Concrete batching machine for concrete stirring station

A concrete and batching machine technology, which is applied in mixing plants, batching and batching equipment, clay preparation equipment, etc., can solve the problems of simple structure of concrete batching machine, affecting the quality of concrete, uneven mixing, etc., to prevent excessive load-bearing deformation and desoldering , prevent deformation and damage, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

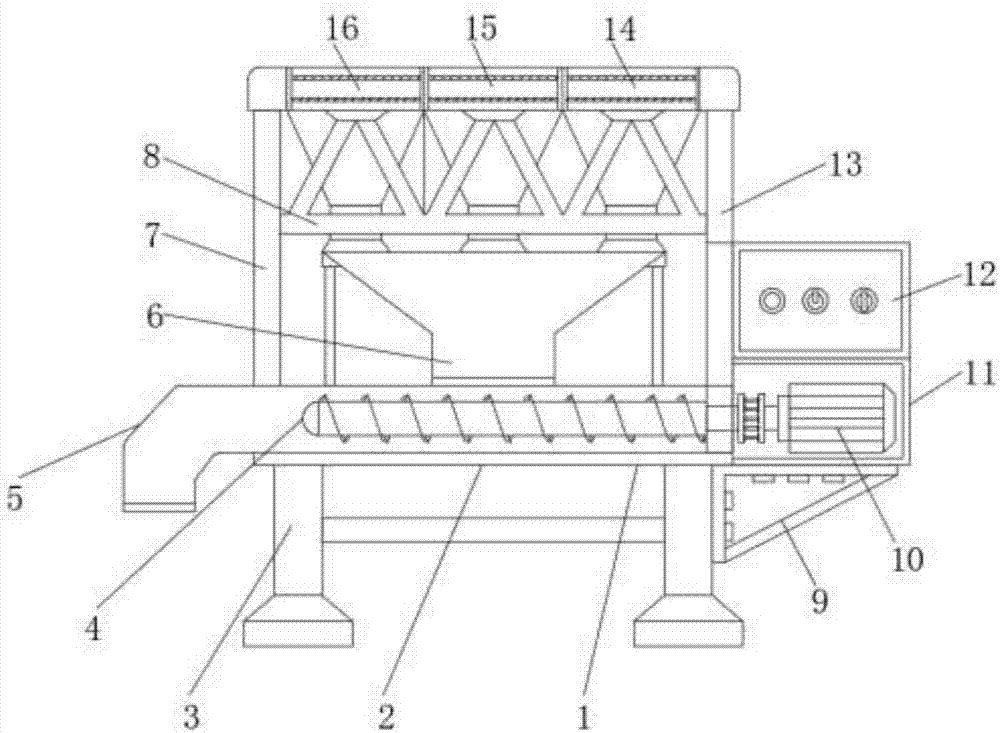

[0023] Embodiment one, with reference to Figure 1-4 , a concrete batching machine for a concrete batching plant, comprising a batching machine body 2, a feeding pipe 1 is welded on the batching machine body 2, and a discharge port 5 is welded at one end of the feeding pipe 1, and the batching machine body 2 is located on the feeding One side of the pipe 1 is screw-fixed with a motor box 11 through a tripod 9, and a feeding motor 10 is fixed inside the motor box 11, and the feeding motor 10 is connected to the screw feeding rod 4 inside the feeding pipe 3 through a transmission shaft. The electric control box 12 is fixed on the top of the motor box 11, the first support frame 7 and the second support frame 13 are welded symmetrically on both sides of the top of the batching machine body 2, and the first support frame 7 and the second support frame 3 are welded between the top One batching bin 14, the second batching bin 15 and the third batching bin 16, the bottom batching por...

Embodiment 2

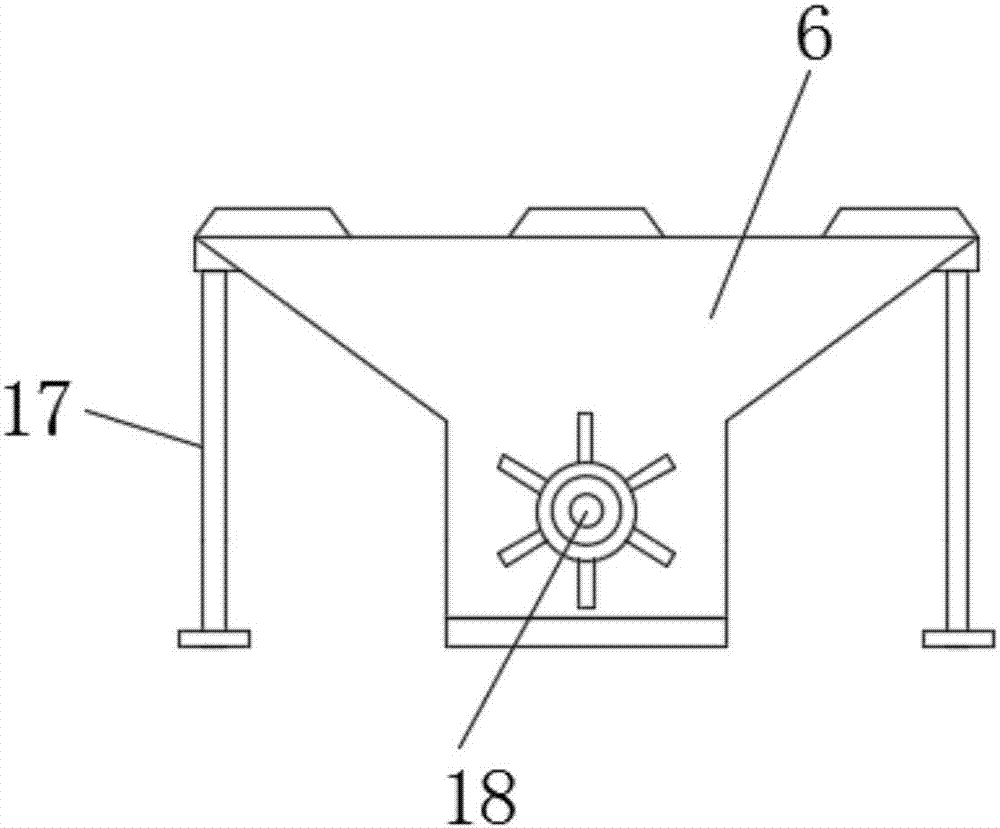

[0024] Embodiment two, refer to Figure 1-2 , the two sides of the mixing bin 6 are symmetrically welded with the auxiliary support 7 for auxiliary support of the mixing bin 6, the inner vertical center line of the mixing bin 6 is connected with the stirring shaft 18 through the rotating shaft, and the two auxiliary brackets 7 can be used for mixing. Auxiliary welding is performed on the material bin 6, so as to prevent the vibration generated during the operation of the equipment from causing the de-soldering of the mixing bin, and at the same time enhance the stability of the mixing bin.

Embodiment 3

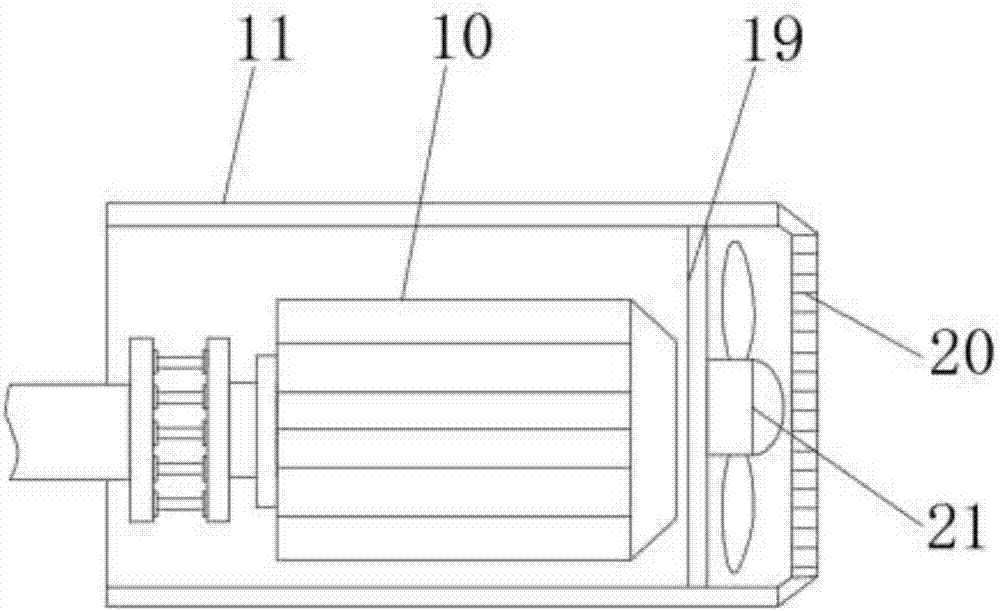

[0025] Embodiment three, refer to figure 1 and 3 , the inside of the motor box 11 is located on the outside of the feeding motor 10 and is welded with a heat dissipation fan 21 through the fan fixing frame 19, and a heat dissipation dust cover 20 is welded on the outer shell of the motor box 11, and the heat dissipation fan 21 can dissipate heat to the feeding motor 10, Prevent the feeding motor 10 from heating and prolong its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com