Processing method of soaking, vacuum preloading and slurry injecting for sand piles of collapsible loess foundation

A technology of collapsible loess and a treatment method, applied in the field of foundation treatment, can solve the problems of unsatisfactory treatment effect of collapsible loess foundation, unsatisfactory bearing capacity of composite foundation, long period, etc., and achieves increased compressive stress and simple construction. , the effect of improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

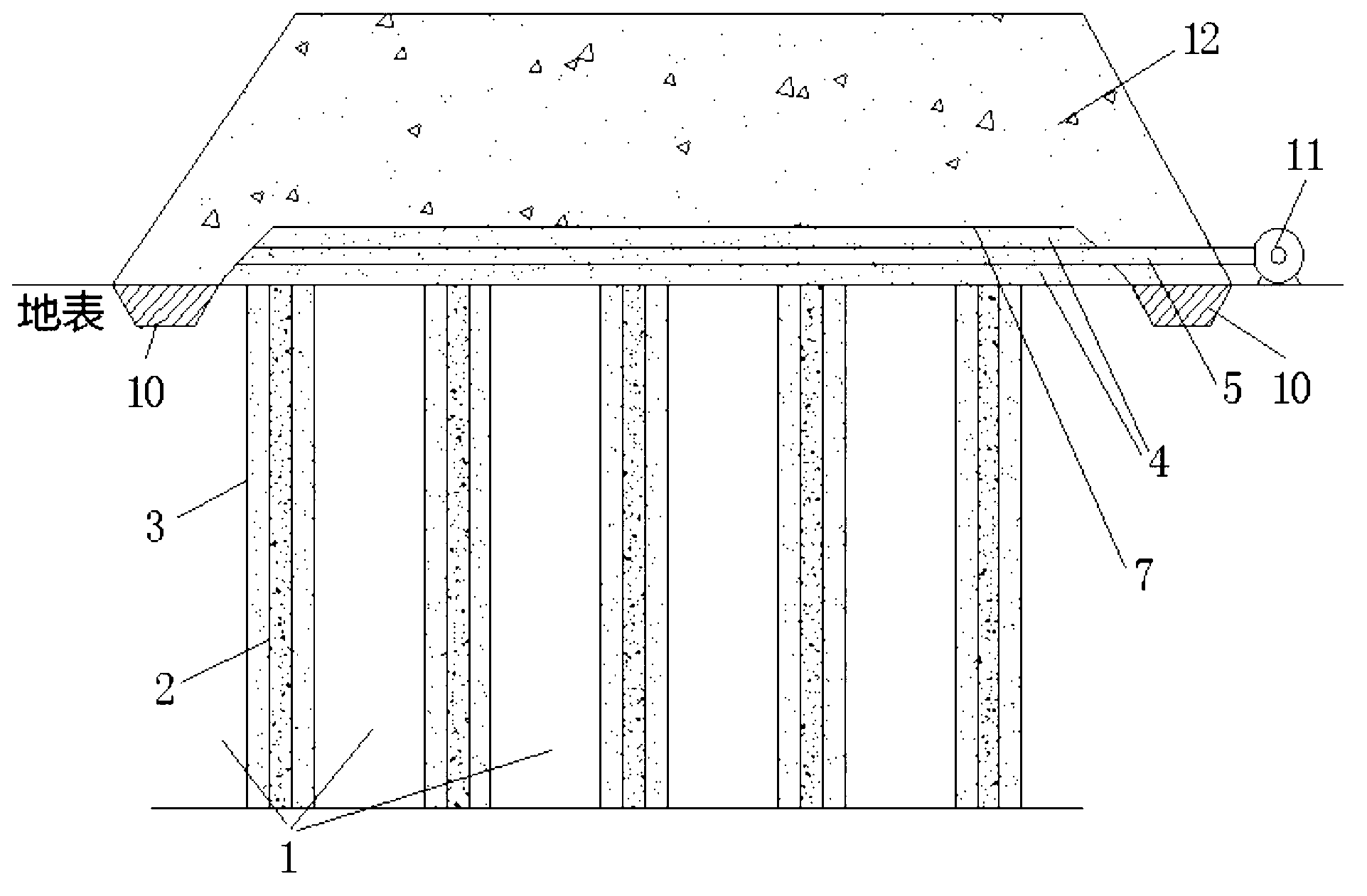

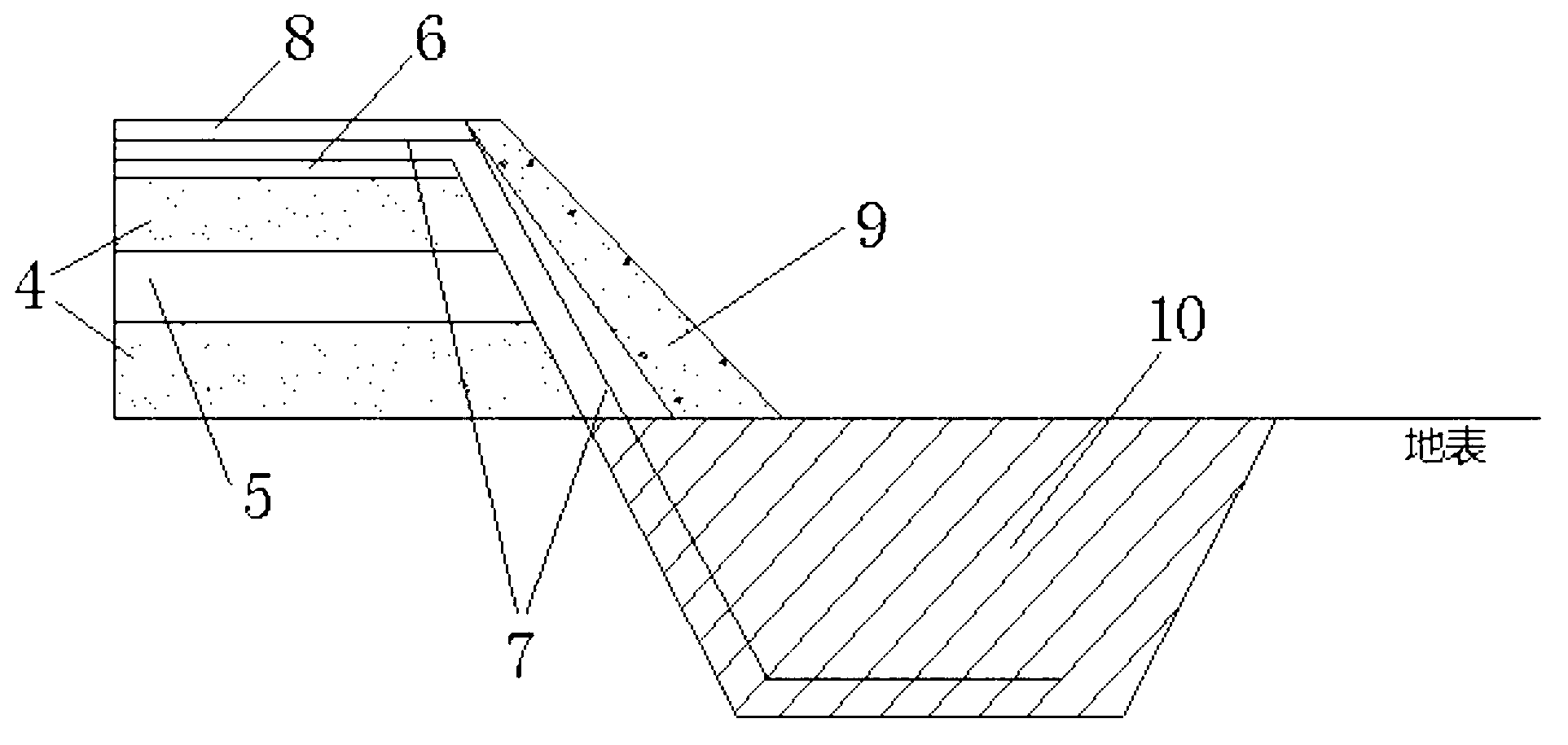

[0022] refer to figure 1 , figure 2 , the sand pile immersion vacuum preloading and grouting treatment method of the collapsible loess foundation of the present invention, implement according to the following steps:

[0023] Step 1, sinking pile pipes into holes (or drilling holes) in the collapsible loess stratum 1 of the selected pre-compression area to make pile pipes, and embedding a grouted steel pipe 2 in each pile pipe, Make the grouting steel pipe 2 be located on the axis line of the pile pipe, and pour sand into the outer periphery of the grouting steel pipe 2 to form a sand pile 3, and seal the top hole of the grouting steel pipe 2; when all the sand piles 3 are made, pass the sand Pile 3 is injected with water to saturate the collapsible loess foundation, which promotes the self-weight collapsibility of the foundation and elimin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com