Flexible multi-point forming device for plates

A technology of multi-point forming and sheet metal, which is applied in the field of flexible multi-point forming devices for sheet materials, can solve the problems of high manufacturing cost, high device cost, and inability to carry out the forming process, and achieve simple operation and use, reasonable structure of the device, and suppression of sheet metal formation. wrinkled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

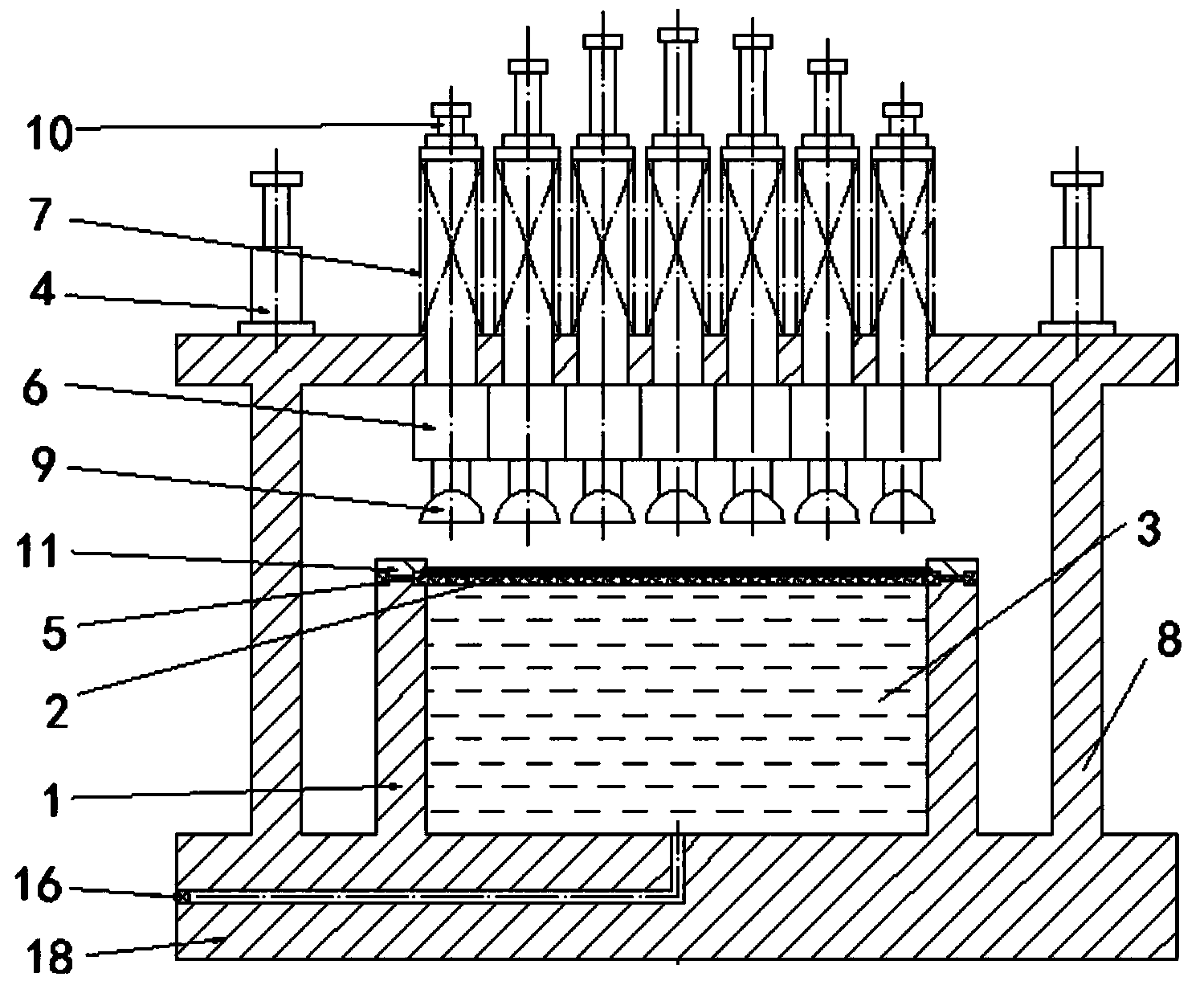

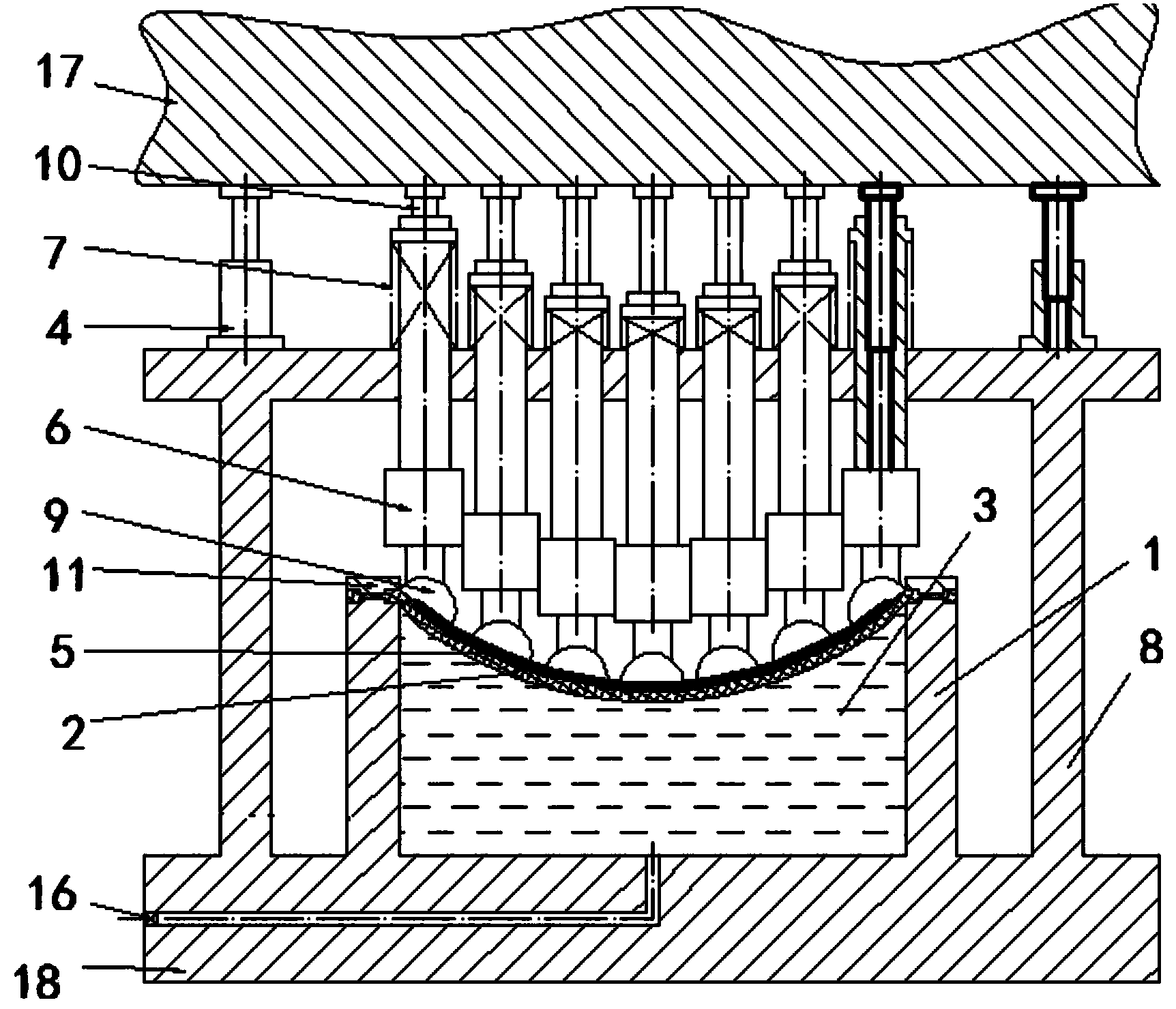

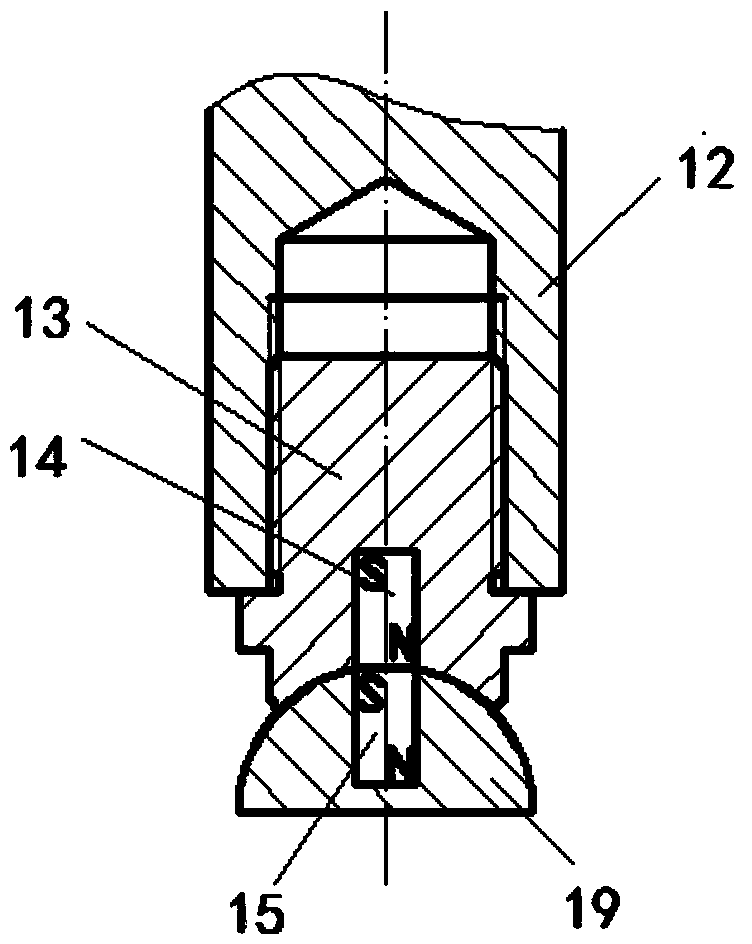

[0024] Please refer to Figure 1 to Figure 3 , the present invention provides a flexible multi-point forming device for plates, comprising: a hydraulic container 1, the hydraulic container 1 has an opening; a flexible diaphragm 2 is installed at the opening, and the flexible diaphragm 2 seals the interior of the hydraulic container 1 to form a hydraulic cavity 3. The pressure regulating unit communicates with the hydraulic chamber 3; a plurality of pressurizing units are movable relative to the flexible diaphragm 2; a plurality of pressurizing units move toward the direction of the flexible diaphragm 2, so that the flexible diaphragm 2 and the The plates 5 to be formed between the pressurizing units deform synchronously with the deformation of the flexible diaphragm 2 into the hydraulic chamber 3 until the plates 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com