Automatic fertilizer stirring and applying device

A fertilization device and automatic stirring technology, applied in the field of automatic stirring and fertilizing devices, can solve the problems of manual fertilization, low work efficiency, long fertilization time, etc., so as to prolong the pure operation time of machines and tools, improve work efficiency and improve the efficiency of fertilization. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

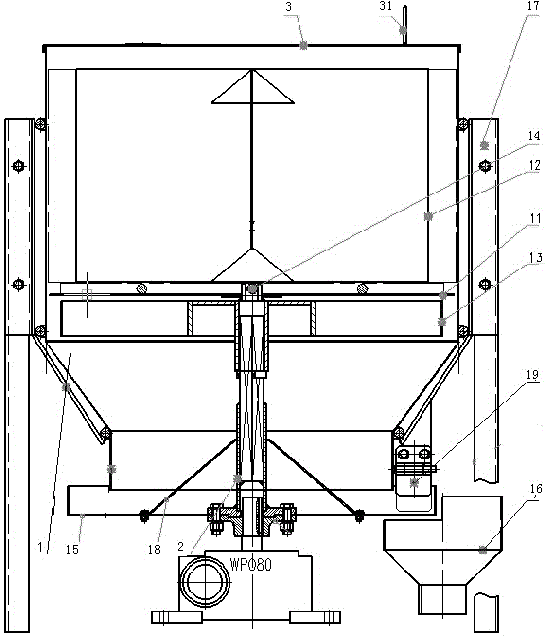

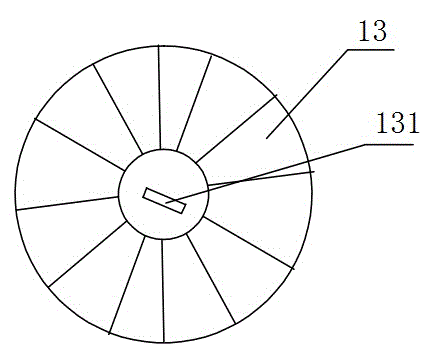

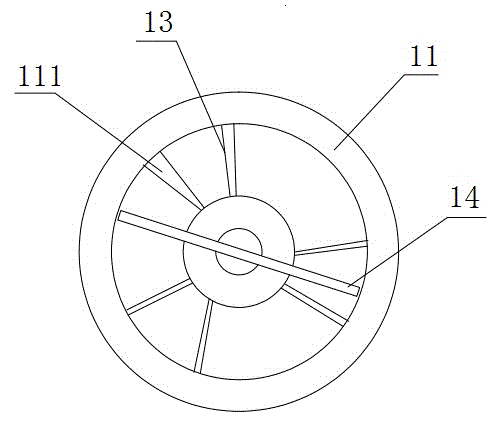

[0025] Such as Figures 1 to 3 Shown is the embodiment of the automatic stirring fertilization device of the present invention, and the fertilization device comprises fertilization tube 1 and the first leaking plate 11 that is placed in fertilization tube 1, and the first leaking plate 11 is matched with fertilization tube 1; Fertilization tube 1 and above the first drain plate 11 are provided with three isolation grids 12, and the three isolation grids 12 divide the fertilization cylinder 1 into three areas; the first drain plate 11 is in the three areas divided by the isolation grid 12 Both are provided with a material leakage port 111; the fertilization cylinder 1 is located under the first material leakage plate 11 and is provided with a rotatable impeller 13, and the impeller 13 is provided with a number of blades with spacing; Rod 14, stirring rod 14 is positioned at the top of the first leaking material plate 11 and is positioned at the below of barrier 12; The lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com