Patents

Literature

88results about How to "High kinematic viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

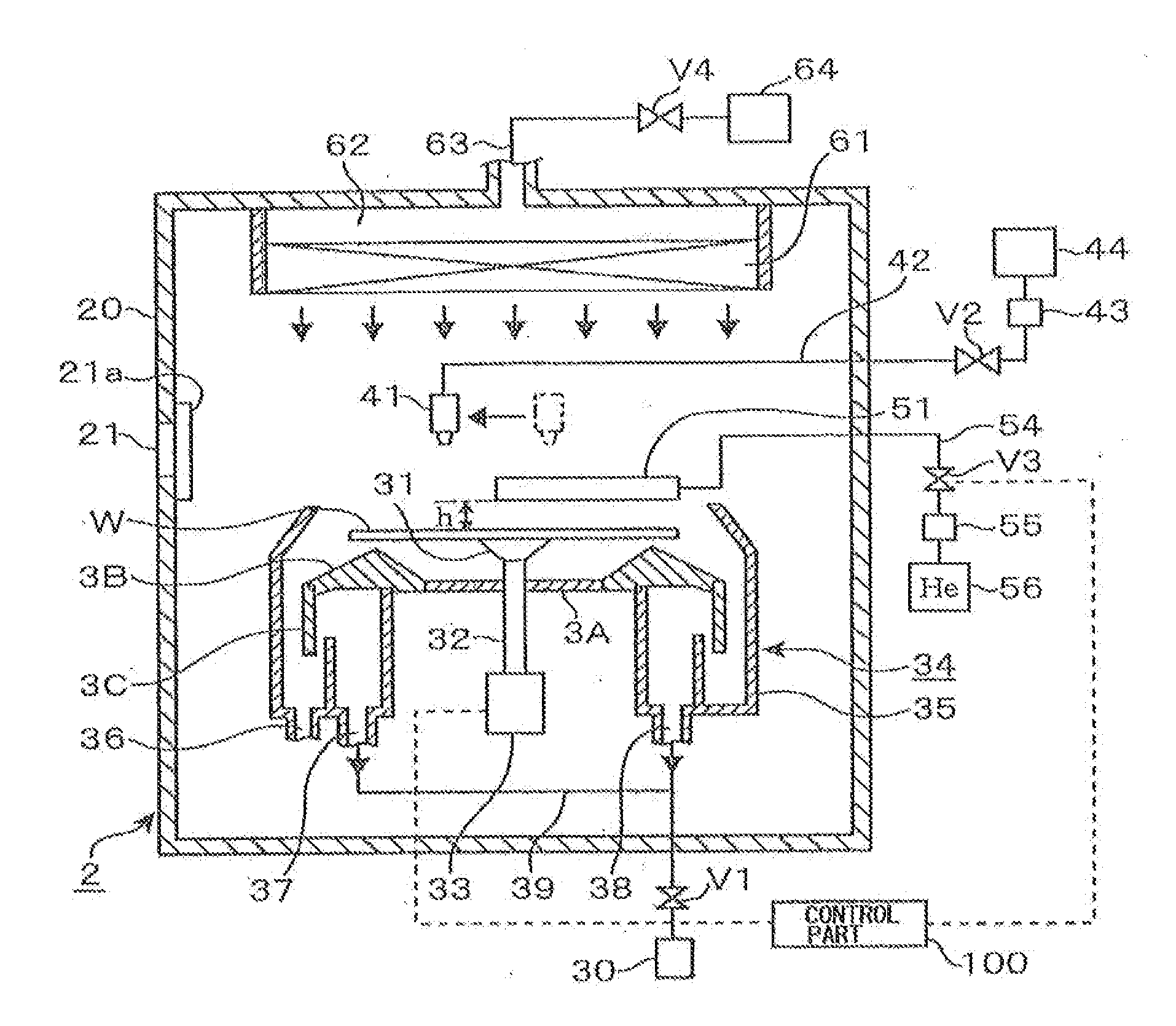

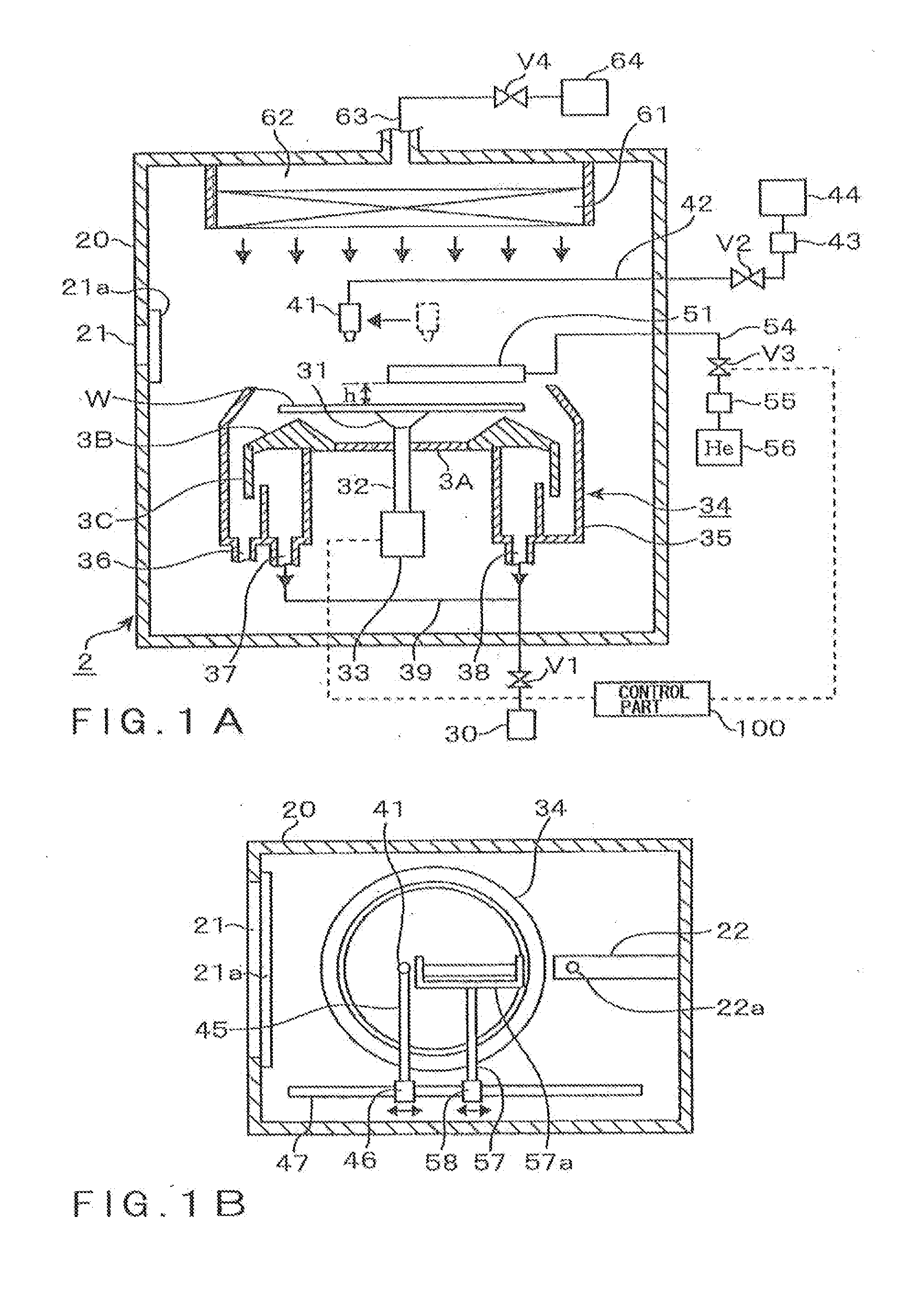

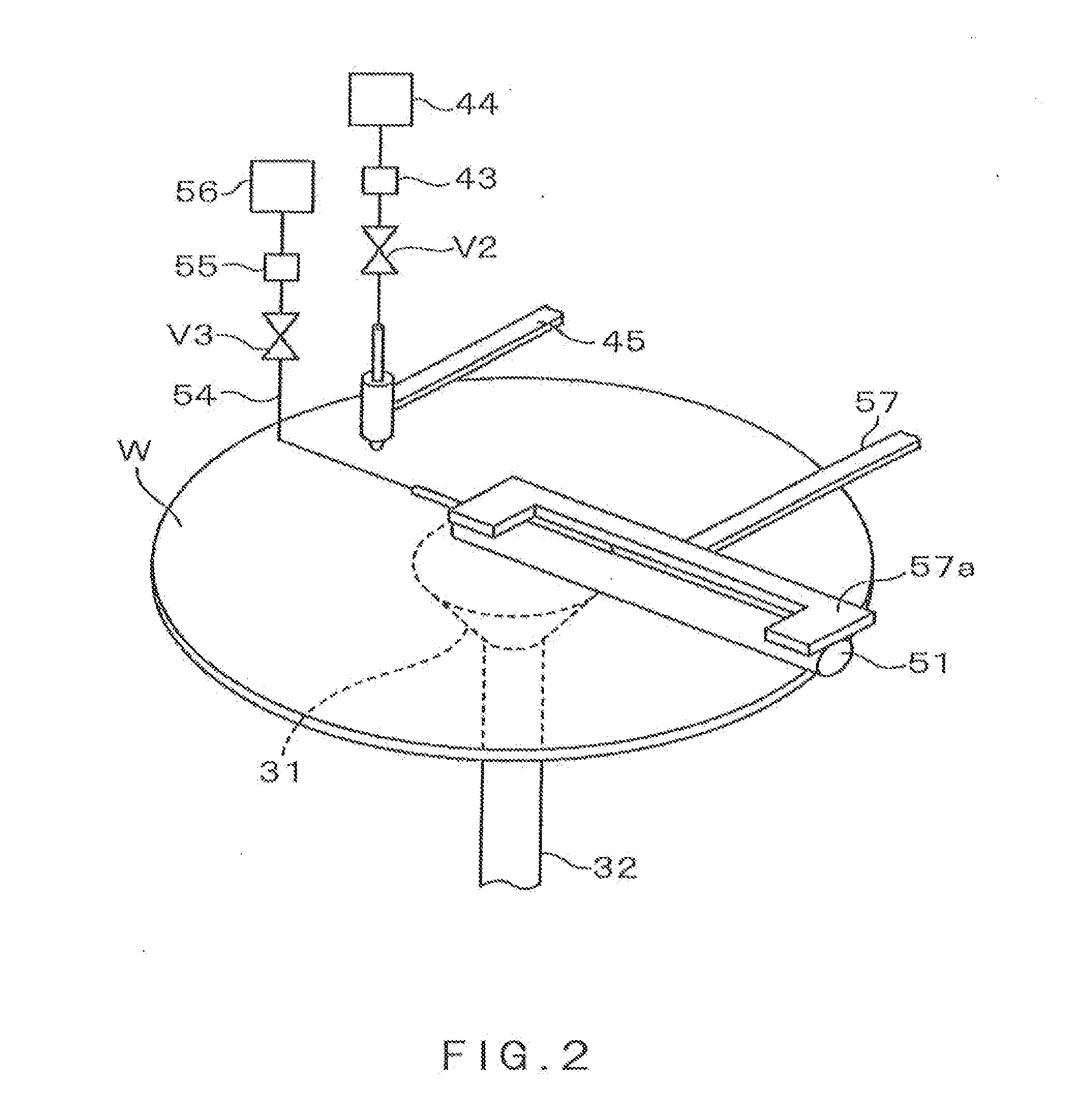

Coating Apparatus and Coating Method

InactiveUS20090162547A1Inhibition is effectiveEfficient solutionSpraying apparatusPhotomechanical apparatusForming gasSpray nozzle

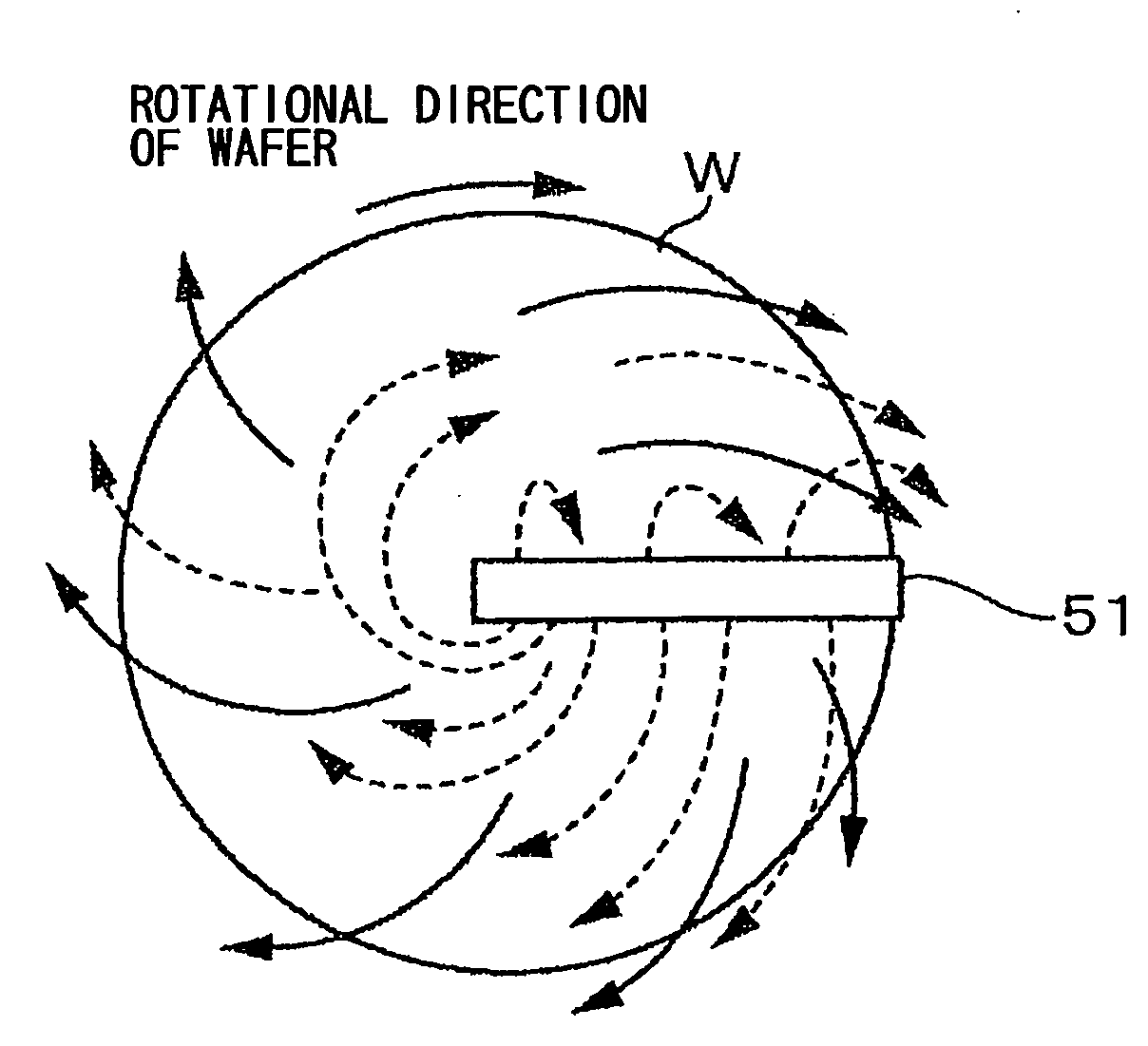

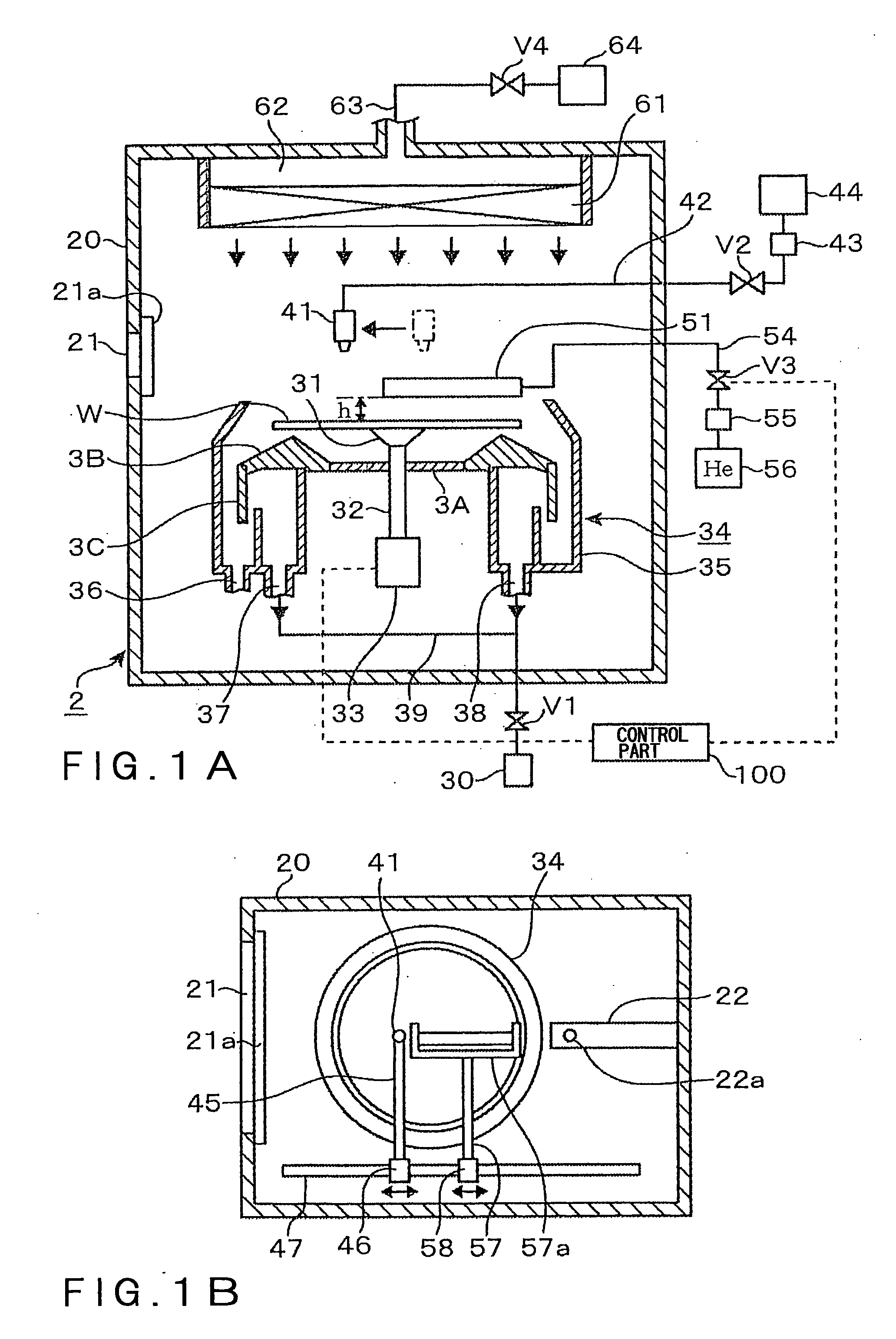

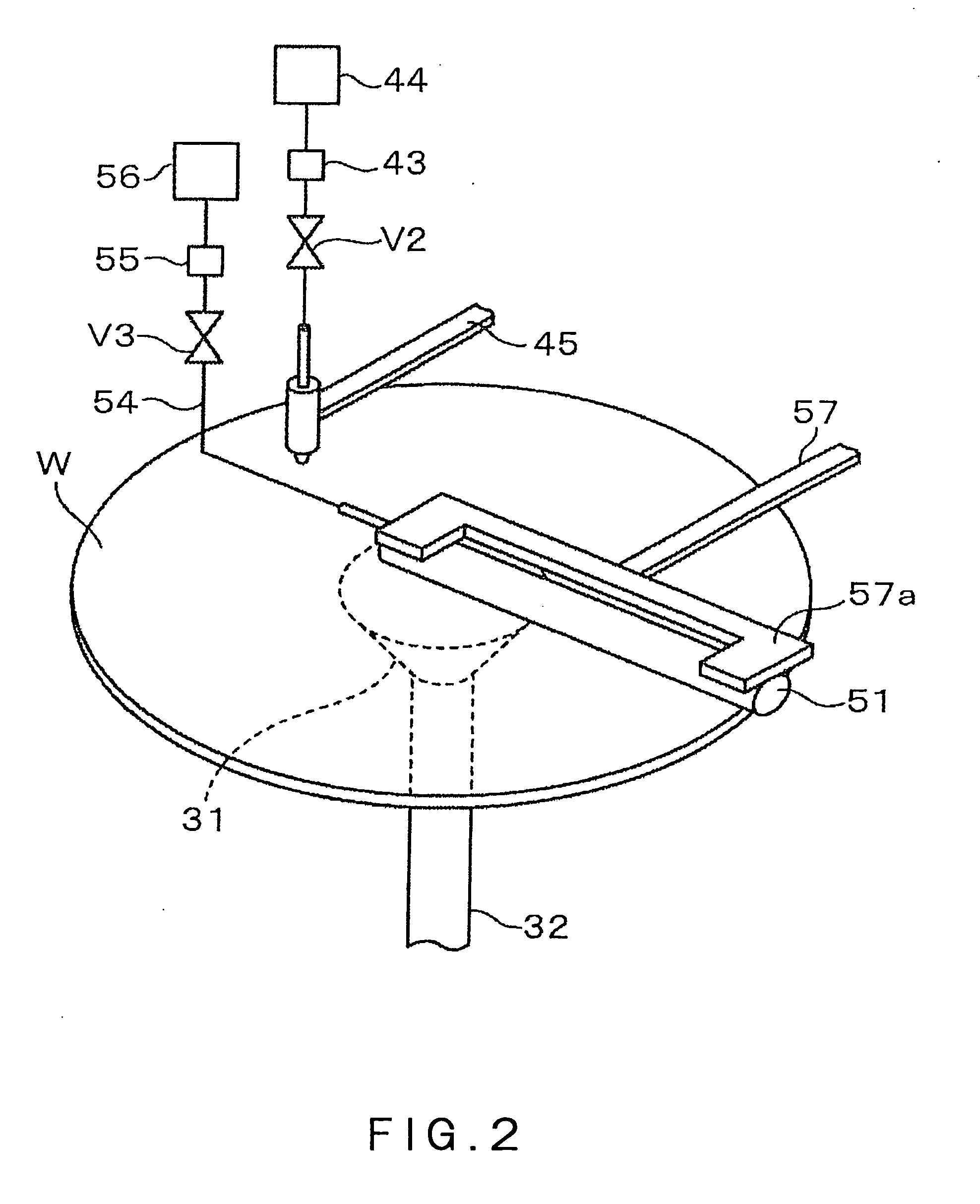

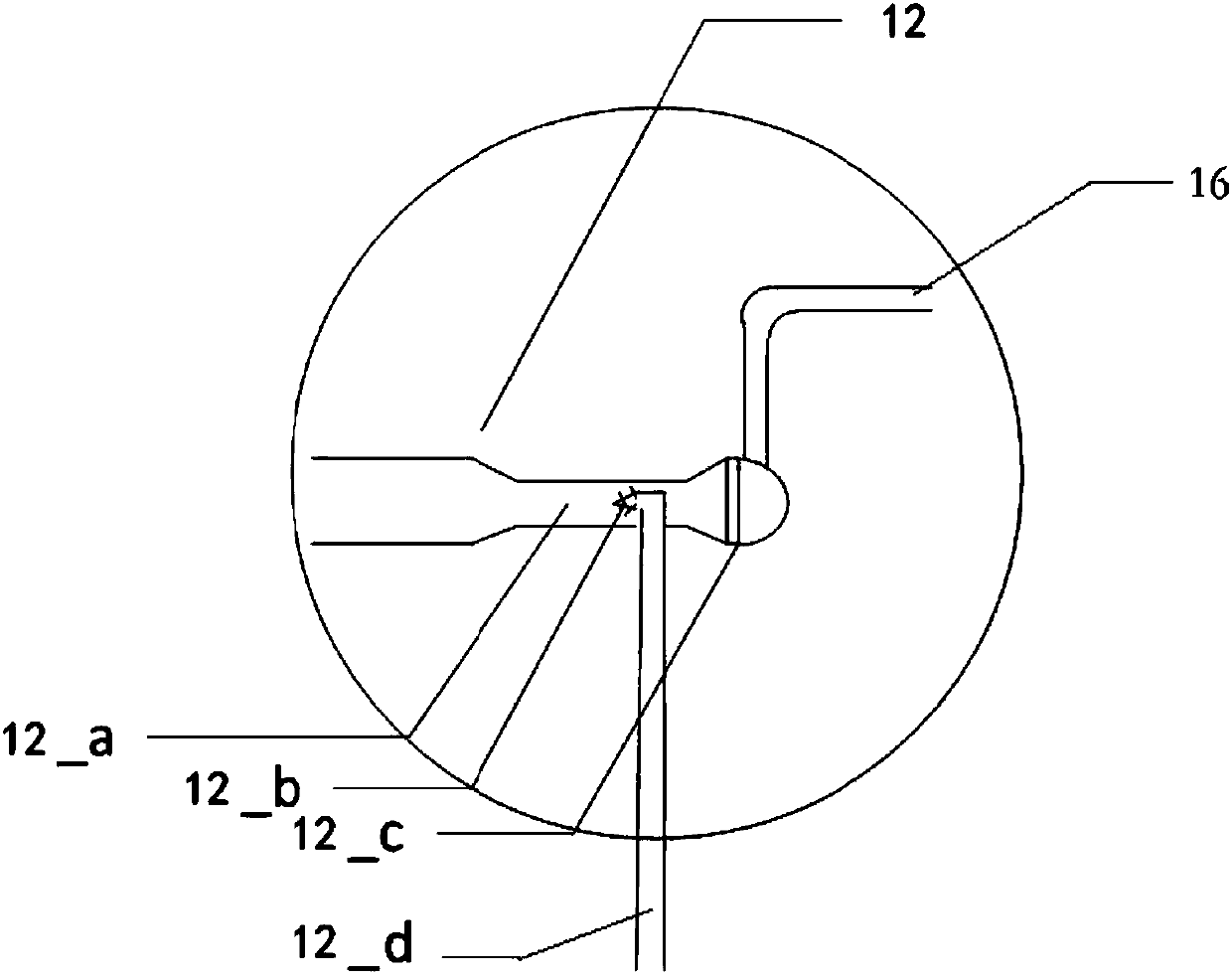

The invention is a coating apparatus including: a substrate-holding part that holds a substrate horizontally; a chemical nozzle that supplies a chemical to a central portion of the substrate horizontally held by the substrate-holding part; a rotation mechanism that causes the substrate-holding part to rotate in order to spread out the chemical on a surface of the substrate by a centrifugal force, for coating the whole surface with the chemical; a gas-flow-forming unit that forms a down flow of an atmospheric gas on the surface of the substrate horizontally held by the substrate-holding part; a gas-discharging unit that discharges an atmosphere around the substrate; and a gas nozzle that supplies a laminar-flow-forming gas to the surface of the substrate, the laminar-flow-forming gas having a coefficient of kinematic viscosity larger than that of the atmospheric gas; wherein the atmospheric gas or the laminar-flow-forming gas are supplied to the central portion of the substrate.

Owner:TOKYO ELECTRON LTD

Synthetic fibers and cementitious systems including same

InactiveUS20060188719A1Superior basic hydrolysis resistanceReduce cohesionConstruction materialYarnCement compositesCementitious composite

Owner:SELIVANSKY DROR

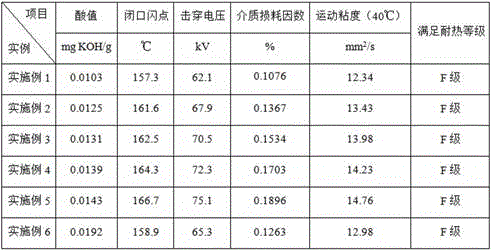

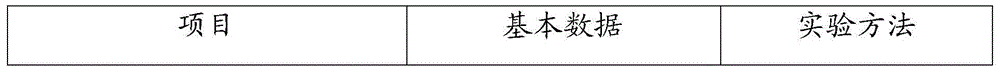

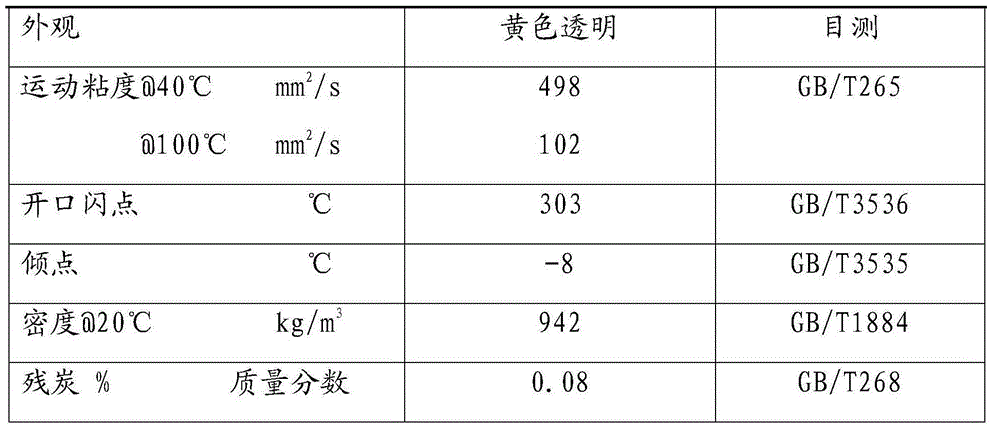

High-overload transformer oil and preparation process thereof

ActiveCN106635246AIncrease the breakdown voltage valueImprove overload capacityBase-materialsTransformer oilUltrasonic oscillation

The invention belongs to the technical field of insulating oil for power transformers with high overload capacity, and particularly relates to high-overload transformer oil and a preparation process thereof. The high-overload transformer oil is prepared from natural ester insulating oil and mineral insulating oil according to the volume percentage of (40%-50%):(60%-43%). The preparation process comprises the following steps: firstly, heating the natural ester insulating oil to 80 to 95 DEG C under a vacuum stirring condition; then under a vacuum condition, adding the mineral insulating oil into the natural ester insulating oil, and carrying out mechanical stirring and then ultrasonic oscillation; finally, carrying out two-stage vacuum filtering treatment on treated transformer oil, wherein the closed-cup flash point of a treated oil product is greater than or equal to 155 DEG C. The transformer oil disclosed by the invention is high in physical, chemical and electrical properties, low in kinematic viscosity, high in flowability and long in service life; the transformer with high overload capacity is high in overload capacity; faults of the transformer are reduced, and the problem of 'load returning' is effectively solved; the safety stability of the transformer is improved; the high-overload transformer oil has a high popularization and application value.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Synthetic fibers and cementitious systems including same

InactiveUS7045209B1Reduces degree of crackReduce slumpConstruction materialSynthetic resin layered productsSynthetic fiberCement composites

The present invention discloses novel fibers for use as secondary reinforcement materials in cementitious composites, which fibers are effective in preventing cracking far better than prior art fibers. Also disclosed are methods of producing the fibers and methods for producing cementitious composite containing the fibers.

Owner:SELIVANSKY DROR

Butenedioic acid resin, preparation method thereof, and preparation of aluminum-casted crystallizer demoulding oil therewith

The invention provides butenedioic acid resin, a preparation method thereof, and preparation of a degradable micro-scale lubricant therewith. The butenedioic acid resin is characterized by being prepared from following raw materials: butenedioic acid or butenedioic acid anhydride and fatty alcohol, wherein the molar ratio of the butenedioic acid or the butenedioic acid anhydride to the fatty alcohol is 1:1.9-2. Raw materials for preparing aluminum-casted crystallizer demoulding oil include the butenedioic acid resin. The aluminum-casted crystallizer demoulding oil is stable, is uniform in dispersion and is low in kinematic viscosity.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

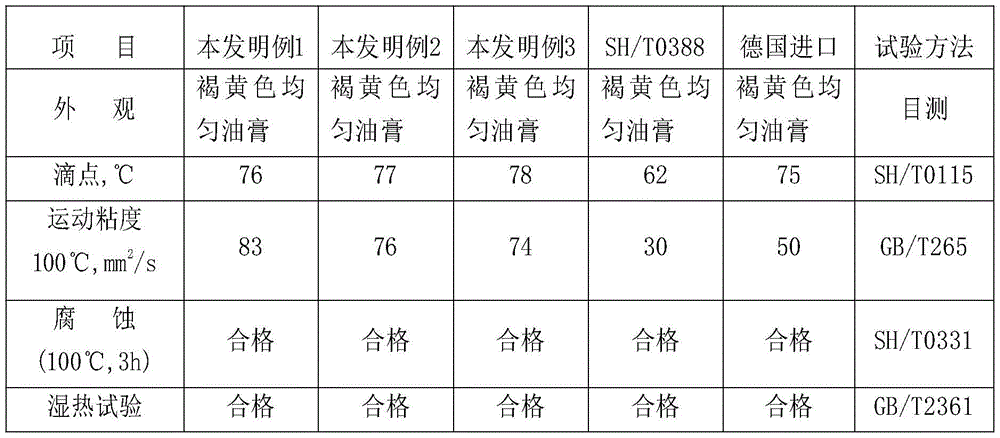

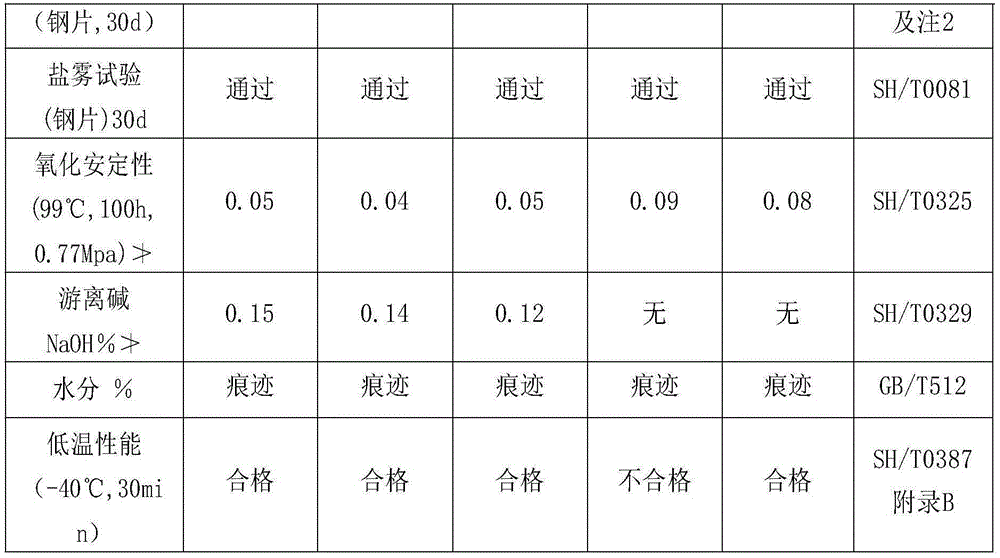

Lubricating grease for changing anti-rust effect

InactiveCN102453593AHigh kinematic viscosityImprove rust resistanceLubricant compositionLithium soapMetallurgy

The invention relates to lubricating grease for changing the anti-rust effect. The lubricating grease comprises lithium soap thickening agents, base oil, antioxidants, anti-rust agents and viscosifiers and solves the problems that steel and iron are easy to rust under special conditions, and thus equipment can not be used and the resources are wasted. The lubricating grease has the beneficial effect the anti-rust effect of the lubricating grease is improved through improving the kinematic viscosity of the base oil and adding the proper antioxidants, anti-rust agents and viscosifiers to the lubricating grease. Through the damp heat test and the salt spray test in the lubricating analysis evaluation, the anti-rust effect in the evaluation results is greatly improved through being compared with the anti-rust effect of the ordinary lubricating grease. After the actual use, the equipment can still maintain a good state under the influence of external oxygen, water and acid media.

Owner:WUXI FEITIAN GREASE

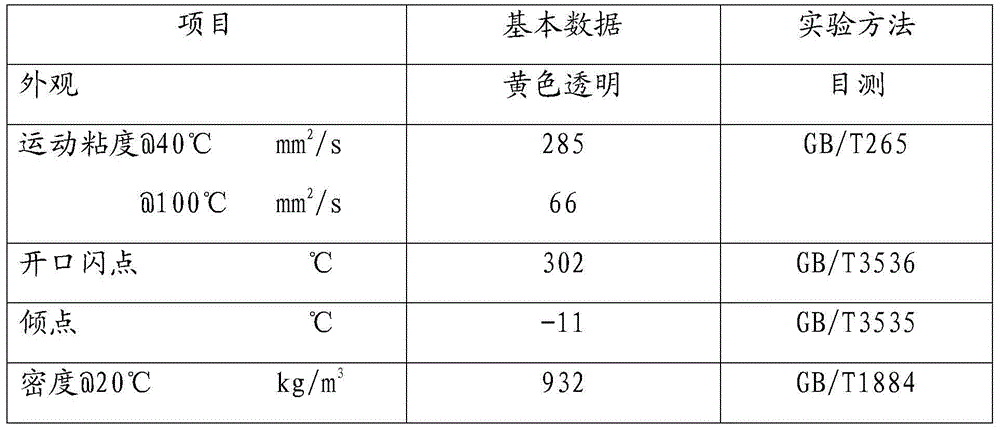

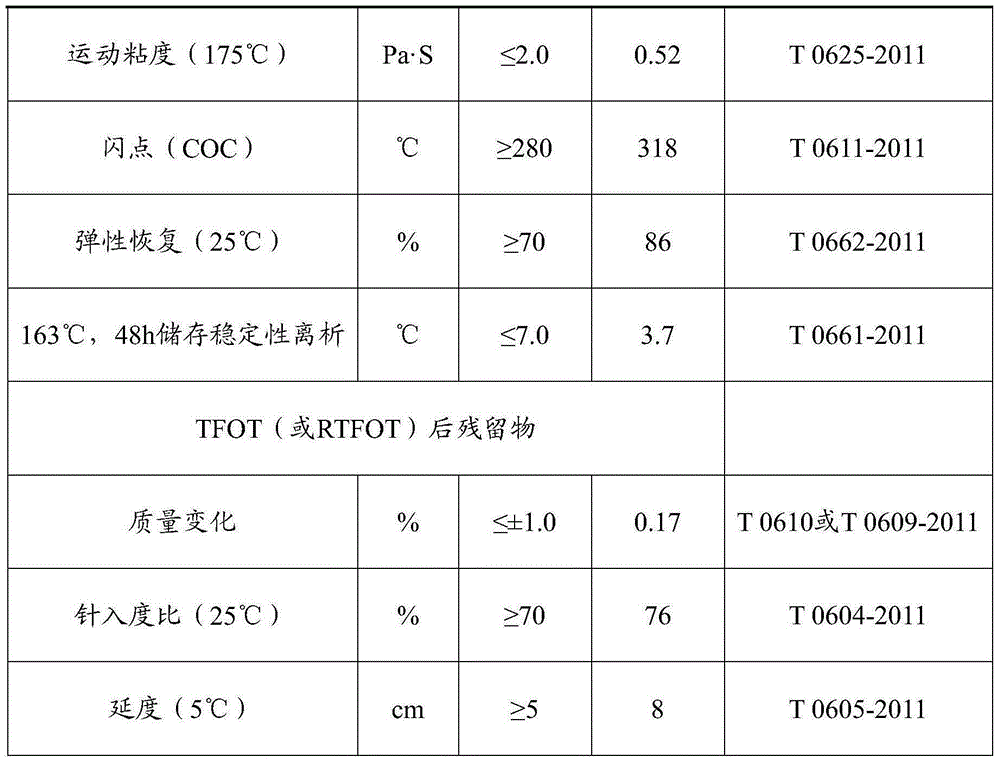

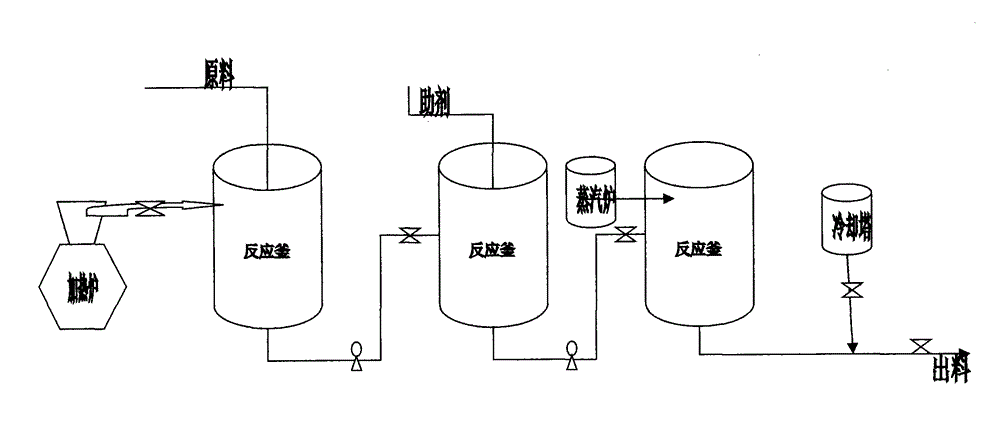

Modified asphalt master batch and preparing method and application thereof

The invention relates to the technical field of modified asphalt and particularly provides a modified asphalt master batch. The modified asphalt master batch is prepared from, by weight, 40-60 parts of EVA, 10-20 parts of extract oil of aromatic hydrocarbon, 5-10 parts of rubber powder, 5-10 parts of organic wax, 5-15 parts of polyethylene, 3-5 parts of stearic acid, 2-5 parts of plasticizer, 2-4 parts of nano-particle and 0.1-0.5 part of antioxidant. The invention further provides a preparing method and application of the modified asphalt master batch. According to the modified asphalt master batch, asphalt is modified by organically combining the EVA, the rubber powder, the organic wax, the nano-particles and other raw materials, the high-low temperature performance and stability of the asphalt can be remarkably improved, separation of the asphalt in the use process can be effectively relieved through the good compatibility with the asphalt, and the good modified effect is achieved; the production process is simple, use is convenient, and quick and large-scale production of modification of the asphalt can be achieved.

Owner:SUZHOU TOPOLINE TECH

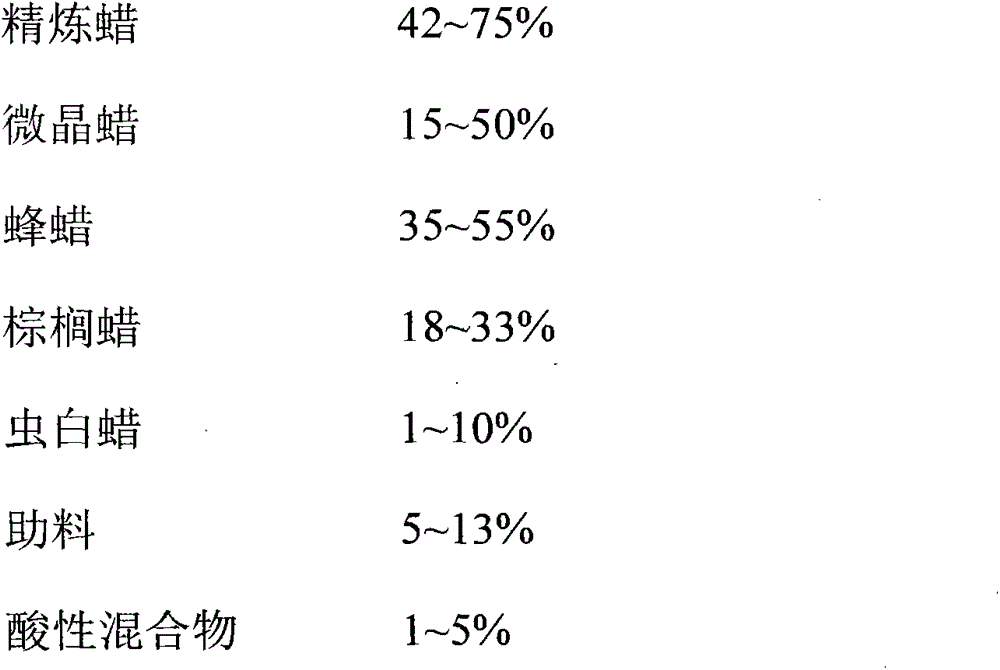

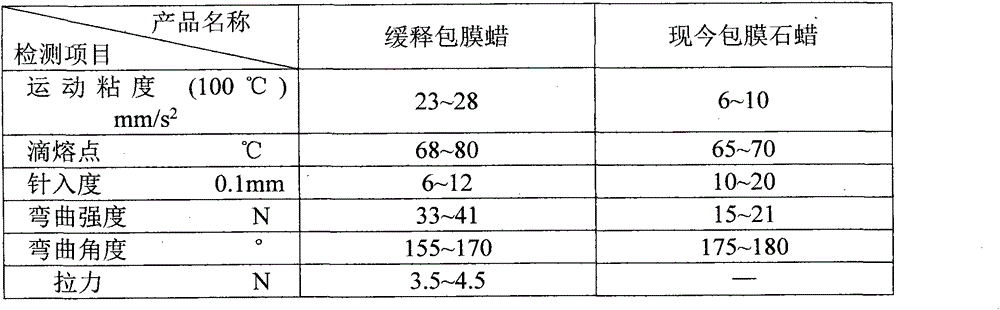

Slow release coated wax of efficient slow release composite fertilizer

InactiveCN104003784AAdjustable and controllable drop melting pointNo damage to technical indicatorsFertilizer mixturesMicrocrystalline waxUltimate tensile strength

The invention relates to a slow release coated wax of an efficient slow release composite fertilizer. The slow release coated wax of an efficient slow release composite fertilizer is glistened particles, and is prepared through a reaction of main raw materials comprising 42-75wt% of refined wax, 15-50wt% of microcrystalline wax, 35-55wt% of beeswax, 18-33wt% of palm wax and 1-10wt% of Chinese insect wax, and substances comprising an additive, an assistant, a biodegradation promotion substance, an acidic mixture and an organic material at 95-105DEG C for 20-40min. The slow release coated wax of an efficient slow release composite fertilizer has the advantages of simple preparation, wide raw material sources, good toughness and strength, good slow release effect in soil, neutralization of alkaline soil, and no pollution to the environment.

Owner:DALIAN NINGHUA MICROCRYSTALLINE WAX CHEM

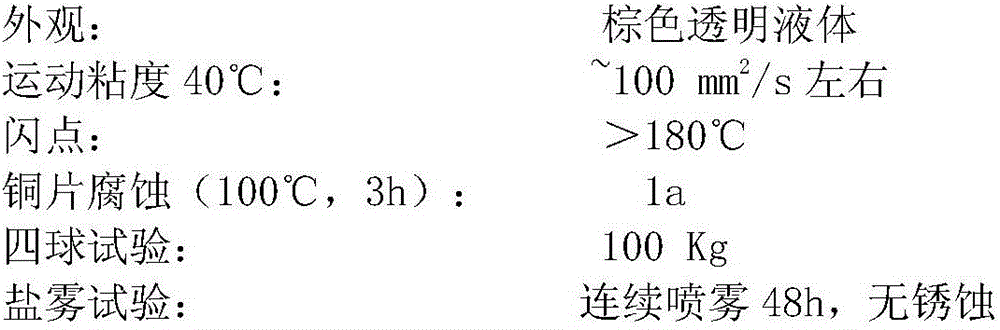

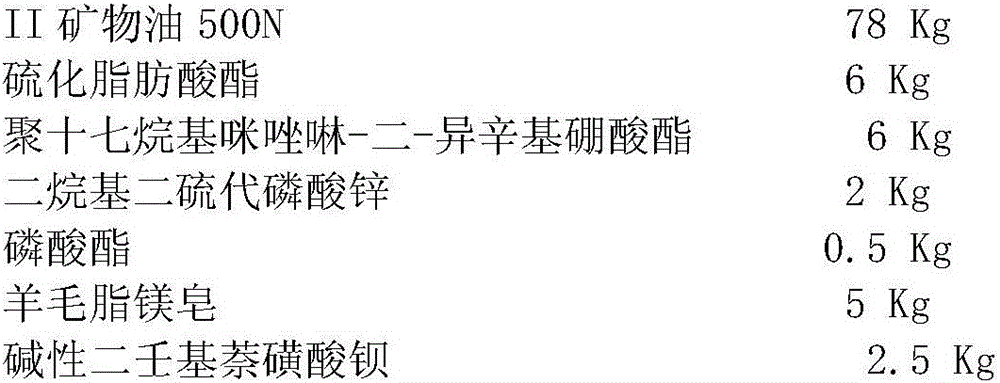

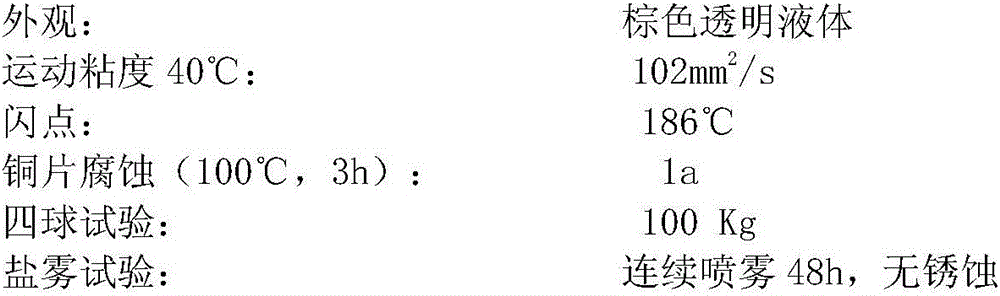

High-performance punching oil used for thick plate

The invention discloses high-performance punching oil used for a thick plate, belongs to the field of metal processing operating fluid, and particularly relates to operating fluid for metal stamping processing. The high-performance punching oil comprises, by mass, 60%-80% of refined mineral oil, 5%-10% of a sulfur-containing extreme pressure agent, 5%-15% of a macromolecule polymerization ester extreme pressure agent, 0.5%-5% of an antiwear agent and 5%-10% of an antirust agent. One of sulfide aliphatic acid ester and over-based sulfosalt or a mixture of the sulfide aliphatic acid ester and the over-based sulfosalt is selected as the sulfur-containing extreme pressure agent. Polyheptadecylimidazoline-di-isooctyl borate is selected as the macromolecule polymerization ester extreme pressure agent. According to the high-performance punching oil, under the synergistic effect of the macromolecule polymerization ester extreme pressure agent and the sulfur-containing extreme pressure agent, excellent lubricating performance and anti-corrosion performance can be given to the punching oil, and the high-performance punching requirements for the thick plate are met. Moreover, the rusting problem of punched products and the ecological environment problem are solved without chlorinated paraffin.

Owner:BOER TECH WUHAN

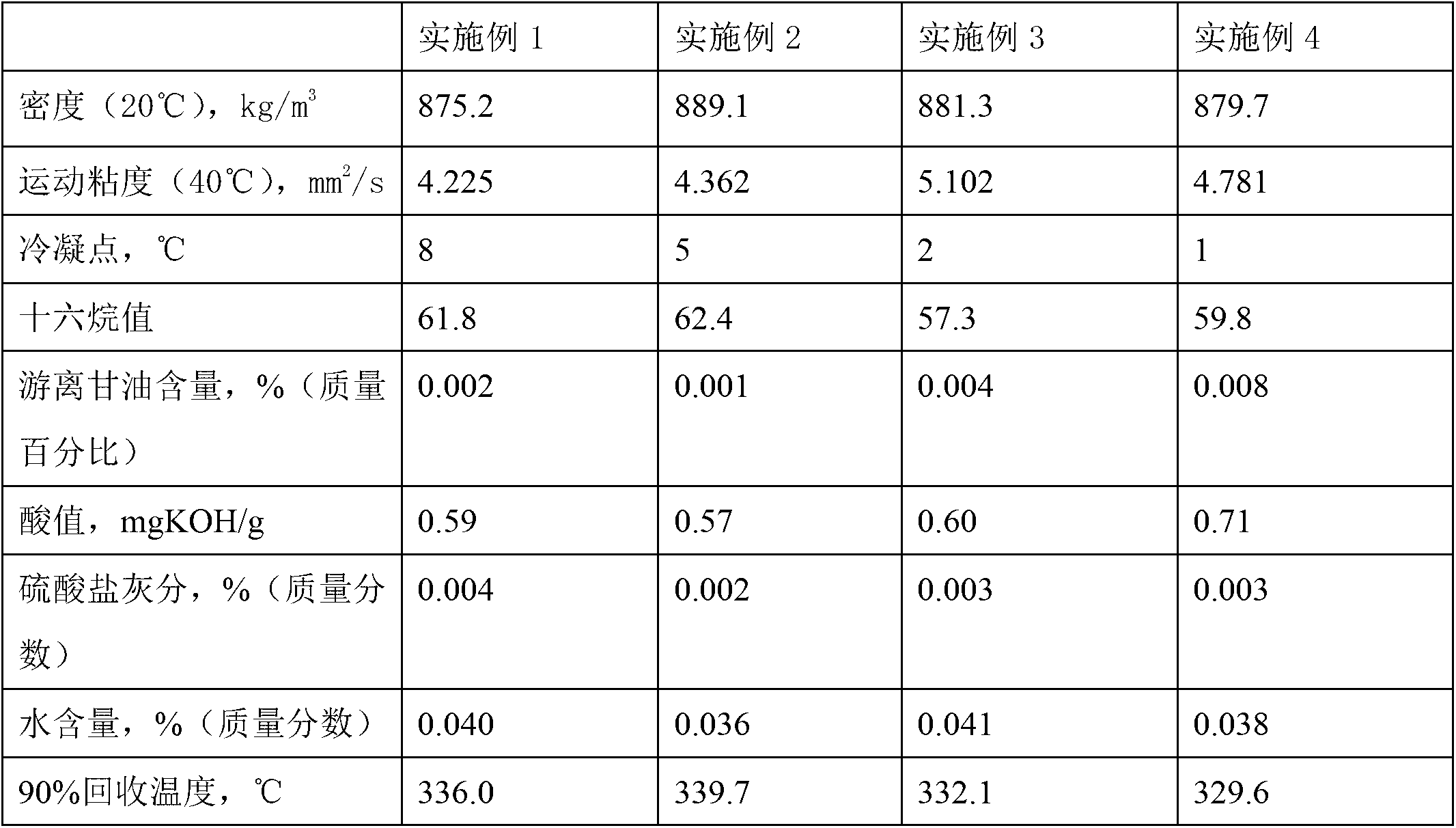

Biodiesel with low temperature liquidity and preparation method of biodiesel

InactiveCN103834446AGood fluidity at low temperatureGood pour point depressing effectBiofuelsLiquid carbonaceous fuelsProcess engineeringOxidation stability

The invention discloses a biodiesel with low temperature liquidity and a preparation method of the biodiesel. The biodiesel with low temperature liquidity comprises 2.5-30 percent by volume of direct coal liquefaction hydro-upgraded modified full-fraction oil and 70-97.5 percent by volume of illegal cooling oil biodiesel. The preparation method of the biodiesel comprises the step: after mixing the illegal cooking oil biodiesel and the direct coal liquefaction hydro-upgraded modified full-fraction oil, and standing for 8-12 hours to obtain the biodiesel with low-temperature liquidity. According to the biodiesel with low temperature liquidity, the pour point, the cloud point, the flash point, the kinematic viscosity, the oxidation stability, the heat value, the density and the acid value of mixed oil are detected according to the GB_T20828-2007, and accord with relevant requirements of EN14214 and ASTMD6751 for the technical performance of the biodiesel through detection. Compared with the illegal cooking oil biodiesel, the biodiesel has the advantages that the cloud point is reduced by 1-8 DEG C, the pour point is reduced by 2-10 DEG C, namely, the low temperature liquidity is remarkably improved, and the preparation method is simple and effective.

Owner:SHANGHAI APPLIED TECHNOLOGIES COLLEGE

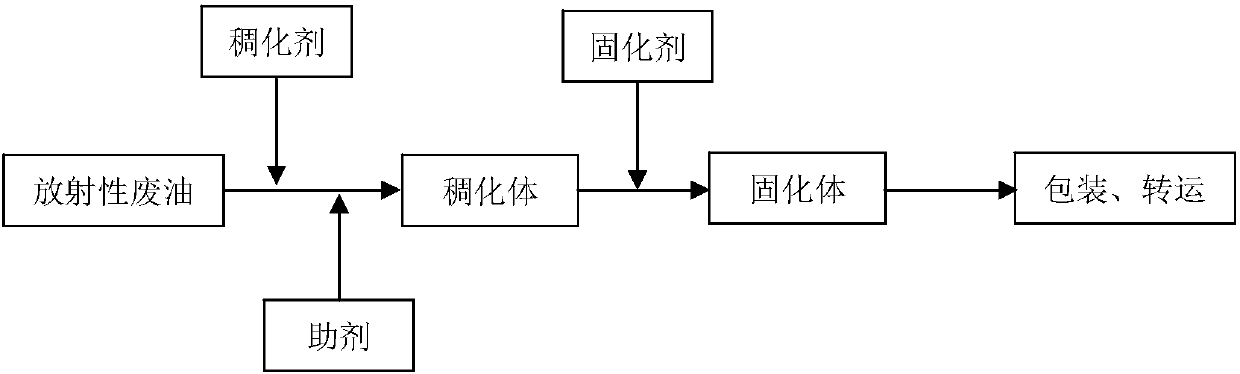

Composite treatment method of radioactive waste oil

ActiveCN107910091AOptimize the addition ratioRaise the ratioRadioactive decontaminationRoom temperatureEngineering

The invention relates to a composite treatment method of radioactive waste oil. The method sequentially includes the steps that 1, at the room temperature, a thickening agent is added into the waste oil during stirring, and even stirring continues to obtain a first material; 2, an addition agent is added into the first material during stirring, and even stirring continues to obtain a second material; 3, a curing agent is added into the second material during stirring, and even stirring continues to obtain a cured product. The method can be completed at the room temperature and has good compatibility with different waste oils or waste liquids, the obtained cured body is low in oil penetration rate, has certain strength and is easy to recycle after scattering and good for transportation, andthe cured body is combustible, so that subsequent incineration treatment is convenient.

Owner:BEIJING UNIV OF CHEM TECH +1

Immersion liquid for water-immersion microscopy

ActiveUS7285231B2Exact matchEliminate disadvantagesOther chemical processesMicroscopesWater immersionRefractive index

An immersion liquid for microscopy using water immersion objectives has a refractive index in the range from 1.25 to 1.4 and a kinematic viscosity of greater than 20 mm2 / s at 20° C.

Owner:CARL-ZEISS-STIFTUNG TRADING AS CARL ZEISS

Poly-alpha-olefin base oil and preparation method thereof

ActiveCN111019734AHigh oligomerization reactivityIncrease chlorine contentPhysical/chemical process catalystsHydrocarbonsPolyolefinPtru catalyst

The invention relates to a preparation method of poly-alpha-olefin base oil. The method comprises the following steps: S1, catalyzing an oligomerization reaction of an alpha-olefin mixture for 3-8 hours by using a Cr-AlCl3 / Al2O3 immobilized catalyst at a temperature of 50-120 DEG C under a pressure of 0.1-1.0 MPa and an alpha-olefin / solvent volume ratio of (1:0)-(1:1); and S2, after the reaction is stopped, filtering the catalyst, washing with distilled water, carrying out atmospheric distillation to remove the solvent, carrying out reduced pressure distillation to remove the unreacted alpha-olefin and part of the alpha-olefin dimer, and carrying out hydrogenation to obtain the poly-alpha-olefin base oil. The invention also relates to the poly-alpha-olefin base oil prepared by the method.The PAO base oil prepared by the method does not need to be mixed with low-viscosity PAO oil for PAO with a kinematic viscosity range of 30-40 mm<2> / s at 100 DEG C, so that the volatility of lubricating oil can be greatly reduced.

Owner:PETROCHINA CO LTD

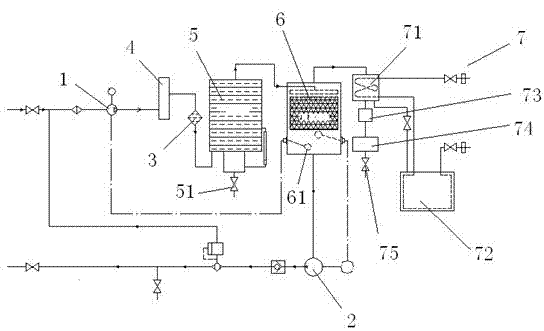

Reusable lubricating oil filtering device

InactiveCN102824760AEfficient removalHigh kinematic viscosityNon-miscible liquid separationLubricant compositionWater circulationOil water

The invention discloses a reusable lubricating oil filtering device which comprises an oil feed pump, an oil drain pump, an infrared heater, an oil-water separator, a vacuum stereoscopic separating tank and a water circulating condensation separation device, wherein the oil-water separator is connected with the oil feed pump through the infrared heater; a coarse filter is arranged between the oil-water separator and the infrared heater; the upper end of the vacuum stereoscopic separating tank is connected with the oil-water separator and the water circulating condensation separation device; and the lower end of the vacuum stereoscopic separating tank is connected with the oil drain pump. The reusable lubricating oil filtering device disclosed by the invention can be used for carrying out dewatering and impurity removal on oil products seriously containing water or muddy emulsive oil products, improving the kinematical viscosity, flash point and demulsibility of the oil products, lowering the oil consumption cost and reducing the equipment failure rate.

Owner:NANJING IRON & STEEL CO LTD

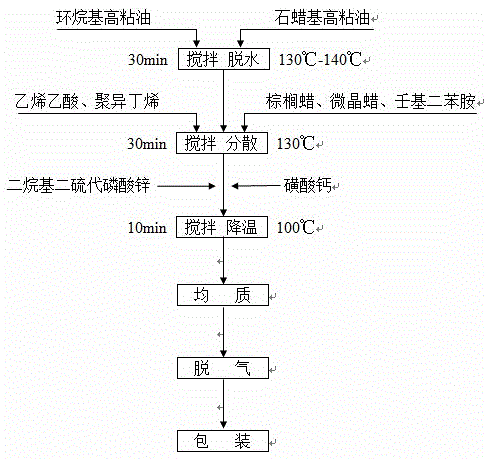

Long-acting wire rope hemp core grease

InactiveCN105542924AGood compatibilityHigh melting point (dropping point)Textile cablesLubricant compositionParaffin waxMicrocrystalline wax

The invention relates to a long-acting wire rope hemp core grease. The long-acting wire rope hemp core grease comprises 13-17wt% of palm wax, 16-19wt% of microcrystalline wax, 15-19wt% of naphthenic high-viscosity oil, 24-28wt% of paraffinic high-viscosity oil, 1.6-4.6wt% of zinc dialkyl dithiophosphate, 1.4-4.4wt% of nonyldiphenylamine, 4.5-8.5wt% of vinylacetic acid, 8.5-12.5wt% of polyisobutylene and 0.1-1wt% of calcium sulfonate. Compared with hemp core greases in the prior art, the long-acting wire rope hemp core grease has the advantages of high dropping point, no flowing in hot weather, fast online solidification after rope immersion, no loss, energy saving, no pollution to environment, large kinematic viscosity data, good adhesiveness, and realization of good fluidity and no flowing of a grease film in the motion and compressed processes. Prominently, the property of traditional hemp core greases (including imported hemp core greases) is changed to become weakly alkaline (the free base value is not greater than 0.15, NaOH%), so oxidation is effectively inhibited, generated free acids are neutralized, SH / T0325 oxidation stability test and SH / T0331 corrosion test are extremely well passed, the safe service life of a wire rope is effectively prolonged, and use environment is purified.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Coating apparatus and coating method

InactiveUS20130011555A1Improve the overall coefficientSimple coating processPhotomechanical apparatusPretreated surfacesForming gasSpray nozzle

Owner:TOKYO ELECTRON LTD

Environment friendly energy conservation diesel oil

InactiveCN101314738AHigh flash pointHigh kinematic viscosityBiofuelsLiquid carbonaceous fuelsLower gradePulp and paper industry

The invention discloses an environment-friendly energy-saving diesel, which contains, by weight, 0<#> or +5<#> diesel 600 to 800 parts, ethanol 200 to 400 parts, water 200 to 400 parts, SA-20 emulsifying agent 1.5 to 2.5 parts, NP-15 emulsifying agent 100 to 200 parts, and animal or plant oleic acid 100 to 200 parts. The environment-friendly energy-saving diesel can be obtained by adding the above materials in a high-pressure vibration kettle and stirring. The environment-friendly energy-saving diesel is synthesized from low-grade diesel and biological materials, thus improving the diesel efficiency and reducing emission of toxic tail gas of vehicles and benefiting to human health.

Owner:高建华

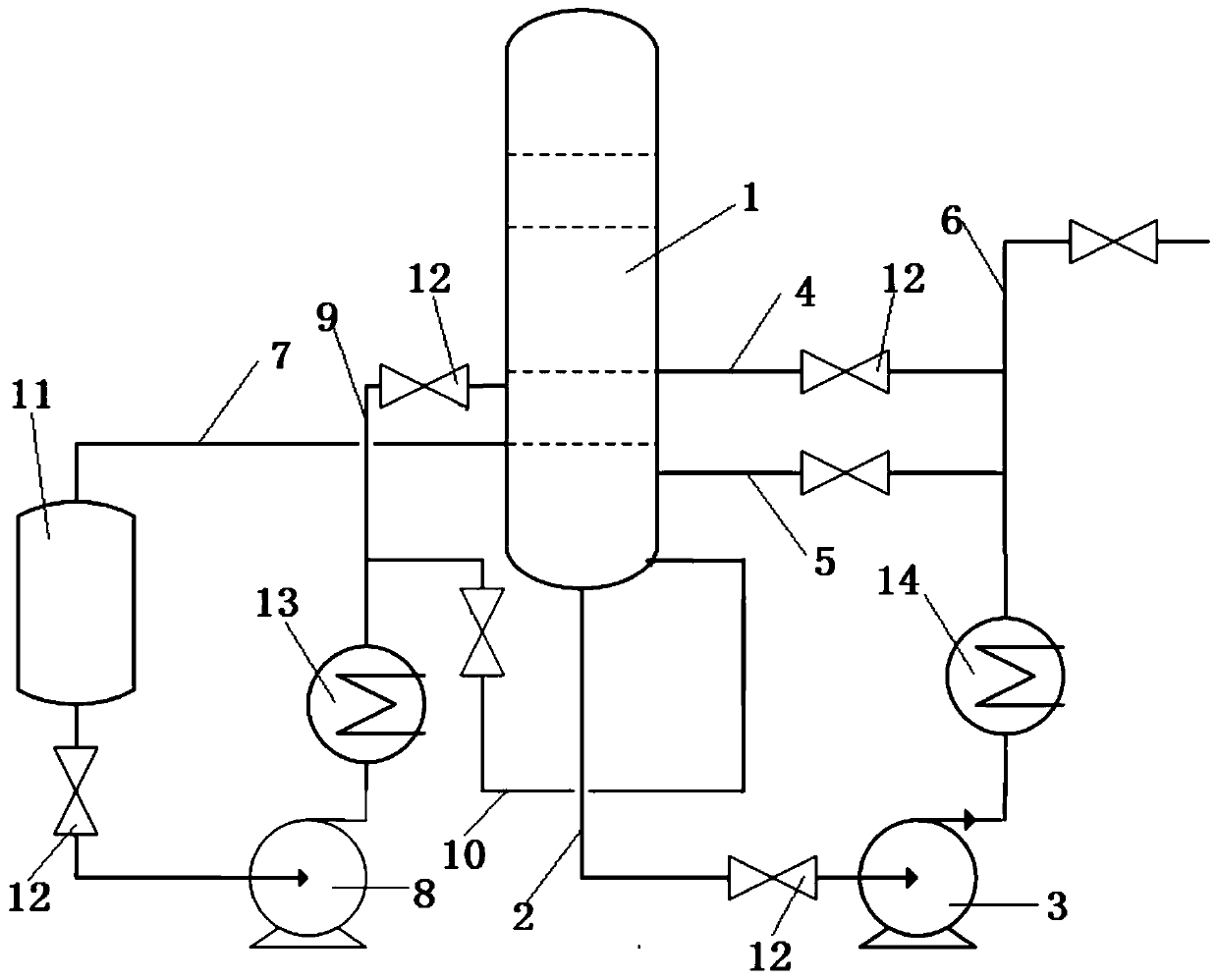

Catalytic cracking fractionating tower oil slurry circulating heating system

PendingCN111321004AReduce the temperatureSolve cokingDistillation regulation/controlTreatment with plural serial stages onlyOil processingFractionating column

The invention discloses a catalytic cracking fractionating tower oil slurry circulating heat removal system, and belongs to the technical field of petroleum processing. The technical scheme is as follows: the system comprises a fractionating column, an oil slurry outlet at the bottom of the fractionating column is connected with an oil slurry discharge pipe; an oil slurry pump is arranged on the oil slurry discharging pipe; an outlet of the oil slurry discharging pipe is connected with a feeding hole of the first heat exchanger; a discharge port of the first heat exchanger is respectively connected with an upper return column oil slurry pipe, a lower return column oil slurry pipe and an FCC slurry oil pipe, an outlet of the upper return column oil slurry pipe is connected with an upper return column oil slurry port of the fractionating column, an outlet of the lower return tower oil slurry pipe is connected with a lower return column oil slurry port of the fractionating column, and anoutlet of the FCC slurry oil pipe is connected with the tank area; a recycle oil outlet of the fractionating column is connected with a recycle oil discharge pipe, a recycle oil pump is arranged on the recycle oil discharge pipe, and an outlet of the recycle oil discharge pipe is connected with a feed port of the second heat exchanger. According to the invention, the coking problem caused by overhigh fractionating column bottom temperature is solved, the oil slurry quality is improved, and the long-period operation of the system is ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

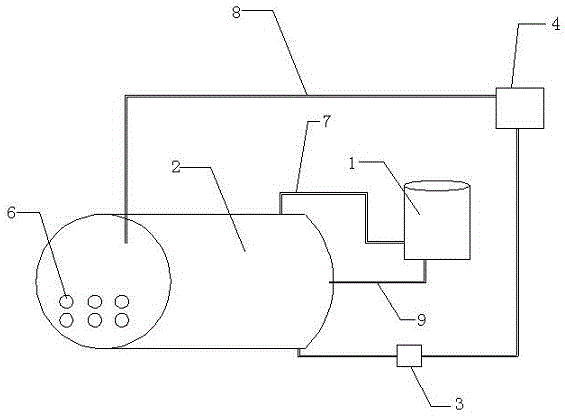

Conduction oil system

The invention relates to a conduction oil system. The conduction oil system comprises a conduction oil loop (8) and a conduction oil anti-oxidation device. The conduction oil loop (8) is formed by connecting an oil storage tank (2), a gear oil pump (3) and a reaction kettle (4) in series through an oil pipe. The conduction oil anti-oxidation device comprises a cold oil container (1) filled with conduction oil with the temperature lower than 70 DEG C. A thermometer is fixedly connected to the cold oil container (1). The bottom of the cold oil container (1) is communicated with the oil storage tank (2) through an oil pipe (9). An exhaust pipe (7) at the upper portion of the oil storage tank (2) is communicated with the cold oil container (1). A pipe opening, in the cold oil container (1), of the exhaust pipe (7) is located below the conduction oil liquid level. Air is isolated through the conduction oil in the cold oil container, and the conduction oil is prevented from making contact with air. The moving viscosity of the conduction oil is prevented from being increased, equipment corrosion is avoided as well, and soot generated by the high-temperature conduction oil is prevented from being discharged outward.

Owner:铜陵翔宇商贸有限公司

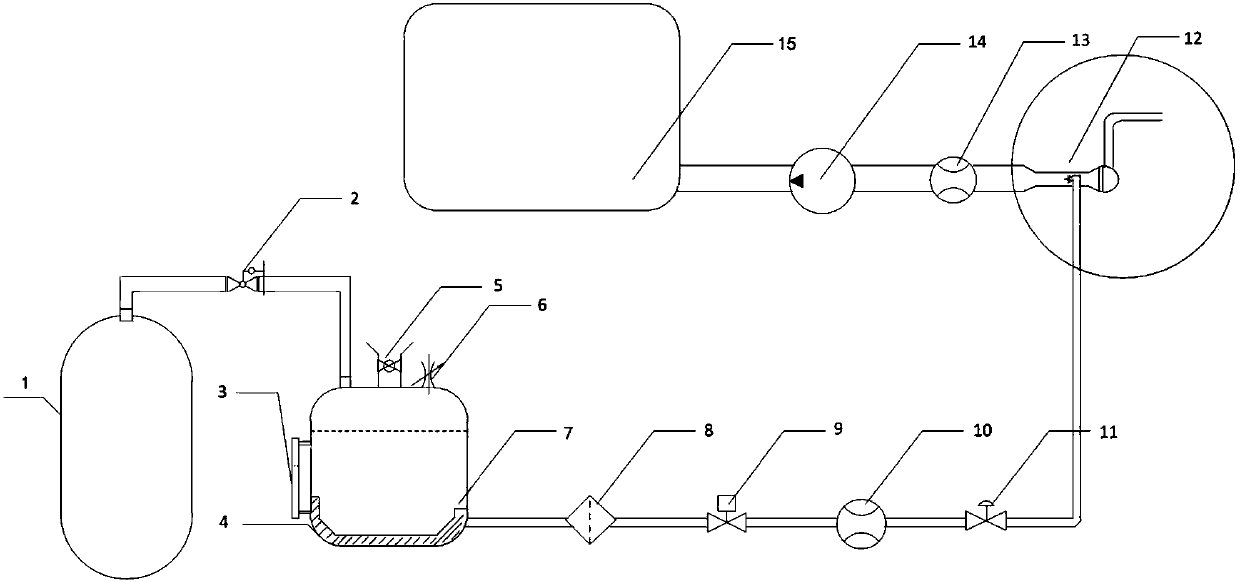

Engine oil blending combustion device and method for GPF aging of gasoline direct injection engine in cylinder

PendingCN108035825AGood kinematic viscosityFlexible adjustmentNon-fuel substance addition to fuelMachines/enginesRelief valveNitrogen gas

The invention provides an engine oil blending combustion device and method for GPF aging of a gasoline direct injection engine in a cylinder. The device includes a nitrogen gas tank, a pressure-adjustable reducing valve, an engine oil tank, an engine oil filter, an electromagnetic valve, an engine oil flowmeter, a one-way valve, an even blending intensifying device, a gasoline flowmeter, a gasoline pump and a gasoline tank; the nitrogen gas tank, the pressure-adjustable reducing valve and the engine oil tank are sequentially connected in series through pipes, the engine oil tank is provided with a pressure-adjustable relief valve, and the nitrogen gas tank is combined with the pressure-adjustable reducing valve and the pressure-adjustable relief valve to form an air pressure passage; the engine oil tank, the engine oil filter, the electromagnetic valve, the engine oil flowmeter, the one-way valve and the even blending intensifying device are sequentially connected with one another in series to form an engine oil pipeline; the gasoline tank, the gasoline pump and the gasoline flowmeter are sequentially connected with one another in series to form a gasoline pipeline, and the tail end of the gasoline pipeline is connected with the even blending intensifying device. Even blending combustion of gasoline and engine oil in a GPF aging experiment of the gasoline direct injection engine in the cylinder is achieved, and the blending combustion proportion of the engine oil to the gasoline can be flexibly adjusted according to different work conditions of running of an engine.

Owner:CHINA AUTOMOTIVE TECH & RES CENT

A kind of nitrated coal tar alcohol-containing fuel and preparation method thereof

ActiveCN104449888BImprove performanceHigh kinematic viscosityLiquid carbonaceous fuelsFuel oilWater content

The invention relates to the technical field of fuel oil, and in particular relates to a nitrated coal tar alcohol-containing fuel and a preparation method thereof. By proportioning raw oil, a catalyst, a nitric acid solution, an alcohol and urea, combining process parameters in process steps and controlling the adding sequence and time of various raw materials, the performance of raw oil can be accurately modified, then the kinematic viscosity of oil, the water mass percentage and the content of alcohol substances are improved, and the performance of the raw oil is further improved; and moreover, compared with pure alcohol and the conventional alcohol-containing fuels, the nitrated coal tar alcohol-containing fuel provided by the invention has superior kinematic viscosity, is lower in water content and less in smoke dust discharge after burning, and can be completely burnt to a greater extent, the combustion value of the fuel is improved, and the consumption of energy sources is reduced.

Owner:GUIZHOU QIANSHENG NEW ENERGY IND

Nitrated coal tar alcohol-containing fuel and preparation method thereof

ActiveCN104449888AExcellent kinematic viscosityReduce moisture contentLiquid carbonaceous fuelsFuel oilWater content

The invention relates to the technical field of fuel oil, and in particular relates to a nitrated coal tar alcohol-containing fuel and a preparation method thereof. By proportioning raw oil, a catalyst, a nitric acid solution, an alcohol and urea, combining process parameters in process steps and controlling the adding sequence and time of various raw materials, the performance of raw oil can be accurately modified, then the kinematic viscosity of oil, the water mass percentage and the content of alcohol substances are improved, and the performance of the raw oil is further improved; and moreover, compared with pure alcohol and the conventional alcohol-containing fuels, the nitrated coal tar alcohol-containing fuel provided by the invention has superior kinematic viscosity, is lower in water content and less in smoke dust discharge after burning, and can be completely burnt to a greater extent, the combustion value of the fuel is improved, and the consumption of energy sources is reduced.

Owner:GUIZHOU QIANSHENG NEW ENERGY IND

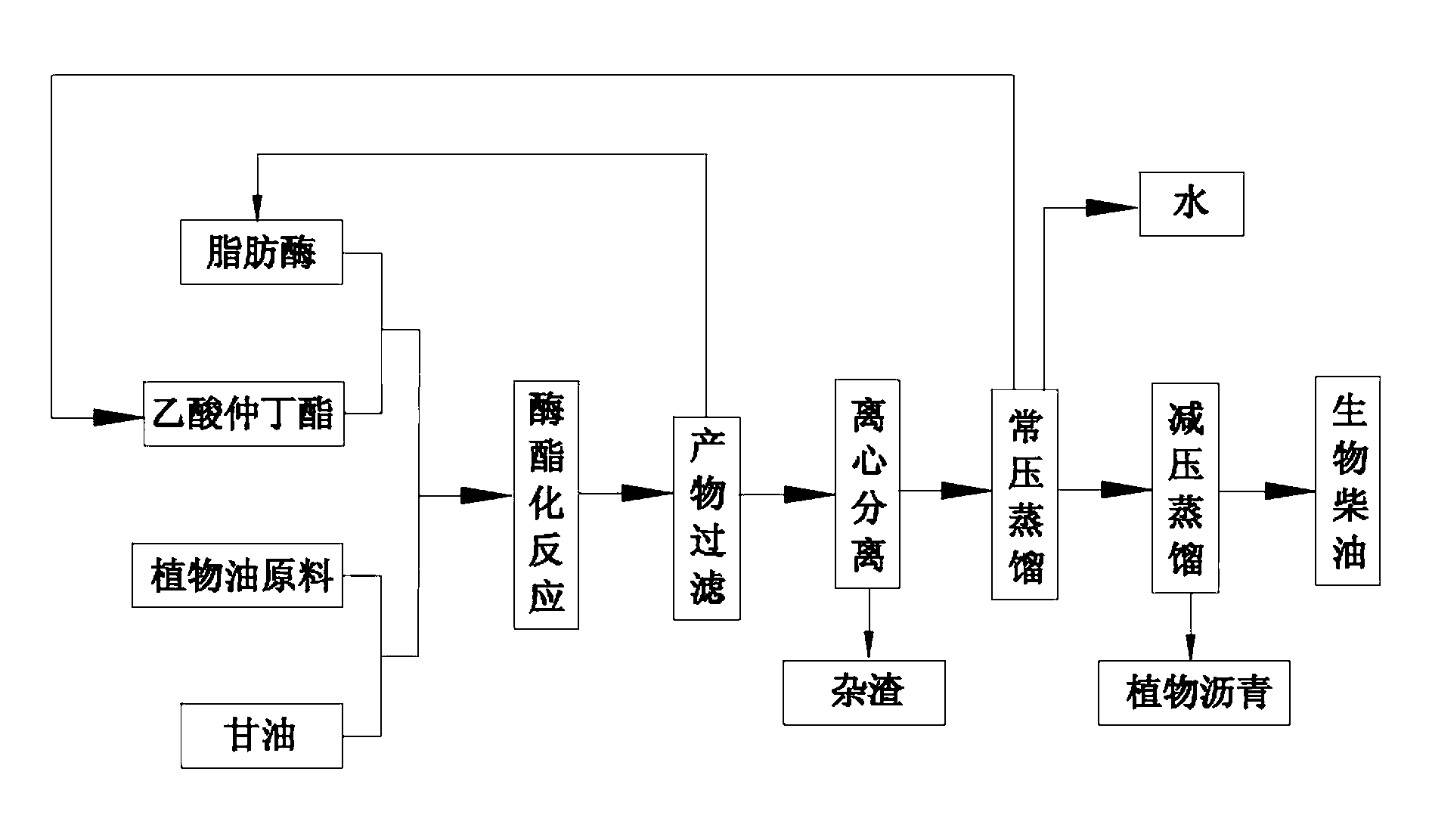

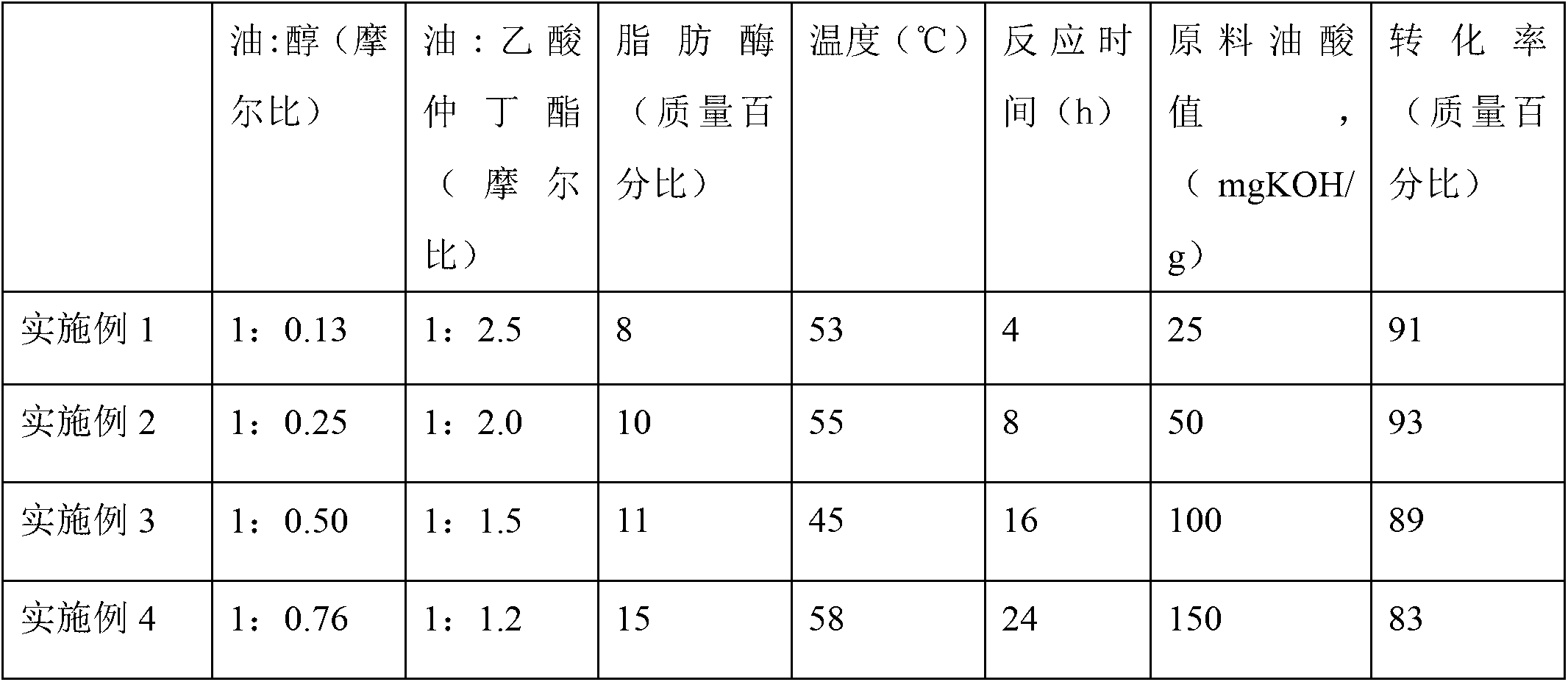

Method for preparing biodiesel by using biological enzyme

InactiveCN103074389AHigh catalytic efficiencyIncrease profitBiofuelsFermentationFiltrationDistillation

The invention provides a method for preparing biodiesel by using a biological enzyme. The method comprises the following steps of: (1) raw material mixing: uniformly mixing raw oil and glycerin into a solution A, mixing sec-butyl acetate and lipase into a solution B, and mixing the solution A and the solution B in an enzyme esterification reactor for further performing a complete esterification reaction and a complete ester exchange reaction; (2) product filtration: precisely filtering crude diesel generated by the esterification reaction, separating and recovering an enzyme from the crude diesel, centrifugally separating the crude diesel from which lipase is separated, and removing foreign residues; and (3) product purification: performing normal-pressure distillation on the centrifugally separated crude diesel, separating excessive sec-butyl acetate and water generated by reacting, and rectifying under a reduced pressure of 0.002MPa to obtain biodiesel and plant asphalt. The biodiesel prepared with the method has high kinematic viscosity, a high cetane number and a high grease transformation ratio during production.

Owner:DONGGUAN HENENG MICROBIOLOGY ENERGY

High-strength waterborne wood coating and manufacturing method thereof

InactiveCN109456669AHigh strengthHigh modulusAntifouling/underwater paintsPaints with biocidesFiberMaterials science

The invention discloses a high-strength waterborne wood coating and a manufacturing method thereof. The high-strength waterborne wood coating is prepared by taking polyurethane acrylate grafted acrylate, starch grafted sodium acrylate, water-soluble alkali, aluminum borate whisker, silicon carbide powder, CF (carbon fiber), tackifier extracted from cornu gorais powder, blocked isocyanate, polyether-siloxane copolymer, and aqueous adhesion promoter as raw materials and deionized water as medium for sufficient reaction at 70-85 DEG C, wherein the tackifier is prepared through the steps of moisturizing, pelletizing, boiling, purifying and concentrating; the waterborne adhesion promoter is prepared through the steps of soaking, microorganism fragmentation, collagen releasing and activating, and concentrating. The high-strength waterborne wood coating has the technical advantages of being applicable to wood surface, waterborne, free from damage to wood, high in strength and wearing resistance, lubricant in surface and good in texture.

Owner:JIANGSU HIMONIA TECH

Green and environment-friendly metal rust inhibitor

InactiveCN106833849ABiodegradableExtended service lifeLubricant compositionChemical industrySODIUM METAPHOSPHATE

The invention mainly relates to the technical field of chemical industry and discloses a green and environment-friendly metal rust inhibitor. The green and environment-friendly metal rust inhibitor is prepared from the following raw materials: wool grease, oleic acid, carboxymethylcellulose sodium, polyvinyl alcohol, sodium hexametaphosphate, fatty alcohol polyoxyethylene ether, sulfamic acid, glycolic acid, L-sodium lactate and water. The green and environment-friendly metal rust inhibitor is green and environmental-friendly, is safe and healthy, has biodegradability and can be self-degraded in soil within 15 months; health of human bodies are not damaged in preparation and utilization processes and the rust inhibition period reaches 5.5 years so that the service life of metal is prolonged for 10.3 percent; a plurality of types of raw materials belong to a food grade and are safe and non-toxic; waste liquid generated after the green and environment-friendly metal rust inhibitor is used does not cause environment pollution and can be biologically degraded; the L-sodium lactate can increase the weather resistance of the rust inhibitor, the shelf life is prolonged and the economic income is improved by 12.7 percent; the rust inhibitor is convenient to use and can be directly wiped; stains on a metal surface can be removed, color and luster are increased and rusting is prevented so that the service life of the metal is prolonged.

Owner:ANHUI BAOHENG ADVANCED MATERIAL TECH CO LTD

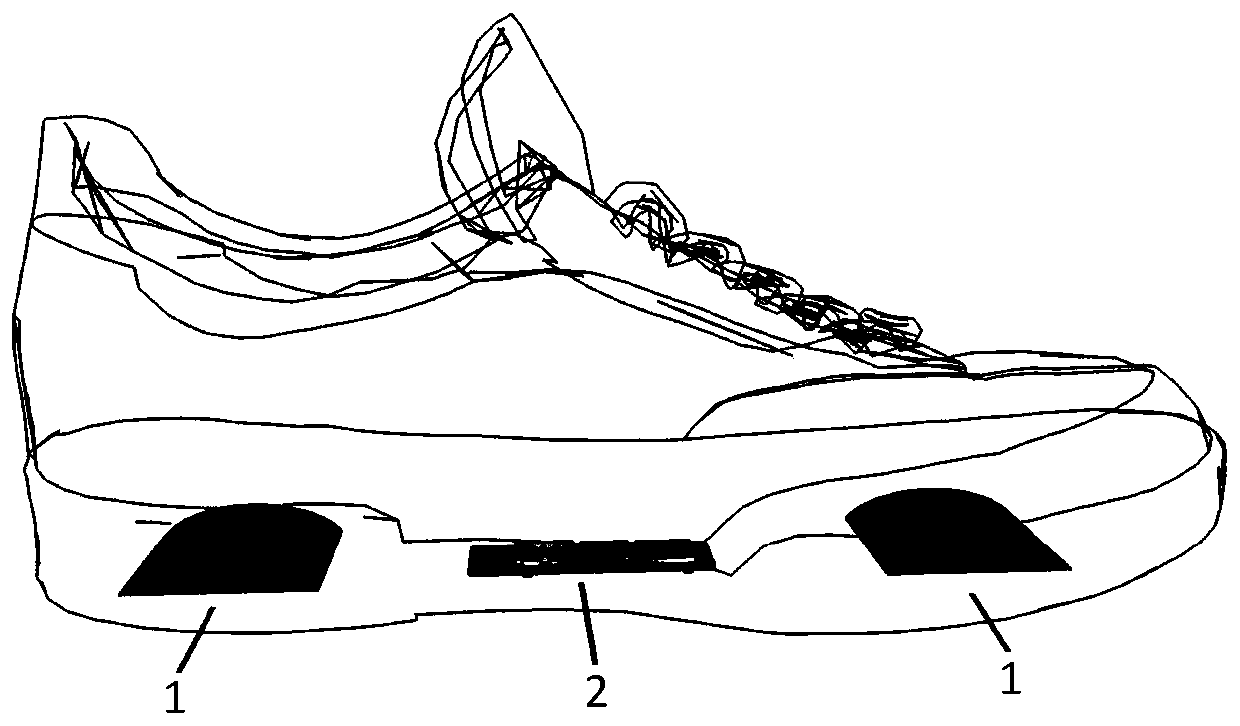

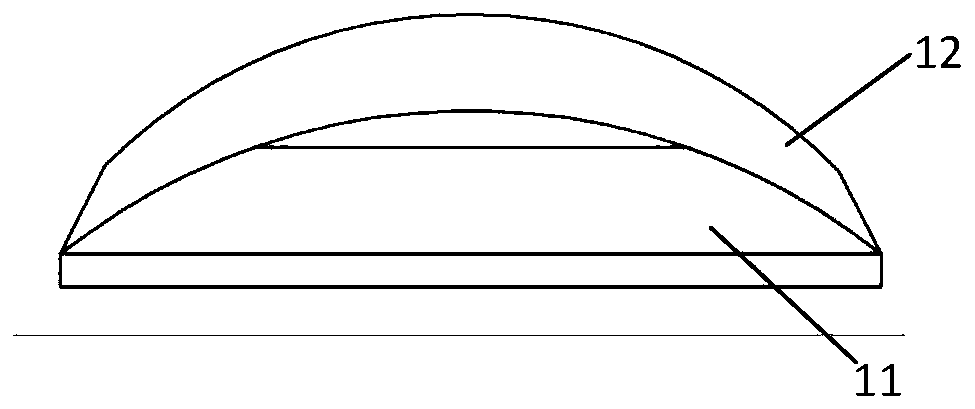

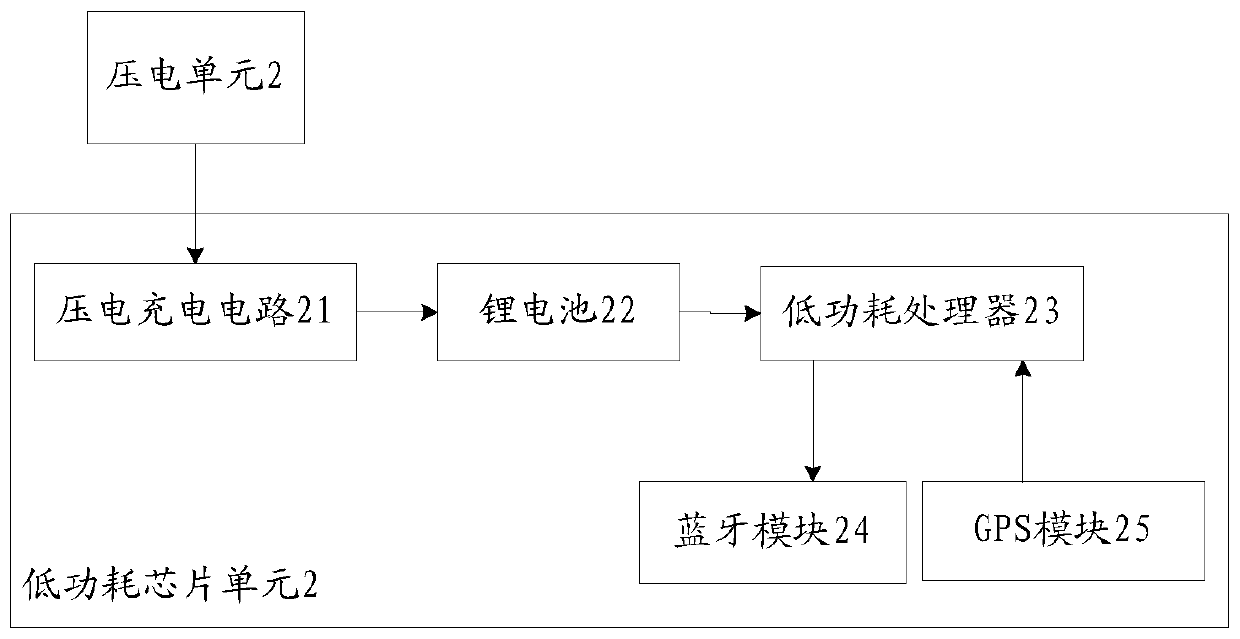

Intelligent sneaker, sales platform and method thereof

InactiveCN110403294ARemove damageMeet trackPerson identificationEvaluation of blood vesselsElectricityEngineering

The invention discloses an intelligent sneaker, a sales platform and method thereof. The intelligent sneaker comprises a piezoelectric unit, a low-power-consumption chip unit and an environment monitoring sensor, wherein the piezoelectric unit, the low-power-consumption chip unit and the environment monitoring sensor are embedded in a shoe sole; and geographic position information, piezoelectric information and environment information are sent to the sales platform of terminal equipment through a Bluetooth module. Through monitoring of the intelligent sneaker, various body index data are tracked in real time, and the current physical condition is accurately judged; the surrounding environment conditions are detected in real time; motivation of a virtual currency mode is generated through sports, so that the sports viscosity of a user is increased, and the continuously generated virtual currency is converted into directional purchasing power; virtual games stimulate the interest of sports, and the sports power is improved in various manners; and earnings are obtained while the sports initiative of the user is improved, thereby expanding the commodity audience side, and enhancing theuser experience and the marketing effect.

Owner:北京三垣科技有限公司

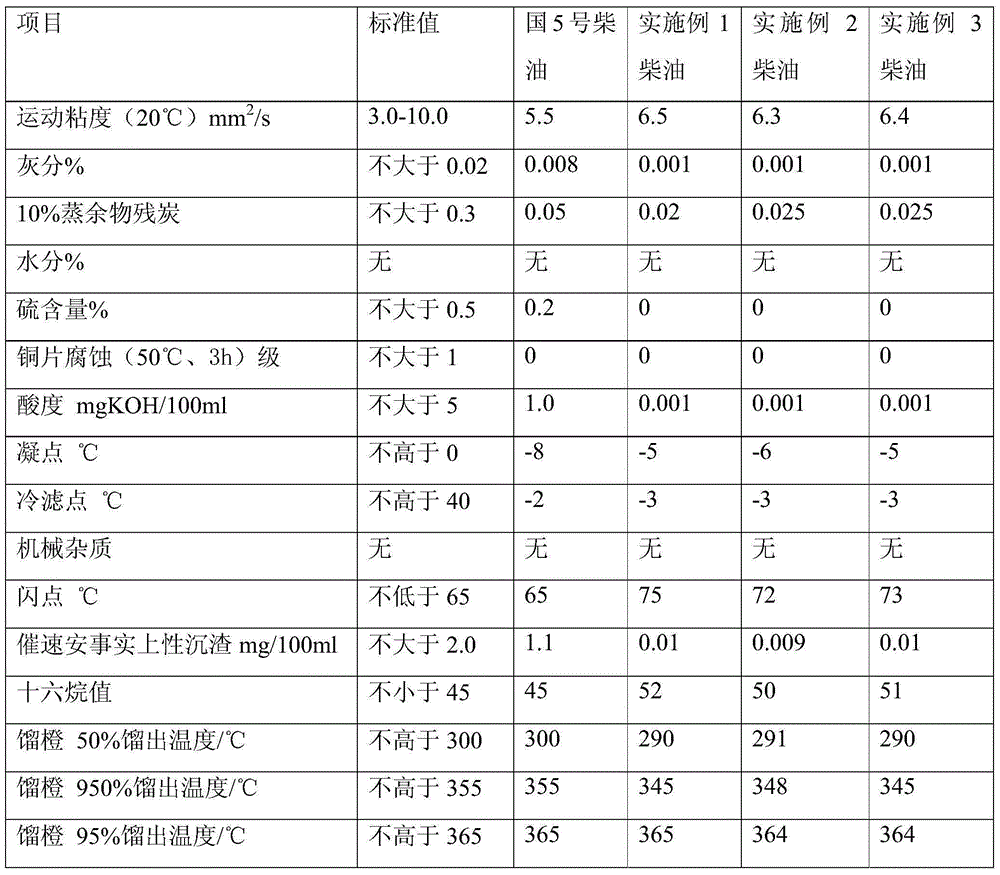

Smokeless vehicle diesel oil and preparation method thereof

The invention discloses a smokeless vehicle diesel oil, which comprises the following components in parts by weight: 180 to 220 parts of aviation kerosene, 90 to 110 parts of plant oil, 245 to 265 parts of finely-processed drainage oil, 290 to 310 parts of self-made smokeless oil, 45 to 55 parts of anti-freezing and pour point reducing agent, 8 to 12 parts of upgrading agent, and 30 to 40 parts of flame retardant. The finely-processed drainage oil is prepared by the following steps: heating drainage oil, removing impurities from drainage oil, carrying out primary filtration by a filter screen, and carrying out secondary filtration through pressurization. The smokeless vehicle diesel oil is prepared by the following steps: mixing smoke oil and edible vinegar according to a weight ratio of 1000:10-15, stirring for 40 to 50 minutes at a temperature of 11 to 12 DEG C in a rotation speed of 60 to 120 r / min, allowing the system to stand still, when the precipitate has a dark-red color and the supernatant oil has a white-green color so as to obtain the self-made smokeless oil (supernatant oil); mixing kerosene, plant oil, and finely-processed drainage oil, stirring until specific gravity reaches 0.85, transferring the mixture to another container, adding self-make smokeless oil, an anti-freezing and pour point reducing agent, an upgrading agent, and a flame retardant, stirring until the specific gravity of the mixture reaches 0.85, stopping stirring, and completely transferring the mixture to an oil storage tank so as to obtain the smokeless vehicle diesel oil. The raw material costs of the smokeless vehicle diesel oil are reduced, moreover, the diesel oil is smokeless and environment-friendly, and the quality of the diesel oil meets the standards of DB11 / 239-2010.

Owner:郭永秋 +2

Environmentally friendly grease and preparation method thereof

InactiveCN108285818AAffect the service lifeHigh kinematic viscosityAdditivesWorking environmentViscosity

The invention provides environmentally friendly grease. The grease is characterized in that the grease is prepared from, by weight, 20-50% of environmentally friendly grease precursor and 50-80% of poly castor oil acid ester. According to the grease, beeswax has a pleasant and fragrant smell and can be used for improving a working environment, the beeswax reacts with borate to generate organic borate, the organic borate has better friction reducing and rust resisting effects, the poly castor oil acid ester has higher kinematic viscosity, the poly castor oil acid ester does not easily escape from a grease structural system to affect the service life of the grease, and the components of the grease are obtained from natural raw materials, so that the grease is good in environmental protectionperformance.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

High adhesion waterborne wood coating and manufacturing method thereof

InactiveCN109321055ALow costEnhanced environmental performance and functionalityCoatingsIonSodium silicate

The invention discloses a high adhesion waterborne wood coating and a manufacturing method thereof. The waterborne wood coating takes waterborne acrylic resin, sodium silicate, water-soluble alkali, titanium dioxide powder, activated carbon powder, CNC cellulose nanocrystal, a tackifier extracted from goat horn, blocked isocyanate, a waterborne defoamer, and a waterborne adhesion promoter extracted from peach branches as raw materials, and takes deionized water as a medium to obtain a product through sufficient reaction at 70 DEG C to 85 DEG C; wherein the preparation process of the tackifierincludes infiltration, dicing, braising, purification and concentration; the preparation process of the waterborne adhesion promoter includes foaming, microbial wall breaking, collagen release and activation, and concentration. The high adhesion waterborne wood coating disclosed by the invention has the technical effects of specific application to the surface of woodware, waterborne property, non-injuring to wood, high adhesion, high wear resistance, self-lubricating surface and good texture.

Owner:JIANGSU HIMONIA TECH

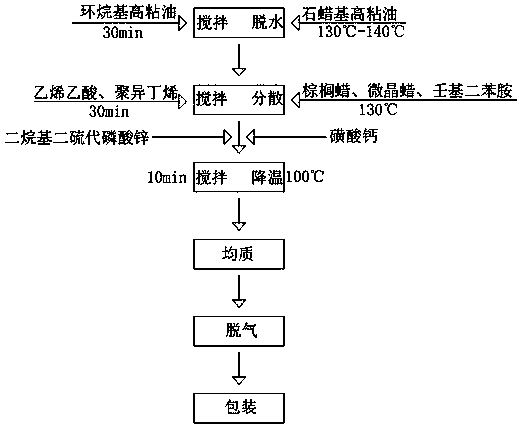

Long-acting steel wire rope hemp core grease

The invention provides long-acting steel wire rope hemp core grease. The long-acting steel wire rope hemp core grease is prepared from the following components in parts by weight: 13 to 17 percent ofpalm wax, 16 to 19 percent of microcrystalline wax, 15 to 19 percent of naphthenic high-viscosity oil, 24 to 28 percent of paraffin-based high-viscosity oil, 1.6 to 4.6 percent of zinc dialkyl dithiophosphate, 1.4 to 4.4 percent of nonyldiphenylamine, 4.5 to 8.5 percent of ethylene acetic acid, 8.5 to 12.5 percent of polyisobutene and 0.1 to 1 percent of calcium sulfonate. The invention also provides a preparation method of the long-acting steel wire rope hemp core grease. The preparation method comprises the following steps: S1) putting naphthenic high-viscosity oil and paraffin-based high-viscosity oil into a reaction tank, heating to 130-140 DEG C, stirring for 30 minutes, and dehydrating to obtain a first prefabricated material; and S2) successively adding palm wax, microcrystalline wax, nonyldiphenylamine, ethylene acetic acid and polyisobutene into the first prefabricated material. The long-acting steel wire rope hemp core grease is high in dropping point, high in kinematic viscosity and capable of inhibiting free acidic bodies generated by oxidation and neutralization so that a steel wire rope is not liable to rust, and the service life of the steel wire rope can be effectively prolonged.

Owner:融润化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com