Patents

Literature

350results about How to "Easy to stir and mix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

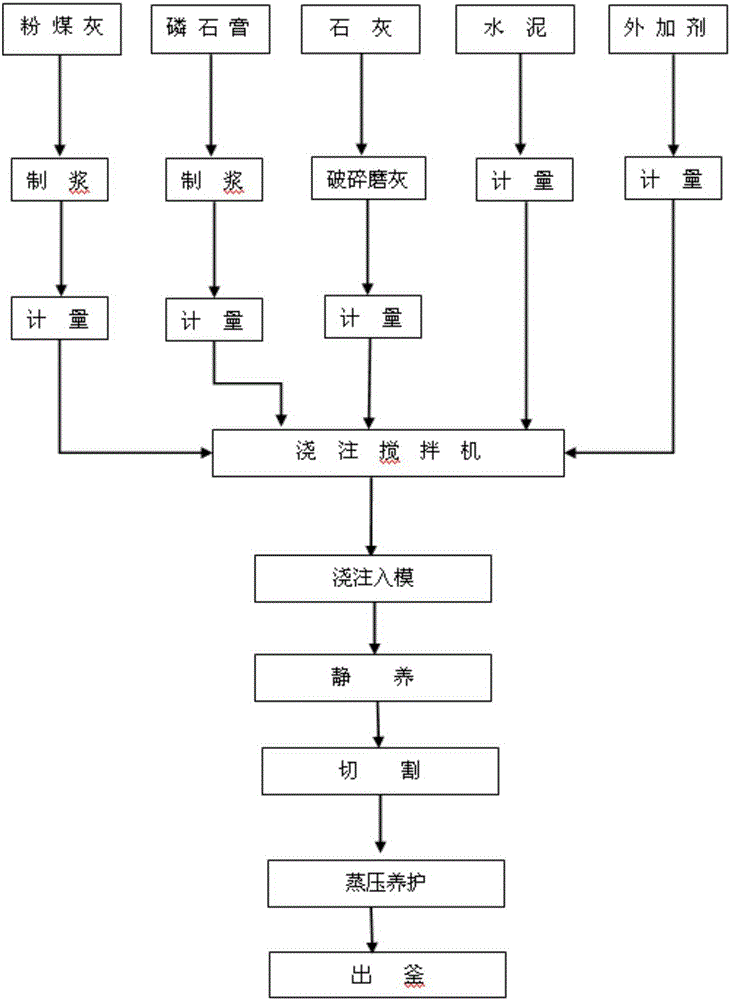

Production technology for autoclaved aerated concrete building block

InactiveCN105174833AReduce weightGood insulation performanceCeramic shaping apparatusGrinding millAluminium

The invention discloses a production technology for an autoclaved aerated concrete building block. The production technology is characterized in that the material formula comprises, by weight, 65% of fly ash, 15% of cement, 14% of lime, 5.5% of phosphogypsum and 0.5% of aluminum powder. The production technology comprises the following steps: firstly, slurries are prepared, namely, fly ash is ground by utilization of a ball grinding mill to prepare a fly ash slurry, phosphogypsum is added with water, then stirring is carried out for 1h, a phosphogypsum slurry is prepared, and then lime is crushed and ground to lime powder by utilization of the ball grinding mill; secondly, blending and stirring are carried out, namely, all the materials are sent to a casting mixer, the casting mixer is started, stirring is carried out and a concrete slurry is obtained; thirdly, casting and die entering are carried out, namely, all the concrete slurry in the casting mixer is placed in a die, and casting is carried out; fourthly, namely, a green body is thickened and condensed gradually; fifthly, cutting is carried out, namely, the shaped green body is cut according to a designed size; sixthly, autoclaved curing is carried out, namely, the cut green body is sent to an autoclaved curing kettle for autoclaved curing, and a finished product aerated concrete building block is obtained.

Owner:JIANGSU GOLDEN CUBE ENVIRONMENTAL TECH CO LTD

Production process of garden plant waste compost bacterium and uses thereof

InactiveCN101306961APromote degradationAccelerates the rate of compost maturityBio-organic fraction processingOrganic fertiliser preparationWarm waterEvery Two Weeks

The invention relates to a method for making landscape plant waste compost inoculum and an application of the same. The method is as follows: bacillus subtilis, trichoderma viride, lactobacillus plantarum, paracoccus denitrification, aspergillus oryzae and saccharomyces cerevisiae respectively occupying 10 to 20 mass portions are inoculated in a solid state fermentation medium so as to carry out cultivation and fermentation in dark sealing for 1 to 3 weeks at a temperature of between 25 and 30 DEG C; one week later, 250 mass portions of saw dust is added and evenly stirred and then cultivation and fermentation are continued; two weeks later, hay is placed to absorb surplus moisture and then is removed, and powdery inoculum can be obtained through drying in the shade for further use. Garden wastes are piled up and then are inoculated with inoculum with the weight occupying 1 to 3 per mill of that of a pile and dipped in warm water at a temperature of between 30 and 40 DEG C; compost is carried out at a temperature of between 55 and 65 DEG C, and pile turning and water replenishing are carried out every 3 to 4 days; then, pile turning and water replenishing are carried out every two weeks so as to keep pile water content of between 50 and 60 percent; thus, compost is completed after three weeks so as to reach to rotten innocuity standards. The strain has simple making and low cost, and can be directly used or bred continuously; moreover, the strain has no variation, no inactivation and long storage period, and the obtained compost can improve soil and increase nutrient utilization rate.

Owner:龙地(上海)建设发展有限公司

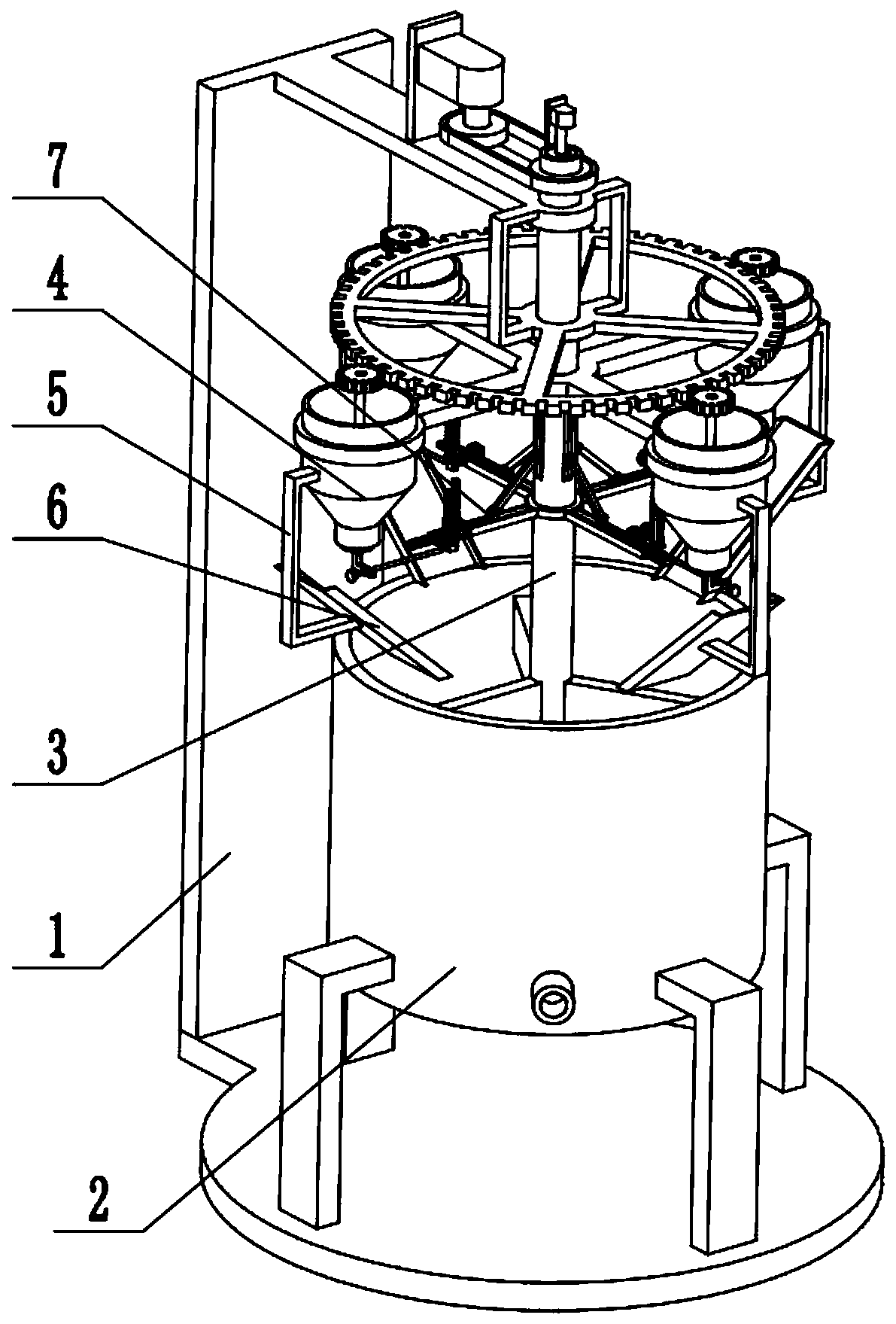

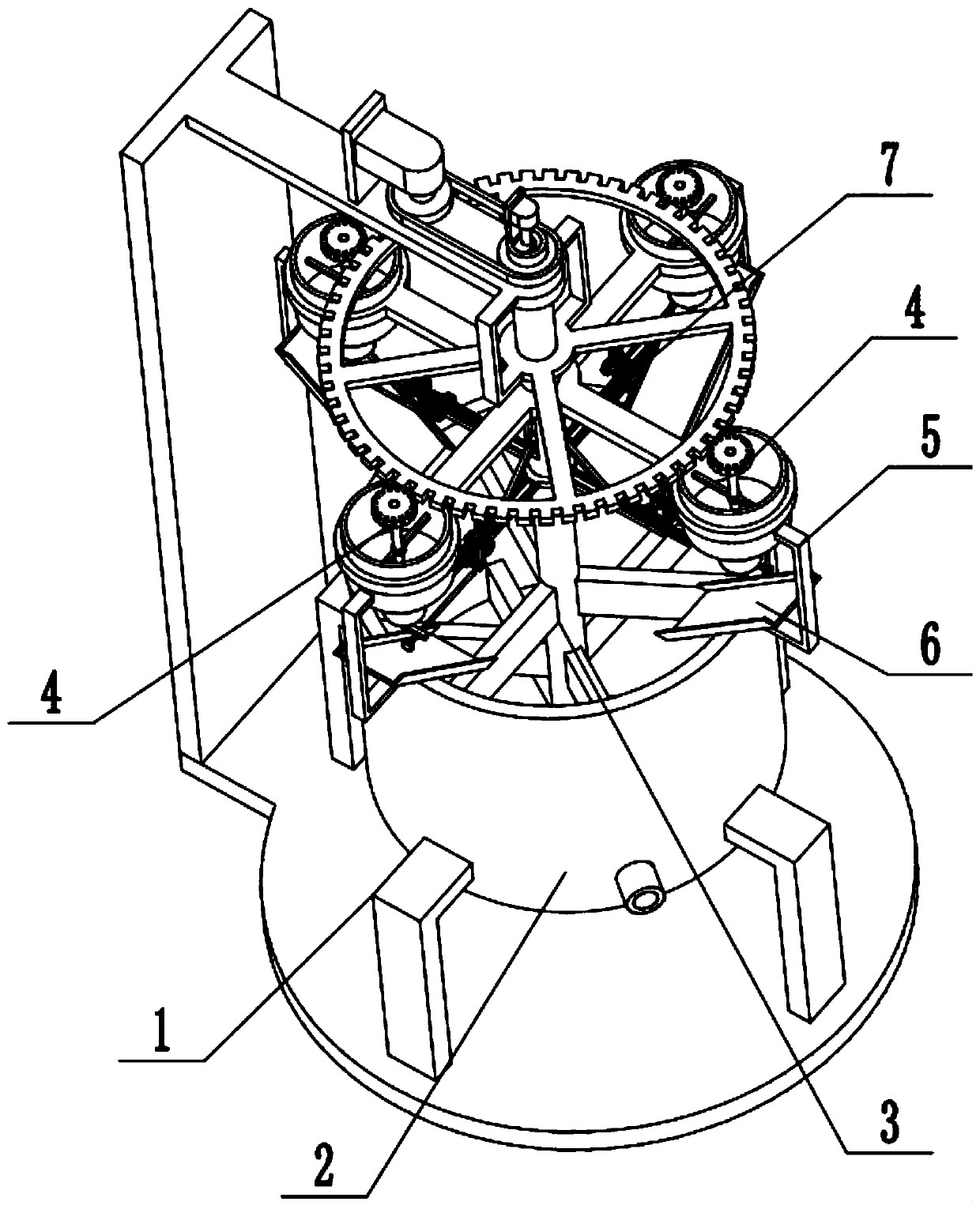

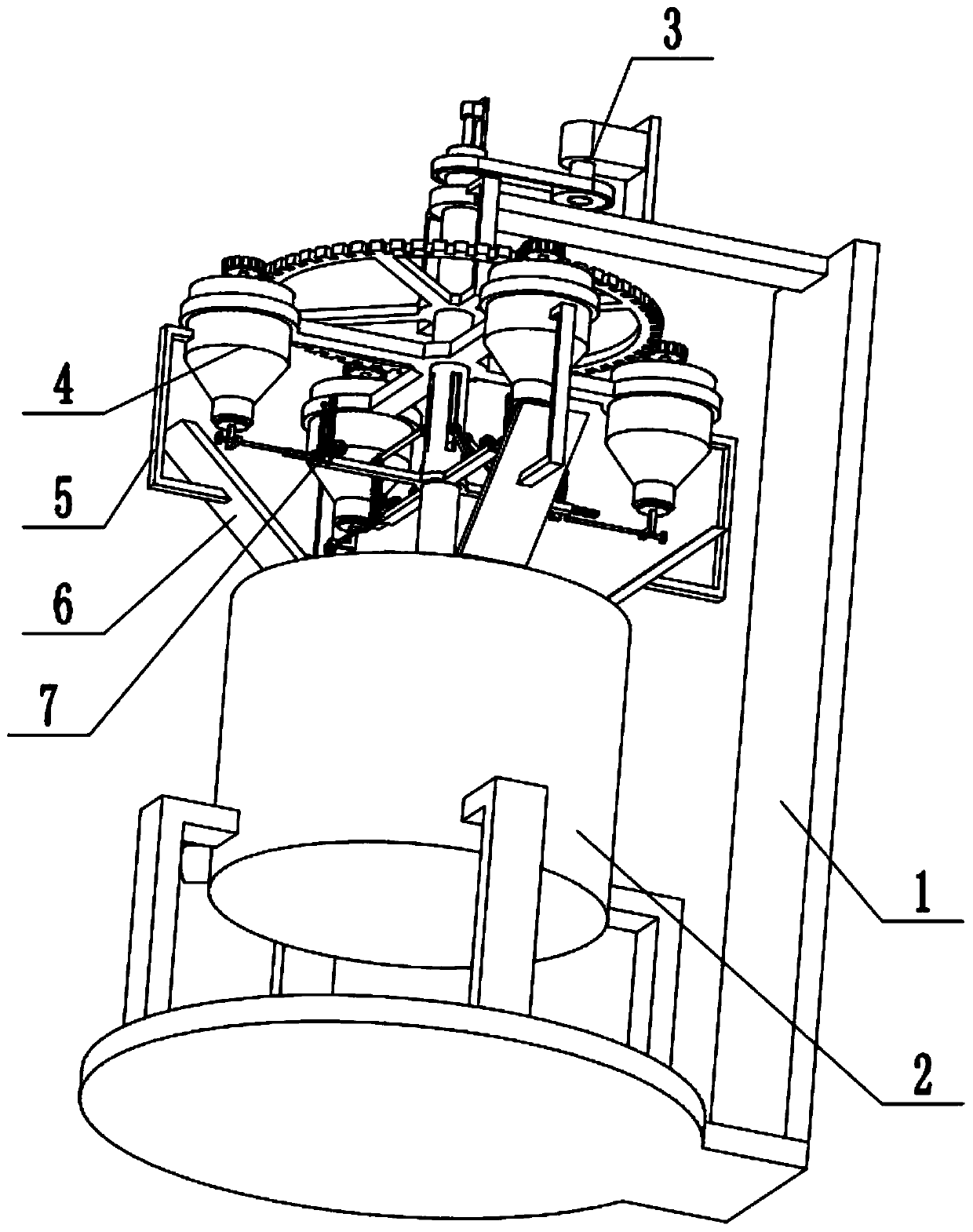

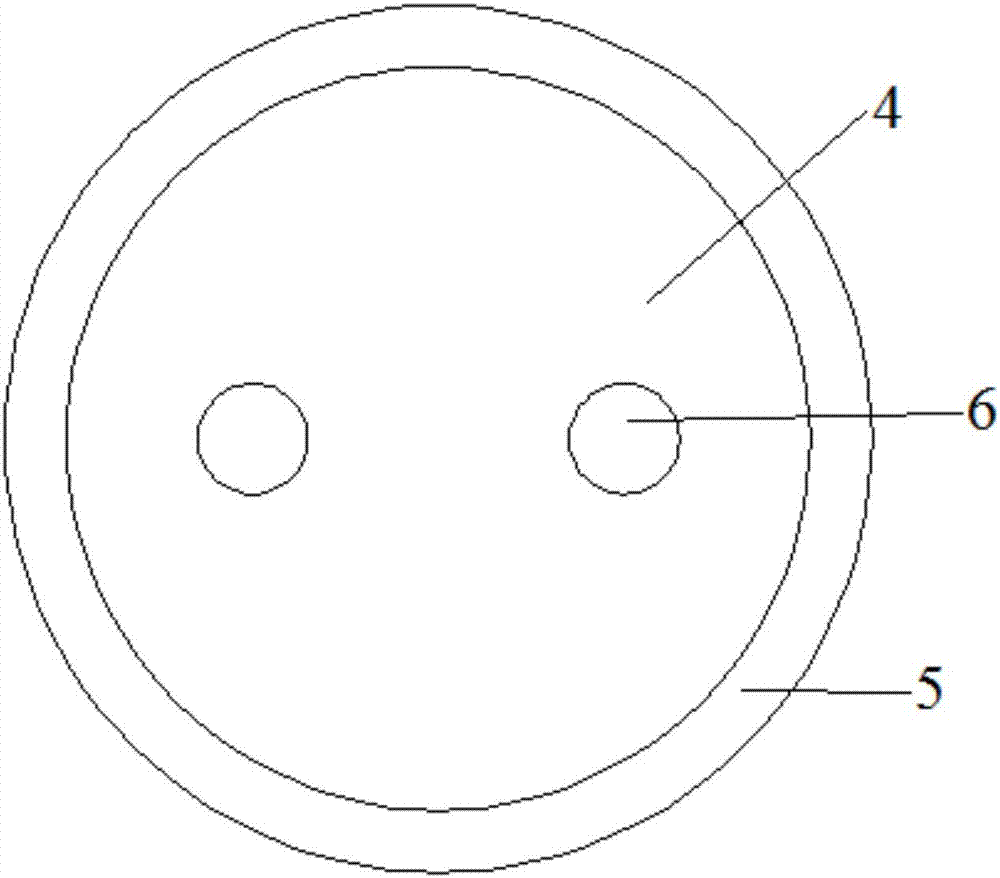

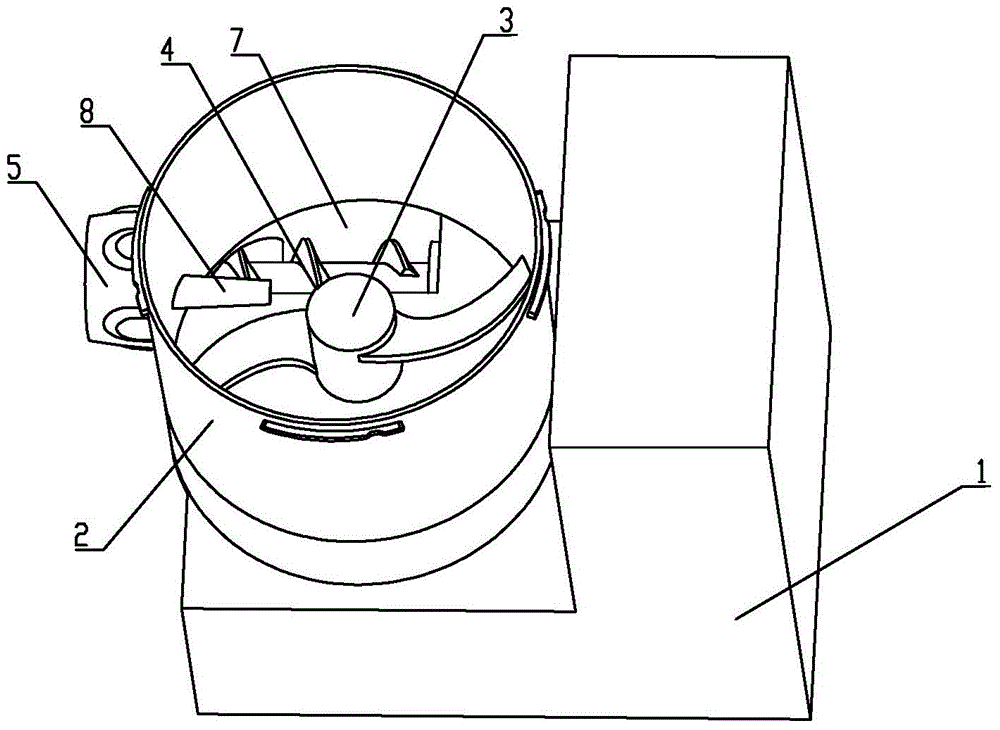

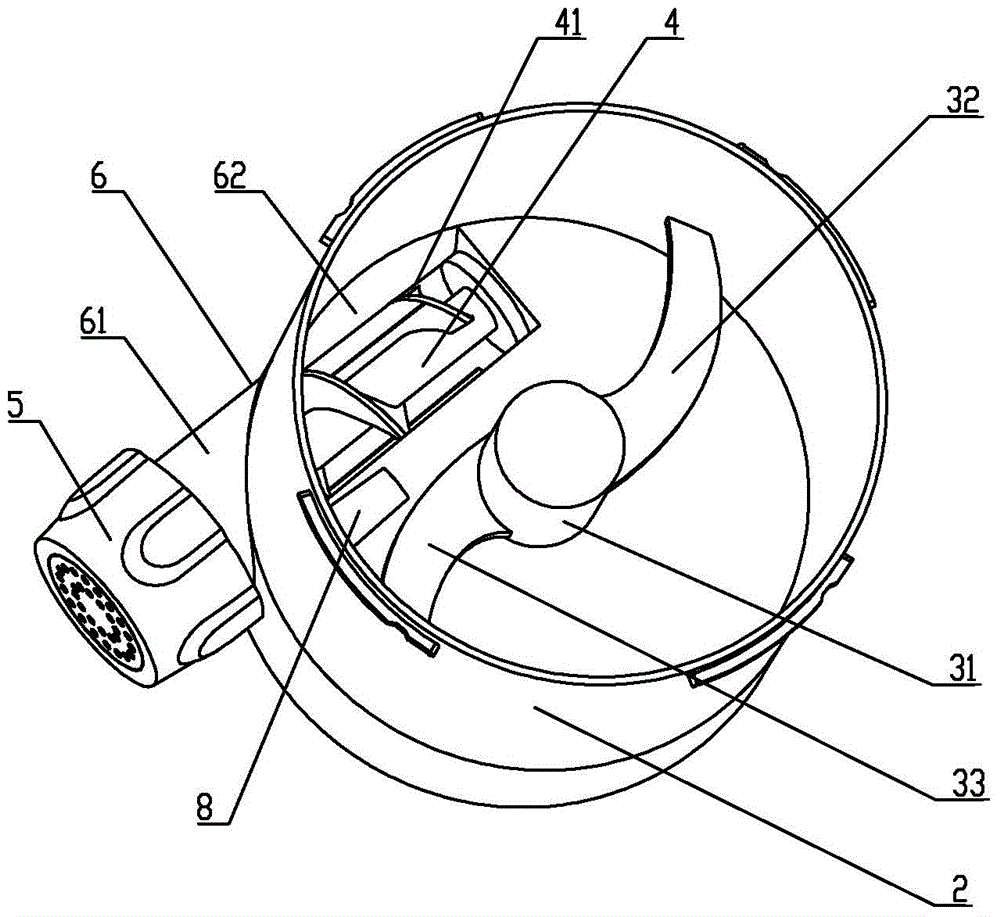

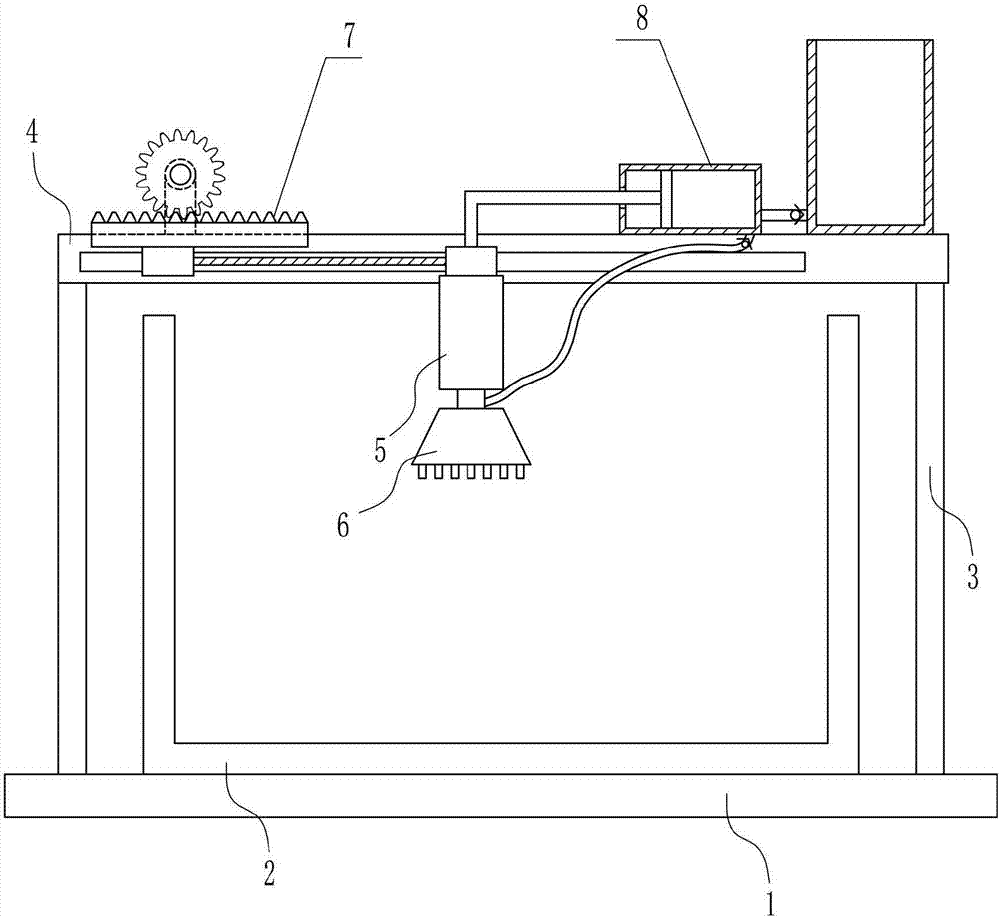

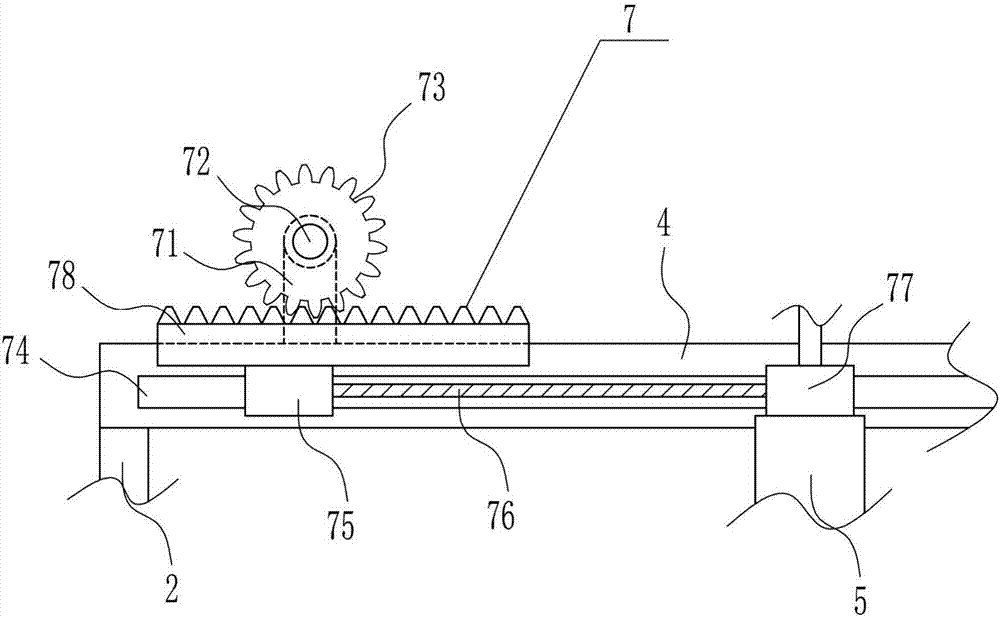

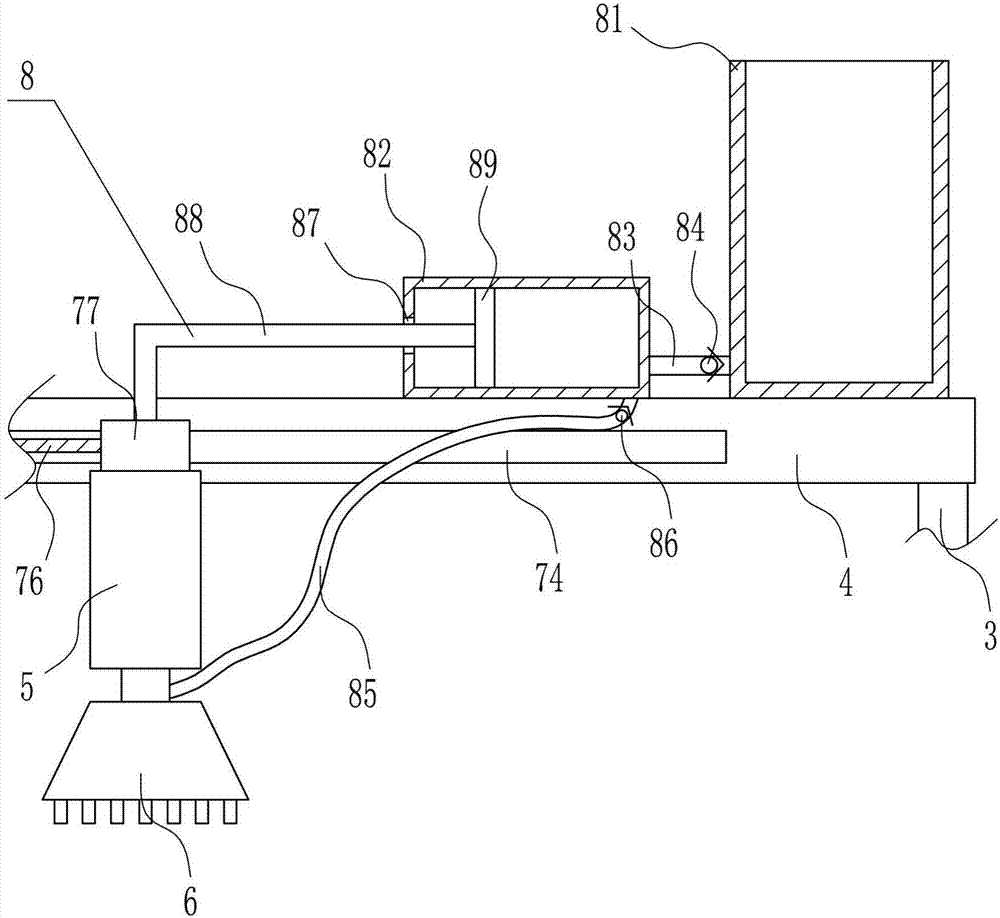

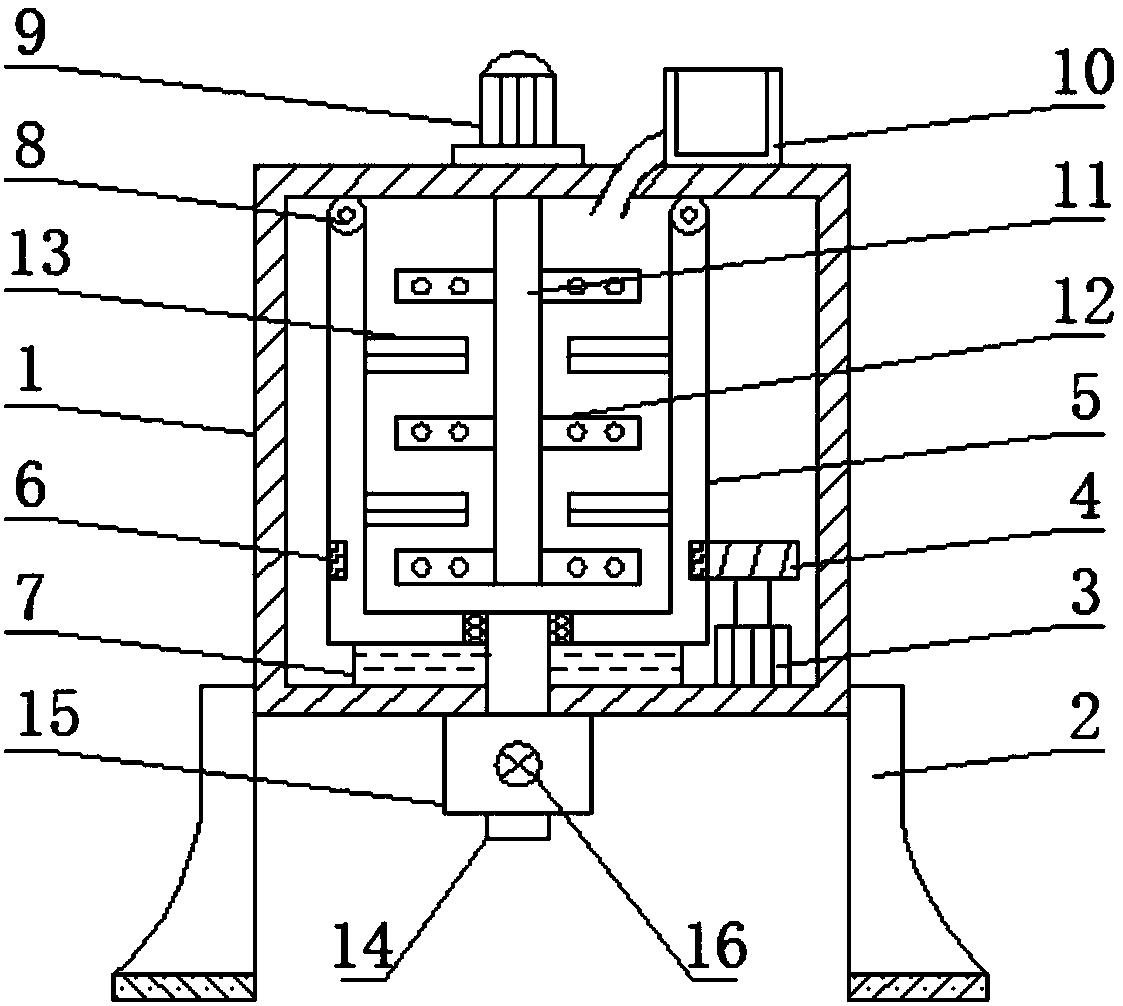

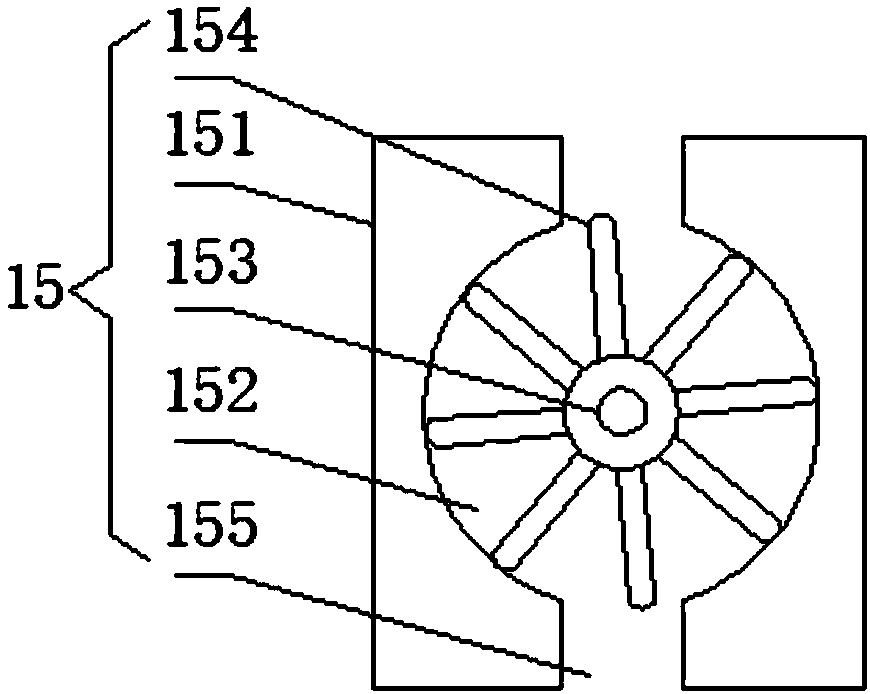

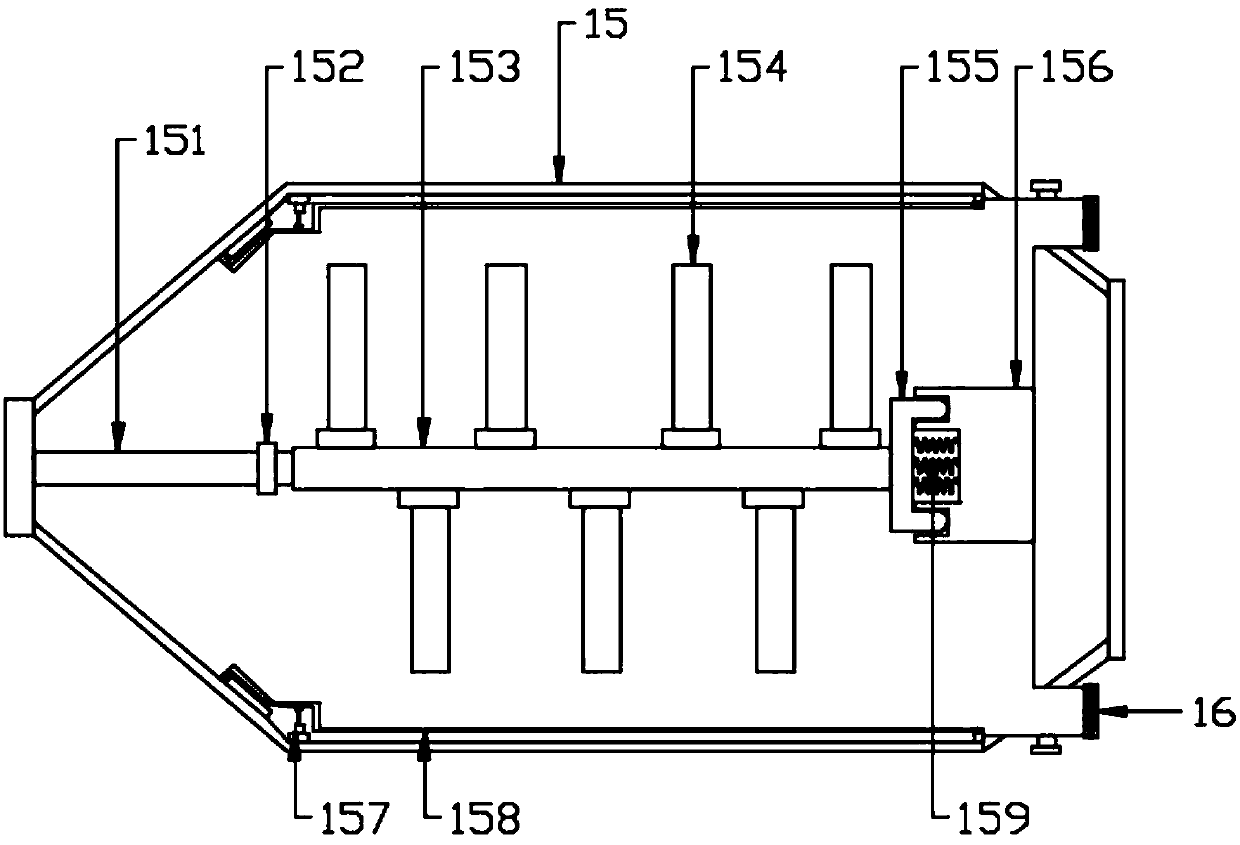

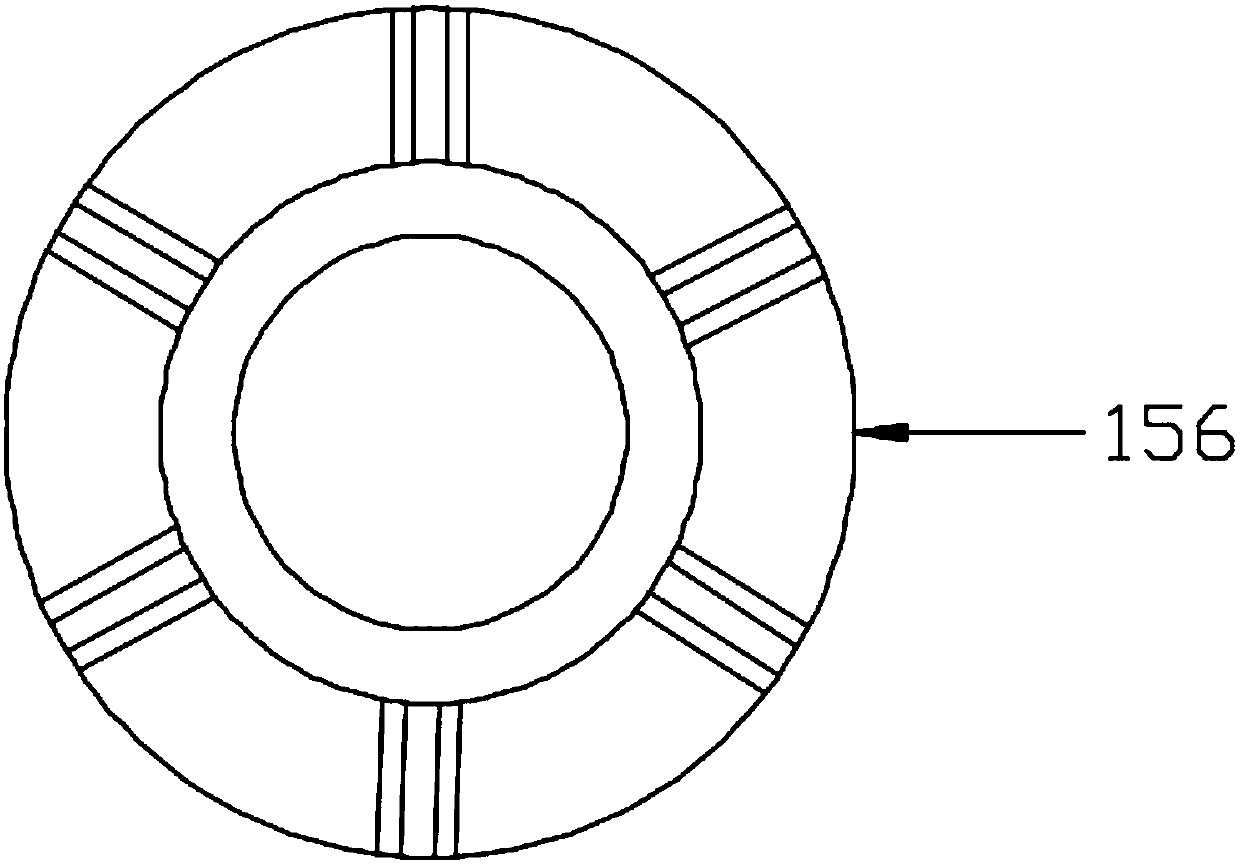

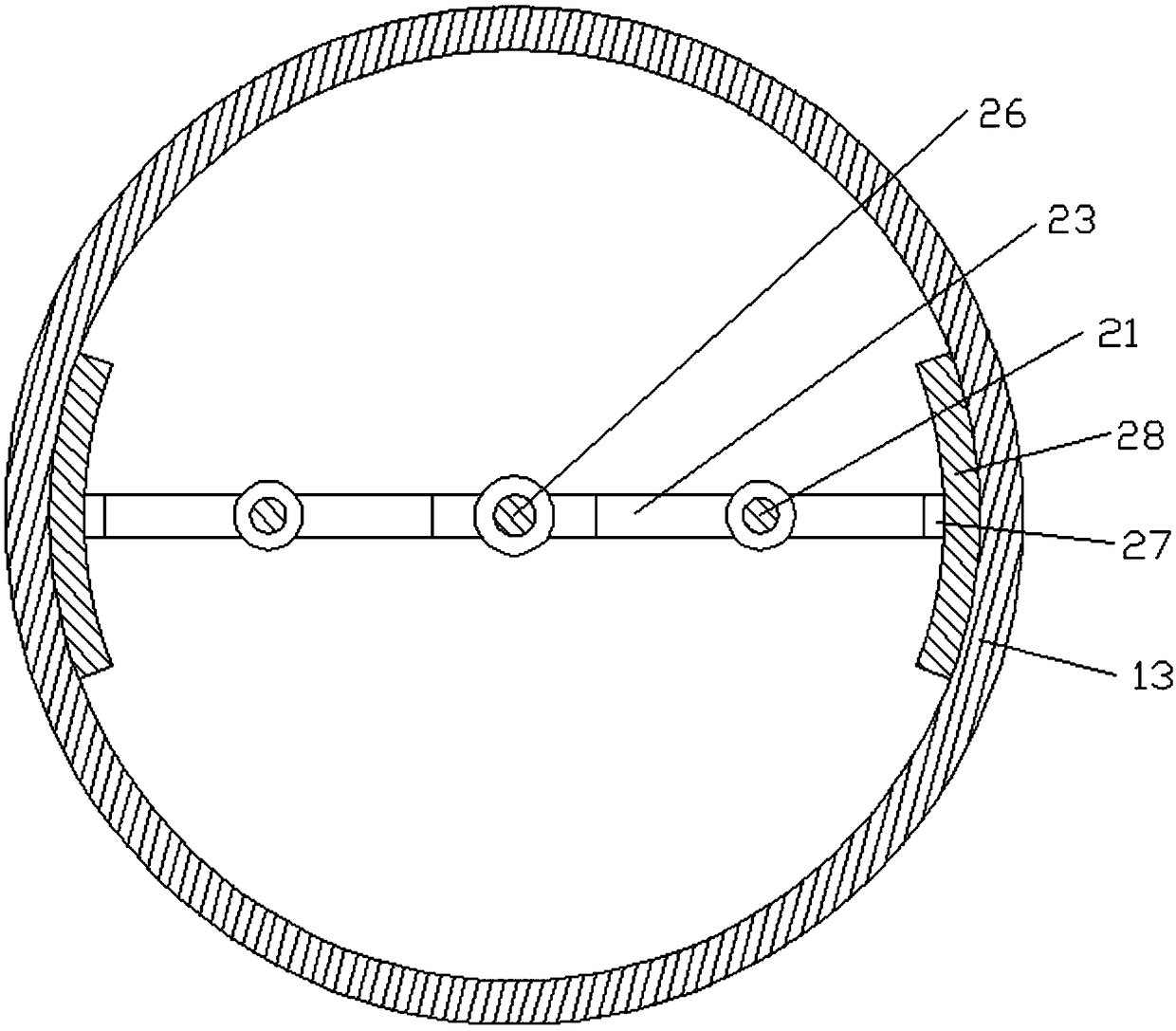

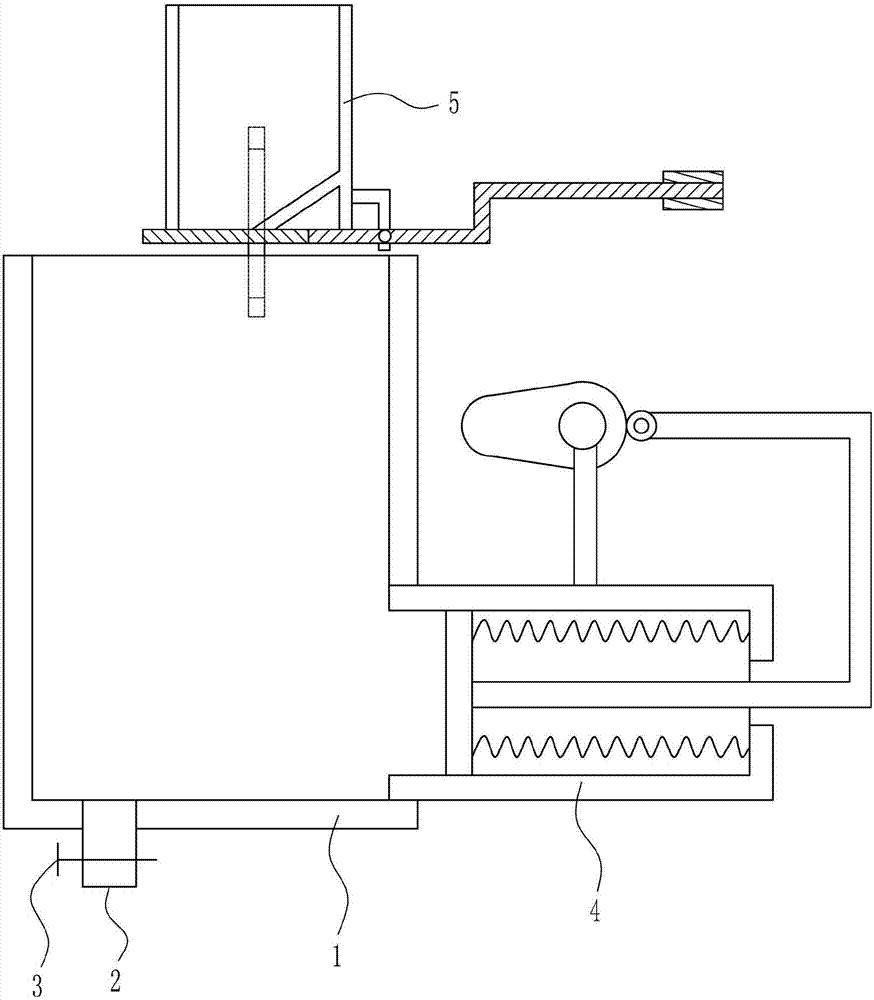

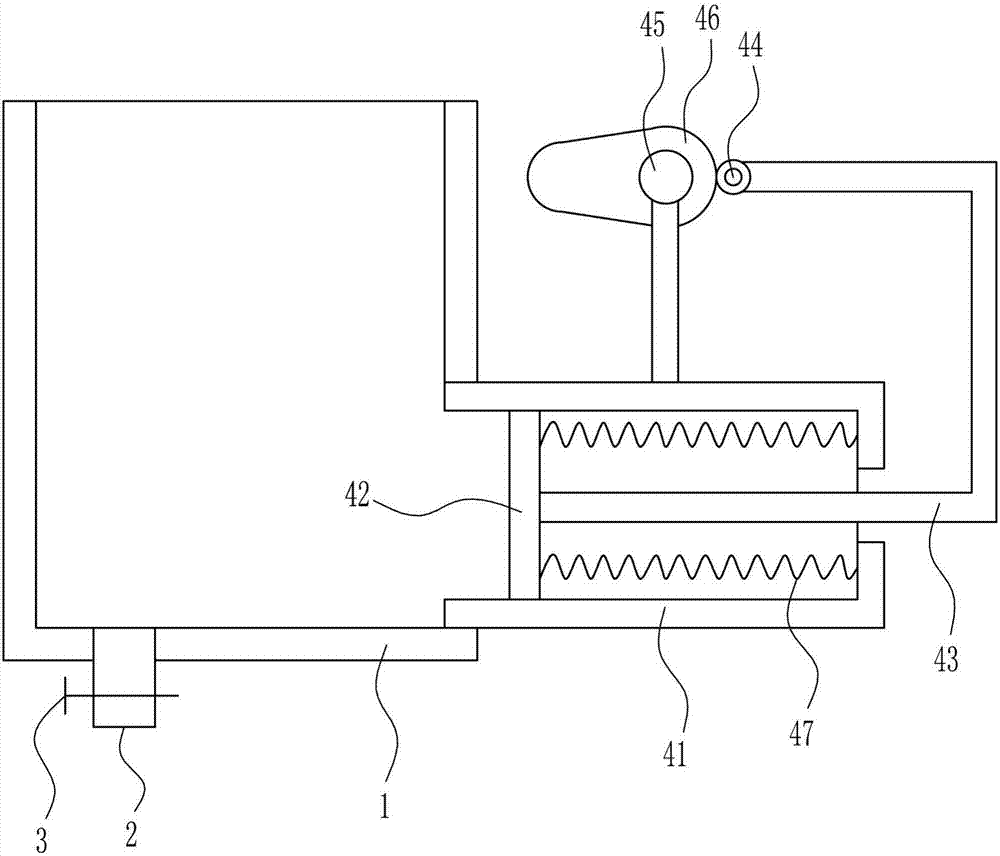

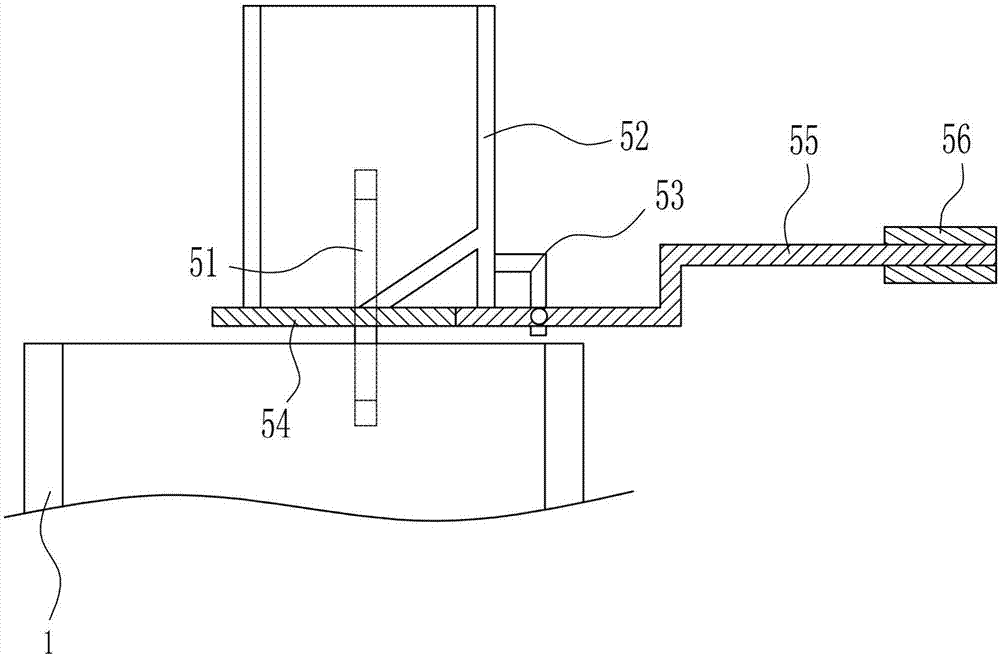

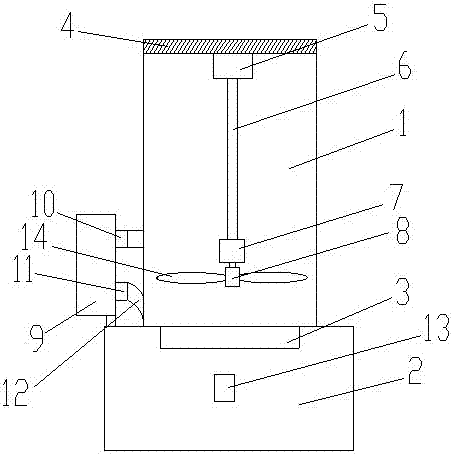

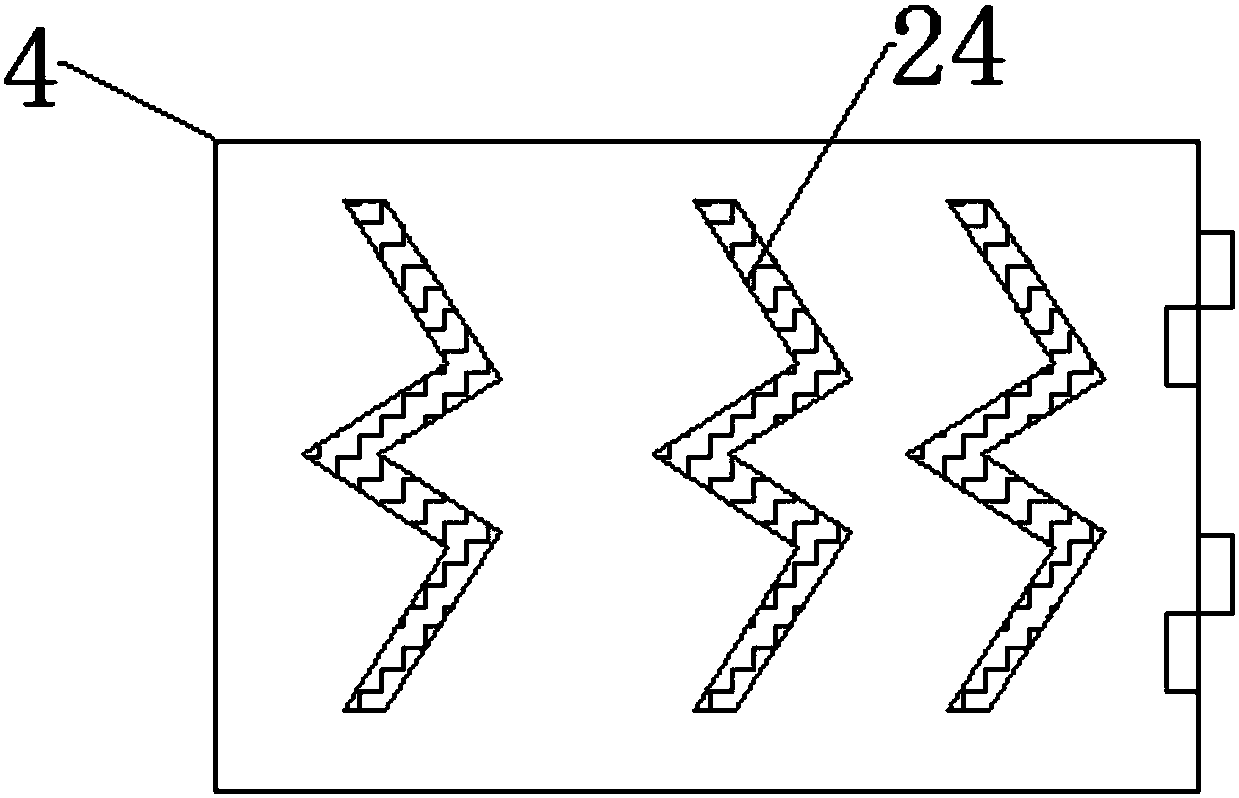

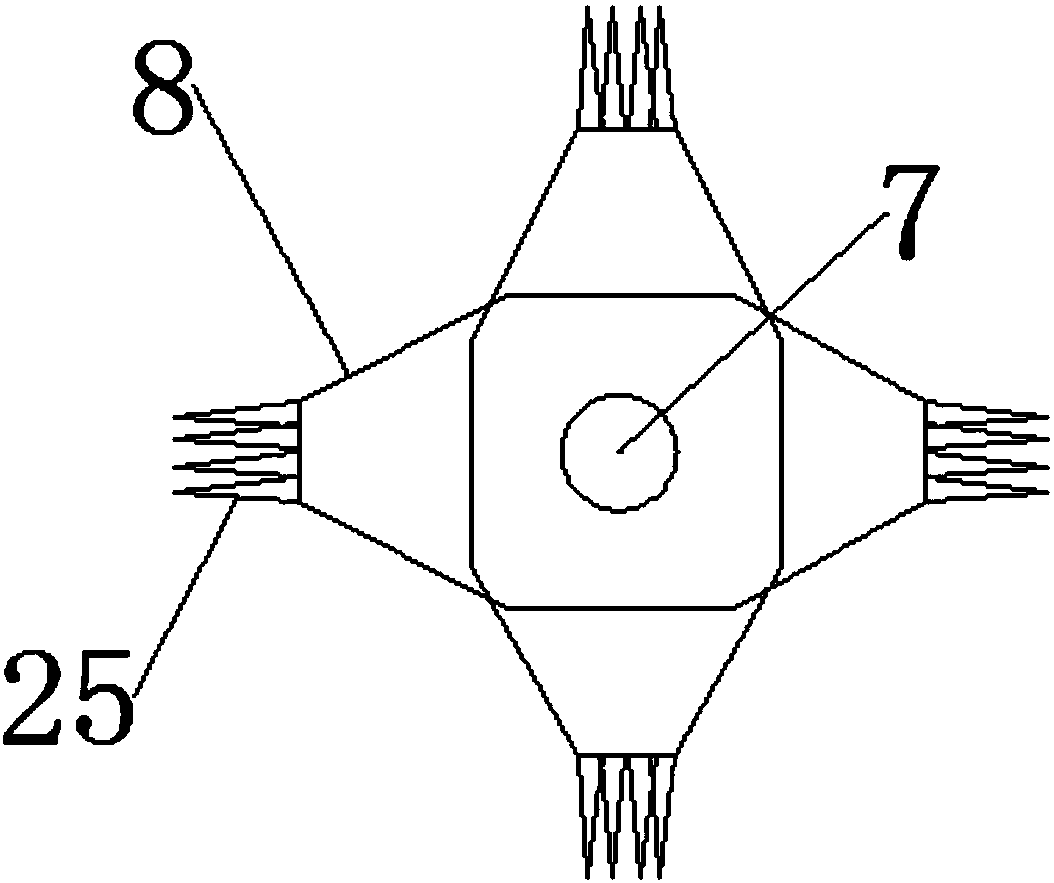

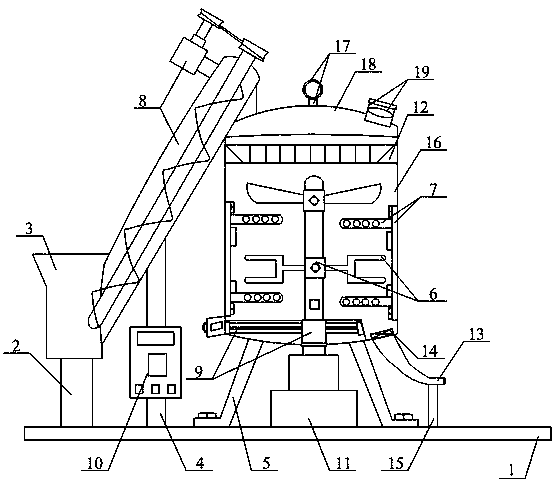

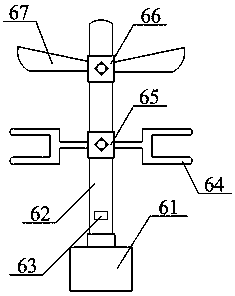

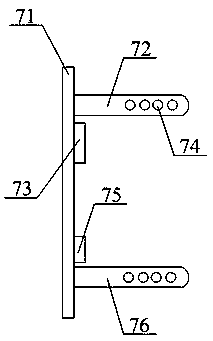

Preparation system for waterproof paint

ActiveCN110354718AAvoid cloggingEasy to stir and mixRotary stirring mixersTransportation and packagingEngineeringLinkage concept

The invention provides a preparation system for waterproof paint, belonging to the technical field of paint processing equipment. The preparation system comprises a frame, a mixing drum, a stirring device, feeding barrel assemblies, connecting arms, an inclined feeding plate and a feeding linkage control mechanism. The preparation system has the beneficial technical effects that the preparation system can control simultaneous addition of a variety of ingredients, realizes uniform dispersion and mixing of the various ingredients during filling of materials, allows a finished product to have high quality, and avoids the phenomenon of material blockage. The mixing drum is fixedly arranged on and connected with the frame; the lower end of the mixing drum is provided with a liquid discharging pipe which has a control valve; the upper end of the stirring device is arranged on the frame, and the lower end of the stirring device is located in the mixing drum; four feeding barrel assemblies arearranged and evenly around the stirring device; the four feeding barrel assemblies are all located above the mixing drum; the four feeding barrel assemblies are in transmission connection with the frame; and four feeding barrel assemblies are all fixedly connected with the inclined feeding plate through the connecting arms.

Owner:浙江圆程科技股份有限公司

Formulation of water soluble micro-capsule fat powder feed and manufacturing process thereof

InactiveCN1883294AImprove digestion and absorption utilizationEasy to stir and mixAnimal feeding stuffAccessory food factorsSodium CaseinateSodium stearyl

The invention discloses a water-soluble microcapsule fat powder preparation for animals and process for production, wherein the preparation comprises (by weight percent) sodium caseinate 0.3-5%, composite emulsifying agent F 0.8-4%, sodium stearyl lactate 0.8-4%, oil 30-70%, sodium citrate 0.2-1.2%, disodium hydrogen phosphate 0.2-1.2%, coating articles 70-30% and water 80-150% of the total raw material amount.

Owner:SINGAO

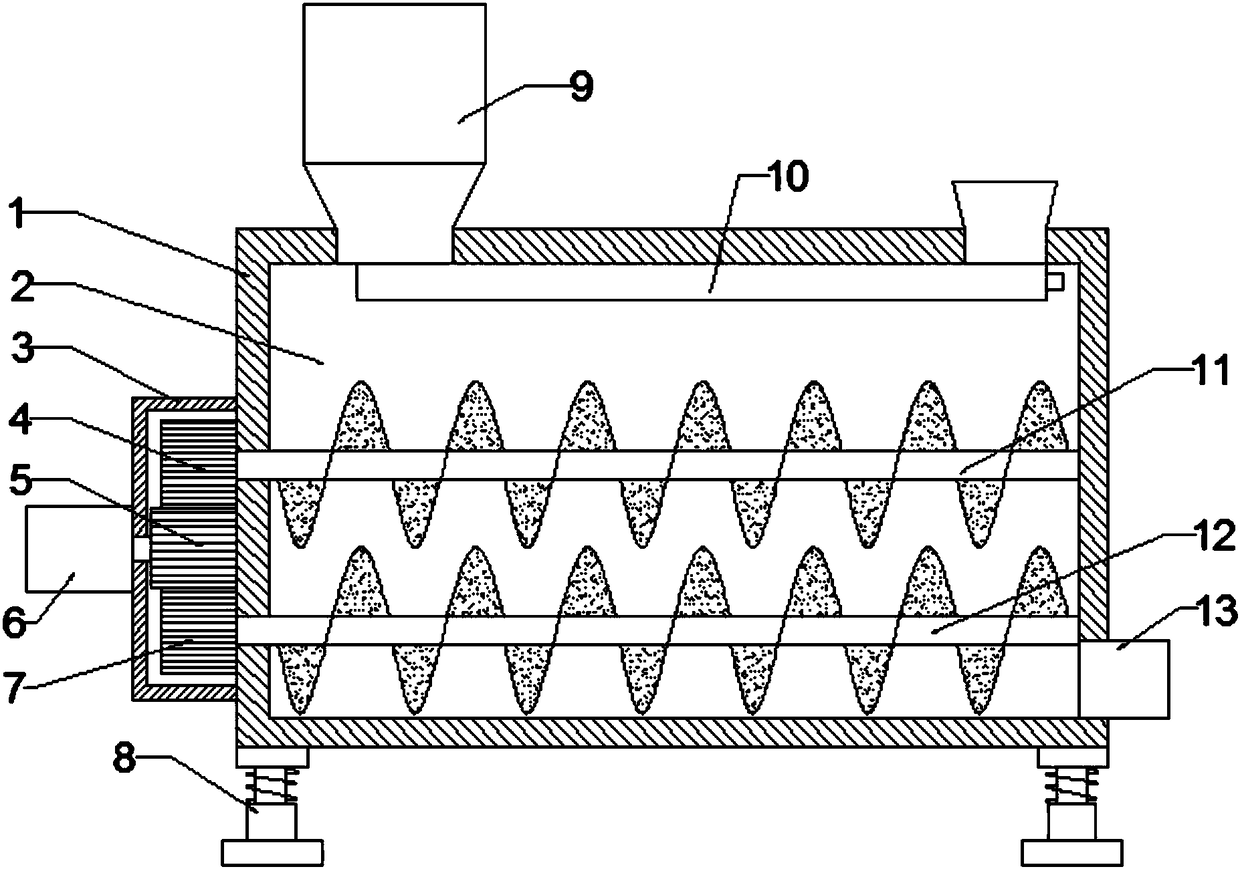

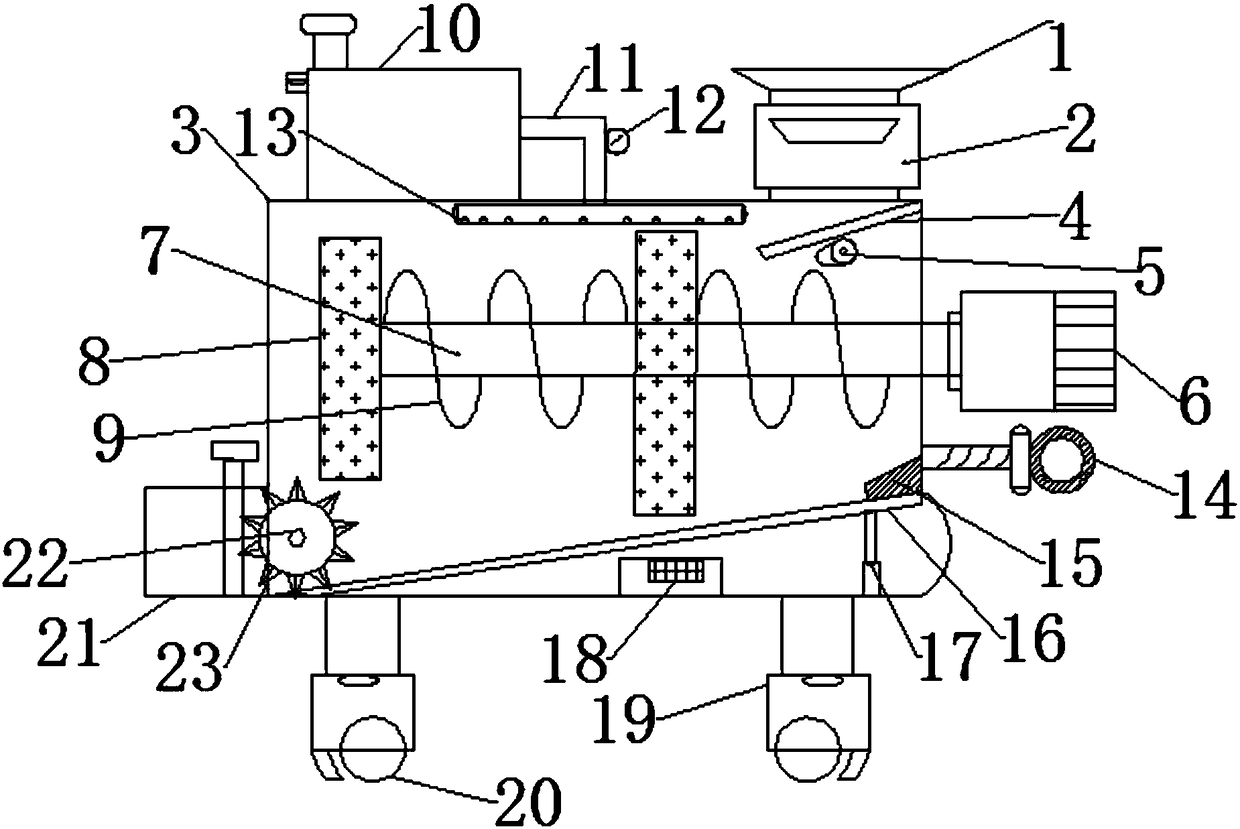

Aquatic feed processing device

PendingCN108095173AIncreased efficiency of impact extrusionImprove the bactericidal effectFeeding-stuffRotary stirring mixersPunchingAquatic product

The invention discloses an aquatic feed processing device. The device comprises a processing box, a base, a crushing box and a cut-off box; the processing box is installed on the top of the base, a punching tube is installed at the bottom inside the processing box, a feed delivery pipe is installed on the top of the punching tube, a solenoid electric valve is installed on the feed delivery pipe, aforming die is installed on one side of the punching tube, and die holes are uniformly formed in the forming die. Accordingly, by installing the crushing box, a crushing roll is installed in the crushing box, the crushing roll is driven by a motor to rotate at a high speed, raw materials such as fish bones are ground and crushed, and processing and shaping are facilitated; by arranging a feedingpipe, other organic matter is added into the crushed materials conveniently; meanwhile, by installing a stirring shaft, stirring blades are uniformly installed on the stirring shaft, and different rawmaterials are fully stirred and mixed conveniently.

Owner:GUIZHOU UNIV

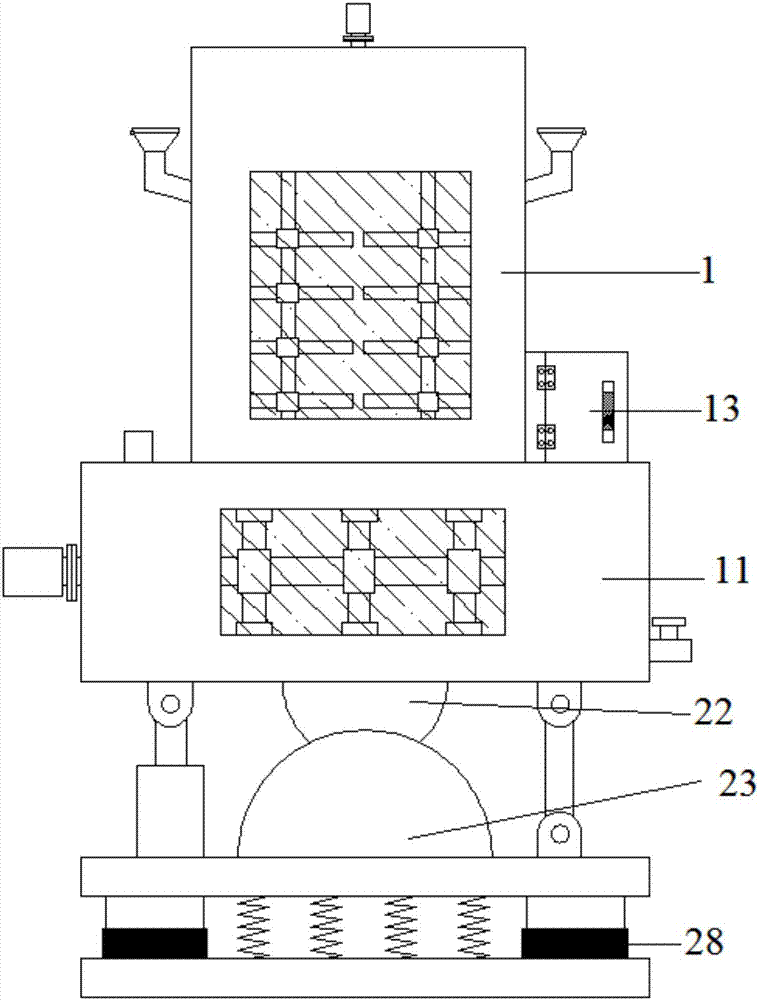

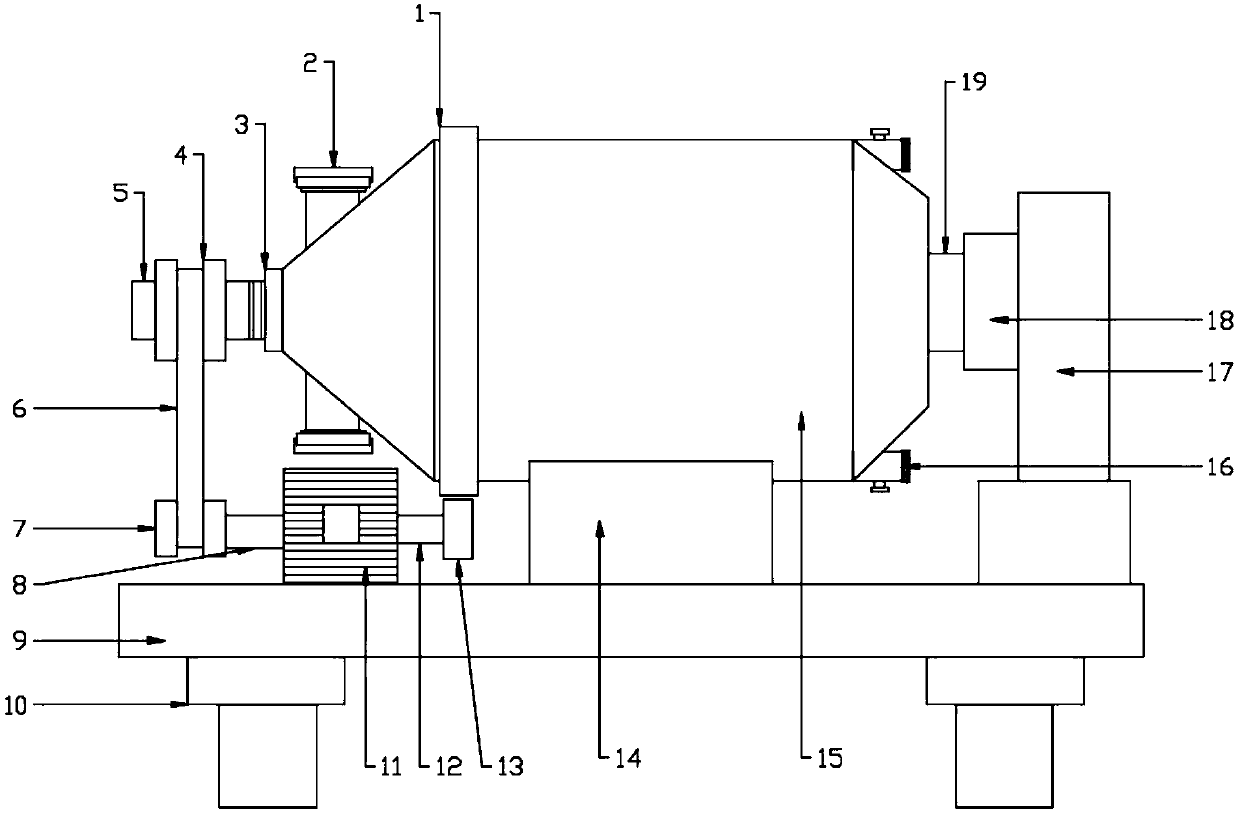

Concrete stirring equipment

InactiveCN107253273AImprove mixing efficiencyEasy to stir and mixCement mixing apparatusPulp and paper industryElectric control

The invention discloses concrete stirring equipment comprising a mixing box. Feeding ports are formed in the upper ends of the left side and the right sides of the mixing box; a stirring box is arranged on the lower side of the mixing box; a water adding pipe is arranged at the left end of the upper side of the stirring box; an electric control box is arranged at the right end of the upper side of the stirring box; a discharging pipe is arranged at the lower end of the right side of the stirring box; first mounting seats are arranged at the four corners of the lower side of the stirring box; a telescopic rod is arranged on the lower side of the first mounting seat at the left end; a connecting rod is arranged on the lower side of the first mounting seat at the right end; a second mounting seat is arranged on the lower side of the connecting rod; a connecting semicircle plate is arranged in the middle of the lower side of the stirring box; a connecting semicircle groove is formed in the lower side of the connecting semicircle plate; and a supporting plate is arranged on the lower sides of the connecting semicircle groove, the telescopic rod and the second mounting seat. A damping pad is arranged inside the supporting plate; linkage notches are formed in the four corners of the lower side of the supporting plate; connecting blocks are arranged on the lower sides inside the linkage notches; damping rings are arranged on the outer sides of the connecting blocks; and a bottom plate is arranged on the lower sides of the connecting blocks. According to the concrete stirring equipment, the working efficiency of the equipment can be effectively improved, unloading is facilitated, and the equipment is effectively protected.

Owner:陈仲义

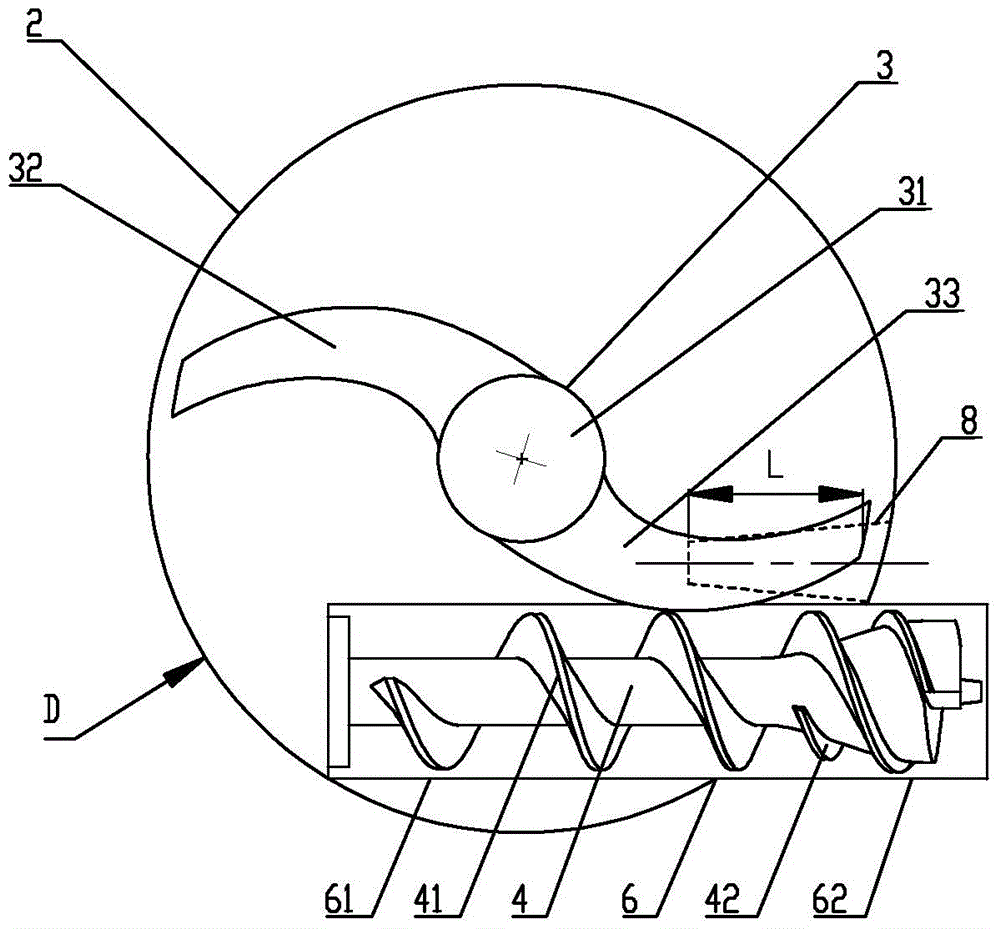

Domestic vertical type noodle maker

ActiveCN104542788AAccelerate the mixing speedImprove mixing efficiencyMixing/kneading with vertically-mounted toolsDough extruding machinesEngineeringExtrusion

The invention discloses a domestic vertical type noodle maker which comprises a base, a stirring cup, a stirring rod, a dough extrusion cylinder, a screw rod, a mold head and a control unit, wherein the base is provided with motors; the stirring cup is connected with the base; the stirring rod comprises a rod body as well as upper stirring teeth and lower stirring teeth which are arranged on the rod body; a dough inlet is formed in the communicating part of the stirring cup and the dough extrusion cylinder; a dough cutting rod is arranged on the inner wall of the stirring cup; the dough cutting rod is positioned between the upper stirring teeth and the lower stirring teeth; the stirring rod rotates to drive the upper stirring teeth and the lower stirring teeth to rotate and mix and stir flour with water to make dough; the dough cutting rod cooperates with the upper stirring teeth and the lower stirring teeth to cut off or tear and deform the dough into dough pieces which are smaller than the dough inlet; when the upper stirring teeth and / or the lower stirring teeth rotate to the dough cutting rod, the projects of the dough cutting rod and the upper stirring teeth and / or the lower stirring teeth in the horizontal direction are at least partially overlapped. By adopting the mode, the effects of no residue, high possibility of dough feeding and high processing efficiency can be achieved.

Owner:JOYOUNG CO LTD

Microbial culture starter used for feed preparation, and preparation method of microbial culture starter

InactiveCN107712278AShort fermentation cycleImprove stabilityFood processingAnimal feeding stuffDecompositionMicrobial agent

The invention provides a microbial culture starter used for feed preparation, and a preparation method of the microbial culture starter. The microbial culture starter provided by the invention comprises three parts, including a complex enzyme preparation, a complex microbial agent and a carrier; the existence of the carrier is beneficial for enhancing the stability of the complex enzyme preparation and the complex microbial agent, and prevents degeneration which influences the fermenting property. The microbial culture starter has relatively high capacity of decomposition for straw, is short in fermentation period, and effectively prevents secondary fermentation.

Owner:王甲林

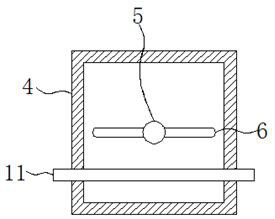

High-efficient mixer for medical treatment package, production, and printing

PendingCN106890582AEasy to stir and mixImprove liquidityRotary stirring mixersTransportation and packagingEngineeringBolt connection

The invention relates to a mixer for medical treatment package, production, and printing, and particularly relates to a high-efficient mixer for medical treatment package, production, and printing. The technical problem to be solved is to provide a time-saving and labor-saving high-efficient mixer with high working efficiency, capable of preventing material overflow and saving materials and used for the medical treatment package, production, and printing. In order to solve the technical problem, the invention provides the high-efficient mixer for medical treatment package, production, and printing, comprising a bottom plate, a mixing frame, a supporting plate, a top plate, a connecting plate, and a nozzle; the left and right sides of the top part of the bottom plate are equipped with the supporting plate through bolt connection, and the top part of the supporting plate is equipped with the top plate through the bolt connection. Through cross movement of the nozzle, the materials can be more evenly sprayed in the mixing frame, thus the mixing blade can better mix and stir the materials; meanwhile, the material fluidity is better through the second through hole.

Owner:滁州钰禾文具制品有限公司

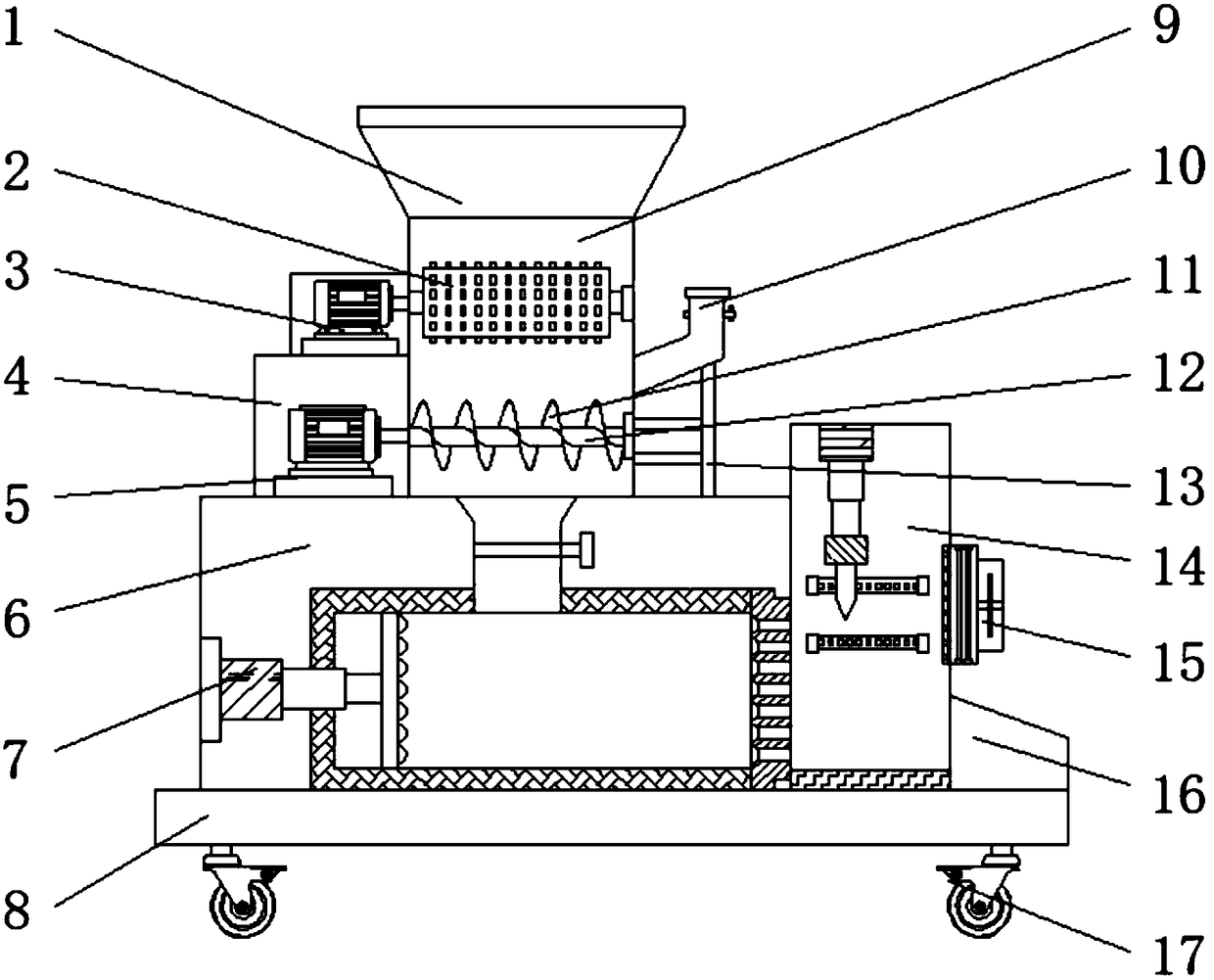

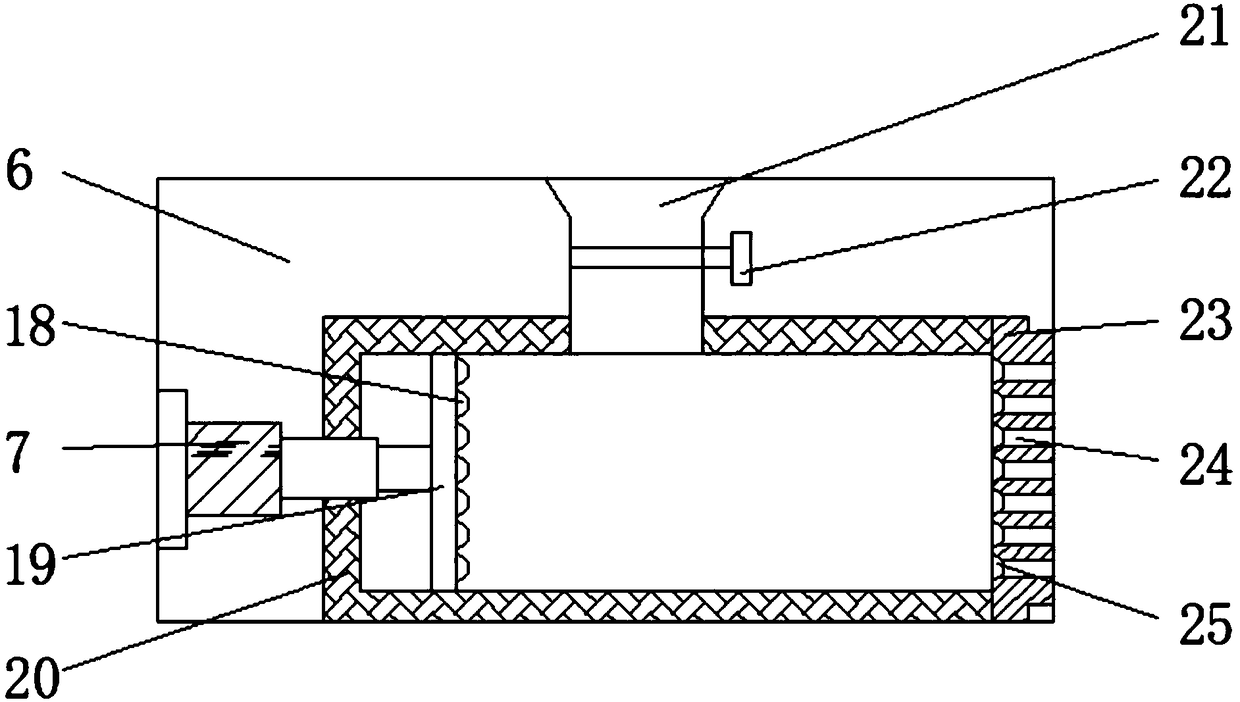

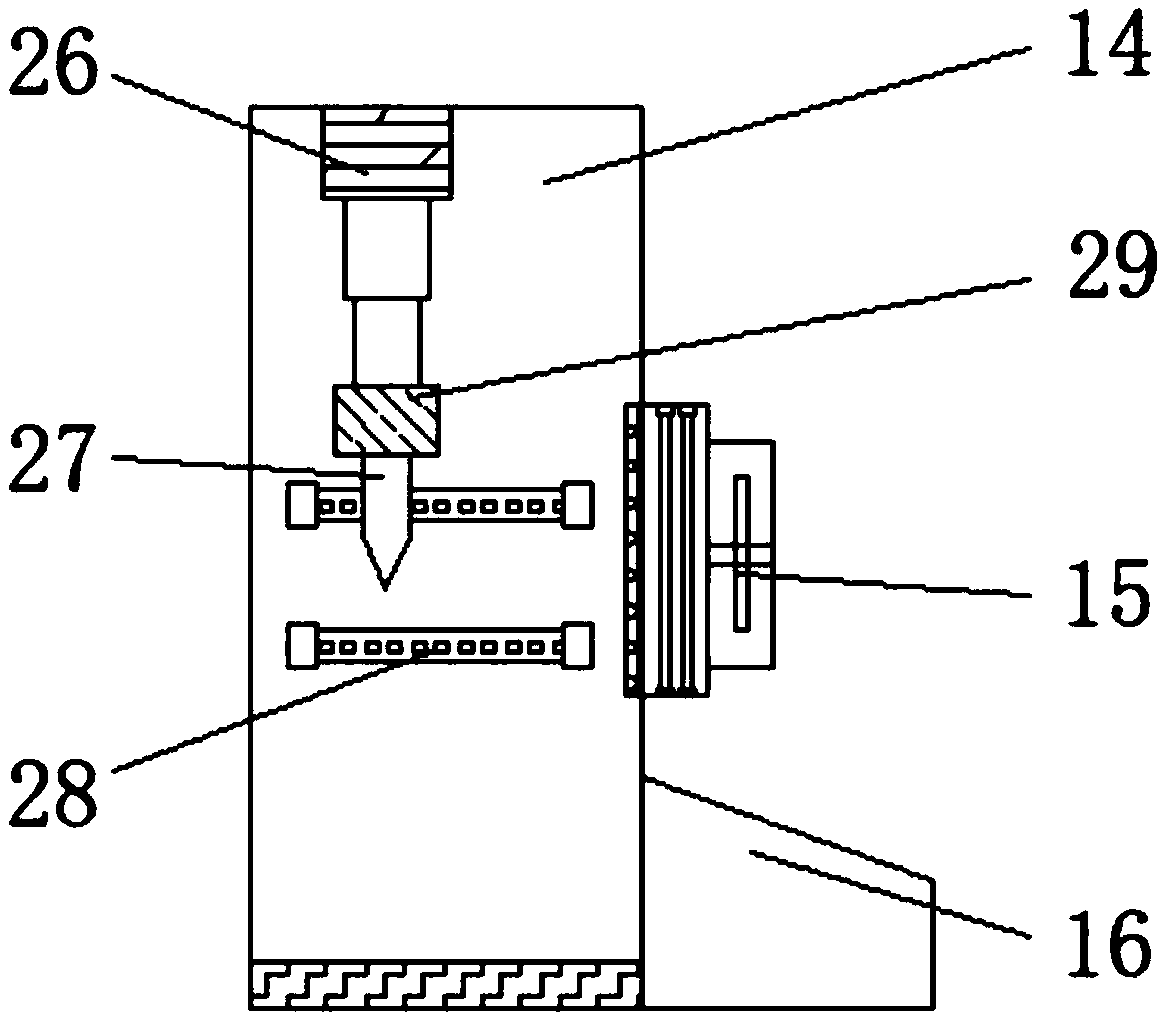

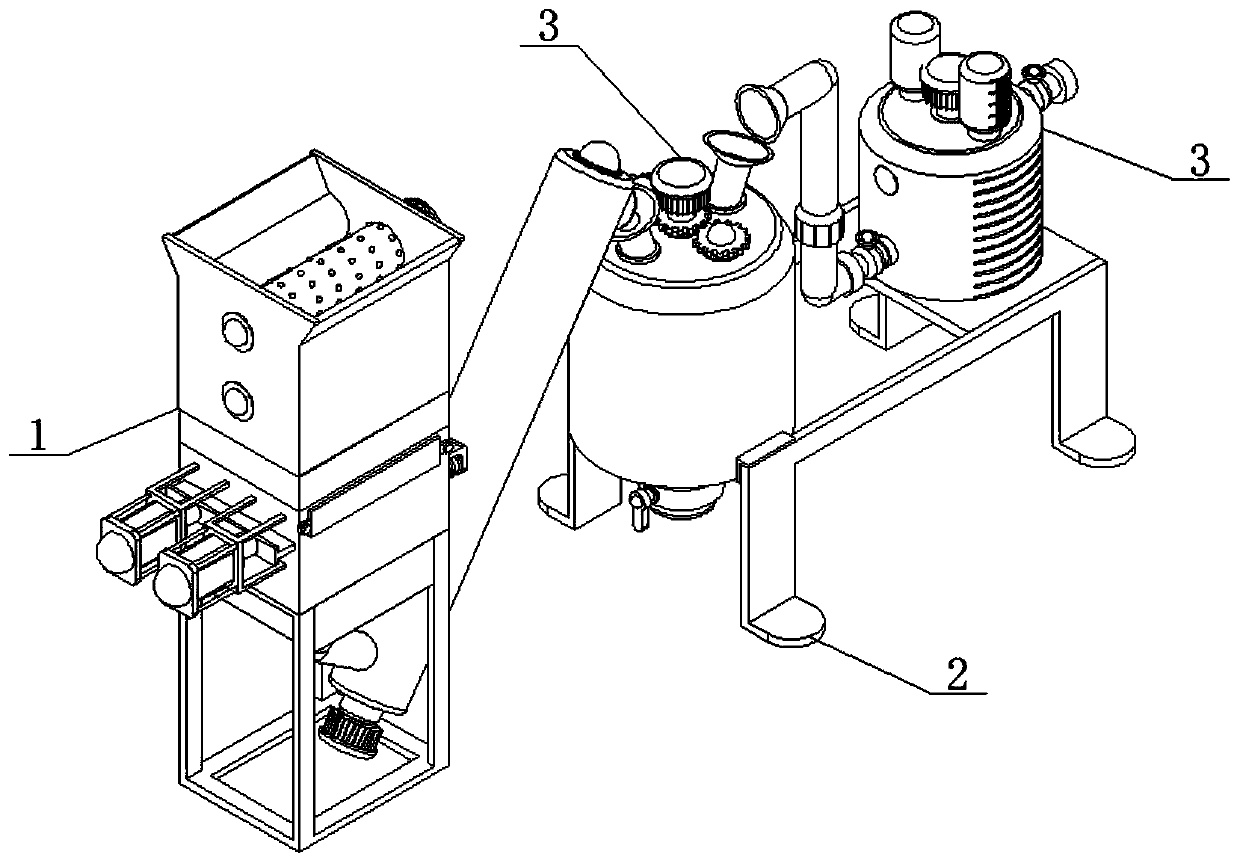

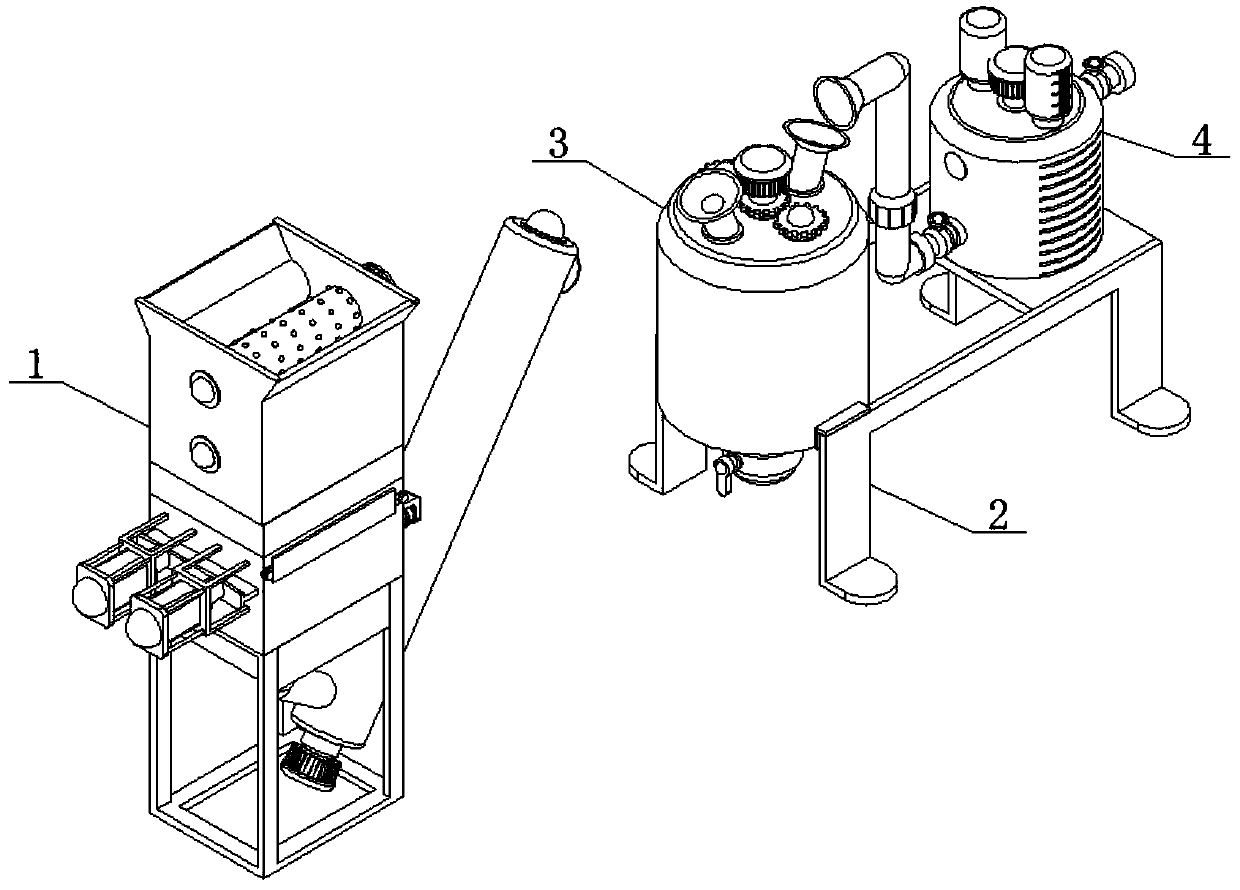

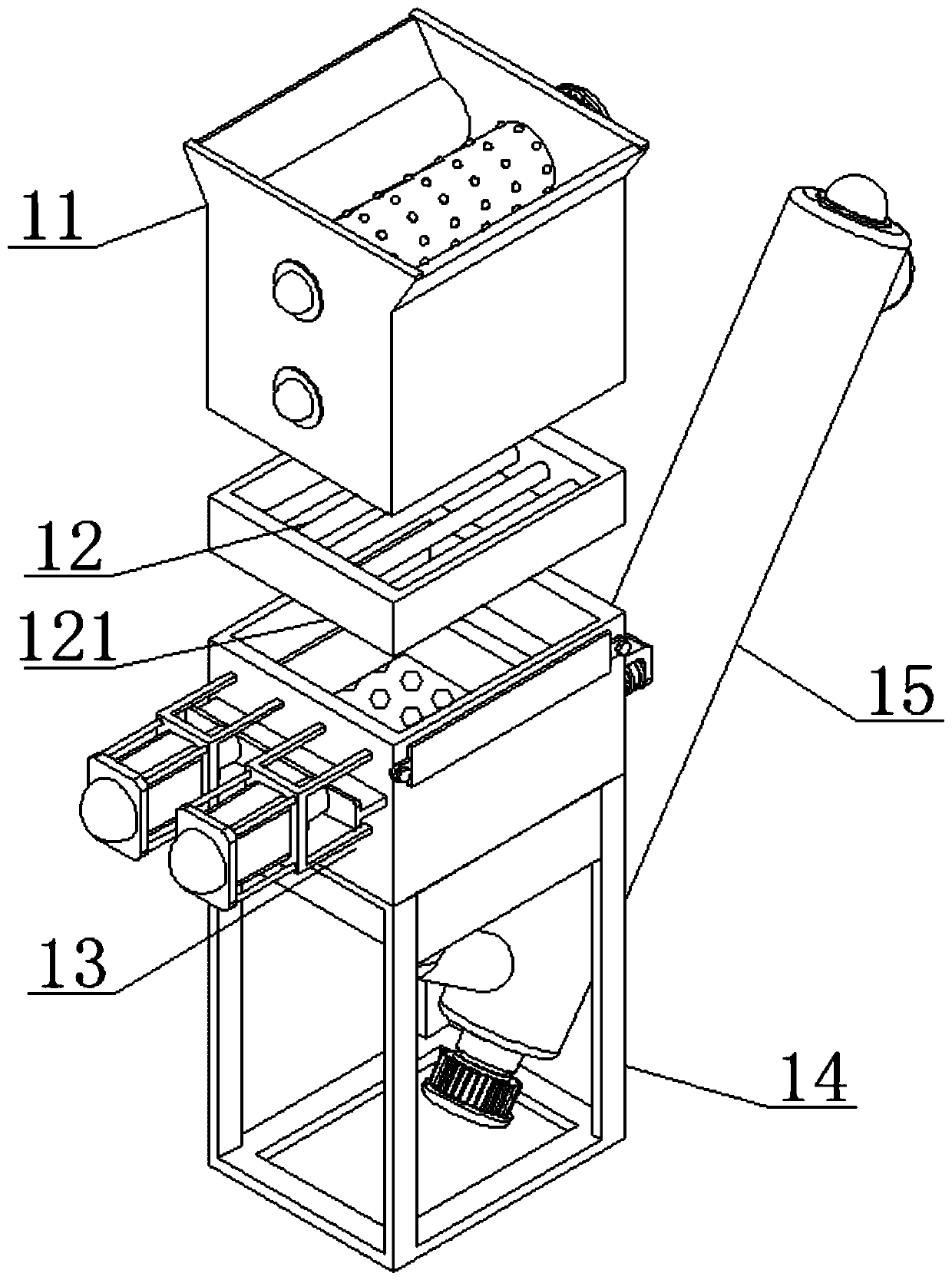

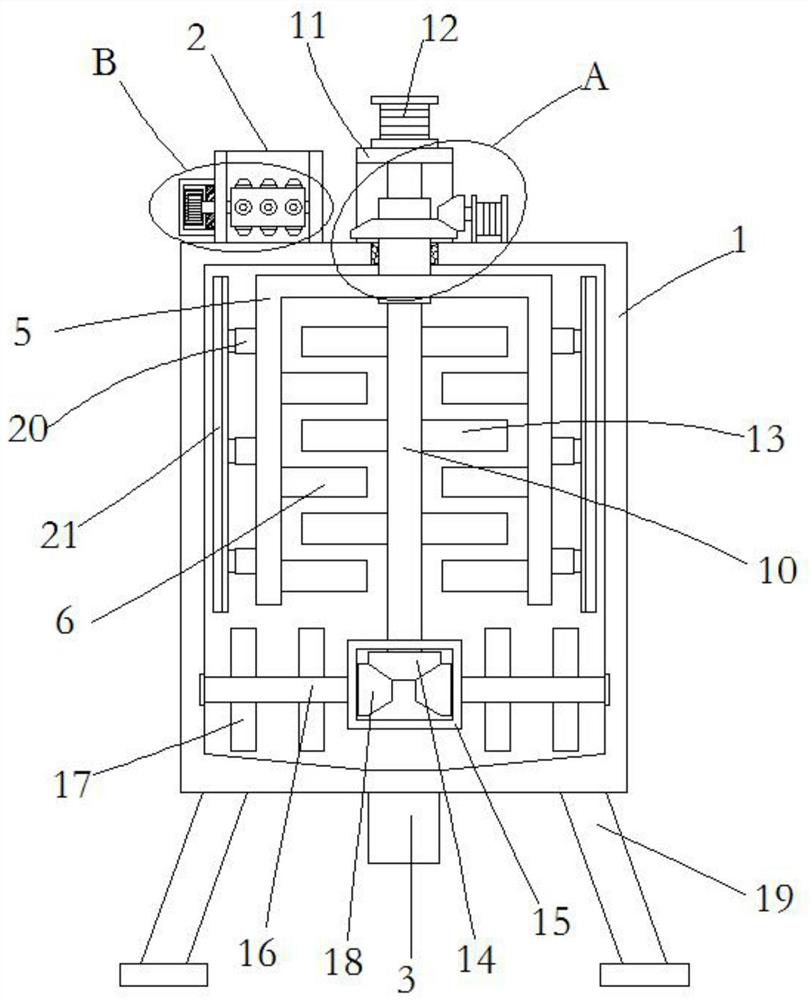

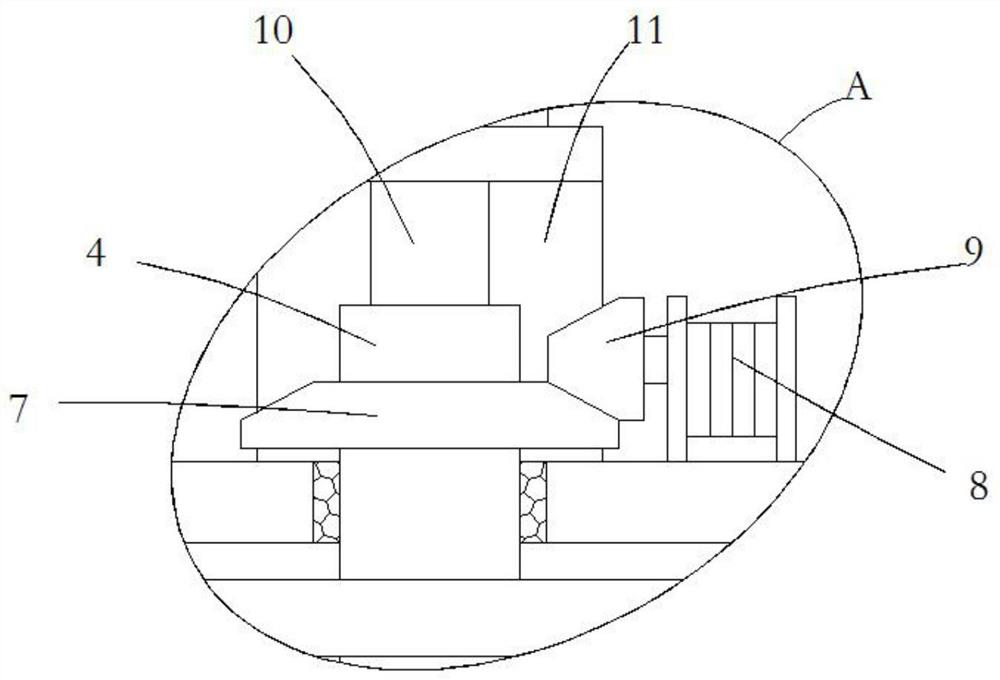

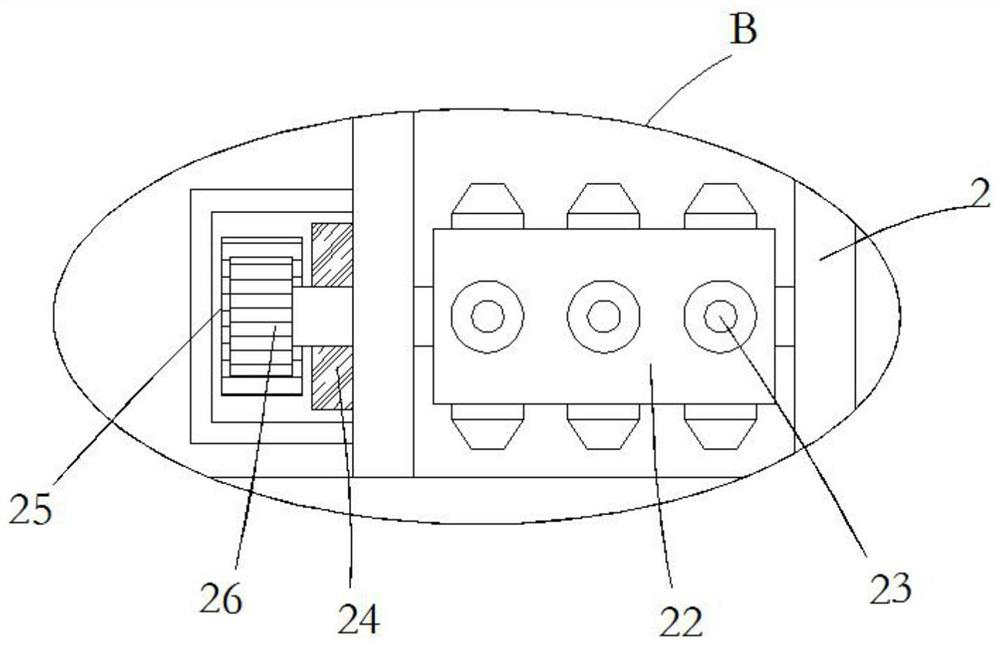

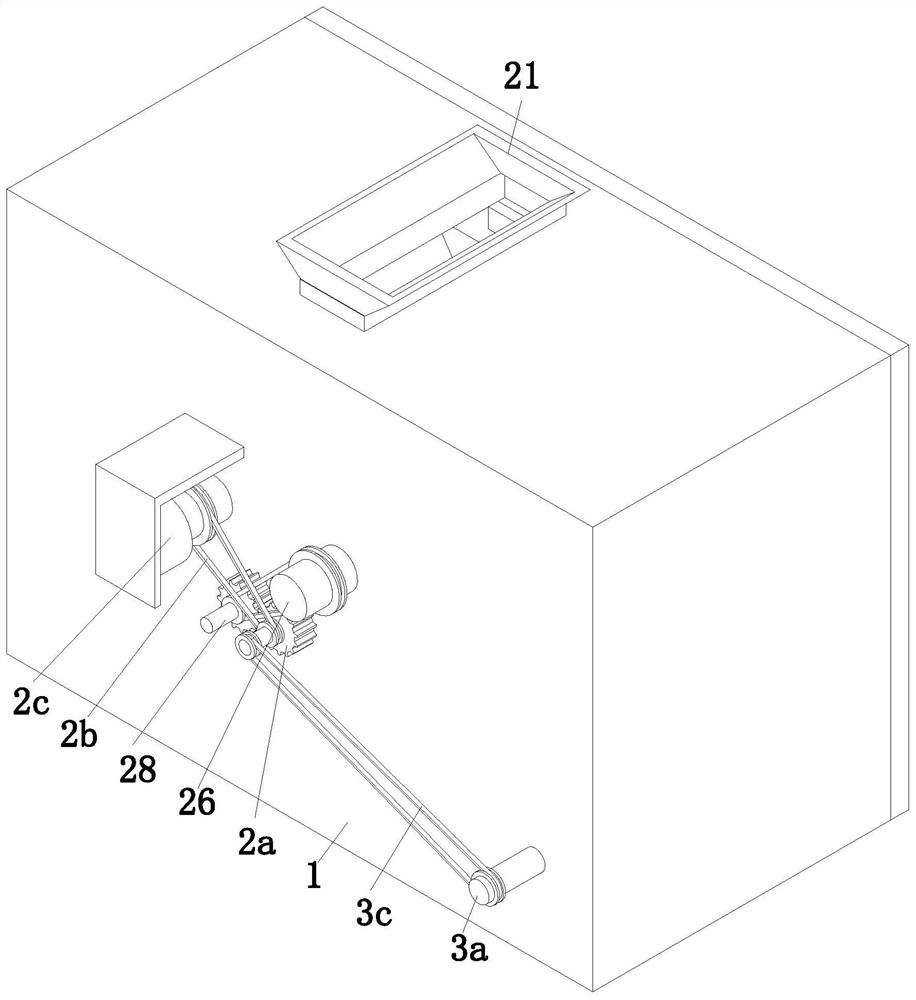

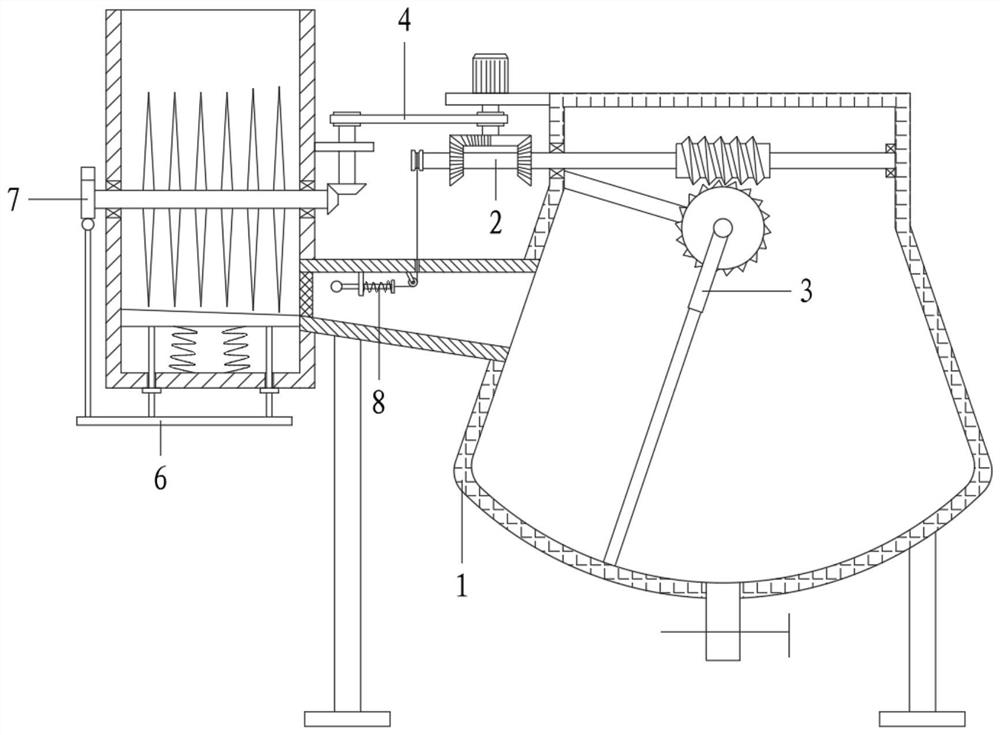

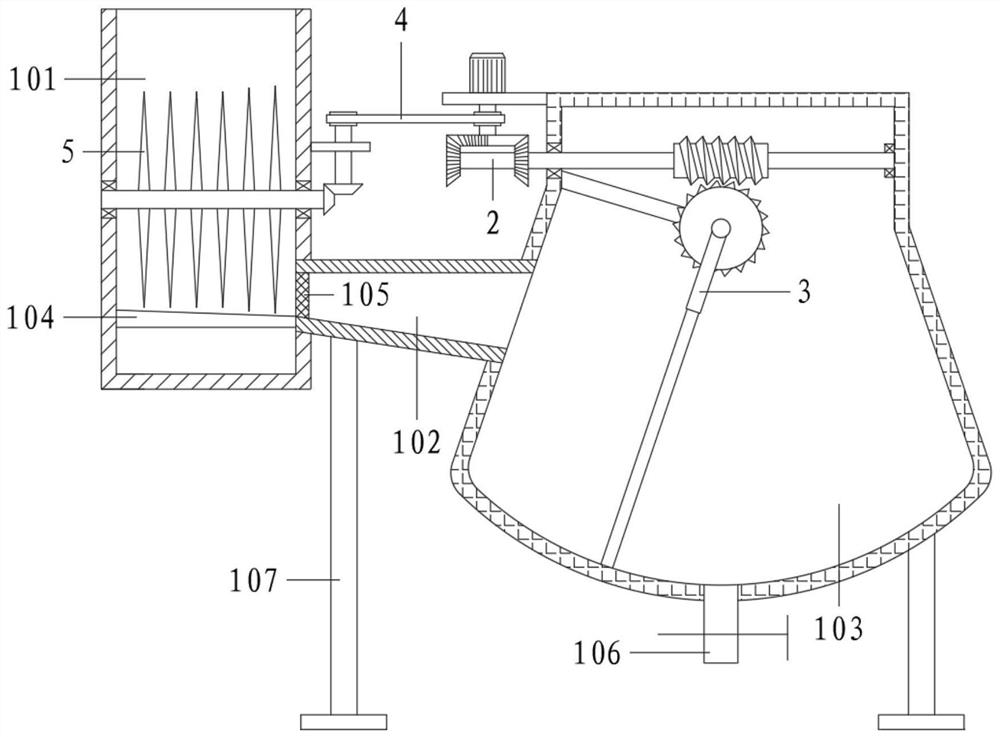

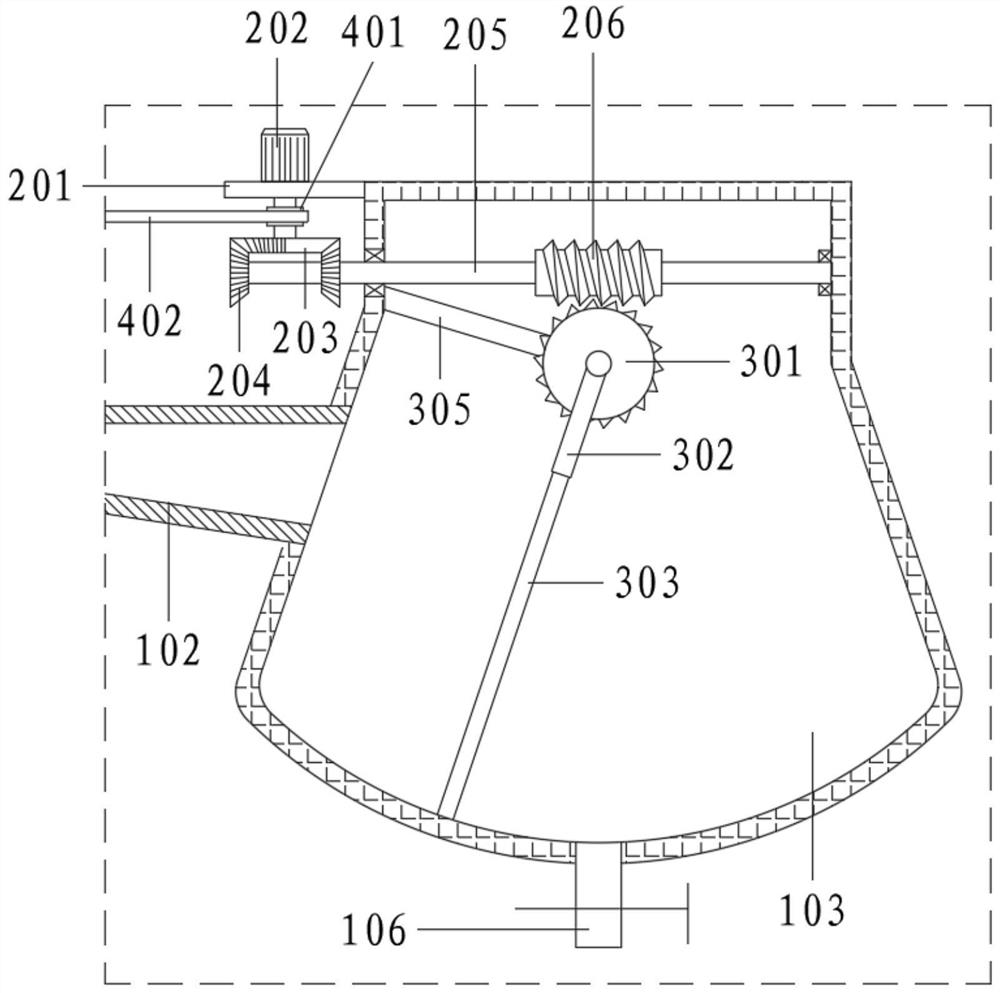

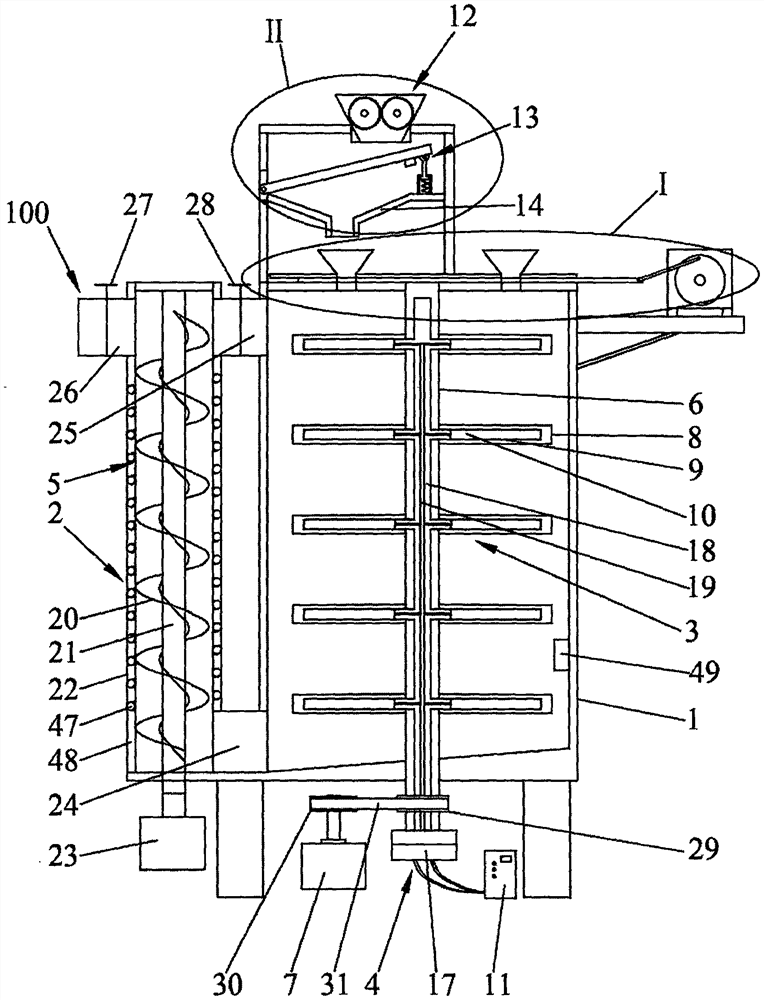

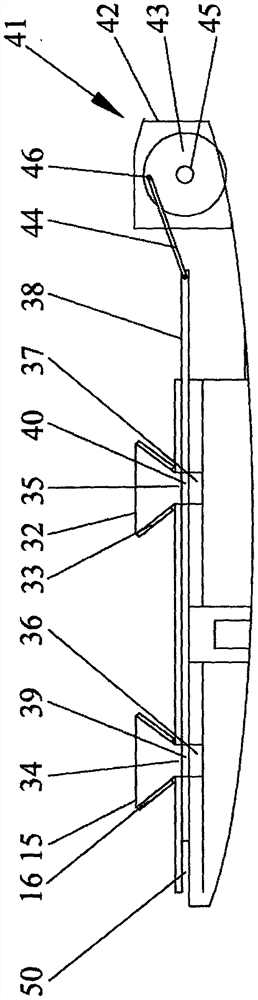

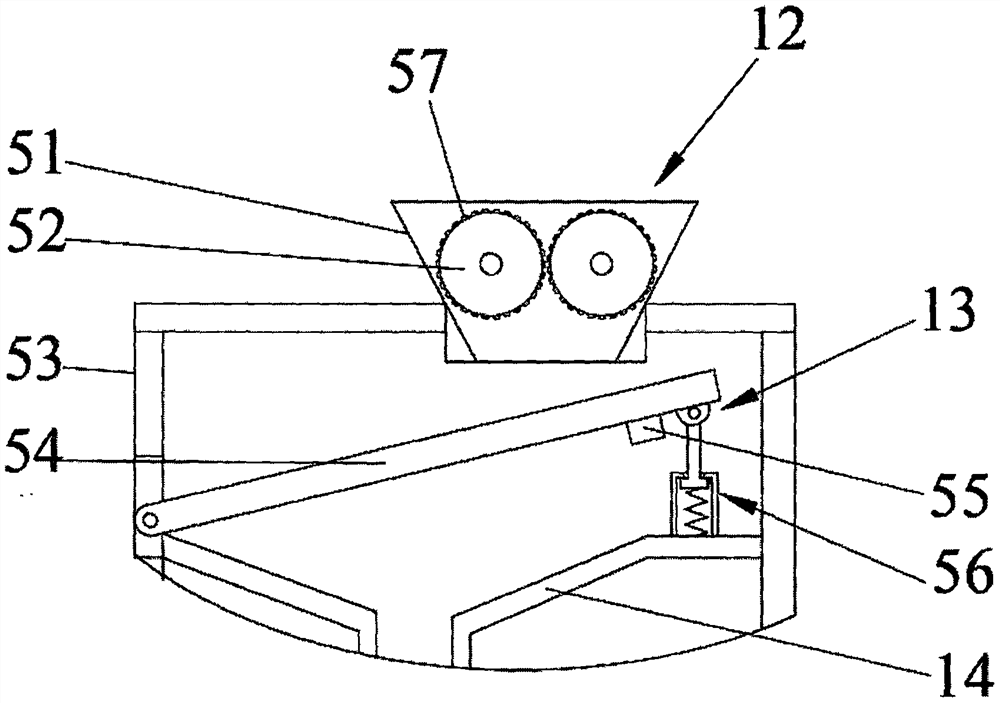

Automatic mechanical equipment for feed stirring

InactiveCN111068566AWell mixedPromote absorptionFeeding-stuffTransportation and packagingAgricultural engineeringStructural engineering

The invention discloses automatic mechanical equipment for feed stirring. The automatic mechanical equipment comprises a crushing structure, a bracket, a mixing structure and a batching structure, thecrushing structure is composed of a crushing frame, a magnetic separation frame, a screening frame, a material guiding structure and a conveying structure. The crushing frame, the magnetic separationframe, the screening frame and the material guiding structure are sequentially connected in a through a welding mode from top to bottom. The conveying structure is obliquely fixed to the bottom end of the material guiding structure, the conveying structure is connected with the material guiding structure in a penetrating mode, the bracket is arranged on one side of the crushing frame, the mixingstructure and the batching structure are arranged on the bracket, and the crushing structure and the batching structure are arranged on the two sides of the mixing structure respectively. The equipment is convenient for automatic mixing of a feed and traditional manually treated fresh forage, so that the use amount of workers is reduced, the labor intensity is reduced, the discharge efficiency isimproved, the labor cost in feed processing is reduced, the feed stirring treatment efficiency is improved, accurate matching between the feed and additives is facilitated, and the feed mixing and proportioning precision is improved.

Owner:白沚玄

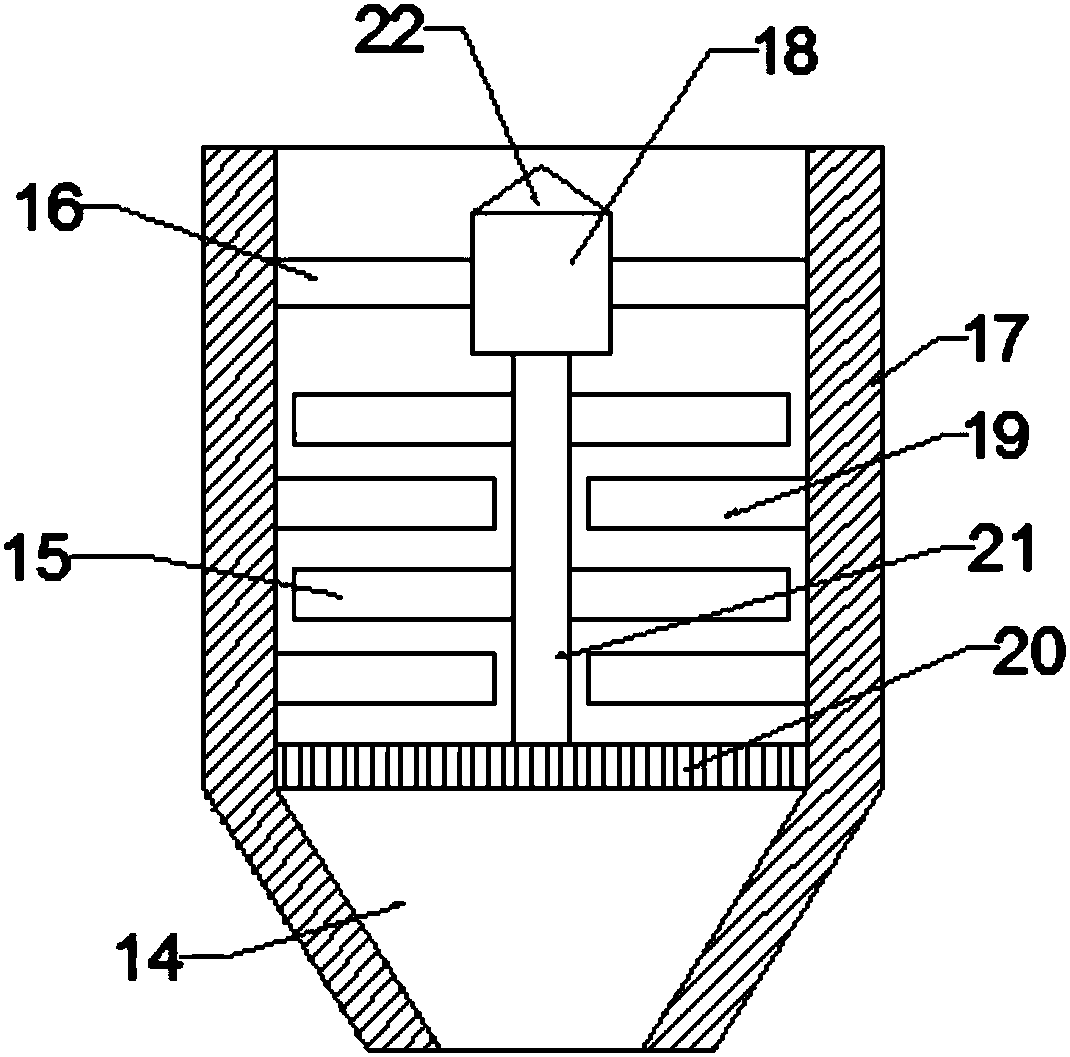

Premix feed production ingredient control feeding device

PendingCN111420588AEasy to stackEasy to stir and mixFeeding-stuffRotary stirring mixersEngineeringFodder

The invention discloses a premix feed production ingredient control feeding device. The device comprises a mixing box, a main material pipe sleeves the upper part of the side wall of the mixing box, the bottom of the side wall of the mixing box is sleeved with a discharge pipe, a sealing cover is clamped in the discharge pipe, a batching box is mounted at the top of the mixing box, a feeding mechanism is installed between a batching box and the mixing box, an equipartition disc is clamped between the inner walls of the mixing box at the top of the main material pipe, a plurality of blanking holes are formed in the equipartition disc, a vertical shaft is sleeved between the equipartition disc and a bottom plate of the mixing box, the bottom of the vertical shaft penetrates through a bottomplate of the mixing box and is fixedly connected with an output shaft of a motor, and multiple stirring rods are installed on the vertical shaft. Main materials are directly put into the mixing box from the main material pipe, ingredients are poured into the ingredient box, a putting mechanism intermittently puts the ingredients onto the equipartition disc, the motor drives the vertical shaft to rotate, and the equipartition disc is pushed by the putting mechanism while rotating, so that the ingredients uniformly fall to the tops of the main materials from the blanking holes, the ingredients are uniformly dispersed, and stirring and mixing of the stirring rod are facilitated.

Owner:OMEGA BIOTECH LUAN CO LTD

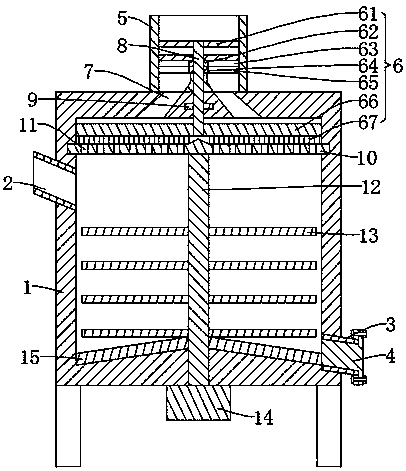

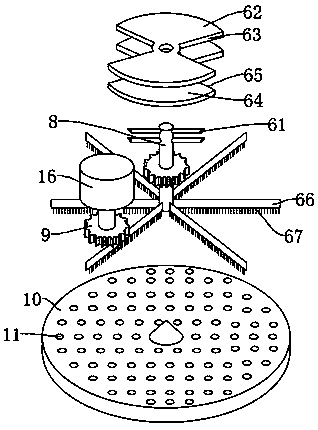

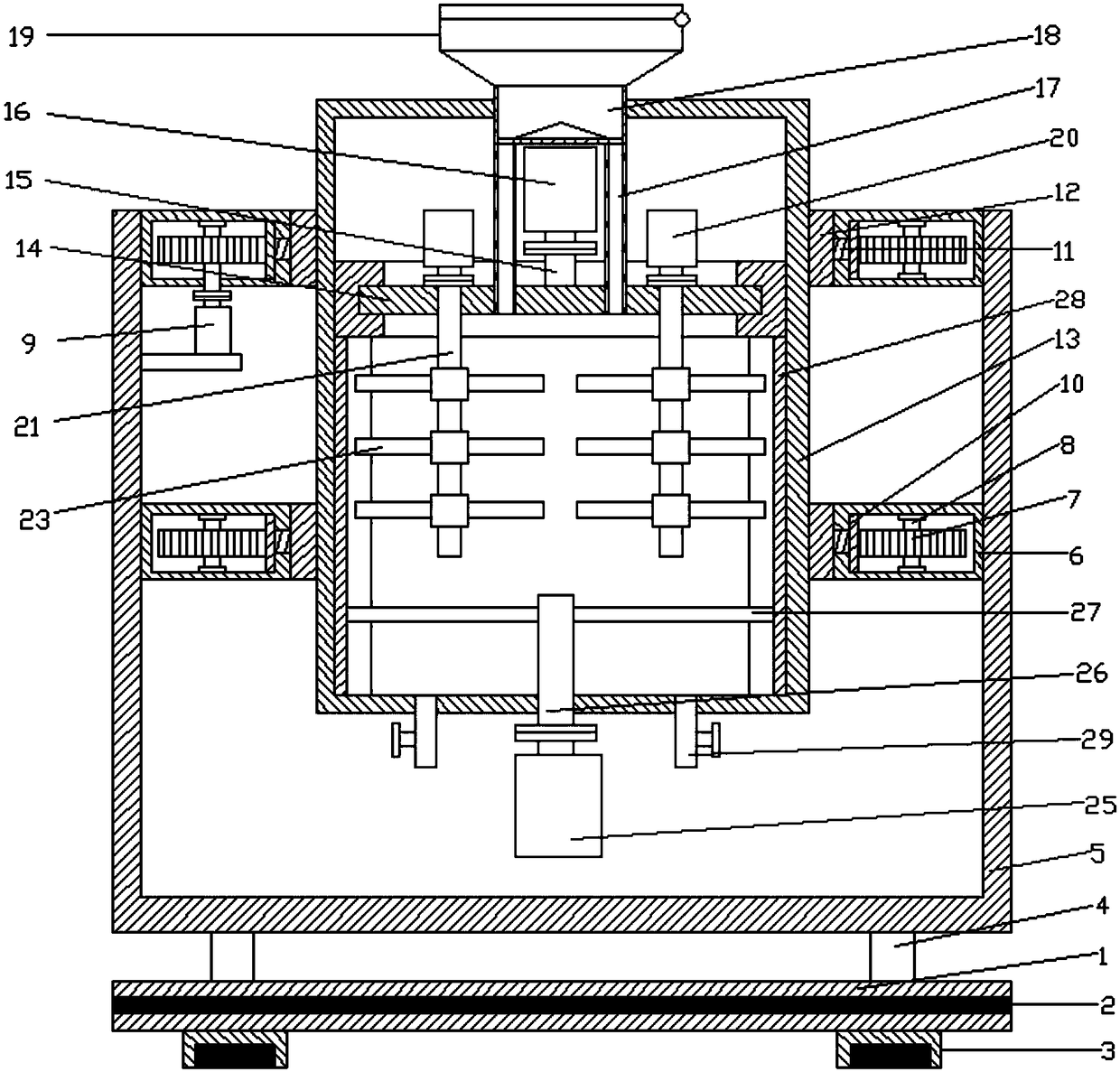

Bidirectional agitating tower-type multilayer liquid washing agitating kettle

InactiveCN108273428AEasy to stir and mixQuick Stir to MixRotating receptacle mixersTransportation and packagingMotor driveHeater Rod

The invention discloses a bidirectional agitating tower-type multilayer liquid washing agitating kettle in the technical field of daily chemical product production equipment. The kettle comprises a housing, wherein a first motor is mounted on the right side of the bottom of an inner cavity of the housing; an outer wall on the left side of a gear is connected with a kettle body; a second motor anda feed hopper are mounted on the left side and the right side of the top of the housing respectively; heating rods are uniformly arranged on an inner wall of the kettle body; the bottom of a dischargepipe extends to the outer side of the bottom of the housing; and a quantitative discharge device is mounted at the bottom of the discharge pipe. The kettle is simple to operate; rotation directions of the first motor and the second motor are opposite; the kettle facilitates quickly agitating and mixing a liquid washing product in the kettle body; the heating rods are mounted in the kettle body; the control of the temperature of the liquid washing product in the kettle body is facilitated; a discharge motor drives separating plates on a rotating shaft to rotate; the liquid washing product canfurther pass through the discharge pipe; quantitative outflow of agitated and qualified raw materials in the kettle body at regular time is achieved; the discharge is controlled conveniently accordingto the quantity required by a user; and the raw material waste is avoided.

Owner:扬州市钰翔轻工机械设备厂

Stirring and mixing device for oil production

InactiveCN107583535AStir wellEasy to stir and mixRotating receptacle mixersTransportation and packagingEngineeringOil production

The invention discloses a stirring and mixing device for oil production. The stirring and mixing device comprises a first rotating shaft, a fixed bottom plate, a double-shaft motor and a stirring andmixing tank, wherein a supporting column is fixed on the upper surface of the fixed bottom plate; a connecting post is fixed on the right side of the stirring and mixing tank; a discharge pipe is arranged on the stirring and mixing tank and at each of the upper end and the lower end of the connecting post; an annular rack is arranged on the left side of the stirring and mixing tank; a feed pipe isarranged at each of the upper end and the lower end of the stirring and mixing tank and on the left side of the annular ruler; a first belt runner is arranged on the first rotating shaft; the left side of the double-shaft motor is rotationally connected with a second rotating shaft; a second belt runner is arranged on the second rotating shaft; the right side of the double-shaft motor is rotationally connected with a third rotating shaft; a gear is arranged on the third rotating shaft and is meshed with the annular rack. According to the stirring and mixing device for oil production disclosedby the invention, high-efficiency uniform stirring of oil is realized due to opposite rotating directions of the stirring and mixing tank and stirring paddles, and complete discharging is realized.

Owner:陈式好

Raw material mixing equipment used for composite material production

InactiveCN108722270AImprove work efficiencyEasy to useRotating receptacle mixersTransportation and packagingEquipment useRaw material

The invention discloses raw material mixing equipment used for composite material production. The equipment comprises a base board, supporting legs are arranged on the upper side of the base board, aconnecting frame is arranged on the upper sides of the supporting legs, a connecting groove is formed in the interior of the connecting frame, gears are arranged in the connecting groove, annular racks are arranged on the inner sides of the gears, annular bulges are arranged on the inner sides of the annular racks, a fixing sleeve is arranged on the outer sides of the annular bulges, a stirring tank is arranged in the fixing sleeve, a rotating disk is arranged at the upper end of the interior of the stirring tank, a connecting ring is arranged on the middle part of the upper side of the rotating disk, a receiving groove is formed in the upper side of the connecting ring, a charging port is formed in the upper side of the receiving groove, third motors are arranged at the left and right ends of the upper side of the rotating disk, stirring shafts are arranged on the lower sides of the third motors, stirring rods are arranged on the left and right sides of the stirring shafts, a fourth motor is arranged on the middle part of the lower side of the stirring tank, a second rotating shaft is arranged on the upper side of the fourth motor, connecting rods are arranged at the upper ends ofthe left and right sides of the second rotating shaft, and scrapers are arranged on the outer sides of the connecting rods. According to the equipment, the working efficiency of the equipment is effectively improved, use of the equipment is facilitated, and cleanness in the equipment is ensured.

Owner:金寨县鑫和新能源科技有限公司

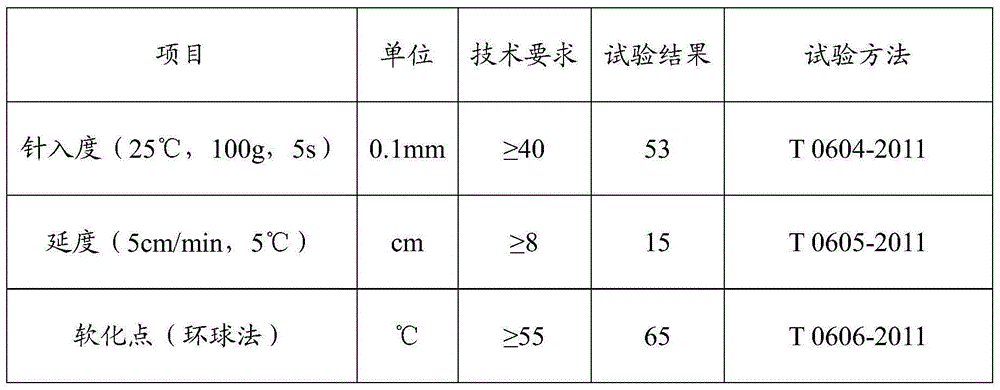

Modified asphalt master batch and preparing method and application thereof

The invention relates to the technical field of modified asphalt and particularly provides a modified asphalt master batch. The modified asphalt master batch is prepared from, by weight, 40-60 parts of EVA, 10-20 parts of extract oil of aromatic hydrocarbon, 5-10 parts of rubber powder, 5-10 parts of organic wax, 5-15 parts of polyethylene, 3-5 parts of stearic acid, 2-5 parts of plasticizer, 2-4 parts of nano-particle and 0.1-0.5 part of antioxidant. The invention further provides a preparing method and application of the modified asphalt master batch. According to the modified asphalt master batch, asphalt is modified by organically combining the EVA, the rubber powder, the organic wax, the nano-particles and other raw materials, the high-low temperature performance and stability of the asphalt can be remarkably improved, separation of the asphalt in the use process can be effectively relieved through the good compatibility with the asphalt, and the good modified effect is achieved; the production process is simple, use is convenient, and quick and large-scale production of modification of the asphalt can be achieved.

Owner:SUZHOU TOPOLINE TECH

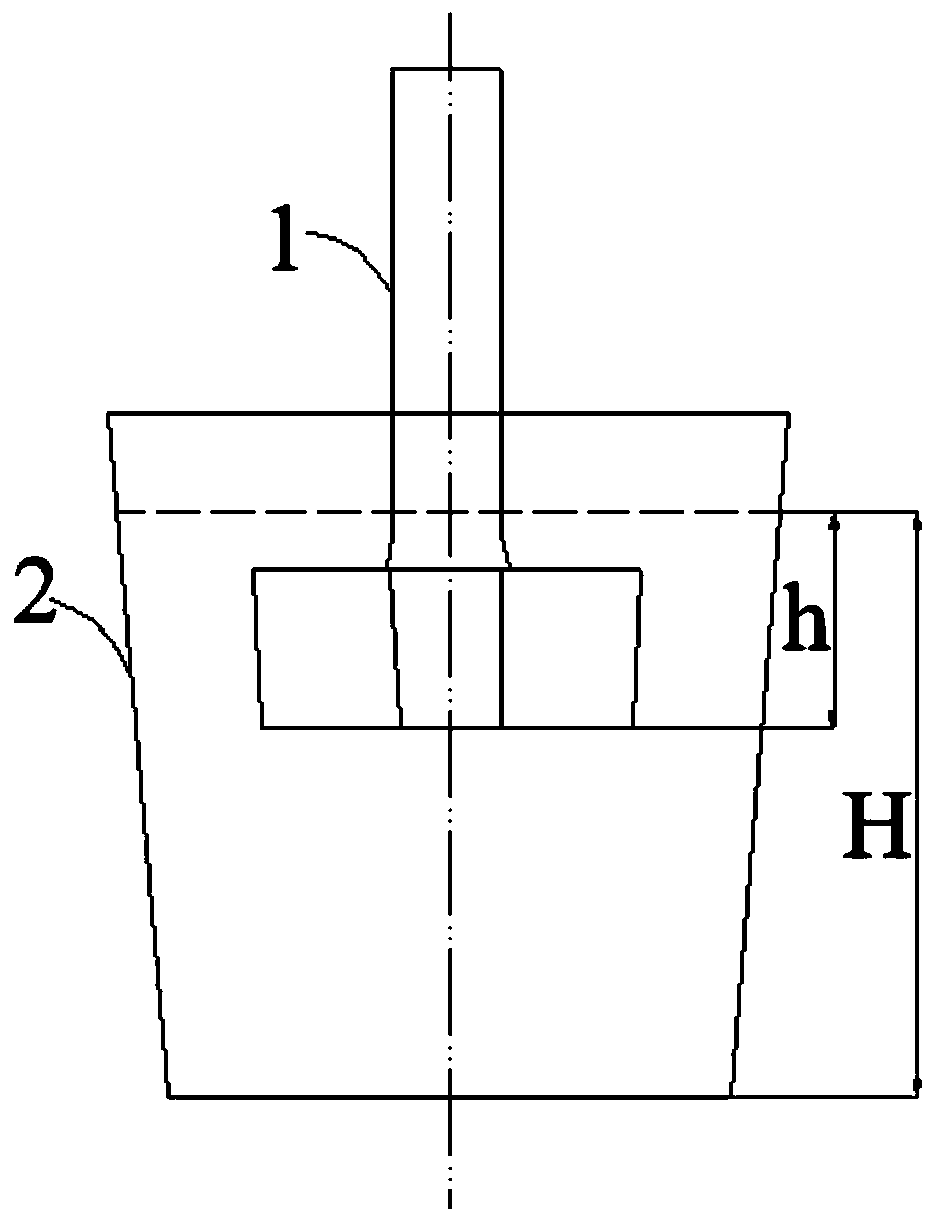

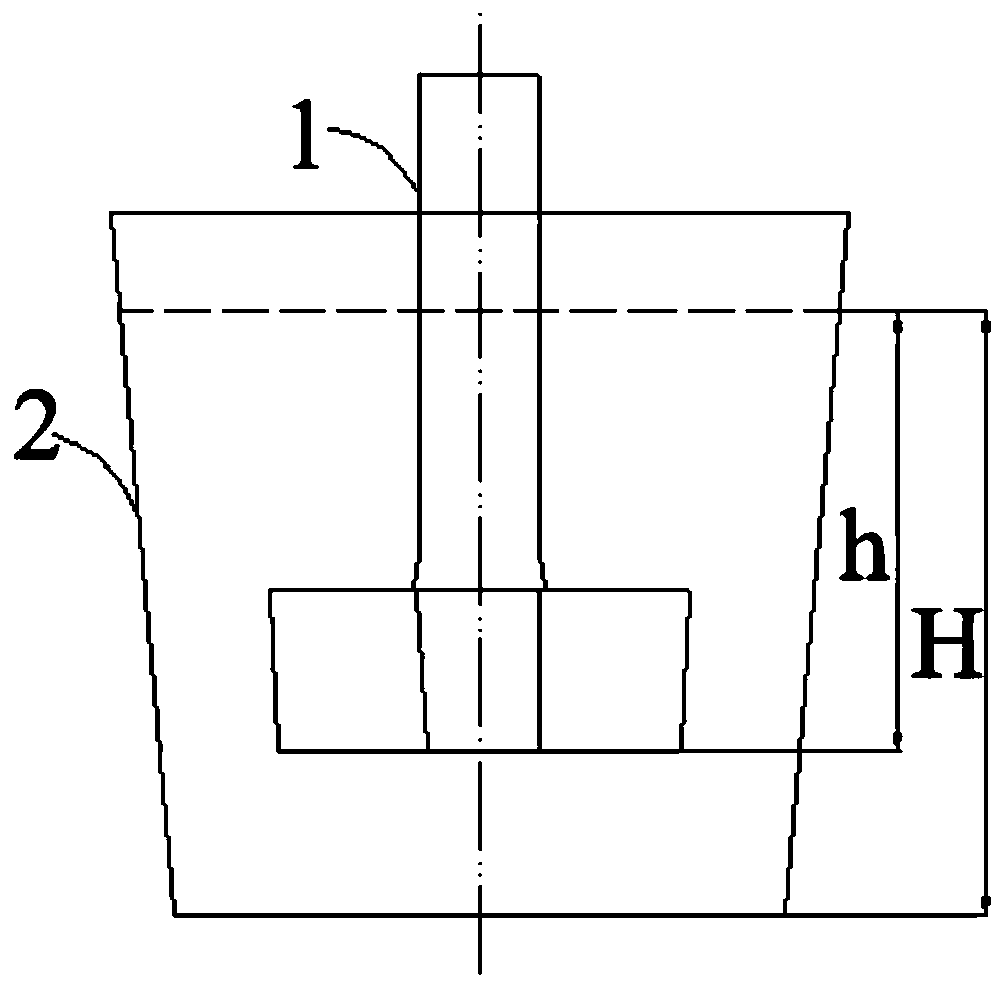

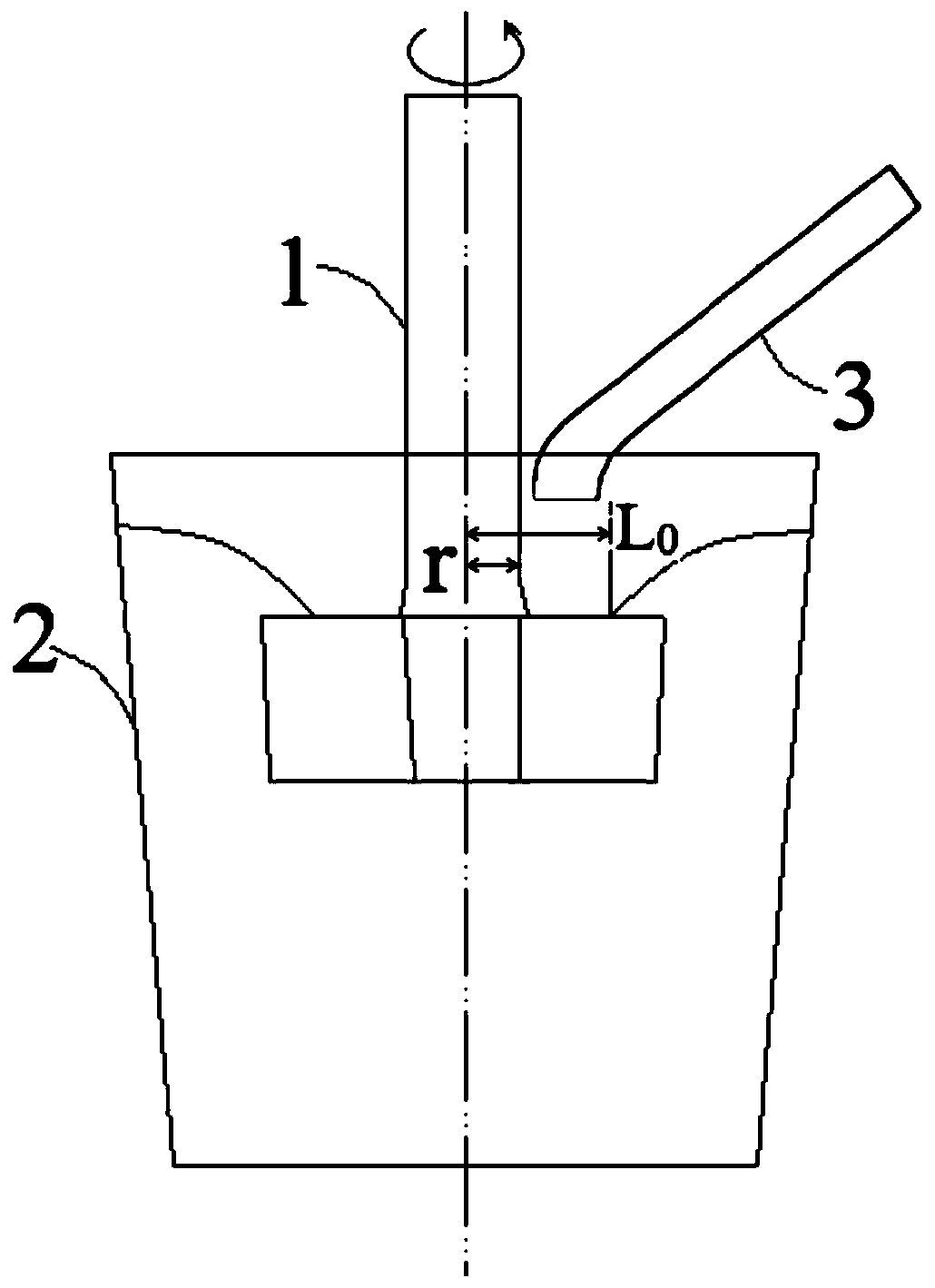

Step-by-step molten iron KR stirring desulfurization method

InactiveCN111394535AOptimize volumeRealize mixing and dispersingRotary stirring mixersTransportation and packagingSteelmakingMolten bath

The invention discloses a step-by-step molten iron KR stirring desulfurization method, and belongs to the technical field of molten iron external desulfurization before converter steelmaking. The method comprises the following steps of 1, slagging off molten iron, measuring the depth of the liquid level, and measuring the temperature and sampling; 2, inserting a stirrer into the shallow layer of the liquid level of the molten iron, and rotating to a working speed; 3, keeping the stirring depth and the rotating speed, and adding a desulfurizing agent; 4, adjusting the insertion depth and the working rotating speed of the stirrer; and 5, stirring until the desulfurization is finished, and carrying out slagging-off, temperature measurement and sampling again. According to the step-by-step molten iron KR stirring desulfurization method, in the initial stage of stirring, a shallow stirrer insertion depth and a low stirring rotating speed are adopted, entrainment, mixing and dispersion of the desulfurizing agent are facilitated, and energy consumption and blade abrasion can be reduced; and a deep stirring depth is adopted in the later stage of stirring, so that uniform stirring and mixing of a molten pool are facilitated, the upward floating stroke of the desulfurizing agent is increased, the stirring and mixing area of the molten pool is effectively expanded, and the reaction dynamic condition of the bottom area of the molten pool is improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

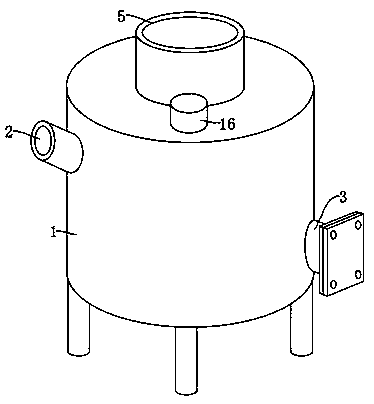

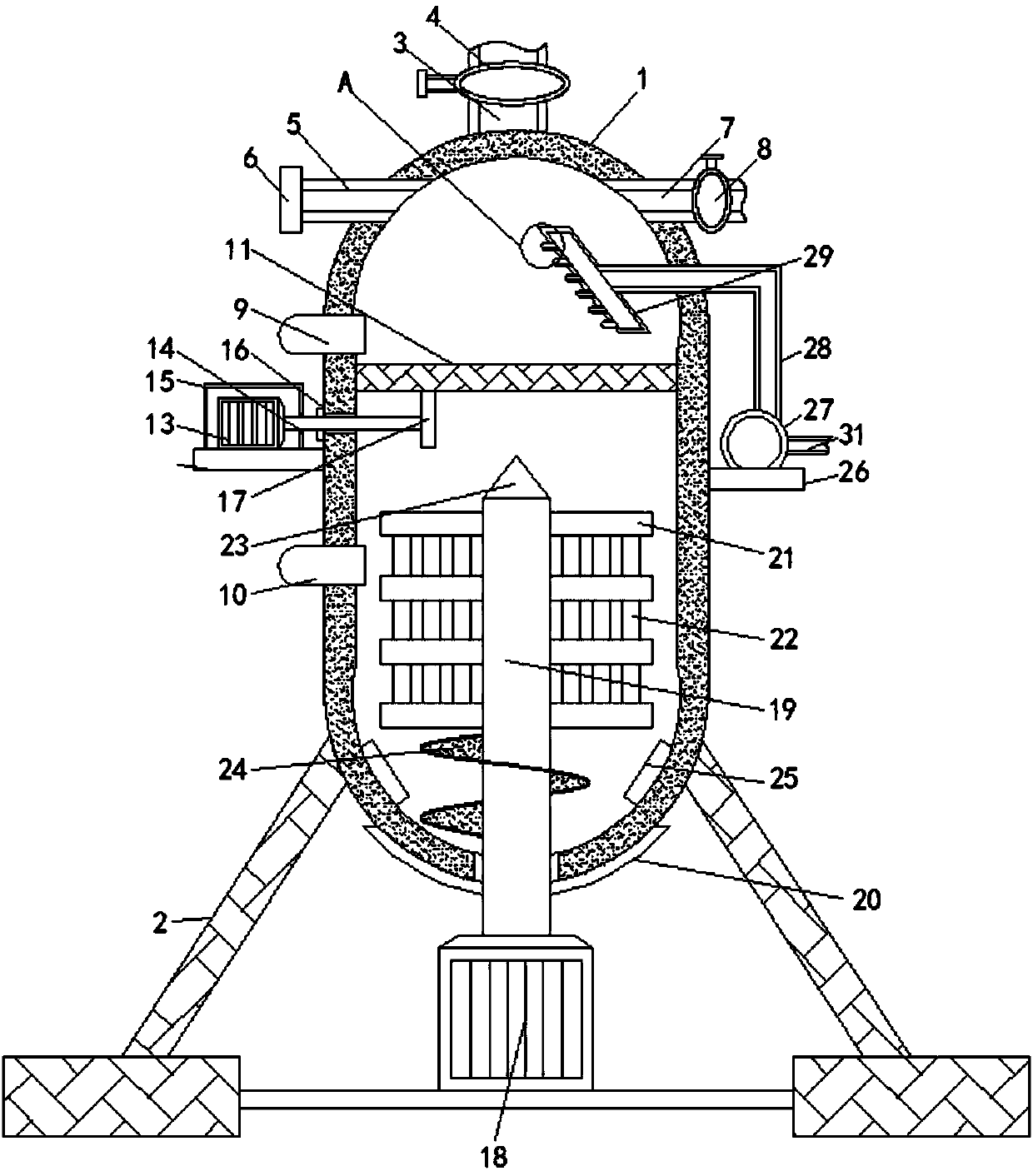

New energy material fermentation device

ActiveCN107828632AEasy to adjust and useImprove efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryPiezometer

The invention belongs to the technical field of new energy, and discloses a new energy material fermentation device. The new energy material fermentation device comprises a fermentation tank; the leftside and the right side of the bottom of the fermentation tank are fixedly connected with support legs; the top of the fermentation tank is communicated with a gas exhaust pipe; the gas exhaust pipeis provided with a snuffle valve; the left side of the top of the fermentation tank is communicated with a fermentation material inlet pipe; the left end of the fermentation material inlet pipe is provided with a material blocking cover. According to the design, fermentation materials can be introduced into the fermentation tank through the fermentation material inlet pipe, a filter screen is usedfor effective filtering of the fermentation materials, a first drive motor is turned onto to drive a fist transmission shaft to rotate, and the filter screen is tapped by an eccentric block rhythmically, so that it is beneficial for screening and feeding of materials; a piezometer and a thermometer are used for effective monitoring on the gas pressure and temperature in the fermentation tank, sothat preferable adjusting and applications are realized, and fermentation broth energy production efficiency is increased.

Owner:泰州禾益新材料科技有限公司

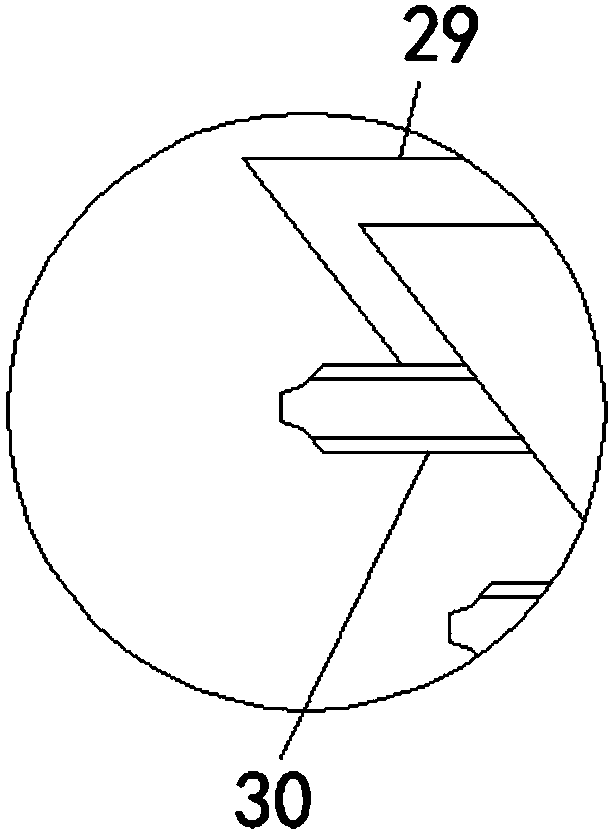

Viscosity adjustment device realizing intermittent graphite feeding and used for printing

InactiveCN107335372AImplement intermittent additionEasy to stir and mixShaking/oscillating/vibrating mixersTransportation and packagingGraphiteViscosity

The invention relates to a viscosity adjustment device, in particular to a viscosity adjustment device realizing intermittent graphite feeding and used for printing. The viscosity adjustment device realizing intermittent graphite feeding and used for printing can intermittently add viscosity adjustment powder and sufficiently mix the viscosity adjustment powder and the graphite. To solve the technical problem, the viscosity adjustment device realizing intermittent graphite feeding and used for printing is provided and comprises a mixing box and the like, wherein a material discharging pipe is connected at the bottom of the mixing box, a valve is arranged on the material discharging pipe, a stirring mechanism is connected at the top of the mixing box, and a feeding mechanism is connected at the lower part of the right side of the mixing box. The viscosity adjustment device realizing intermittent graphite feeding and used for printing is designed and provided with the stirring mechanism, so that graphite and the viscosity adjustment powder can be stirred conveniently, quickly and sufficiently.

Owner:朱礼鹏

Anti-caking type mixing device for microbial fertilizer

PendingCN111921414AImprove mixing efficiencyEasy to stir and mixTransportation and packagingRotary stirring mixersFertilizerEngineering

Owner:MAANSHAN KEBANG ECO FERTILIZER

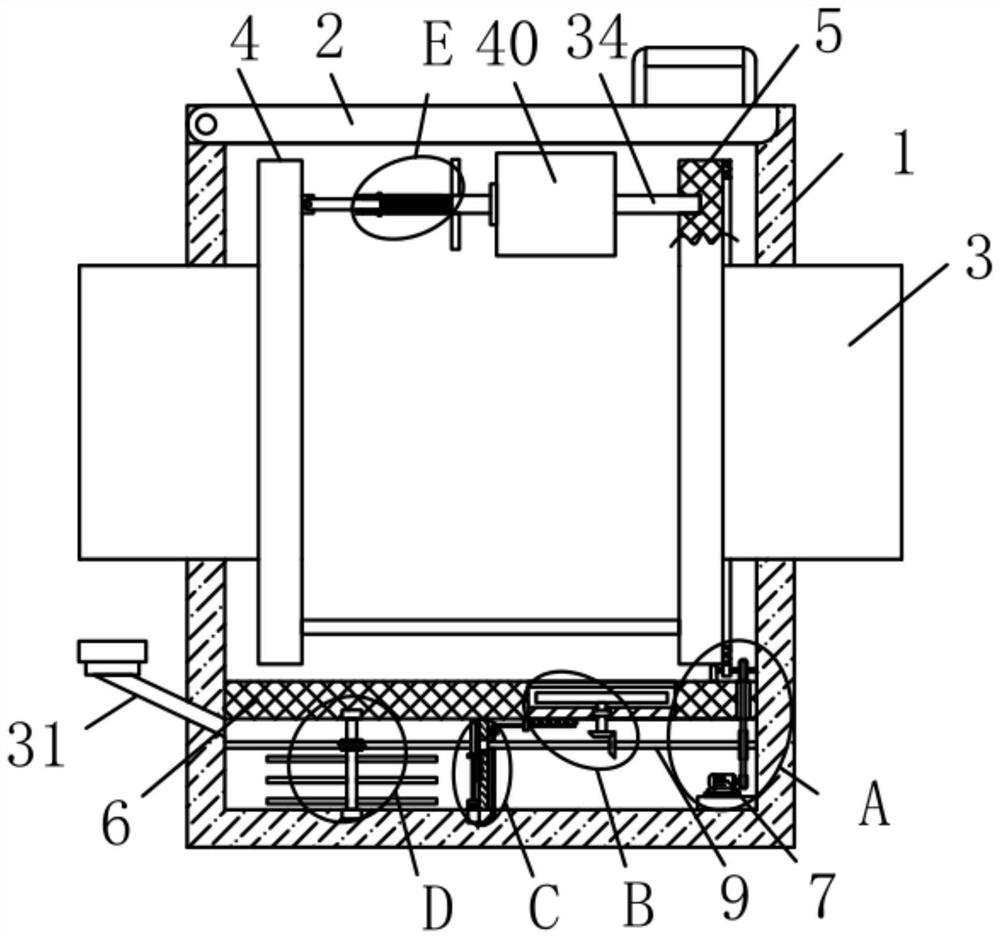

Automatic binding device for surgical nursing and using method thereof

ActiveCN112618172AEasy to operateEasy to replaceLavatory sanitoryMedical applicatorsMedicineNursing care

The invention relates to the technical field of surgical nursing, and discloses an automatic binding device for surgical nursing and a using method thereof. The automatic binding device for surgical nursing comprises a box body, a cover plate is arranged at the top of the box body, a U-shaped handle is arranged at one end of the top side of the cover plate, and hollow cylinders are rotationally installed on the two sides of the box body; a first rotary disc and a second rotary disc are rotationally installed at the ends, close to each other, of the two hollow cylinders correspondingly, and a same connecting rod is fixedly installed between the first rotary disc and the second rotary disc. The automatic binding device provided by the invention is reasonable in design, automatic binding is achieved, the bandage can be wrapped around the wound of a wounded person through rotation of the first rotary disc and the second rotary disc instead of manual work, through cooperation of an atomization spray head, a blowing fan blades, a pressing plate and other components, different agents can be treated and sprayed on the bandage, the binding efficiency is effectively improved, and a large amount of manpower is liberated.

Owner:HUNAN PROVINCIAL TUMOR HOSPITAL

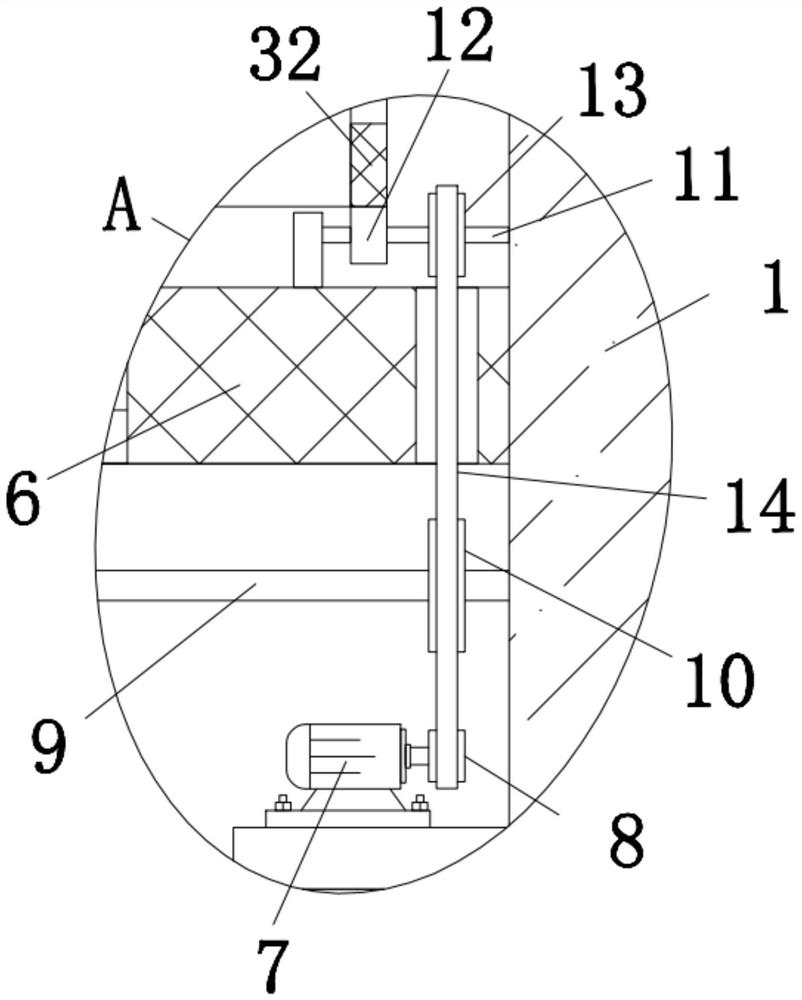

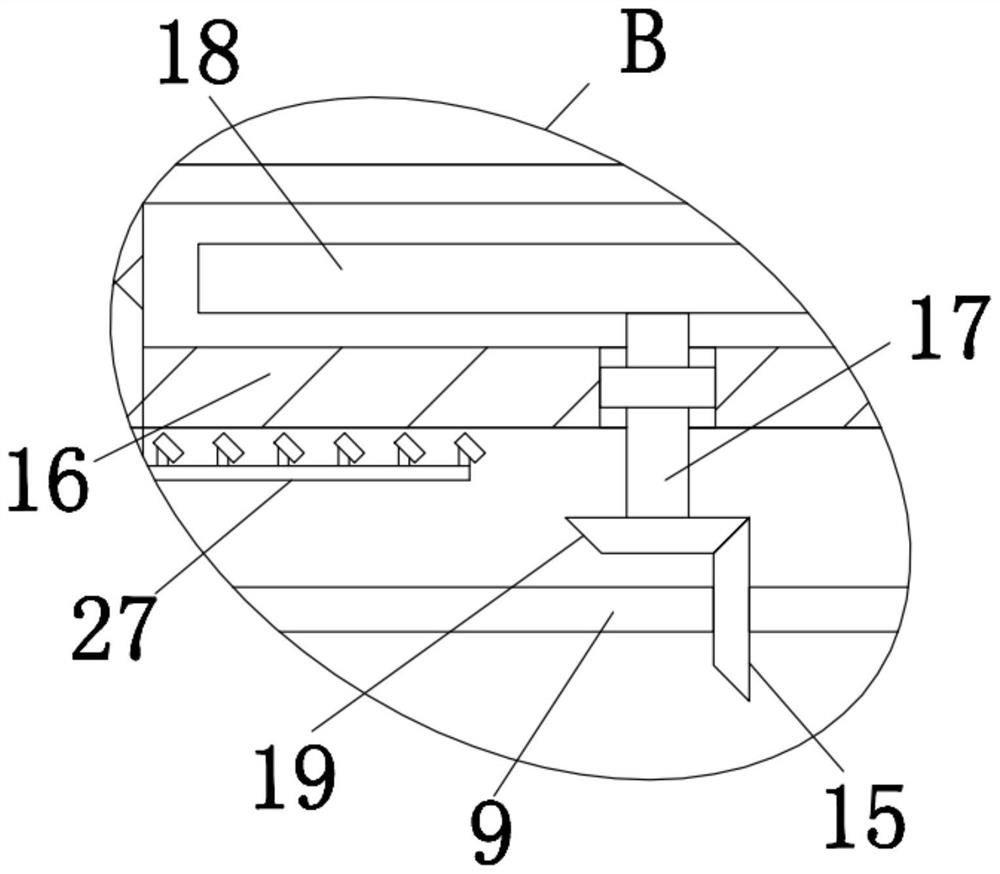

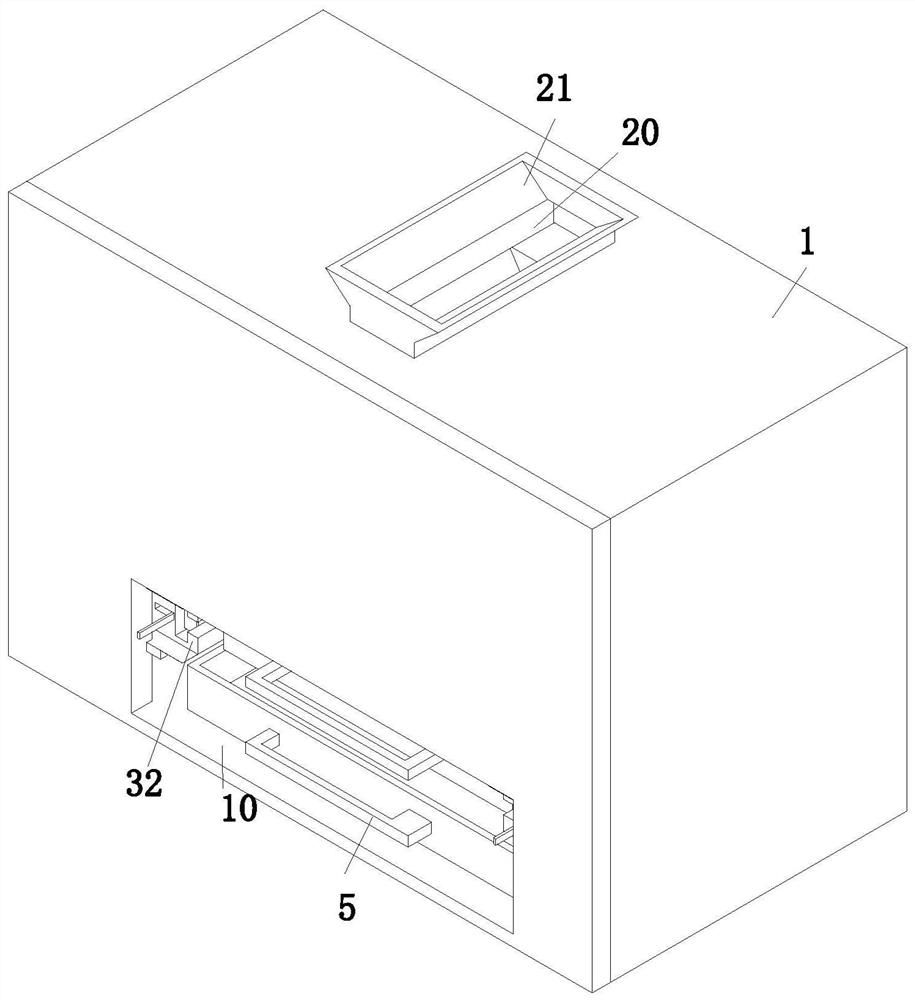

Water-based printing ink preparation method

InactiveCN113134423AFine ink raw materialsEasy to stir and mixSievingScreeningPrinting inkGrinding mill

The invention relates to a water-based printing ink preparation method. A water-based printing ink preparation device is used. The water-based printing ink preparation device comprises a preparation box, a grinding mechanism, a screening mechanism, a scraping mechanism and a collecting box, the preparation box is of a rectangular structure, the grinding mechanism, the screening mechanism and the collecting box are sequentially arranged on the inner wall of the preparation box from top to bottom, and the scraping mechanism is arranged on the grinding mechanism. According to the method, the grinding mechanism can conduct double grinding on ink raw materials, so that the ground ink raw materials are finer, mixing and stirring of the ink raw materials are facilitated, the mixing stirring effect behind the ink raw materials is prevented from being influenced due to the fact that the grinding of the ink raw materials is not fine, meanwhile, the ink raw materials adhered to a first grinding roller and a second grinding roller on the grinding mechanism are scraped off by adopting the scraping mechanism, so that the adhered raw materials are prevented from influencing the grinding of a grinding roller, and therefore, the grinding effect of the grinding roller is not good.

Owner:有限会社林平

Mixing and stirring equipment for coating production

InactiveCN112452239AEasy to stir and mixImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingTransmission beltCrushed stone

The invention relates to the technical field of powder coating preparation, in particular to mixing and stirring equipment for coating production. A servo motor is adopted to drive a motor shaft to rotate, the motor shaft enables a second rotating shaft to rotate under the action of a transmission wheel set and a transmission belt, a first bevel gear at the bottom end of the second rotating shaftalso rotates along with the second rotating shaft, and the second bevel gear is driven to drive a third rotating shaft to rotate, so that a crushing knife crushes stone powder, and caked stone powderis refined again, stone powder is guided by the material guide plate and screened by the screen, so that the stone powder meeting the requirements passes through the material guide plate and falls into the stirring tank after passing through the material guide pipe, and subsequent mixing and stirring are facilitated, an incomplete bevel gear at the bottom end of a motor shaft also rotates synchronously and is in intermittent fit with the first driven bevel gear, so that a second rotating shaft drives a worm to rotate forwards and backwards in a reciprocating manner, the worm drives the worm wheel to rotate in a reciprocating manner, and drives the stirring blades to swing in a reciprocating manner in the stirring tank through the connecting shaft, so that the stone powder raw materials aremixed.

Owner:安徽云至信电子商务有限公司

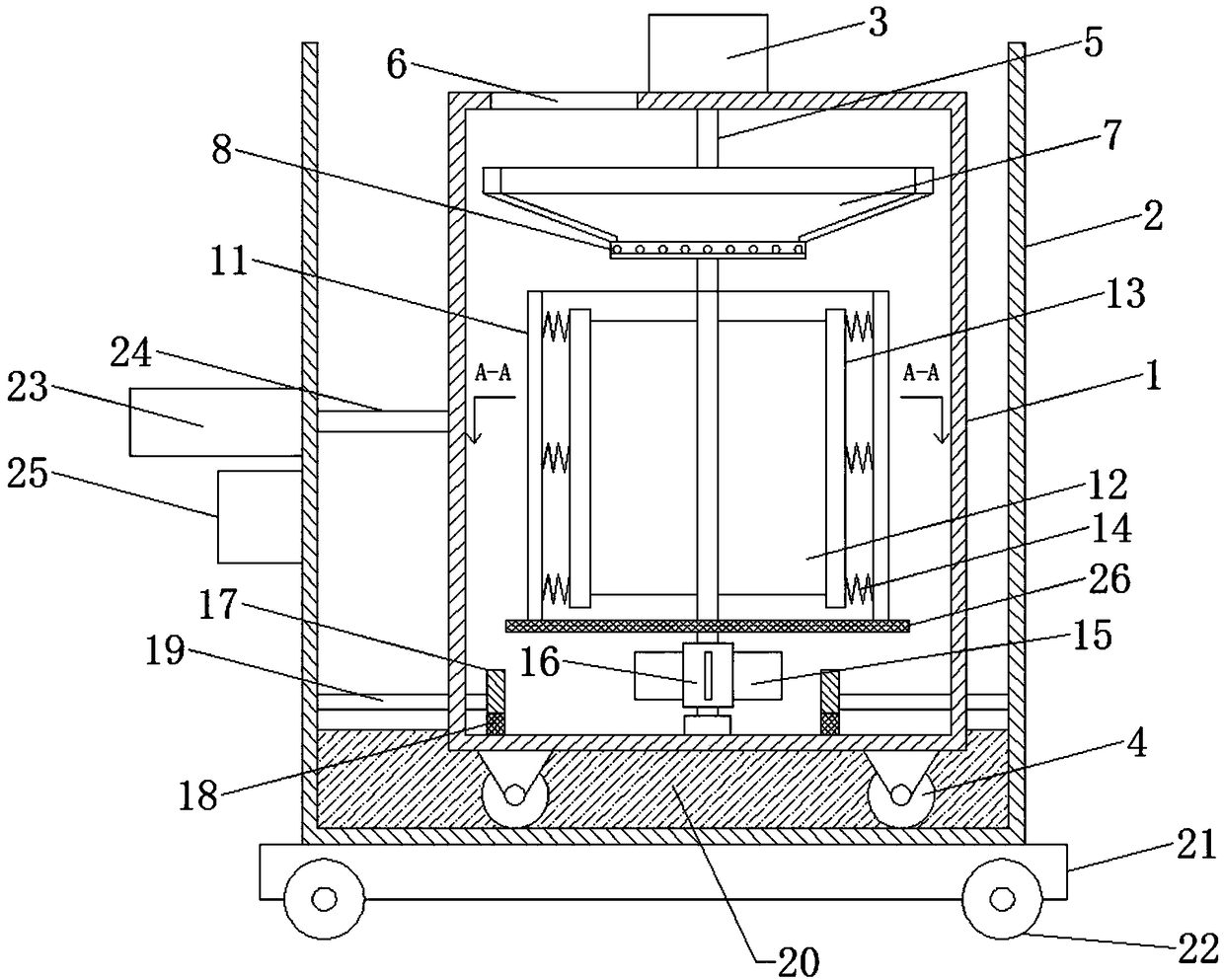

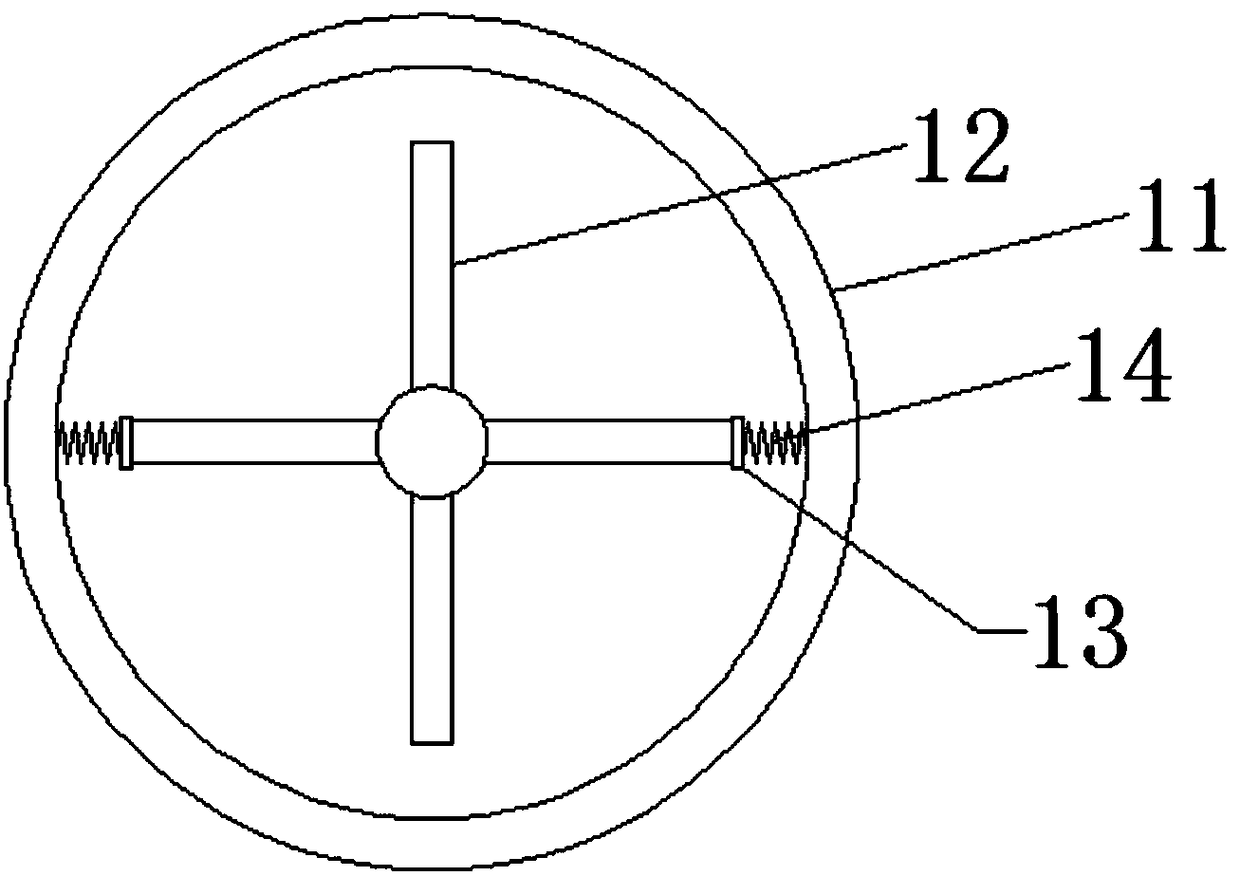

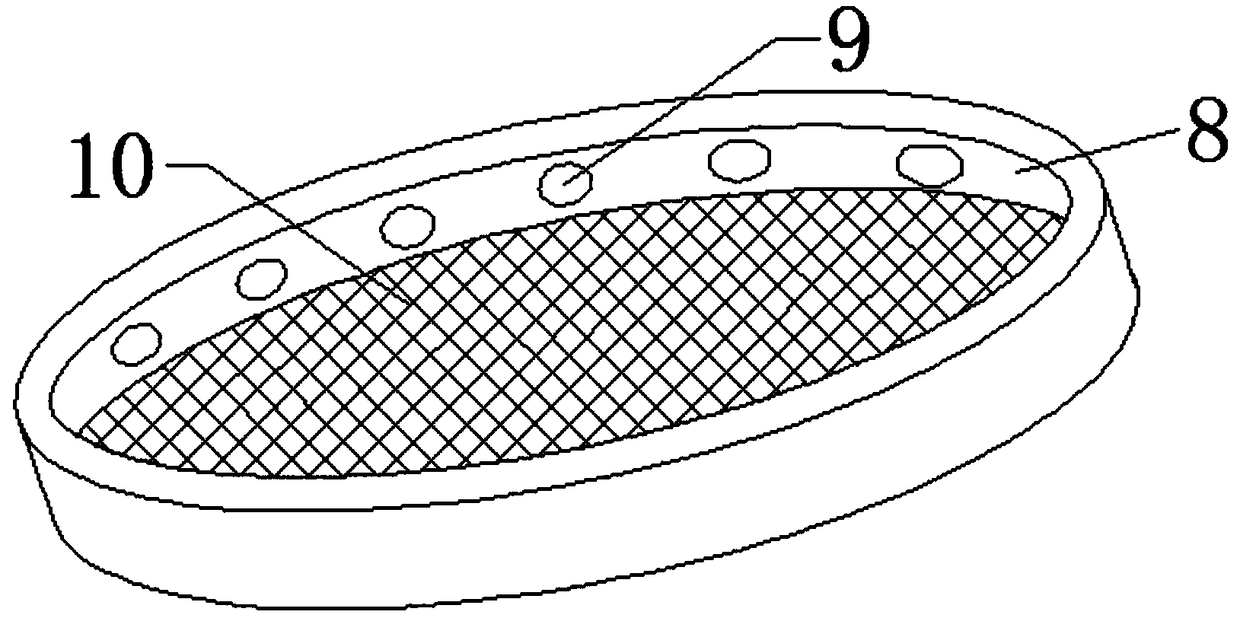

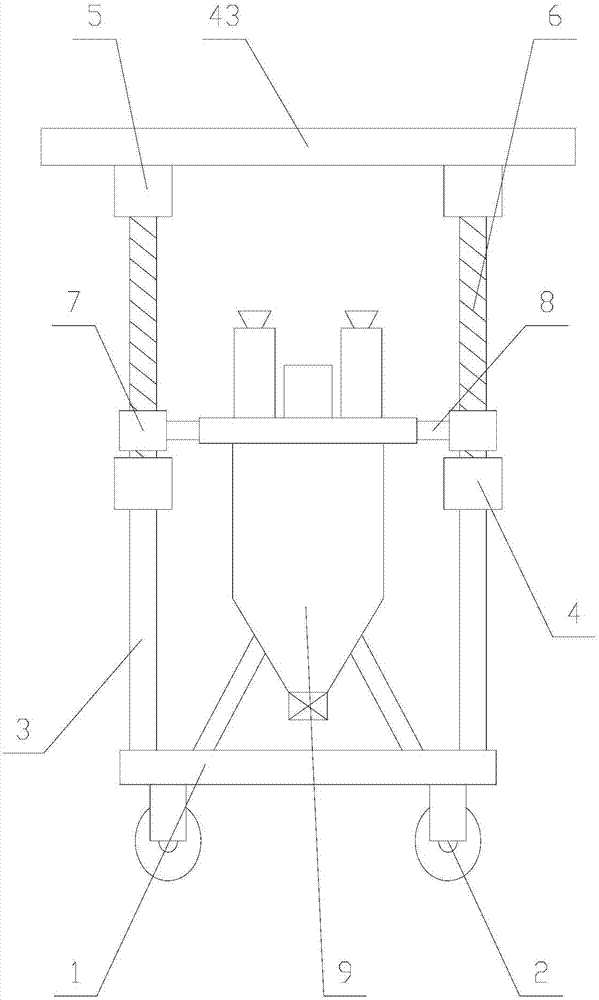

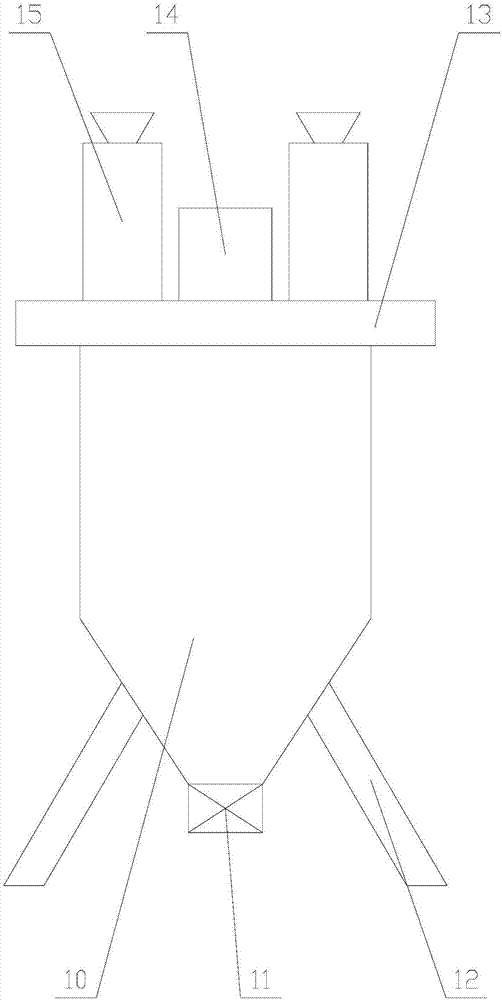

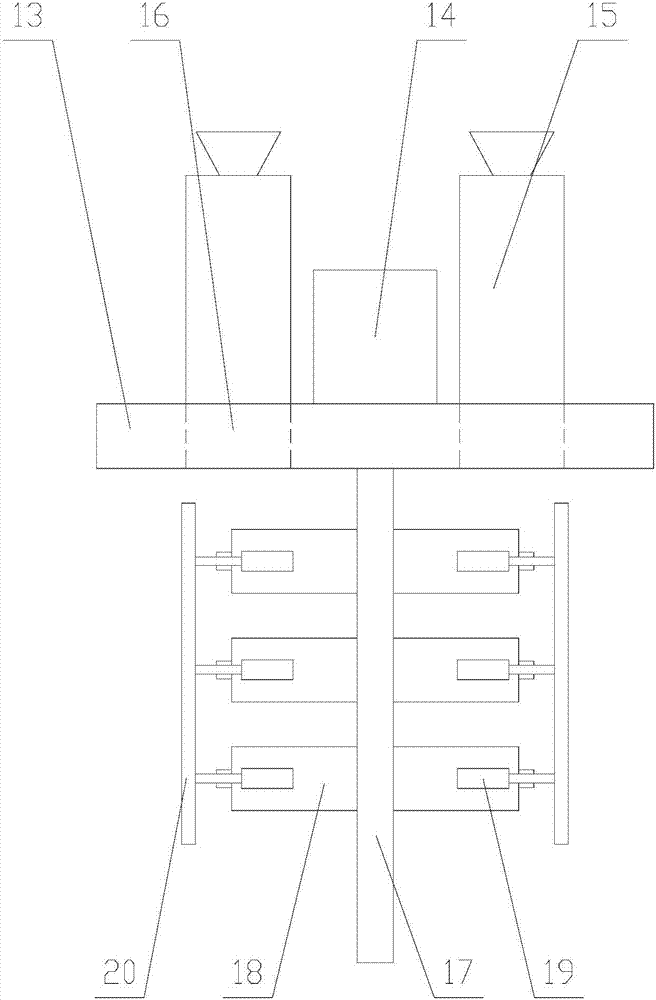

Movable material mixing equipment for building

InactiveCN108556139AAvoid Stirring Dead AngleLarge swingMixing operation control apparatusPretreatment controlPneumatic cylinderDrive shaft

The invention discloses movable material mixing equipment for building. The movable material mixing equipment comprises a cylinder body, a shell, a motor and a feeding opening. Multiple moving wheelsare fixedly installed on the bottom of the cylinder body. A horizontal connecting rod is fixedly connected to a piston rod of a pneumatic cylinder. The connecting rod extends into the tail end in theshell and is fixedly connected with the cylinder body. A horizontal material guide hopper is coaxially fixed to a transmission shaft. A horizontal dispersing disc is fixed to the lower end of the material guide hopper. A supporting screen plate is provided with a screen cylinder which is arranged on the outer side of a main stirring blade in a sleeving manner. A plurality of connecting springs arefixedly connected to the left side and the right side of the inner wall of the screen cylinder. According to the equipment, by means of the arranged material guide plate and the rotating dispersing disc, materials entering the equipment are spread in the cylinder body uniformly, the materials make contact with materials in the cylinder body uniformly, and the materials are stirred and mixed conveniently and fast. The cylinder body moving left and right enables the materials in the cylinder body to waggle left and right, the materials in the cylinder body can move conveniently in the horizontal direction, and the stirring dead angle is avoided.

Owner:南安泰达农业科技有限公司

High-uniformity slurry stirring barrel for powdery materials

InactiveCN107159007AStir wellEasy to stir and mixRotary stirring mixersMixing methodsEngineeringSlurry pump

The invention discloses a high-uniformity slurry stirring barrel for powdery materials, which includes a slurry stirring barrel body and a fixed base. The fixed base is fixedly installed on the lower end of the slurry stirring barrel body. An electromagnetic heater is installed on the center of the top end surface of the fixed base. A barrel cover is installed on the upper end of the slurry stirring barrel body. A lifting telescopic mechanism is installed on the bottom end surface of the barrel cover. A rotational driving motor mechanism is fixedly installed on the lower end of a telescopic rod. A stirring blade head is connected to the lower end of the rotational driving motor mechanism. A slurry pump is fixedly installed on the outer cylinder wall of the slurry stirring barrel body. By means of the structure, the barrel is used for stirring a slurry material prepared from powdery materials.

Owner:WUXI KUAKE MICRONUTRIENT

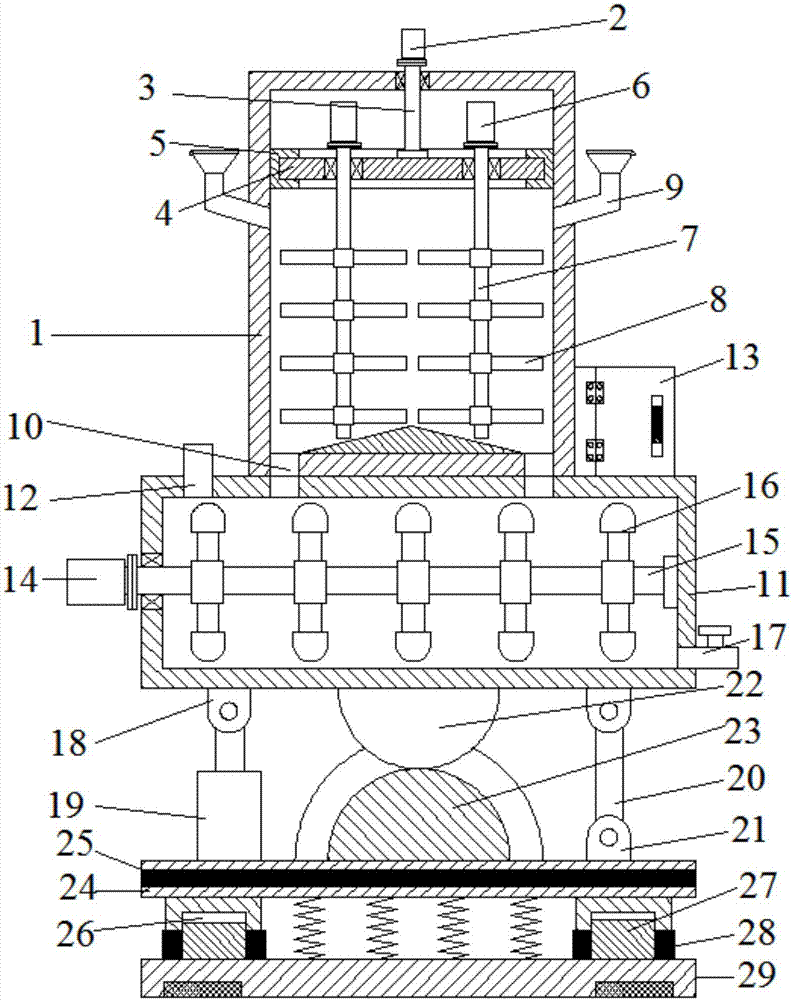

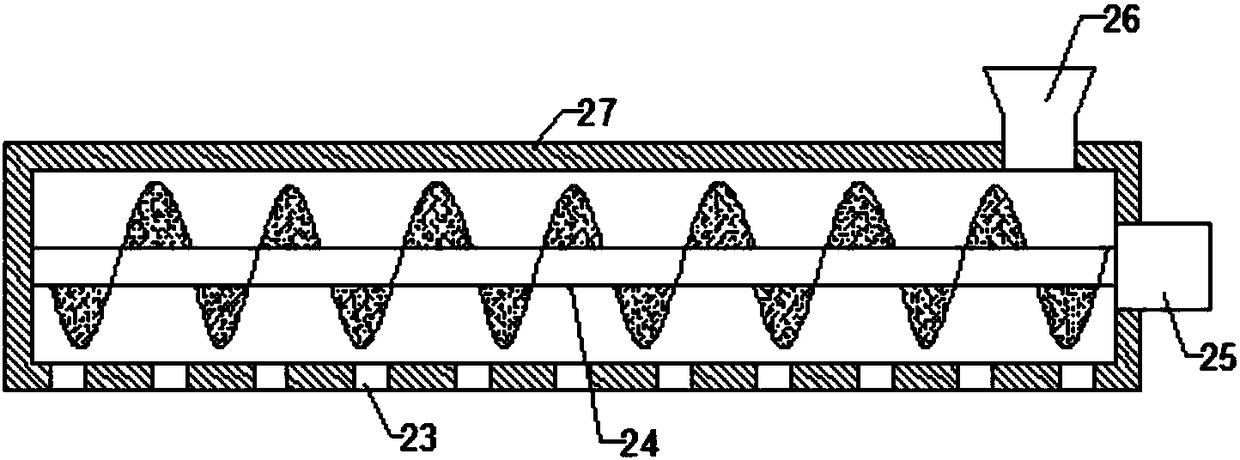

Soil restoration processing apparatus used for garden maintenance

InactiveCN108160238ASimple structureReasonable designTransportation and packagingNon-rotating vibration suppressionEngineeringMixing chamber

The invention discloses a soil restoration processing apparatus used for garden maintenance, and belongs to the technical field of polluted soil restoration. The apparatus comprises a mixing box, which is internally provided with a mixing chamber, the top end of which is provided with a feeding device, and the bottom end of which is provided with damping pedestals; a rotary motor is arranged at the right end of a repairing agent adding pipe and is fixedly connected to an outer wall of the mixing box through screws; and a plurality of discharging holes are uniformly formed in the bottom of therepairing agent adding pipe. The apparatus is reasonable in structural design. The feeding device is used for pulverizing the polluted soil, thereby improving the mixing efficiency of polluted soil and a repairing agent. A first spiral stirring device and a second spiral stirring device are arranged to well mix the polluted soil with the repairing agent via stirring, so that polluted soil and therepairing agent are completely mixed. A repairing agent adding device allows the repairing agent to be uniformly added to the mixing chamber via a spiral feeding apparatus, thereby further improving the soil restoration quality.

Owner:SHENZHEN RUNFENG INVESTMENT CONSULTATION CO LTD

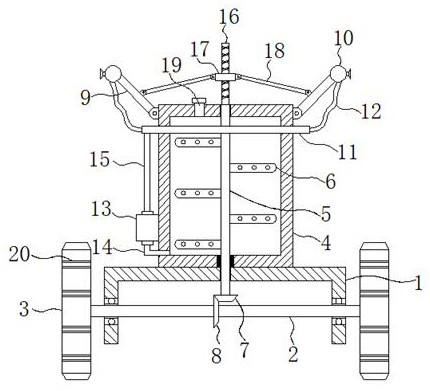

Agricultural mechanical equipment for herbicide spraying

InactiveCN112167232AEasy to stir and mixEasy accessSpraying apparatusWeed killersAgricultural scienceAgricultural engineering

The invention relates to the technical field of agricultural machinery, and discloses agricultural machinery equipment for herbicide spraying. The agricultural machinery equipment comprises a U-shapedplate and a rotating rod penetrating through the U-shaped plate. The rotating rod is rotatably connected with the side wall of the U-shaped plate through a ball bearing, walking wheels are fixedly mounted at the two ends of the rotating rod, a liquid storage tank is fixedly mounted in the center of the top of the U-shaped plate, a stirring rod is arranged in the liquid storage tank, a plurality of stirring blades which are evenly distributed in a staggered mode are welded to the outer rod wall of the stirring rod, the bottom end of the stirring rod sequentially penetrates through the bottom of the liquid storage tank and the U-shaped plate and is fixedly connected with a driven bevel gear, the stirring rod is rotationally connected with the bottom of the liquid storage tank through a sealing bearing, and the stirring rod is rotationally connected with the U-shaped plate. According to the agricultural machinery equipment for herbicide spraying, reciprocating swing spraying of herbicideliquid medicine is convenient, the herbicide liquid medicine is conveniently stirred, precipitation of the herbicide liquid medicine is avoided, and therefore the spraying quality is effectively improved.

Owner:西安汇龙中鼎机械设备有限公司

Asphalt mixing device

PendingCN112827418AGuaranteed heating temperatureGuaranteed temperatureFlow mixersTransportation and packagingHeater RodEngineering

The invention discloses an asphalt mixing device, and relates to the technical field of asphalt production and processing. A vertical lifting device is fixedly connected with a mixing box, the vertical lifting device can lift asphalt on the bottom layer in the mixing box to the surface layer, and a second heating device can heat the asphalt in the vertical lifting device. A stirring shaft is rotatably connected into the mixing box around a vertical shaft, a plurality of stirring rods are fixedly arranged on the circumferential face of the stirring shaft, a heating cavity is formed in each stirring rod, and a heating rod is fixedly installed in each heating cavity. A smashing device is fixedly arranged at the top of the mixing box, and a vibration screening device is arranged below the smashing device. A collecting disc is arranged below the vibration screening device and can collect screened ingredients, a first hopper is arranged below a discharging port of the collecting disc, the first hopper is fixedly arranged at the top of the mixing box and is communicated with the mixing box, and a third heating device is fixedly arranged on the outer surface of the first hopper. The heating effect is good, mixing is more uniform, and the finished product quality is guaranteed.

Owner:河北中科同创科技发展有限公司

Mixing equipment for cosmetic production

InactiveCN107096452AEasy to stir and mixWell mixedRotary stirring mixersTransportation and packagingWork periodProcess engineering

The invention relates to mixing equipment for cosmetic production. The mixing equipment comprises a mixing mechanism, wherein the mixing mechanism comprises a mixing assembly and two feeding units, the mixing assembly consists of a second driving shaft and mixing units arranged on two sides of the second driving shaft, each mixing unit comprises a scraper plate and a plurality of mixing paddles, telescopic units are arranged on two sides of each mixing paddle; each telescopic unit consists of a sleeve, a sliding rod, a first coil and a second coil; each feeding unit consists of a shell; a storage box, a first guide pipe, a support rod and an orientation unit are arranged in the shell. According to the mixing equipment for cosmetic production, the angle of a nozzle can be always adjusted through the orientation unit, and raw materials are dispersed and distributed on a mixing cylinder, so that the raw materials can be thoroughly mixed conveniently by the equipment, the working time can be shortened, and the mixing efficiency can be improved; furthermore, the scraper plate is contacted with the inner wall of the mixing cylinder through the telescopic units, so as to scrape the raw materials adhered on the edges and lead the scraped raw materials to be mixed, and therefore, the loss of the raw materials can be decreased, and the practicability of the equipment can be increased.

Owner:泉州惠安长圣生物科技有限公司

Efficient concrete mixing device for municipal construction

ActiveCN108098995AConvenient Efficiency and EffectivenessEasy feedingDischarging apparatusMixing operation control apparatusImpellerWater pipe

The invention discloses an efficient concrete mixing device for municipal construction. The device comprises a feeding pipe, a batching tank, a shaking plate, stirring blades, a water storage tank, aspray row, a heater, a discharging pipe, a revolving drum and overturning scrapers, wherein the feeding pipe is arranged at the top end of the batching tank; one side of the shaking plate is hinged with the side wall of the top end of the batching tank; the water storage tank is arranged at the top end of the batching tank; a water pipe is arranged on the water storage tank; the spray row is arranged at an outlet end of the water pipe; a stirring motor is arranged on the side wall of the batching tank; the stirring blades are arranged on a rotating shaft; a screw impeller winds around the outer wall of the rotating shaft; one side of an inclined guide plate is hinged with the inner wall of the bottom end of the batching tank; the discharging pipe is arranged on the side wall of the batching tank; the heater is arranged on the inner wall of the bottom end of the batching tank; the revolving drum is arranged in the batching tank; the overturning scrapers are arranged on the external wallof the revolving drum. According to the efficient concrete mixing device for municipal construction, an appropriate ratio of concrete is guaranteed, preparation speed of the concrete is increased, preparation effect of the concrete is improved, the concrete is prevented from sticking to the bottom end, discharge of the concrete is accelerated, construction requirements are met, the device is simple in structure and convenient to use, and popularization is facilitated.

Owner:深圳市金鑫华建设集团有限公司

Intelligent high-speed hybrid equipment for multi-functional new material processing

InactiveCN108355525AConvenient control of the progress of the mixing operationEasy to stir and mixRotary stirring mixersTransportation and packagingIntelligent lightingSolenoid valve

The invention provides intelligent high-speed hybrid equipment for multi-functional new material processing. The intelligent high-speed mixing equipment comprises a fixed base, a supporting column, afeeding hopper, a supporting rod, a supporting frame, a speed measuring hybrid stirring rod structure, a temperature measuring flow guide plate structure, a convenient feeding device, a heating bin structure, an intelligent control cabinet structure, a motor base, a filter screen plate, a discharging pipe, a solenoid valve, a telescopic pole, a hybrid kettle, a hoisting ring, a protective kettle lid and an observation mirror tube. The intelligent high-speed mixing equipment provided by the invention has the benefits that through the arrangement of a speed sensor, the rotating speed of a hybridstirring motor is favorably calculated, so that a basis is provided for the mixing speed of a new material, and the mixed operation process is conveniently controlled; through the arrangement of thestirring rod and stirring blades, the new raw material in the hybrid kettle is favorably mixed and stirred; through the arrangement of a rotating auger, the raw material in the feed hopper is favorably conveyed to the mixed kettle, so that the manual feeding time is saved, the functions of the hybrid equipment are increased, and the labor efficiency is improved.

Owner:无棣县棣棠花服装加工厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com