Patents

Literature

41results about How to "Guaranteed paste effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

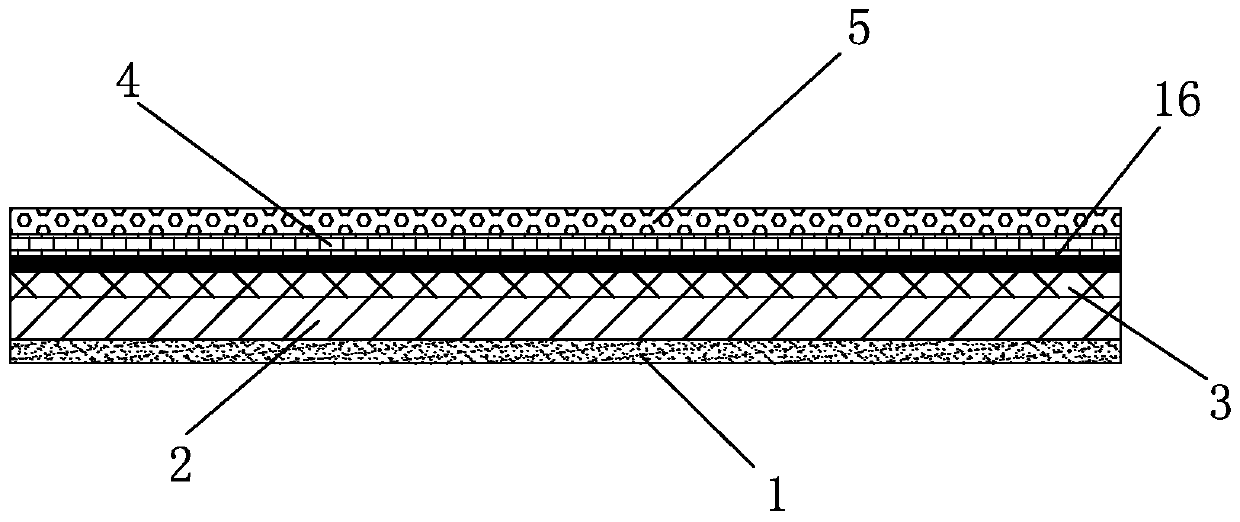

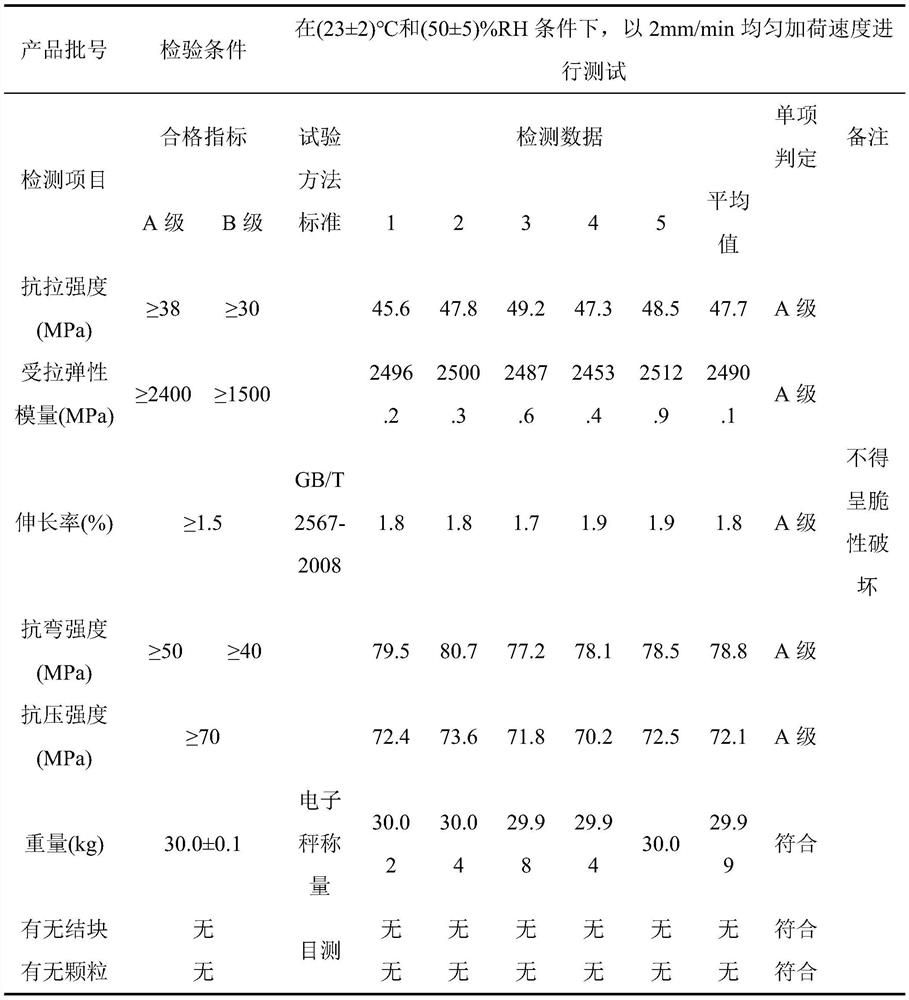

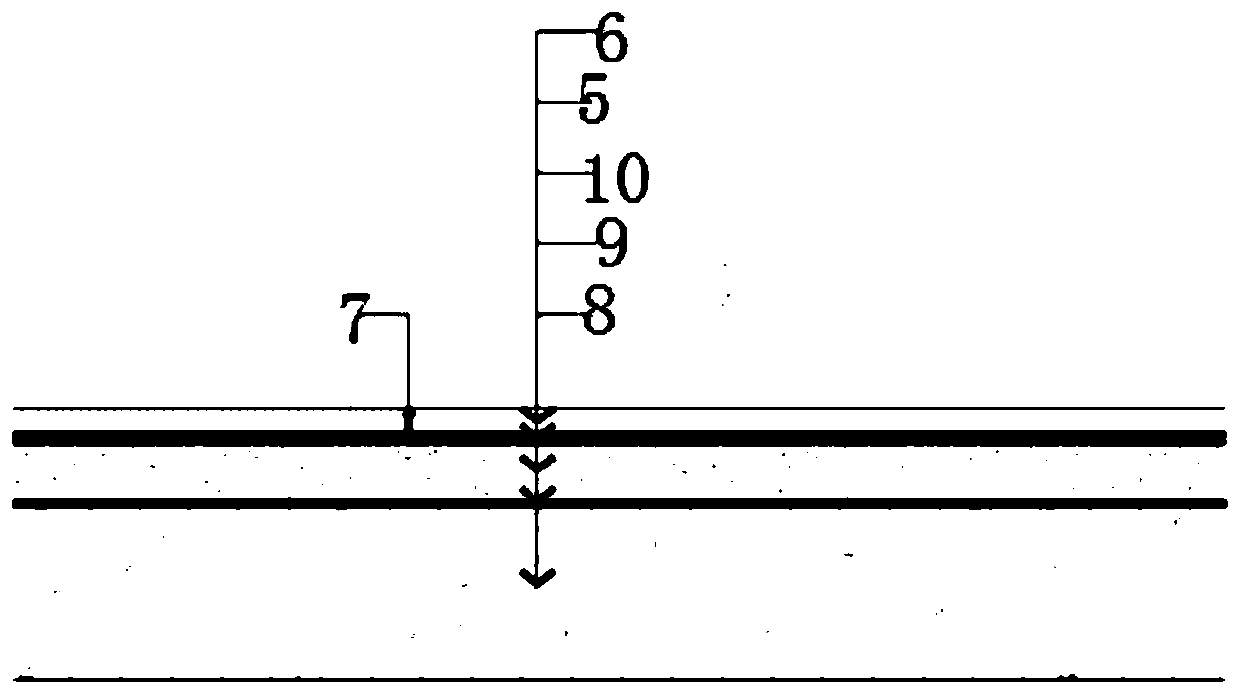

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253AHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsChemical fiber clothMacromolecule synthesis

The invention relates to a manufacturing method of a rubber and chemical fiber synthetic waterproof sheet and a product thereof, and the rubber and chemical fiber synthetic waterproof sheet is formed by compounding three layers of material, wherein the middle layer is a chemical fiber cloth or felt composite layer, and the chemical fiber cloth or felt composite layer is a waterproof layer enabling polymer synthetic rubber composite material and chemical fiber cloth or felt to infiltrate and adhere mutually; when in manufacturing, the chemical fiber cloth or felt of the middle layer is firstlyplaced in a dip coating groove for enabling the chemical fiber cloth or felt to soak polymer synthetic rubber waterproof rubber material, and the middle sheet layer is further manufactured; and two layers of the chemical fiber cloth or felt are stuck on two surfaces of the middle sheet layer respectively, thereby forming the three-layer compound synthetic waterproof sheet. The polymer synthetic rubber waterproof rubber material takes rubber as main material, and a high polymer and other auxiliary materials are added for manufacturing the waterproof rubber material; the auxiliary materials comprise an accelerant, filling material, a softener, a cross-linking agent or an anti-aging agent; and the middle sheet layer can be manufactured by one of three forms respectively, namely the cold working method, the hot working method and the rolling method.

Owner:杨太龙

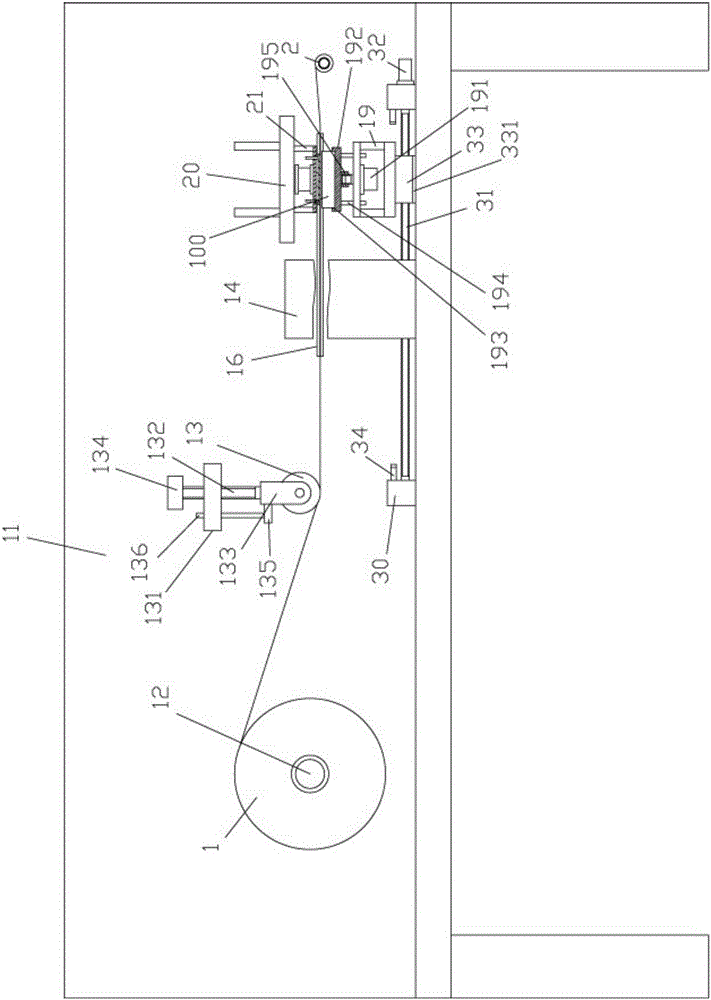

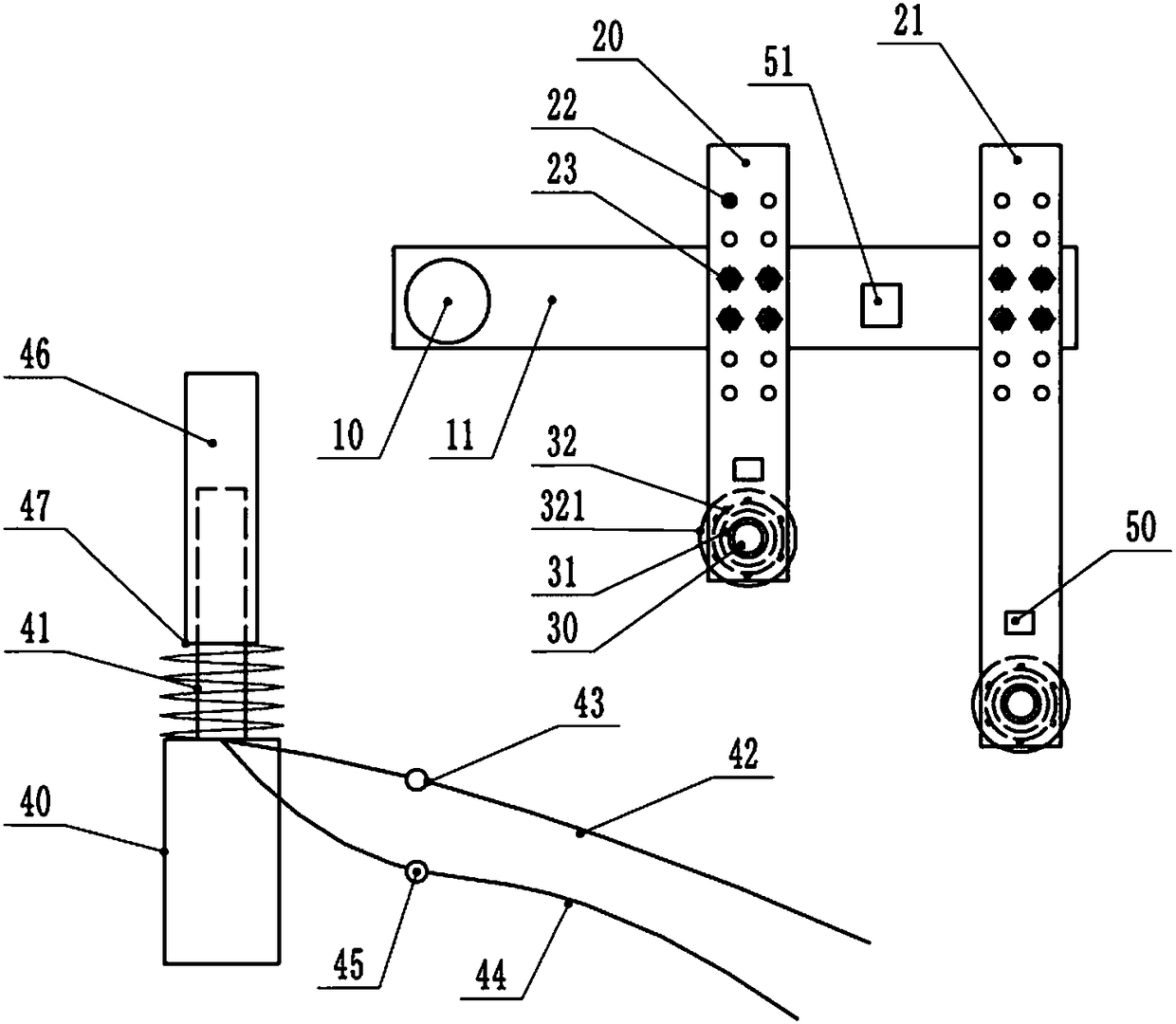

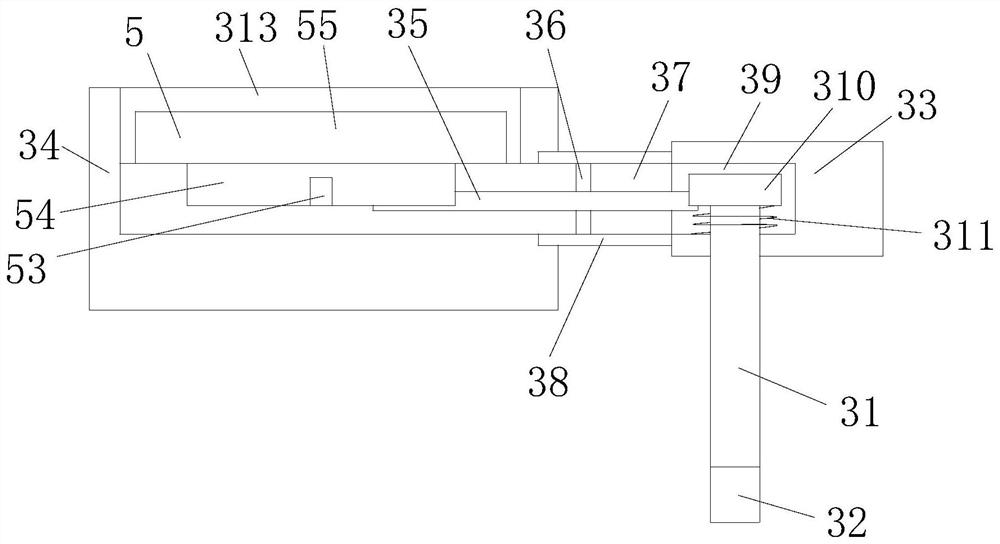

Automatic feeding type cutting and labelling mechanism

ActiveCN106628471AImprove pasting efficiencyGuaranteed paste effectLabelling machinesWebs handlingPulp and paper industryLabelling

The invention discloses an automatic feeding type cutting and labelling mechanism. The mechanism comprises a rack; a main supporting plate is fixed on the top surface on the back side of a top plate of the rack; a main rotating shaft is hinged to the front wall surface of the left side of the main supporting plate; a label roll is mounted on the main rotating shaft; an adjusting plate is fixed on the front wall surface of the main supporting plate on the right side of the main rotating shaft; an adjusting screw is in threaded connection with the adjusting plate; the lower end of the adjusting screw is hinged to a roller body connecting frame; a tensioning roller is hinged in the roller body connecting frame; the lower end of the tensioning roller extends out of the roller body connecting frame; a rotating part is fixed at the top end of the adjusting screw; a side connecting part is fixed on the left side wall of the roller body connecting frame; a limiting rod is fixed at the top of the side connecting part and is sleeved with the adjusting plate in an inserted manner; a front supporting plate is fixed at the front part of the top plate of the rack on the right side of the tensioning roller; and a front guiding strip is fixed on the inner side wall of the front supporting plate. According to the mechanism, the label roll without release paper bonded is adopted, a label is cut and bonded automatically, the cost is reduced, waste is reduced, and the bonding efficiency is high.

Owner:贵阳渝冠技术服务中心

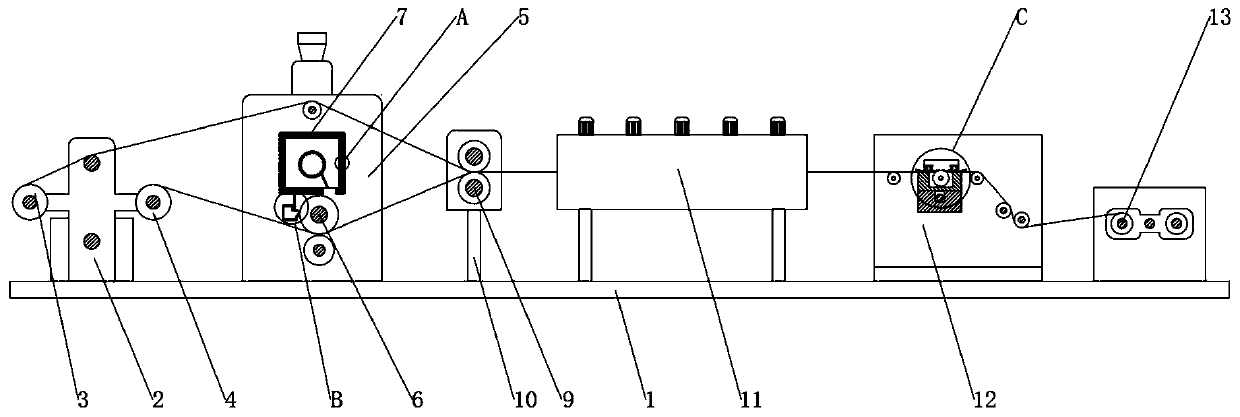

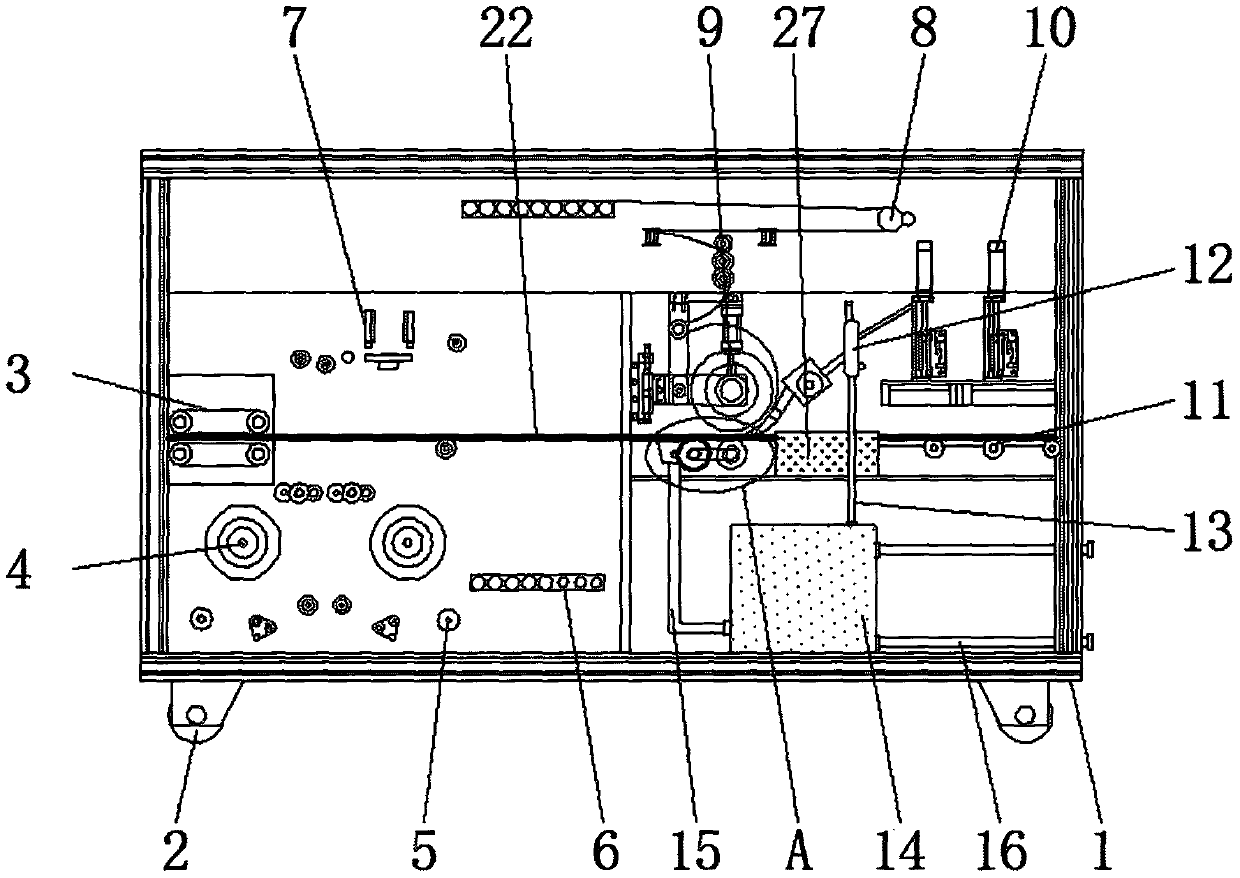

Energy-saving type high-speed laminating composite unit

ActiveCN110201835AGuaranteed uniformityGuaranteed temperatureLiquid surface applicatorsCoatingsProcessing costElectric energy

The invention discloses an energy-saving type high-speed laminating composite unit. The energy-saving type high-speed laminating composite unit comprises a base plate, feeding plates, a first feedingroller, a second feeding roller, a laminating device, a rubber roller, a heat preservation device, an auxiliary device, a composite roller, a supporting frame, a drying device, a cutter adjusting device and a collecting device, wherein the feeding plates are fixed on the top of one side of the base plate; the first feeding roller is arranged between the feeding plates and the first feeding rolleris rotationally connected with the feeding plates; the second feeding roller is arranged between the feeding plates and the second feeding roller is rotationally connected with the feeding plates; andthe laminating device is arranged on one side of the feeding plate. According to the energy-saving type high-speed laminating composite unit, the heat preservation device is additionally arranged onan original laminating compound machine, so that the temperature of the laminating machine is ensured, the electric energy consumption of heating is reduced, and the processing cost is reduced; and the adjusting device is additionally arranged at the laminating position, waste on the surface of the rubber roller is removed, the uniformity of laminating is ensured, the adhesion of compounding is ensured, and the product quality is improved.

Owner:浙江康骏机械有限公司

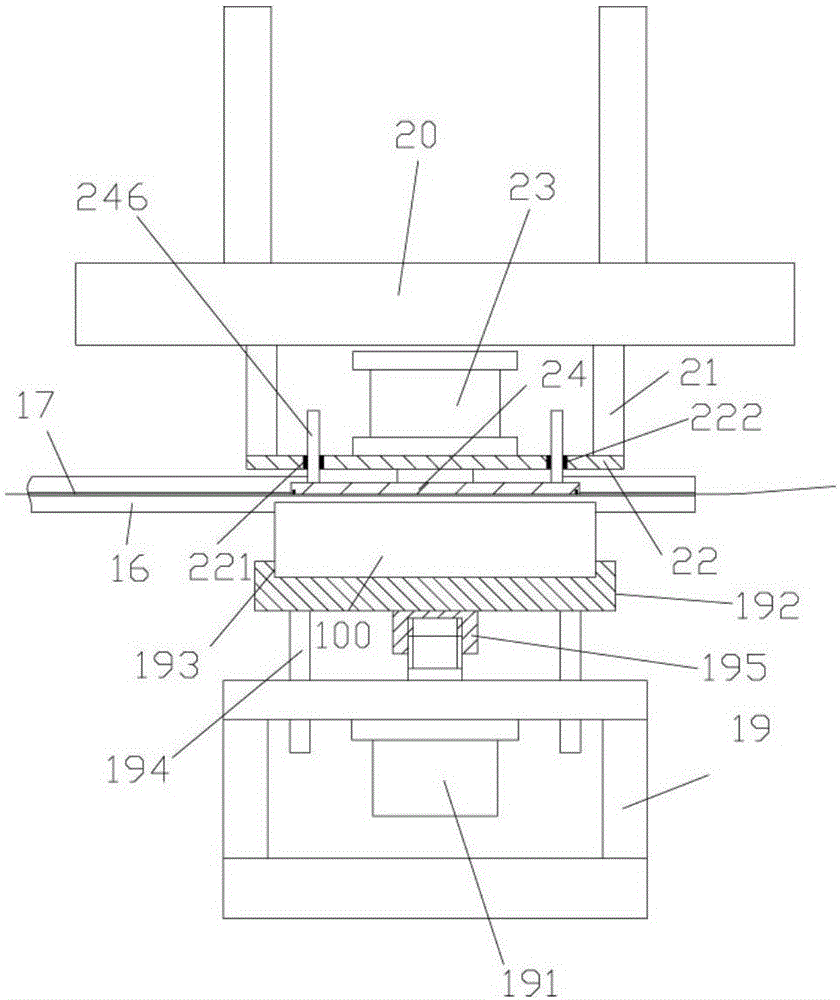

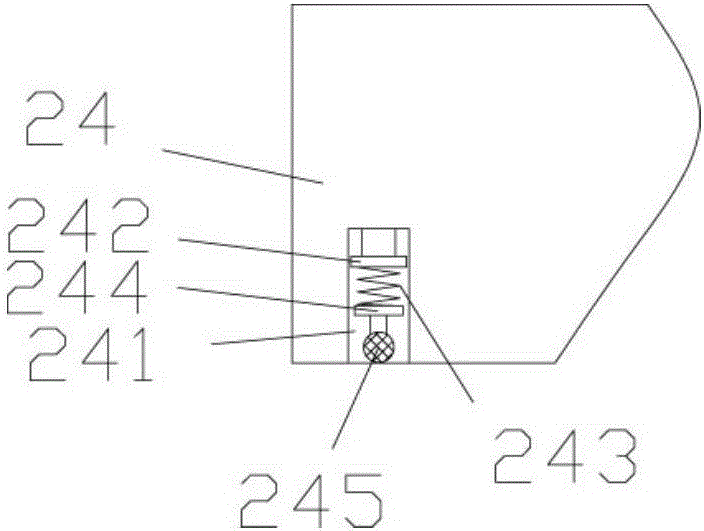

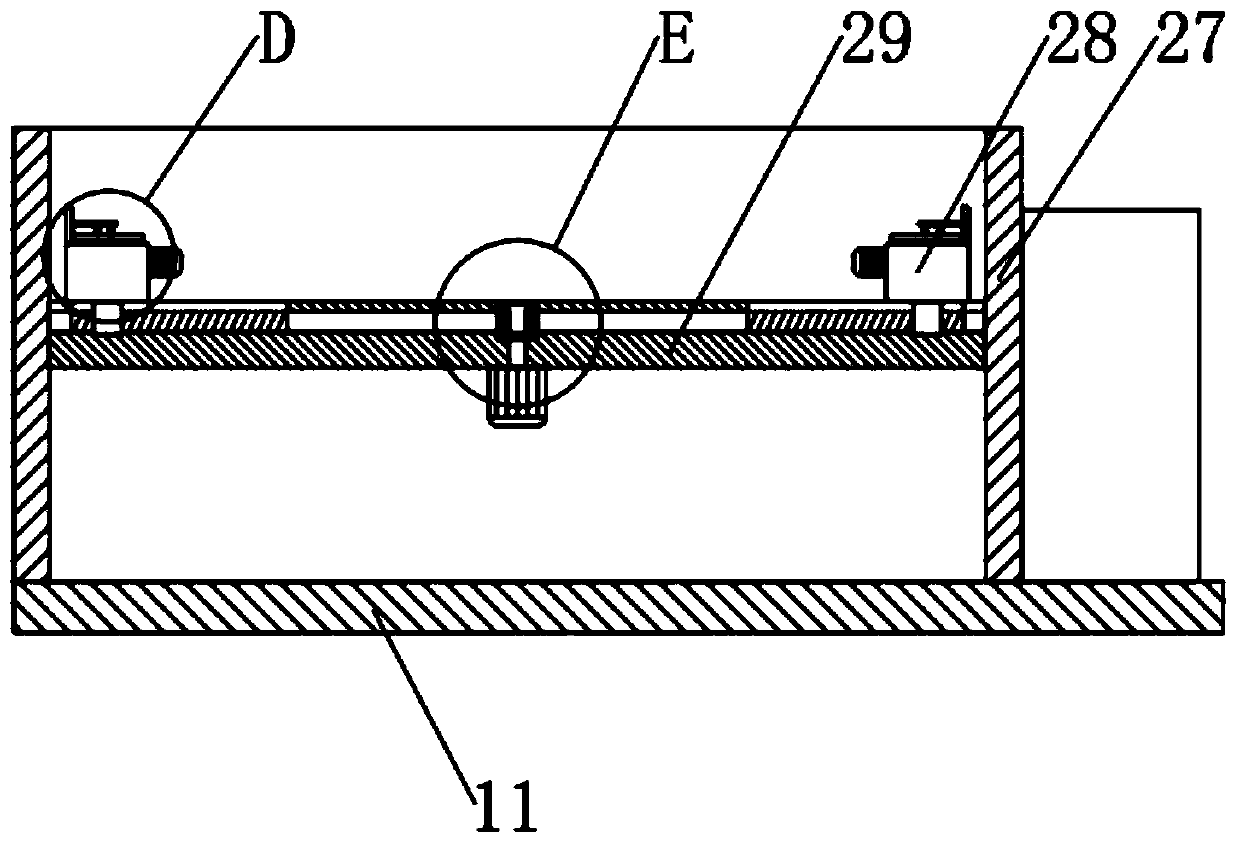

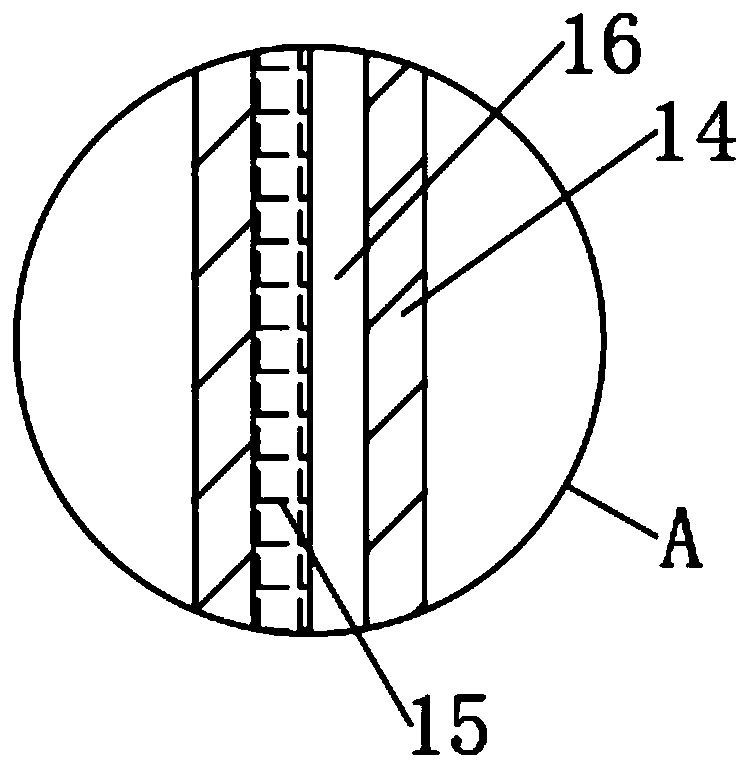

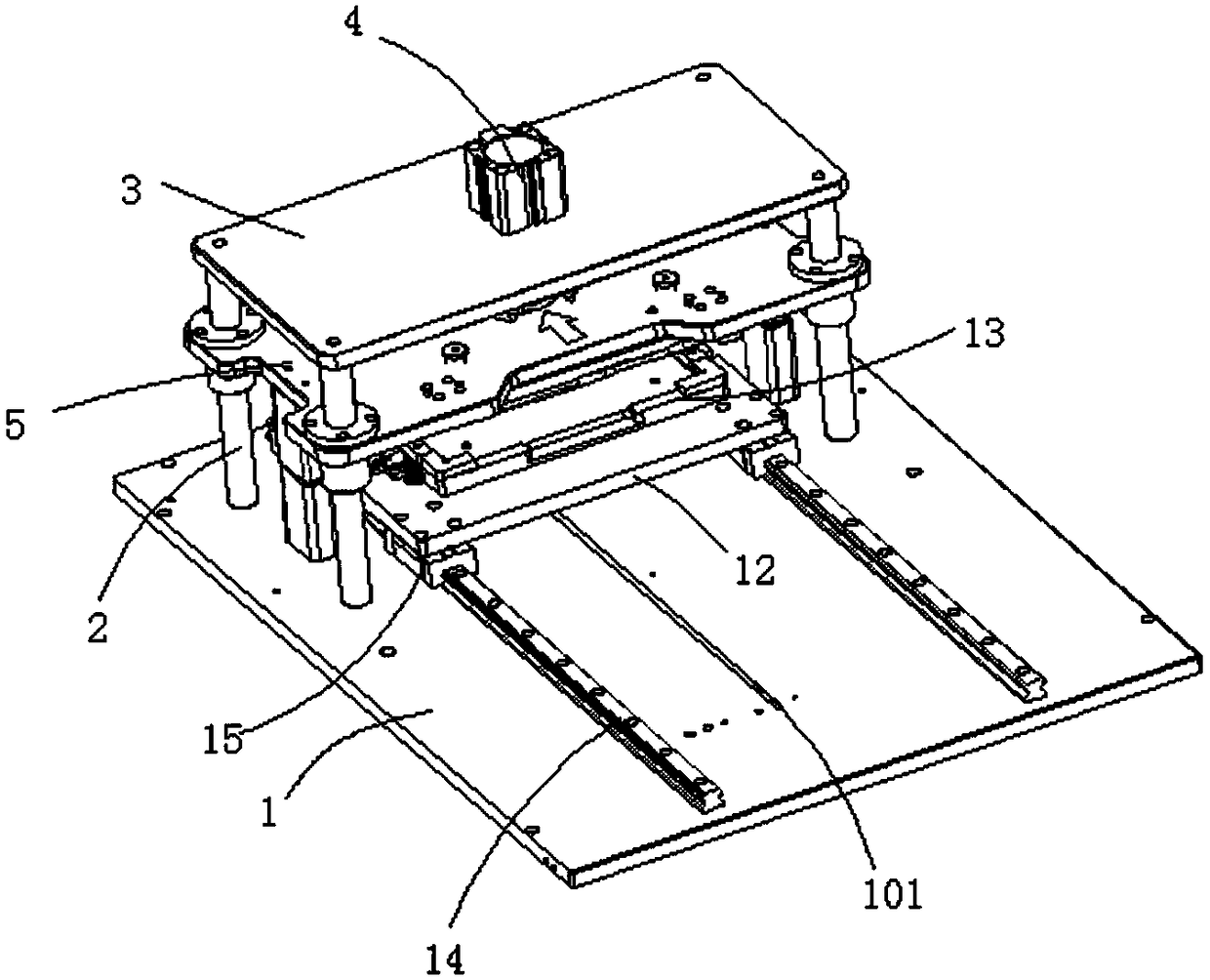

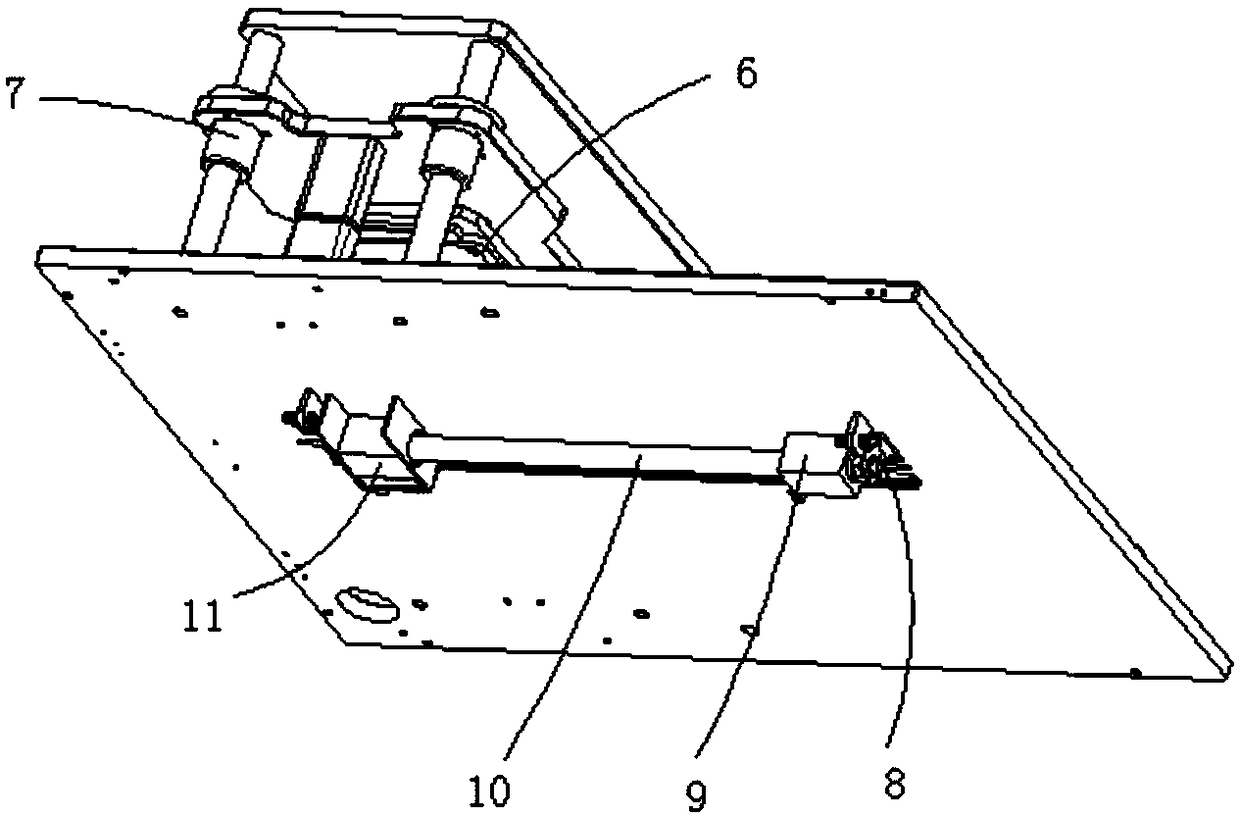

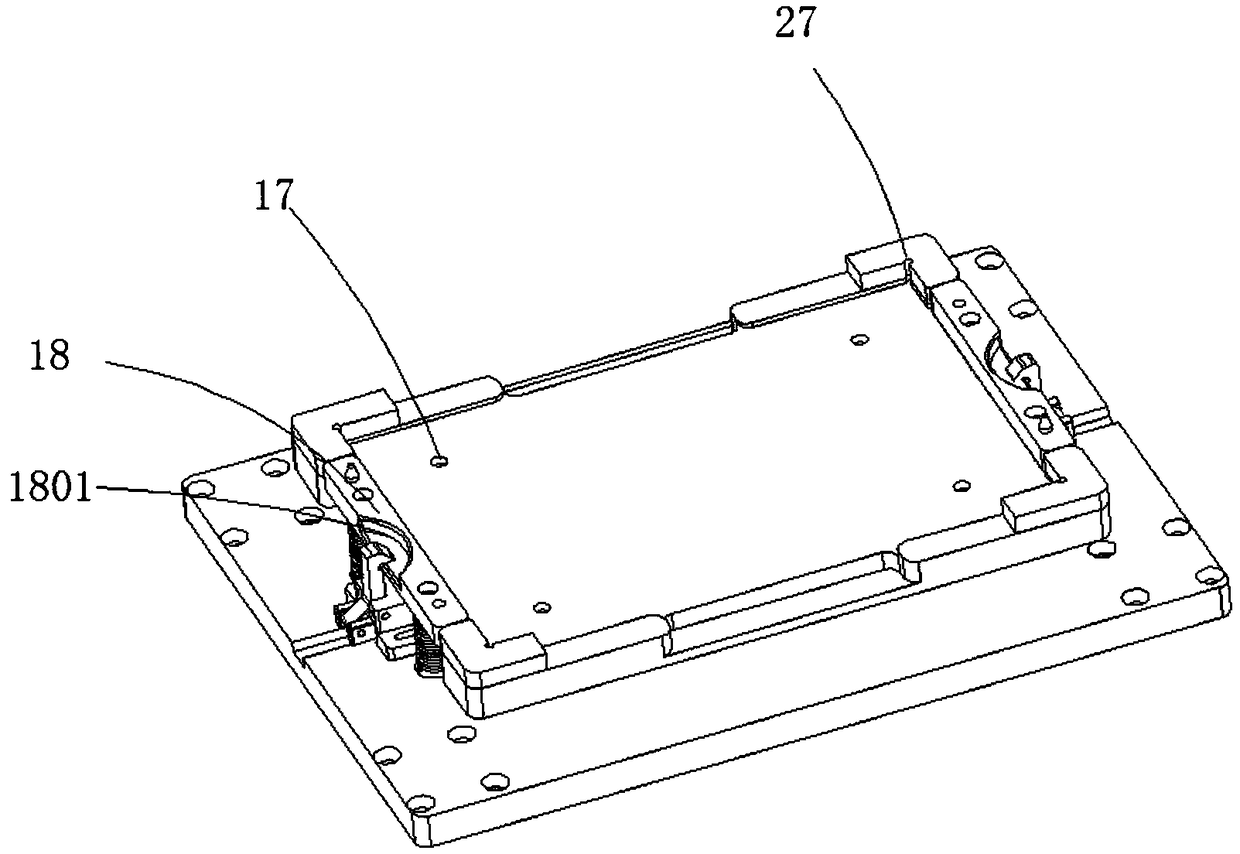

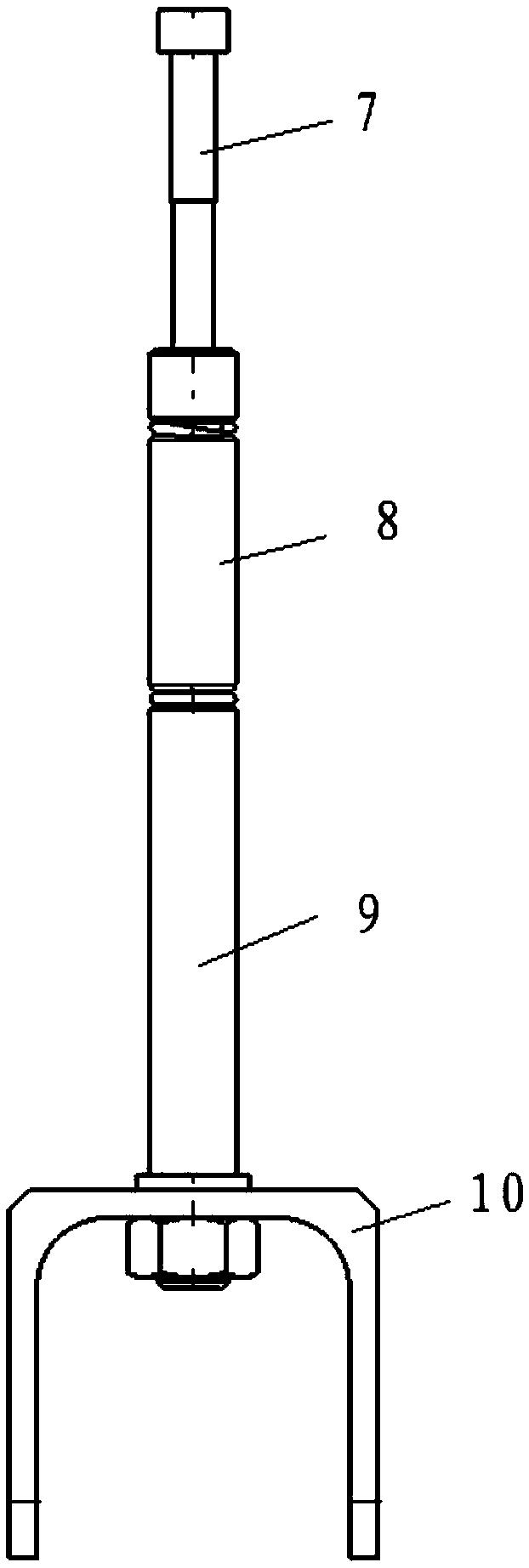

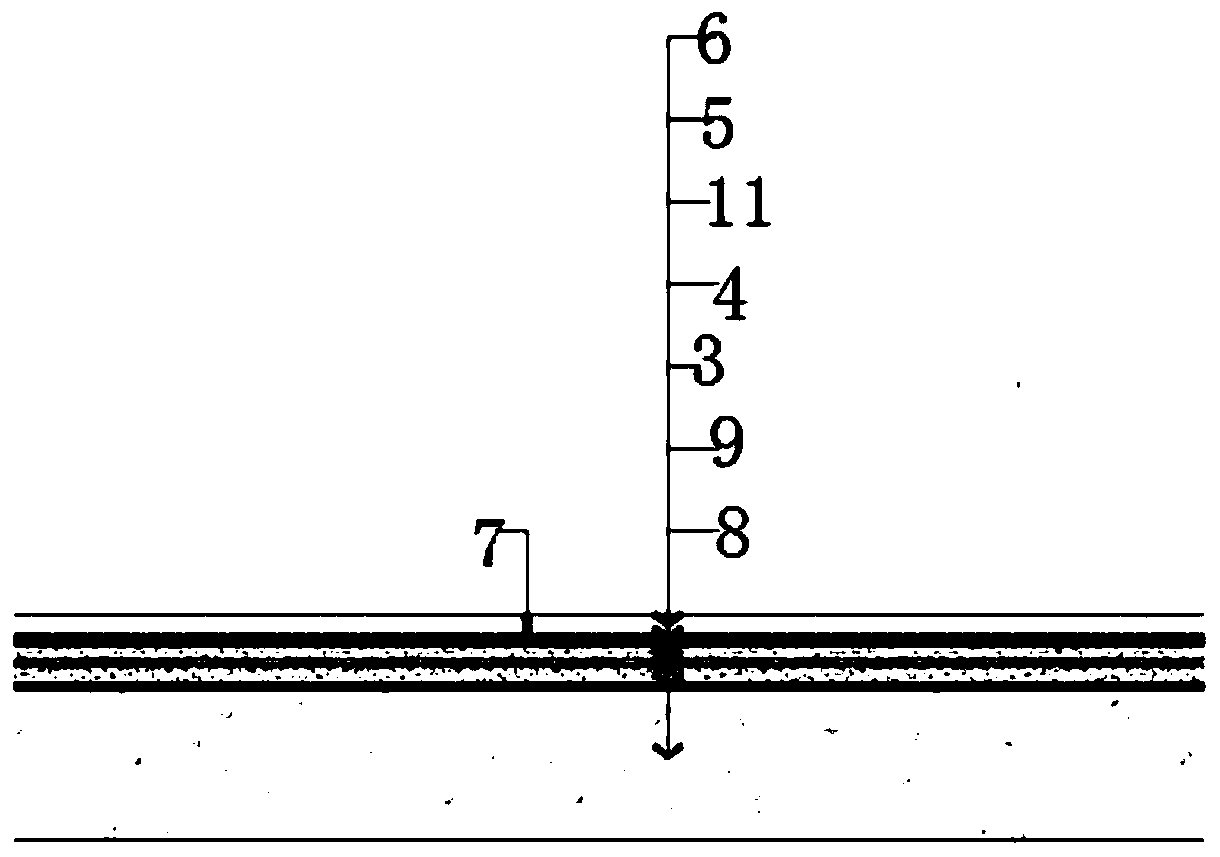

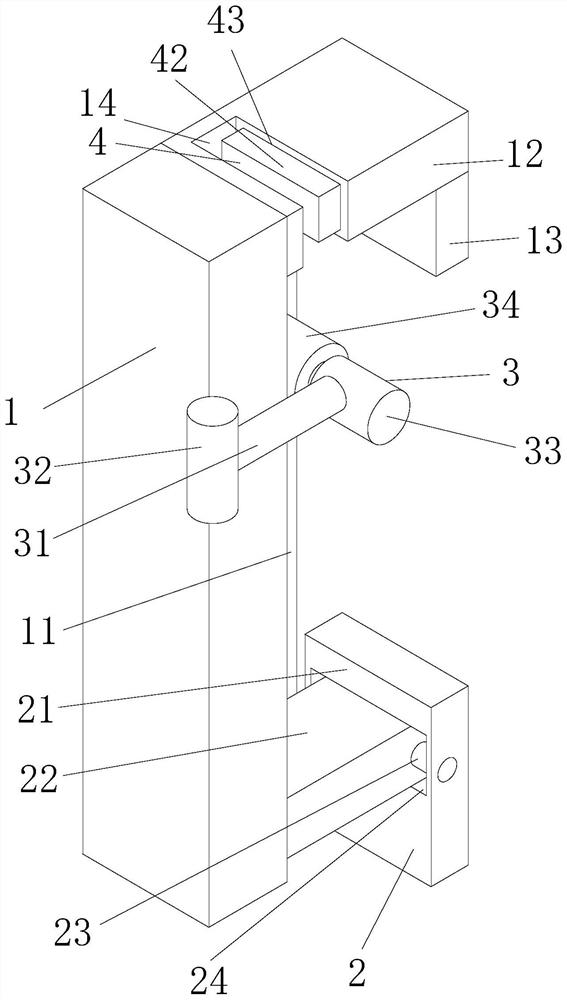

Precise pressure attachment mechanism

The invention relates to a precise pressure attachment mechanism. A carrier drive device drives a carrier to move directly below a downwards-pressing assembly, the downwards-pressing assembly pressesa workpiece and a product, and a pressure sensor performs pressure detection display; a drive unit of a clamping mechanism drives a clamping claw to move, and the clamping claw limits ascending of a movable positioning assembly; after pressing, the carrier drive device drives the carrier to move to the initial position, and a finished product subjected to attachment is taken out; and the drive unit of the clamping mechanism drives the clamping claw to move, the clamping claw is separated from the movable positioning assembly, and the movable positioning assembly ascends and resets. By means ofthe precise pressure attachment mechanism, attachment of SPA, HAF, protective films, labels and the like on the product is realized, the movable positioning assembly can play a role of protecting theattachment workpiece and product, the attachment effect is improved, the carrier and the movable positioning assembly can be subjected to local design according to the product shape, adjustment is performed according to the required pressure, universality is high, and simple attachment can be performed on different products.

Owner:BOZHON PRECISION IND TECH CO LTD

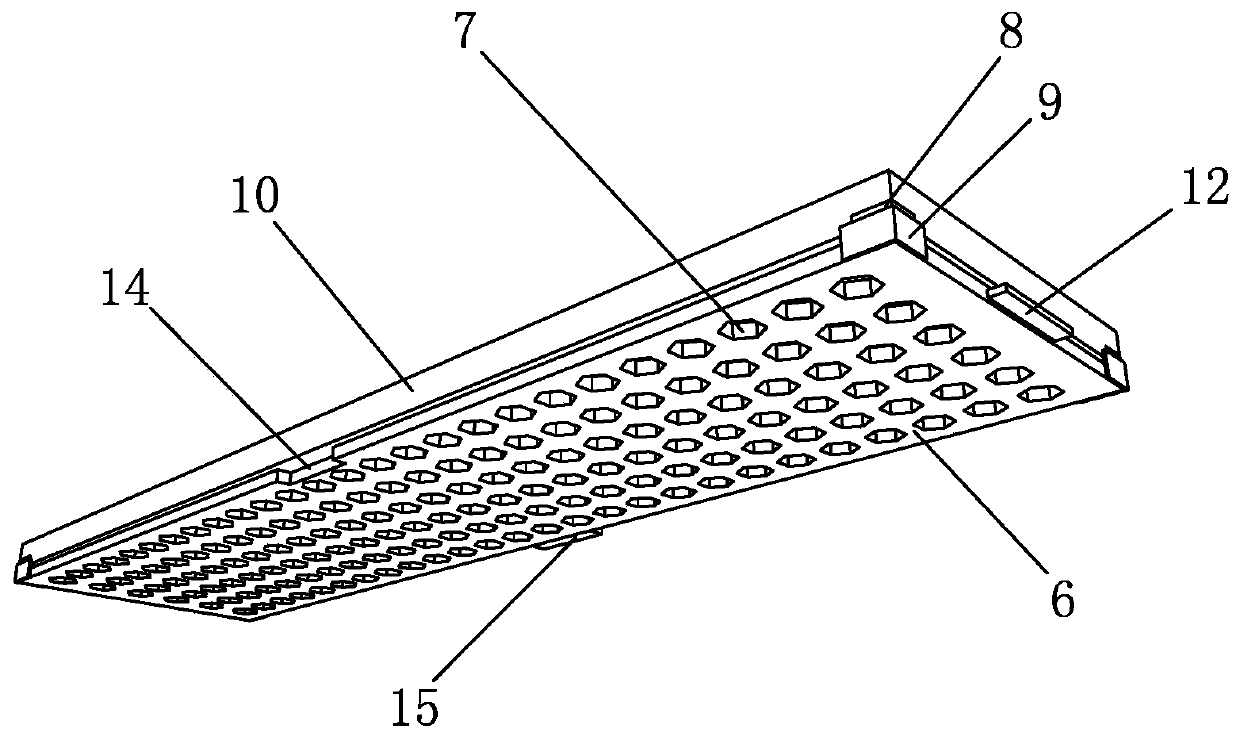

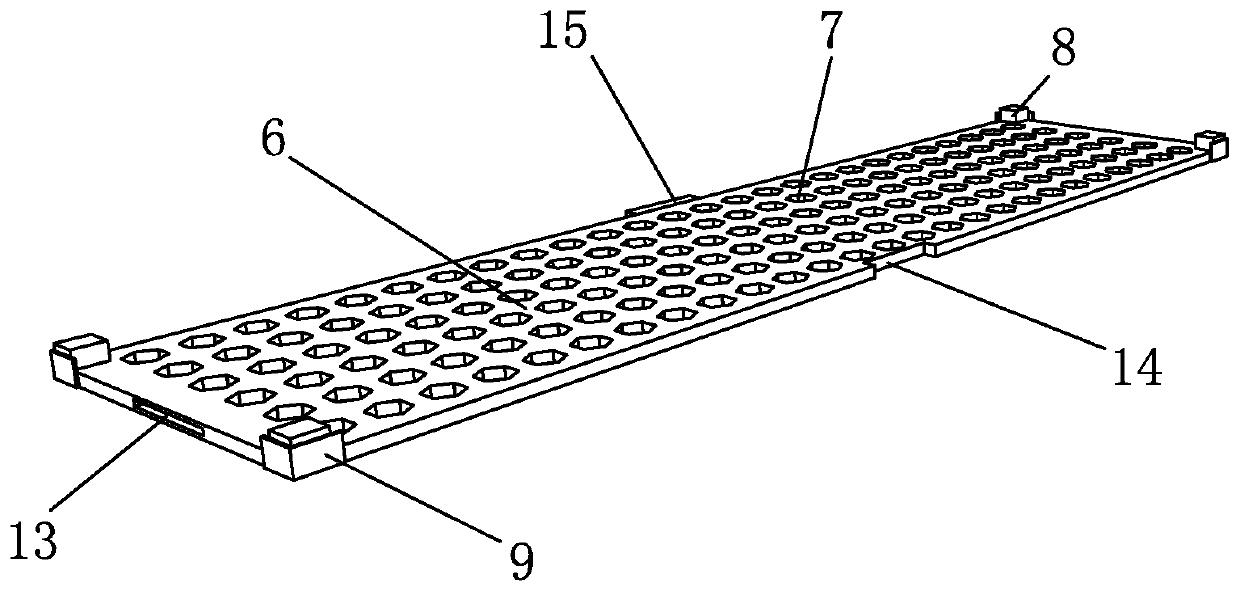

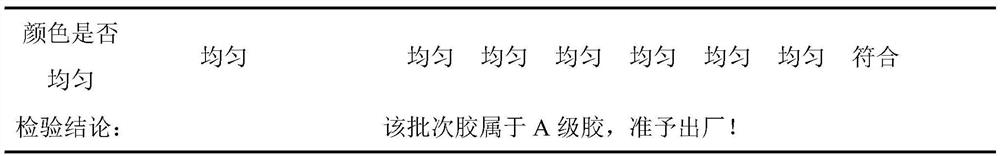

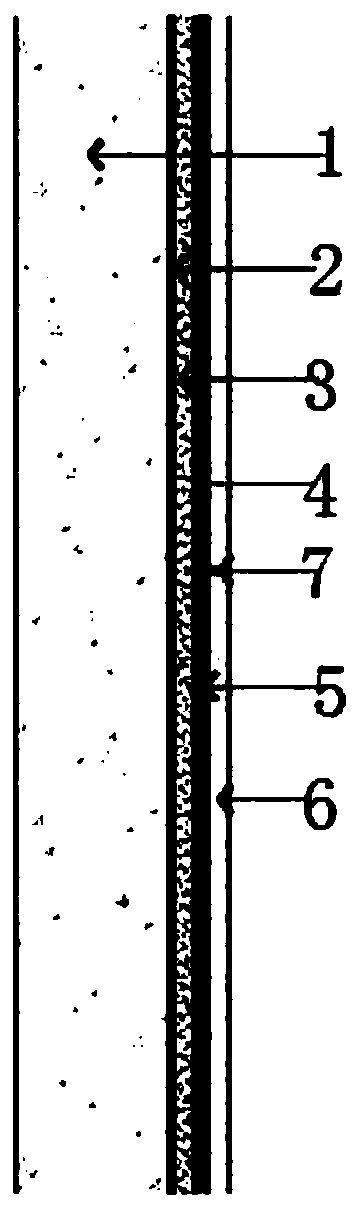

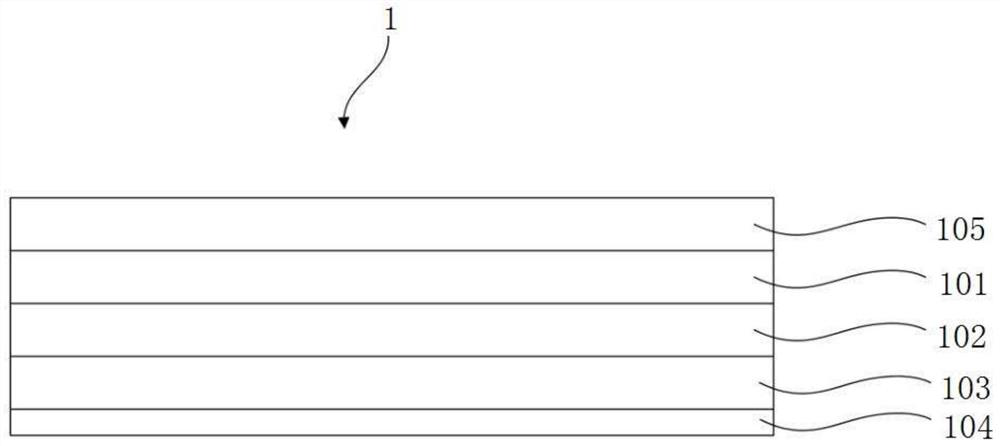

Anti-seepage structure for balcony and construction method of anti-seepage structure

InactiveCN110005049AStable structureNot easy to deform and misplaceBalconiesBuilding insulationsEngineeringProtection layer

The invention discloses an anti-seepage structure for a balcony. The anti-seepage structure comprises a waterproof coating layer, a coiled material waterproof layer, an anti-seepage film layer and a protecting layer, the protecting layer comprises a supporting plate layer and a ceramic tile layer which are arranged from bottom to top, the supporting plate layer is formed by supporting plates in anassembled mode, clamping blocks are arranged on the corners around the top face of each supporting plate correspondingly, the ceramic tile layer is formed by ceramic tiles in an assembled mode, clamping grooves are formed in the corners around the bottom face of each ceramic tile correspondingly, and the clamping blocks and the clamping grooves are matched. A construction method comprises the following steps of (1) base layer treatment, (2) treatment of the waterproof coating layer, (3) laying of the coiled material waterproof layer, (4) layering of the anti-seepage film layer and (5) layingof the protecting layer. The anti-seepage structure for the balcony is ingenious and reasonable in overall structural design, through the anti-seepage structure, the anti-seepage effect of the balconycan be improved effectively, the protecting layer is divided into the supporting plate layer and the ceramic layer, the waterproof effect of the balcony can be further improved under the situation ofensuring the surface attractive degree of the balcony, and the upper ceramic tile layer can also be conveniently laid through the supporting plate layer.

Owner:ZHEJIANG COLLEGE OF CONSTR

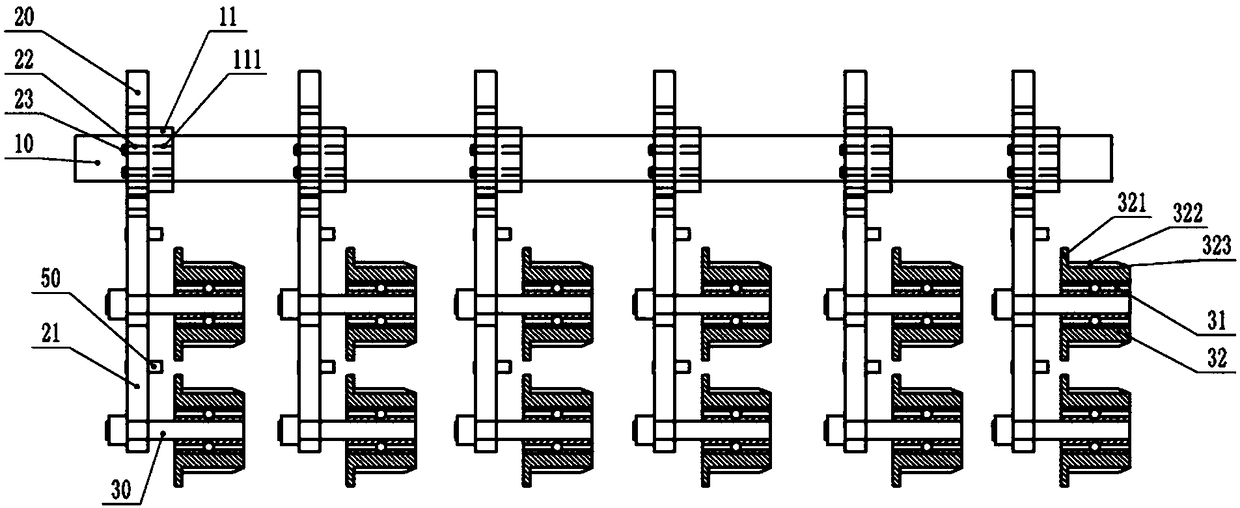

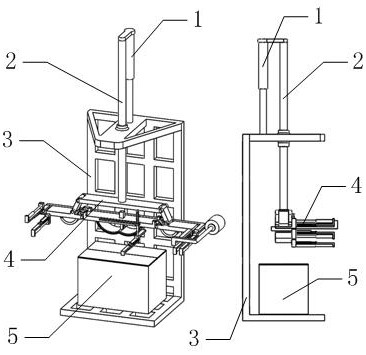

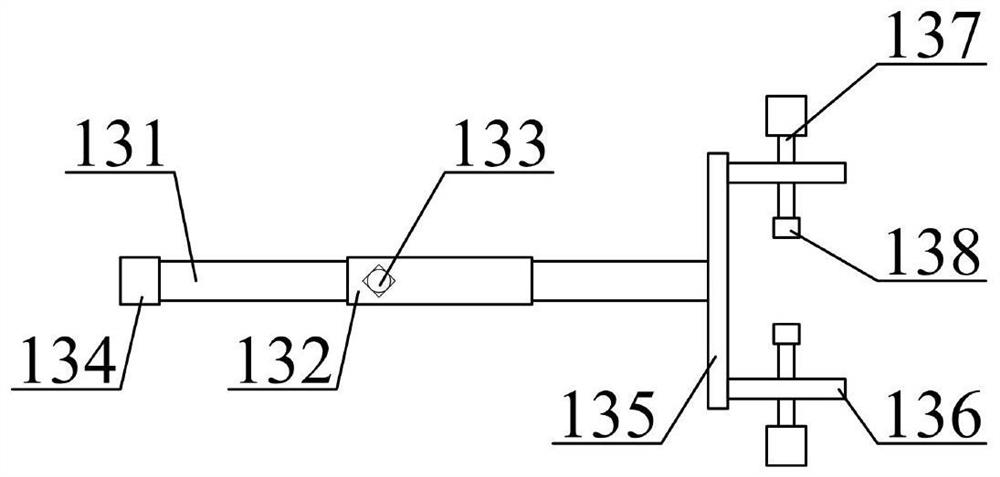

Automatic packaging tape pasting mechanism for packaging box production

InactiveCN108454971ARealize automatic replacementGuarantee the effect of pasting tapeWrapping material feeding apparatusWrapper twisting/gatheringPaperboardCarton

The invention belongs to the technical field of paperboard manufacturing, and particularly discloses an automatic packaging tape pasting mechanism for packaging box production. The automatic packagingtape pasting mechanism comprises a transverse rod fixed to cutting equipment, a plurality of pasting units fixed to the transverse rod and corresponding to cutting knives in position and roll replacing units corresponding to the pasting units in quantity; each pasting unit comprises a support plate, a first vertical plate and a second vertical plate, wherein the support plate is fixed to the transverse rod in the corrugated board conveying direction, and the first vertical plate and the second vertical plate are vertically fixed to the support plate; short shafts are fixed to the lower ends of the first vertical plates and the second vertical plates, the other ends of the short shafts are fixedly provided with first bearings, and the short shafts are perpendicular to the corrugated boardconveying direction; and a rotating sleeve used for fixing a packaging tape roll is fixed to the exterior of each first bearing, and the positions, close to the transverse rod, of the short shafts arehigher than the positions, far away from the transverse rod, of the short shafts. Compared with the prior art, packaging tapes can be quickly and conveniently pasted to corrugated boards through themechanism in a time-saving and labor-saving manner, the pasting effect of the packaging tapes is guaranteed, and the production efficiency of packaging boxes is improved.

Owner:重庆合信包装印刷有限公司

Insulating tape with high temperature resistance and preparation method thereof

PendingCN112322218ALow manufacturing costGood high temperature resistanceMacromolecular adhesive additivesPressure sensitive film/foil adhesivesThin membraneChemistry

The invention discloses an insulating tape with high temperature resistance and a preparation method thereof, and the prepared insulating tape is a polyimide tape and is composed of a polyimide film and an organic silicon pressure-sensitive adhesive layer, the organic silicon pressure-sensitive adhesive layer is prepared from the following components in parts by weight: 45-90 parts of organic silicon rubber, 5-10 parts of a heat-resistant additive, 9-18 parts of an adhesion promoter, 2-4 parts of polyhedral oligomeric silsesquioxane, 1-3 parts of a catalyst and 55-100 parts of a solvent. The insulating tape prepared by the invention is different from polyimide adhesive tapes on the market, and the high temperature resistance, the electrical insulation property and the adhesive force of theinsulating tape are ensured while the manufacturing cost is reduced. The insulating tape is a polyimide adhesive tape prepared from specific components and has excellent high-temperature resistance,electrical insulation performance and adhesive force, and the prepared organic silicon pressure-sensitive adhesive layer does not contain MQ resin and is low in cost, high in cohesion and low in silicon residue.

Owner:东莞市哲华电子有限公司

Online thermosensitive adhesive tape gluer device with gluing effect guaranteed easily

The invention discloses an online thermosensitive adhesive tape gluer device with the gluing effect guaranteed easily. The device comprises a framework. A traction machine is mounted at the left end of the interior of the framework, and adhesive tape unwinding bars are arranged on the lower side of the traction machine; and in addition, moving wheels are mounted at the lower end of the framework,and an adhesive tape conveying device is mounted on the upper-right side of the traction machine. Adhesive tape thin film winding bars are arranged on the lower side of the adhesive tape unwinding bars, and an adhesive tape storage support is arranged on the right side of the adhesive tape thin film winding bars. A driving roller group is arranged on the right side of the upper portion of the adhesive tape storage support. According to the online thermosensitive adhesive tape gluer device with the gluing effect guaranteed easily, the temperature of a rubber strip can be guaranteed to be the same before the rubber strip is heated by a heat gun, and accordingly, the effect for gluing the thermosensitive adhesive tape to the rubber strip is guaranteed; and in addition, exchanging of air inside and outside of the device can be reduced, the situation that the rubber strip temperature is not uniform due to exchanging of the air inside and outside of the device can be reduced, and the effectfor gluing the thermosensitive adhesive tape to the rubber strip can be further guaranteed easily.

Owner:青岛瑞鹏机电设备有限公司

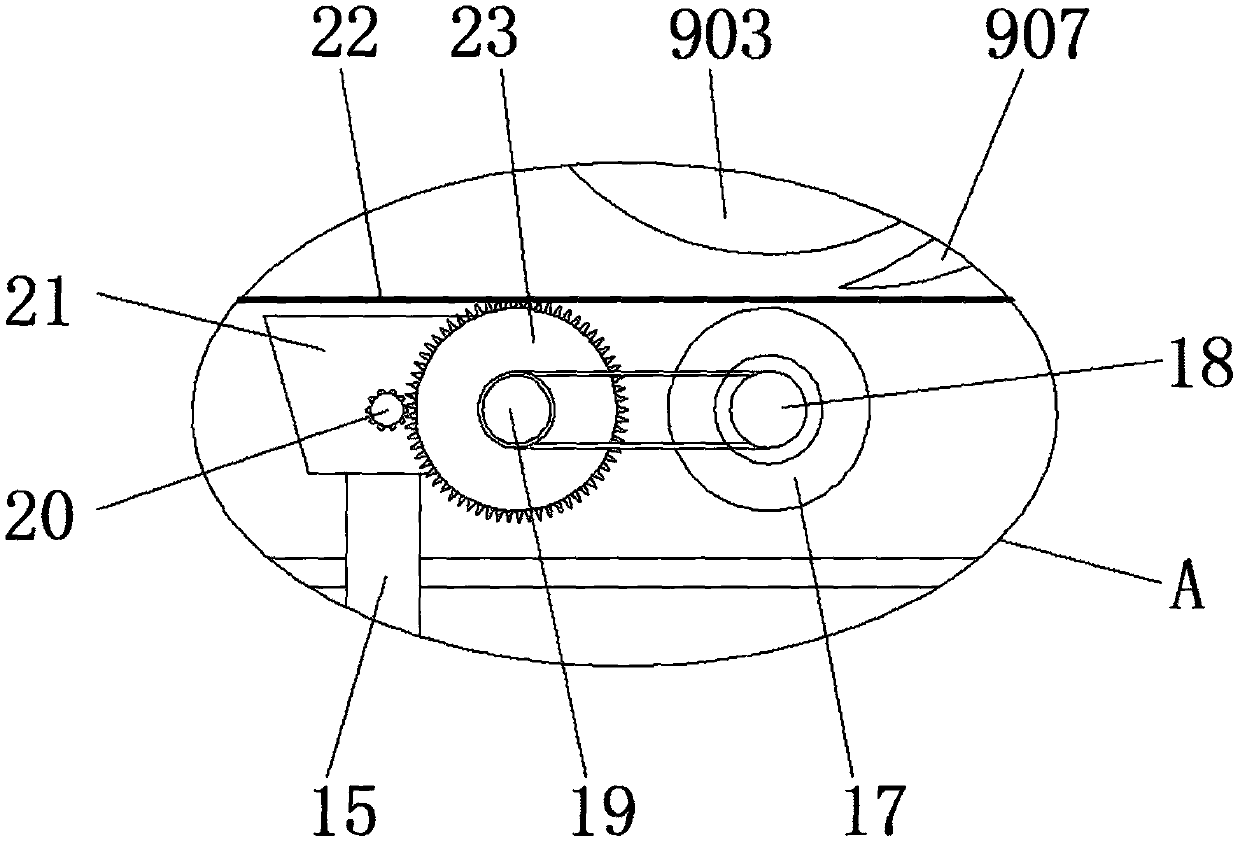

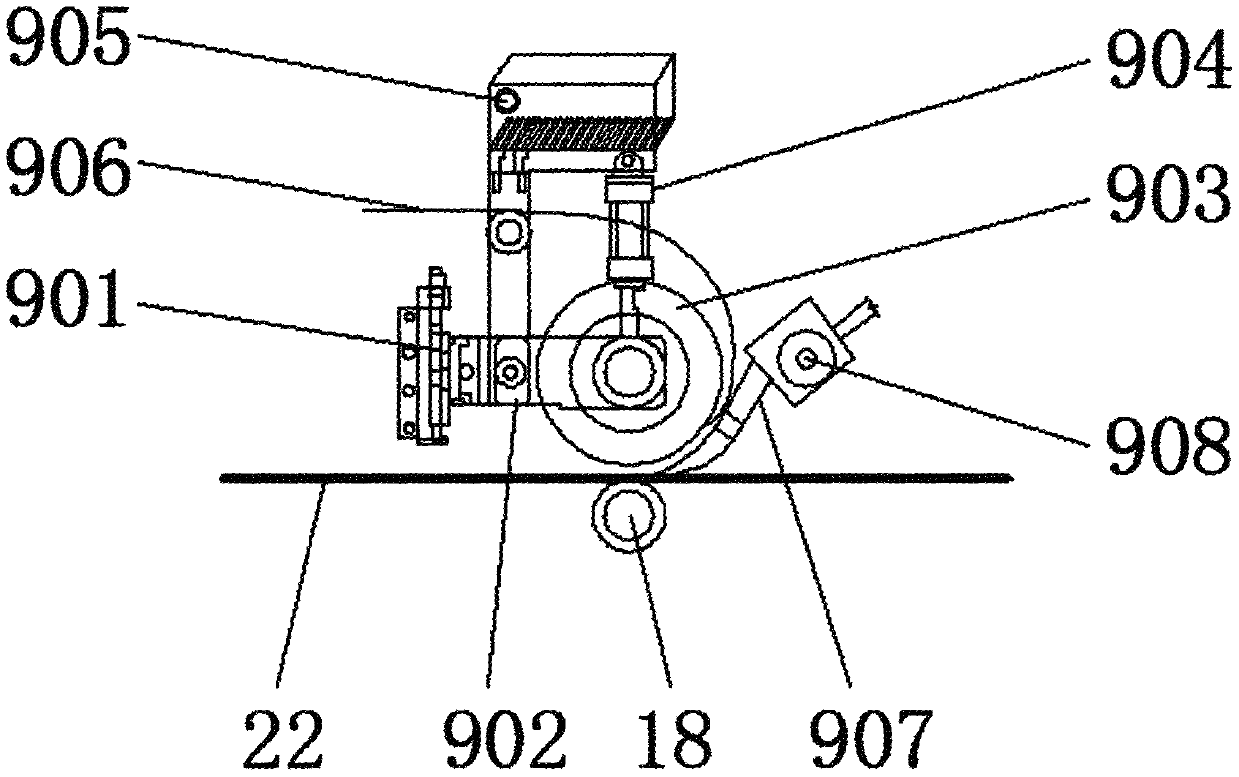

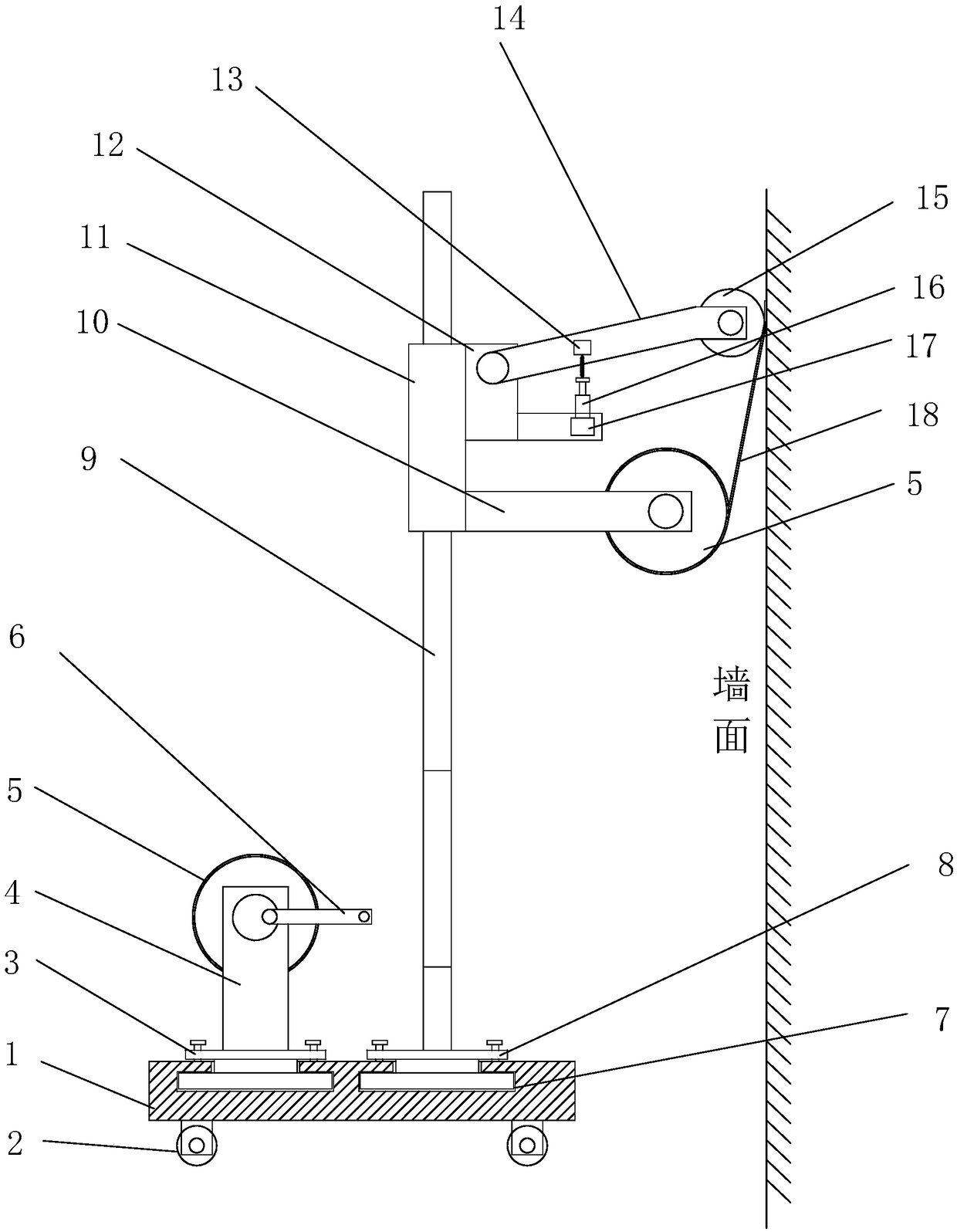

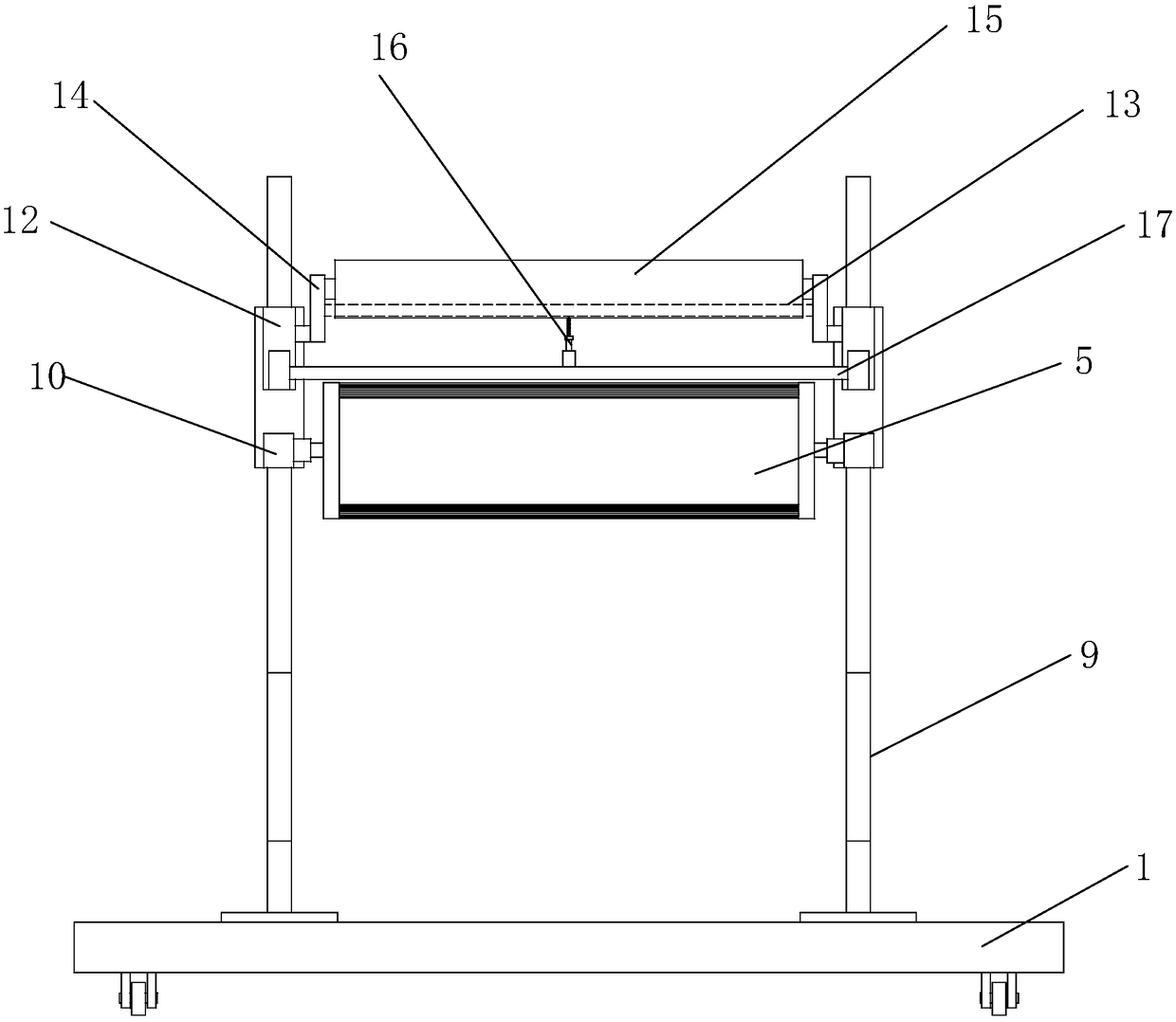

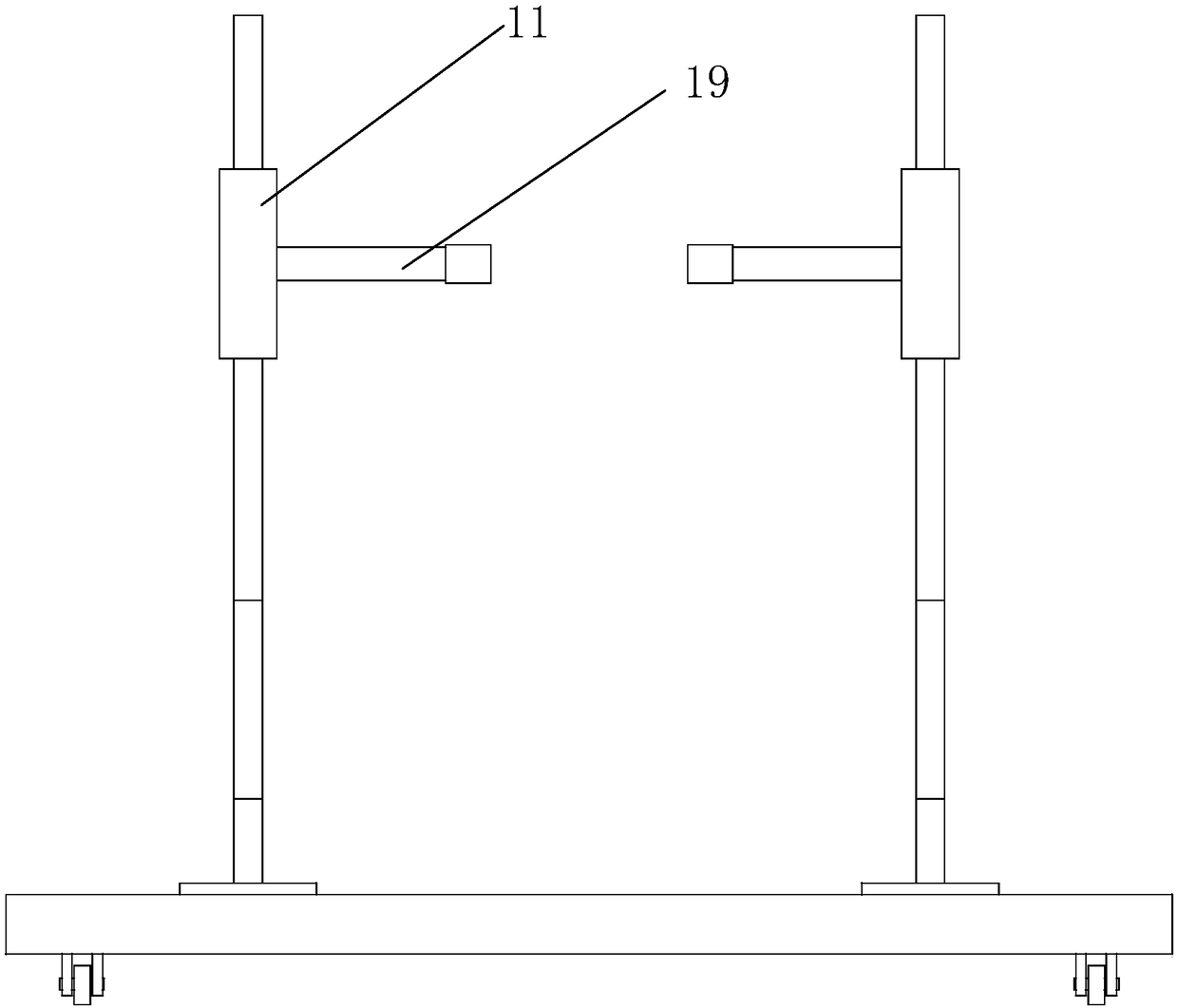

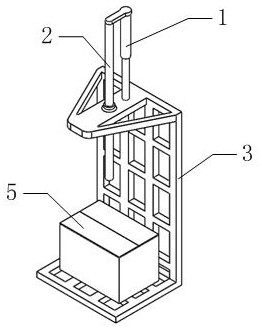

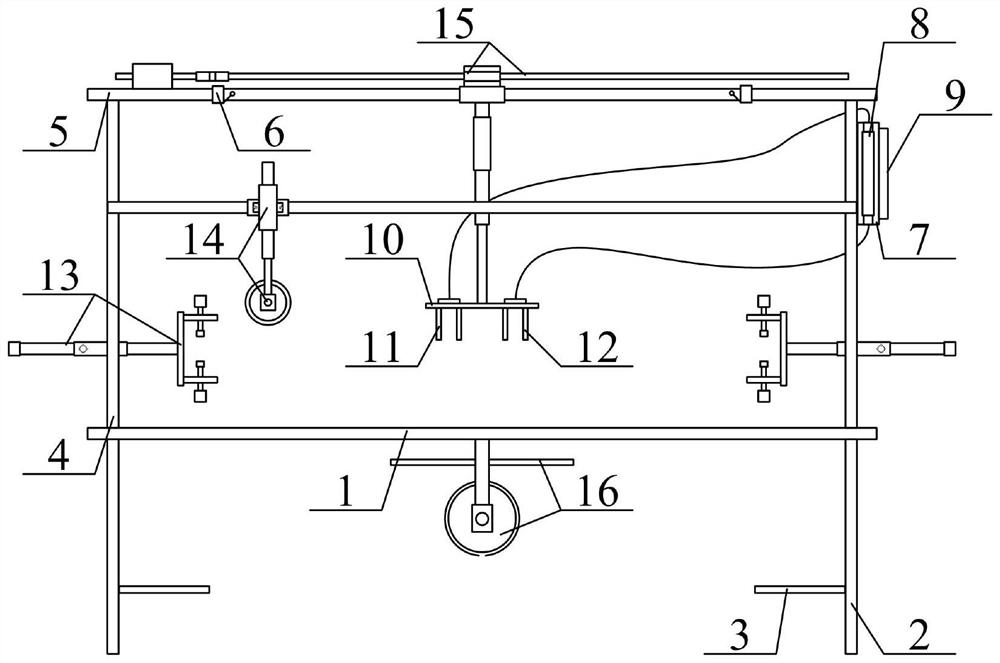

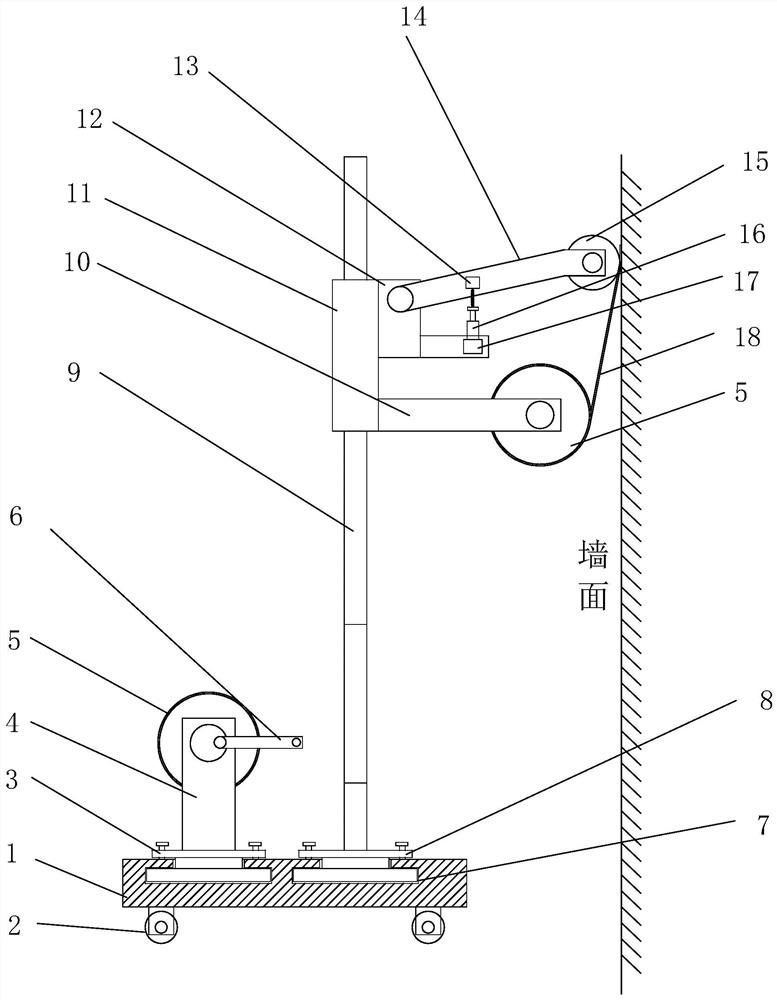

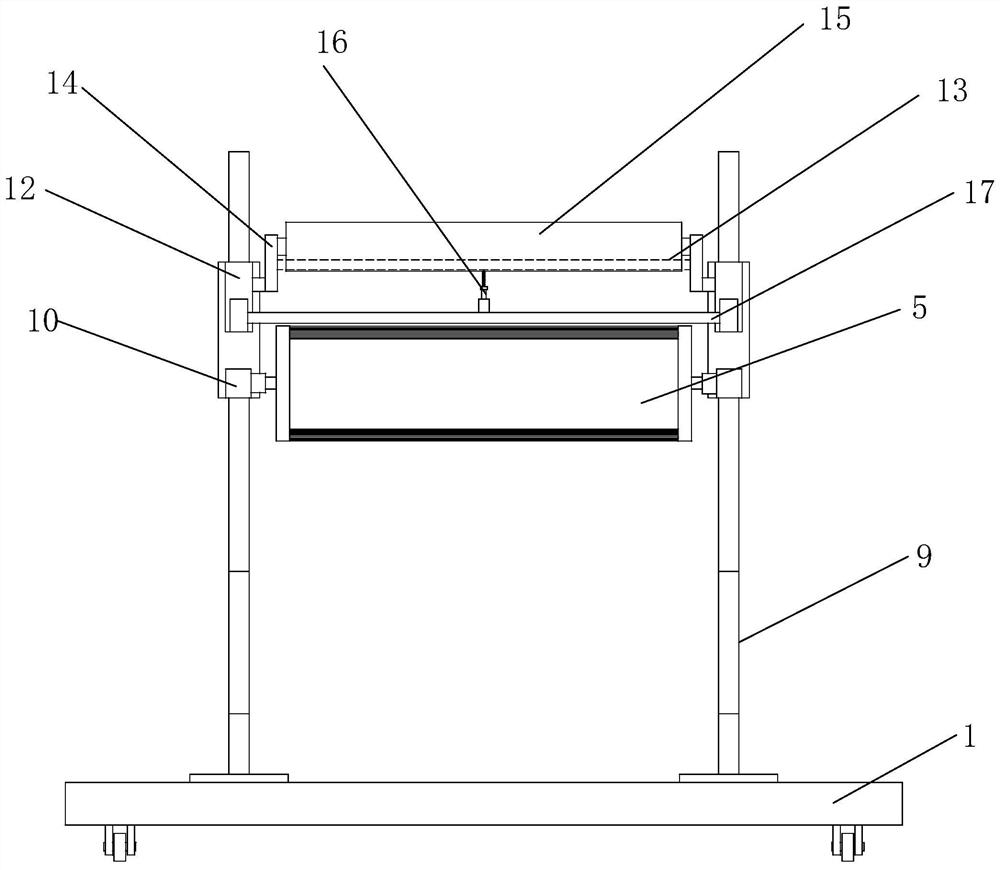

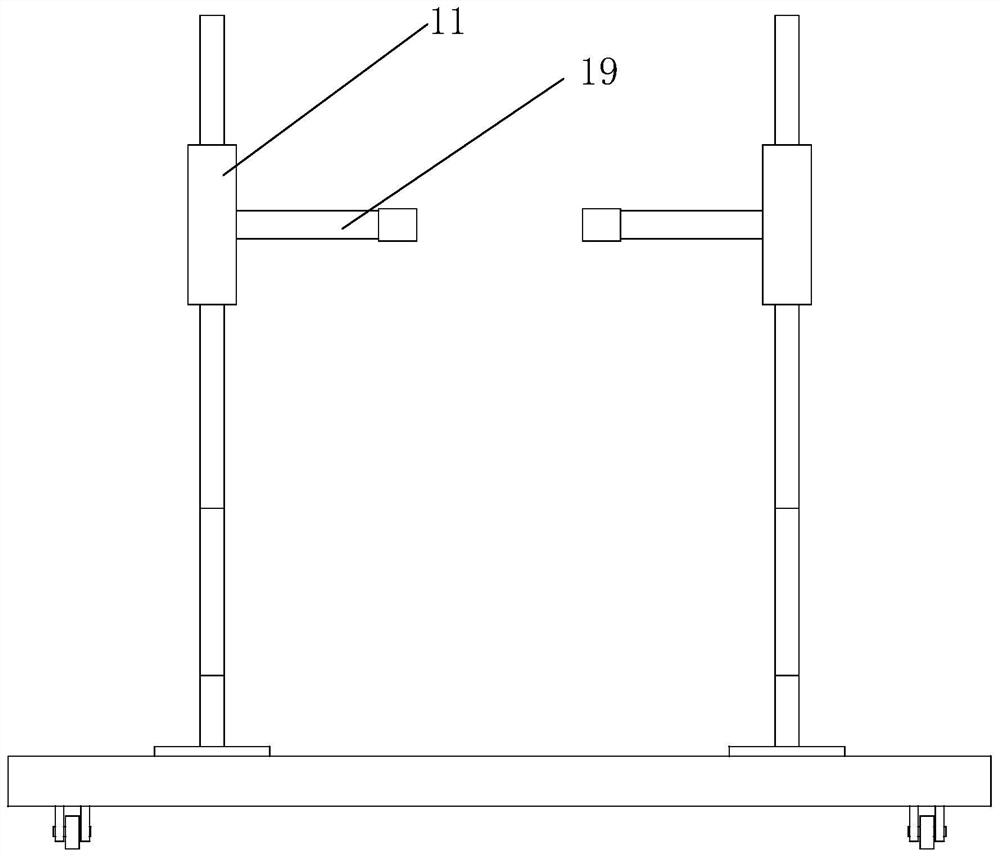

Split mounting type wallpaper laminator

The invention provides a split mounting type wallpaper laminator. The split mounting type wallpaper laminator comprises a base. Wheels capable of being locked are arranged under the base, a primary supporting assembly is arranged on the base, the primary supporting assembly comprises two vertically arranged vertical columns, each column is composed of multiple sections of steel tubes which are spliced, a mounting plate is arranged at the bottom of each column, and the mounting plate can slide and can be locked on the base to adjust the distance between the two vertical columns; a lifting assembly is arranged on the columns, a lifting and locking mechanism is arranged on the lifting assembly, a wallpaper paving assembly is also arranged on the lifting assembly, a wallpaper compression assembly is arranged above the wallpaper paving assembly, and a compression force adjusting mechanism is arranged below the wallpaper compression assembly. Debugging equipment can be assembled quickly by way of site splicing, so that the split mounting type wallpaper laminator is extremely convenient to carry and use, can fit wallpaper of nearly all width dimensions, and is high in universality.

Owner:黄山市亿华装饰材料有限公司

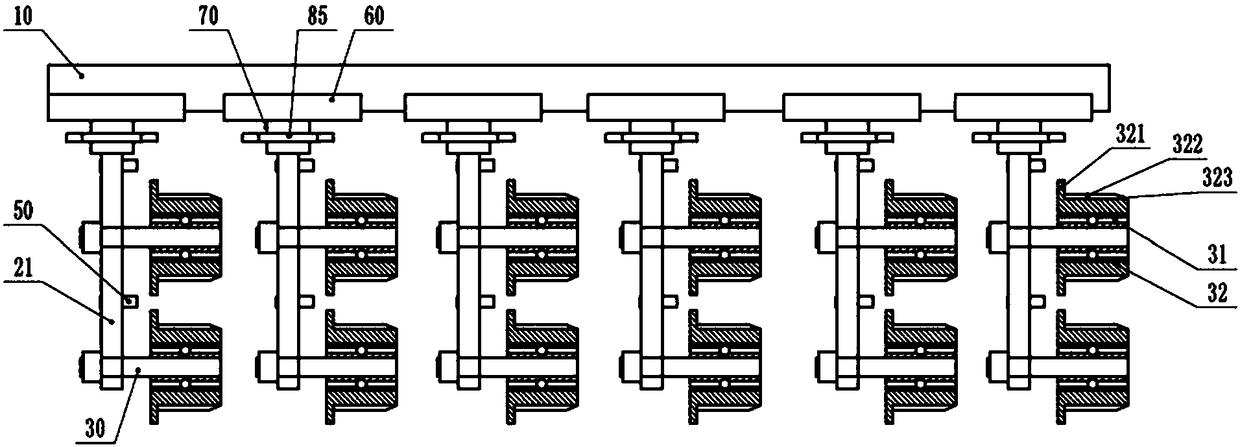

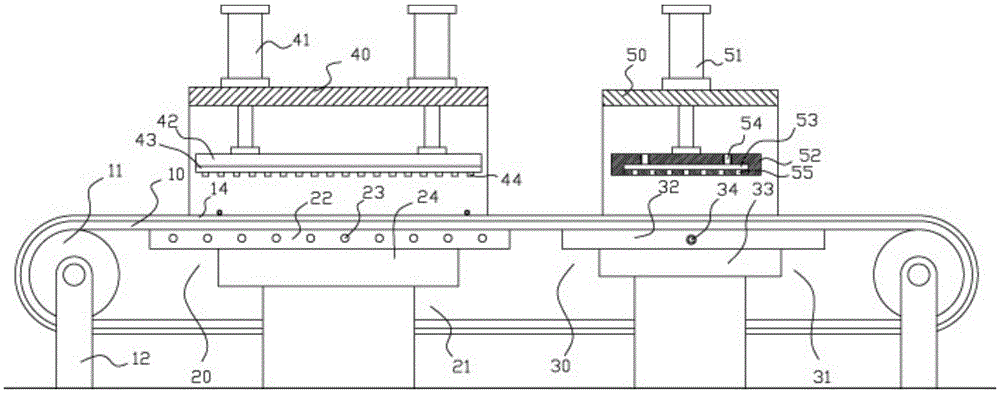

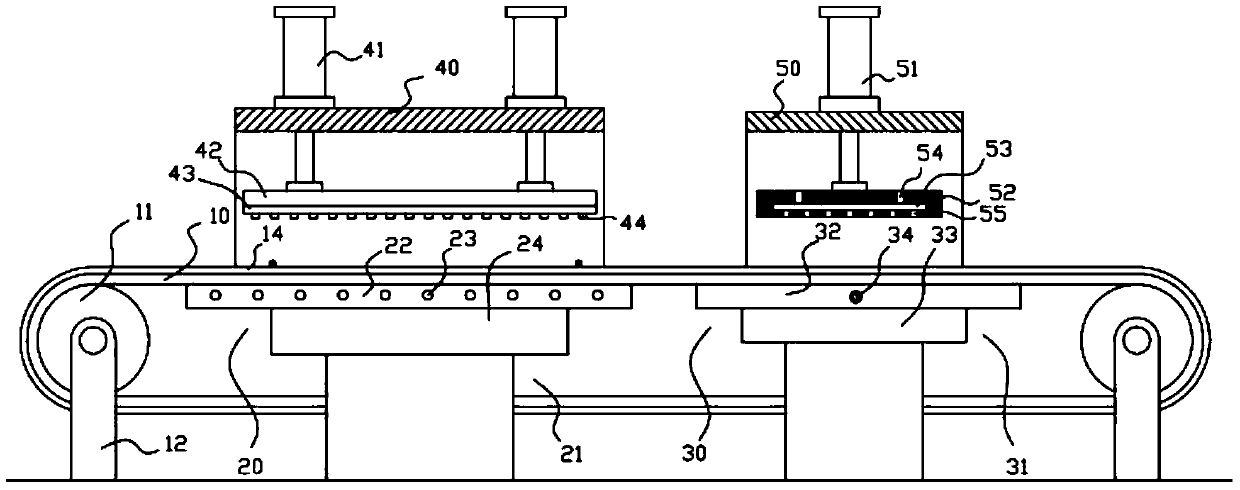

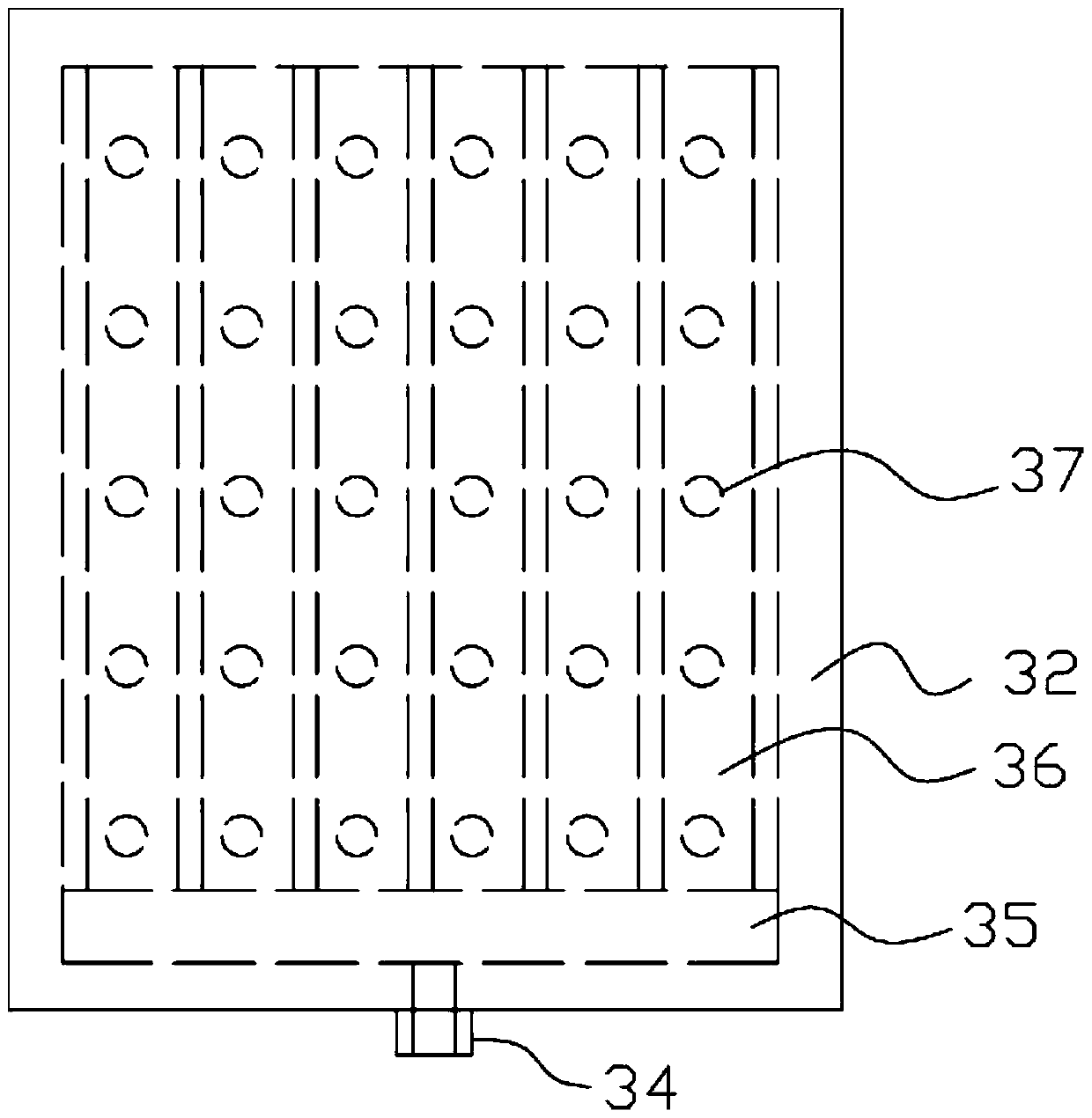

Paperboard pasting mechanism

ActiveCN105538867ADry fastGuaranteed paste effectLamination ancillary operationsLaminationPaperboardDrive motor

The invention discloses a paperboard pasting mechanism. The paperboard pasting mechanism comprises a driving belt. The driving belt is tensioned on two driving rollers. Landing legs are hinged to the two ends of each driving roller, the supporting legs are fixed to the ground, a drive motor is fixed to one landing leg, and an output shaft of the drive motor drives one driving roller to rotate. Limiting edges are fixed to the walls of the two sides of the conveying belt, multiple air holes are evenly distributed in the middle of the conveying belt, a heating device is fixed to a first support, and a blowing device is fixed to a second support. A pressing connecting frame is fixed to the first support, a top plate of the pressing connecting frame is located over the conveying belt, multiple pressing air cylinders are fixed to the top face of the top plate, push rods of the pressing air cylinders penetrate through the top plate in a vertically-downward mode and are fixedly provided with a pressing plate, and the pressing plate is located over the conveying belt. It is guaranteed that glue of glued paperboards cannot be blow-dried during conveying, the paperboards are firmly pasted, the dryness of the glue can be rapidly improved after pasting, and therefore the pasting effect is guaranteed.

Owner:安徽新隆泰包装股份有限公司

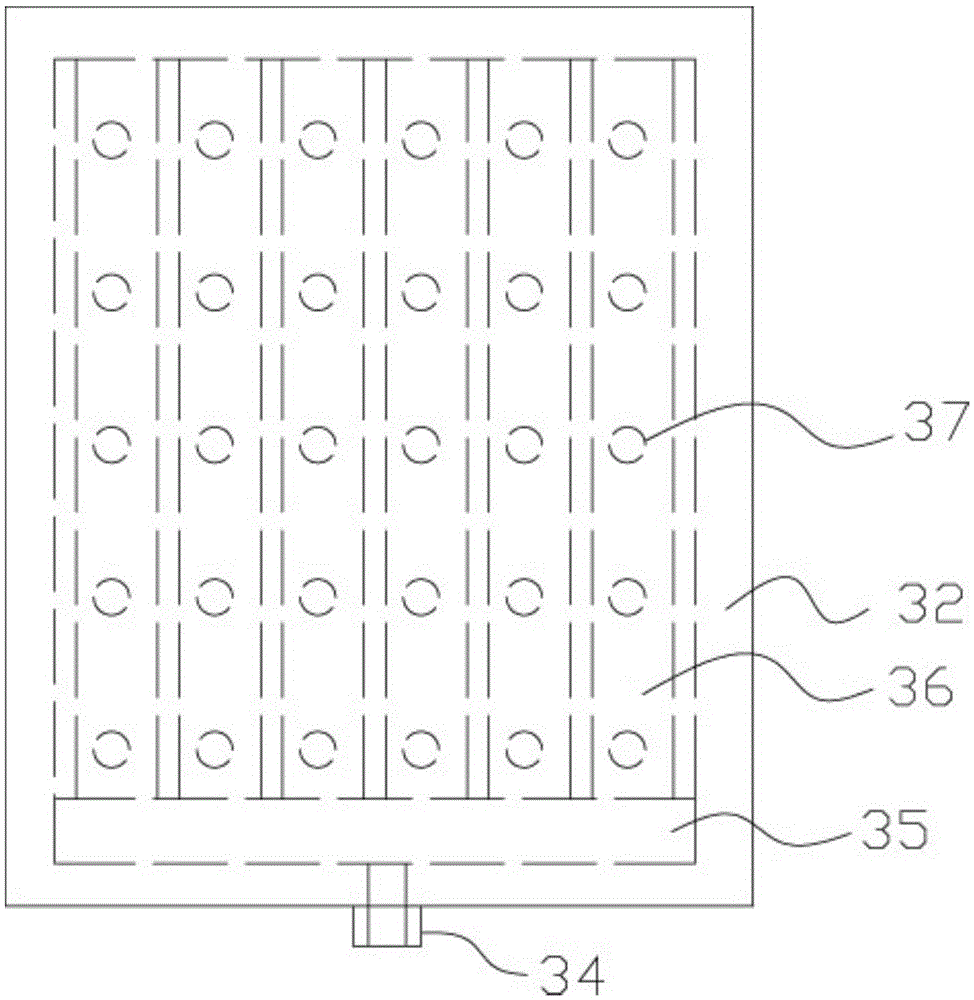

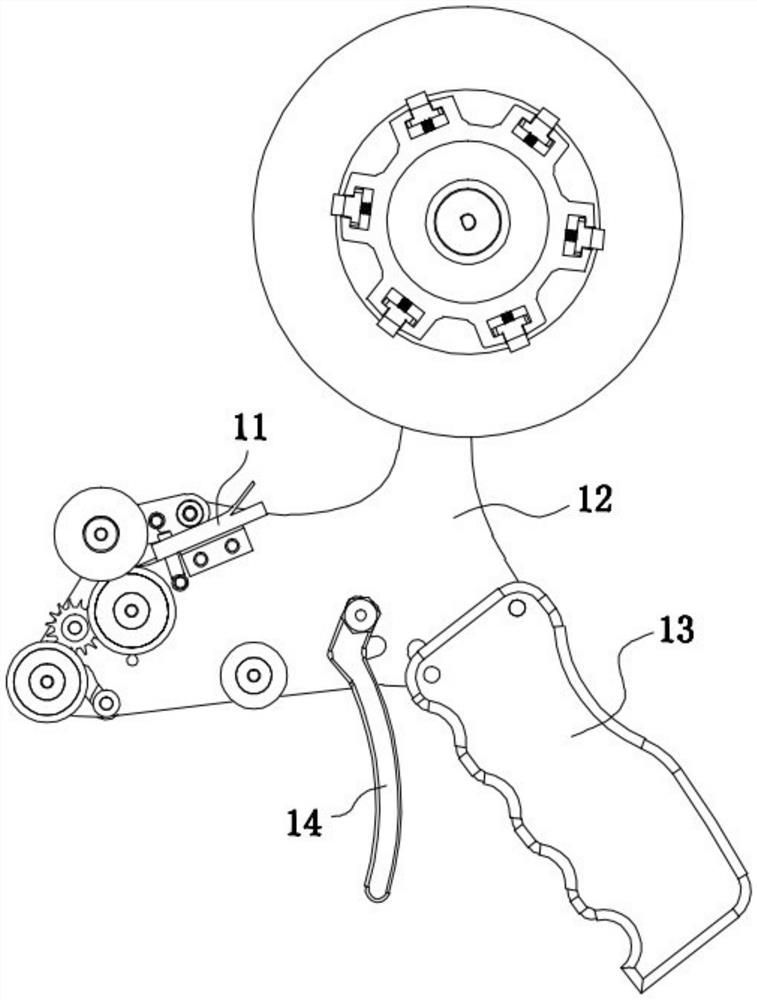

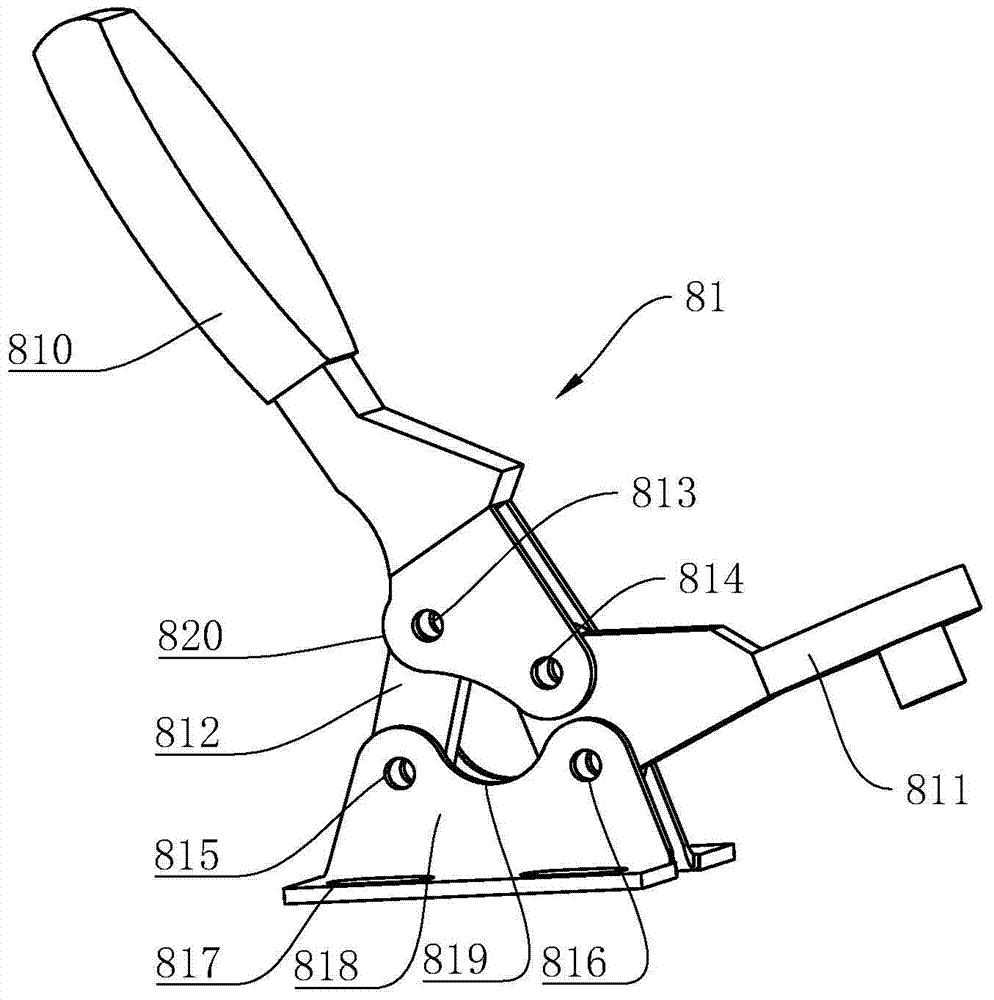

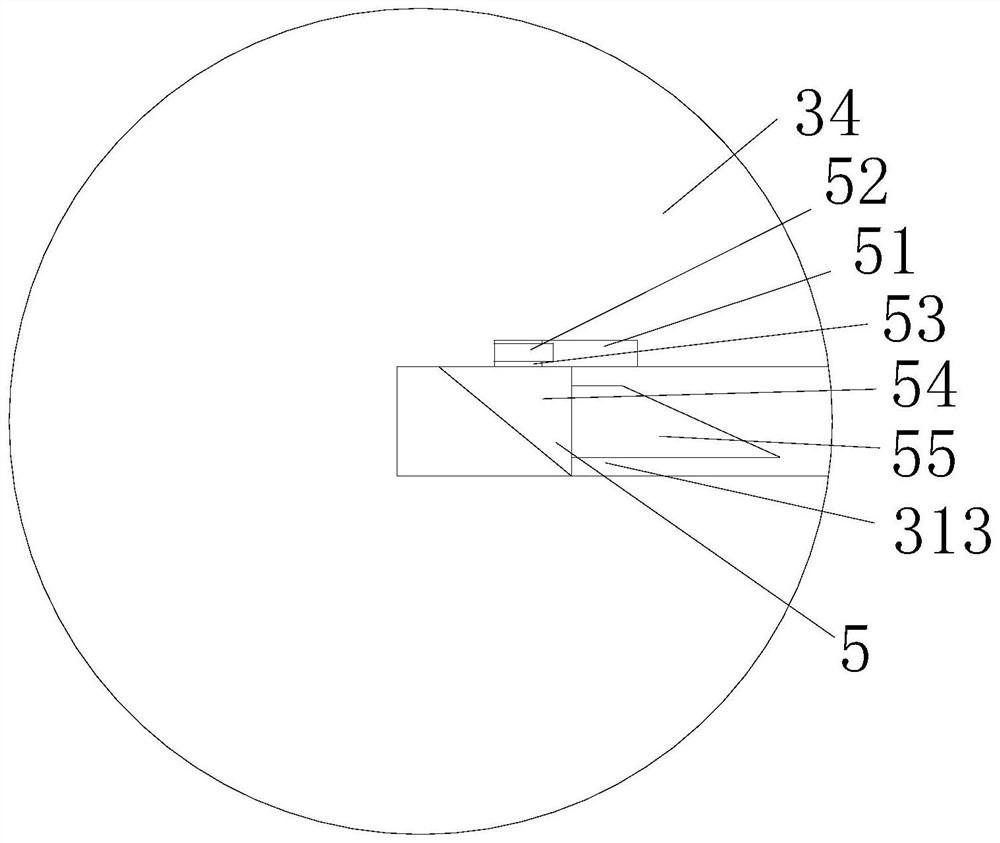

Adhesive tape sticking machine with pull-apart mechanism

PendingCN112896702AImprove pasting efficiencyGuaranteed paste effectLabelling machinesEngineeringStructural engineering

The invention discloses an adhesive tape sticking machine with a pull-apart mechanism. The adhesive tape sticking machine comprises a material storage wheel for storing an adhesive tape in a winding state, an adhesive tape sticking wheel, a movable wheel and the pull-apart mechanism; the adhesive tape led out from the material storage wheel is in contact with the adhesive tape sticking wheel, the adhesive tape of the adhesive tape sticking wheel is composed of release paper and a double-faced adhesive tape which are mutually attached to each other, and after the adhesive tape passes through the adhesive tape sticking wheel, the double-faced adhesive tape and the release paper are conveyed in different directions and are separated; the movable wheel is arranged between the adhesive tape sticking wheel and the material storage wheel along the conveying path of the adhesive tape, and the movable wheel and the adhesive tape sticking wheel are in contact with the front face and the back face of the adhesive tape correspondingly; the pull-apart mechanism comprises a trigger and a lever, the material storage wheel, the adhesive tape sticking wheel and the movable wheel are jointly and fixedly provided with a connecting plate, the trigger and the lever are movably assembled with the connecting plate through a first rotating shaft of the trigger and a second rotating shaft of the lever correspondingly, one end of the lever is connected with the trigger through a pull rod, and the other end of the lever is connected with the movable wheel; and along with swinging of the lever, the movable wheel has the freedom degree of getting close to or getting away from the of the adhesive tape sticking wheel. By means of the adhesive tape sticking machine, the adhesive tape pasting efficiency is improved, and the action coherence is high.

Owner:FARO AUTOMATION (SUZHOU) CO LTD

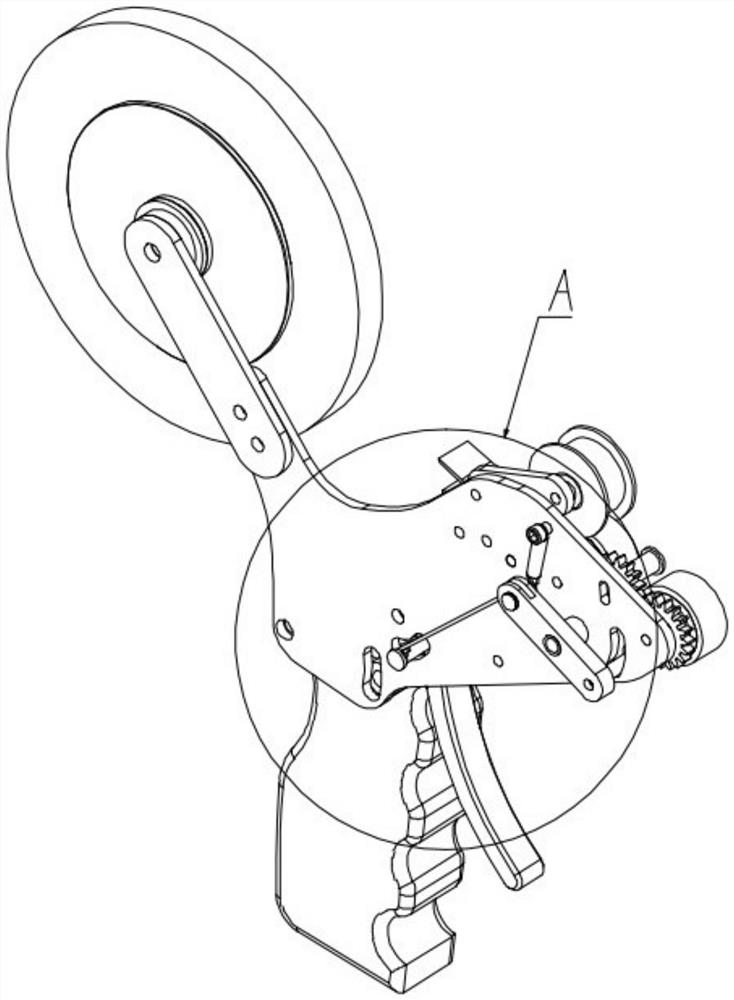

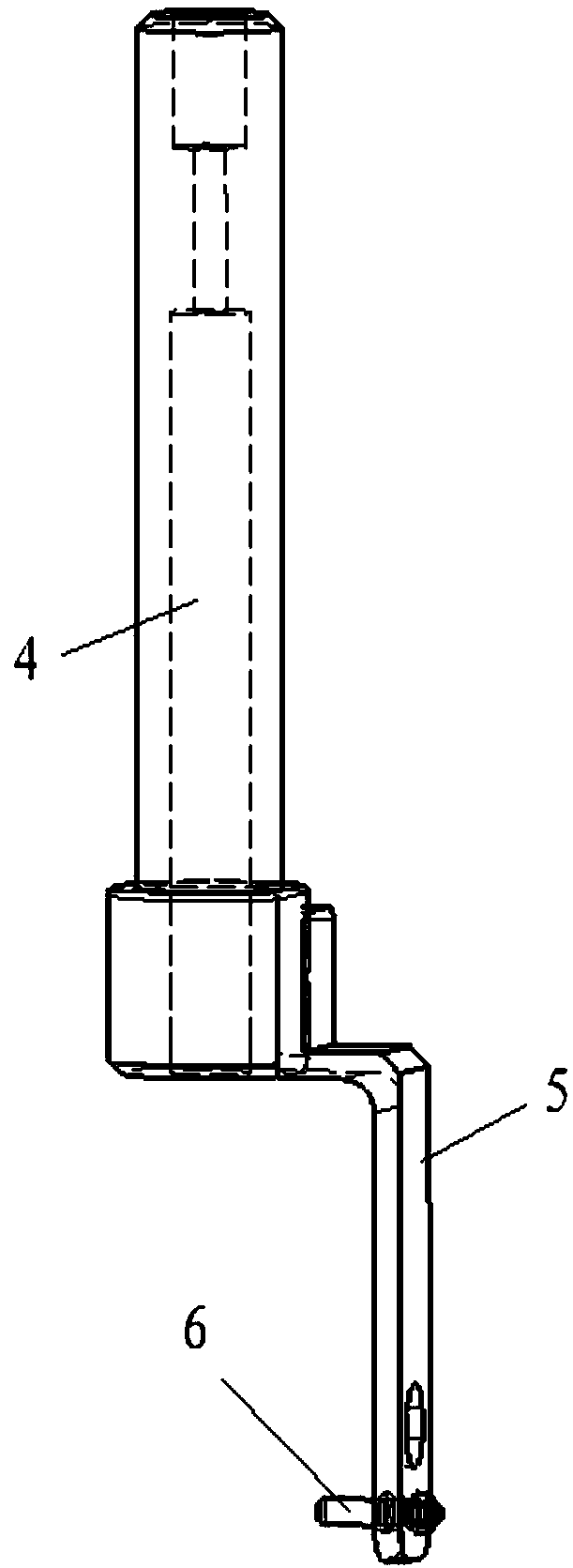

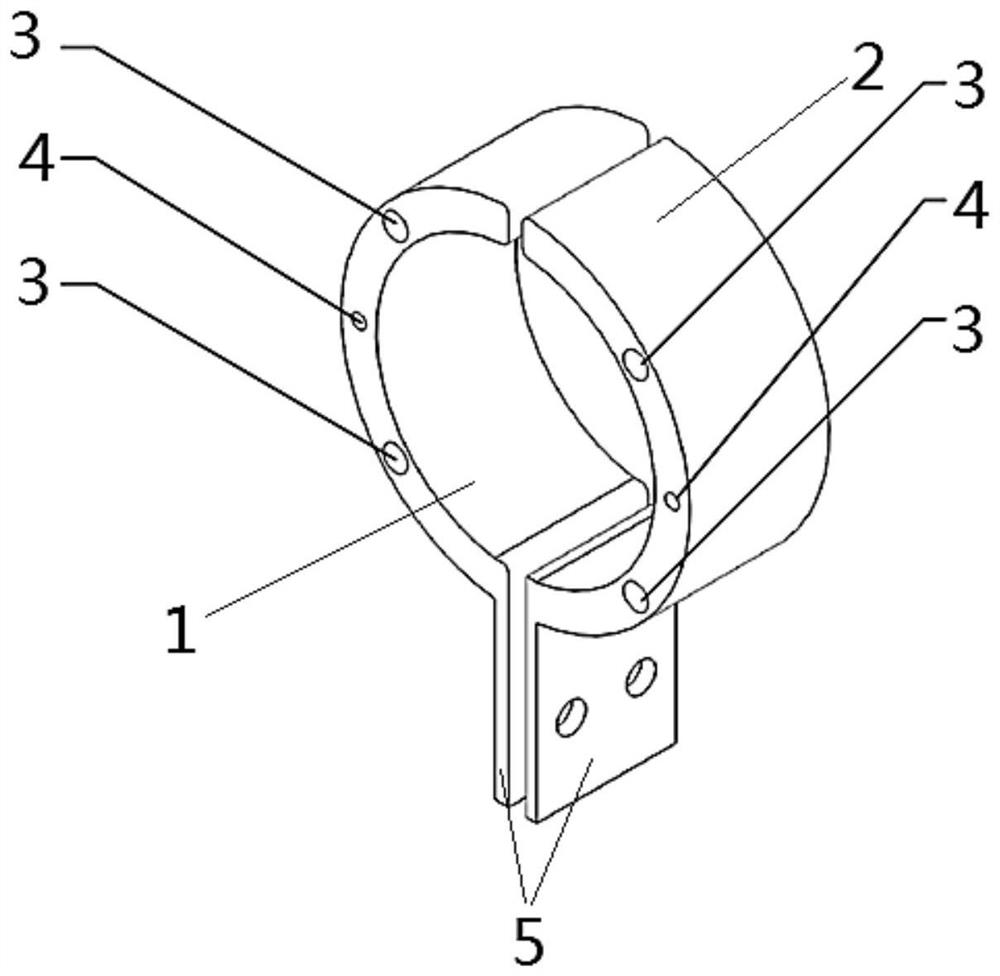

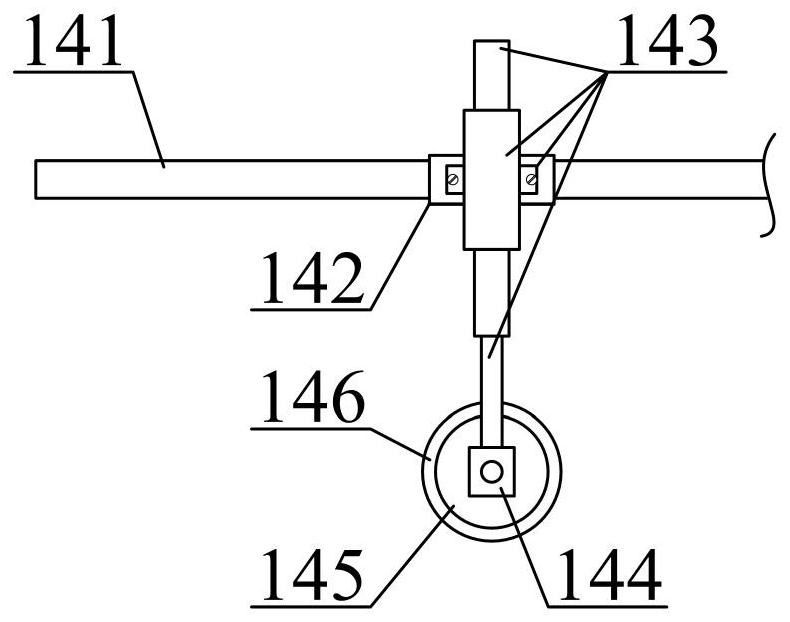

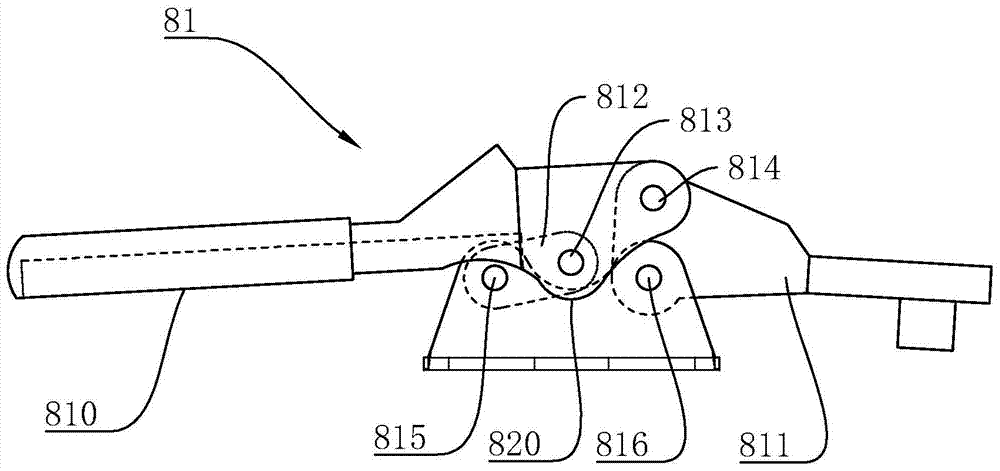

Rolling tool

InactiveCN108860881AGuaranteed paste effectLabelling machinesArticle deliveryEngineeringMechanical engineering

The invention discloses a rolling tool comprising a handle, a pressure adjusting part and a rolling part. The handle is internally provided with a cavity, a limiting bracket is arranged on the outer side of the handle and provided with a limiting pin; the pressing adjusting part is provided with an elastic device, the elastic device is sleeved with the cavity, one end of the elastic device is connected with a force-transferring rod, the force-transferring rod is slidably sleeved with the cavity, one end of the force-transferring rod stretches out of the cavity, and a mounting bracket is mounted on the extending part of the force-transferring rod; the rolling part is provided with a roller, the roller is mounted on the mounting bracket through a rotating shaft, and the rolling part is provided with a limiting gear coaxial with the rotating shaft; and the limiting pin moves between the first position and the second position relative to the limiting gear, at the first position, a limitingrod is clamped into the limiting gear, and at the second position, the limiting rod is disengaged from the limiting gear. According to the rolling tool, the minimum pressure can be limited, and the pasting effect of a vehicle body LOGO, a sealing strip and the like is ensured.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

A cardboard pasting mechanism

ActiveCN105538867BDry fastGuaranteed paste effectLamination ancillary operationsLaminationCardboardDrive motor

Owner:安徽新隆泰包装股份有限公司

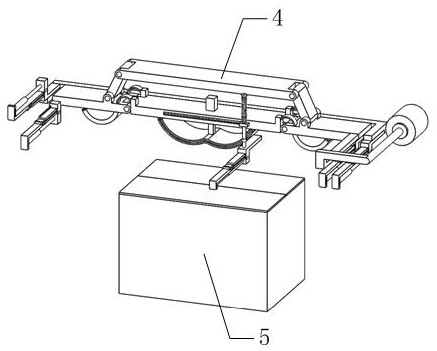

Packaging adhesive tape sealing equipment

ActiveCN113387010AFully automatedGuaranteed paste effectWrapper twisting/gatheringPackaging automatic controlCartonEngineering

The invention belongs to the technical field of adhesive tape sealing, and particularly relates to packaging adhesive tape sealing equipment, which comprises an electric push rod, a lifting mounting rod, a support and a packaging mechanism. By means of the designed equipment, automation of adhesive tape pasting is achieved, the labor cost is greatly reduced, and the efficiency is relatively high; in addition, an adhesive tape is pressed in the pasting process through a designed positive pressing elastic piece and a designed side pressing elastic piece while automatic pasting is achieved, and the pasting effect of the adhesive tape is guaranteed. After the adhesive tape is used, a stress signal of a sensor on a mounting rod disappears, a transverse plate of an upper pressing plate of a pressing anti-falling mechanism is tightly attached to a transverse plate of a pressing bottom plate, the adhesive tape is pressed, the remaining adhesive tape is pasted to a carton, then a non-pasting area is manually pasted, waste of the remaining adhesive tape which is not used for one time can be prevented, the adhesive tape corresponding to the pressing anti-falling mechanism needs to have a certain length, and if the adhesive tape is too short, the compression amount of a second spring is not enough, and the adhesive tape cannot be used.

Owner:HANGZHOU FUYANG HONGXIANG TECH SERVICES CO LTD

Construction method for adhering fiber cloth with underwater impregnated glue

InactiveCN112942889ASlow down the curing speedGuaranteed paste effectBuilding repairsFiberEngineering

The invention relates to a construction method for adhering fiber cloth with underwater impregnated glue. The construction method comprises the following steps of washing impurities on a base surface; using a rope for distinguishing the grinding range, removing marine organisms and a loose layer, grinding off edges and corners and the concrete surface, and repairing till smoothness is achieved; cutting the fiber cloth according to the size, and preparing two layers of plastic films; uniformly mixing the glue A and the glue B; coating a plastic film with the impregnating glue, covering the impregnating glue with fiber cloth, coating the fiber cloth with a layer of impregnating glue, slicking, covering the fiber cloth with a second layer of plastic film, wrapping the fiber cloth into a small roll, and immediately putting the roll into water for later use; and driving a constructor to the pasting position to tear off the plastic film, placing one end of the fiber cloth right and slowly rolling towards the other end along the rope, scraping and pressing through a scraping plate in the filament direction, and tearing off the outer-layer plastic film one day after the fiber cloth is pasted. According to the construction method, the problems that according to an existing construction method, the accuracy of the carbon cloth pasting position is difficult to guarantee, the construction time is short, and the base plane reinforcing effect is easily affected can be effectively solved.

Owner:南京曼卡特科技有限公司

Manufacturing process of high-reliability heat-conducting adhesive tape for electronic component

PendingCN112500806AImprove thermal conductivityImprove anti-static effectNon-macromolecular adhesive additivesFilm/foil adhesive primer layersThermal adhesiveSilicone tape

The invention discloses a manufacturing process of a high-reliability heat-conducting adhesive tape for an electronic component. The manufacturing process comprises the following steps: (1) preparinga base material layer; (2) coating an anti-static layer on the bonding surface of the base material layer, and drying; (3) coating the anti-static layer with the prepared adhesive solution containingthe adhesion promoter to obtain a thermal bonding layer, and uniformly paving a plurality of graphite particles on the surface of the thermal bonding layer; (4) pressing a plurality of graphite particles into the thermal bonding layer to form a plurality of grooves for accommodating the graphite particles on the surface of the thermal bonding layer, and drying; and (5) finally, pasting a release material layer on the surface of the thermal bonding layer to obtain the heat-conducting adhesive tape. The process mainly aims at the characteristic that heat and static electricity coexist in an electronic device, the manufactured adhesive tape can have excellent heat conductivity and excellent anti-static performance at the same time, the bonding strength of the contact strength of the adhesivetape and the electronic device can be kept for a long time, and the stability of the heat dissipation performance is achieved.

Owner:东莞市哲华电子有限公司

High-strength stone binder as well as preparation method and application thereof

InactiveCN110564306AGuaranteed paste effectImprove interfacial bond strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseSilicon oxide

The invention discloses a high-strength stone binder which comprises the following components: 30-60 parts of dispersible rubber powder; 2-5 parts of cellulose ether; 0.5 to 2 parts of starch ether; 1-5 parts of a water reducing agent; 10 to 15 parts of organic silicon powder; 10 to 15 parts of nanometer silicon oxide; 300 to 700 parts of cement; and 300 to 700 parts of sand. The high-strength stone binder has good impermeability, water resistance and aging resistance with guaranteed stone binding effect; the probability of occurrence of common problems such as hollowing and falling can be reduced by 10-34%; the probability of occurrence of lesion problems such as water spots, efflorescence, re-rusting and greening can be reduced by 20-40%; and the cost of production enterprises and construction enterprises is greatly reduced.

Owner:GOLD MANTIS CONSTR DECORATION

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253BHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsRubber materialPolymer science

Owner:杨太龙

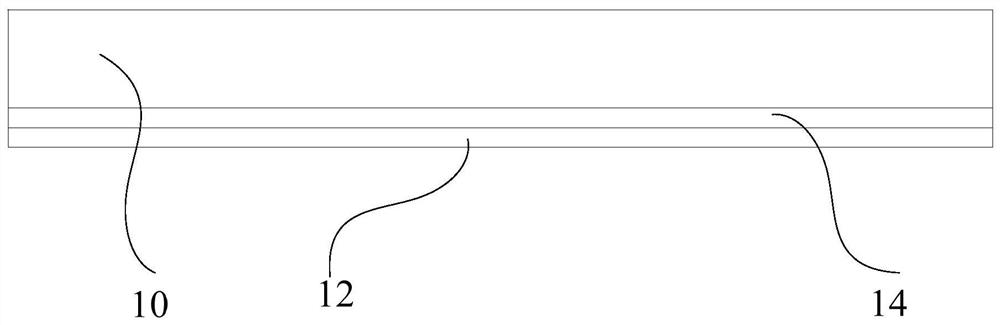

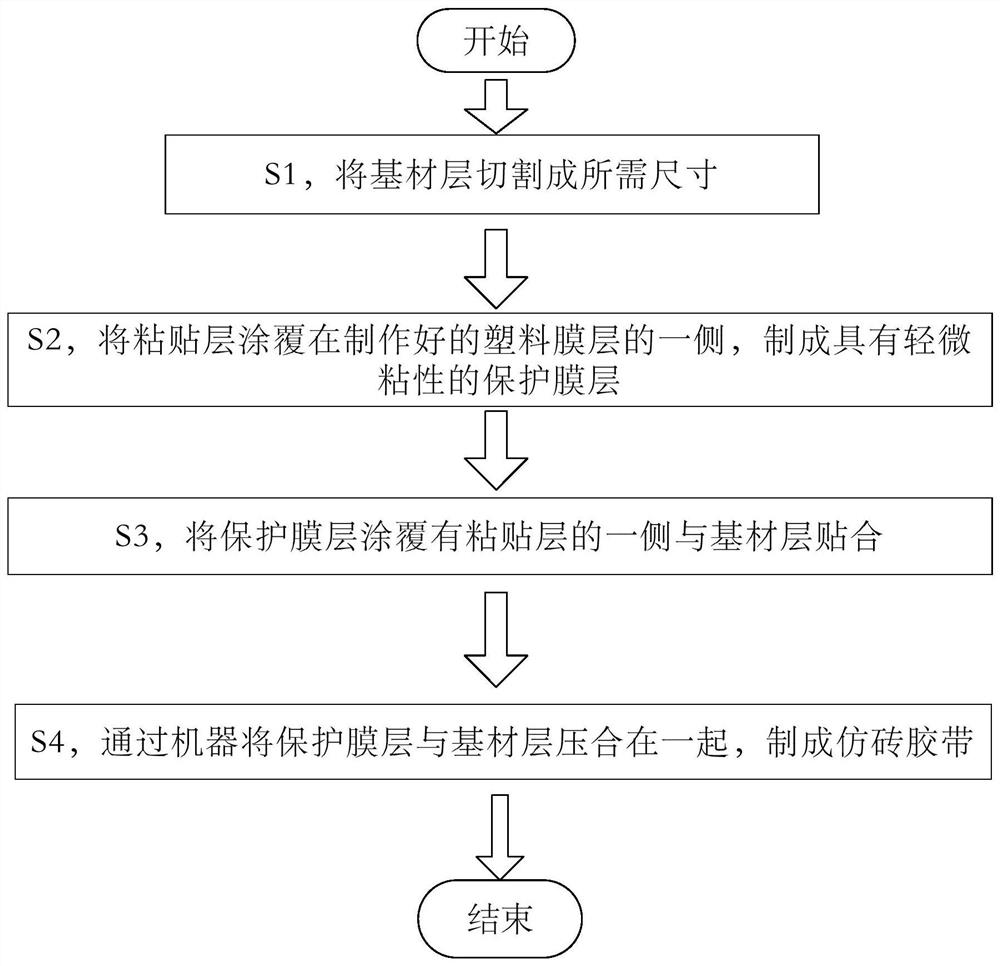

Brick-imitating adhesive tape

PendingCN112126361AQuick decorationEasy to manufactureFilm/foil adhesivesUnsaturated alcohol polymer adhesivesAdhesive beltPlastic film

The invention provides a brick-imitating adhesive tape, which is prepared by the steps of S1, cutting a base material layer into a required size to meet the use requirements of customers so as to facilitate sticking; S2, coating one side of a manufactured plastic film layer with a bonding layer to manufacture a protective film layer with slight viscosity so as to facilitate direct combination of the plastic film layer and the base material layer; S3, attaching the side, which is coated with the bonding layer, of the protective film layer to the base material layer to form the brick-imitating adhesive tape so as to facilitate decoration of a wall body; and S4, laminating the protective film layer and the base material layer together through a machine so as to increase the adhesion degree between the plastic film layer and the base material layer of the brick-imitating adhesive tape, thereby avoiding the problem that the base material layer loses the viscosity due to falling of the plastic film layer. The bonding layer is directly coated on the surface of the plastic film layer, and then the plastic film layer is directly attached to the base material layer, so that the operation steps of sticking on the base material layer for many times, cutting the bonding layer and the like are replaced, the production cost is reduced, and the production cost does not exceed the budget.

Owner:沈阳德鑫包装材料有限公司

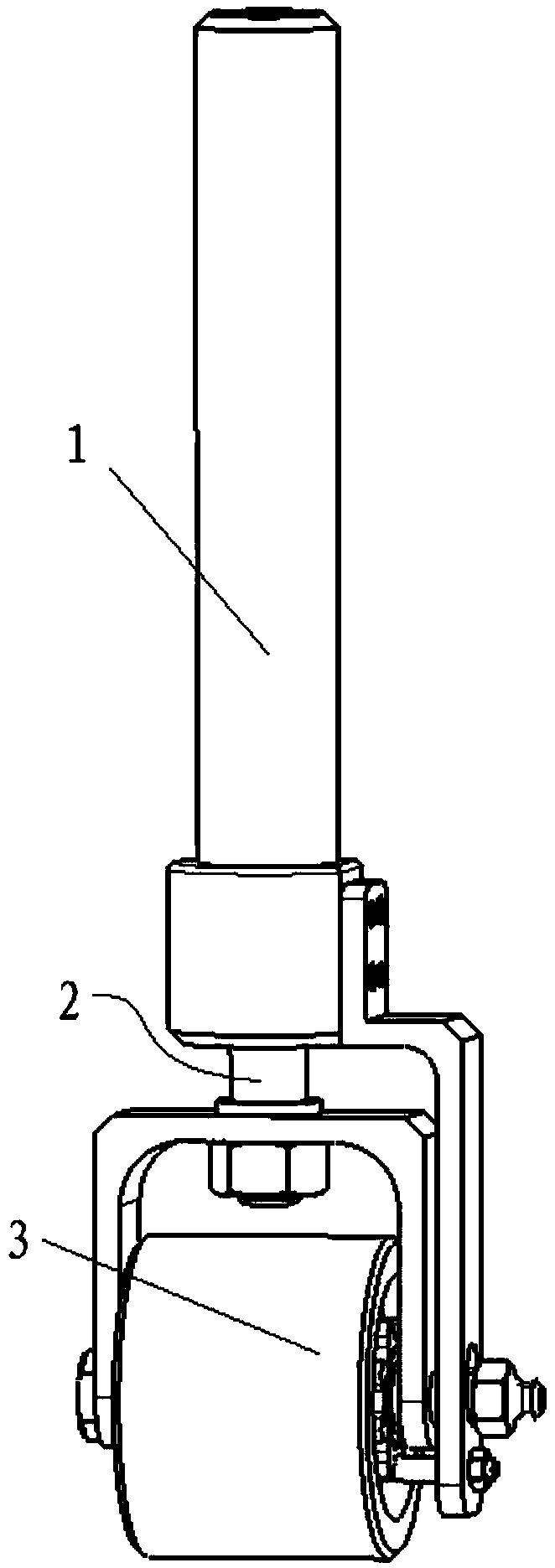

Glue supply temperature control device of cigarette making machine

ActiveCN114868959ASolve temperature instabilityGuaranteed paste effectLiquid surface applicatorsCigarette manufactureTemperature controlElectric control

The invention discloses a cigarette making machine glue supply temperature control device, the main design concept of the device is that the device is composed of a heating assembly, a pneumatic assembly and an electric control assembly, specifically, the heating assembly comprises a first heating ring and a second heating ring, the two heating rings are annularly arranged on the periphery of a glue supply pipe after being closed, and the pneumatic assembly is arranged on the periphery of the glue supply pipe; a heating pipe and a temperature detection component are arranged in the heating ring body; the pneumatic assembly comprises a shifting air cylinder and a moving mechanism, the moving mechanism is connected with the extending part on the heating ring body, and the shifting air cylinder drives the two heating rings to be separated or closed; the electric control assembly is electrically connected with the heating pipe, the temperature detection part and an electric control valve of the displacement air cylinder and used for triggering the heating function of the glue supply pipe to start and stop and regulating and controlling the heating temperature according to the set temperature. The problem of unstable glue temperature caused by glue supplement can be effectively solved, so that the cigarette bar pasting effect is guaranteed, and the cigarette production quality is remarkably improved.

Owner:CHINA TOBACCO HENAN IND

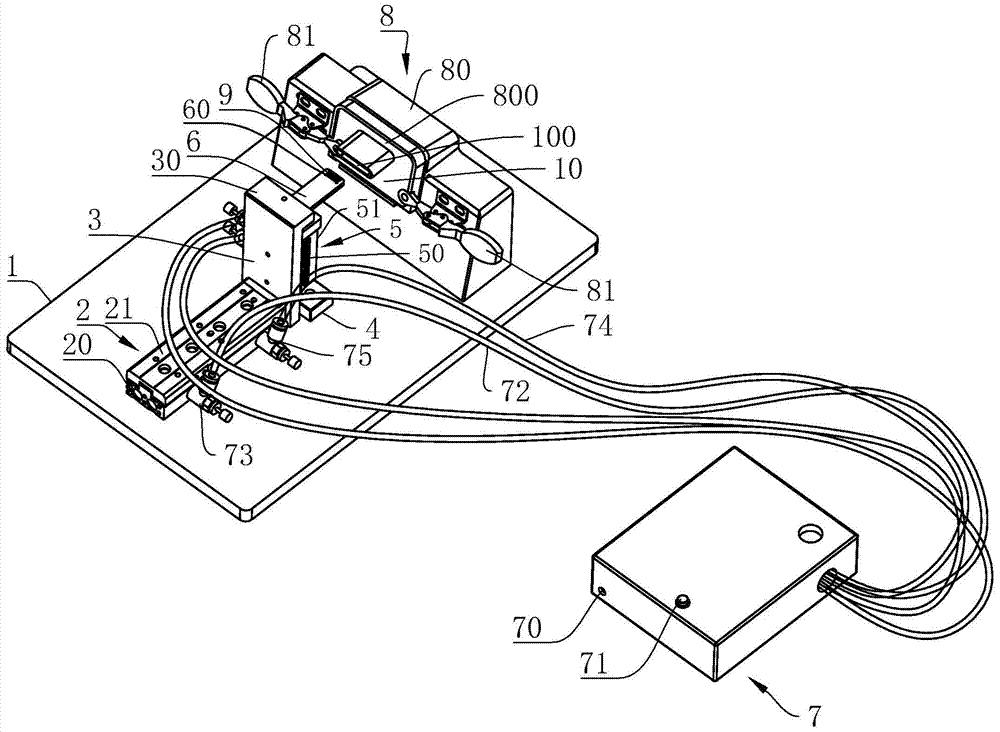

A detection device for coated glass

ActiveCN112798528BEasy to operateGuaranteed detection stabilityOptically investigating flaws/contaminationBolt connectionLimit switch

The invention provides a detection device for coated glass, which includes a frame, support legs, baffles, stand, beams, limit switches, control box, host, alarm, detection board, power emitter probe and power receiver For the probe, the four corners of the bottom of the rack are bolted to support legs; Bolted connections have baffles. According to the setting of adjustable pull rod, fixed sleeve, square head bolt, adjustment cap, clamping seat, clamping plate, clamping bolt and anti-damage block according to the length and thickness of the coated glass, loosen the square head bolt and hold the adjustment cap Adjust the position of the adjustable pull rod inside the fixed sleeve, loosen the clamping bolts, place the coated glass between the clamping seats and between the clamping plates, drive the anti-injury block to rotate through the clamping bolts, clamp the coated glass Tighten, and finally lock the lag bolts, and the detection operation can be carried out.

Owner:莱芜连云玻璃股份有限公司

The method used to paste parts on the inner wall of the product

ActiveCN105485111BAchieve precise pastePrecise paste solutionServomotor componentsMaterial gluingEngineeringAutomation

The invention relates to a device for pasting a part on the inner wall of a product. The device comprises a base. A horizontally-arranged first air cylinder is arranged on the base. A sliding part of the first air cylinder is connected with a vertical connecting plate. A limiting part is arranged on the vertical connecting plate. A limiting block is arranged on the opposite side, far away from the first air cylinder, of the vertical connecting plate. A vertically-arranged second air cylinder is arranged at the position, below the limiting part, of the vertical connecting plate. A sliding part of the second air cylinder is connected with a carrier plate. A containing groove is formed in the carrier plate. A product fixing structure is arranged on the side, opposite to the carrier plate, of the base. The device is high in pasting precision, good in pasting effect and high in operation automation degree, and time and labor are saved.

Owner:GOERTEK INC

Wall surface wallpaper rapid pasting device for decoration

The invention relates to the technical field of decoration equipment, and discloses a wall surface wallpaper rapid pasting device for decoration. The device comprises a plate body, a side plate is fixedly connected to the rear end of the plate body, a side groove is formed in the side plate, a pushing and pressing mechanism is arranged in the side groove, and the pushing and pressing mechanism comprises a pressing wheel, a rotating column and a round roller. According to the wall surface wallpaper rapid pasting device for decoration, by arranging the pushing and pressing mechanism and a cutting mechanism, when a user straightens wallpaper, a control rod is rotated, a short rod is driven to enable a push plate to rotate, the push plate rotates to drive a warping plate to extrude and push an inclined block and a tool bit at the same time, the tool bit transversely cuts off the straightened wallpaper, meanwhile the control rod is controlled to move a pressing wheel to the front side of the wallpaper, and the control rod drives the pressing wheel to roll up and down so as to press the wallpaper and the wall surface, so that the wallpaper is firmly adhered to the wall surface, meanwhile, the wallpaper can be quickly cut and pasted through the cooperation of the pushing and pressing mechanism and the cutting mechanism, and the wallpaper pasting efficiency of a user is improved.

Owner:陆水龙

An assembled wallpaper laminating machine

The invention provides a split mounting type wallpaper laminator. The split mounting type wallpaper laminator comprises a base. Wheels capable of being locked are arranged under the base, a primary supporting assembly is arranged on the base, the primary supporting assembly comprises two vertically arranged vertical columns, each column is composed of multiple sections of steel tubes which are spliced, a mounting plate is arranged at the bottom of each column, and the mounting plate can slide and can be locked on the base to adjust the distance between the two vertical columns; a lifting assembly is arranged on the columns, a lifting and locking mechanism is arranged on the lifting assembly, a wallpaper paving assembly is also arranged on the lifting assembly, a wallpaper compression assembly is arranged above the wallpaper paving assembly, and a compression force adjusting mechanism is arranged below the wallpaper compression assembly. Debugging equipment can be assembled quickly by way of site splicing, so that the split mounting type wallpaper laminator is extremely convenient to carry and use, can fit wallpaper of nearly all width dimensions, and is high in universality.

Owner:黄山市亿华装饰材料有限公司

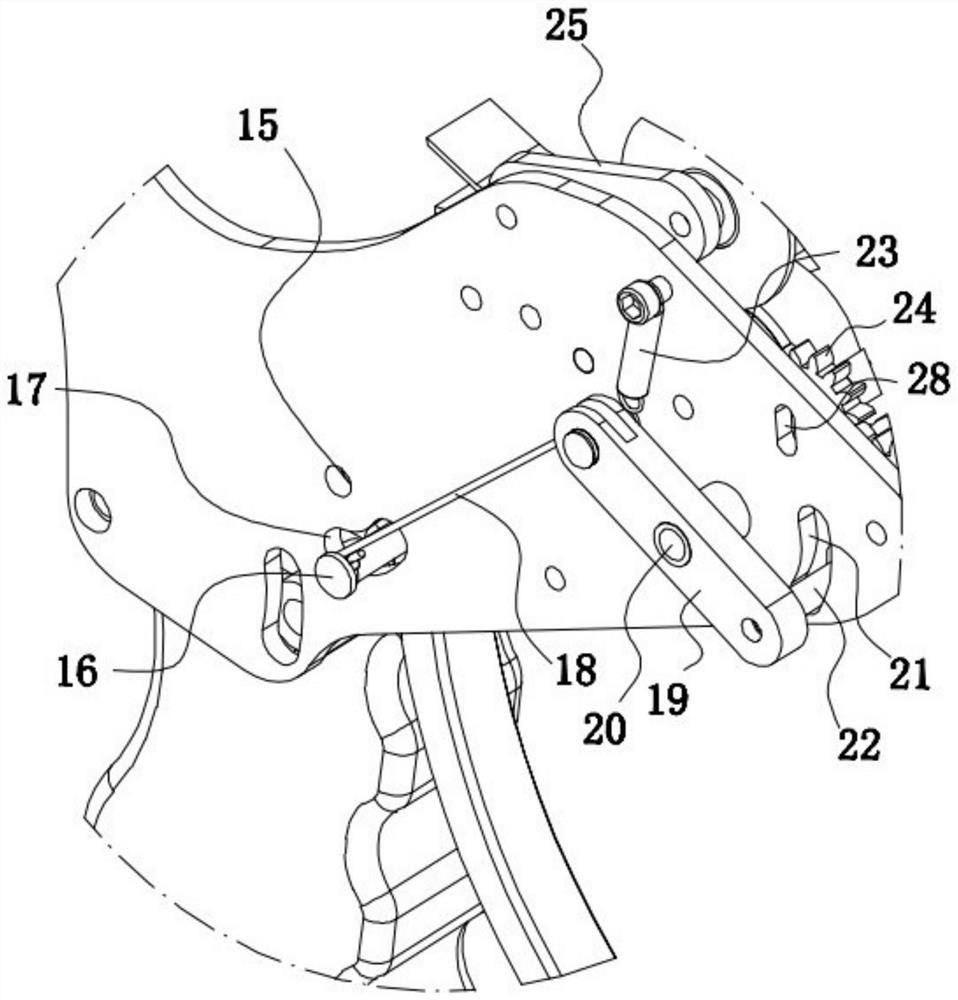

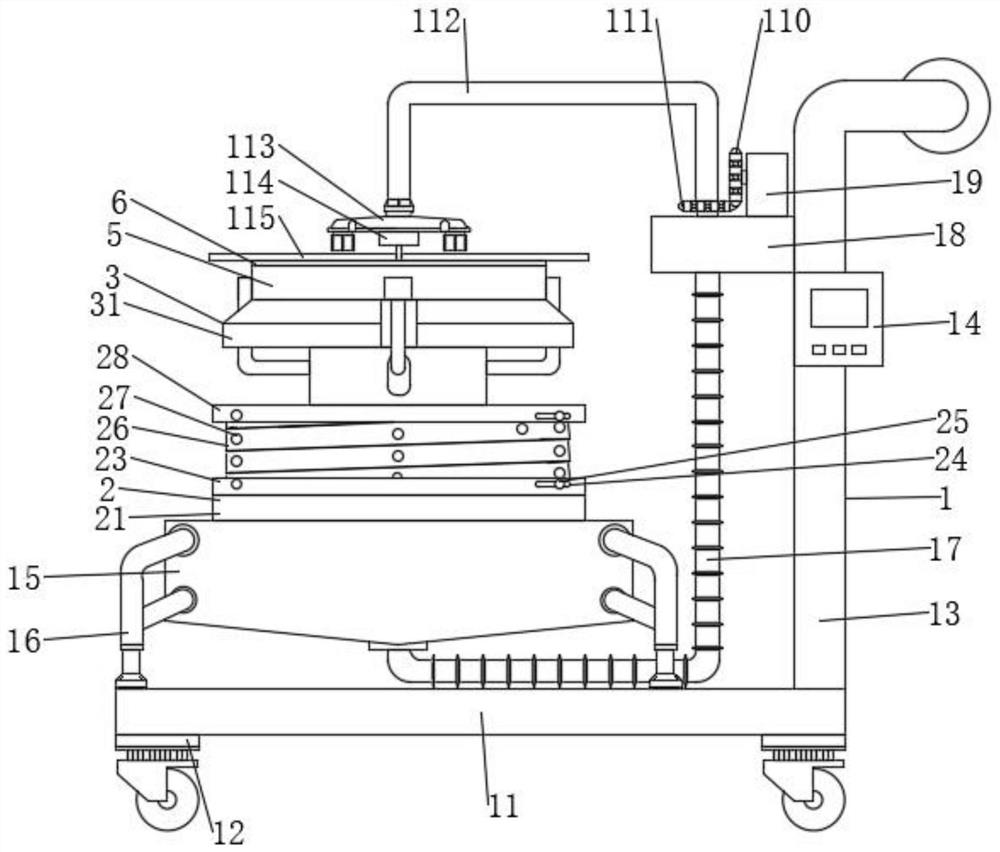

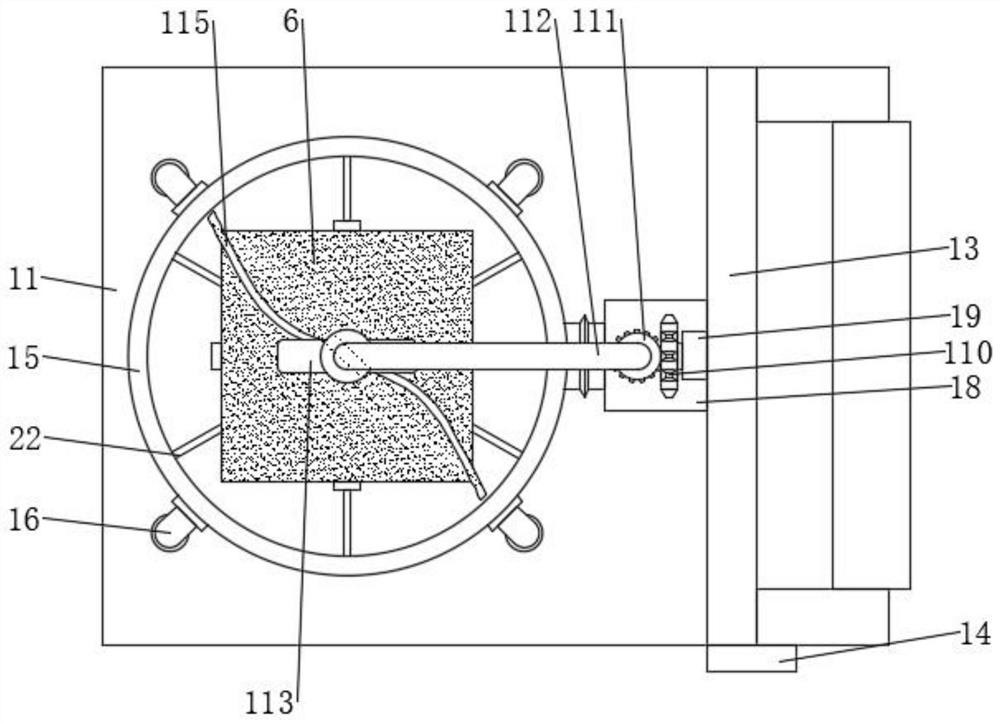

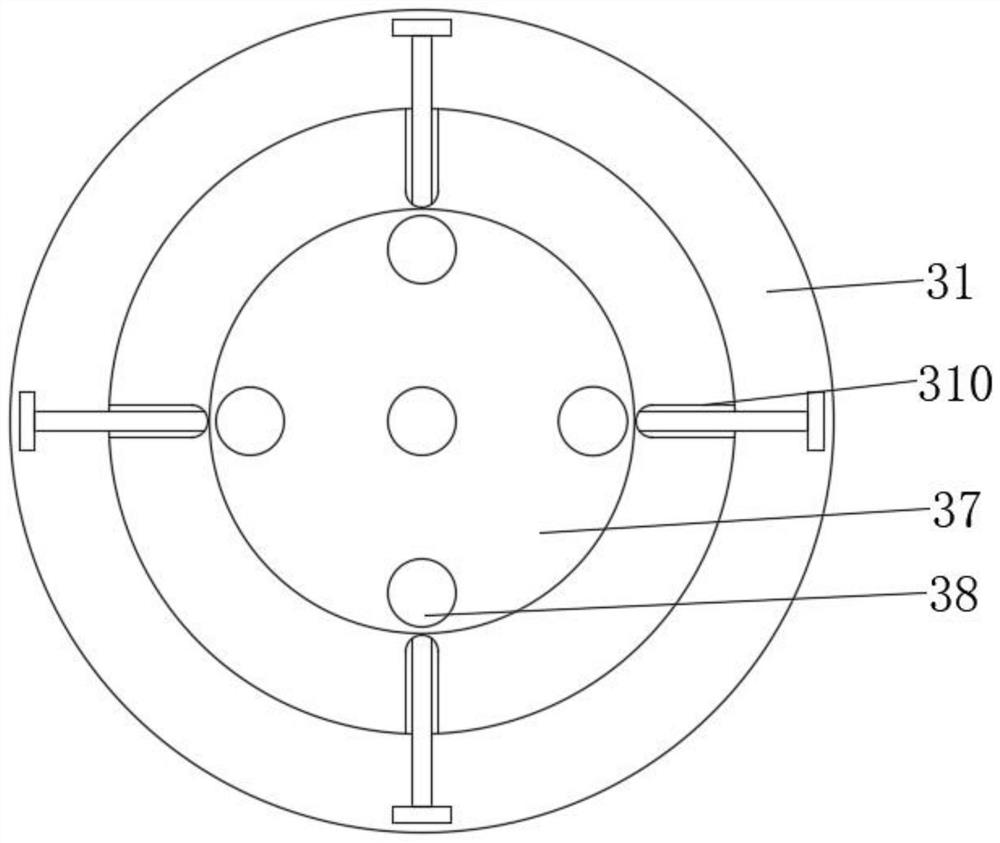

Automatic tiling equipment for high-rise building construction

InactiveCN113006433AGuaranteed paste effectAchieve reuseBuilding constructionsGear wheelArchitectural engineering

The invention relates to the technical field of building construction, in particular to automatic tiling equipment for high-rise building construction. The equipment comprises a tiling device body; the tiling device body comprises a vehicle plate; universal wheels are mounted on the left side of the bottom surface of the vehicle plate; a push rod is fixedly mounted at the right end of the top surface of the vehicle plate; a controller is mounted on the front surface of the push rod; a cement cylinder is installed at the left end of the top face of the vehicle plate; supporting legs are welded to the side face of the cement cylinder; a through pipe is installed on the bottom face of the cement cylinder; a supporting plate is fixedly installed on the left side face of the push rod; a first motor is installed on the top face of the supporting plate; a first gear is installed on the left side face of the first motor; and a second gear is mounted on the left side of the first gear. According to the automatic tiling equipment for high-rise building construction, cement can be automatically and evenly smeared on the back faces of tiles, the tile pasting effect is guaranteed, meanwhile, redundant cement is recycled, raw materials are saved, and the use range of the equipment can be widened by adjusting the height.

Owner:严静摇

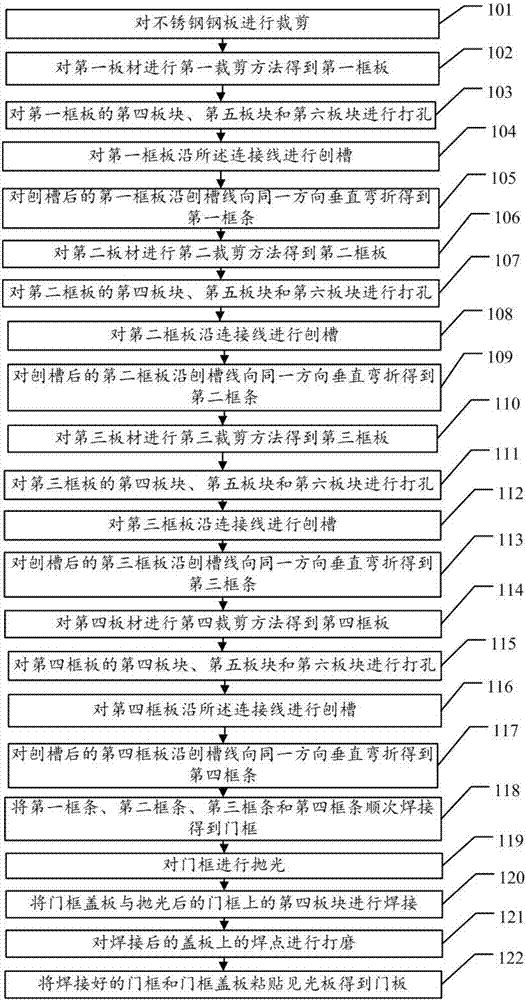

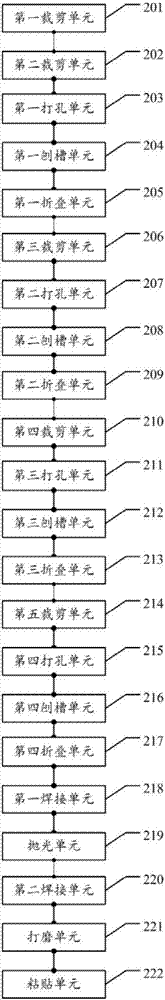

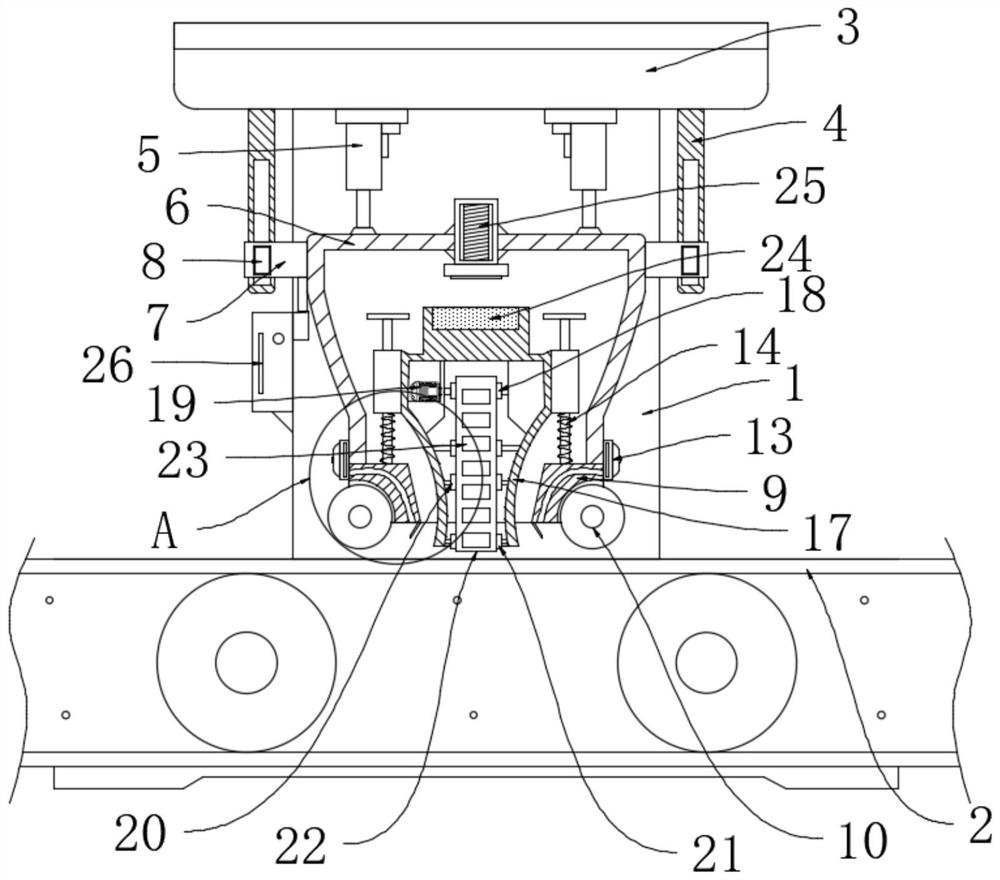

Method and system for processing glass door panels

The invention discloses a glass door plank machining method and system and provides a manufacturing technique of a frameless stainless steel glass door plank. The machining technique for manufacturing a frameless glass door plank through stainless steel and the 45-degree splicing manufacturing technique are achieved. The glass door plank machining method comprises the steps that S1, a stainless steel plate is cut, and a first plate, a second plate, a third plate and a fourth plate are obtained; S2, a first cutting method is conducted on the first plate, a first frame plate is obtained, and the first frame plate comprises a first board, a second board, a third board, a fourth board, a fifth board and a sixth board; S3, the fourth board, the fifth board and the sixth board of the first frame plate are punched; S4, dadoing is conducted on the first frame plate along connection lines; and S5, the first frame plate subjected to dadoing is bent perpendicularly along a dadoing line in the same direction, and a first frame strip is obtained.

Owner:沈奕荣

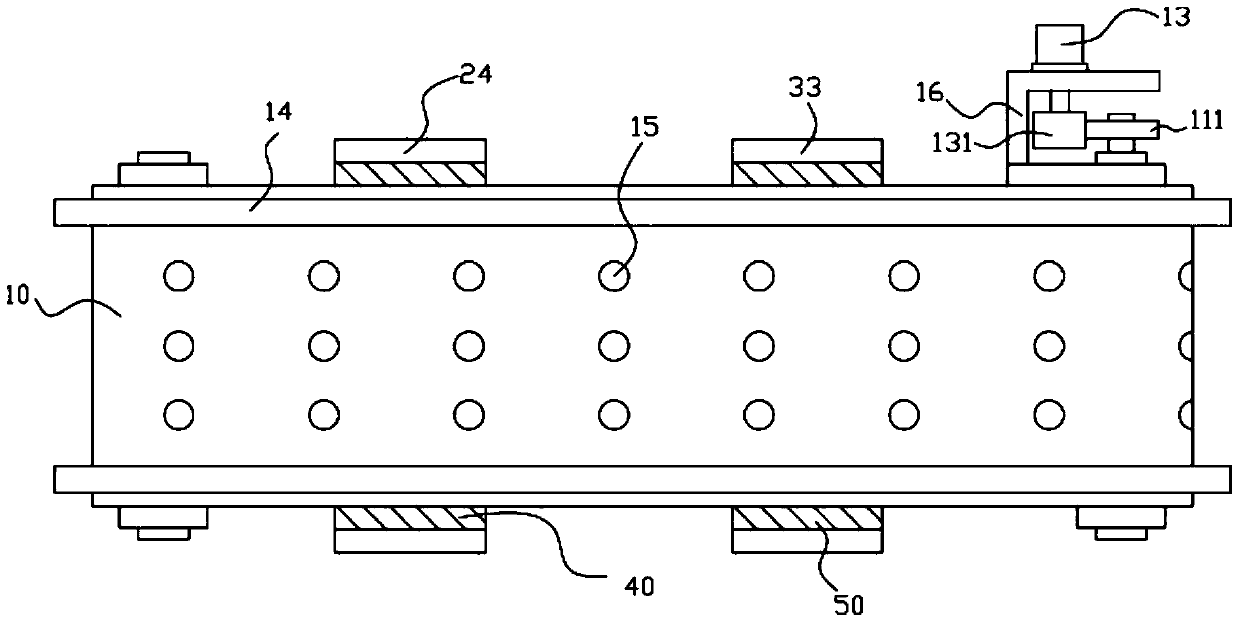

Garment sample labeling machine

ActiveCN112046882AQuick levelingImprove visibilityLabelling deformable materialsLabelling machinesStructural engineeringMechanical engineering

The invention relates to the technical field of garment processing, in particular to a garment sample labeling machine. The garment sample labeling machine comprises a support; a conveying belt is installed on the support, a top plate is fixedly installed on the support, a sliding rail is fixedly installed on the top plate, a hydraulic rod is fixedly installed on the top plate, a movable frame isfixedly connected to the hydraulic rod, a wing plate is fixedly installed on the movable frame, rolling wheels are rotatably installed on the wing plate, a base is fixedly installed on the movable frame, extension wheels are rotatably installed on the base, an air groove is formed in the base, a guide plate and a fan are fixedly installed on the base, and a sliding rod is fixedly installed on thebase. Labels are pasted through a driving roller wound with the release paper, a supporting roller and a pasting roller, the movable frame is provided with the double-reforming flattening structure, rapid local flattening of garments is conducted, and then the pasting roller pastes the labels on the local parts of leveled garments, so that the labels are is effectively prevented from being pastedon wrinkles.

Owner:四川九五一七实业有限公司

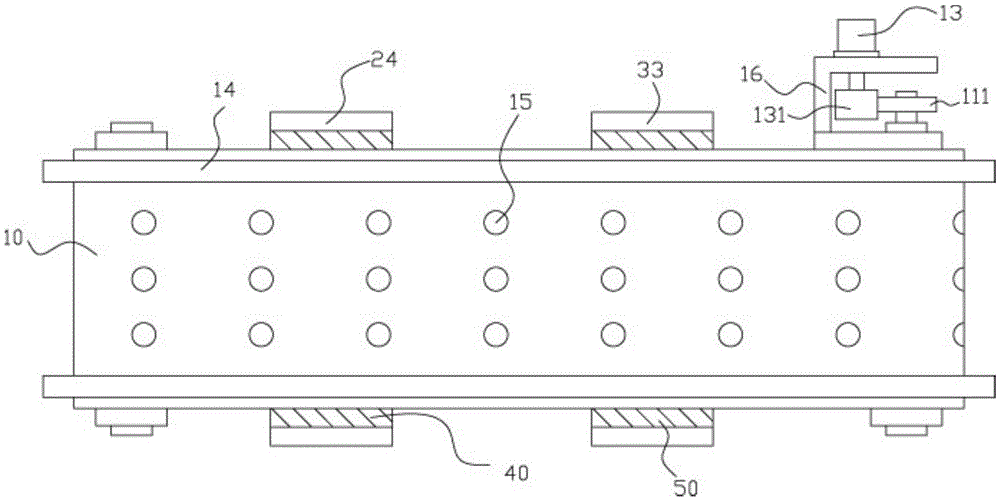

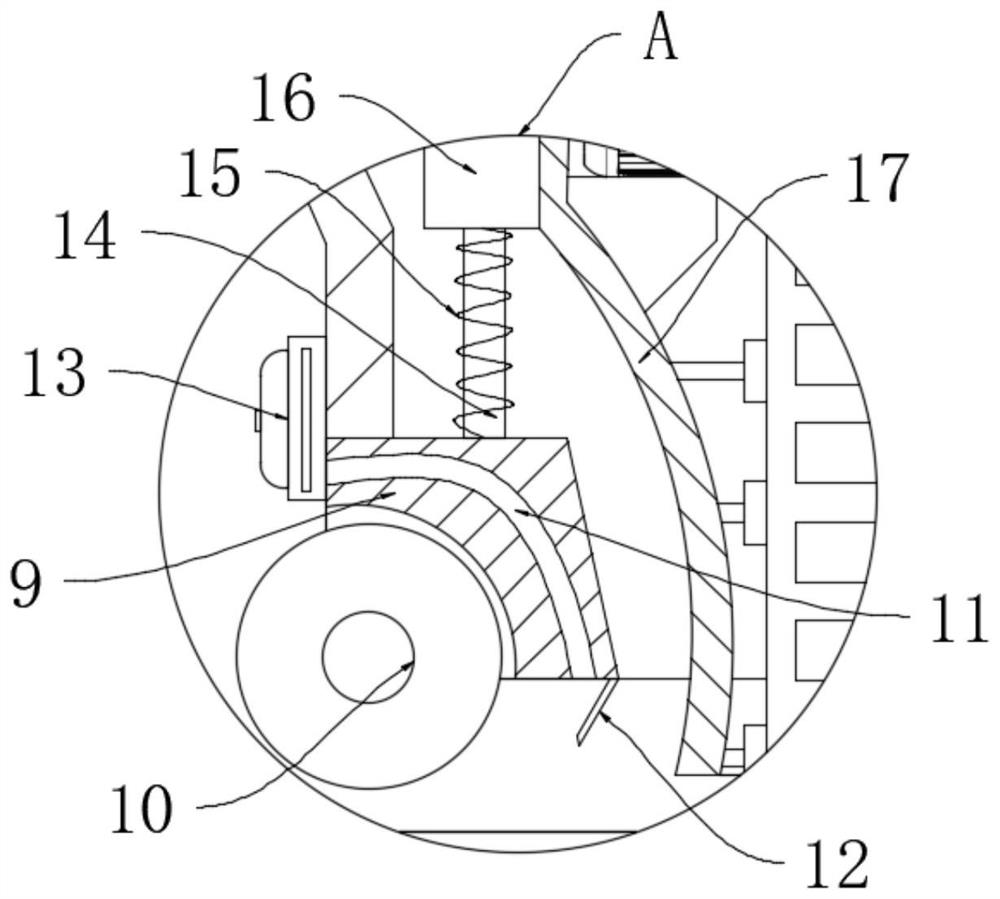

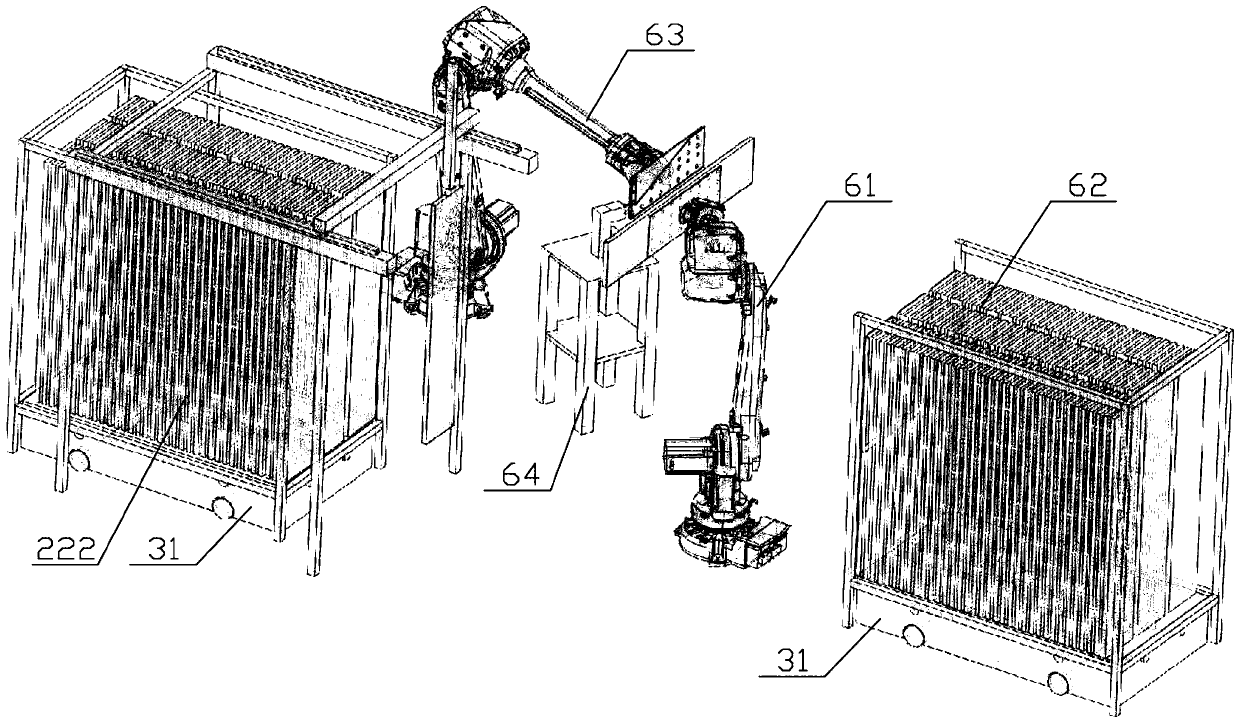

A kind of sponge unit automatically sticking the sheet metal parts of two air conditioners and using method thereof

ActiveCN105526220BAutomatic paste implementationAvoid the defects of manual peelingMaterial gluingConveyor partsAdhesion processManipulator

The invention discloses an automatic sponge adhesion unit for sheet metal parts of evaporators and condensers of air conditioners and a use method thereof. The automatic sponge adhesion unit comprises a sheet metal part grabbing device (61), a sponge component bracket (62), a sponge component grabbing device (63), a locating film stripping device (64) and an electronic control component; the sheet metal part grabbing device and the sponge component grabbing device comprise mechanical arms and grabbing and stacking manipulators; the locating film stripping device is arranged between the sheet metal part grabbing device and the sponge component grabbing device and comprises a supporting frame and a film stripping and clamping manipulator, wherein the film stripping and clamping manipulator is fixedly installed at the top end of the supporting frame. According to the automatic sponge adhesion unit for the sheet metal parts of the evaporators and the condensers of the air conditioners, automatic film stripping and automatic adhering are realized through the movement of the sponge component grabbing device relative to the locating film stripping device and the sheet metal part grabbing device, the automation degree is high, intelligent operation can be realized, the production efficiency is high, and the unit is especially suitable for the automatic sponge adhesion process of the sheet metal parts of the evaporators and the condensers of the air conditioners of digital bus factories.

Owner:XUZHOU DKEC ELECTRICAL TECH

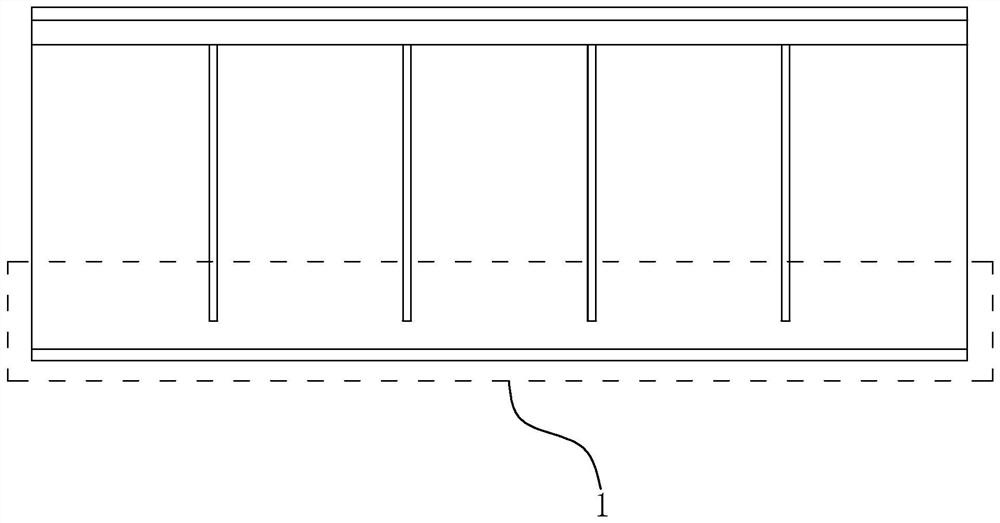

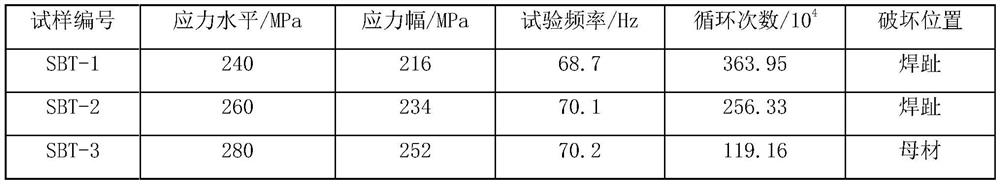

Method for improving fatigue performance of steel plate and butt-welded joint

ActiveCN112251596AImprove pasting effectQuality improvementLamination ancillary operationsLaminationFatigue damageButt welding

The application relates to the field of material surface strengthening, in particular to a method for improving the fatigue performance of a steel plate and a butt-welded joint. The method comprises the following steps: step A, ultrasonic impact treatment: firstly, carrying out impact treatment on a weld toe part of a welded joint of the steel plate by using an ultrasonic impact head, and then carrying out full-coverage impact treatment on the welded joint; and step B, CFRP reinforcing treatment: after ultrasonic impact treatment of the weld joint of the steel plate is completed, performing CFRP reinforcing treatment on the steel plate and the weld joint, which includes surface treatment, glue treatment and pasting and surface reinforcing. According to the application, ultrasonic impact treatment is conducted on the welded joint, then CFRP reinforcing treatment is conducted on the welded joint and the steel plate, fatigue crack development is delayed in the microcrack stage and the macrocrack propagation stage before fatigue damage, and the fatigue performance of the joint is comprehensively improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Sticking film group, and magic tape and children teaching aid manufactured from same

PendingCN111793446AAppropriate paste strengthGuaranteed paste effectFilm/foil adhesives without carriersTeaching apparatusPolymer scienceAdhesive

The invention discloses a sticking film group, and a magic tape and a children teaching aid manufactured from the same. The sticking film group comprises an adhesive layer, a supporting layer, an adhesive force enhancing layer and a printing layer which are stacked in sequence; the adhesive force enhancing layer is an organic silicon modified high polymer film layer; and the supporting layer is aPP film or a PET film. Under the interaction of the adhesive layer, the supporting layer and the adhesive force enhancing layer which are stacked in sequence, the sticking film group is adhered to thesubstrate; the sticking film group has proper adhesive strength, so that the adhesive effect and the service life of the sticking film group are ensured, the sticking film group is easy to peel off and reuse, adhesive is not easy to remain after the sticking film group is peeled off from an adhesive surface, and the sticking film group has high application value and is particularly suitable for preparing teaching aids and the like.

Owner:上海想印就印印刷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com