Modified asphalt master batch and preparing method and application thereof

A modified asphalt and masterbatch technology, which is applied in the field of its preparation and modified asphalt masterbatch, can solve the problems of reducing the performance of SBS modified asphalt, complex production process, uneven quality, etc., and achieve good asphalt compatibility, The production process is simple and the quality is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The method for preparing the above-mentioned modified asphalt masterbatch of the present application comprises adding 40-60 parts of EVA, 5-15 parts of polyethylene, 3-5 parts of stearic acid and 5-10 parts of organic compounds by weight in a high-speed mixer. Wax to form evenly mixed fine particles; add 10-20 parts of aromatic hydrocarbon extraction oil and 2-5 parts of plasticizer, mix evenly, so that a layer of liquid film is attached to the surface of the particles; add 5-10 parts of rubber powder, 2-4 parts of Nanoparticles and 0.1-0.5 parts of antioxidant are mixed evenly, so that the powder is attached to the surface of the particles as much as possible, and the sum of the weight percentages of the above components is 100%; Pellet through a pelletizer.

[0032] For the application of the modified asphalt masterbatch of the present application, by weight percentage, 90-99 parts of base asphalt are heated to 170°C-180°C, 1-10 parts of the above-mentioned modified a...

Embodiment 1

[0036]In the high-speed mixer, firstly add 50 parts of EVA, 10 parts of polyethylene, 10 parts of PE wax and 3 parts of stearic acid according to the weight ratio and mix well. In this embodiment, the content of VA in EVA is 20%, and the poly Ethylene is low-density polyethylene, and then 15 parts of furfural extraction oil and 2 parts of epoxidized soybean oil are added to mix evenly, so that a layer of liquid film is attached to the surface of the particles, and then 7 parts of 50-mesh waste tire rubber powder and 2.5 parts of nano calcium carbonate are added. , 0.5 parts of antioxidant 1010 mixed evenly, so that the powder adheres to the particle surface as much as possible. Finally, the uniformly mixed material is extruded and granulated through a double screw rod, and then diced by a granulator to obtain the modified asphalt masterbatch.

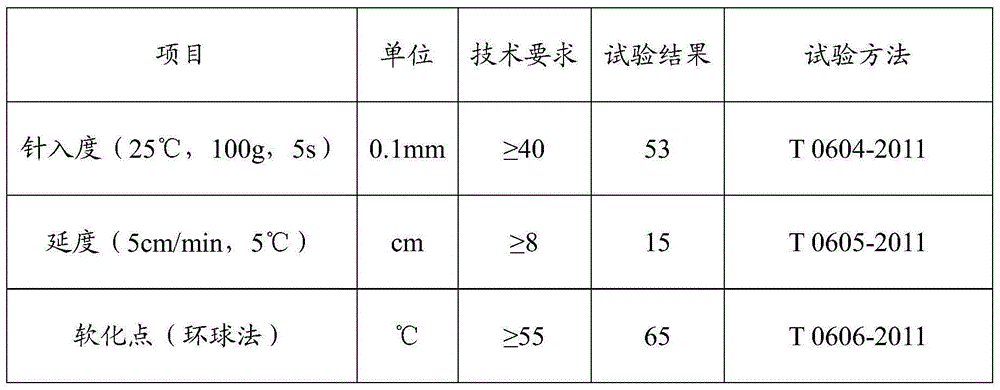

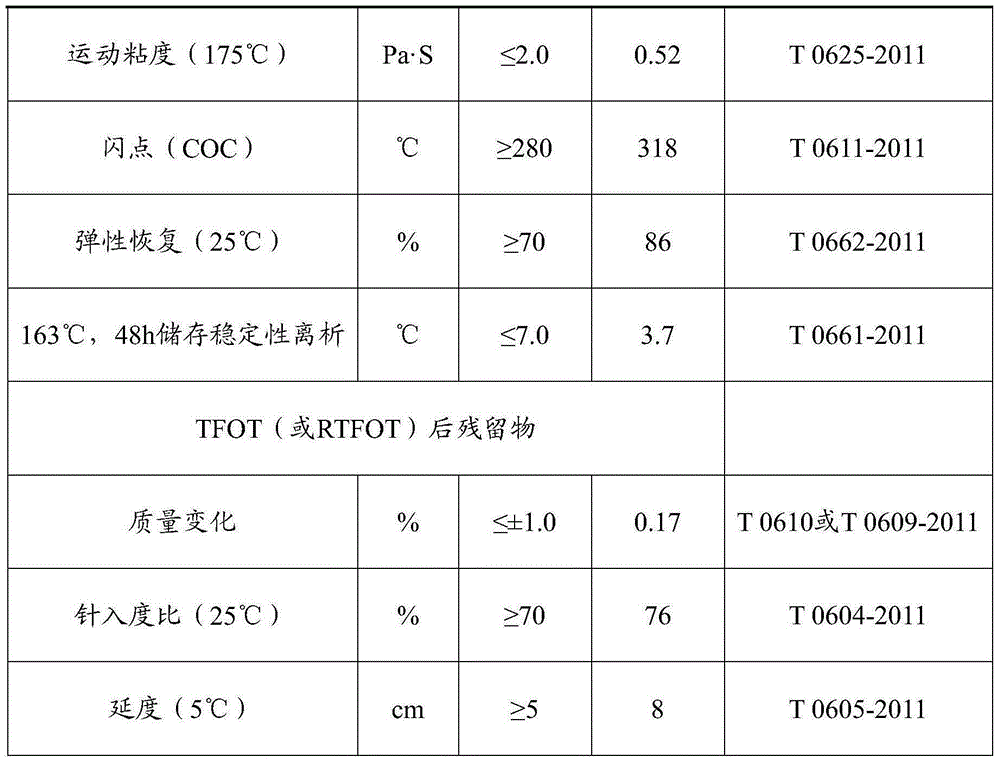

[0037] In the specific application of this embodiment, 5 parts of modified asphalt masterbatch and 95 parts of base asphalt are respec...

Embodiment 2

[0048] In the high-speed mixer, firstly add 60 parts of EVA, 10 parts of polyethylene, 5 parts of 70 parts by weight # Microcrystalline wax and 4 parts of stearic acid are mixed evenly. In this embodiment, the content of VA in EVA is 14%, and polyethylene is low-density polyethylene, and then 10 parts of rubber extraction oil and 3.5 parts of epoxy soybean oil are added to mix. uniform, so that a layer of liquid film is attached to the surface of the particles, and then 5 parts of 40 mesh waste tire rubber powder, 2 parts of nano-titanium dioxide, and 0.5 part of antioxidant 1076 are added and mixed evenly, so that the powder adheres to the surface of the particles as much as possible. Finally, the uniformly mixed material is extruded and granulated through a double screw rod, and then diced by a granulator to obtain the modified asphalt masterbatch.

[0049] In the specific application of this embodiment, 5 parts of modified asphalt masterbatch and 95 parts of base asphalt ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com