Patents

Literature

322 results about "Diaphragm seal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A diaphragm seal is a flexible membrane that seals and isolates an enclosure. The flexible nature of this seal allows pressure effects to cross the barrier but not the material being contained. Common uses for diaphragm seals are to protect pressure sensors from the fluid whose pressure is being measured.

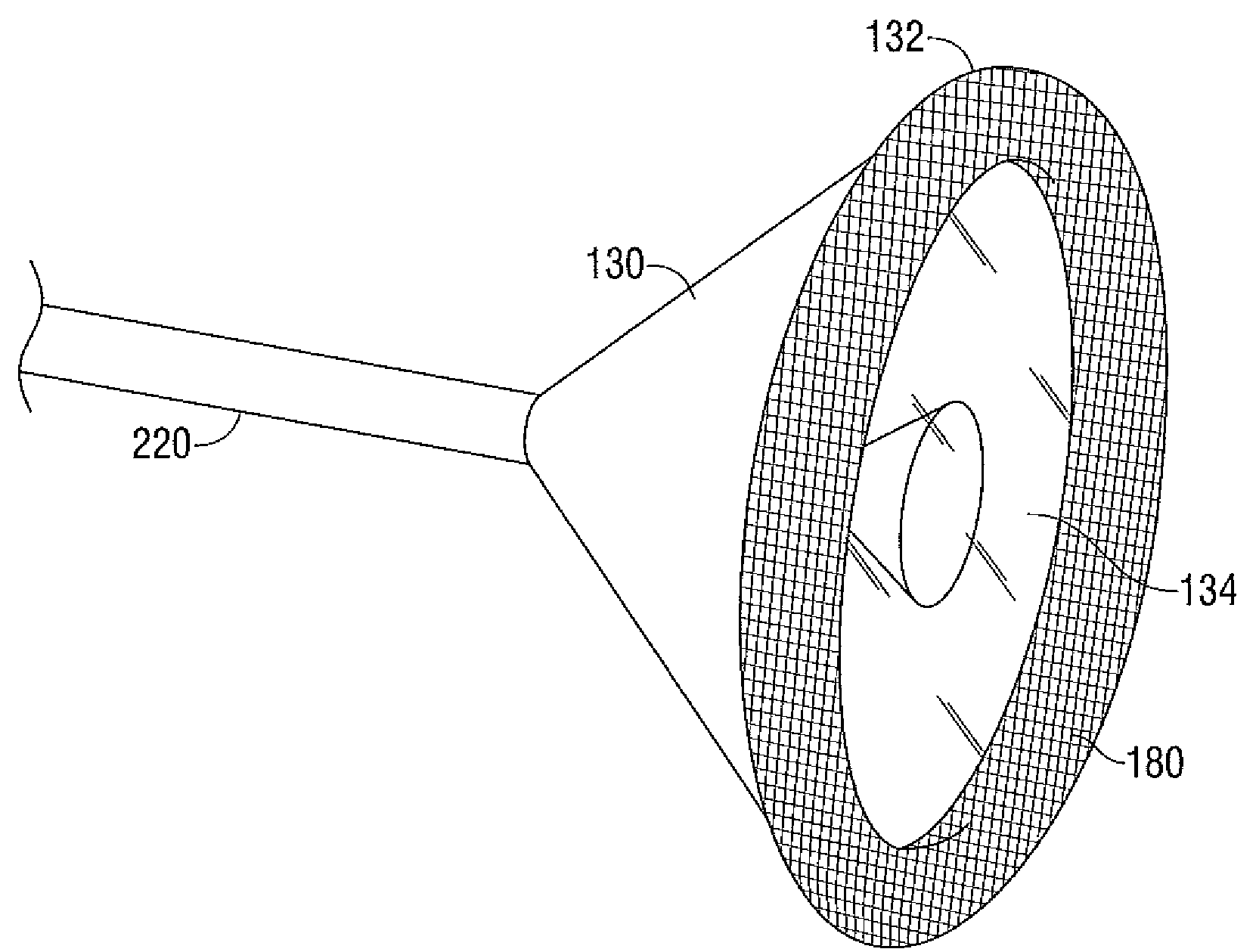

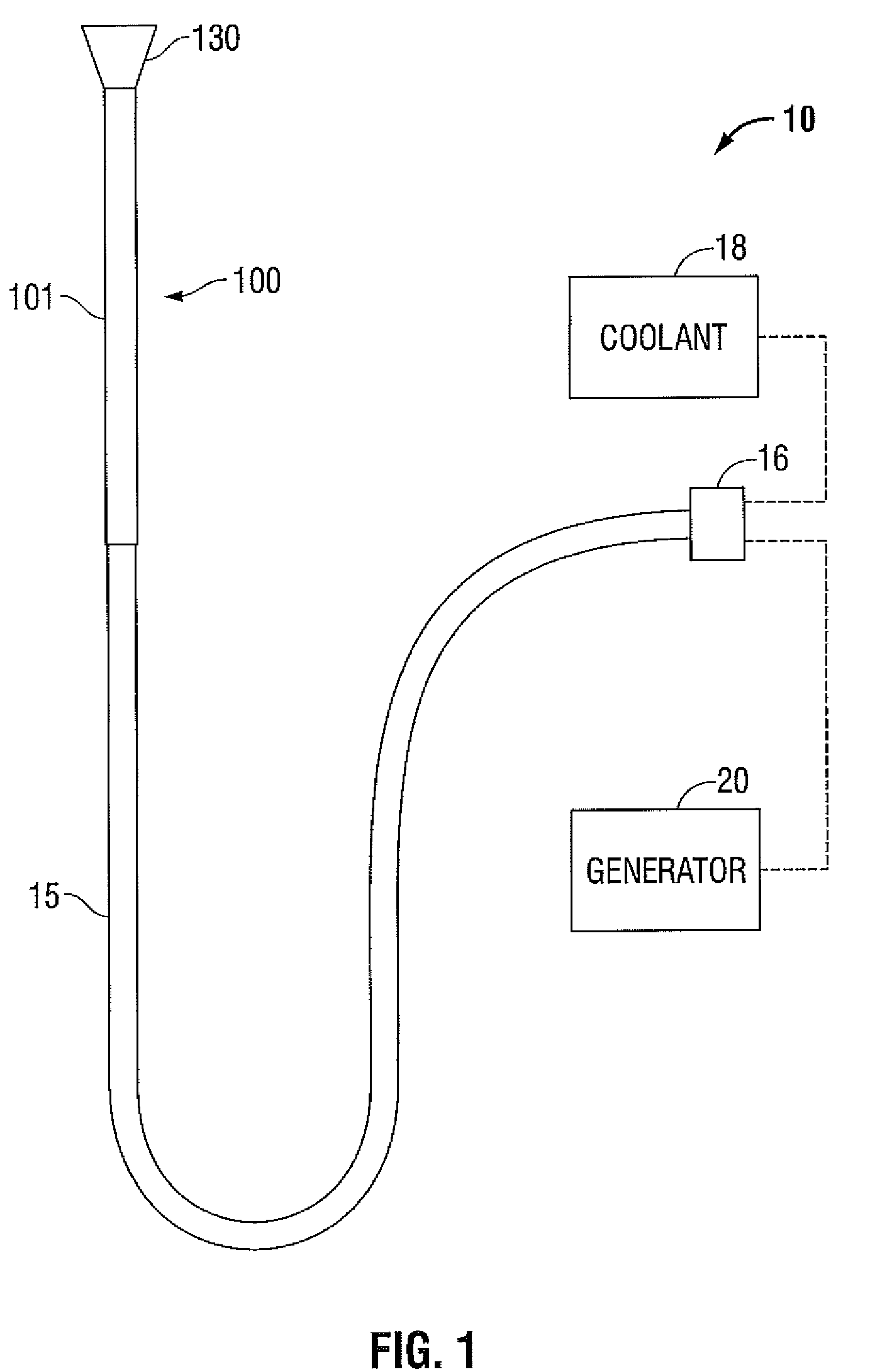

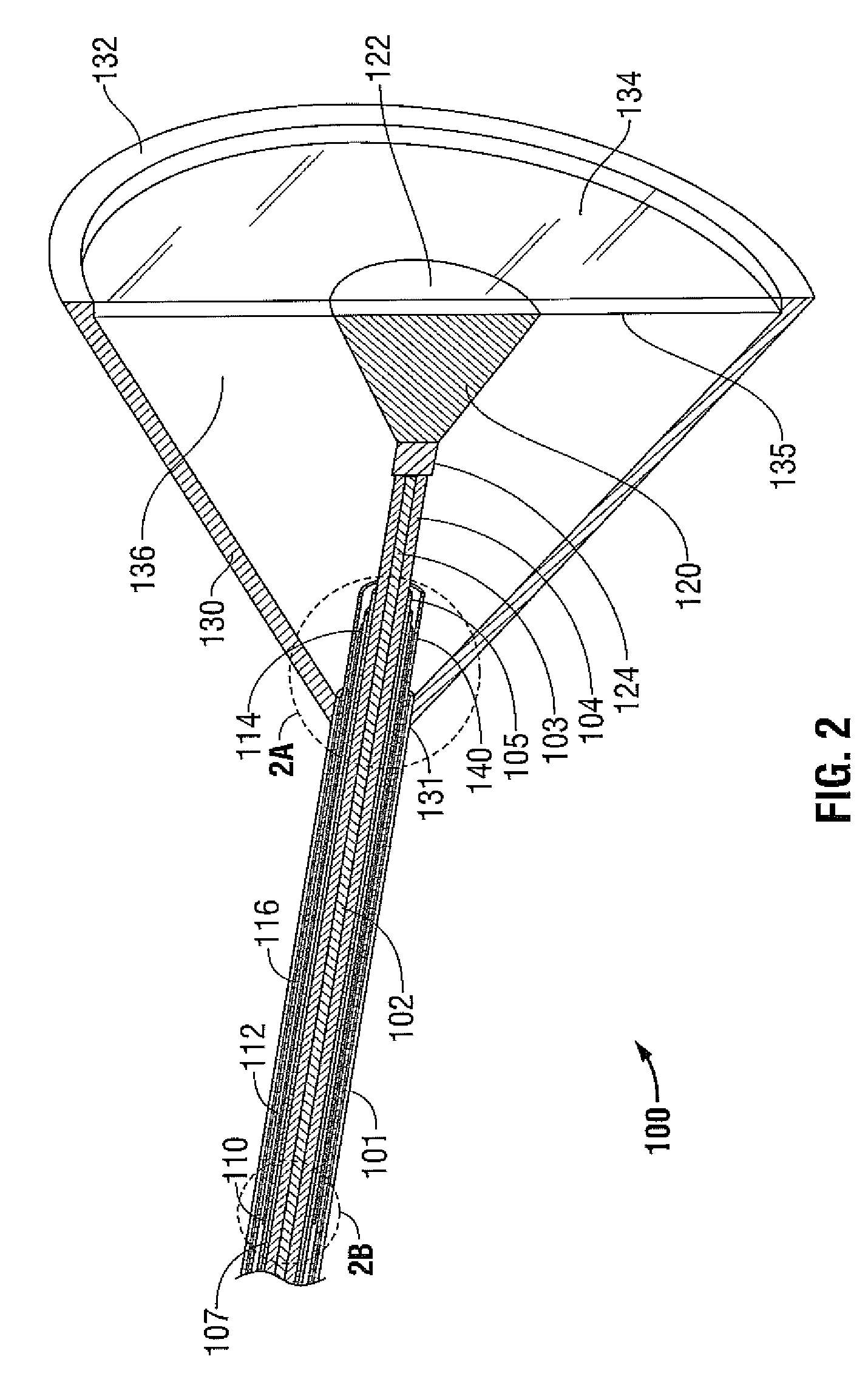

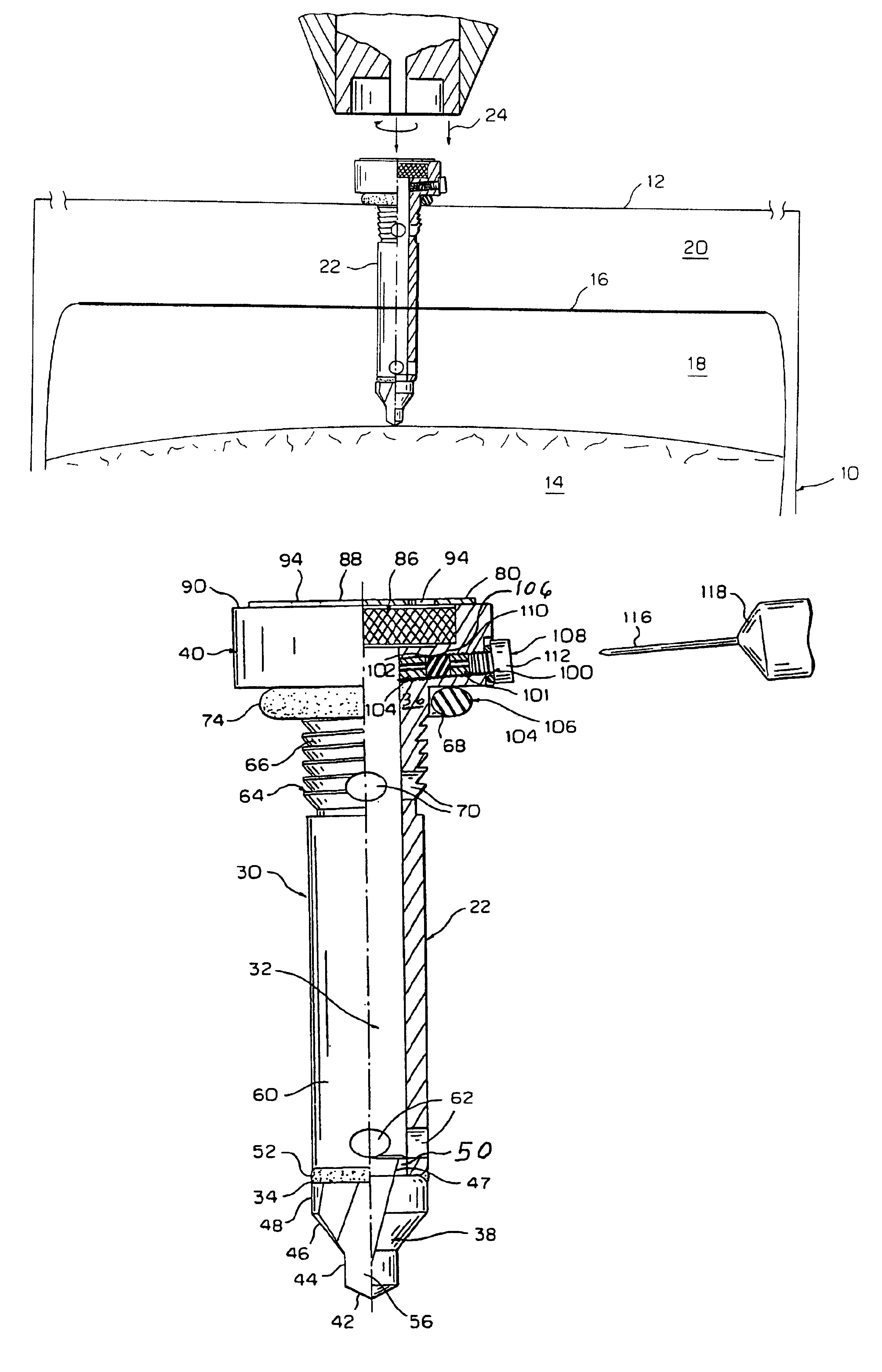

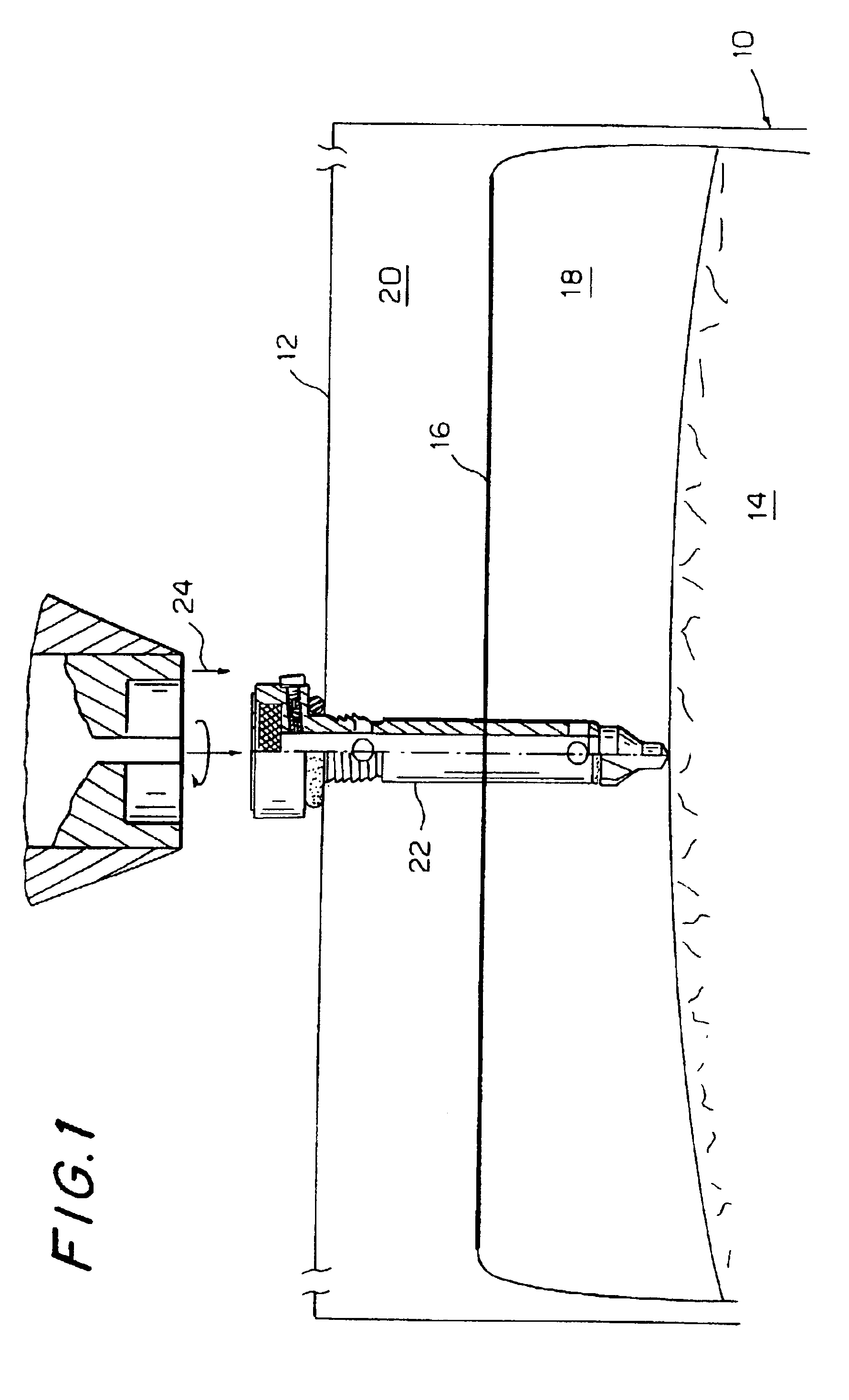

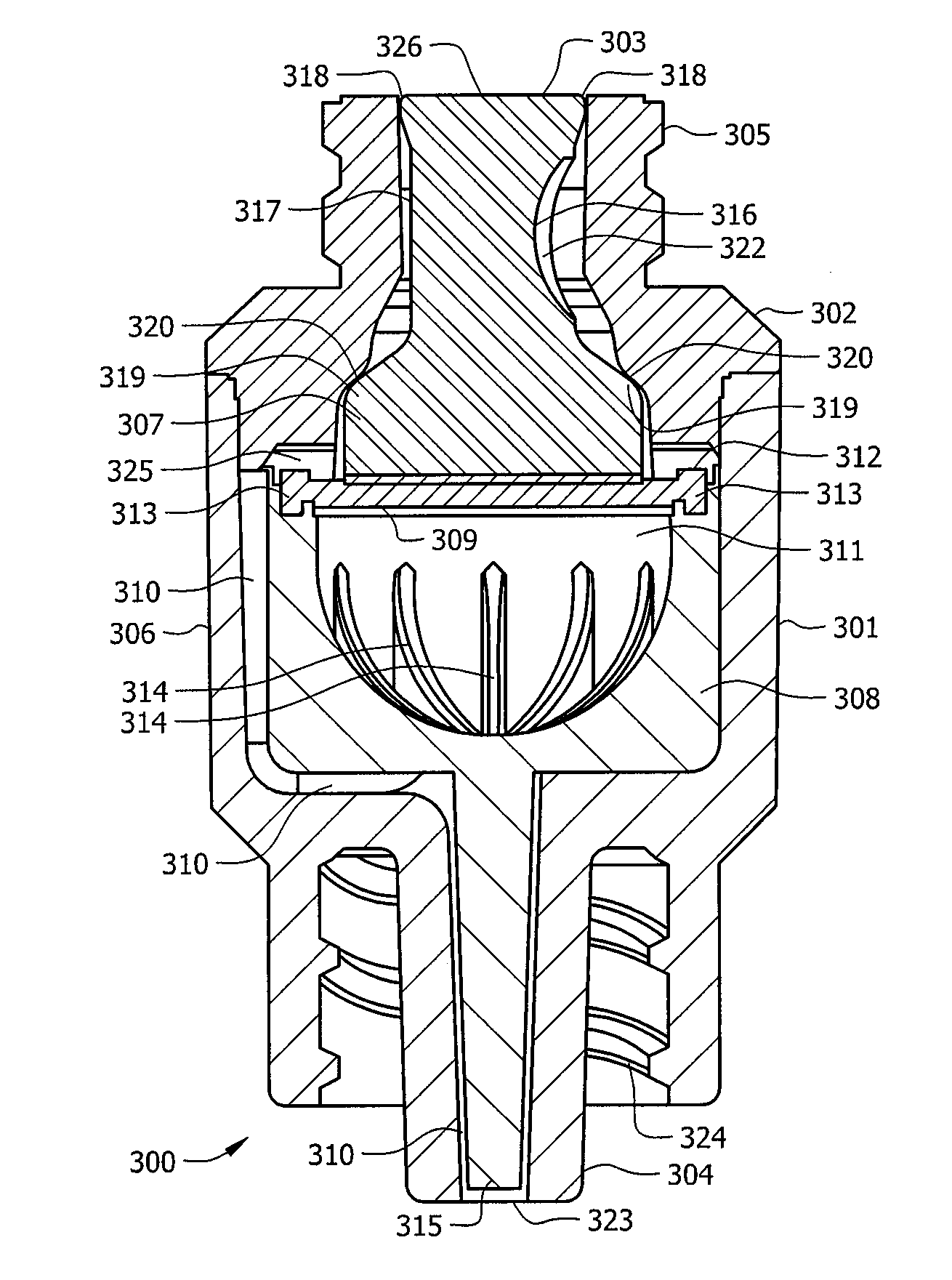

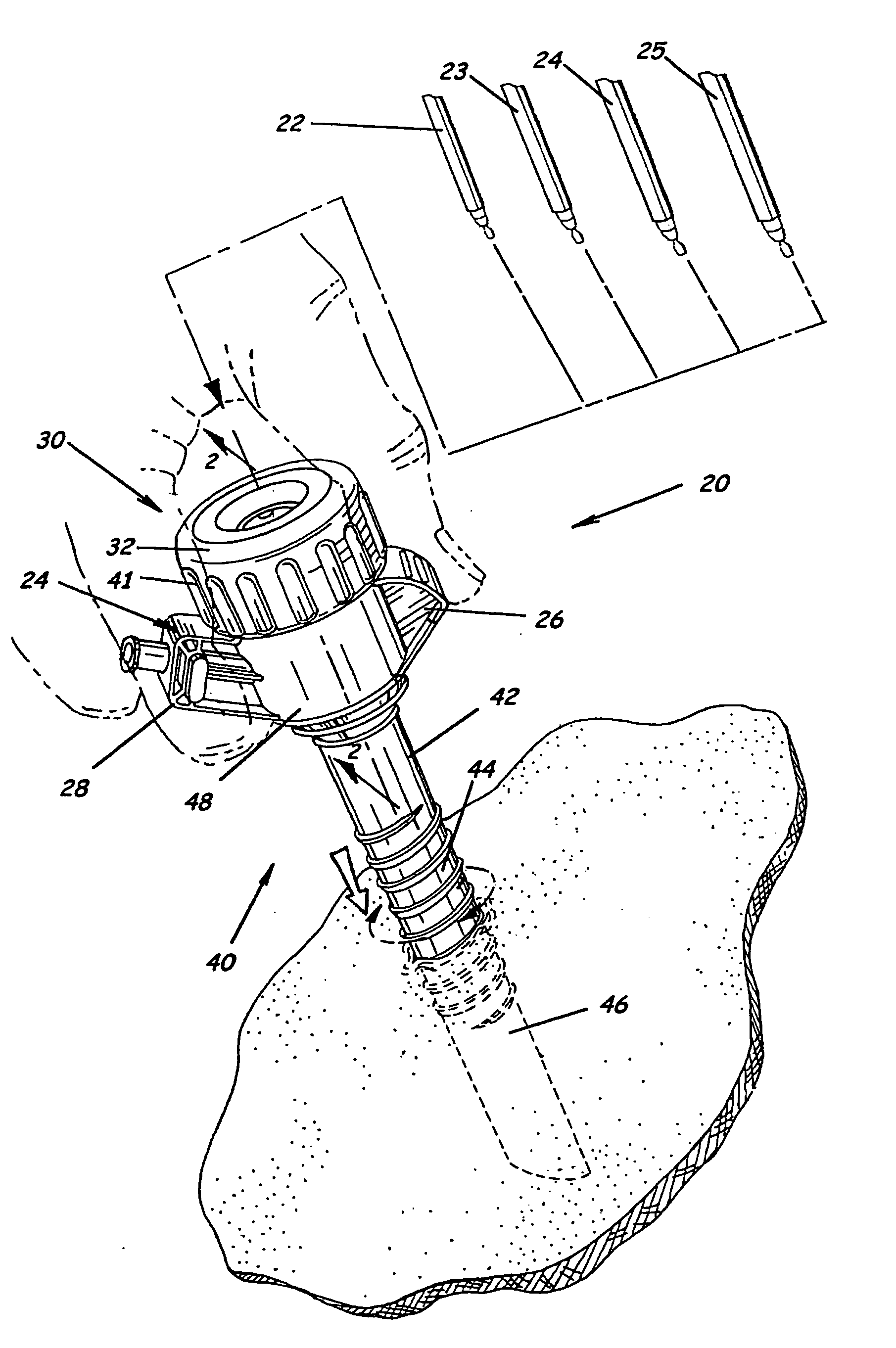

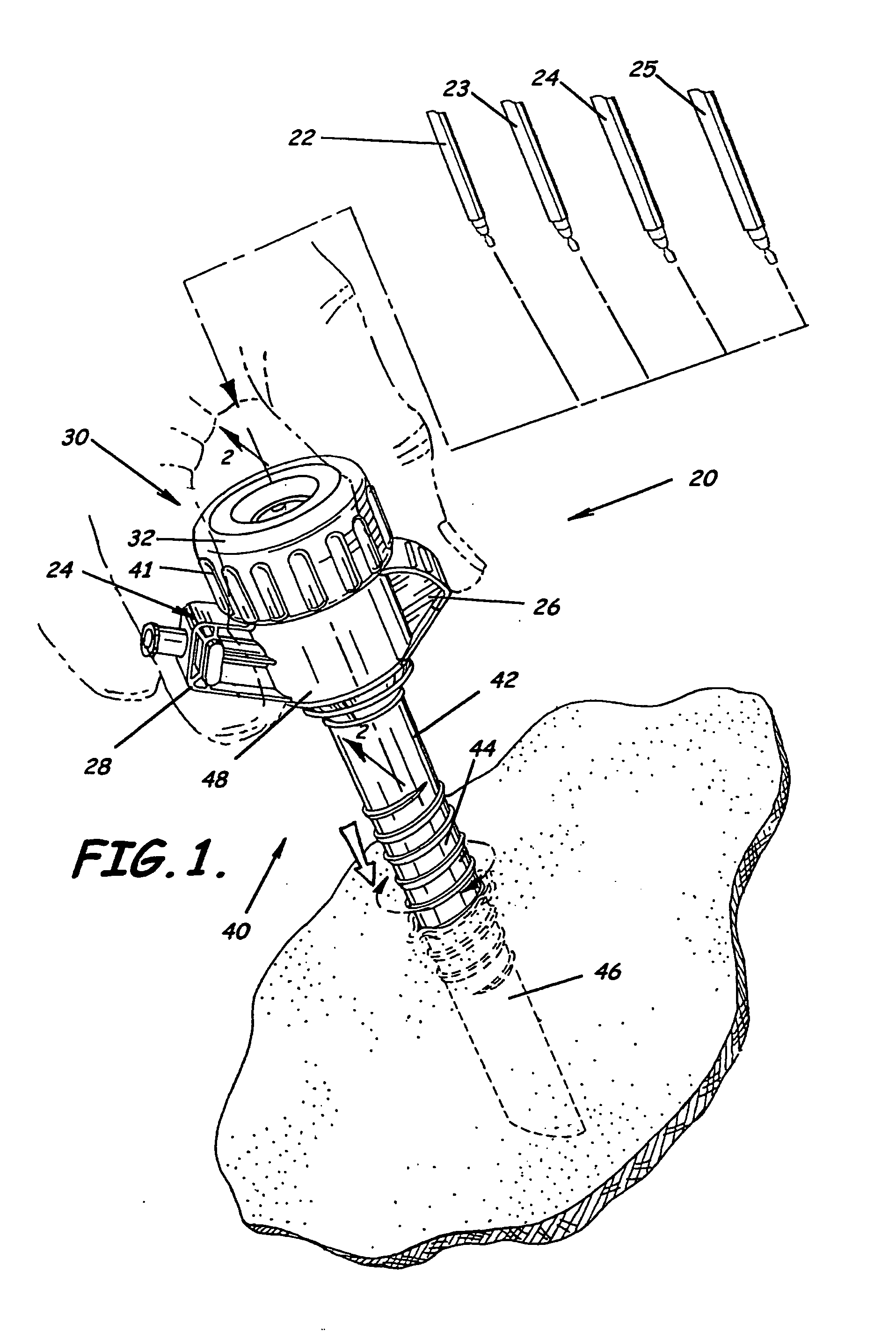

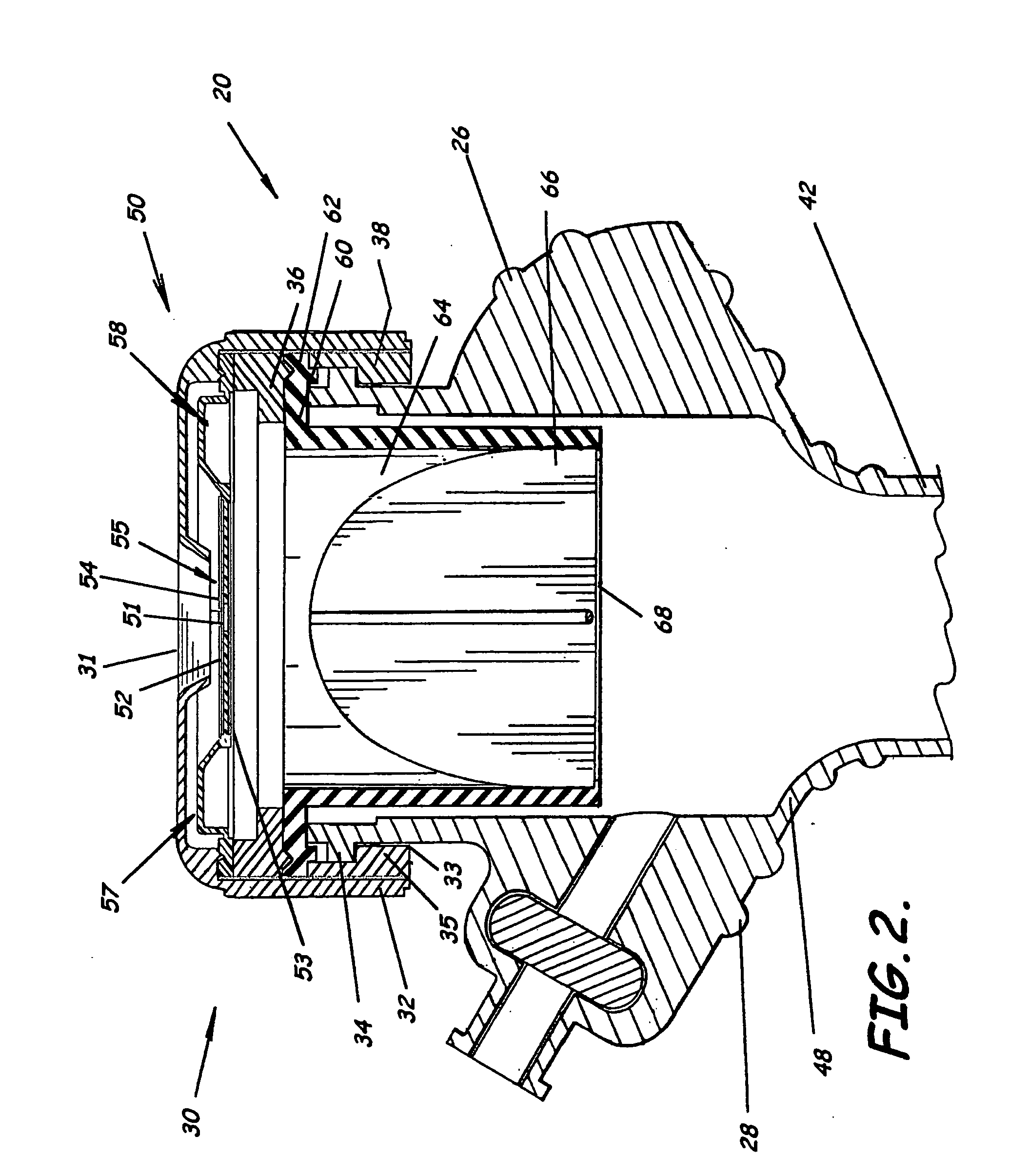

Microwave surface ablation using conical probe

ActiveUS8343145B2Improve performanceHigh strengthElectrotherapyCatheterElectrical conductorMicrowave

An electromagnetic surgical ablation probe having a conical hood reflector and method of manufacture thereof is disclosed. The disclosed probe includes a shaft assembly that has a coaxial feedline core having an inner conductor and an outer conductor separated by an insulating layer. A tubular catheter is disposed coaxially around the feedline and is configured to deliver coolant, such as saline or deionized water, to a coolant chamber at a distal end formed within the conical reflector. A radiating section disposed within the conical reflector may have a conical, cylindrical, or other suitable shape. A membrane disposed across a distal opening of the conical reflector seals coolant within the coolant chamber, and may conform to tissue contours during use. A resilient aperture may be included at the periphery of the conical hood. The shaft assembly may include an angled section, an adjustable section, and, additionally or alternatively, a malleable section.

Owner:COVIDIEN LP

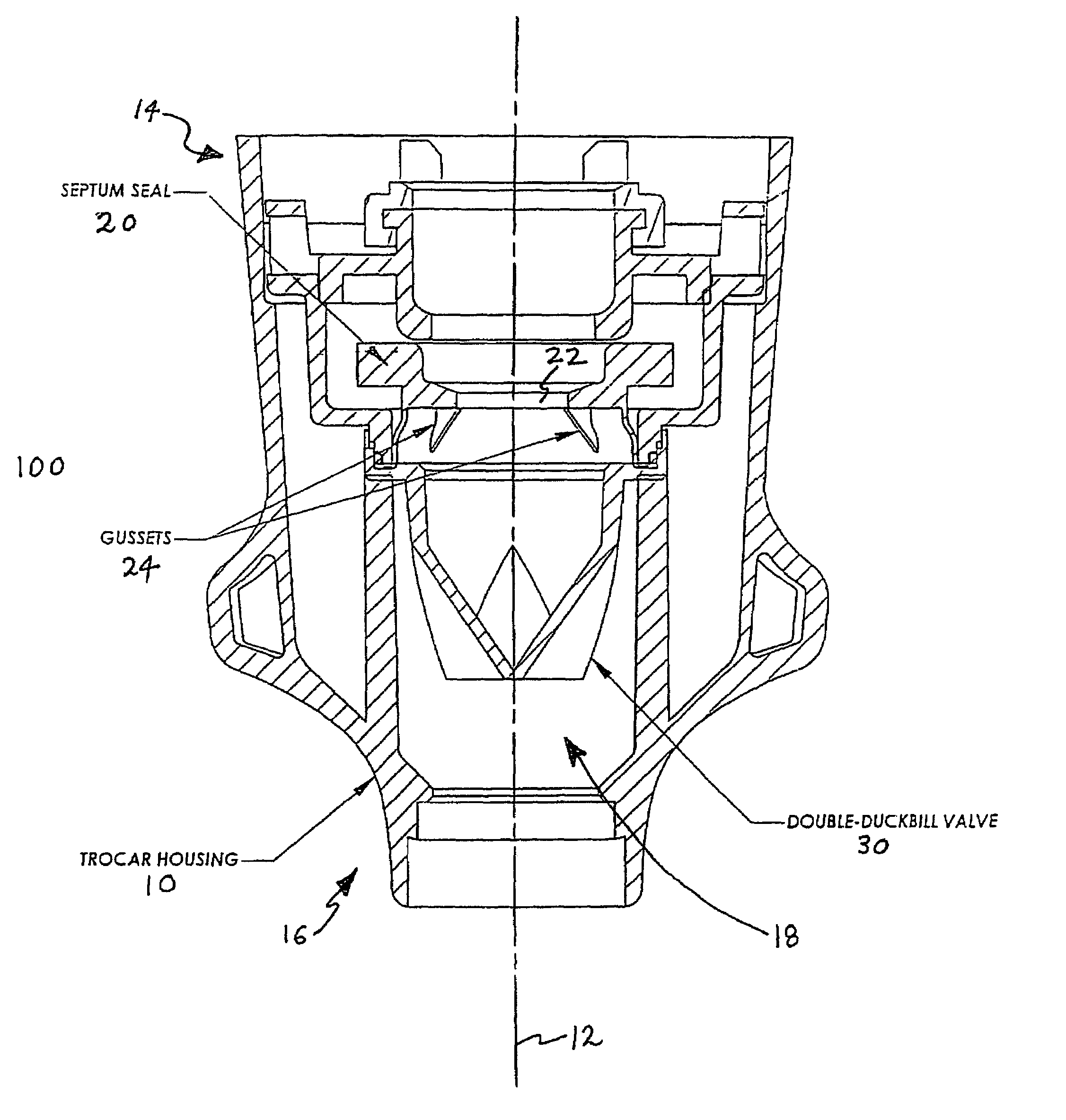

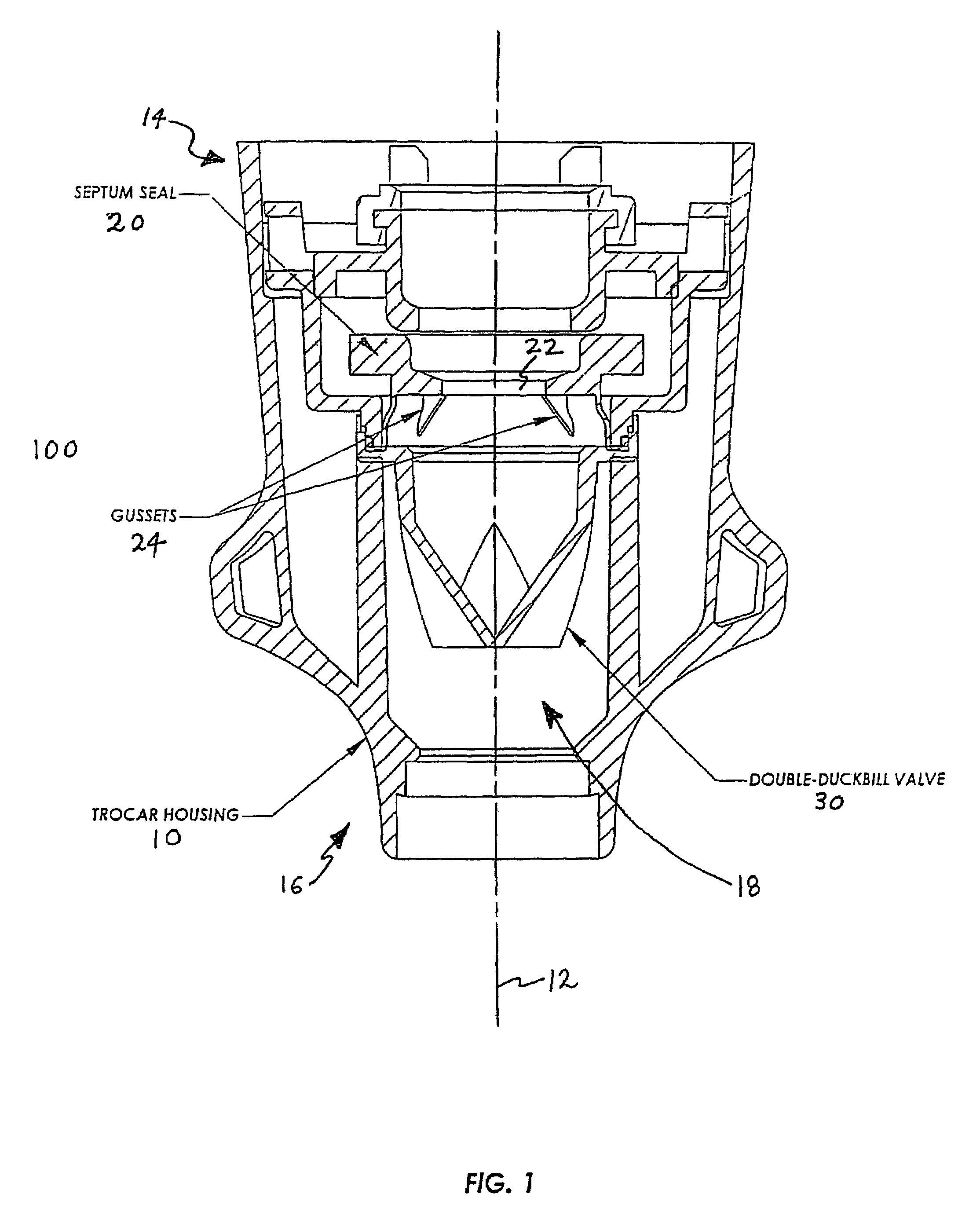

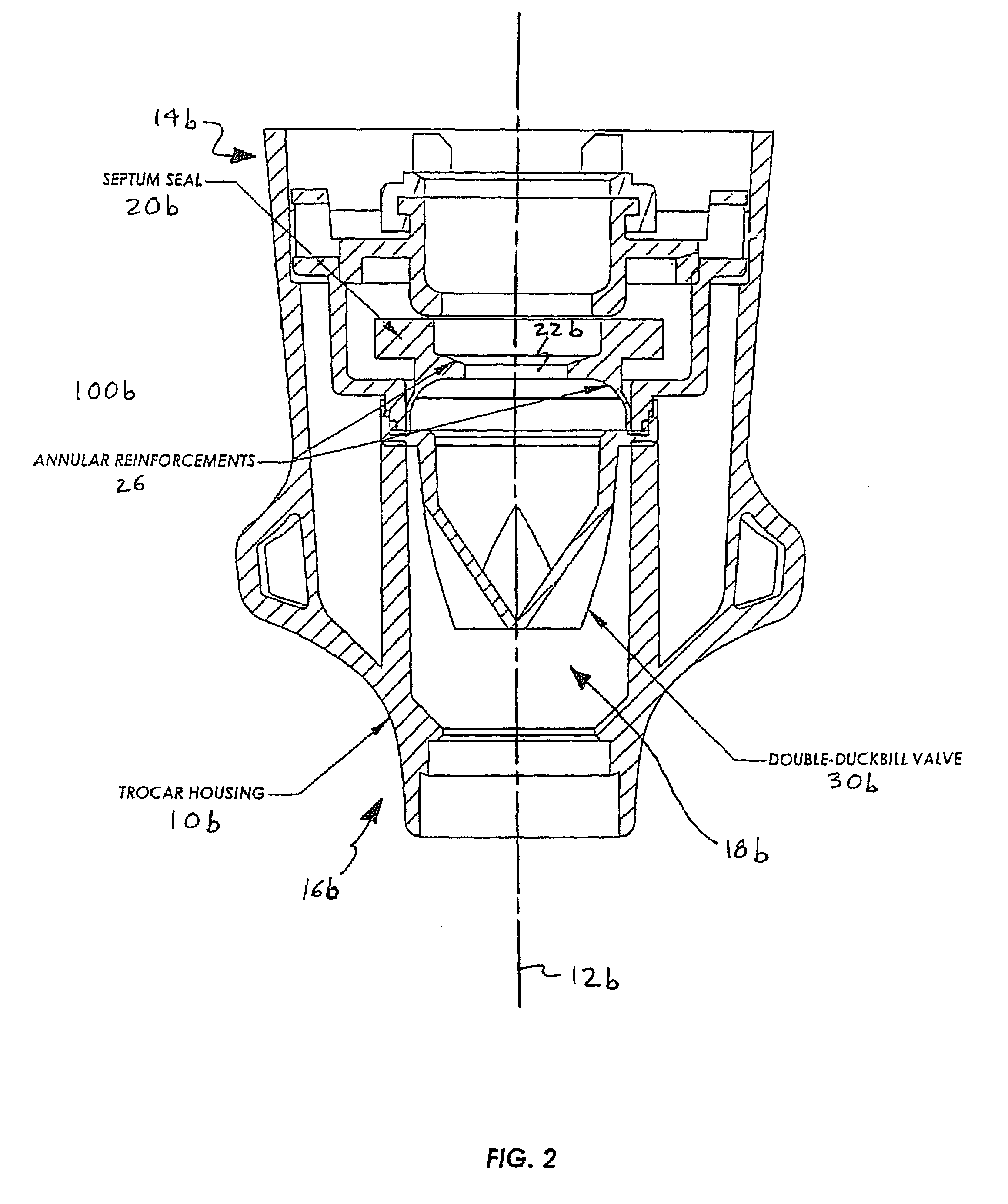

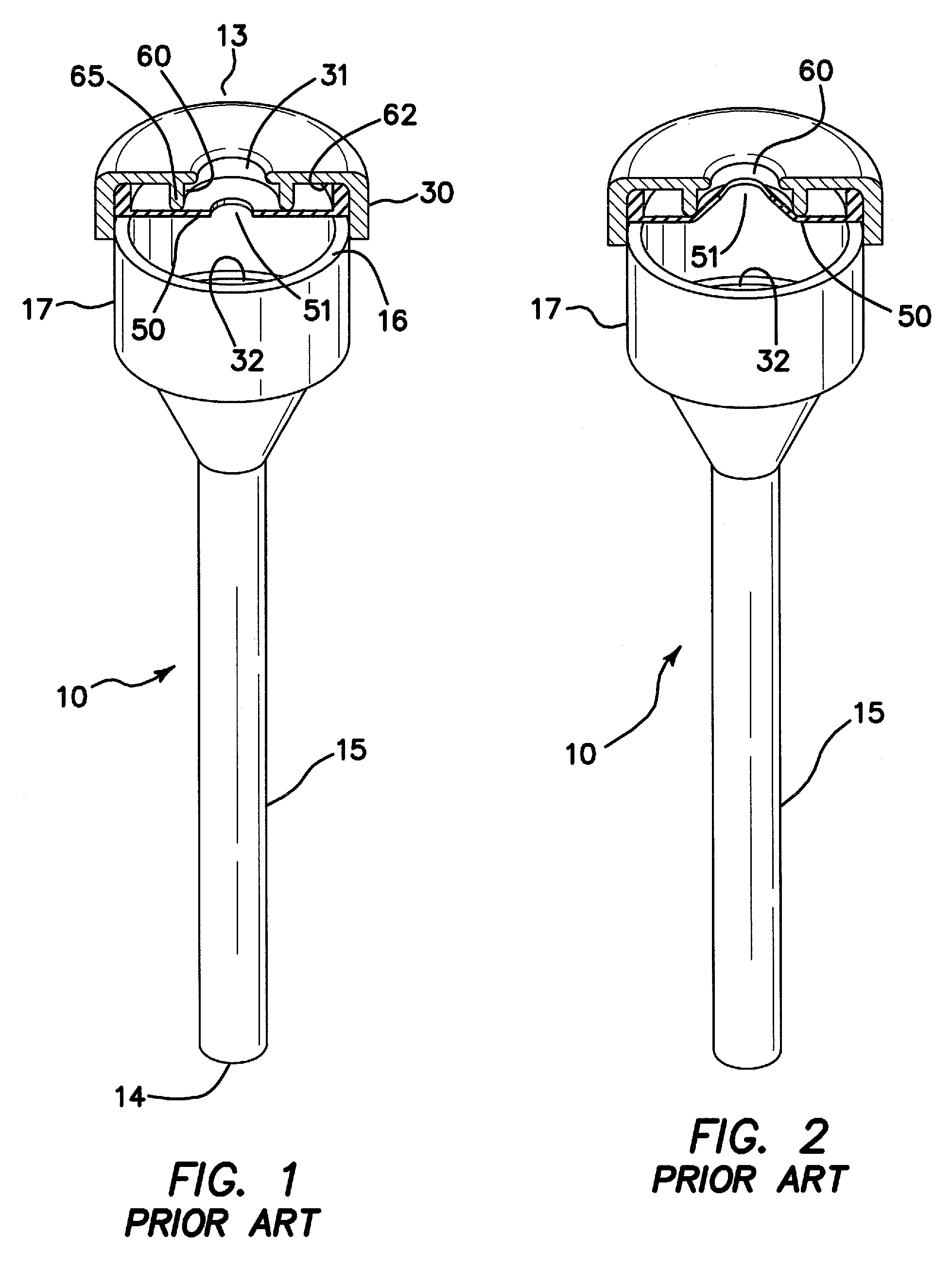

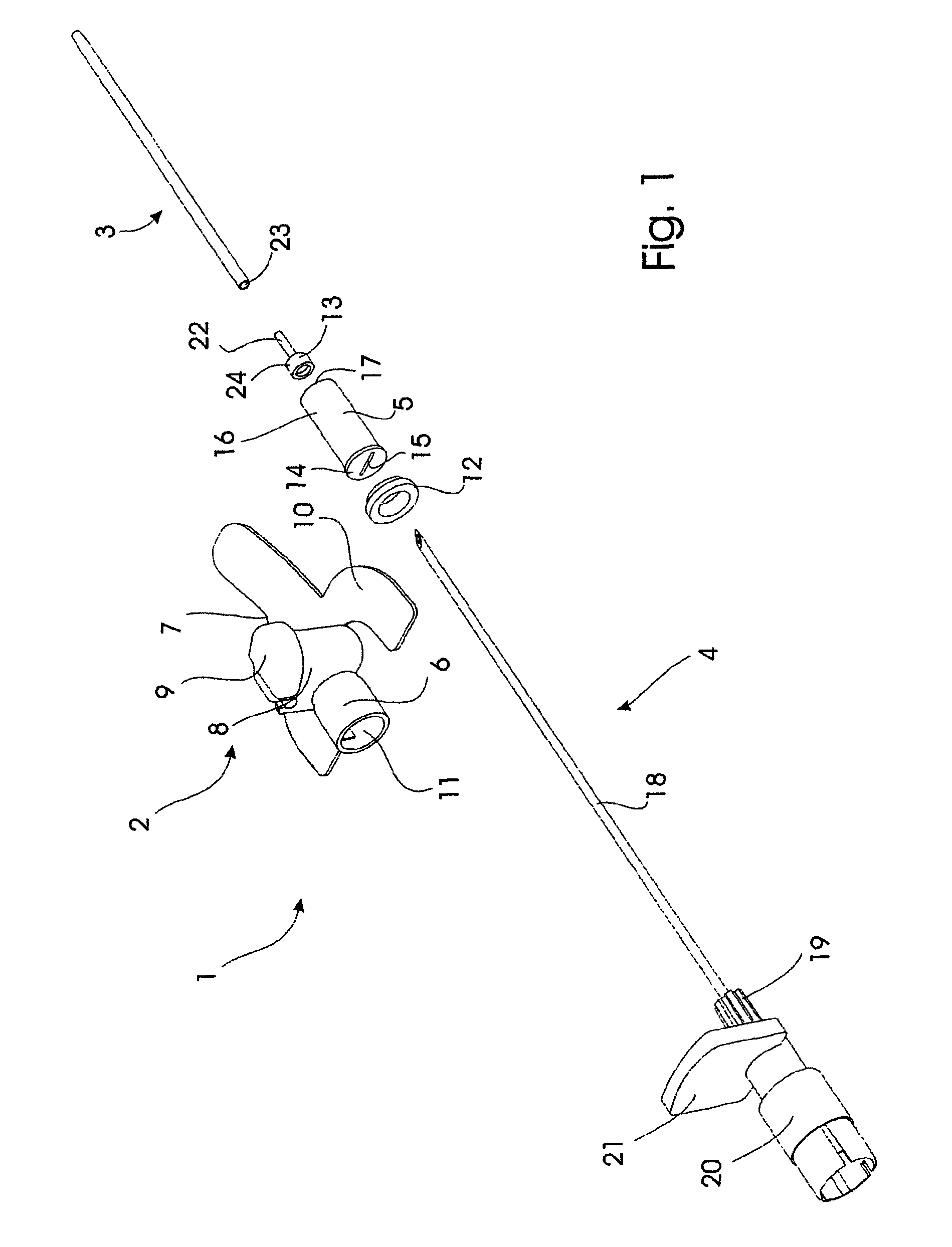

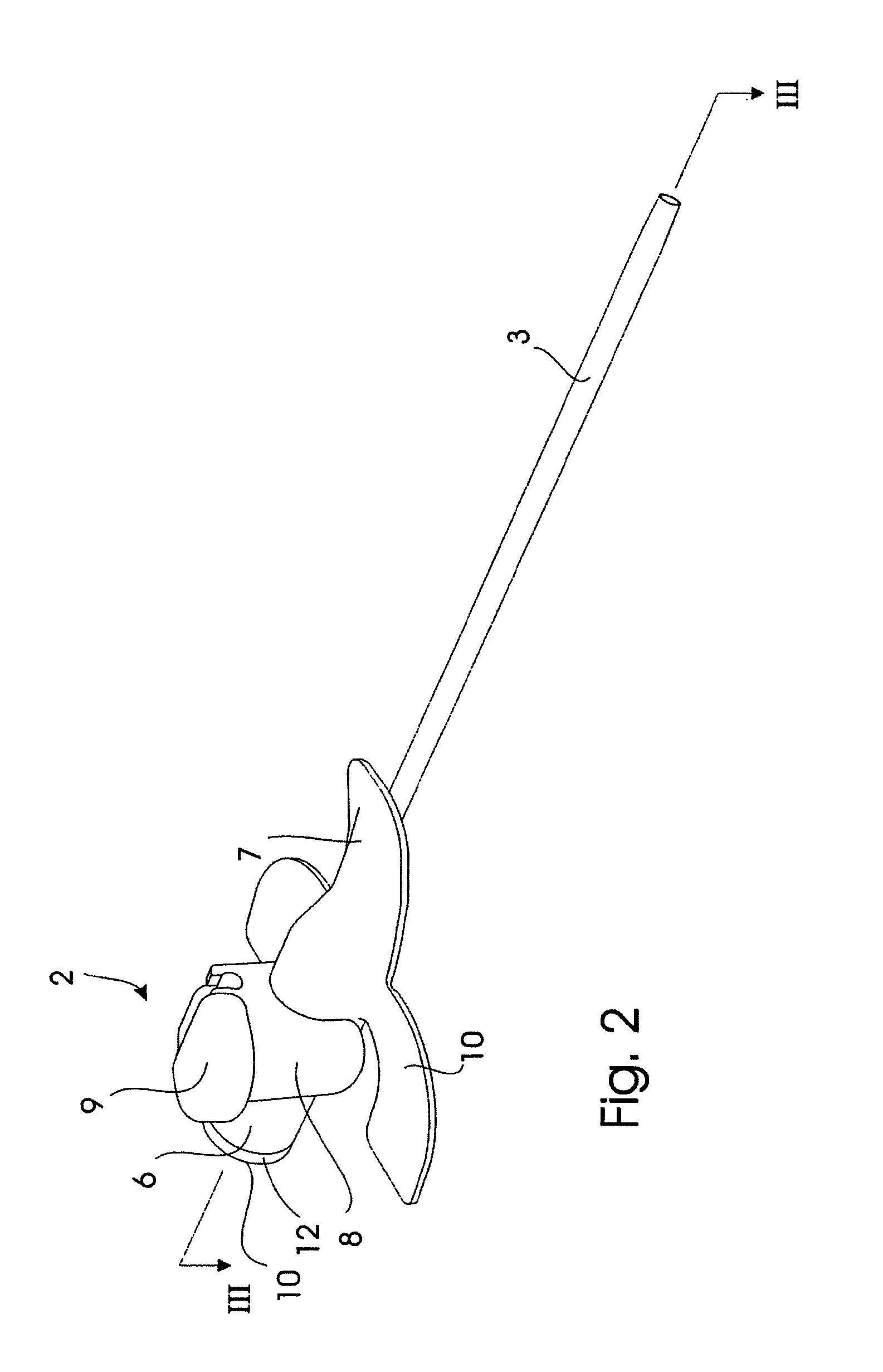

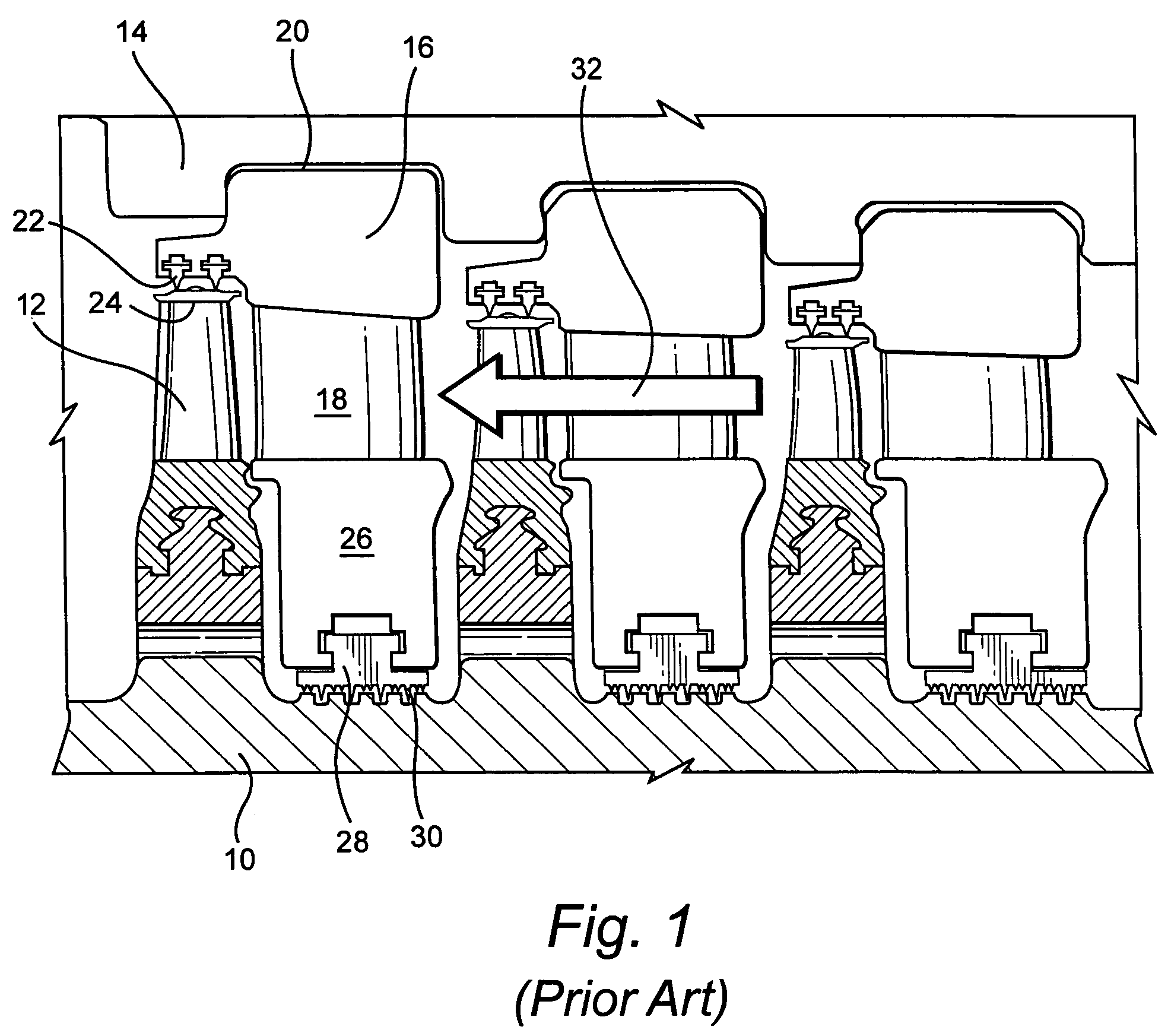

Anti-inversion trocar seal

The invention is directed to a trocar seal adapted to form a seal around a surgical instrument, the trocar seal comprising a housing having an axis extending between a proximal end and a distal end and forming a working channel sized and configured to receive the surgical instrument; an elastomeric septum seal having a proximal face and a distal face, the septum seal being disposed in the housing and extending transverse to the axis of the housing across the working channel; portions of the septum seal defining a hole having a diameter less than or equal to the diameter of the surgical instrument so that during insertion of the instrument along the working channel the septum seal forms a seal with the instrument; and at least one structure formed integrally with or proximate to the septum seal to prevent inversion of the septum seal upon withdrawal of the surgical instrument. The septum seal or the housing may further comprise a sidewall to include the structure extending from the sidewall to the distal face of the seal to tether the seal distally. The structure may be integrally formed with the proximal face of the septum seal to reinforce the seal, or the structure may be integrally formed with the distal face of the septum seal to tether the seal distally. The structure may be an annular reinforcement or rib, and is formed so as to allow side-to-side movement or floatation of the seal. The trocar seal may further comprise a plurality of radially extending ribs formed on the proximal or distal face of the septum seal to reinforce the seal. The trocar seal may further comprise a tensile element formed on the distal face of the septum seal.

Owner:MINEBEA CO LTD +1

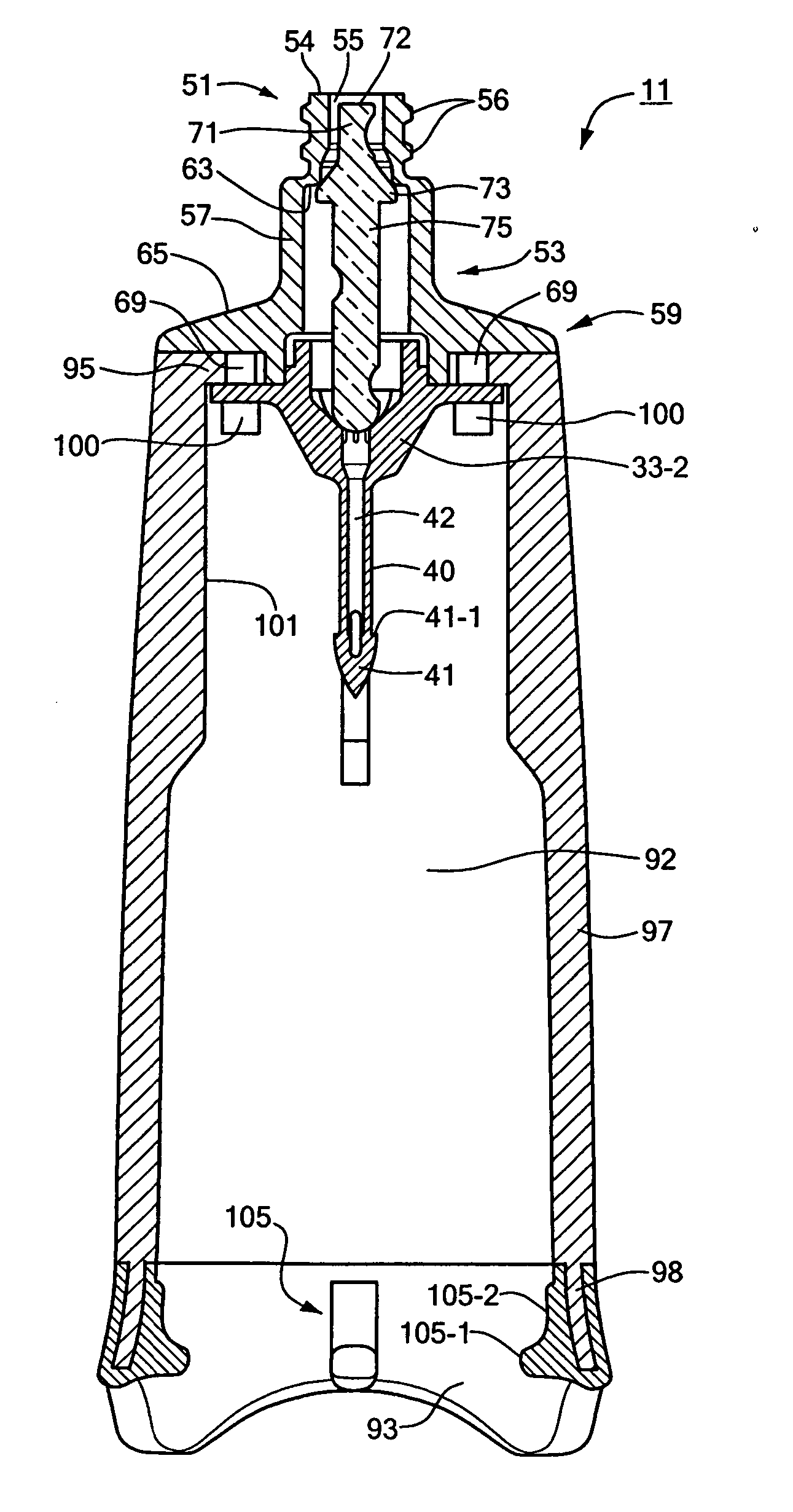

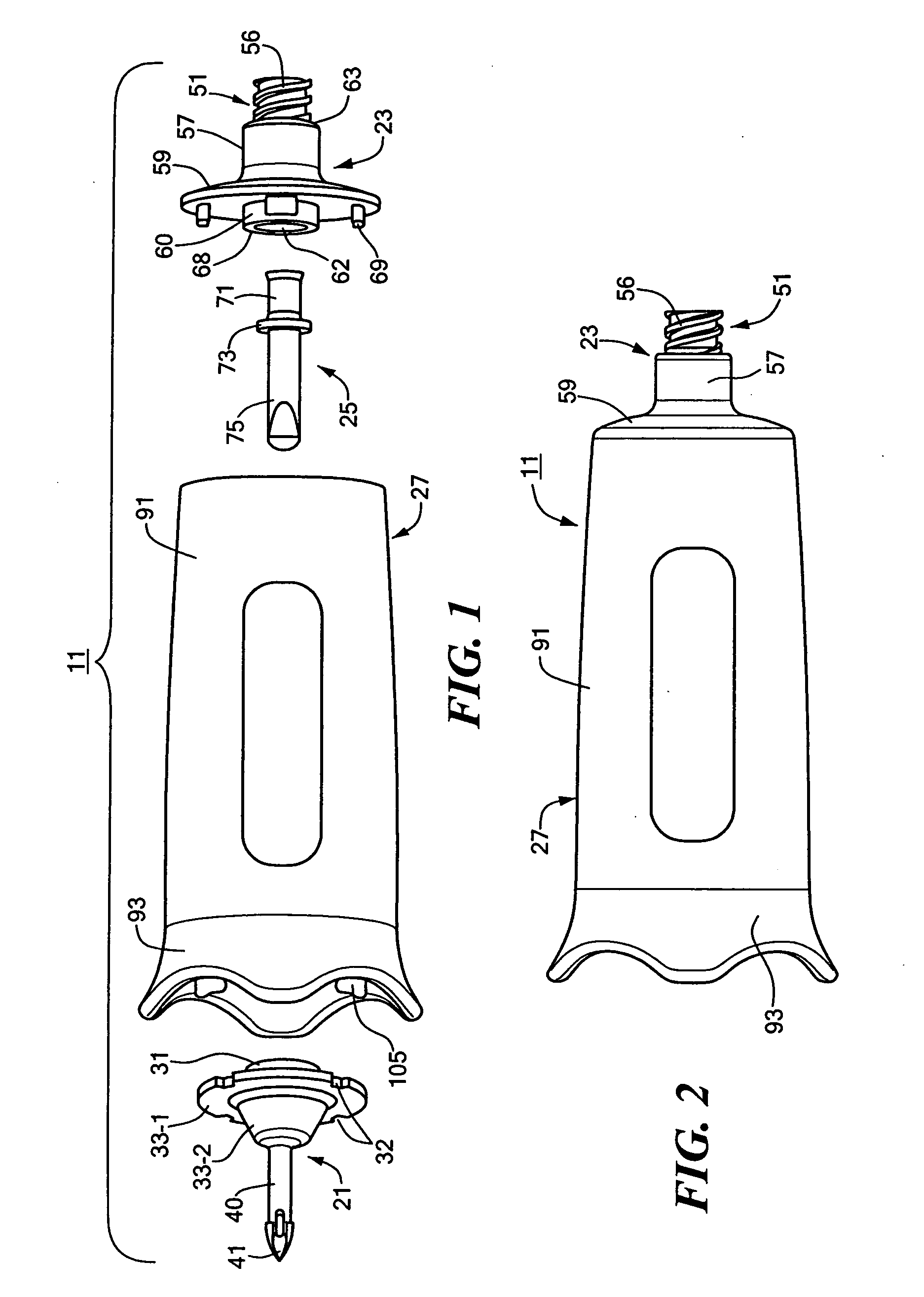

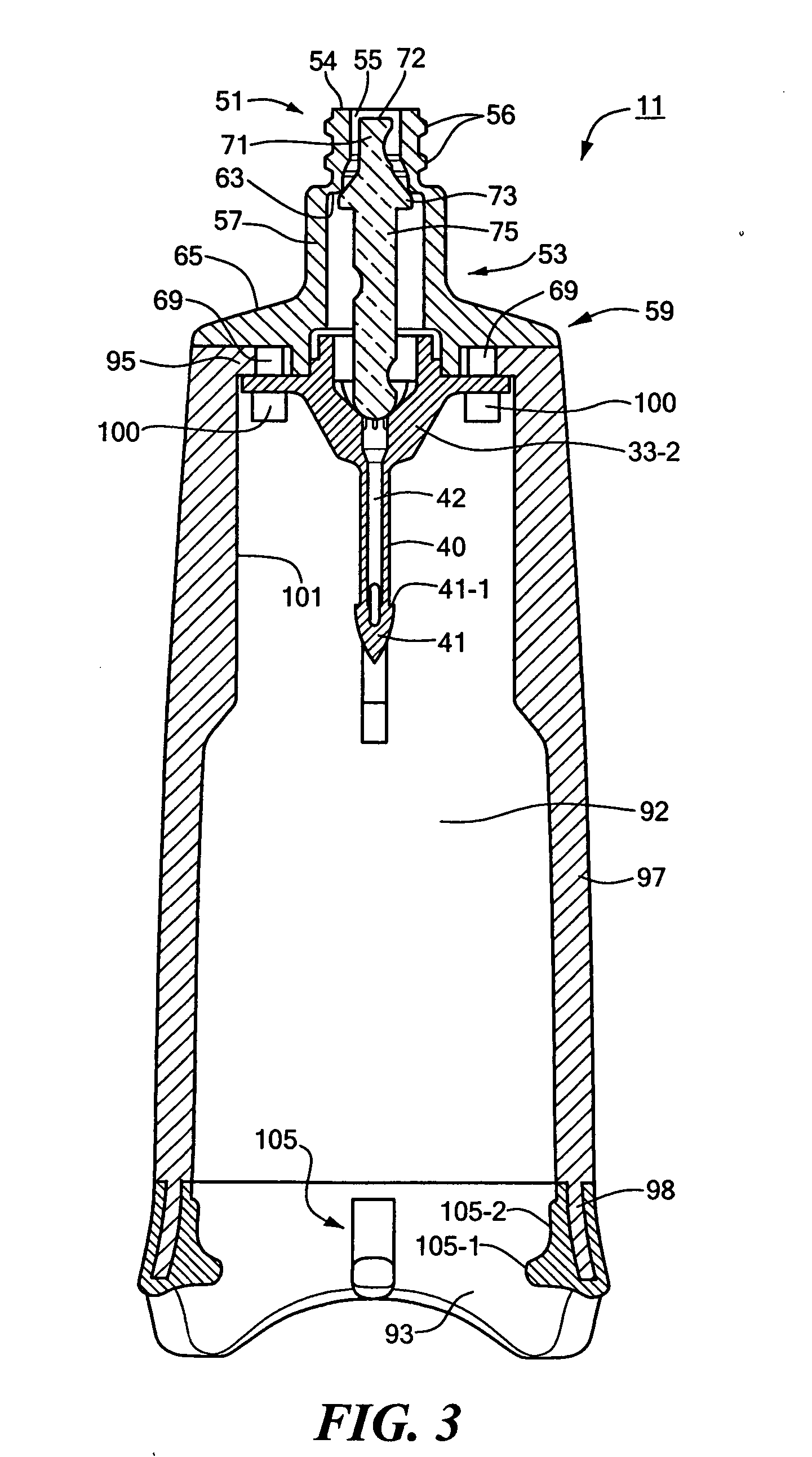

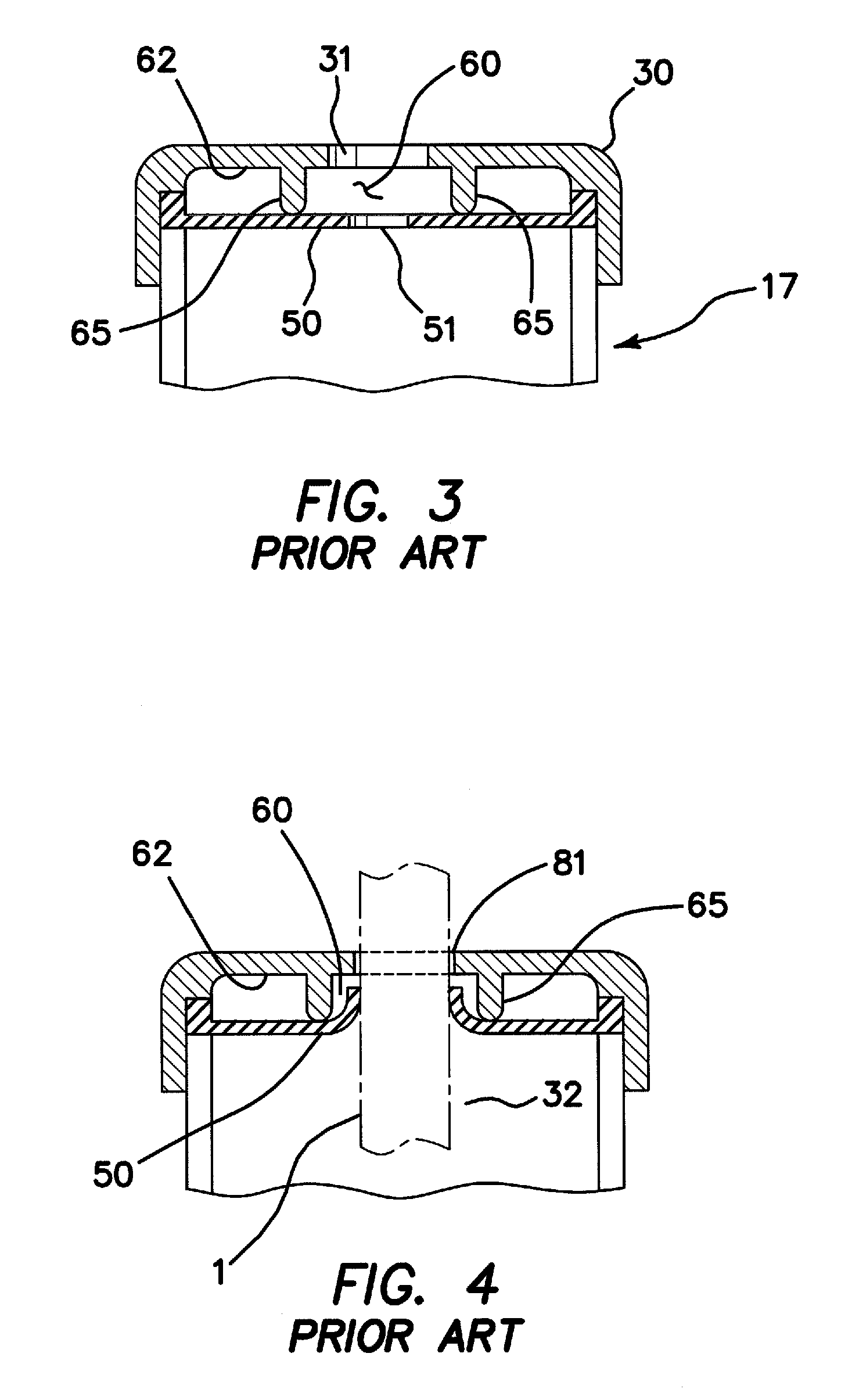

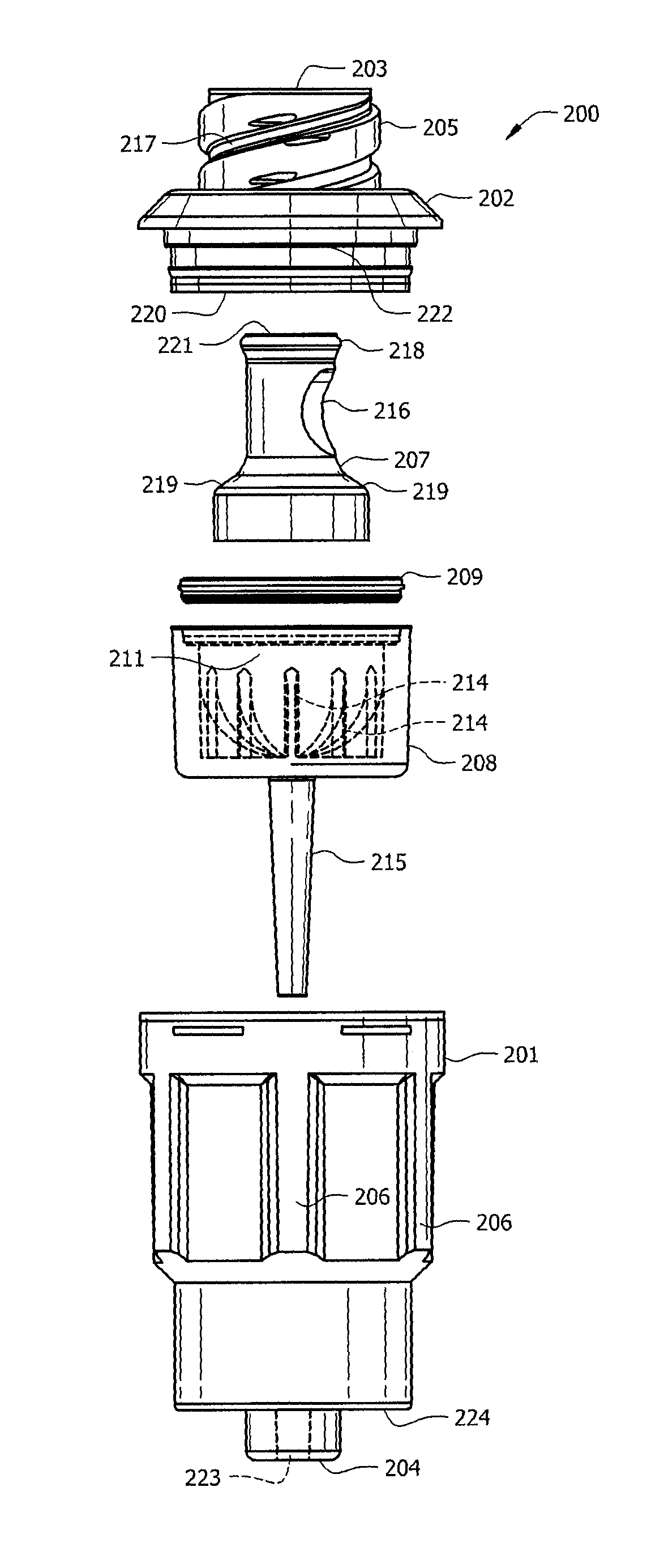

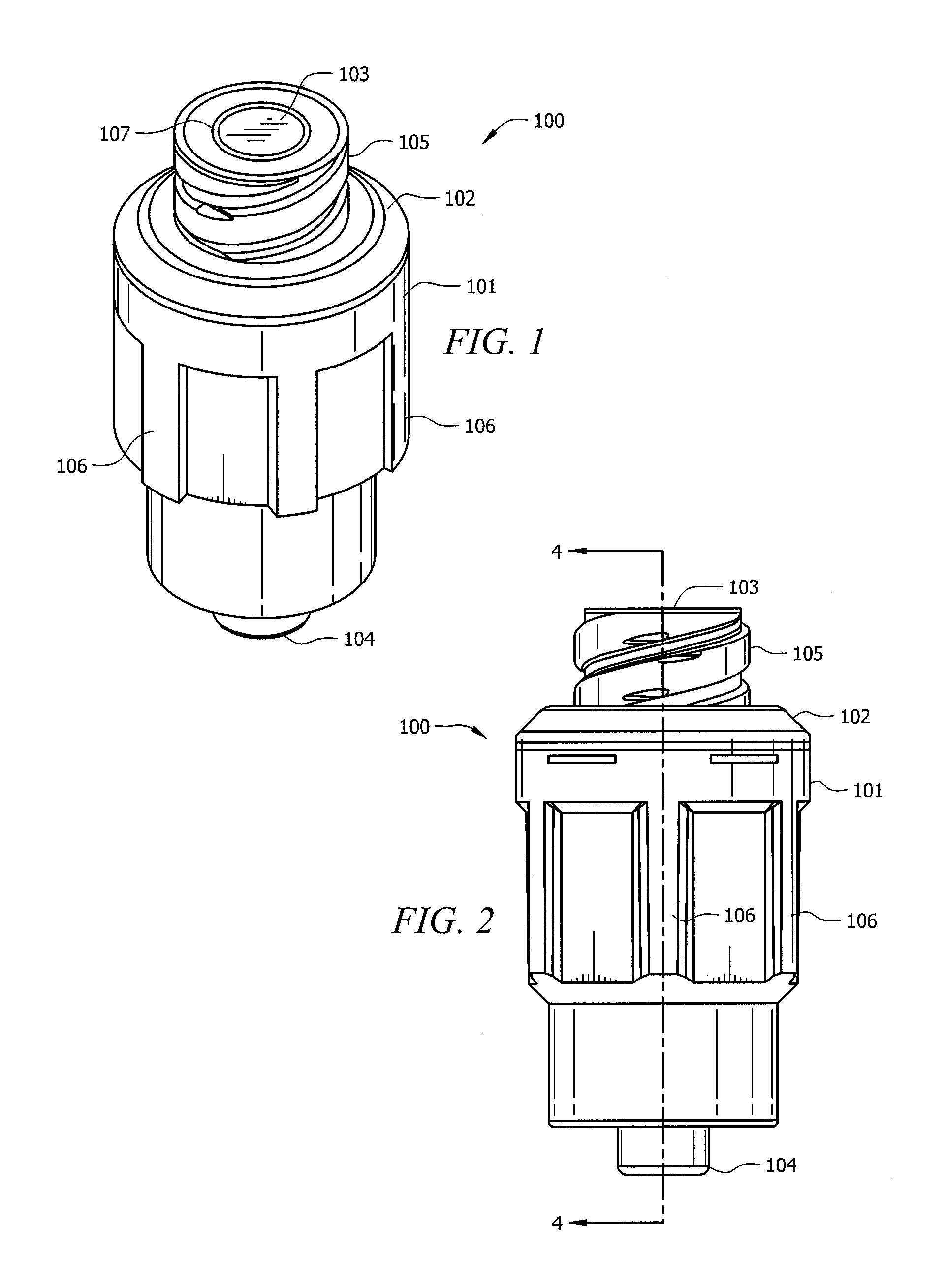

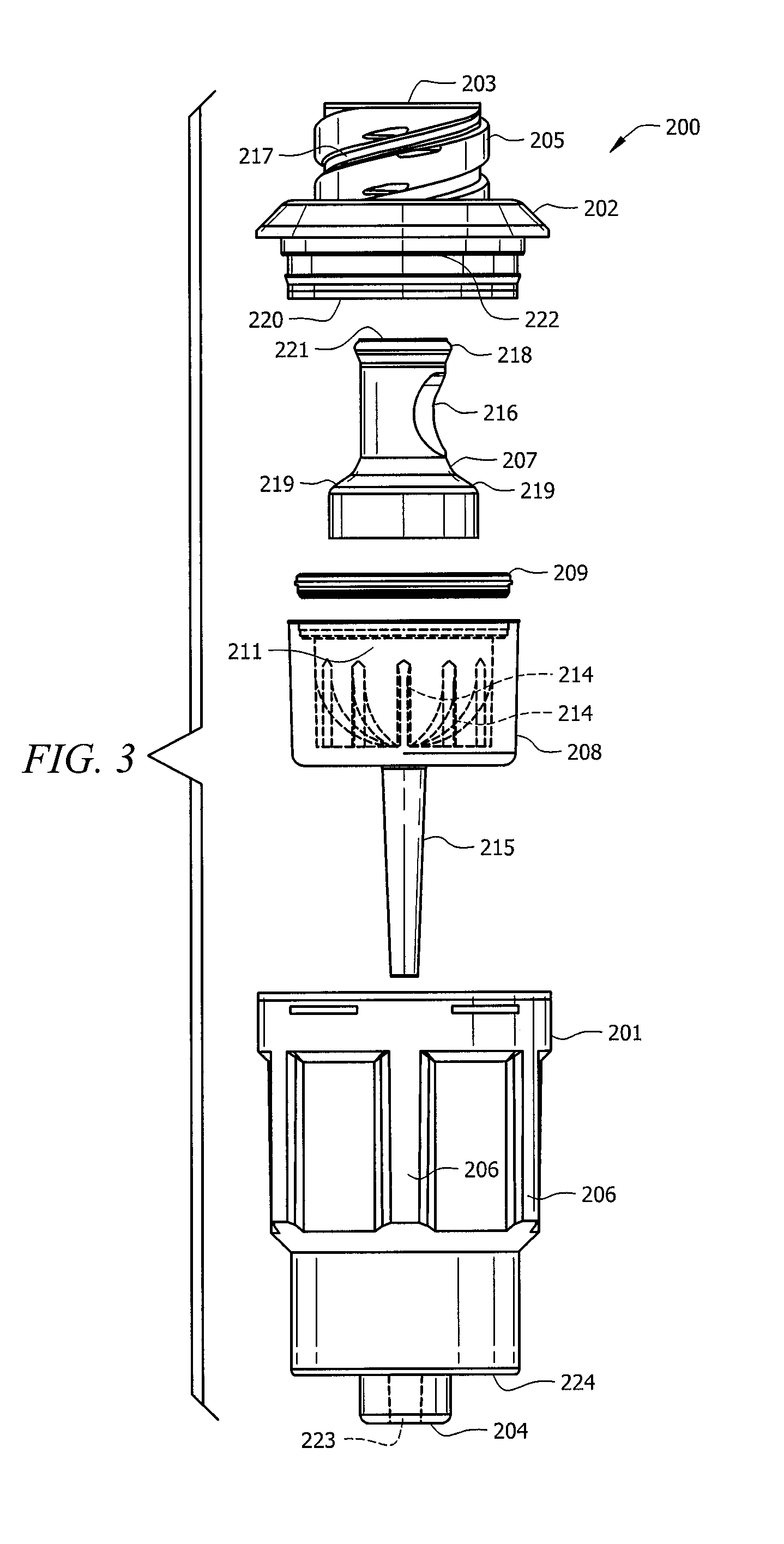

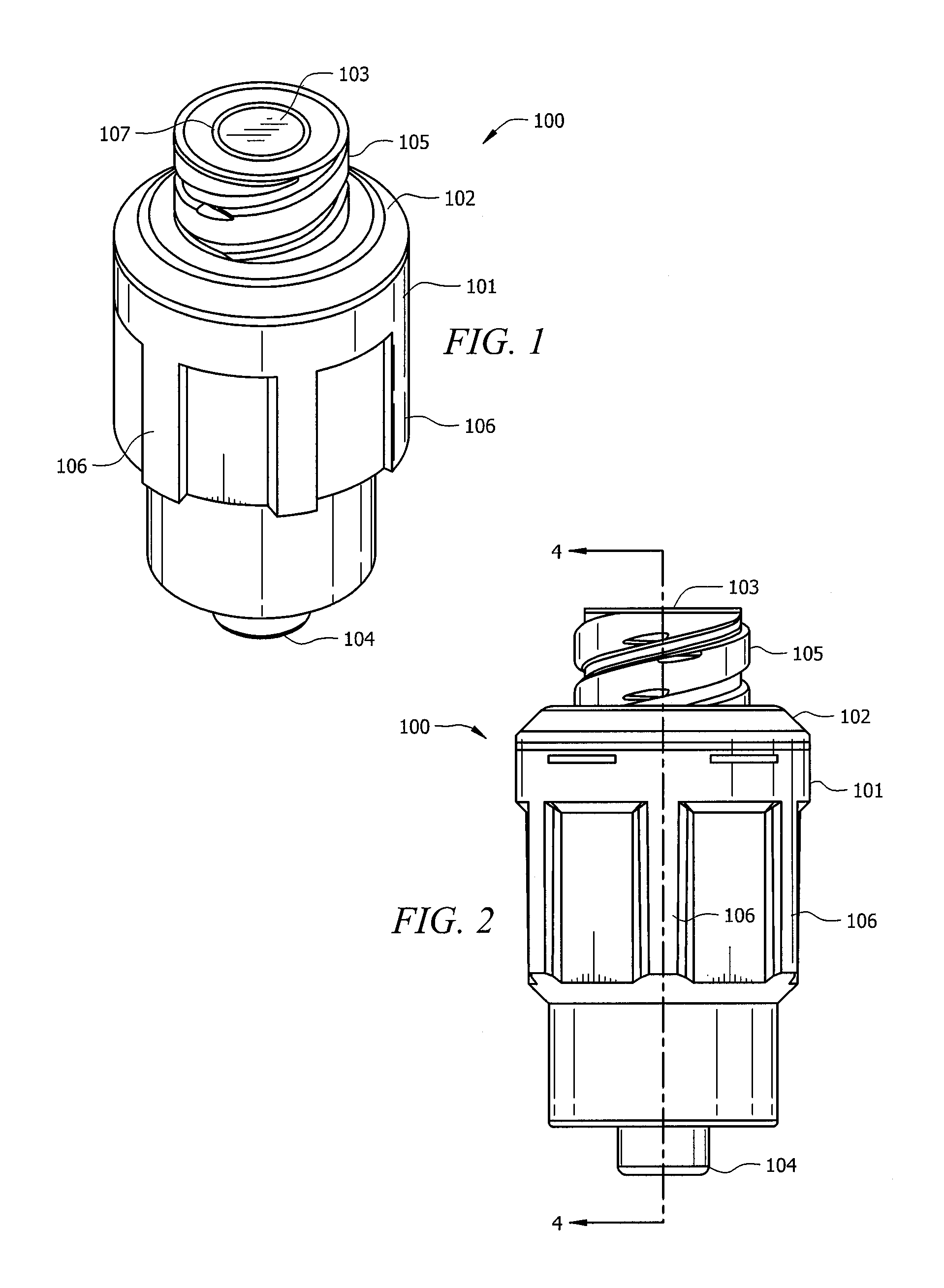

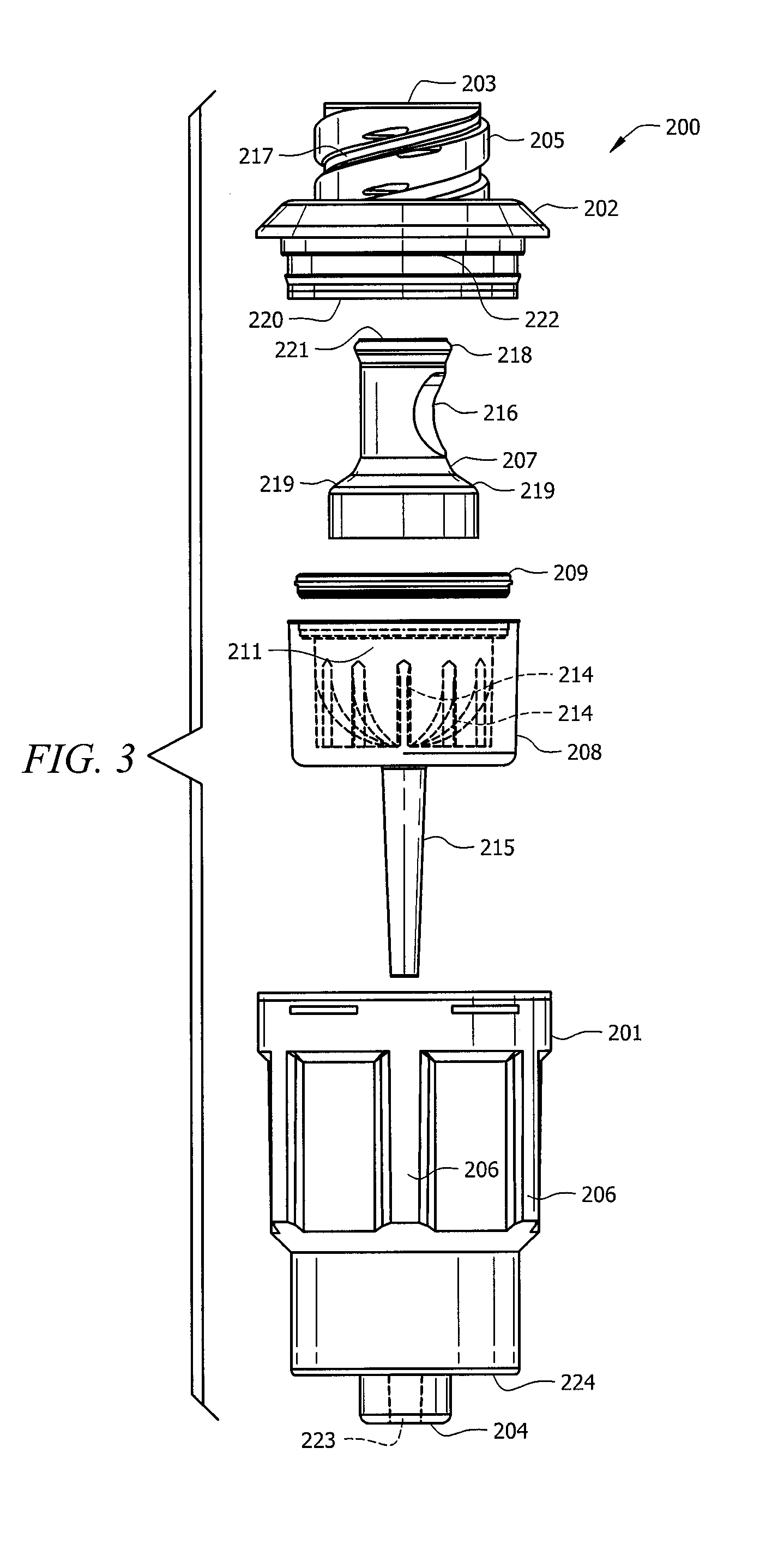

Vial adaptor

A vial adapter suitable for use in transferring fluid from a vial to a needleless syringe, the vial having a top end sealed with a septum. According to one embodiment, the vial adapter comprises (a) a body, the body having a top end, a bottom end and an inner cavity, the inner cavity being dimensioned to receive the vial, with the bottom end of the body extending below the bottom end of the vial; (b) a needle-bearing member mounted within the body, the needle-bearing member comprising a hollow needle extending downwardly into the inner cavity of the body for puncturing the septum of a vial disposed in the inner cavity; (c) a luer-lock-bearing member mounted on the top end of the body, the luer-lock-bearing member comprising a top portion and a bottom portion separated by a radial wall, the top portion being a female luer-lock, the bottom portion including a tubular structure in fluid communication with the hollow needle; and (d) a valve disposed within the luer-lock-bearing member for controlling fluid flow from the bottom portion to the top portion, the valve being opened by attachment of the needleless syringe to the vial adapter.

Owner:BOSTON SCI SCIMED INC

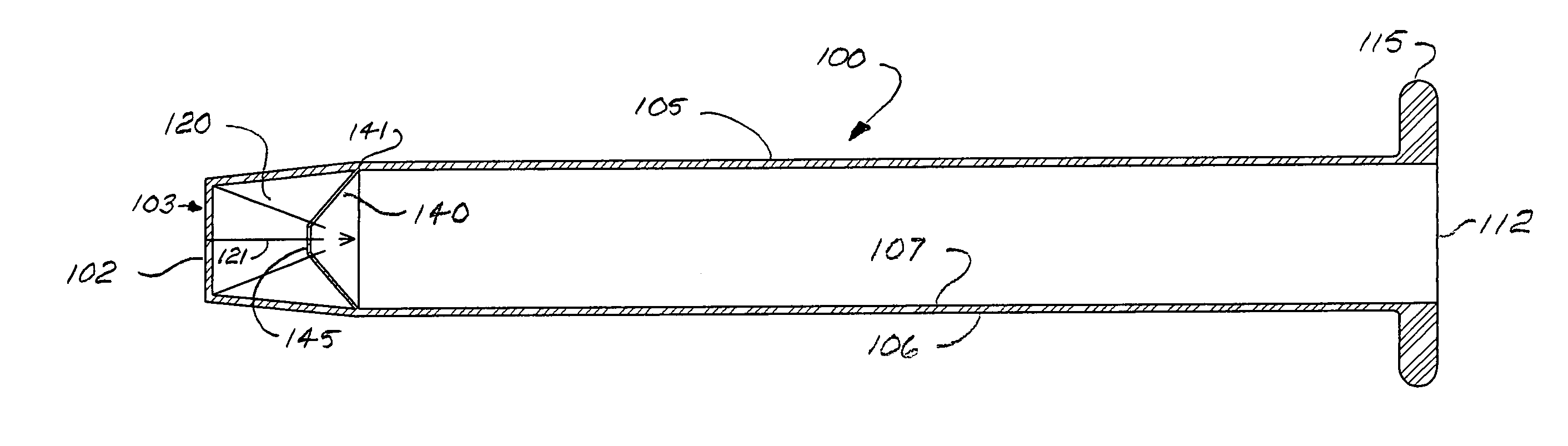

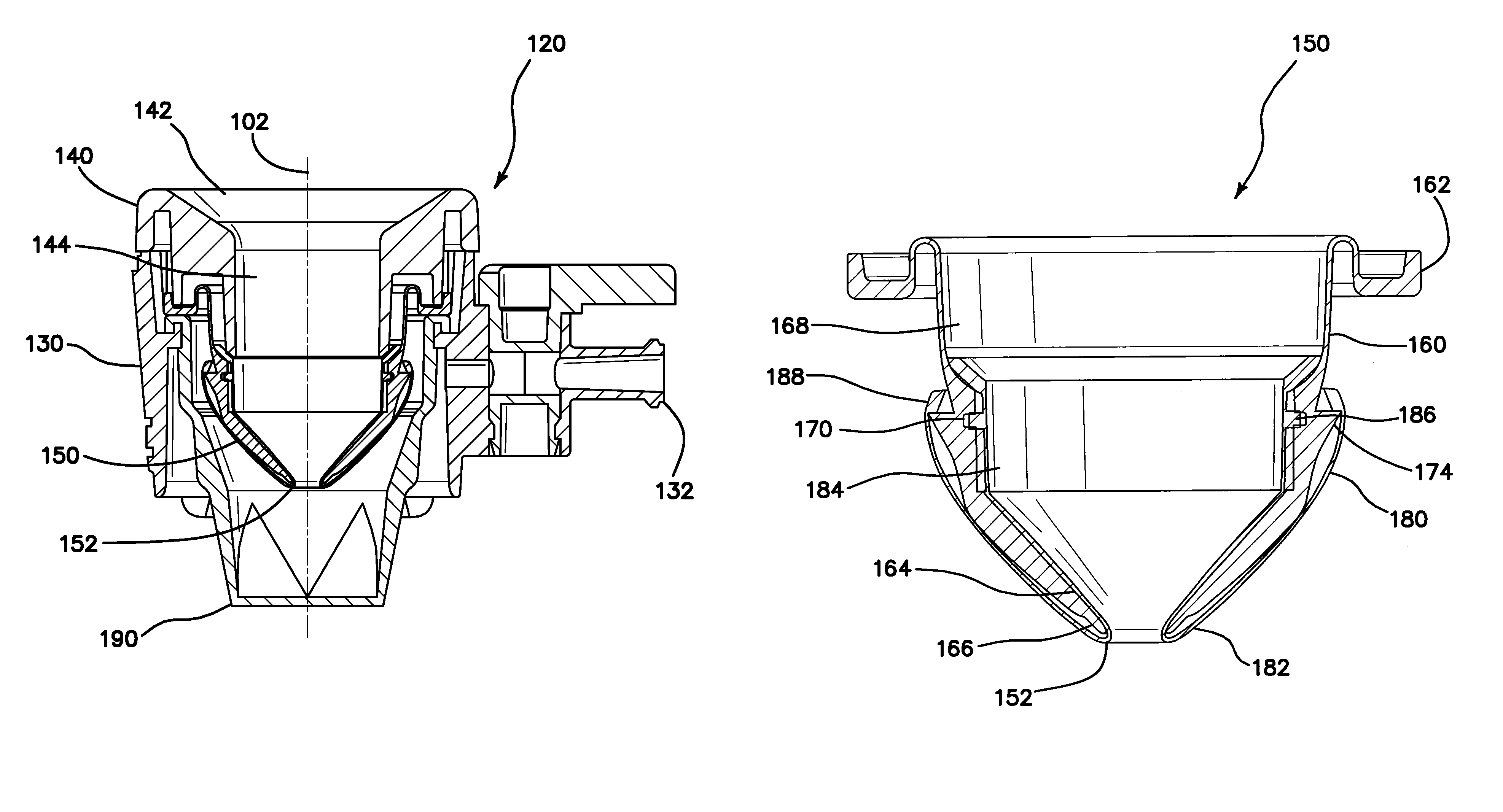

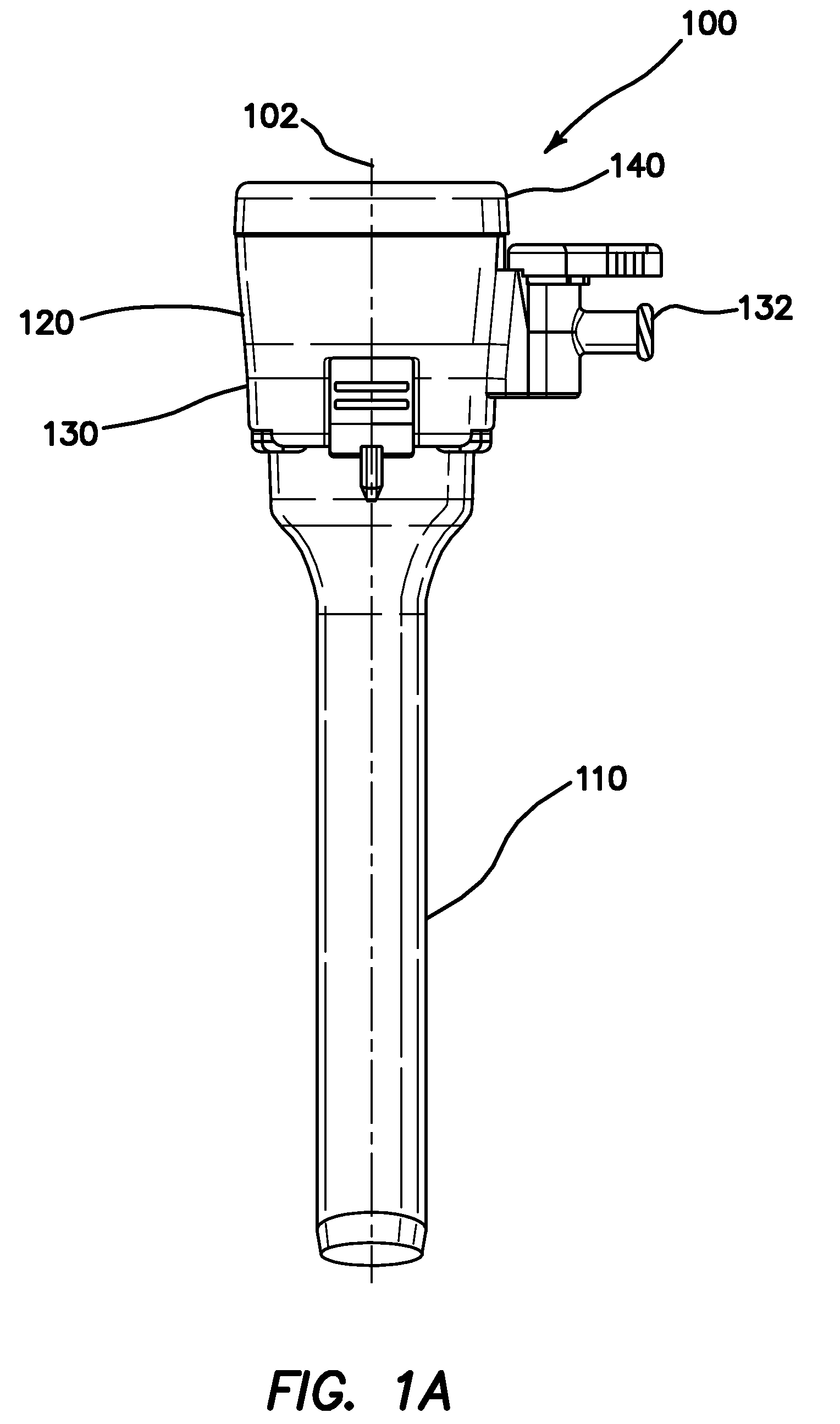

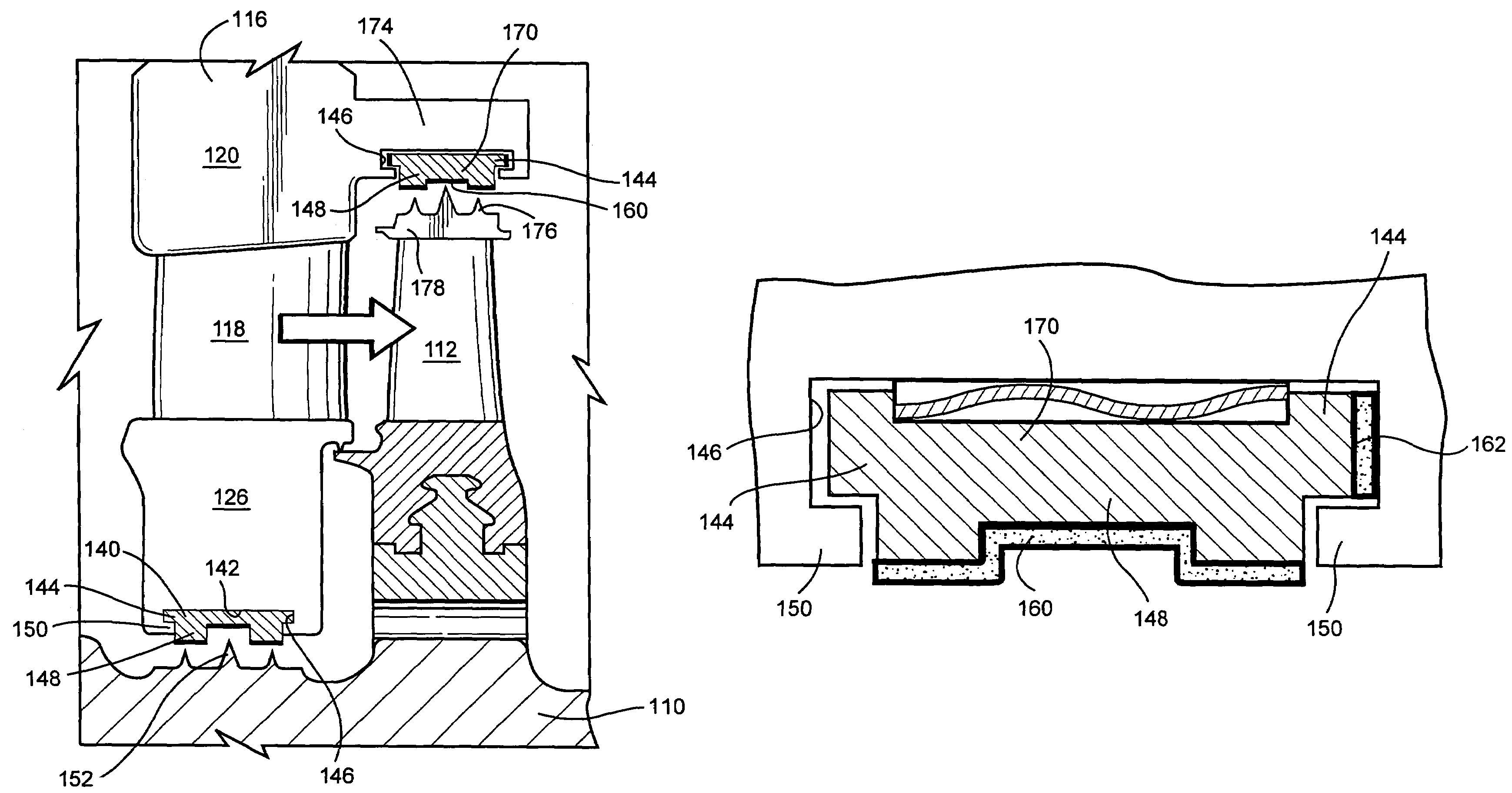

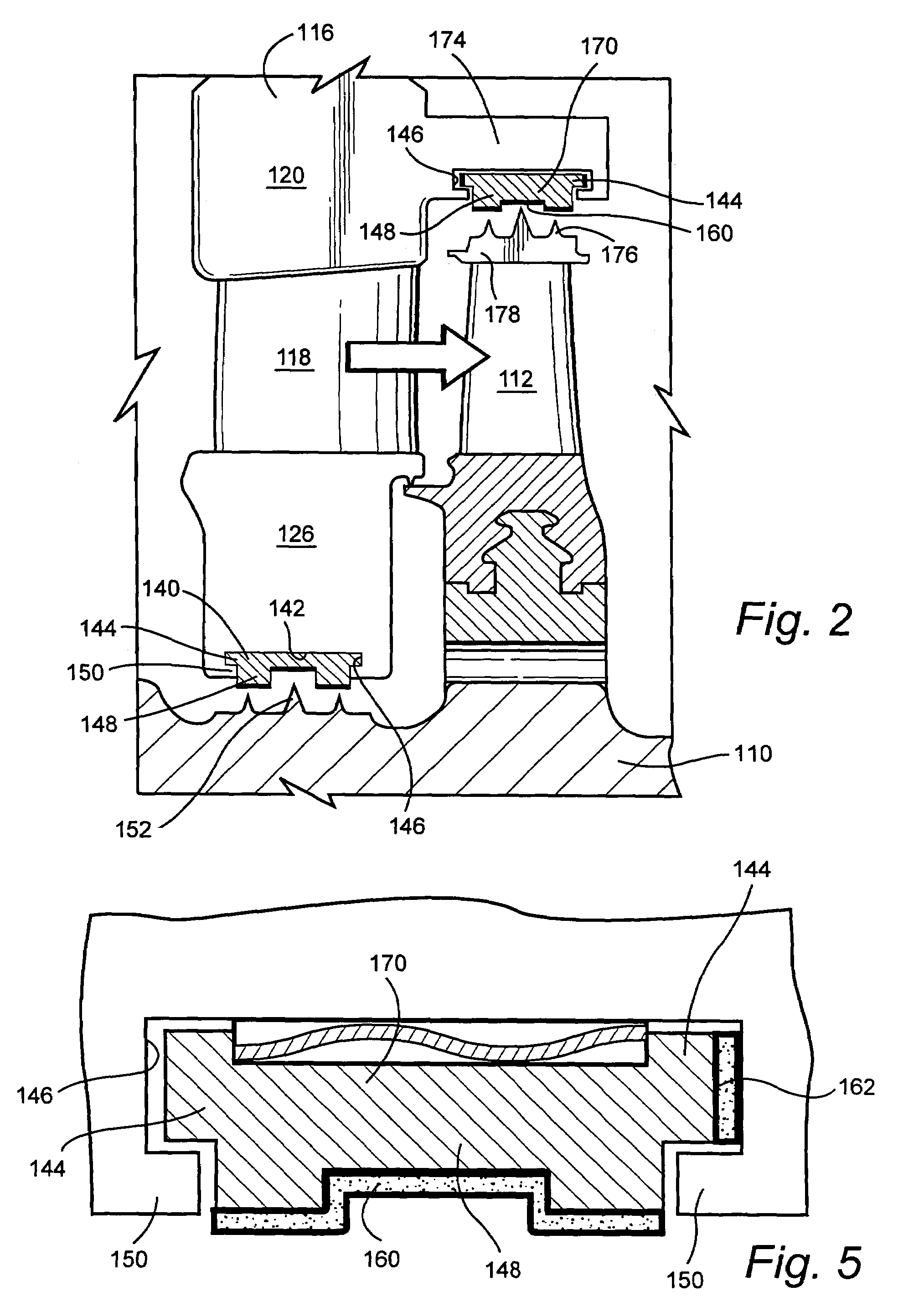

Self-sealing cannula having integrated seals

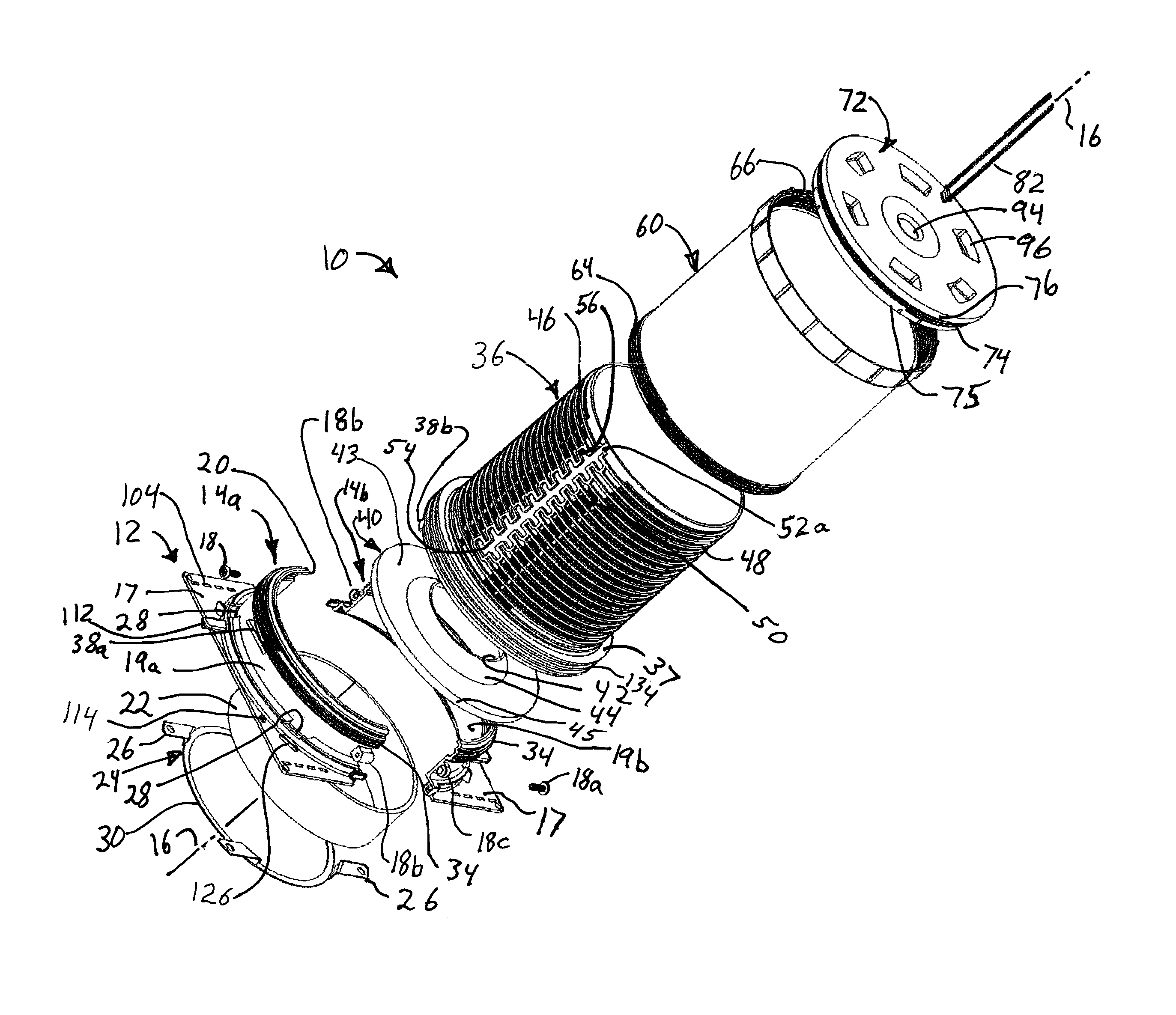

The present invention relates to a surgical access device comprising an elongate tubular member having a working channel and an axis extending between a proximal end and a distal end, a septum seal integrally formed at the distal end of the tubular member, and a zero seal disposed at the distal end of the tubular member and distal to the septum seal, the zero seal being sized and configured to seal when no instrument is in place within the working channel of the tubular member, and the zero seal being coupled to the septum seal and having properties to float with the septum seal relative to the tubular member. The tubular member may be formed from an elastomeric material. The tubular member has a wall that may be rigid or semi-rigid, and the tubular member may be reinforced with a coil along a portion of the tubular member. The tubular member may include a distal, mechanically deployable shielding portion. The zero seal may be a duckbill seal constructed with one or more intersecting sealing portions. The duckbill seal may comprise of opposing lip portions separated by a slit portion. The opposing lip portions are coated with or attached to a soft or occlusive material. The occlusive material is one of Kraton, polyurethane or the like. The occlusive lip portions allow a surgical item such as a suture to extend through the slit portion without disrupting the seal. In one aspect, the tubular member and the septum seal are molded together as a single unit and the zero seal is then bonded or fused to the septum seal. In another aspect, the tubular member, the septum seal and the zero seal are all molded together or integrally formed as a single unit. The tubular member may further comprise flexibility enhancing features to allow the tubular member to flex in response to a motion of a surgical instrument within the working channel of the tubular member.

Owner:APPL MEDICAL RESOURCES CORP

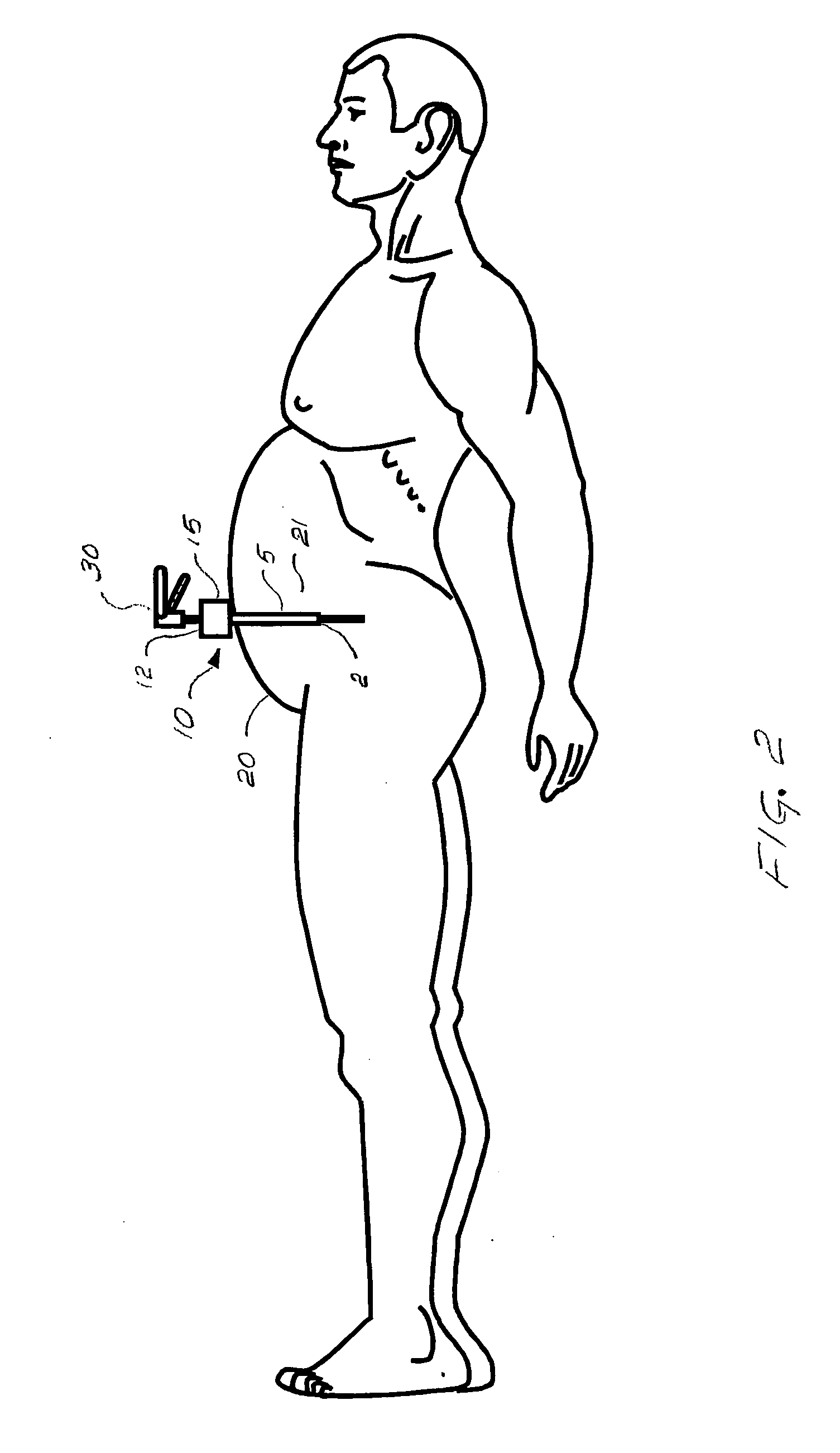

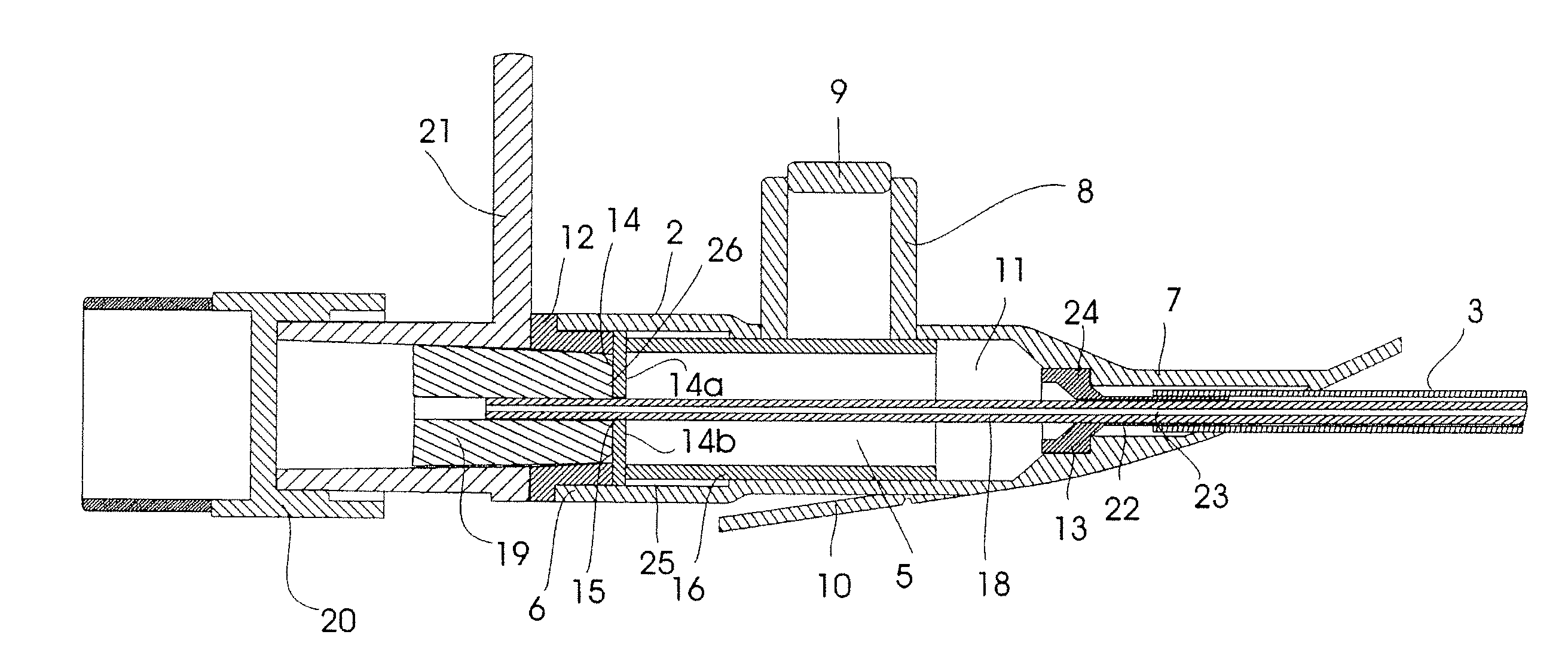

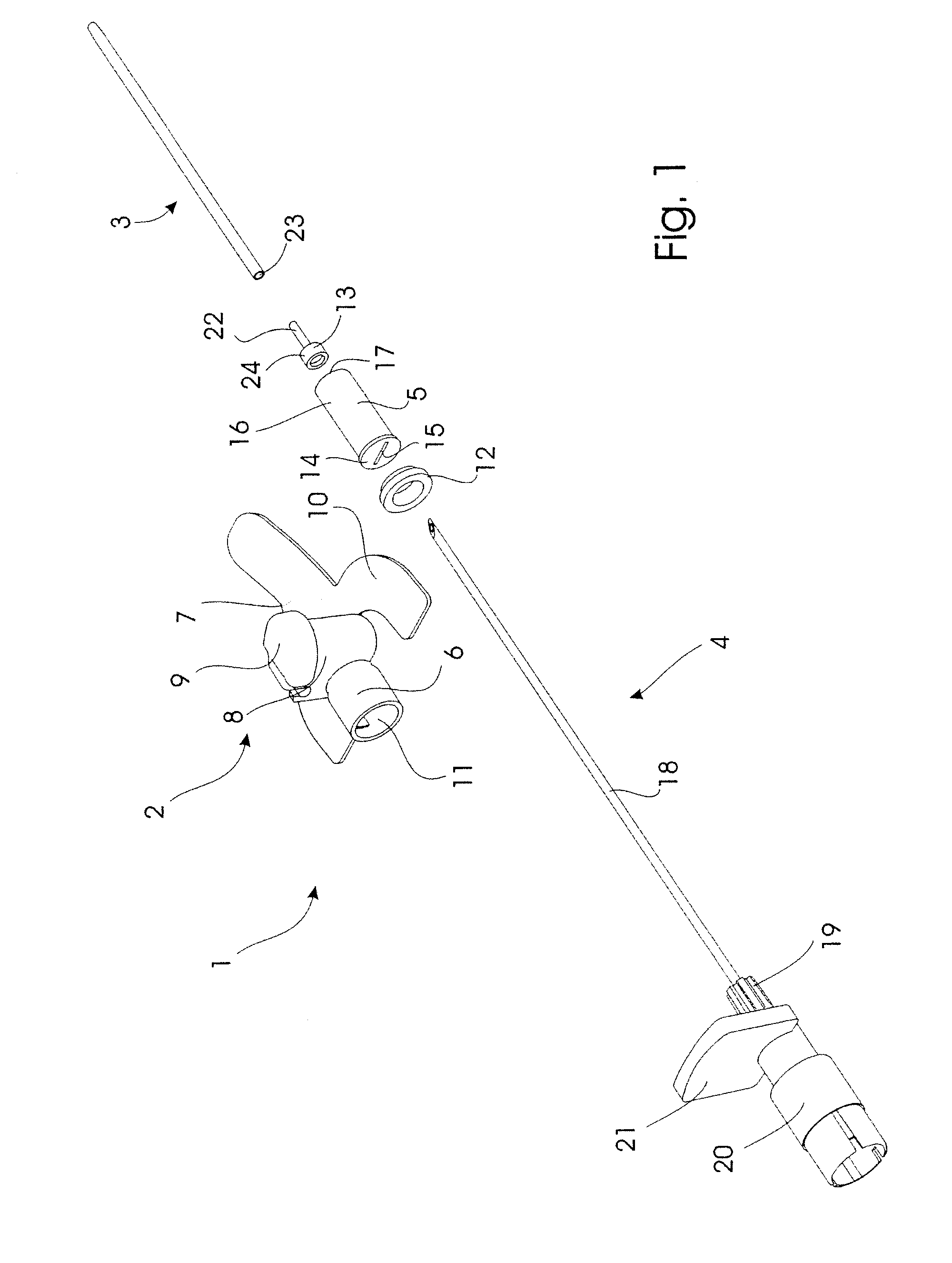

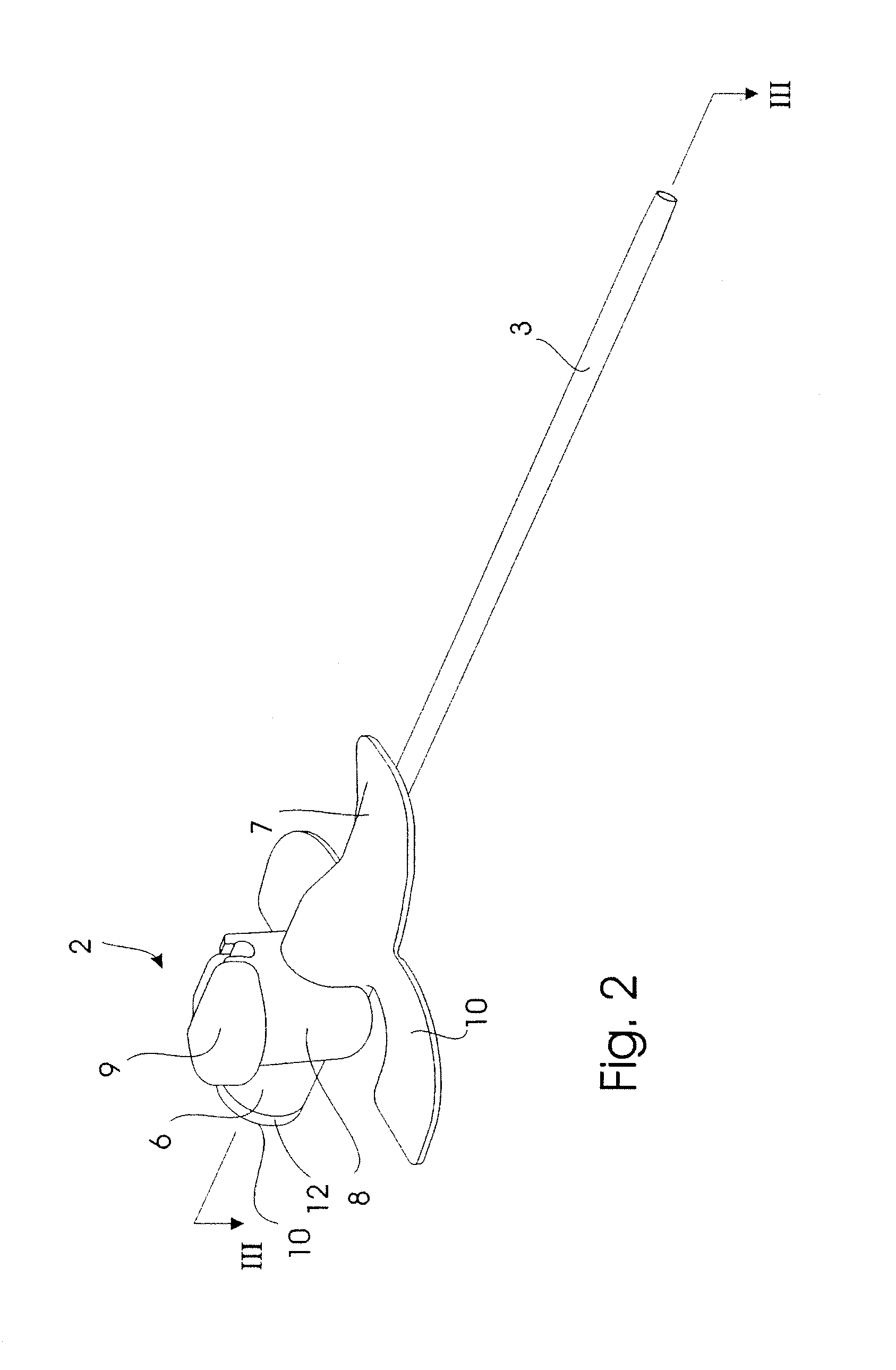

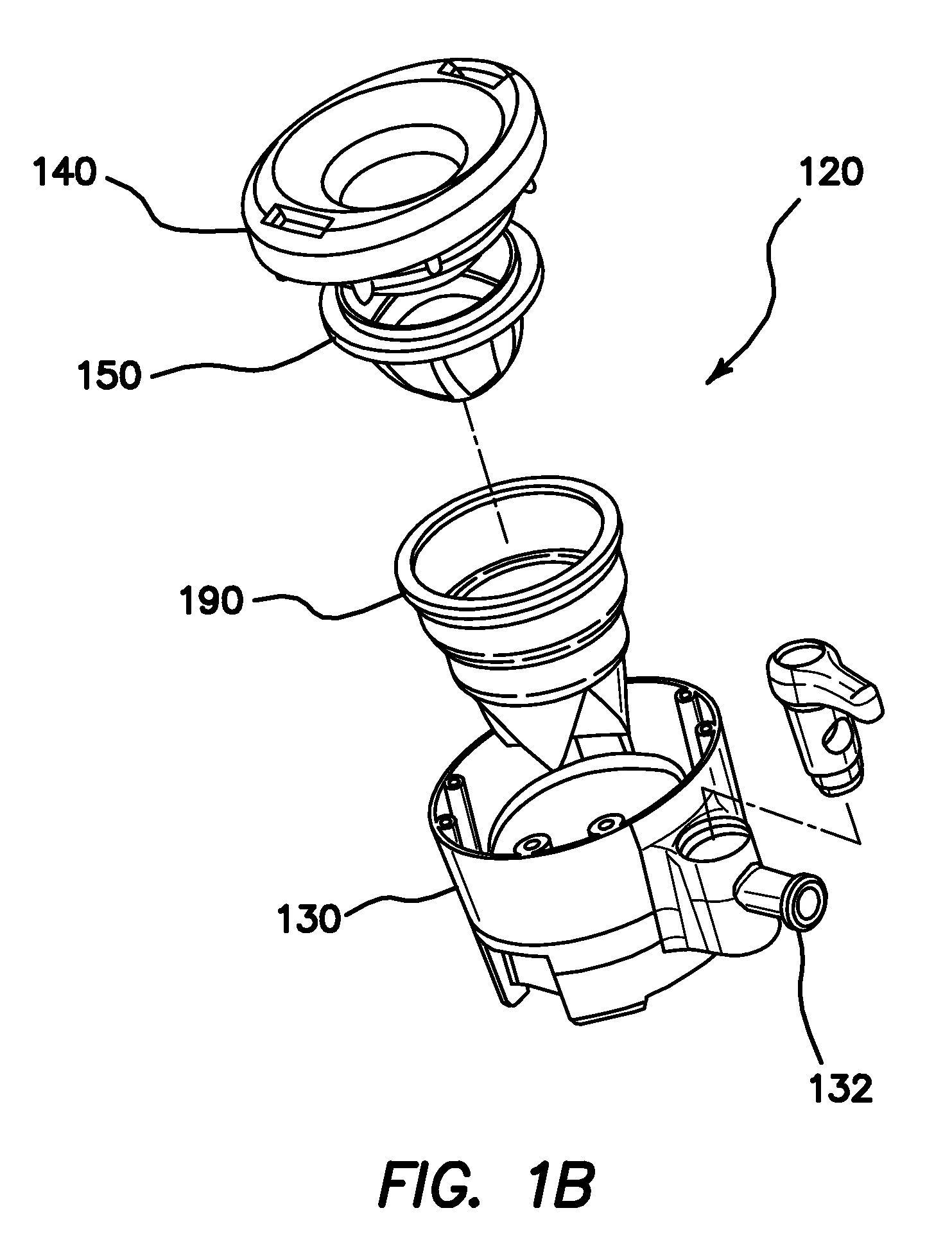

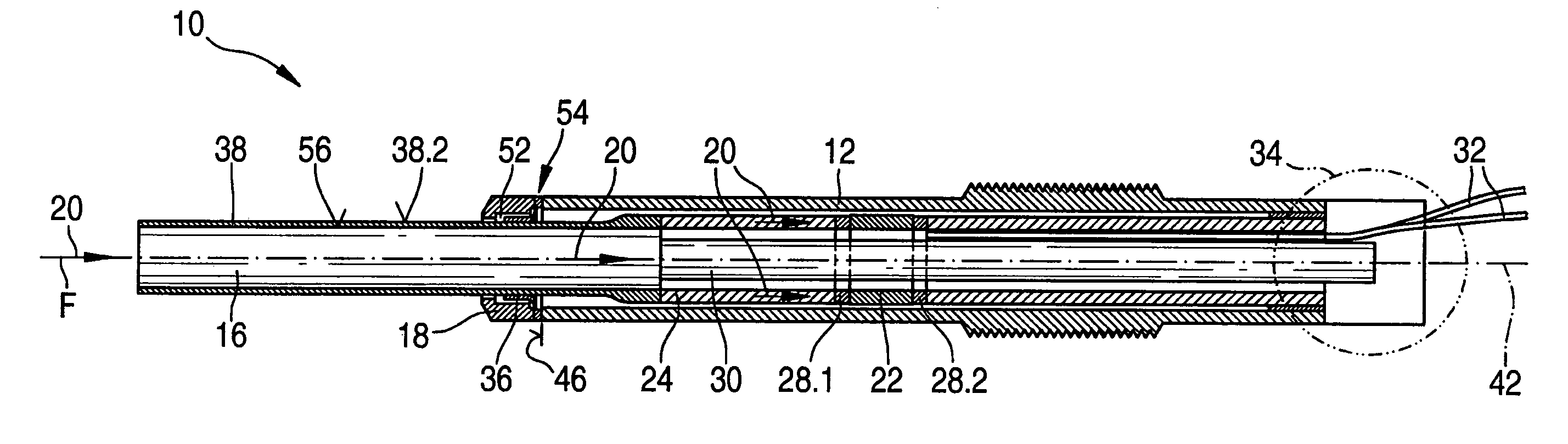

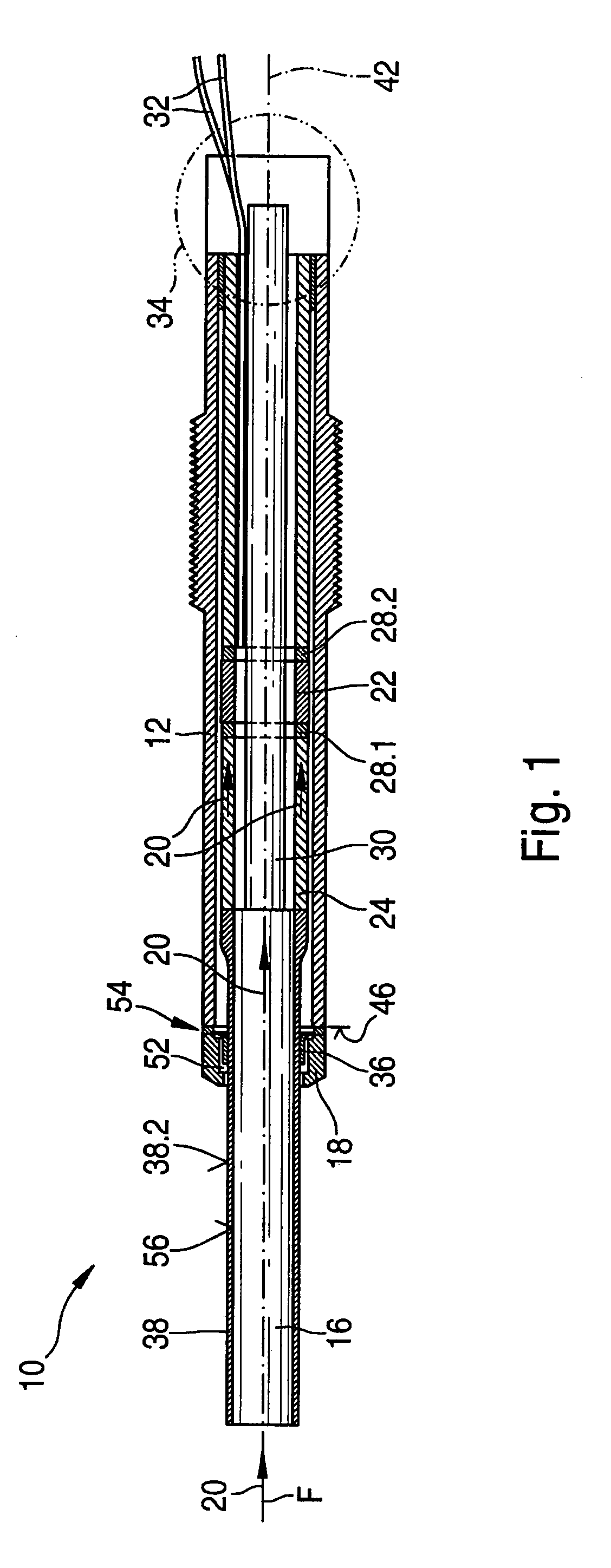

Peripheral catheter assembly and method of using it

ActiveUS20090036836A1Risk is reduced and evenAvoid problemsGuide needlesHaemostasis valvesVeinCatheter hub

A peripheral catheter assembly having a hollow catheter hub, a female proximal end, a distal end provided with a catheter tube, at least one infusion port located between the distal and proximal ends, a hollow needle module that includes a needle held by a male socket arranged to sealingly engage the female proximal end, and a sealing member engaged inside the catheter hub which serves for facilitating venipuncture without unintended splashing of blood. A sealing valve that includes a septum seal having a weakened portion surrounded by deflectable septum walls, and a hollow tubular extension which protrudes towards a free end from the periphery of the septum seal and extends inside the catheter hub past the infusion port towards the distal end of the catheter hub provide a self-closable sealing member which provide the physician the freedom to leave the patient when the needle module is retracted.

Owner:TRADINCO

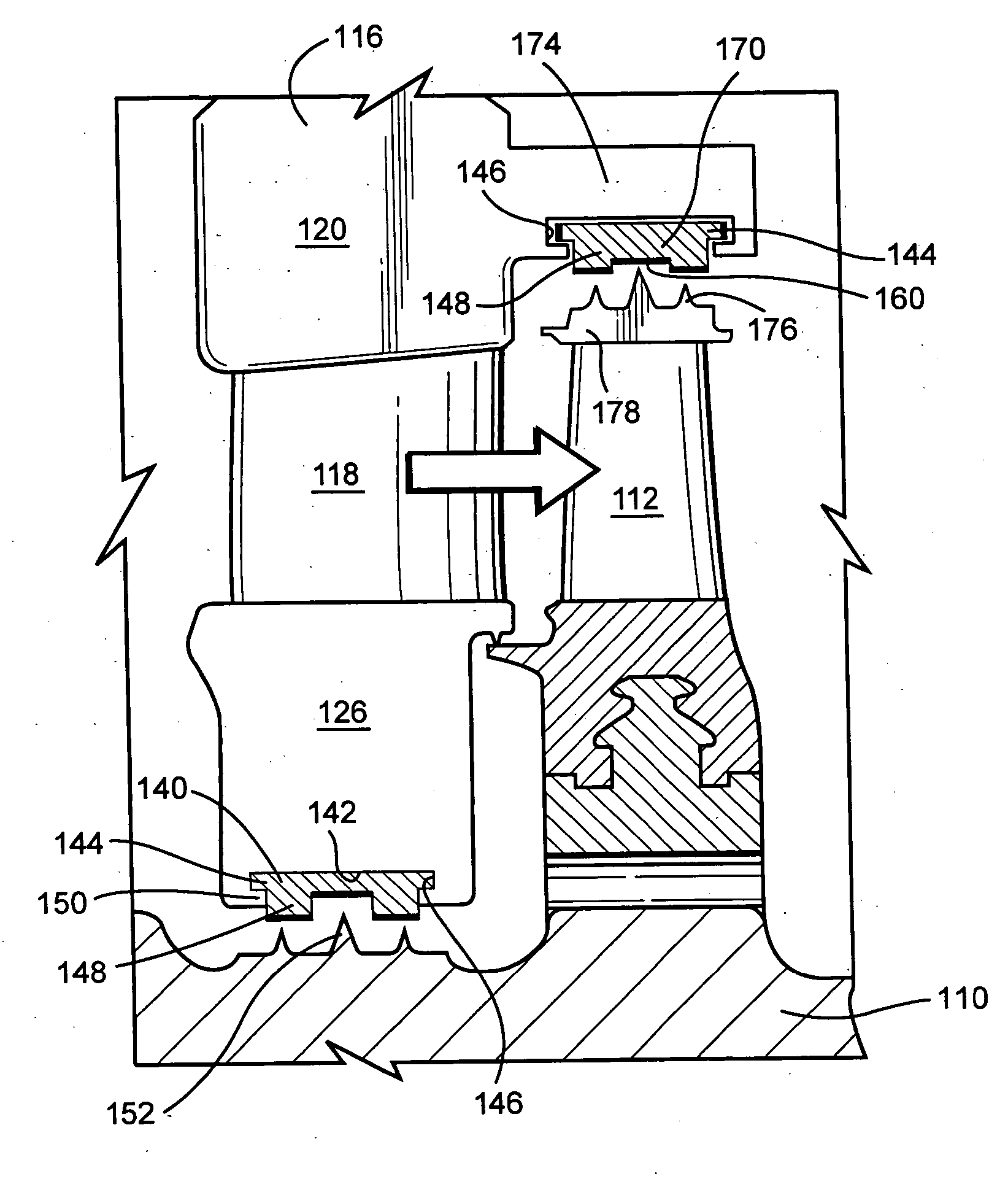

Seal housing having anti-inversion features

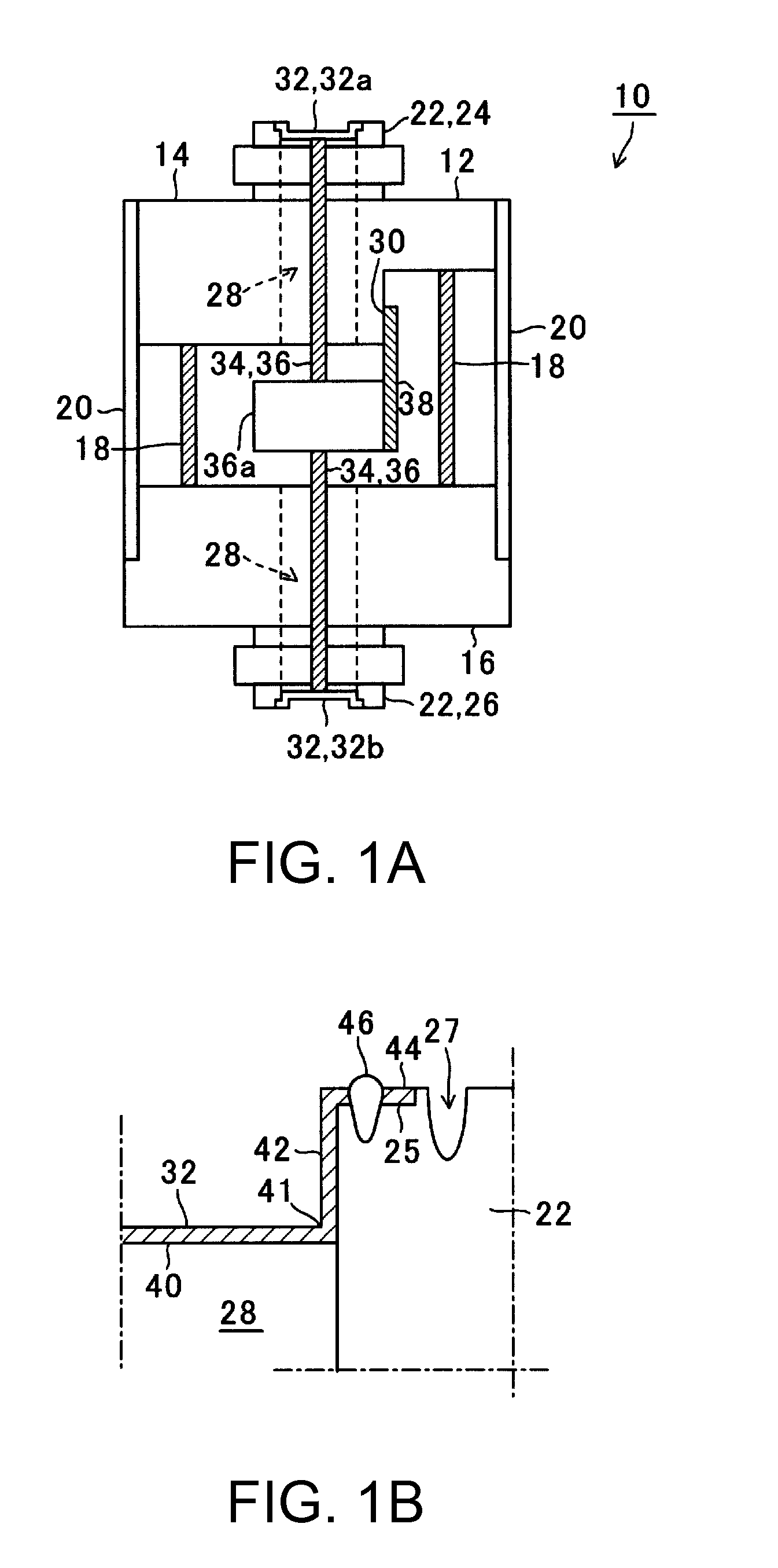

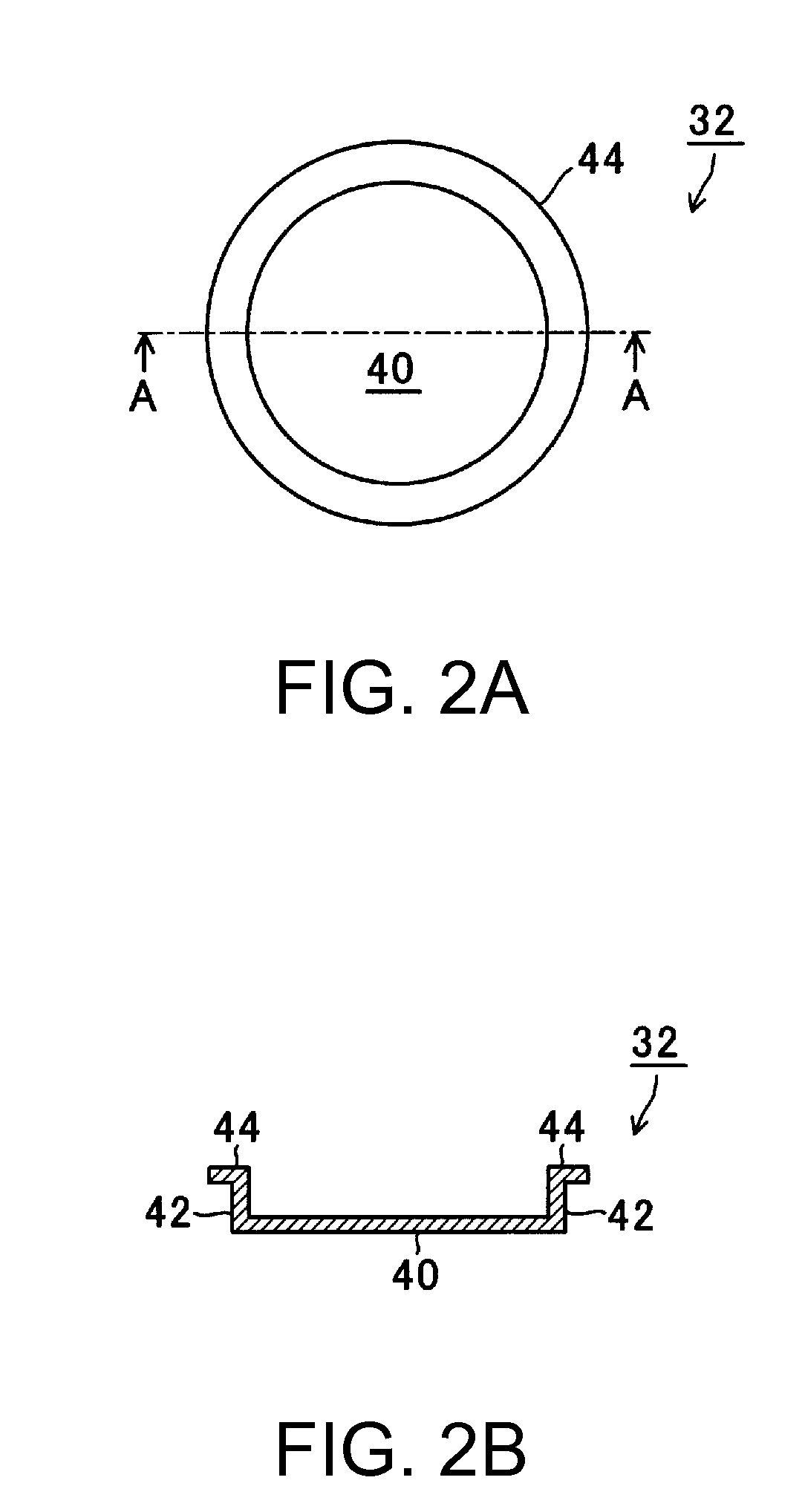

InactiveUS7591802B2Avoid excessive wearFacilitates over-center positioningEar treatmentCannulasDiaphragm sealEngineering

The invention is directed to a trocar adapted to form a seal around a surgical instrument, the trocar comprising a cannula having an axis extending between a proximal end and a distal end; a housing having a proximal wall and forming with the cannula a working channel sized and configured to receive the instrument; a septum seal disposed in the housing and extending transverse to the axis of the cannula across the working channel, the septum seal having a normal state when the instrument is absent from the working channel and a stretched state when the instrument is being withdrawn from the working channel; portions of the proximal wall of the housing defining an orifice sized and configured to receive the instrument into the working channel; and an elastomeric ring-shaped projection extending axially distally between the proximal wall and the septum seal, the ring-shaped projection having an axial length adapted to deform to prevent inversion and binding of the septum seal and the orifice upon withdrawal of the surgical instrument. In particular, the septum seal is prevented from reaching the orifice in the proximal wall of the housing when the instrument is withdrawn. The projection may be bonded, insert-molded, or compressively fitted to the proximal wall of the housing. The projection may be formed of an elastomeric material such as natural or synthetic rubber. The projection may further comprise a plurality of portions or fingers extending axially distally from the proximal wall, each of the extending portions or fingers may further include a living hinge. In another aspect, the ring-shaped projection may be formed on the surface of the septum seal instead of the proximal wall of the housing. That is, the ring-shaped projection may be formed to extend axially proximally from the surface of the septum seal toward the proximal wall of the housing.

Owner:APPL MEDICAL RESOURCES CORP

Luer activated medical connector having a low priming volume

Owner:CAREFUSION 303 INC

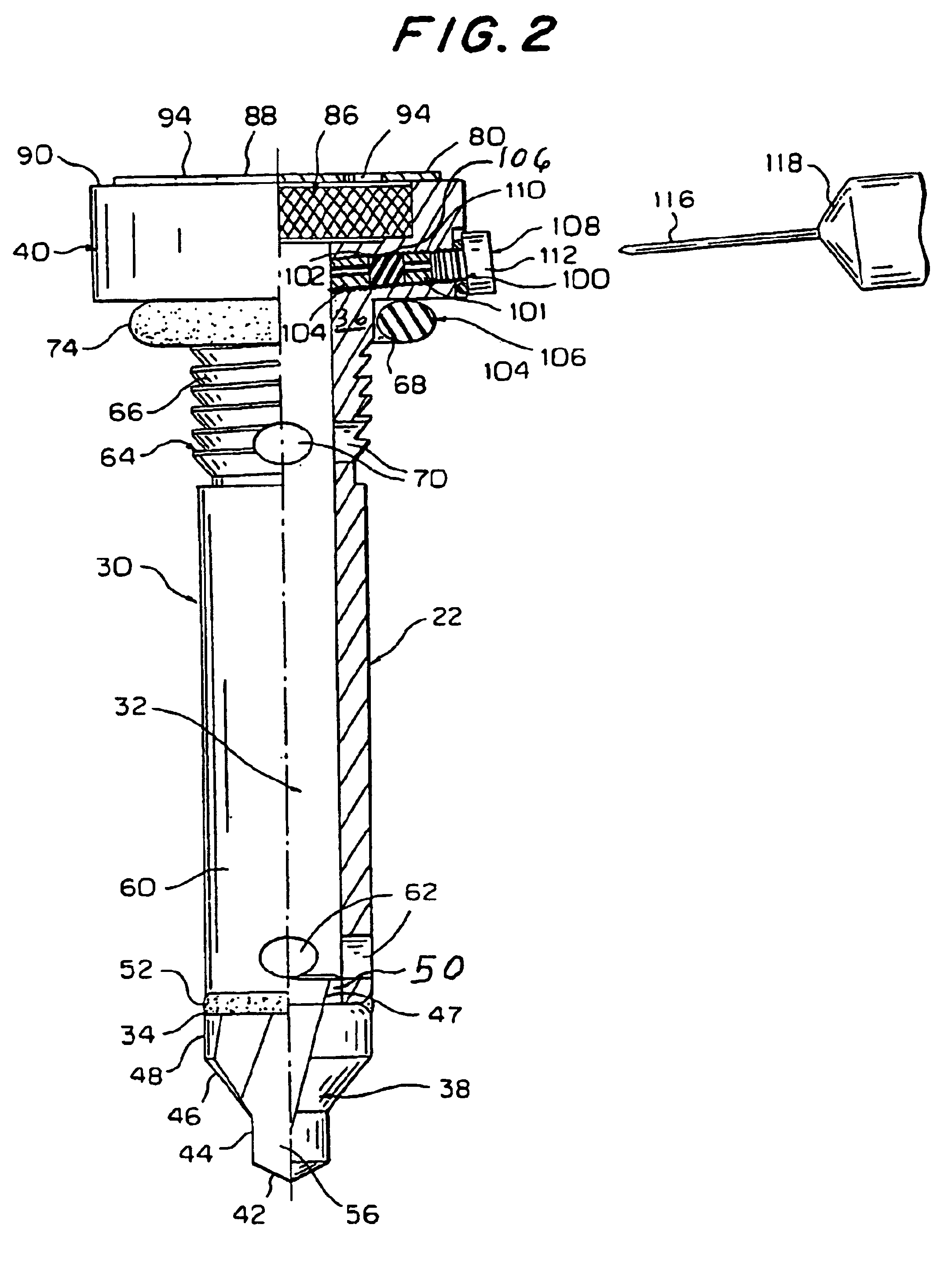

Probe with integral vent, sampling port and filter element

A probe with an integral filtered vent and sampling port has a hollow shaft configured as a drill bit which in use passes through the lid of a drum containing waste products within a liner. The hollow shaft has a penetrating tip and at lest two radial bores, one of which is positioned to open to the space within the liner and the other of which is positioned to open to the space above the liner and between the liner and drum lid. The shaft has a head with a pocket which contains a filter element, the head also having a radial sampling port with a septa seal. In order to sample head space gases, a hypodermic needle is pushed through the septa seal into the longitudinal bore of the hollow shaft, and then withdrawn, allowing the septa seal to close behind the needle. The probe is especially useful for sampling nuclear waste stored within drums having liners. This is because the probe has a first radial port adjacent the penetrating tip thereof which samples gas within the liner and a second radial port disposed between the liner and lid for sampling gas which has escaped past the liner.

Owner:NUCFIL LLC

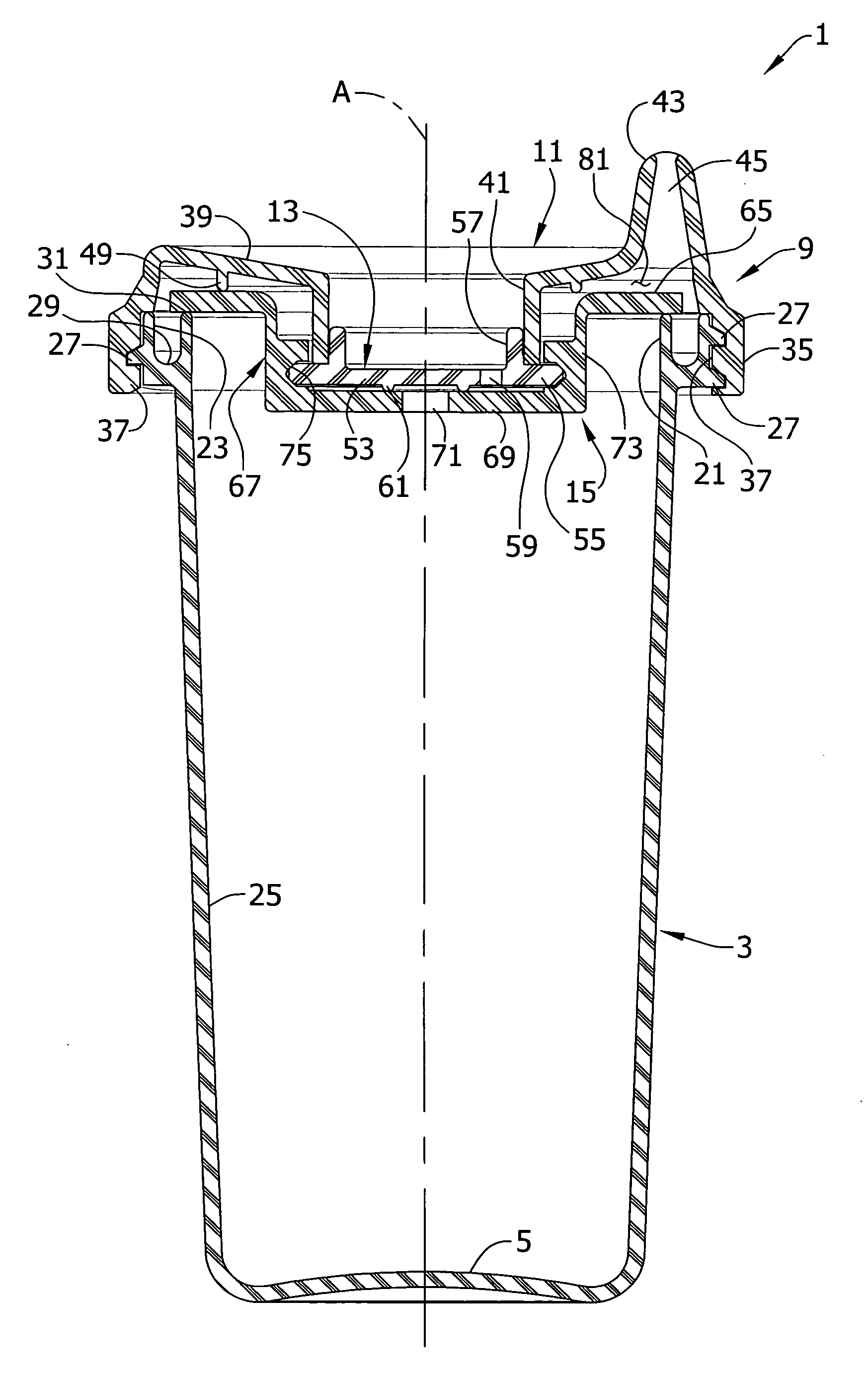

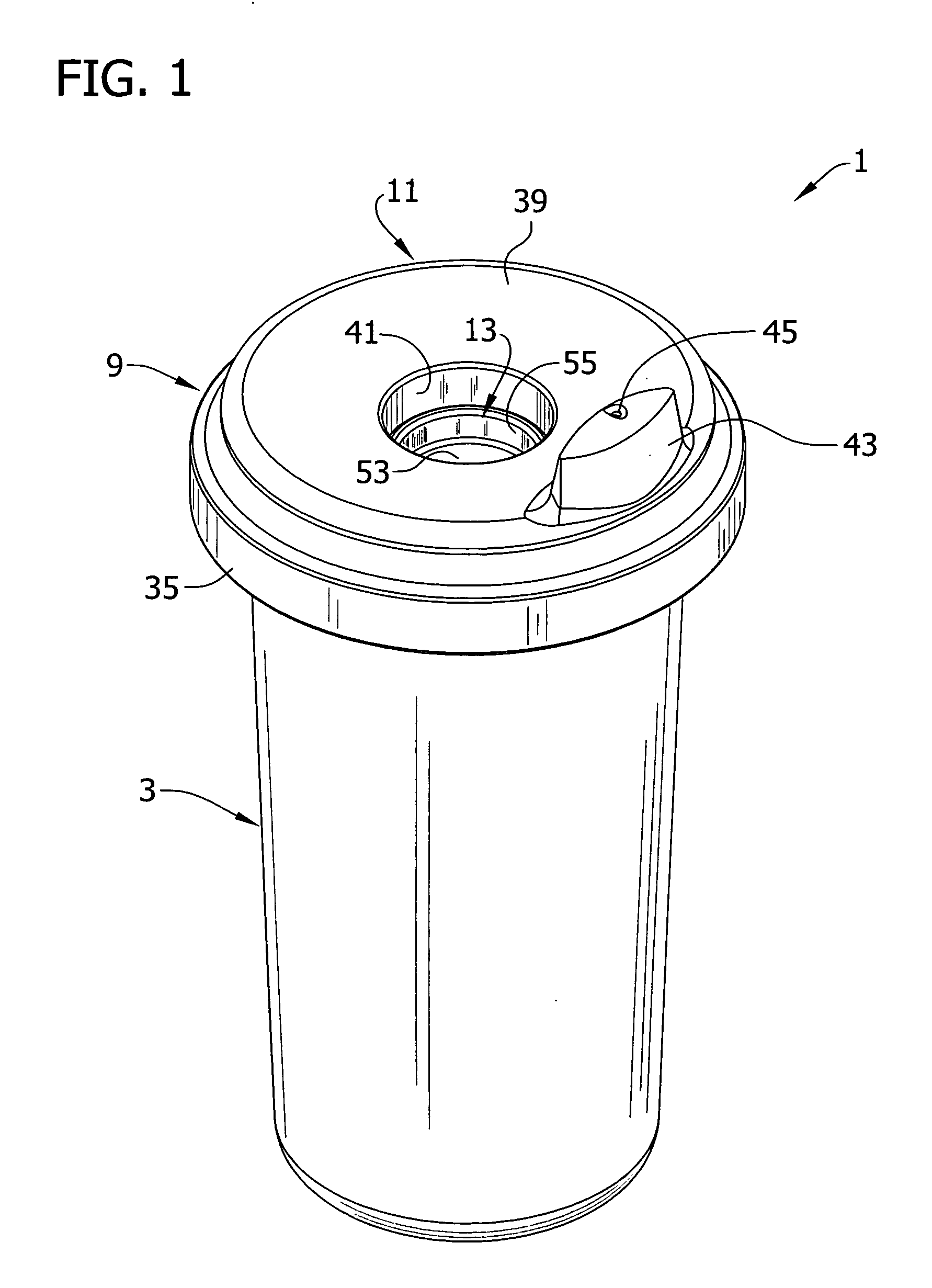

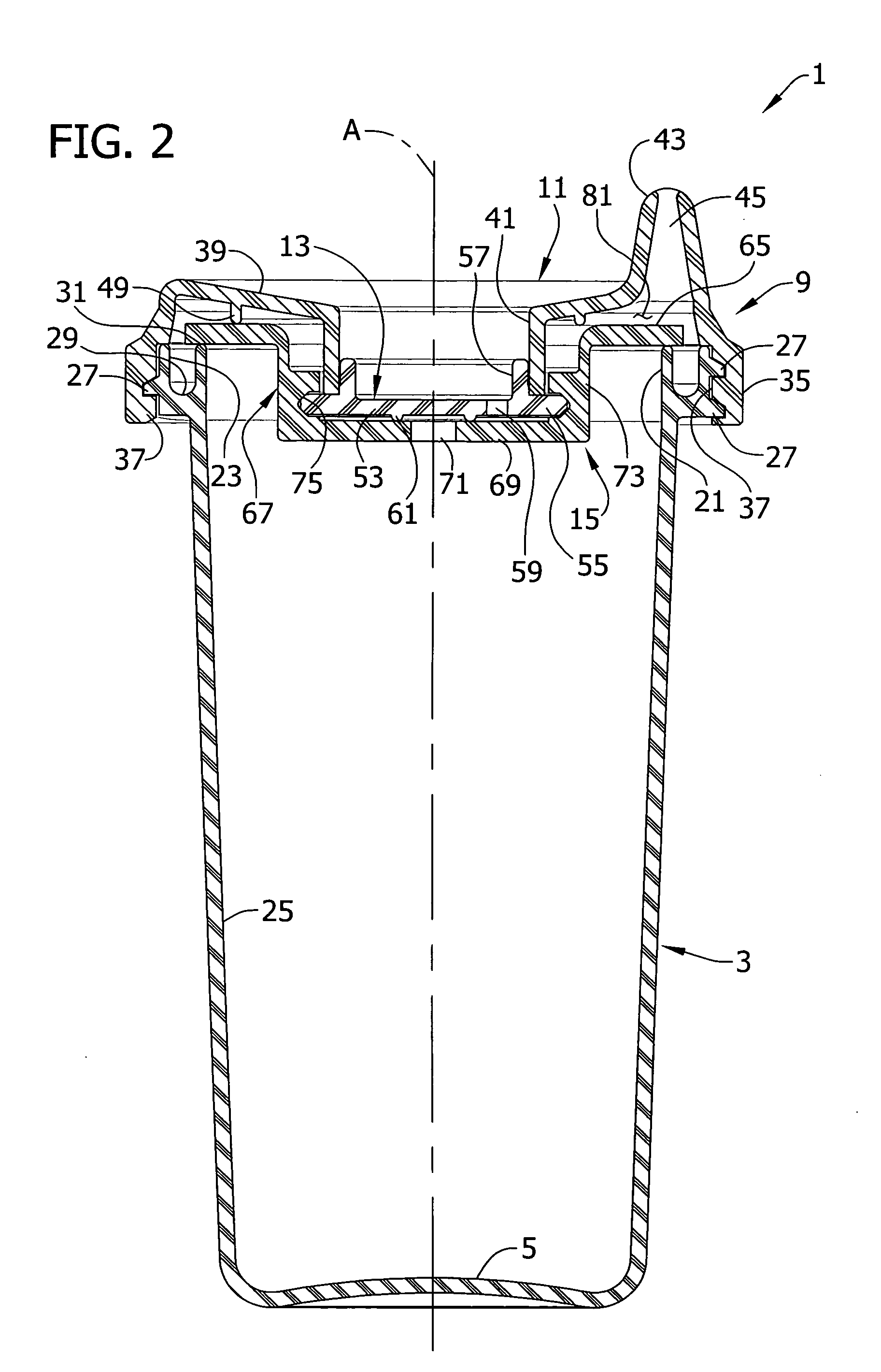

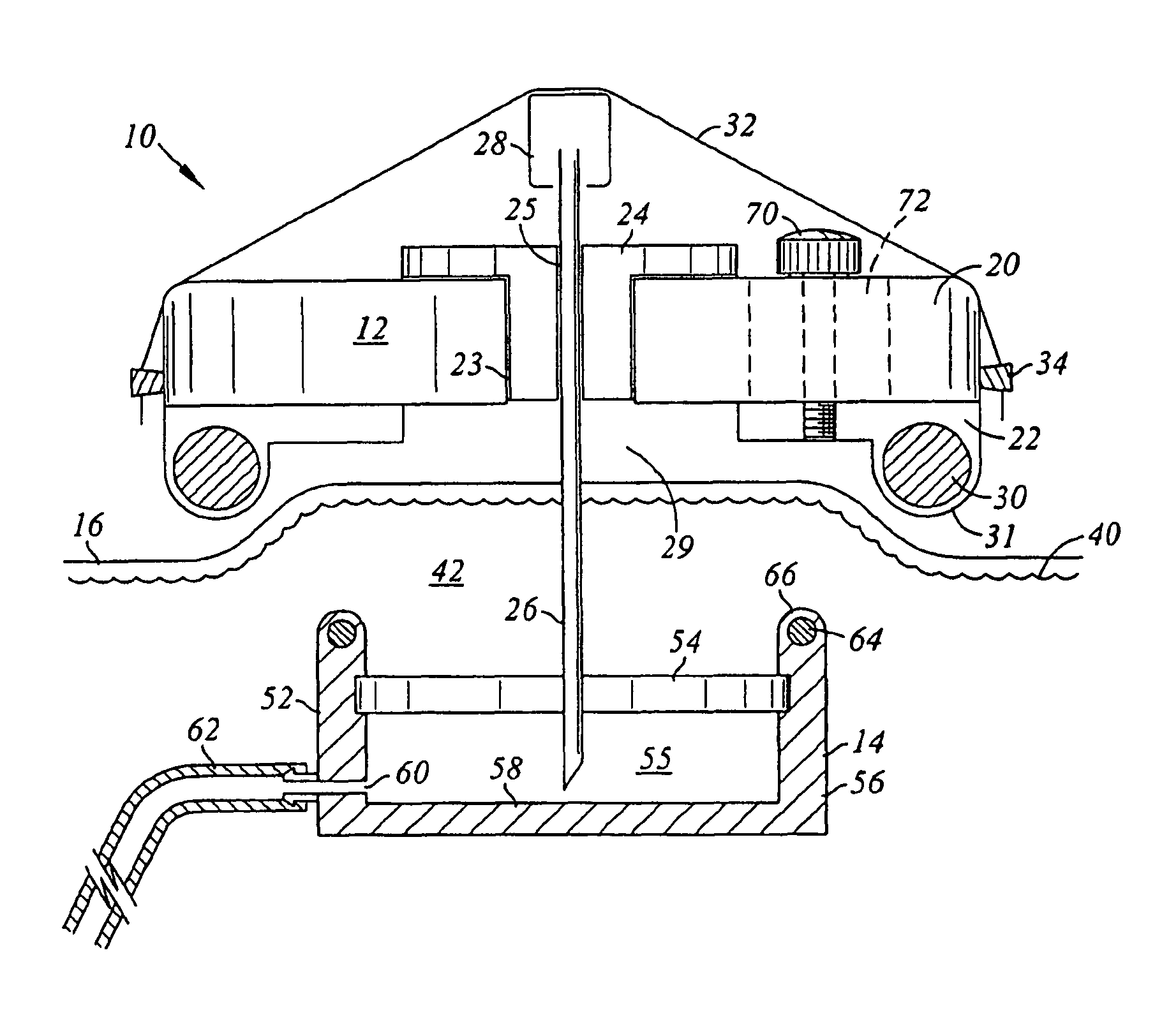

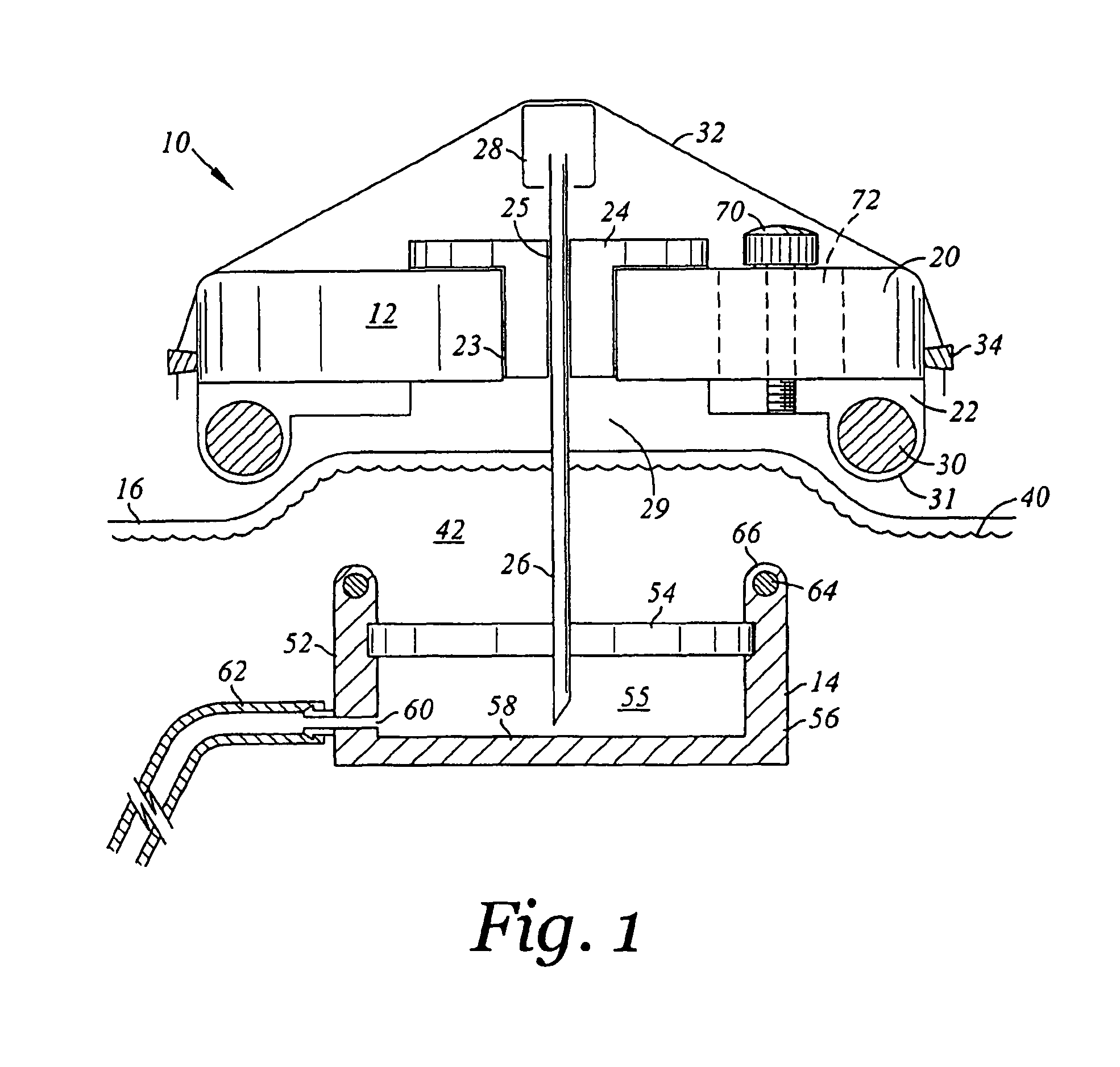

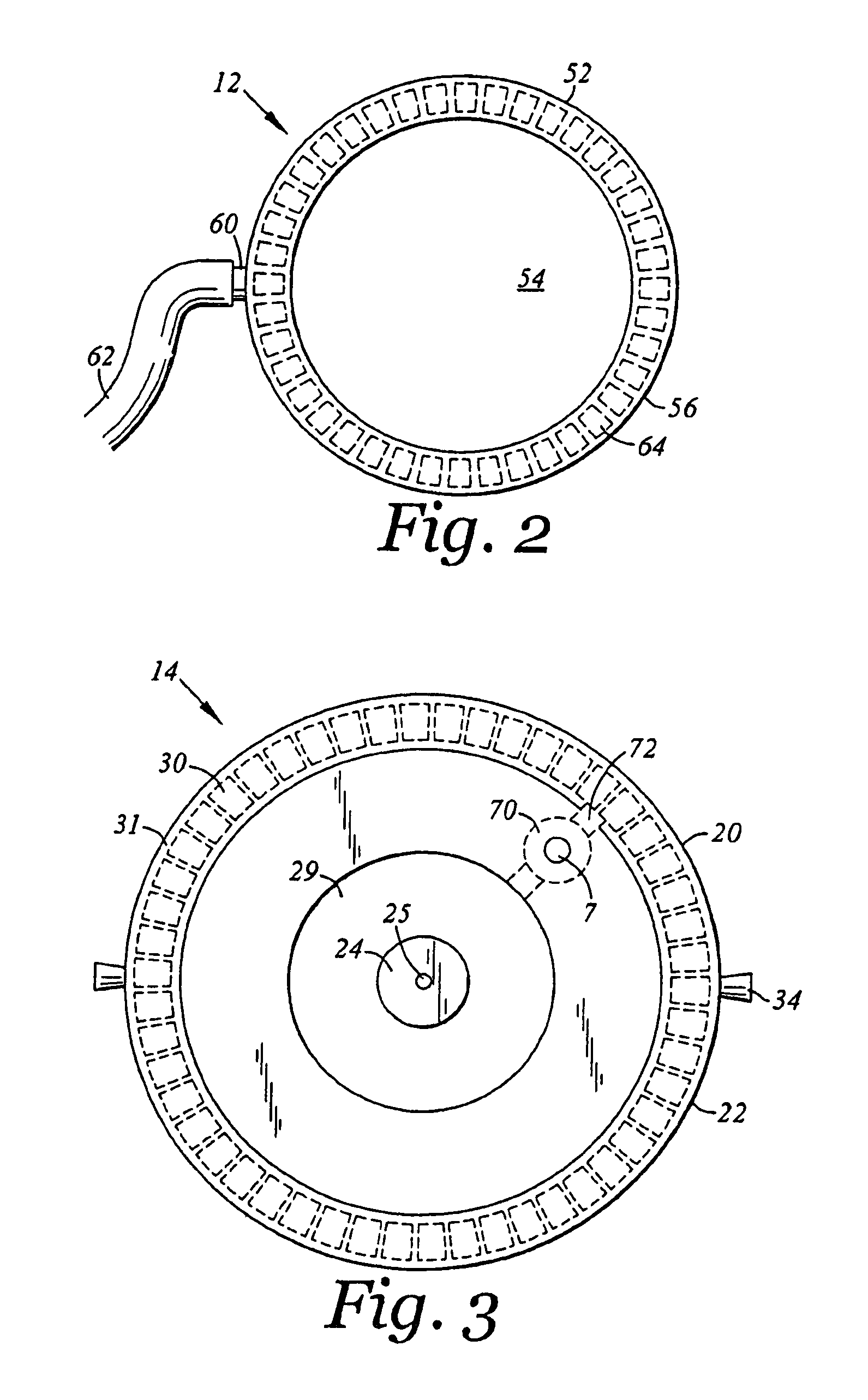

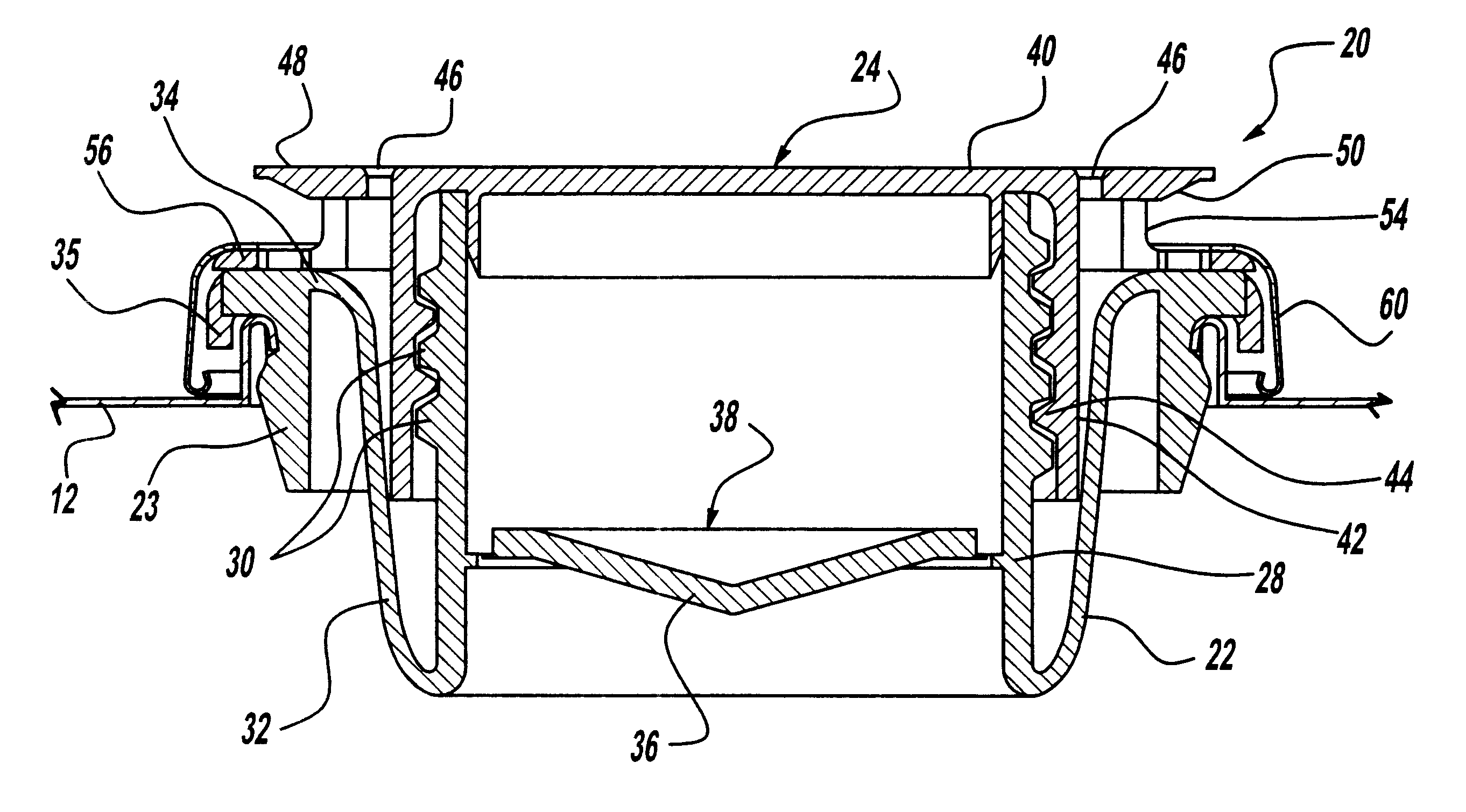

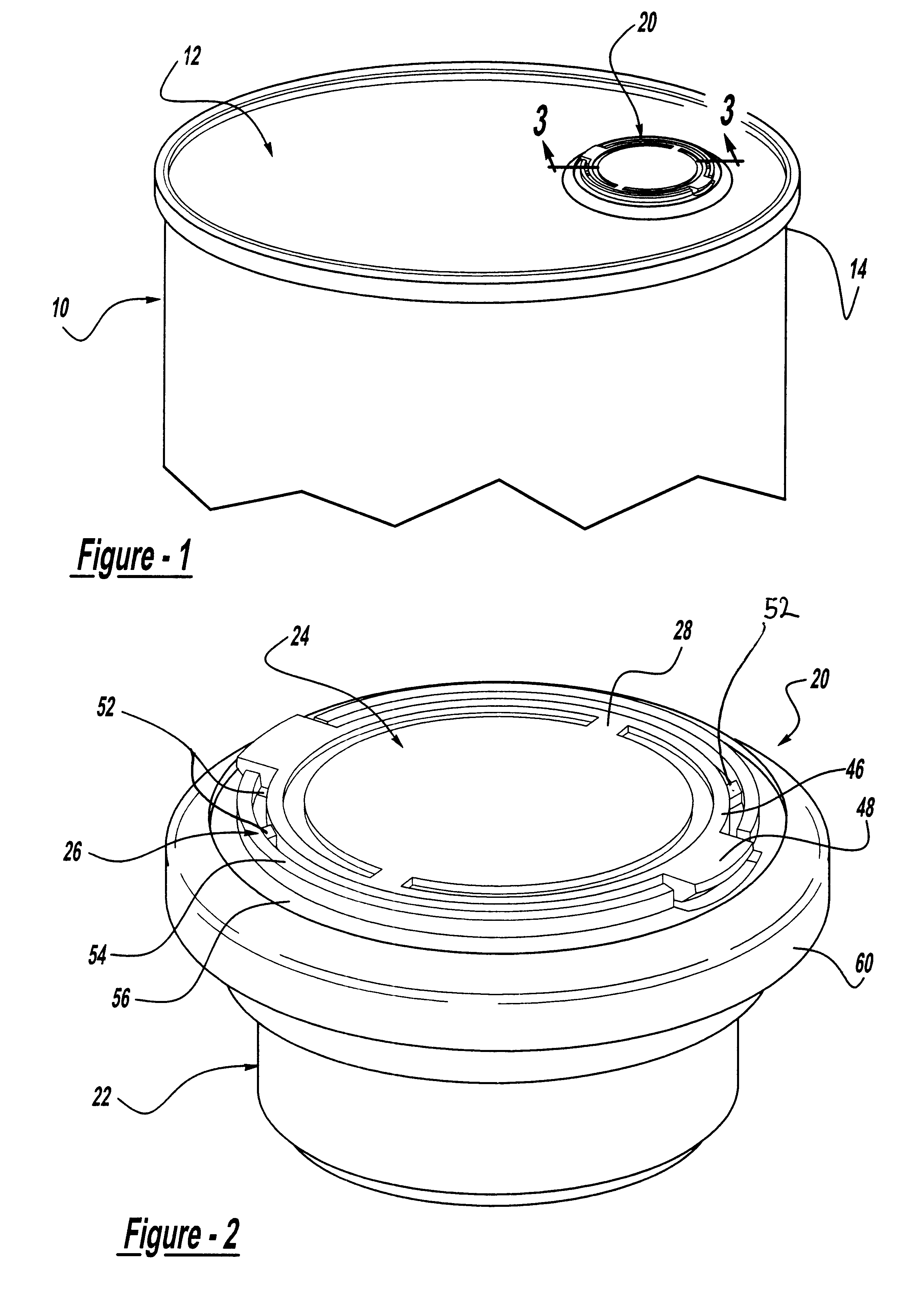

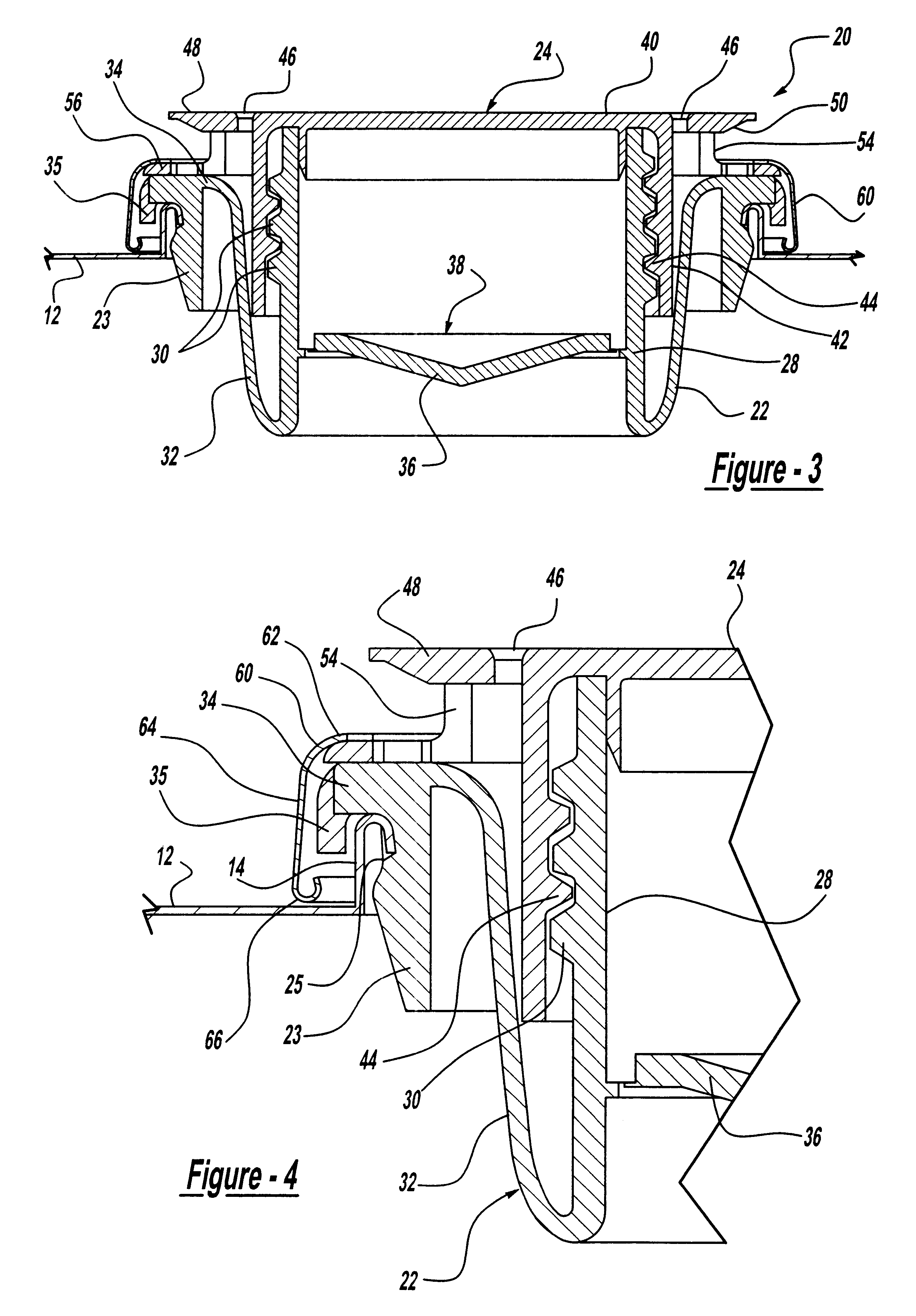

Leak resistant drinking cup

A leak resistant drinking cup has a diaphragm seal for normally closing an open top of a liquid container of the cup. The seal can be opened to permit liquid to flow past it and out of the cup upon application of a vacuum pressure by the person, typically a small child, drinking from the cup. The diaphragm seal has a peripheral edge margin that can be deflected upward by the vacuum pressure to open a path out of the drinking cup. A hold down rib may be employed to control the locations where the peripheral edge margin is permitted to deflect.

Owner:HANDI CRAFT

Luer activated medical connector having a low priming volume

Owner:CAREFUSION 303 INC

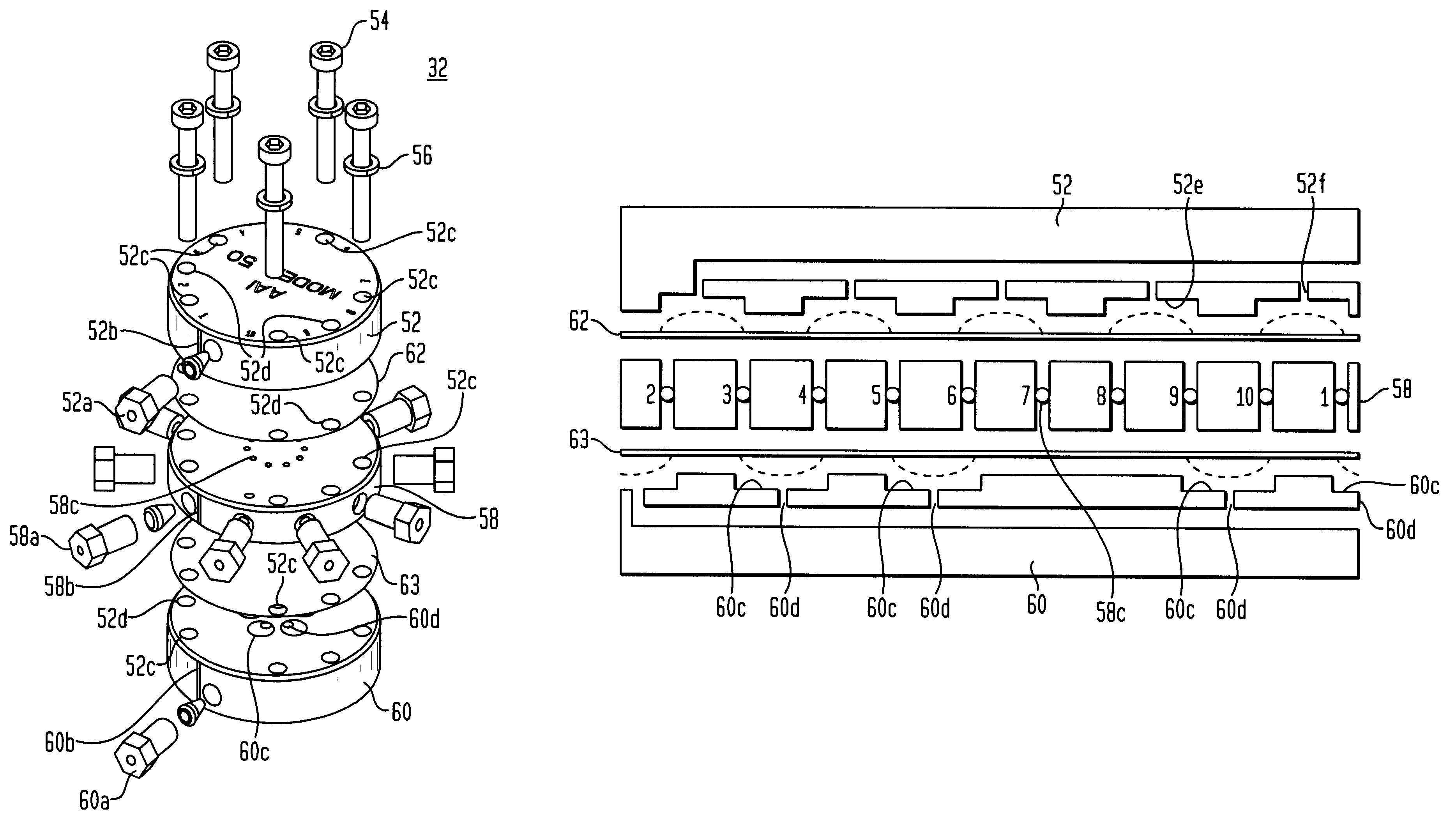

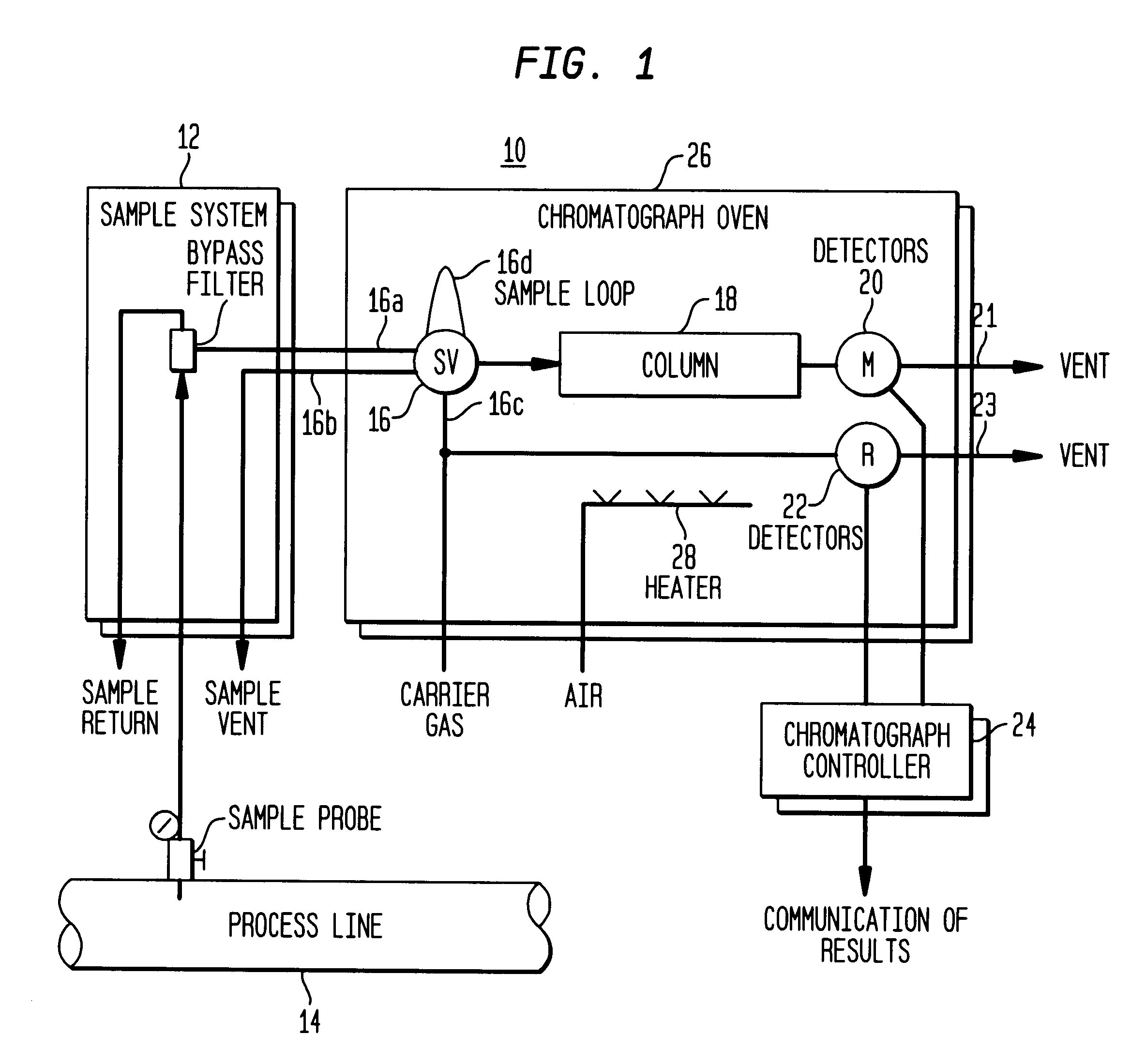

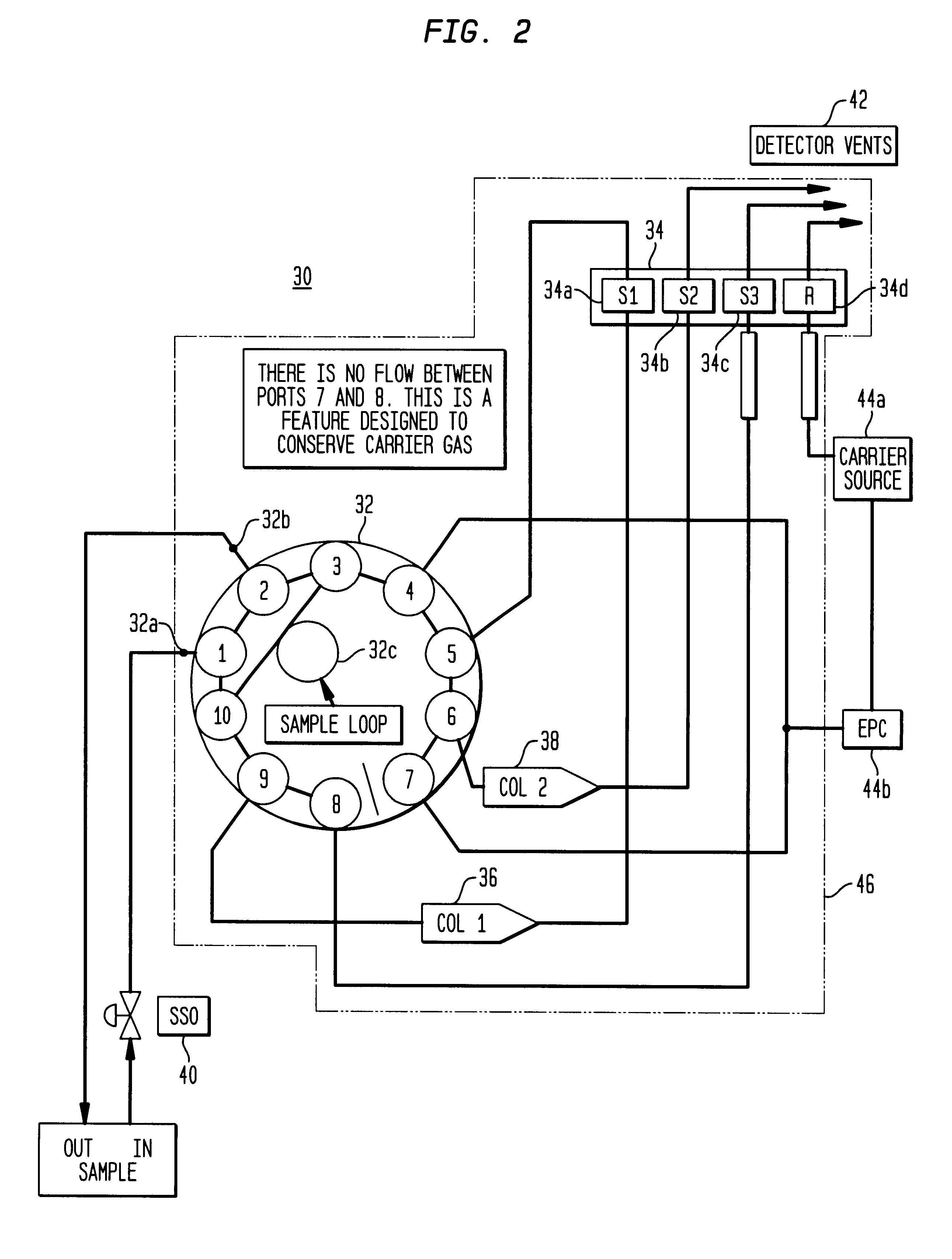

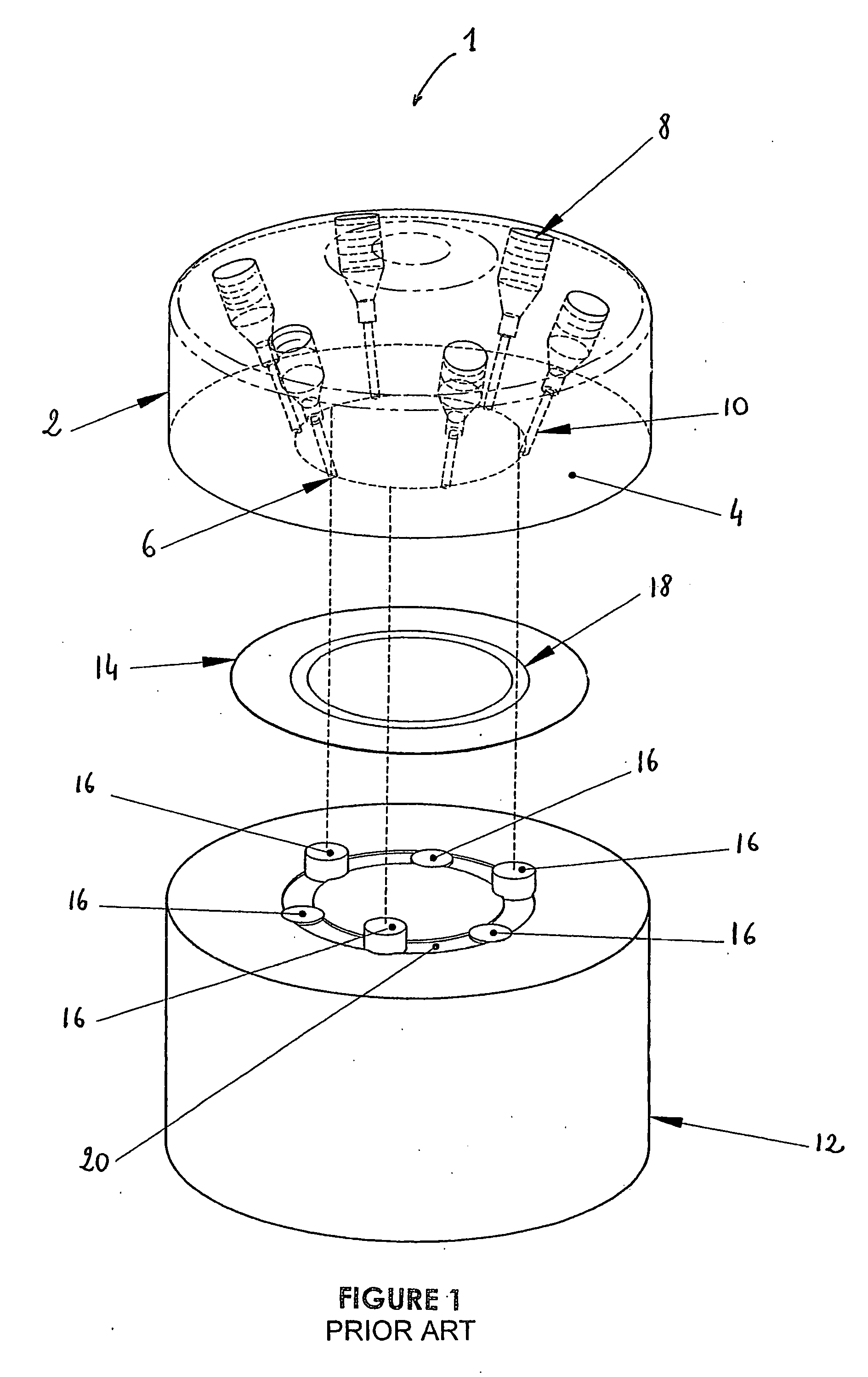

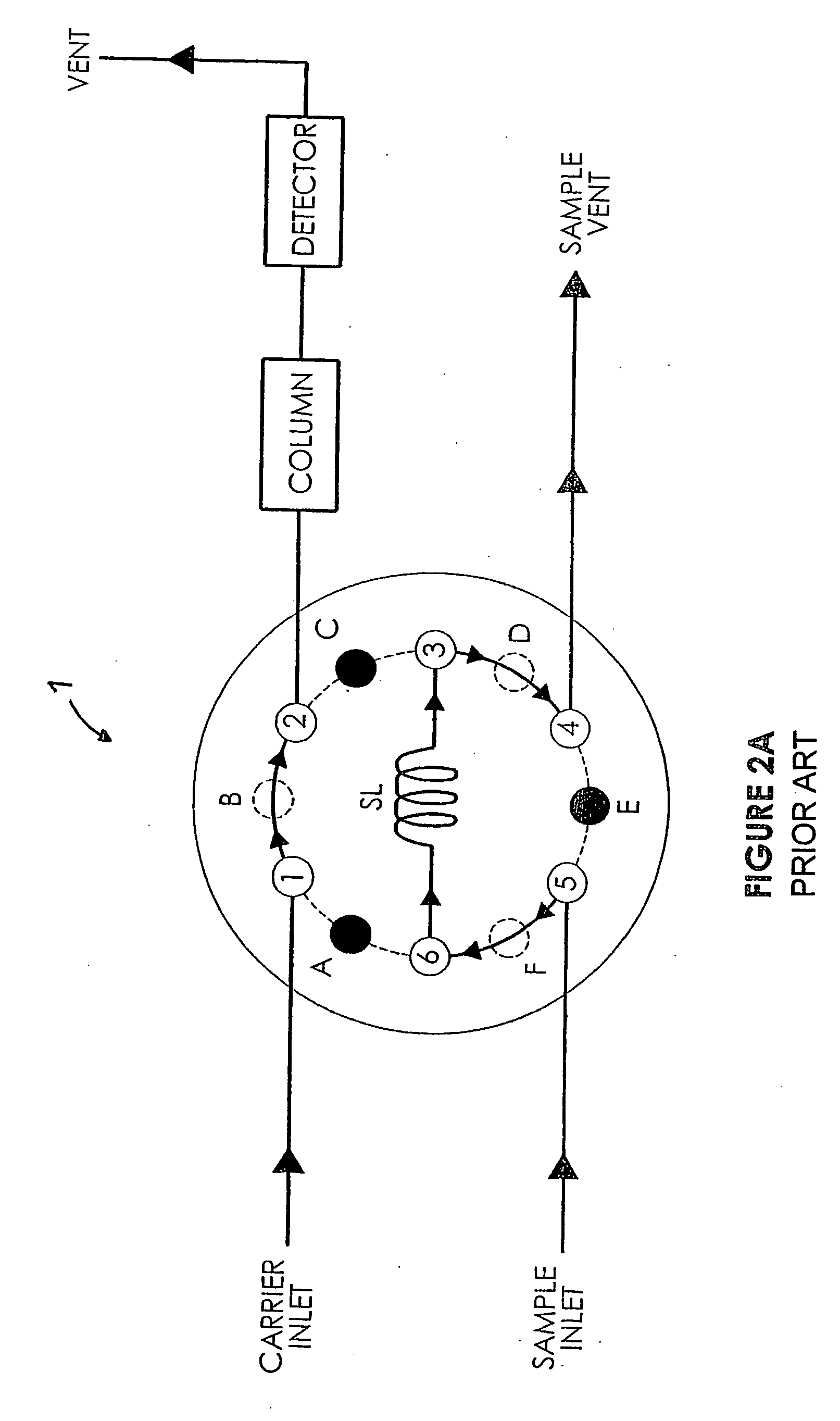

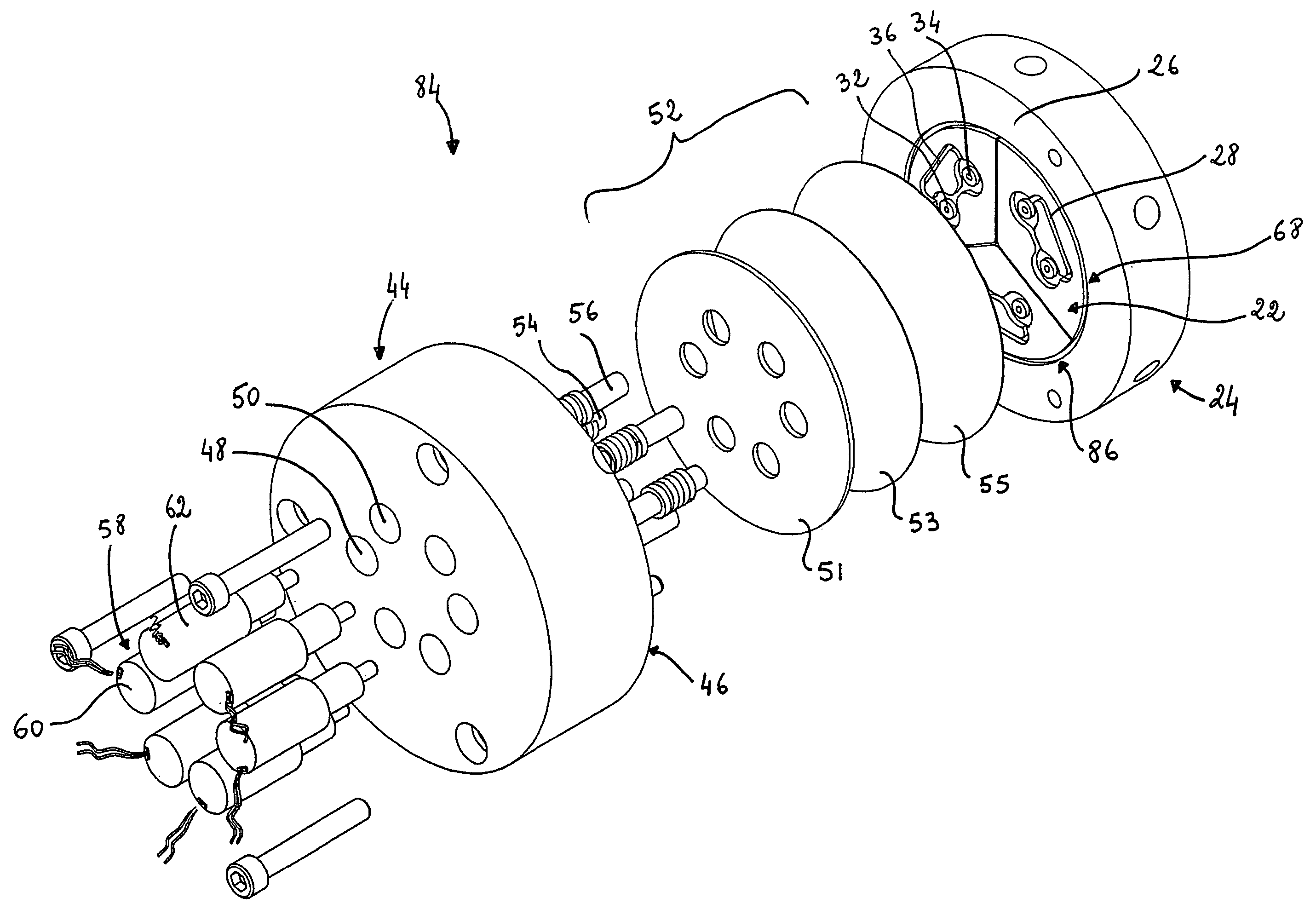

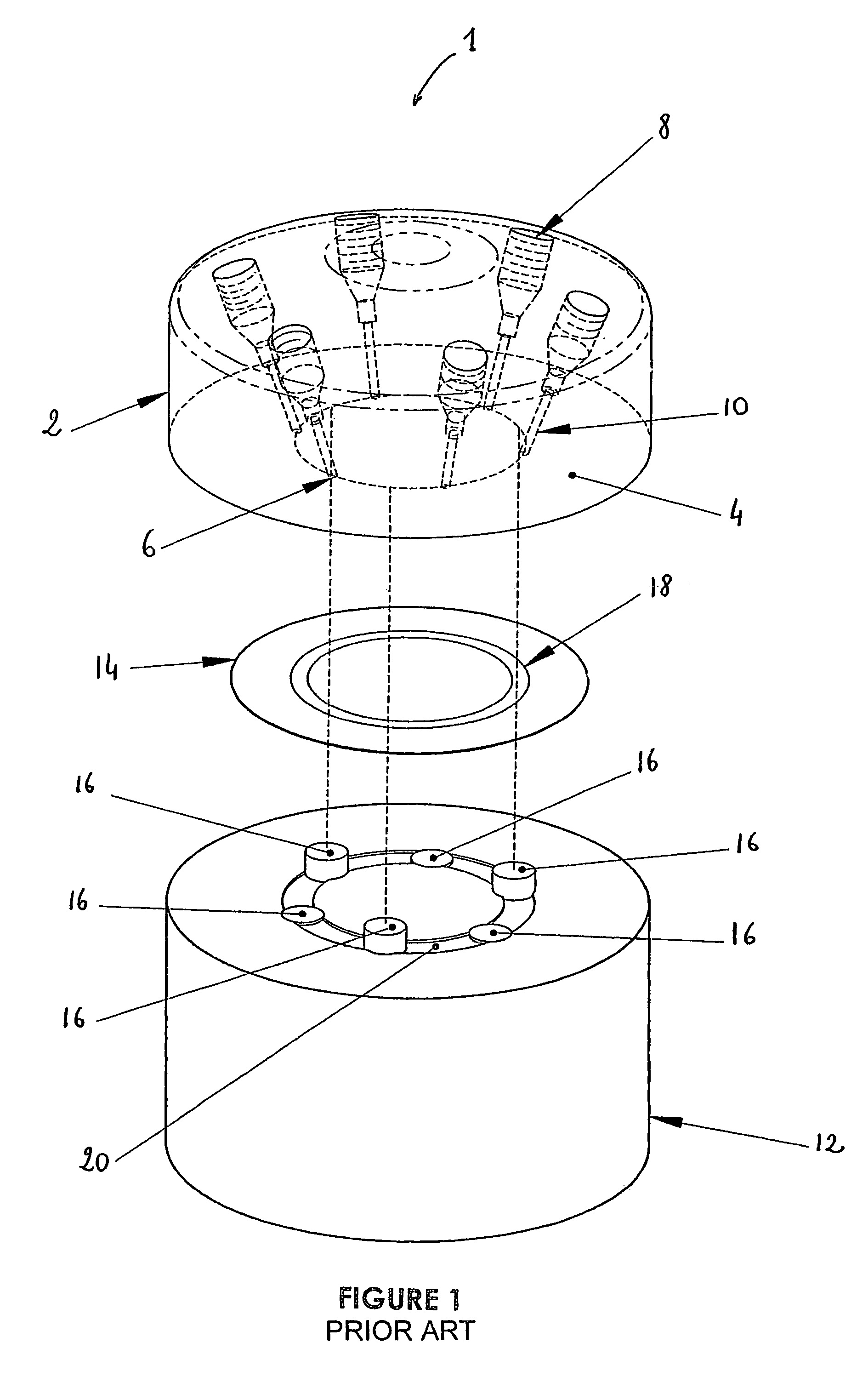

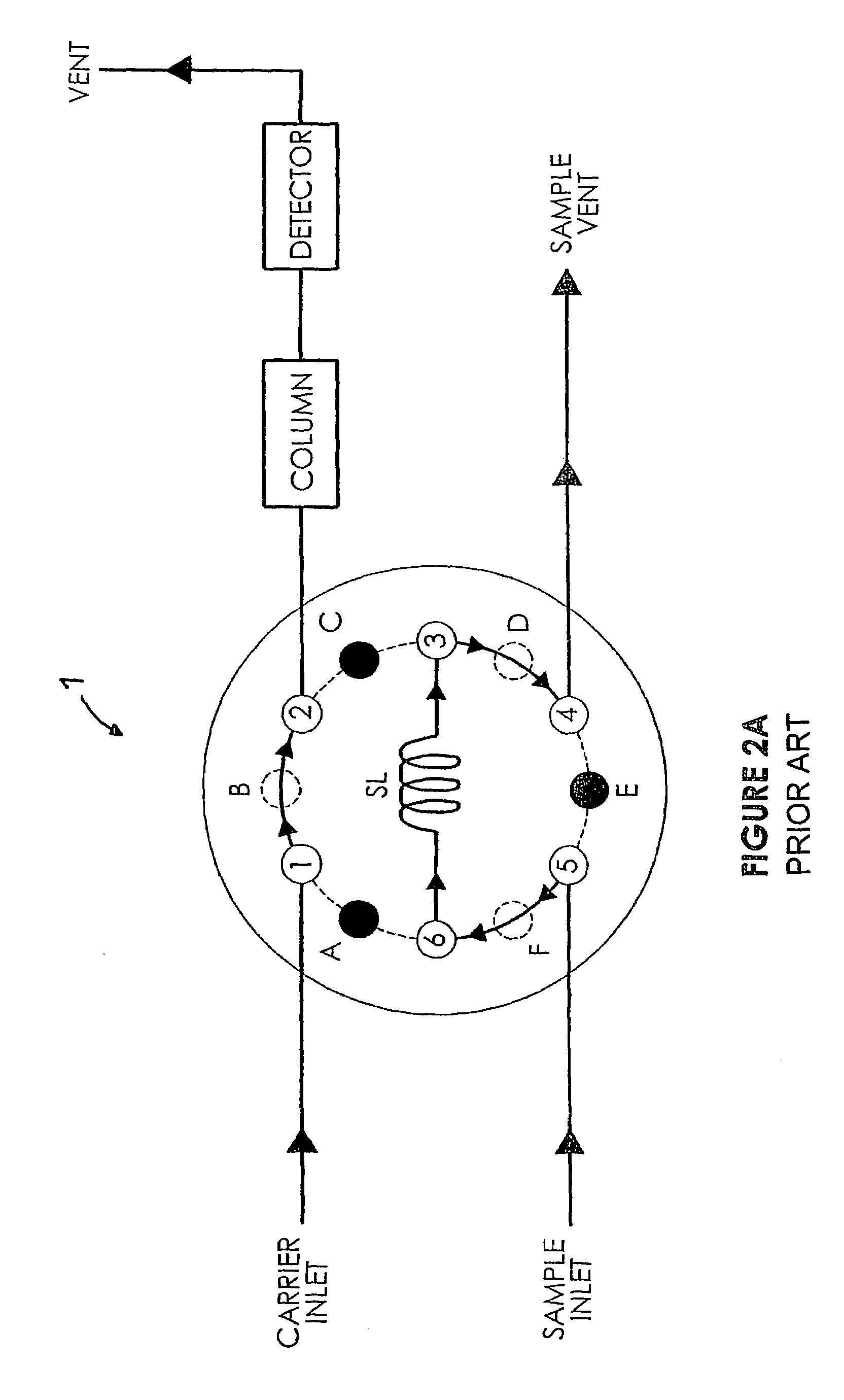

Gas chromatograph sample and column-switching valve

InactiveUS6453725B1Diaphragm valvesOperating means/releasing devices for valvesColumn switchingEngineering

A multiport, diaphragm sealed valve suitable for use as both a sampling and column switching valve. The valve is constructed to internally block fluid communication between one or more pairs of ports in a valve operating mode. Such blocking may be used to conserve carrier gas when the valve is in the ON position.

Owner:SIEMENS AG +1

Two site infusion apparatus

An apparatus for use in delivering pain medication to separate locations from a single source of pressurized medication includes a valve housing, a cap, and a flexible diaphragm. The valve housing includes a first end and a second end and an inlet passage. The first end includes first and second outlet orifices. The cap has a closed end and an open end and is removably coupled to the valve housing at the open end. The flexible diaphragm is coupled between the cap and the valve housing and is movable from a closed position to an open position. The flexible diaphragm seals a pressure chamber from the first and second outlet orifices when in the closed position and opens the first and second outlet orifices to the pressure chamber when in the open position.

Owner:STRYKER CORP

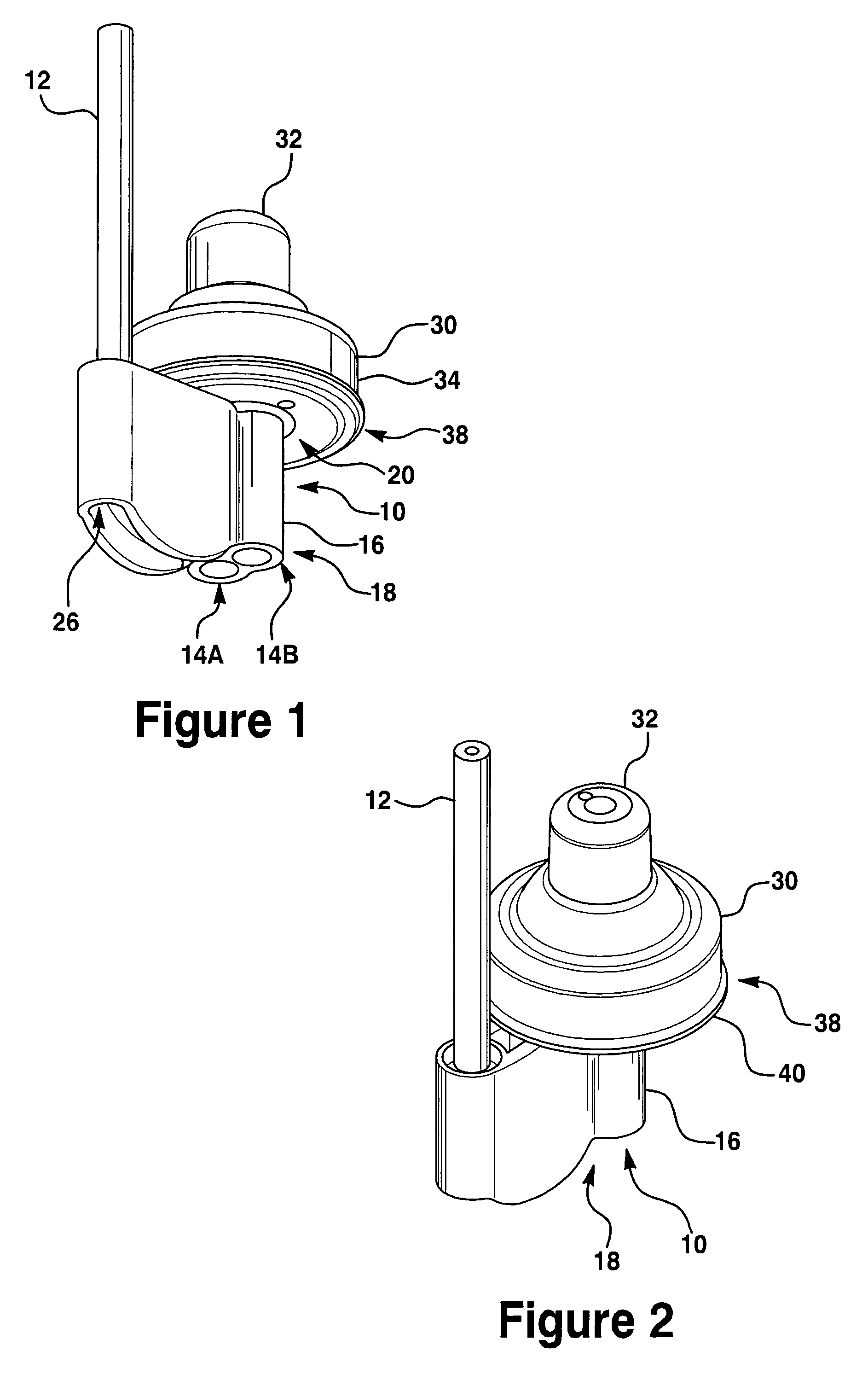

Instrument seal

A surgical access port comprises a valve or instrument seal that separates the instrument contact function from the instrument conforming function. Embodiments of the instrument seal comprise in instrument contact element that extends through an opening in a compression element, thereby defining an instrument orifice that seals with an instrument extending therethrough. Embodiments of the instrument contact element comprise a non-distensible membrane or film, for example, as a tube or cylinder. Some embodiments of the instrument contact element have an hourglass configuration with a first end proximal of the opening of the compression element and a second end distal of the opening of the compression element. Other embodiments of the instrument contact element “wrap around” the opening in the compression element, with the first end and the second end secured to the same side of the opening, for example, proximal of the opening. Embodiments of the compression element comprise an elastomeric seal, for example, a septum seal and / or a gel seal.

Owner:APPL MEDICAL RESOURCES CORP

Peripheral catheter assembly and method of using it

ActiveUS8622972B2Risk is reduced and evenAvoid problemsGuide needlesInfusion syringesVeinCatheter hub

A peripheral catheter assembly having a hollow catheter hub, a female proximal end, a distal end provided with a catheter tube, at least one infusion port located between the distal and proximal ends, a hollow needle module that includes a needle held by a male socket arranged to sealingly engage the female proximal end, and a sealing member engaged inside the catheter hub which serves for facilitating venipuncture without unintended splashing of blood. A sealing valve that includes a septum seal having a weakened portion surrounded by deflectable septum walls, and a hollow tubular extension which protrudes towards a free end from the periphery of the septum seal and extends inside the catheter hub past the infusion port towards the distal end of the catheter hub provide a self-closable sealing member which provide the physician the freedom to leave the patient when the needle module is retracted.

Owner:TRADINCO

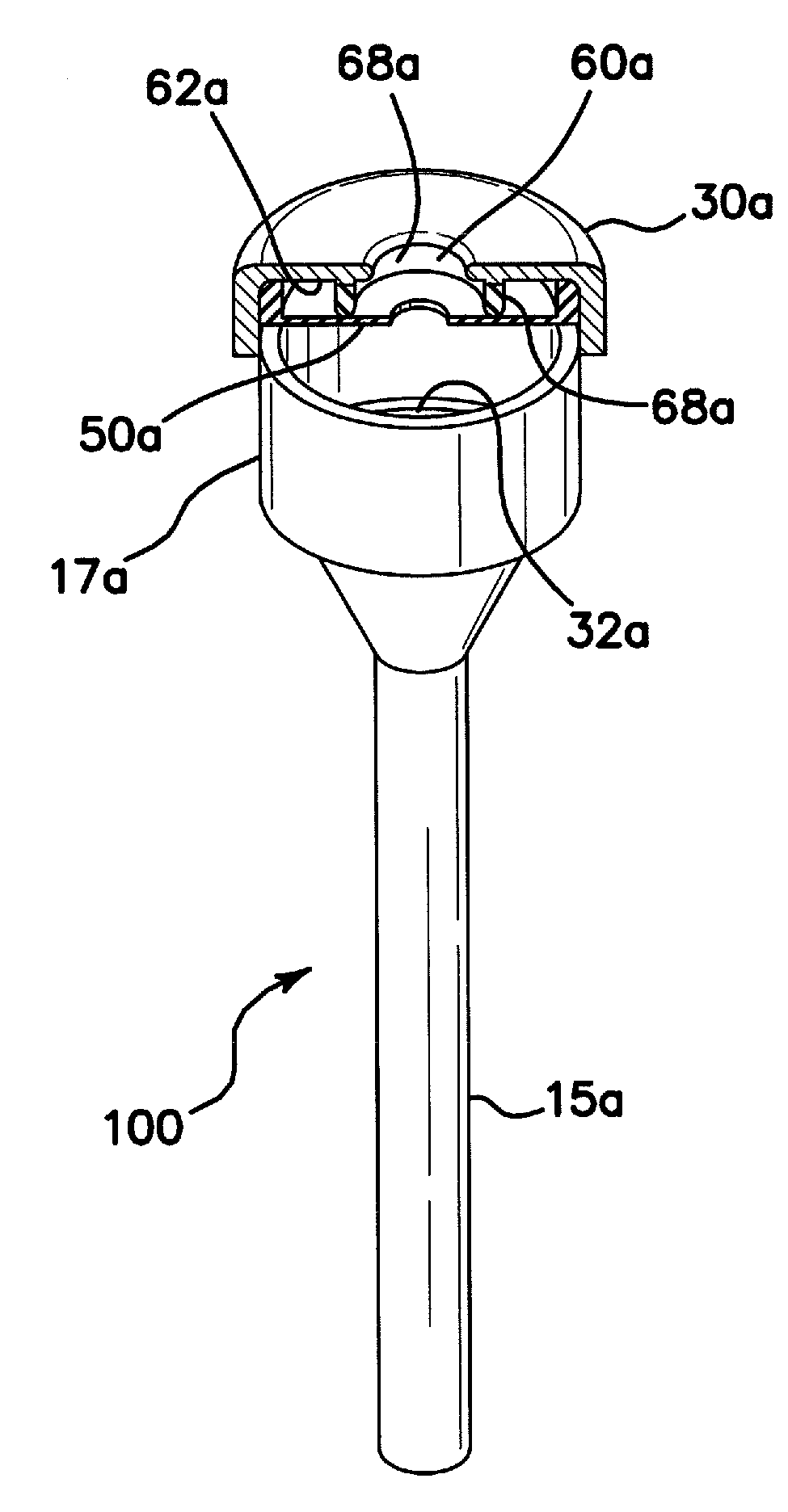

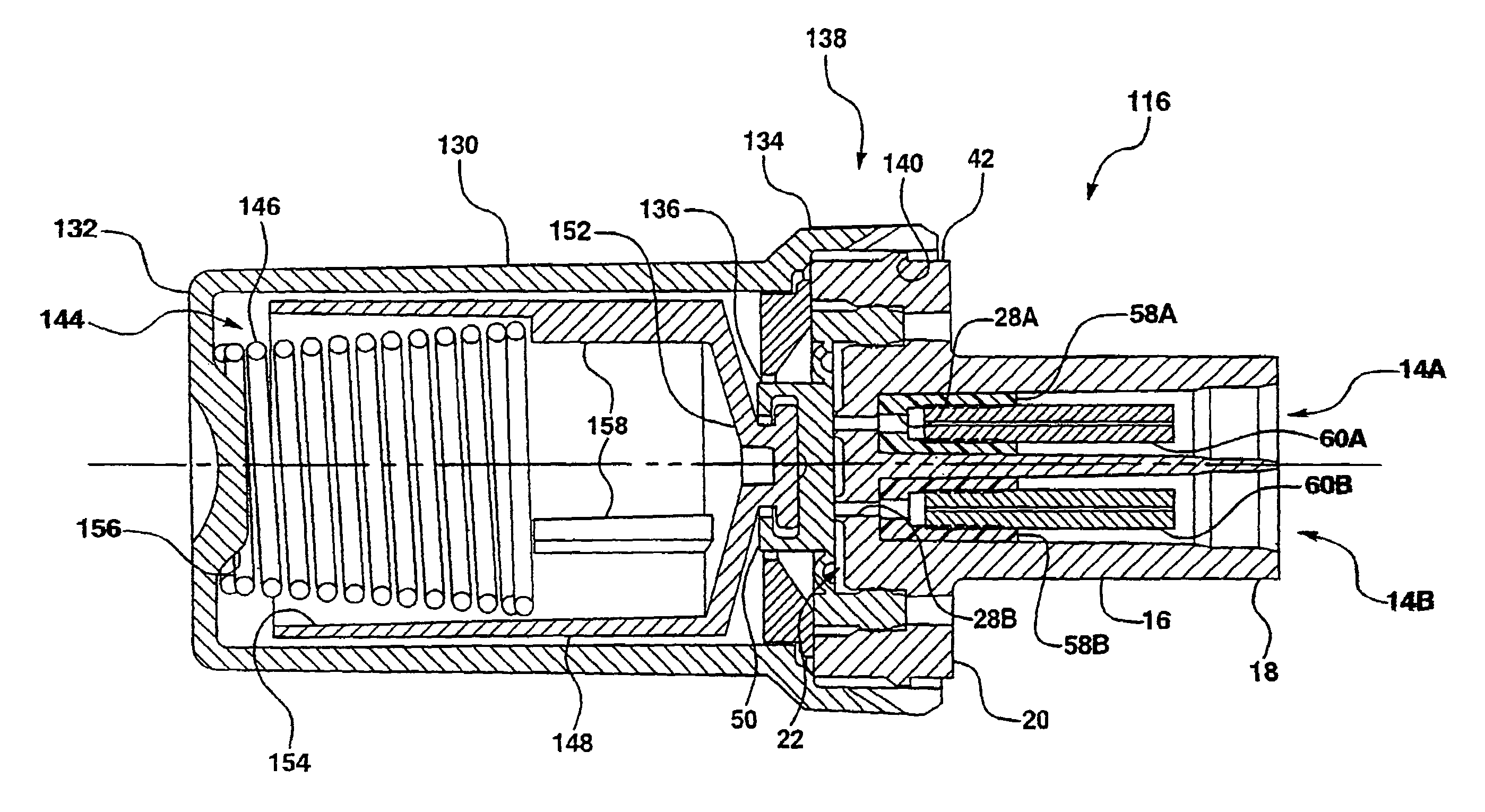

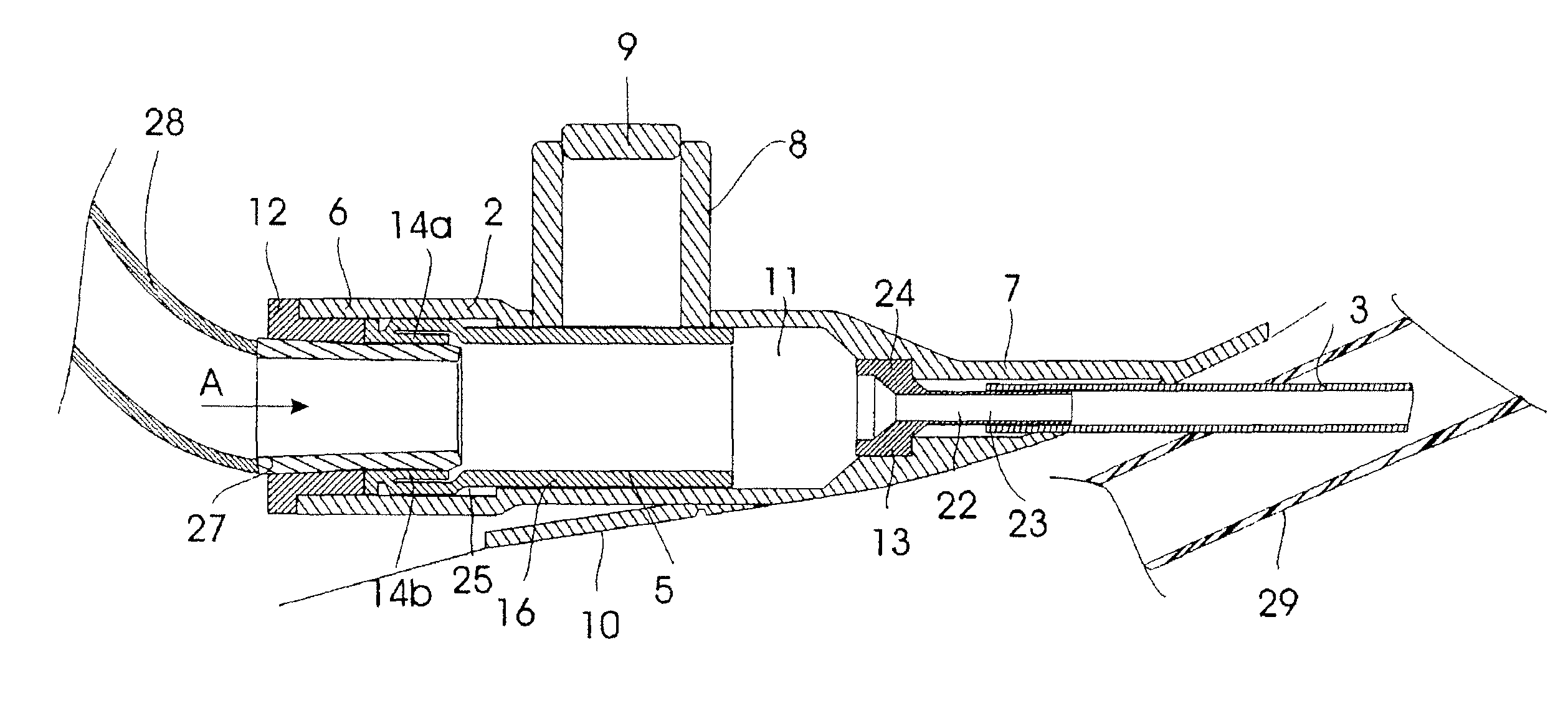

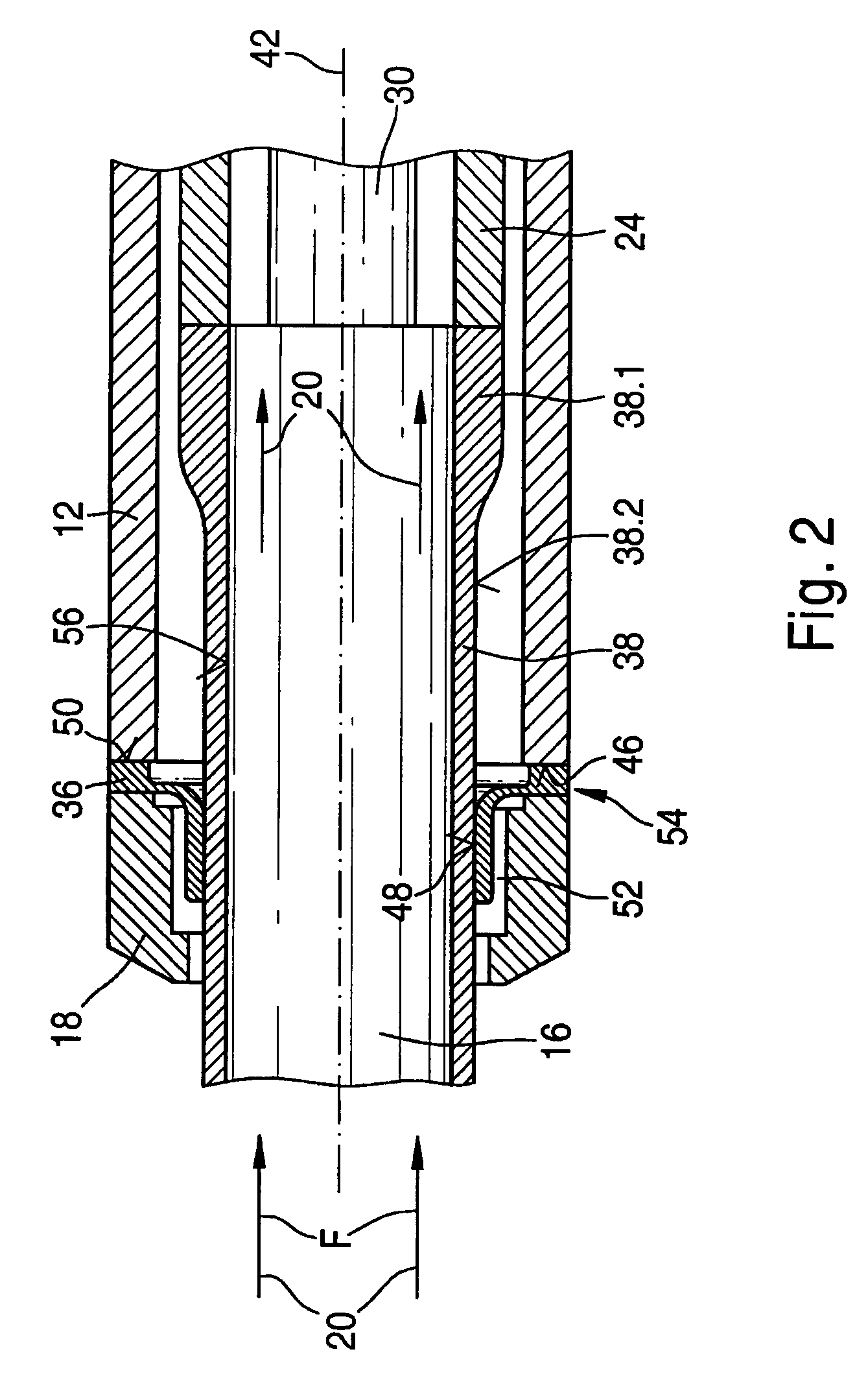

Pencil-type glow plug having an integrated combustion chamber pressure sensor

InactiveUS7581520B2Improve fatigue strengthAvoid failureIncandescent ignitionLamp incadescent bodiesCombustion chamberDiaphragm seal

A pencil-type glow plug for a self-igniting internal combustion engine is described. The pencil-type glow plug includes a plug body in which a combustion chamber pressure sensor is integrated, and a bar-shaped heating element that protrudes out from the plug body at one end, into the combustion chamber of the internal combustion engine. A force-measuring element of the combustion chamber pressure sensor is accommodated behind the heating element, which moves axially under the influence of force. The force-measuring element is sealed against combustion chamber gases by a steel diaphragm made of a stainless precipitation-hardened maraging steel.

Owner:ROBERT BOSCH GMBH

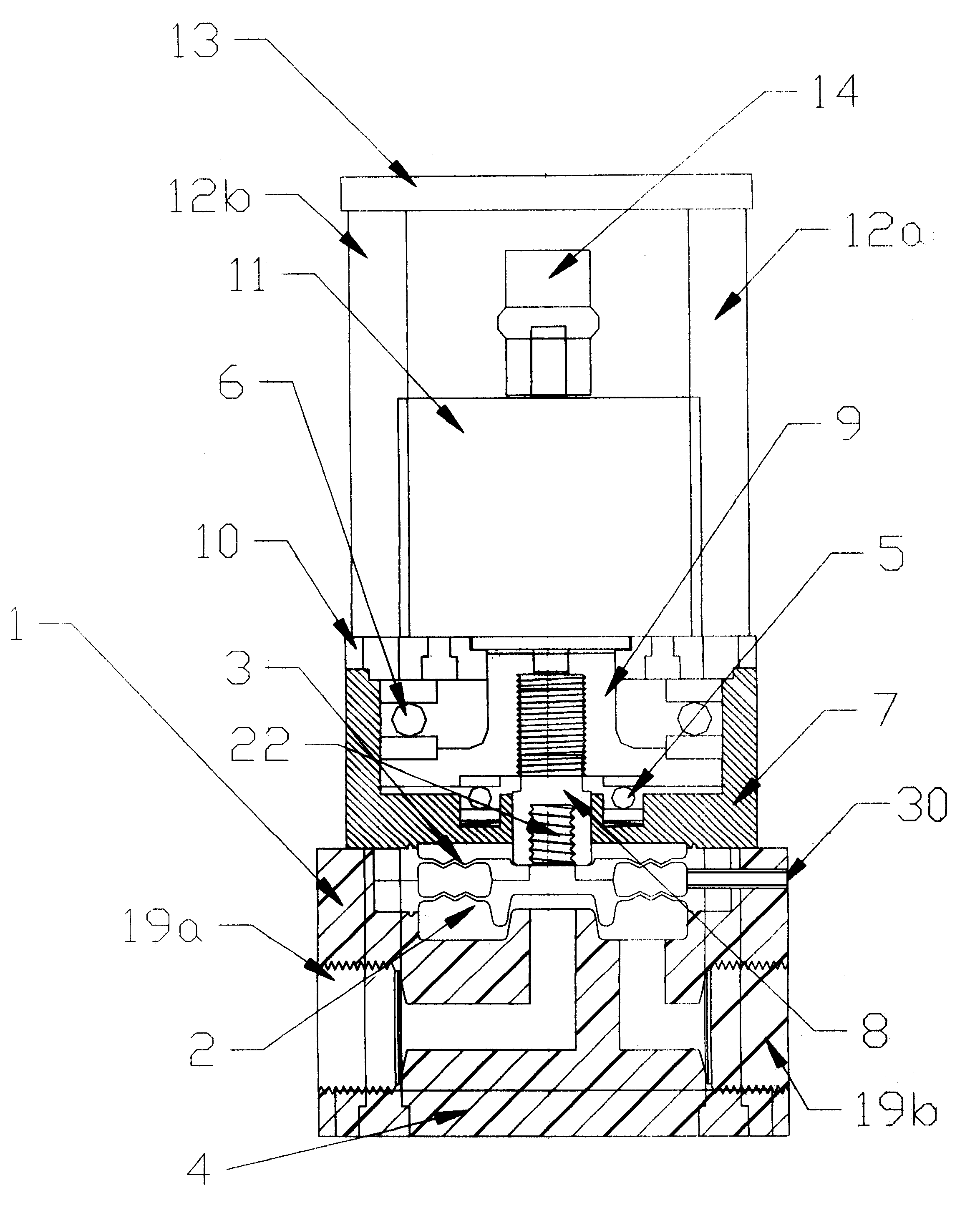

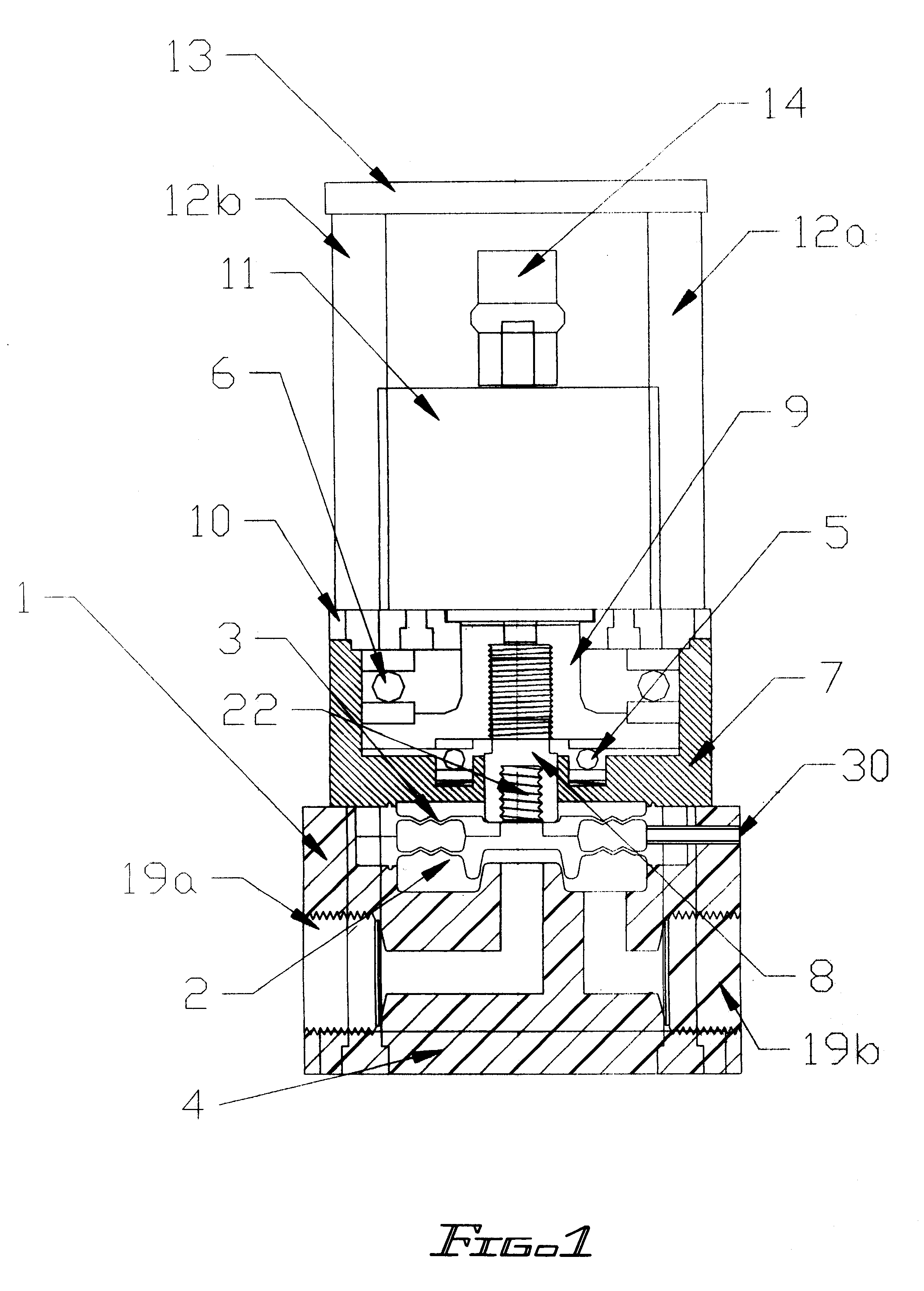

Double diaphragm precision throttling valve

InactiveUS6321776B1Conservative marginMinimize backlashDiaphragm valvesOperating means/releasing devices for valvesFluid controlDiaphragm seal

A throttling valve assembly actuated by a stepper motor having a double diaphragm seal and integral throttling surface. The throttling surface interfaces to a mating orifice and port arrangement to provide a smooth control regime for various process fluids. Because of the unique design of the flow paths the fluids will remain in a laminar flow state throughout the throttling range, thus providing smooth and continuous response to the control input. The valve opening to the fluid controlled by a stepper motor through a direct drive mechanism. The embodiment shown here employees all PTFE construction for the wetting parts, but any material could be used that would be compatible with the process fluid. Additional features are minimal capture of the process fluid, free draining, and no metallic parts in close communication with the process fluid.

Owner:ENTEGRIS INC

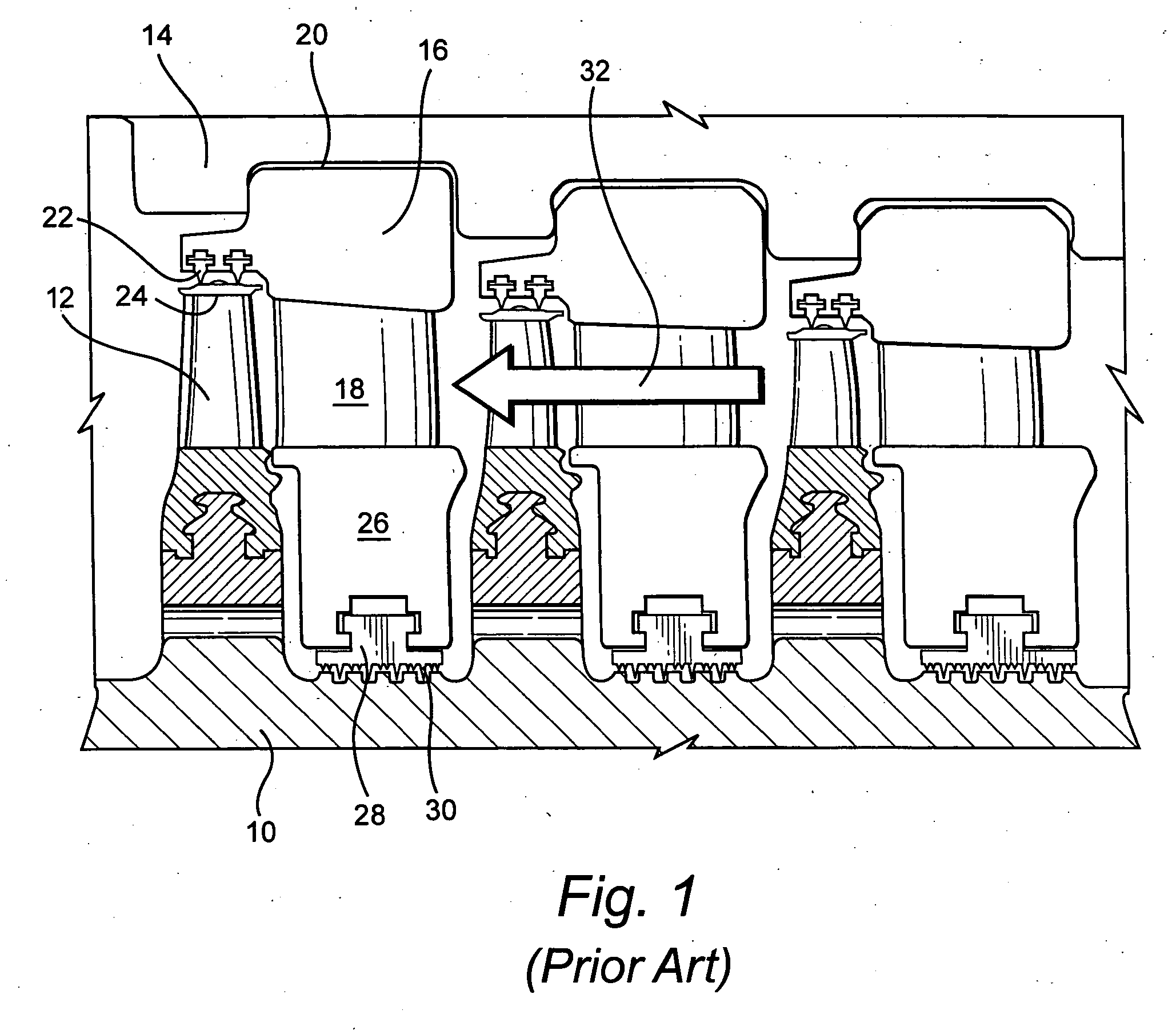

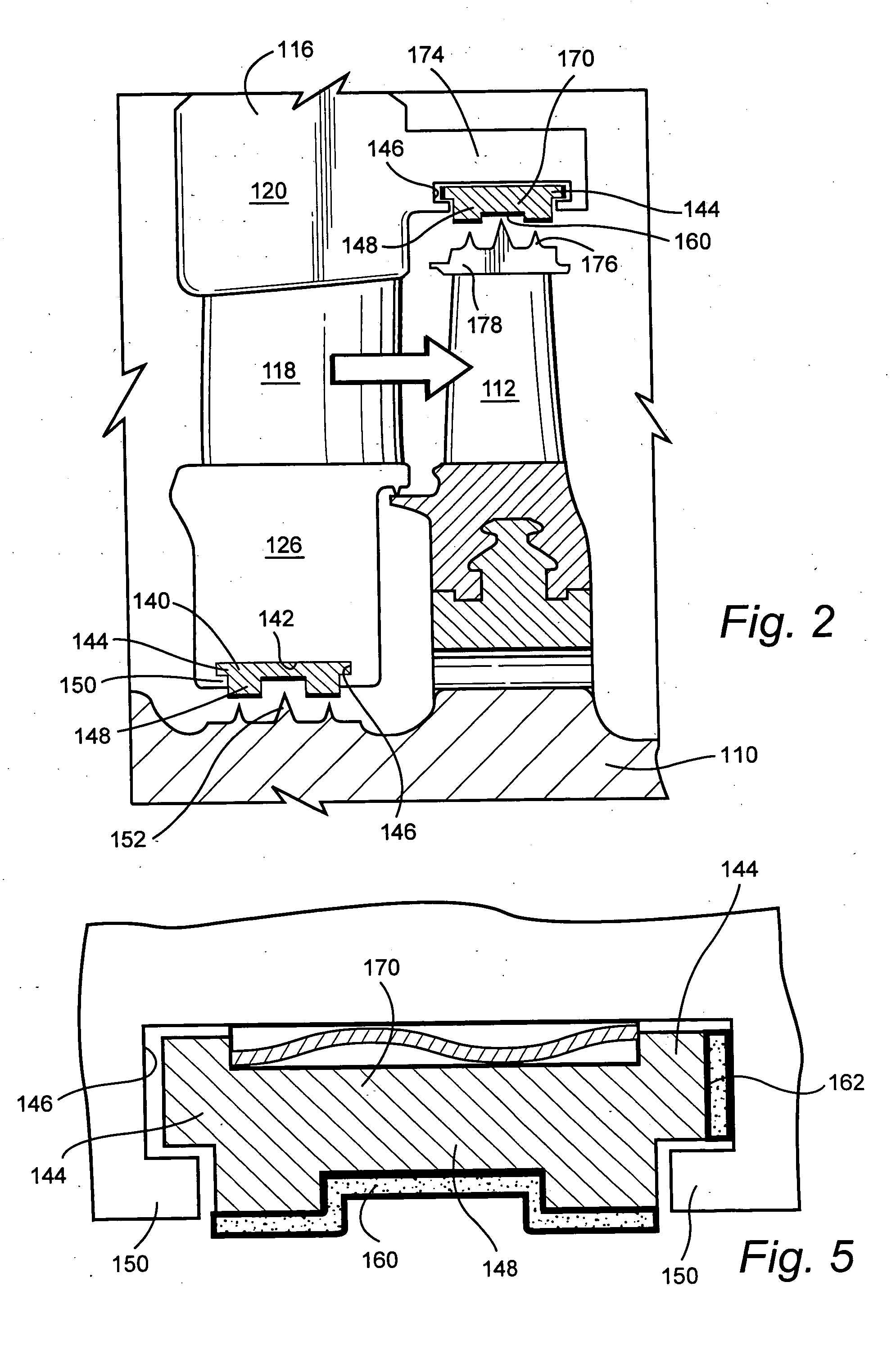

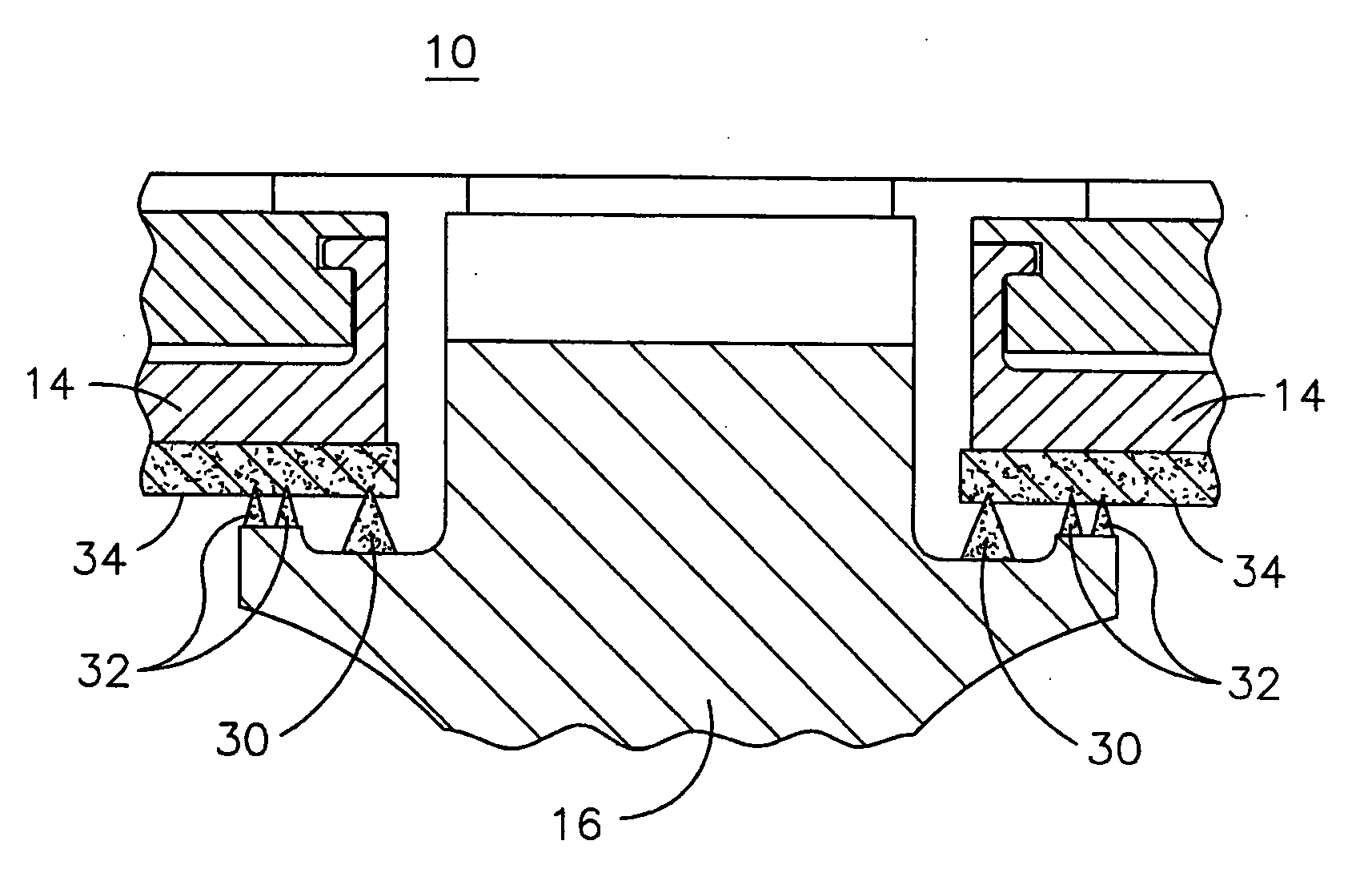

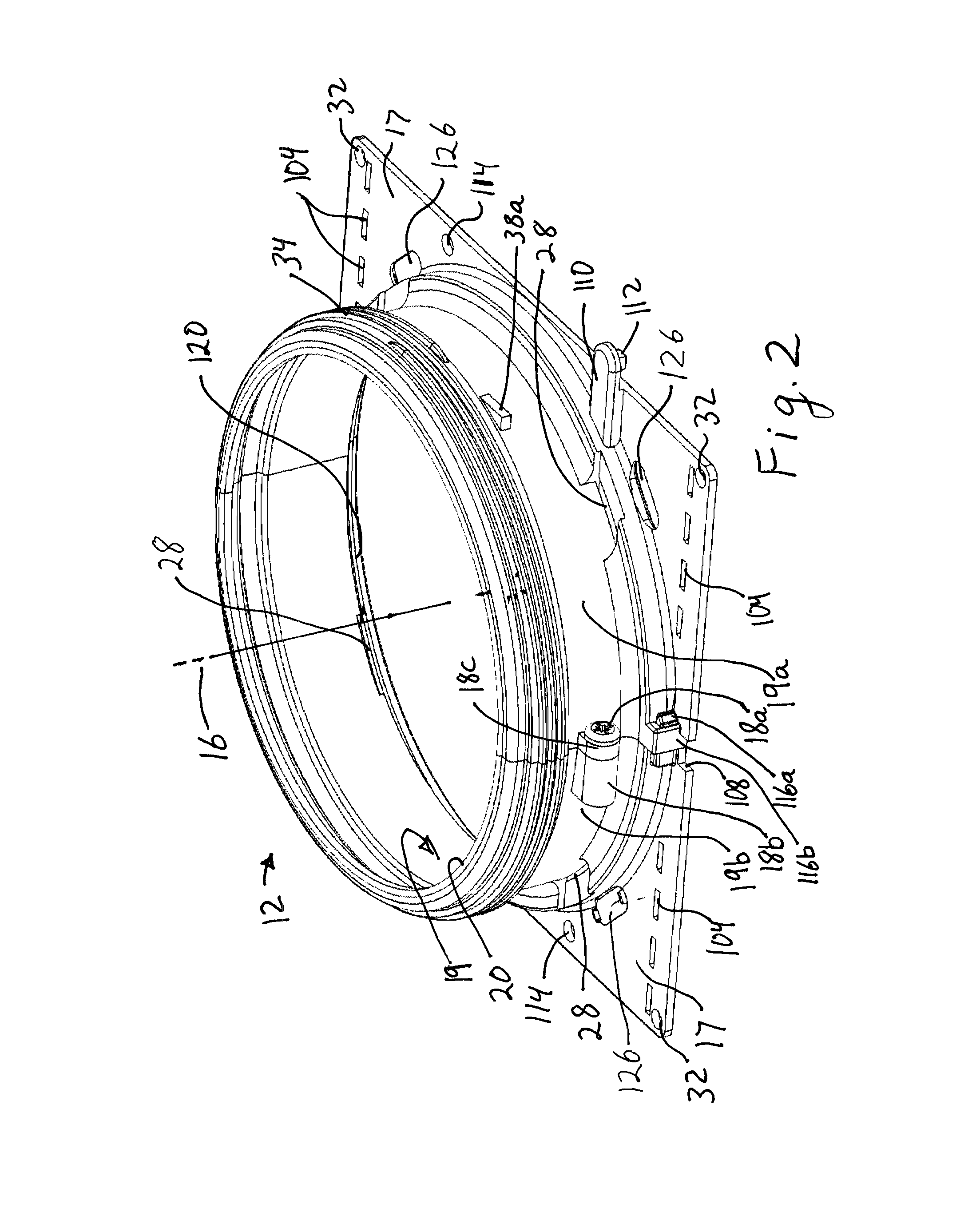

Removable abradable seal carriers for sealing between rotary and stationary turbine components

The turbine includes a diaphragm having a seal carrier mounted in opposition to seal teeth carried by the rotary component. The seal carrier includes a seal face having a coating of abradable material enabling the rotary component to abrade the material from the seal face. The seal carrier is removable from the diaphragm and is carried by an axial extension integral with or removable from the outer diaphragm ring. A spring may be interposed between the seal carrier and the stationary component.

Owner:GE INFRASTRUCTURE TECH INT LLC

Removable abradable seal carriers for sealing between rotary and stationary turbine components

The turbine includes a diaphragm having a seal carrier mounted in opposition to seal teeth carried by the rotary component. The seal carrier includes a seal face having a coating of abradable material enabling the rotary component to abrade the material from the seal face. The seal carrier is removable from the diaphragm and is carried by an axial extension integral with or removable from the outer diaphragm ring. A spring may be interposed between the seal carrier and the stationary component.

Owner:GENERAL ELECTRIC CO

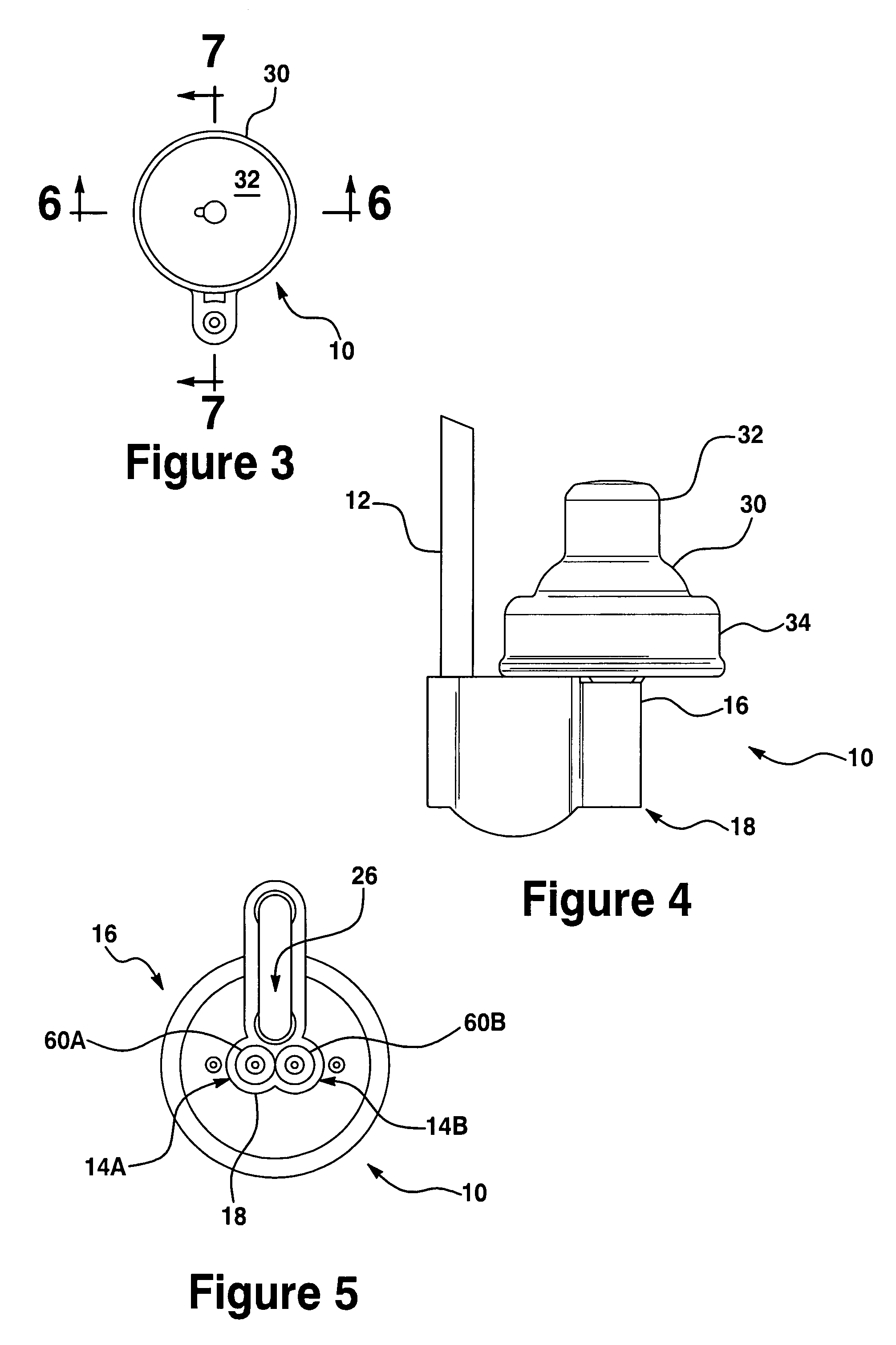

Trocar having planar fixed septum seal and related methods

InactiveUS20050165433A1Improve performanceAvoid less flexibilityCannulasSurgical needlesEngineeringDiaphragm seal

A septum valve having peripheries thereof adapted to be fixedly positioned in a valve housing of a trocar system is provided. The septum valve includes a valve body having an opening positioned in a medial portion of the valve body and adapted to individually and separately receive a plurality of different elongate tools each having a different diameter therethrough so that when any one of the plurality of elongate tools is positioned through the valve opening a septum seal is maintained between peripheries of the valve body surrounding the valve opening and abuttingly contacting outer peripheries of the any one of the plurality of elongate tools extending therethrough. The valve body has first and second layers of a fabric material and a layer of elastomeric material positioned between and contacting each of the first and second layers of the fabric material. The septum valve also includes a periphery valve section connected to and extending radially outwardly from peripheries of the valve body and having an outer perimeter thereof adapted to be fixedly connected to the valve housing. The periphery valve section has a plurality of rib members each radially extending substantially an entire distance between an outer perimeter of the valve body and the outer perimeter of the periphery valve section and symmetrically positioned spaced-apart from each other. The periphery valve section has a greater flexibility than the valve body.

Owner:GENICO

Implantable central venous injection port and external needle guide

An assembly for subcutaneous injections comprising an implantable injection port comprising a body with a plenum, an elastomeric self-sealing diaphragm sealed to the body or with a plenum, an outlet connecting the plenum to a conduit, and one or more ferromagnetic compatible elements positioned about the elastomeric self-sealing diaphragm and near the top side; and a needle support platform comprising a body having a top side and bottom side, with a needle guide extending from the top side to the bottom side, a needle secure; and an attachment base with a top side and bottom side, a center hollow open to the top and bottom sides, and one or more ferromagnetic compatible elements positioned about the center hollow and near the bottom side of the attachment base, the bottom side of the body of the needle support platform resting on the top side of the attachment base and slidable thereon, the position of the body on the attachment base adapted to be detachably secured.

Owner:CHUTER TIMOTHY A M +1

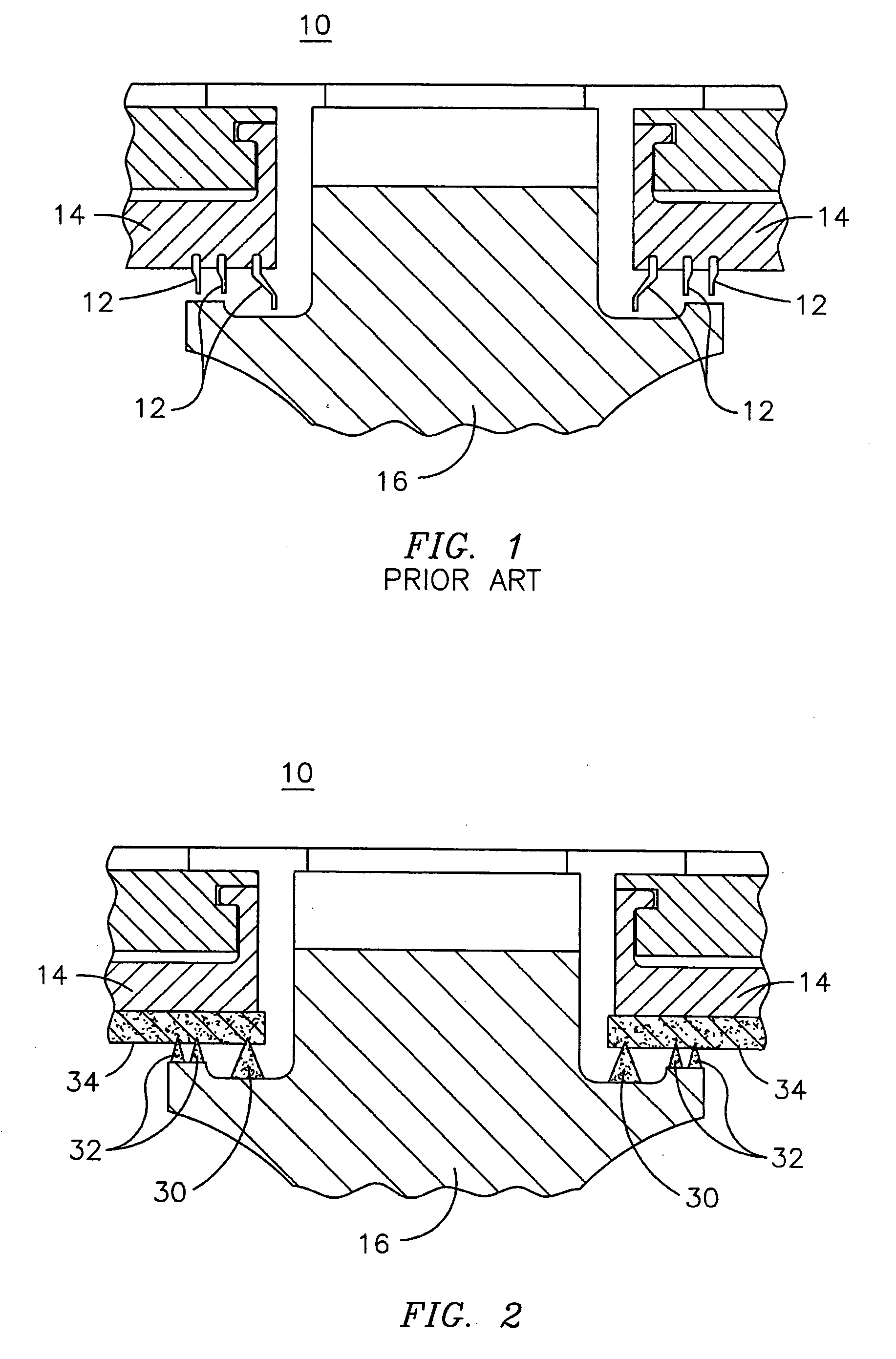

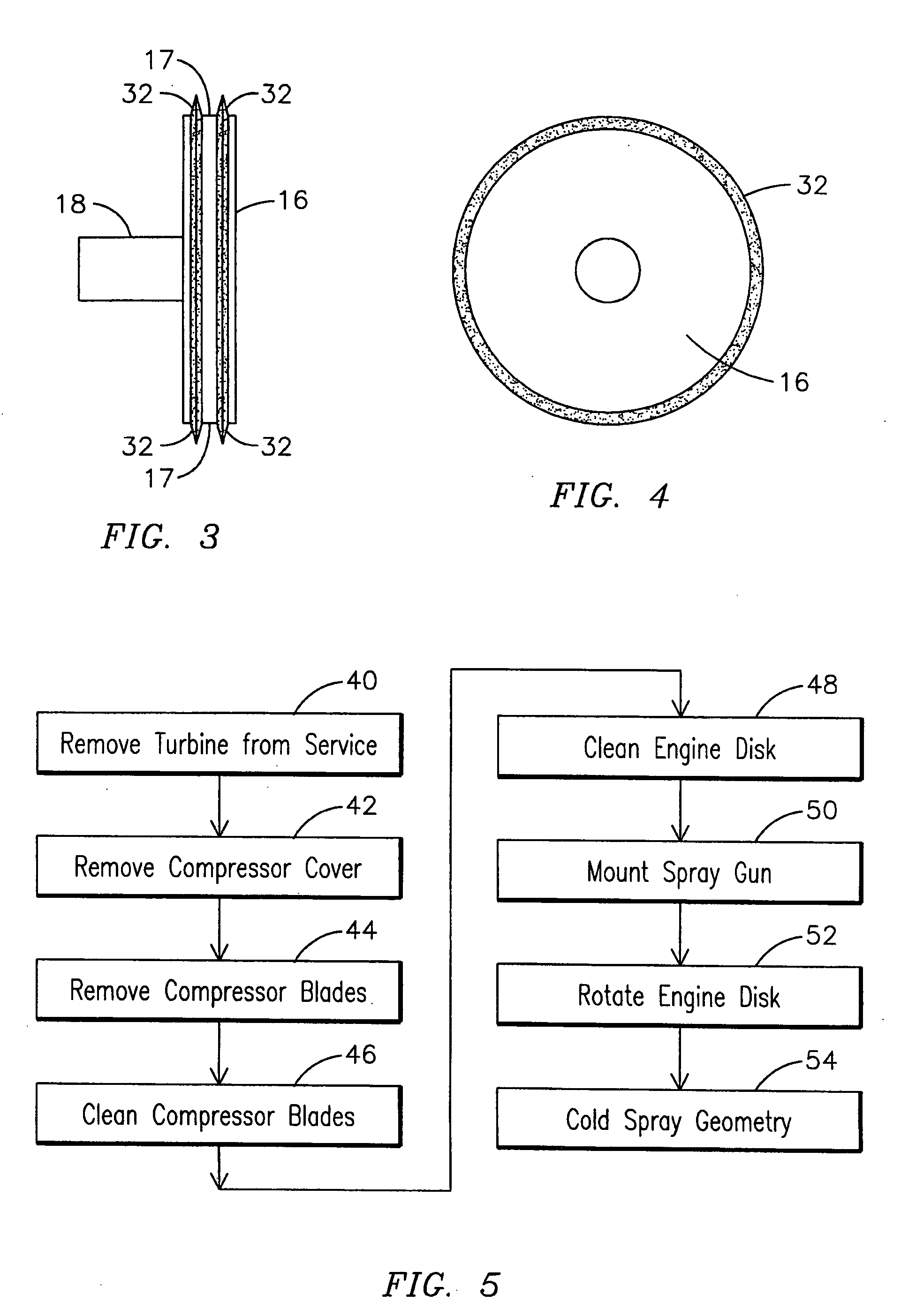

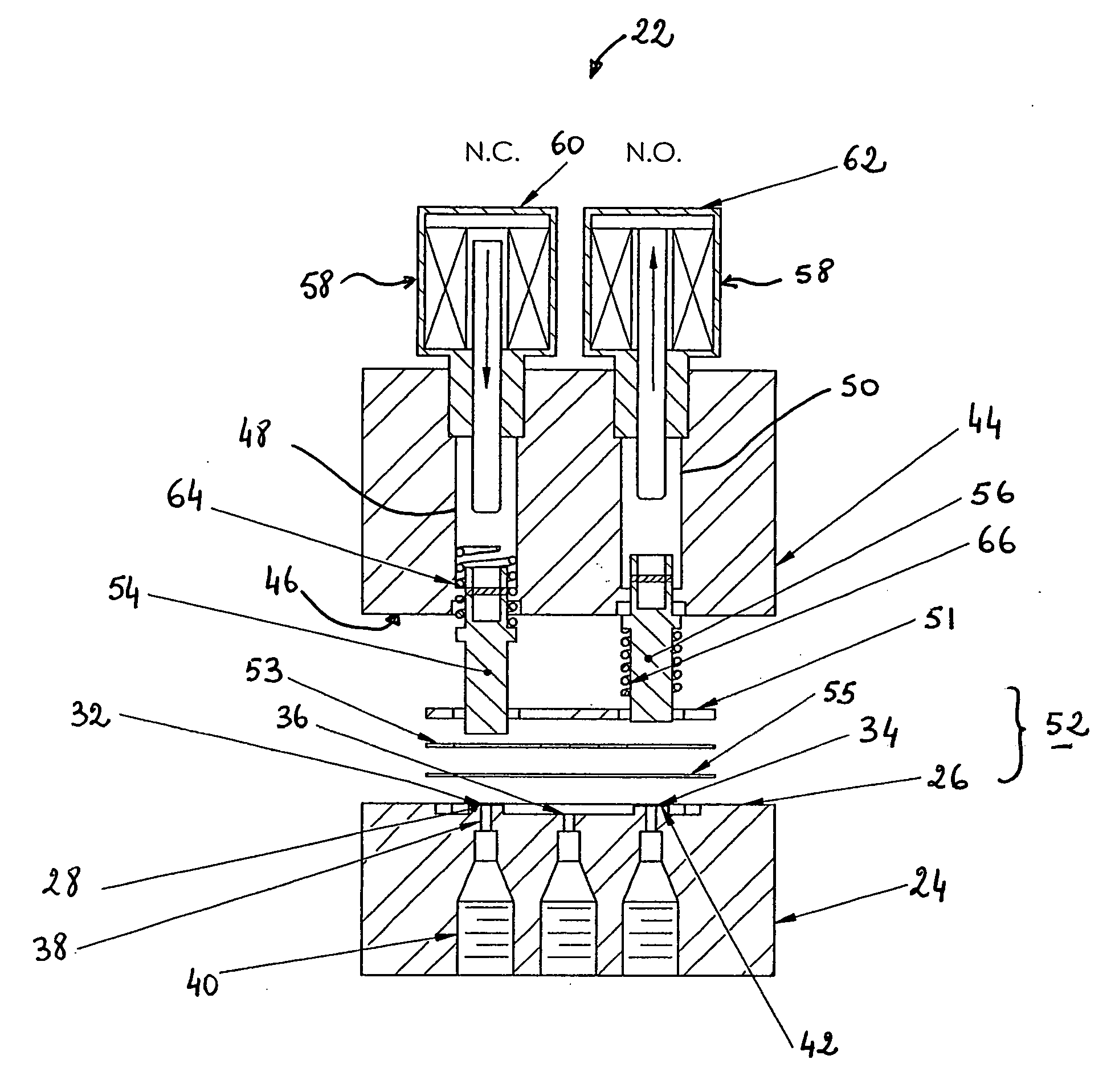

Cold spray process for seal applications

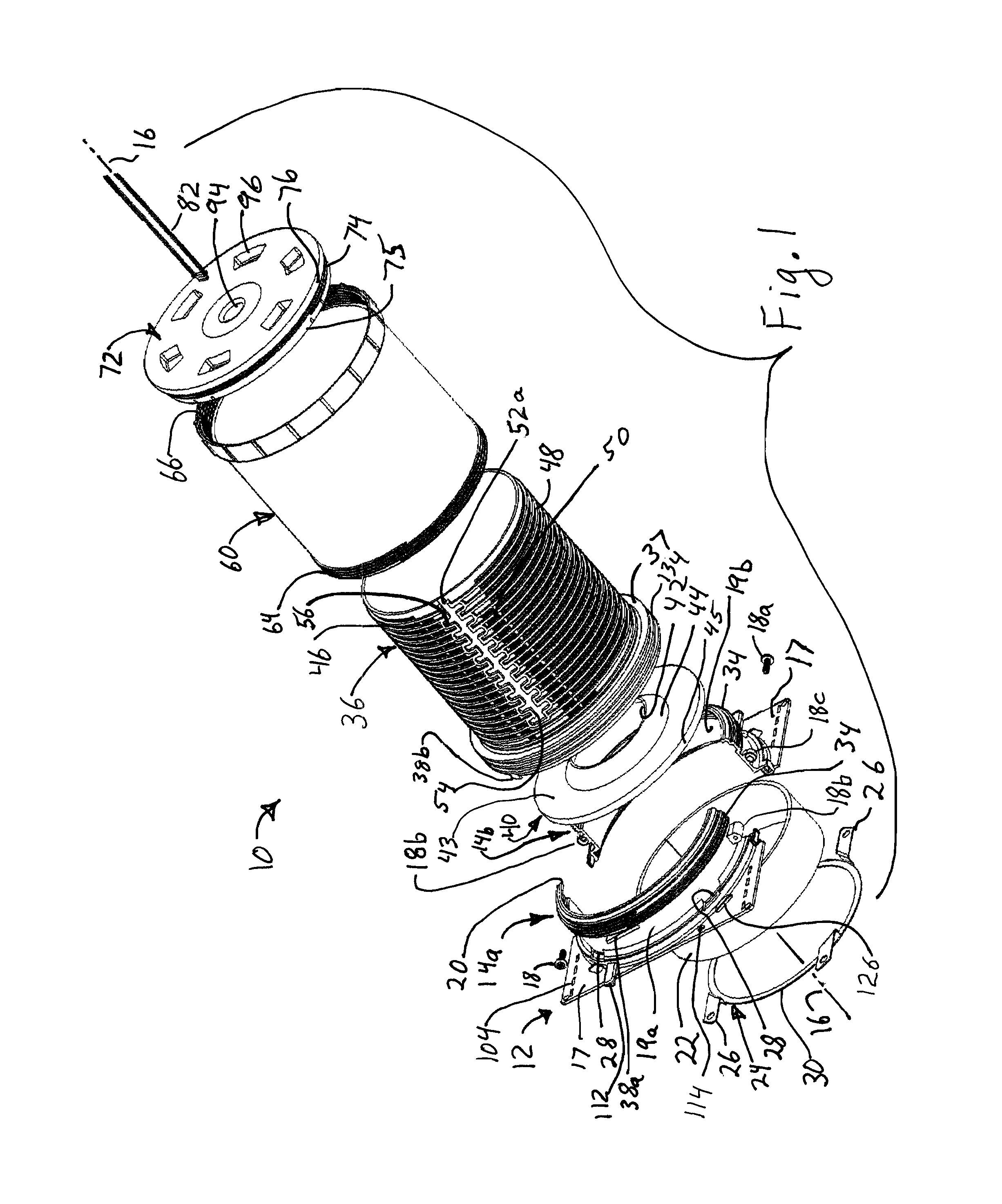

A method of forming an interstage seal including removing a diaphragm seal box (14) from a gas turbine compressor assembly (10) and removing a labyrinth sealing member (12) from the diaphragm seal box (14). An abradable material layer (34) may be deposited on the diaphragm seal box (14). A spray gun may be mounted in relation to an engine disk (16) of the gas turbine compressor assembly (10) for cold-spraying a quantity of particles toward the engine disk (16). The particles may be sprayed at a velocity sufficiently high to cause at least a portion of the quantity of particles to adhere to the engine disk (16). The spray gun may be controlled to deposit a quantity of particles on the compressor disk (16) to form a geometry (32) that will abrade the abradable material layer (34) during operation of the gas turbine compressor assembly (10). The geometry (32) abrading the abradable material layer (34) forms an interstage seal. Rotation of the engine disk (16) within the gas turbine compressor assembly (10) may be controlled during the step of controlling the spray gun. The diaphragm seal box (14) may be reinstalled within the gas turbine compressor assembly (10) so that the geometry (32) aligns with the abradable material layer (34).

Owner:SIEMENS ENERGY INC

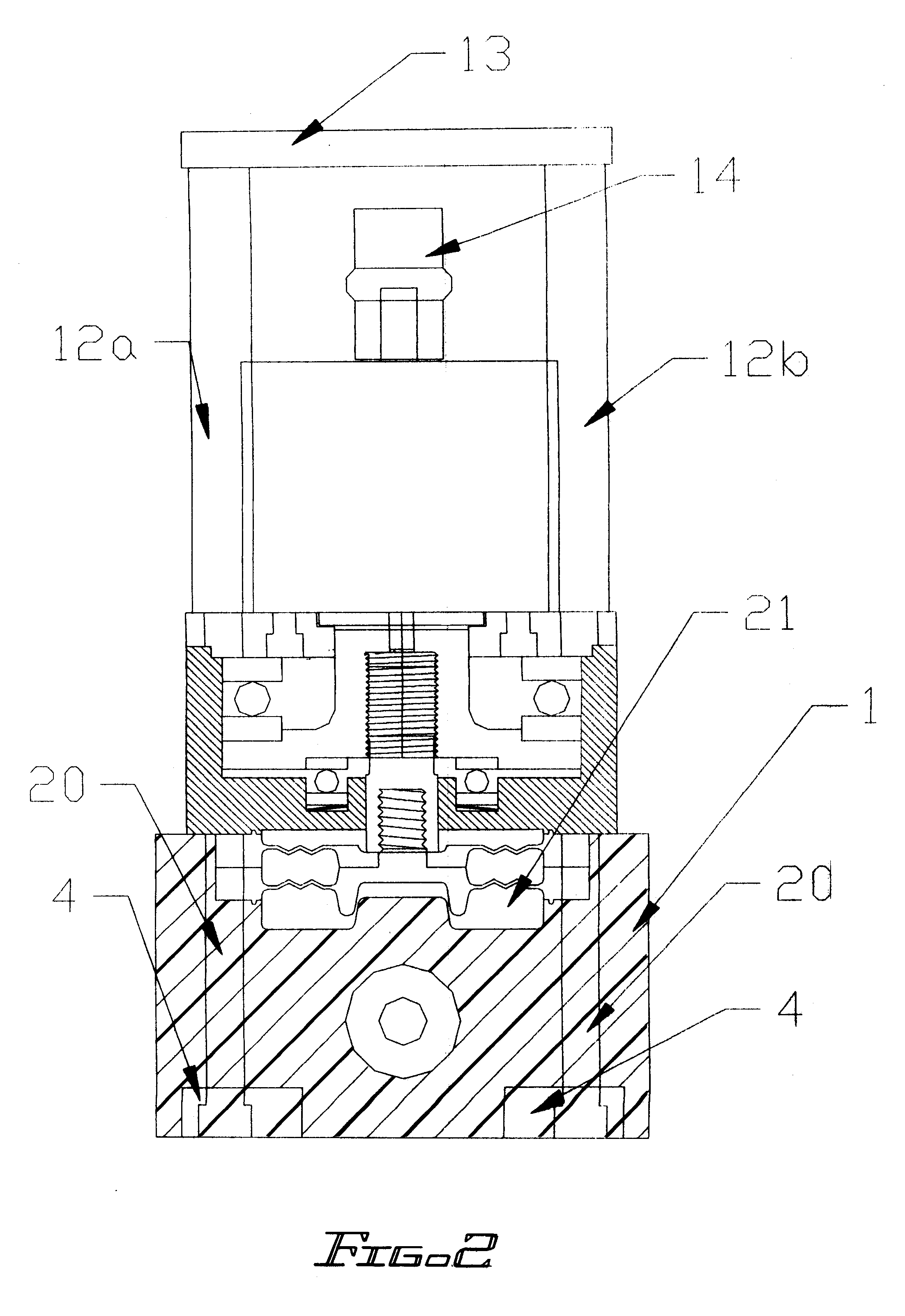

Diaphragm-sealed valve, analytical chromatographic system and method using the same

There is provided a diaphragm sealed valve particularly advantageous in chromatographic systems. The valve is provided with first and second body and a seal member compressibly positioned therebetween. The first body comprises a first, a second and a common port, each opening and being interconnected to the others in a recessed fluid communication channel extending in a first interface of the first body. The valve is also provided with first and second plungers, each having a closed position wherein the plunger presses down the seal member against the seat of the corresponding port for closing said corresponding port, and an open position wherein the plunger extends away from the seat for allowing a fluid communication between the corresponding port and the channel. Complex valves are also provided as well as chromatographic systems and methods.

Owner:APN INC

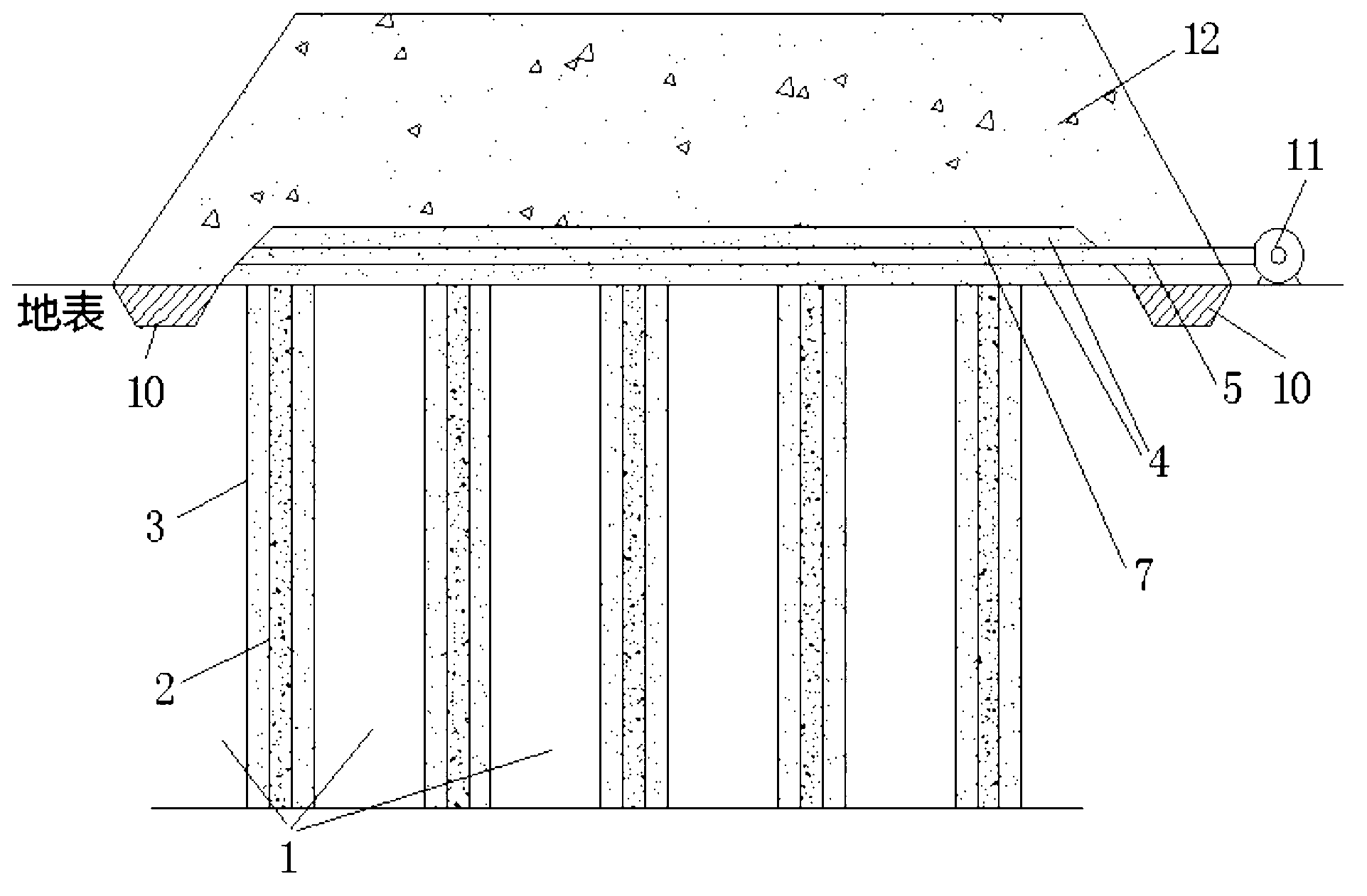

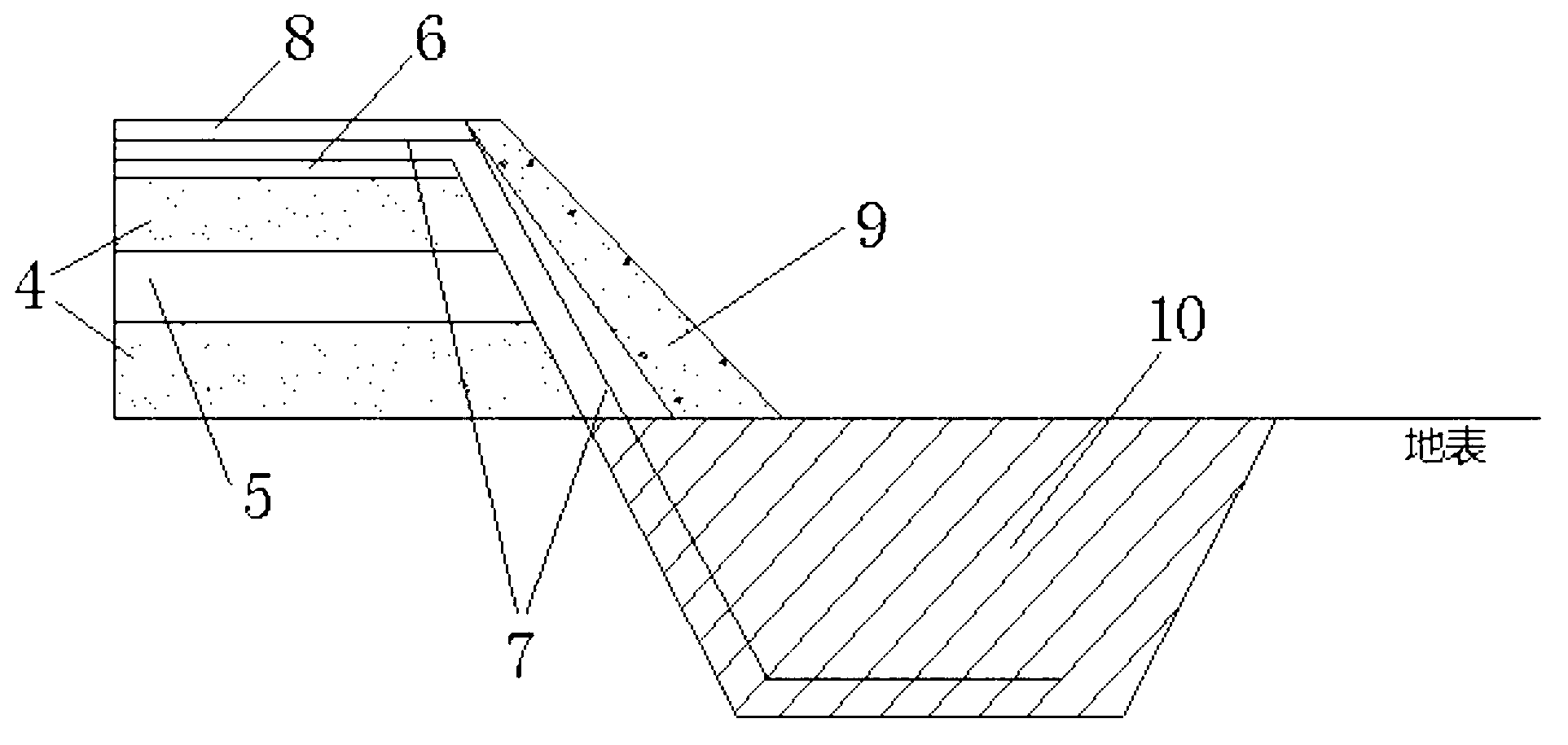

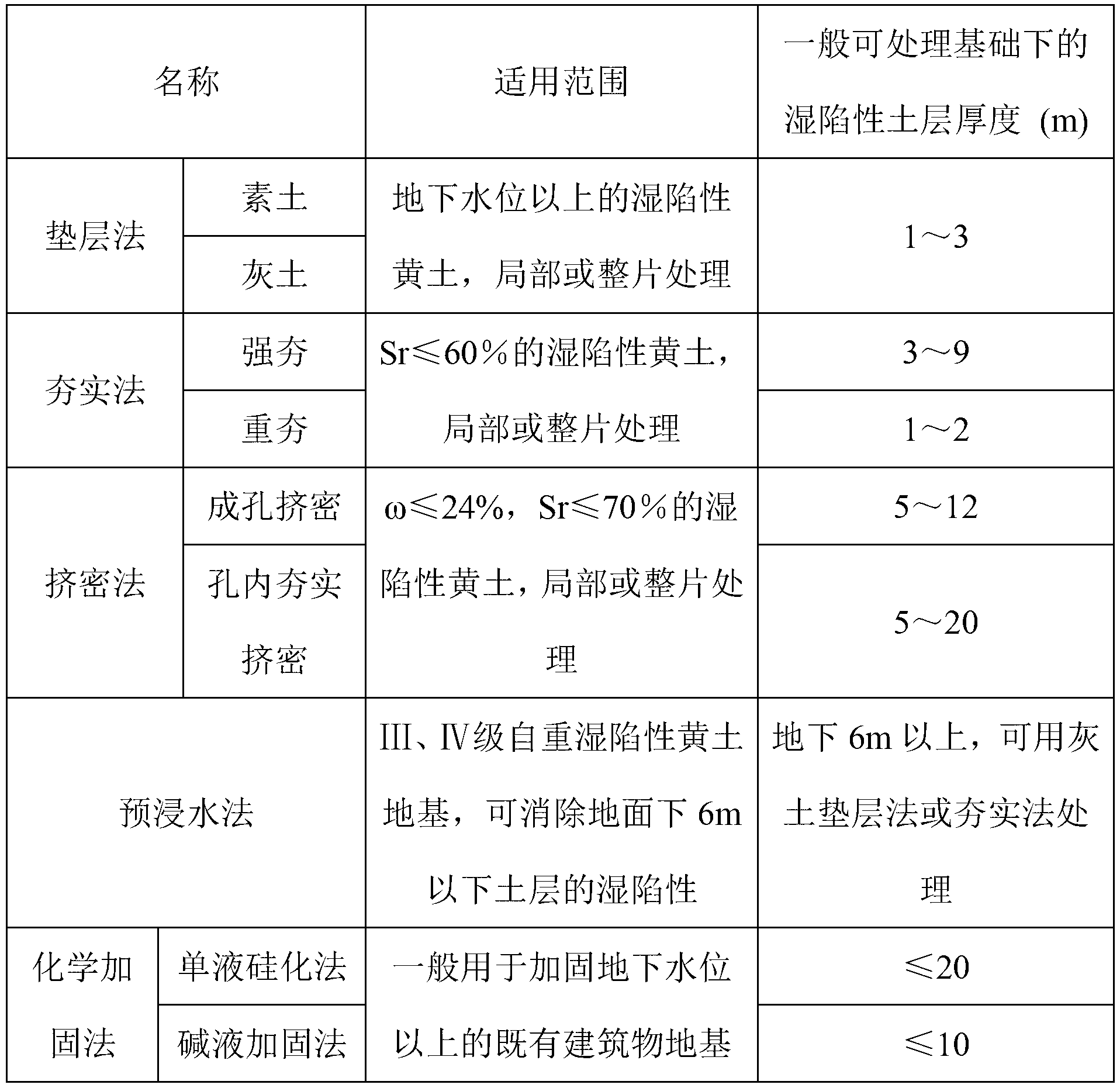

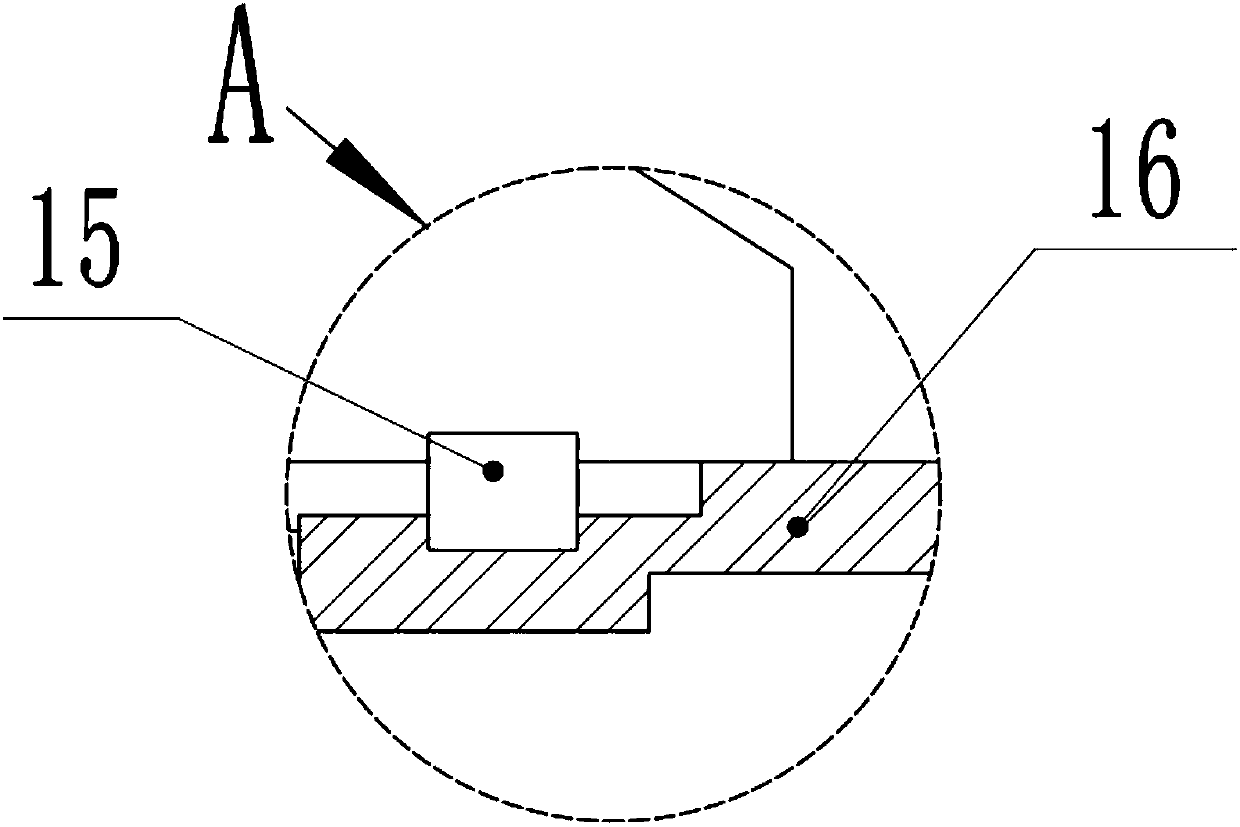

Processing method of soaking, vacuum preloading and slurry injecting for sand piles of collapsible loess foundation

InactiveCN103233454AIncrease the compressive stress of collapsible deformationImprove the level ofSoil preservationVacuum pumpingVacuum extraction

The invention discloses a processing method of soaking, vacuum pre-pressing and slurry injecting for sand piles of a collapsible loess foundation, which comprises the following steps: 1, manufacturing pile pipes in a collapsible loess stratum in a pre-pressing region, embedding a slurry injection steel pipe in each pile pipe, pouring sand at circumferences of the slurry injection steel pipes to form the sand piles, and laying a sand mat at the upper ends of all the sand piles while laying a vacuum extraction pipe; 2, digging sealing ditches at the periphery of the pre-pressing region, sequentially laying a first layer of geotextile, a diaphragm seal and a second layer of geotextile above the sand mat, backfilling clay layers and a heaping load body, filling water in the collapsible loess foundation of the sand piles, performing vacuum-pumping after saturation of the foundation, and completing consolidation and deformation under action of vacuum preloading; and 3, digging out the heaping load body, filling slurry into the slurry injection steel pipes, and pulling out the slurry injection steel pipes to form the slurry injected sand piles. The method provided by the invention has a better effect for the processing of the collapsible loess foundation.

Owner:XIAN UNIV OF TECH +1

Diaphragm-sealed valve, analytical chromatographic system and method using the same

There is provided a diaphragm sealed valve particularly advantageous in chromatographic systems. The valve is provided with first and second body and a seal member compressibly positioned therebetween. The first body comprises a first, a second and a common port, each opening and being interconnected to the others in a recessed fluid communication channel extending in a first interface of the first body. The valve is also provided with first and second plungers, each having a closed position wherein the plunger presses down the seal member against the seat of the corresponding port for closing said corresponding port, and an open position wherein the plunger extends away from the seat for allowing a fluid communication between the corresponding port and the channel. Complex valves are also provided as well as chromatographic systems and methods.

Owner:APN INC

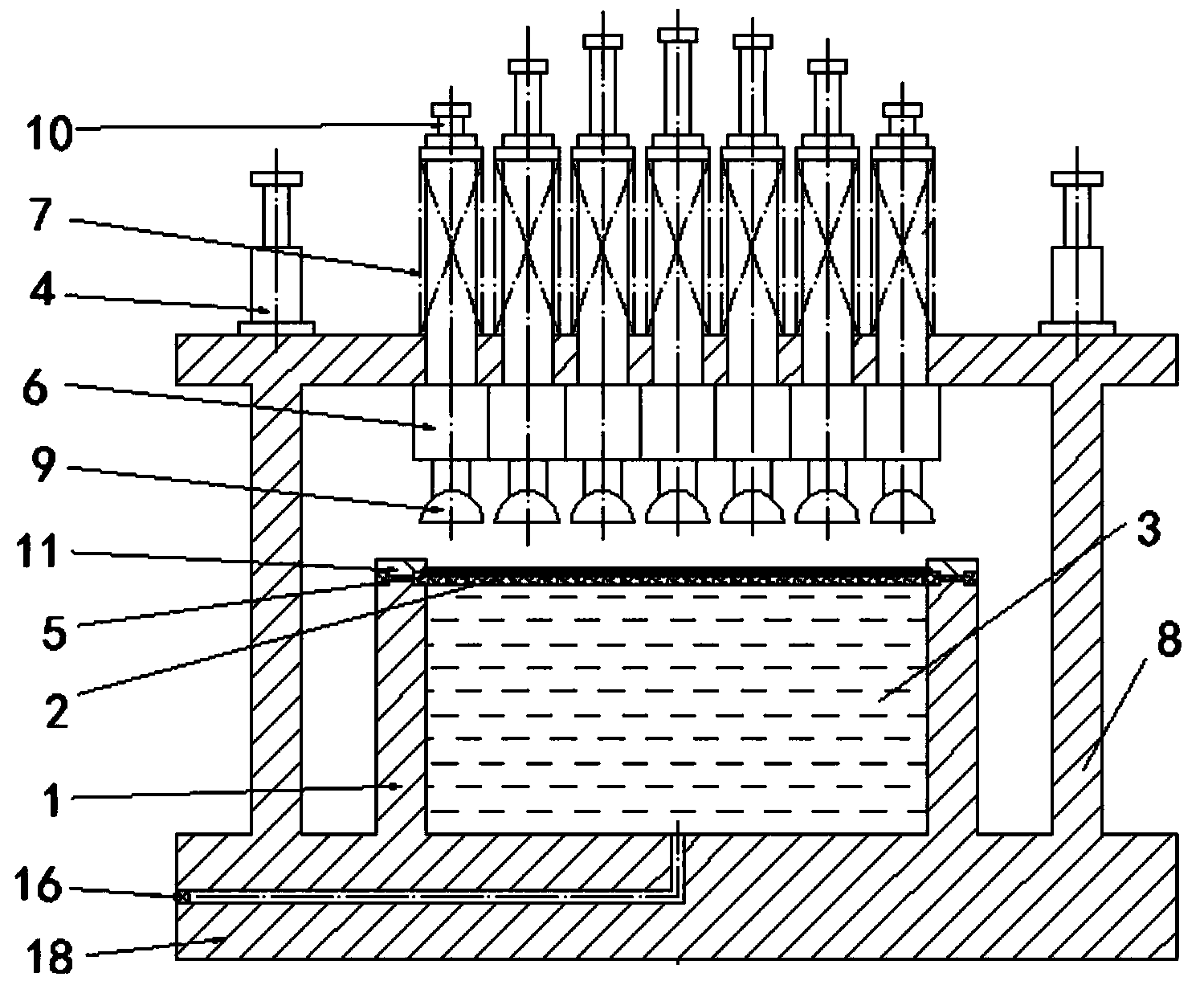

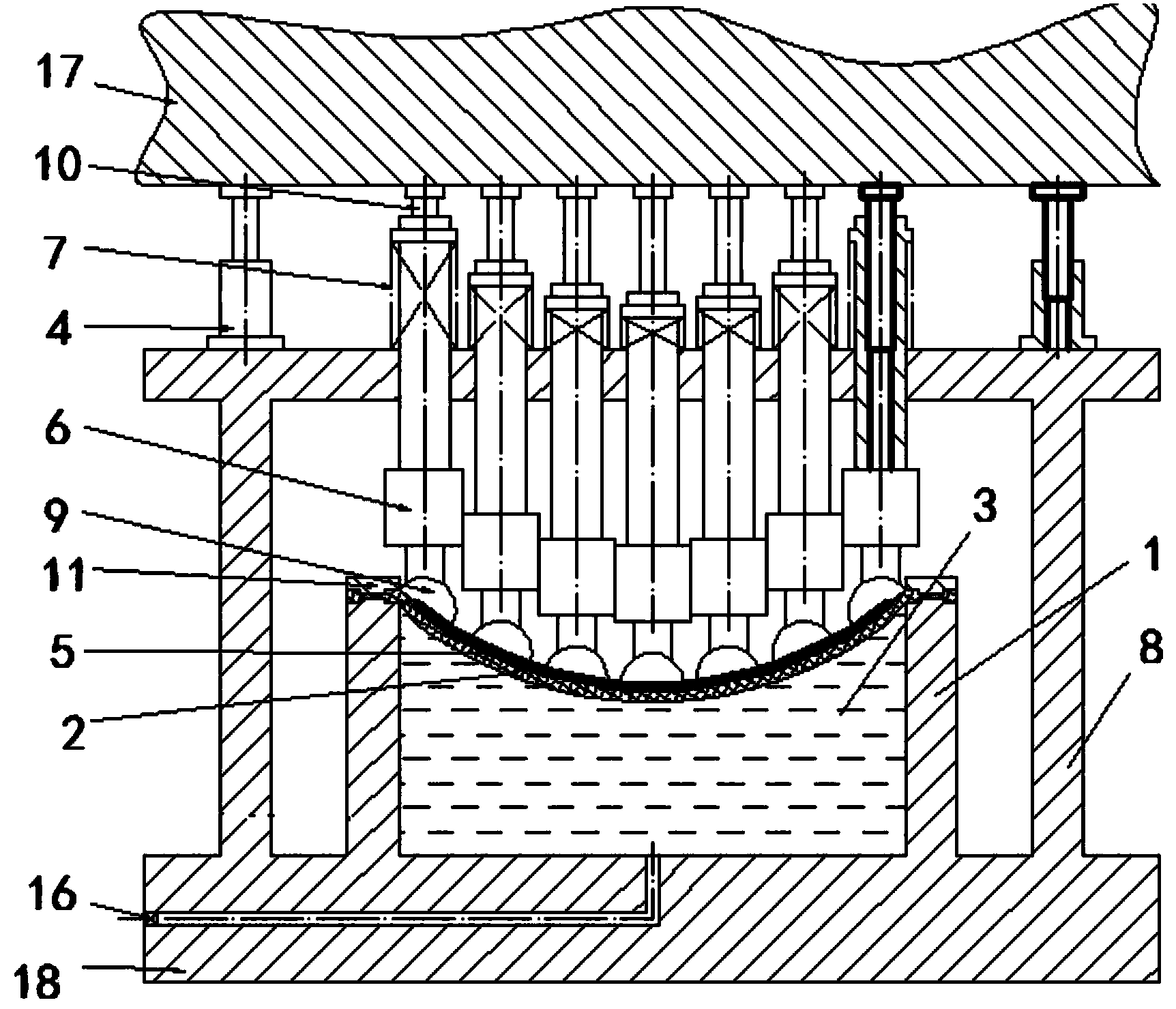

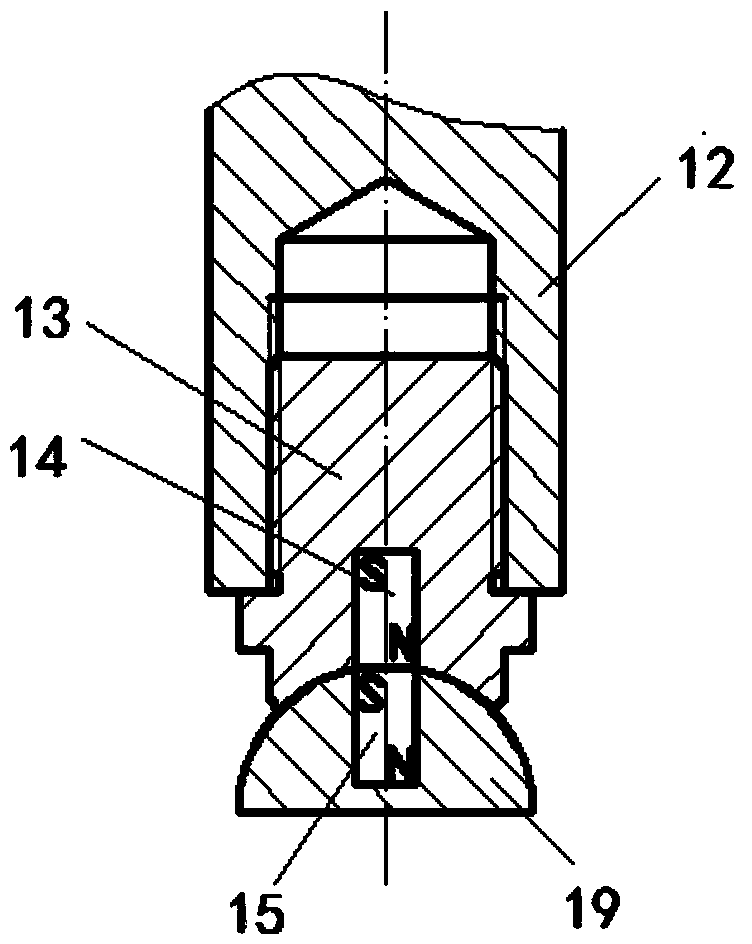

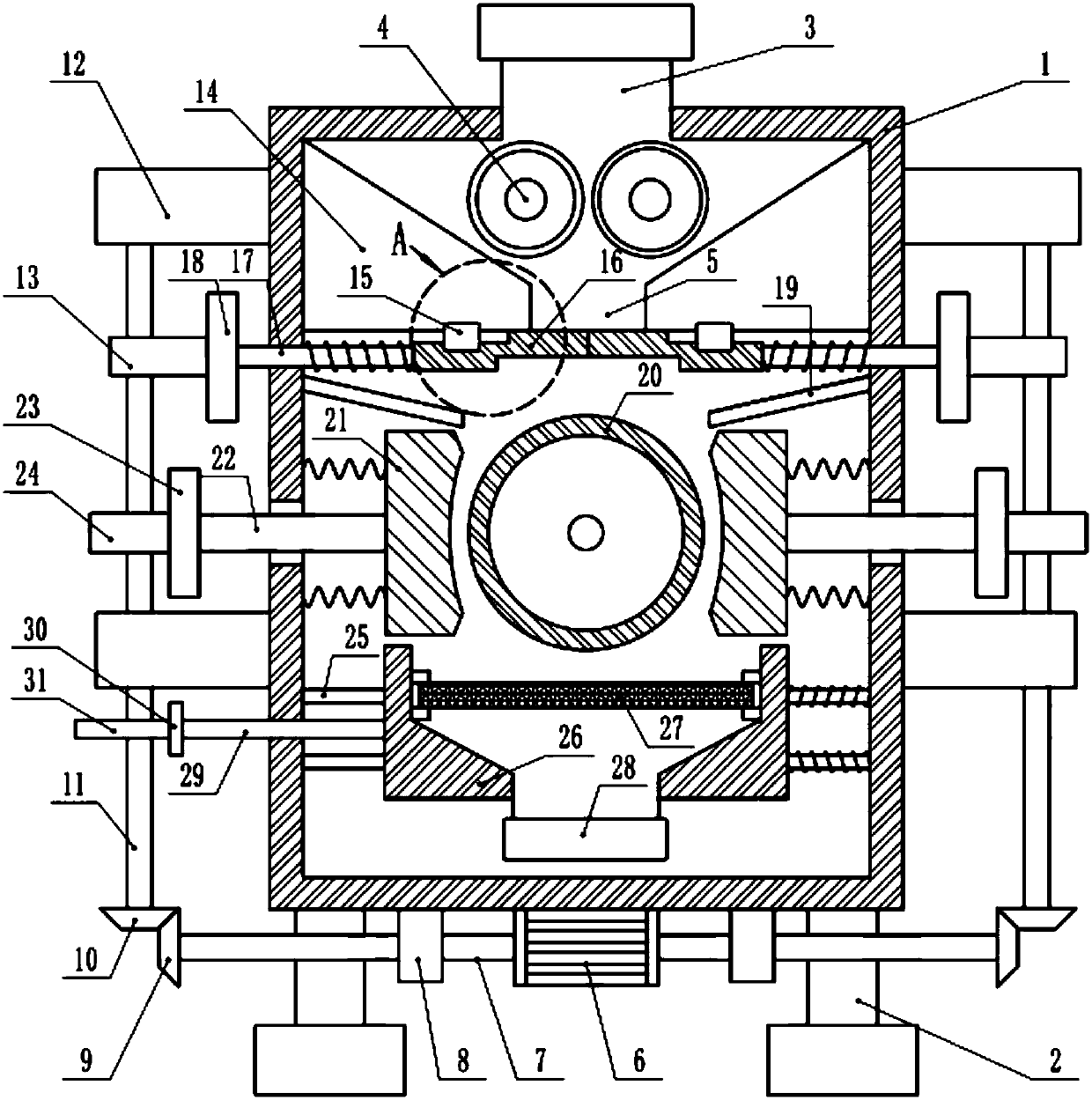

Flexible multi-point forming device for plates

Owner:HARBIN INST OF TECH AT WEIHAI

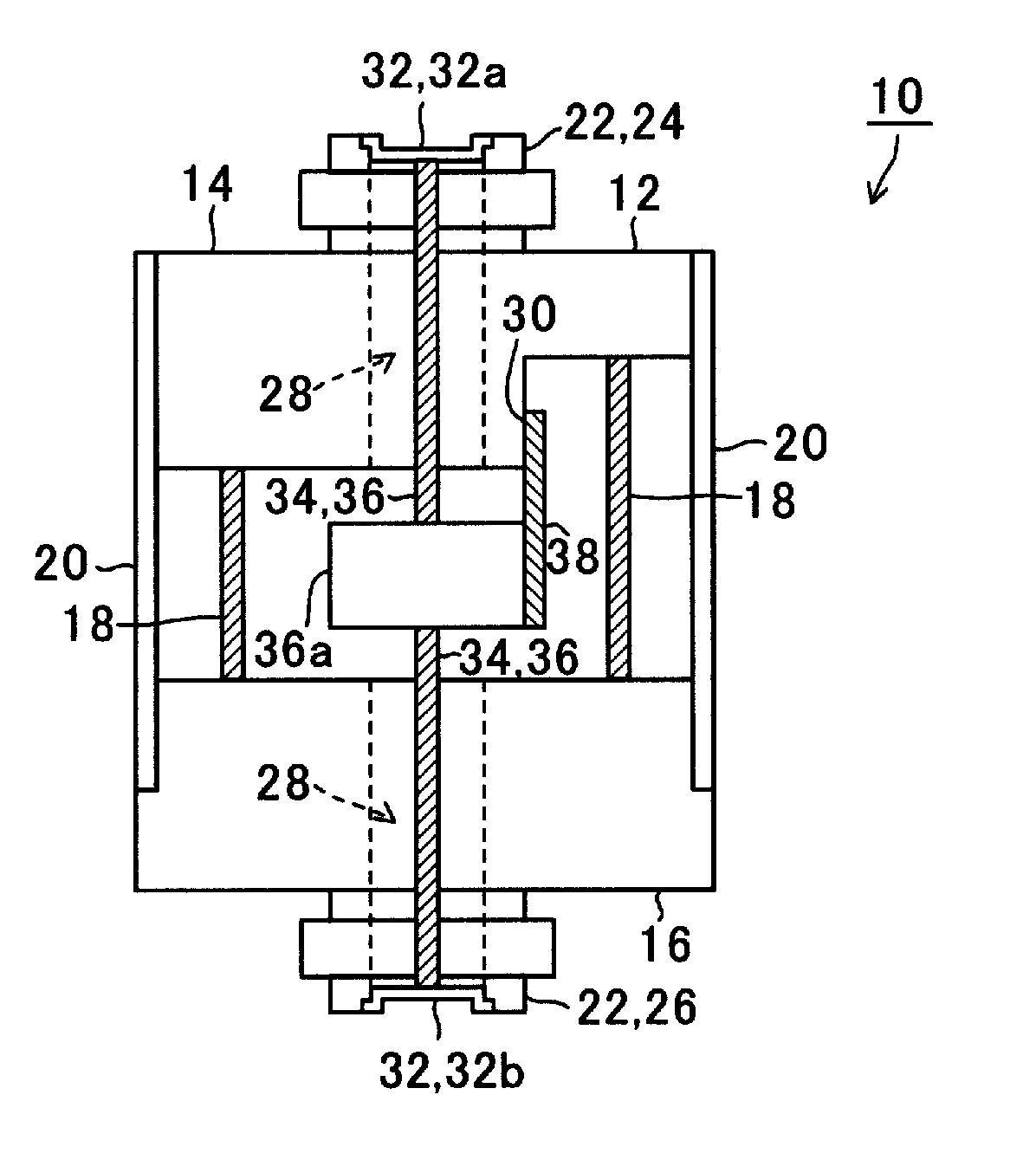

Diaphragm for pressure sensor and pressure sensor

InactiveUS20090308168A1Less occurrenceLess susceptibilityFluid pressure measurement using piezo-electric devicesFluid pressure measurement using elastically-deformable gaugesEngineeringDiaphragm seal

A diaphragm for a pressure sensor includes: a central section serving as a diaphragm body, the central section including: an external surface deformed upon receipt of an external pressure; and an internal surface transmitting a force to a pressure sensitive element inside a housing of the pressure sensor; a peripheral section that is an exterior of the central section and welded to an outer circumference of a pressure input orifice that is provided to the housing; and a step wall provided between the central section and the peripheral section. The central section and the peripheral section are integrally and concentrically provided. The diaphragm seals the pressure input orifice.

Owner:SEIKO EPSON CORP

Extendable sleeve for poured concrete deck

Owner:RELIANCE WORLDWIDE CORP

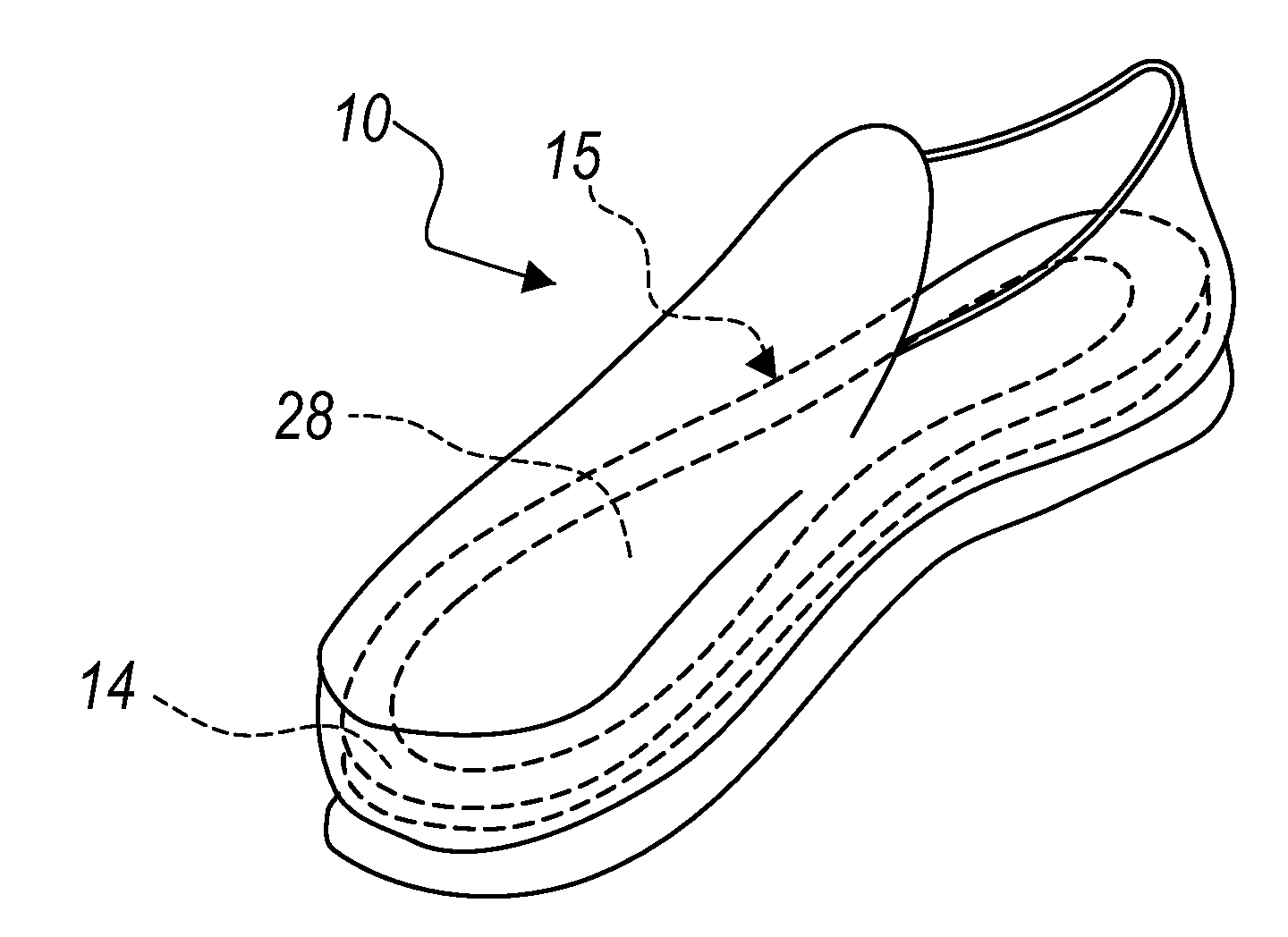

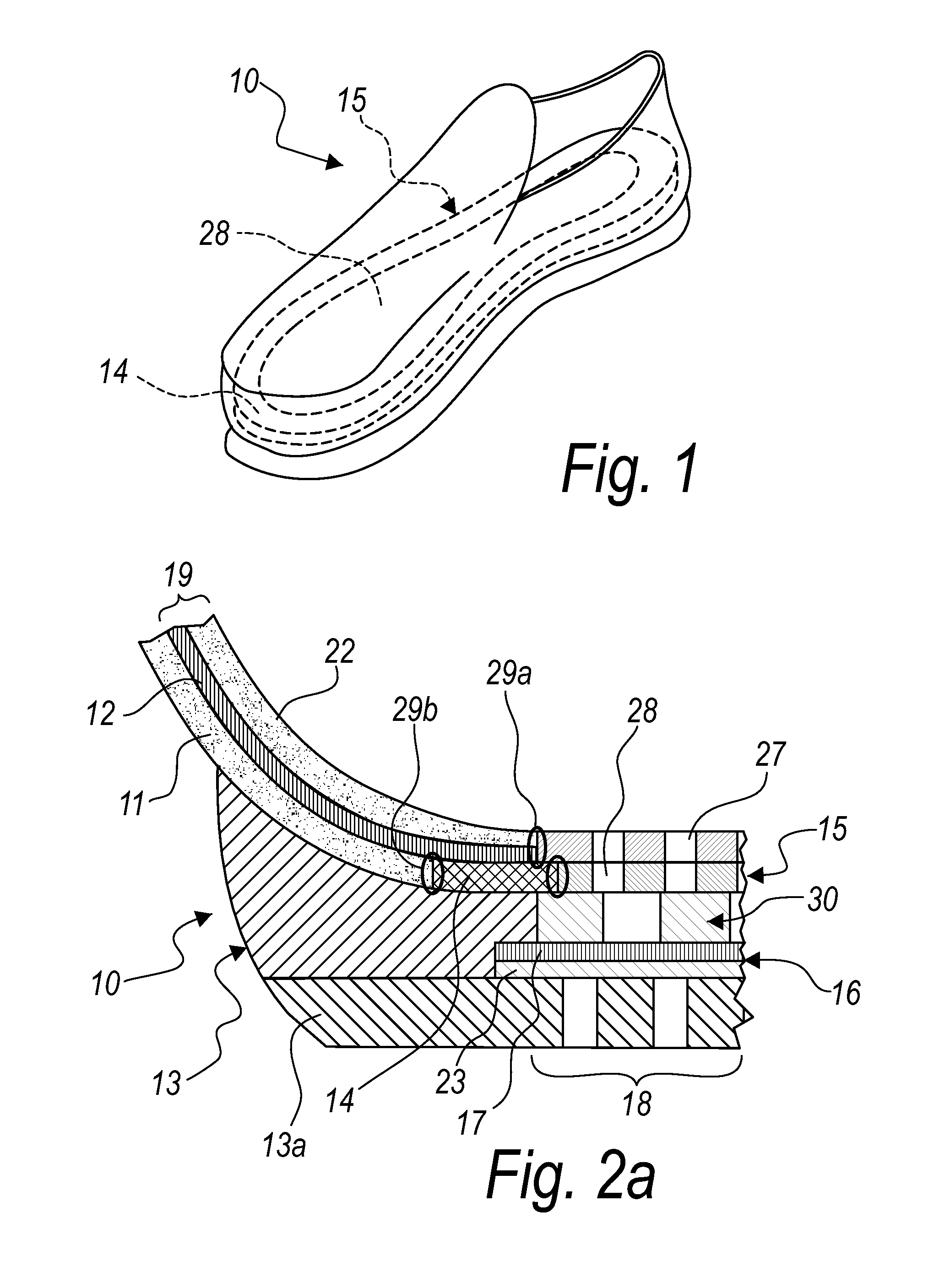

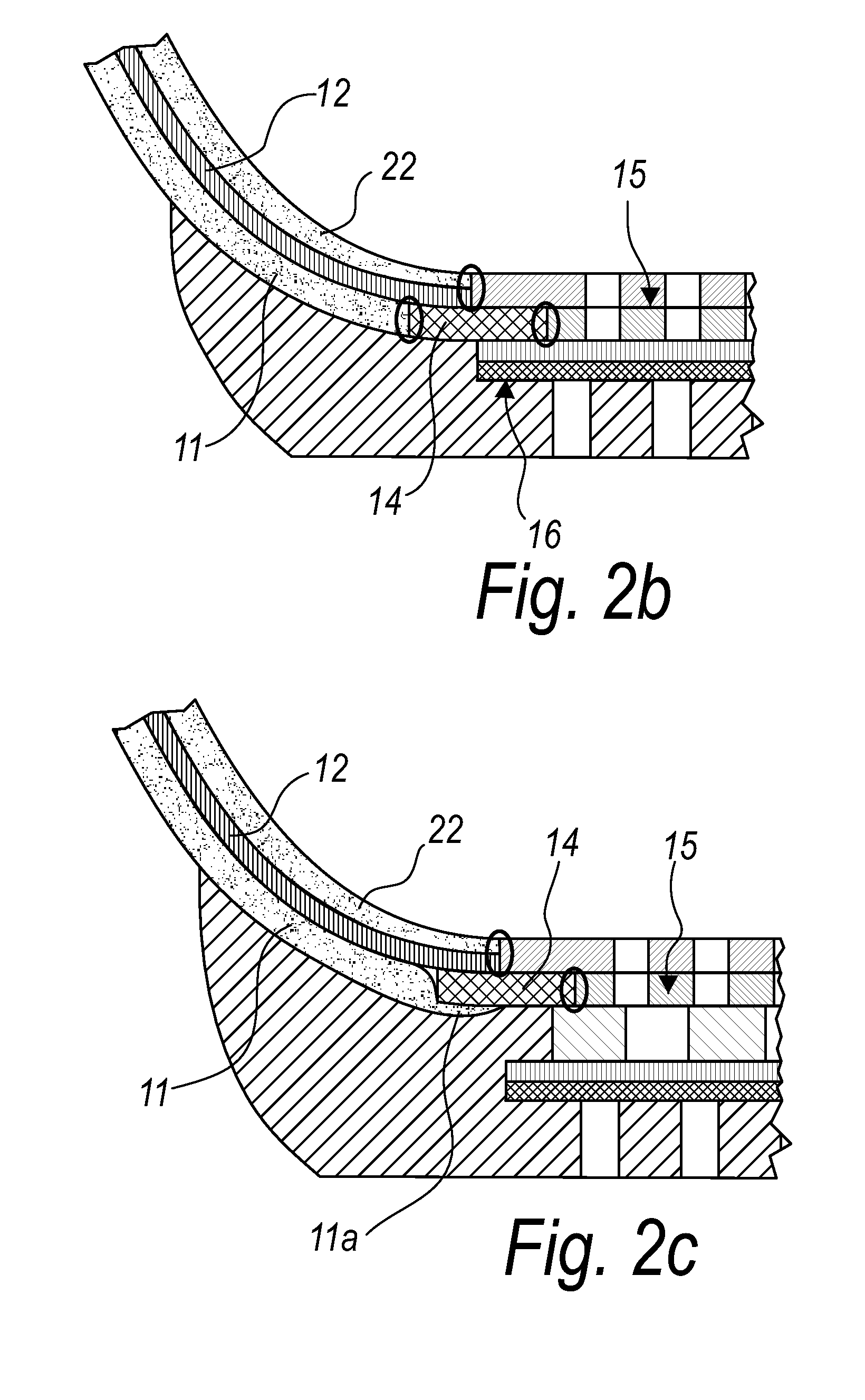

Waterproof and vapor-permeable shoe

A waterproof and vapor-permeable shoe, including an upper that is lined at least partially by an upper membrane impermeable to water in a liquid state and permeable to water vapor. The upper membrane is connected hermetically to a sole which is impermeable to water in the liquid state. The hermetic connection is provided by a sealing element included in an assembly insole. The sealing element is permeable with respect to sealing material, or a glue, sealing adhesive, or polymeric material for providing the sole, and is impregnated with the sealing material, which grips the upper membrane and is connected to the sole or forms a single body therewith, sealing it to the upper membrane.

Owner:GEOX SPA

Tamper evident pouring spout

InactiveUS6237818B1Overcome disadvantagesGood removal effectClosuresLiquid flow controllersDiaphragm sealEngineering

A flexible pouring spout for material containers incorporating a tamper evident ring having a nested flexible spout capable of being selectively moved between a nested position and an extended position, a cap threadedly attached to the spout, a tamper-evident ring attached to the cap by a plurality of frangible elements, and a metal ring for attaching the closure to the container. The metal ring is secured over the peripheral flange of the spout and over the tamper-evident ring, preventing the closure from being removed or the spout from being extended without detection. A flexible bail handle is attached to the cap member to facilitate extending the spout member and removing the cap. For additional tamper evidence, an internal diaphragm is used to seal off the spout until the closure is opened and the diaphragm removed.

Owner:RIEKE

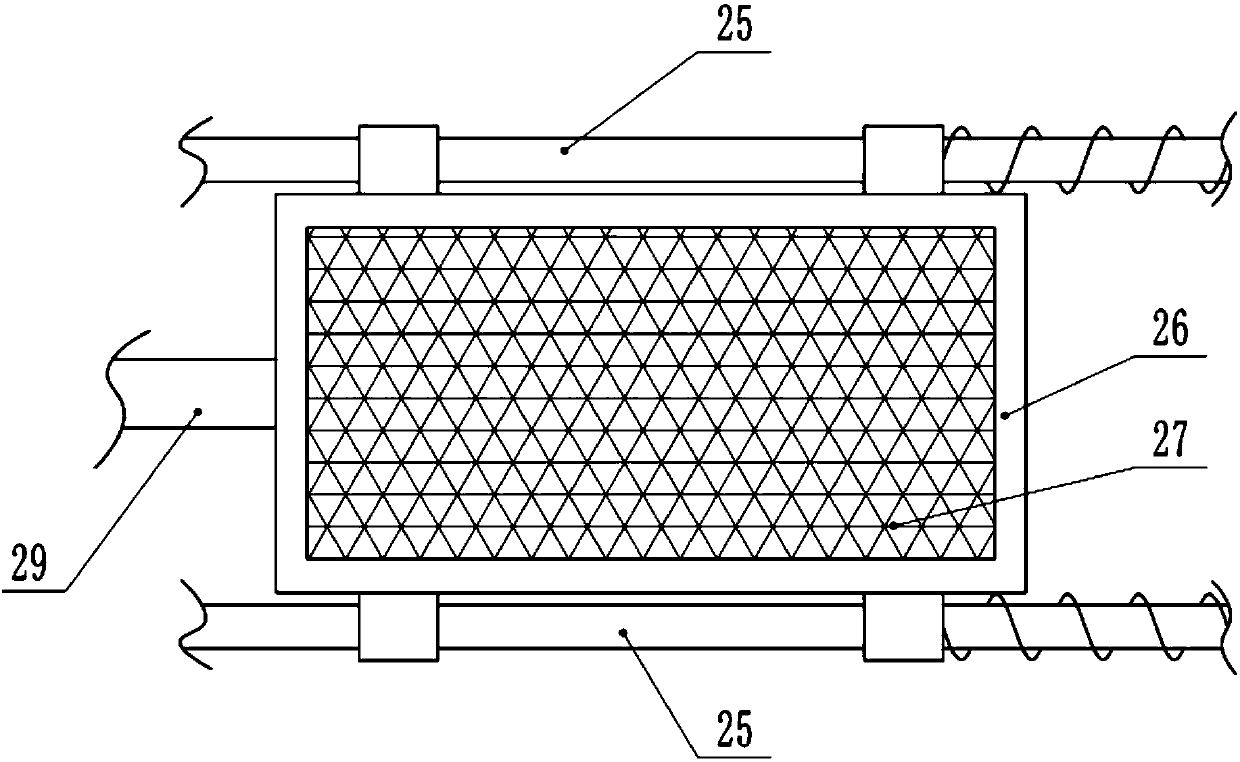

Dry soil fine grinding and screening device for analyzing soil in contaminated area

InactiveCN107684953AImprove screening efficiencyReduce work stressSievingScreeningAgricultural engineeringDry soil

The invention discloses a dry soil fine crushing and screening device for soil analysis in a polluted area, which comprises a device case, a preliminary crushing roller, a double-axis motor, a first cam, a sealing partition, a fine crushing roller and a screening box. A slider is slidably installed on the lower side of the material plate A, and a packing plate is fixedly installed on the lower side of the sliding block. One side of the packing plate is fixedly connected with a first connecting rod, and the first connecting rod passes through the device chassis and is connected with a top block. A. A fine crushing roller is installed in rotation inside the casing of the device, and arc-shaped plates are arranged on the left and right sides of the fine crushing roller; a screening box is slidingly installed on the guide rod. The crushing and screening device can carry out preliminary crushing and fine crushing, so as to improve the effect of crushing. At the same time, it can carry out fine crushing in batches when performing fine crushing after preliminary crushing, thereby reducing the working pressure of the fine crushing roller and improving the effect of crushing. At the same time, after the crushing is completed, the arc-shaped plates on both sides can be moved to both sides, so as to facilitate the falling of the crushed dry soil.

Owner:王连军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com