Patents

Literature

1880results about "Advancing/retarding ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

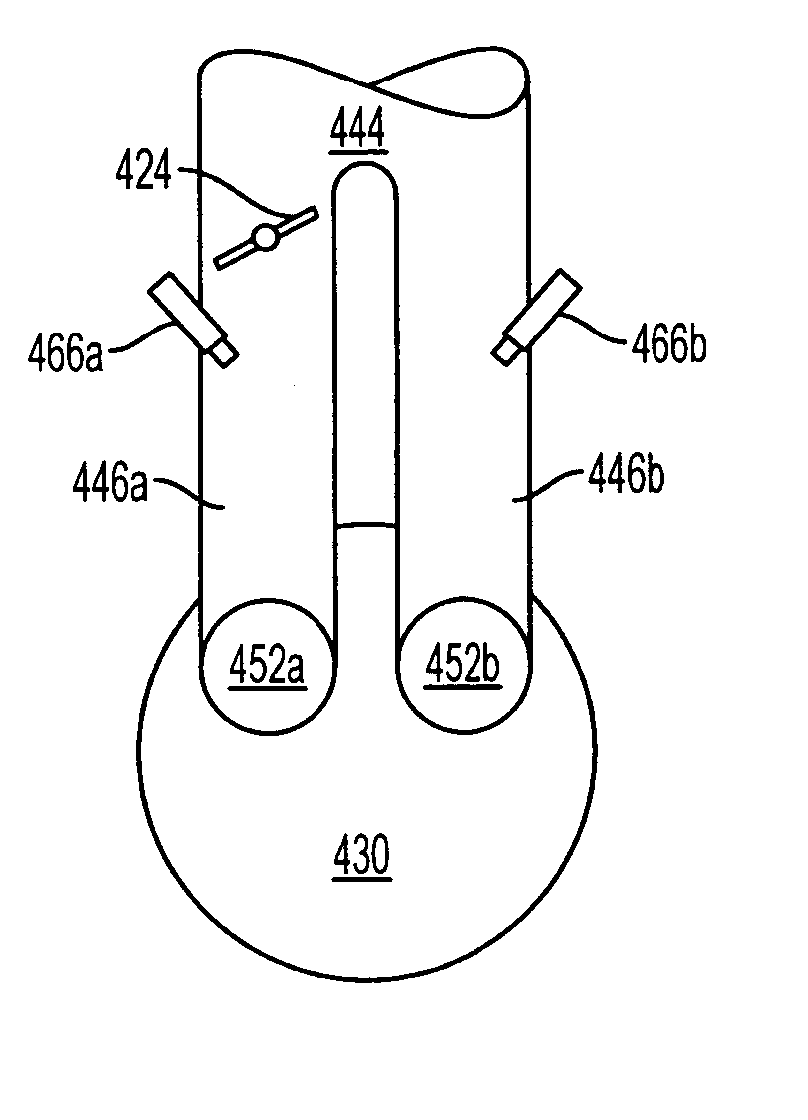

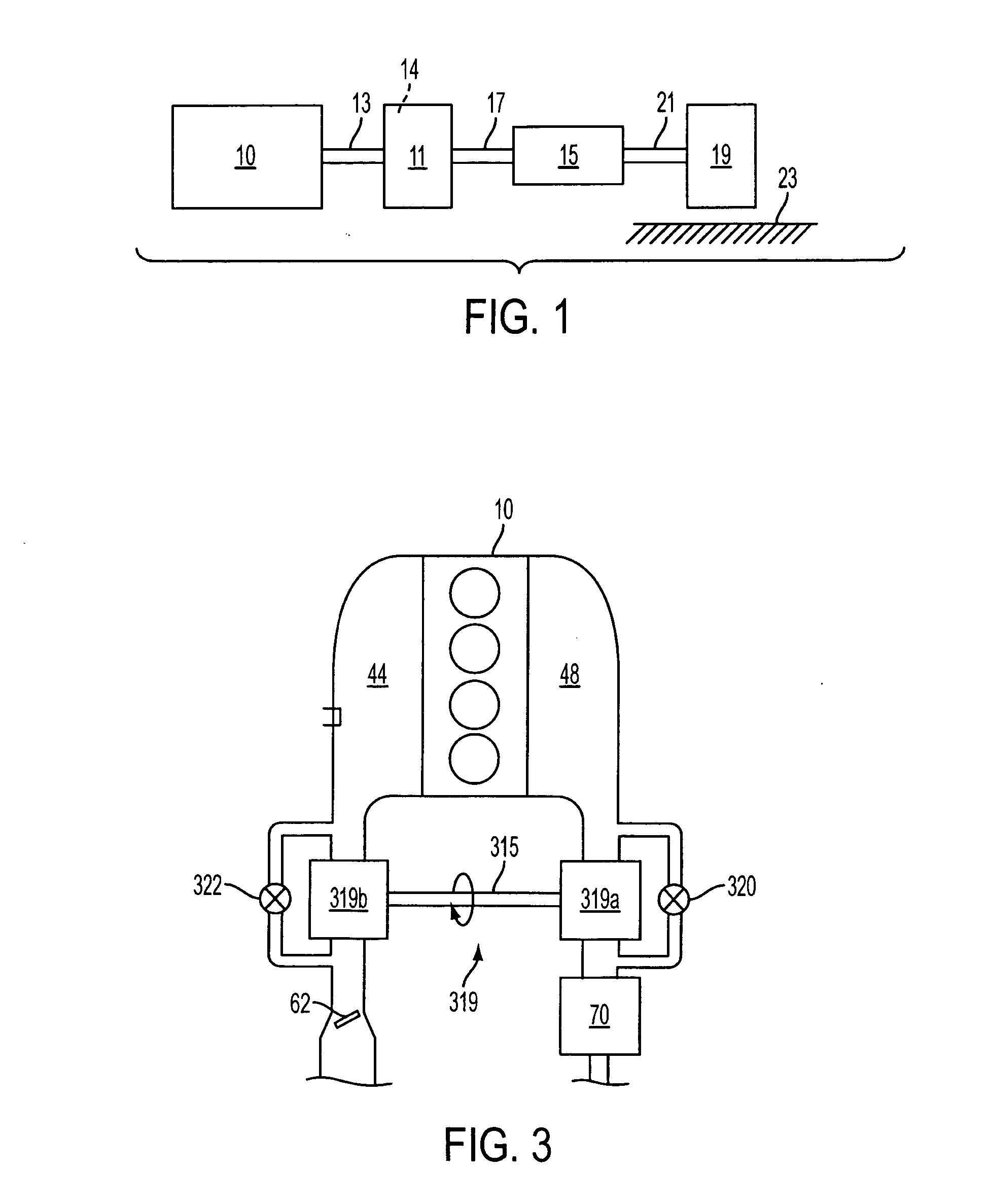

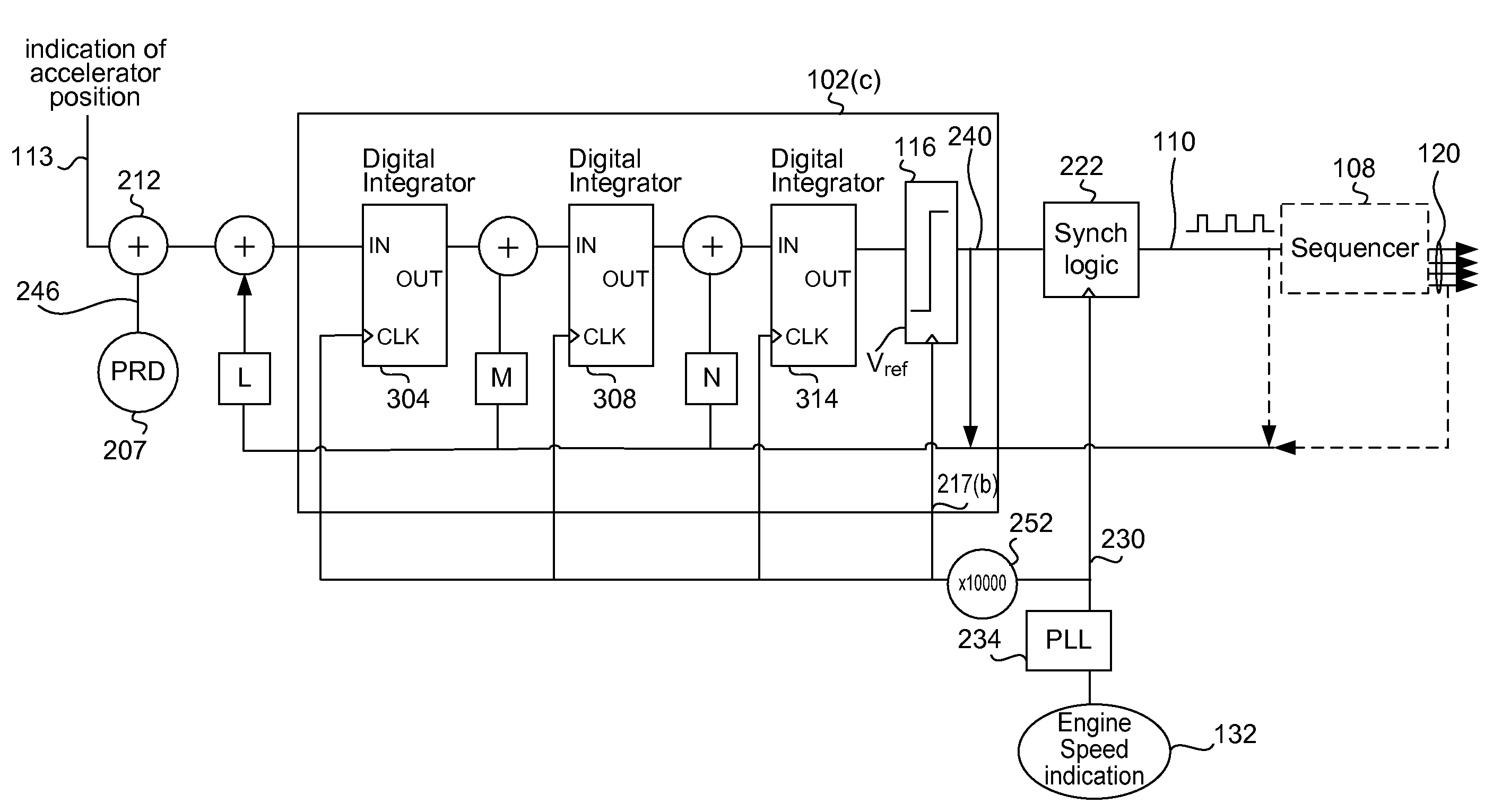

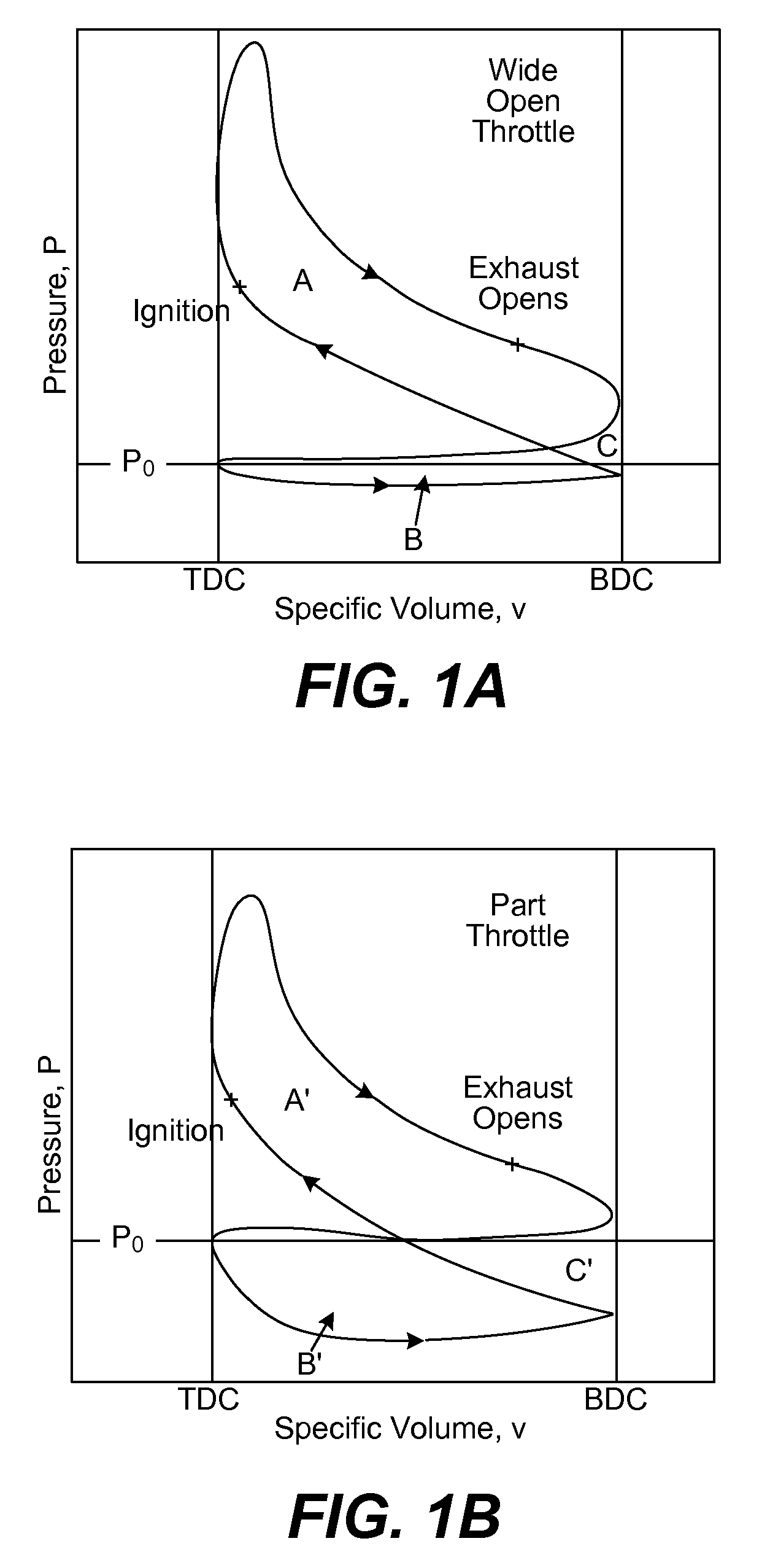

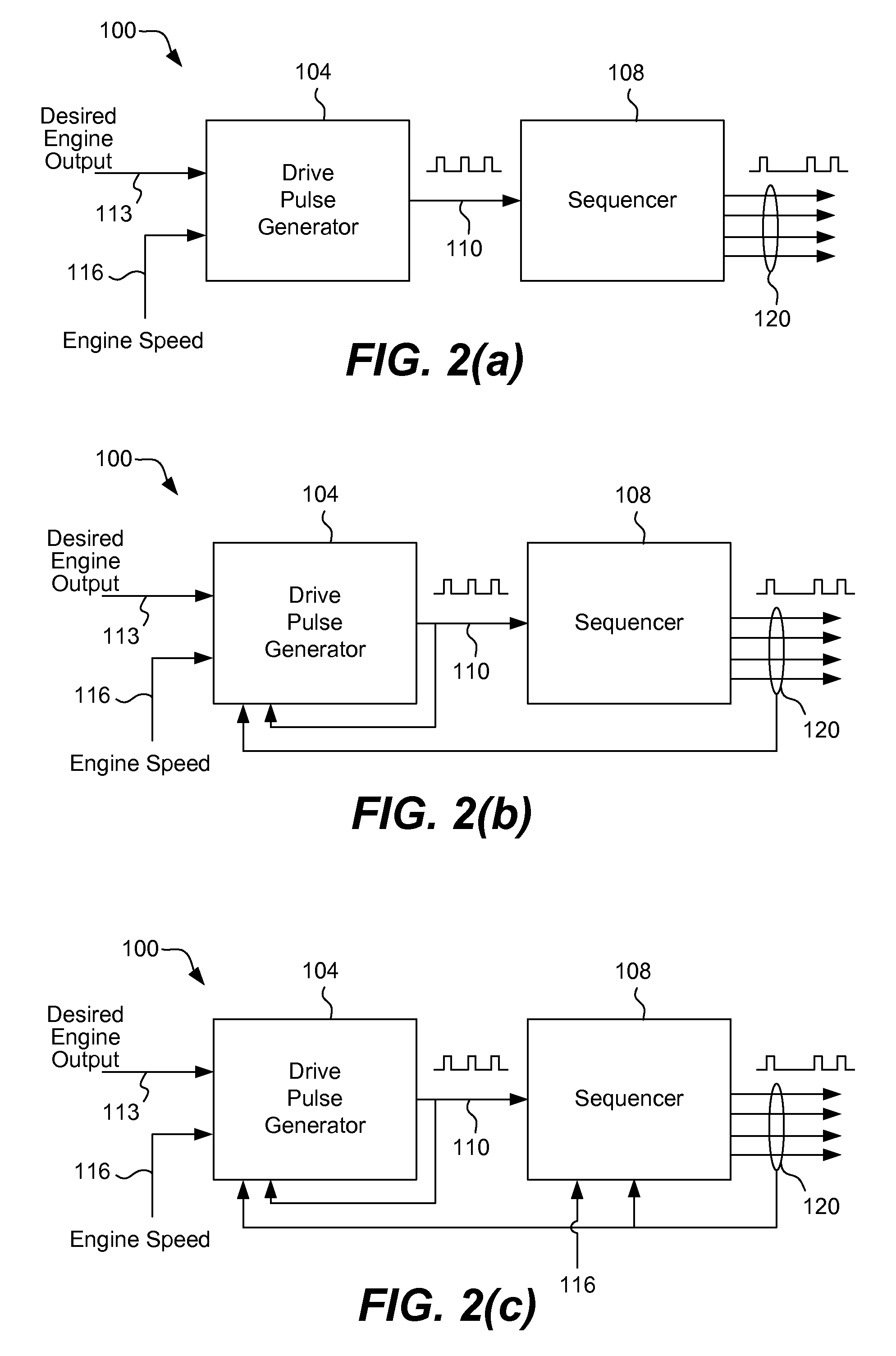

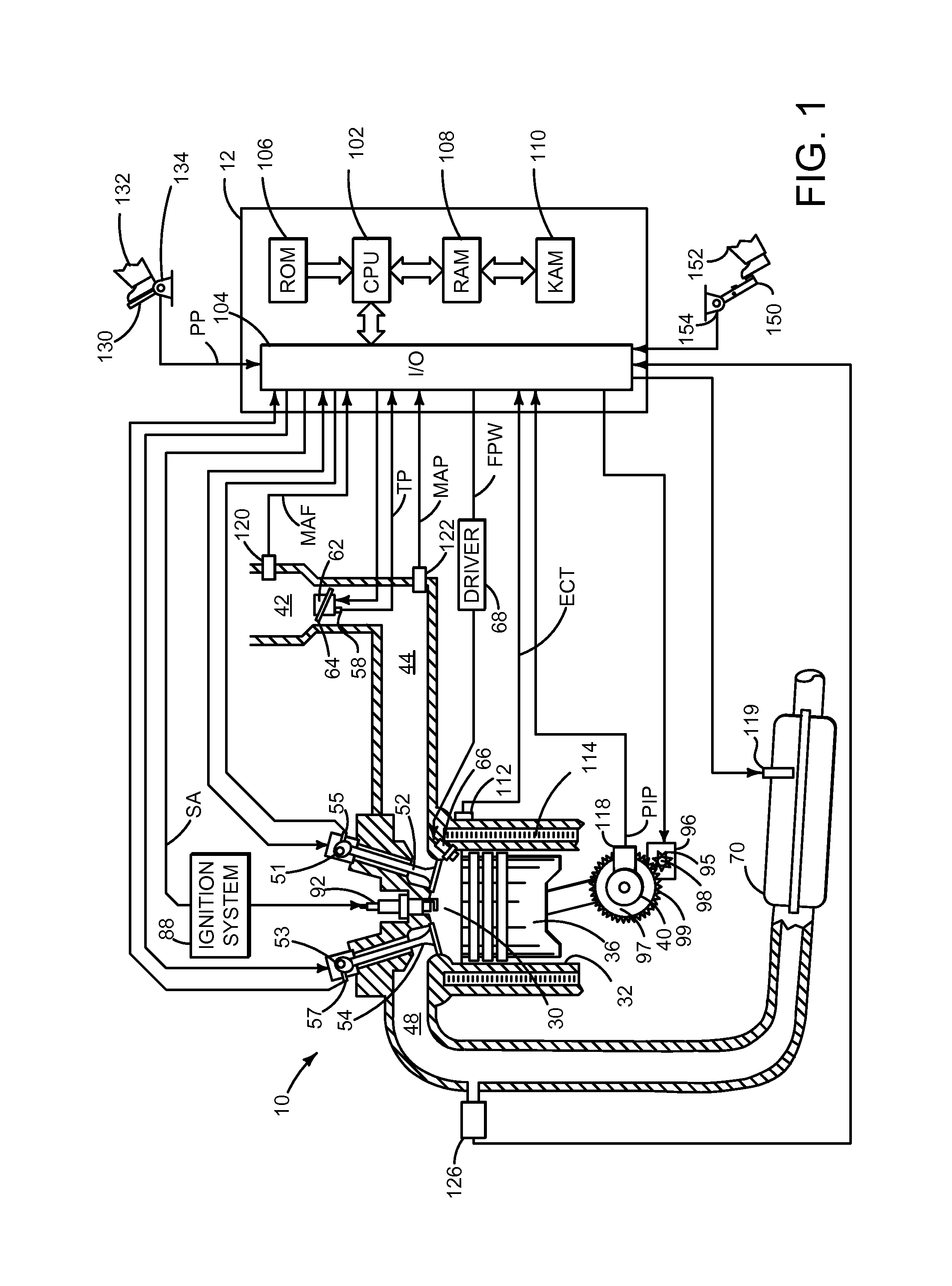

Internal combustion engine control for improved fuel efficiency

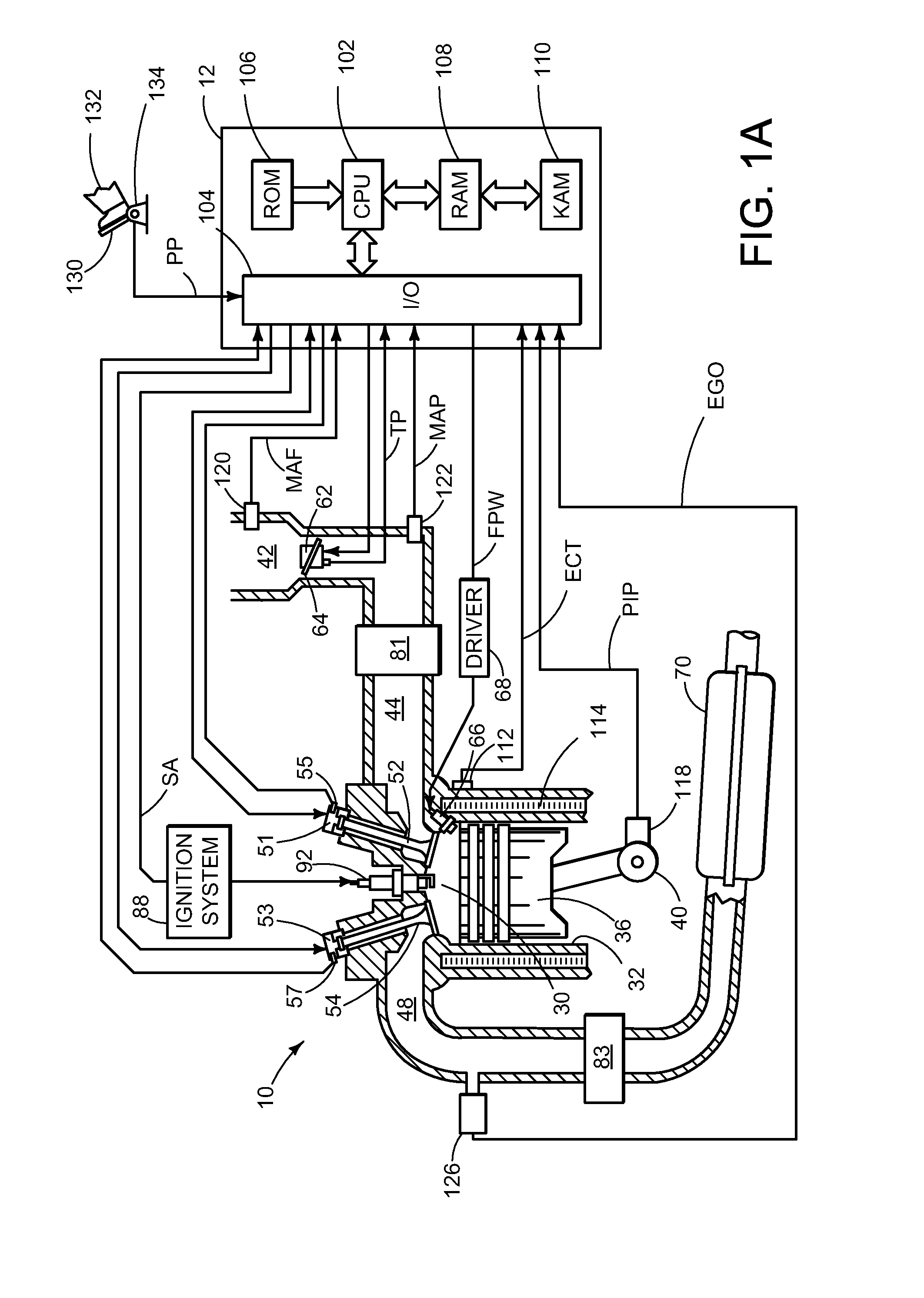

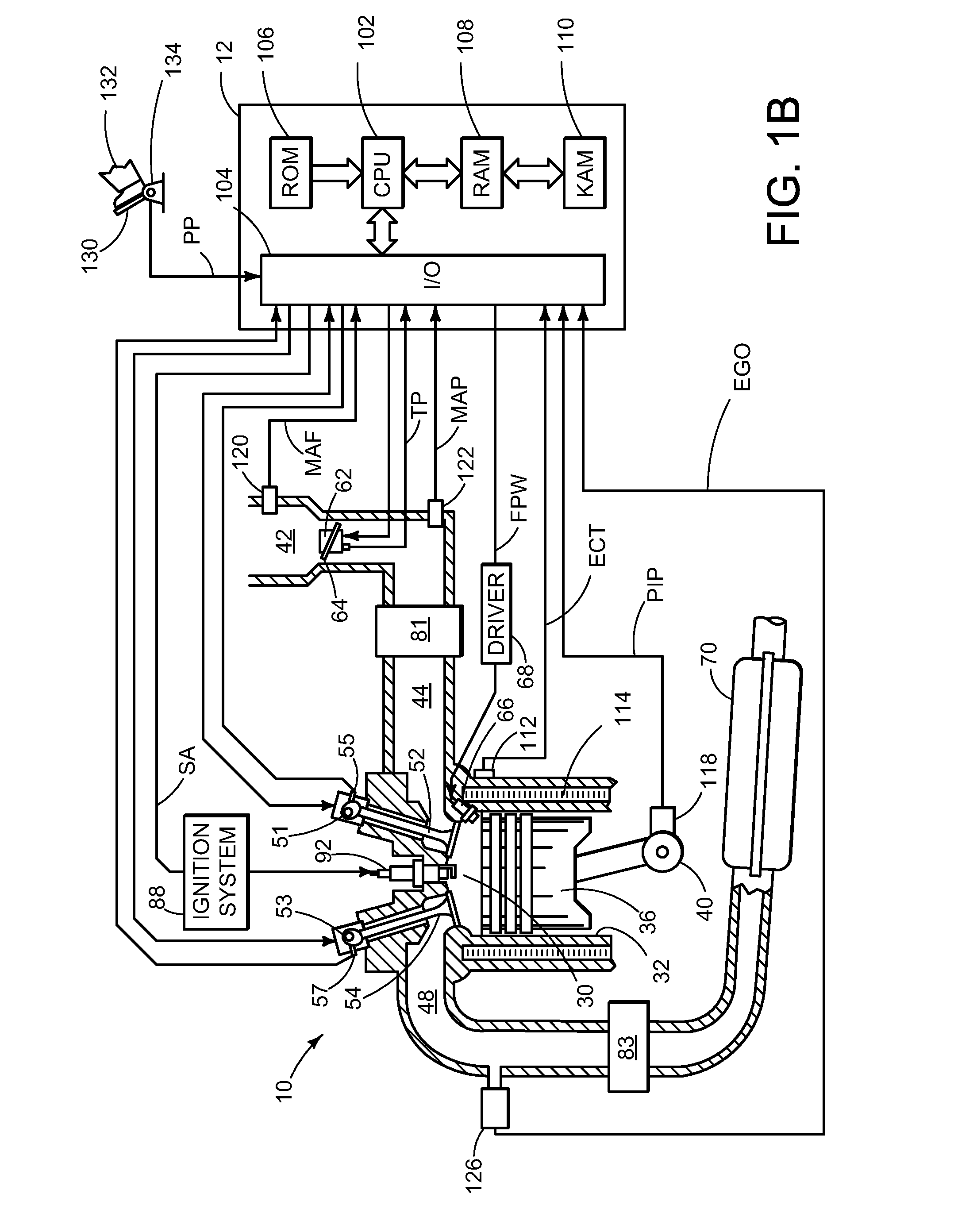

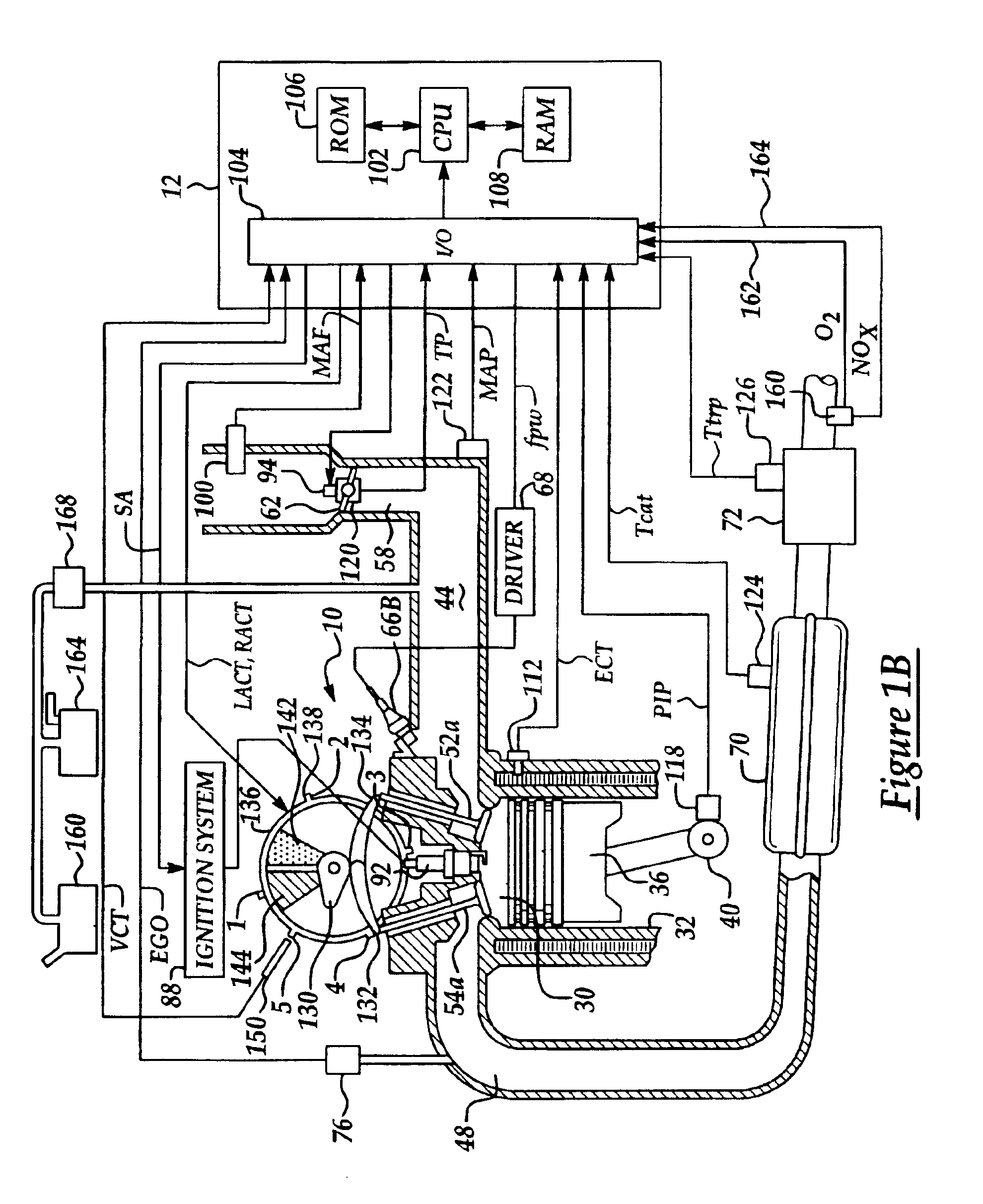

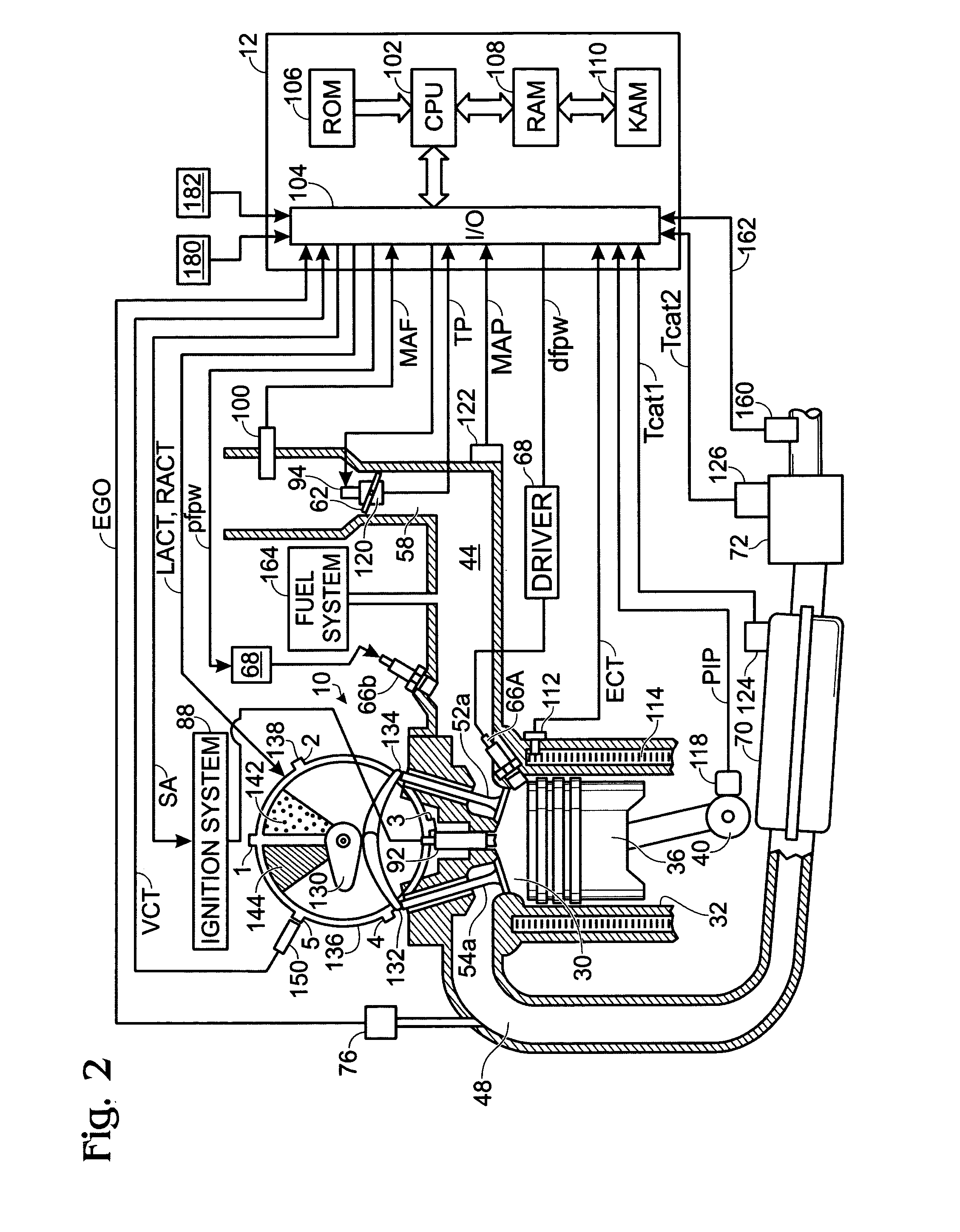

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

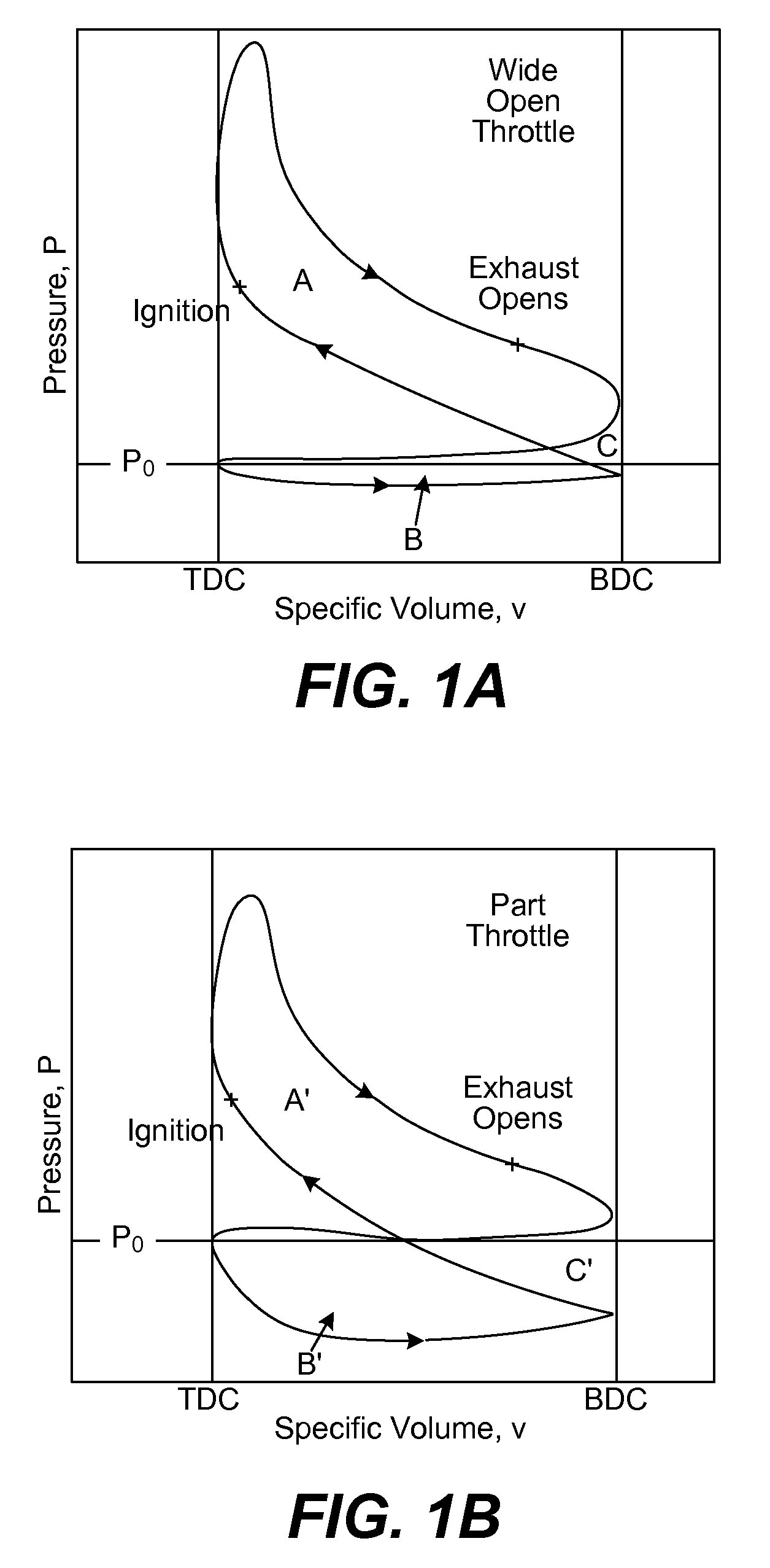

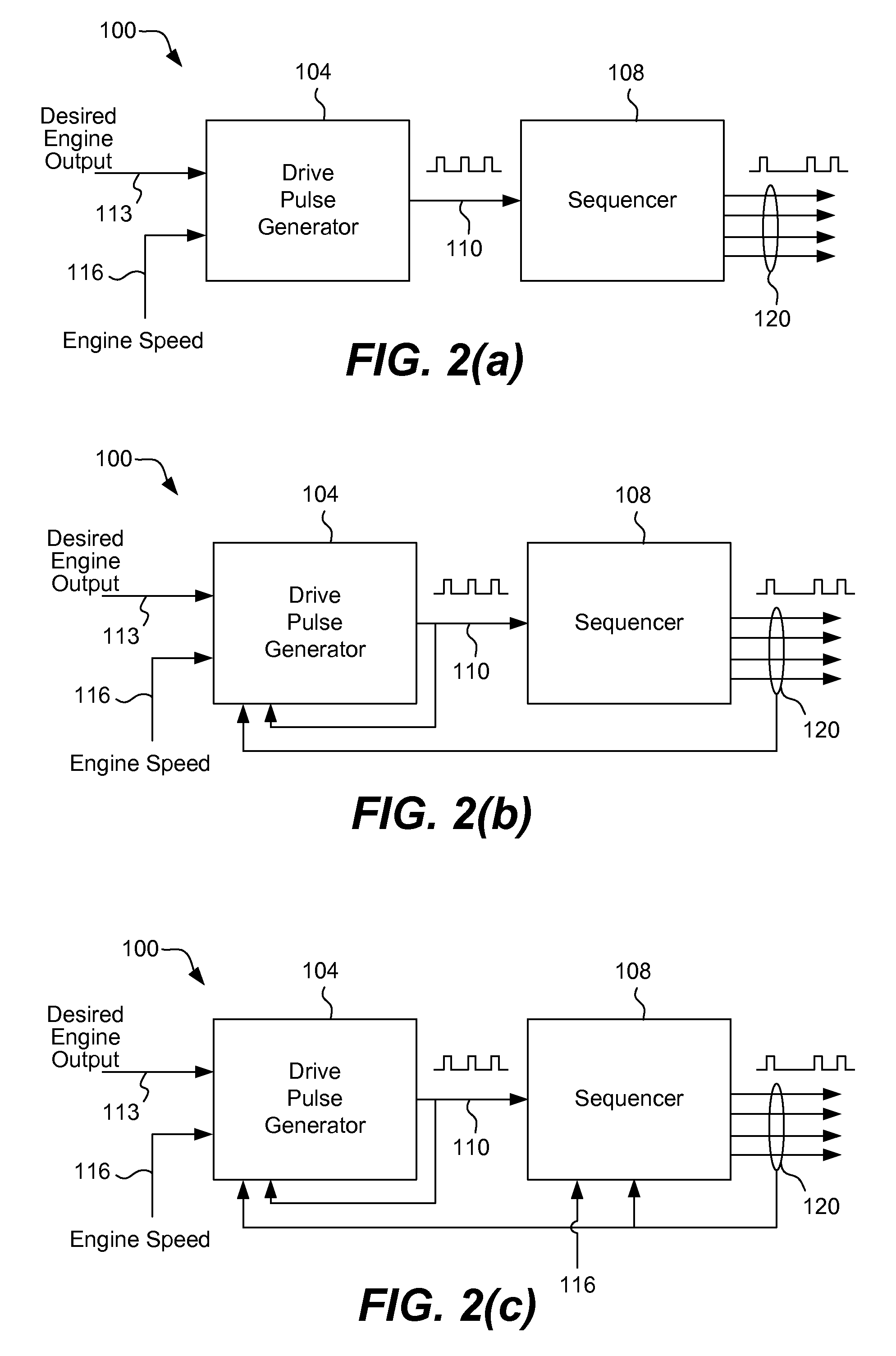

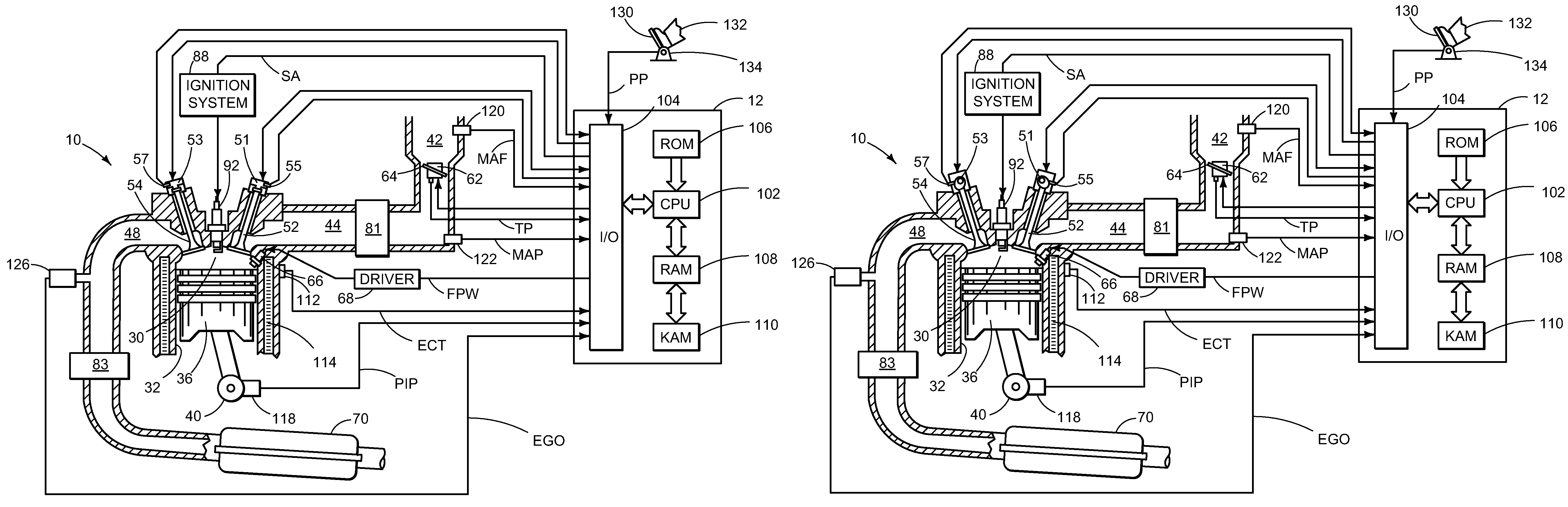

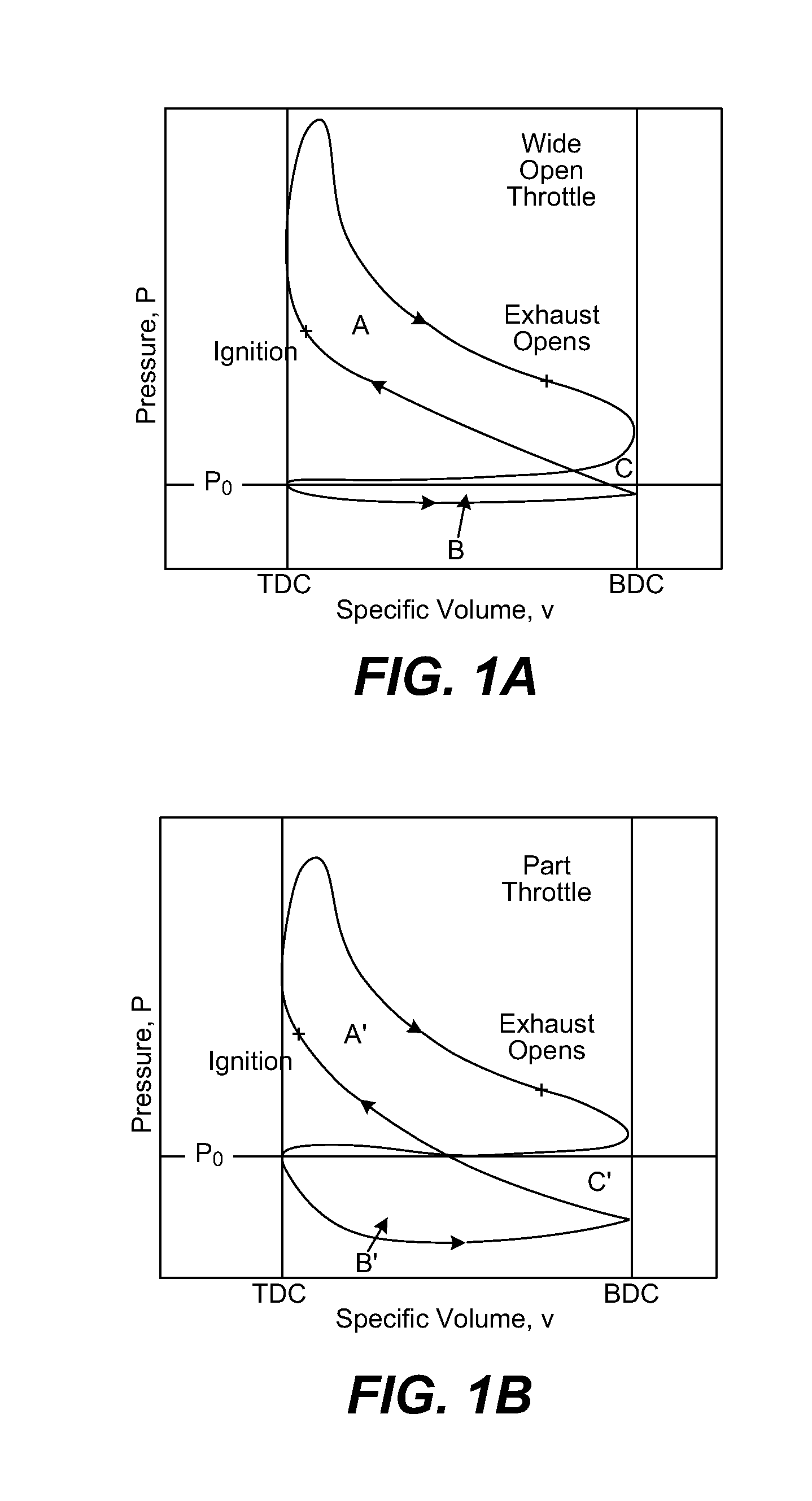

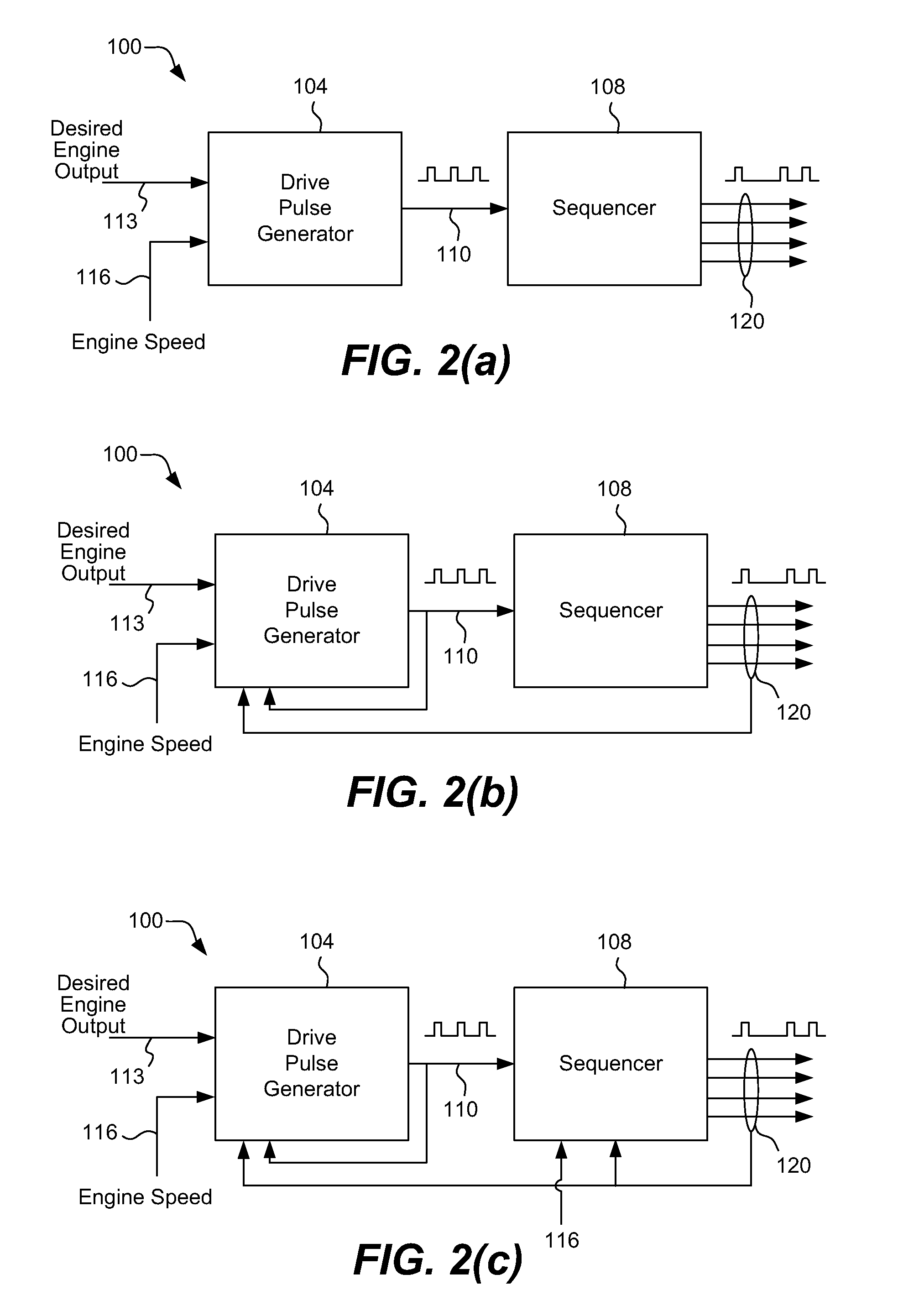

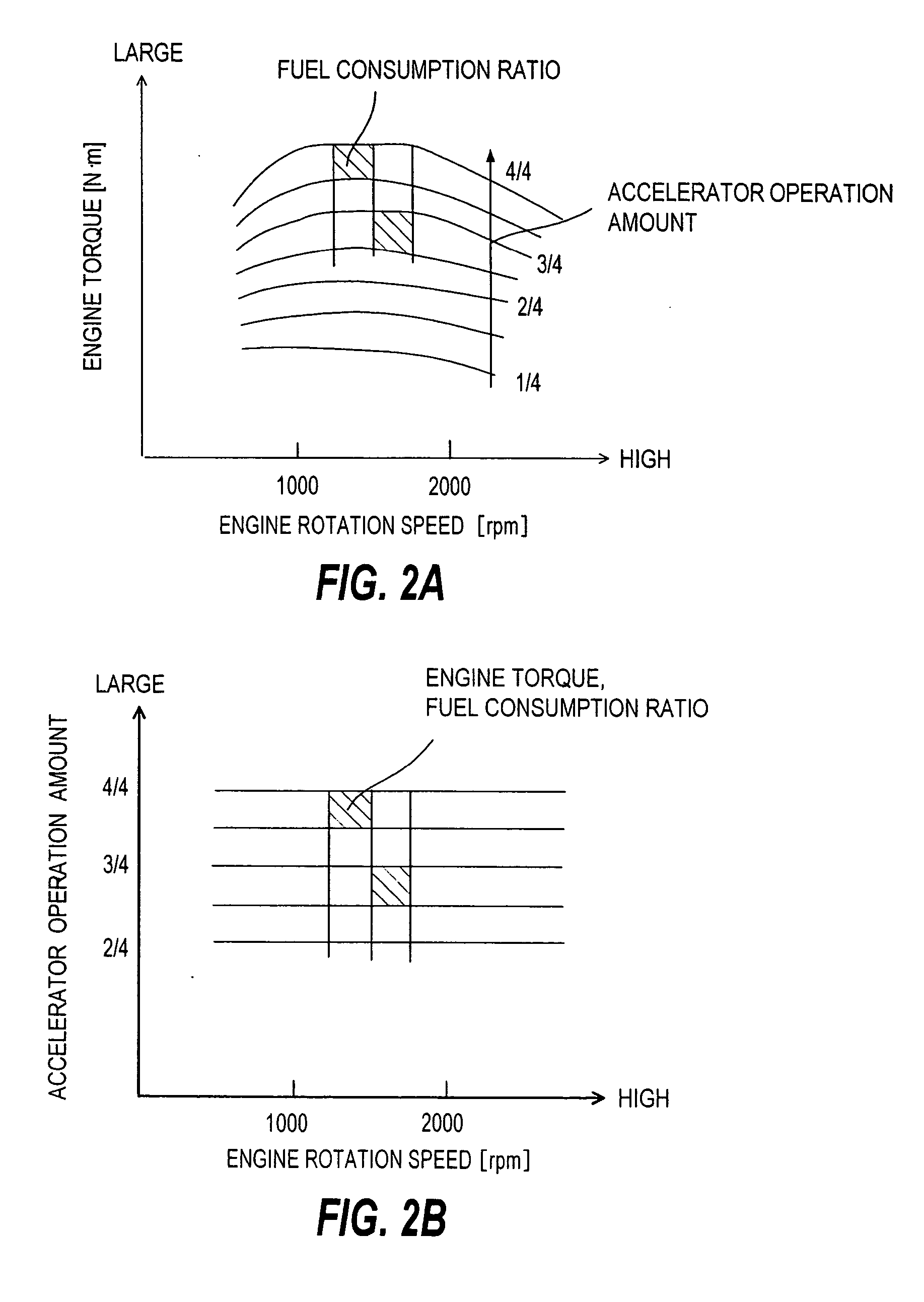

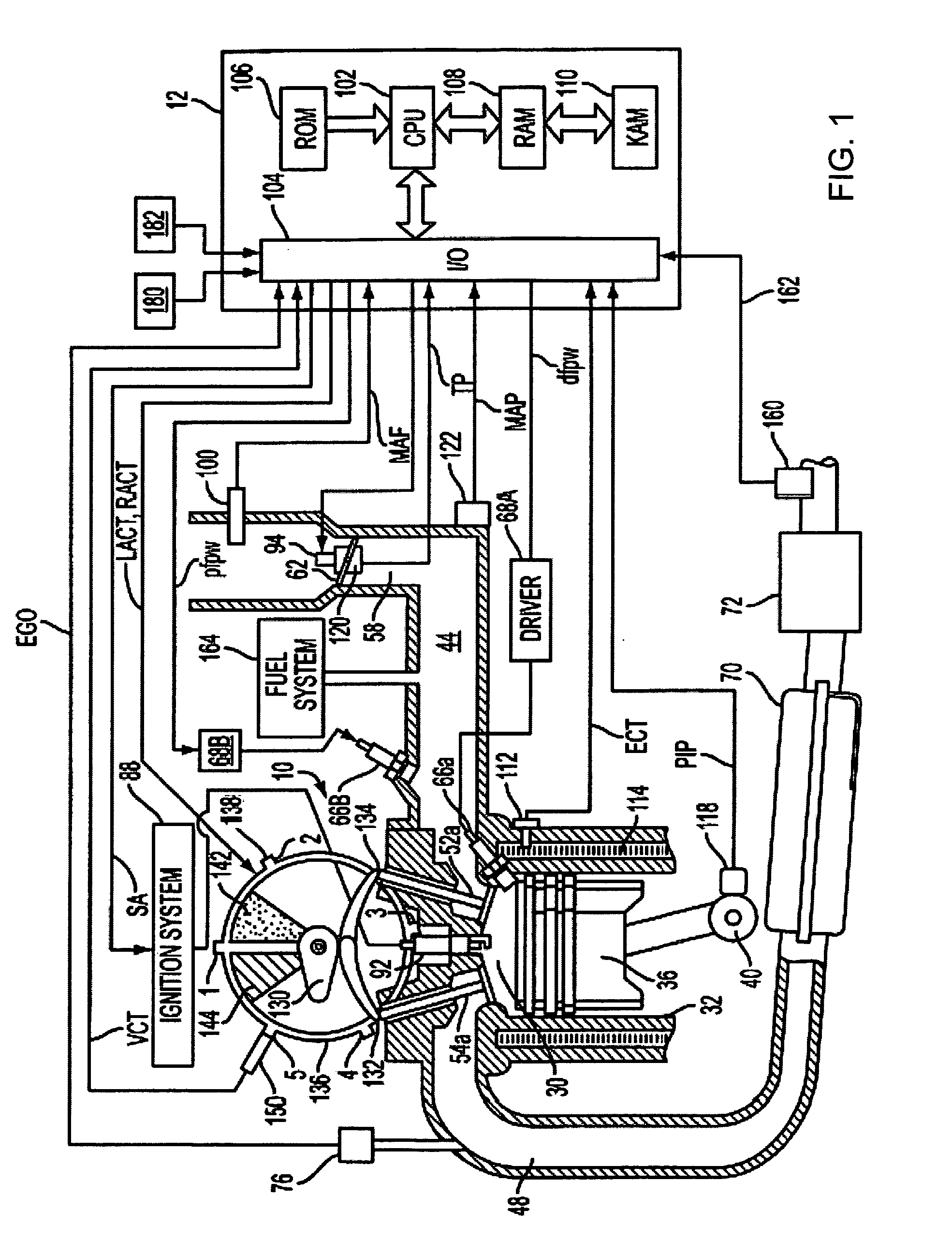

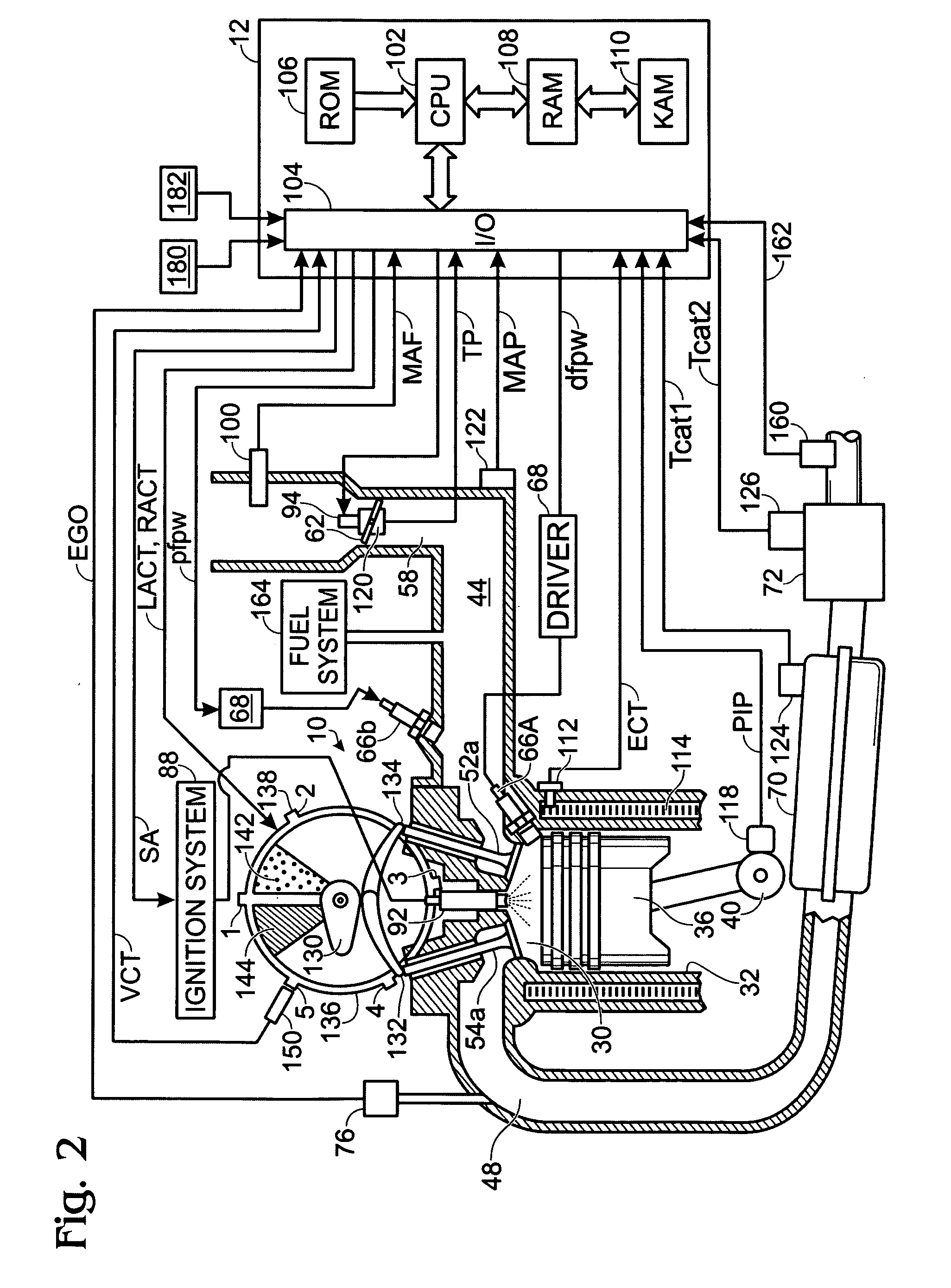

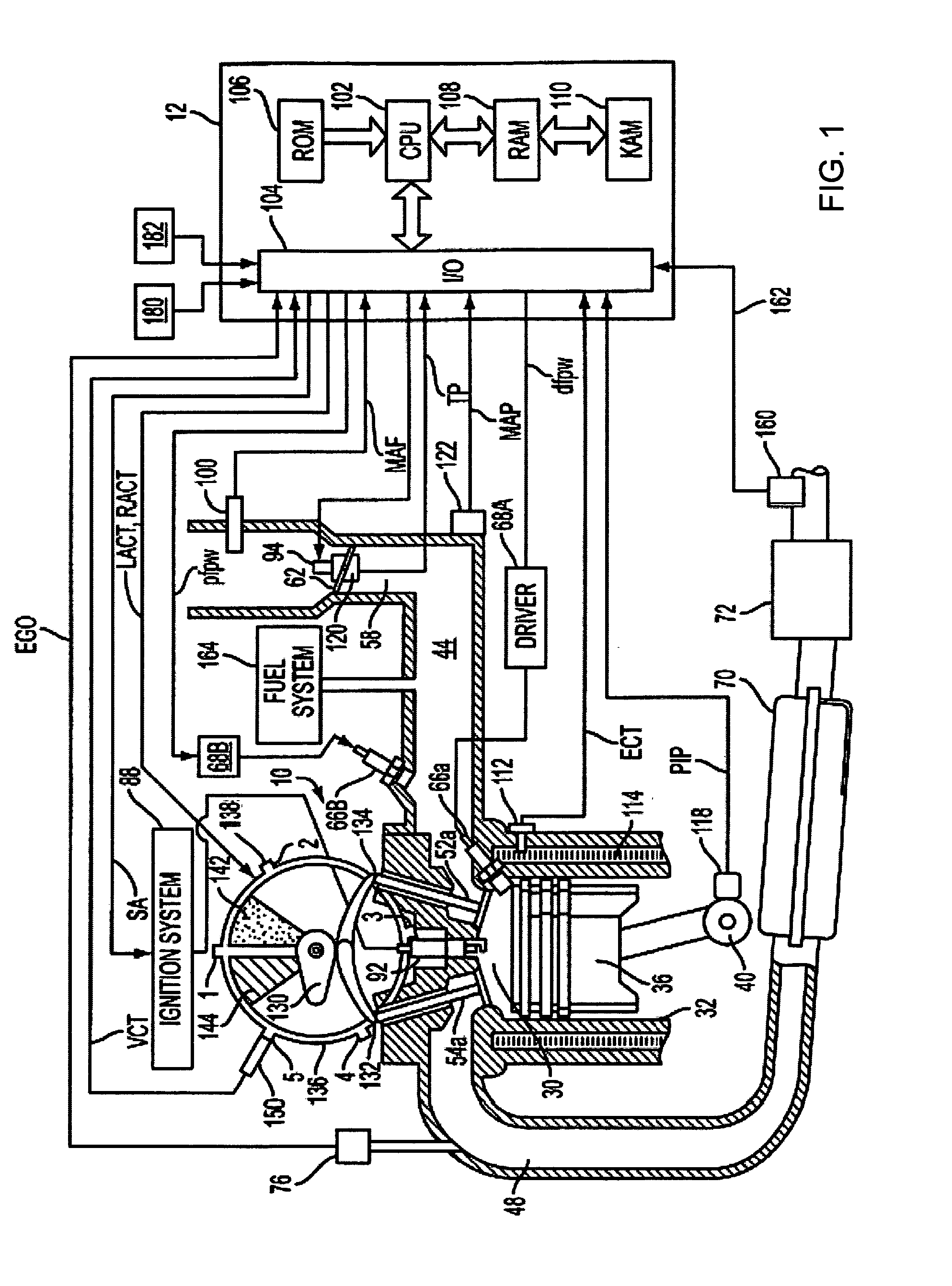

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

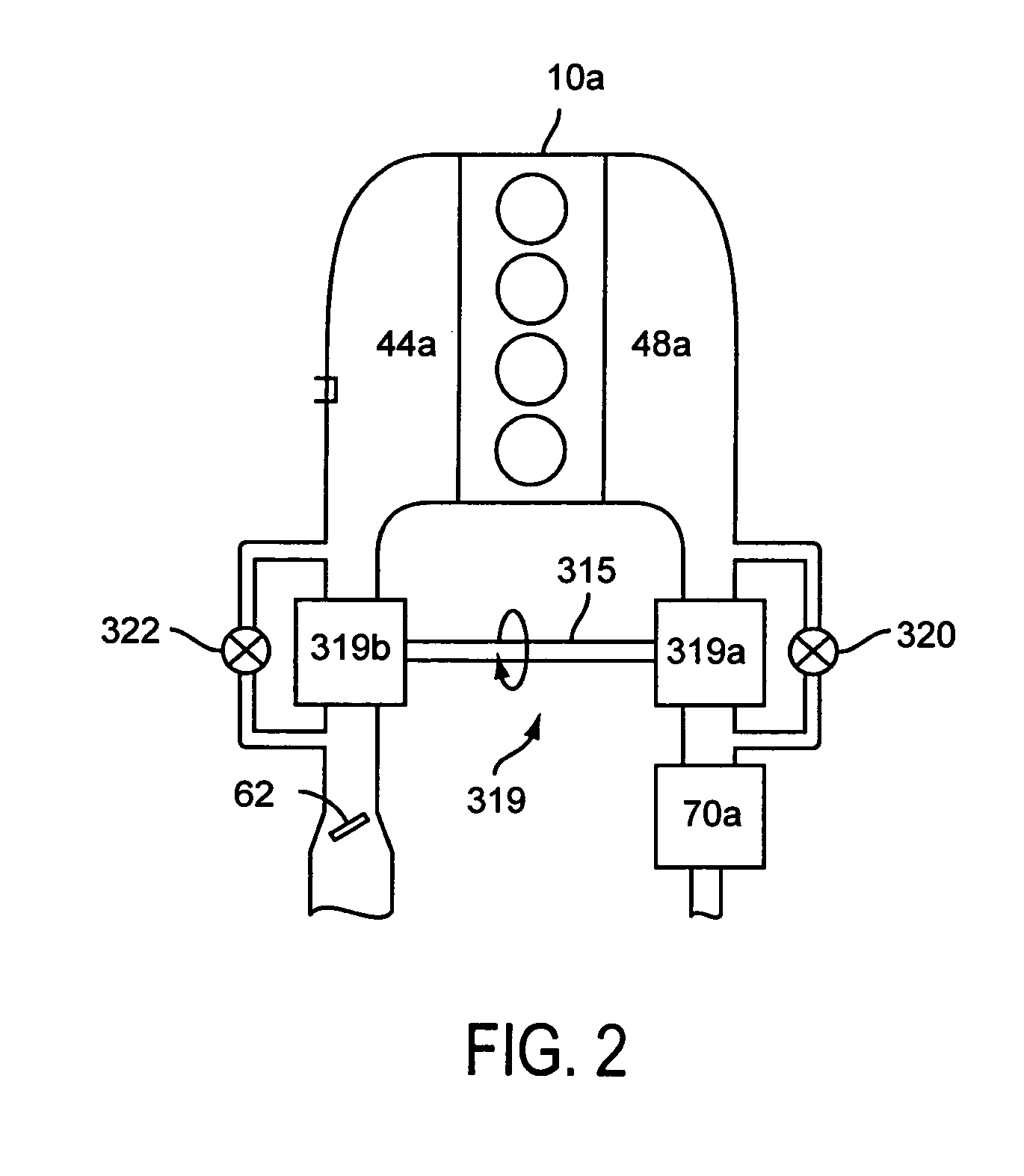

Differential torque operation for internal combustion engine

InactiveUS7503312B2Improve internal efficiencyImprove fuel efficiencyElectrical controlInternal combustion piston enginesInternal combustion engineControl theory

A method of operating an internal combustion engine having a plurality of cylinders including at least a first cylinder and a second cylinder, the method comprising firing the first cylinder and the second cylinder in an alternating sequence; during a first mode, adjusting an operating parameter of the engine to produce a first difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; during a second mode, adjusting the operating parameter of the engine to produce a second difference between an amount of torque produced by the firing of the first cylinder and an amount of torque produced by the firing of the second cylinder; and performing the first mode at a higher engine speed than the second mode; wherein the first difference is greater than the second difference.

Owner:FORD GLOBAL TECH LLC

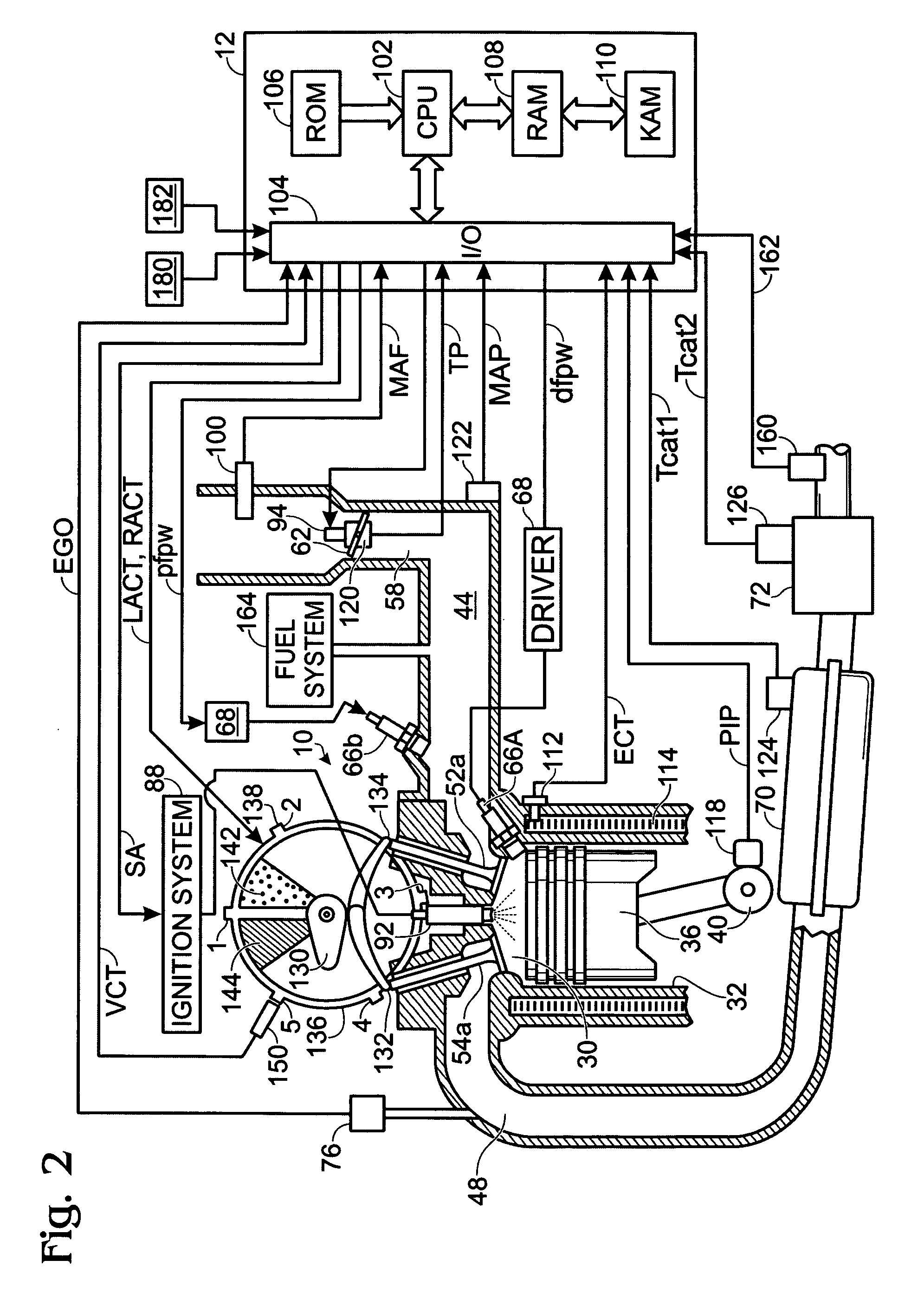

Method for rapid catalyst heating

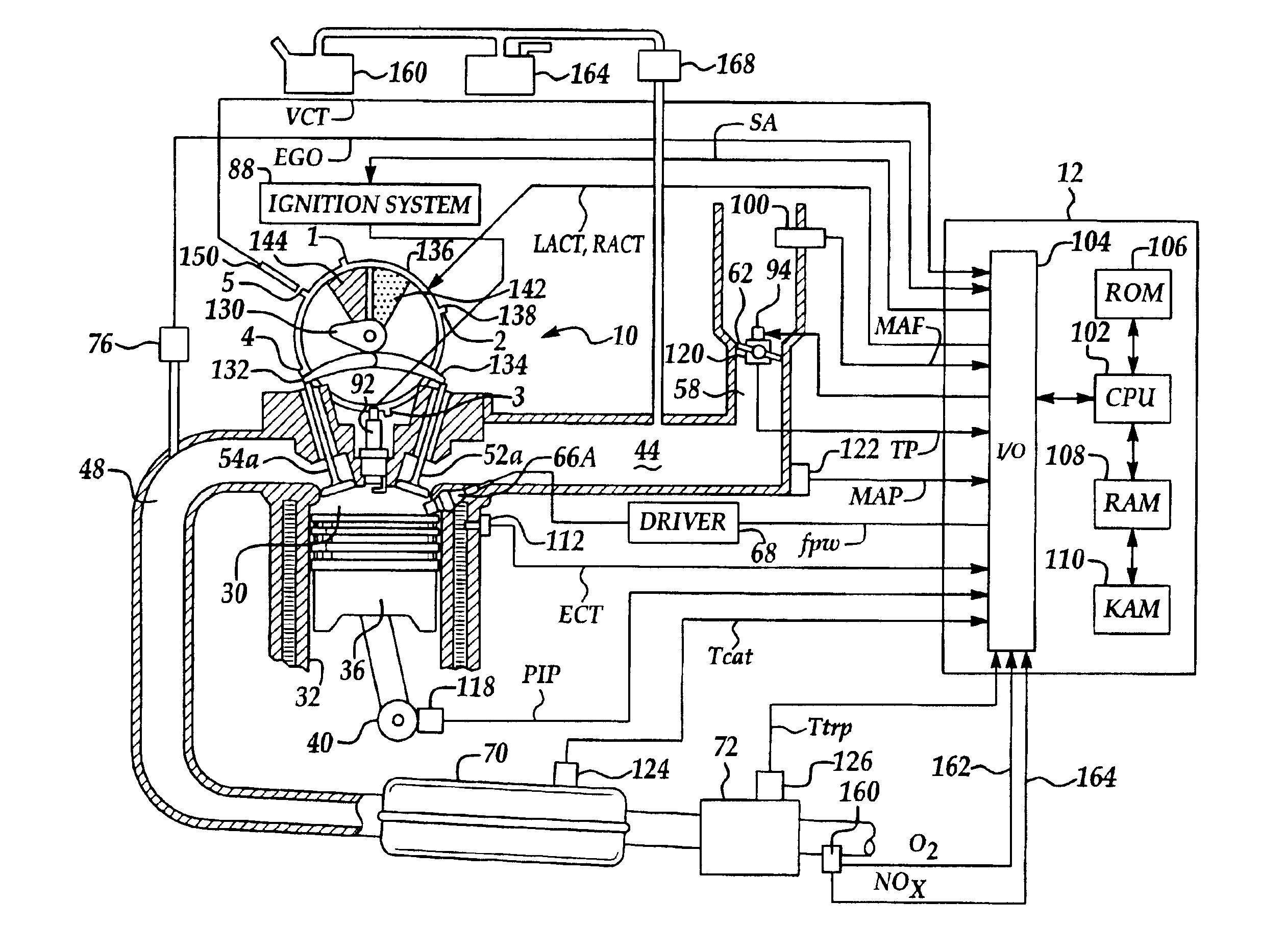

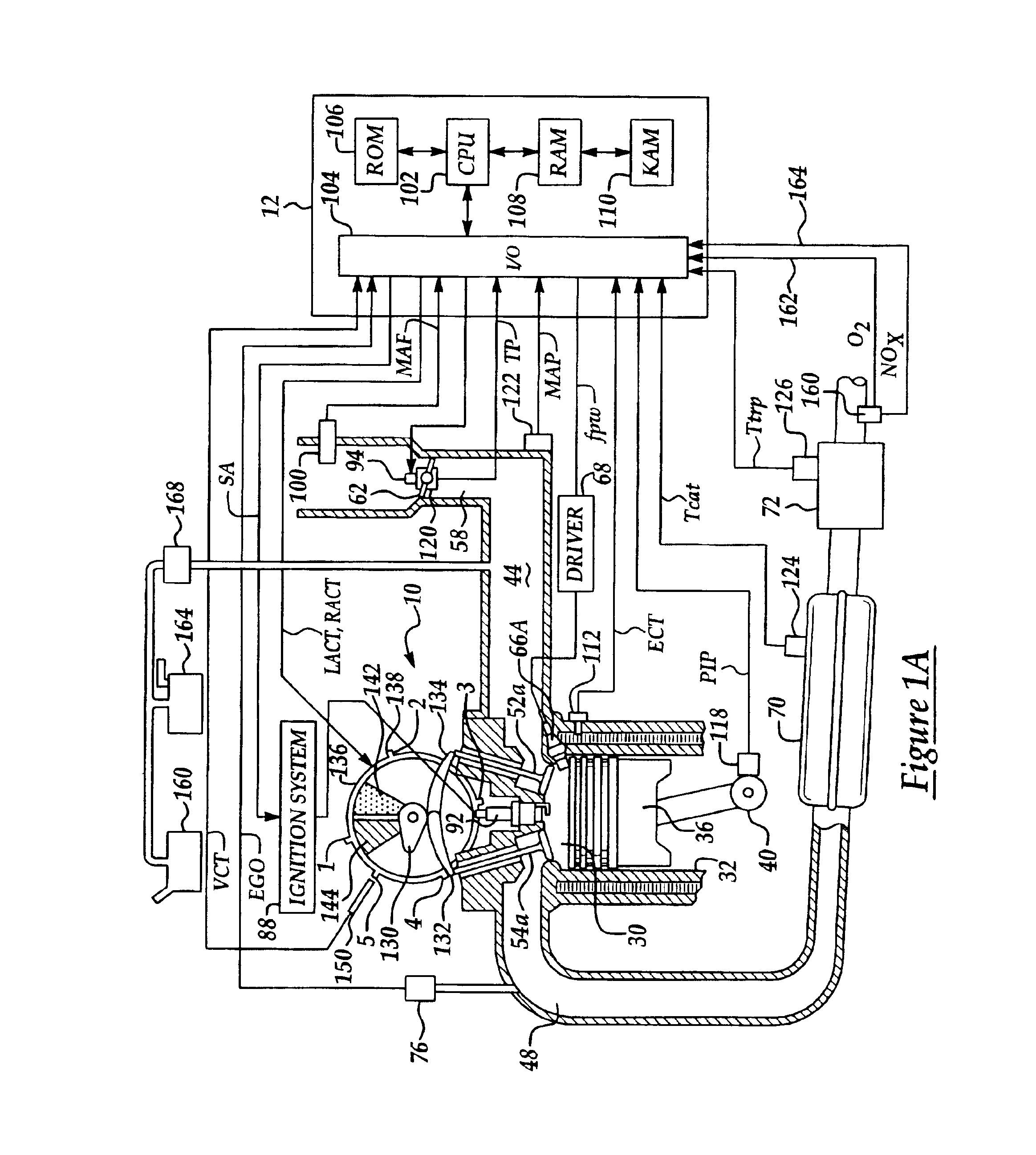

InactiveUS6568177B1High load conditionMore ignition timingElectrical controlInternal combustion piston enginesTemperature controlAdaptive learning

A method is disclosed for controlling operation of an engine coupled to an exhaust treatment catalyst. Under predetermined conditions, the method operates an engine with a first group of cylinders combusting a lean air / fuel mixture and a second group of cylinders pumping air only (i.e., without fuel injection). In addition, the engine control method also provides the following features in combination with the above-described split air / lean mode: idle speed control, sensor diagnostics, air / fuel ratio control, adaptive learning, fuel vapor purging, catalyst temperature estimation, default operation, and exhaust gas and emission control device temperature control. In addition, the engine control method also changes to combusting in all cylinders under preselected operating conditions such as fuel vapor purging, manifold vacuum control, and purging of stored oxidants in an emission control device.

Owner:FORD GLOBAL TECH LLC

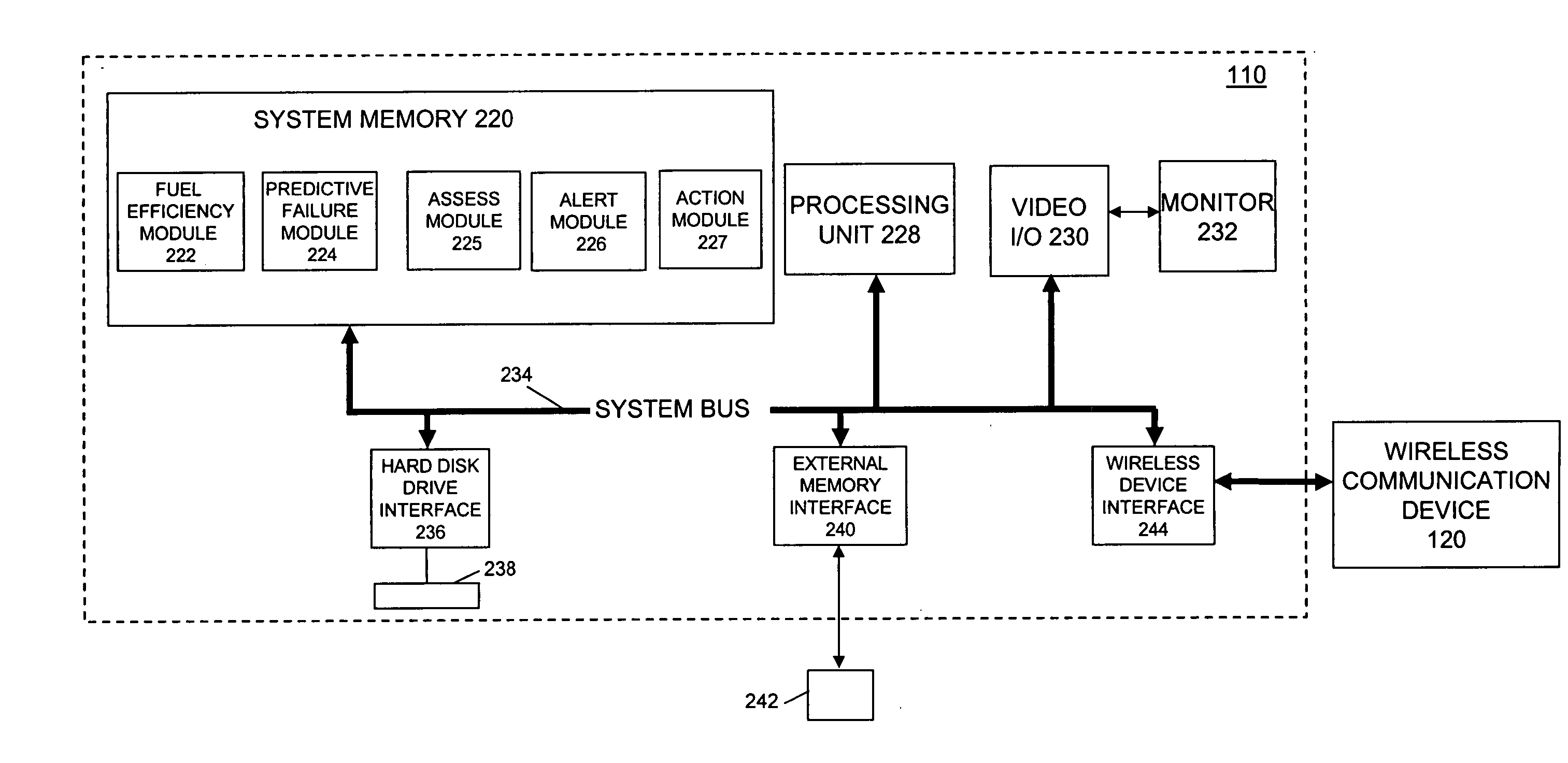

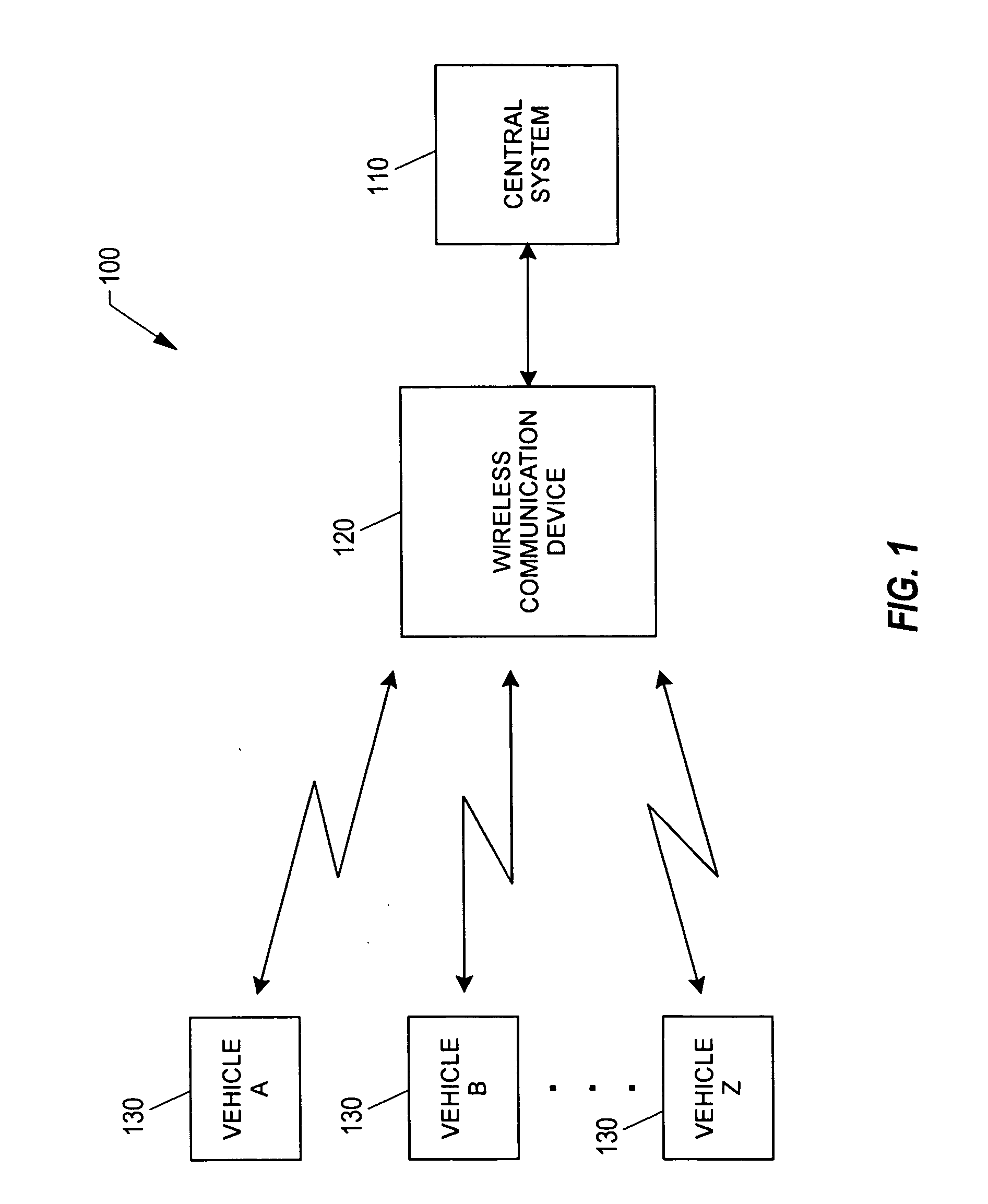

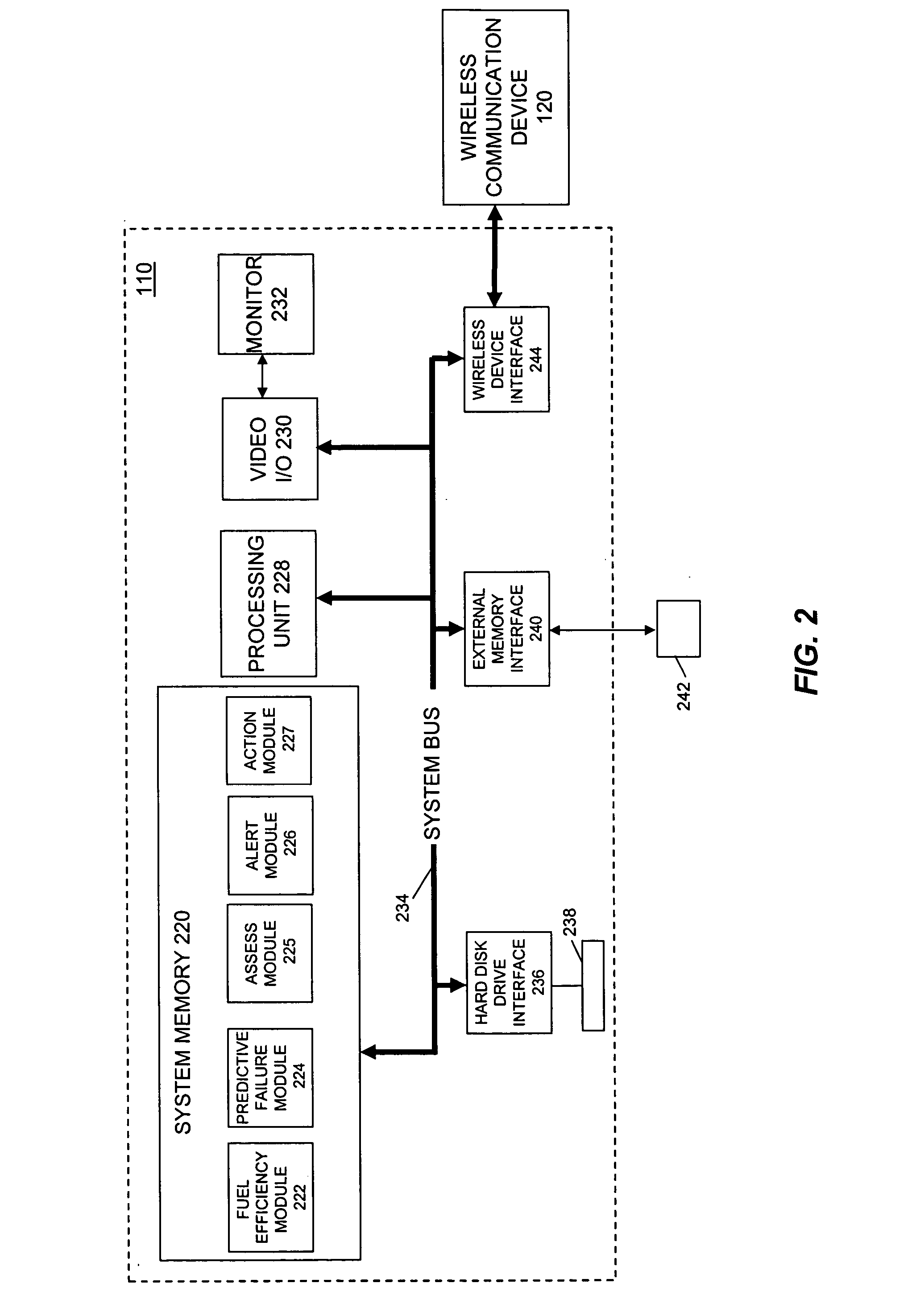

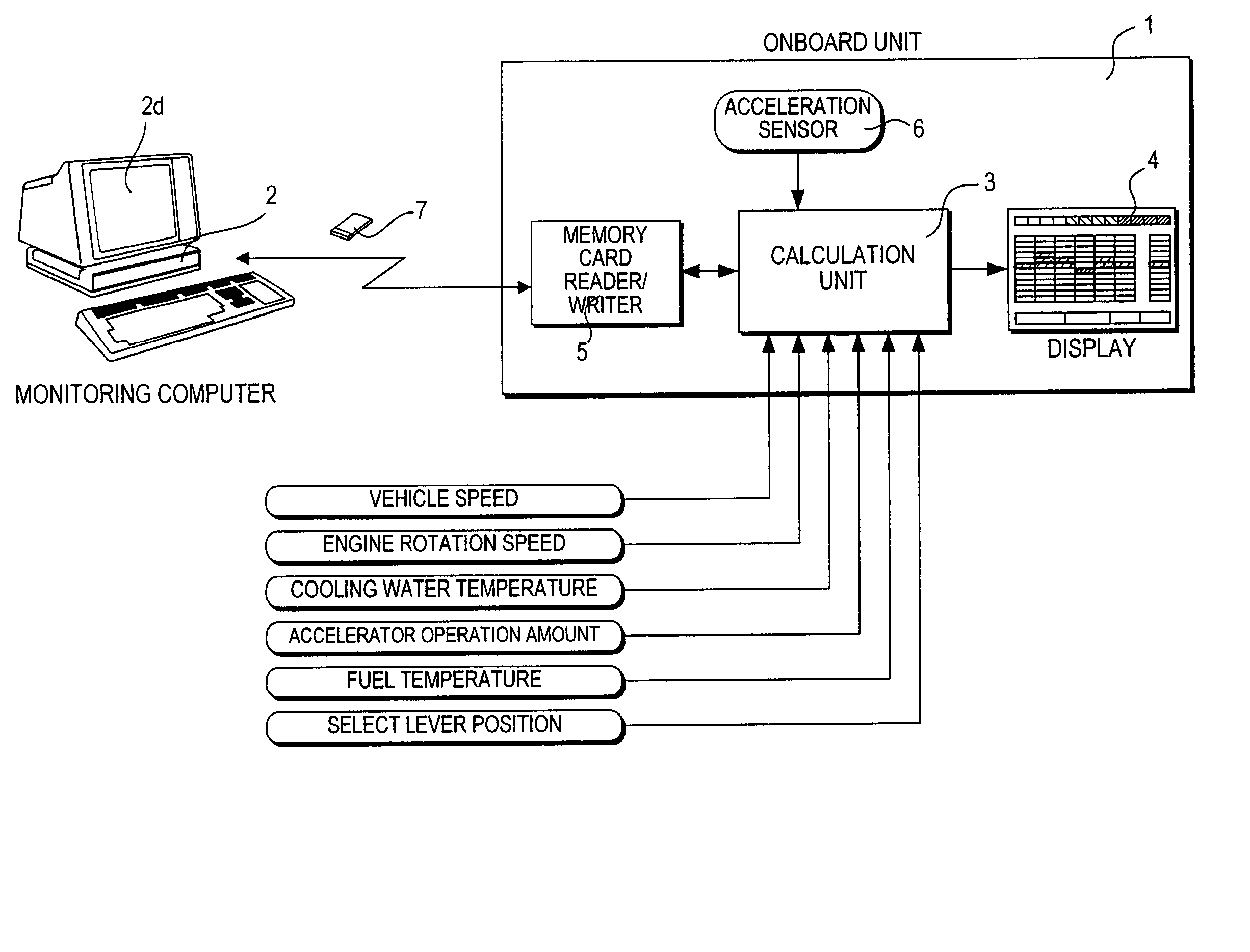

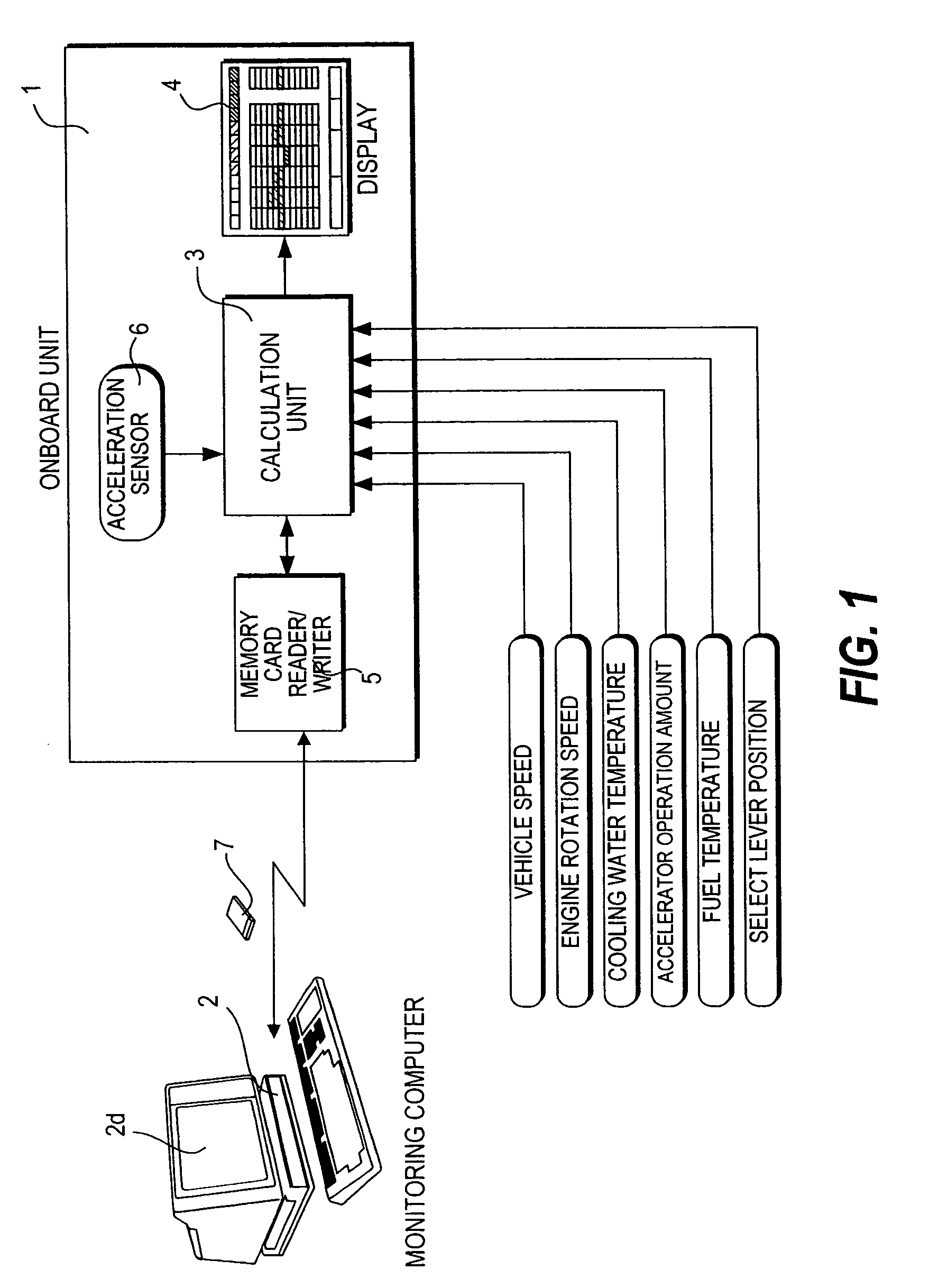

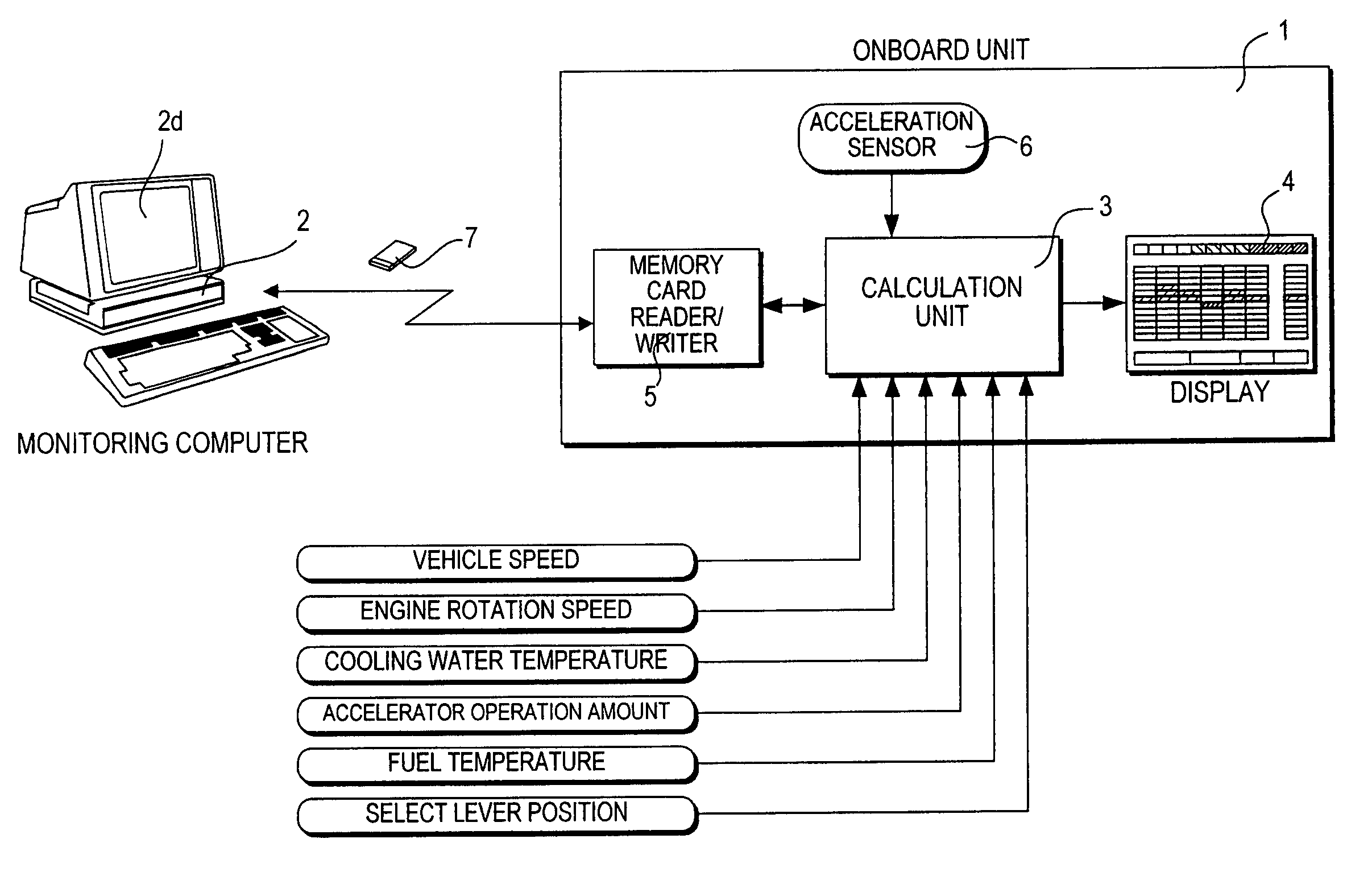

Predictive monitoring for vehicle efficiency and maintenance

ActiveUS20070027593A1Improve efficiencyVehicle testingAnalogue computers for vehiclesDriver/operatorFuel efficiency

A system and method for monitoring fuel efficiency of a vehicle is provided. Fuel efficiency of a vehicle may be monitored in real-time using telemetry transmitted from the vehicle. The telemetry may be analyzed in combination with a fuel efficiency model in order to determine whether the real-time fuel efficiency determination deviates from a baseline fuel efficiency. The real-time fuel efficiency monitoring system and method may be used for feedback for the driver, such as sending real-time messages to the driver to modify operation of the vehicle to increase fuel efficiency. The fuel efficiency model may further be used to assign vehicles in a fleet to particular routes, vehicles to particular drivers, or vehicles to particular routes with particular drivers.

Owner:ACCENTURE GLOBAL SERVICES LTD

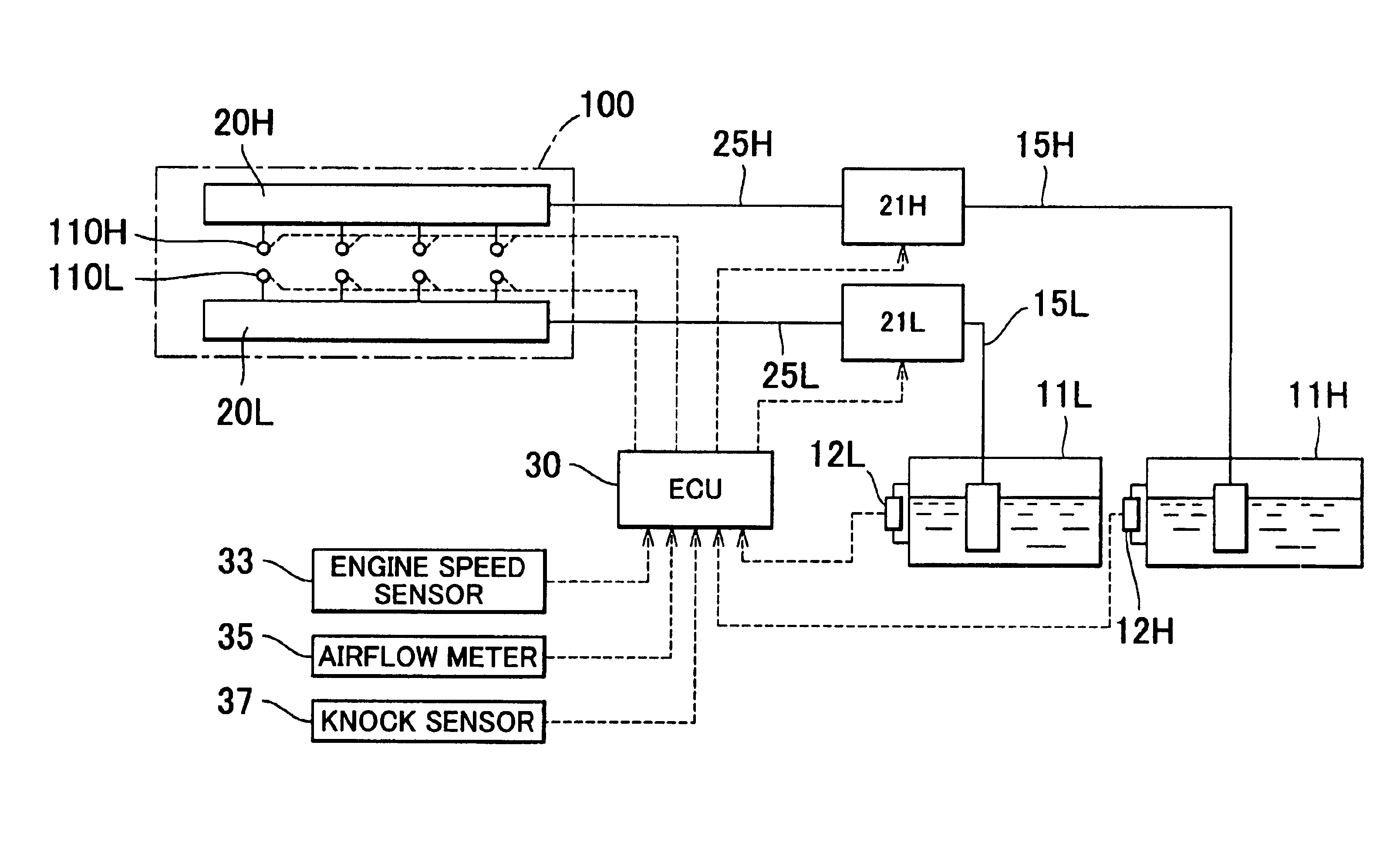

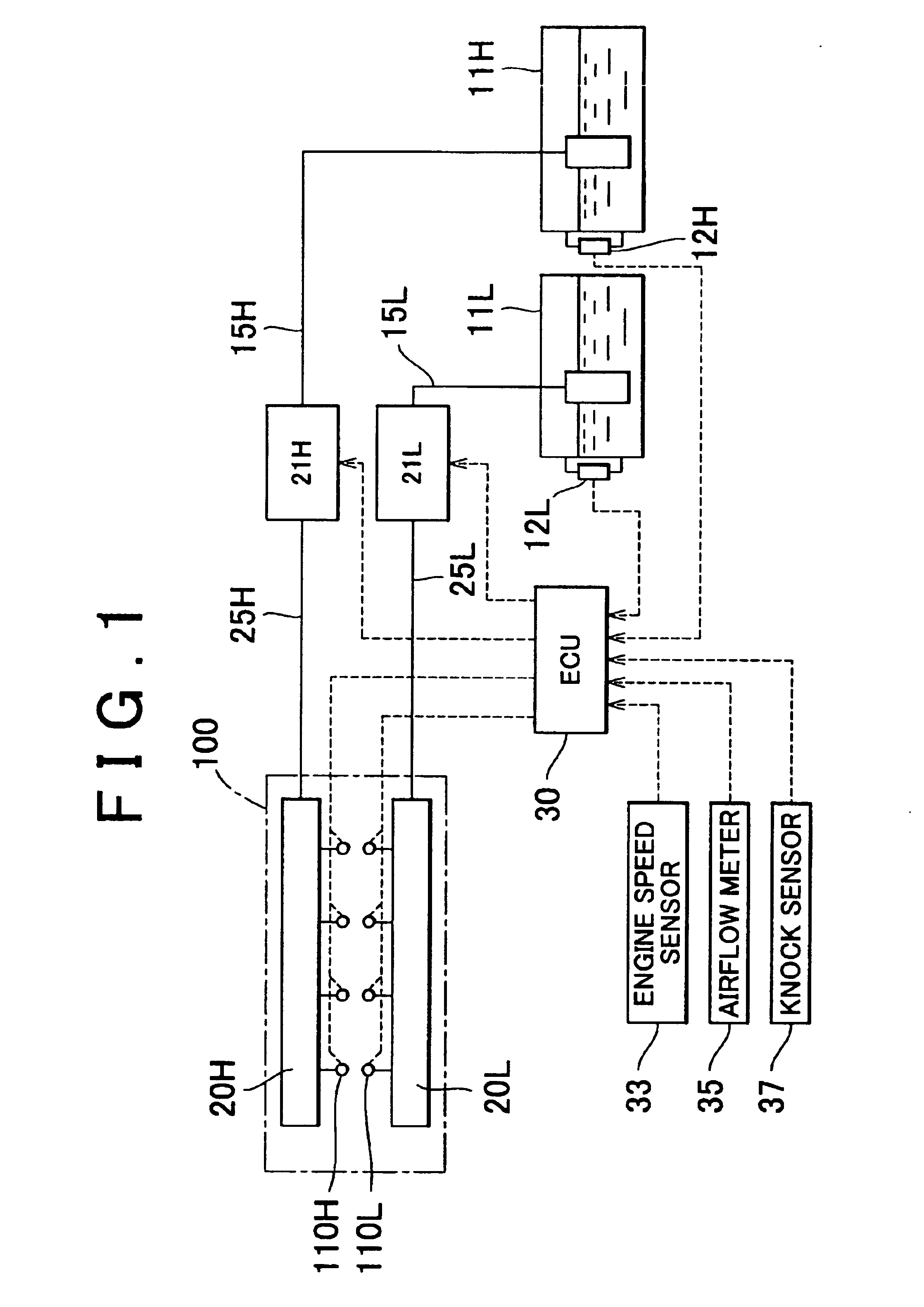

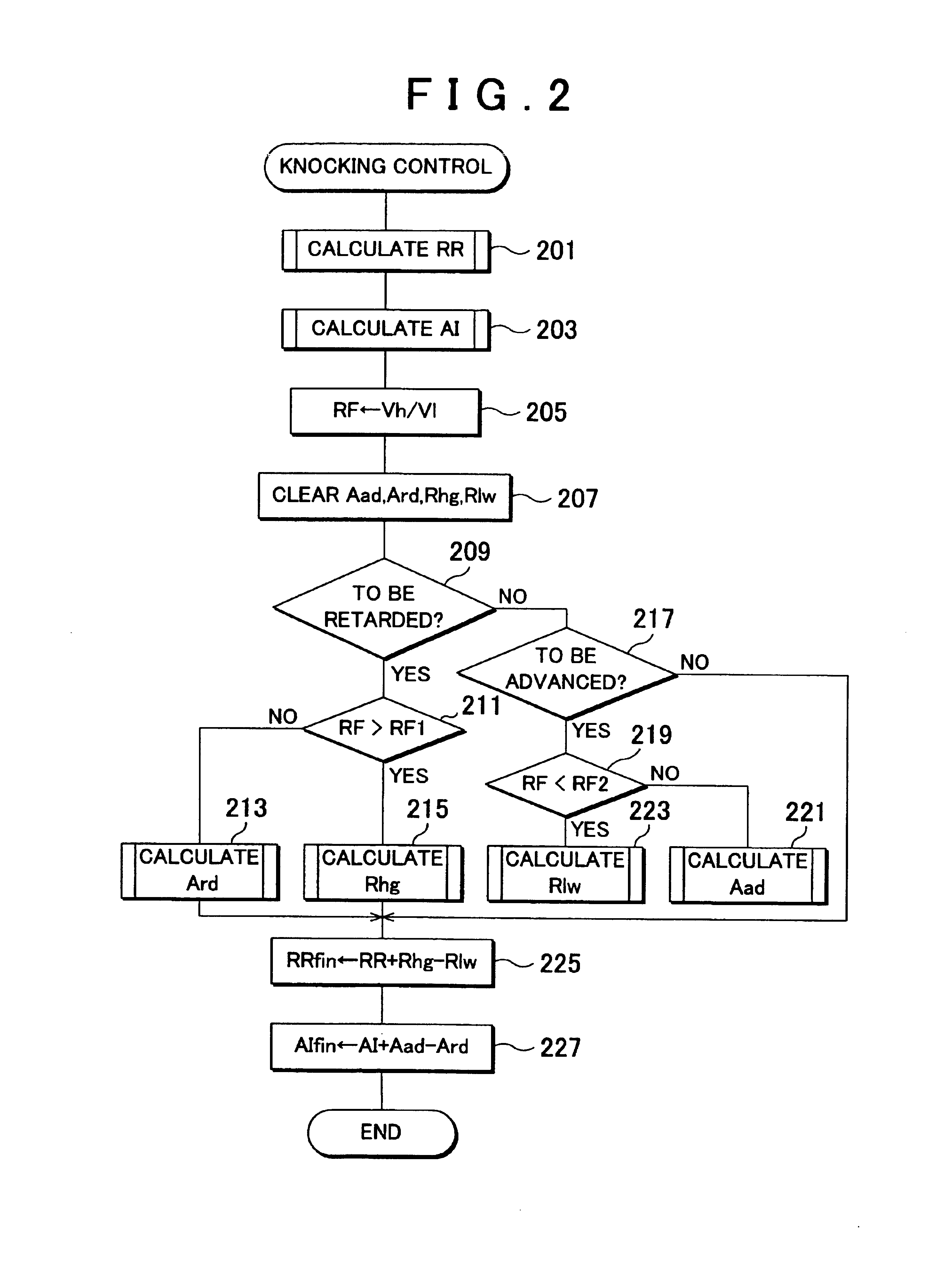

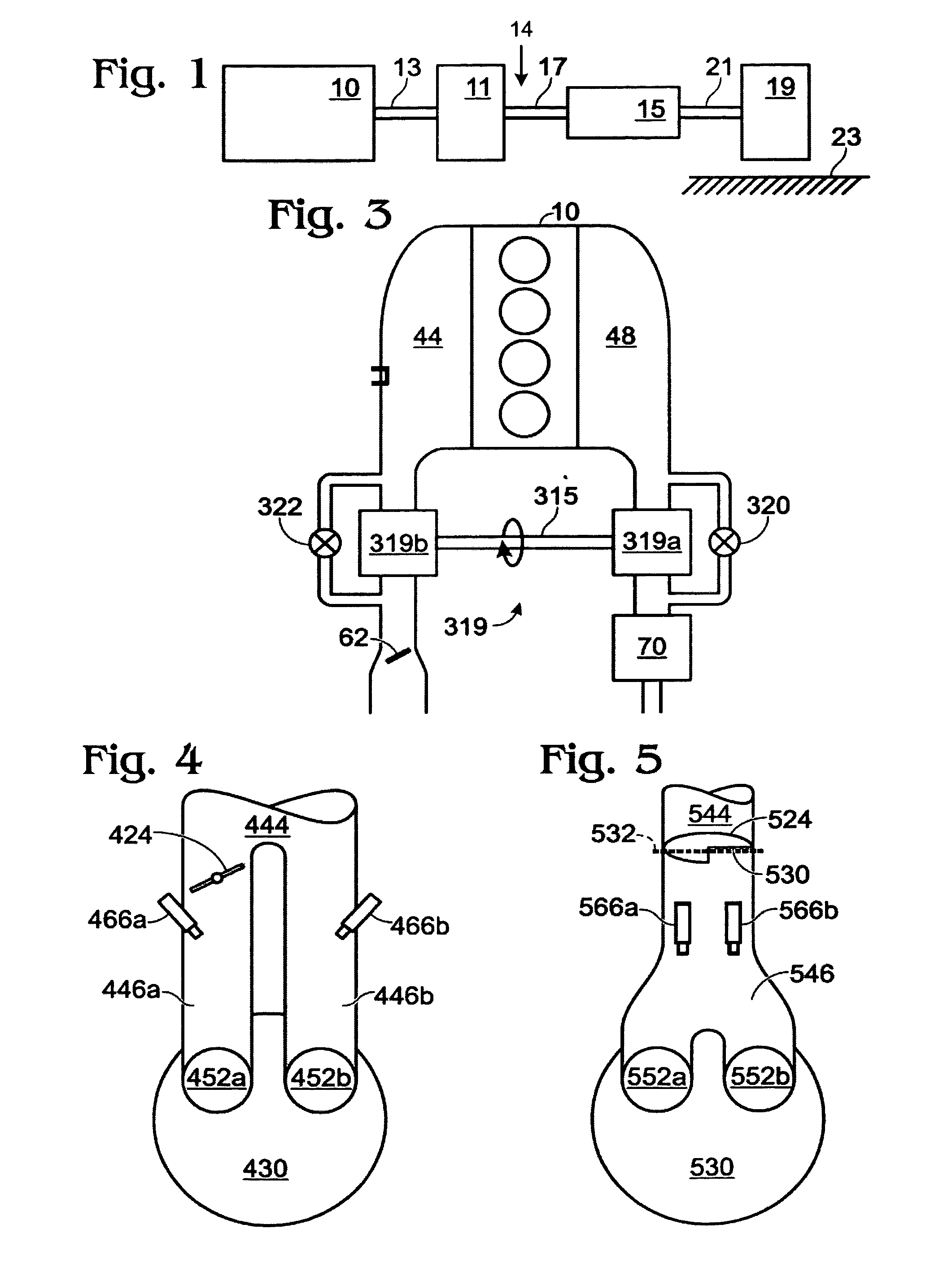

Knocking control system and method for internal combustion engine using multiple fuels

InactiveUS6951202B2Maintain balanceImprove balanceElectrical controlInternal combustion piston enginesMultifuelCombustion chamber

High octane fuel and low octane fuel are supplied into the combustion chamber of an engine from high-octane fuel tank and low octane fuel tank via a high octane fuel injector and a low octane fuel injector. During a knocking control, if the quantity of high and low octane fuels in the respective tanks has been unbalanced, the supply ratio between high octane fuel and low octane fuel is changed 1 to control a knocking occurring in the engine without changing the ignition timing.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine control for improved fuel efficiency

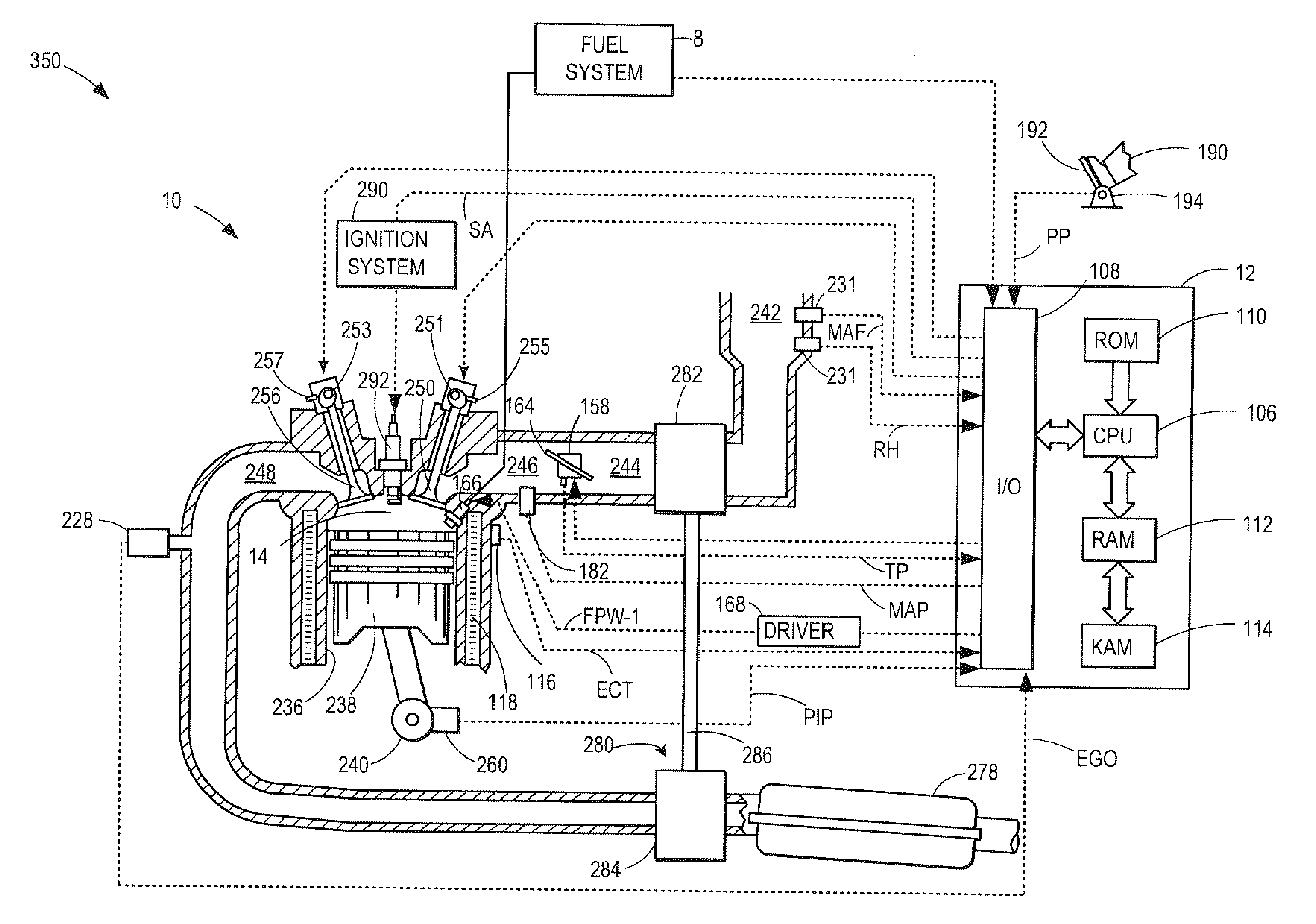

ActiveUS20110208405A1Improve fuel efficiencyUndesirable vibration reductionAnalogue computers for vehiclesElectrical controlCombustionExternal combustion engine

Owner:TULA TECH INC

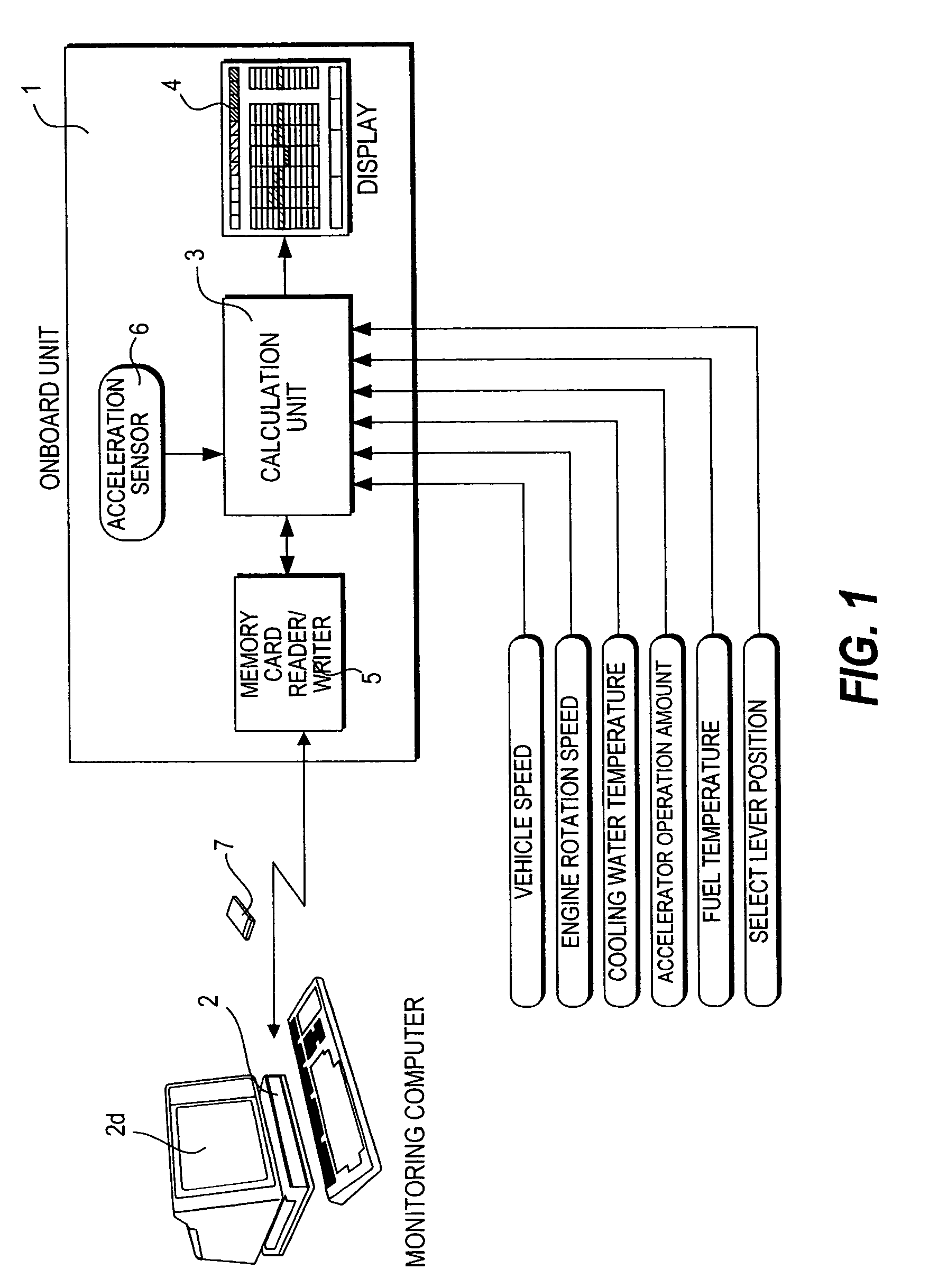

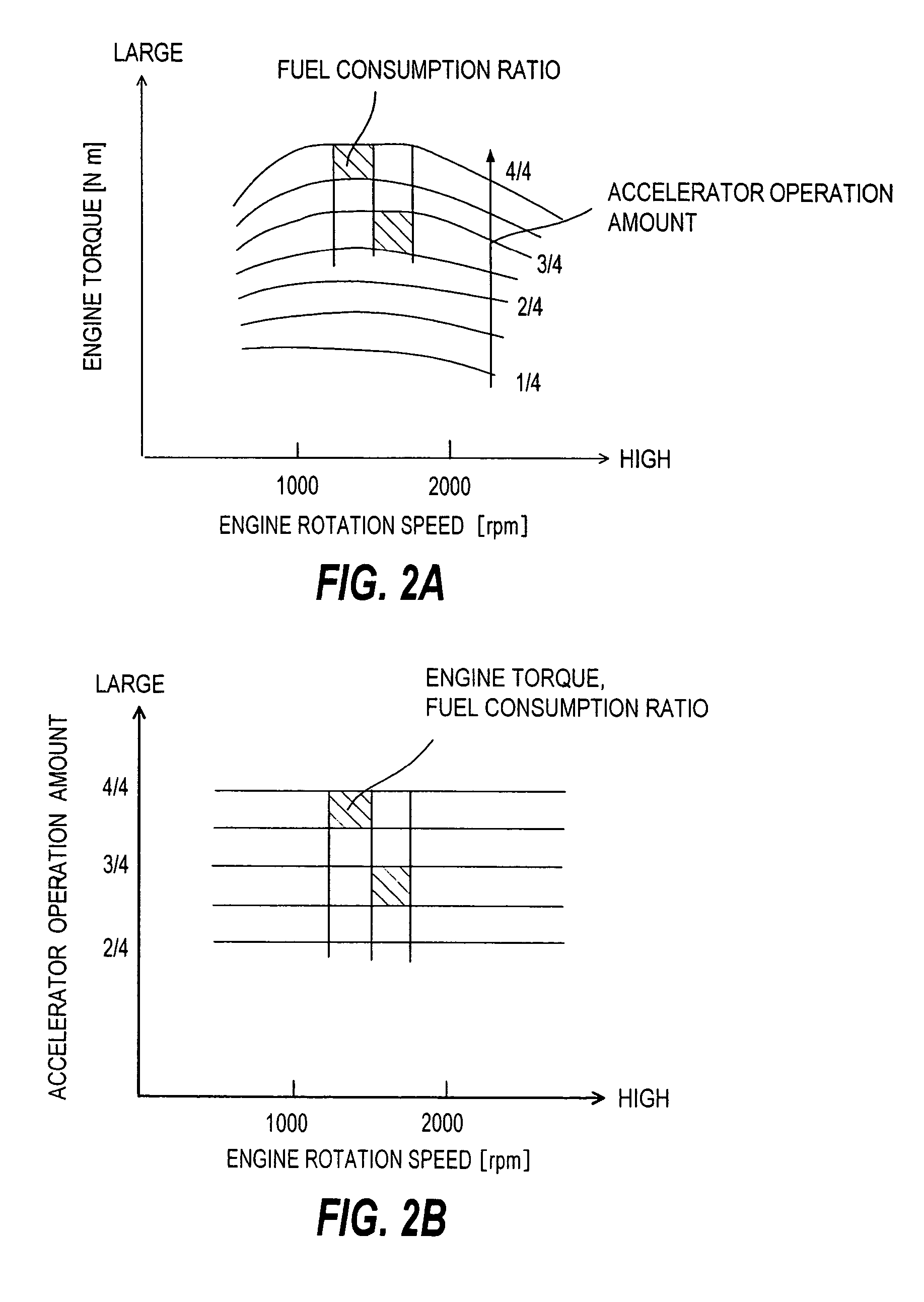

Evaluation system for vehicle operating conditions and evaluation method thereof

InactiveUS20050021222A1Improve fuel economyImprove economyVehicle testingAnalogue computers for vehiclesDisplay deviceEvaluation system

Owner:MIYAMA

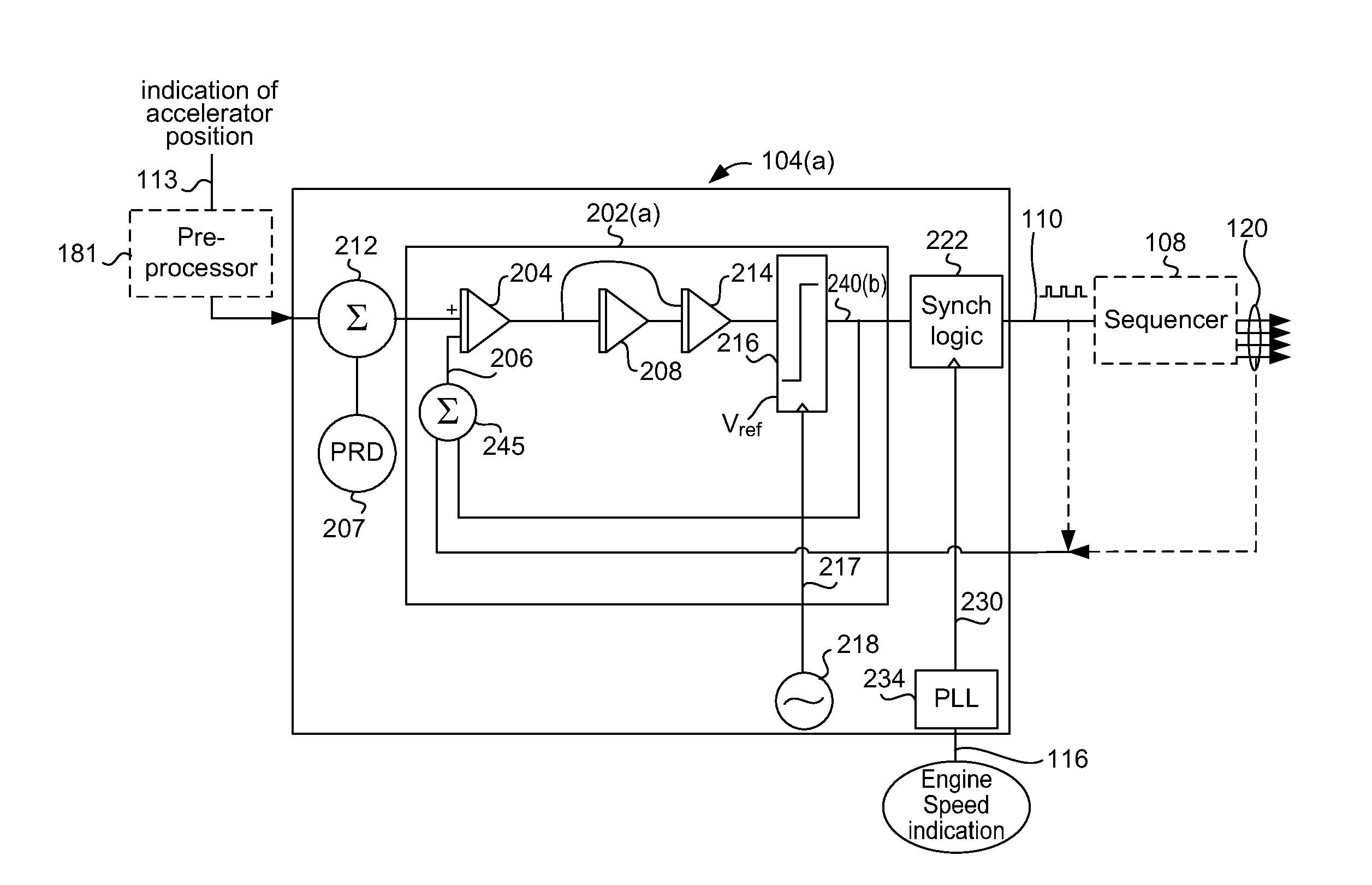

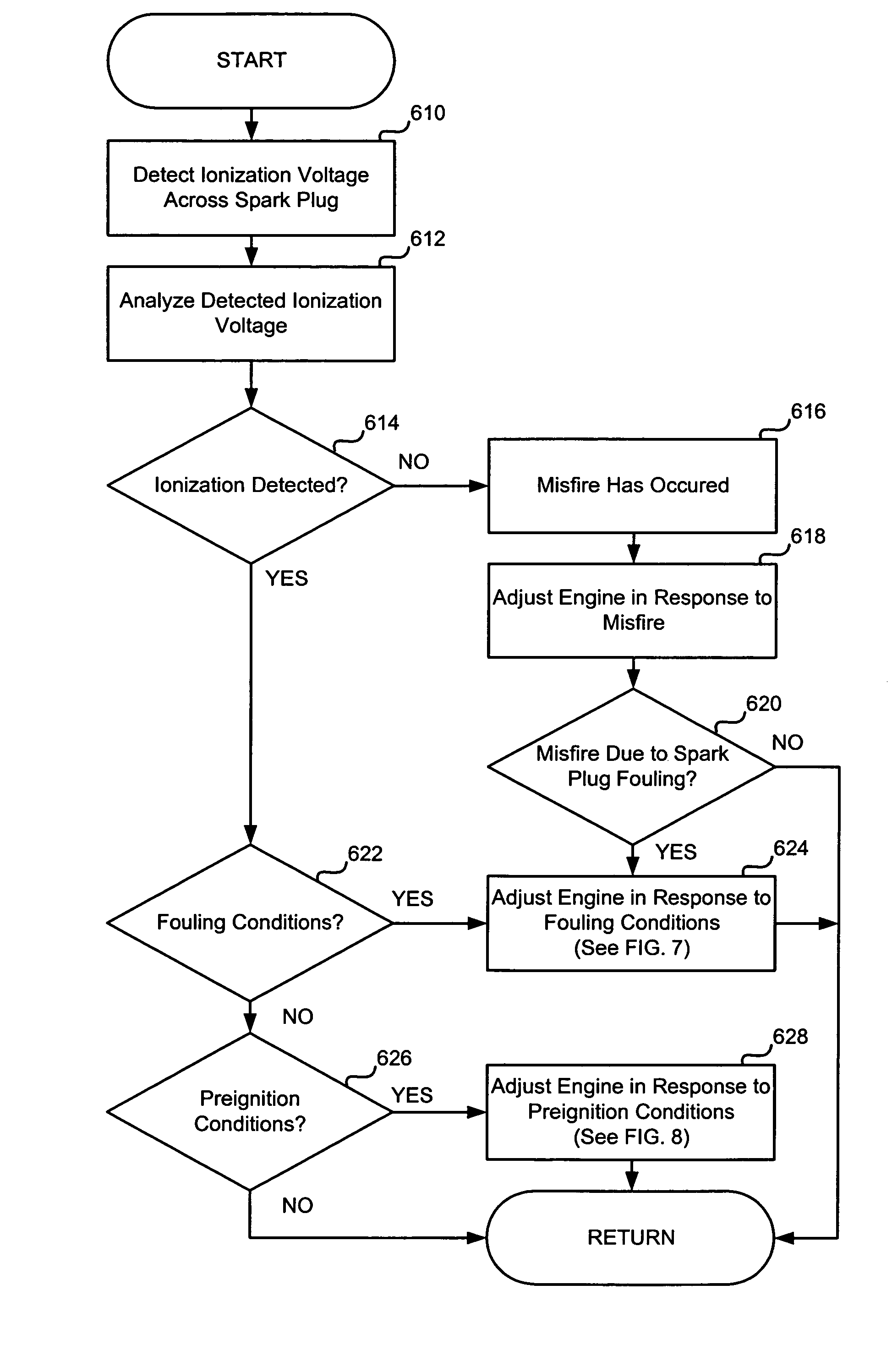

Spark control for improved engine operation

InactiveUS20070215130A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberControl system

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a substance to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, and a control system configured to vary a number of sparks performed by the spark plug in relation to a combustion event of the combustion chamber responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

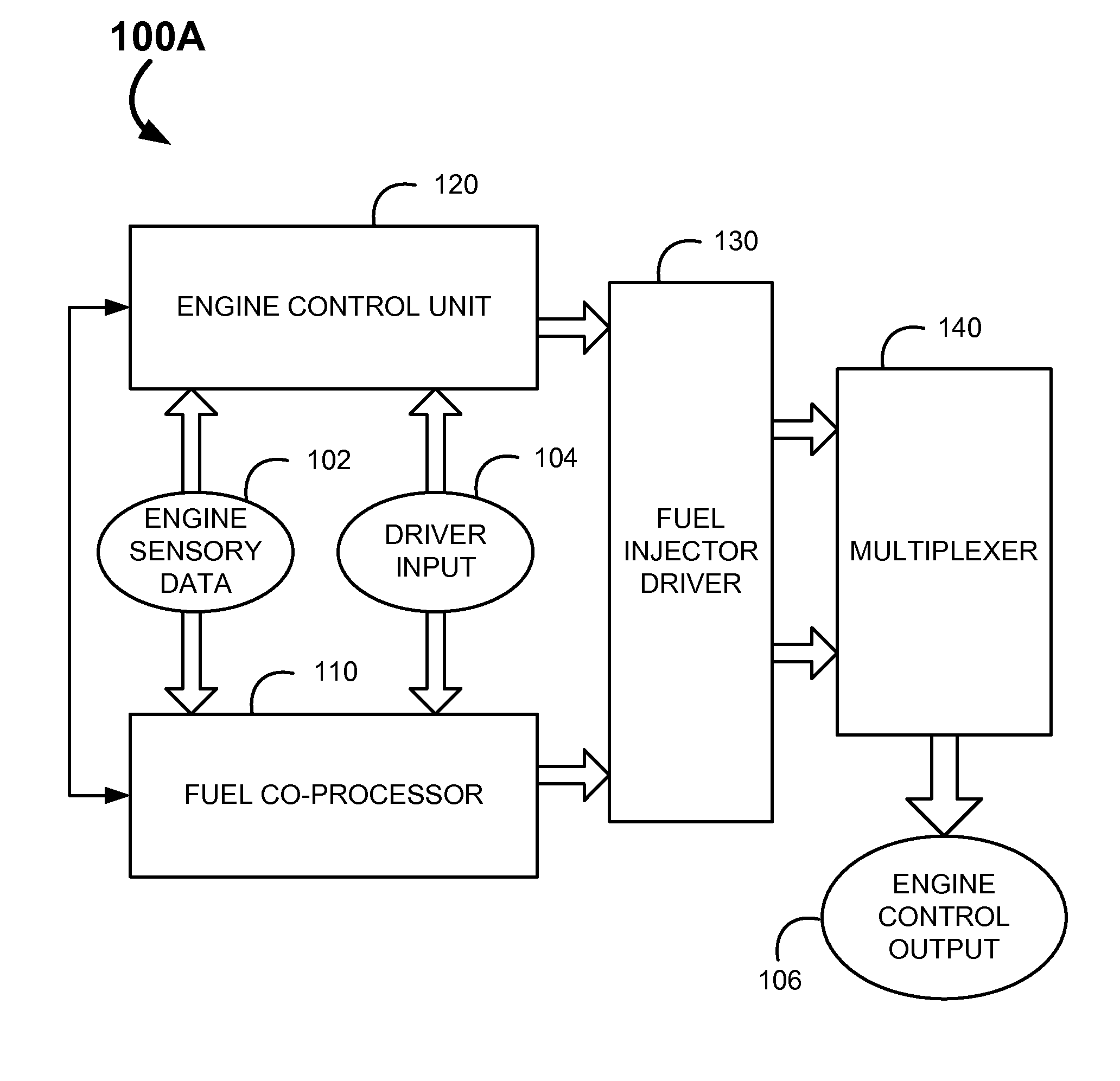

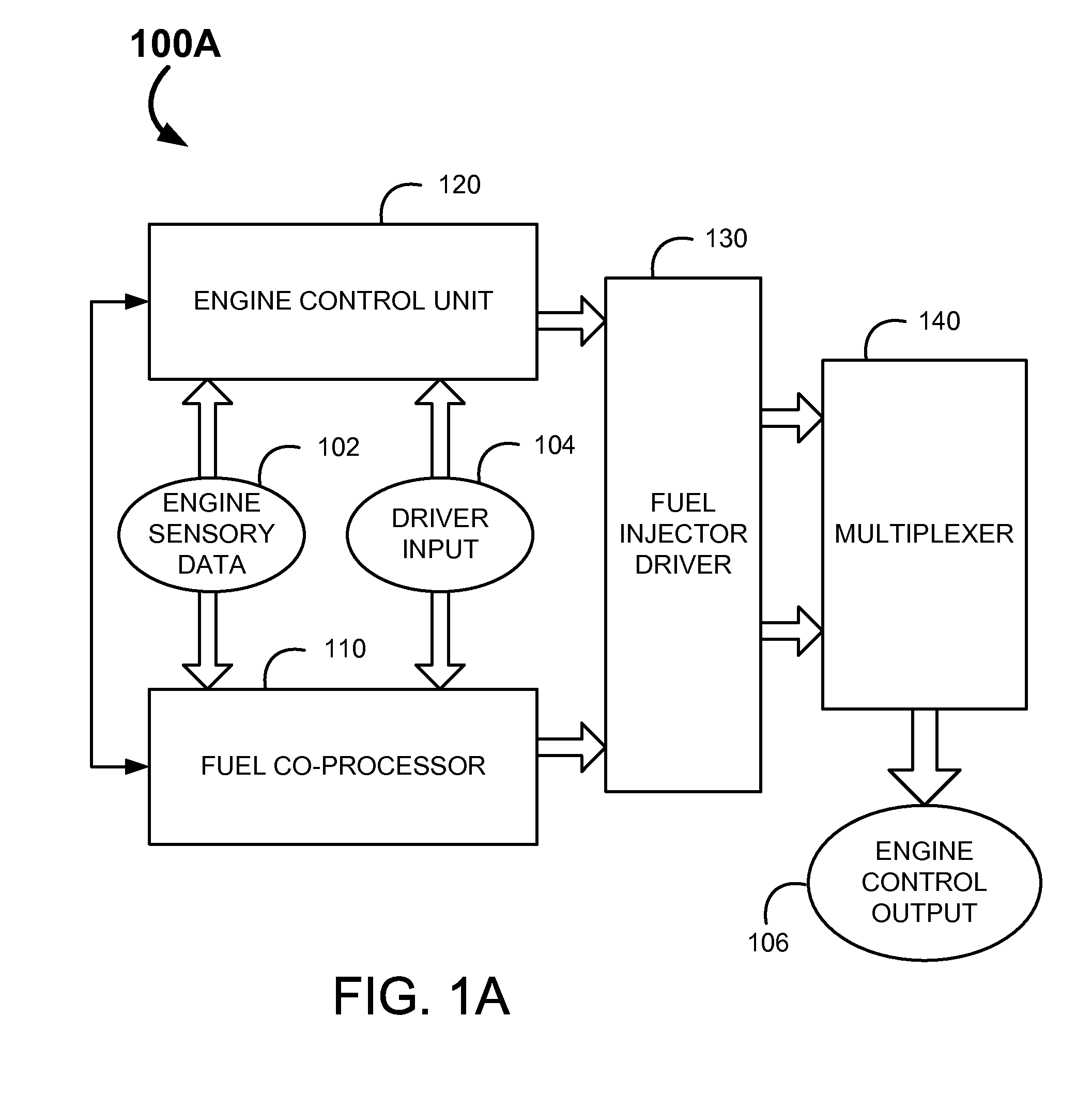

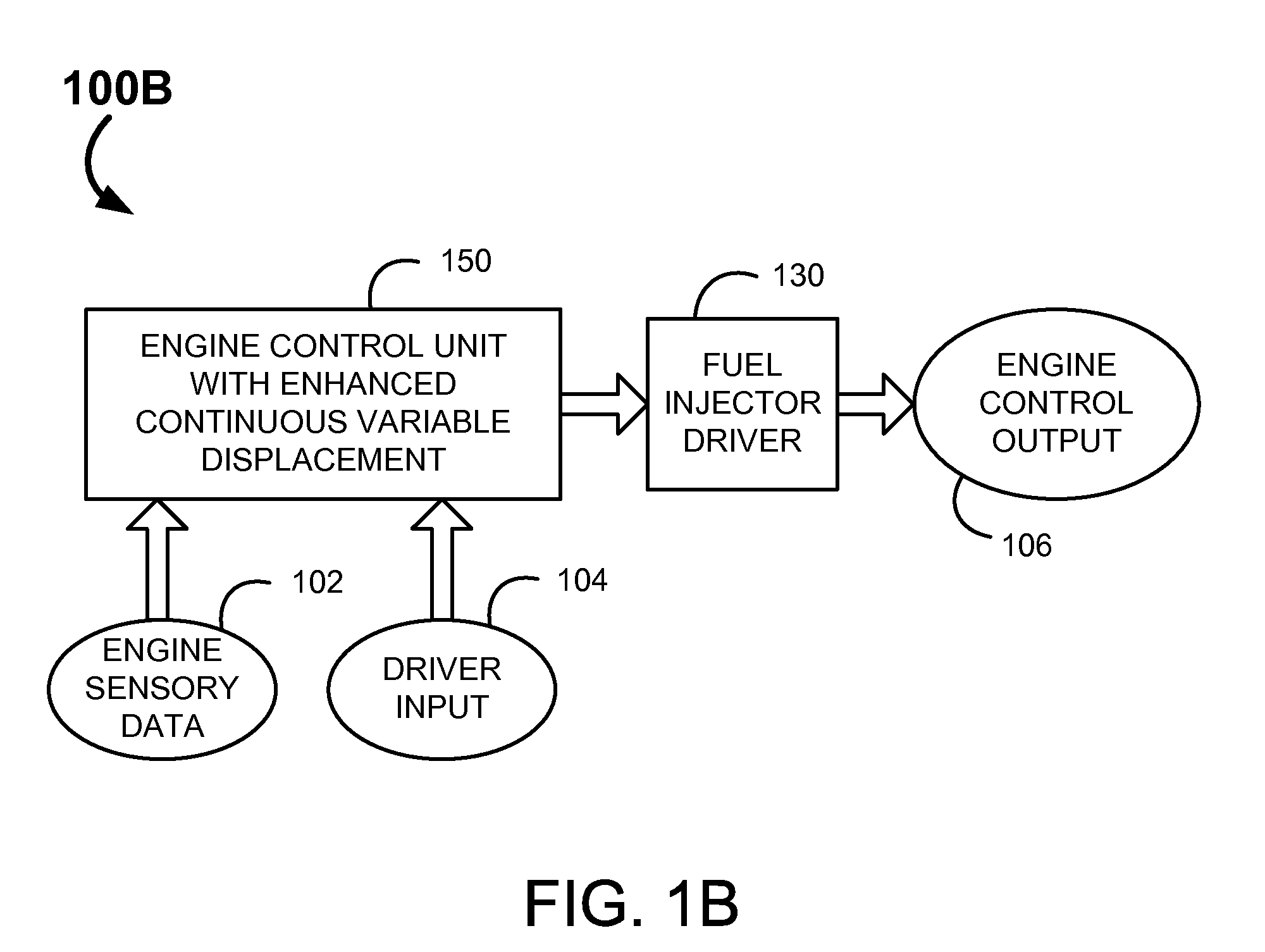

System and Methods for Improving Efficiency in Internal Combustion Engines

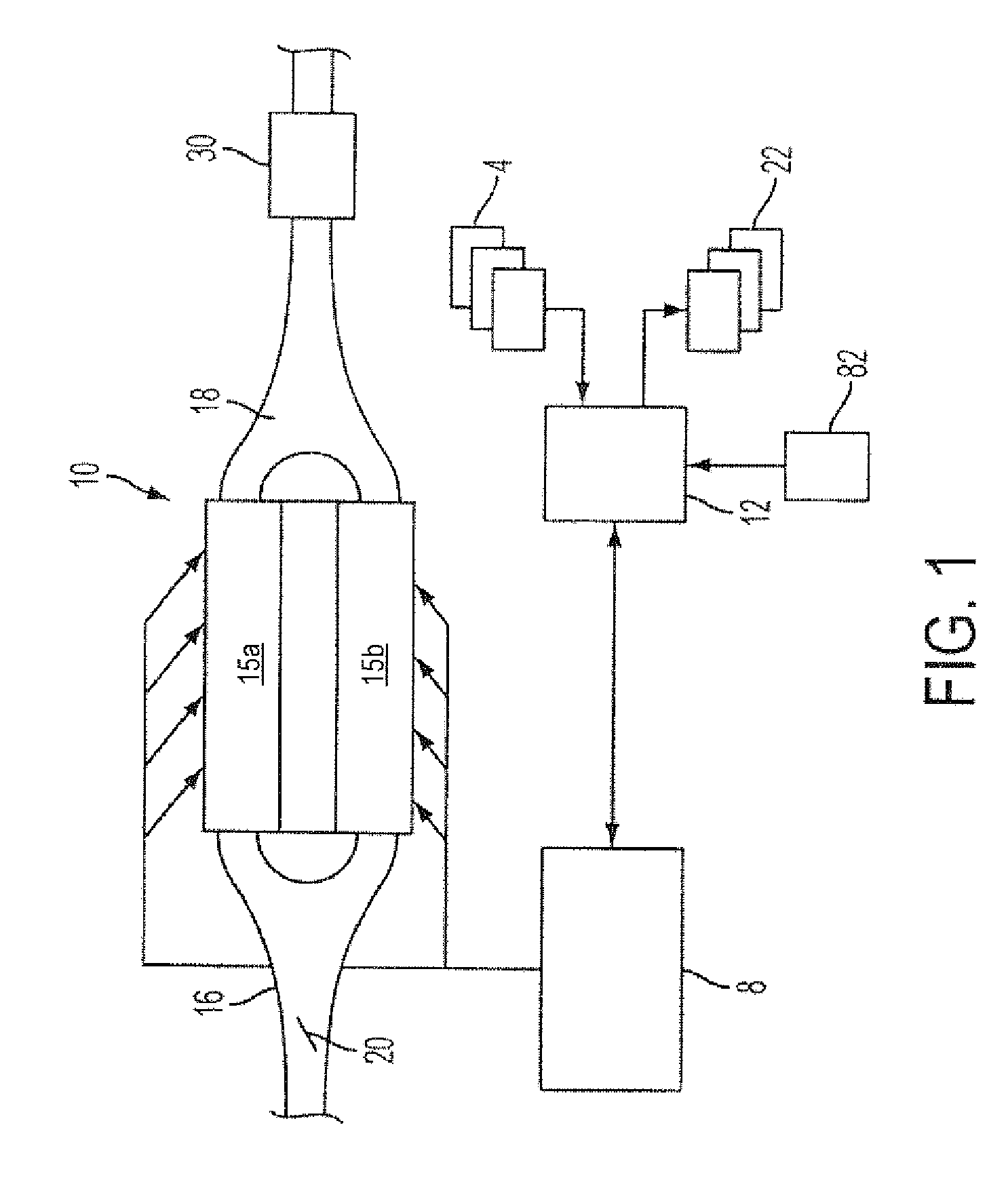

ActiveUS20100100299A1Improve efficiencyMaximizes timeAnalogue computers for vehiclesElectrical controlCombustionInternal combustion engine

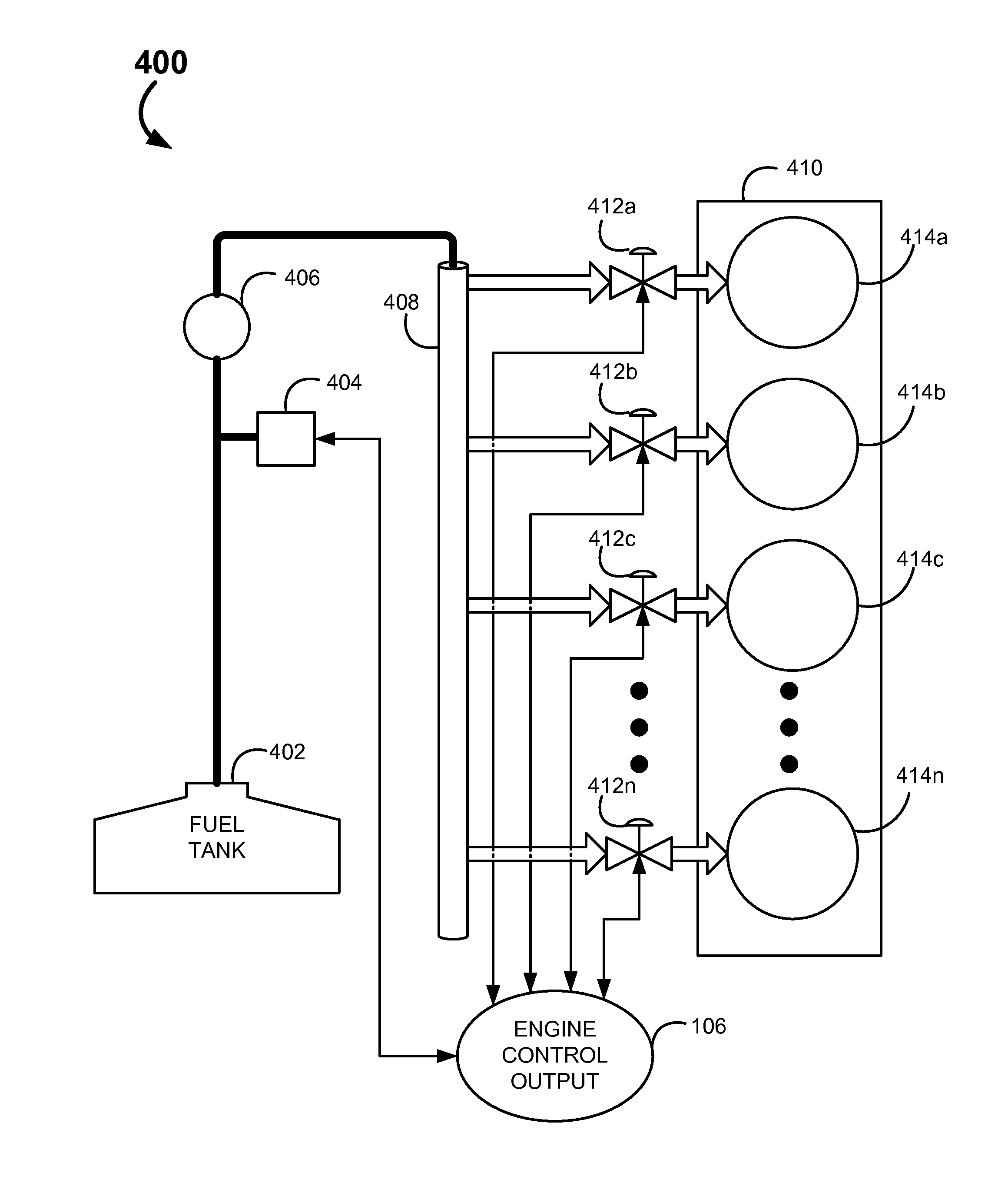

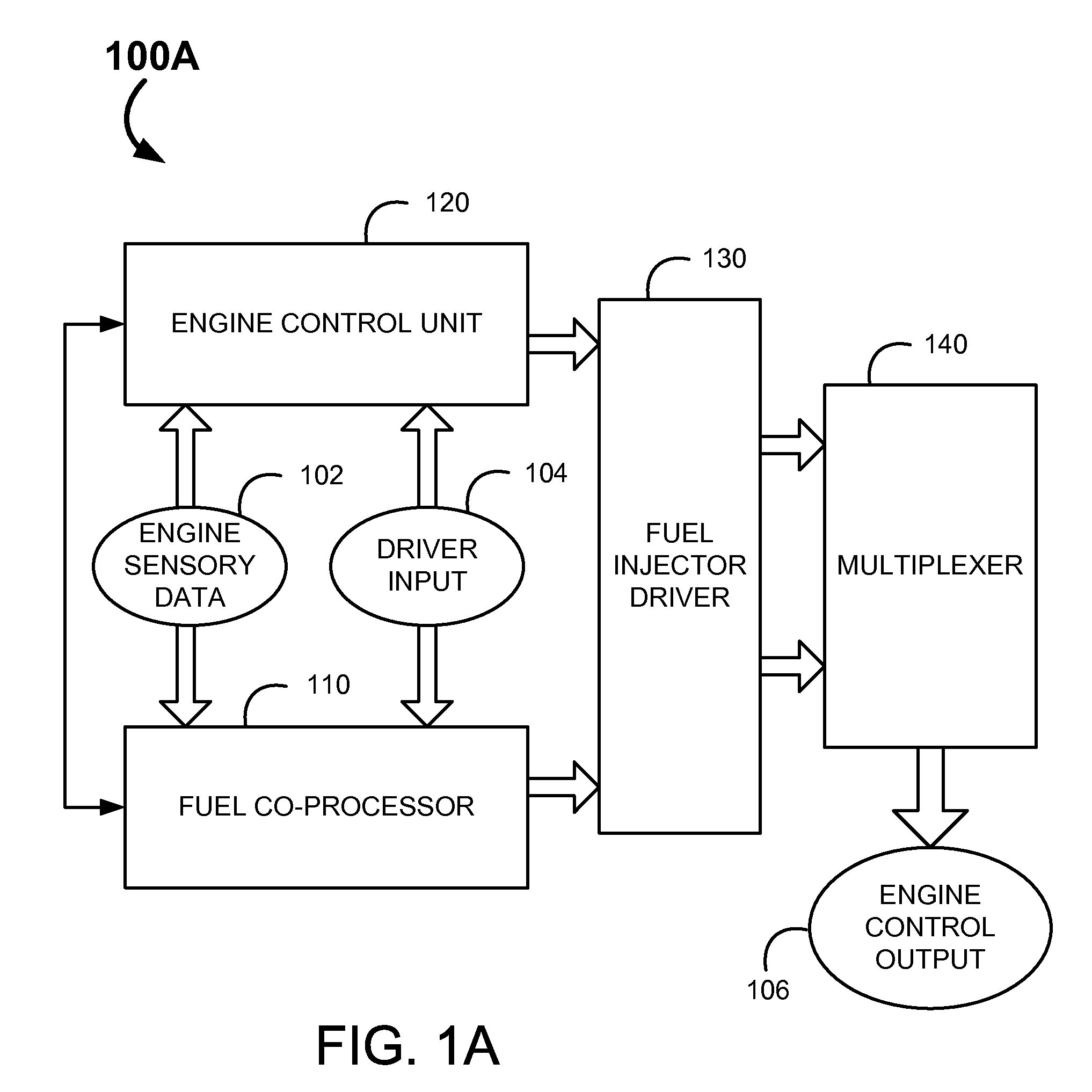

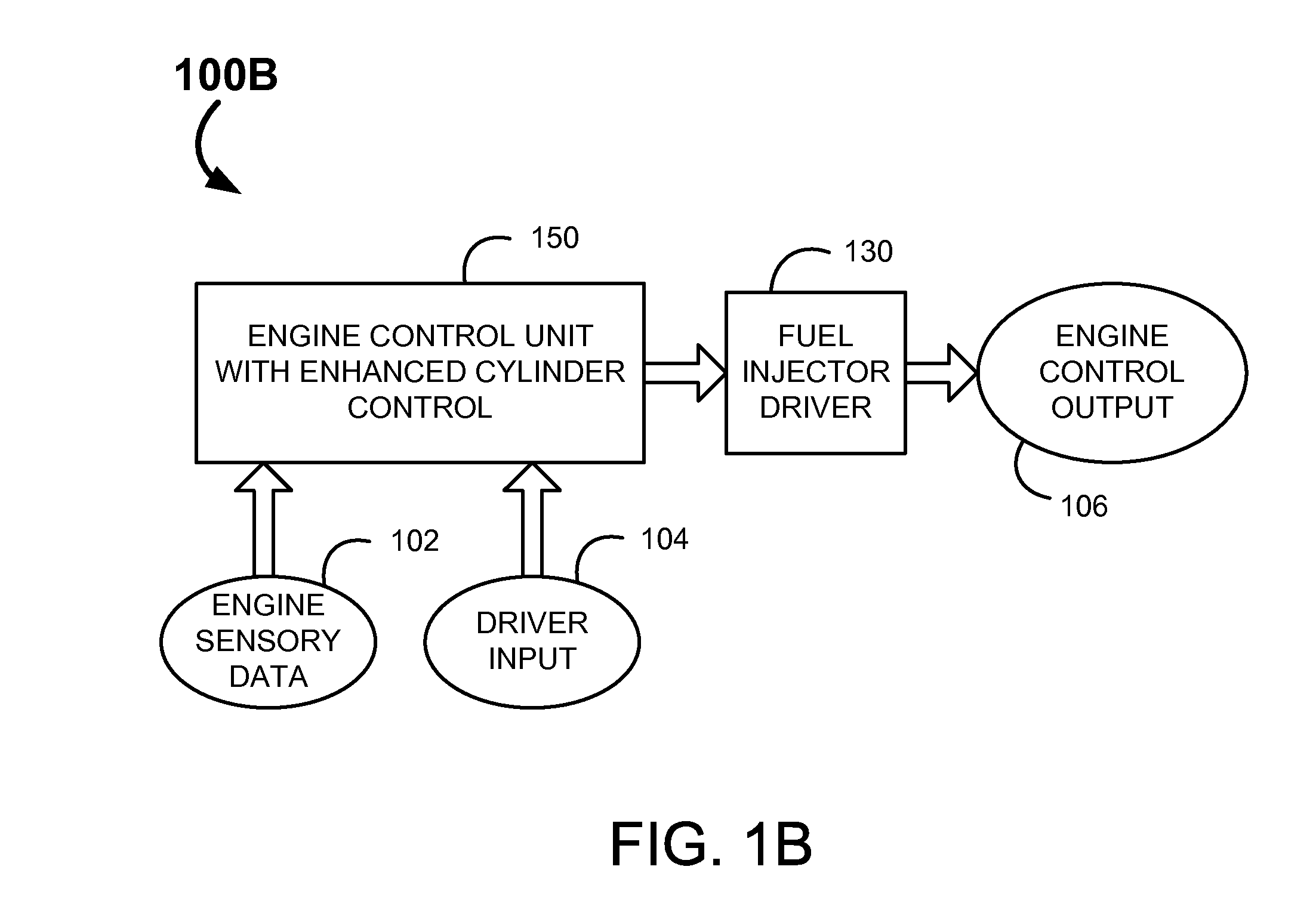

The present invention relates to system and methods for improving efficiency of an internal combustion engine. This system may include a fuel processor. The system receives instructions for a desired engine output and operating conditions. The system may then determine an operational state corresponding to the desired output. The operational state includes designating the cylinders into one of three categories: working, deactivated and passive. The number of working cylinders is calculated by dividing the desired output by the power provided by one cylinder operating at substantially optimal efficiency. Then the system substantially disables fuel flow to and air flow to the deactivated cylinders, substantially disables fuel flow to and firing of the passive cylinders, and substantially regulates fuel flow to, air flow to and firing of the working cylinders. Firing of the working cylinders is synchronized with engine speed to reduce unwanted engine vibrations. The number of working, passive and deactivated cylinders may be continually altered in response to changes in desired output or operating conditions.

Owner:TULA TECH INC

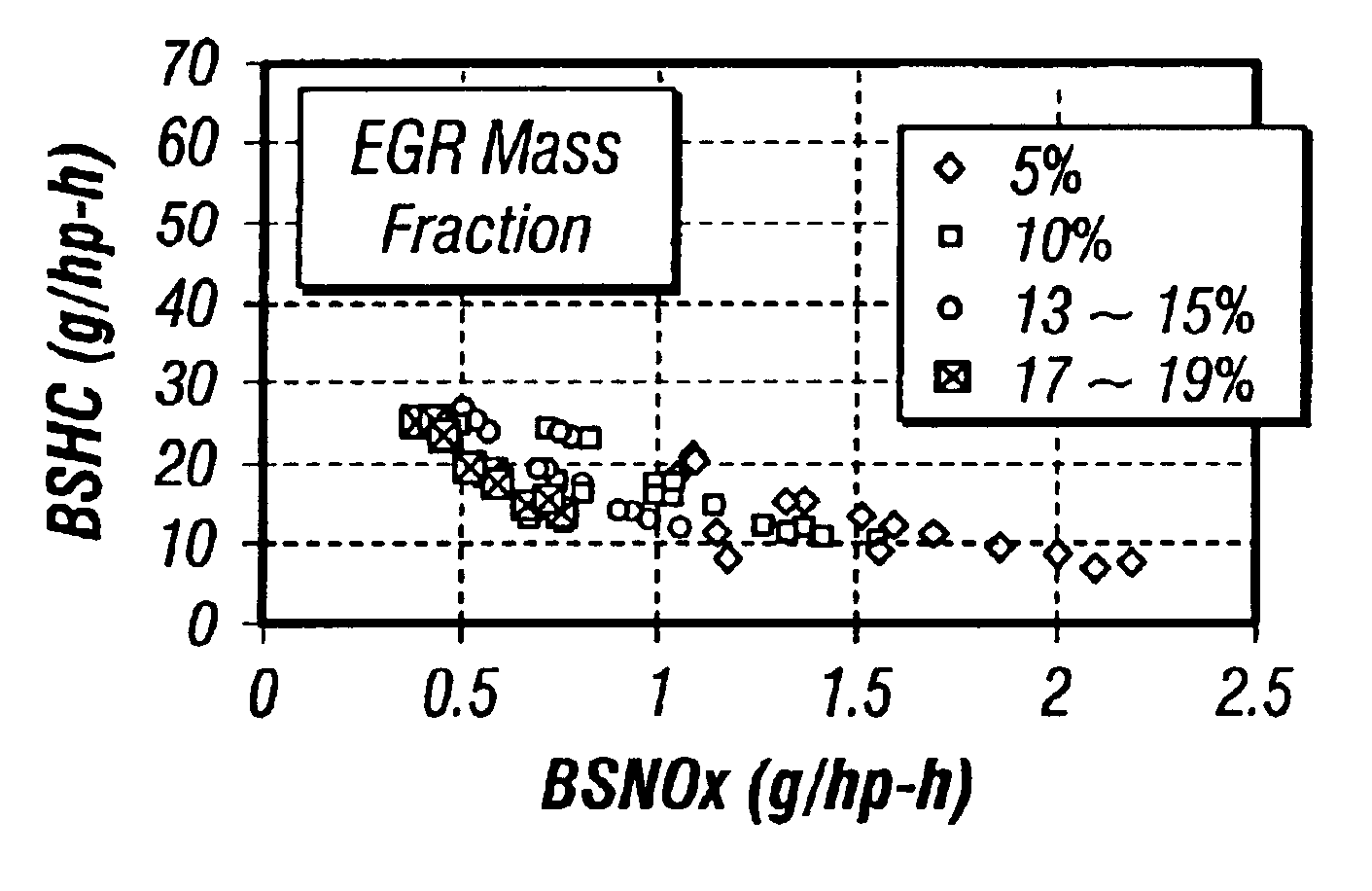

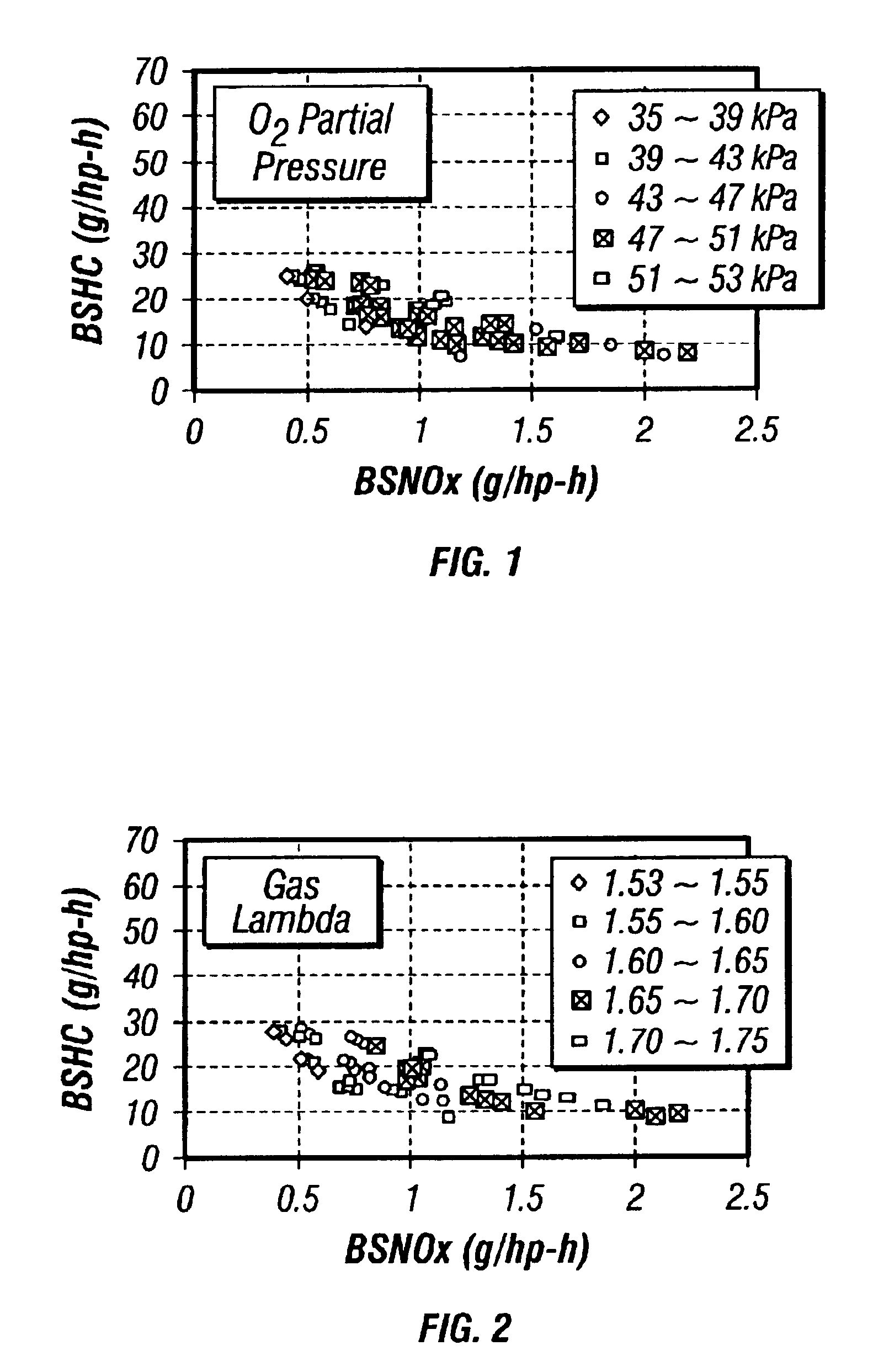

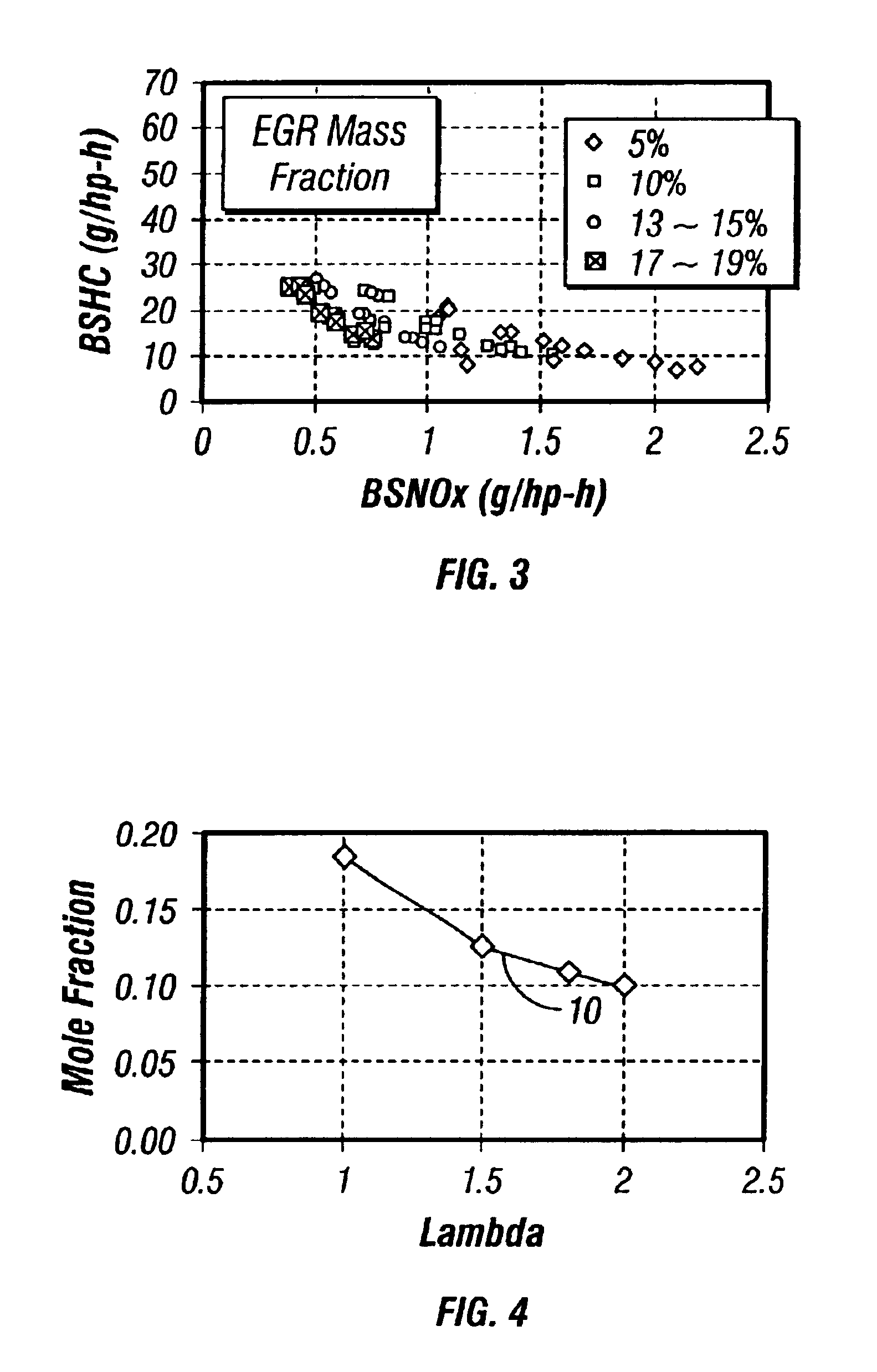

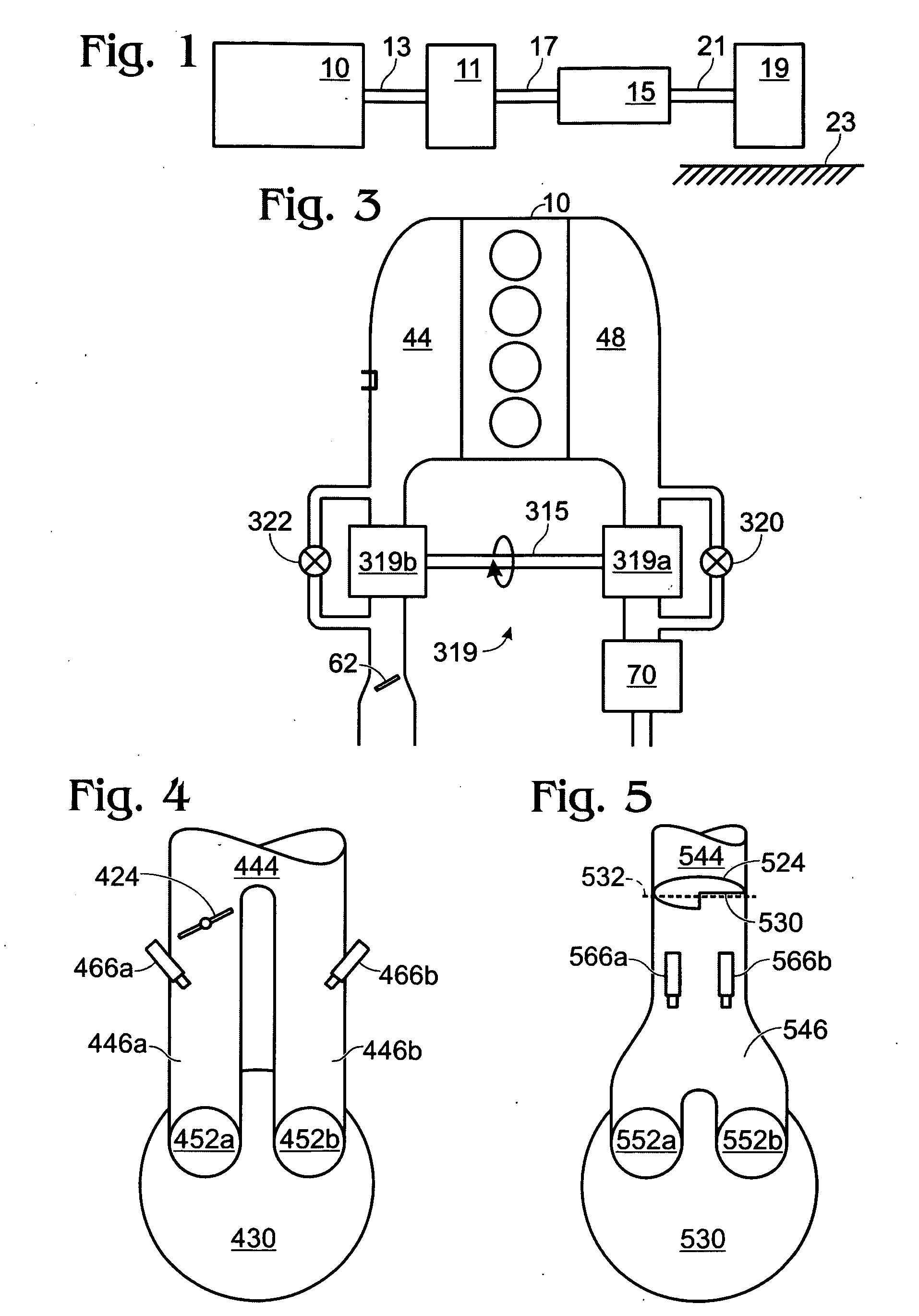

Optimized combustion control of an internal combustion engine equipped with exhaust gas recirculation

InactiveUS6948475B1Avoid condensationImprove concentrationElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An EGR equipped internal combustion engine is controlled to maximize the beneficial effects and minimize the detrimental effects of EGR on engine operation. Specifically, at least one parameter indicative of the O2 concentration in the intake mixture and / or at least one parameter indicative of the H2O concentration in the intake mixture is monitored, and the monitored parameter is relied on to control one or more aspects of engine operation by open loop adjustment of other control strategies and / or by a separate closed loop control strategy. These controls are applicable to virtually any engine, and are particularly beneficial to lean burn engines such as diesel (compression ignition) engines, spark ignited natural gas engines, and dual fuel or other compression ignited natural gas engines. The engine may be equipped with either actively controllable EGR or passive and uncontrolled EGR.

Owner:CLEAN AIR POWER

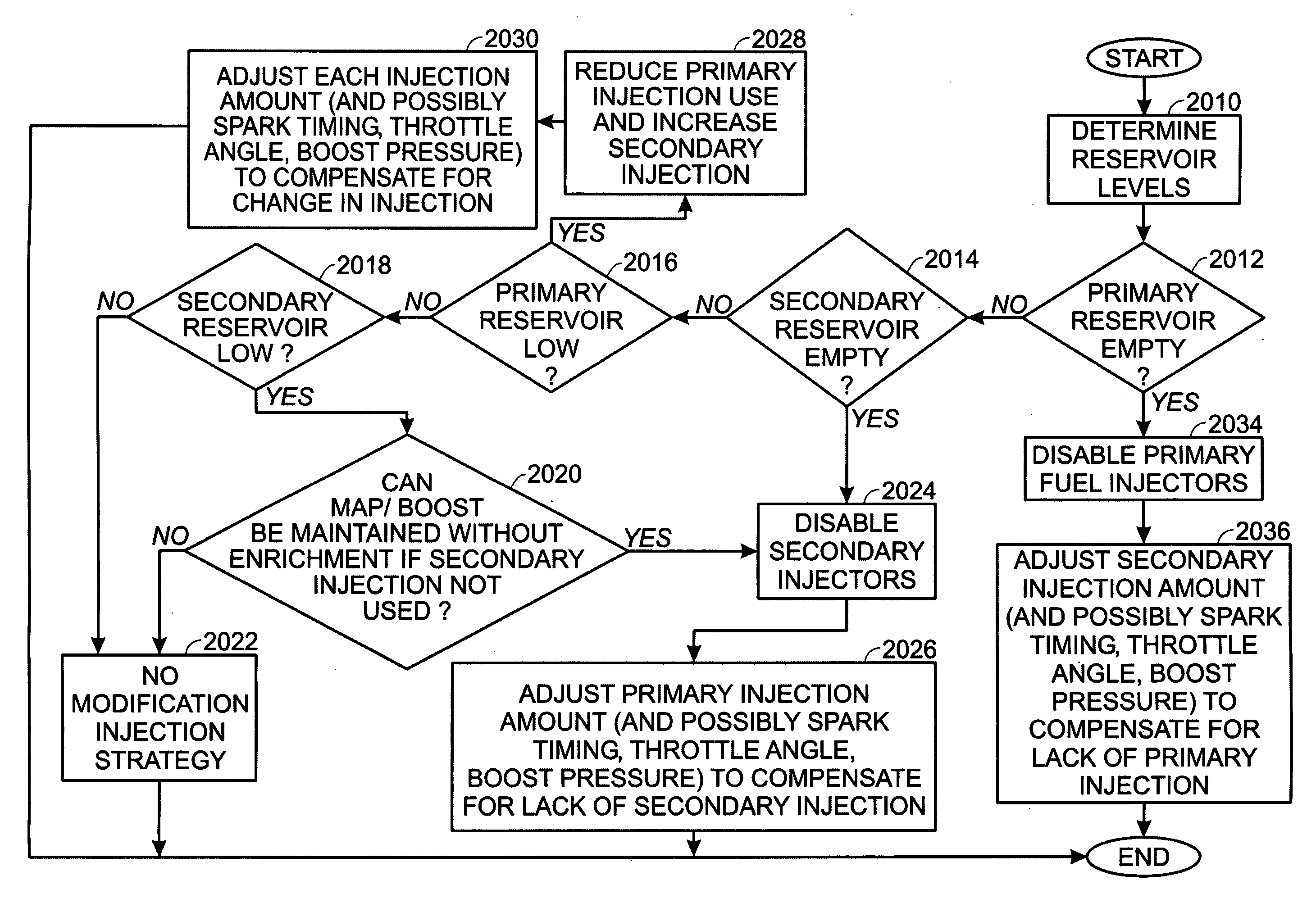

Control strategy for engine employing multiple injection types

ActiveUS20070215110A1Improve engine performanceLow costElectrical controlInternal combustion piston enginesMultiple injectionAutomotive engineering

A system for an engine, comprising a cylinder, a first injection subsystem for injecting a first substance into the cylinder, a second injection subsystem for injecting a second substance into the cylinder, and an electronic engine controller configured to control a plurality of operating parameters of the engine, where the electronic engine controller is configured to cause variation of at least one of the operating parameters in response to a shortfall condition of the second injection subsystem.

Owner:FORD GLOBAL TECH LLC

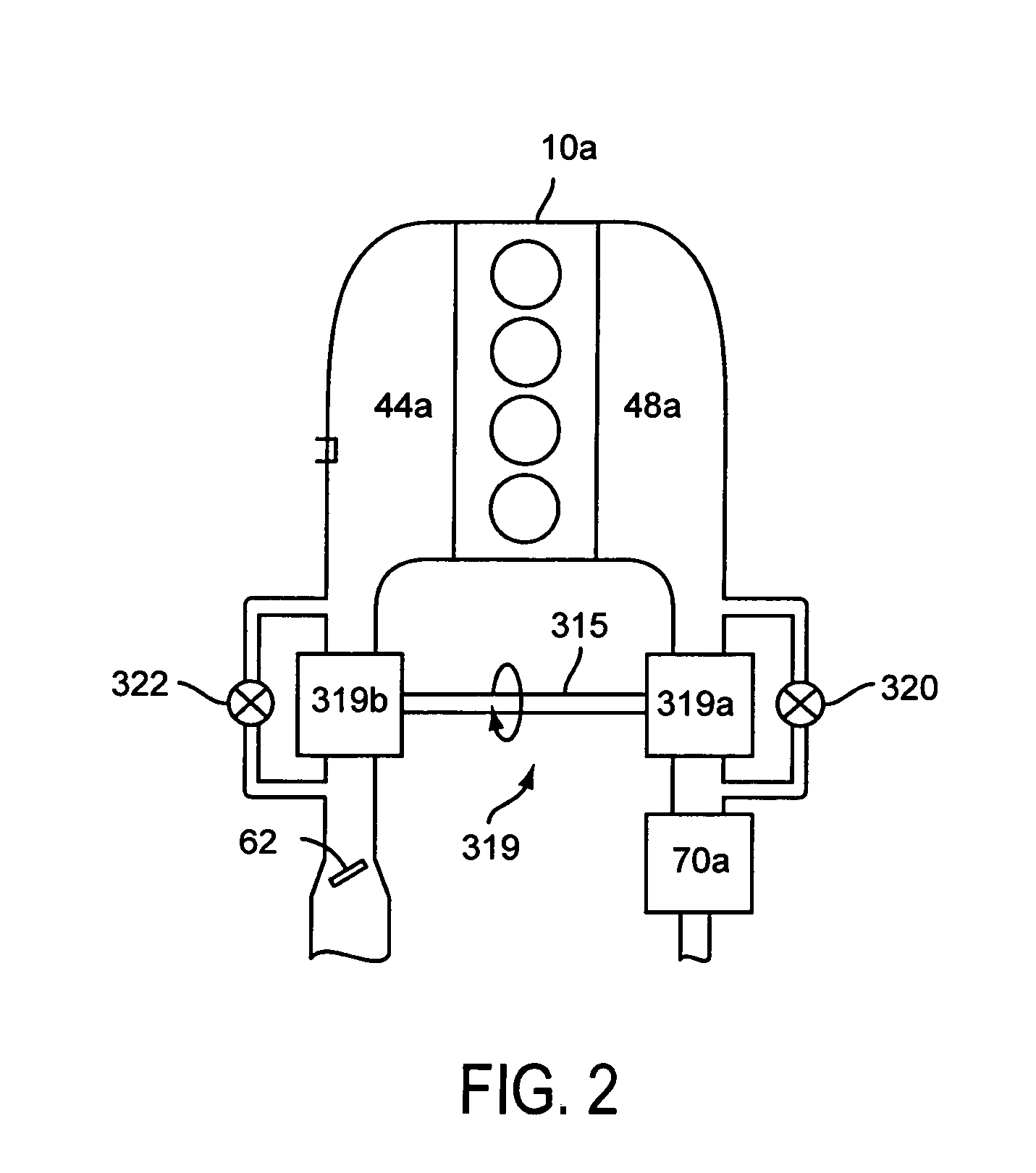

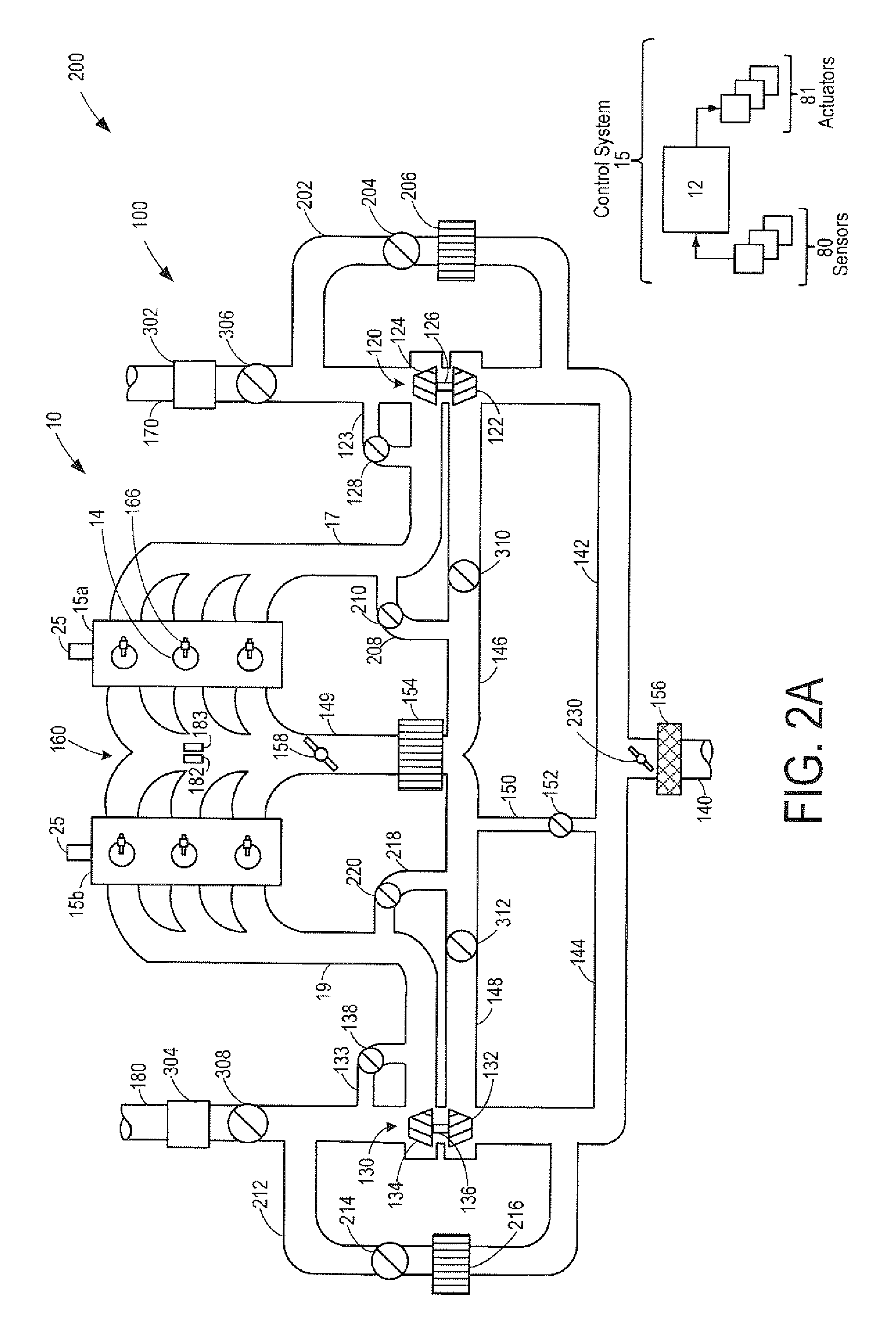

Methods and Systems for Variable Displacement Engine Control

ActiveUS20120285161A1Reliable detectionGood correlationElectrical controlInternal combustion piston enginesEngineeringThrottle

Methods and systems are provided for selecting a group of cylinders for selective deactivation, in a variable displacement engine system, based at least on a regeneration state of an exhaust catalyst. The position of one or more valves and throttles may be adjusted based on the selective deactivation to reduce back-flow through the disabled cylinders while also maintaining conditions of a downstream exhaust catalyst. Pre-ignition and knock detection windows and thresholds may also be adjusted based on the deactivation to improve the efficiency of knock and pre-ignition detection.

Owner:FORD GLOBAL TECH LLC

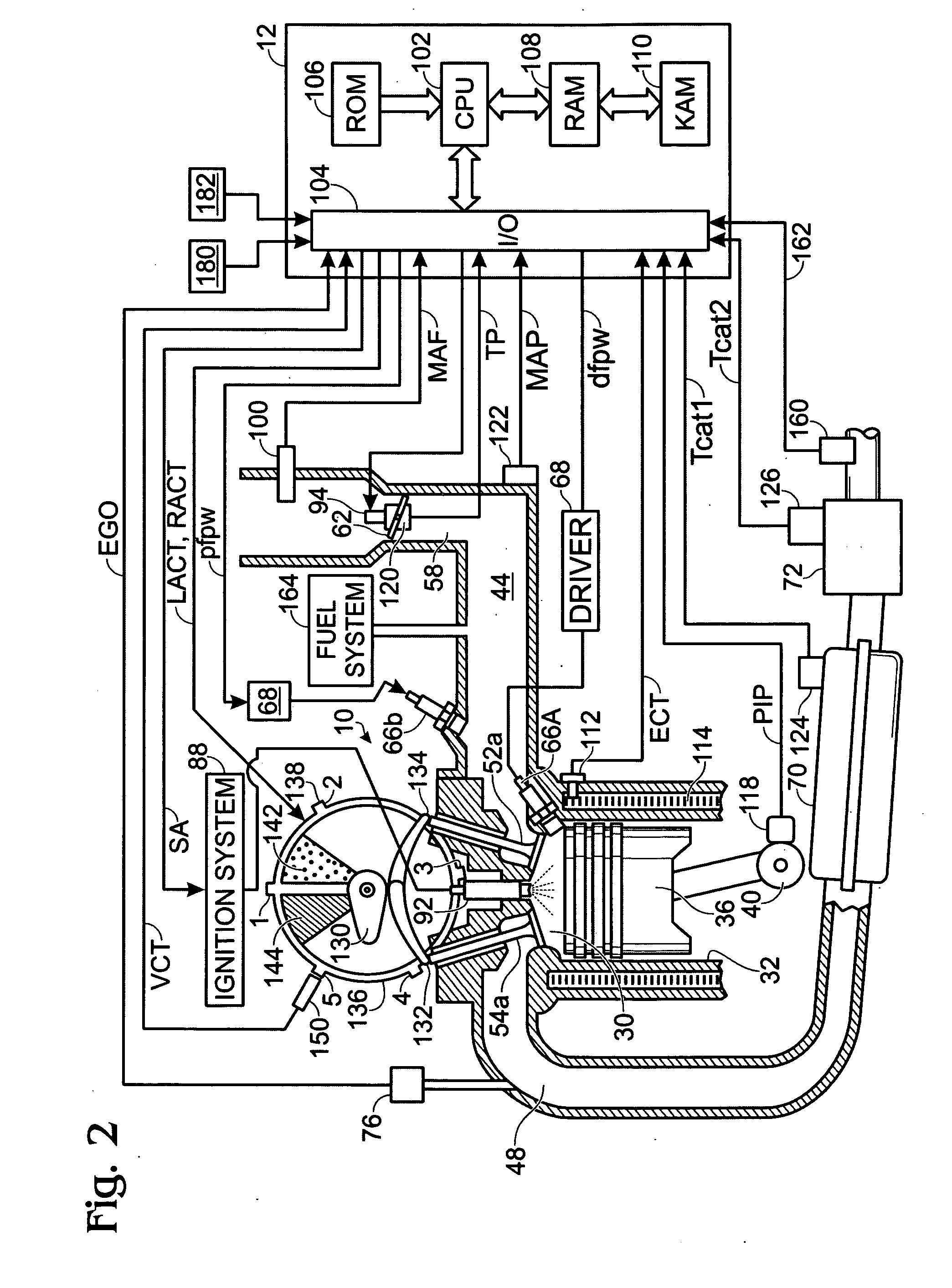

System and method for engine air-fuel ratio control

InactiveUS20070119415A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelOxygen sensorOperant conditioning

A method for operating an engine having a first injector for injecting a first fuel into a cylinder of the engine and a second injector for injection a second fuel into said cylinder of the engine, the engine further having at least an exhaust gas oxygen sensor, the method comprising of varying an amount of said first fuel injection in response to said sensor under a first operating condition, and varying an amount of said second fuel injection in response to said sensor under a second operating condition.

Owner:FORD GLOBAL TECH LLC

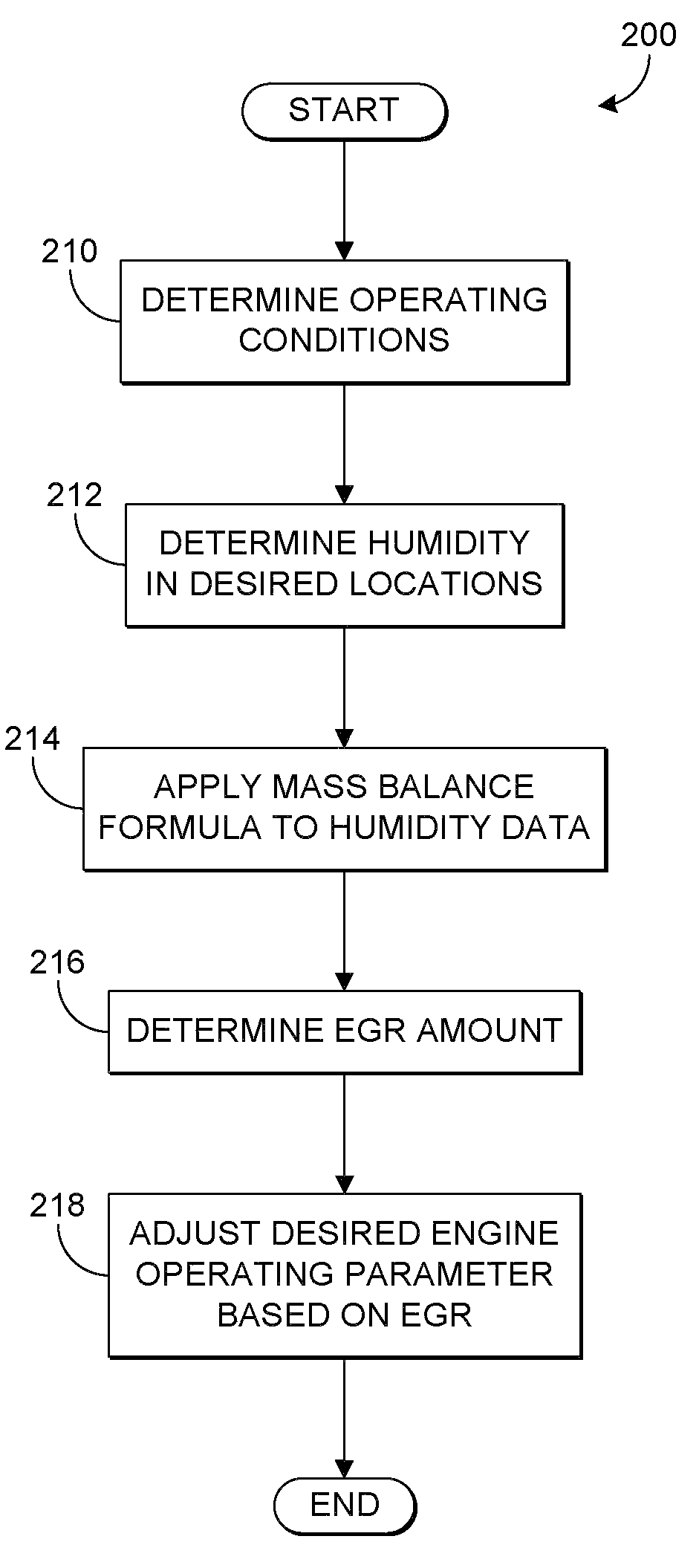

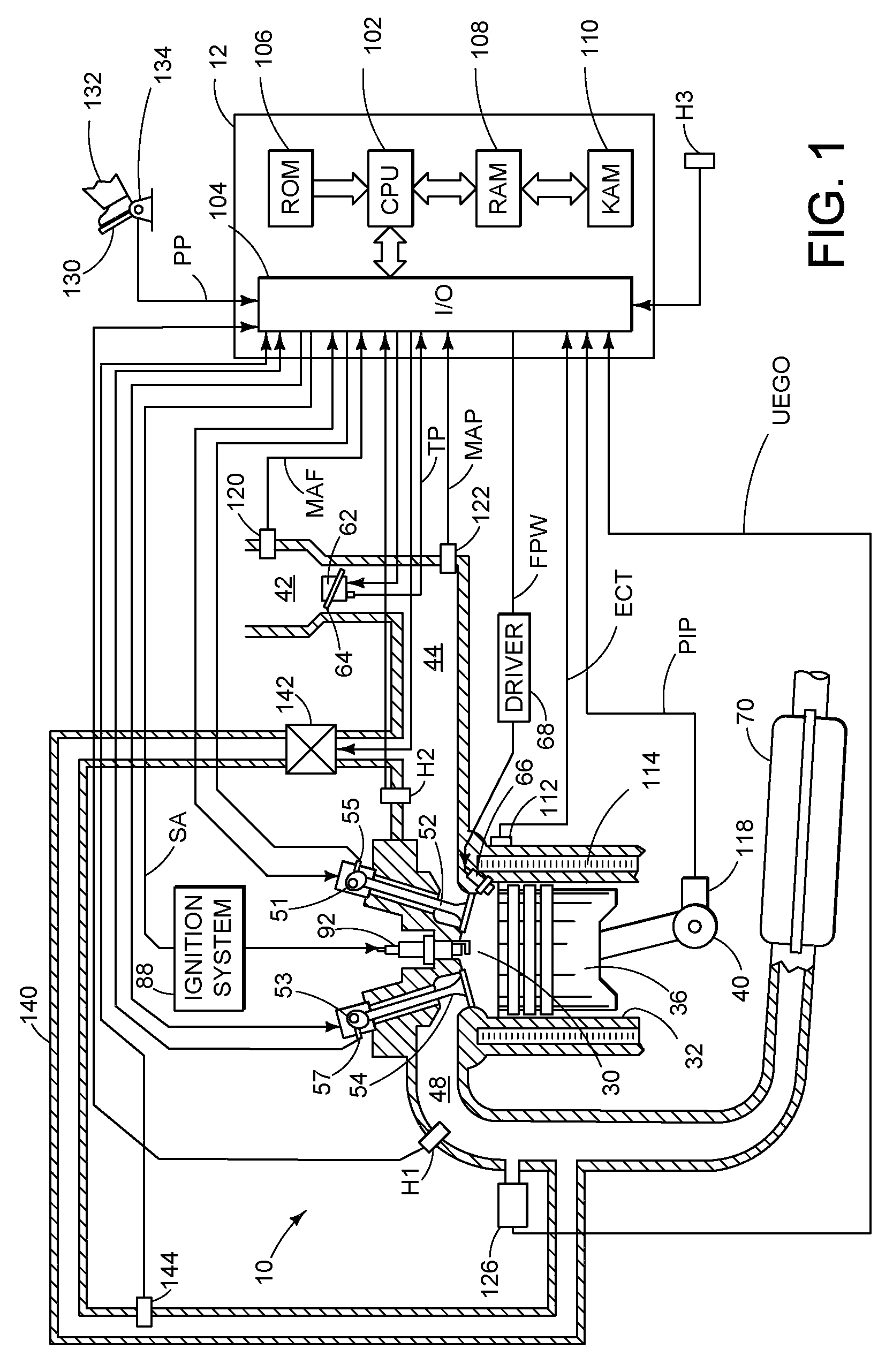

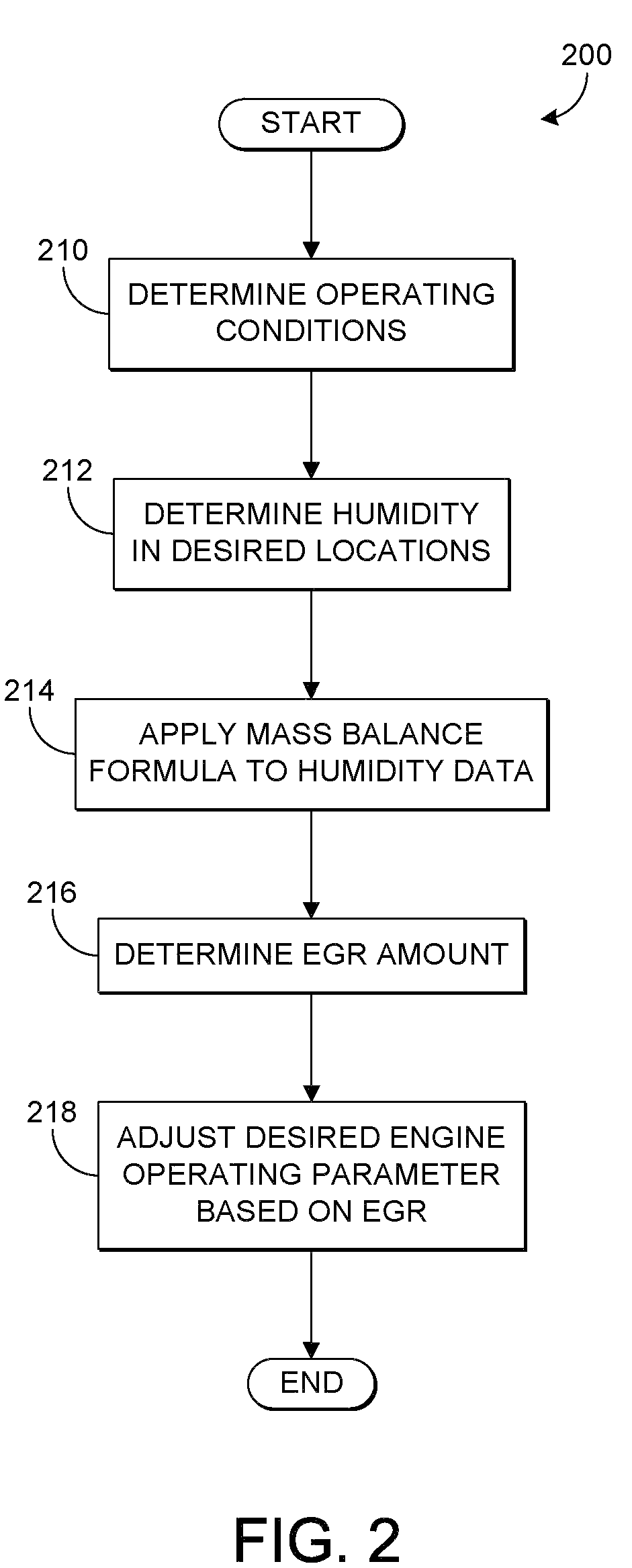

EGR detection via humidity detection

InactiveUS7715976B1Amount of EGRAccurately determineElectrical controlInternal combustion piston enginesExhaust gas recirculationMoisture sensor

Various systems and methods are described for controlling an engine in a vehicle which includes an exhaust passage and an exhaust gas recirculation system. One example method comprises adjusting an engine operating parameter based on an exhaust gas recirculation amount, the exhaust gas recirculation amount based on a first humidity and a second humidity, the first humidity generated from a first humidity sensor at a first location and the second humidity generated from a second humidity sensor located in the exhaust passage of the engine.

Owner:FORD GLOBAL TECH LLC

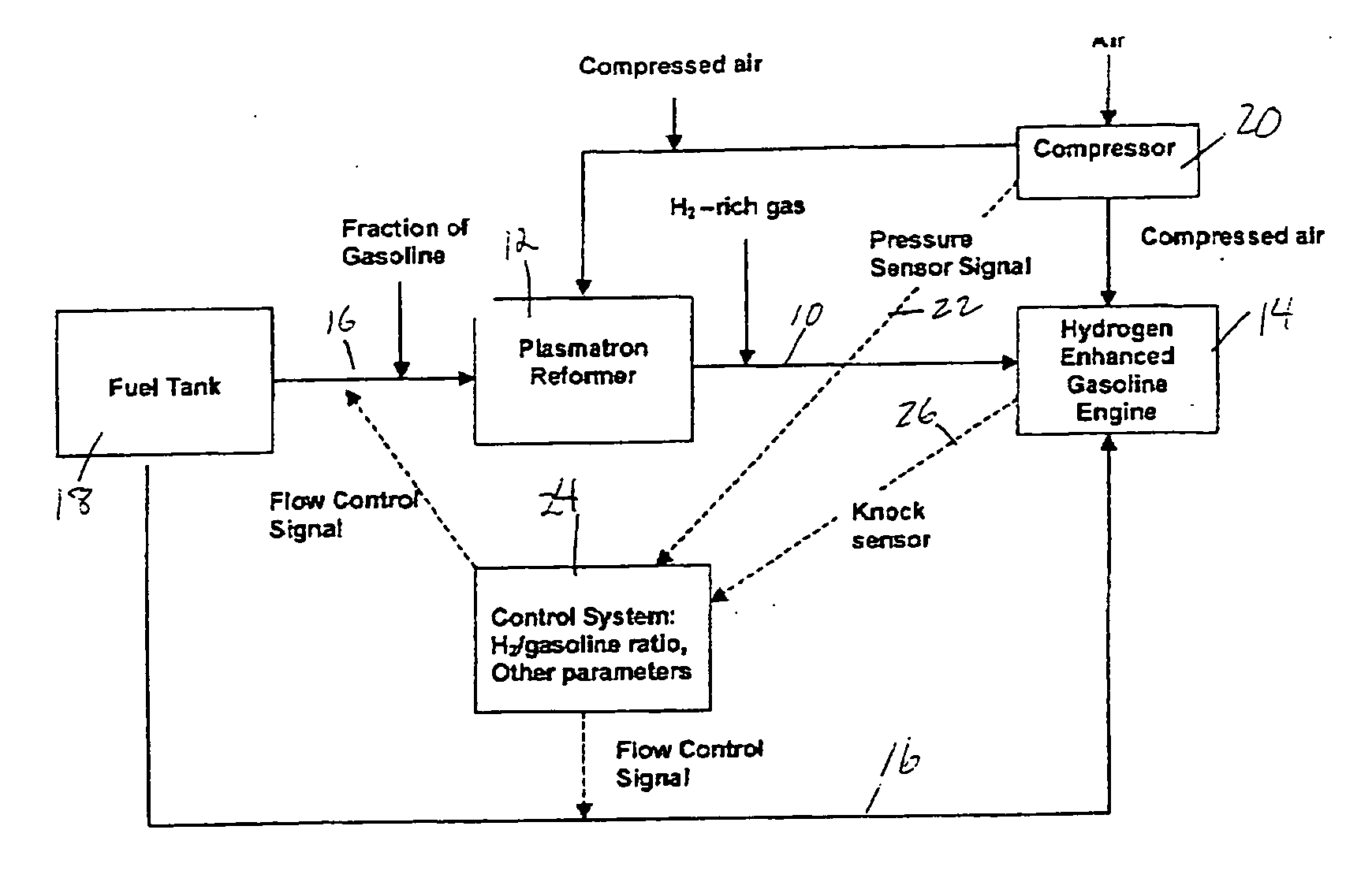

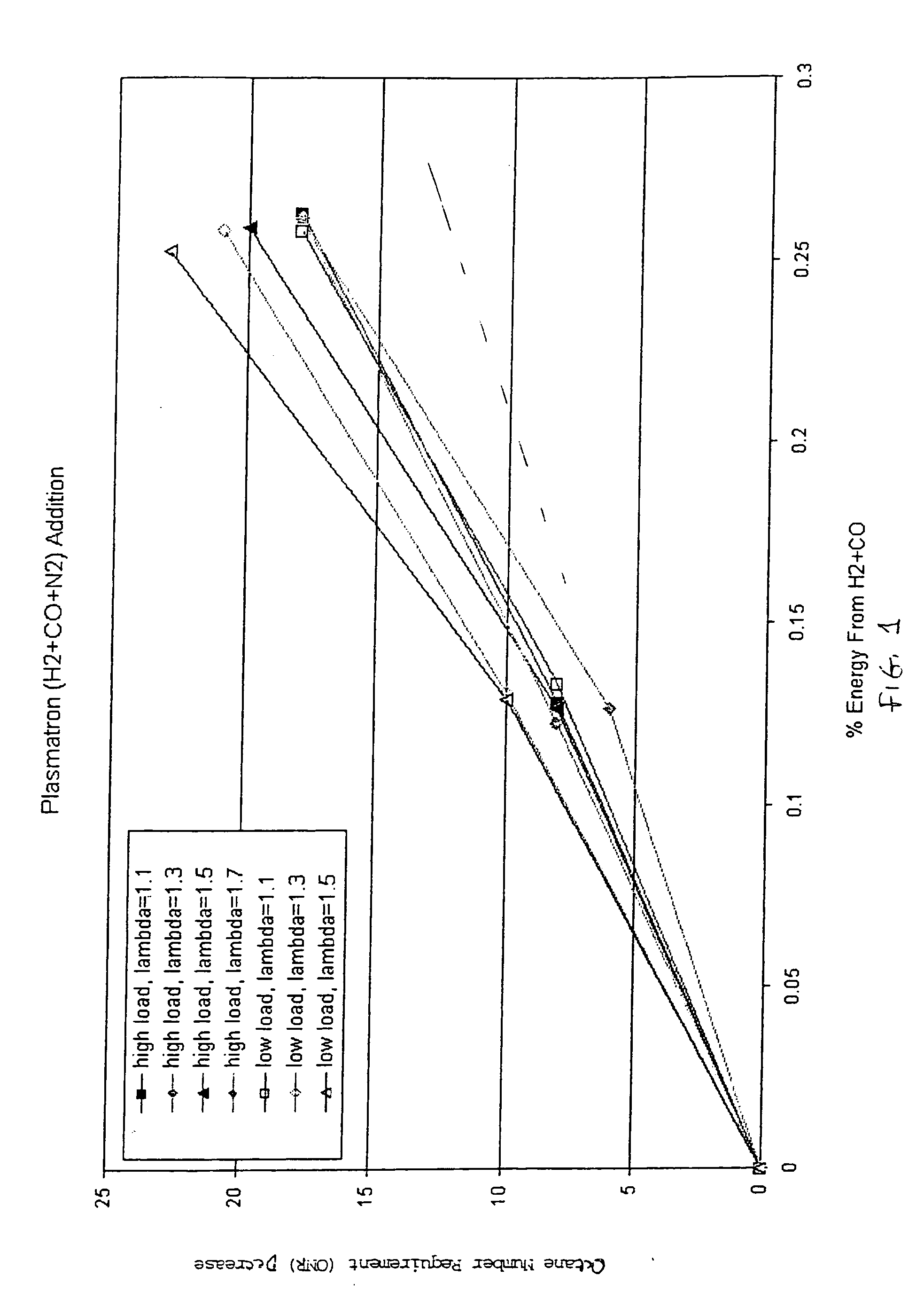

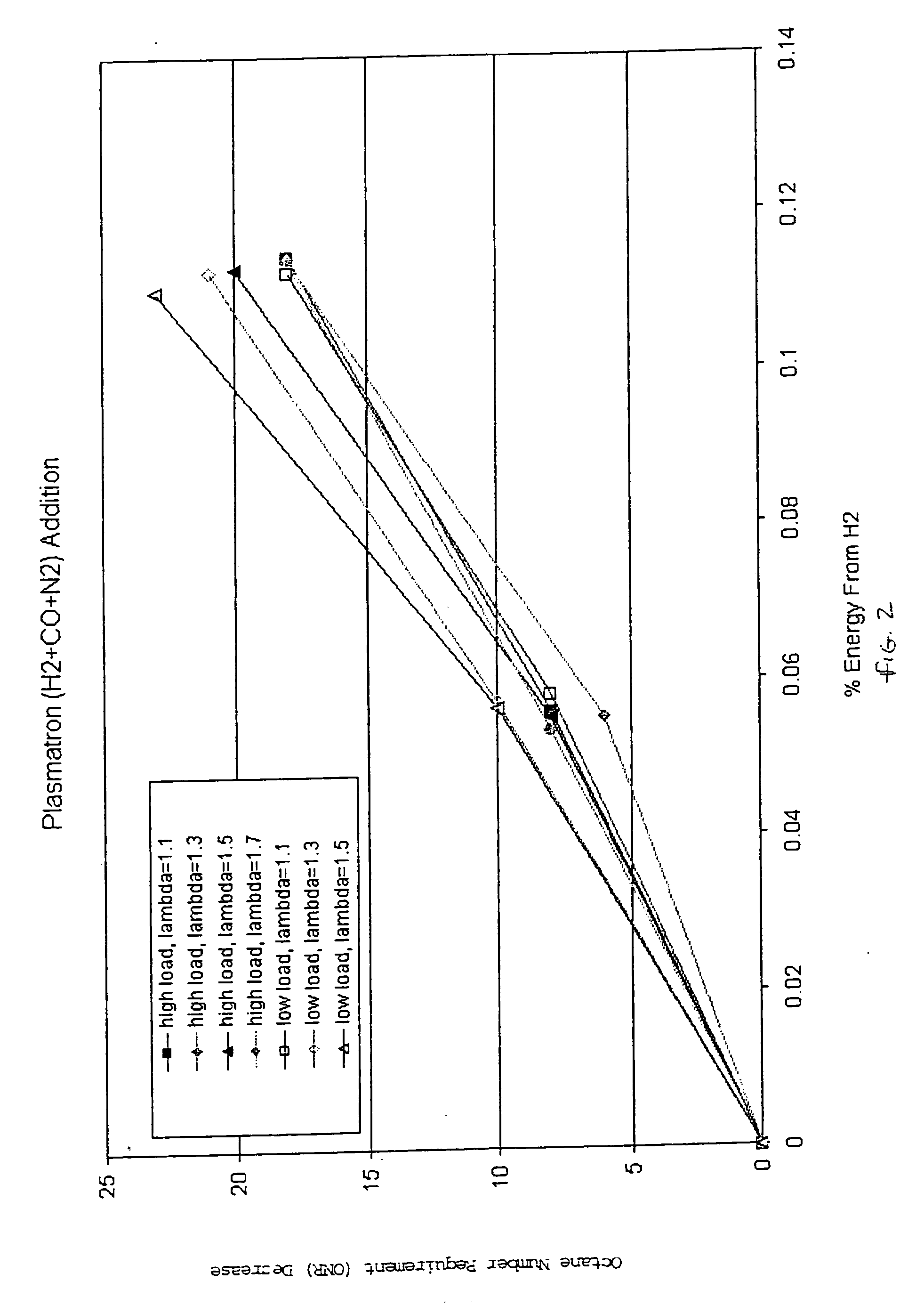

Hydrogen and carbon monoxide enhanced knock resistance in spark ignition gasoline engines

InactiveUS20060075991A1Good anti-knock performanceGreater spark retardElectrical controlNon-fuel substance addition to fuelHydrogenCombustion

A method for reducing required octane number and a spark ignition gasoline engine system with hydrogen-enhanced knock resistance. The method for reducing required octane number of gasoline needed to prevent knock includes the addition of hydrogen or hydrogen-rich gas containing carbon monoxide to gasoline. Octane number can be improved by 5 or more for a hydrogen energy fraction of 10%. The spark ignition gasoline engine system includes a spark ignition gasoline engine and a source of gasoline and hydrogen or hydrogen-rich gas. Apparatus is provided to supply the gasoline and the hydrogen or hydrogen-rich gas to the engine at a varying hydrogen or hydrogen-rich gas to gasoline ratio selected both to prevent knock and to ensure a desired level of combustion stability throughout a full range of engine operation. The engine system may be normally aspirated or boosted; the compression ratio may be high such as greater than 11 or below 11, and EGR may be added. The hydrogen or hydrogen-rich gas to gasoline ratio may be controlled as a function of boost pressure, torque, engine speed, or air / fuel mixture ratio.

Owner:HEYWOOD JOHN B +4

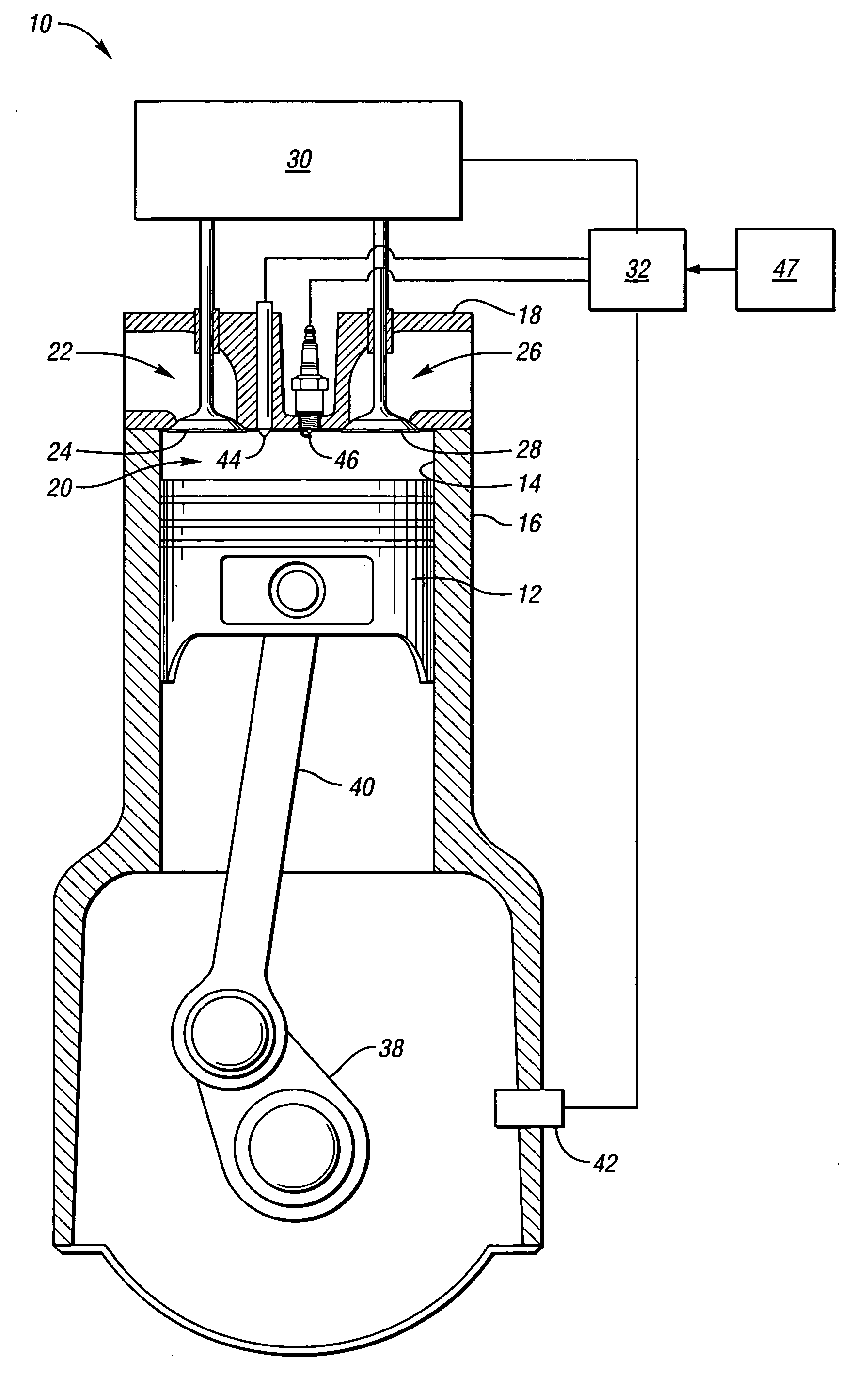

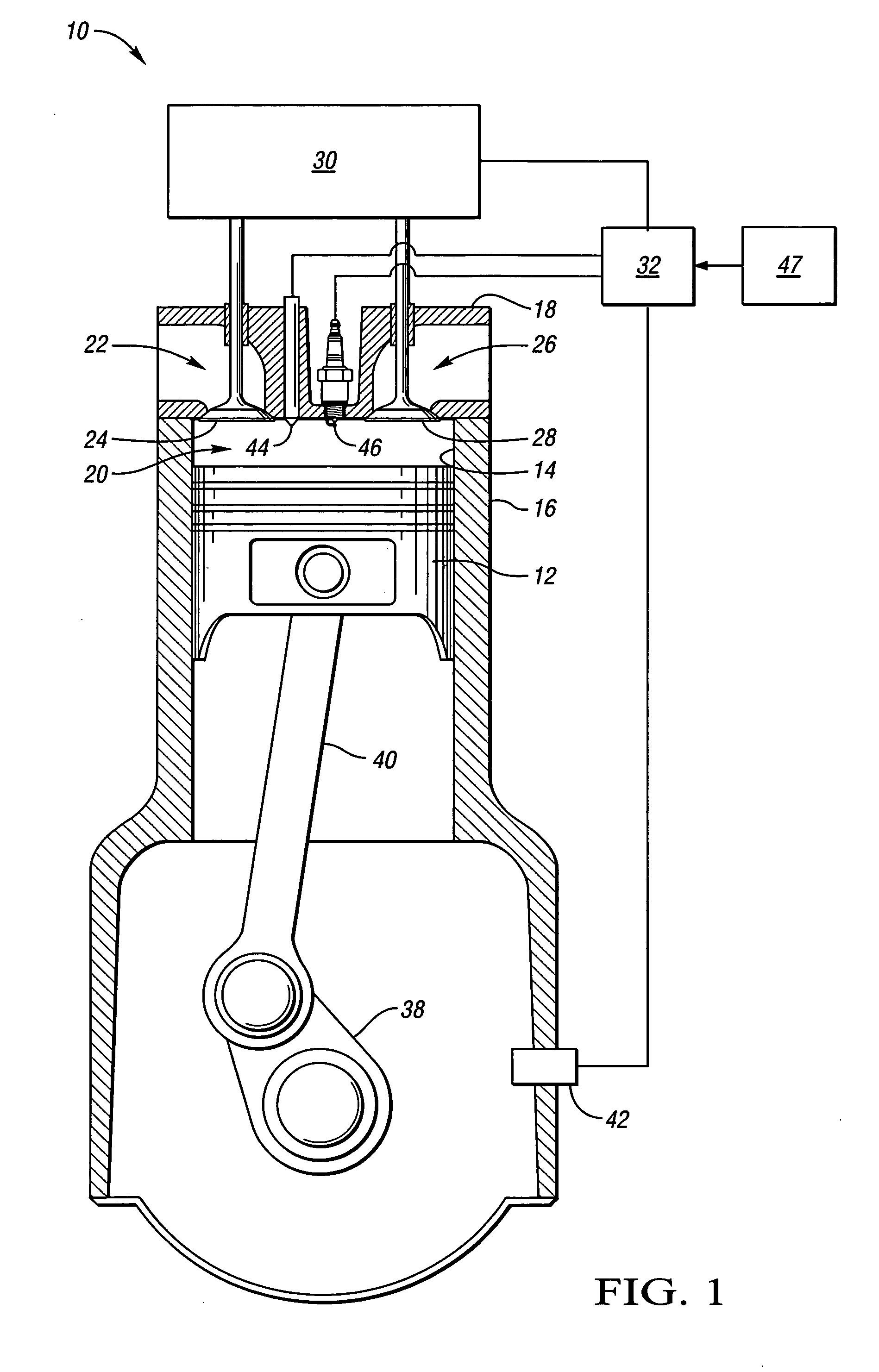

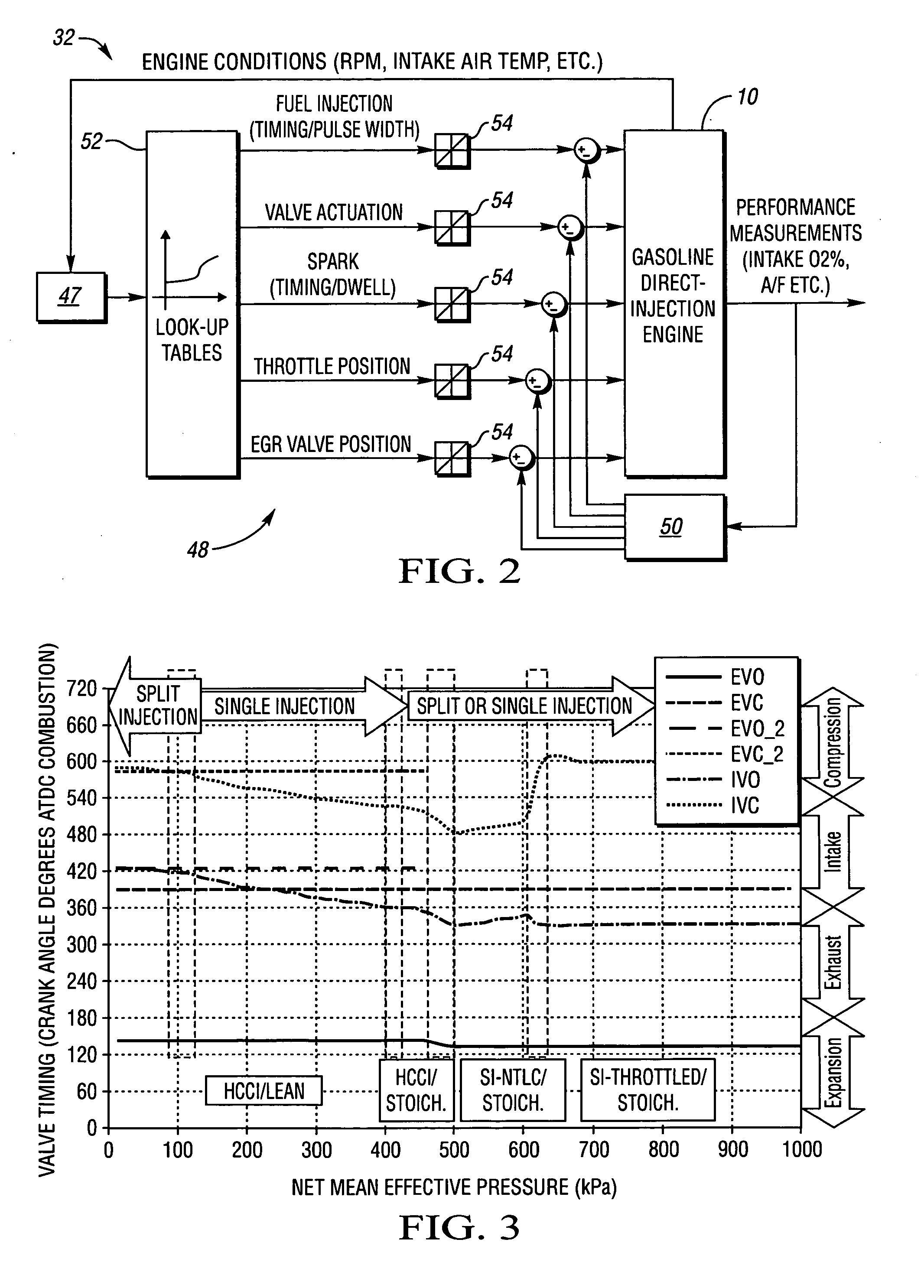

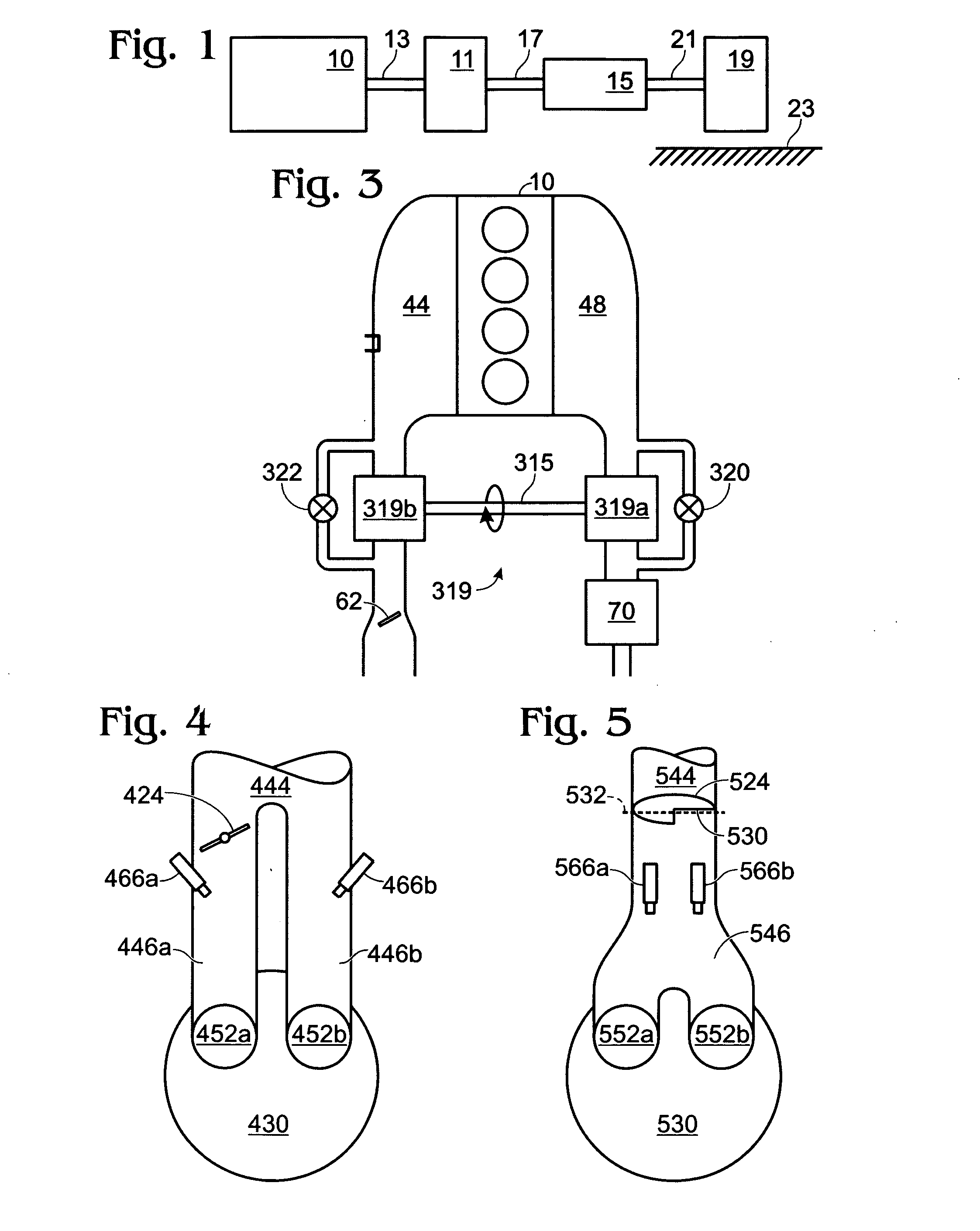

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

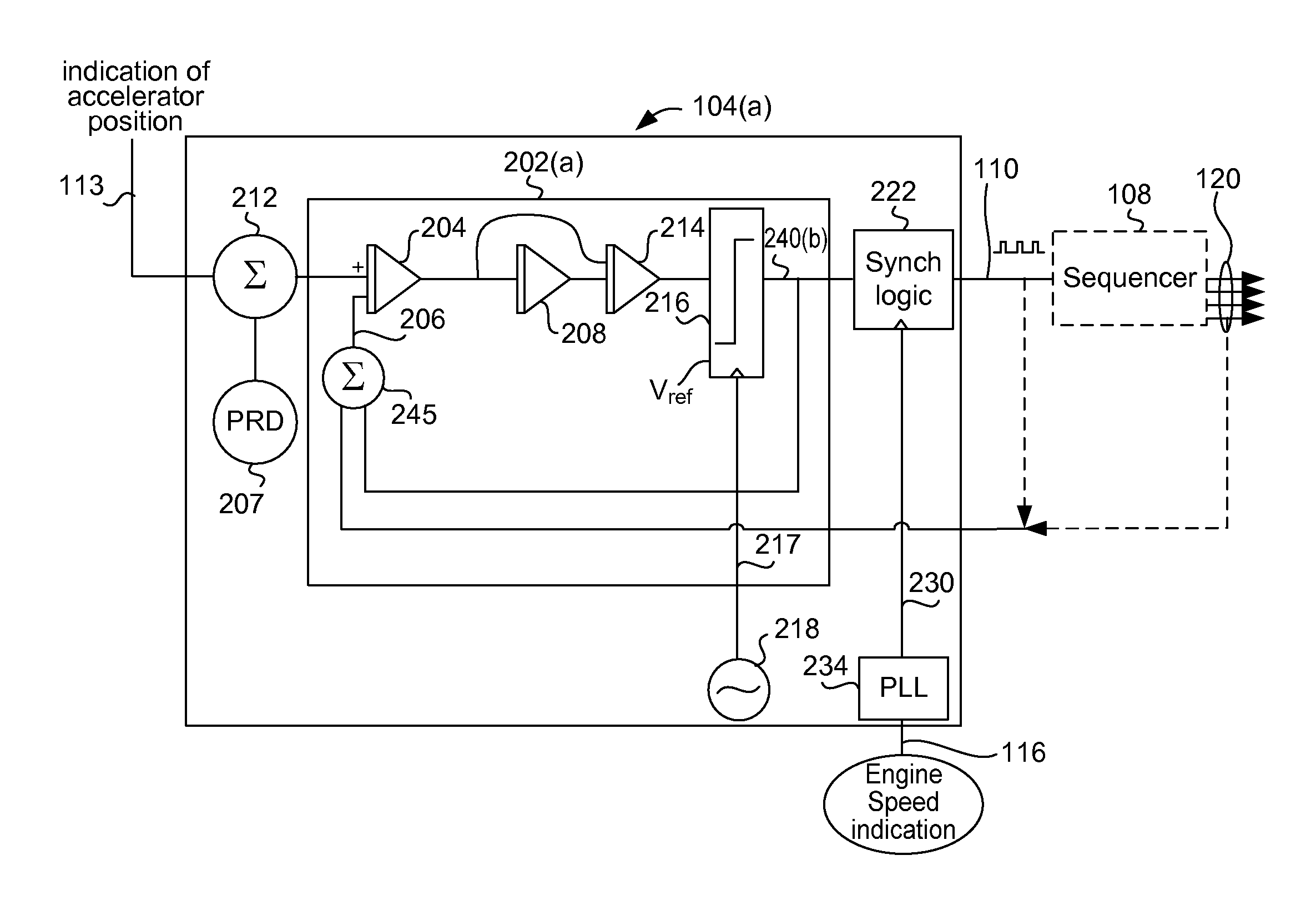

Internal combustion engine control for improved fuel efficiency

ActiveUS20100010724A1Smoother and precise controlReduce probabilityElectrical controlInternal combustion piston enginesCombustionWork cycle

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

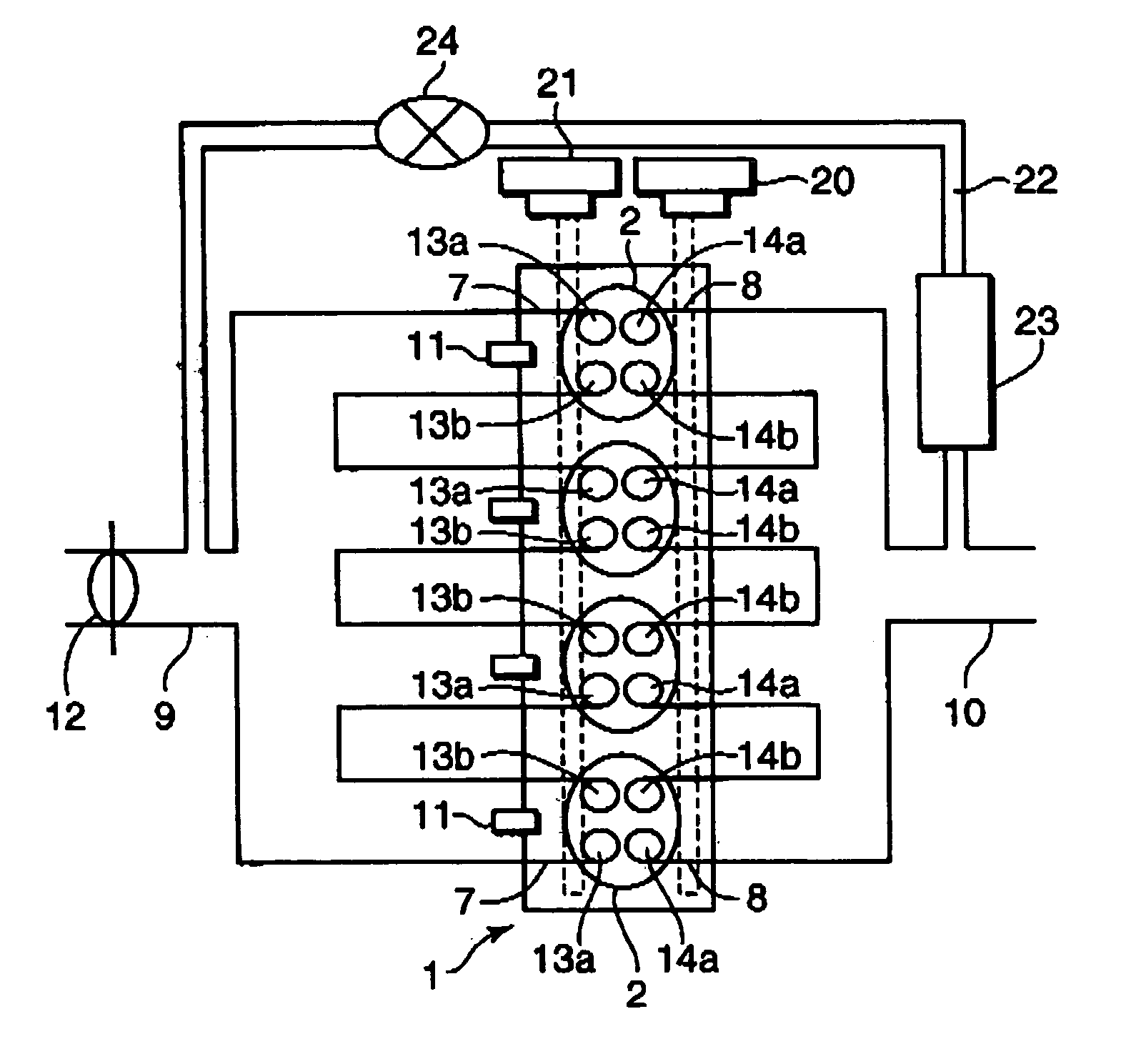

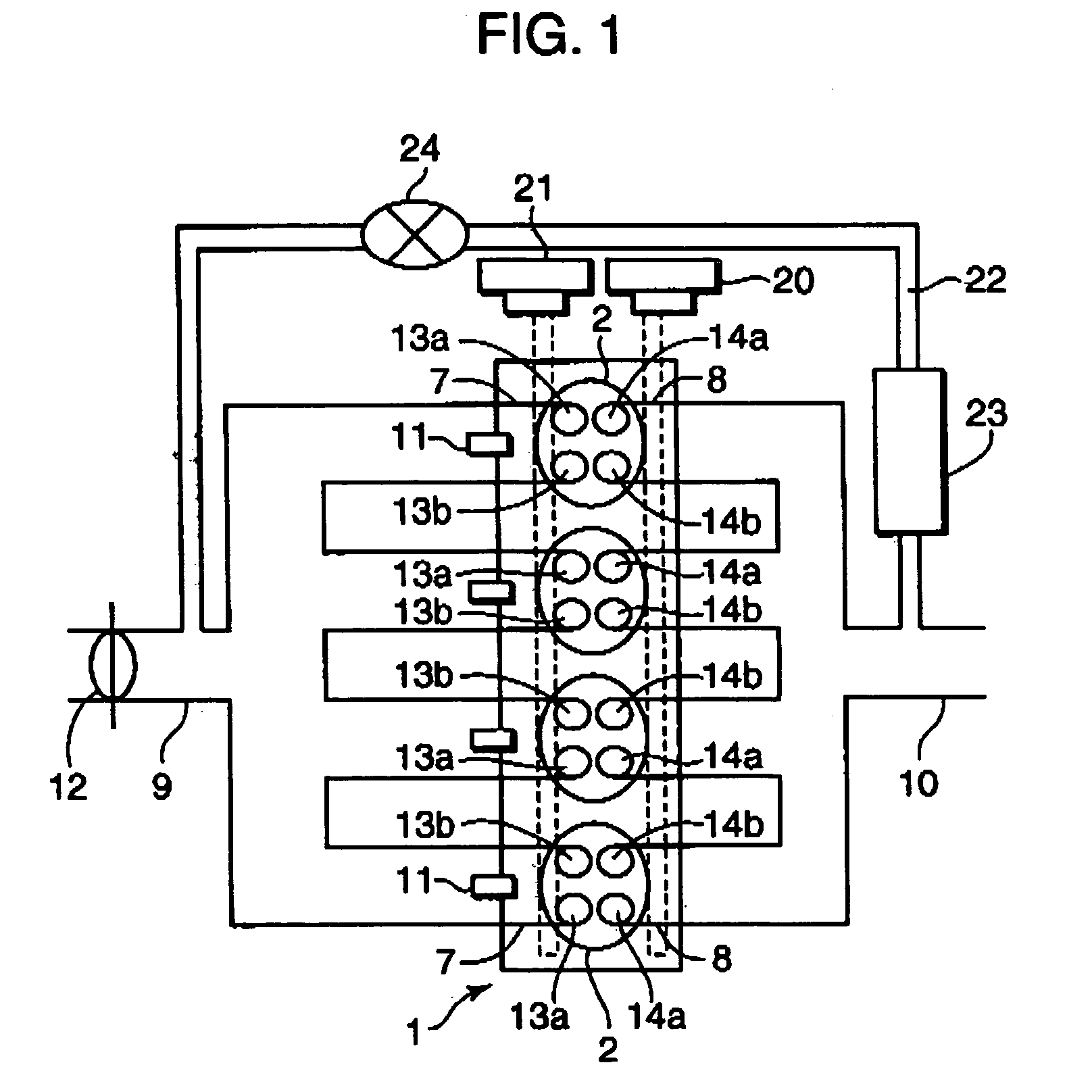

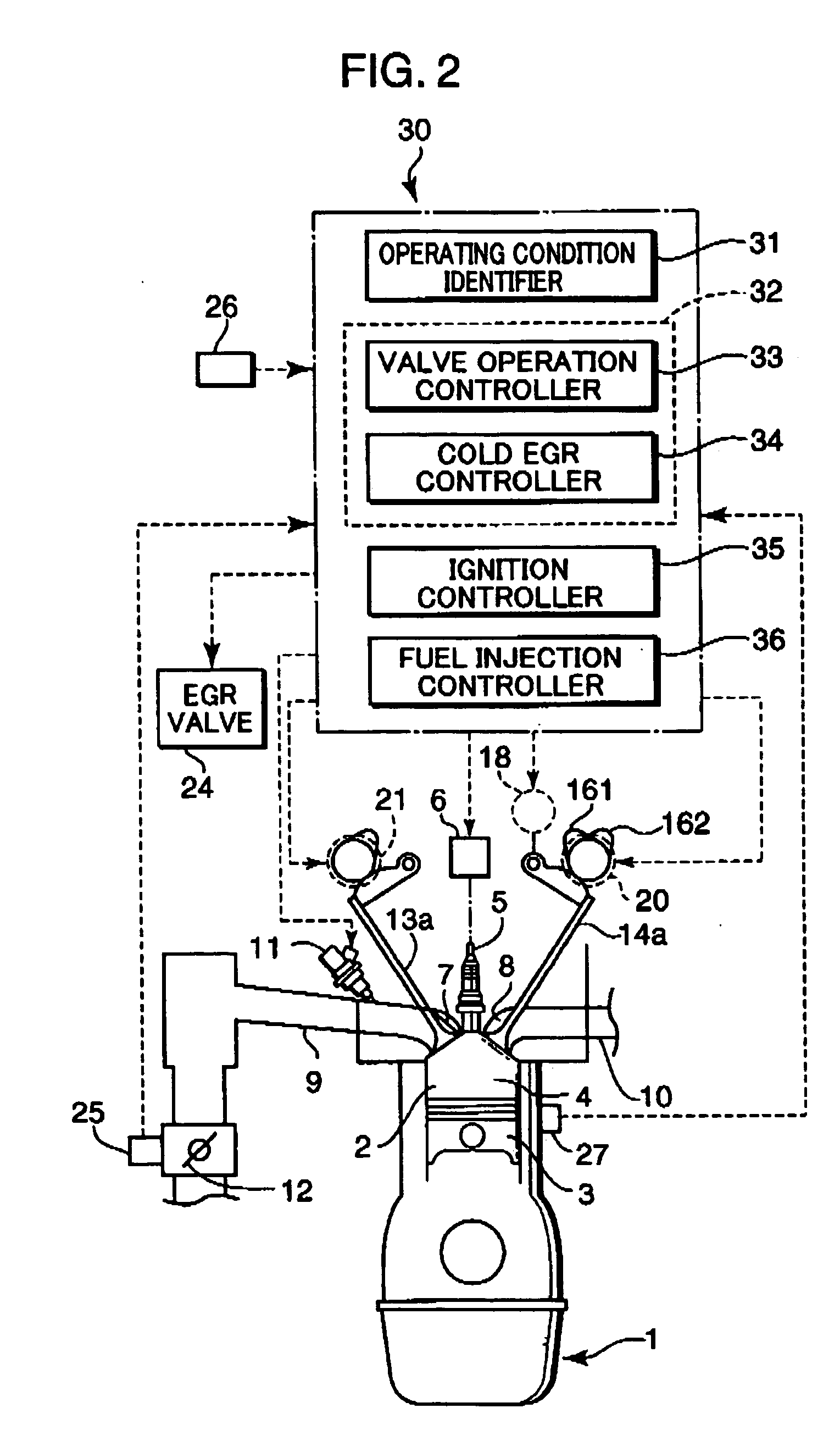

Control device for spark-ignition engine

InactiveUS20050016496A1Increase rangeEfficiently prevent knockingValve arrangementsElectrical controlCombustion chamberLow speed

A control device for a spark-ignition engine, in which a mixture in a combustion chamber is fired by compression ignition in a part-load range under warm-running conditions, includes an EGR controller incorporating a valve operation controller for controlling internal EGR of hot burned gas and a cold EGR controller for controlling external EGR of cold burned gas. The EGR controller performs EGR control operation to leave the hot EGR gas in the combustion chamber in a lower-load, lower-speed region within a compression ignition combustion range and to introduce the cold EGR gas into the combustion chamber in a higher-load, higher-speed region within the compression ignition combustion range. The control device further includes a firing assist unit for inducing the compression ignition at least when ignitability of the mixture decreases due to introduction of the cold EGR gas in the compression ignition combustion range.

Owner:MAZDA MOTOR CORP

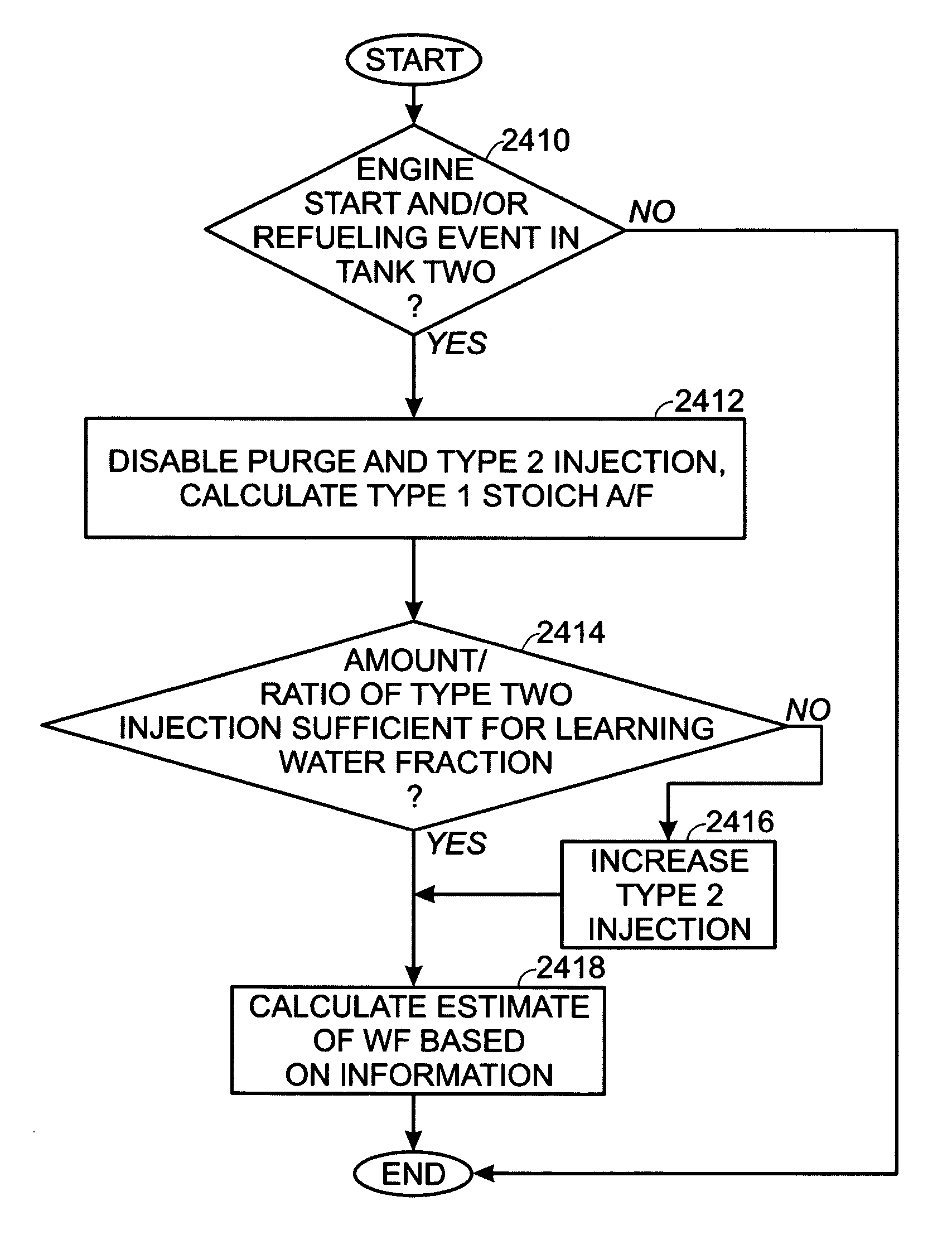

Fuel mass control for ethanol direct injection plus gasoline port fuel injection

ActiveUS20070119394A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesPort fuel injectionOperant conditioning

A system for an engine of a vehicle traveling on the road, comprising of a cylinder located in the engine, a delivery system configured to delivery fuel and a fluid to at least an engine cylinder of the while the vehicle is traveling on the road, said fluid containing at least some water, and a controller for varying an engine operating parameter based on an amount of water in said fluid, where said amount is determined based on an operating condition.

Owner:FORD GLOBAL TECH LLC

System and Methods for Stoichiometric Compression Ignition Engine Control

ActiveUS20110048372A1Enhanced skip fire operationEasy to controlElectrical controlInternal combustion piston enginesCombustionControl system

The present invention relates to a diesel engine control system and methods for substantially operating a diesel engine at stoichiometric fuel to air ratios. The system may include a fuel processor which receives instructions for a desired engine output and current operating conditions. The fuel processor may also generate fueling instructions for the cylinders, including: substantially regulating fuel delivery into to a first group of cylinders at or near stoichiometric fuel levels, and substantially disabling fuel injection into to a second grouping of cylinders. The number of cylinders being fueled, and therefore undergoing a combustion event corresponds to the desired engine output. This may be calculated by dividing the desired output by the power provided by one cylinder operating at substantially stoichiometric fuel levels. The number of cylinders receiving fuel may be varied over a succession of engine revolutions such that the actual average engine power output conforms to the desired output.

Owner:TULA TECH INC

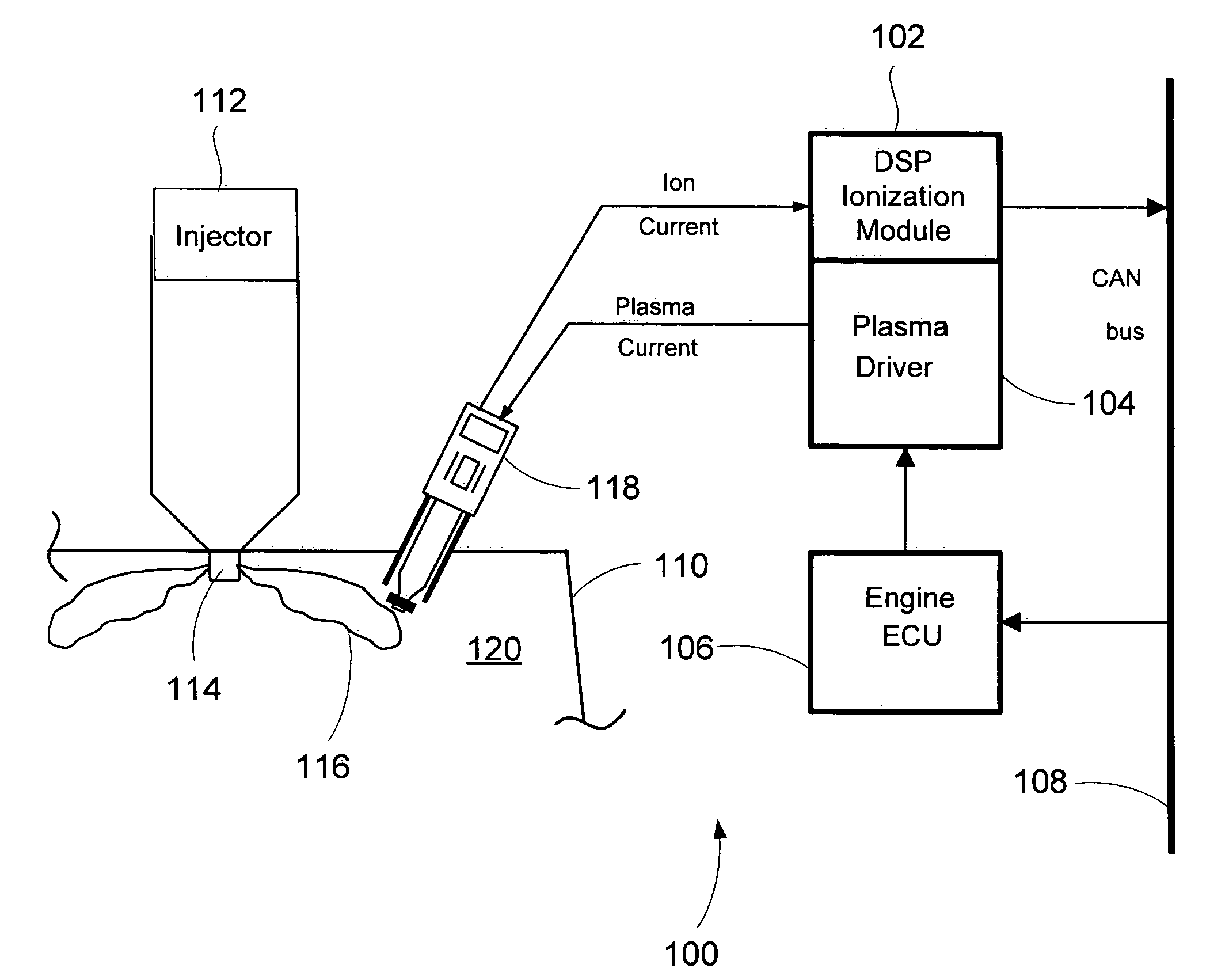

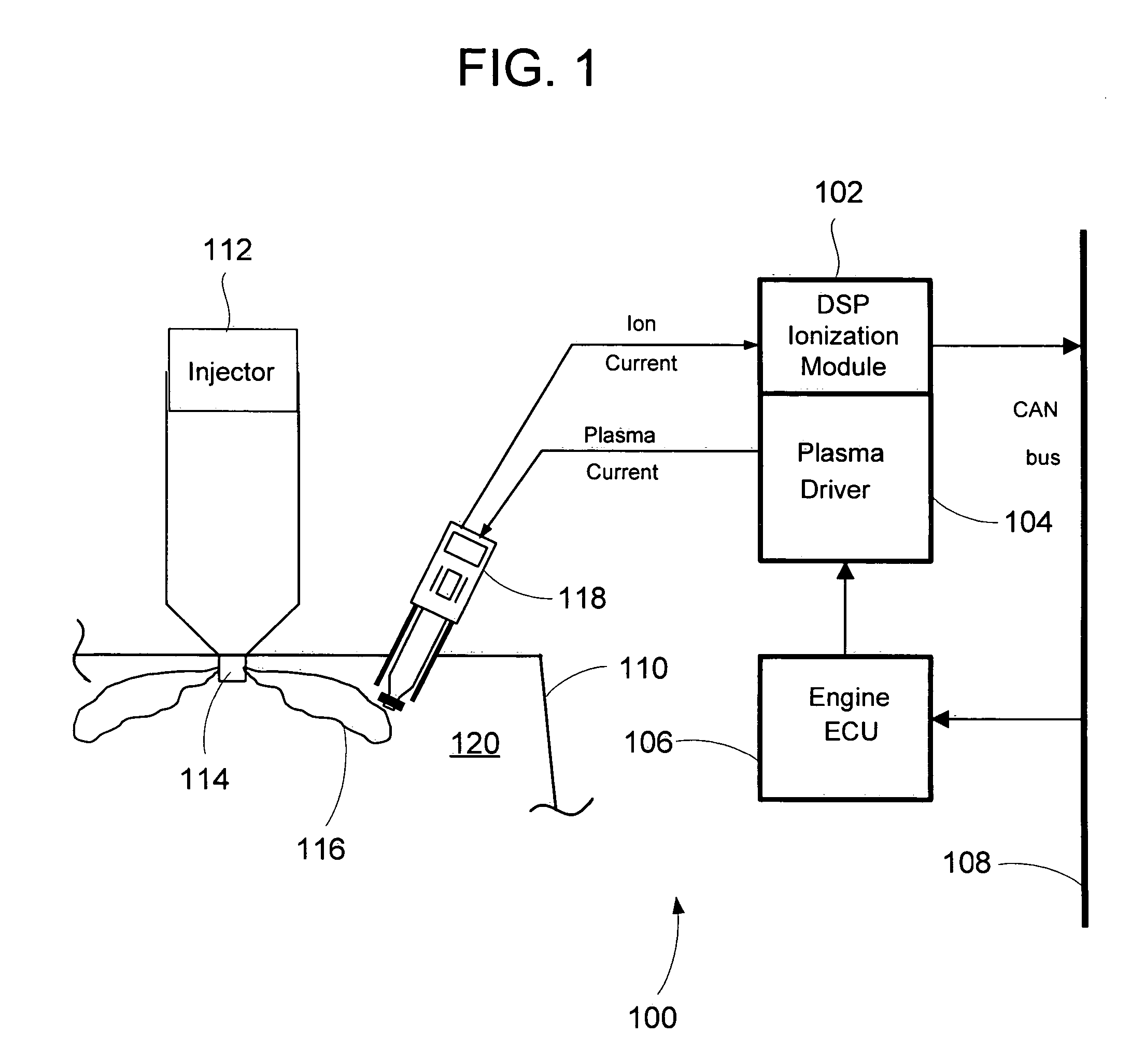

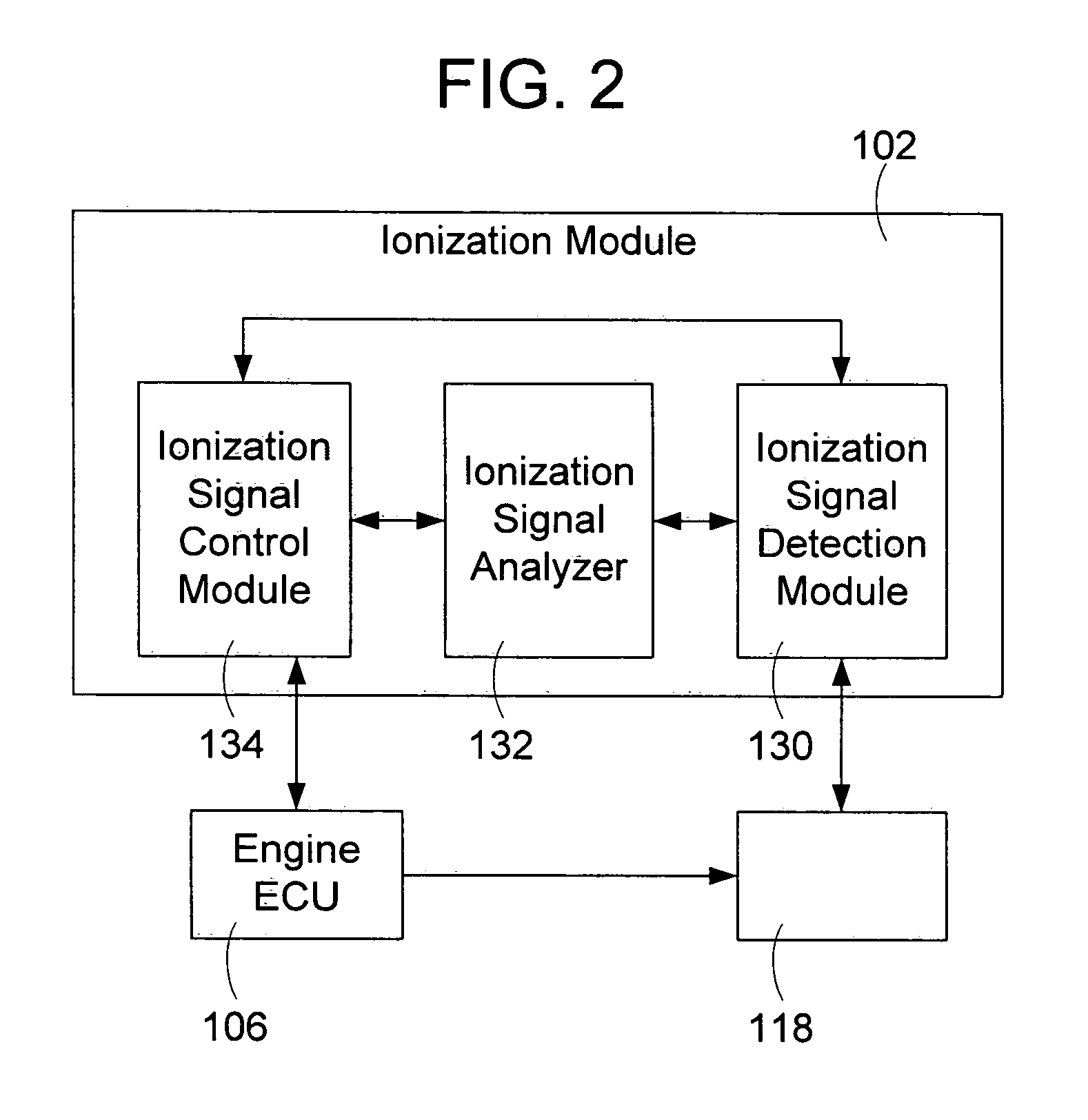

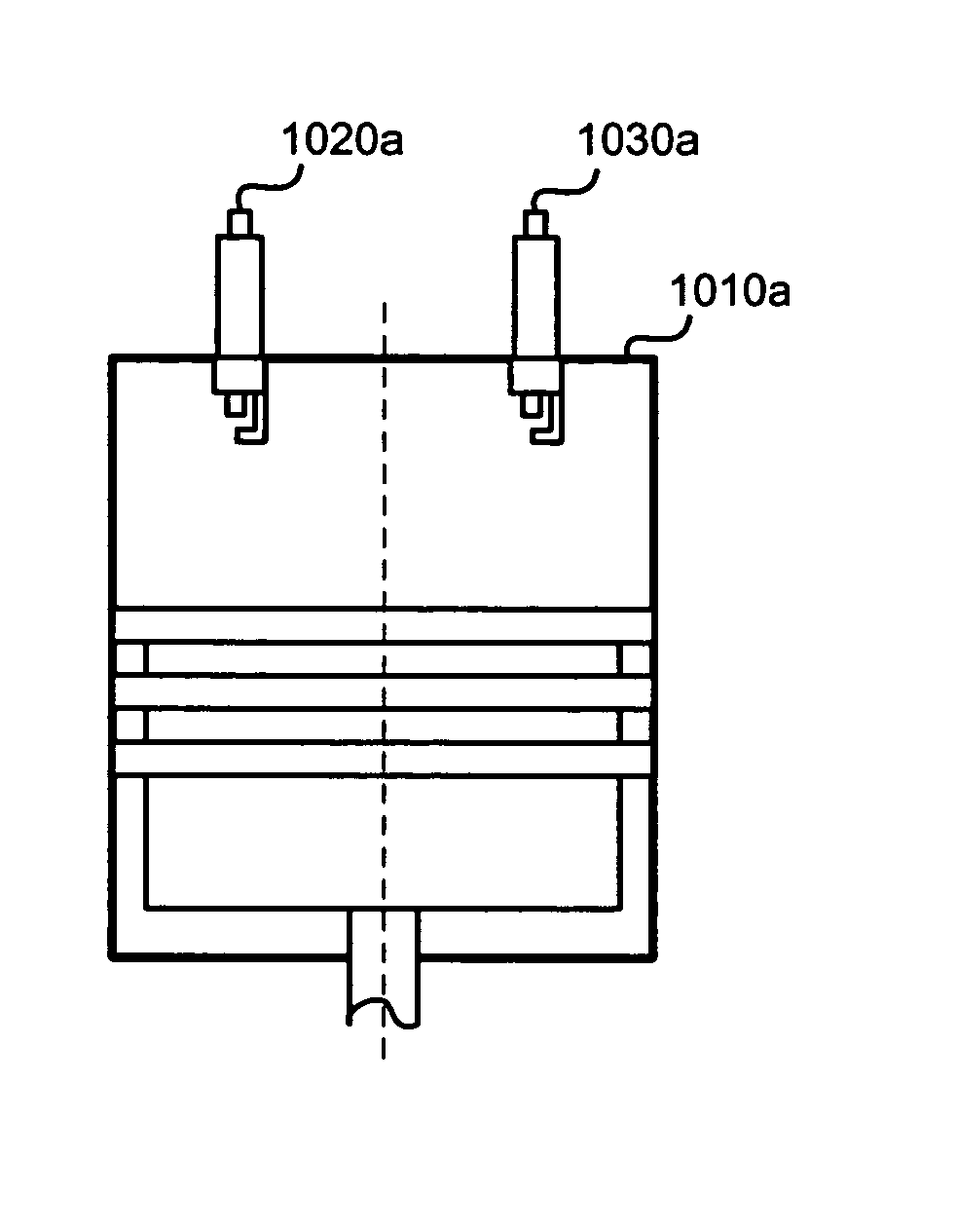

Method and apparatus for detecting ionization signal in diesel and dual mode engines with plasma discharge system

Owner:WOODWARD GOVERNOR CO

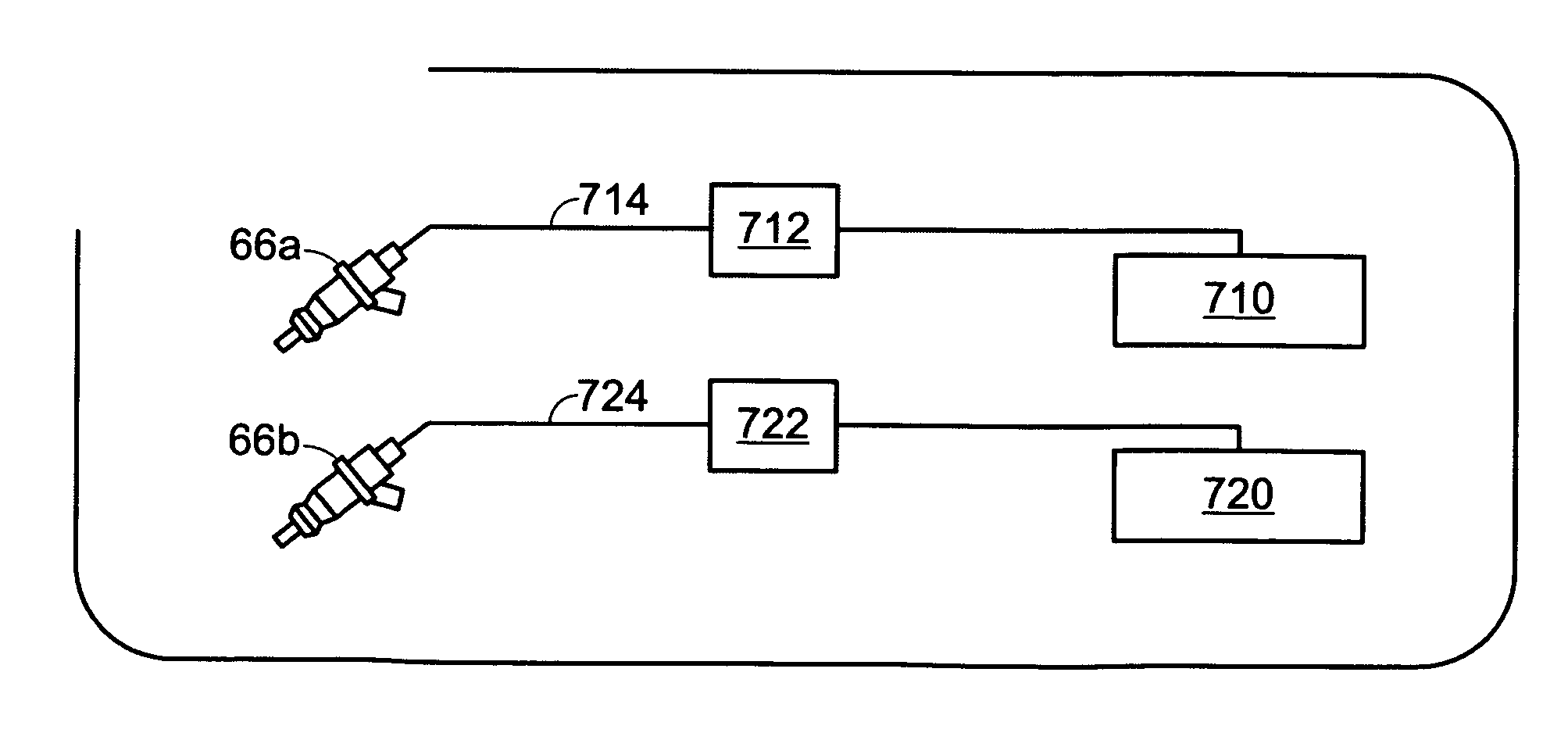

First and second spark plugs for improved combustion control

InactiveUS20070215102A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberHydrocotyle bowlesioides

An engine system, comprising of a combustion chamber; a first spark plug configured to perform a spark within the combustion chamber, said first plug configured to have a first heat range; a second spark plug configured to produce a spark within the combustion chamber, said second plug configured to have a second heat range different from said first heat range of said first plug; and a delivery system configured to deliver a hydrocarbon fuel and a fluid including an alcohol to the combustion chamber in varying resulting ratios.

Owner:FORD GLOBAL TECH LLC

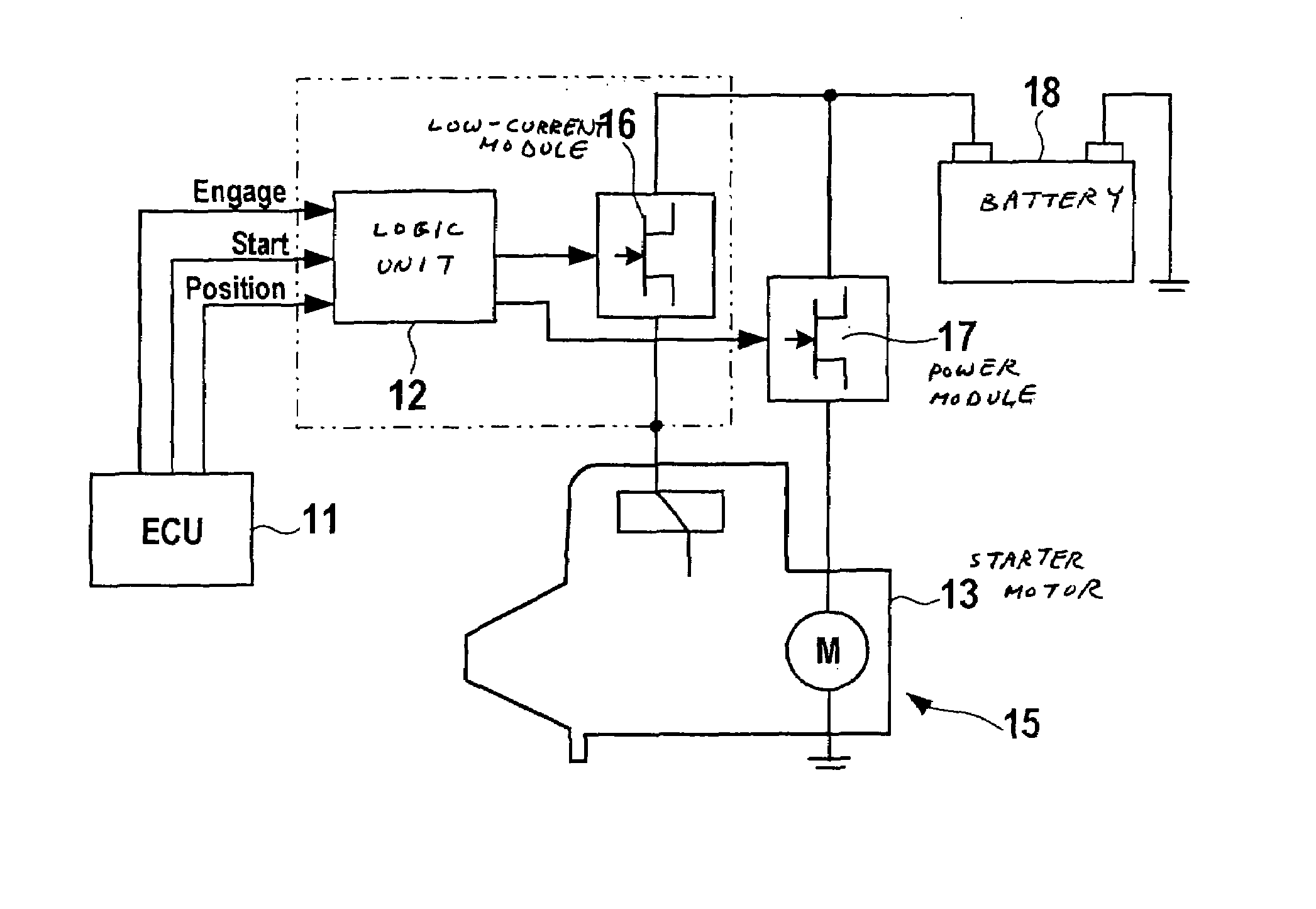

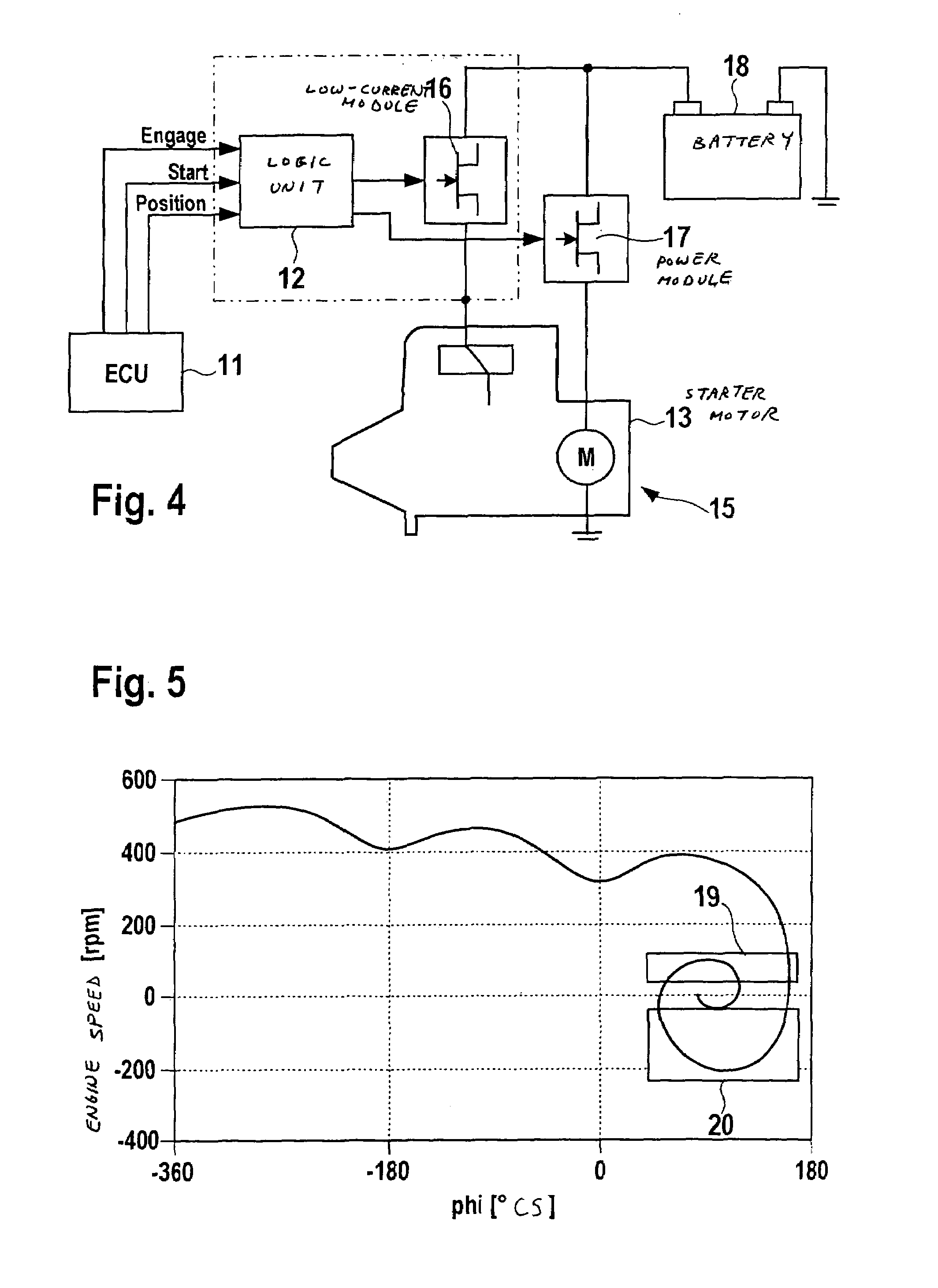

Method for engaging the starter pinion of a starter with the starter ring gear of an internal combustion engine during the running-down of the internal combustion engine

InactiveUS7275509B2Relieve stressEngage with obstructionPower operated startersInternal combustion piston enginesEngineeringInternal combustion engine

A method is provided for engaging a starter pinion of a starter with a starter ring gear of an internal combustion engine during the running-down of the internal combustion engine, which internal combustion engine has an arrangement for determining rotational speed and rotational direction of a crankshaft. The starter pinion is engaged with the starter ring gear when the following conditions are satisfied: a) the speed of the internal combustion engine is below a maximum speed and above a minimum speed; and b) the rotational direction corresponds to the forward rotational direction of the crank shaft.

Owner:ROBERT BOSCH GMBH

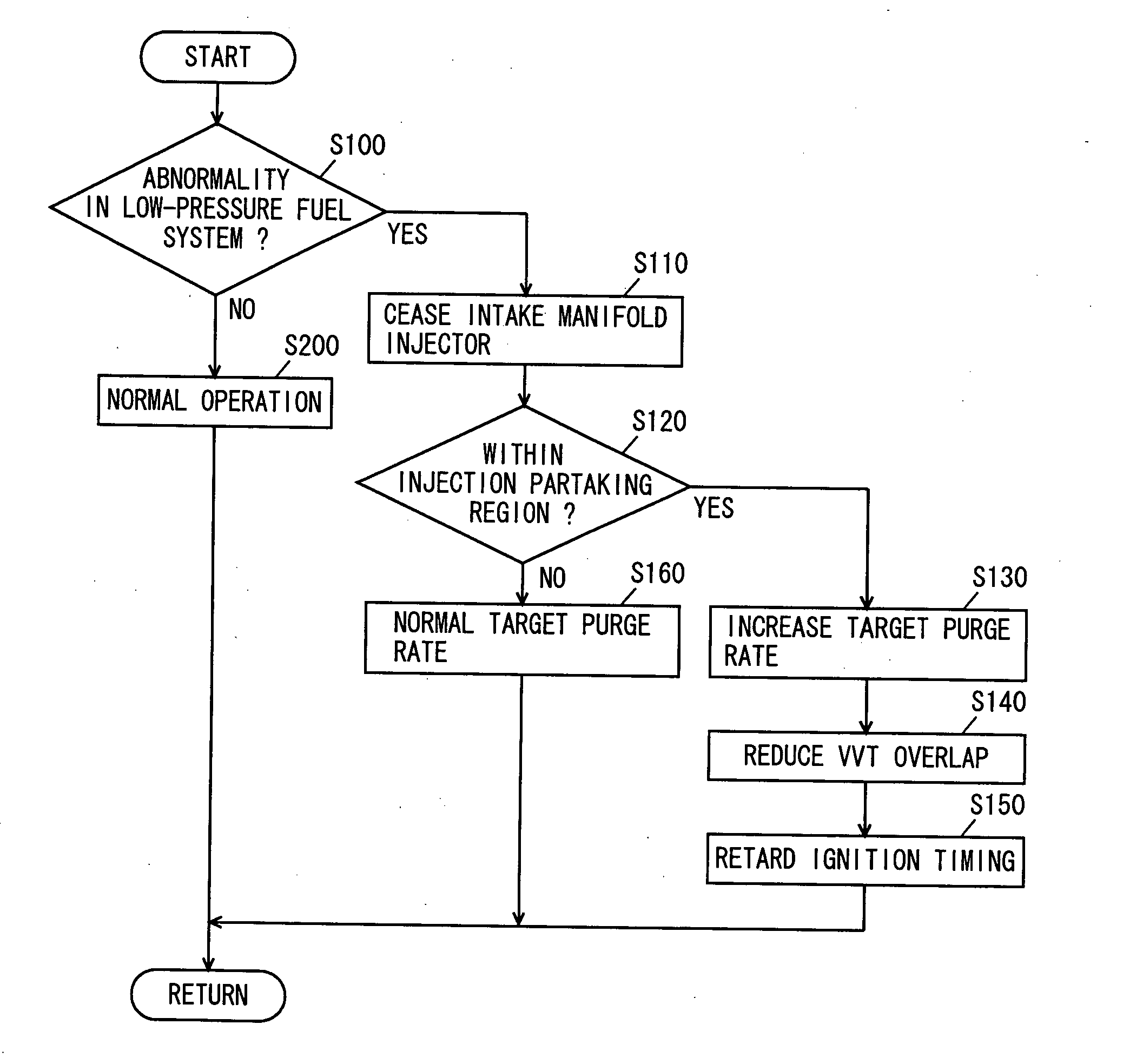

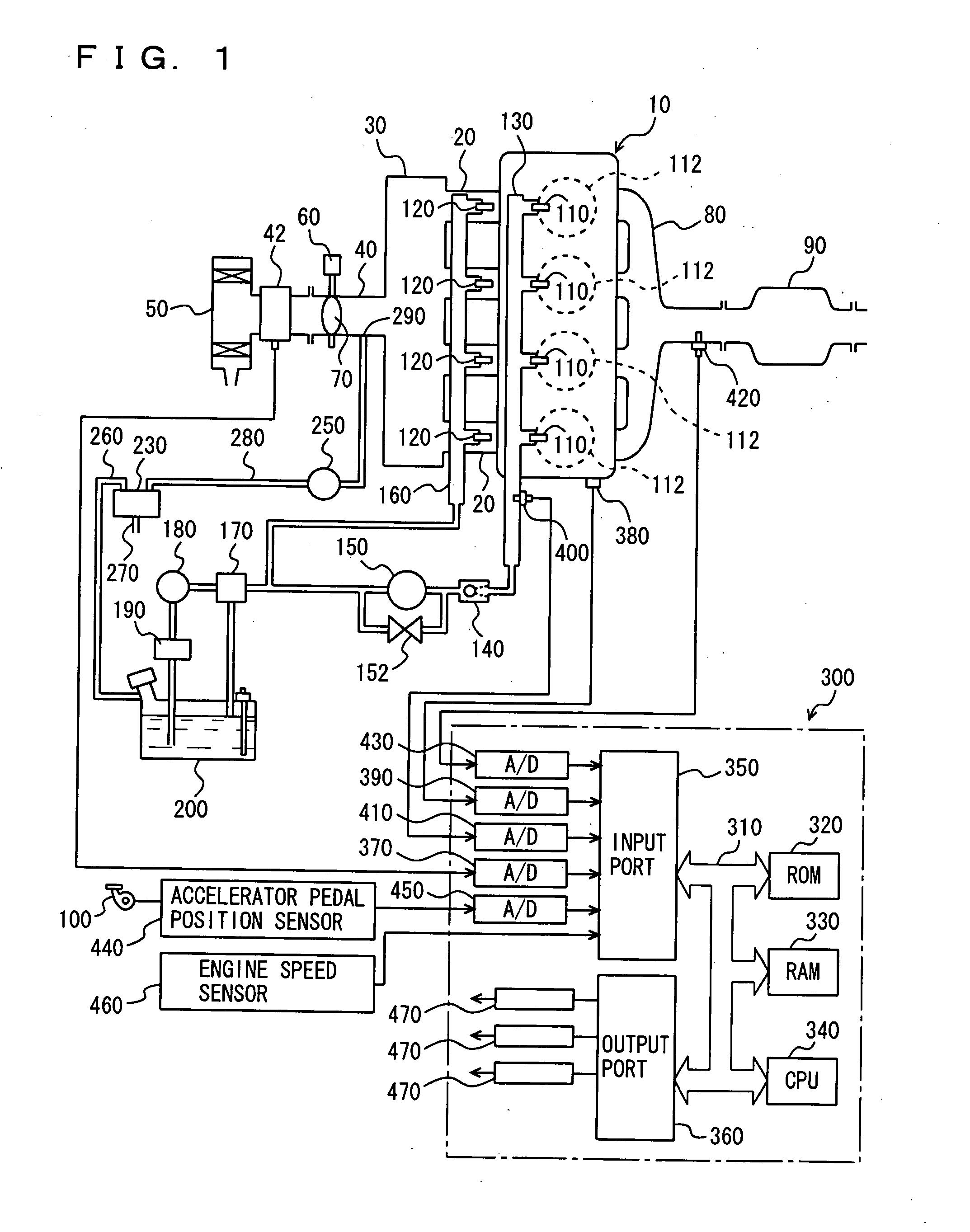

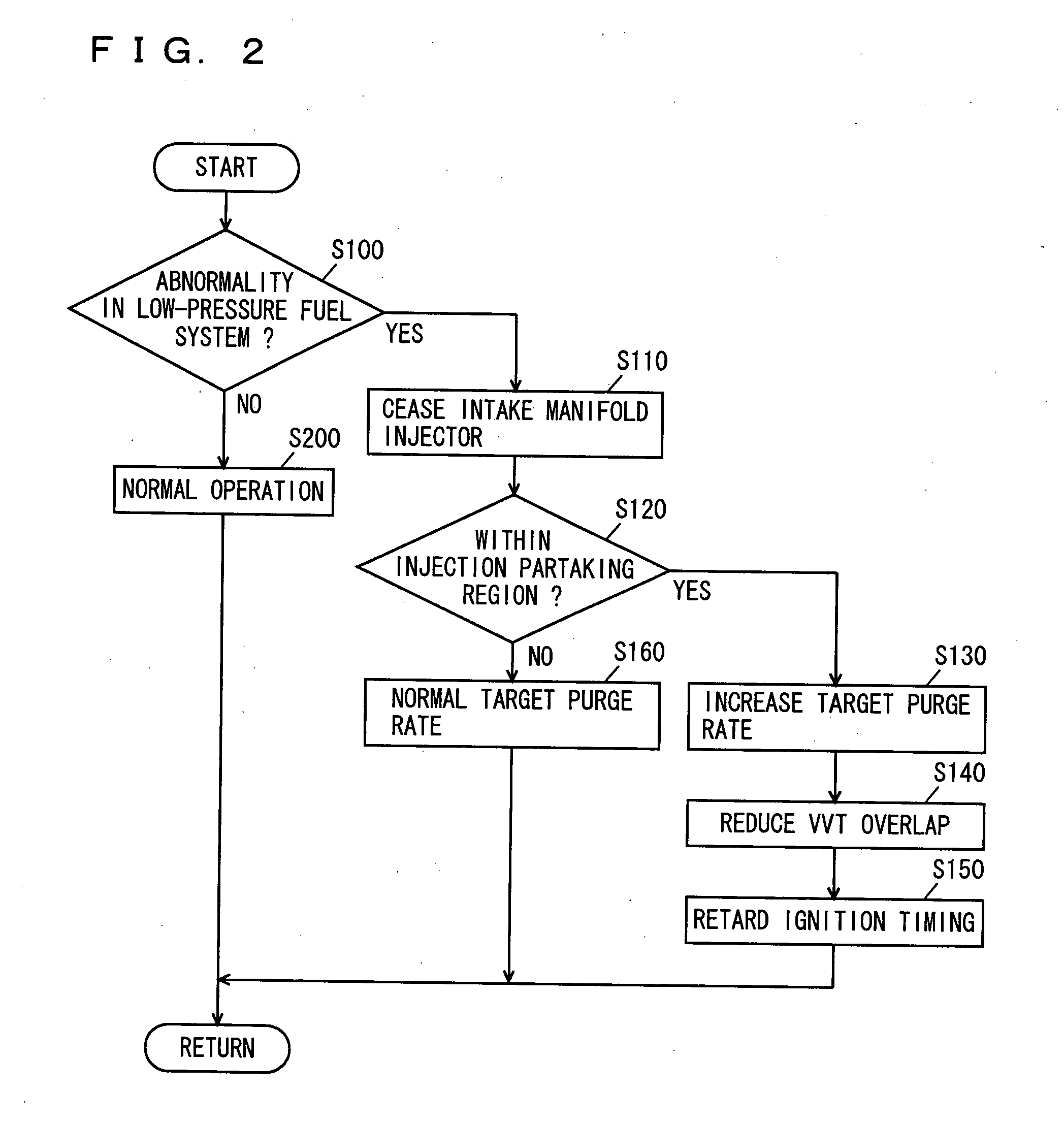

Control apparatus for internal combustion engine

InactiveUS20060090732A1Increasing purge rateVariation can be suppressedValve arrangementsElectrical controlIgnition timingInlet manifold

An engine ECU executes a program including the steps of: determining presence of abnormality in a low-pressure fuel system; ceasing an intake manifold injector when determination is made of abnormality in the low-pressure fuel system; increasing the target purge rate when the engine operation state attains an injection partaking state between an in-cylinder injector and an intake manifold injector; reducing the VVT overlap; and retarding the ignition timing.

Owner:TOYOTA JIDOSHA KK

System and method for engine with fuel vapor purging

ActiveUS20070119411A1Improve engine performanceLow costElectrical controlNon-fuel substance addition to fuelEngineeringFirst relationship

A method for controlling engine operation of an engine having a cylinder receiving fuel from a first and a second fuel injector, the first injector having a first relationship between a first input signal and a first amount of injected fuel, and the second injector having a second relationship between a second input signal and a second amount of injected fuel; the method comprising of varying injection from the first injector into the cylinder, varying injection from the second injector into the cylinder, purging fuel vapors from a fuel system into the cylinder, and adaptively learning said first and second relationships based on sensed operating conditions.

Owner:FORD GLOBAL TECH LLC

Evaluation system for vehicle operating conditions and evaluation method thereof

InactiveUS7024306B2Improve fuel economyImprove economyVehicle testingAnalogue computers for vehiclesGasolineDisplay device

Owner:MIYAMA

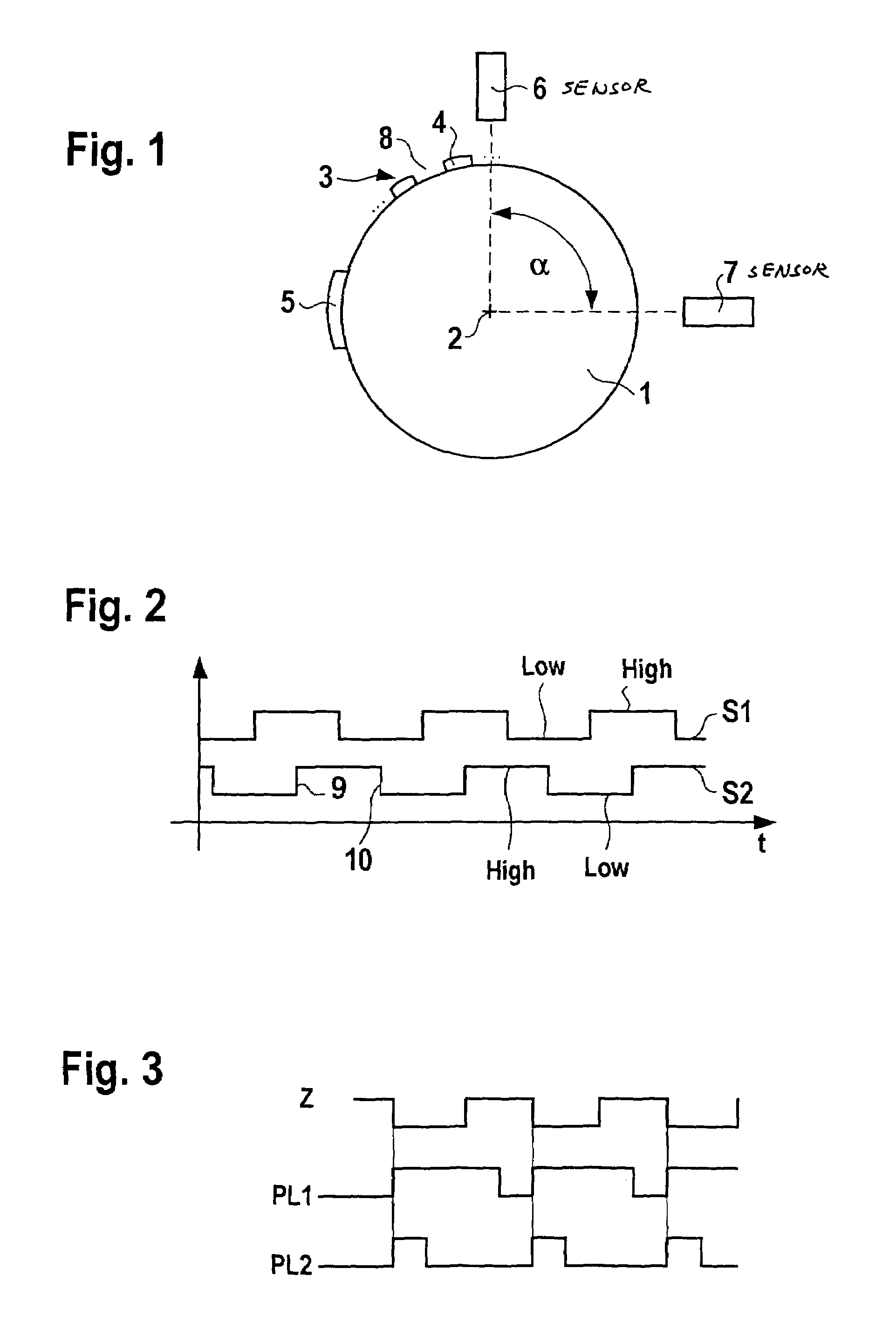

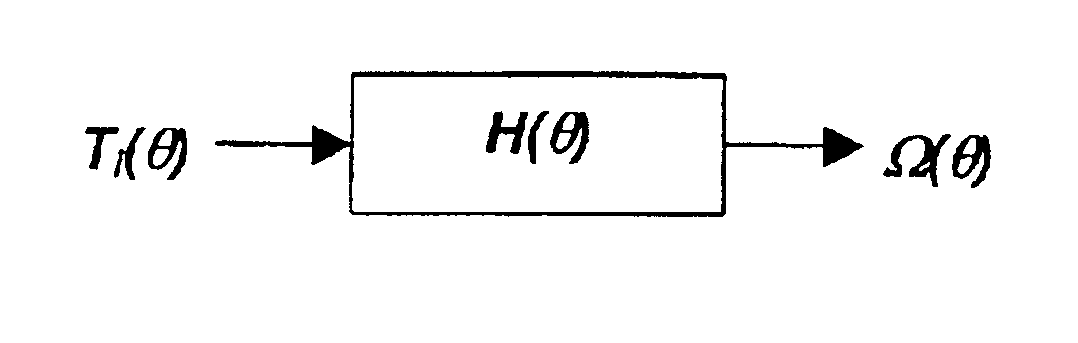

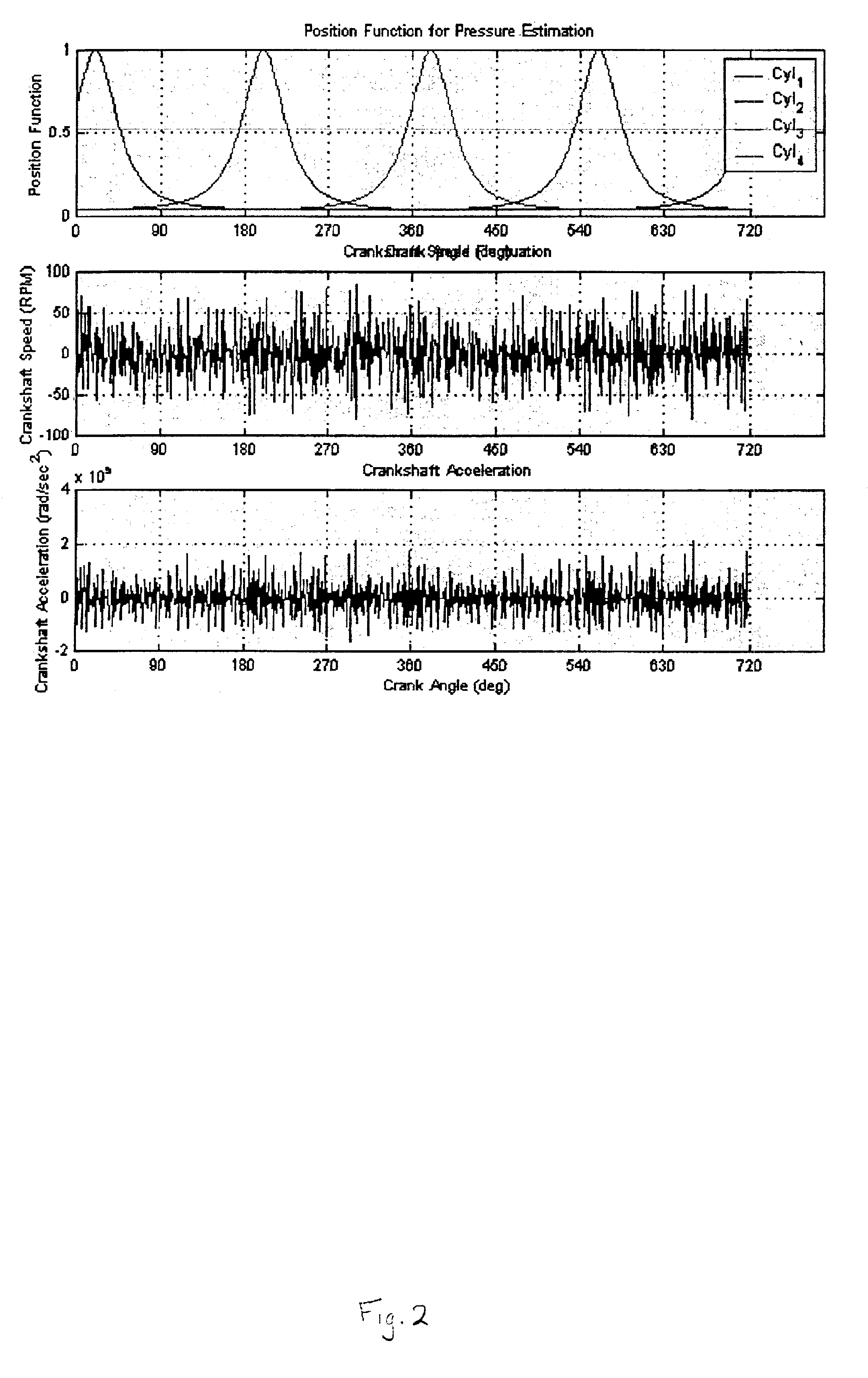

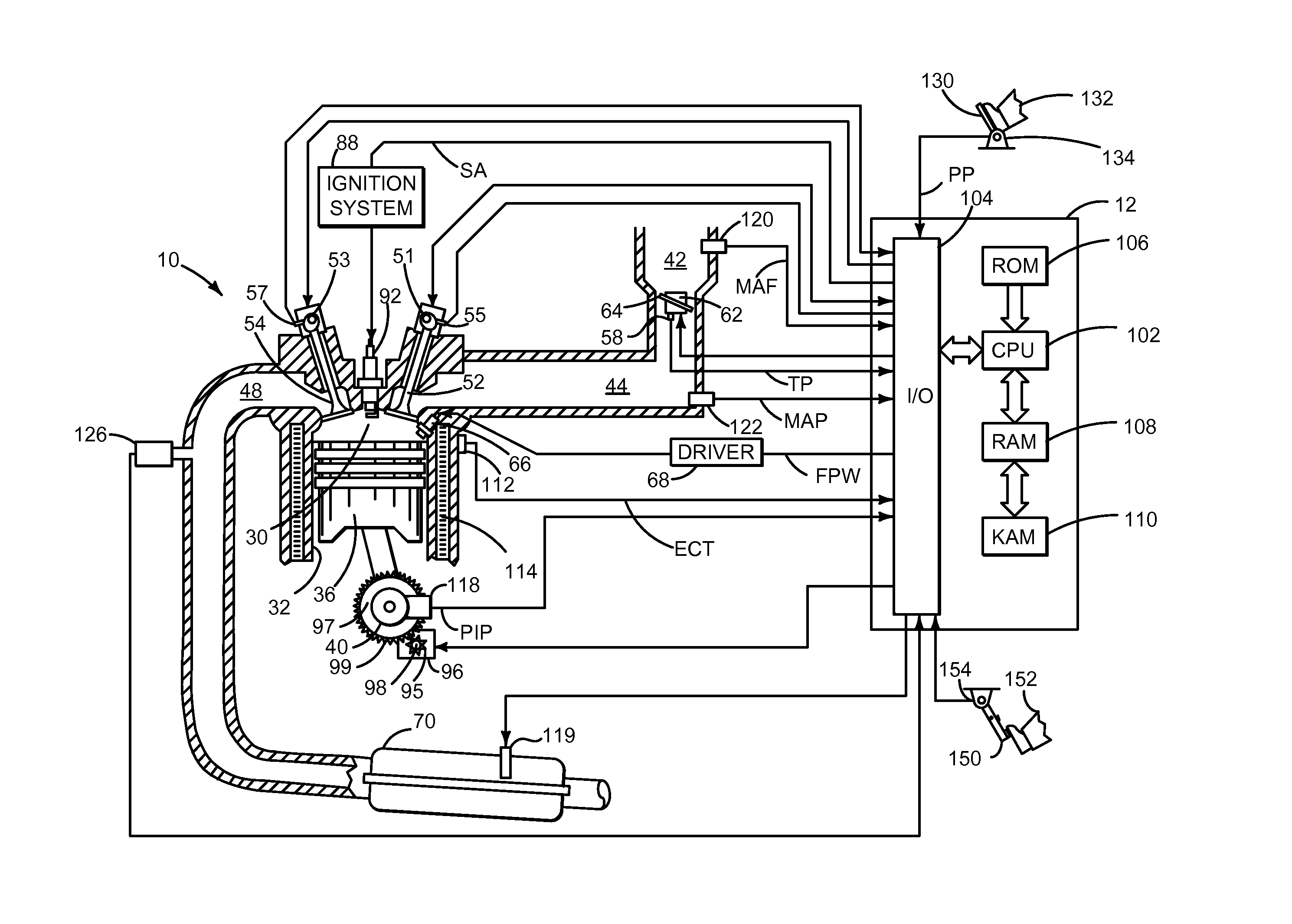

Engine control using torque estimation

InactiveUS6866024B2Good estimateAnalogue computers for vehiclesElectrical controlEstimation methodsComputation process

Torque estimation techniques in the real-time basis for engine control and diagnostics applications using the measurement of crankshaft speed variation are disclosed. Two different torque estimation approaches are disclosed—“Stochastic Analysis” and “Frequency Analysis.” An estimation model function consisting of three primary variables representing crankshaft dynamics such as crankshaft position, speed, and acceleration is used for each estimation approach. The torque estimation method are independent of the engine inputs (air, fuel, and spark). Both approaches have been analyzed and compared with respect to estimation accuracy and computational requirements, and feasibility for the real-time engine diagnostics and control applications. Results show that both methods permits estimations of the indicated torque based on the crankshaft speed measurement while providing not only accurate but also relatively fast estimations during the computation processes.

Owner:OHIO STATE INNOVATION FOUND

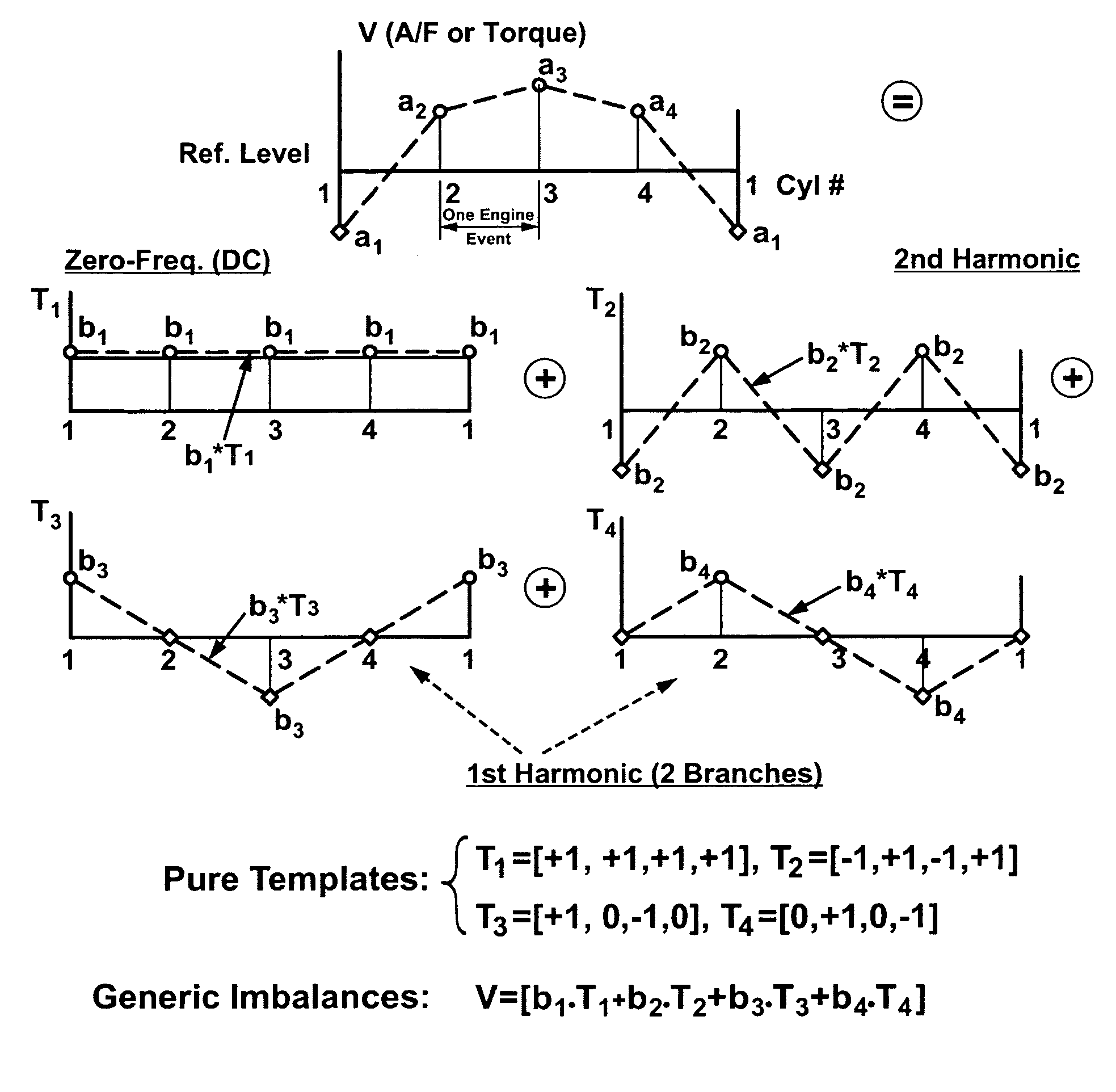

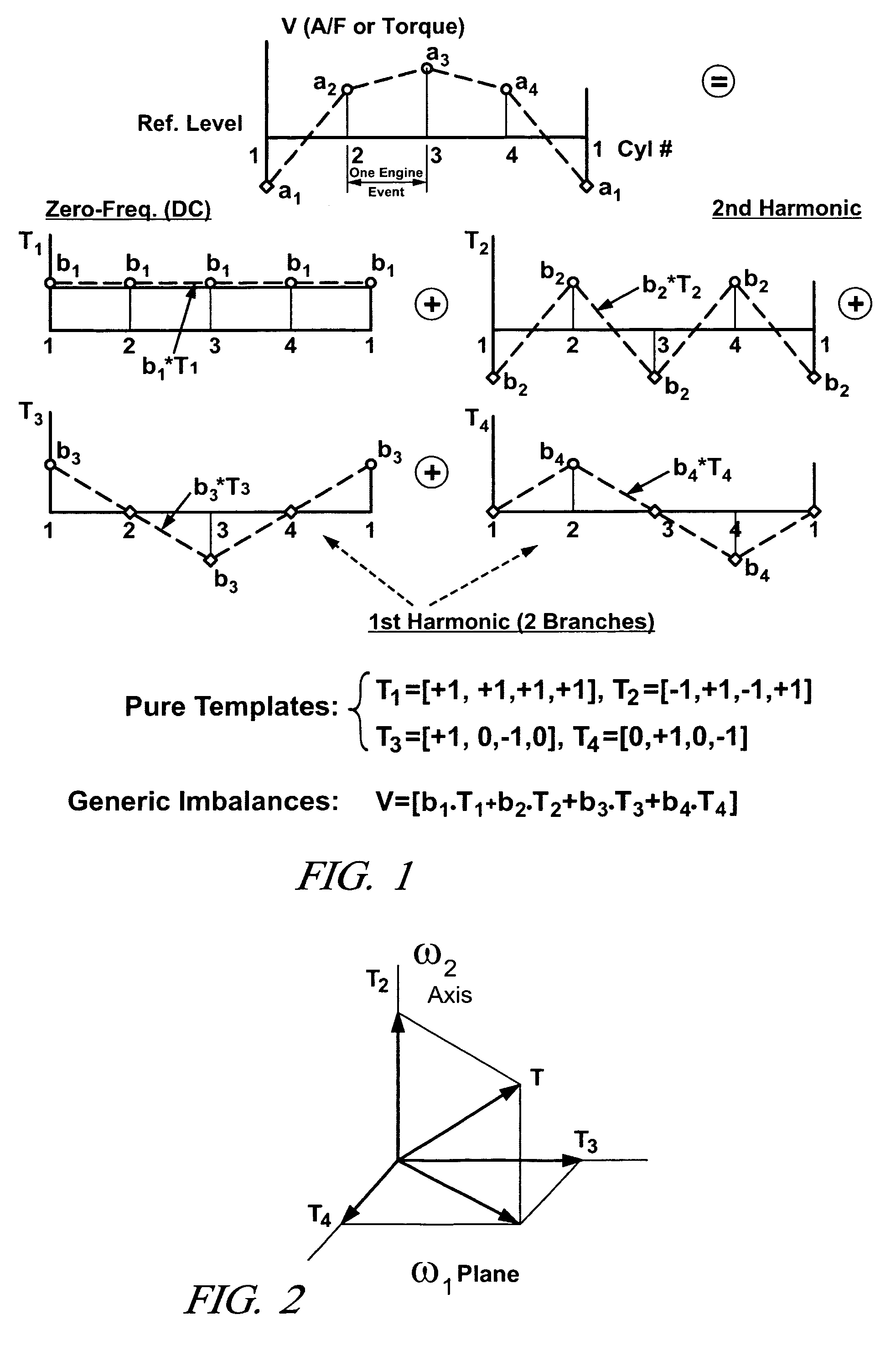

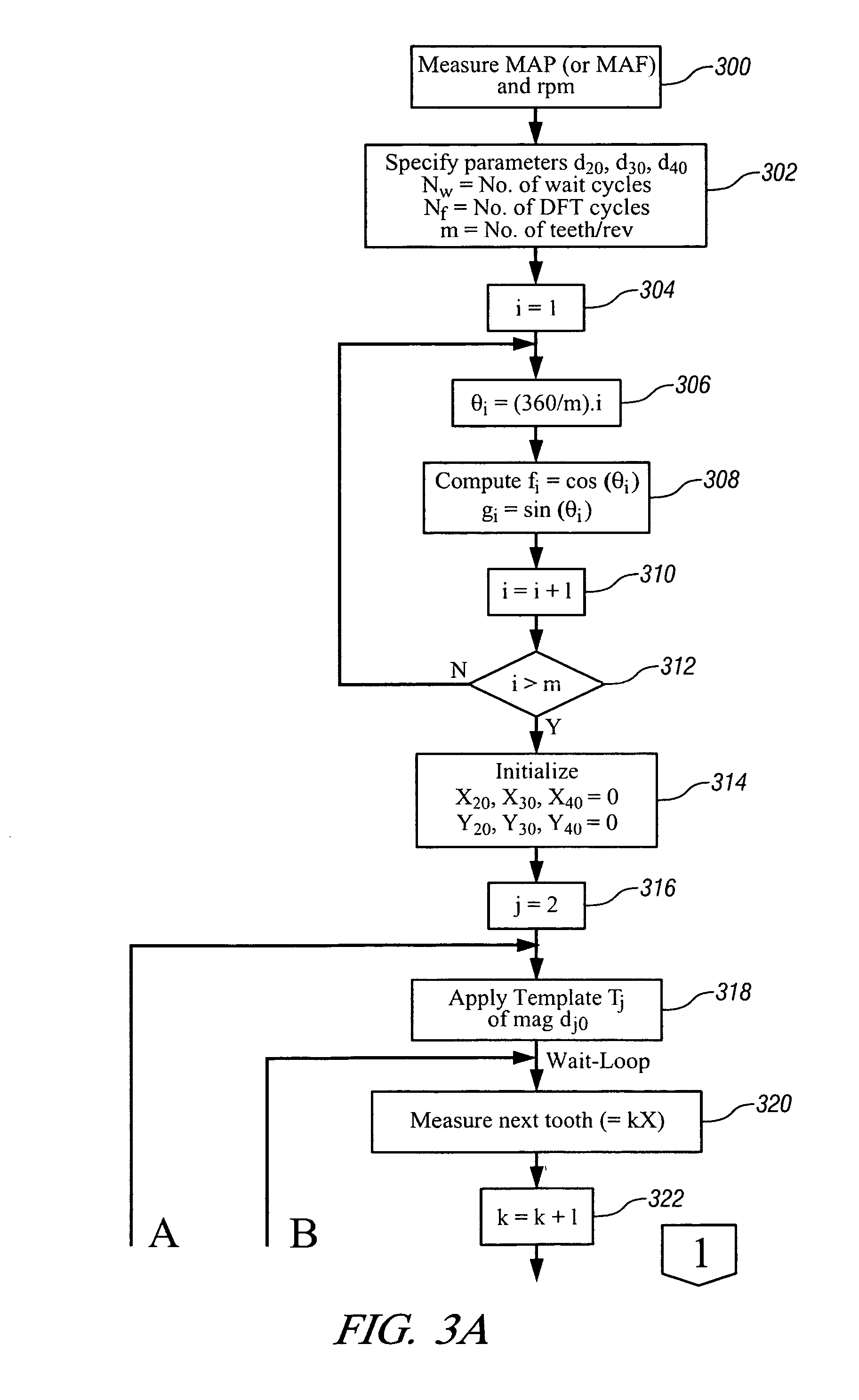

Individual cylinder controller for four-cylinder engine

A generic technique for the detection of air-fuel ratio (or torque) imbalances in a 4-cylinder engine equipped with either a production oxygen sensor or a wide-range A / F sensor (or a crankshaft torque sensor) is developed. The method is based on a novel frequency-domain characterization of pattern of imbalances and its geometric decomposition into four basic templates. Once the contribution of each basic template to the overall imbalances is computed, templates of opposite direction are imposed to restore air-fuel ratio (or torque) balance among cylinders. At any desired operating condition, elimination of imbalances is achieved within few engine cycles. The method is applicable to current and future engine technologies with variable valve actuation, fuel injectors and / or individual spark control.

Owner:GM GLOBAL TECH OPERATIONS LLC

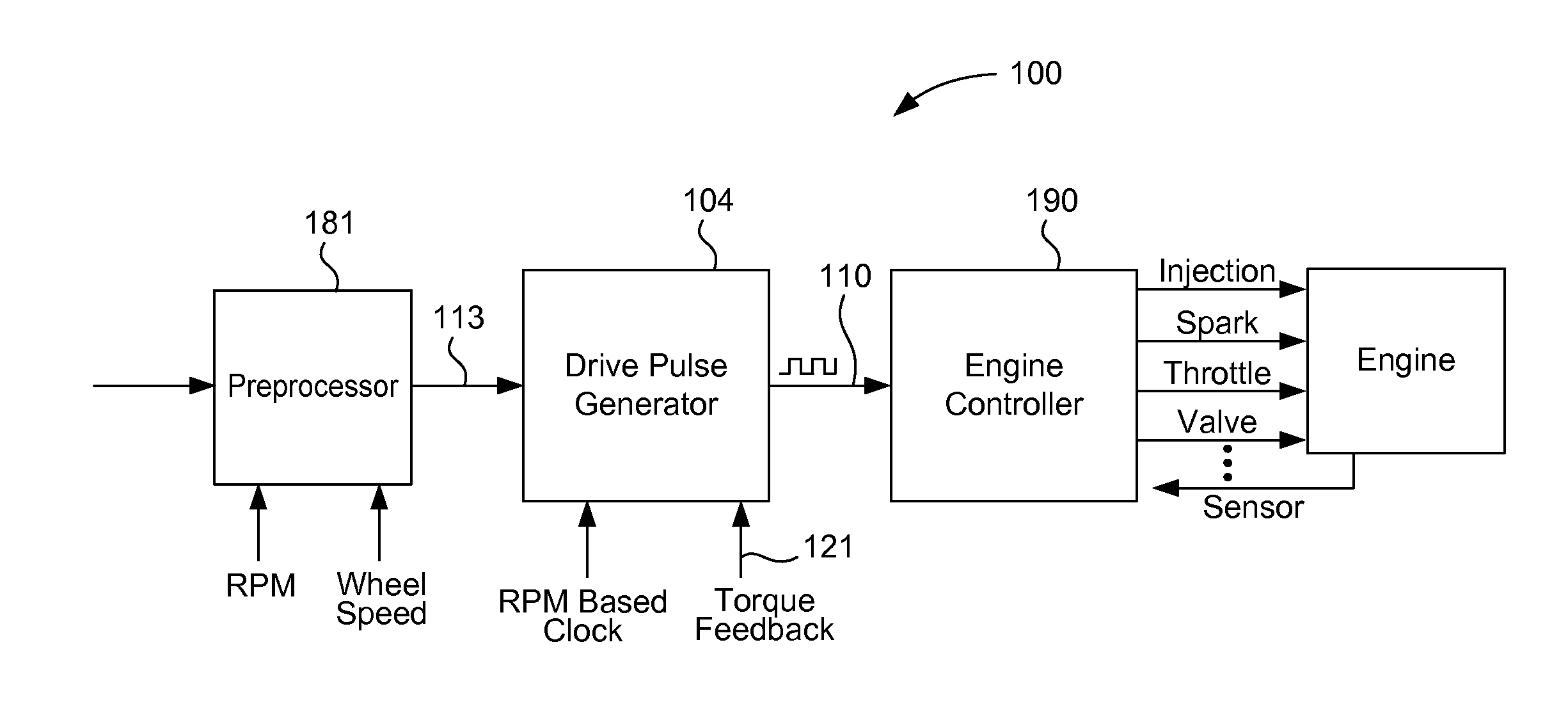

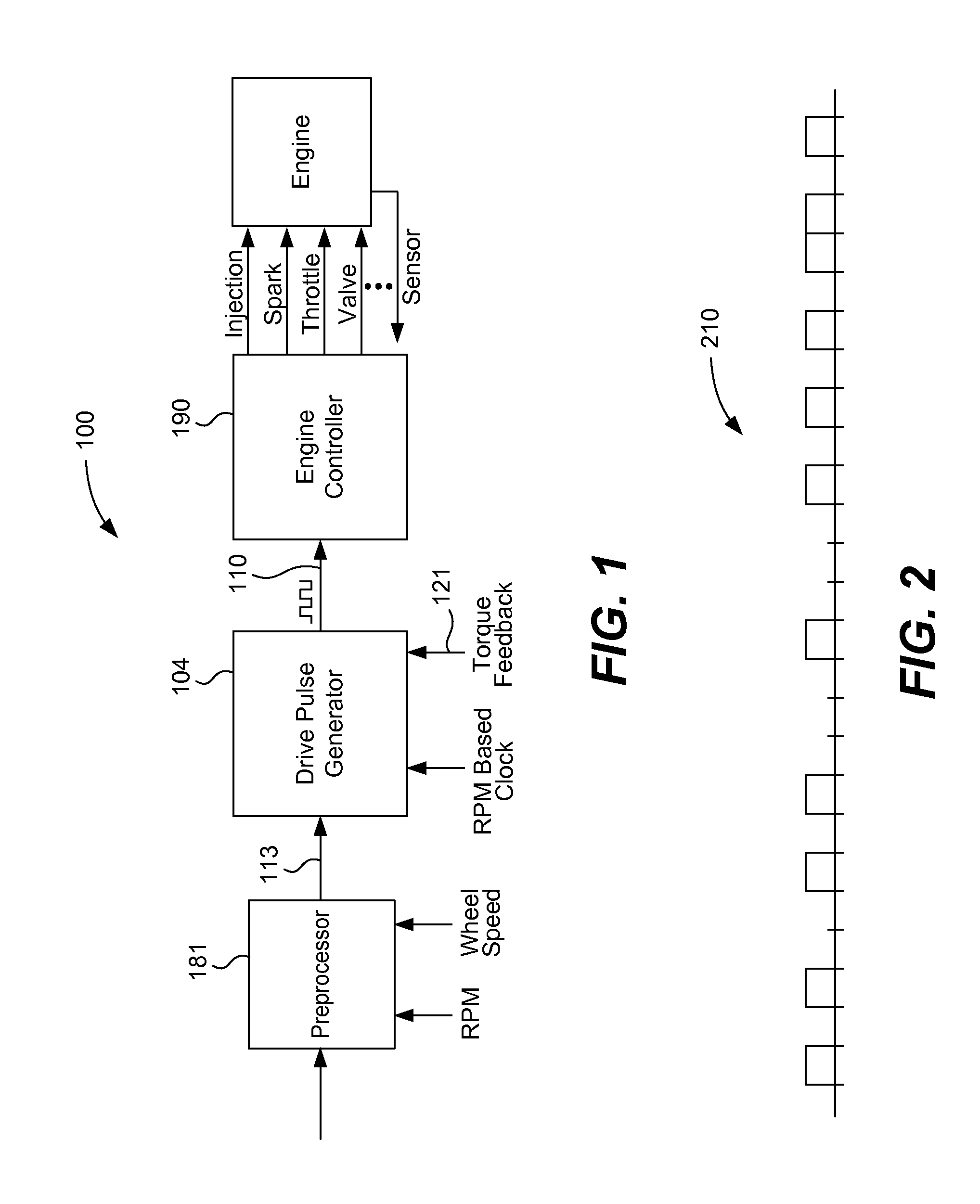

Skip fire internal combustion engine control

ActiveUS20120109495A1System stabilityAnalogue computers for vehiclesElectrical controlInternal combustion engineControl theory

A variety of methods and arrangements for controlling the operation of an internal combustion engine in a skip fire variable displacement mode are described. In one aspect, the working chamber firing that are selected to deliver the desired engine output are determined at least in part based on torque feedback. The torque feedback may be an indication of the torque output of the engine or the torque experienced at some other location in the drive train. In some embodiments, the torque feedback signal is filtered to remove high frequency components of the torque feedback signal in order to help stabilize the system. In another aspect, other operational parameters are used as feedback in the determination of the firing sequence. In yet another aspect, a filter is arranged to filter a feedback signal to provide a filtered feedback signal that is used in the determination of the working chamber firings.

Owner:TULA TECH INC

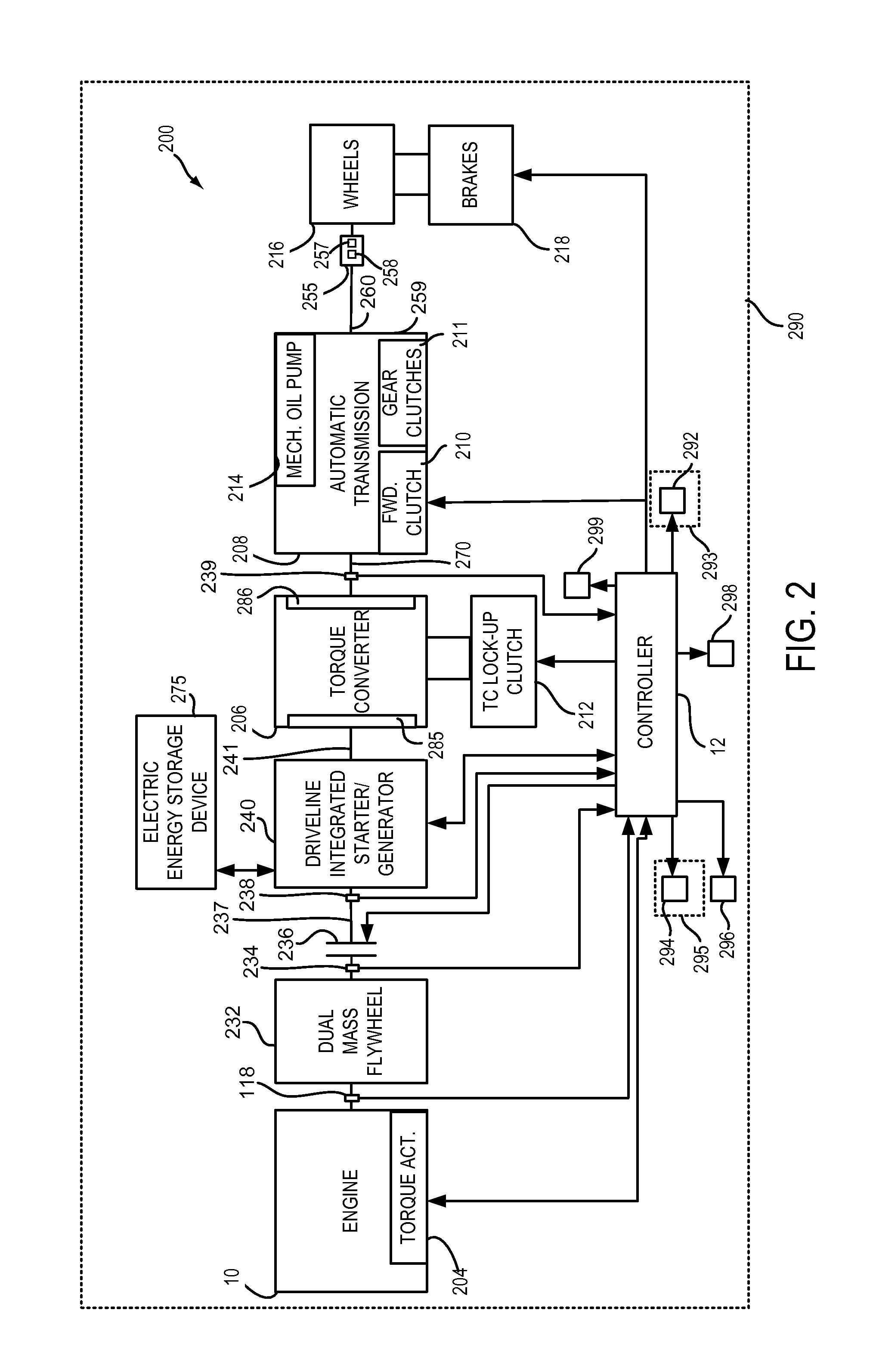

Methods and systems for engine cranking

ActiveUS20130296126A1Low power output capacityExtend driver demand torque rangeHybrid vehiclesPower operated startersElectric machineHybrid vehicle

Systems and methods for improving operation of a hybrid vehicle are presented. In one example, an engine may be started in one of two ways depending on operating conditions. In particular, the engine may be started via a lower power output electric machine or a higher power output electric machine.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com