Patents

Literature

30results about How to "Realize civilized construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightly calcined dolomite thermal insulation mortar

InactiveCN102070320ALow costIncrease the use of functionsSolid waste managementCeramicwareThermal insulationPolystyrene

The invention relates to lightly calcined dolomite thermal insulation mortar, which comprises the following components in part by weight: 20 to 60 parts of lightly calcined dolomite, 1 to 60 parts of flyash, 5 to 35 parts of retarding agent, 1 to 40 parts of strengthening and thickening agent, 1 to 20 parts of kieselguhr, 5 to 35 parts of expanded aggregate, 0.5 to 5 parts of polystyrene foam particle, 0.01 to 0.2 part of polypropylene fiber, 0.5 to 8 parts of water resistance additive, and 0.05 to 2 parts of water reducer. The thermal insulation mortar has the advantages of excellent thermal insulation property, good compression strength, freezing resistance and water resistance, good volume stability, low production cost, energy conservation, environmental friendliness and the like. The construction process is simple; and after construction, the lightly calcined dolomite thermal insulation mortar is not hollowed or cracked, and is particularly suitable for a thermal insulation material for building walls.

Owner:内蒙古祥响新型建材开发有限责任公司 +2

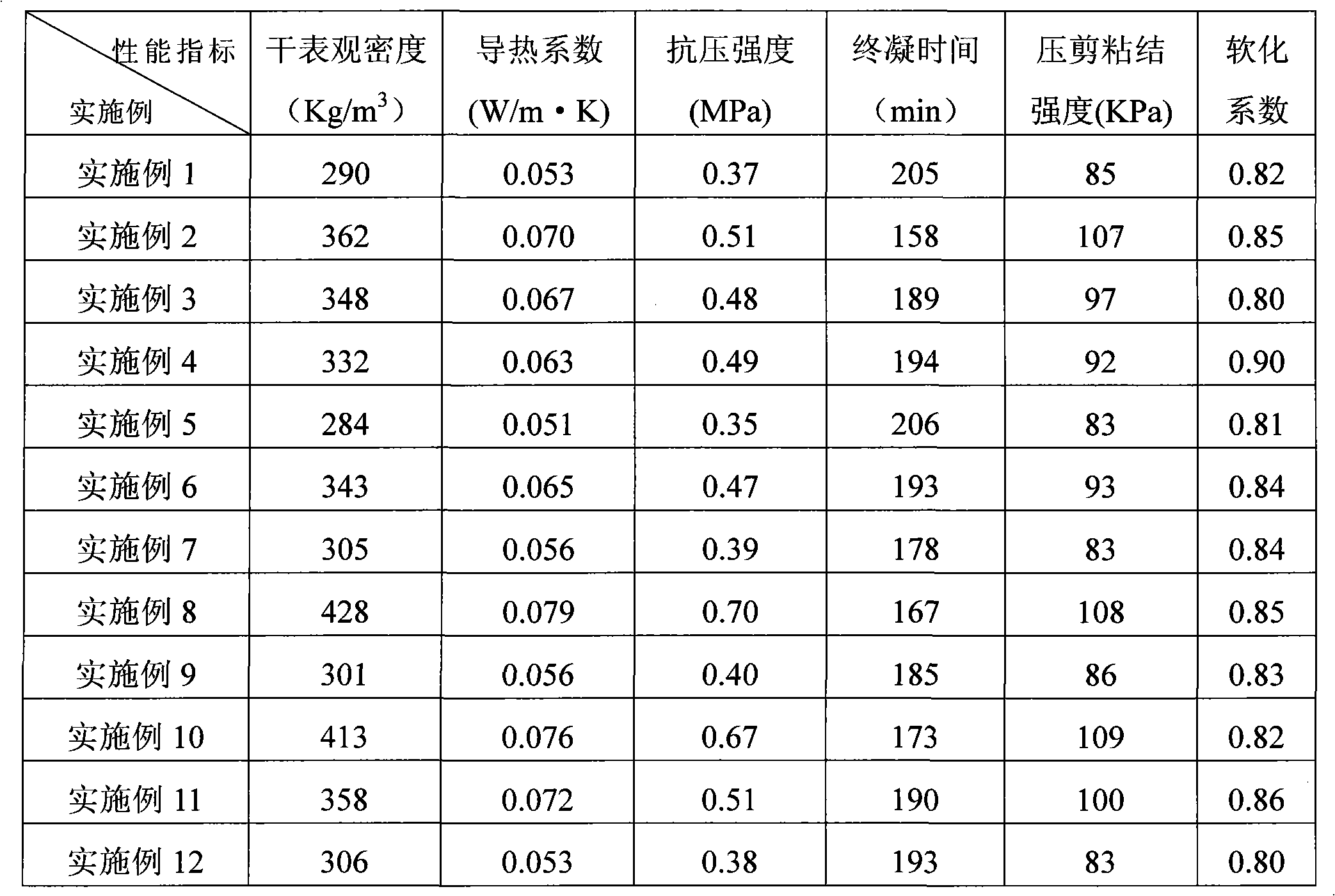

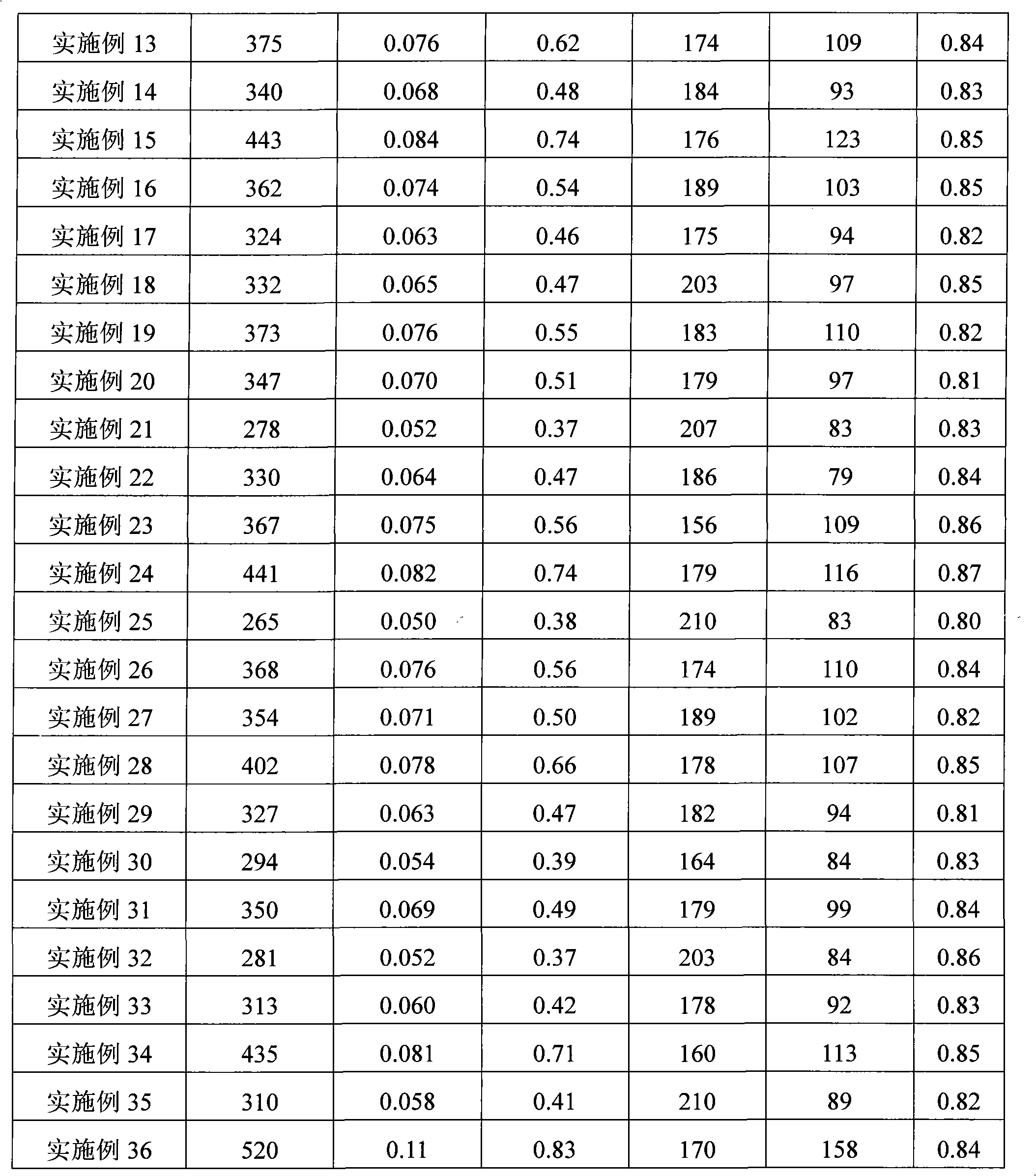

Polystyrene foam particle heat insulation mortar

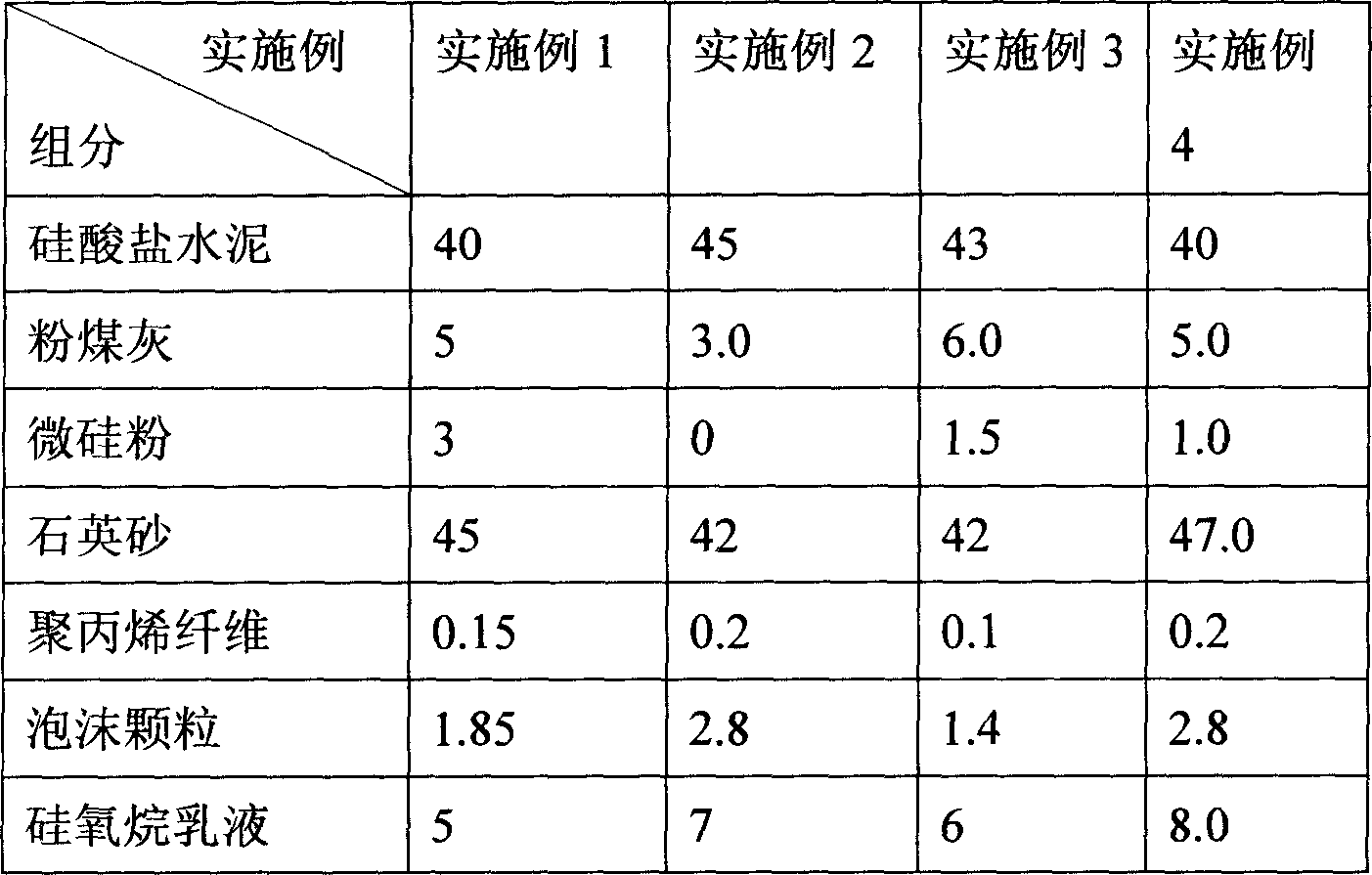

The heat insulating foamed polystyrene particle mortar used in building engineering consists of portland cement 40-45 wt%, flyash 3-6 wt%, fine silica powder 0-3 wt%, foamed polystyrene particle 1.3-2.8 wt%, polypropylene fiber 0.1-0.2 wt%, quartzite 42-47 wt% and water-thinned silane / siloxane emulsion 5-8 wt%. The present invention has light bulk weight, dry density 300-480 kg / cu m; good heat insulating and sound isolating performance, and heat conducting coefficient 0.07-0.13 W / m.k. The present invention utilizes partial flyash to replace cement and the product has no environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

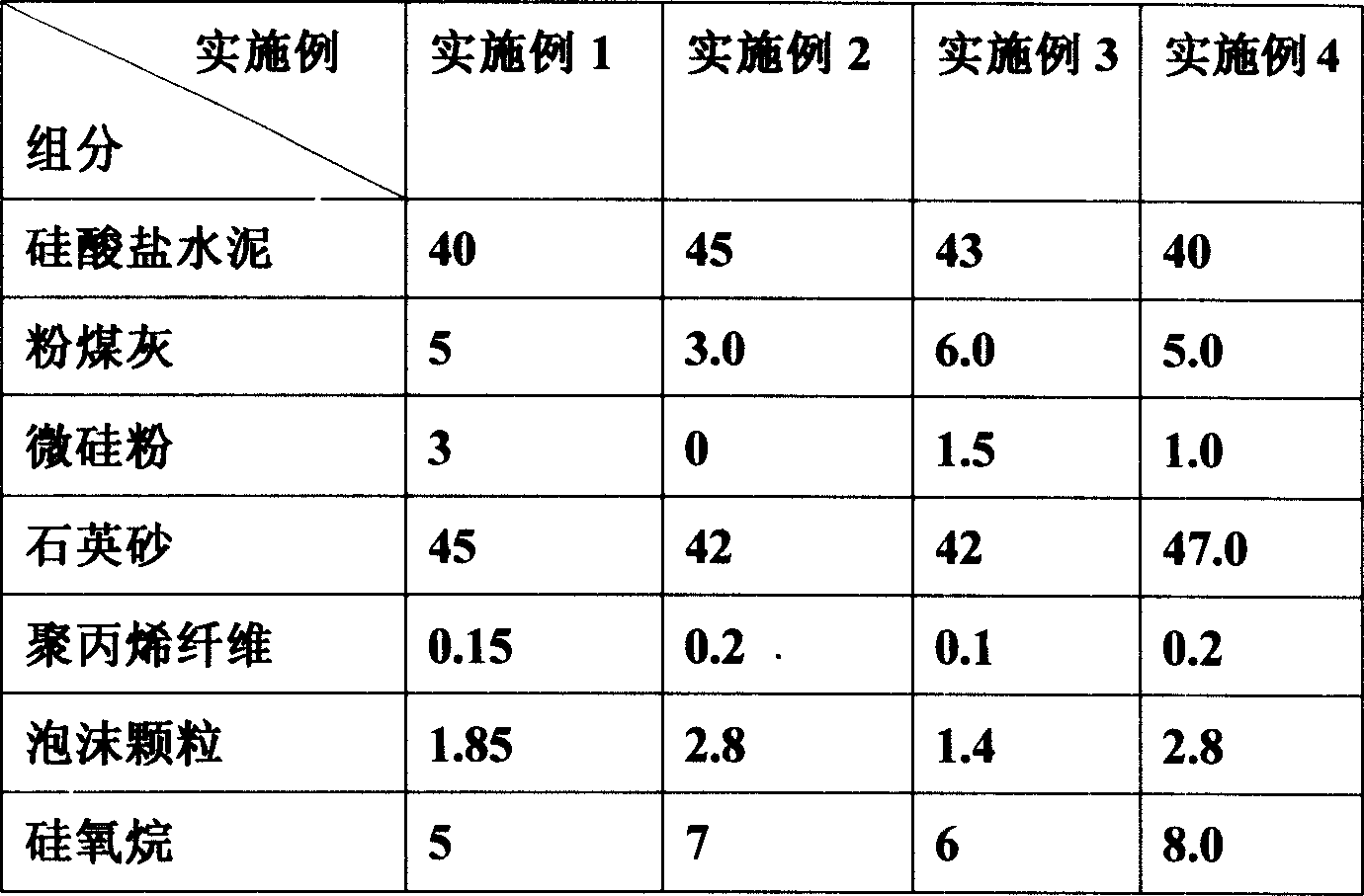

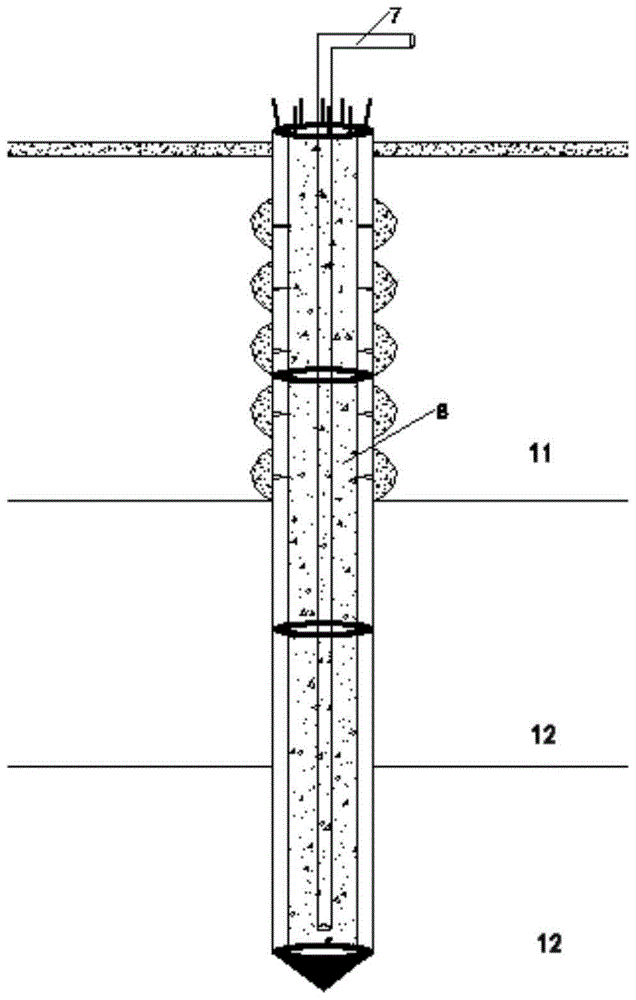

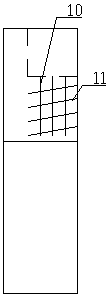

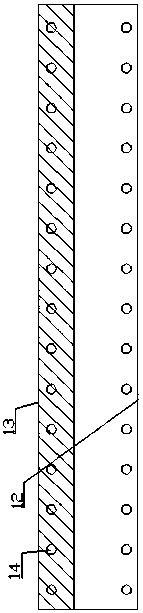

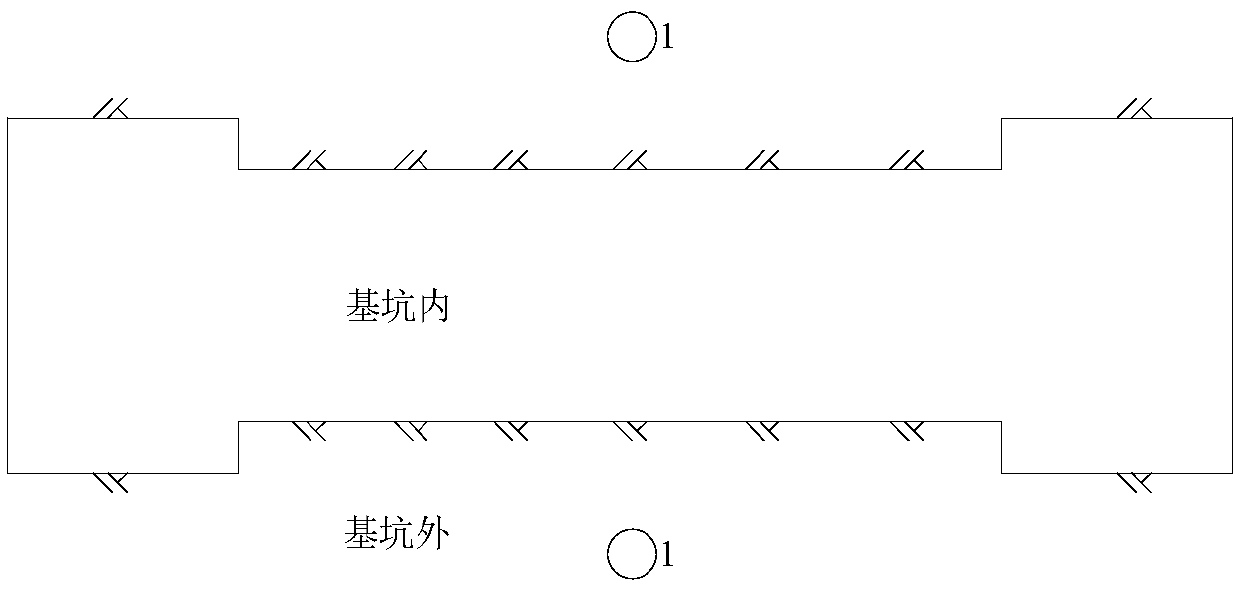

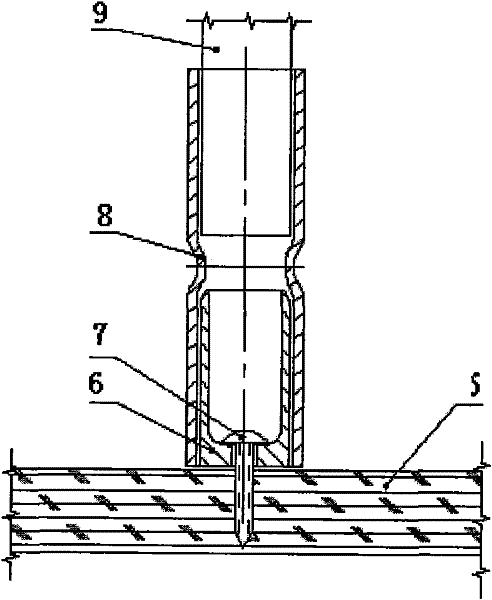

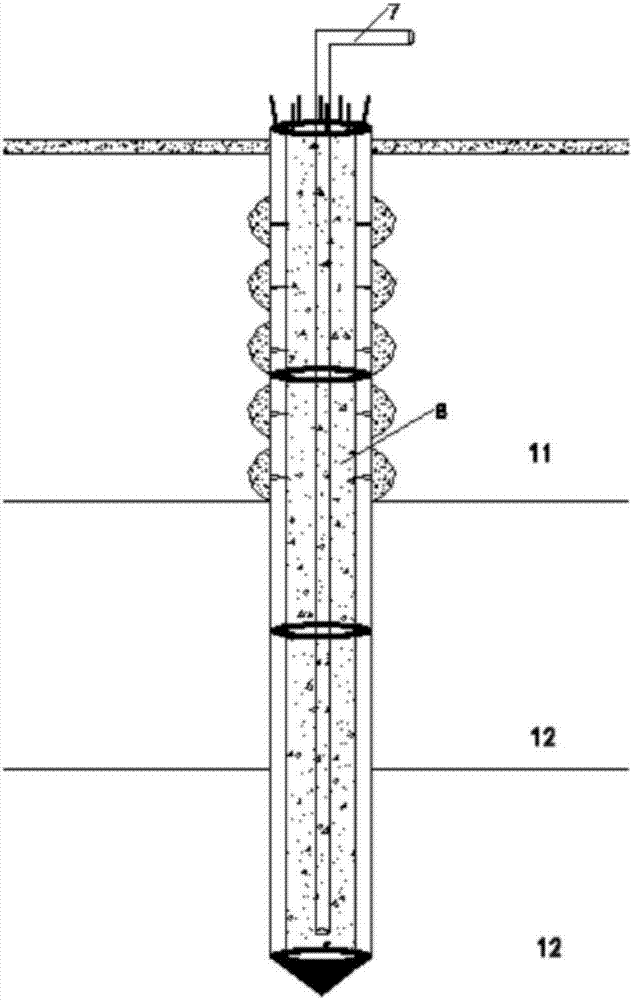

Prefabricated downcast pipe pile in building foundation pit and use method thereof

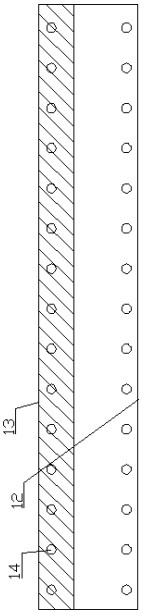

The invention relates to a prefabricated downcast pipe pile in a building foundation pit and a use method thereof. The prefabricated downcast pipe pile is a hollow cylinder and comprises a pipe wall and a conical tip. A plurality of water permeable holes are formed in the upper portion of the pipe wall at intervals. A filter barrel is arranged inside the prefabricated downcast pipe pile, the upper end of the filter barrel is open, and the lower end of the filter barrel is closed. The use method of prefabricated downcast pipe piles sequentially includes the first step of prefabricating the prefabricated downcast pipe piles, the second step of determining the total quantity and arrangement intervals of the prefabricated downcast pipe piles, the third step of installing the prefabricated downcast pipe piles and injecting water to clean the piles one by one, the fourth step of placing immersible pumps and water outlet pipes into the prefabricated downcast pipe piles, and the fifth step of stopping the immersible pumps from pumping water, cleaning holes, injecting cement mortar, and making part of the cement mortar permeate outwards via the water permeable holes and solidify to the outside soil of the prefabricate downcast pipe piles. By means of the prefabricated downcast pipe pile, the construction period of pipe wells is shortened. Meanwhile, the anti-floating performance of the prefabricated downcast pipe pile is improved by changing the pile to be an uplift pile.

Owner:JIANGXI THE SECOND CONSTR

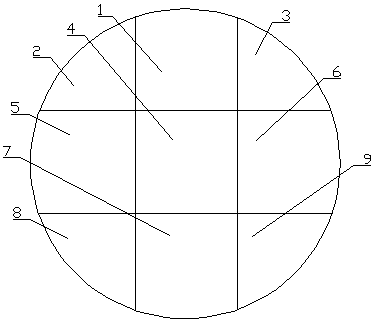

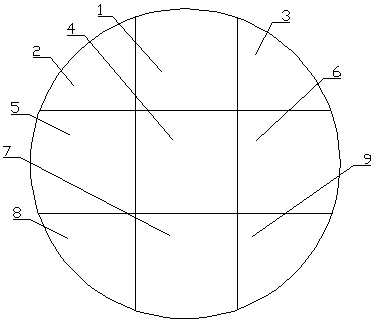

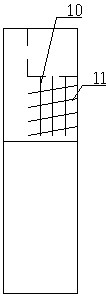

Construction method for breaking end socket tunnel portal retaining structure of shield section

ActiveCN108868784AMinimize origination riskShort construction periodTunnelsReinforced concreteSlurry

The invention discloses a construction method for breaking an end socket tunnel portal retaining structure of a shield section. The method comprises the following steps of 1, drilling holes in a circular tunnel portal of the retaining structure; 2, stirring expansion slurry; 3, injecting the stirred expansion slurry into vertical holes and longitudinal holes, sealing the holes, and pre-cracking concrete; 4, chiseling a launching surface of the circular tunnel portal; 5, dividing the circular tunnel portal into a first area, a second area, ... and an nth area; 6, sequentially carrying out concrete peeling and reinforced concrete breaking on the launching surface of the circular tunnel portal in the first area, the second area, ... and the nth area; 7, chiseling a soil surface of the circular tunnel portal; 8, carrying out shield launching / reception tunneling construction. According to the method, through reasonable drilling arrangement and precise drilling depth, it is ensured that theconcrete breaking range of the tunnel portal can meet clearance requirements of design and construction; the whole process has high safety, collapse does not easily occur, the construction is fast, and meanwhile, the safety of construction personnel is ensured.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

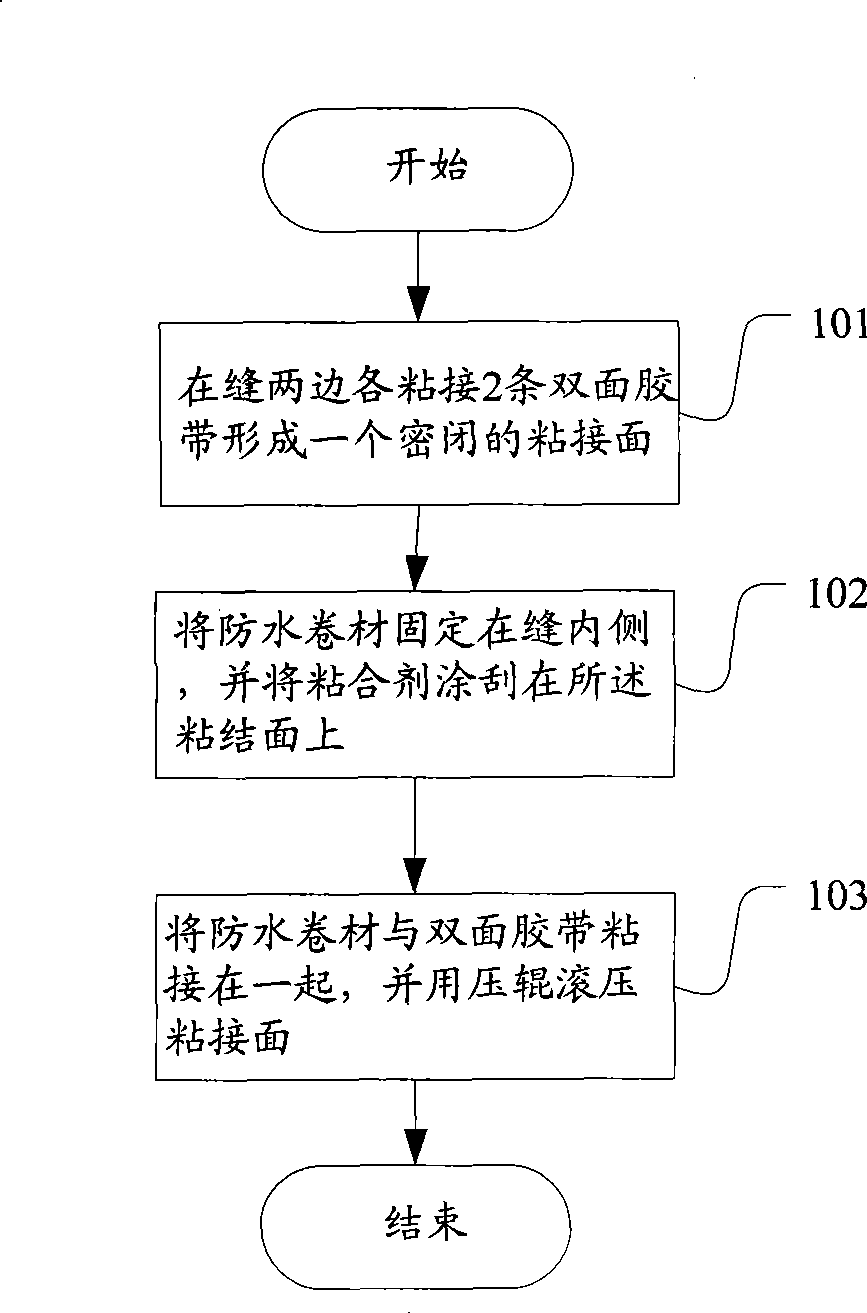

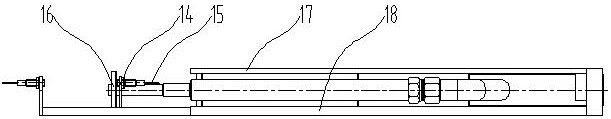

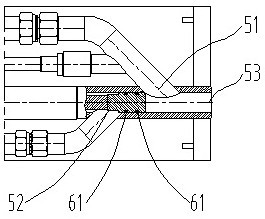

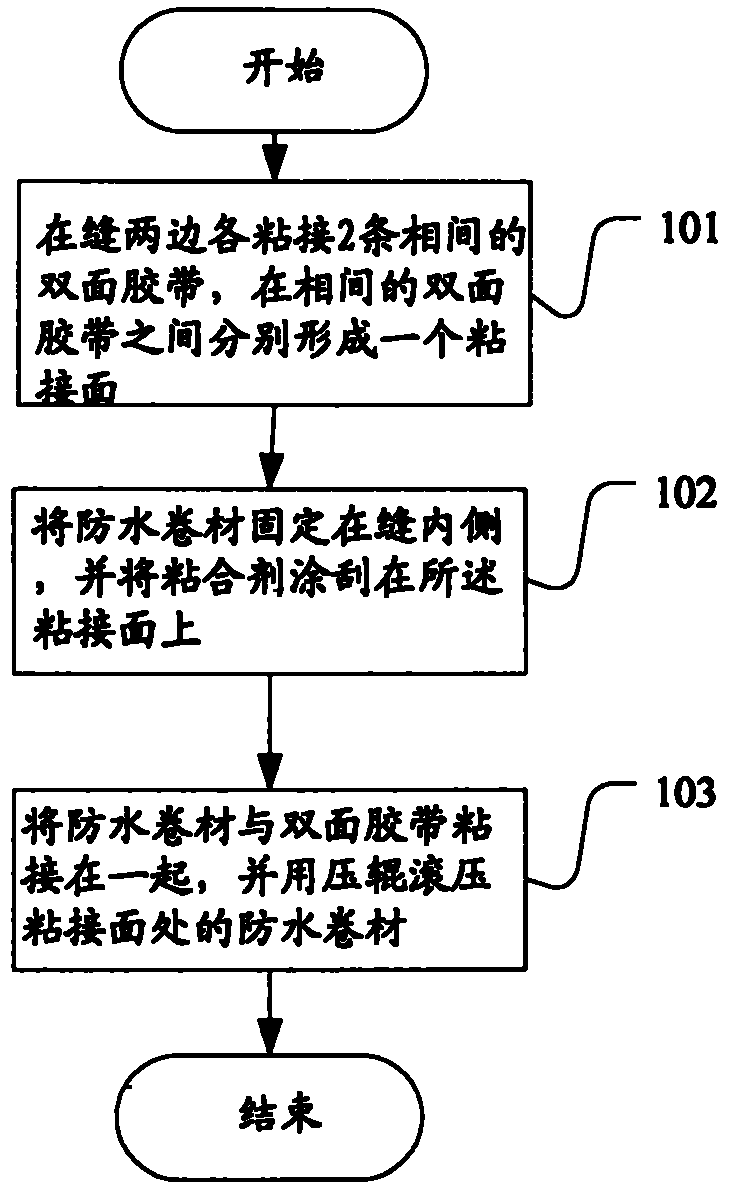

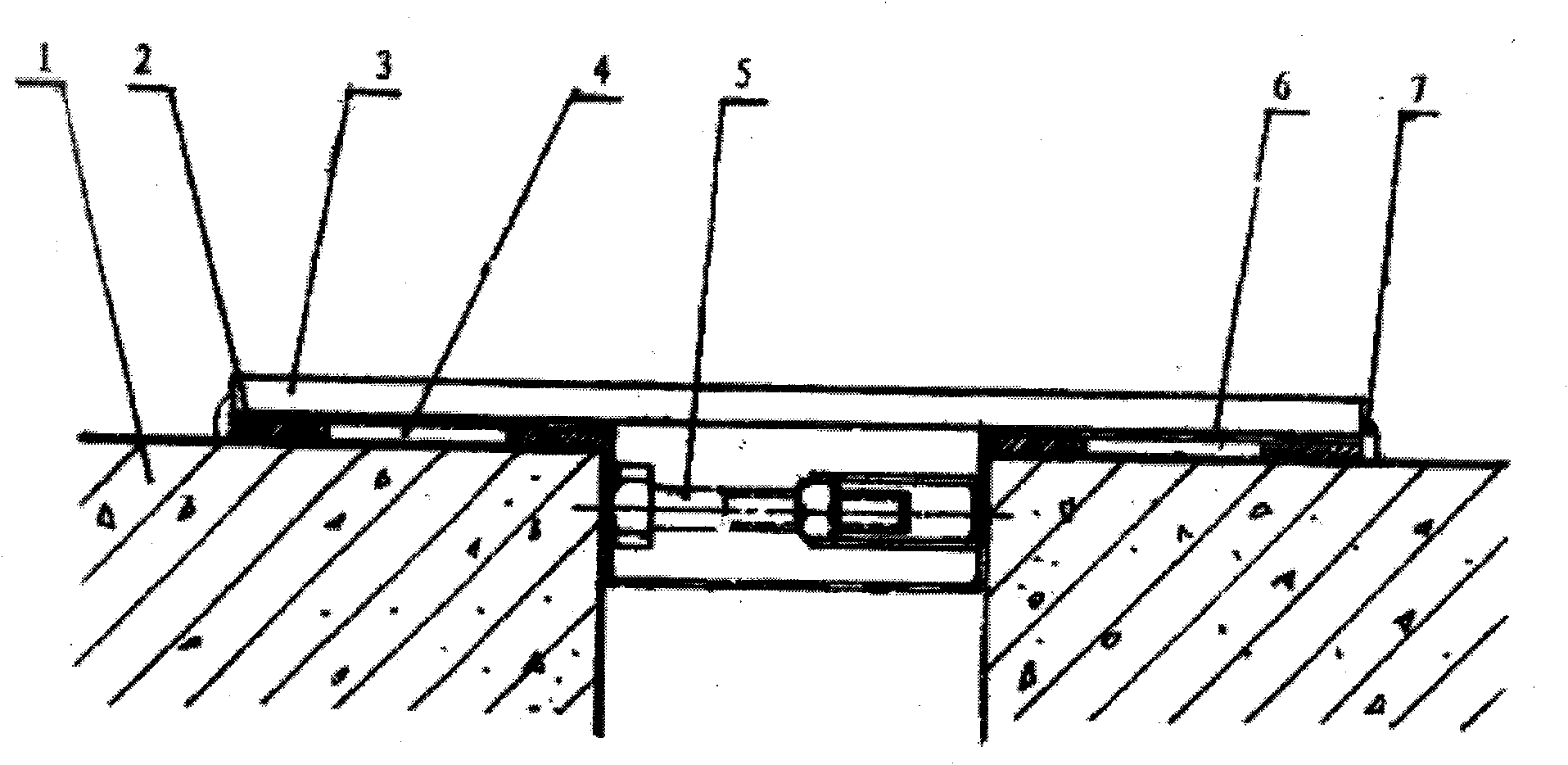

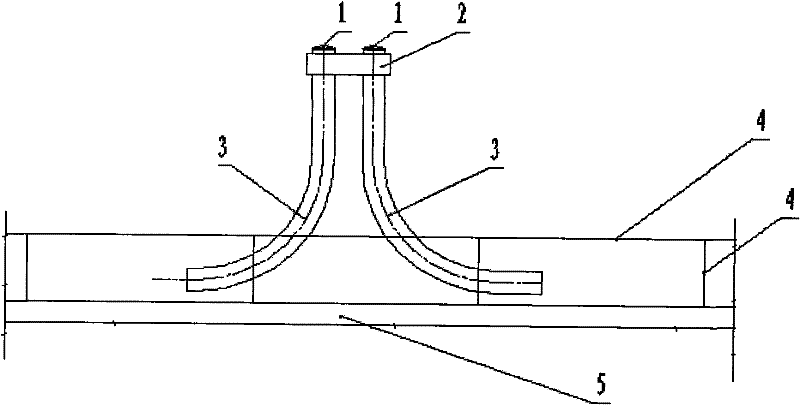

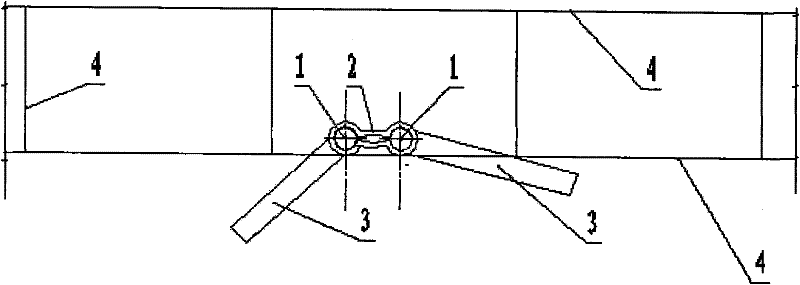

Construction method for bonding polymer water-proof coiled material

InactiveCN101429784AWon't overflowRealize civilized constructionBuilding insulationsAdhesive beltArchitectural engineering

The invention discloses a construction method for splicing a macromolecular waterproof roll, which comprises the following steps: a. two double sticky tapes are adhered to both ends of a joint respectively to form a closed cohesive surface; b. the waterproof roll is fixed inside the joint, and an adhesive is coated on the cohesive surface; and c. the waterproof roll and the double sticky tapes are adhered to each other, and the cohesive surface is rolled by a pressure roller. The construction method improves the prior construction method, adopts the double sticky tape as the epoxy adhesive to form a closed receiving space, uses the pressure roller to grind a cohesive position of the waterproof roll and discharge air bubbles in the epoxy adhesive, makes the waterproof roll in a cohesive area practically combined with the epoxy adhesive which can not be overflowed from the cohesive position, realizes civilized construction, reduces the engineering cost, can perform visualized check on the construction quality through the transparent waterproof roll, and widen the application range.

Owner:吴兆圣

Thermal mortar of ceramic tile slag particles and fabrication method thereof

ActiveCN103864366ALight weightImprove corrosion resistanceSolid waste managementSlagSuperplasticizer

The invention discloses thermal mortar of ceramic tile slag particles. The thermal mortar is characterized by being prepared from the following raw materials in parts by weight: 290-330 parts of cement, 200-245 parts of ceramic tile slag particles, 35-50 parts of calcium sulfate whiskers, 85-105 parts of mica, 90-110 parts of aluminum nitride powder, 105-130 parts of kaoline, 75-90 parts of reed stems, 9-13 parts of naphthalene-based superplasticizer, 8-12 parts of sodium tripolyphosphate, 6-9 parts of calcium saccharate and 3-6 parts of assistants. The thermal mortar is light in unit weight, excellent in corrosion resistance, good in heat preservation and sound insulation performances, low in heat conductivity coefficient, and good in water-retaining property, and the product is stable in physical property, free of cracking, free of hollowing, good in ageing resistance and long in service life. The product can be applied by adding water, and is convenient to use, civilized construction can be achieved, and the product is free of toxicity, free of taste, free of harm to a human body, and free of environmental pollution, and belongs to the environment-friendly insulating and energy-saving material.

Owner:深圳绿景环保再生资源有限公司

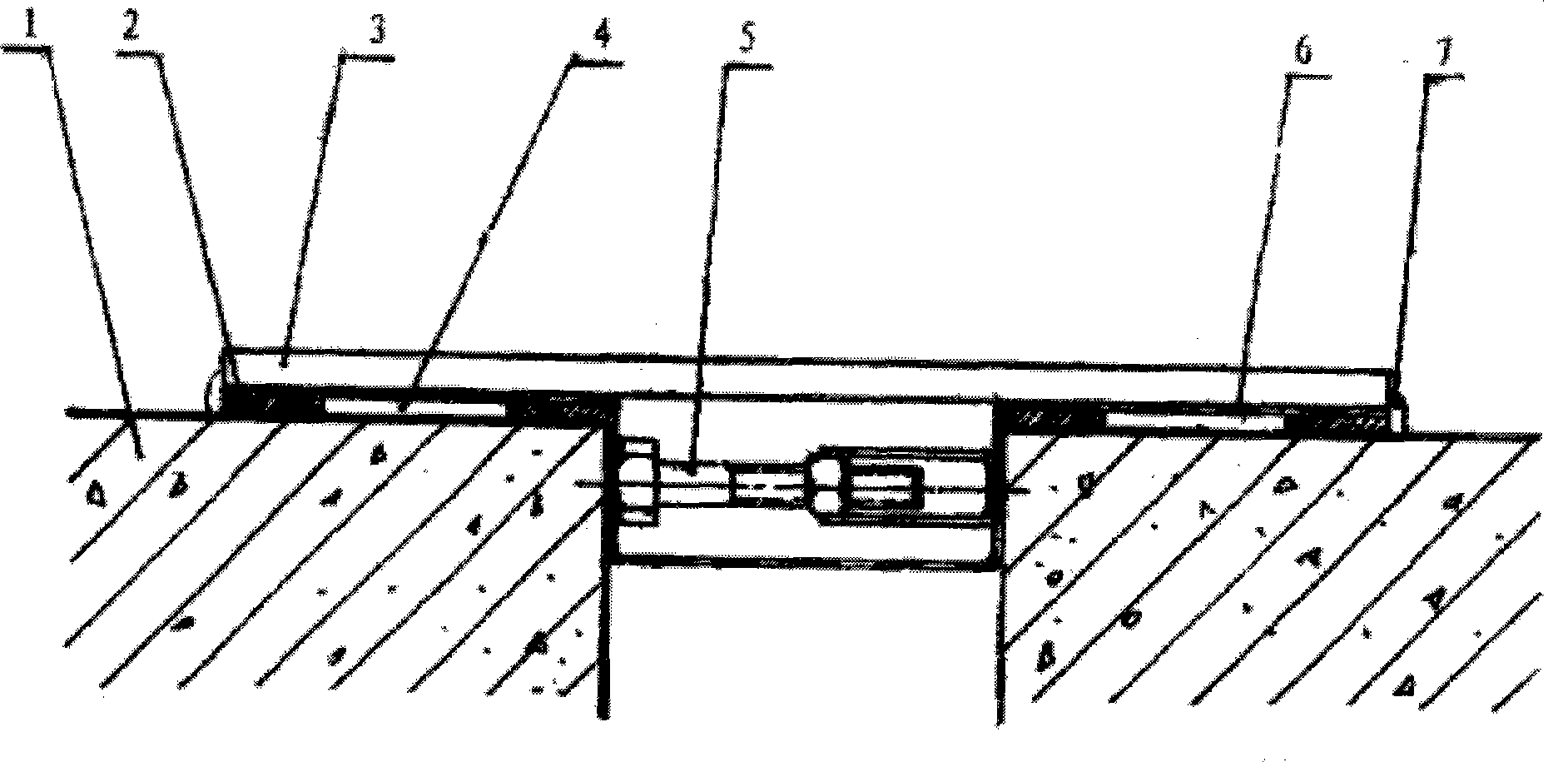

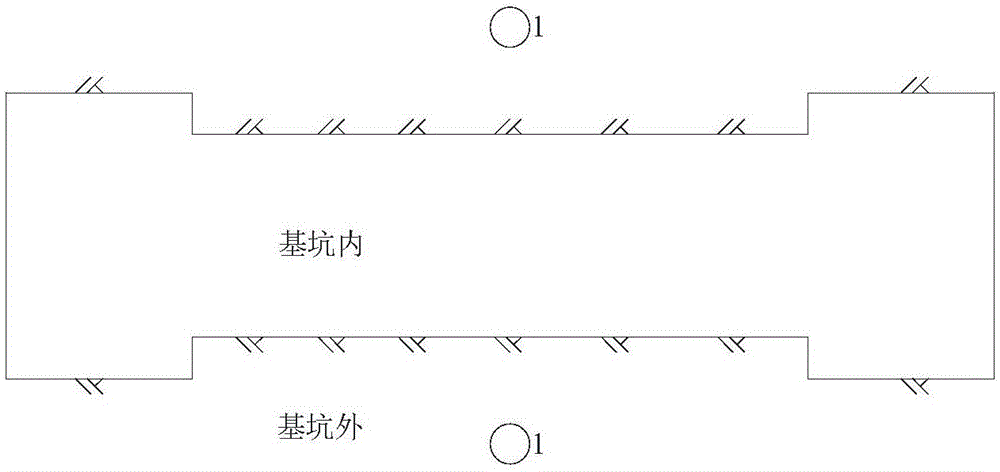

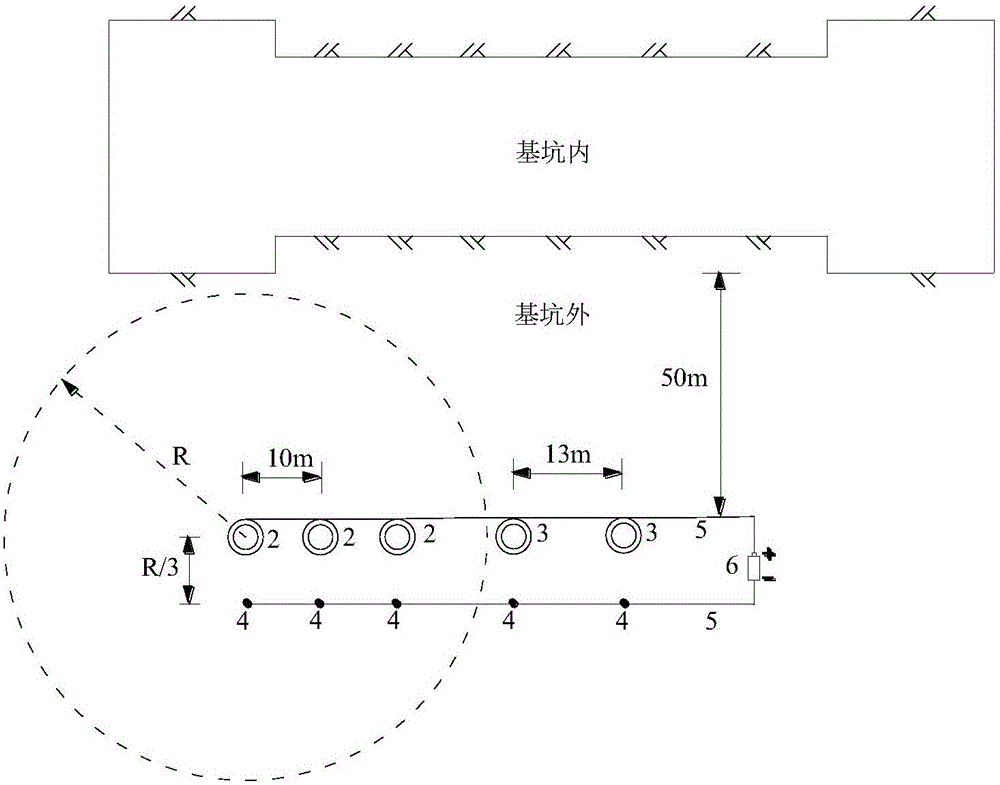

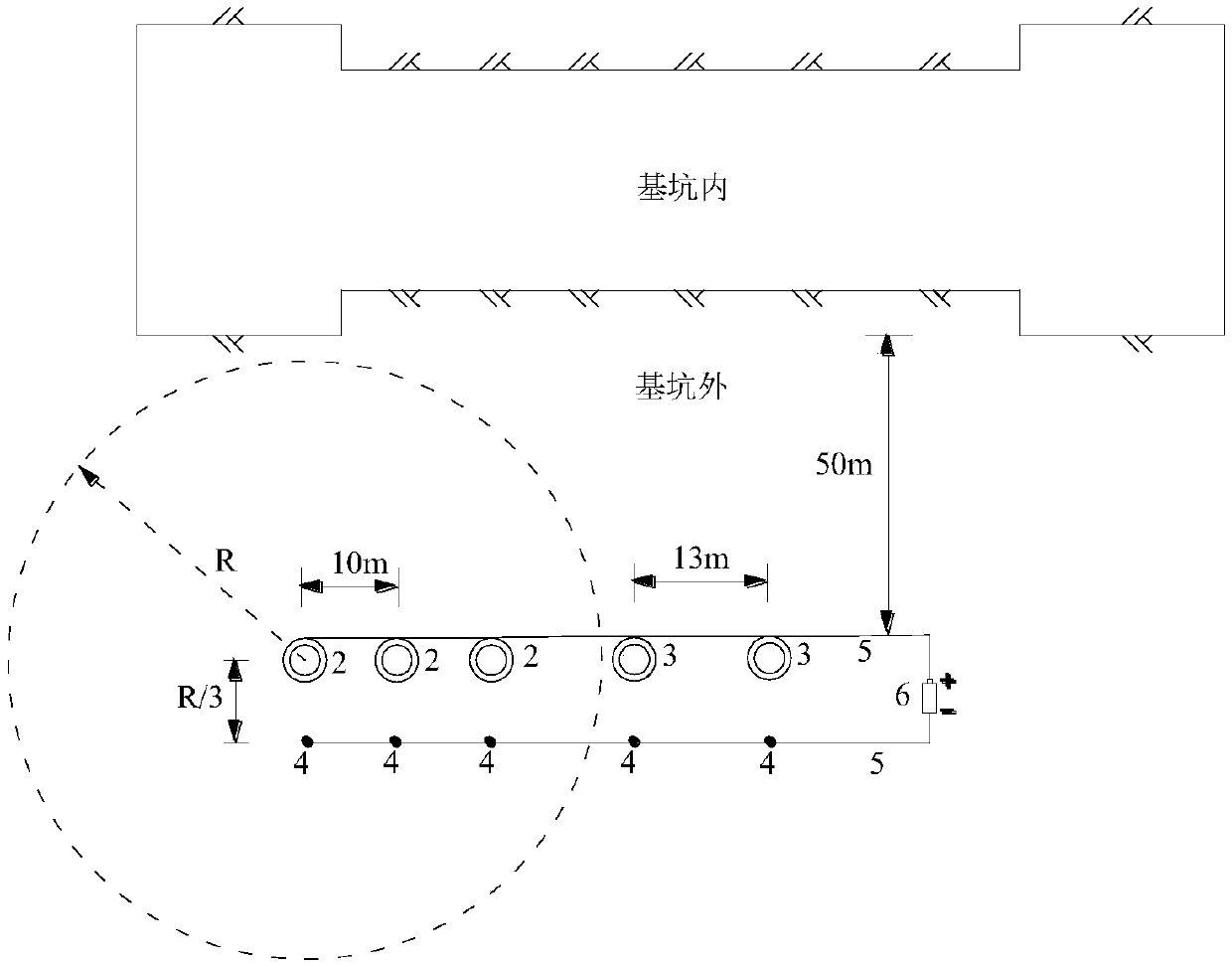

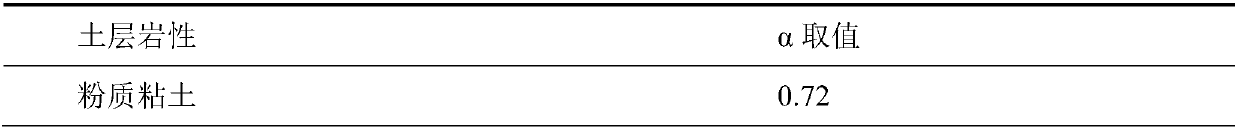

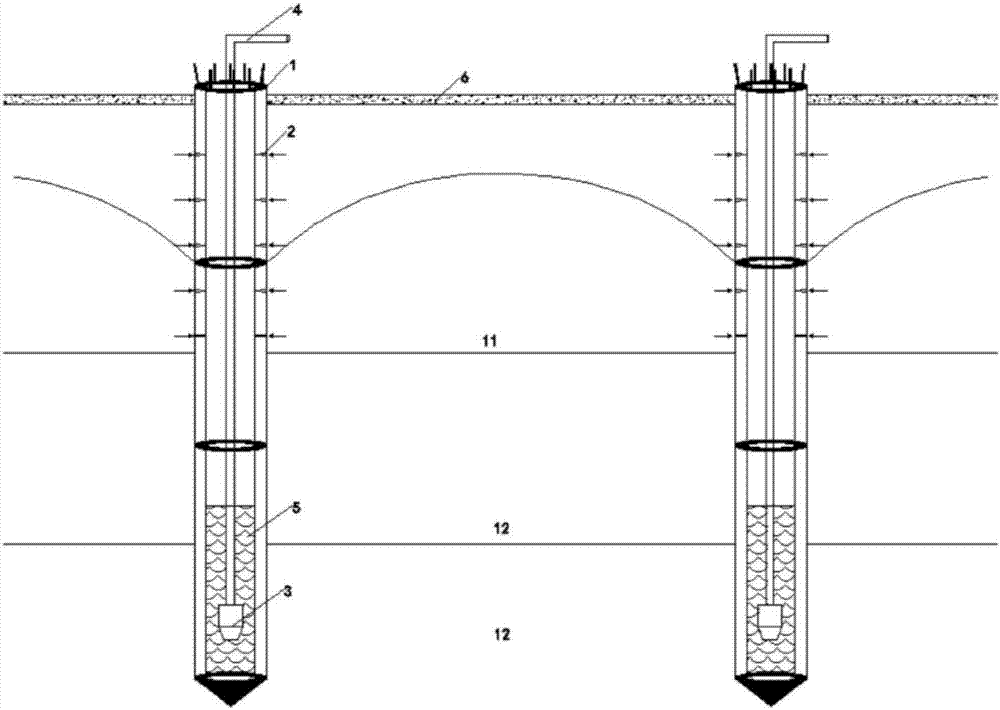

Recharge well construction method adopting electroosmosis

ActiveCN106245621AImproved permeabilityAccelerated dissipationIn situ soil foundationSoil preservationTube wellAnode

The invention discloses a recharge well construction method adopting electroosmosis. The method comprises the following steps: determining groundwater level depth and soil layer lithologic distribution of a recharge field; according to a recharge target aquifer, constructing multiple recharge tube wells on the same side outside a foundation pit, performing a pumping test and a recharge test on the recharge tube wells to determine a permeability coefficient, a recharge influence radius and a recharge quantity; further determining a recharge scheme according to results of the pumping test and the recharge test, and constructing other recharge tube wells outside the foundation pit in the recharge field; arranging electrodes in positions certain distances away from the corresponding recharge tube wells and on one sides, away from the foundation pit in the recharge field, of the recharge tube wells; connecting the recharge tube wells through wires to form a recharge tube well conductive circuit, connecting the electrodes to form an electrode conductive circuit, connecting the recharge tube well conductive circuit with a power cathode, and connecting the electrode conductive circuit with a power anode. With adoption of electroosmosis, the permeability of soil mass around the recharge wells is improved, dissipation of recharge water is accelerated, and interference in the groundwater environment can be reduced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

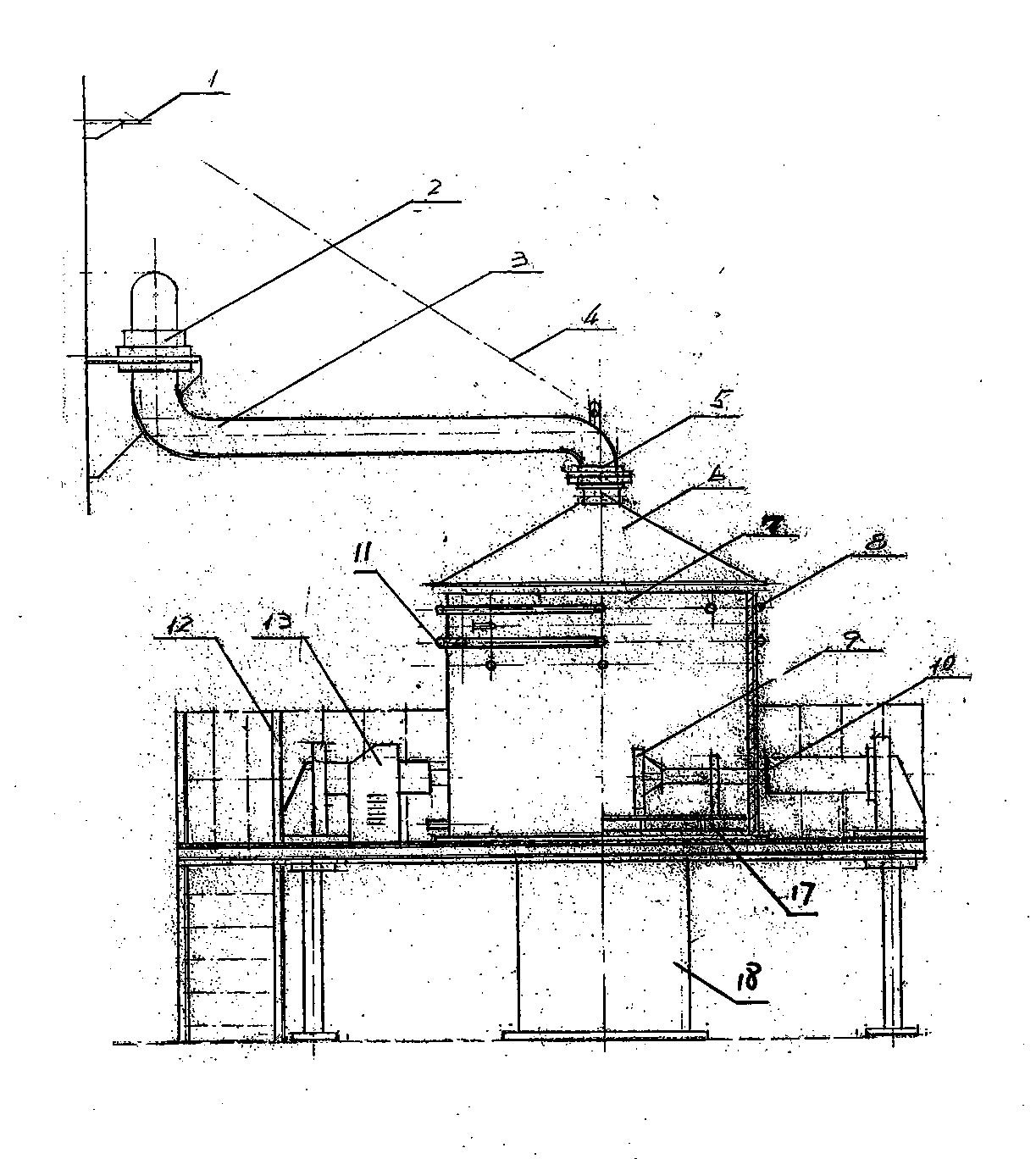

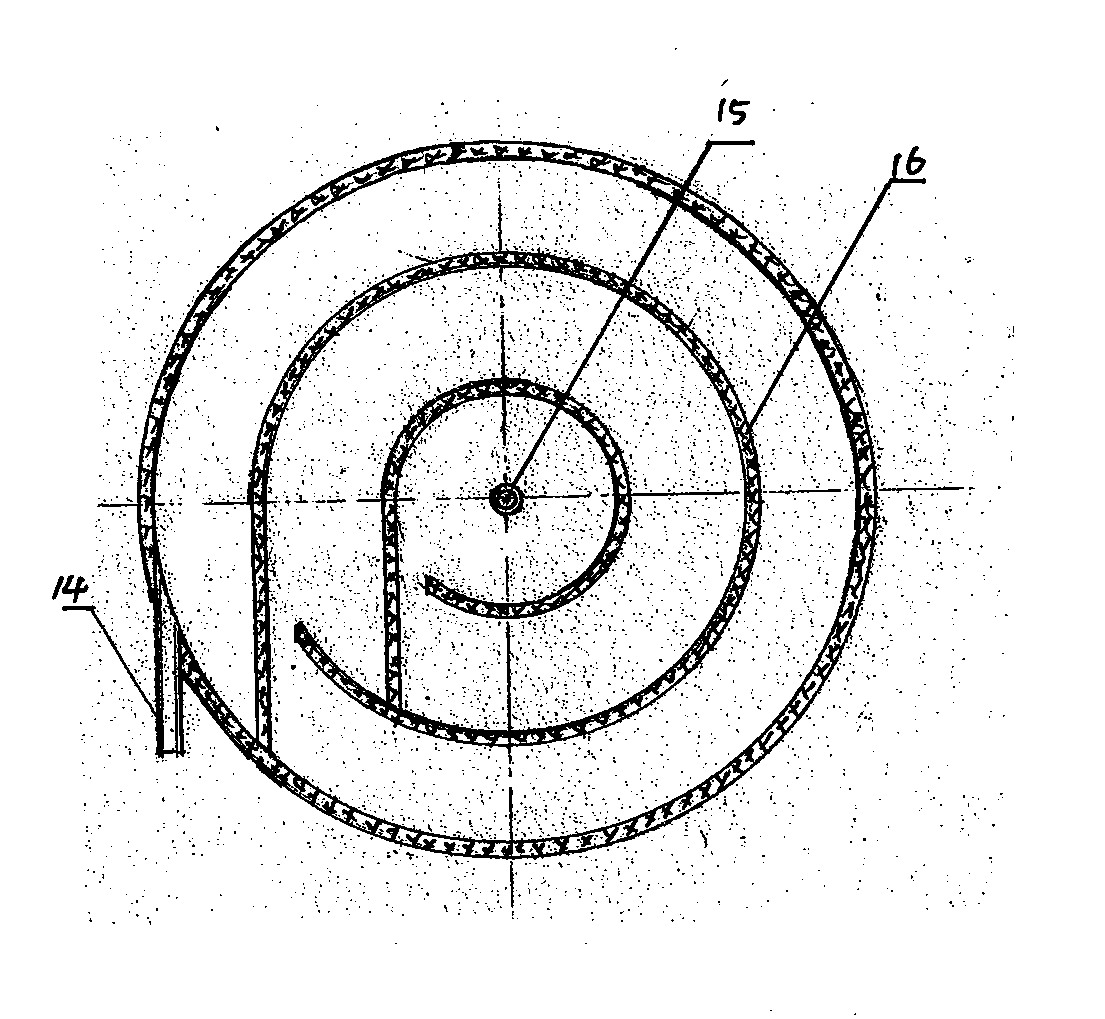

Drainage method of underground water pipe in dam concrete warehouse area

ActiveCN102287003ALittle construction disturbanceCivilization ConstructionDamsClimate change adaptationEngineeringDraining tube

The invention relates to a dam concrete cabin surface water accumulation hidden pipe discharge method. A water discharge main pipe is arranged in a preset region and is communicated with the upstream and the downstream of a dam, water discharge branch pipes are introduced to the left side and the right side of the dam body of the dam from the water discharge main pipe and are communicated with each dam block in a region, and a vertical water discharge branch pipe is connected onto the water discharge branch pipes of each dam block and is communicated with each concrete cabin position in each dam block. The dam concrete cabin surface water accumulation hidden pipe discharge method is characterized in that in the dam concrete casting construction process, the pre-buried water discharge pipenetwork continuously extends and expands to all concrete casting dam blocks along with the dam body concrete casting progress, each newly cast concrete cabin position in the dam region is fully covered, the water discharge problem of large-area accumulated water of the dam concrete cabin surface is solved, a dry ground construction environment condition is created for the concrete casting, the concrete casting quality is ensured, the construction interference is reduced, and the engineering civilization construction is realized.

Owner:CHINA GEZHOUBA GROUP CO LTD

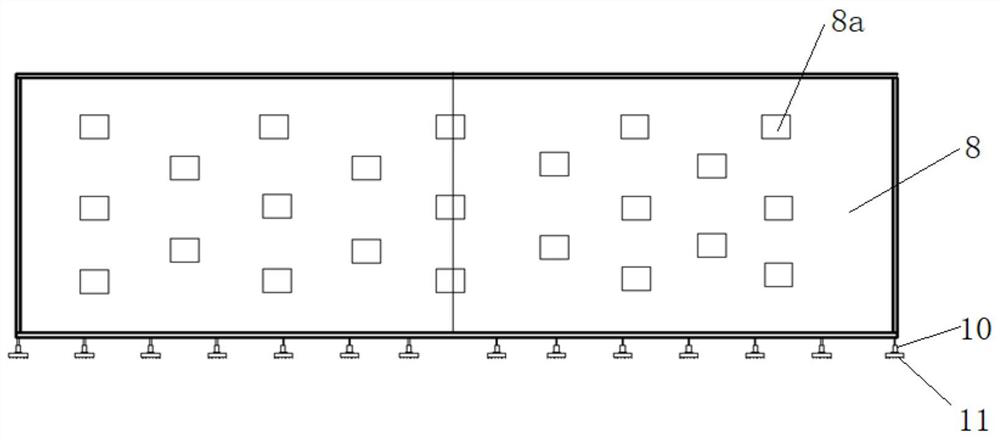

High efficiency construction method of cast-in-situ hollow core floor slab

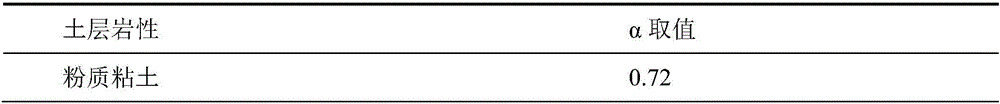

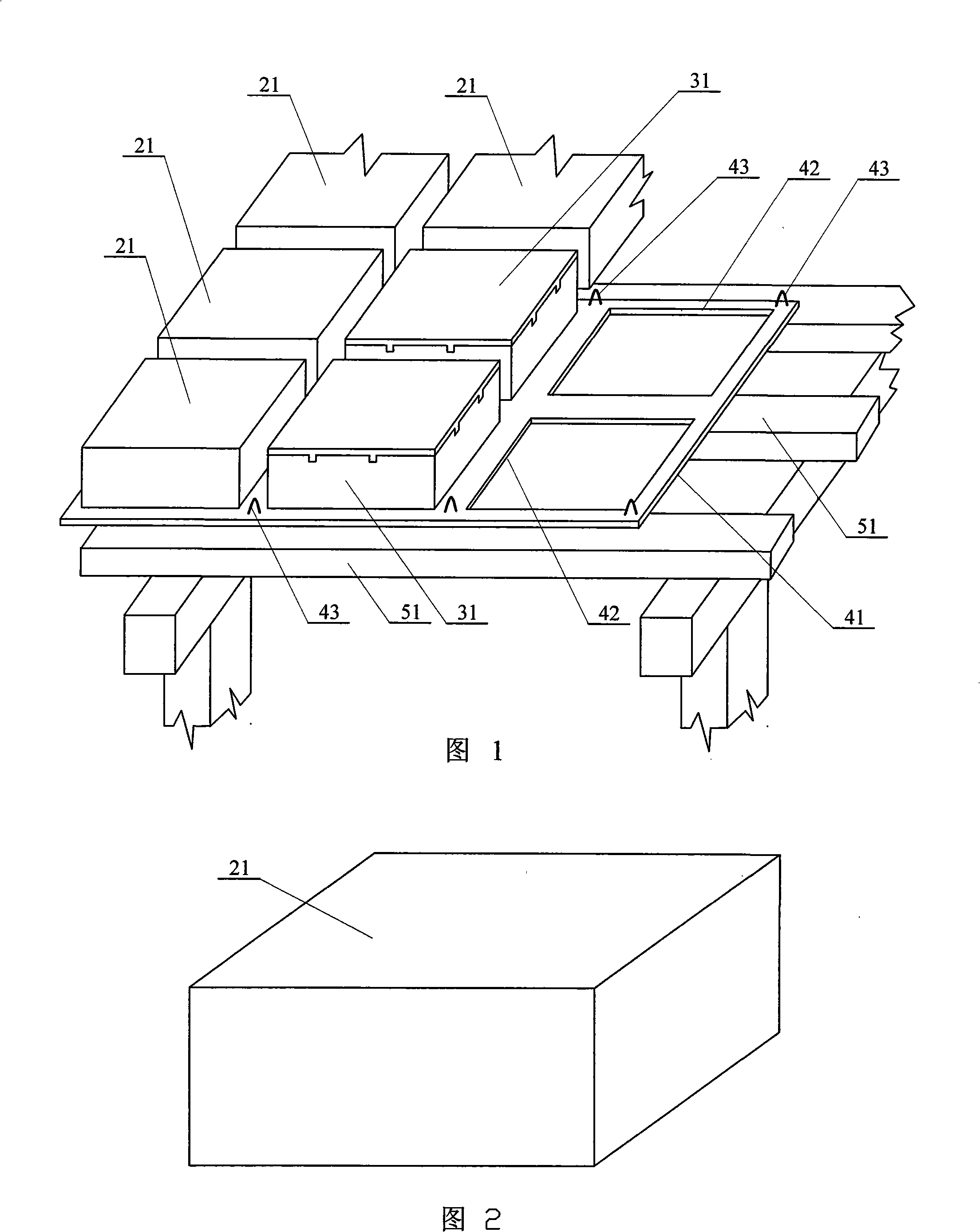

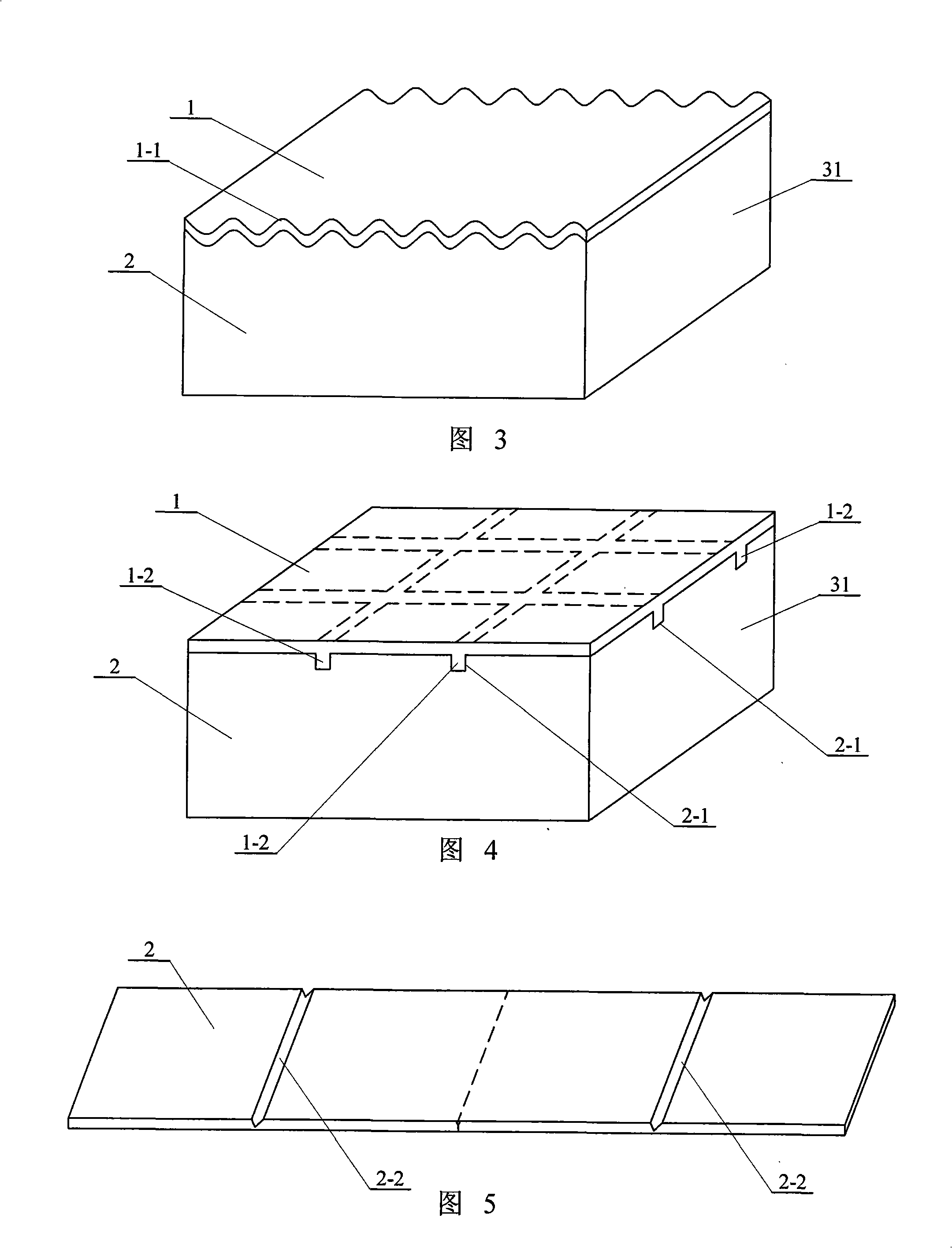

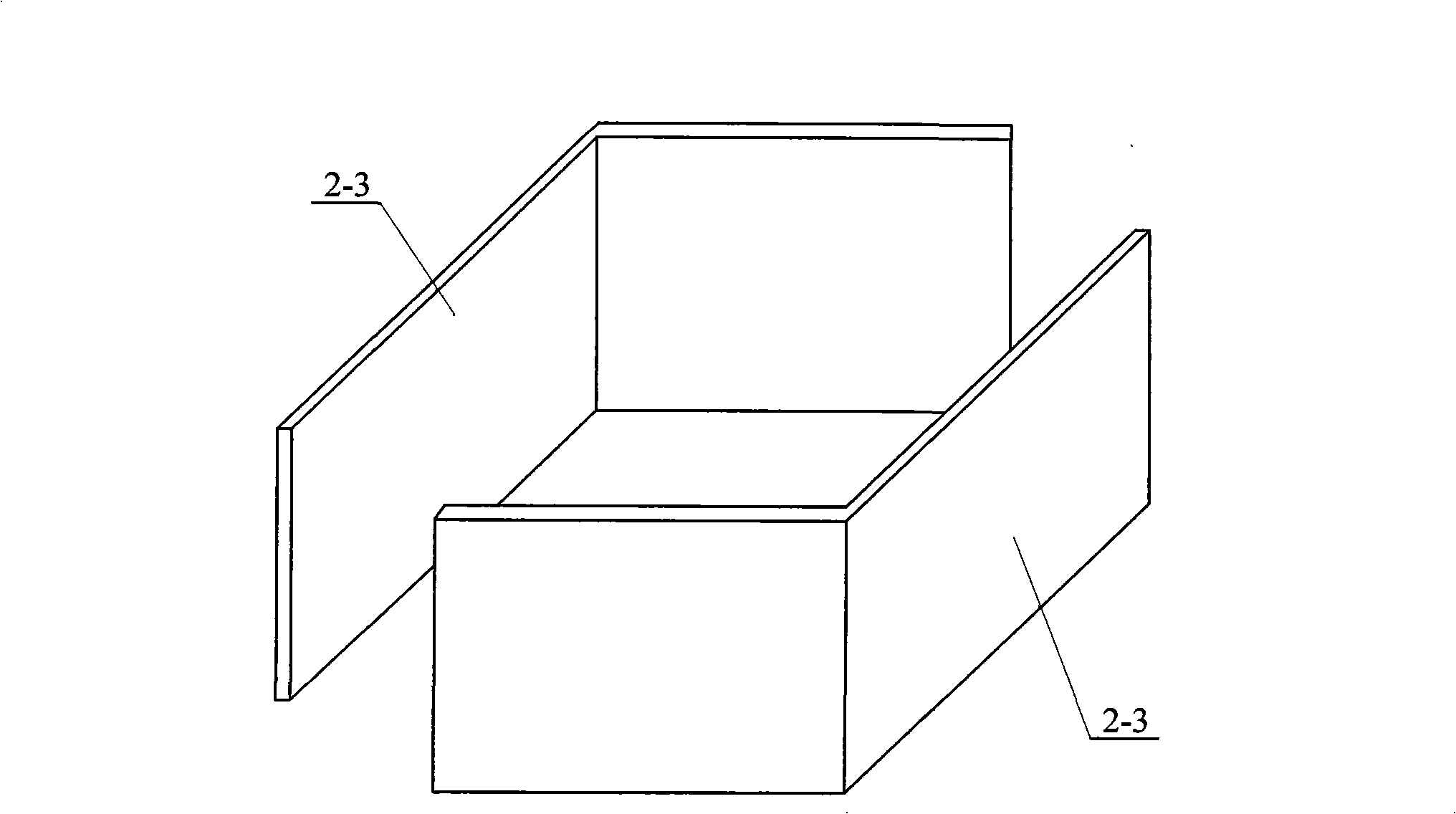

An efficient construction method of cast-in-situ hollow floor relates to a construction method of the cast-in-situ hollow floor. The invention aims to solve problem that the damage ratio in producing, conveying and construction process is high and a filler element on a molding plate is not easy to position by a thin wall hollow box that mainly adopts cement material. The invention is provided with a plurality of ceilings without gap at upper side of a temporary supporting beam; a gas-entrapping block of magnestite material or an assembling hollow box placing the magnestite material is placed on the ceiling as the molding plate. The gas-entrapping block of magnestite material or an assembling hollow box placing the magnestite material matches a concave and convex line of the ceiling. The construction method of the invention places the gas-entrapping block of magnestite material or the assembling hollow box placing the magnestite material in site, which implements a batch of works in a large scale. The temporary molding plate for the exchange in site is saved and the filler element is easy to fix on the molding plate. The sunshade is not need to be plastered after detached. Self-weight of the floor is light, which saves a lot of reinforcing steel bar and concrete and other construction materials.

Owner:高家榕

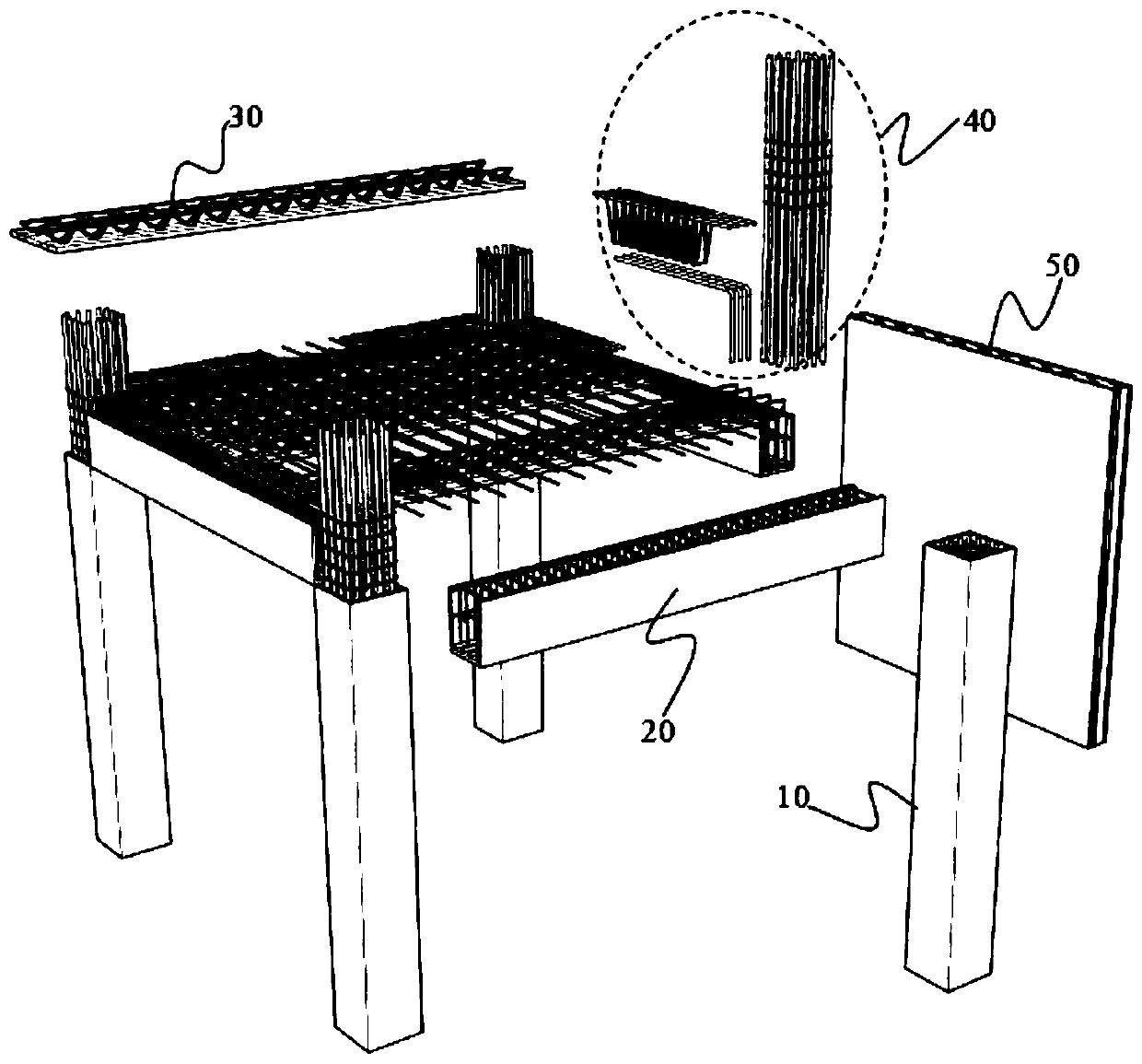

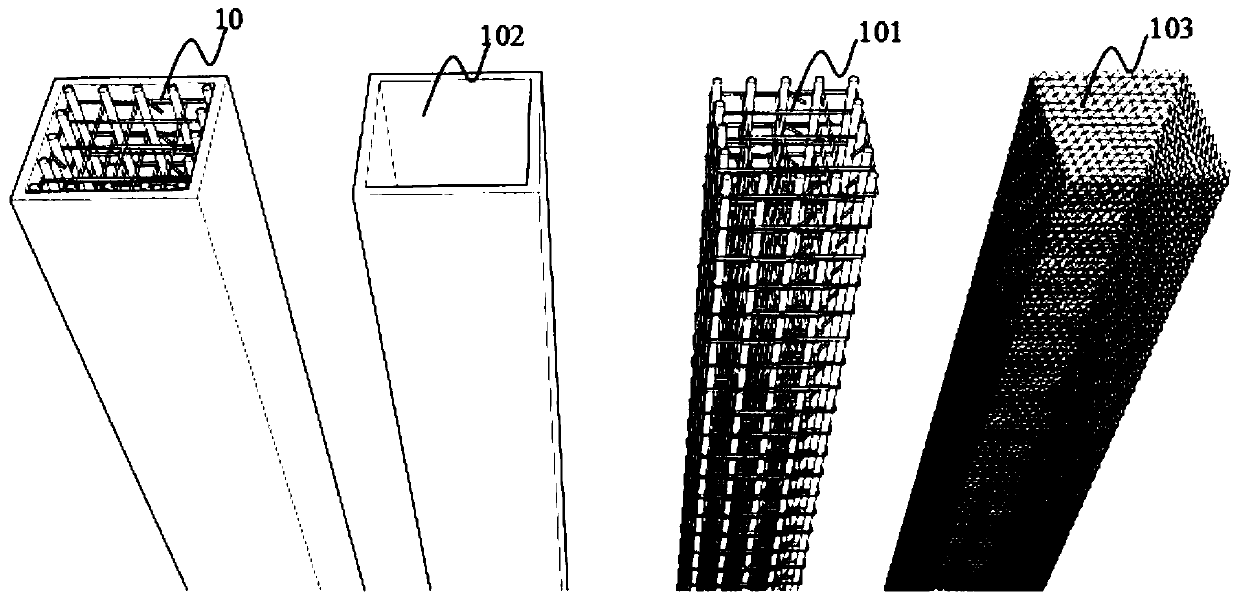

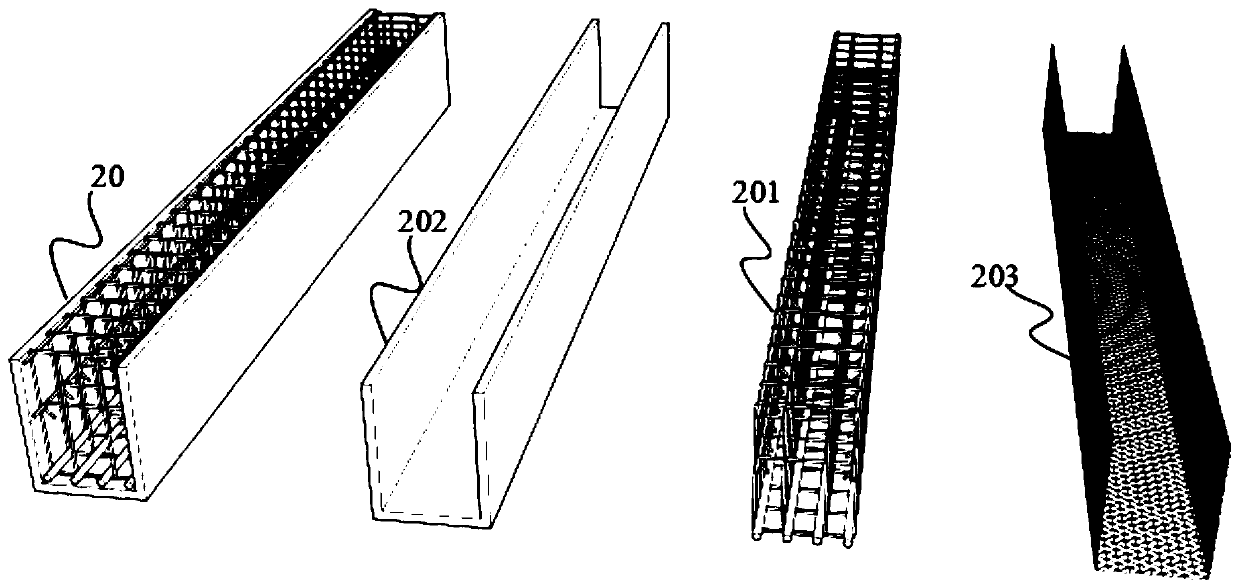

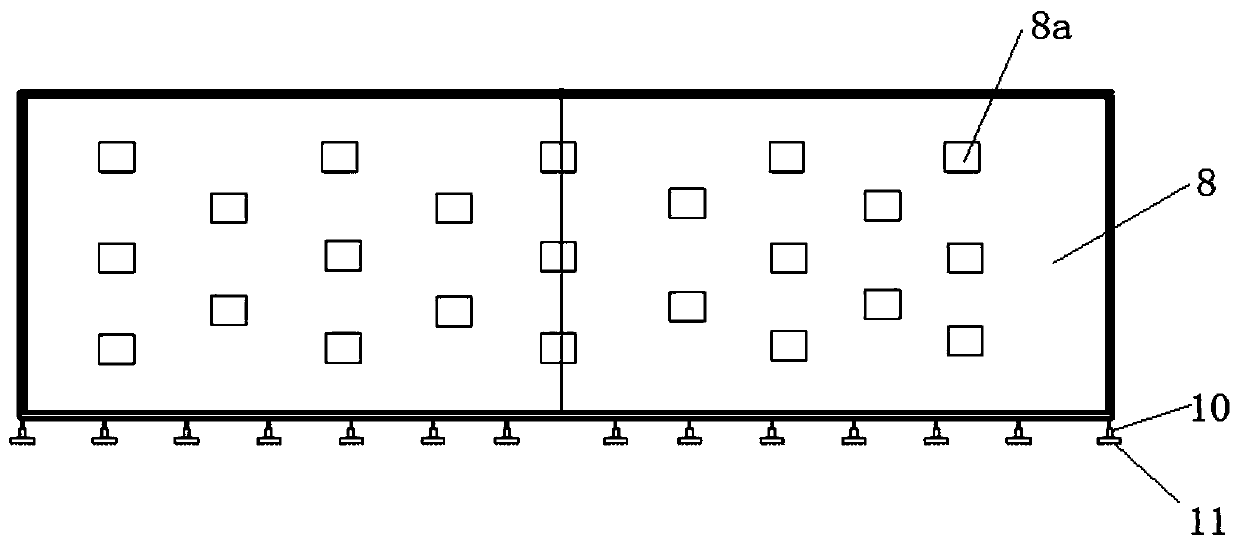

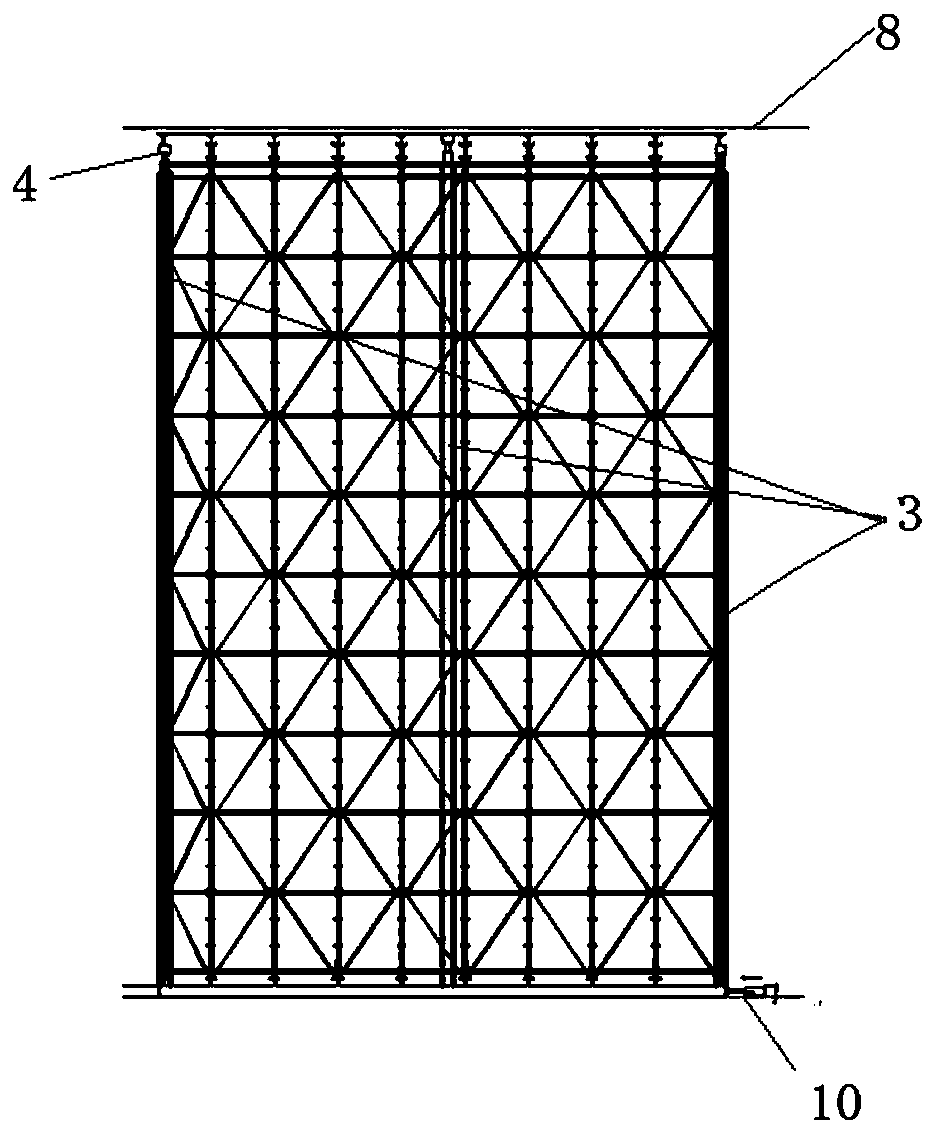

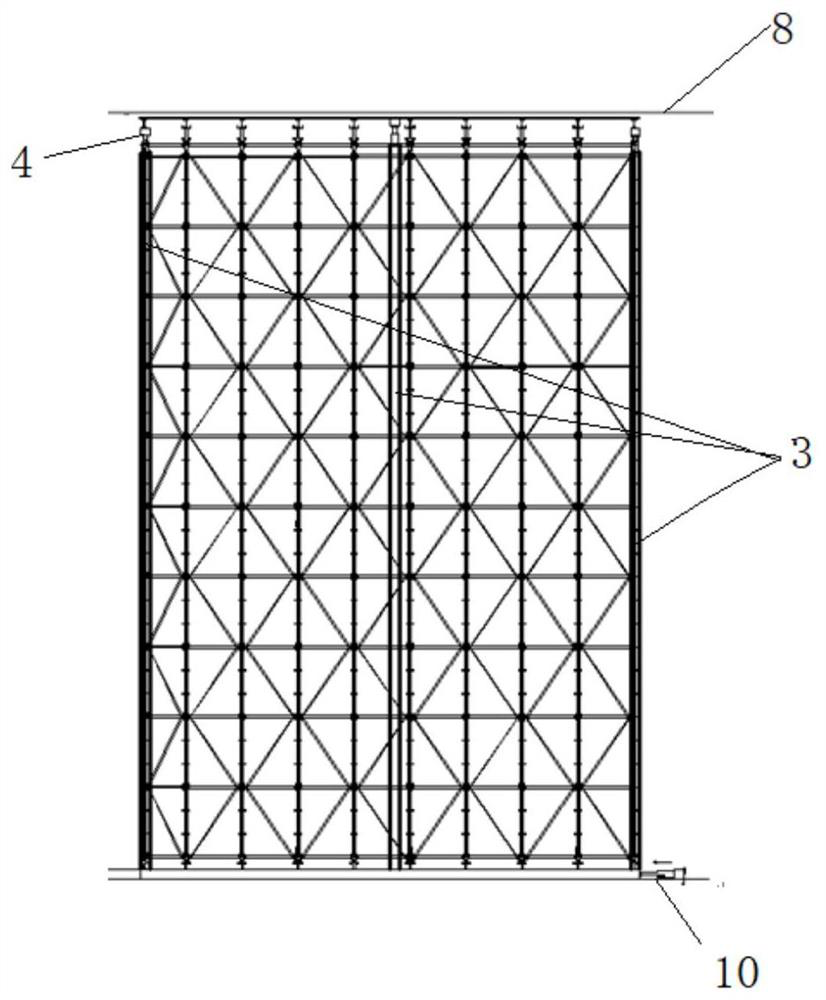

Integrally-assembled concrete overlapping structure system and construction method thereof

PendingCN111206677AReduce workloadImprove project qualityBuilding material handlingArchitectural engineeringRebar

The invention discloses an integrally-assembled concrete overlapping structure system and a construction method thereof. Prefabricated overlapping columns, prefabricated overlapping beams as well as load-bearing steel bars, namely first reinforcement cages, second reinforcement cages and truss steel bars of prefabricated overlapping plates are prefabricated therein, so load-bearing steel bars do not need to be installed on site as long as connecting steel bars at joints of beam columns, longitudinal load-bearing steel bars positioned at the upper parts of the overlapping beams and upper and lower steel bars which are vertical to the truss steel bars in the overlapping plate are installed, and thus the workload for binding the steel bars on site is greatly reduced. By utilizing the integrally-assembled concrete overlapping structure system disclosed by the invention, the construction quality can be effectively improved, the construction progress can be quickened, the labor productivitycan be improved, the cost can be lowered and civilized construction can be realized.

Owner:EAST CHINA ARCHITECTURAL DESIGN & RES INST +1

Push sliding type disk lock support heavy lining trolley and method for constructing lining form

ActiveCN111456764AElevation and labor savingImprove pouring qualityUnderground chambersTunnel liningArchitectural engineeringJackscrew

The invention discloses a push sliding type disk lock support heavy lining trolley. The trolley comprises a lining form system, a disk lock type full framing, a trolley chassis and stand columns, wherein a screw jack is installed at the top end of each stand column, and all the screw jacks can jointly jack or lower the lining form system through a longitudinal through beam, a plurality of horizontal pushing oil cylinders are arranged on the rear portion of the trolley chassis in a left-right spaced mode, the rear end of each horizontal pushing oil cylinder abuts against a transversely-extendedoil cylinder support, and at least two pieces of threaded steel are adopted at the rear portion of each oil cylinder support to be inserted into tunnel bottom plate concrete as counter force supports. Meanwhile, the invention also discloses a method for constructing a lining form by utilizing the above-mentioned push sliding type disk lock support heavy lining trolley. The lining trolley specially used for ultra-large-span tunnel lining construction can be recycled and reused, so that the time-consuming and cost-consuming caused by the fact that the trolley is built again after being dismantled are avoided, and the trolley is safe, reliable and high bearing capacity.

Owner:中铁隧道集团一处有限公司

Production method of lightweight concrete prefabricated big panels

ActiveCN105906371AOptimize mix ratioExcellent preparation strengthCeramicwareFoaming agentArchitectural engineering

The invention discloses a production method of lightweight concrete prefabricated big panels. The method comprises the following steps: 1, selecting raw materials according to a case that every cubic meter of lightweight concrete prefabricated big panels contains 450-550kg of cement, 65-195kg of stone flour, 3.25-9.75kg of a water reducer and 0.01-0.05kg of a foaming agent, foaming the foaming agent, uniformly mixing cement, the stone flour and the water reducer to prepare a cement mortar, adding the foamed foaming agent to the cement mortar, and uniformly stirring the foamed foaming agent and the cement mortar to prepare lightweight concrete; and 2, pouring the lightweight concrete in a die, and carrying out demolding treatment and curing to produce the lightweight concrete prefabricated big panels. The method solves the problem of adverseness of too large weight of common prefabricated big panels to transportation and hoisting installation, the weight of the lightweight concrete prefabricated big panels produced in the invention is about 50% lower than that of common concrete prefabricated big panels, and the construction efficiency of prefabricated wallboards is effectively increased.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

A thickened powder for preparing dry-mixed plaster

The invention relates to thickening powder for preparing dry-mixed plastering mortar, which belongs to the thickening powder of building auxiliary materials. The thickening powder is formed by organic materials, and comprises the following components by weight percentage: 11-13 percent of hydroxypropyl methyl cellulose ether, 22-24 percent of wood fiber, 57-61 percent of calcium lignosulphonate and 6-7 percent of starch ether. The thickening powder is used as an additive of the dry-mixed plastering mortar, which can obviously improve the workability, water retention property, mechanical property and durability of the dry-mixed plastering mortar. The invention has the advantages that the thickening powder is formed by organic materials, less in using amount, low in cost and suitable for industrialized production of the dry-mixed plastering mortar, has high requirement on quality control and no pollution, can obviously improve the workability, water retention property, mechanical property and durability of the dry-mixed plastering mortar, is convenient to store and convenient and rapid to use, has no radioactivity and corrosivity, reforms the preparation mode for building mortar in the prior art, eliminates the lime pool and the stirring mill built on the construction site, reduces dust raising and noises, realizes civilized construction, and produces favorable social and economic benefits.

Owner:CHINA UNIV OF MINING & TECH

Turnover type intelligent garbage chamber used on building construction site

PendingCN112520265AReduce weightEasy to useRefuse receptaclesSpecial buildingAutomatic controlRemote control

The invention discloses a turnover type intelligent garbage chamber used on a building construction site. Four garbage chamber bodies are arranged in parallel, a remote control type electric roller shutter door is arranged on each garbage chamber body, guide rails are arranged on the ground of each chamber body and lead to the outside, an electric flatcar is mounted on the guide rails in a matchedmode, wheels of the electric flatcars are matched with the guide rails, a garbage ship is mounted on each electric flatcar, signal induction receivers are arranged on the positions, on the front faces, of the garbage chamber bodies and connected with a controller through wires, and the controller automatically controls the electric roller shutter doors and motors of the electric flatcars to work.The turnover type intelligent garbage chamber is reasonable in structure, easy and convenient to install and operate and convenient to move, standard accessories are adopted, tooled assembling and disassembling are realized, in addition, the intelligent garbage chamber has an automatic control function, the garbage ships automatically move, chamber doors can be automatically opened and closed, then the environmental pollution of the building construction site can be effectively prevented, and environment protection and sanitation as well as civilized construction are achieved.

Owner:中建新疆建工集团第一建筑工程有限公司

Construction method of special-shaped floor formwork without scaffold

InactiveCN113027120AReduce usageImprove usage turnoverForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksSupport surfaceScaffolder

The invention discloses a construction method of a special-shaped floor formwork without a scaffold. The construction method comprises the following steps that metal angle irons or angle aluminium with holes in corresponding quantity and size are customized according to the size of a metal module frame of a to-be-constructed special-shaped floor part; then, the customized metal angle irons or angle aluminum with the holes are installed on the lower portion of the inner side of a metal frame of the to-be-constructed special-shaped floor part in the mode that a bottom plate faces upwards or downwards according to needs; and finally, according to the size requirement of the to-be-constructed special-shaped floor part, a rubber formwork or a wood formwork matched with the size of the special-shaped floor part is directly paved on a bottom plate of the metal angle irons or angle aluminum with the holes installed on the inner side of the metal frame of the special-shaped floor; or a rubber formwork or a wood formwork matched with the size of the special-shaped floor part is laid on a supporting face formed by a load bearing part and the metal angle irons or angle aluminum with the holes. The method has the advantages that construction is convenient and fast, the construction effect is good, wood can be effectively saved, and the turnover rate of components is increased.

Owner:广东沃尔世家新型建材科技有限公司

Polystyrene foam particle heat insulation mortar

The heat insulating foamed polystyrene particle mortar used in building engineering consists of portland cement 40-45 wt%, flyash 3-6 wt%, fine silica powder 0-3 wt%, foamed polystyrene particle 1.3-2.8 wt%, polypropylene fiber 0.1-0.2 wt%, quartzite 42-47 wt% and water-thinned silane / siloxane emulsion 5-8 wt%. The present invention has light bulk weight, dry density 300-480 kg / cu m; good heat insulating and sound isolating performance, and heat conducting coefficient 0.07-0.13 W / m.k. The present invention utilizes partial flyash to replace cement and the product has no environment pollution.

Owner:SHANGHAI JIAOTONG UNIV

A kind of construction method of electroosmosis recharge well

ActiveCN106245621BAccelerated dissipationImprove permeabilityIn situ soil foundationSoil preservationWater tableWater level

The invention discloses a recharge well construction method adopting electroosmosis. The method comprises the following steps: determining groundwater level depth and soil layer lithologic distribution of a recharge field; according to a recharge target aquifer, constructing multiple recharge tube wells on the same side outside a foundation pit, performing a pumping test and a recharge test on the recharge tube wells to determine a permeability coefficient, a recharge influence radius and a recharge quantity; further determining a recharge scheme according to results of the pumping test and the recharge test, and constructing other recharge tube wells outside the foundation pit in the recharge field; arranging electrodes in positions certain distances away from the corresponding recharge tube wells and on one sides, away from the foundation pit in the recharge field, of the recharge tube wells; connecting the recharge tube wells through wires to form a recharge tube well conductive circuit, connecting the electrodes to form an electrode conductive circuit, connecting the recharge tube well conductive circuit with a power cathode, and connecting the electrode conductive circuit with a power anode. With adoption of electroosmosis, the permeability of soil mass around the recharge wells is improved, dissipation of recharge water is accelerated, and interference in the groundwater environment can be reduced.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

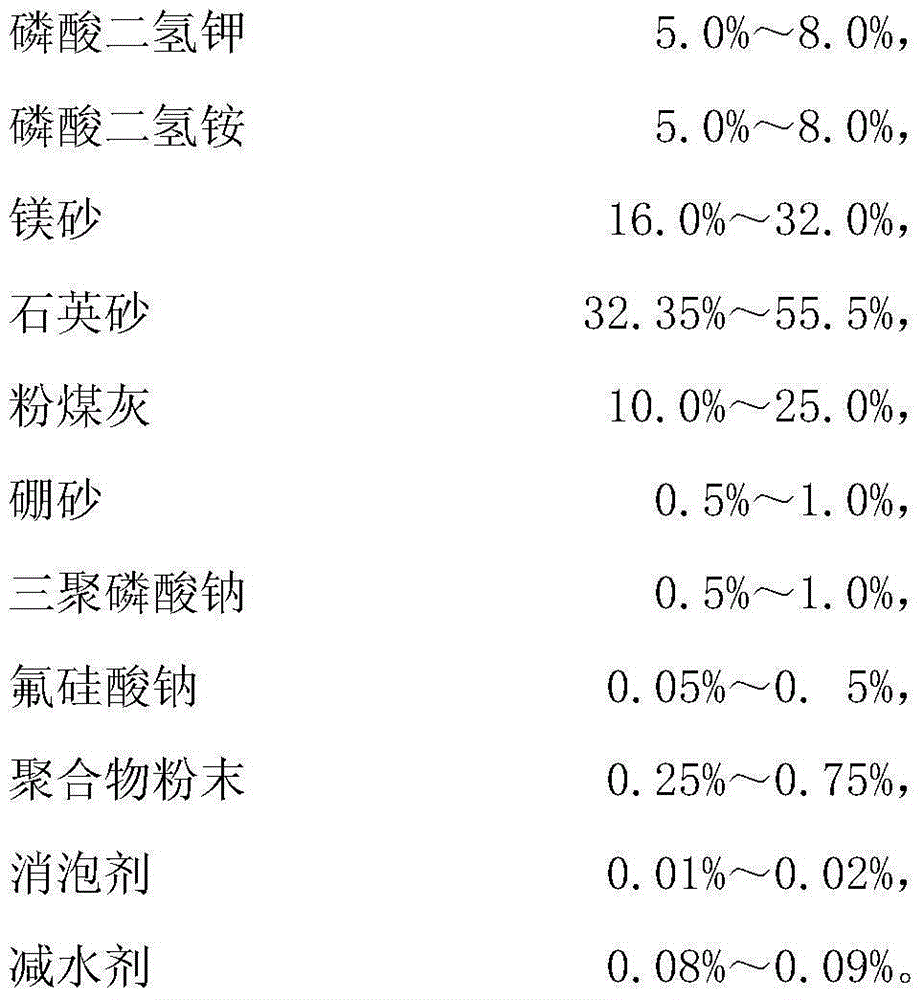

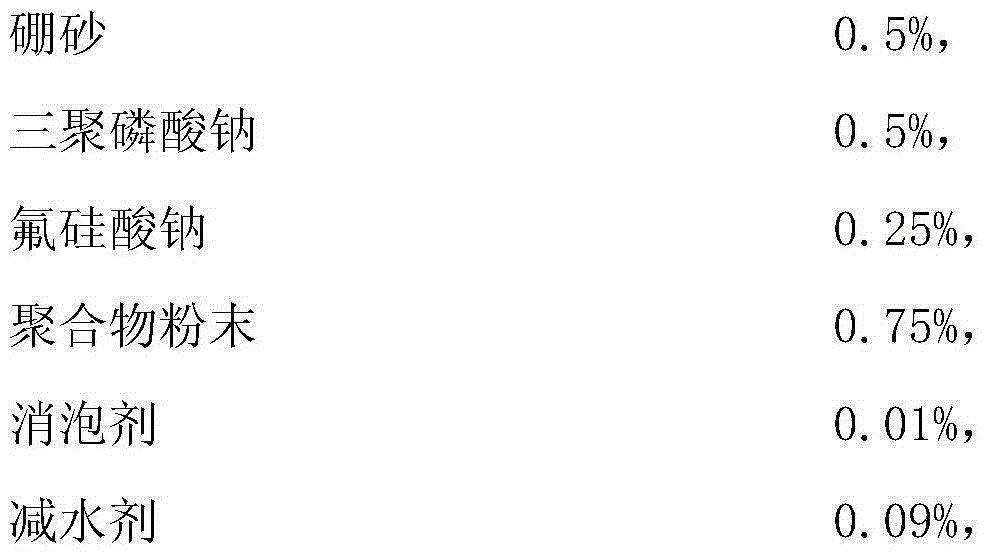

Rapid repair grouting mortar for high-speed rail ballastless track mortar layer

InactiveCN103922695BMeet the needs of rapid repair and opening to trafficLiquidityPhosphatePotassium

The invention provides grouting mortar used for restoring a high-speed rail ballastless track mortar layer. The grouting mortar used for restoring the high-speed rail ballastless track mortar layer comprises the following components in percentage by weight: 5.0-8.0% of potassium dihydrogen phosphate, 5.0-8.0% of ammonium dihydrogen phosphate, 16.0-32.0% of magnesium oxide, 32.35-55.5% of quartz sand, 10.0-25.0% of coal ash, 0.5-1.0% of borax, 0.5-1.0% of sodium tripolyphosphate, 0.05-0.5% of sodium fluorosilicate, 0.25-0.75% of polymer powder, 0.01-0.02% of defoaming agent and 0.08-0.09% of water reducer. The grouting mortar used for restoring the high-speed rail ballastless track mortar layer can be quickly set and hardened, strength is more than 30MPa, and the requirements for quickly restoring a high-speed rail ballastless track and being open to traffic can be met; liquidity is high, construction is easy and fallibility is strong; bonding capacity between the high-speed rail ballastless track mortar layer and an old mortar layer is strong; physical properties are stable, minimum inflation in volume is caused during setting and hardening, and impact resistance is strong.

Owner:CHINA RAILWAYS CORPORATION +1

Manufacturing method of rubber and chemical fiber synthetic waterproof sheet and product thereof

ActiveCN102182253BHigh strengthImprove toughnessUnderground chambersRoof covering using flexible materialsRubber materialPolymer science

Owner:杨太龙

A construction method for removing the enclosure structure of the end portal of the shield section

ActiveCN108868784BMinimize origination riskShort construction periodTunnelsReinforced concreteArchitectural engineering

The invention discloses a construction method for breaking an end socket tunnel portal retaining structure of a shield section. The method comprises the following steps of 1, drilling holes in a circular tunnel portal of the retaining structure; 2, stirring expansion slurry; 3, injecting the stirred expansion slurry into vertical holes and longitudinal holes, sealing the holes, and pre-cracking concrete; 4, chiseling a launching surface of the circular tunnel portal; 5, dividing the circular tunnel portal into a first area, a second area, ... and an nth area; 6, sequentially carrying out concrete peeling and reinforced concrete breaking on the launching surface of the circular tunnel portal in the first area, the second area, ... and the nth area; 7, chiseling a soil surface of the circular tunnel portal; 8, carrying out shield launching / reception tunneling construction. According to the method, through reasonable drilling arrangement and precise drilling depth, it is ensured that theconcrete breaking range of the tunnel portal can meet clearance requirements of design and construction; the whole process has high safety, collapse does not easily occur, the construction is fast, and meanwhile, the safety of construction personnel is ensured.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

A kind of preparation method of lightweight concrete prefabricated slab

ActiveCN105906371BOptimize mix ratioExcellent preparation strengthCeramicwareFoaming agentStone dust

The invention discloses a production method of lightweight concrete prefabricated big panels. The method comprises the following steps: 1, selecting raw materials according to a case that every cubic meter of lightweight concrete prefabricated big panels contains 450-550kg of cement, 65-195kg of stone flour, 3.25-9.75kg of a water reducer and 0.01-0.05kg of a foaming agent, foaming the foaming agent, uniformly mixing cement, the stone flour and the water reducer to prepare a cement mortar, adding the foamed foaming agent to the cement mortar, and uniformly stirring the foamed foaming agent and the cement mortar to prepare lightweight concrete; and 2, pouring the lightweight concrete in a die, and carrying out demolding treatment and curing to produce the lightweight concrete prefabricated big panels. The method solves the problem of adverseness of too large weight of common prefabricated big panels to transportation and hoisting installation, the weight of the lightweight concrete prefabricated big panels produced in the invention is about 50% lower than that of common concrete prefabricated big panels, and the construction efficiency of prefabricated wallboards is effectively increased.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Quartz high temperature melting lump waterpower spurting breaking device

ActiveCN102527482BImprove first-class rateSave resourcesGrain treatmentsSputteringMechanical pressure

A quartz high temperature melting lump waterpower spurting breaking device comprises a corrosion resistant cylinder body arranged on a machine frame. A water cooling base plate is positioned at the bottom of the cylinder body, a gas collection cover is arranged at the top of the cylinder body, a pair of extrusion heads are positioned on the water cooling base plate, and a cylinder body wall self-cooling system and a high temperature melting lump inflowing water spurting system are arranged on the cylinder body. Quartz ore is arranged in a resistor furnace to be melted into a lump shape to be arranged on the water cooling base plate which is arranged in the cylinder body. Simultaneously, two groups of spurting water are started to perform cold explosion on quartz high temperature melting lump, and when high temperature quartz melting lump is in a shock cooling physical state, the ore generates concentrated cracks and is loosened, the extrusion heads further exert mechanical pressure on the quartz lump bodies, and finally, quartz is smashed into fine blocks of about 10mm. The quartz high temperature melting lump waterpower spurting breaking device achieves civilized construction and environments, improves quality and stability of products, remarkably improves rate of first products and provides conditions for large-scale industrial production.

Owner:江苏省晶瑞石英工业开发研究院有限公司

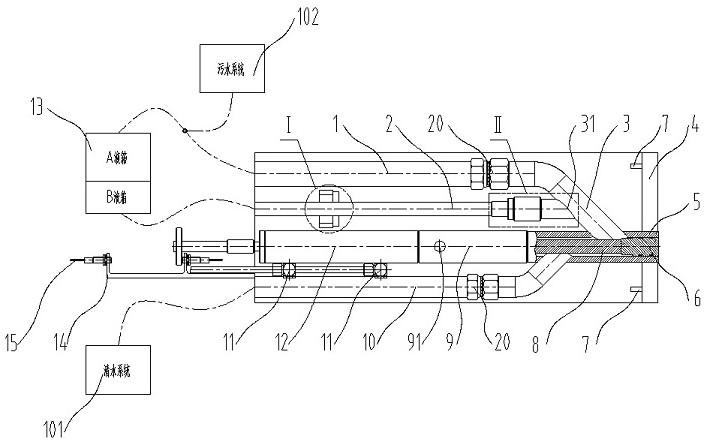

Shield tail double-liquid synchronous grouting mixer

PendingCN114517683AAvoid clogged tubingRealize automatic mixingSolid waste managementUnderground chambersSlurryPipe

The shield tail double-liquid synchronous grouting mixer comprises a liquid A conveying pipe, a liquid B conveying pipe, a slurry mixing pipe, a slurry discharging pipe, a conversion piston, a hydraulic oil cylinder, a stroke sensing device, a flushing water pipe, a material storage box, an upper cover plate, a lower cover plate and a water system. Independent grouting of the liquid A and the liquid B is achieved, and grouting can be conducted by selecting a proper grout proportion according to different geological environments; automatic mixing and discharging of the liquid A and the liquid B in the pipe are achieved, and the situation that the conveying pipe is blocked due to slurry solidification is effectively avoided; a special sealing ring of the piston is switched, so that the pressure bearing capacity is higher, and the problem of pipeline blockage caused by grout backflow during grouting can be effectively prevented; a special sealing ring of the piston is switched, bidirectional sealing is achieved, and the problem that clear water flows into the gap between the excavation face and the pipe piece during flushing, and consequently the slurry proportion is changed can be effectively solved.

Owner:YINGNUOWEI VALVE IND

Construction method for bonding polymer water-proof coiled material

InactiveCN101429784BWon't overflowRealize civilized constructionBuilding insulationsArchitectural engineeringEngineering

The invention discloses a construction method for splicing a macromolecular waterproof roll, which comprises the following steps: a. two double sticky tapes are adhered to both ends of a joint respectively to form a closed cohesive surface; b. the waterproof roll is fixed inside the joint, and an adhesive is coated on the cohesive surface; and c. the waterproof roll and the double sticky tapes are adhered to each other, and the cohesive surface is rolled by a pressure roller. The construction method improves the prior construction method, adopts the double sticky tape as the epoxy adhesive toform a closed receiving space, uses the pressure roller to grind a cohesive position of the waterproof roll and discharge air bubbles in the epoxy adhesive, makes the waterproof roll in a cohesive area practically combined with the epoxy adhesive which can not be overflowed from the cohesive position, realizes civilized construction, reduces the engineering cost, can perform visualized check on the construction quality through the transparent waterproof roll, and widen the application range.

Owner:吴兆圣

Assembly construction method for PVC wire pipe hidden lying

InactiveCN101841143BImprove work efficiencyHigh construction quality and reliabilityApparatus for laying cablesShop drawingEngineering

Owner:HUNAN NO 6 ELECTROMECHANICAL INSTALLATION

Prefabricated dewatering pipe pile in building foundation pit and its application method

The invention relates to a prefabricated dewatering pipe pile in a building foundation pit and a method for using the same. The prefabricated dewatering pipe pile is hollow and cylindrical and includes a pipe wall and a conical pile point. The upper part of the pipe wall is arranged with a plurality of water-permeable piles at intervals. hole. A filter cartridge is provided inside the prefabricated downwater pipe pile, and the upper end of the filter cartridge is open and the lower end is closed. The method for using the prefabricated dewatering pipe piles includes the following steps in turn: (1) prefabricated prefabricated dewatering pipe piles; (2) determining the total number and arrangement spacing of the prefabricated dewatering pipe piles; (3) installing the prefabricated dewatering pipe piles, and (4) put submersible pump and water outlet pipe in the prefabricated downwater pipe pile; (5) stop submersible pump pumping, clear hole, pour cement mortar, and part of cement mortar penetrates outwards through the permeable hole and connects with all Describe the consolidation of soil outside the prefabricated downfall pipe pile. The invention shortens the construction period of the pipe well, and at the same time, the prefabricated downwater pipe pile is changed into an uplift pile, and the anti-floating performance of the prefabricated downwater pipe pile is improved.

Owner:JIANGXI THE SECOND CONSTR

Construction method of heavy-duty lining trolley and lining formwork of push-pull type buckle support

ActiveCN111456764BGuaranteed smooth progressHigh strengthUnderground chambersTunnel liningArchitectural engineeringJackscrew

Owner:中铁隧道集团一处有限公司

A kind of ceramic tile waste slag particle insulation mortar and its preparation method

The invention discloses thermal mortar of ceramic tile slag particles. The thermal mortar is characterized by being prepared from the following raw materials in parts by weight: 290-330 parts of cement, 200-245 parts of ceramic tile slag particles, 35-50 parts of calcium sulfate whiskers, 85-105 parts of mica, 90-110 parts of aluminum nitride powder, 105-130 parts of kaoline, 75-90 parts of reed stems, 9-13 parts of naphthalene-based superplasticizer, 8-12 parts of sodium tripolyphosphate, 6-9 parts of calcium saccharate and 3-6 parts of assistants. The thermal mortar is light in unit weight, excellent in corrosion resistance, good in heat preservation and sound insulation performances, low in heat conductivity coefficient, and good in water-retaining property, and the product is stable in physical property, free of cracking, free of hollowing, good in ageing resistance and long in service life. The product can be applied by adding water, and is convenient to use, civilized construction can be achieved, and the product is free of toxicity, free of taste, free of harm to a human body, and free of environmental pollution, and belongs to the environment-friendly insulating and energy-saving material.

Owner:深圳绿景环保再生资源有限公司

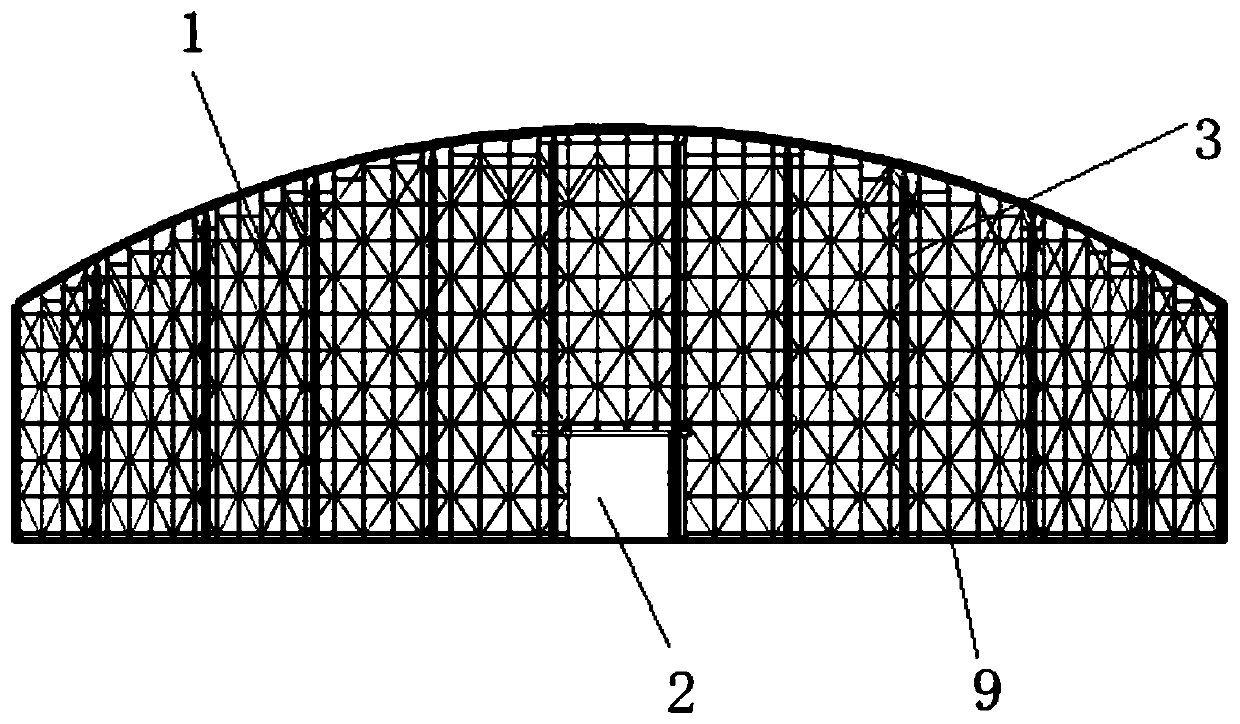

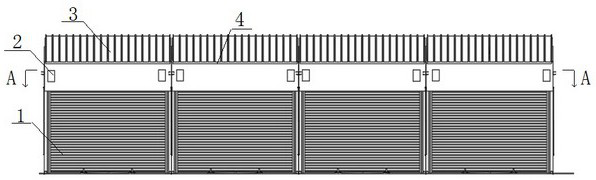

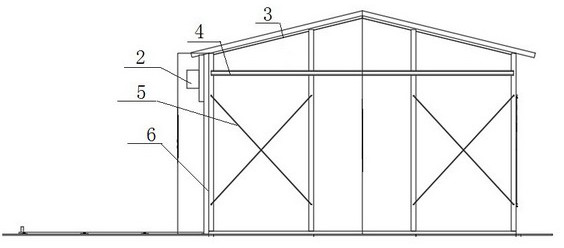

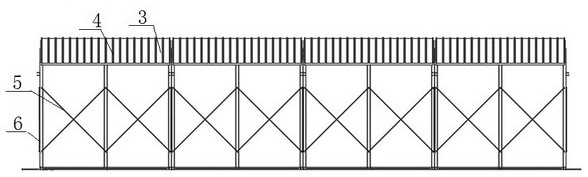

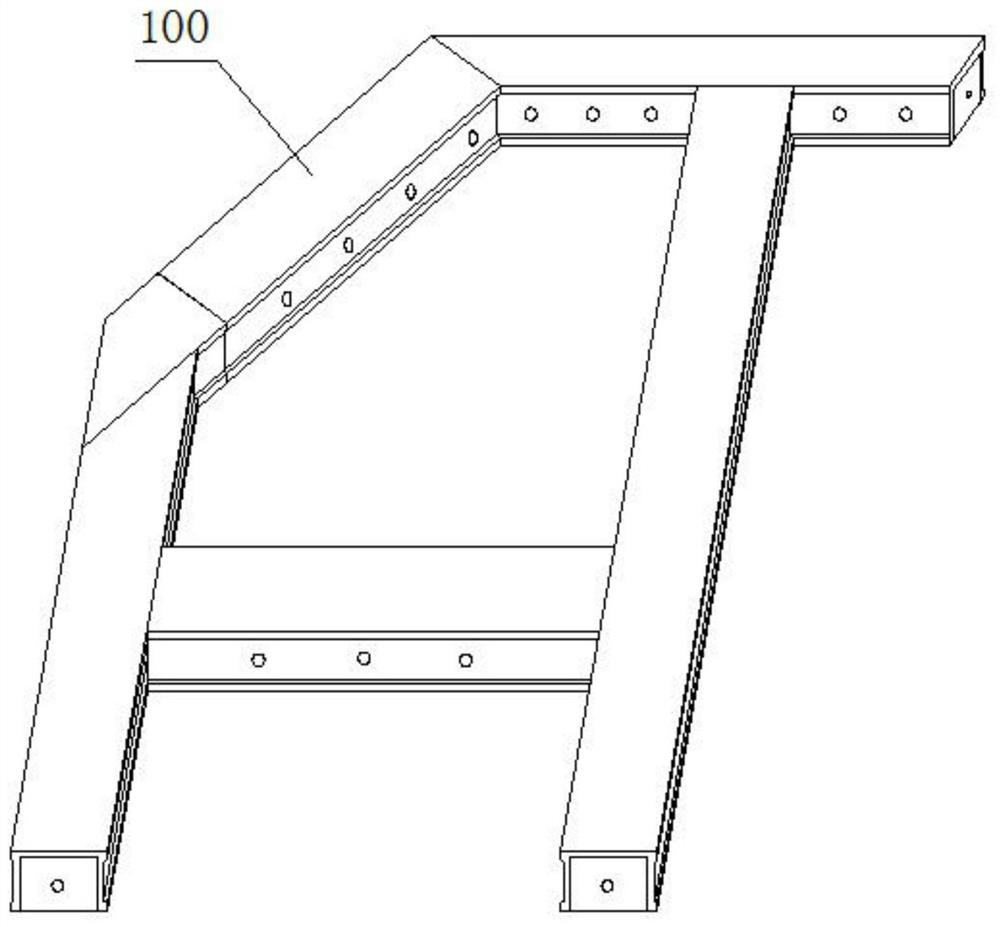

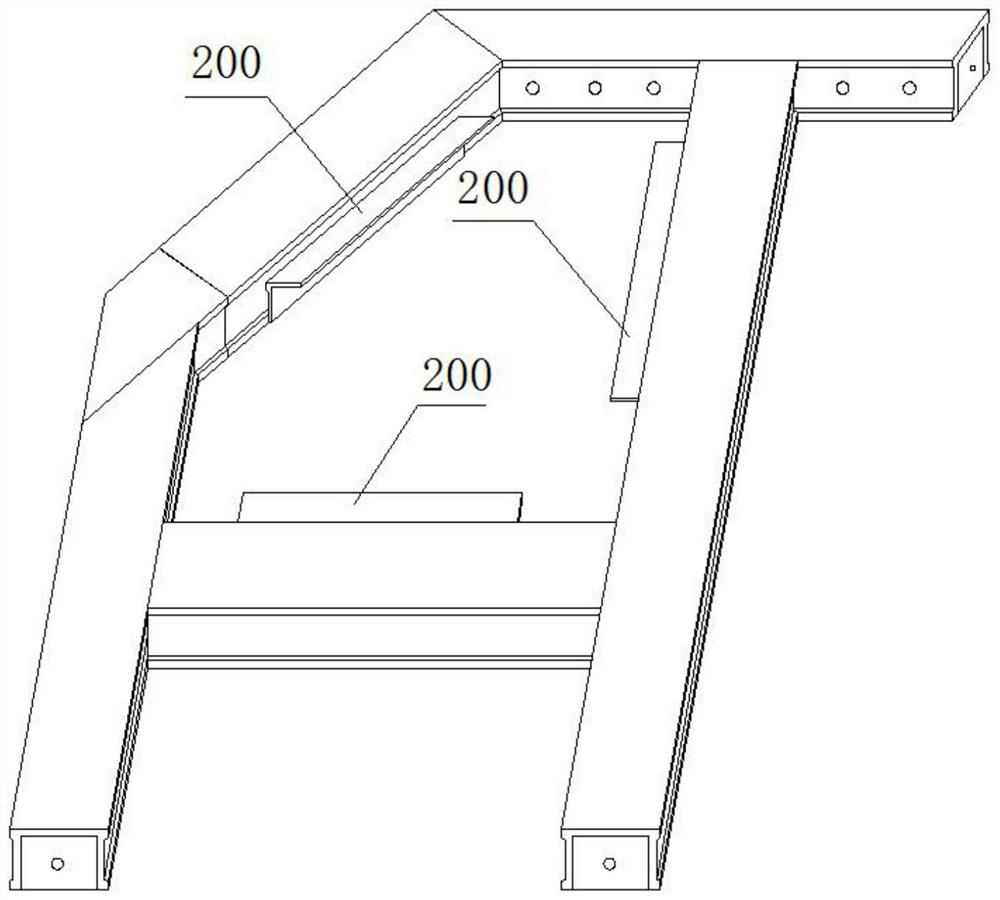

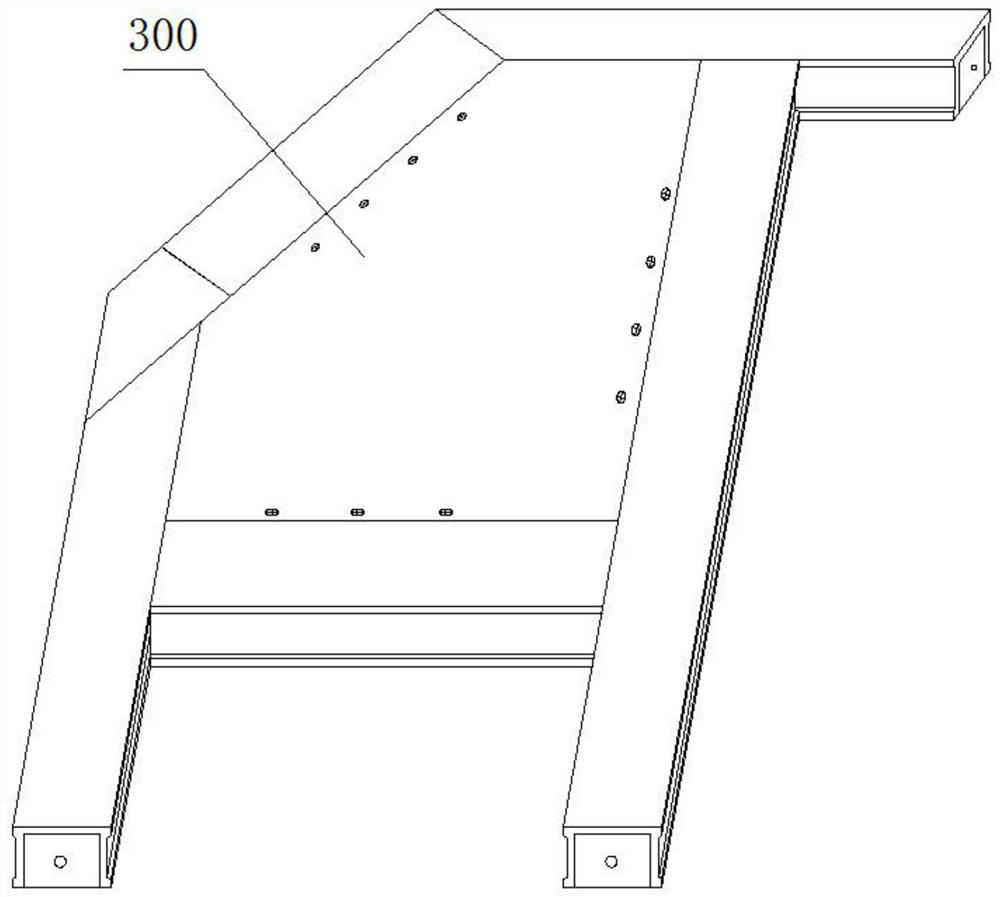

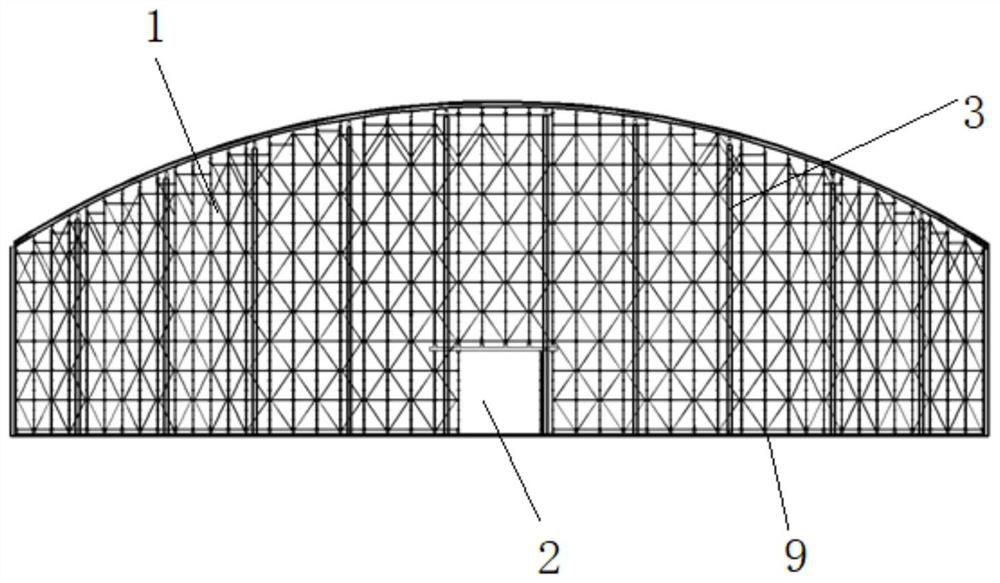

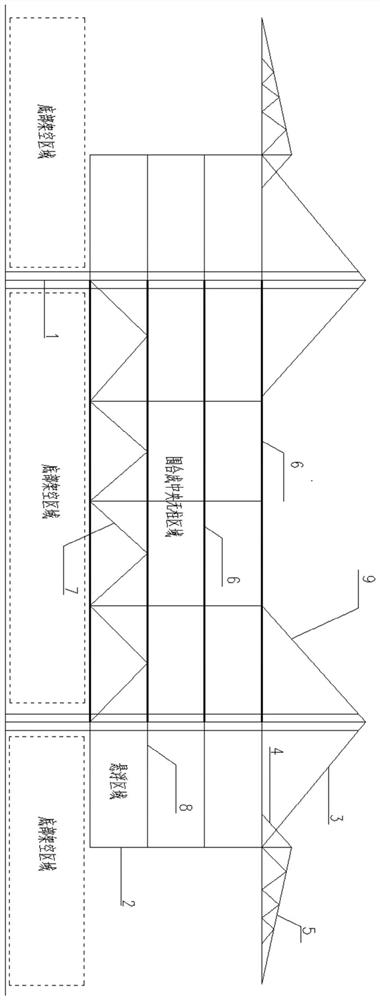

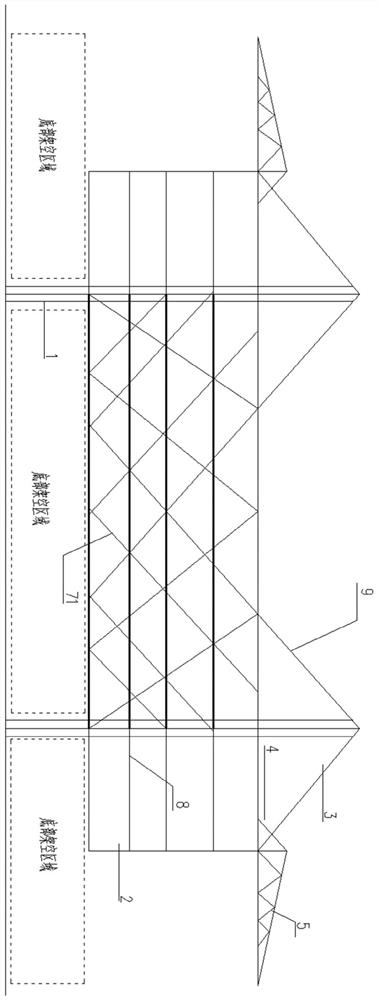

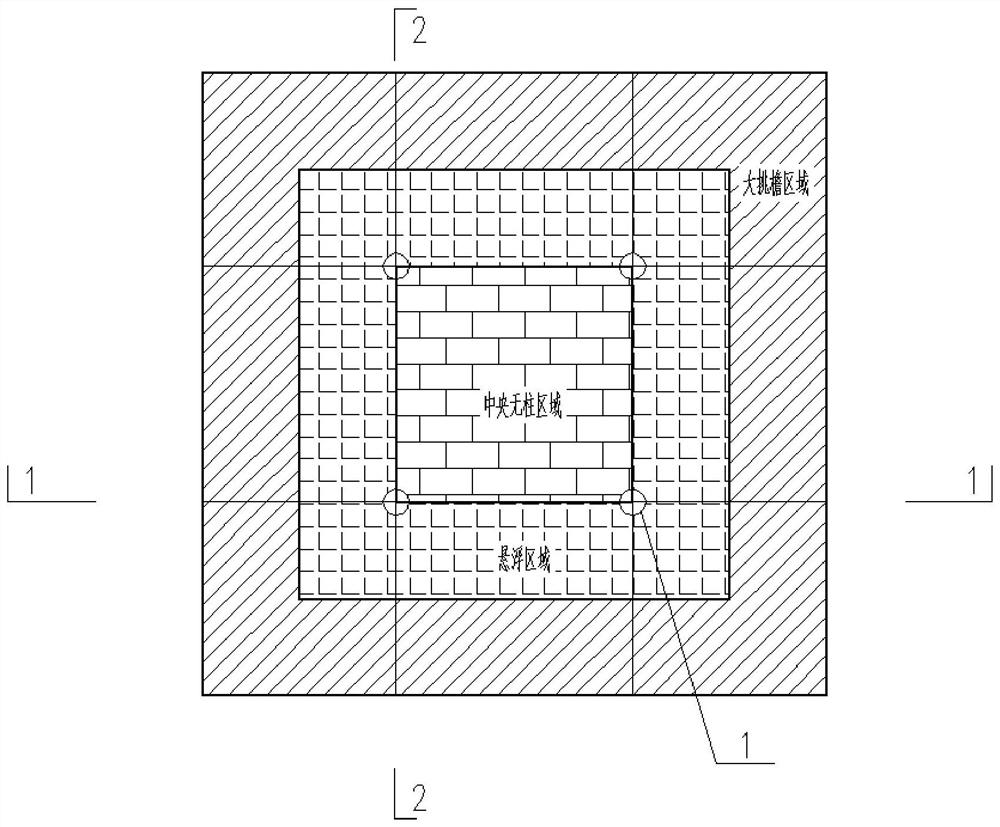

Large-span elevated building without column at center and wall at bottom and construction method

PendingCN112709333ARealize the floating architectural effectIncrease the use of spaceBuilding material handlingFloor slabArchitectural engineering

The invention relates to a large-span elevated building without a column at the center and a wall at the bottom and a construction method, and belongs to the field of buildings. According to the large-span elevated building, frame columns in the elevated building are arranged in a multi-point mode, a plurality of frame beams are arranged on the frame columns from top to bottom, the plurality of frame beams are mutually encircled, the frame beams encircled on the same horizontal plane form a beam frame of a single-storey floor, floor slabs are arranged between beam frames defined by each layer of frame beam set to form a closed structure, and the frame beam located at the bottom is erected away from the ground through the hanging columns. According to the large-span elevated building without the column at the center and the wall at the bottom, the number of columns (or walls) can be reduced to the minimum, the horizontal distance of the columns (or walls) is about 30-50 m, the outward-protruding area of the columns (or walls) is about 30 m, no column (or wall) exists around the building, and the suspension type building effect is achieved; only four columns (or walls) are arranged on the bottom layer of the building and can be used as large open-type activity spaces for performances, exercises and the like; and the upper layers are large in use space, the occupied space of the columns (or walls) is small, flexible division can be achieved, and diversified use is achieved.

Owner:南京大学建筑规划设计研究院有限公司

Dam concrete cabin surface water accumulation hidden pipe discharge method

ActiveCN102287003BGuarantee the pouring qualityLittle construction disturbanceDamsClimate change adaptationWater dischargeEngineering

Owner:CHINA GEZHOUBA GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com