Shield tail double-liquid synchronous grouting mixer

A technology of synchronous grouting and mixer, which is applied in the field of shield tail double-liquid grouting and tunnel construction equipment, can solve problems such as blocked pipelines, achieve the effects of protecting pipelines, realizing timeliness, and controlling soil settlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

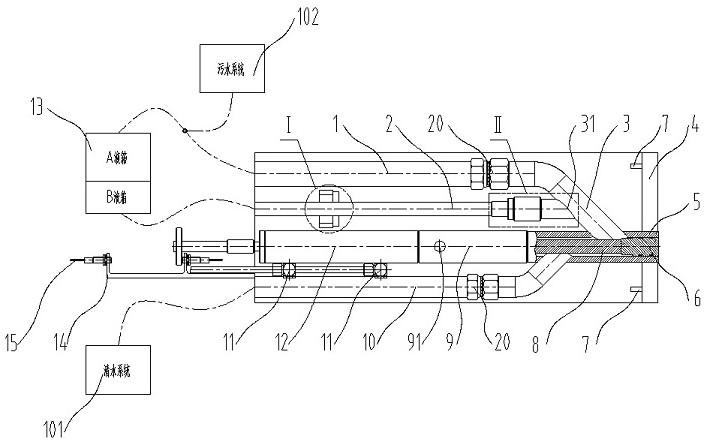

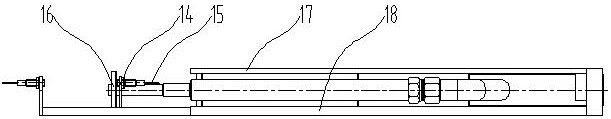

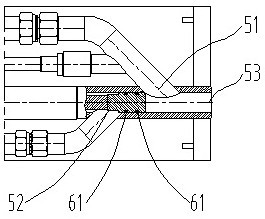

[0028] Such as Figure 1~5 As shown, a double-fluid synchronous grouting mixer for the shield tail is installed in the shield body of the shield tail, including A liquid delivery pipe 1, B liquid delivery pipe 2, slurry mixing pipe 3, support plate 4, slurry discharge pipe 5, conversion Piston 6, positioning plate 7, hydraulic cylinder 11, proximity switch 15, flushing water pipe 10, material storage box 13, upper cover plate 17 and lower cover plate 18;

[0029] The A liquid delivery pipe 1 and the B liquid delivery pipe 2 are connected to the corresponding slurry pipes of the material storage tank 13, and the outlet ends of the slurry pipes are respectively communicated with the slurry mixing pipe 3 through the quick-change joint 20 and the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com