Patents

Literature

96results about How to "Realize automatic mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Kit for automatically-automatic chemiluminescence immunoassay analyzer

ActiveCN102147370AAutomate deliveryRealize automatic mixingChemiluminescene/bioluminescenceBiological testingTectorial membraneTop cap

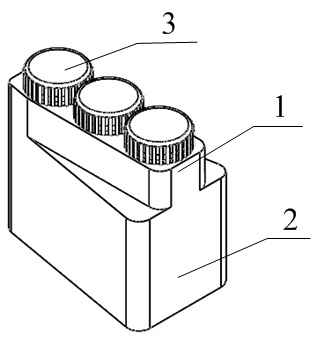

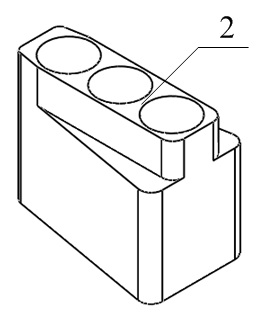

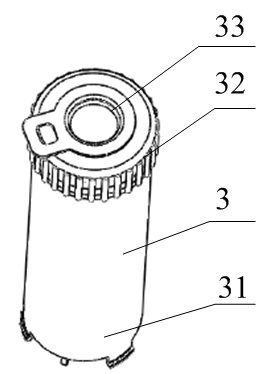

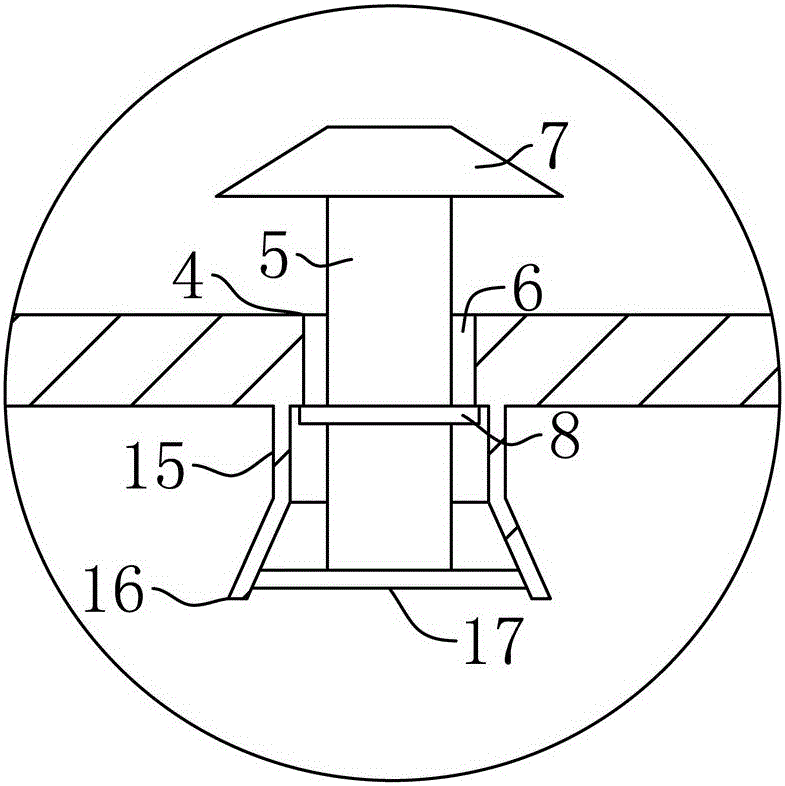

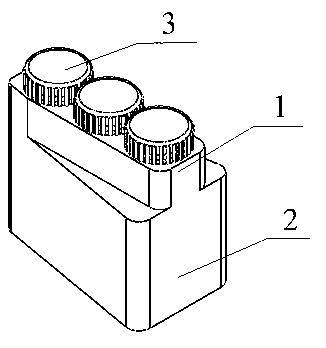

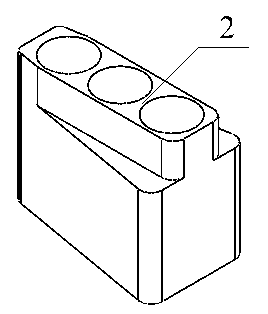

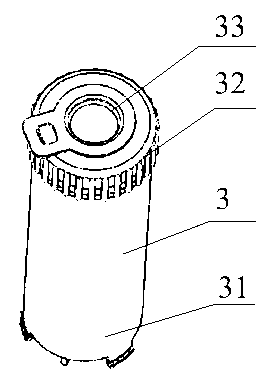

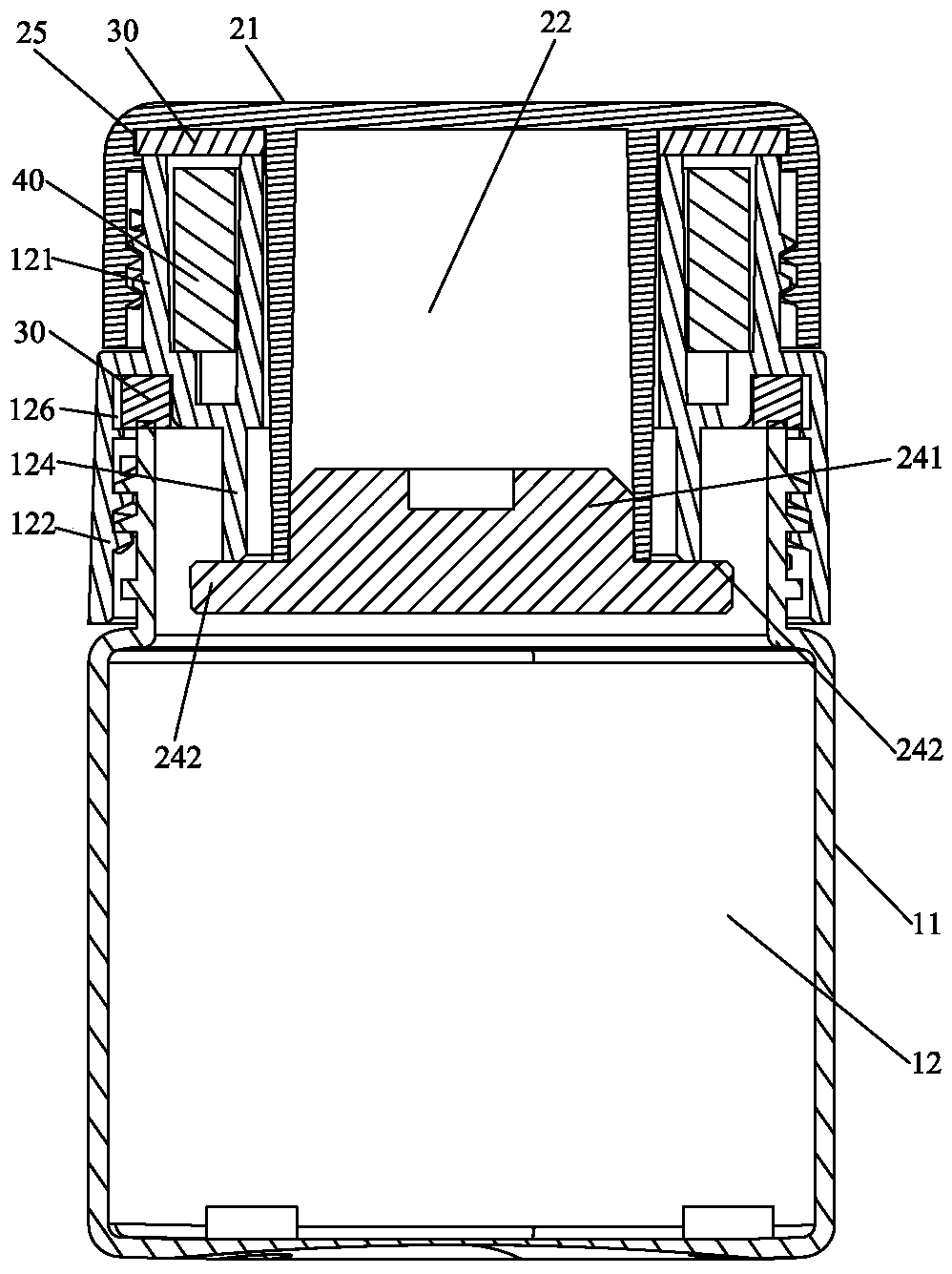

The invention discloses a kit for an automatically-automatic chemiluminescence immunoassay analyzer. The kit is characterized by comprising a reagent cup (3) and a reagent shelf (2), wherein the reagent shelf (2) is provided with a hole passing through the reagent shelf (2); the reagent cup (3) comprises a reagent cup body (31) and a reagent cup cover, wherein the reagent cup cover comprises a movable top cover (33), a protective film (34) and a cover body (32) which are arranged from top to bottom in sequence; and the radius of the cover body is larger than that of the hole. By the specific structure of the kit, the operations of delivery of kits, mixing of reagents, code scanning and the like can be conducted by a matched moving mechanism.

Owner:SICHUAN MACCURA BIOTECH CO LTD

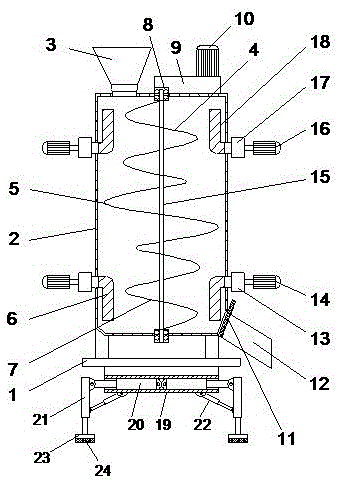

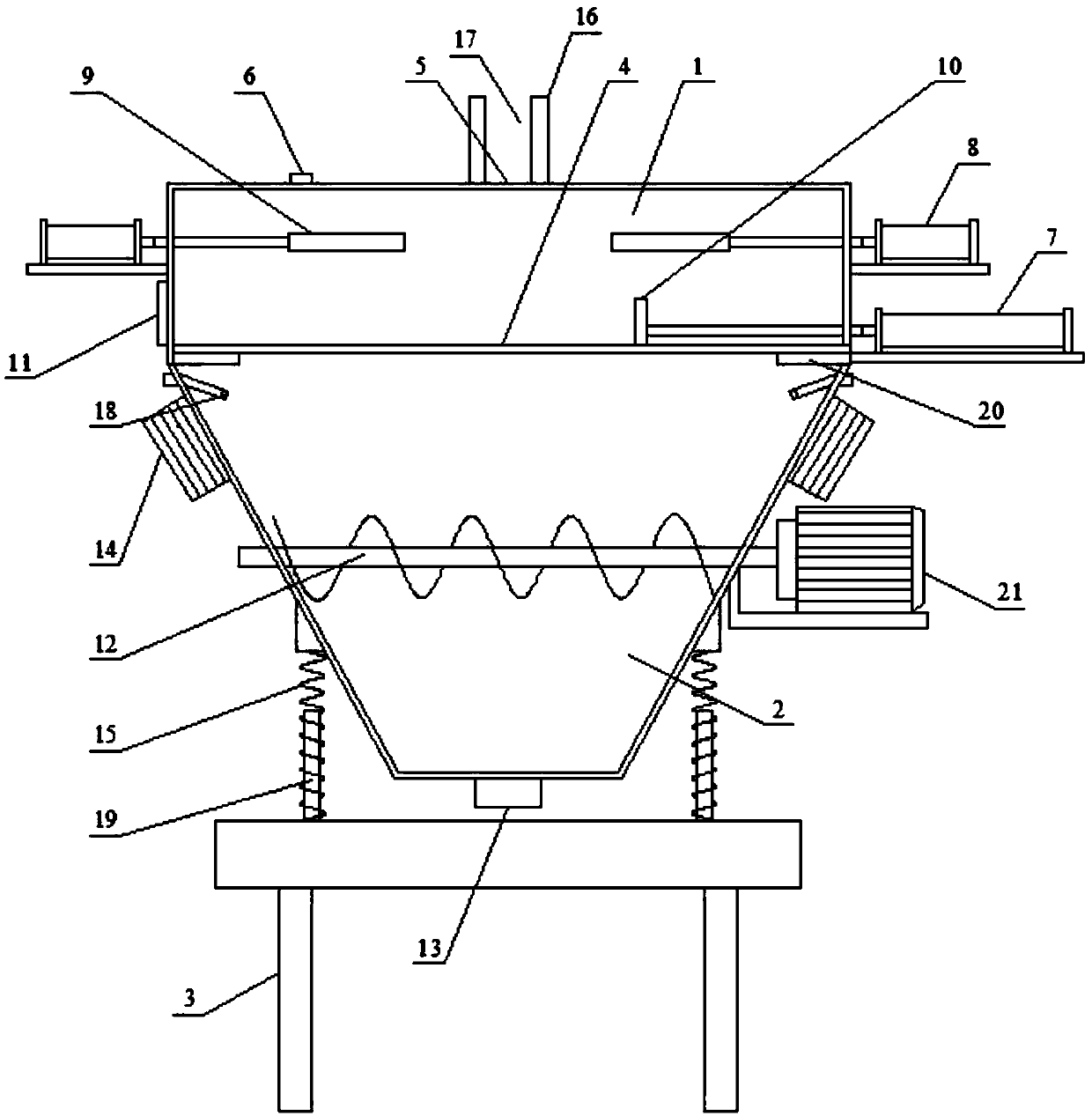

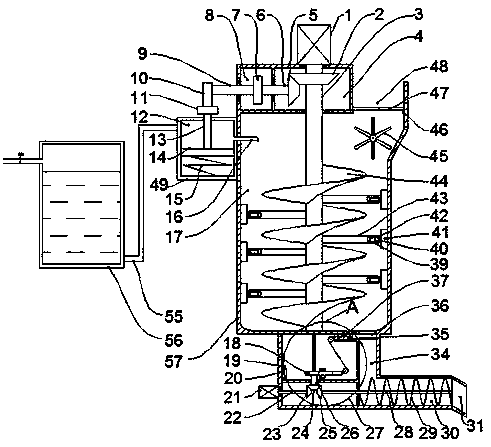

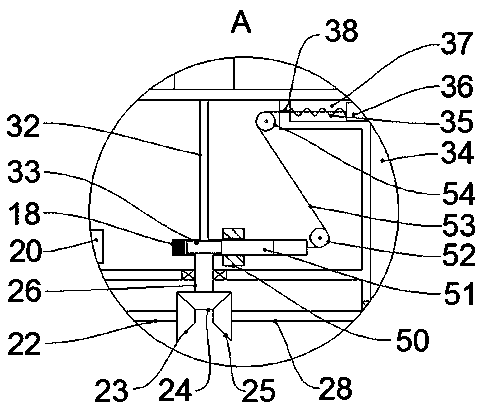

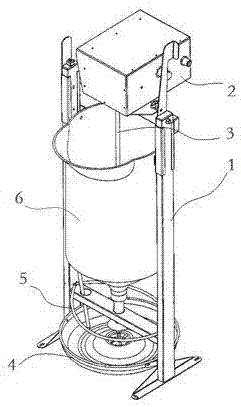

Stable supporting type building stirrer

InactiveCN105582832AImprove stabilityStir wellRotary stirring mixersTransportation and packagingHydraulic cylinderBaseboard

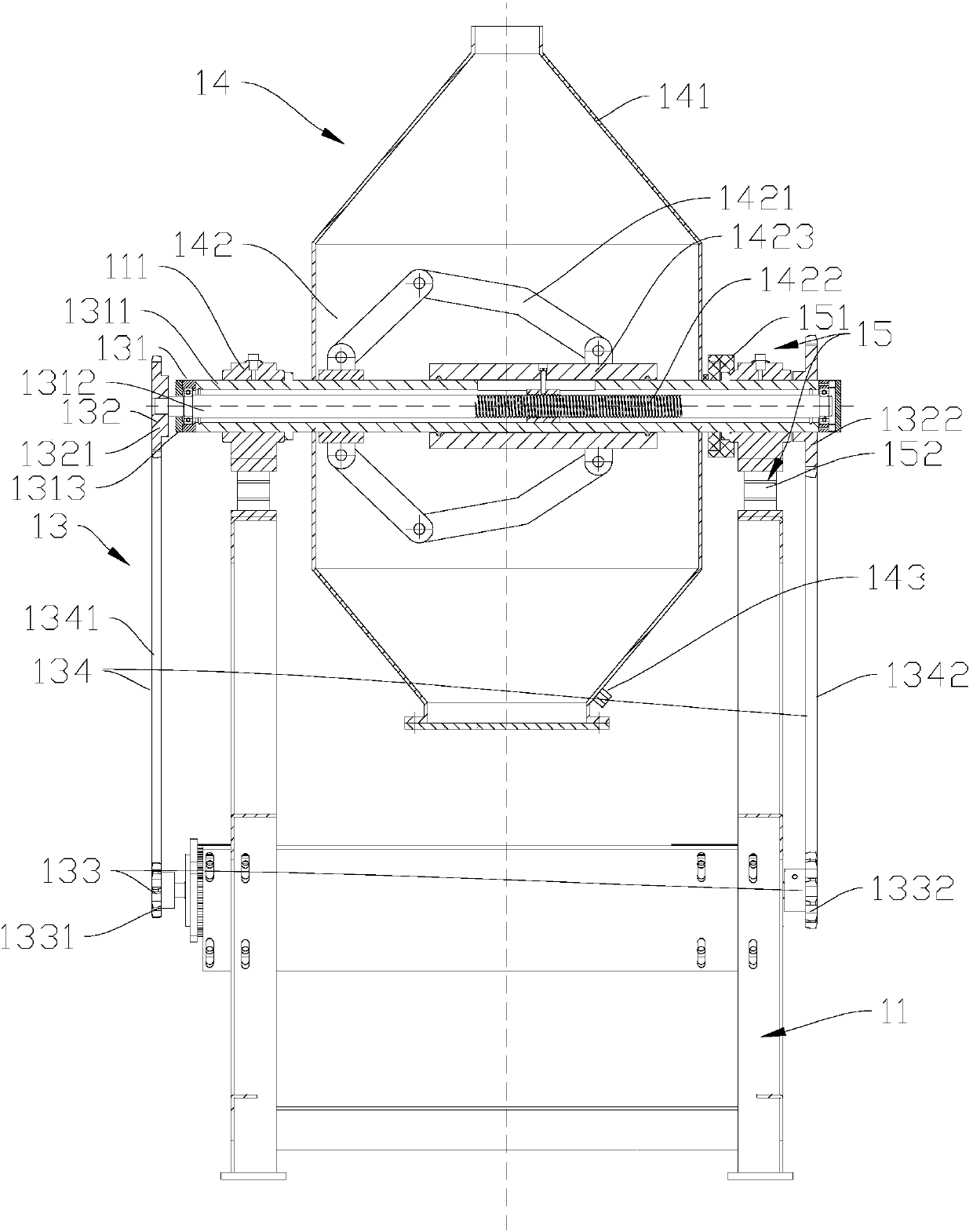

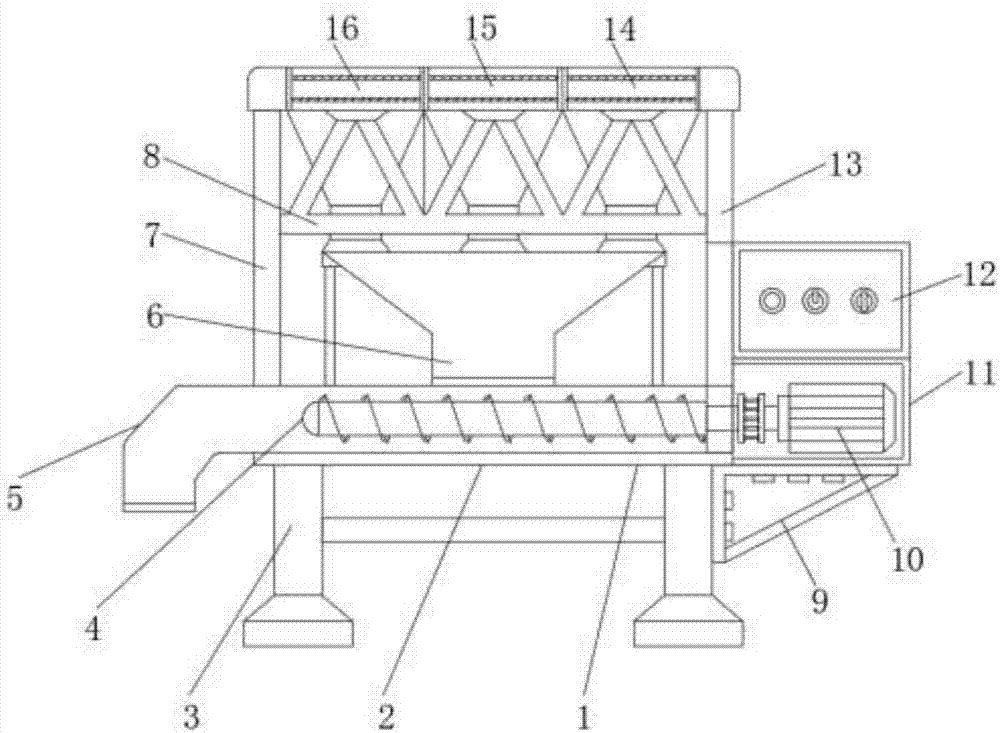

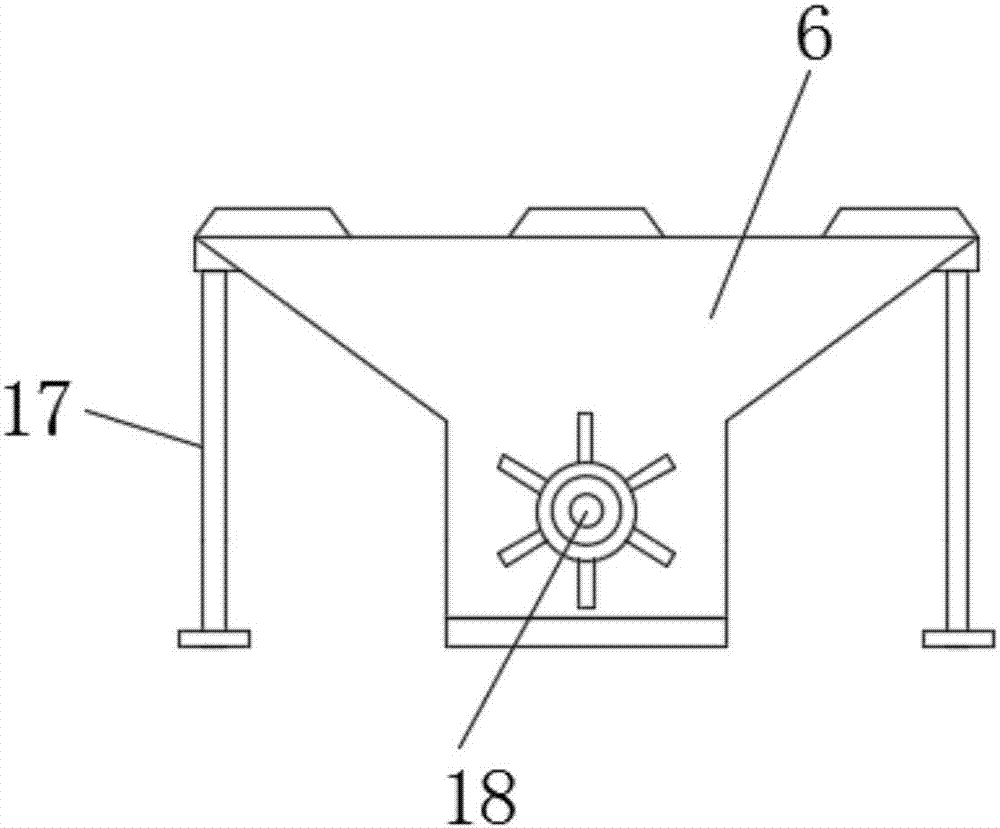

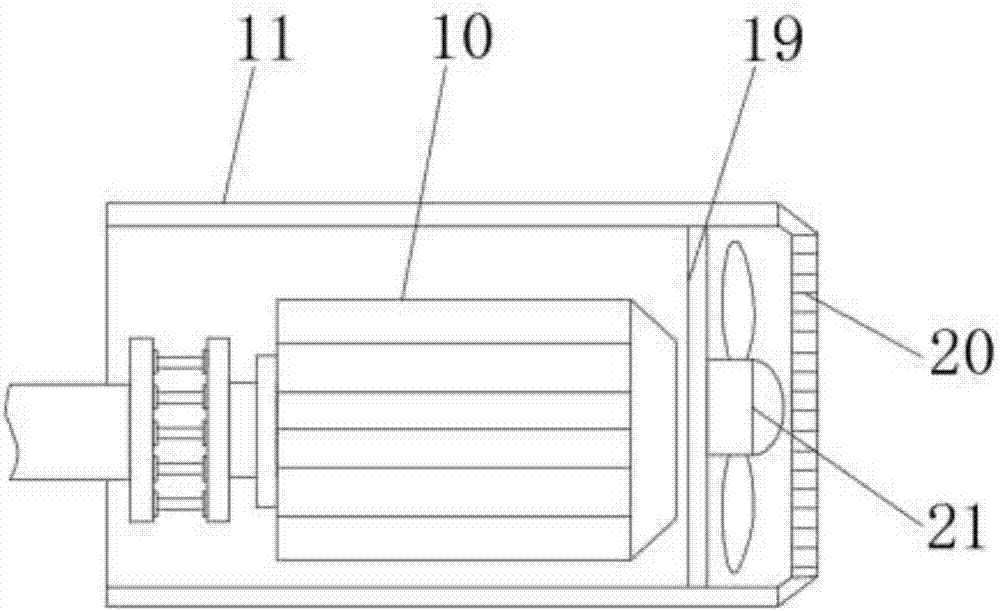

A stable supporting type building stirrer comprises a stirring container, a supporting frame, a feed inlet and a discharge outlet, wherein the supporting frame is fixedly installed on the bottom of the stirring container, the supporting frame is arranged on a supporting guide rail, first hydraulic cylinders are symmetrically arranged inside the supporting guide rail, the end of a piston rod of each first hydraulic cylinder is connected with one end of a corresponding second hydraulic cylinder, a third hydraulic cylinder is arranged between each second hydraulic cylinder and the supporting guide rail, and the end of a piston rod of each second hydraulic cylinder is connected with a corresponding baseboard; the feed inlet is formed in the left side of the top of the stirring container, a feed hopper is arranged above the feed inlet, the discharge outlet is formed in the right side of the bottom of the stirring container, a discharging electromagnetic valve is arranged on the discharge outlet, and a rotary shaft is installed in the middle inside the stirring container through a bearing. Stirring efficiency is high, construction cost is reduced, stirring is uniform, slipping during working of equipment is avoided, and supporting stability is high.

Owner:黄斌

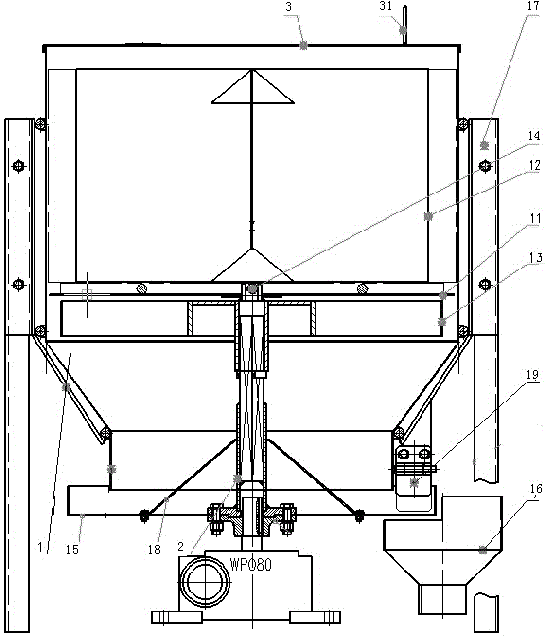

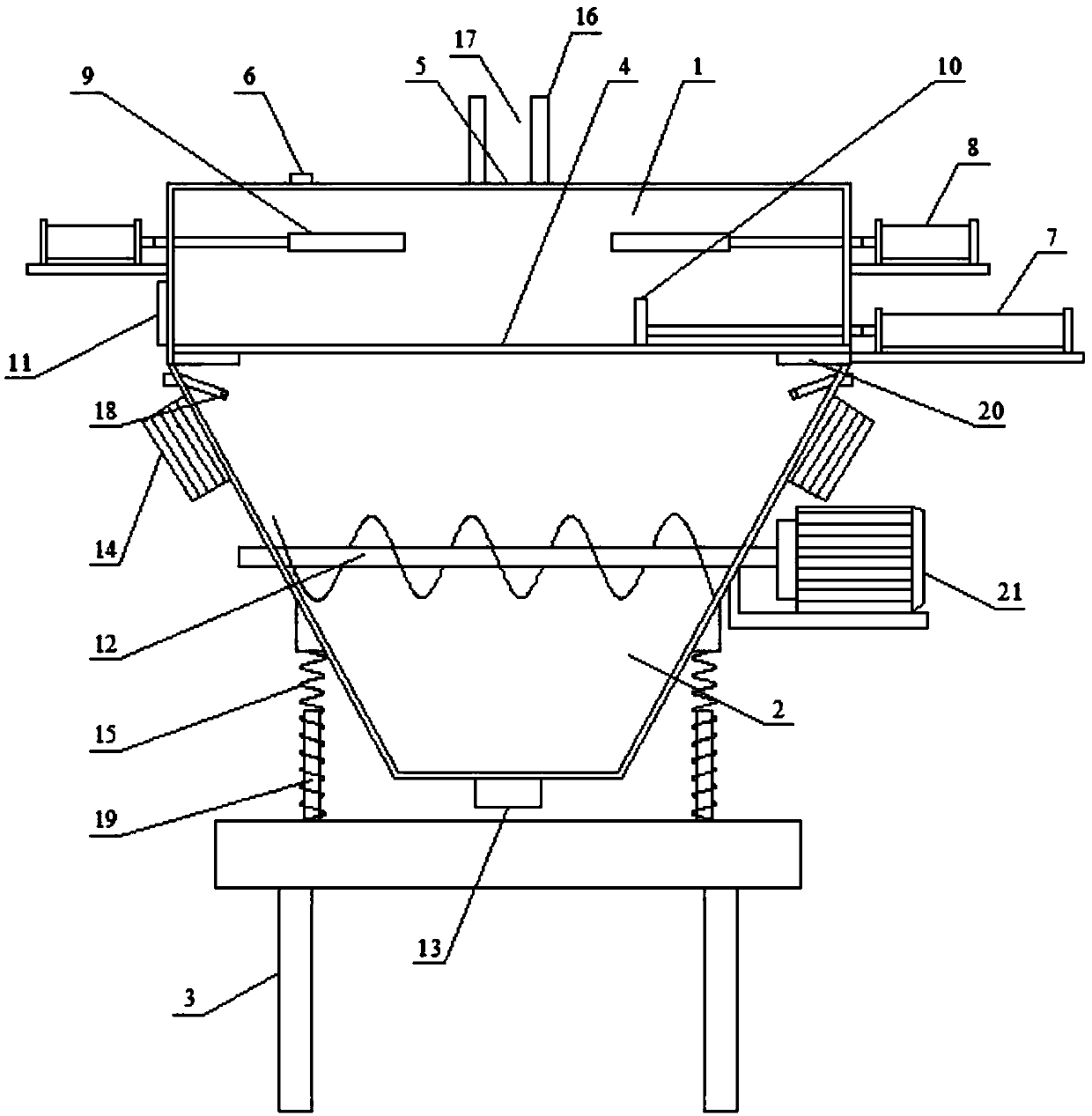

Premixing device for cement blended with concrete early-strength water reducing agent

InactiveCN107756629AEvenly dispersedReduce pollutionCement mixing apparatusSold ingredients supply apparatusWorking environmentWater reducer

The invention discloses a premixing device for cement blended with a concrete early-strength water reducing agent and relates to the technical field of concrete equipment. The premixing device comprises a mixing tank composed of a feeding chamber and a material mixing chamber and a tank body supporting platform, wherein a material passing screen mesh is arranged between the feeding chamber and thematerial mixing chamber. By adopting the structure of the device disclosed by the invention, automatic mixing of the cement and the water reducing agent is realized, so that manpower is saved, the material mixing uniformity is improved and the water reducing agent is uniformly dispersed into the cement; pollution, caused by dust in a cement bag cutting process, on a working environment is alleviated; meanwhile, the sieving of the cement is realized, and a phenomenon that an agglomeration phenomenon occurs in a material mixing process of the cement so that the uniform dispersion of the water reducing agent is influenced is prevented; a vibration motor and a vibration spring are further arranged so that the sieving speed of materials and the material mixing uniformity are improved; a mixedmaterial is humidified through a spraying humidification nozzle so that dust pressure in the material mixing chamber is reduced; meanwhile, further uniform dispersion of the water reducing agent in the cement is promoted.

Owner:马多浩

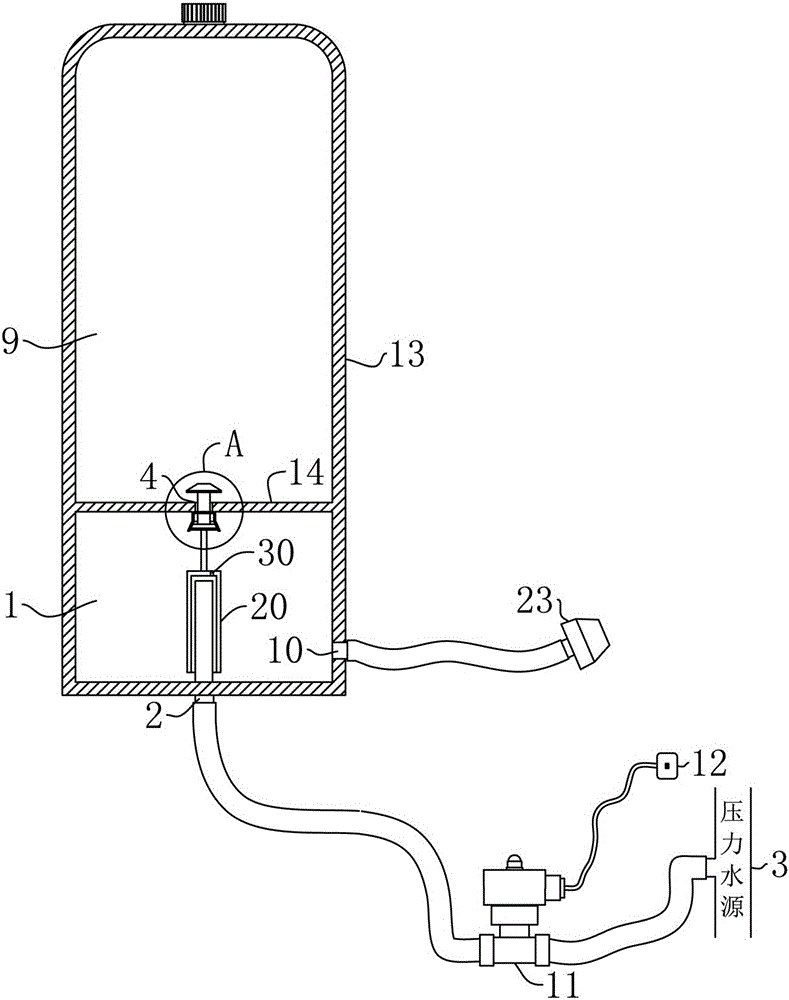

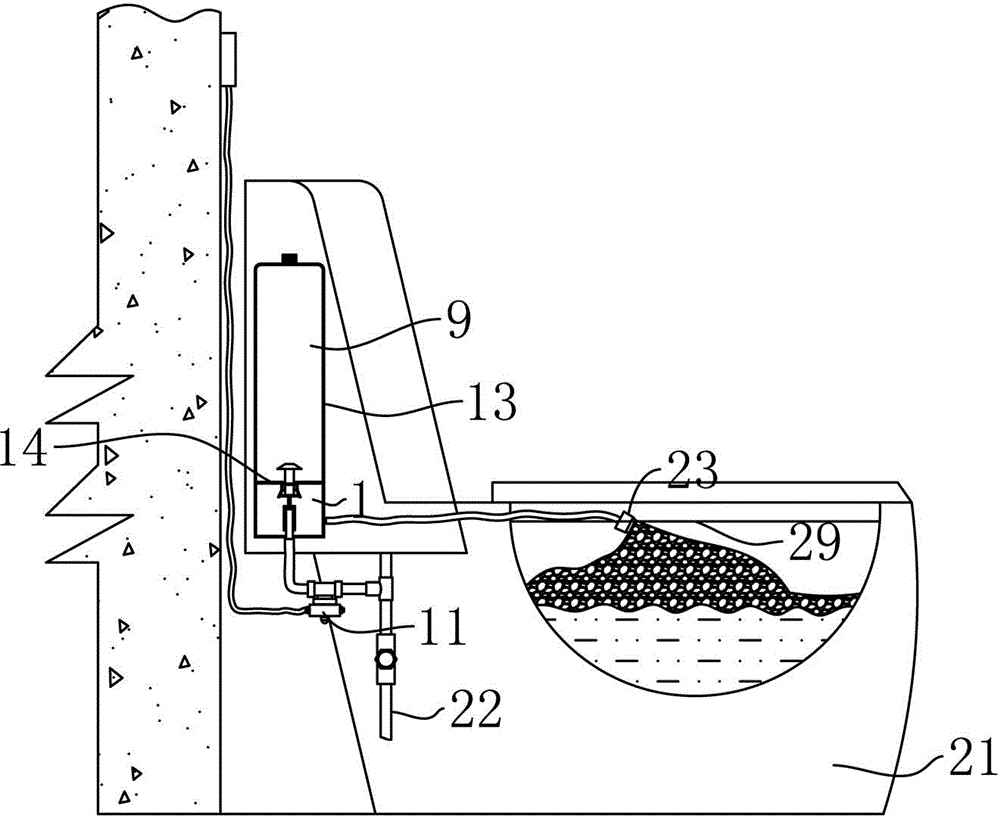

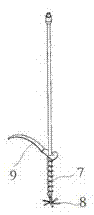

Hydrodynamic foam generator and self-cleaning water closet based on foam generator

InactiveCN106049632ARealize self-cleaningRealization of generationLavatory sanitoryEngineeringCleansing Agents

The invention provides a hydrodynamic foam generator, aiming at solving the technical problem of automatically acquiring raw water and a cleaning agent with the involvement of less equipment and the technical problem of automatically generating foam and spraying the foam without the assistance of electrical equipment. The foam generator comprises a mixing cavity; under hydraulic pressure, the mixing cavity is used for controlling suction of the cleaning agent and the raw water and for blending the cleaning agent and the raw material; a mixed solution is turned into foam by virtue of a spraying head of a foaming device, and the foam is beaten into a water closet; the water closet can achieve self-cleaning mainly by virtue of the foam generator; a water inlet of the foam generator communicates with a water intake pipe of the original water closet by virtue of a pipeline and a switch, and the switch, by virtue of a sensor which can sense the approximate state of a human body, is used for determining whether the foam generator is started or not; the foam generator is simple in structure and low in manufacturing cost; and meanwhile, the foam generator can generate fragrance through the aroma of the cleaning agent, so that people can feel happy.

Owner:田伟

Concrete mixing equipment

ActiveCN110978277ASimple organizationEasy to useDischarging apparatusHollow article cleaningMixing chamberMechanical engineering

The invention provides concrete mixing equipment. The concrete mixing equipment comprises a concrete mixing tank and a cleaning device arranged on the left side of the concrete mixing tank. The concrete mixing tank is internally provided with a mixing chamber. A stirring device is arranged in the mixing chamber. The concrete mixing equipment is simple in structure, easy and convenient to use and capable of implementing automatic feeding, realizes automatic stirring, greatly improves the stirring efficiency and realizes complete mechanical control during cleaning after stirring and feeding. Theconcrete mixing equipment can be accurately cleaned. The situation that mixed materials are cleaned not timely and are cleaned incompletely, residual concrete in the stirring device solidifies and normal operation and the service life of the concrete mixing equipment are affected is avoided. The concrete mixing equipment is low in cost, can be popularized in most of building construction environments and saves the purchase cost for building enterprises.

Owner:阜阳市鑫和诚信混凝土销售有限公司

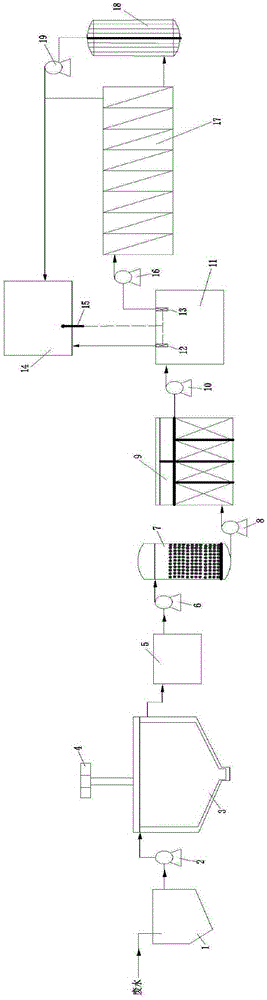

Treatment device and method capable of achieving waste water zero discharge of power plant with large water volume

InactiveCN105254066AExtended service lifeGood removal effectMultistage water/sewage treatmentWater savingEcological environment

The invention relates to a treatment device and method capable of achieving waste water zero discharge of a power plant with large water volume. By means of the treatment device and method, the technical feasibility and the economic feasibility of large water volume waste water zero discharge can be simultaneously met, and large water volume waste water zero discharge engineering application of the power plant is made to be possible. Meanwhile, reused water can be used as replenished water of water bodies such as recycling cooling water from the power plant and industrial water, the water taking amount of the power plant can be decreased, the applied water cost is reduced, discharge of water body pollutants is completely eradicated, and the ecological environment is protected to the maximum extent.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

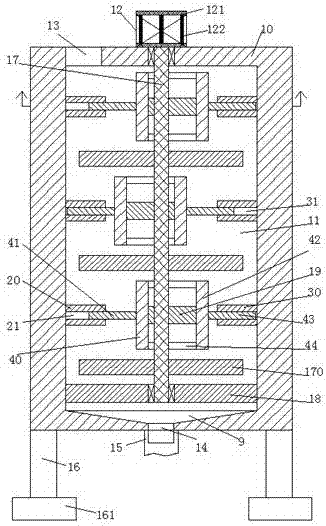

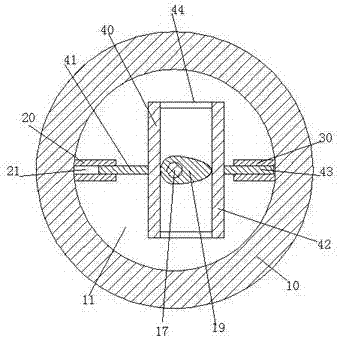

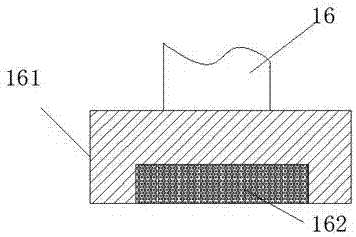

Sewage treatment device

InactiveCN107233823ARealize automatic mixingTo achieve the purpose of removing blood stasisShaking/oscillating/vibrating mixersTransportation and packagingPush and pullLight guide

The invention relates to a sewage treatment device. The sewage treatment device comprises a sewage tank fixedly arranged on an underframe, wherein a stirring cavity is arranged in the sewage tank, a placing plate is fixedly arranged at the bottom of the stirring cavity, a steering shaft is arranged between the placing plate and the top wall of the stirring cavity in a steering way, the upper end of the steering shaft is connected with a motor fixedly arranged at the upper end of the sewage tank, multiple stirring arms and convex wheels are arranged on the steering shaft, orientations of projecting parts of two adjacent convex wheels are opposite, a left guide sliding sleeve and a right guide sliding sleeve which are arranged horizontal to the convex wheels are accordingly arranged on the walls of the left end and the right end of the stirring cavity, a left guide sliding slot and a right guide sliding slot with the oral areas toward the steering shaft are formed in the left guide sliding sleeve and the right guide sliding sleeve respectively, a left guide sliding bar and a right guide sliding bar are arranged in the left guide sliding chute and the right sliding chute smoothly and respectively, and a left push-and-pull plate and a right push-and-pull plate are respectively fixed arranged at one end, toward the steering shaft, of each of the left guide sliding bar and the right guide sliding bar.

Owner:苏州玛斯堡威电子科技有限公司

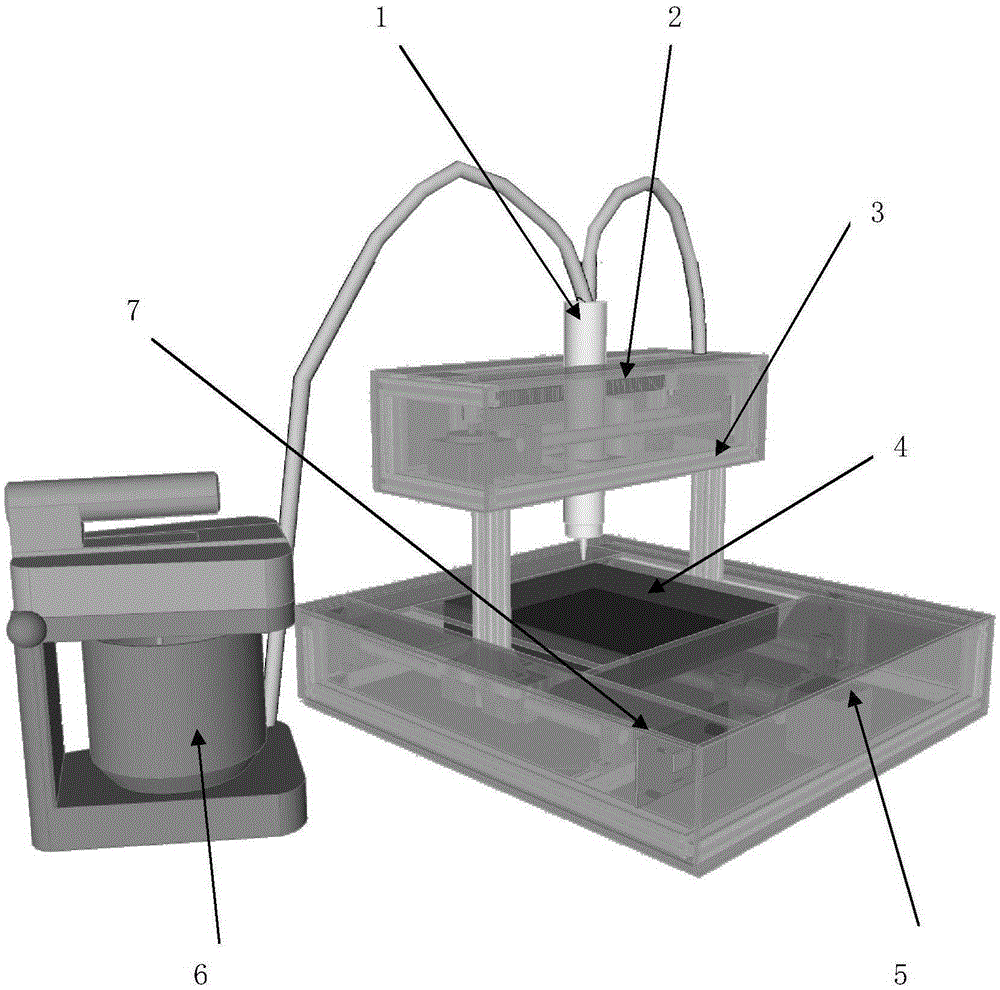

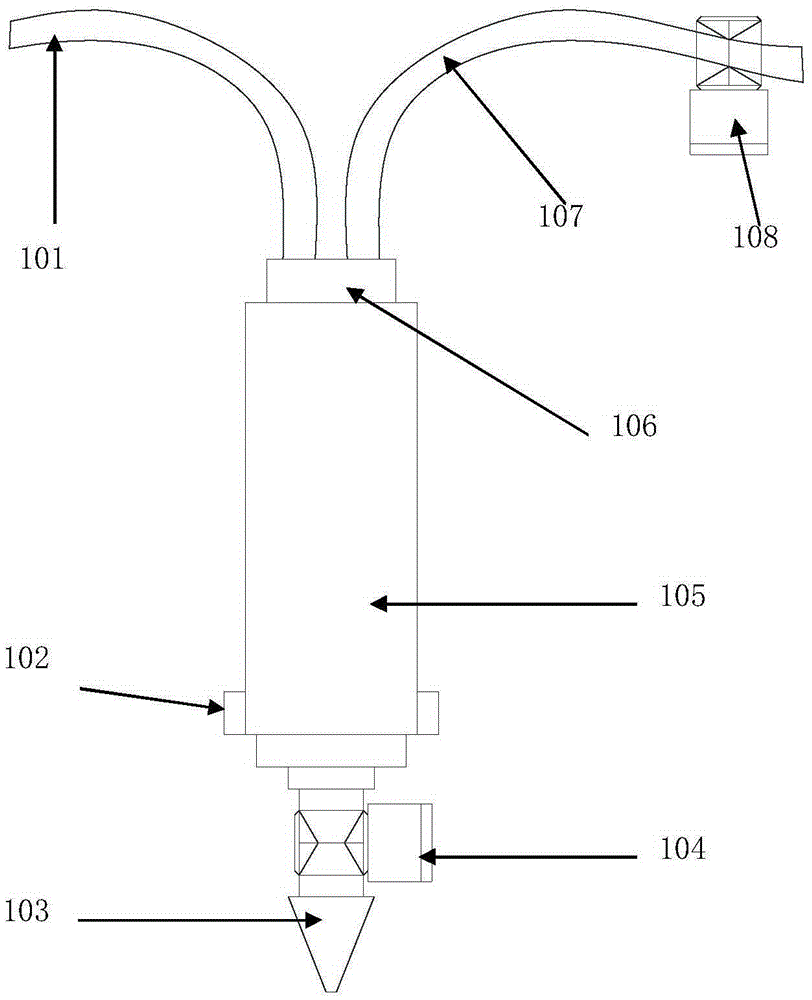

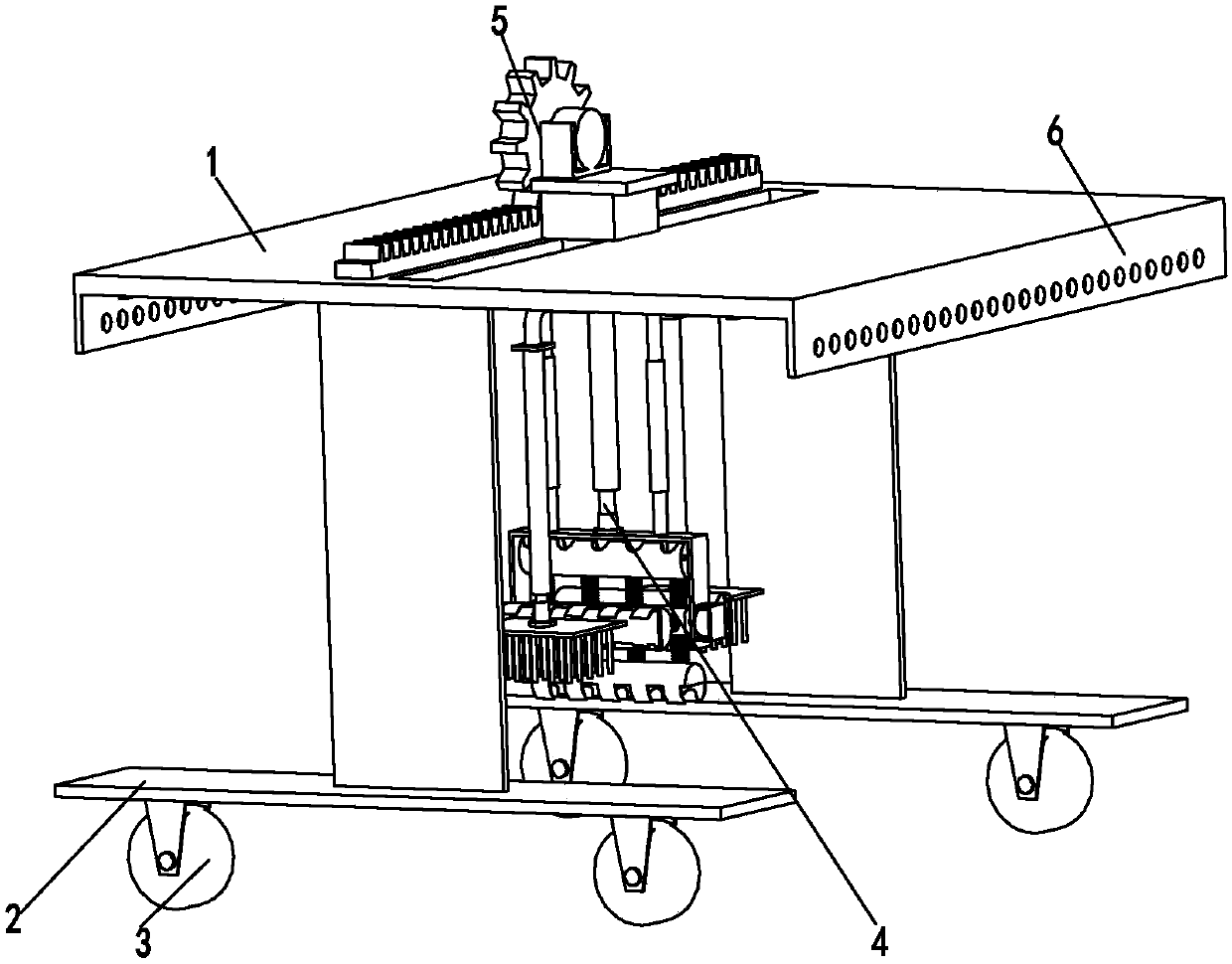

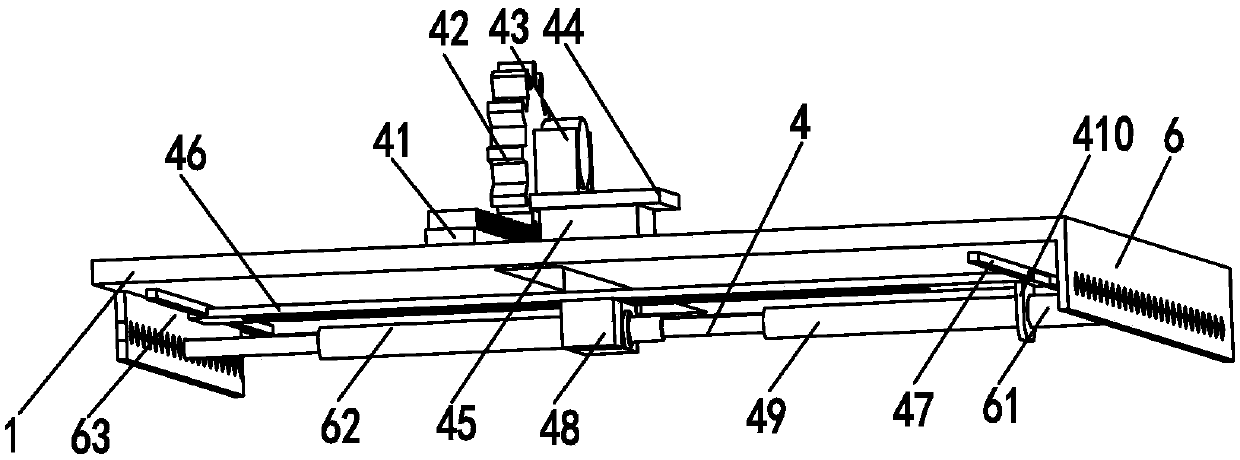

3D (dimensional) food printer capable of automatically charging materials

ActiveCN105284973AReduce manual labor intensityRealize automatic mixingDough shapingFood coatingEngineeringControl circuit

The invention discloses a 3D (dimensional) food printer capable of automatically charging materials. The 3D food printer comprises a raw material containing barrel, a transverse controller, a charging controller, a longitudinal controller, an electric baking tray and a control circuit. The raw material containing barrel (1) is arranged on the transverse controller (2) connected with the longitudinal controller (5) by a gantry structure (3), the electric baking tray (4) is arranged on the longitudinal controller (5) and the raw material containing barrel (1) is connected with the charging controller (6); under the control of the control circuit (7), the transverse controller (2) and the longitudinal controller (5) move together and drive the raw material containing barrel (1) to move front and back and right and left for discharging for the electric baking tray (4); when the raw material containing barrel has insufficient raw materials, the charging controller begins to work, and conveys the automatically stirred-uniform raw materials into the raw material containing barrel, thus realizing automatic stirring and charging. The problem of incapability of automatic stirring and charging in the prior art is solved, and the 3D food printer can be used for making various pancakes.

Owner:尚一民

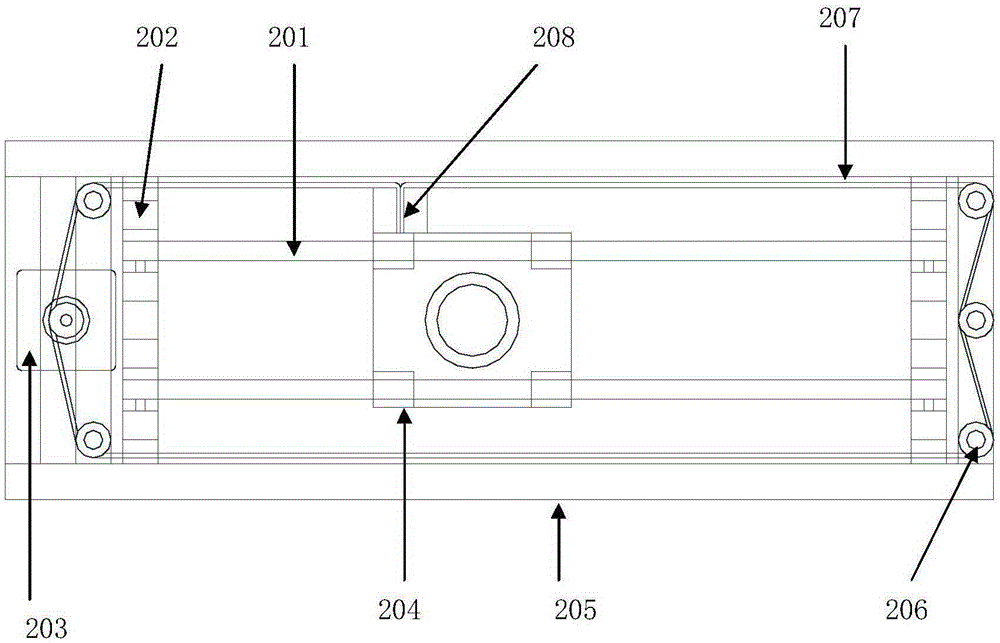

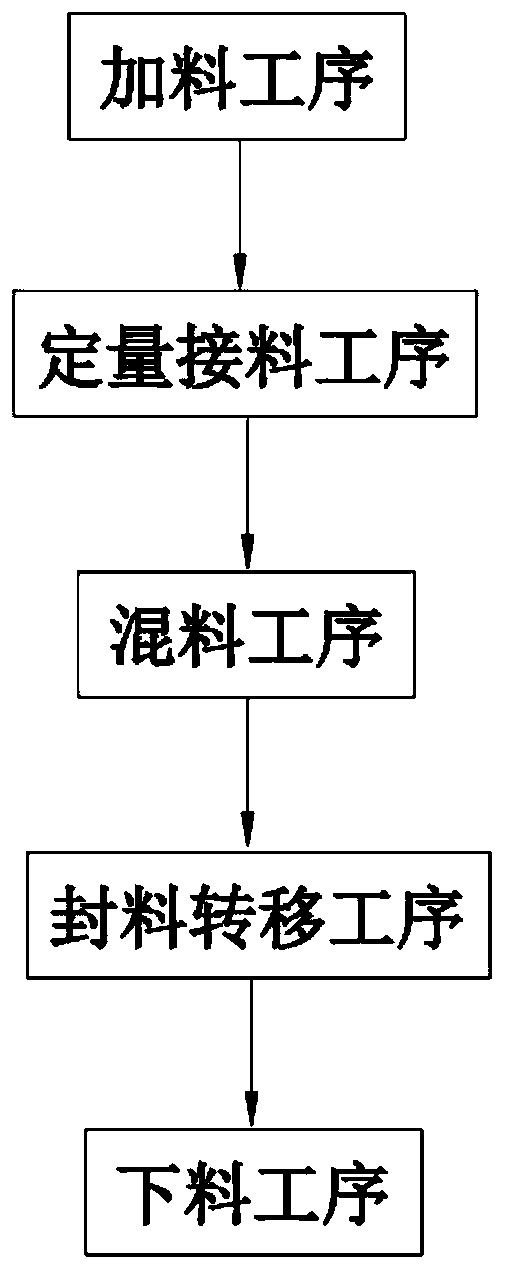

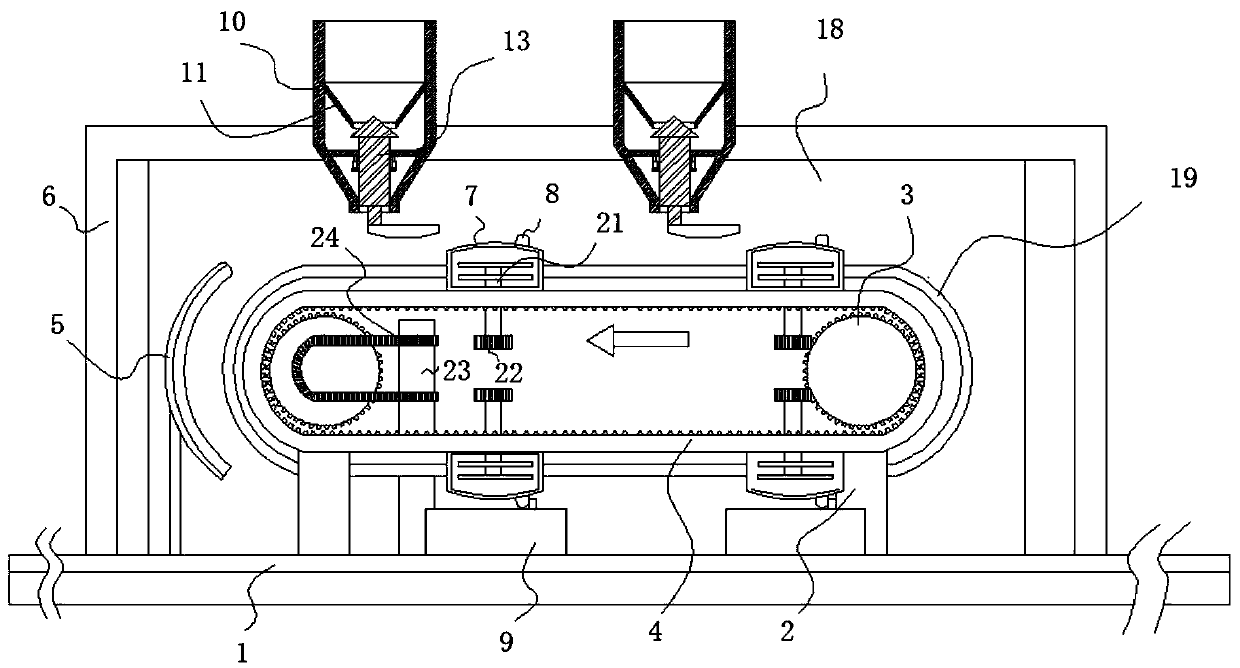

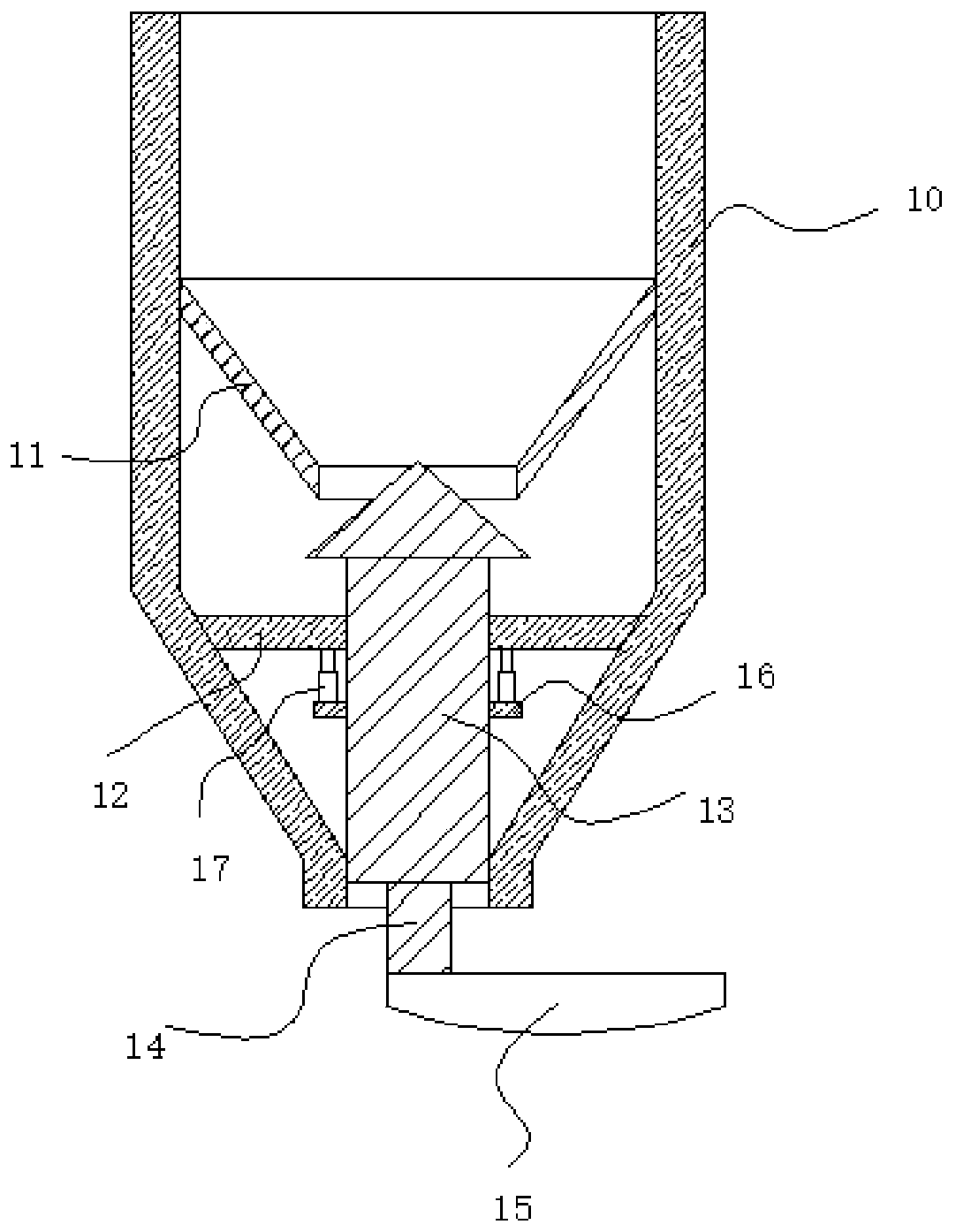

Paint continuous and quantitative charging, mixing and blanking production process

InactiveCN110538608ARealize automatic feedingIngenious structureTransportation and packagingMixer accessoriesTransfer procedureEngineering

The invention provides a paint continuous and quantitative charging, mixing and blanking production process. The production process comprises the following steps: step one, material charging process;step two, quantitative material-receiving process; step three, mixing process; step four, sealing and transferring process; and step five, blanking process; since the material charging, receiving, mixing and blanking processes are combined in the transmission process, the collision linkage between the modules and the driving of the gear module are ingeniously utilized, different materials are orderly and quantitatively received to a material receiving box to be uniformly mixed and then blanked; multiple stations are arranged on a transmission line to work at the same time; the equipment is ingenious in structure, the production efficiency is improved, and the technical problems that the material quantitative charging is tedious, the transferring process is complex and the working efficiency is low in the prior art are solved.

Owner:浙江圣美环保材料有限公司

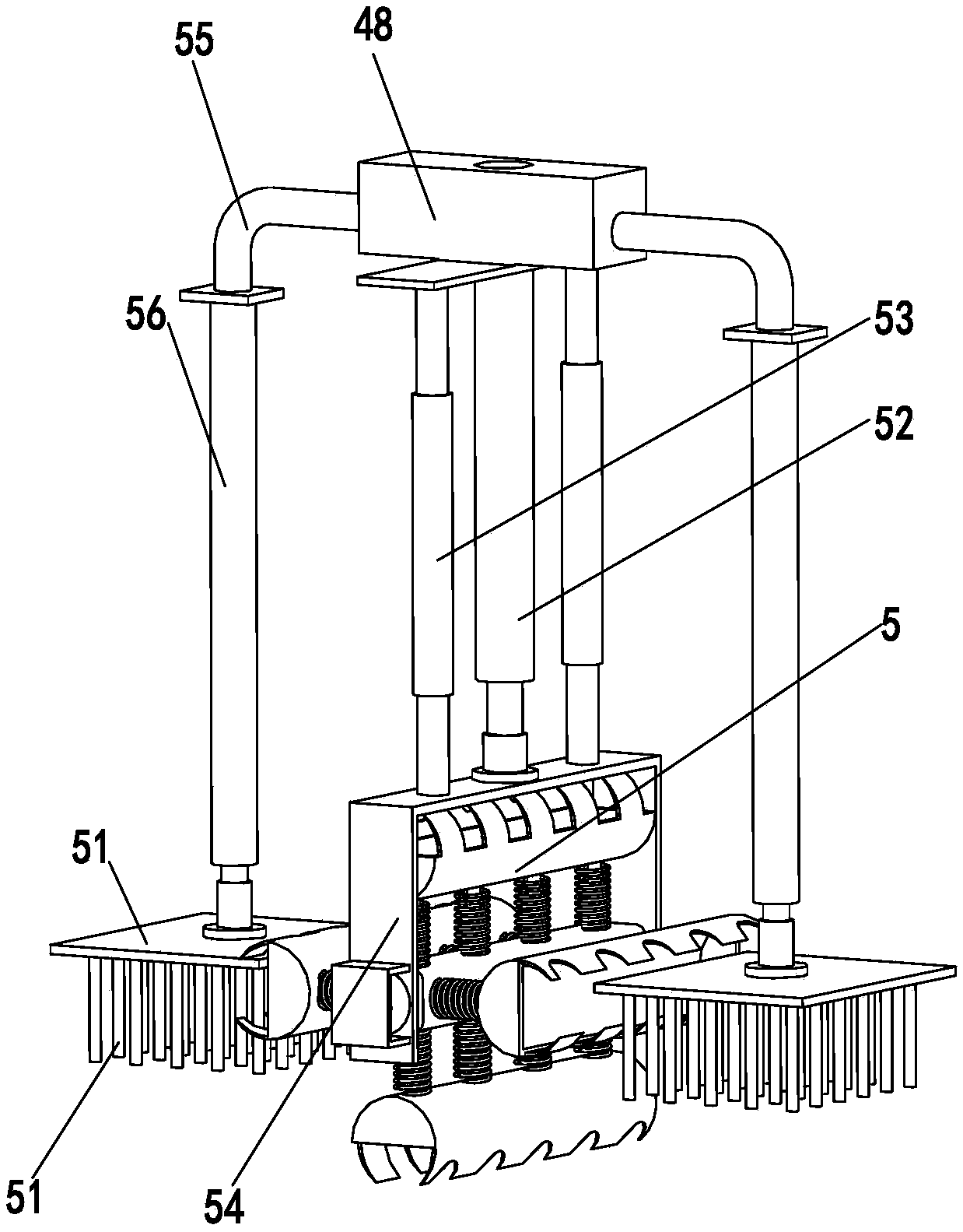

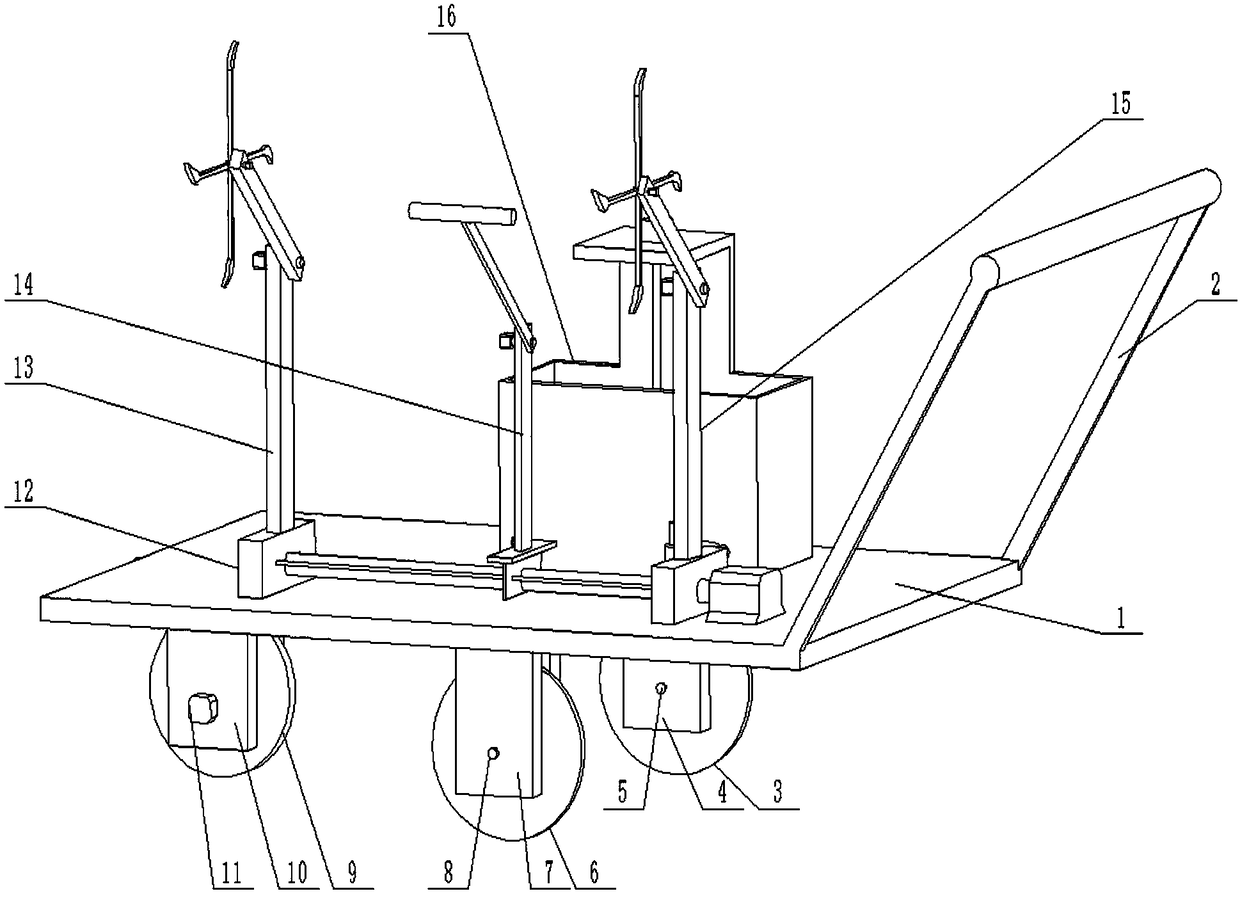

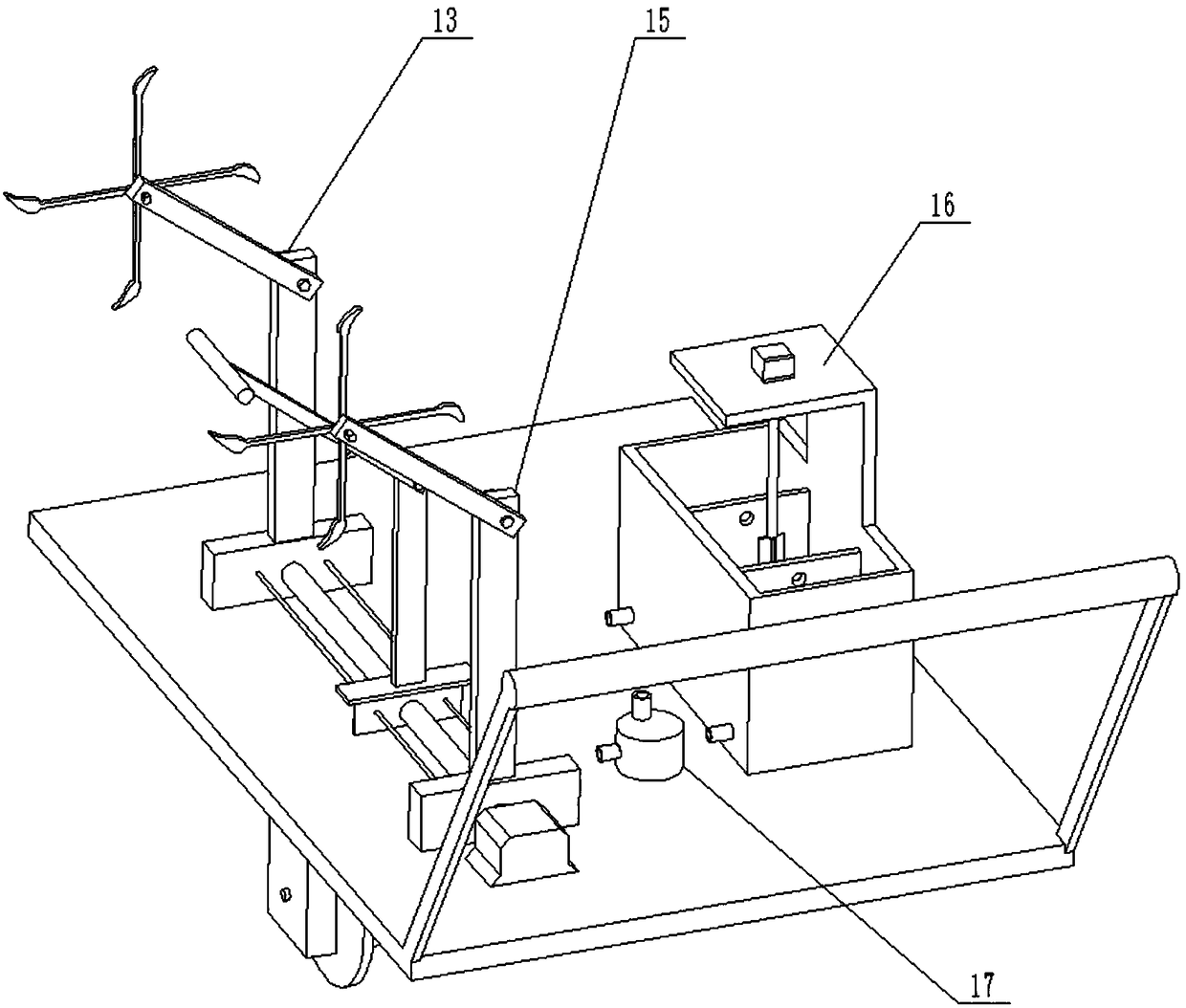

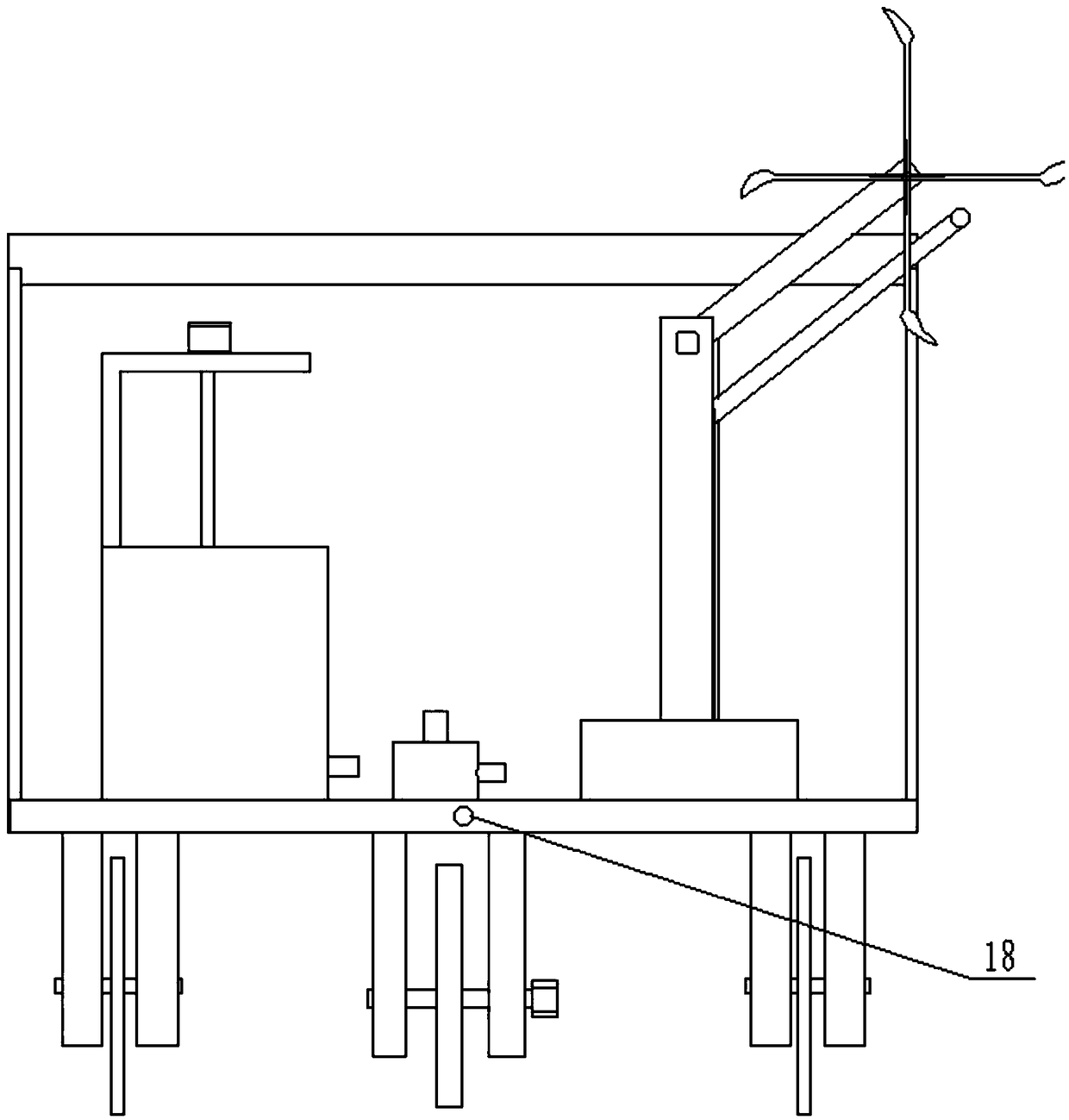

Multi-angle movable wall spraying device

InactiveCN111335594ARealization of automatic sprayingImprove work efficiencyBuilding constructionsElectric machineryStructural engineering

The invention discloses a multi-angle movable wall spraying device which belongs to the technical field of building wall construction. The device comprises a vehicle body, a material containing assembly, a material conveying assembly, a lifting assembly, a supporting assembly, a swinging assembly and a rotating assembly. The material containing assembly is arranged at the top of the rear end of the vehicle body, the material conveying assembly is arranged at the top of the vehicle body and is positioned beside the material containing assembly, the feeding end of the material conveying assemblyis arranged on the material containing assembly and communicates with the material containing assembly, the lifting assembly is vertically arranged at the rear end of the vehicle body, the supportingassembly is arranged on the lifting assembly and is in sliding fit with the lifting assembly, the swinging assembly is arranged on the supporting assembly, and the rotating assembly is arranged on the swinging assembly and is rotatably connected with the swinging assembly. A spraying head is driven to rotate by a rotating motor, multi-angle spraying operation of the spraying head can be realized,walls at different angles in different places can be sprayed, working efficiency is improved, and th labor cost is reduced.

Owner:钟起官

Method for producing fibrous protein-removed original blood from newborn calf blood

ActiveCN104546913AAchieve the purpose of mixingImprove stabilityAerosol deliveryOintment deliveryFiberFiltration

The invention discloses a method for producing fibrous protein-removed original blood from newborn calf blood. The method comprises the following steps: (1) receiving the blood of a newborn calf by a blood bottle and starting to stir the blood by a glass rod with a bulge at the stirring end at a speed of 110-140 rpm when the blood flows to 1 / 6 to 1 / 4 of the holding volume of the blood bottle; (2) stopping the stirring when the blood achieves the holding volume of the blood bottle and sealing the blood bottle; (3) stirring at a speed of 160-200 rpm for 2-4 min, stopping the stirring, standing for 3-4 min, stirring at 110-140 rpm for 5-8 min, stopping the stirring, and taking out the glass rod and the fibrous protein wound on the stirring end. The method provided by the invention has the advantages that the stability is high and the homogenization degree is high; the automatic stirring is realized so as to avoid the interferences of human factors; the standard operation and industrial production can be realized; the fibrous protein can be removed to a relatively complete extent without filtration, so that the time and the labor are saved; the bottle does not need to change and the blood bottle is a storage bottle for the non-solidified original blood; the recovery rate of the original blood is high and has an average of 93%.

Owner:内蒙古维克生生物技术股份有限公司

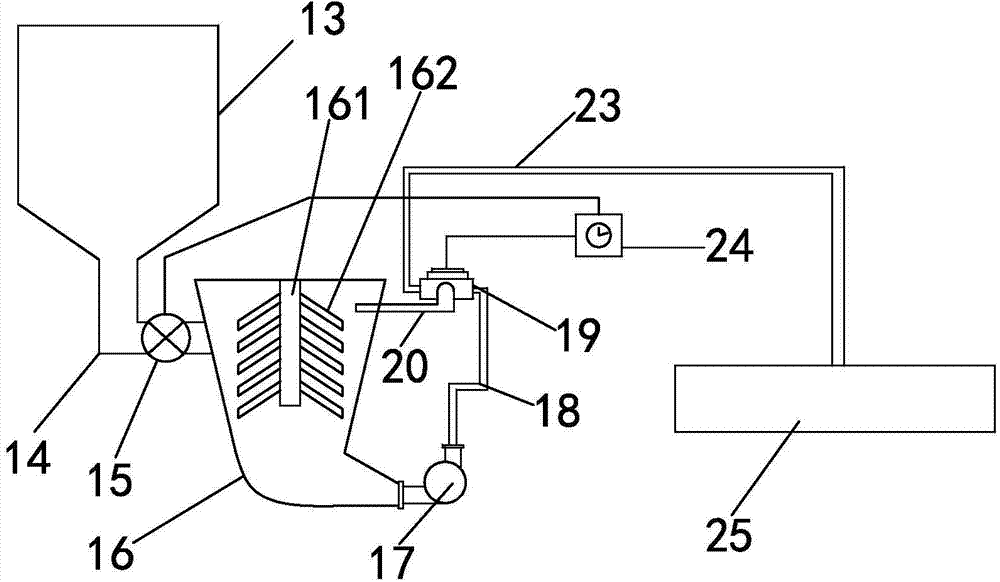

Three-fluid mist spraying dust suppression system and method

ActiveCN106139781AImprove dust suppression effectSpeed up dust suppressionGas treatmentAuxillary pretreatmentWater pipeEngineering

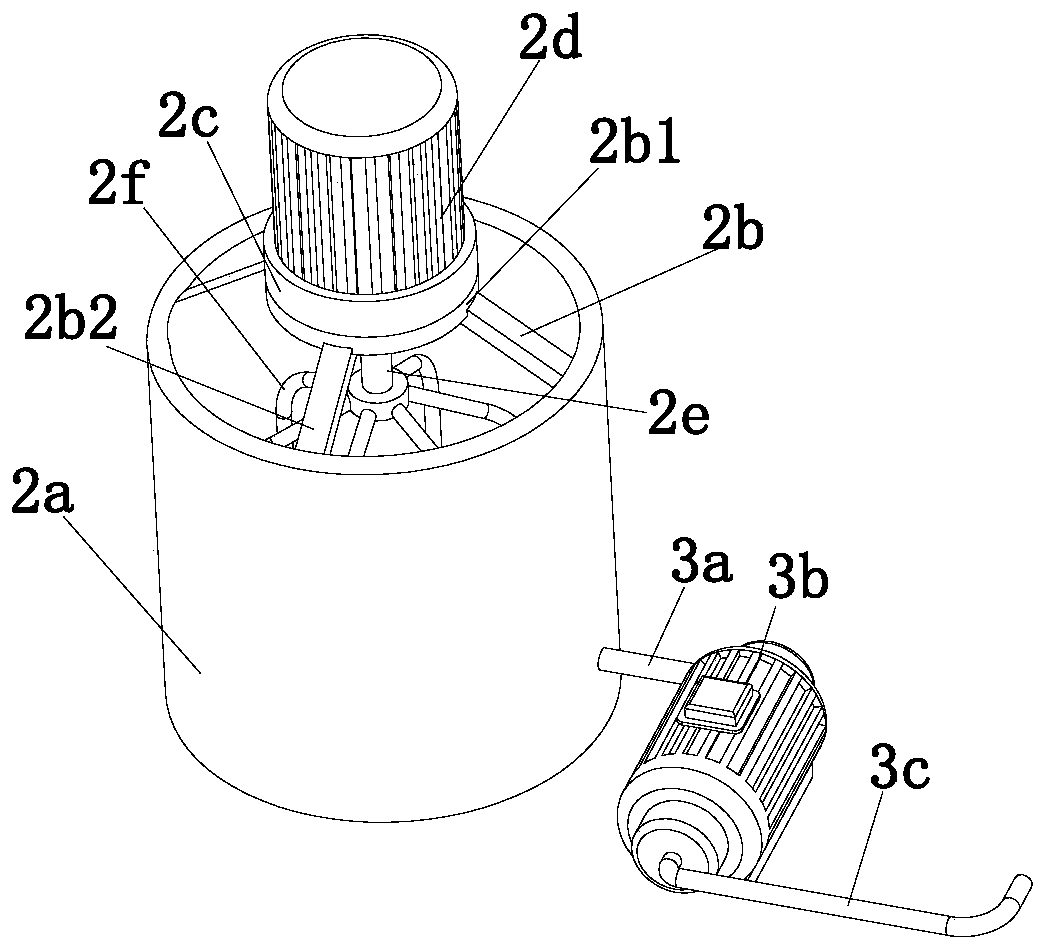

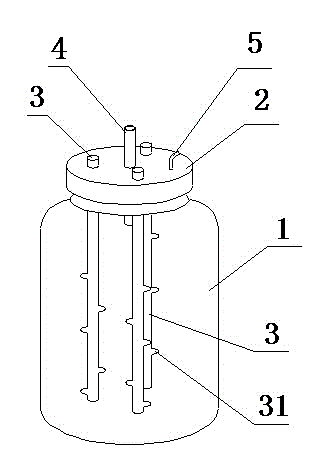

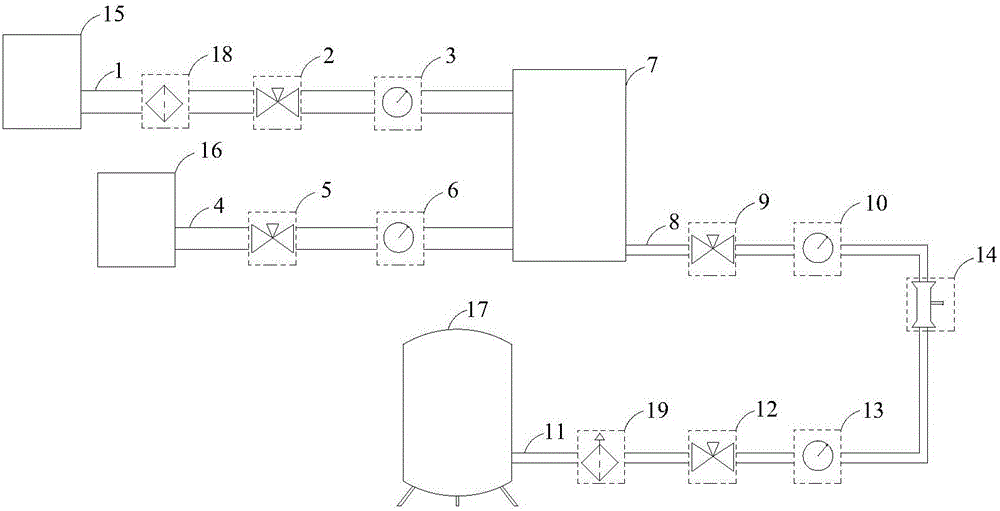

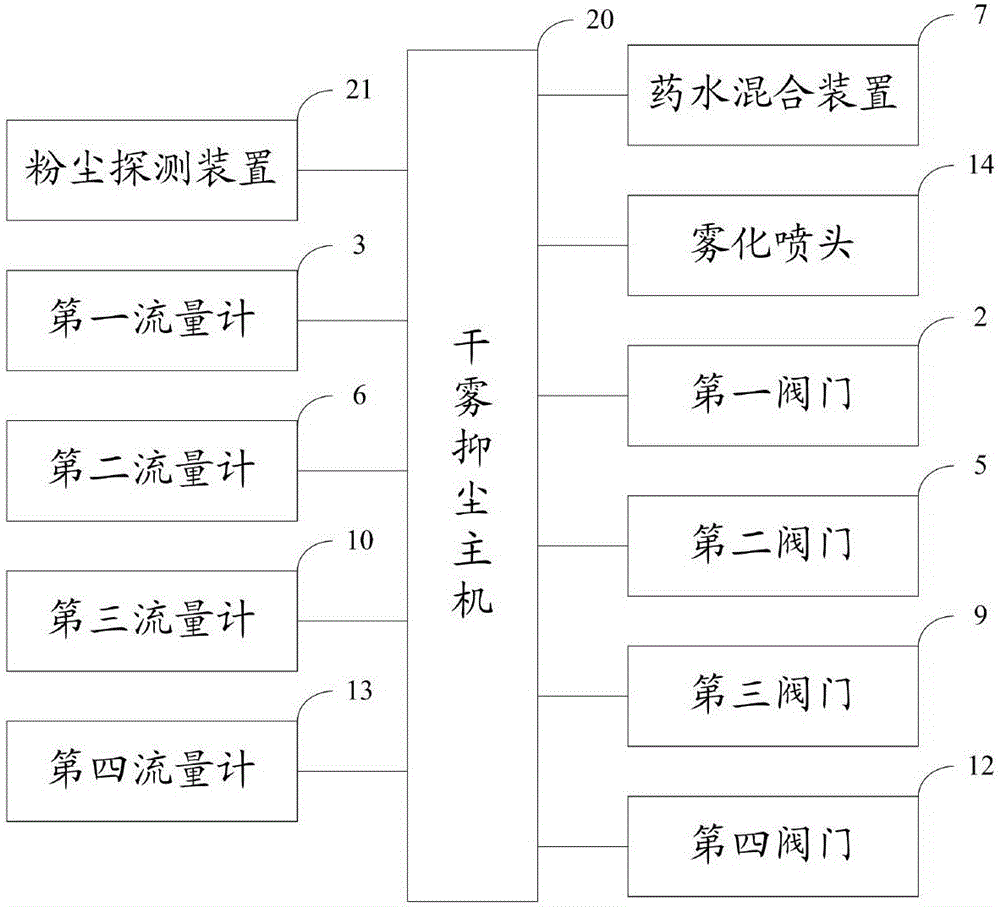

The invention discloses a three-fluid mist spraying dust suppression system and method. The system is characterized in that a first valve and a first flow meter which are installed on a water pipe; a second valve and a second flow meter are installed on a first chemical pipe; the water pipe and the first chemical pipe are connected with a chemical-water mixing apparatus, water flowing into the medicine-water mixing apparatus is mixed with chemical to form a mixture, and the mixture flows out by virtue of a second chemical pipe; a third valve and a third flow meter are installed on the second chemical pipe; a fourth valve and a fourth flow meter are installed on an air pipe; the second chemical pipe and the air pipe are connected with an atomizing spray head, the atomizing spray head utilizes air to crush the mixture into mist particles, and the mist particles are sprayed out; and a dry mist dust suppression main machine receives signals of various flow meters and controls various valves and the atomizing spray head. By adopting the system and method, the research bottleneck of the dust suppression effect in the prior art is broken through, the dust suppression effect is further improved, and the dust suppression speed is increased.

Owner:秦皇岛市民生电力设备有限公司

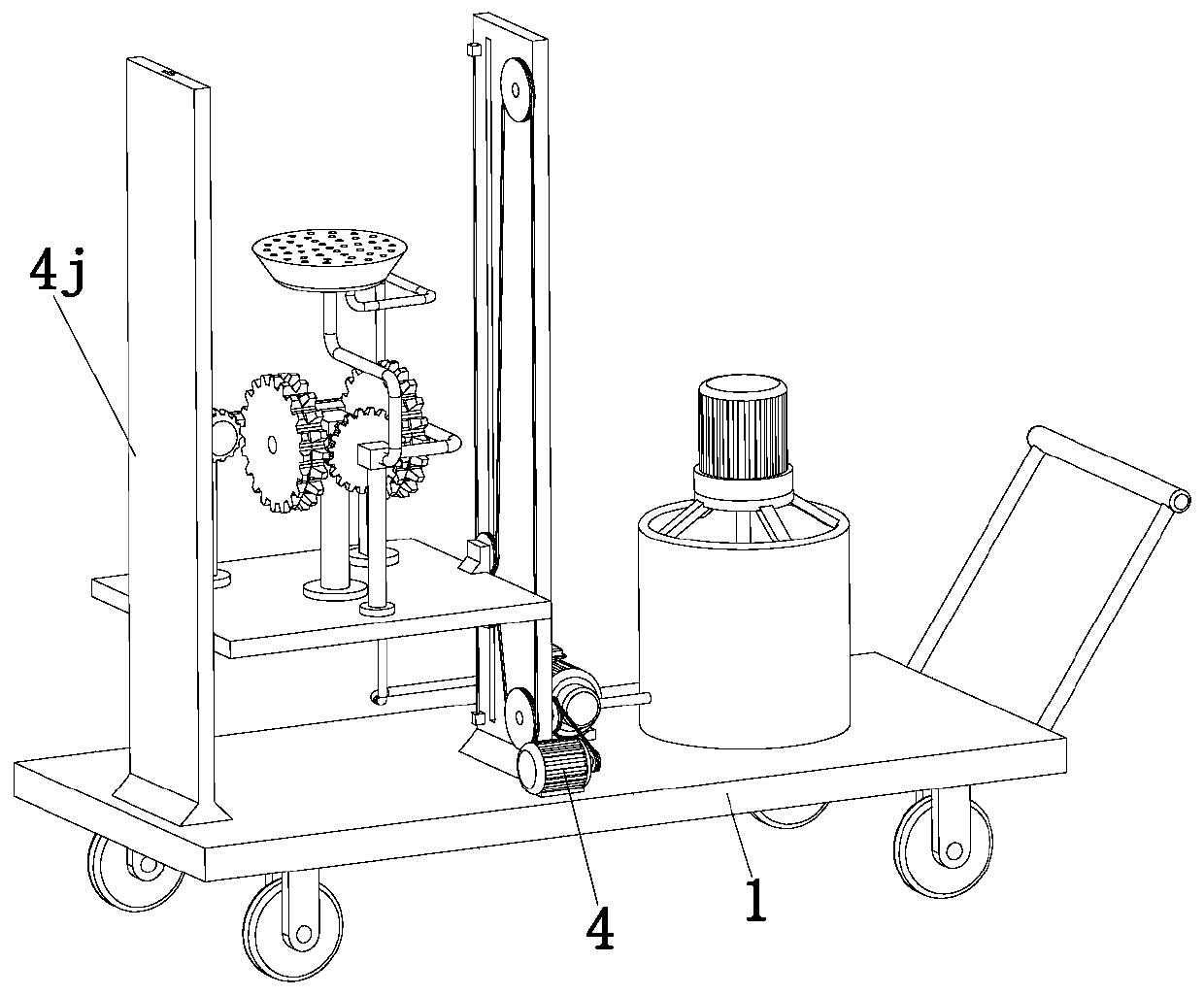

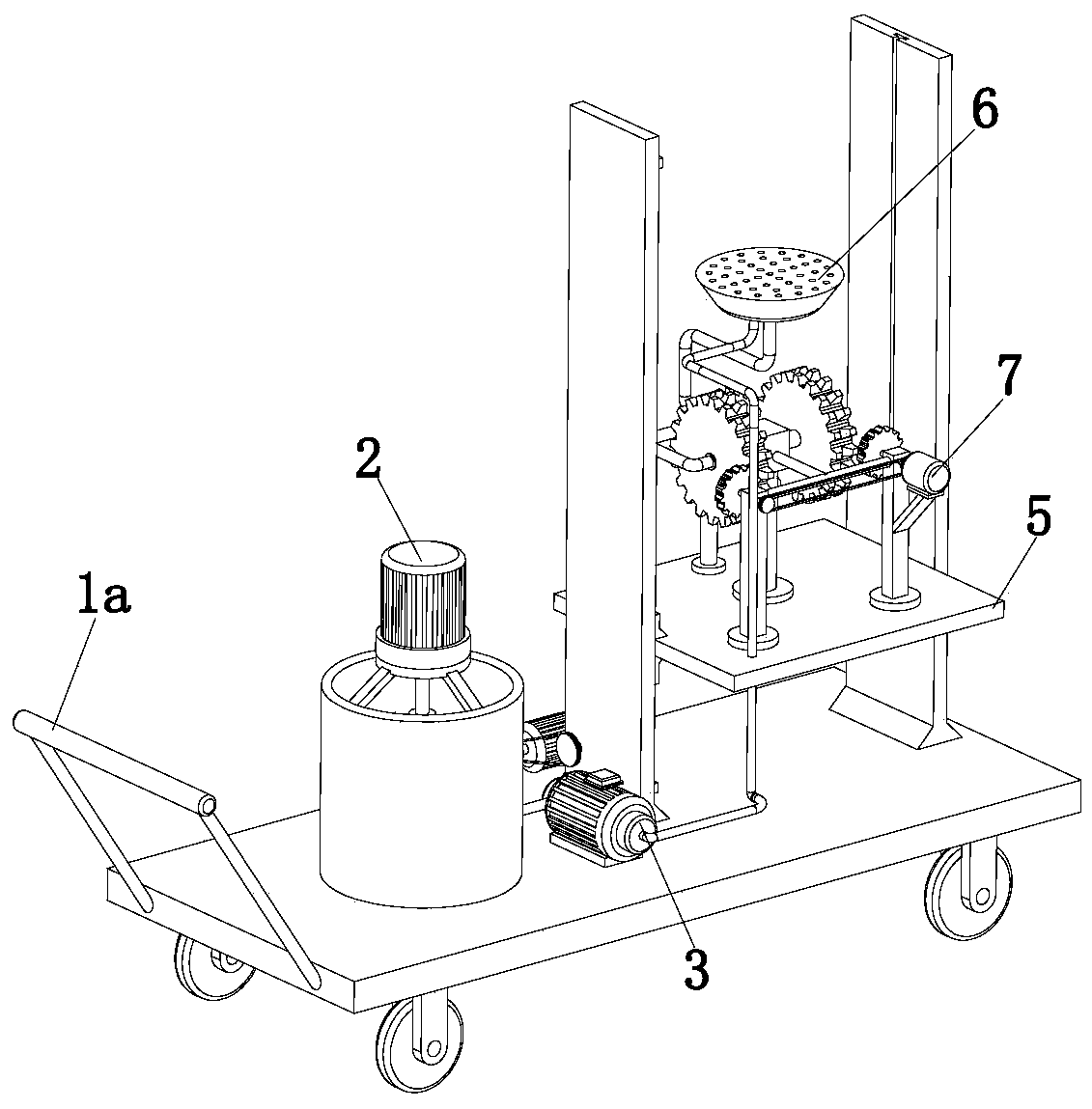

Automatic feeder

InactiveCN106900593ARealize automatic mixingAvoid stacking bugsAvicultureEngineeringAutomatic testing

The invention discloses an automatic feeder, which comprises: a bracket, a material cylinder arranged in the bracket, a control box arranged on the bracket, a material tray arranged under the material cylinder, and a device connected to the control box arranged in the material cylinder. The mixing rod and the water pipe arranged on the support, the water outlet end of the water pipe is arranged in the material pan. The automatic feeder of the present invention realizes automatic stirring and uniform discharge through a controller, ensures that the feed can be evenly discharged onto the feeding tray, avoids manual mixing process, and realizes automatic feeding with mixing.

Owner:刘俊

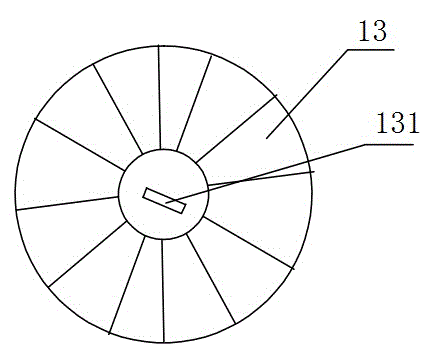

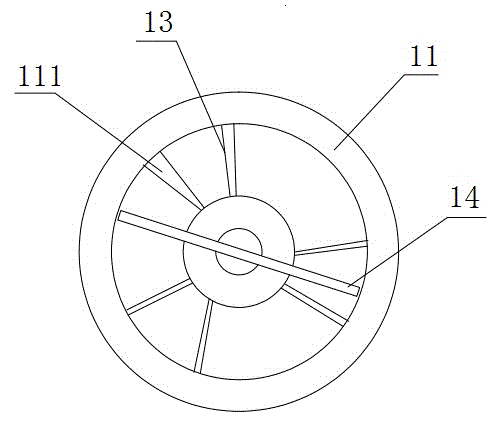

Automatic fertilizer stirring and applying device

ActiveCN104686040ARealize automatic mixingSolve the problem of auxiliary laborFertiliser distributersAgriculture gas emission reductionAgricultural engineering

The invention relates to the technical field of fertilizer applying structures, in particular to an automatic fertilizer stirring and applying device. The automatic fertilizer stirring and applying device comprises a fertilizer applying barrel and a first leakage plate arranged in the fertilizer applying barrel. Three separation fences are arranged in the fertilizer applying barrel and located above the first leakage plate. The three separation fences divide the fertilizer applying barrel into three regions. The first leakage plate is provided with three leakage ports in the three regions divided by the three separation fences respectively. A rotatable impeller is arranged in the fertilizer applying barrel and located below the first leakage plate. The impeller is provided with a plurality of blades at intervals. A stirring rod mounted on the impeller is further arranged in the fertilizer applying barrel. The impeller is connected with a tray through a connecting shaft and drives the tray to rotate. The lower end of the fertilizer applying barrel is further provided with a discharge structure used for leaking out fertilizer. By the adoption of the automatic fertilizer stirring and applying device, a user just needs to pour three different kinds of fertilizer such as urea, phosphatic fertilizer and potash fertilizer into different fertilizer applying boxes, and the three different kinds of fertilizer including powdery fertilizer and granular fertilizer can be automatically blended.

Owner:AGRI MACHINERY INST CHINESE TROPICAL ACAD OF SCI

Chinese herbal medicine feed for keeping chickens

InactiveCN107647170AAvoid wastingPromote digestionAnimal feeding stuffAvicultureFodderVeterinary medicine

The invention relates to the technical field of making of feeds for breeding, and discloses a Chinese herbal medicine feed for keeping chickens. The Chinese herbal medicine feed comprises a housing, wherein a plurality of through holes are formed in the housing; a through pipe is inserted in the housing; two ends of the through pipe respectively extend out of the housing; a spacer is arranged between the through pipe and the housing; a liquid cavity is formed between the spacer and the housing; Chinese herbal medicine liquid is stuffed in the liquid cavity; a plurality of elastic strips are connected to the outer wall of the through pipe; one end away from the through pipe, of each elastic strip sequentially penetrates through the spacer and the corresponding through hole and extends to the outer side of the housing; a feed ball is connected to one end located on the outer side of the housing, of each elastic strip; an impact block and a blocking block are arranged on each elastic strip; the impact blocks are adhered to the surface of the through pipe; and each blocking block is located between the corresponding feed ball and the corresponding through hole, and is used for blockingthe corresponding through hole. Through the adoption of the Chinese medicinal herb feed disclosed by the invention, the defect that a conventional feed needs to be manually mixed with medicines can be overcome, and chickens are promoted to eat.

Owner:贵州松羽禽业有限公司

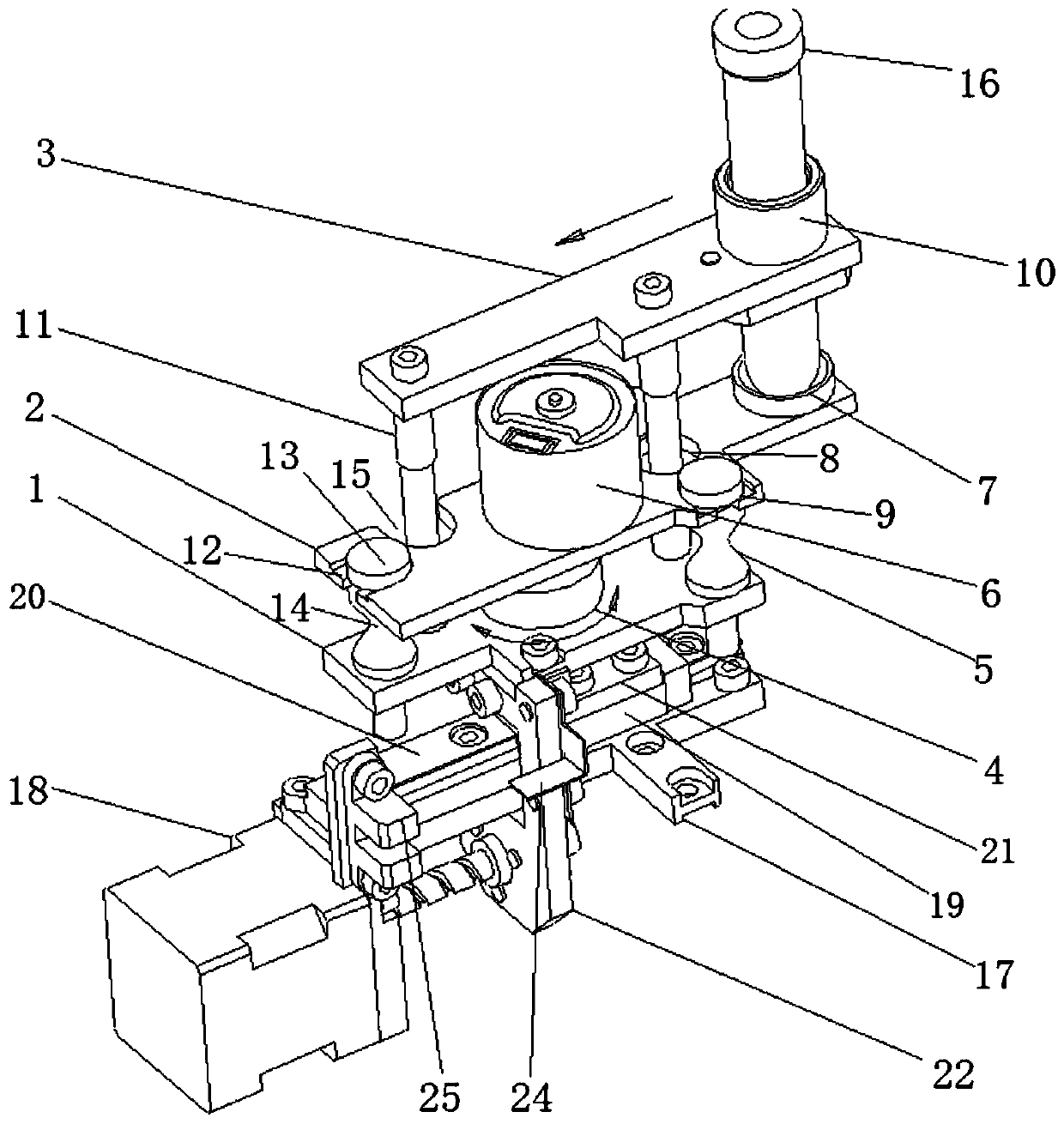

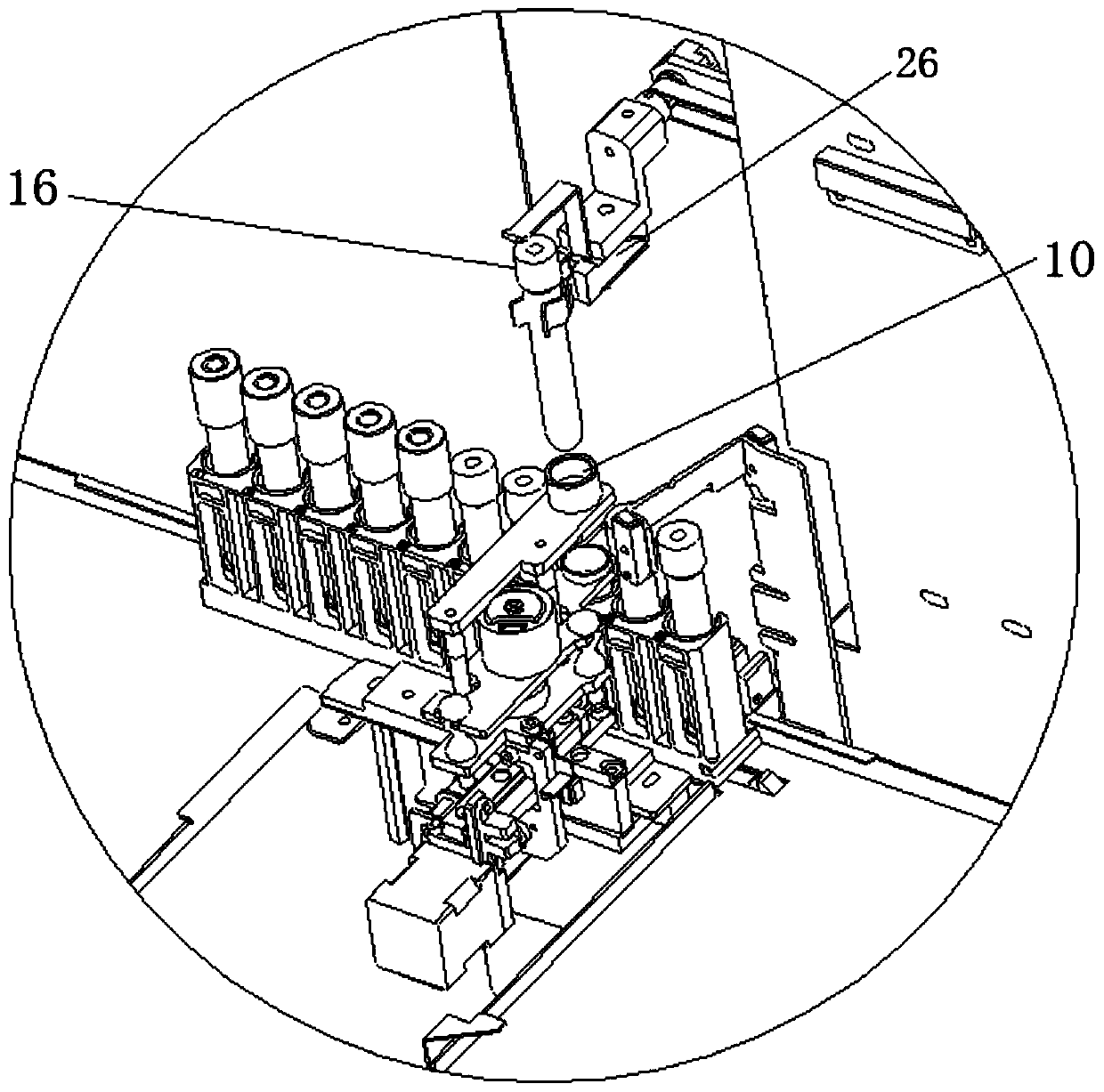

Magnetic bead mixed liquid split charging device and method for nucleic acid substance extraction

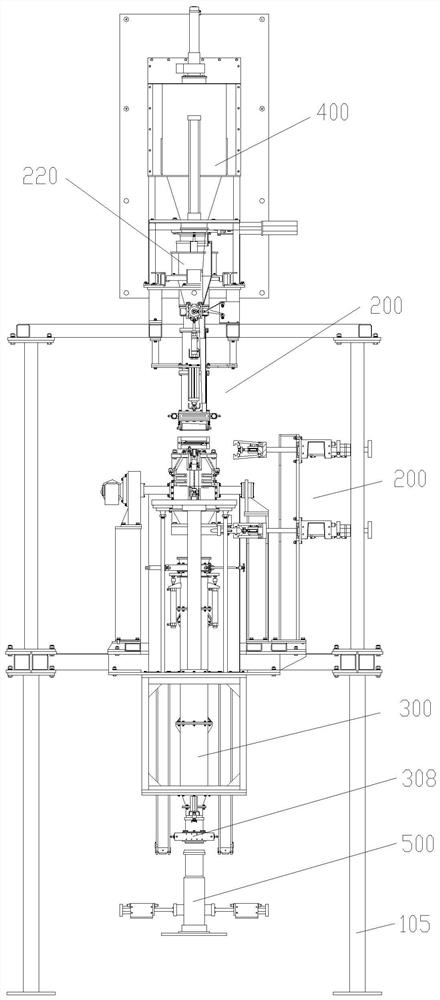

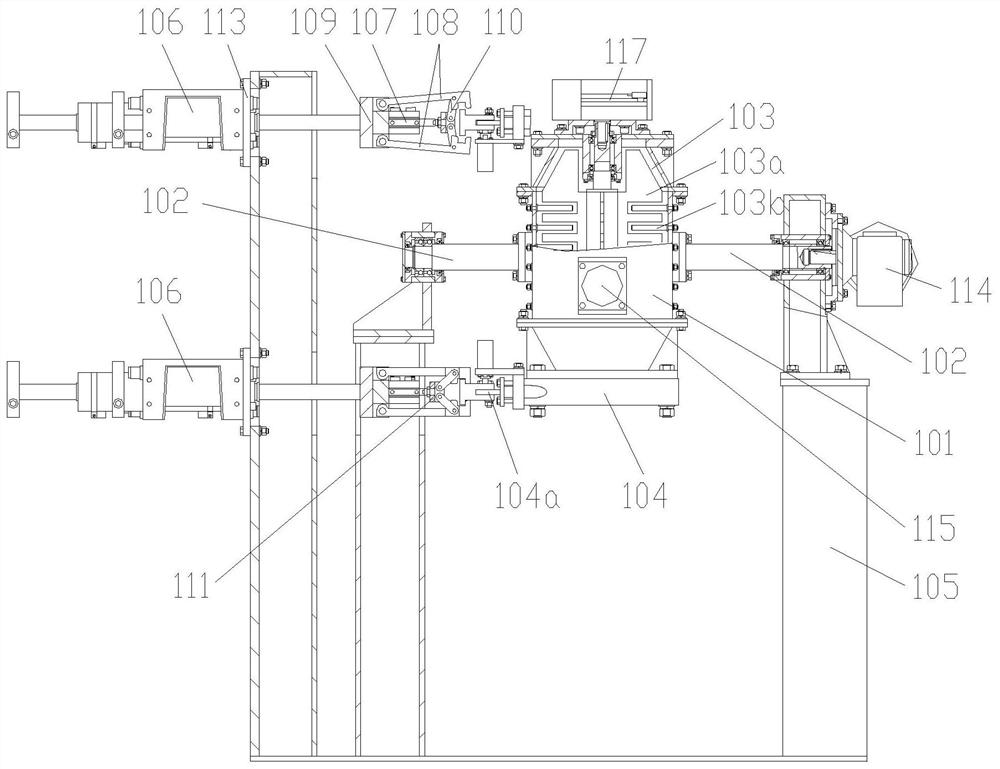

ActiveCN112957947ARealize automatic packagingAchieve mixingRotary stirring mixersTransportation and packagingSuction forceMagnetic bead

The invention discloses a magnetic bead mixed liquid split charging device and method for nucleic acid substance extraction. The device comprises a shell, a stirring device is arranged in the shell, the stirring device comprises a stirring part for stirring, the stirring part is arranged at the middle lower part of an inner cavity of the shell, the stirring part is arranged in the shell, the upper end of the stirring part is fixedly connected with the lower end of a suction pipe of a tubular structure, the upper end of the suction pipe is communicated with a negative pressure device through a conveying pipe, a rotating device used for providing rotating force power is arranged on the suction pipe, the negative pressure device and the rotating device are arranged outside the shell, the rotating device drives the stirring part to rotate through the suction pipe, and the suction pipe is used for discharging the magnetic bead mixed liquid in the shell. By means of the split charging device and the split charging method, automatic even mixing and automatic split charging of the magnetic bead mixed liquid can be achieved, the adsorption performance of the magnetic beads can be guaranteed under the low-temperature condition, time and labor are saved, operation is standard, cost is low, and the device and the method are particularly suitable for industrial production.

Owner:XIAN TIANLONG SCI & TECH

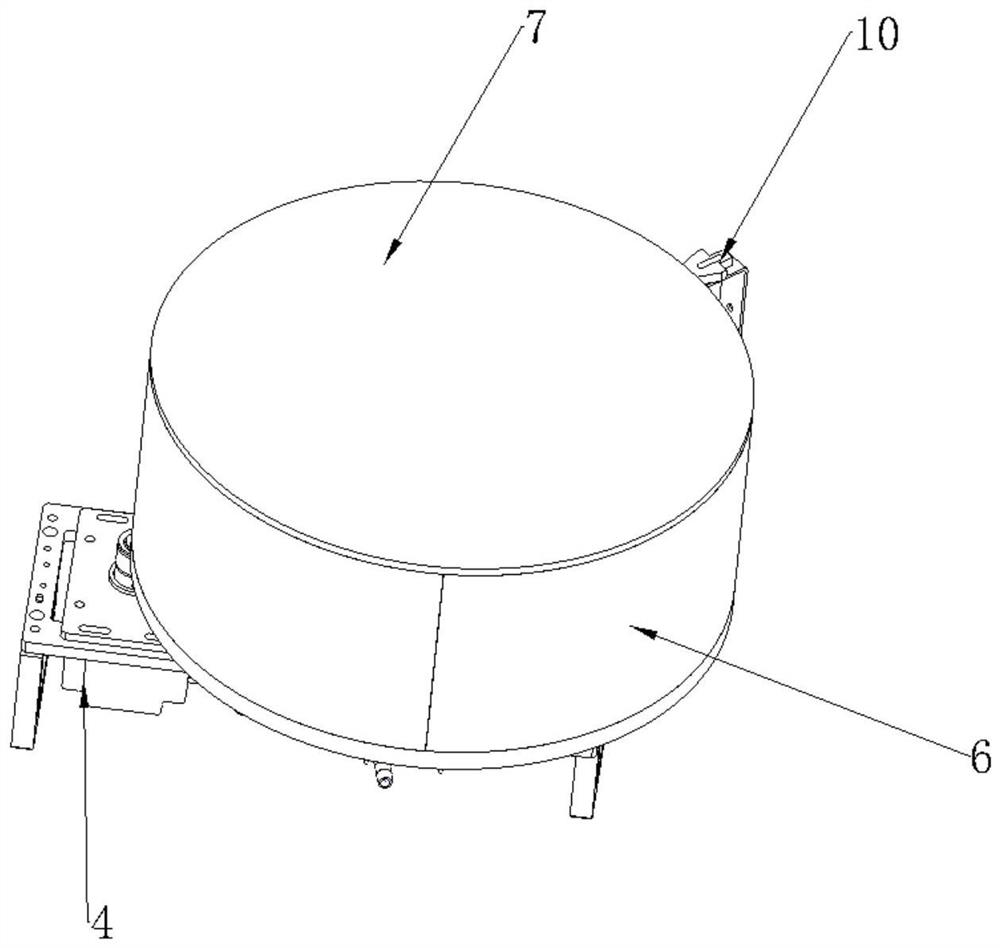

Device for reagent refrigeration and homogenizing

InactiveCN113941269AEasy to refrigerateImprove the mixing effectRotating receptacle mixersTransportation and packagingMagnetic beadCool storage

The invention belongs to the technical field of reagent cold storage devices, and discloses a device for reagent refrigeration and homogenizing. The device comprises a reagent ship, a reagent ship tray and a reagent pot; the reagent ship is arranged in the reagent ship tray; the reagent ship tray is arranged in the reagent pot; the top of the reagent pot is provided with a reagent pot cover; the outer wall of the reagent pot is fixedly provided with a detection optocoupler; a magnetic bead uniform mixing driving module is fixedly mounted at the bottom of one side of the reagent pot; a magnetic bead uniform mixing module is arranged at the bottom of the reagent ship; and thermal insulation cotton is fixedly mounted on the outer wall, the bottom wall surface and the top wall surface of the reagent pot. According to the device for reagent refrigeration and homogenizing, a system refrigeration control and full-automatic uniform mixing technology is adopted, refrigerating and automatic uniform mixing of reagents are achieved through the magnetic bead uniform mixing driving module, the magnetic bead uniform mixing module, a refrigeration module, the thermal insulation cotton and the detection optocoupler, and reagent information is accurately read through a code scanning demisting module, and therefore, the reagents are convenient to refrigerate, and meanwhile, the uniform mixing effect and efficiency of the reagents are improved.

Owner:深圳蓝韵生物工程有限公司

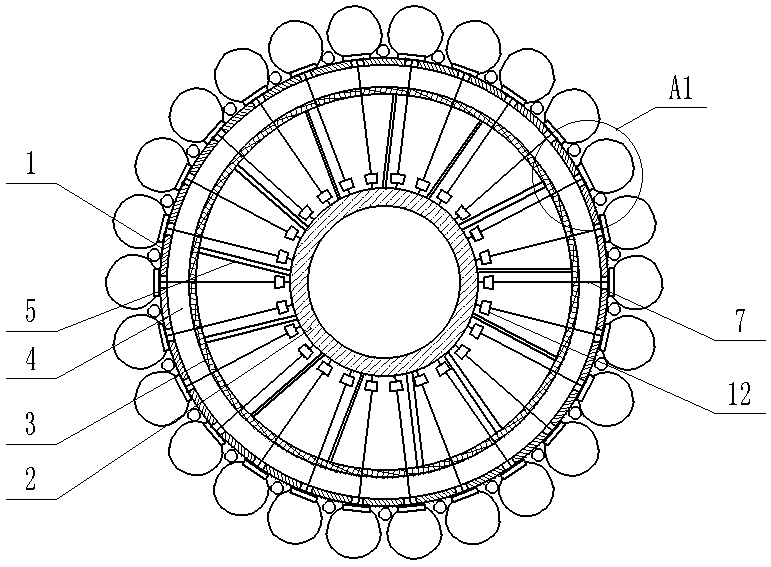

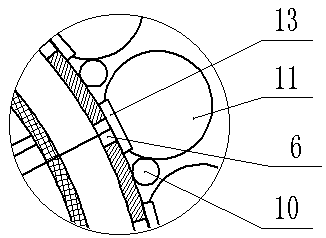

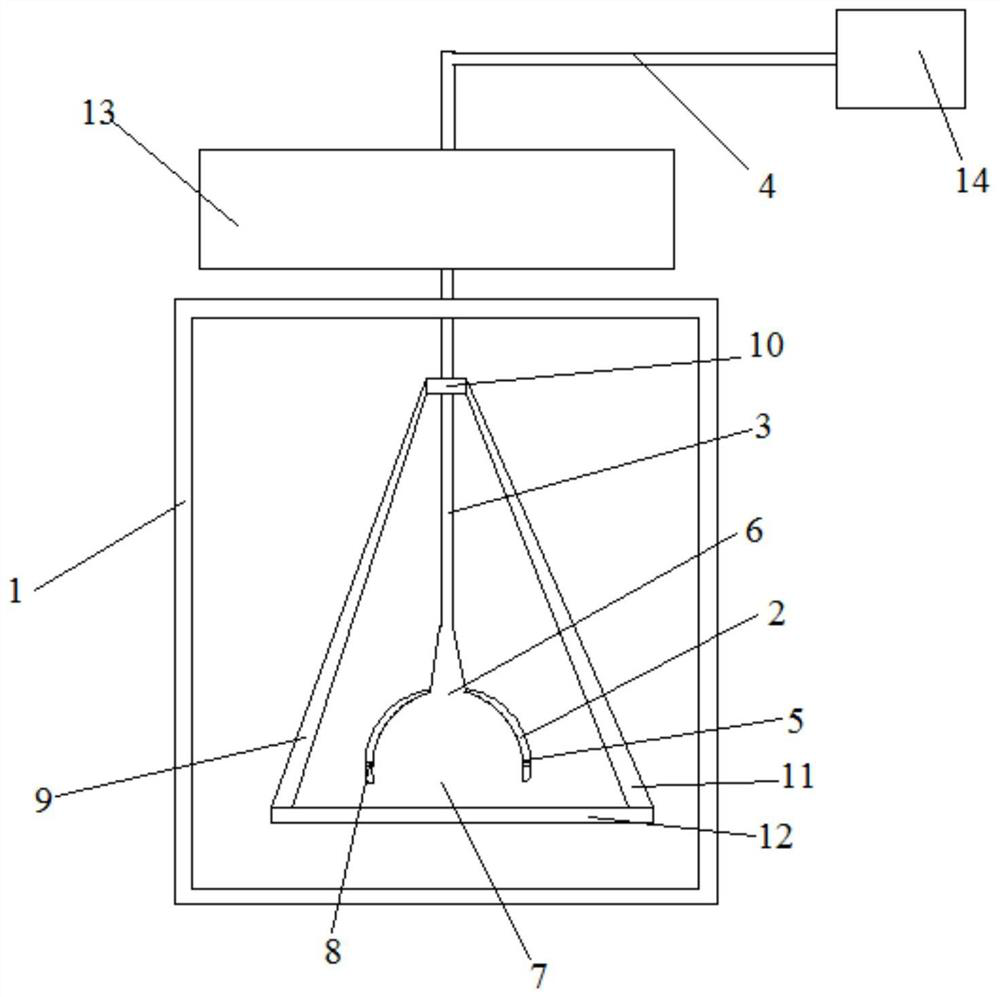

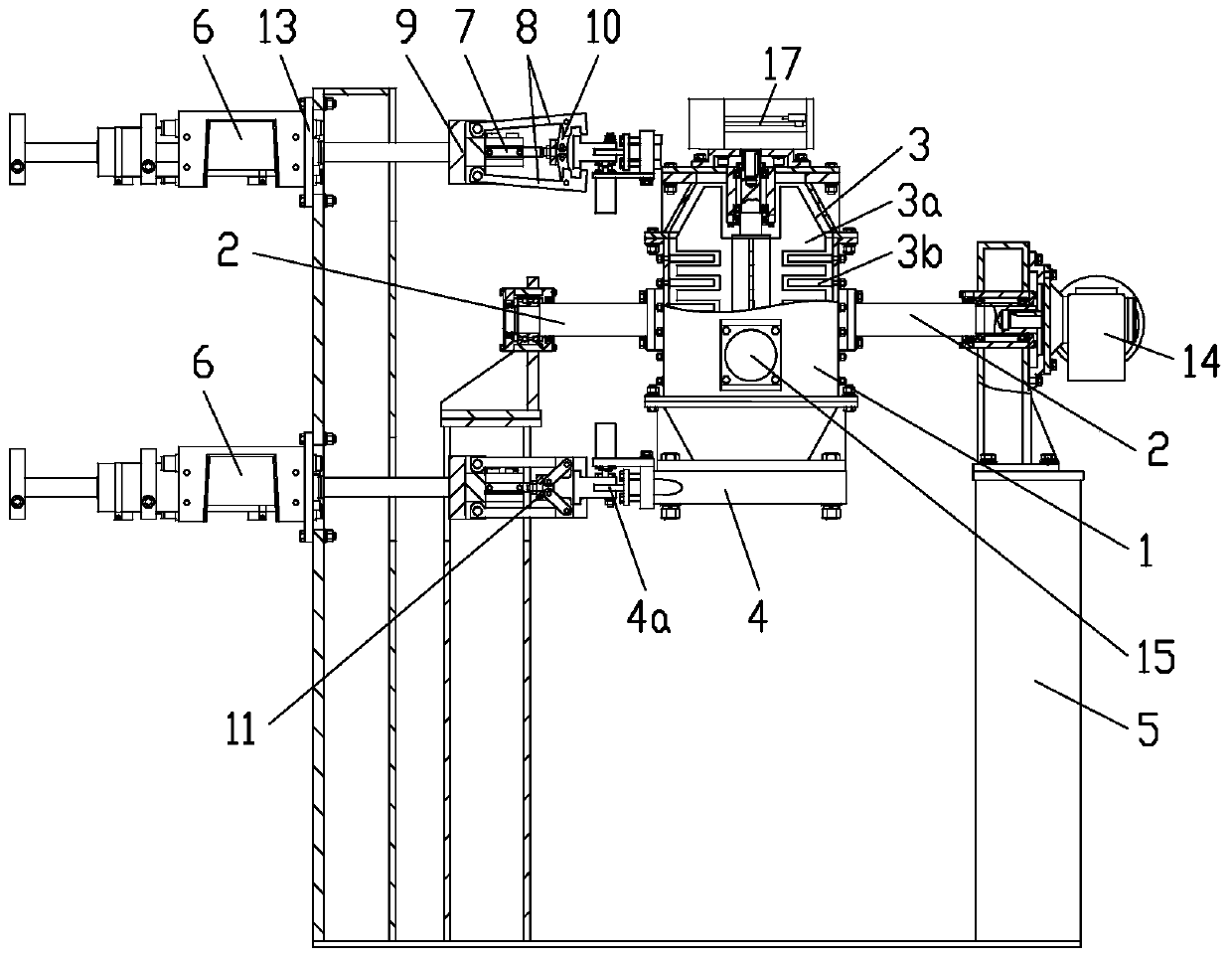

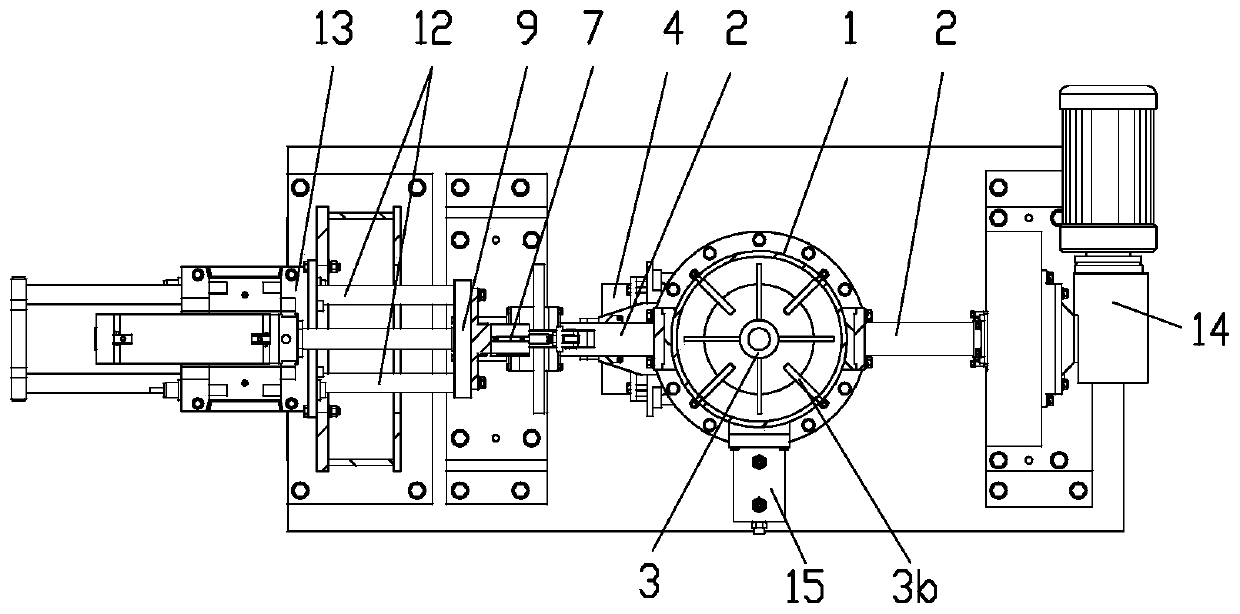

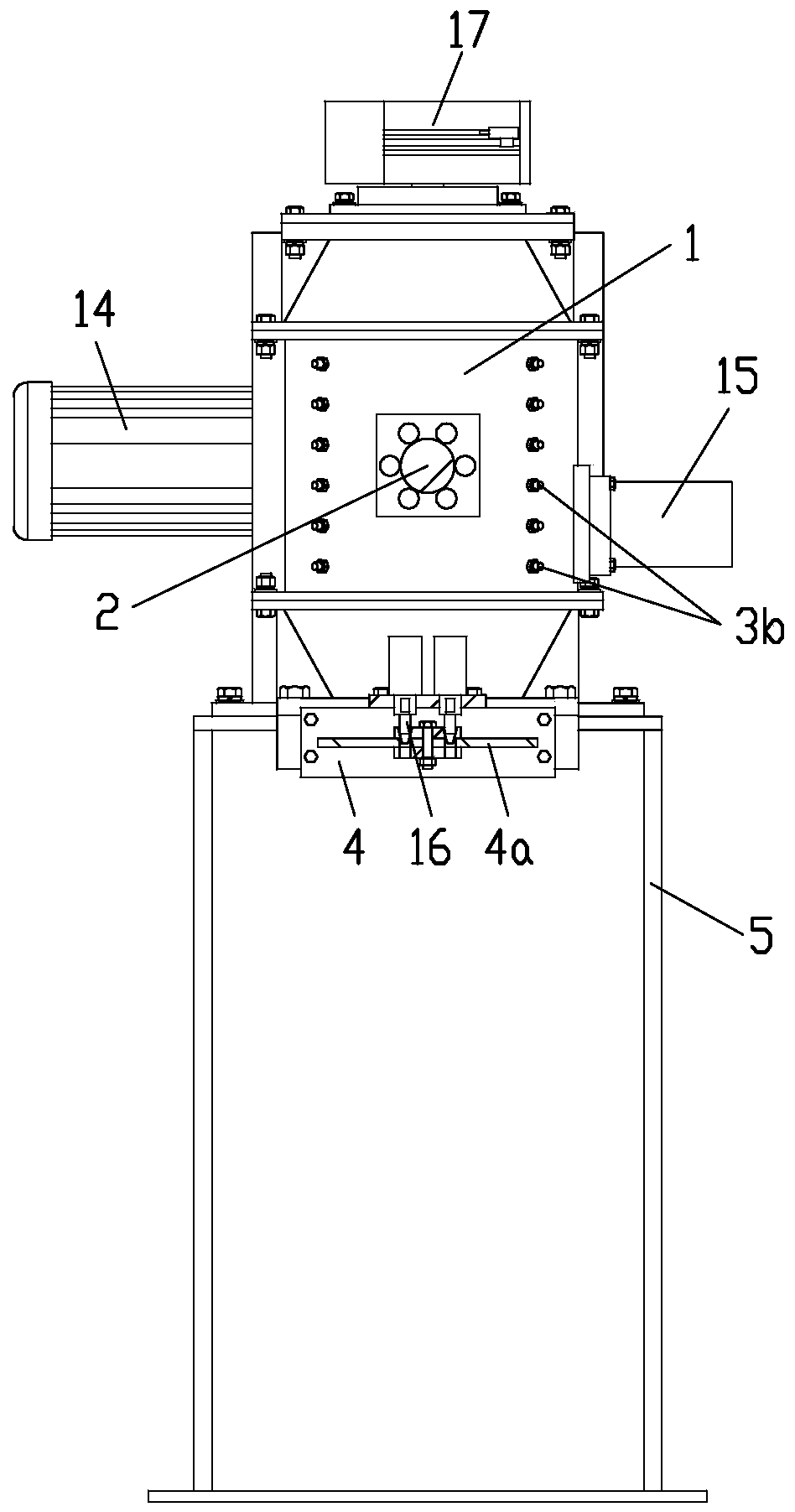

Automatic blood sample blending device and blood cell analysis device

PendingCN110398594ACompact structureImprove work efficiencyShaking/oscillating/vibrating mixersTransportation and packagingBlood cell analysisTime cost

The invention discloses an automatic blood sample blending device and a blood cell analysis device. The automatic blood sample blending device comprises a first support, a second support and a flexible column, wherein the second support is fixedly connected above the first support through the flexible column and enables rotary swing and vibration relative to the first support. The part, between the first support and the second support, of the flexible column is arranged in an hourglass shape. The automatic blood sample blending device and the blood cell analysis equipment can automatically andfully blend trace samples without manual treatment, save labor and time cost, and improve the working efficiency of blending trace samples.

Owner:SHENZHEN DYMIND BIOTECH

Concrete mixing equipment for maintaining municipal road surfaces and roadbeds

InactiveCN107794825ARealize the function of automatic stirringStir wellRoads maintainenceScreedEngineering

The invention relates to a concrete mixing equipment for roadbed maintenance of municipal roads. The mixing device includes a leveling plate, a traction cylinder, a traction telescopic rod, a stirring mechanism, a connecting rod, and a lifting electric push rod auxiliary device. A base plate is installed, and a traveling wheel is installed at the lower end of the base plate. The invention can solve the problems of high labor intensity, high labor cost, low work efficiency, potential safety hazards, unsatisfactory repair effect and waste of raw materials in the process of repairing the cement concrete pavement just poured after the rain, and can realize the automation of the cement concrete pavement Patched functionality.

Owner:储田生

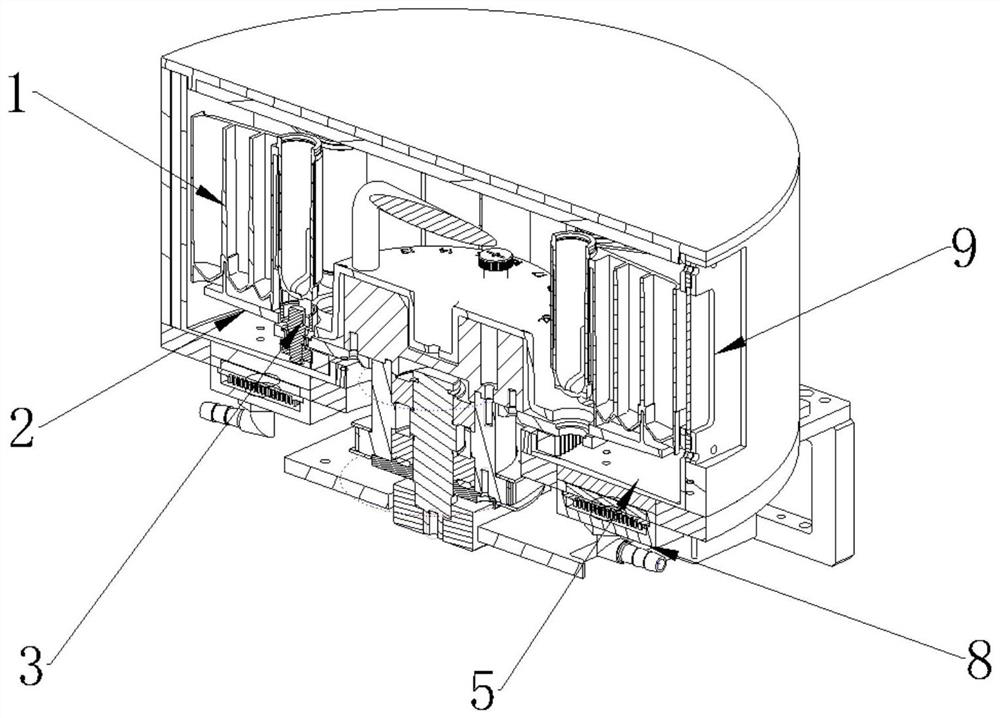

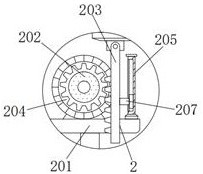

Automatic blender mixer

InactiveCN109806799AStirring intensity is moderateEnsure safetyShaking/oscillating/vibrating mixersBLENDER/MIXERValve opening

The invention discloses an automatic blender mixer, which includes a mixing pot with a sealable pot mouth. The mixing pot is supported by two half shafts arranged on the side wall of a pot body and driven by a gear motor to rotate, the mixing pot is provided with a stirring paddle, and the stirring paddle is driven by a rotating air cylinder arranged at the pot bottom of the mixing pot to swing atthe amplitude of 180 degrees; and preferably, a stirring blade is arranged on the stirring paddle, a fixed blade is arranged on the inner wall of the pot body of the mixing pot, the stirring blade isprovided with a gap for avoiding the fixed blade, a vibrator is arranged on the pot body of the mixing pot, the pot mouth of the mixing pot is provided with a gate valve, and a rack is provided withtwo valve opening and closing devices for corresponding to the pot mouth in upward and downward states correspondingly. The automatic blender mixer has the beneficial effects that automatic mixing andstirring of inflammable and explosive materials are realized through a way of combination of shaking and stirring, the mixing effect is good, the efficiency is high, manual stirring is not required,and the physical and mental health of operators can be effectively guaranteed.

Owner:重庆航天工业有限公司

Pneumatic ultrahigh-pressure intelligent grouting system

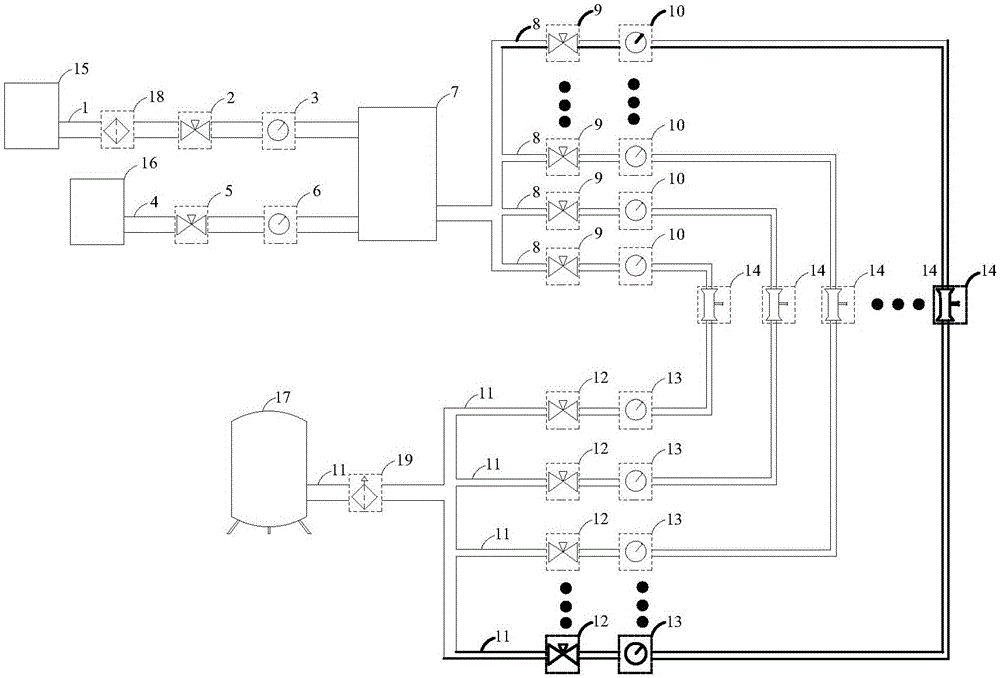

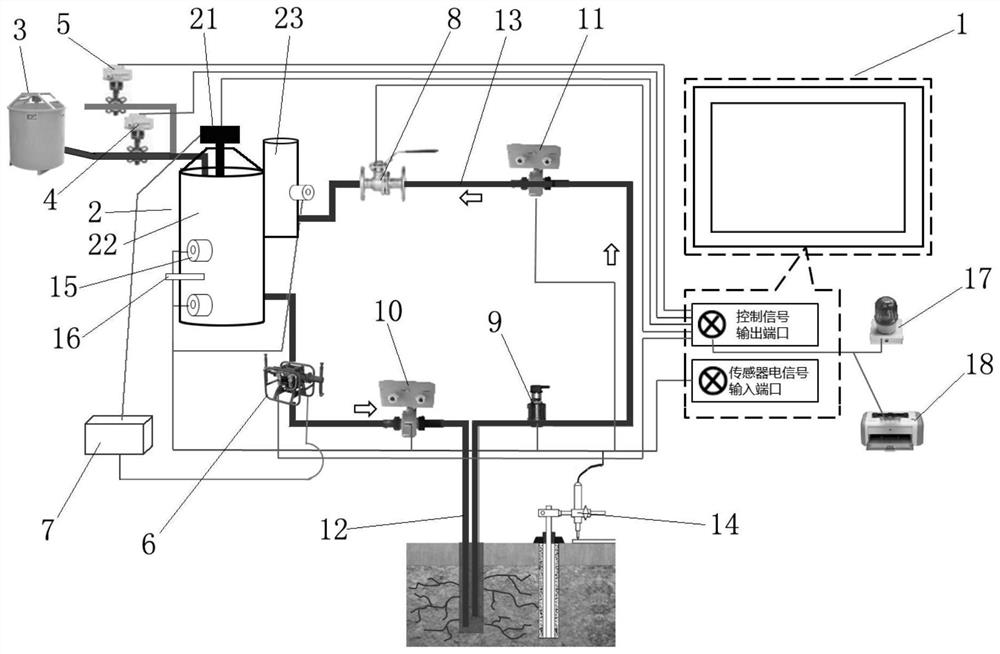

ActiveCN113322957AAvoid pipe burstsPrecise control of grouting pressureFoundation engineeringMarine site engineeringSlurryInlet flow

The invention discloses a pneumatic ultrahigh-pressure intelligent grouting system. The system comprises a central control unit, a slurry preparation unit, a grouting unit and a detection unit. The slurry preparation unit comprises an integrated slurry preparation barrel, a thick slurry storage barrel, a pneumatic thick slurry valve and a pneumatic clean water valve arranged on a water inlet pipeline of the integrated slurry preparation barrel; the grouting unit comprises a pneumatic grouting pump, a high-pressure valve, a slurry inlet flow meter, a slurry return flow meter, a grouting pipeline for connecting a slurry outlet of the integrated slurry preparation barrel and a grouting hole of a working face, and a slurry return pipeline for connecting a slurry return opening of the integrated slurry preparation barrel and the grouting hole of the working face; the detection unit comprises a pressure sensor, a lifting detector, a density sensor and a temperature sensor arranged in the integrated slurry preparation barrel; and the central control unit is in circuit connection with the detection unit, the pneumatic thick slurry valve, the pneumatic clean water valve, the pneumatic grouting pump, the high-pressure valve, the slurry inlet flow meter and the slurry return flow meter. Through the design, accurate control over slurry preparation and grouting is facilitated, the phenomenon of pipe explosion of a grouting pipeline is avoided, the safety of electric shock prevention of operators is improved, power energy consumption is reduced, and meanwhile the intelligent level of slurry preparation and grouting of the grouting system is also improved.

Owner:HUANENG LANCANG RIVER HYDROPOWER +1

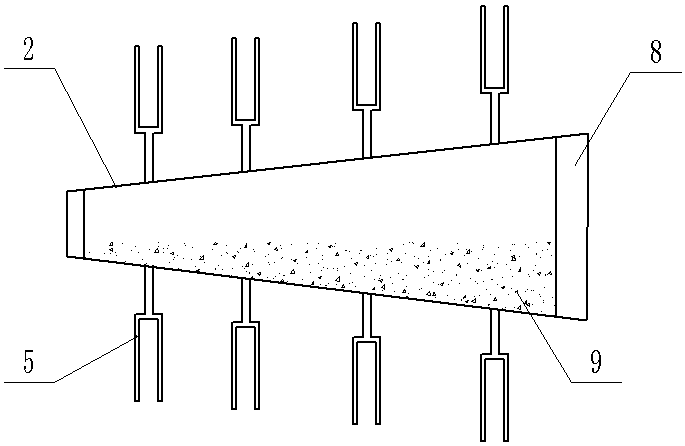

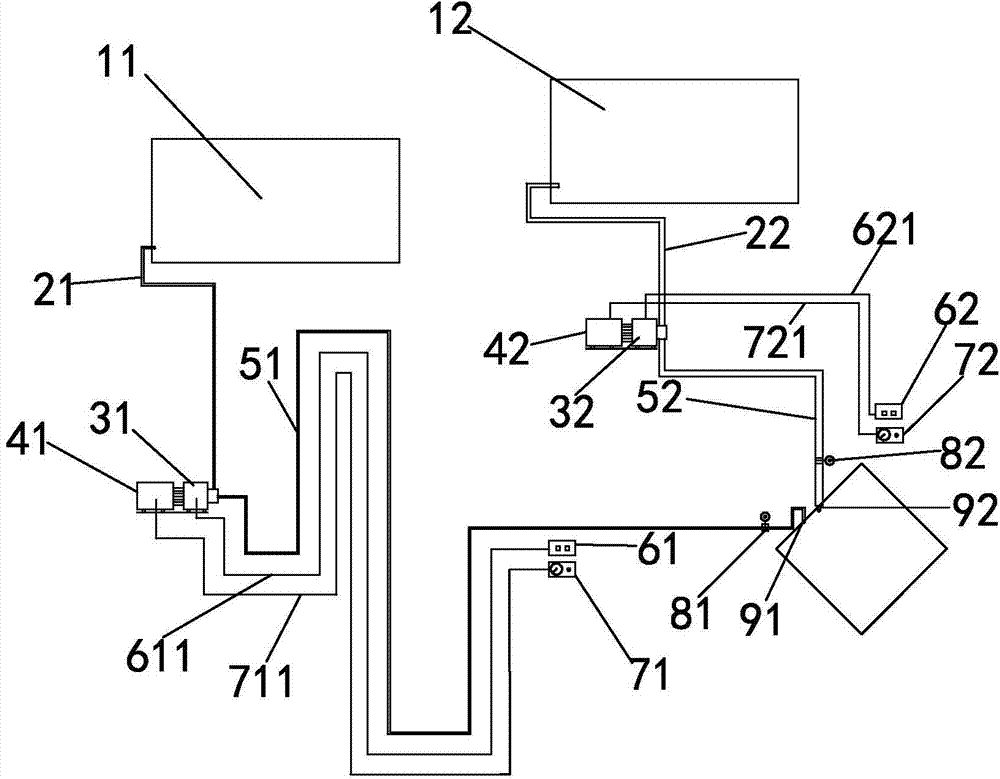

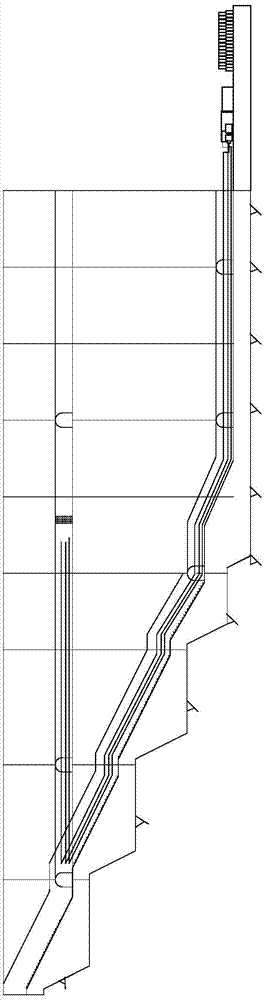

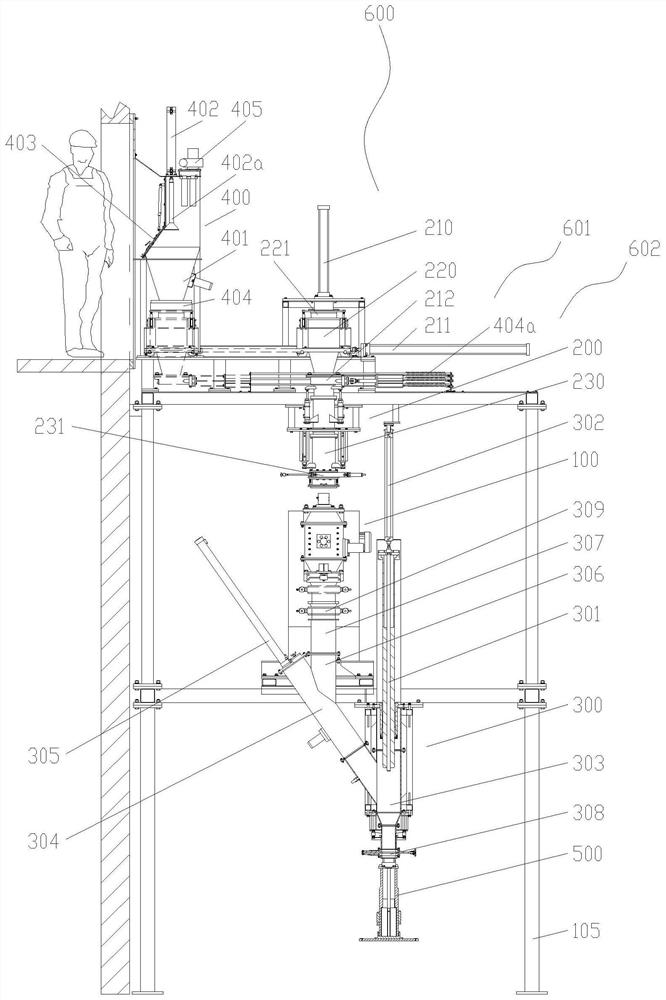

Automatic mortar conveying system applied to large hydropower station and construction method thereof

ActiveCN104120725AReal-time monitoring of flow rateWell mixedFoundation engineeringTraffic congestionMechanical equipment

The invention discloses an automatic mortar conveying system applied to a large hydropower station and a construction method of the system. The automatic mortar conveying system comprises a mortar conveying system body and an automatic mortar manufacturing system. By means of the mortar conveying system body, epoxy base materials and curing agents are gradually conveyed to a construction position, so that a lot of labor and materials are saved, and work efficiency is improved. By means of the automatic mortar manufacturing system, mortar conveying and mortar manufacturing are integrated, and work efficiency is further improved. The construction method of the automatic mortar conveying system includes the following steps of (a) construction preparation, (b) field leveling, (c) construction mechanical equipment and material dispatching, (d) material collecting box installation, (e) mortar absorbing pipeline installation, (f) electric gear pump installation, (g) mortar conveying pipeline installation, (h) automatic mortar manufacturing system instillation, and (i) project acceptance. By means of the system and the method, productivity is freed, cost is reduced, construction efficiency is improved, semi-mechanization construction is achieved, construction of dam galleries, slope dam faces and construction areas where vehicle traffic congestion happens can be achieved through the system and the method, and mortar construction projects are optimized.

Owner:HANGZHOU HUANENG SAFETY ENG POLYTRON TECH CO LTD

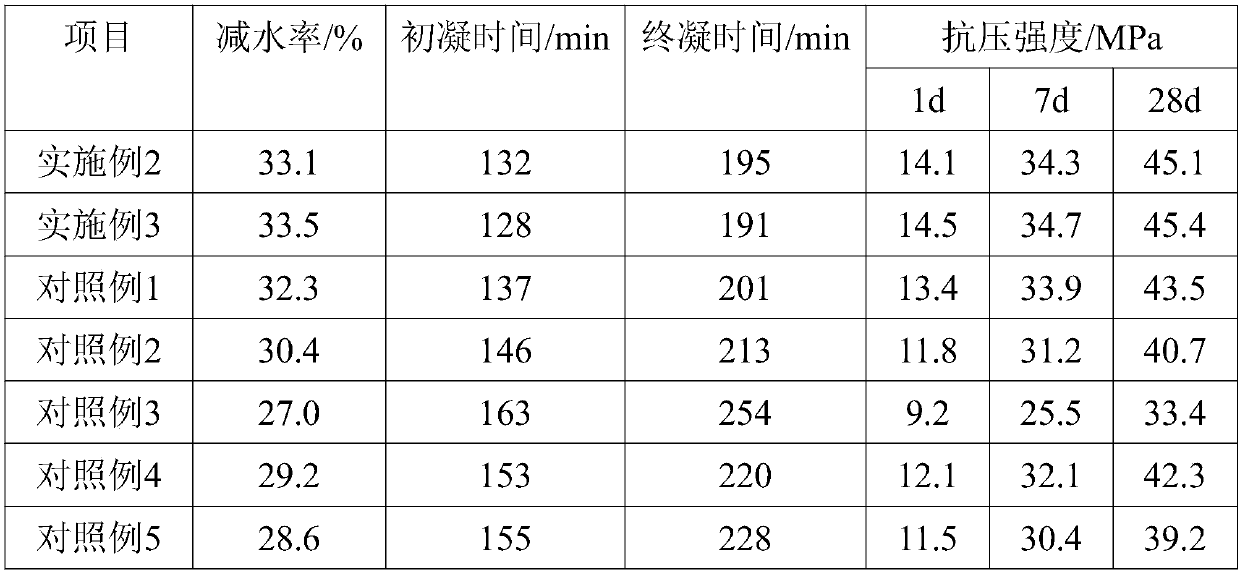

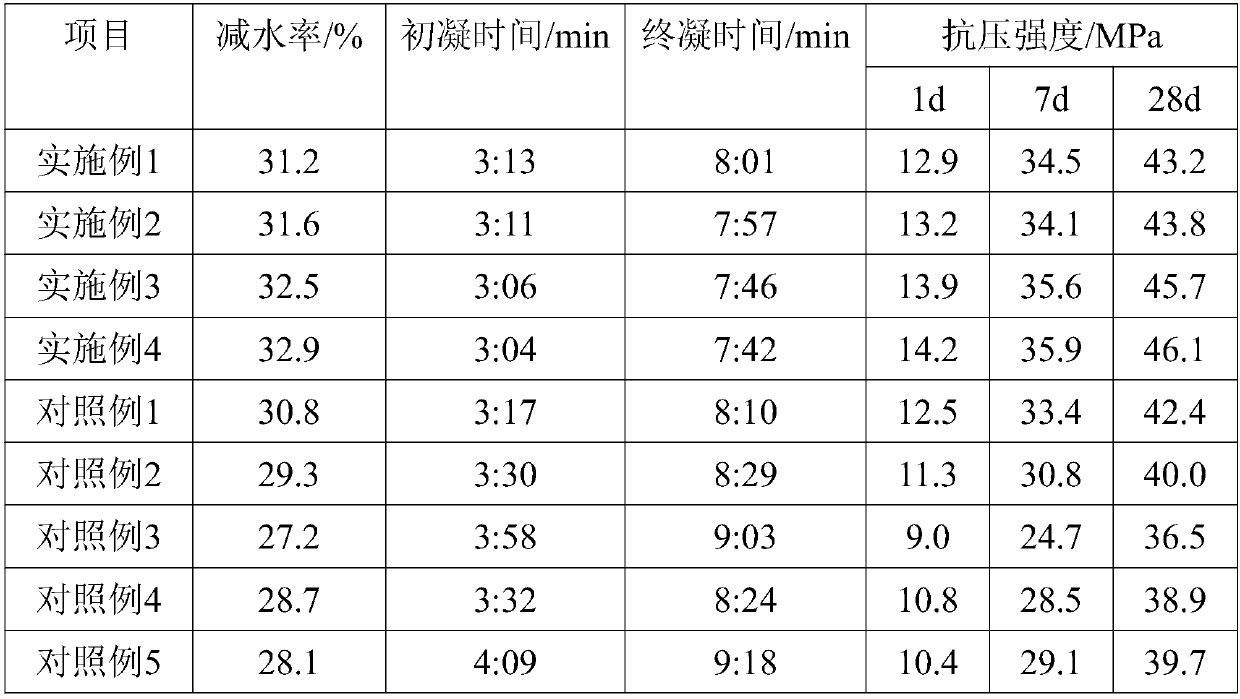

Accelerator for concrete spraying construction and preparation method thereof

The invention discloses a quick-setting agent for shotcrete construction and a preparation method thereof, relates to the technical field of concrete additives, and is prepared from the following raw materials in parts by weight: 35-45 parts of polyglutamic acid, 35-45 parts of polyethylene glycol 20-25 parts of methyl ether, 15-20 parts of superfine wollastonite powder, 5-10 parts of trimethylolpropane triacrylate, 5-10 parts of cationic polyacrylamide, 1-10 parts of trimethylolpropane triglycidyl ether 5 parts, 1-5 parts of microcrystalline cellulose, 0.5-2 parts of asphalt emulsifier, 0.5-2 parts of hydrogenated castor oil. The quick-setting agent prepared by the present invention belongs to the solid non-alkali type accelerator. The solid form of existence avoids the problem that the liquid accelerator is easy to precipitate and precipitate after the storage time is too long, thereby affecting the quick-setting effect. The existence form of the non-alkali type avoids The hidden dangers of alkali-aggregate reaction and corrosion of steel bars exist in the use of alkali-containing accelerators.

Owner:马多浩

Automatic resin mixing system

ActiveCN112248269ARealize automatic mixingHigh degree of automationSievingScreeningElectric machineryEngineering

The invention discloses an automatic resin mixing system which comprises a bottom plate. A long plate is fixedly connected to the top of the bottom plate, a spray gun is fixedly connected to the rightside of the top of the long plate, a vertical plate is fixedly connected to the left side of the top of the long plate, and a vertical rod is fixedly connected to the right side of the top of the long plate; and the upper portion of the front end face of the vertical rod is rotationally connected with a convex block at the right side of the bottom of a box body through a pin shaft, the top of thevertical plate is attached to the left side of the bottom of the box body, a square box is fixedly connected to the top of the box body, and a stirring device is arranged at the left side of the boxbody. According to the automatic resin mixing system, through cooperation of the bottom plate, the spray gun, the vertical plate, the vertical rod, the long plate, the box body, the square box, a feeding opening and the stirring device, when the device is used, a first motor can drive a first gear to rotate, the first gear drives the long rod and a second gear to rotate, and the second gear drivesrotating teeth to rotate, so that automatic stirring and mixing of resin are realized, the automation degree is high, labor is saved, and the working efficiency is improved.

Owner:临沂超邦新材料有限公司

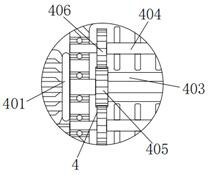

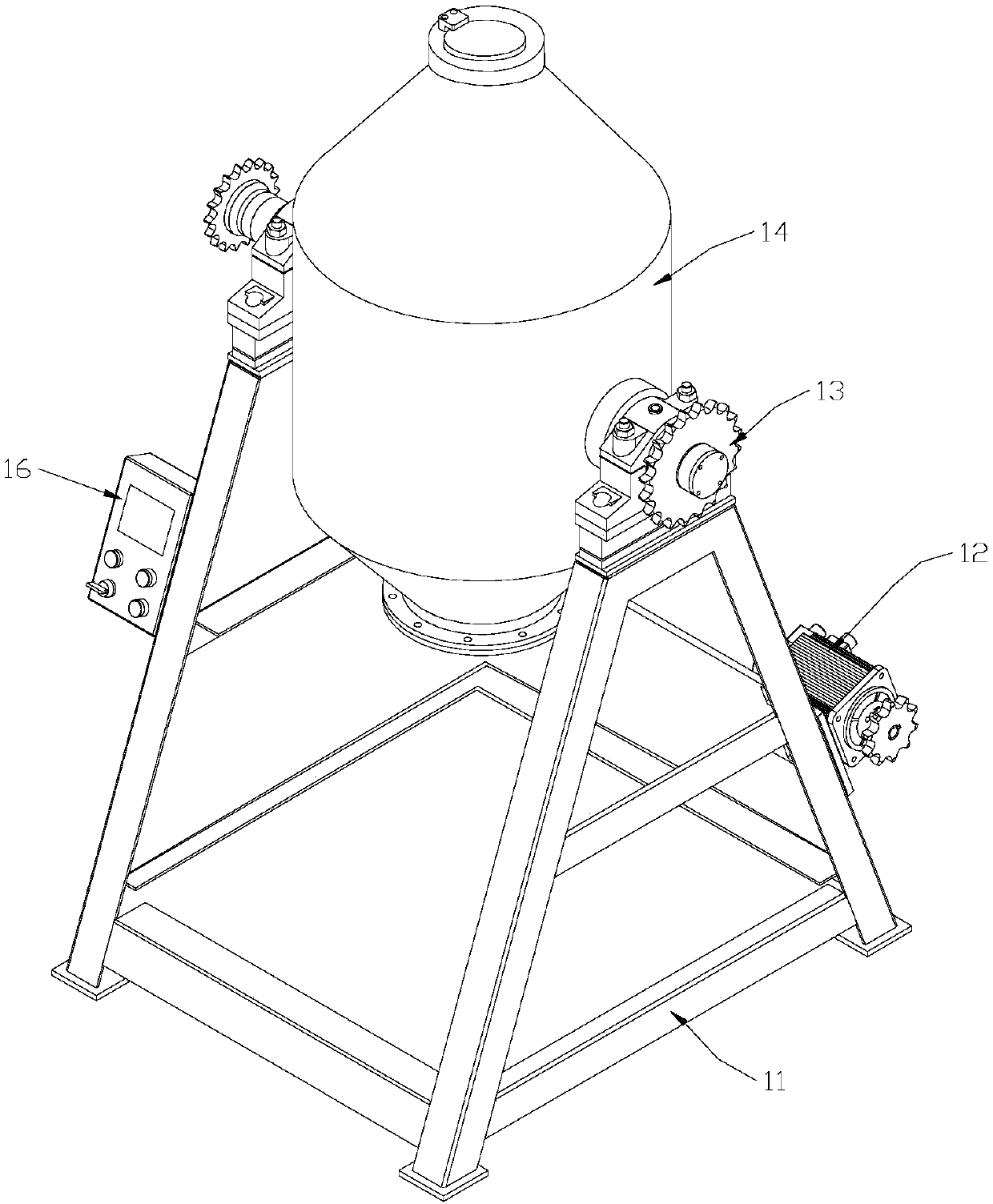

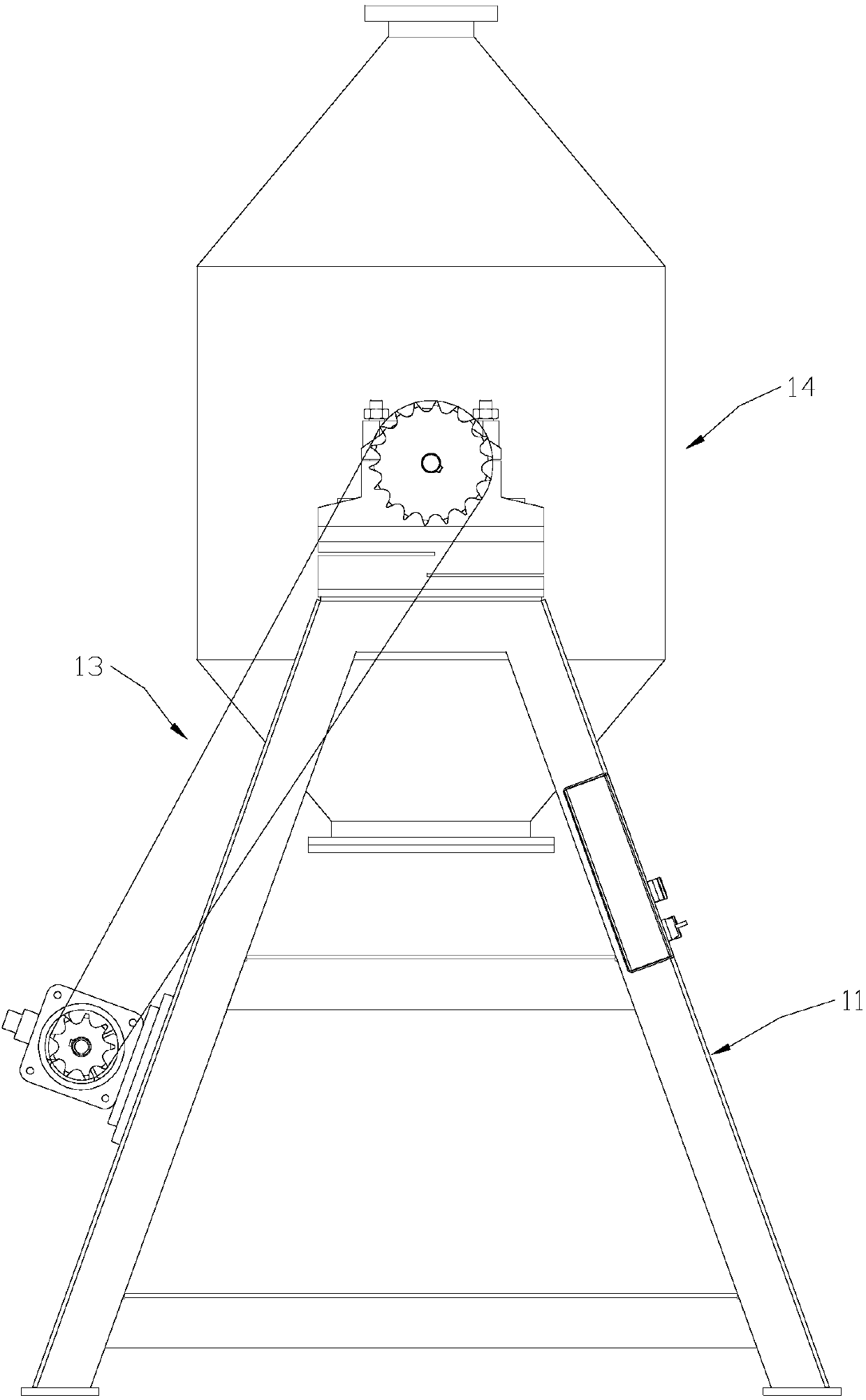

A stirring tank

PendingCN107744757AAchieve regulationHigh quality and precisionRotating receptacle mixersTransportation and packagingDrive shaftEngineering

The invention relates to a stirring tank. The stirring tank includes a support, a stirring tank body disposed on the support, a drive mechanism disposed on the support and used for driving stirring operation of the stirring tank body, and a transmission mechanism disposed on the support, connected to the drive mechanism and driven to rotate by the drive mechanism. The transmission mechanism includes a transmission shaft disposed on the support, passing through the stirring tank body and driving the stirring tank body to rotate. The stirring tank body includes a tank body disposed on the transmission shaft and driven to rotate by the transmission shaft, and a stirring blade assembly disposed in the tank body, connected to the transmission shaft, and driven by the transmission shaft to rotate. The stirring tank can achieve automatic stirring, thus reducing the labor cost. The stirring device can fully stir a material, thus improving quality and precision of prepared powder.

Owner:深圳市富荣新材料科技有限公司

Kit for full-automatic chemiluminescence immunoassay analyzer

ActiveCN102147370BAutomate deliveryRealize automatic mixingChemiluminescene/bioluminescenceBiological testingTectorial membraneChemiluminescence immunoassay

The invention discloses a kit for an automatically-automatic chemiluminescence immunoassay analyzer. The kit is characterized by comprising a reagent cup (3) and a reagent shelf (2), wherein the reagent shelf (2) is provided with a hole passing through the reagent shelf (2); the reagent cup (3) comprises a reagent cup body (31) and a reagent cup cover, wherein the reagent cup cover comprises a movable top cover (33), a protective film (34) and a cover body (32) which are arranged from top to bottom in sequence; and the radius of the cover body is larger than that of the hole. By the specific structure of the kit, the operations of delivery of kits, mixing of reagents, code scanning and the like can be conducted by a matched moving mechanism.

Owner:SICHUAN MACCURA BIOTECH CO LTD

Multilayer grape vine insecticide spraying device

PendingCN108142400ARealize automatic mixingExpand the spraying rangeInsect catchers and killersTravel modeAgricultural engineering

The invention discloses a multilayer grape vine insecticide spraying device which comprises a car body, an armrest, a first rotating wheel, a first rotating wheel support, a first rotating shaft, a second rotating wheel, a second rotating wheel support, a second rotating shaft, a third rotating wheel, a third rotating wheel support, a first motor, a movable device, a first leaf poking machine, aninsecticide spraying machine, a second leaf poking machine, an insecticide box, a first water pump and a camera. The armrest and the camera are welded at the front end and the rear end of the car body, the movable device, the insecticide box and the first water pump are mounted at the upper end of the car body, the first leaf poking machine, the insecticide spraying machine and the second leaf poking machine are mounted on the movable device, and the first rotating wheel support, the second rotating wheel support and the third rotating wheel support are mounted at the low end of the car body.The device is diverse in traveling mode, manual traveling of the device can be achieved, the device can travel forwards under observation of the camera, insecticides are automatically blended, the insecticide spraying machine can be automatically and vertically controlled, and insecticide spraying range is widened.

Owner:孟晴

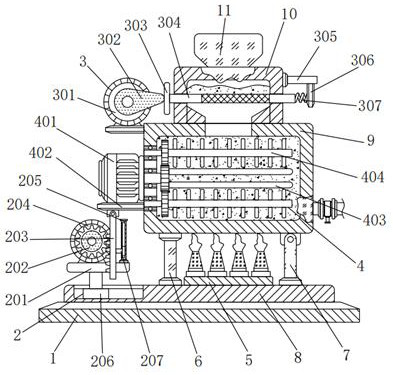

Automatic powder mixing and press-fitting production line

PendingCN112535977AImprove the mixing effectRealize automatic mixingShaking/oscillating/vibrating mixersMixer accessoriesProduction lineProcess engineering

The invention discloses an automatic powder mixing and press-fitting production line. Mixed materials are loaded into a mixing tank of an automatic mixer through a feeder, and the materials are stirred by stirring blades and fixed blades on a stirring paddle while rolling in the tank, so that the purpose of uniform mixing is achieved. Then, the mixed materials are output into a ramming machine through the mixing tank, then the materials are additionally arranged in a tank body mold through the ramming machine and are rammed through the ramming machine, so that the purposes of automatic mixingand injecting are achieved, manual mixing and injecting are replaced, and the manual participation degree is reduced. Due to the fact that the mixing tank has the rotating motion of rolling up and down, and the stirring paddle is arranged inside the mixing tank to vertically stir the materials, automatic mixing of flammable and explosive materials is achieved, and a good material mixing effect isguaranteed.

Owner:重庆航天工业有限公司

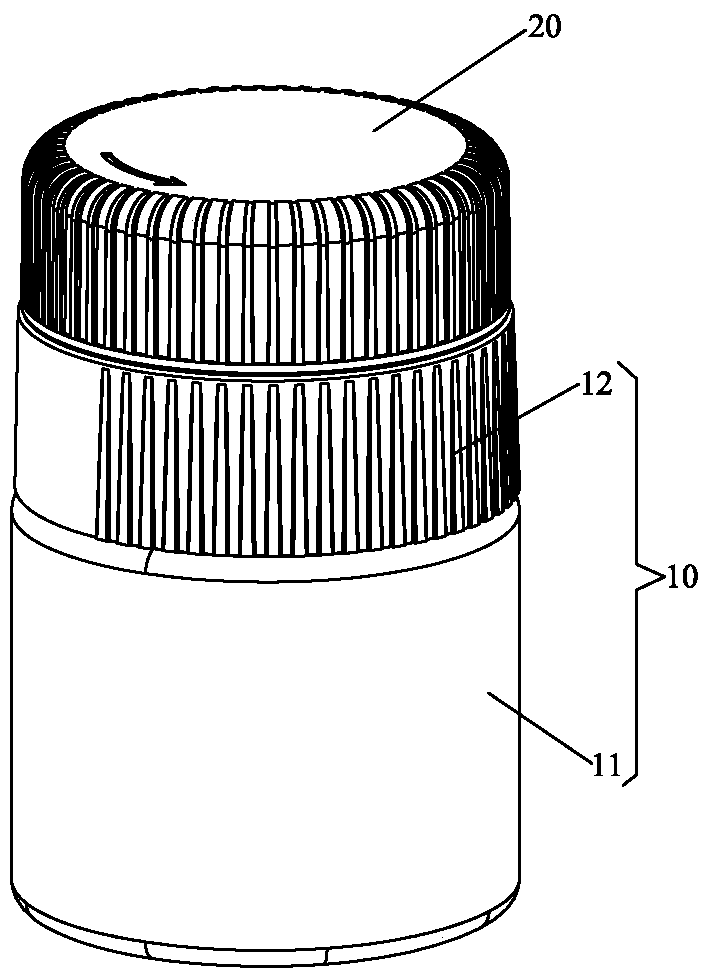

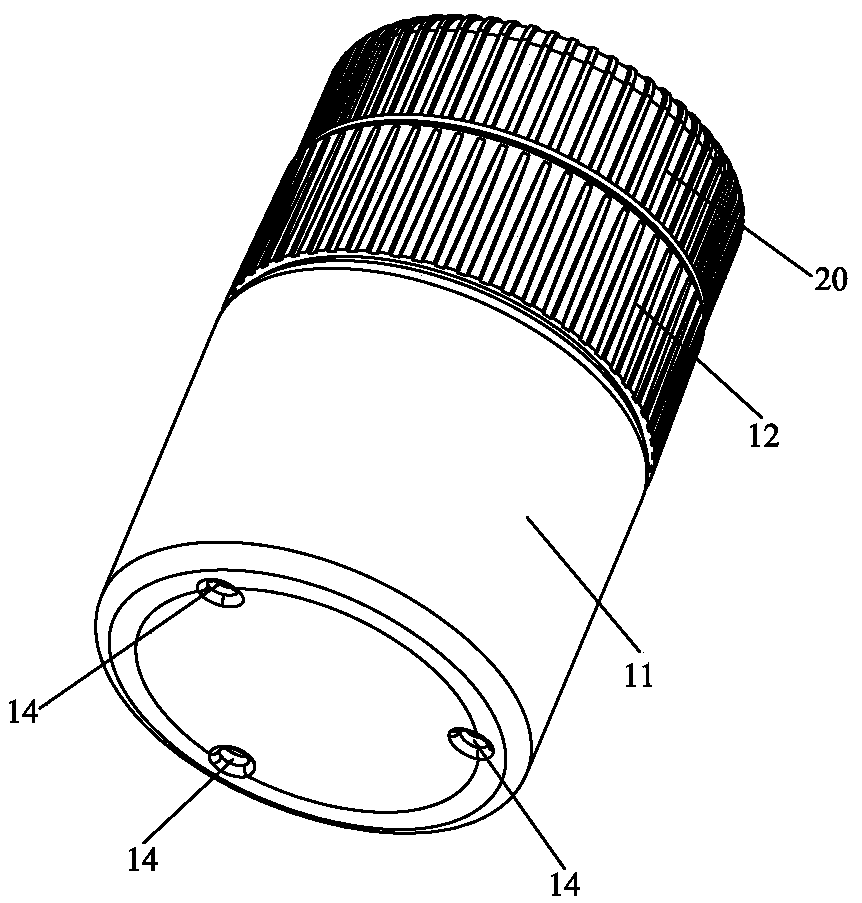

Air purifying device and inner tank thereof capable of automatically proportioning ingredients

PendingCN110665040ARealize automatic mixingEasy to operateGas treatmentDispersed particle separationProcess engineeringAir purification

The invention discloses an air purifying device and an inner tank thereof capable of automatically proportioning ingredients. The device includes the inner tank and a bearing member used for loading the inner tank; the inner tank includes a tank body, a cover body and the bearing member; the inside of the tank body is provided with a cavity used for holding a first ingredient, and a cooperating tube is arranged at the opening of the cavity; the cover body includes a cover main body and an extension tube used for holding a second ingredient; the extension tube can stretch into the cooperating tube, and an end cover is detachably arranged on the lower end of the extension tube; the end cover is located under the cooperating tube, and the periphery of the end cover is provided with a hookingpart which can move upward with the cover body to hook the lower end of the cooperating tube; and when the cover body is screwed upward to separate from the tank body, the hooking part can be hooked on the lower end of the cooperating tube to make the end cover automatically separated from the extension tube, so that the second ingredient in the extension tube can fall into the cavity to mix withthe first ingredient. Thus, through the respective arrangement of the first ingredient and the second ingredient in the tank body and the cover body, the end cover can automatically fall off when thecover body is opened by screwing. Therefore, the automatic mixing of the first and second ingredient can be realized, and simple and fast operation can be achieved.

Owner:BENZHI SHENZHEN INFORMATION TECH CO LTD

Concrete batching machine for concrete stirring station

InactiveCN107225690AEasy to stir and mixIncreased load-bearing capacityMixing operation control apparatusIngredients proportioning apparatusAdditive ingredientBatch machine

The invention discloses a concrete batching machine for a concrete stirring station. The concrete batching machine comprises a batching machine body; a conveying pipe is welded to the batching machine body, and a discharging outlet is welded to one end of the conveying pipe; a motor box is spirally fixed to the side, located on the conveying pipe, of the batching machine body through a tripod; a conveying motor is fixed into the motor box, and the conveying motor is in transmission connection with a spiral conveying rod inside the conveying pipe through a rotating shaft of the motor; and an electric control box is fixed to the top of the motor box. In the concrete batching machine, firstly a mixing bin is arranged, and a stirring rotating shaft is rotatably connected inside the mixing bin, so that ingredients in three batching bins enter the mixing bin simultaneously, then the stirring rotating shaft is automatically driven to rotate, thus the ingredients in the three batching bins are mixed, automatic mixing is achieved, and the situation that the prepared concrete ingredients are separated, thus the concrete ingredients are not uniform enough when being mixed and stirred, and the quality of concrete is affected is effectively prevented.

Owner:黔西南州启腾矿山设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com