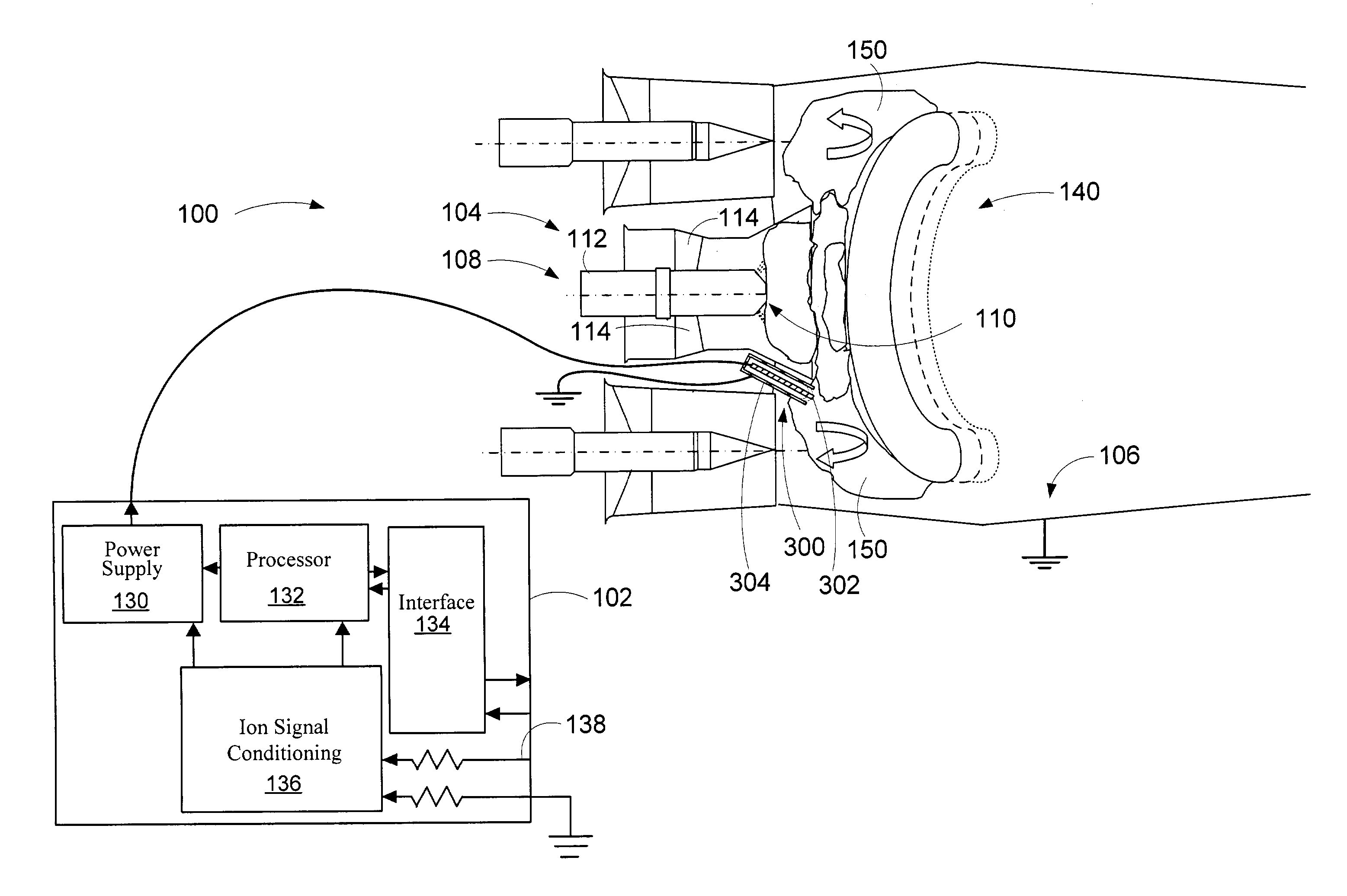

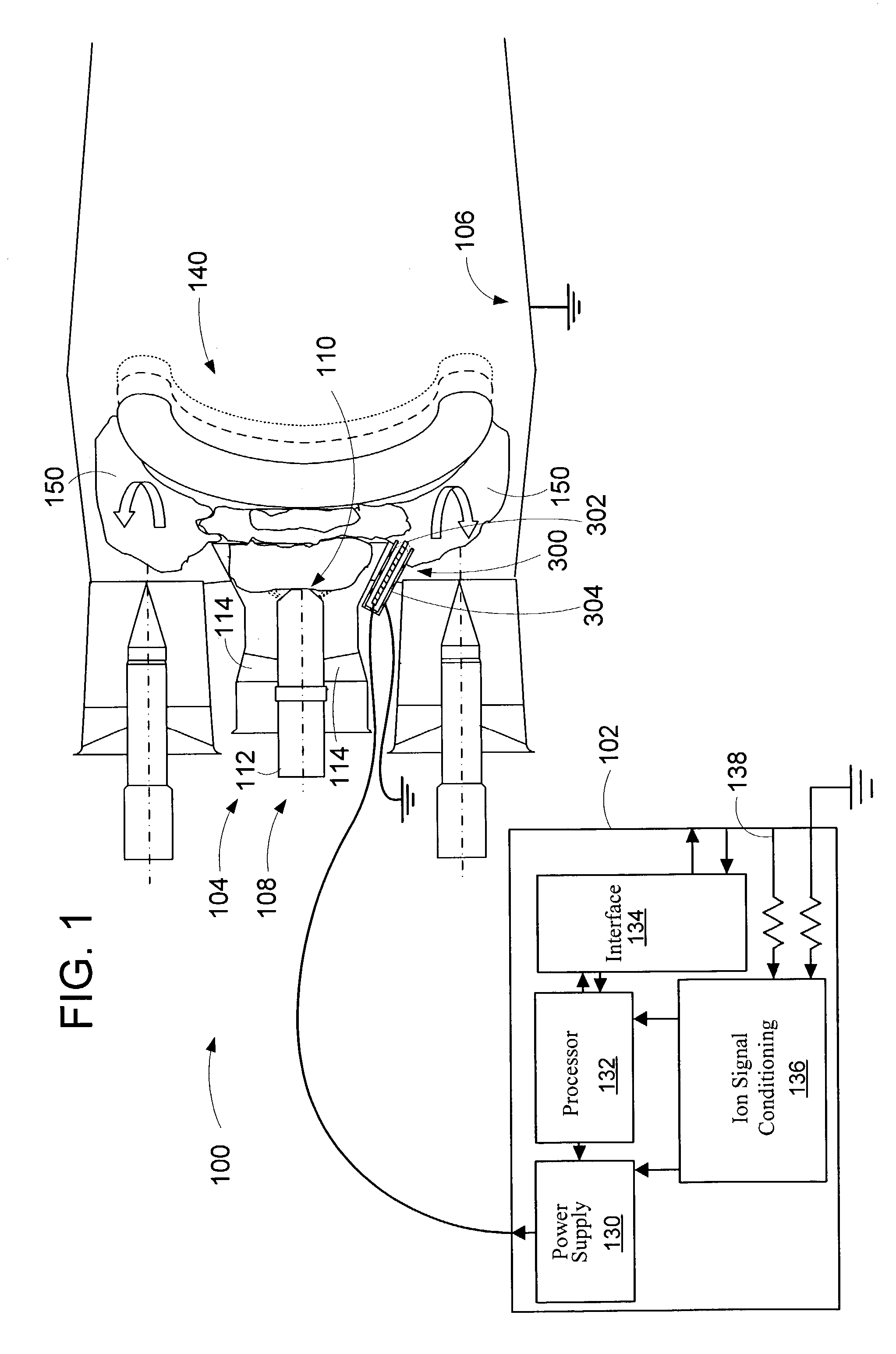

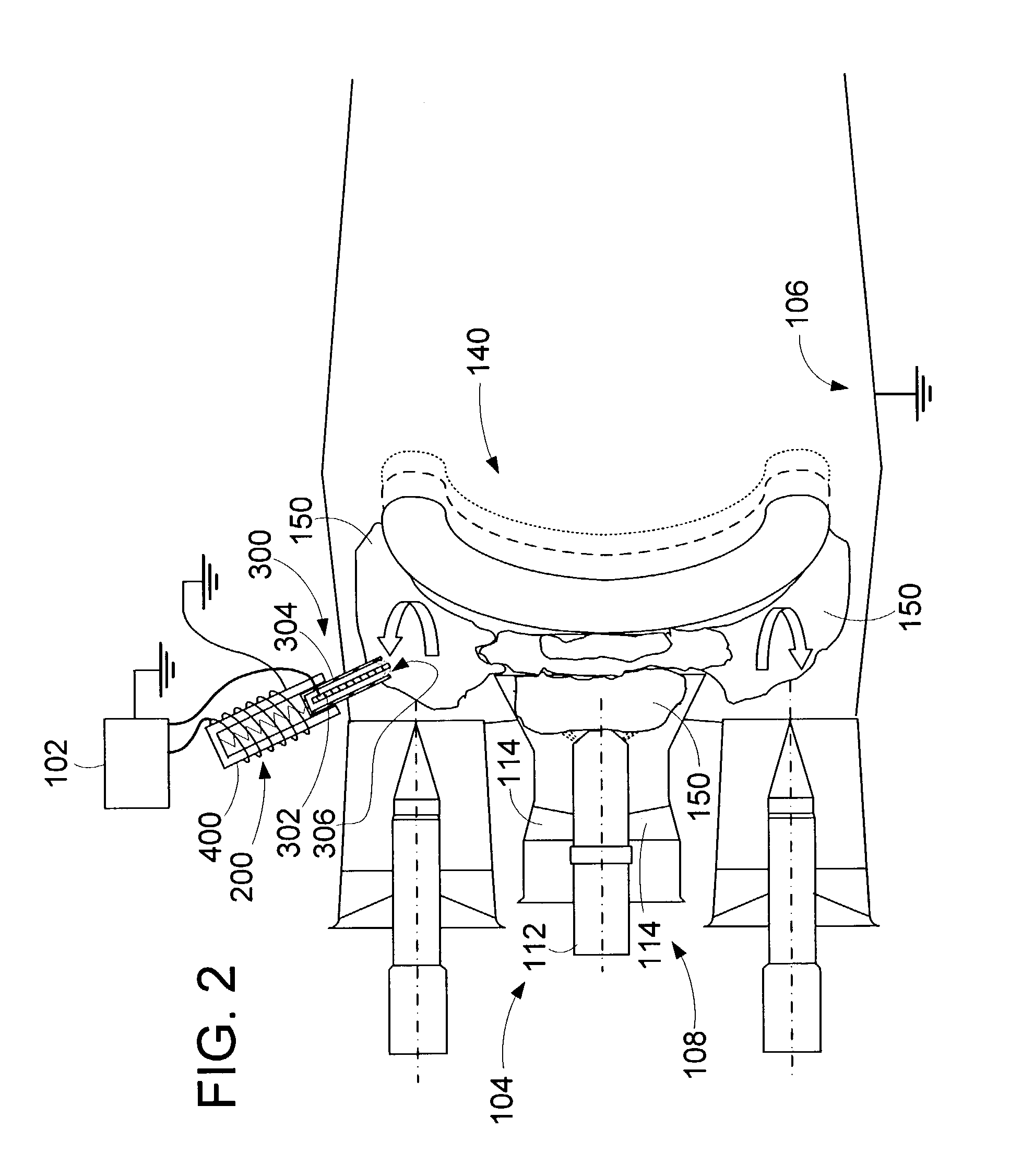

Method and apparatus for detecting combustion instability in continuous combustion systems

Owner:WOODWARD GOVERNOR CO

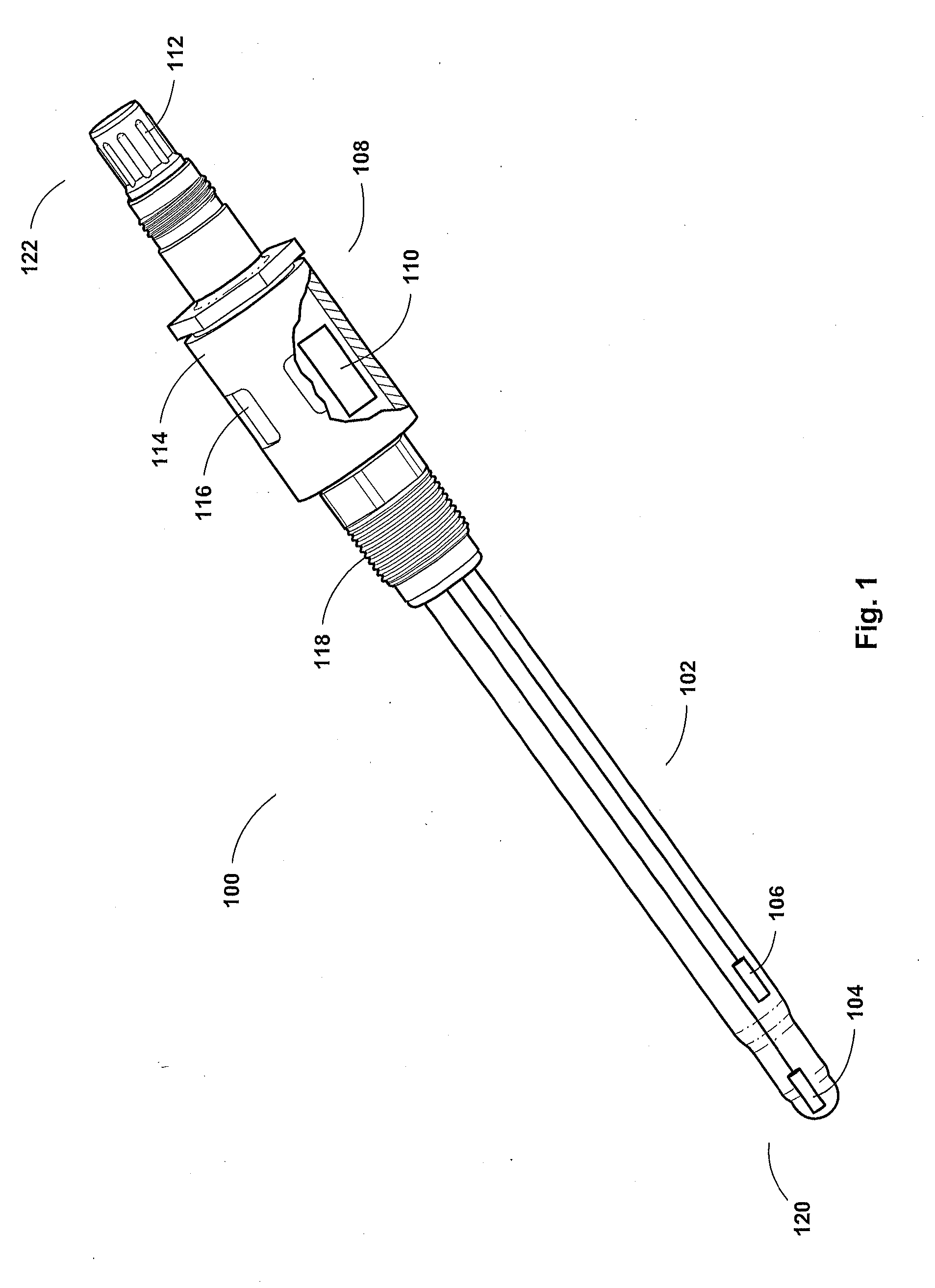

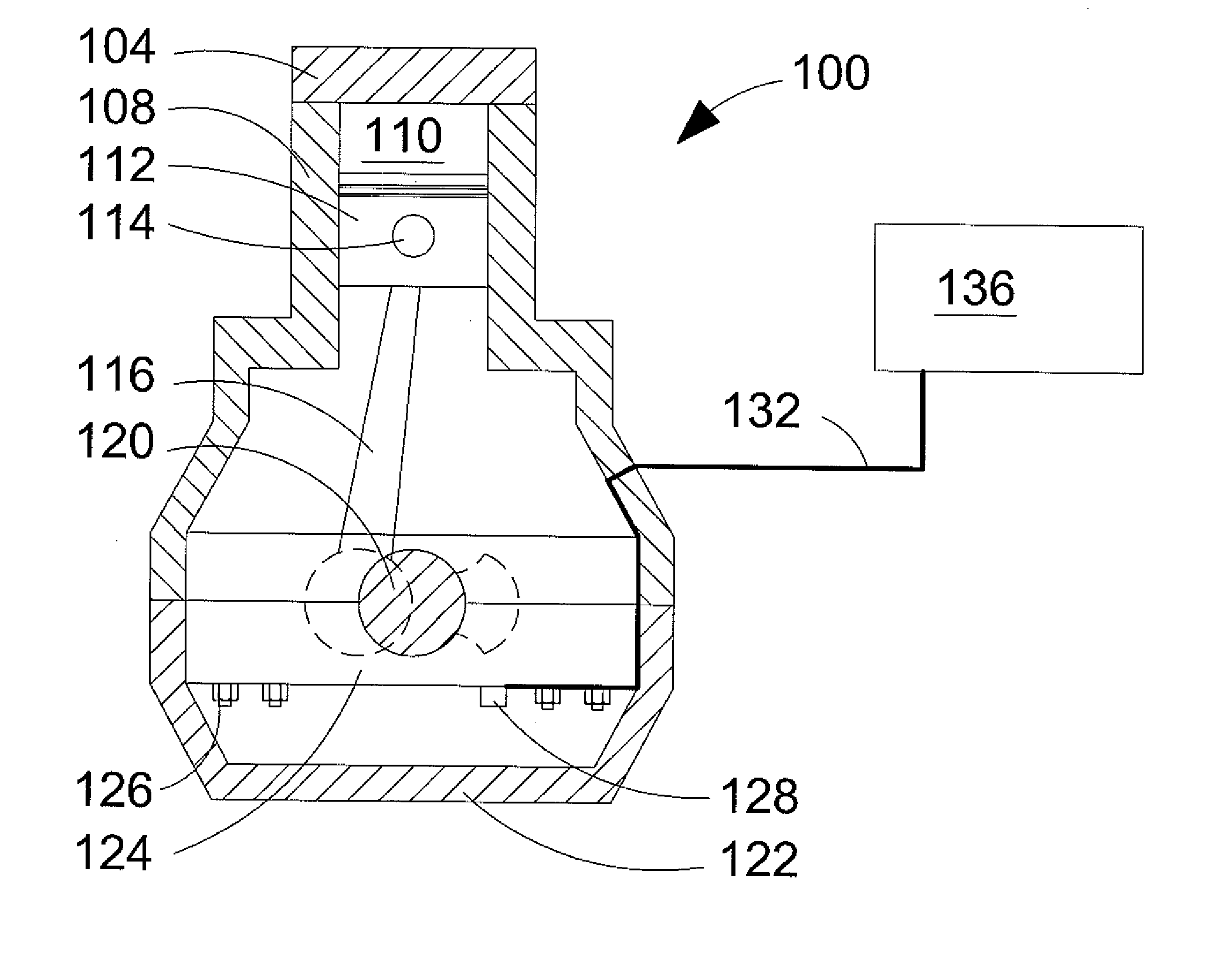

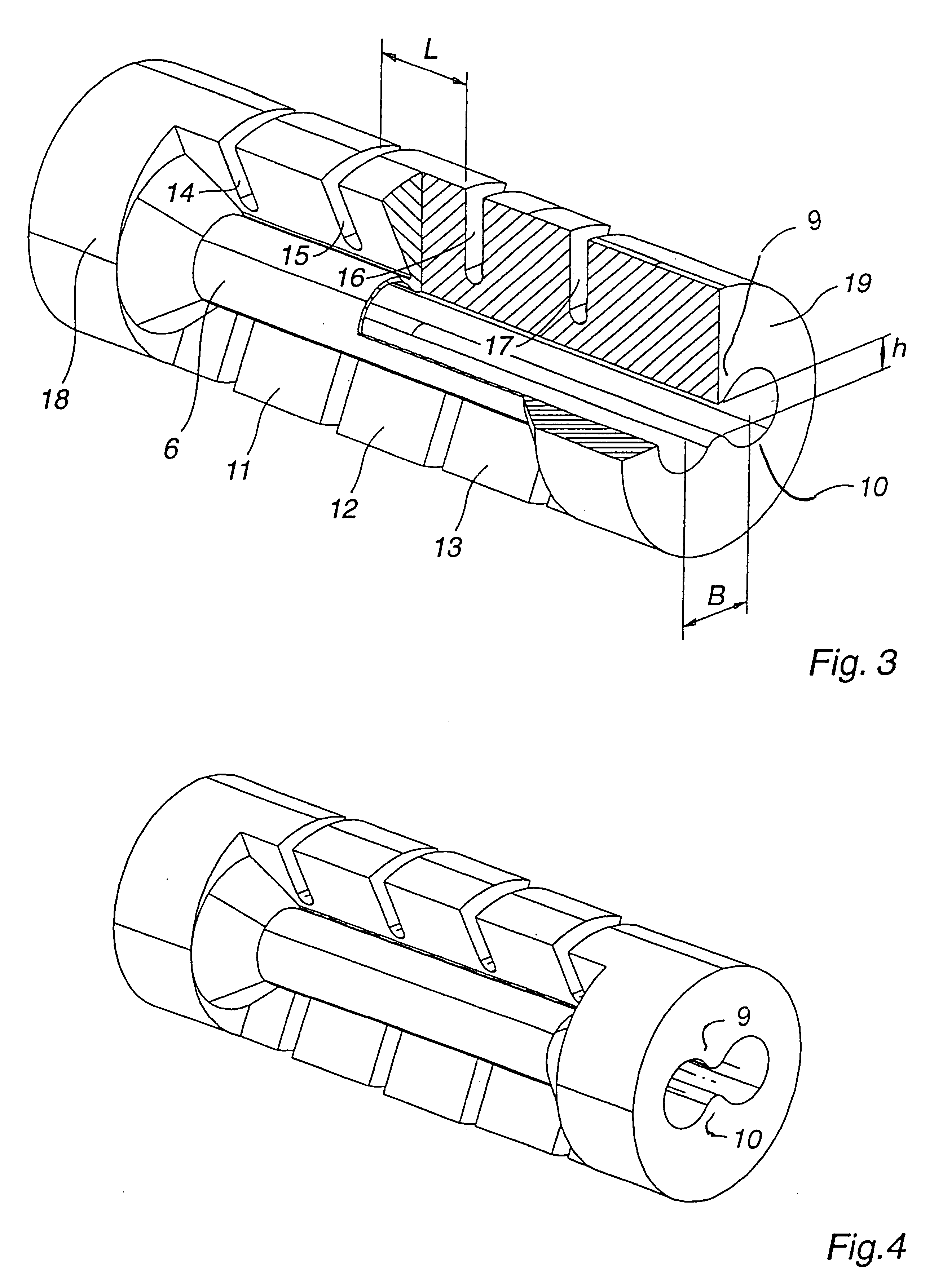

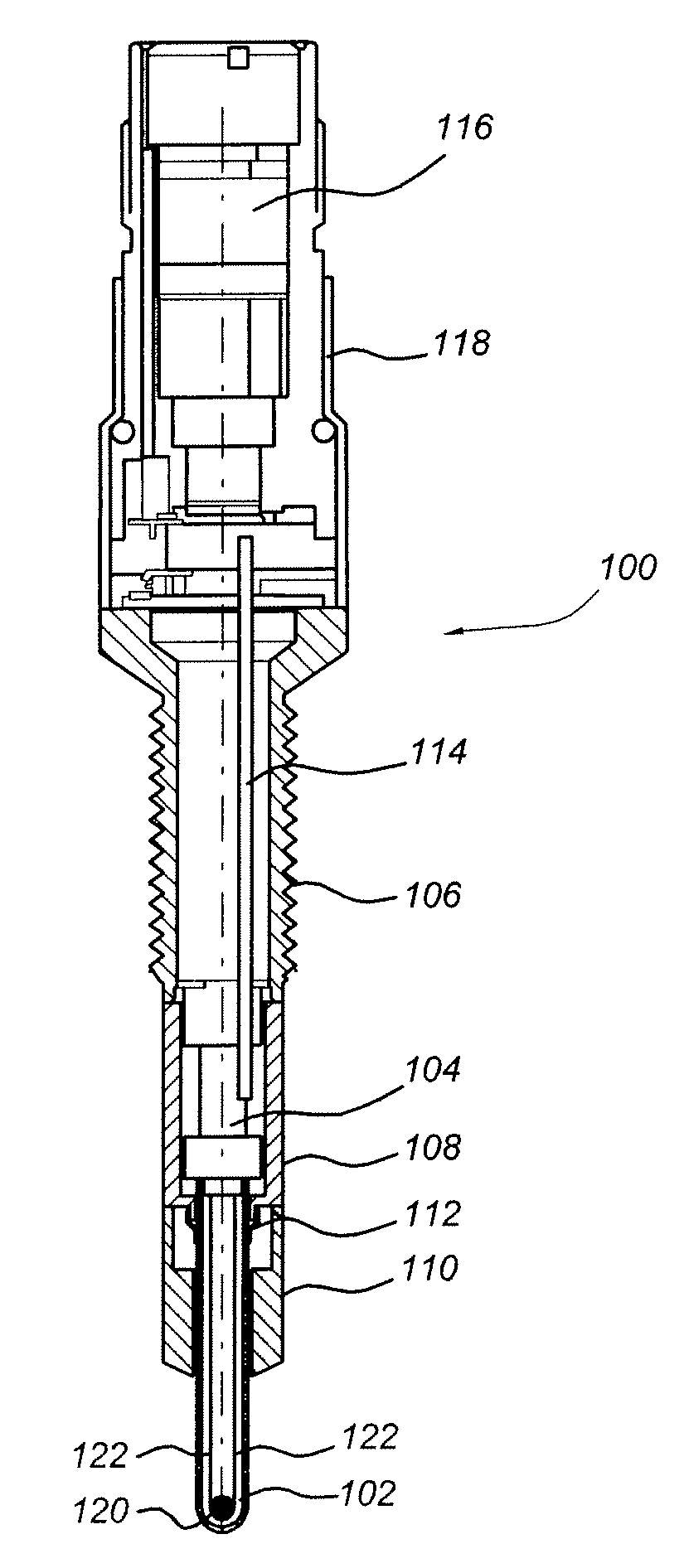

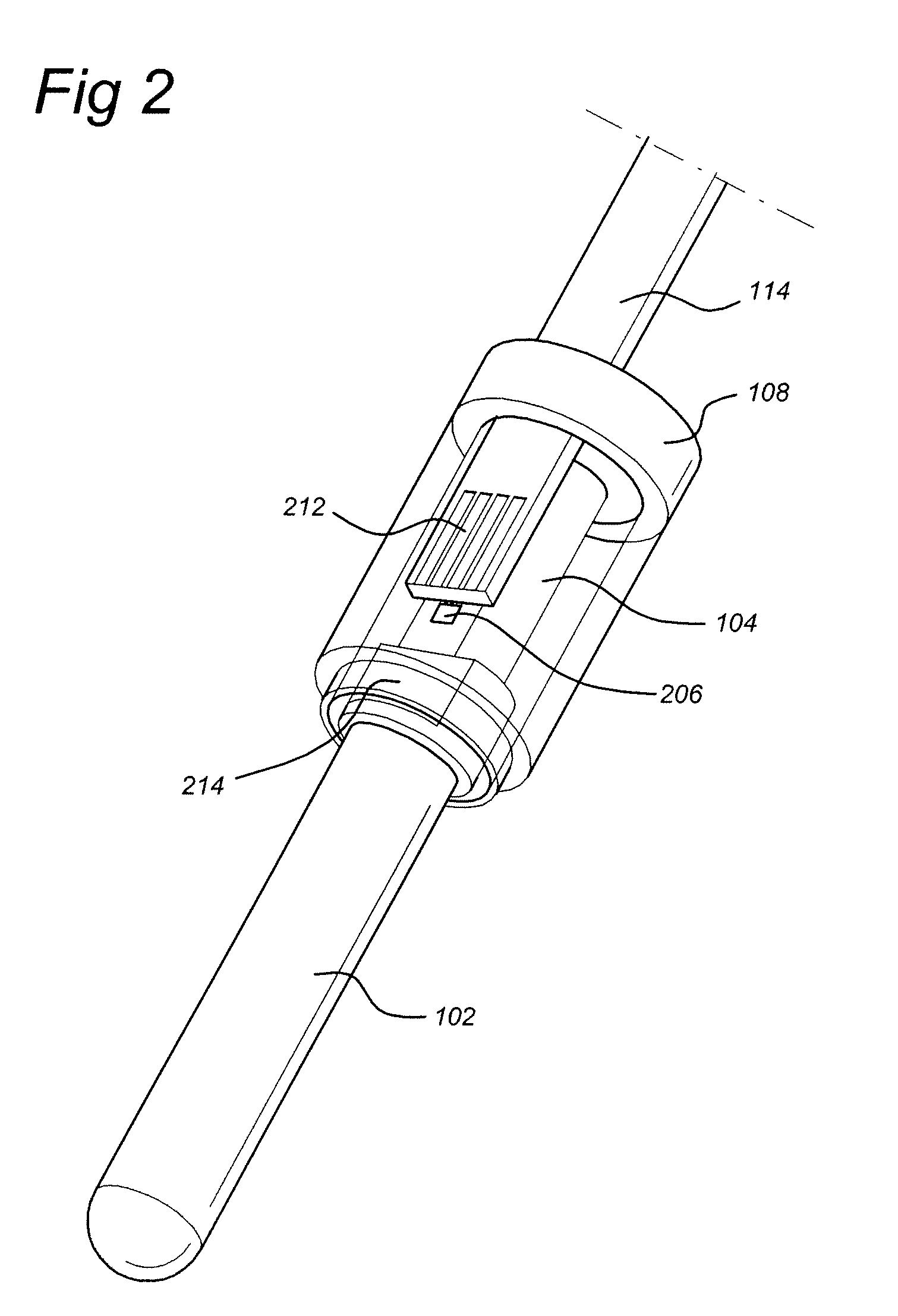

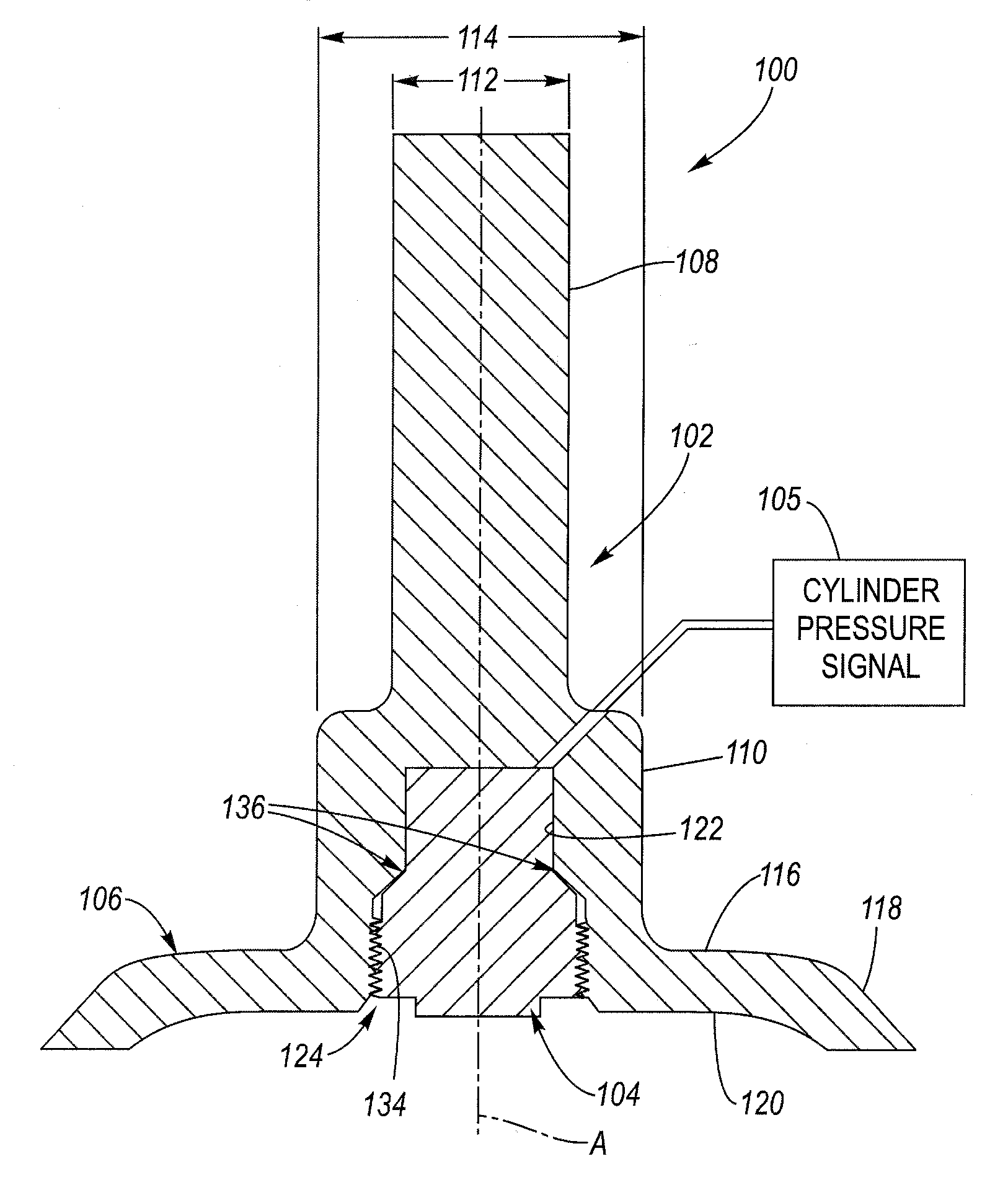

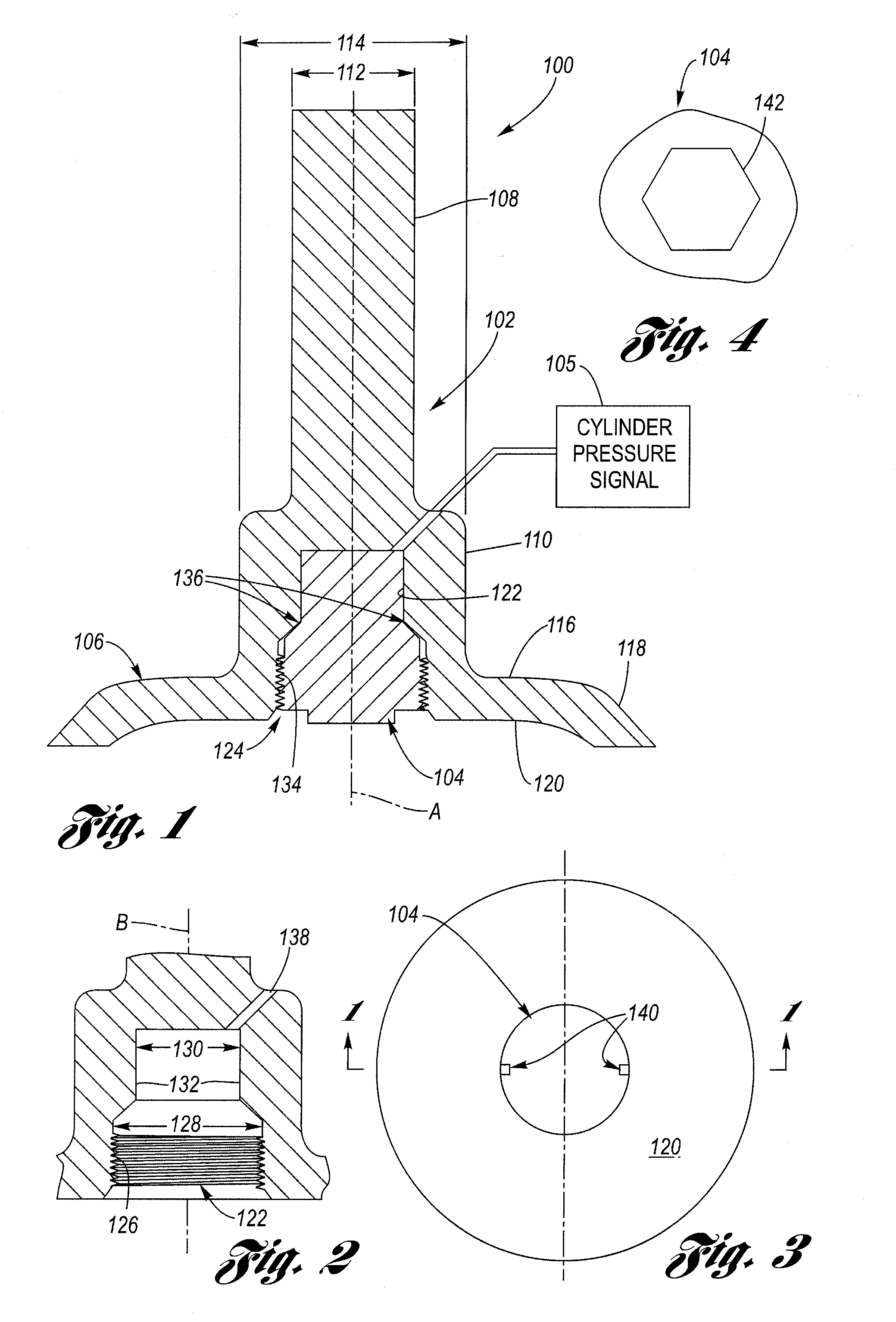

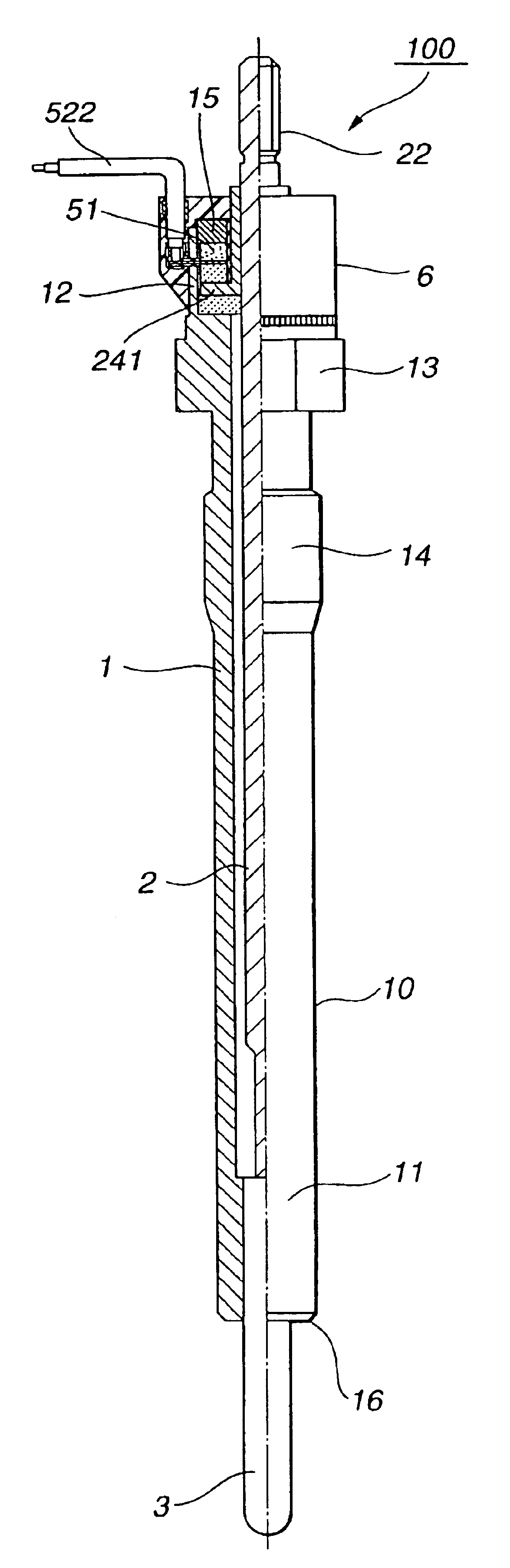

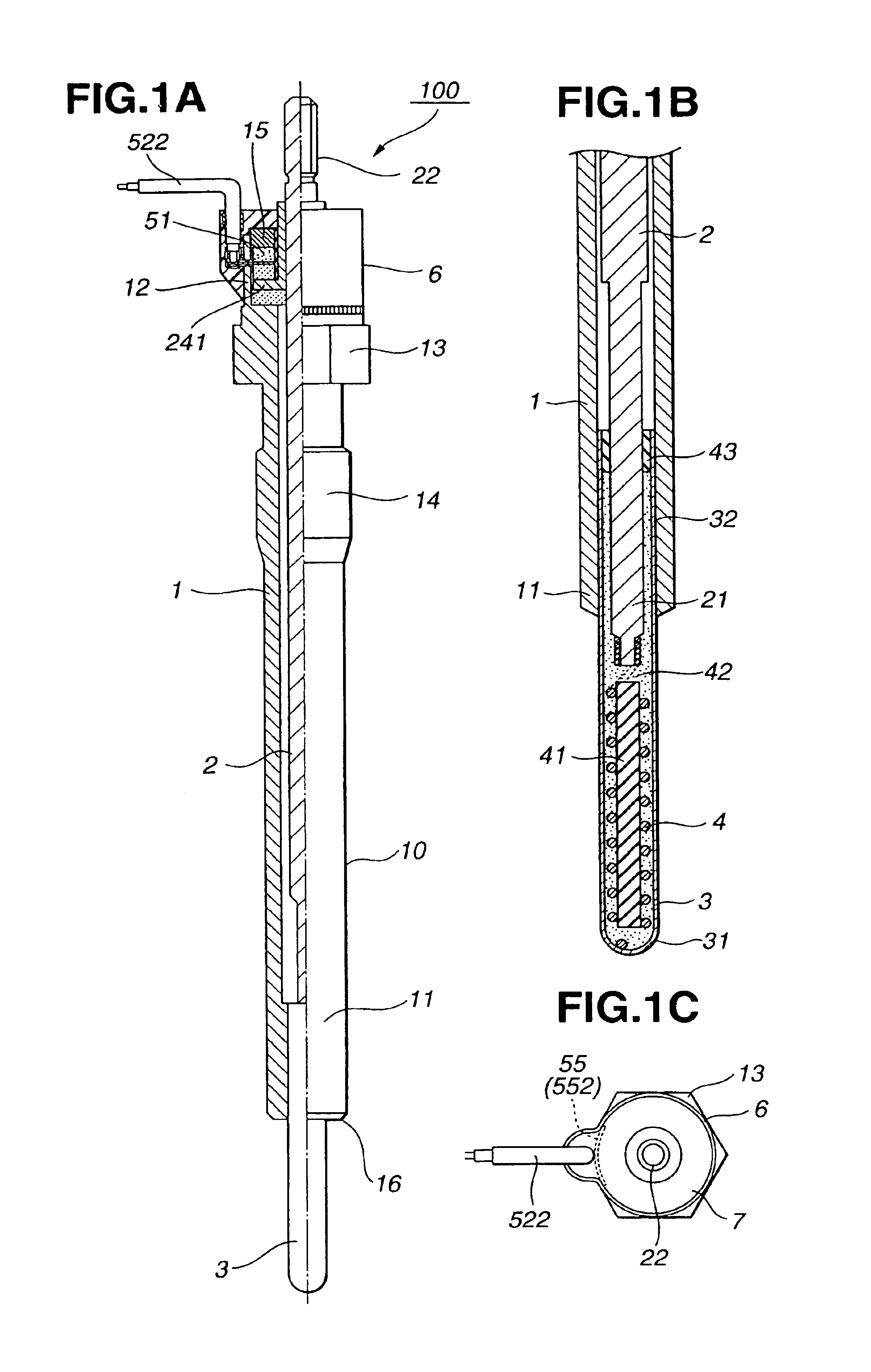

Piezoresistive Pressure-Measuring Plug for a Combustion Engine

ActiveUS20090320576A1Shorten the lengthReduce the total massPiezoelectric/electrostrictive device manufacture/assemblyIncandescent ignitionCombustion chamberEngineering

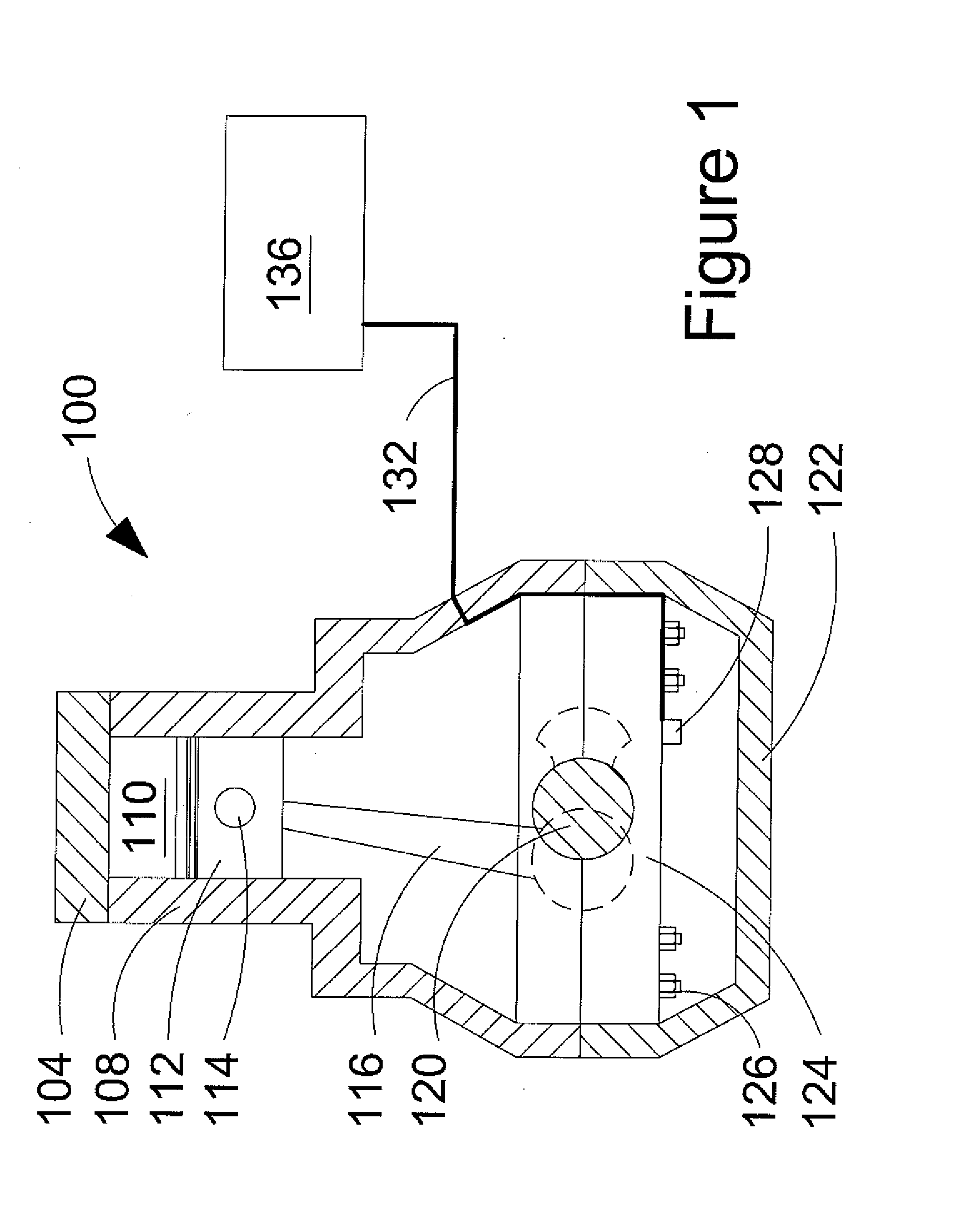

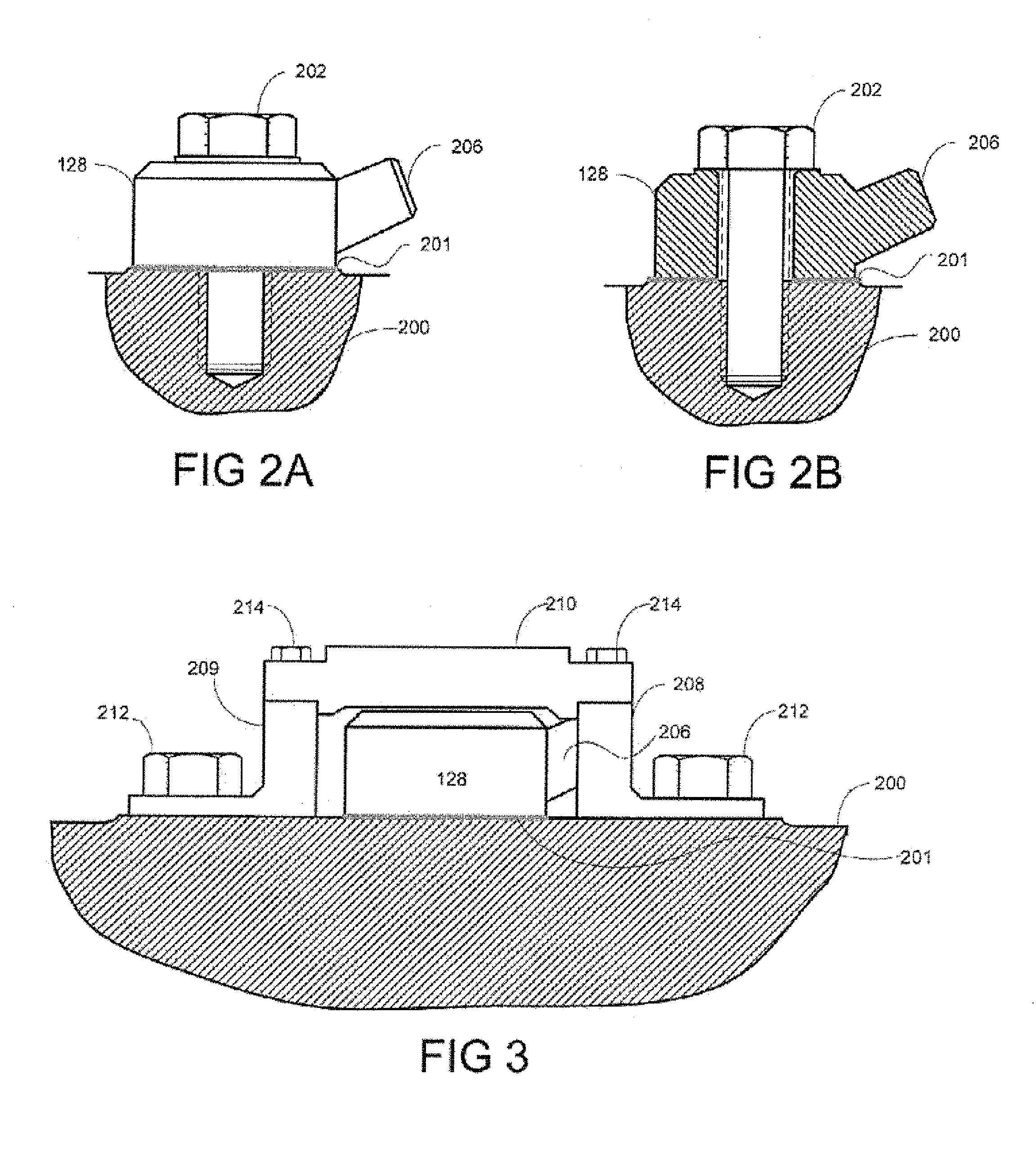

A piezoresistive pressure-measuring plug (100) for a combustion engine for measuring a pressure is disclosed. The piezoresistive pressure-measuring plug (100) comprises:a plug body (106, 108, 110) for insertion into a cylinder of the combustion engine, a rod (102) that is arranged in the plug body (106, 108, 110), a sensing structure (104) comprising a piezoresistive element, that is arranged between the rod (102) and the plug body (106, 108, 110) in such a way that the sensing structure is acted upon, in use, by the pressure prevailing in the combustion chamber of the cylinder, whereby the rod (102) transmits the pressure in the combustion chamber of the cylinder to the sensing structure due to the pressure in the combustion chamber leading to an axial motion of the rod (102) relative to the plug body (106, 108, 110) so as to apply a force to the sensing structure (104) and a PWB (114) provided with sensor electronics for measuring and conditioning a resistance change. The sensing structure (104) is arranged in the plug body (106, 108, 110) and, in use is compressed in axial direction by the force applied to the sensing structure (104) and a piezoresistive element (206) mounted on the sensing structure (104) to provide a resistance change when the sensing structure (104) is compressed in axial direction. Furthermore, the PWB (114) is arranged in the plug body (106, 108, 110). In this way a pressure-measuring plug is obtained with improved bandwidth and reduced build-in height.

Owner:SENSATA TECHNOLOGIES INC

Pressure detection device

ActiveUS20060090566A1Improve sensing characteristicsSuppress mutationFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsPressure transmissionEngineering

A pressure detection device includes a sensing part that outputs an electrical signal responsive to an applied pressure, a pressure receiving diaphragm that receives a pressure from a subject device, a cylindrical stem having a first end connected to the sensing part and a second end connected to the pressure receiving diaphragm, and a pressure transmission member located within the cylindrical member to transmit the pressure received by the pressure receiving diaphragm to the sensing part. In the pressure detection device, a side wall portion of the cylindrical stem has a spring portion which is provided to generate an elastic force in an axial direction of the cylindrical member. Accordingly, fluctuations in a spring characteristic acting on a pressure transmission mechanism of the pressure detection device can be effectively restricted by the spring portion.

Owner:DENSO CORP

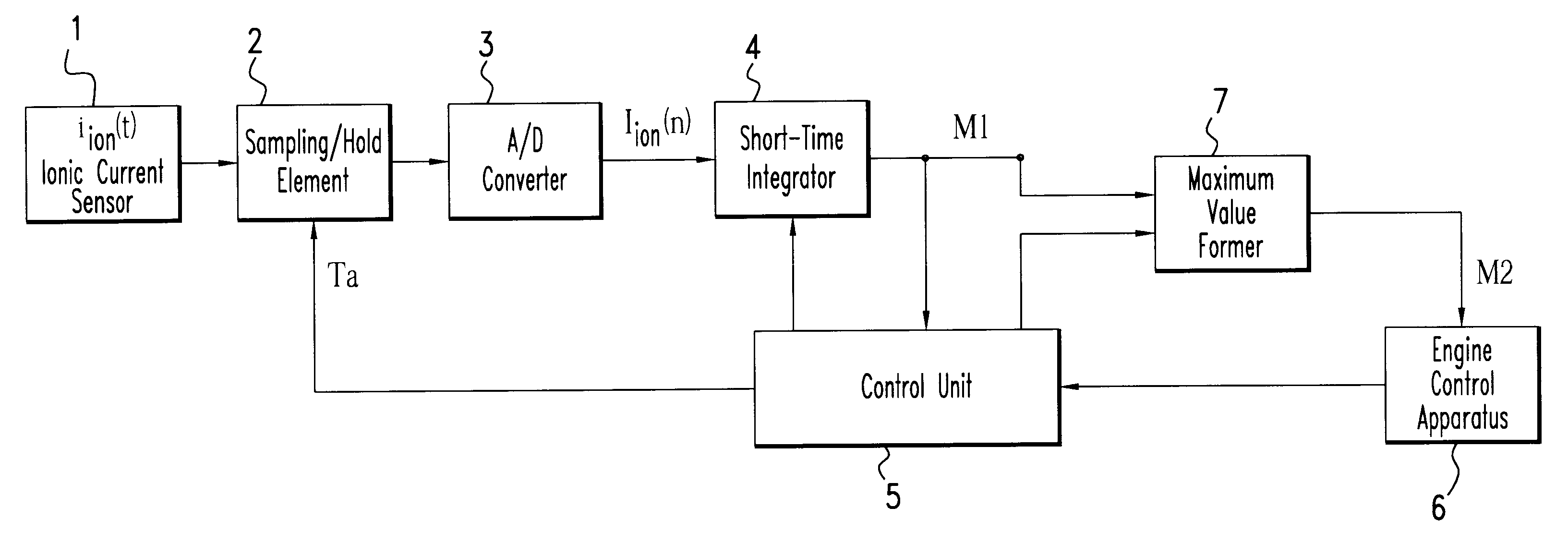

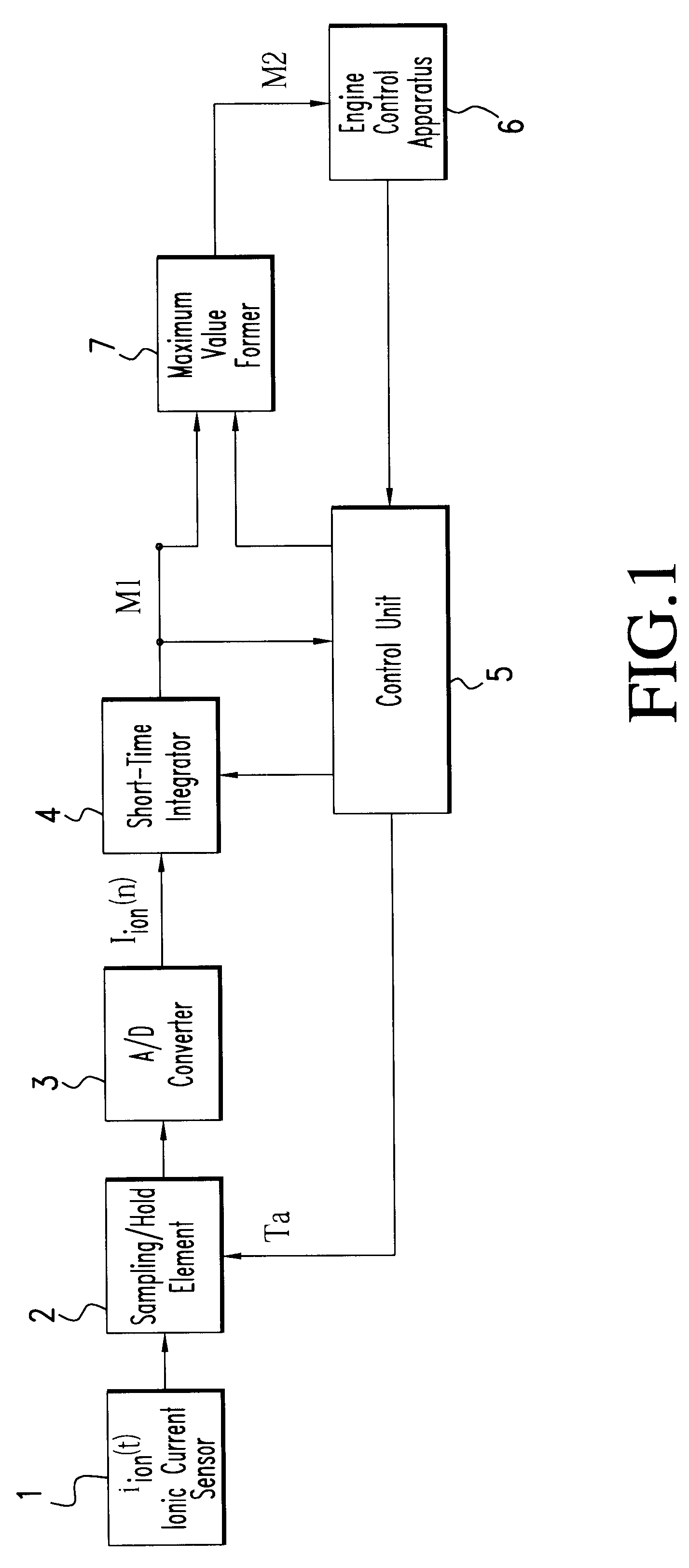

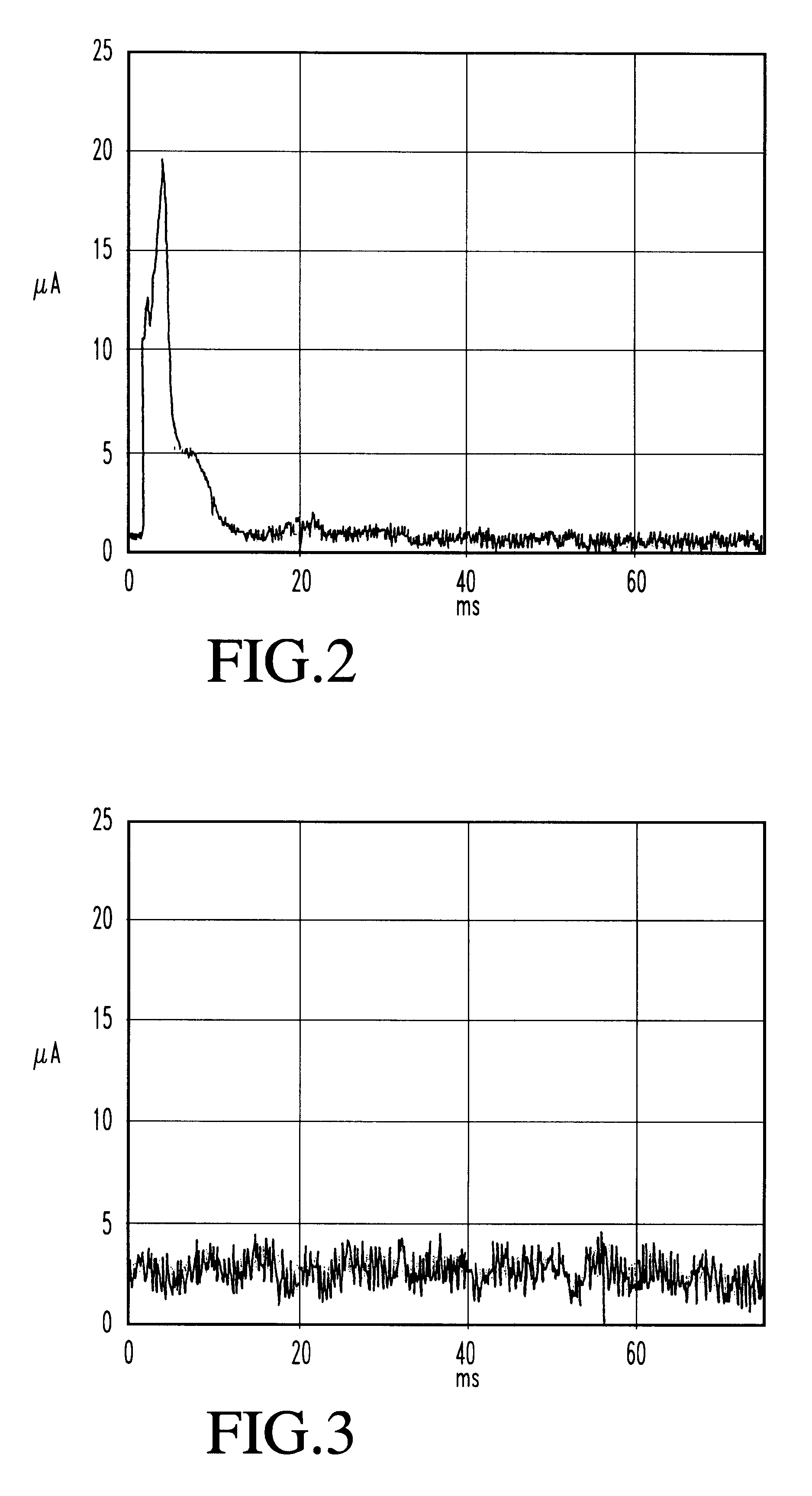

Method and device for evaluating ionic current signals for assessing combustion processes

InactiveUS6483311B1Improve reliabilityEasy to adaptInternal-combustion engine testingElectrical controlIntegratorEngineering

A method and an arrangement for detecting combustion misfires in internal combustion engines are presented where a measured ionic current signal is subjected to a floating short-time integration and a feature is formed which corresponds to the maximum value of the floating short-time integrator within the entire measuring window. The window length of the short-time integrator is shorter than the total measuring window and is floatingly displaced over the measuring window.

Owner:ROBERT BOSCH GMBH

Securing means for a device for detecting the pressure and temperature in the intake tube of an internal combustion engine

A device for detecting the pressure and the temperature in the intake tube of an internal combustion engine, including a temperature sensor, a pressure sensor and a substrate each of which are secured in a housing with as little stress as possible with the pressure sensor secured on a substrate together with an evaluation circuit. The temperature sensor measures precise temperature measurement. In order to introduce a fluid medium that is under pressure, a neck part is secured to the housing and an adapter is joined both to the substrate and to the neck part via adhesive seals that decouple mechanical stress from the pressure and temperature detectors.

Owner:ROBERT BOSCH GMBH

Piezoelectric sensor

InactiveUS20070277618A1Precise positioningAdequate insulation performanceFluid pressure measurement using piezo-electric devicesPiezoelectric/electrostriction/magnetostriction machinesSolderingAcoustics

A piezoelectric sensor, preferably a pressure sensor, comprising at least two piezoelectric measuring elements placed in a housing, which are clamped between a membrane on the pressured side of the housing and a pick-up electrode electrically insulated against the housing. The piezoelectric measuring elements are fixedly attached to the pick-up electrode by thermo-compression or soldering and together with said pick-up electrode form a compact measuring element stack, which will significantly simplify assembly of the piezoelectric sensor.

Owner:PIEZOCRYST ADVANCED SENSORICS

Device for detecting the combustion-chamber pressure in an internal combustion engine

InactiveUS7730771B2Reduce hysteresisReduce heat loadInternal-combustion engine testingIncandescent ignitionCombustion chamberFixation point

A device for detecting the combustion-chamber pressure in an internal combustion engine is configured in such a way that the combustion-chamber pressure is able to be detected in a reliable and reproducible manner. To this end, a heating pin exposed to the combustion-chamber pressure is fixed in place in a housing of the glow plug with the aid of a fixation member. A sensor is affixed in the housing of the glow plug via a fixation element set apart from this fixation member. This sensor detects the elastic longitudinal expansion of the housing caused by the combustion-chamber pressure between the end of the fixation member facing the sensor and the fixation point of the fixation element on the housing. This device is preferably utilized in the automotive industry.

Owner:ROBERT BOSCH GMBH

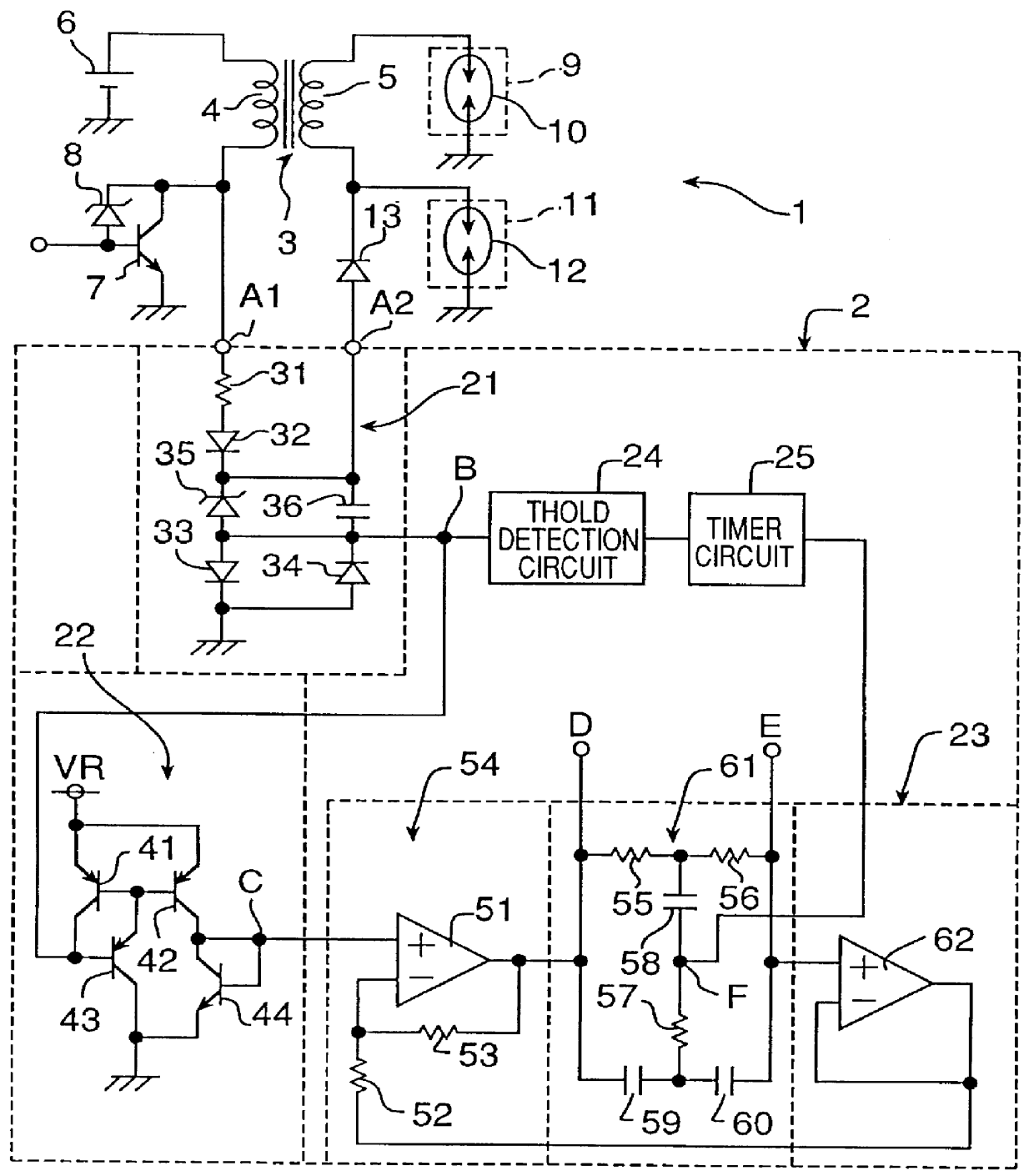

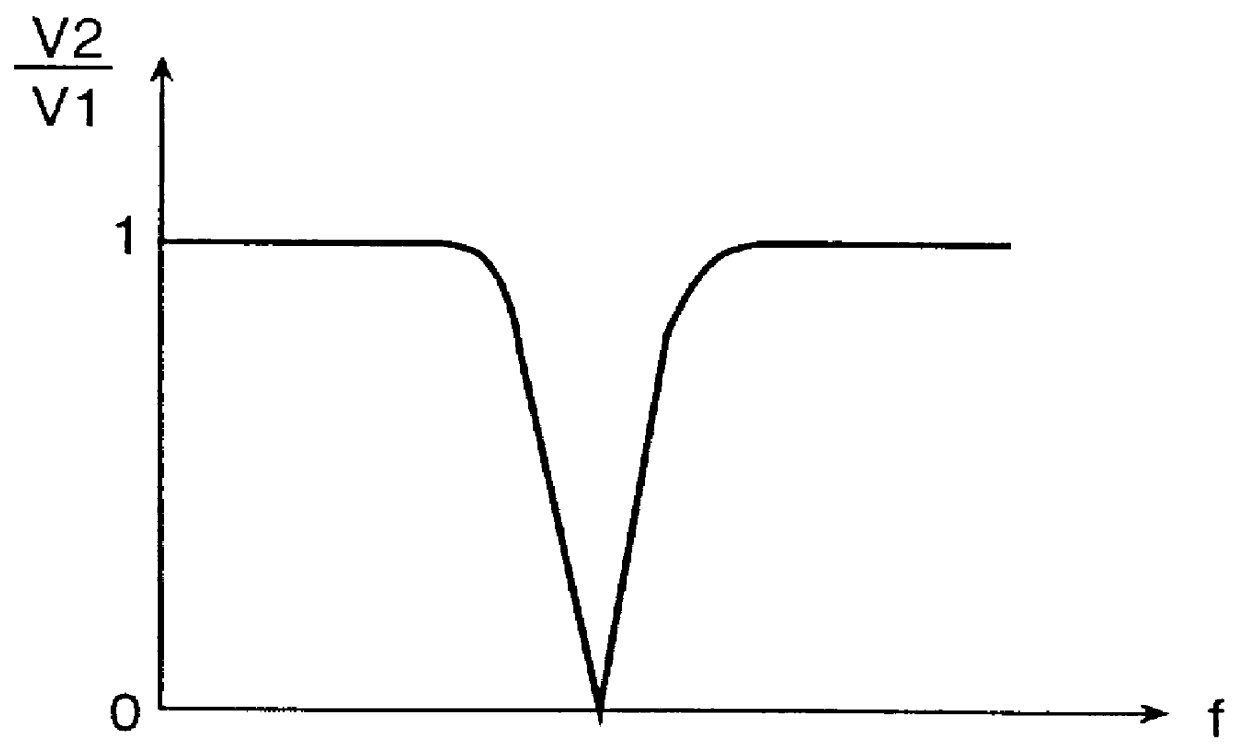

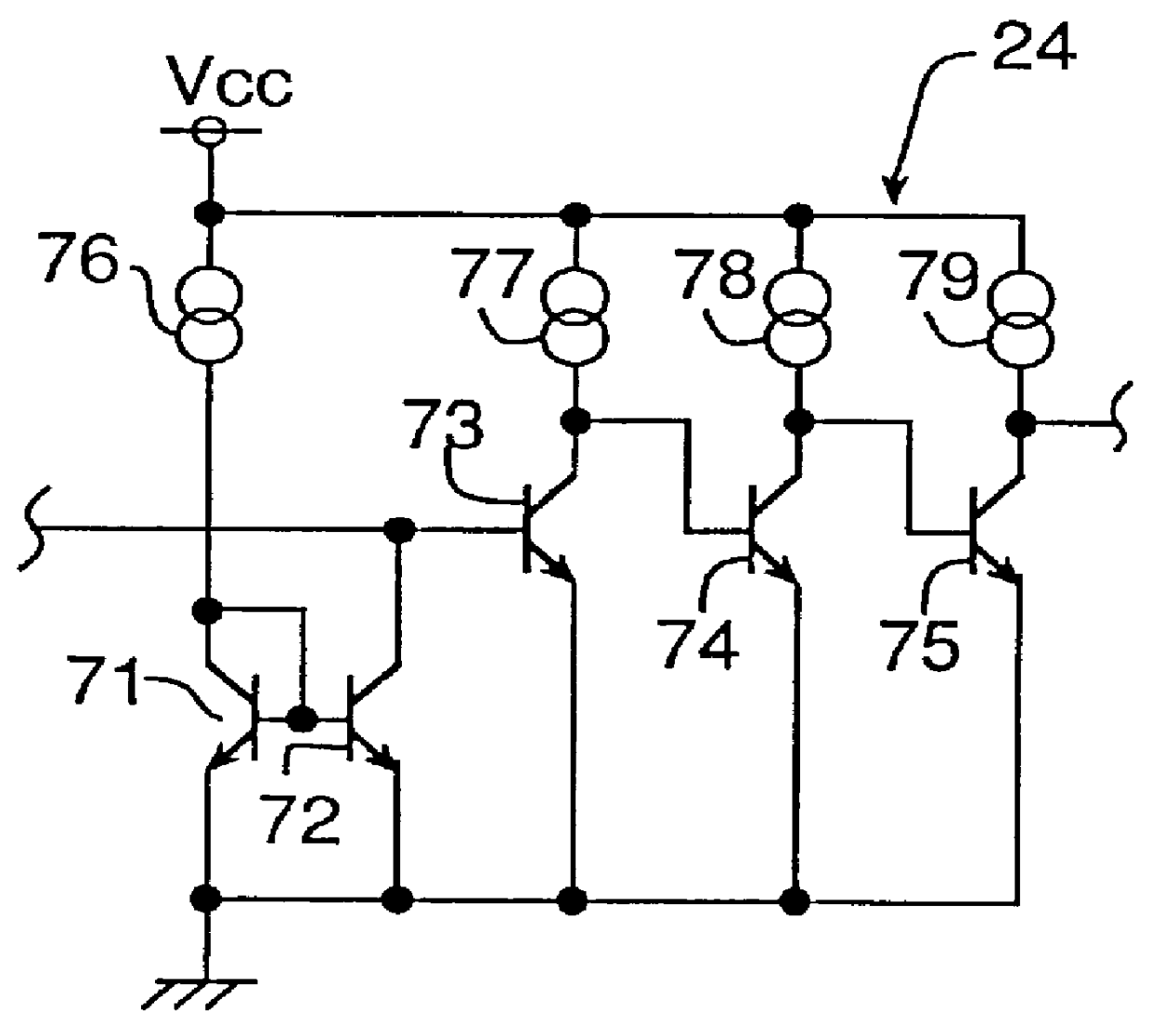

Ion current detection device for internal combustion engine

InactiveUS6011397AInternal-combustion engine testingElectric ignition installationBandpass filteringIon current

An ion current detection device of an internal combustion engine includes a detection voltage generation device which applies a voltage to an ignition plug to generate an ion current in a cylinder of the engine. A current to voltage conversion circuit detects and converts the generated ion current to a voltage signal. A bandpass filter extracts an ac component within a specified frequency range from the voltage signal produced by the current to voltage conversion circuit. An ion current threshold detection portion produces an ion current detection signal when the detected ion current exceeds a predetermined threshold current. A filter characteristic control circuit controls the characteristic of the bandpass filter to suppress the sensitivity of the filter for a predetermined period of time right after the ion current detection signal is detected and, after the predetermined period of time, increase the sensitivity of the filter for detection of the ac signal with the specific frequency.

Owner:MITSUBISHI ELECTRIC CORP

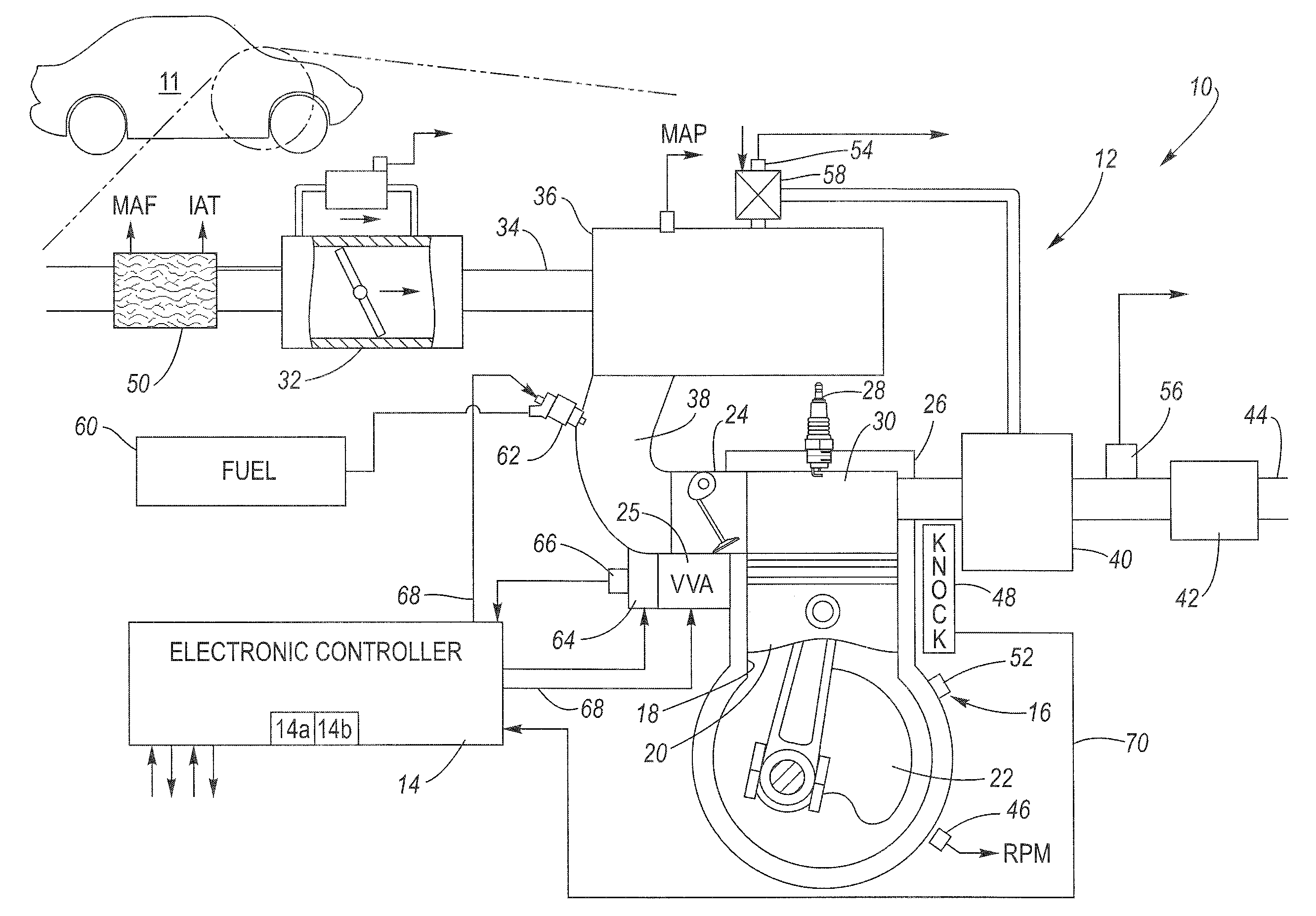

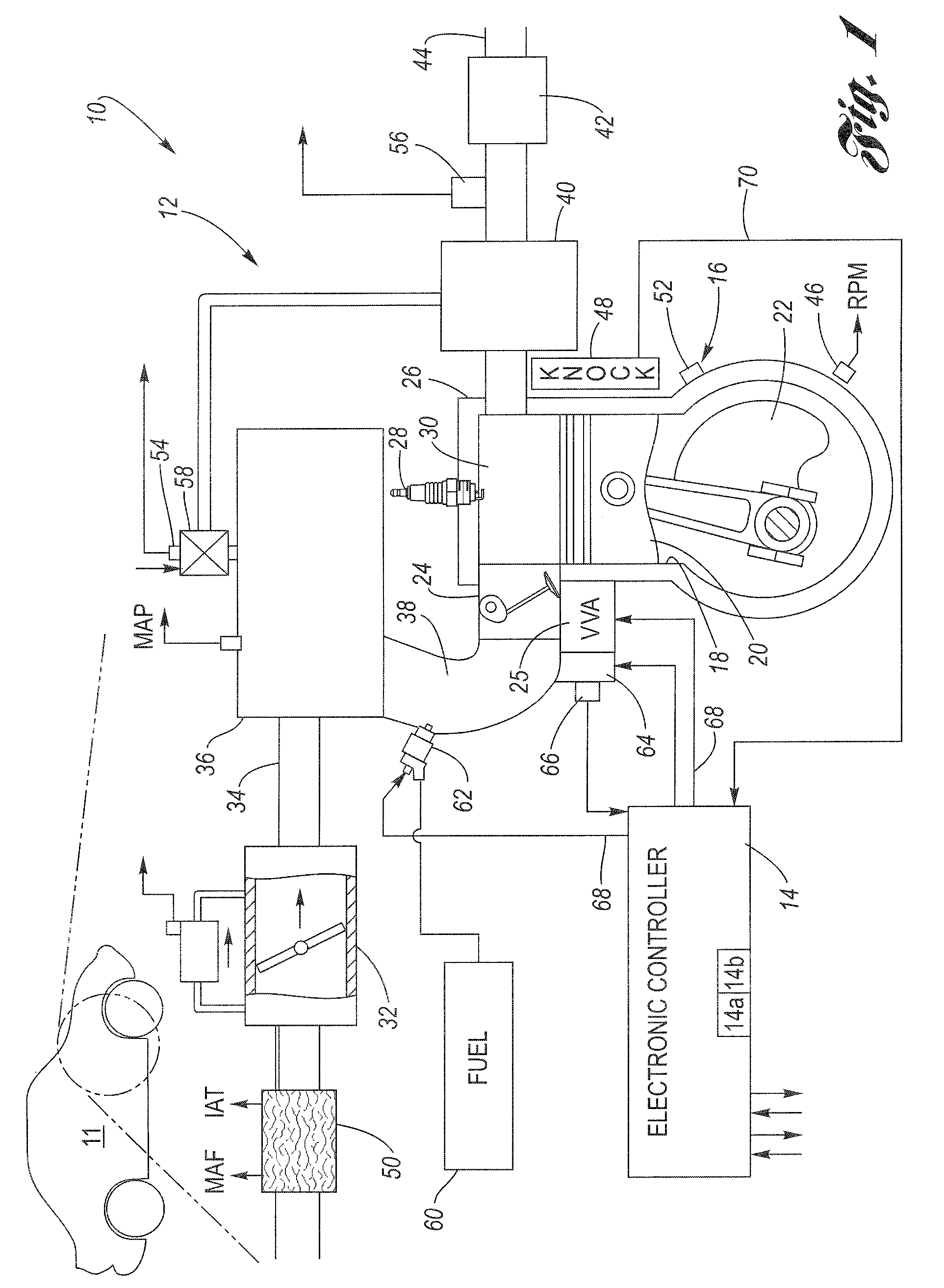

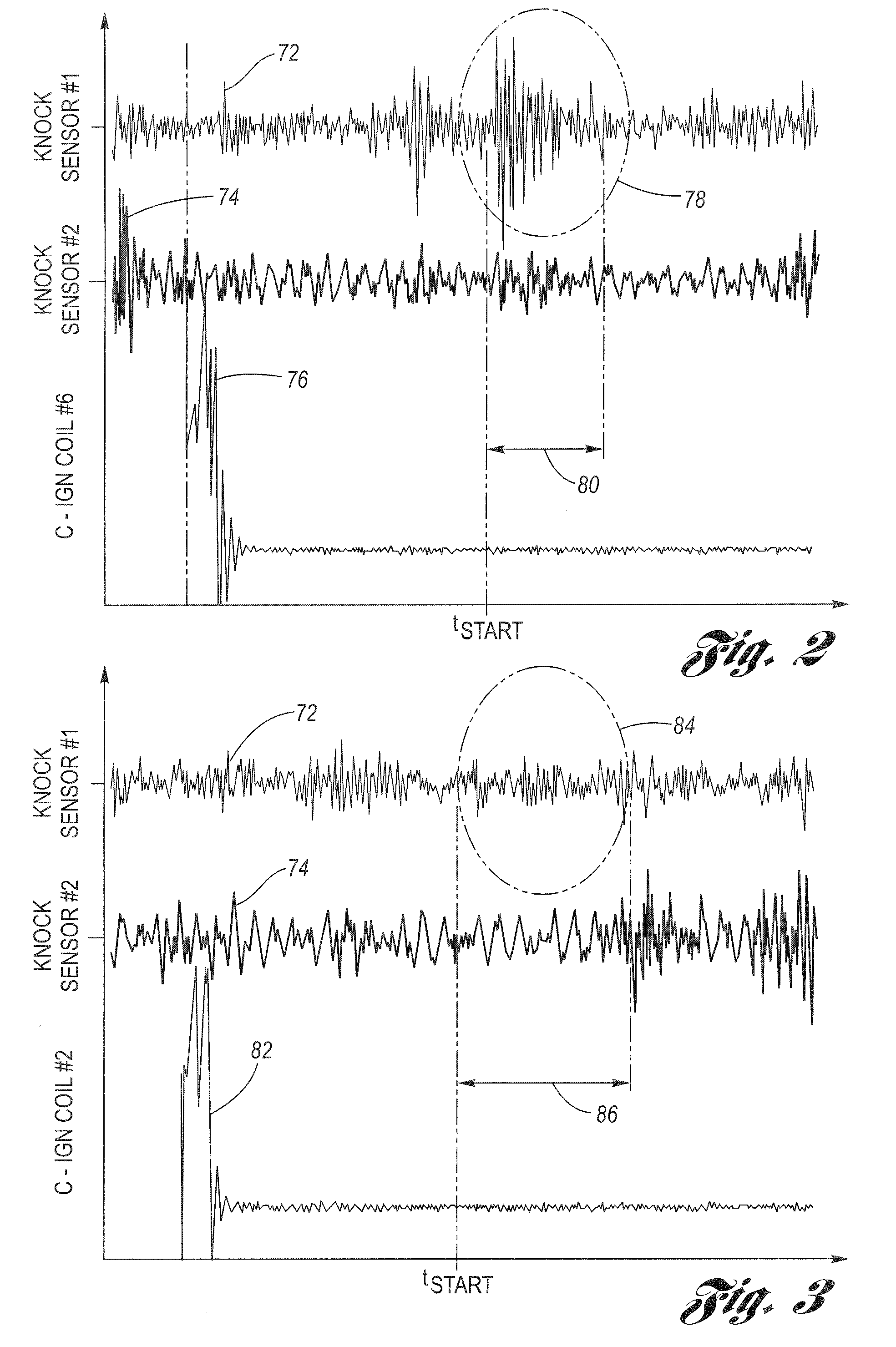

Method for diagnosing the operational state of a variable valve actuation (VVA) device using a knock signal

InactiveUS20090048729A1Increase costVehicle testingInternal-combustion engine testingOperation modeEngineering

A method for determining whether a variable valve actuation (VVA) device or subsystem is operating in an improper mode of operation is performed in real-time by an embedded engine or powertrain controller configured to monitor and evaluate an already-available knock sensor output signal. The knock sensor output is captured during a predefined sampling window, defined to include a valve closing event when the VVA device is operating in a proper mode. The captured knock sensor output signal is processed to detect the presence (or absence) of a valve closing event. The absence of a valve closing event when one is expected is indicative of a malfunctioning VVA device.

Owner:DELPHI TECH INC

Apparatus for measuring the cylinder internal pressure of internal combustion engines

InactiveUS8096170B2Solve bulkyCompact designInternal-combustion engine testingRapid change measurementInternal pressureInterior space

The invention relates to an apparatus for measuring the cylinder internal pressure of internal combustion engines and, in particular, of gas engines, said apparatus having a first valve (5) which opens into the cylinder interior space, a measurement chamber (6) which can be connected to the cylinder interior space (1a) and can be disconnected from the latter by means of the first valve (5), and a pressure sensor (8) which is arranged in the region of the measurement chamber (6) in order to measure the pressure in the cylinder interior space when the first valve (5) is open. Permanent operation without thermal overload is enabled in such a way that at least one second valve (13) is provided in the region of the measurement chamber (6), said second valve being able to be changed to a closed position at least when the first valve (5) is open in order to seal off the measurement chamber (6) towards the outside.

Owner:AVL LIST GMBH

Cylinder pressure sensor system

InactiveUS20090090189A1Improve approachEliminate needFluid pressure measurement by electric/magnetic elementsRapid change measurementInlet valveEngineering

An engine intake valve has a threaded blind bore opening from its top surface facing the engine cylinder. A pressure sensor has a body portion whose exterior is threaded and is configured in size and shape to be completely received within and retained in the blind bore. The pressure sensor is configured to generate a pressure signal indicative of the cylinder pressure.

Owner:DELPHI TECH INC

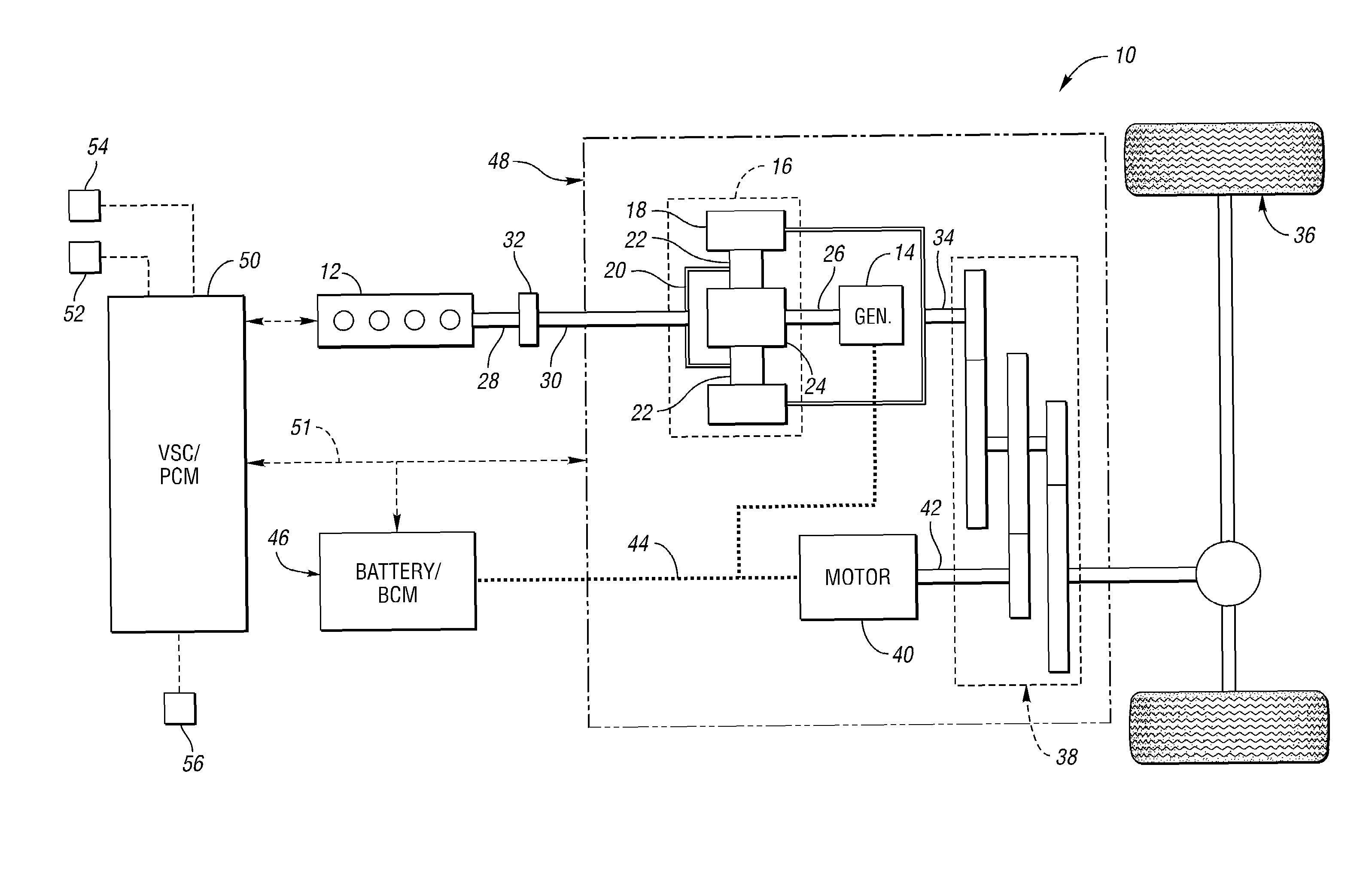

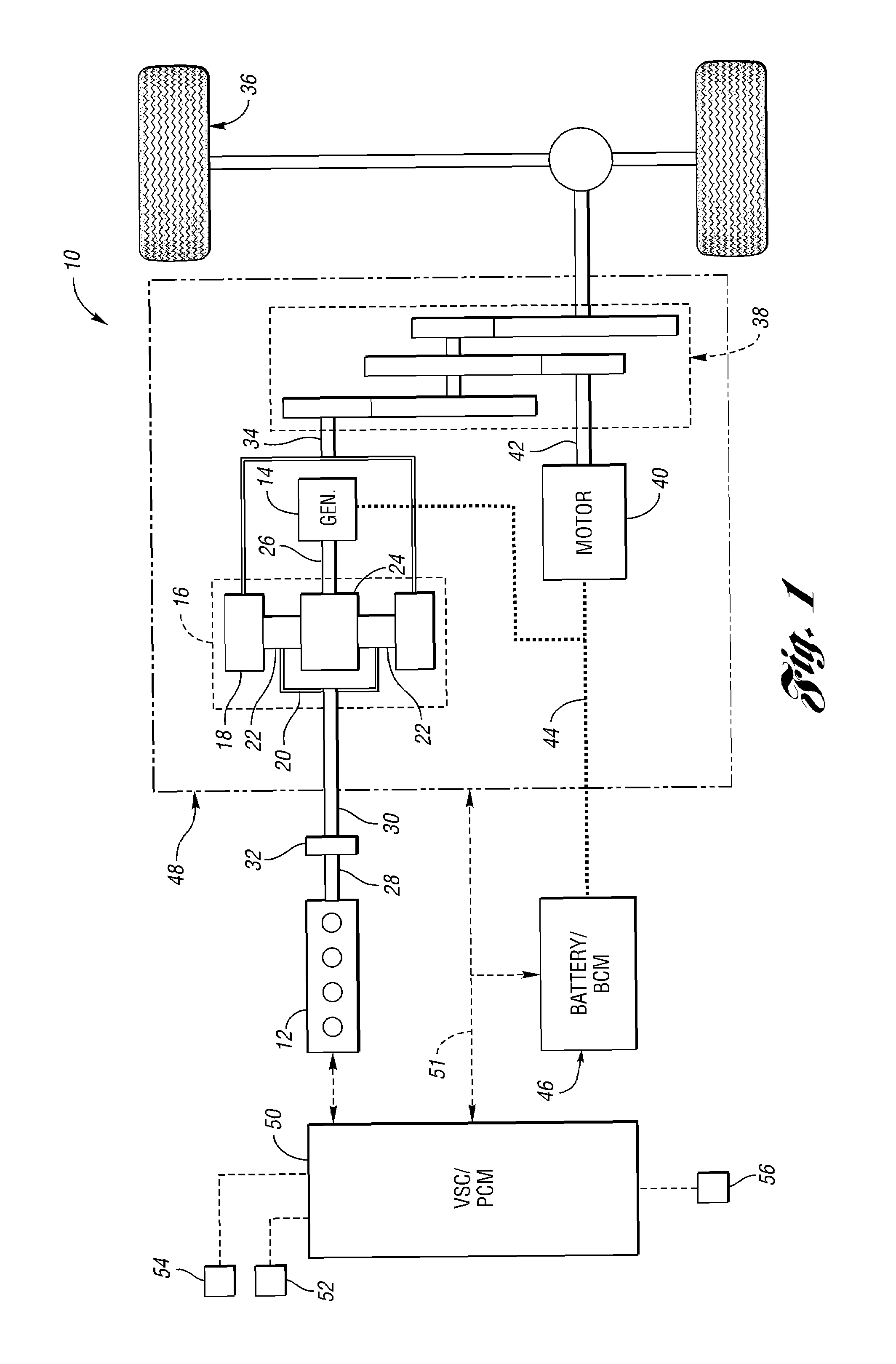

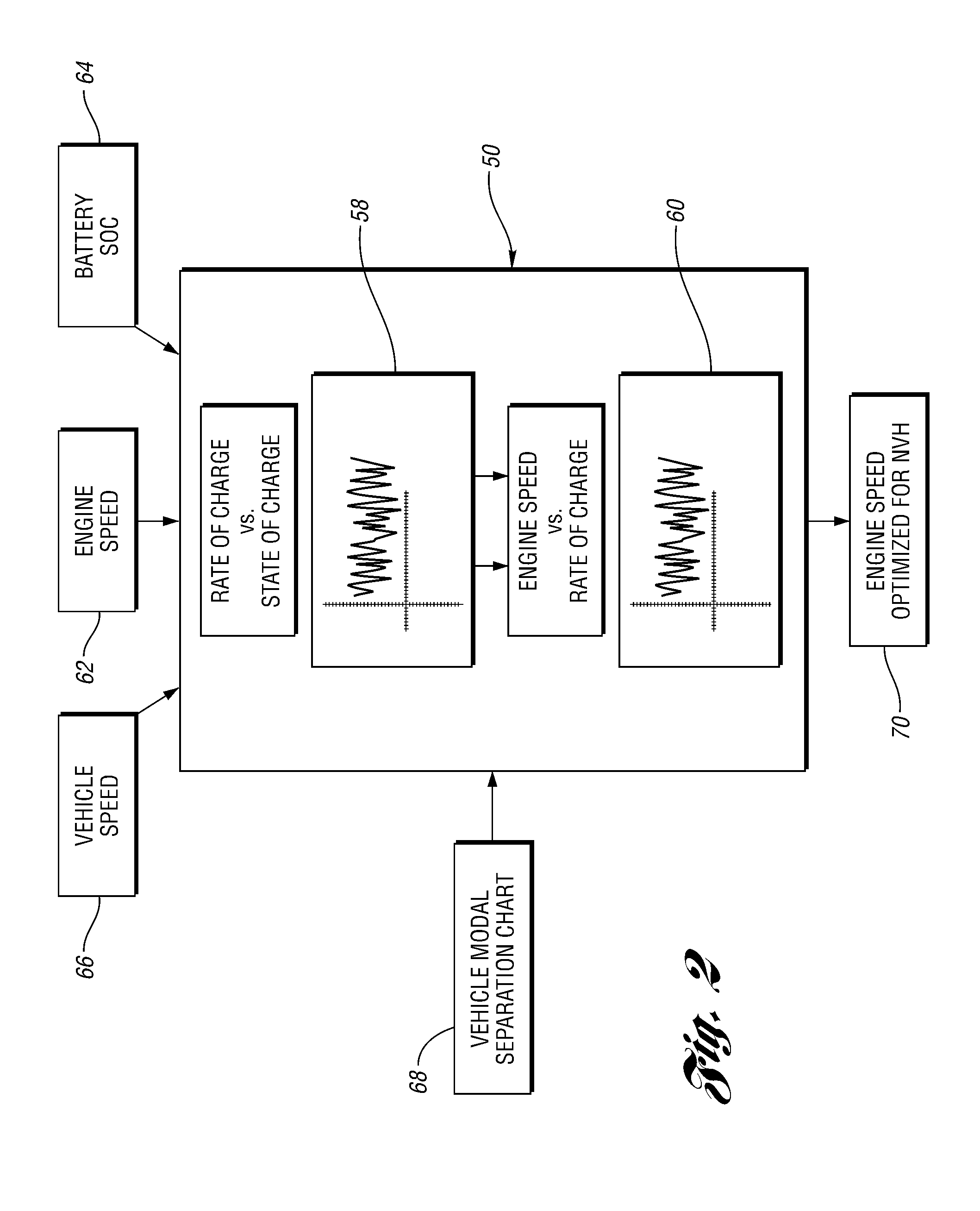

System and method for controlling speed of an engine

ActiveUS7292932B1New noise-vibration level for the vehicle is determinedImprove comfortHybrid vehiclesAnalogue computers for vehiclesNoise levelEngine power

A system and method for controlling the speed of an engine includes determining a desired engine power output and engine speed, and determining whether the desired engine speed is within one of a number of predetermined engine speed ranges. It is then determined whether a noise-vibration level for the vehicle is within a target range when it is determined that the desired engine speed is within one of the predetermined engine speed ranges. The noise-vibration level is a function of at least one of a corresponding vibration level for one or more vehicle mechanical systems, and a noise level for the passenger compartment for the engine operating at the desired engine speed. The engine is then controlled at the desired engine speed when the determined noise-vibration level is within a target range, and it is determined that the desired engine speed is within one of the predetermined engine speed ranges.

Owner:FORD GLOBAL TECH LLC

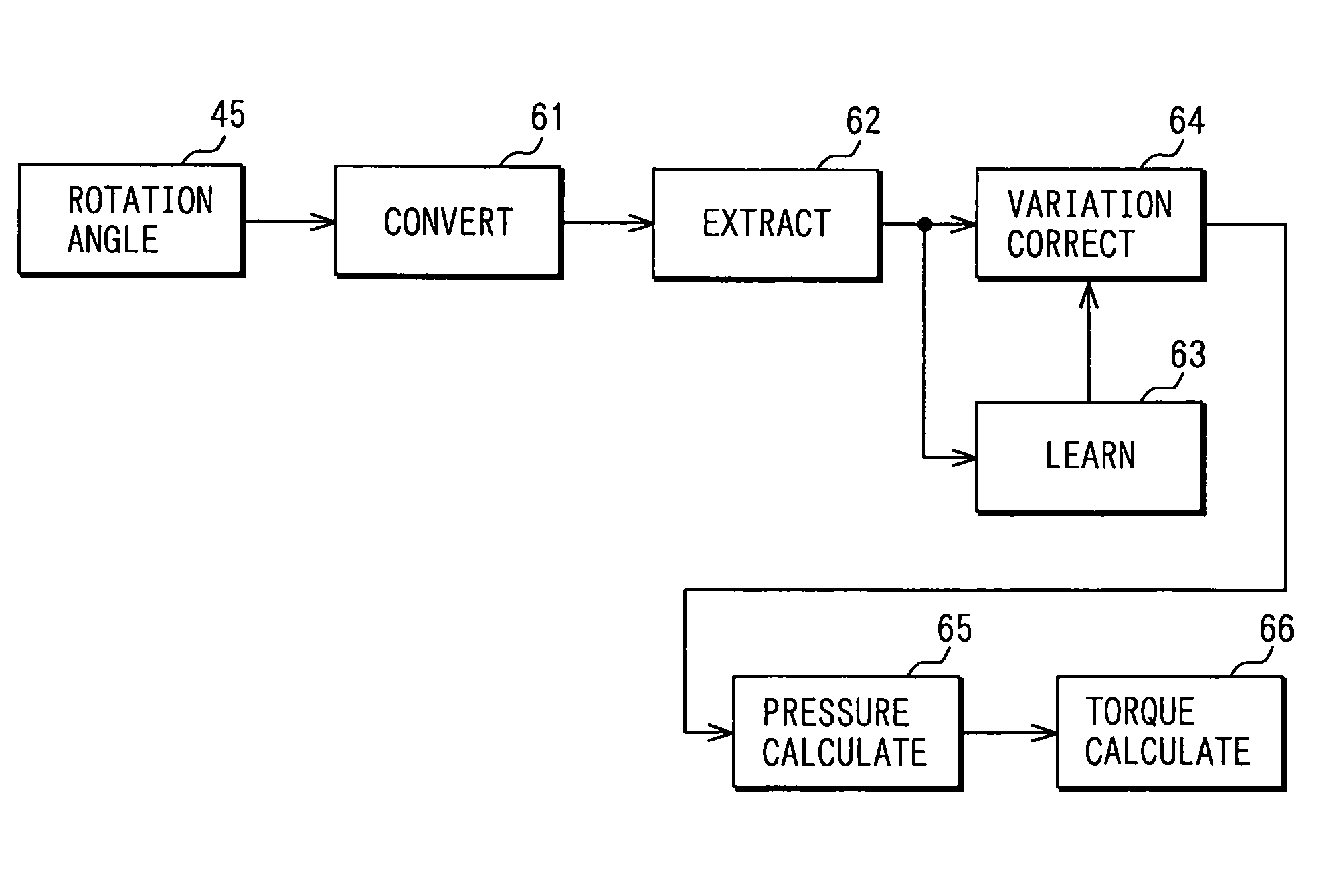

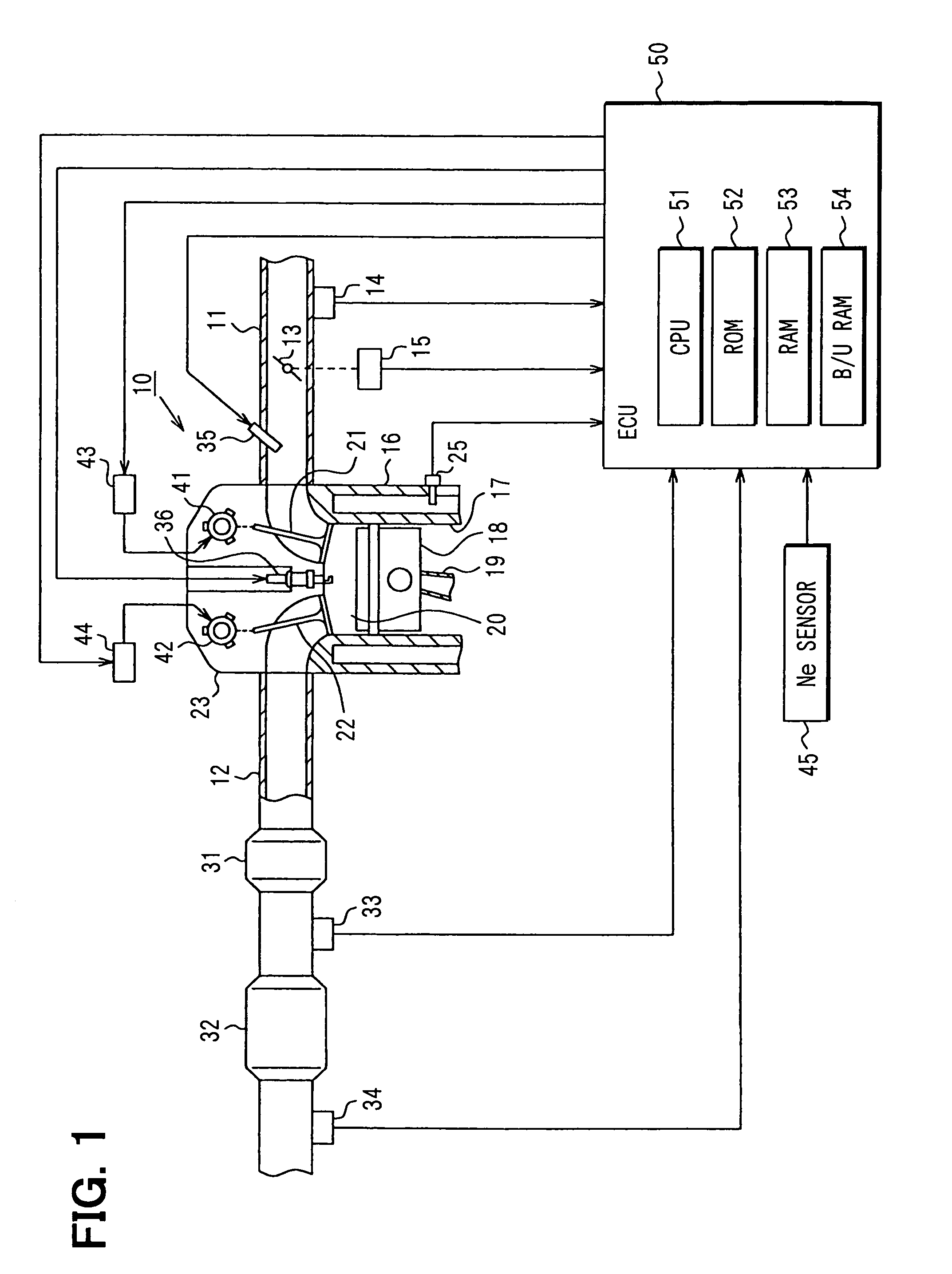

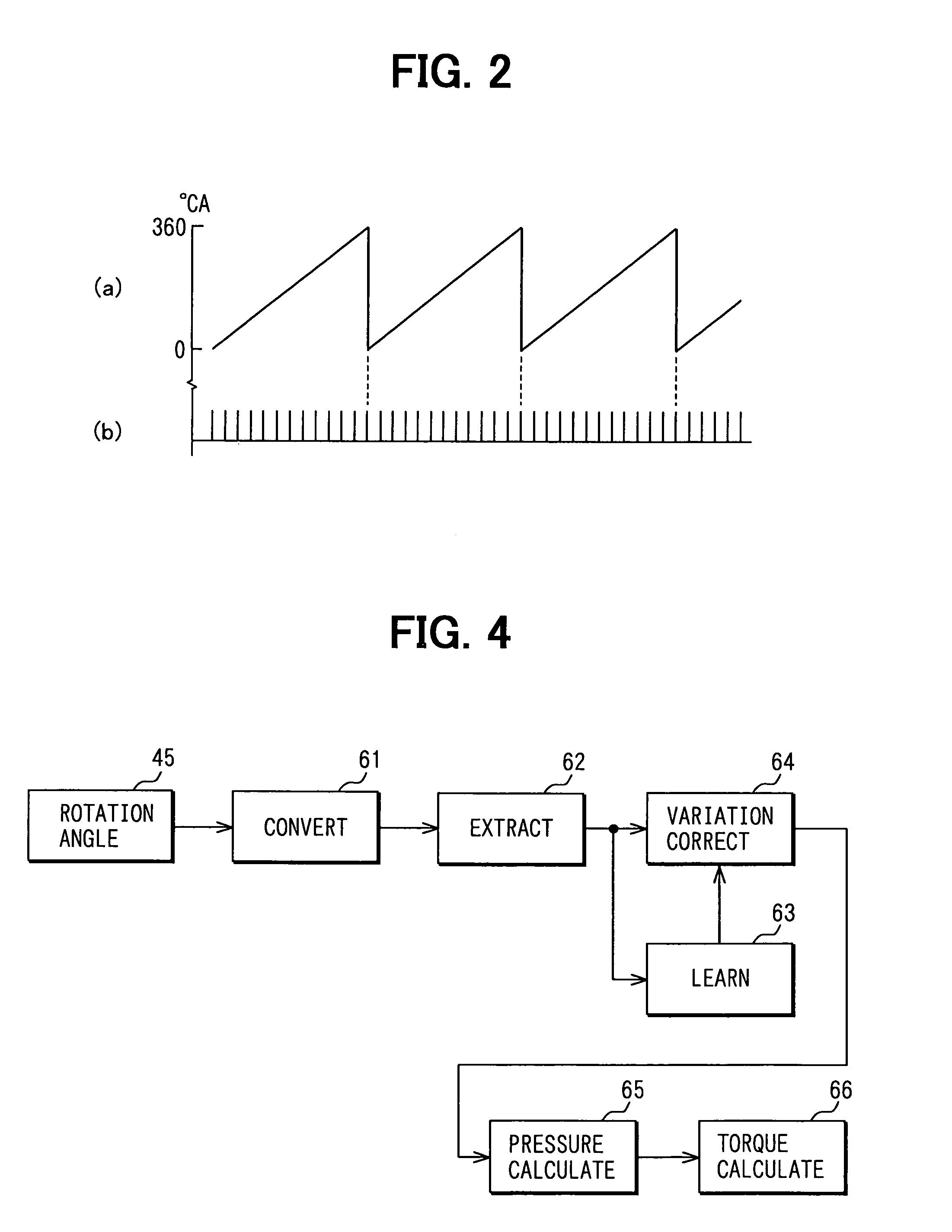

Engine combustion state detection device

InactiveUS7133766B2Accurate detectionIncrease in rotation fluctuationAnalogue computers for vehiclesElectrical controlCombustionRotation velocity

Owner:DENSO CORP

Glow plug with built-in combustion pressure sensor and manufacturing method thereof

A glow plug includes a cylindrical housing having an inward protrusion extending radially inwardly, a threaded portion for screwing the glow plug in an engine plug hole and a sealing portion in a front side of the male threaded portion for airtightly engaging the housing with a given portion of the plug hole, a sheath having a rear sheath end portion airtightly fixed in the housing, a heater disposed in the sheath, a center electrode disposed in the housing and having a front electrode end portion electronically connected with the heater and mechanically connected with the sheath and an outward protrusion protruding radially outwardly, and a combustion pressure sensor having a pressure-sensitive element arranged between a front surface of the inward protrusion and a rear surface of the outward protrusion to generate an electrical signal in response to variations in stress applied thereto.

Owner:NGK SPARK PLUG CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com