Patents

Literature

88results about How to "High oligomerization reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of poly alpha-olefin base oil with high viscosity index

InactiveCN103305263AEasy to makeImmobilized reaction efficiency is highLiquid hydrocarbon mixtures productionHydrogen pressureDistillation

The invention discloses a preparation method of poly alpha-olefin (PAO) base oil with high viscosity index. Suitably, the method comprises the steps of: with ethylene and isobutene and other alpha-olefin of C6-C12 as raw materials and under the conditions of temperature of 20 DEG C-60 DEG C and partial hydrogen pressure of 0.3-0.5, loading a copper (II)-organic aluminum immobilized catalyst with gama-Al2O3, catalyzing ethylene / isobutene / alpha-olefin of C6-C12 for an oligomerization reaction for 2-4 hours by taking tert-butyl chloride as a catalyst promoter, and carrying out washing in water, drying, atmospheric distillation and reduced-pressure distillation on the product to obtain an olefin oligomer; and then under the conditions of temperature of 200 DEG C-280 DEG C, pressure of 2.5-5.0MPa, idle speed of 0.4-1.0h<-1>, and hydrogen-to-oil of 500:1, hydrogenating the oligomer through an Mo-Ni / gama-Al2O3 catalyst to obtain PAO (poly alpha olefin) base oil. According to the method, the yield of the PAO base oil is large, the kinematic viscosity of the oligomer is 27.8-42.4.0mm<2> / s at 100 DEG C, the viscosity index is 147-171, the pour point is minus 37 DEG C-minus 47 DEG C, and the bromine value is less than 0.050 bromine g / 100gPAO.

Owner:上海泰强粘合剂有限公司 +1

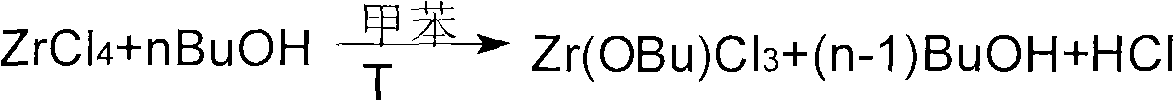

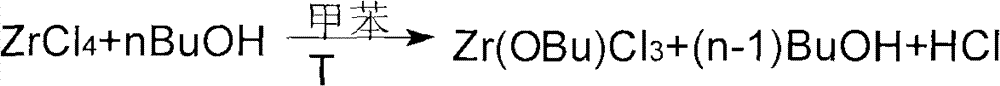

Ethylene oligomerization catalyst and preparation method

ActiveCN101816951AHigh yieldReduce contentOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAlpha-olefin

The invention provides an ethylene oligomerization catalyst, which comprises Zr(OBu)Cl3, SiClx-1R4-x(OBu), BuOH and SiClxR4-x in a mole ratio of 1:(0.5-5.0):(0-5.0):(0-20), wherein Bu is butyl; R is alkyl of C1 to C4 or aryl of C6 to C8; and x is an integer from 1 to 4. The catalyst has high reaction activity in an ethylene oligomerization reaction, a plurality of long chain hydrocarbons of C12 to C20 exist in an oligomerization product and the yield of alpha-olefin is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

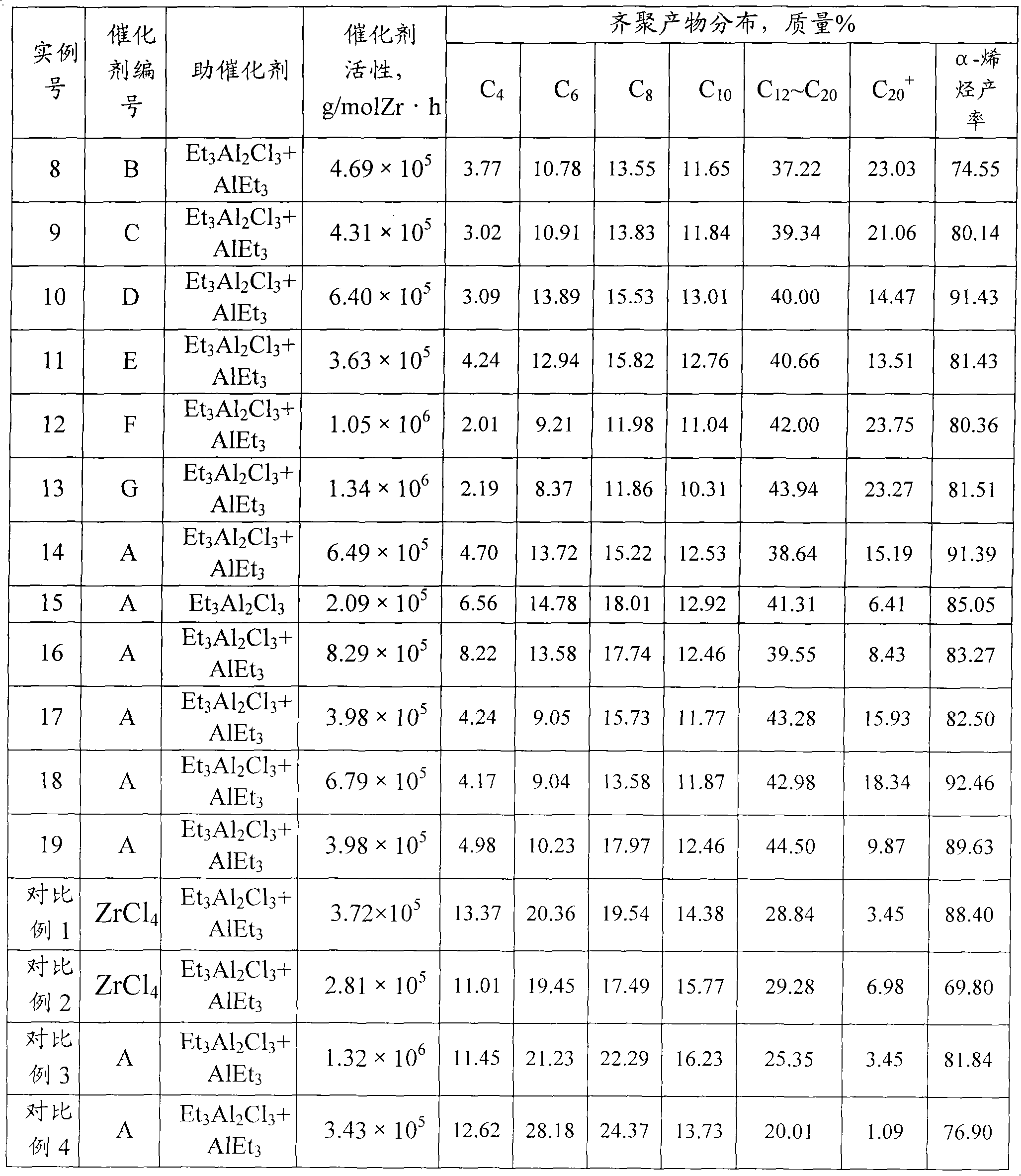

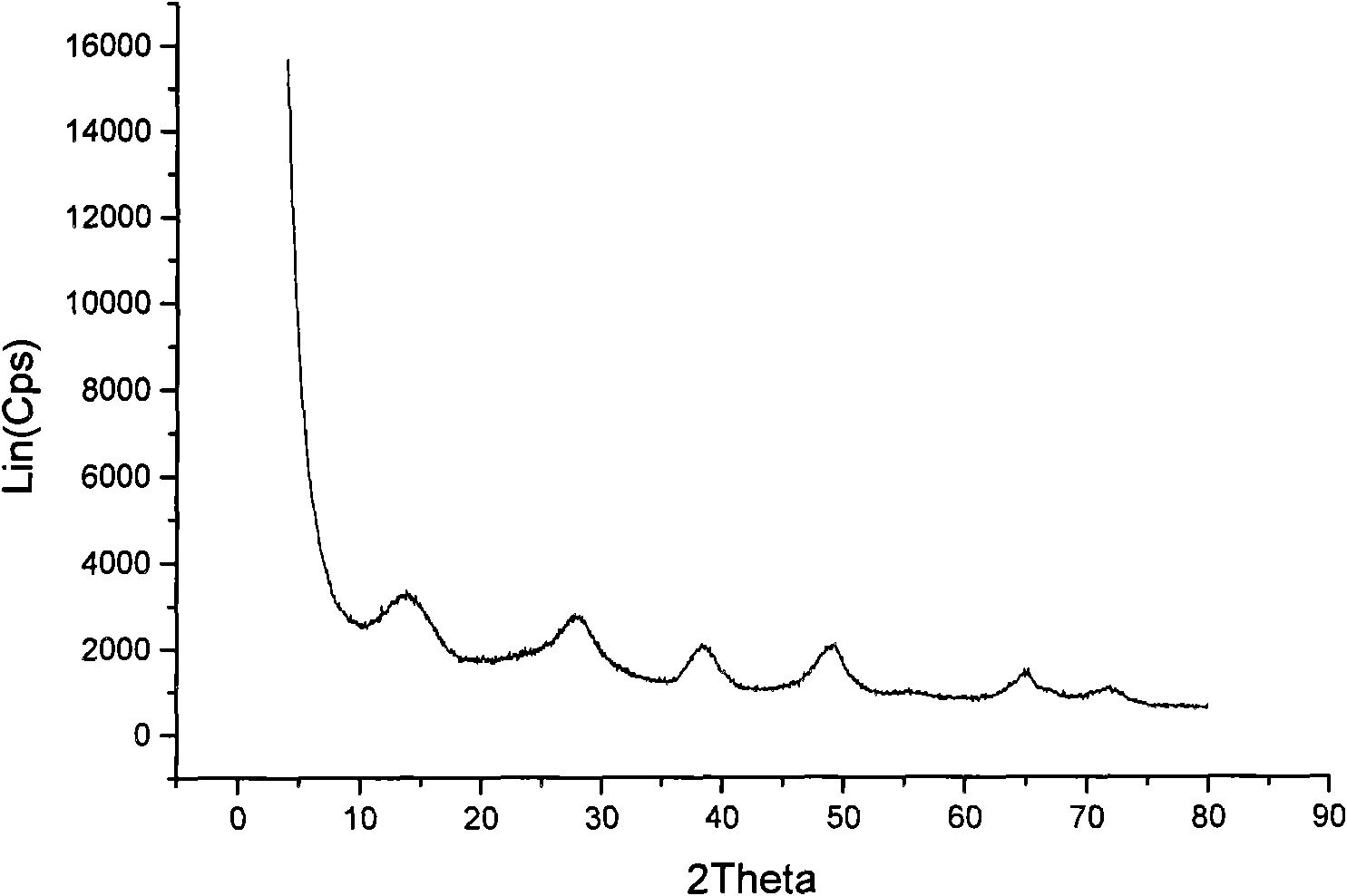

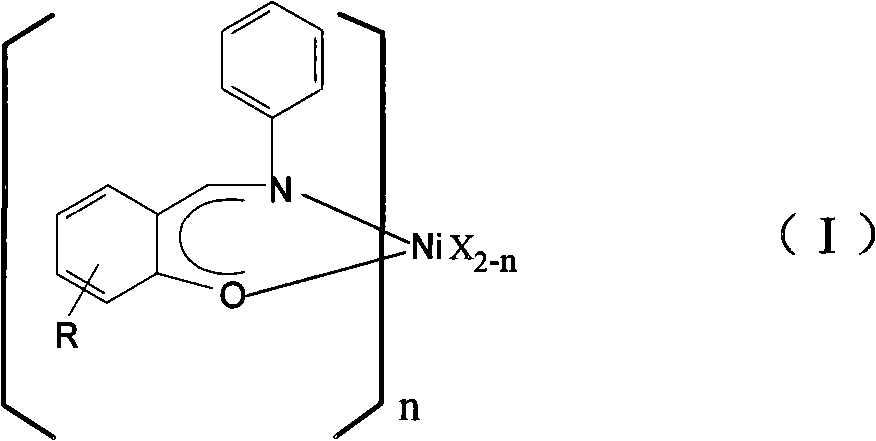

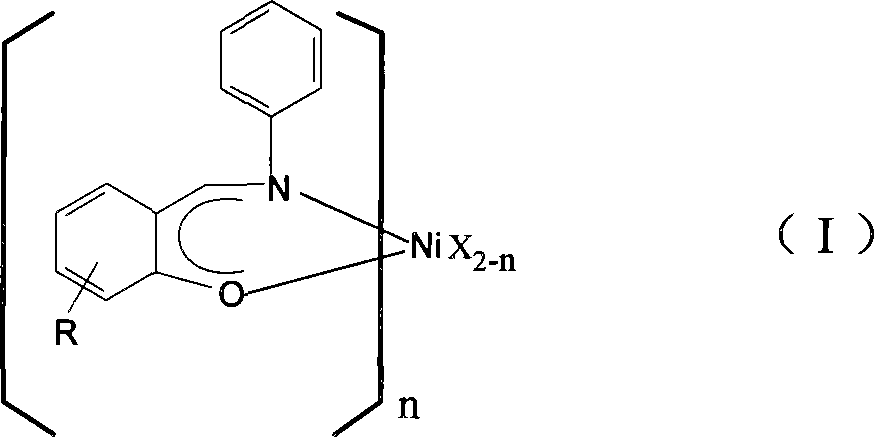

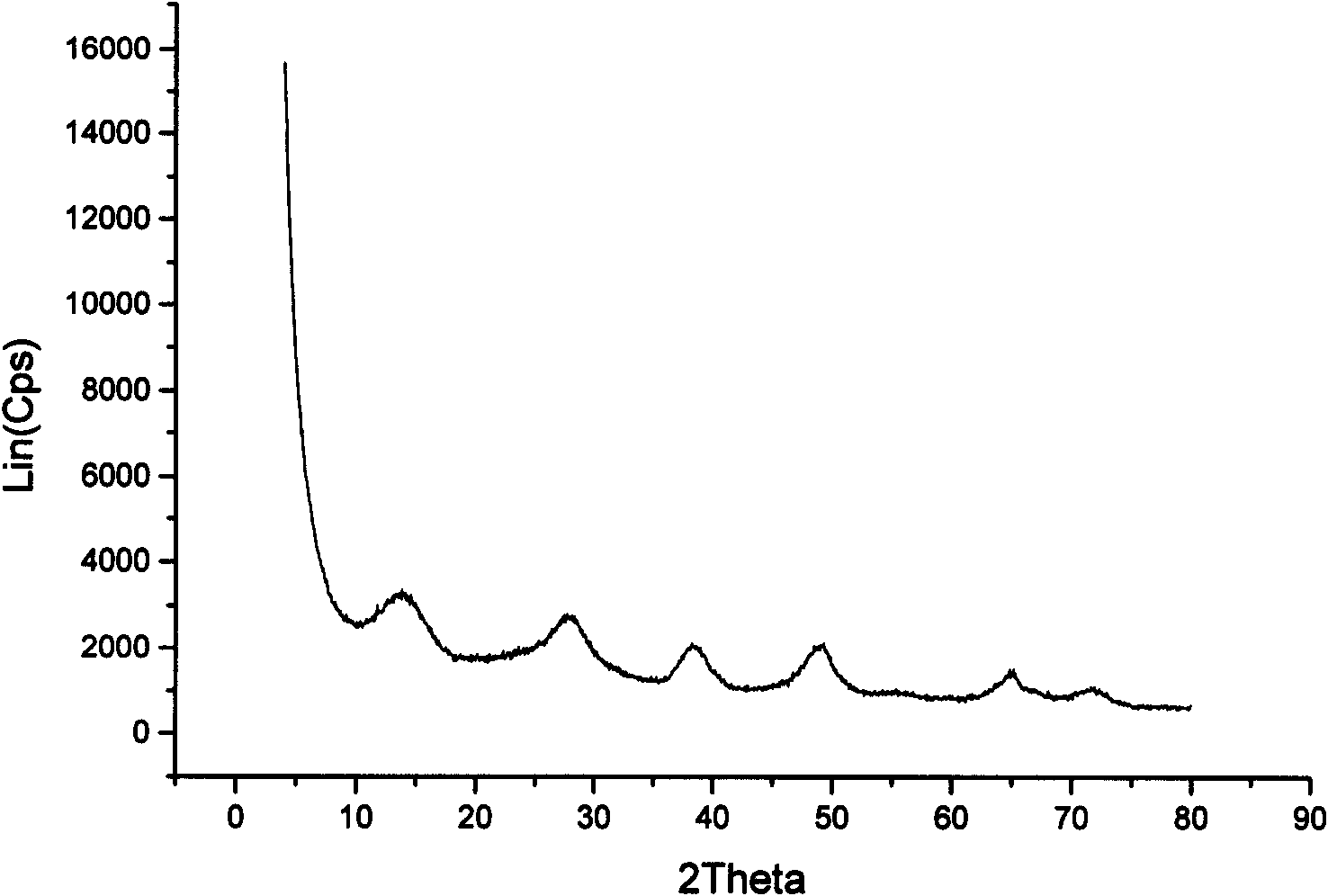

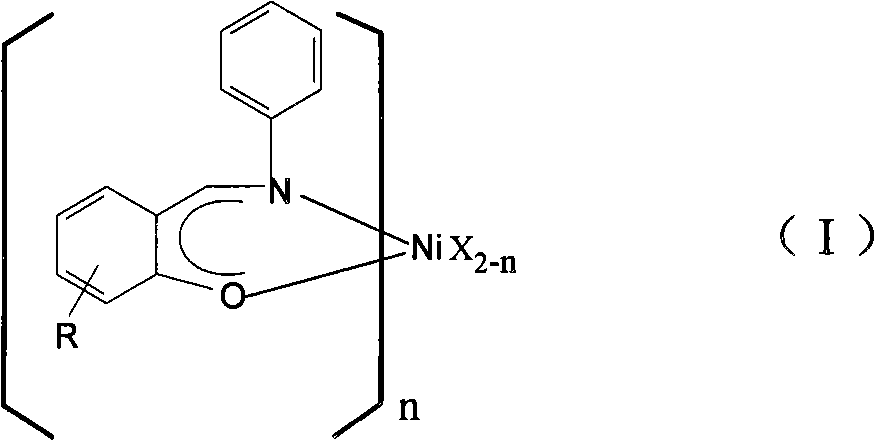

Load-type olefin oligomerization catalyst and preparation method thereof

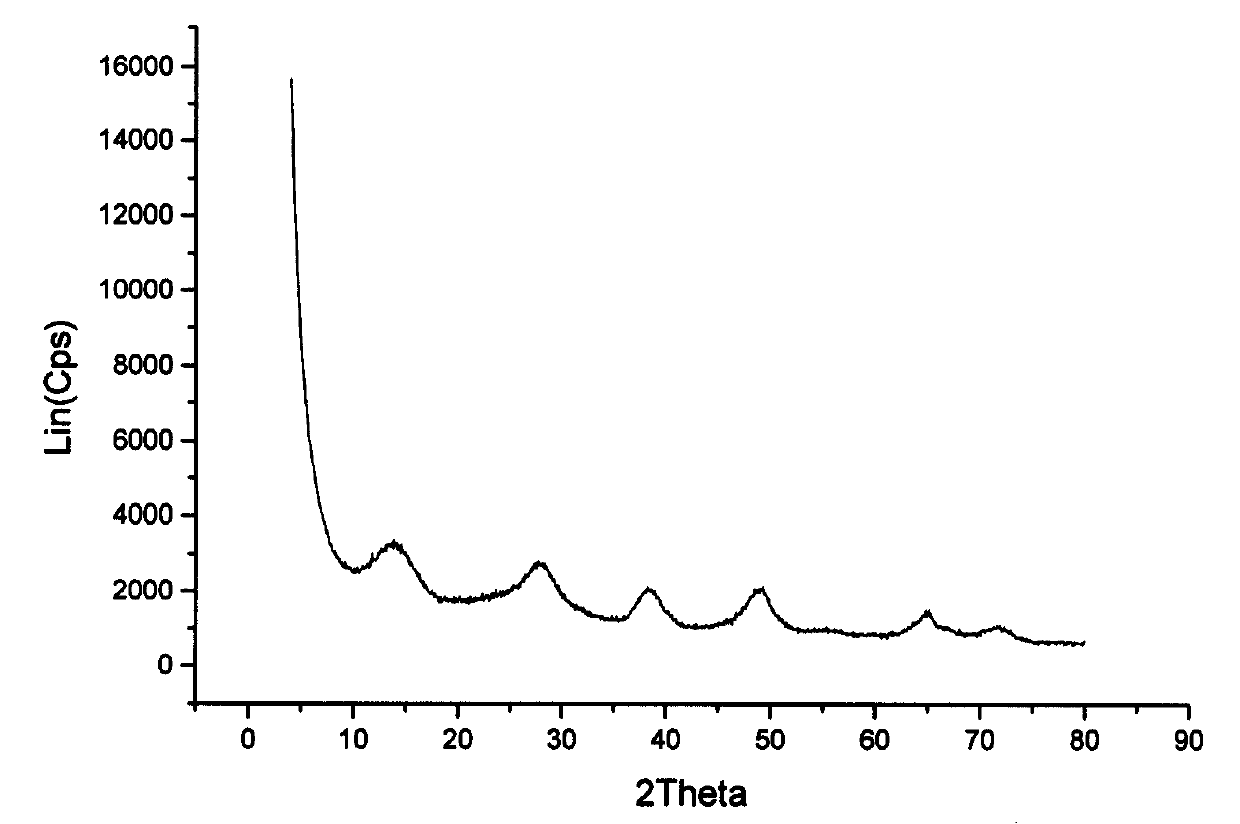

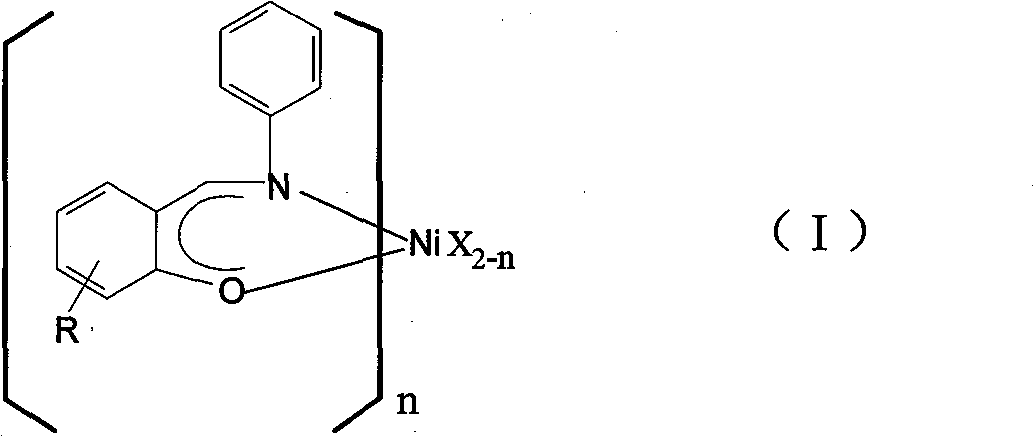

ActiveCN101618343AHigh catalytic activityCarbon number distribution is wideOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAcetic acidChemical composition

The invention relates to a load-type olefin oligomerization catalyst, which comprises a complex and an organic aluminum compound loaded on a medium-pore aluminum silica material and having an expression shown as formula (I). The catalyst contains 0.5 to 5.0 mass percent of nickel and 20 to 30 mass percent of aluminum; in the formula (I), R is selected from hydrogen, alkyl of C1 to C2, alkoxy or nitryl of C1 to C6, X is halogen or acetate moiety, and n is 1 or 2; the medium-pore aluminum silica material has a pseudo-boehmite phase structure, and comprises the anhydrous chemical composition based on the mass of oxide of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2, the specific surface area of the anhydrous chemical composition is between 200 and 400m<2> / g, the pore volume is between 0.5 and 2.0 ml / g, the average aperture is between 8 and 20nm and the most probable aperture is between 5 and 15nm. The catalyst is matched with the alkyl aluminum for olefin oligomerization, and higher reaction activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

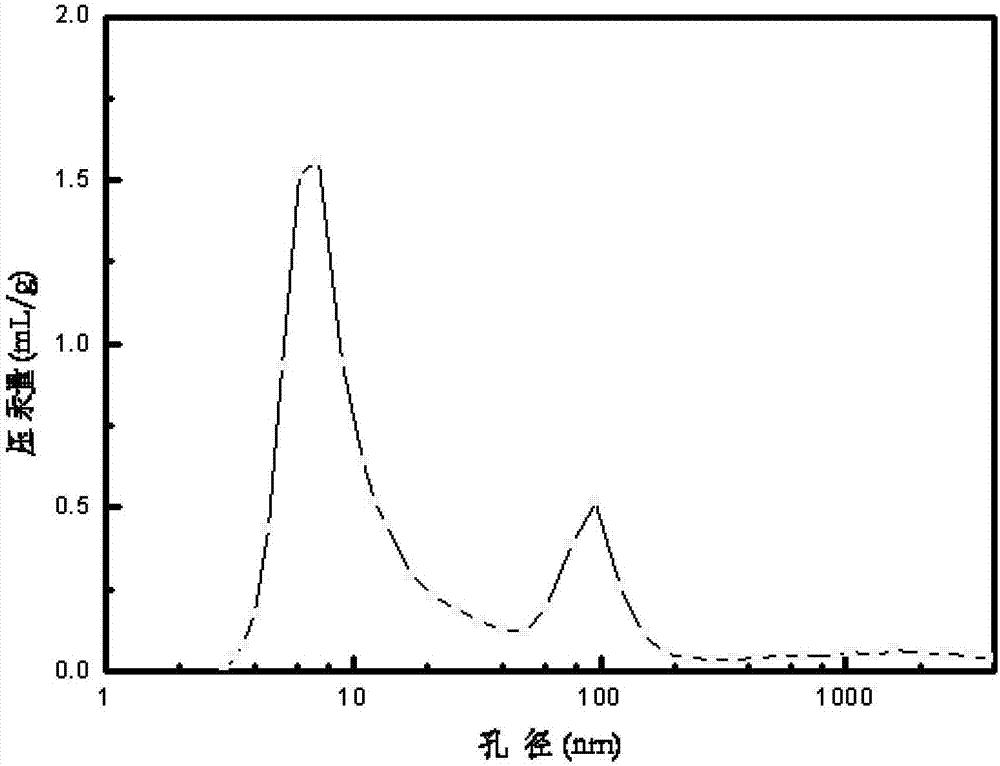

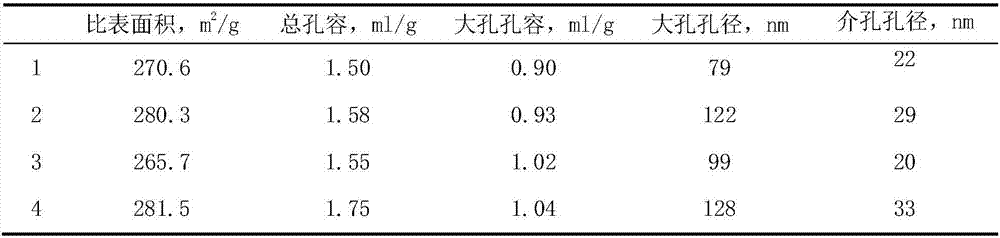

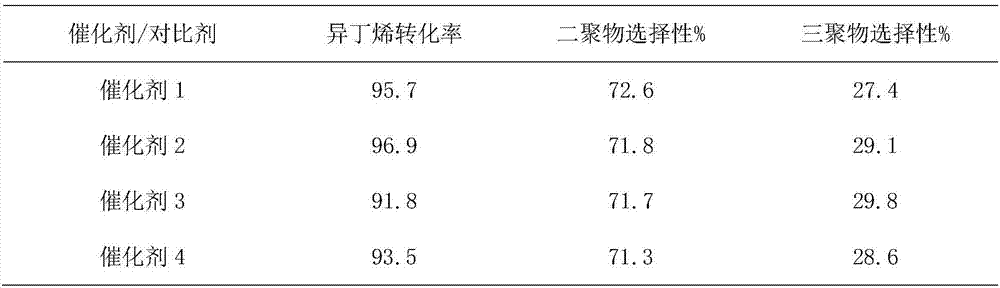

Olefin oligomerization catalyst and preparation method thereof

InactiveCN107185560AAperture size adjustableGood resistance to impuritiesPhysical/chemical process catalystsHydrocarbonsAdditive ingredientSulfate

The invention discloses an olefin oligomerization catalyst and a preparation method thereof. The catalyst is prepared from the following ingredients through being metered by the mass of oxides: 81.0 to 96.0 weight percent of aluminum oxide carriers with macroporous structures (carriers use chitosan as pore-enlarging agents), 2.5 to 11.5 weight percent of active ingredients of ferric sulfate and 1.5 to 7.5 weight percent of nickel sulfate. The olefin oligomerization catalyst has the advantages that the oligomerization activity is high; the dioolymer selectivity is high; the trimer selectivity is low; the operation period of the catalyst is long.

Owner:QINZHOU UNIV

Poly-alpha-olefin base oil and preparation method thereof

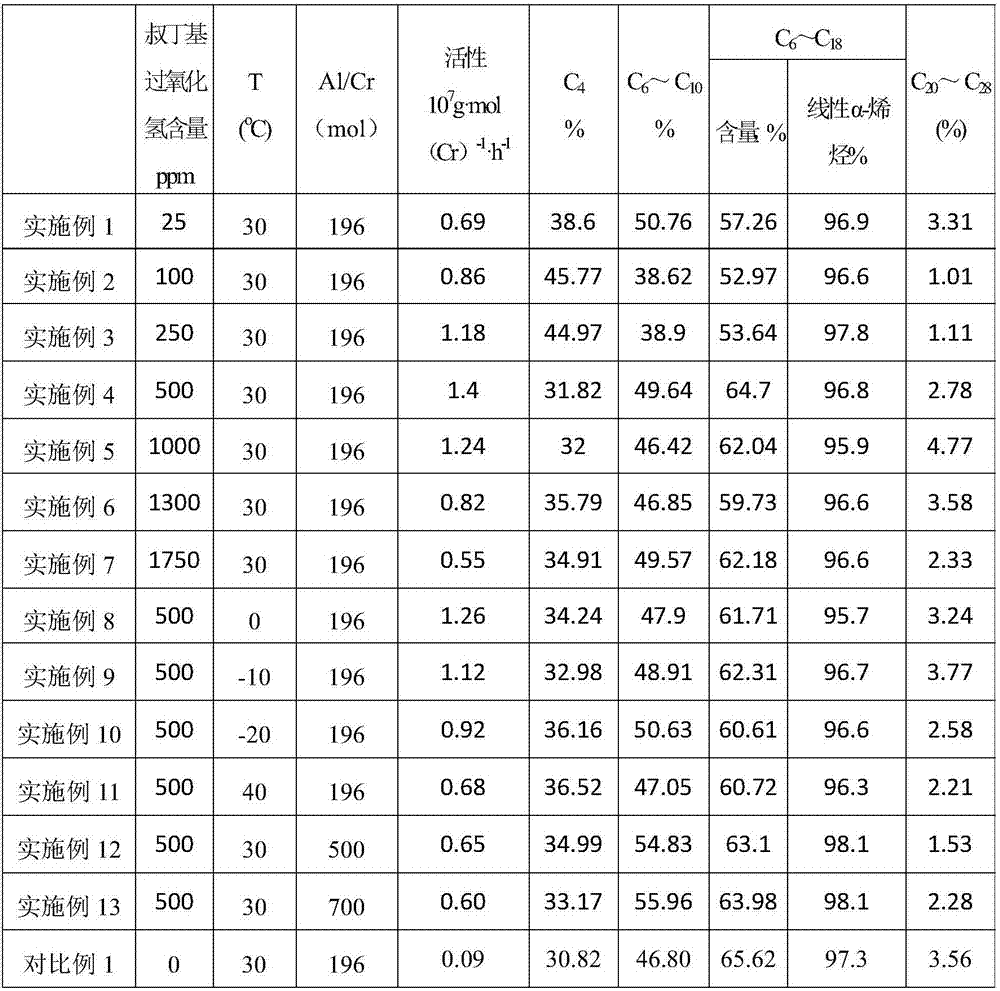

ActiveCN111019734AHigh oligomerization reactivityIncrease chlorine contentPhysical/chemical process catalystsHydrocarbonsPolyolefinPtru catalyst

The invention relates to a preparation method of poly-alpha-olefin base oil. The method comprises the following steps: S1, catalyzing an oligomerization reaction of an alpha-olefin mixture for 3-8 hours by using a Cr-AlCl3 / Al2O3 immobilized catalyst at a temperature of 50-120 DEG C under a pressure of 0.1-1.0 MPa and an alpha-olefin / solvent volume ratio of (1:0)-(1:1); and S2, after the reaction is stopped, filtering the catalyst, washing with distilled water, carrying out atmospheric distillation to remove the solvent, carrying out reduced pressure distillation to remove the unreacted alpha-olefin and part of the alpha-olefin dimer, and carrying out hydrogenation to obtain the poly-alpha-olefin base oil. The invention also relates to the poly-alpha-olefin base oil prepared by the method.The PAO base oil prepared by the method does not need to be mixed with low-viscosity PAO oil for PAO with a kinematic viscosity range of 30-40 mm<2> / s at 100 DEG C, so that the volatility of lubricating oil can be greatly reduced.

Owner:PETROCHINA CO LTD

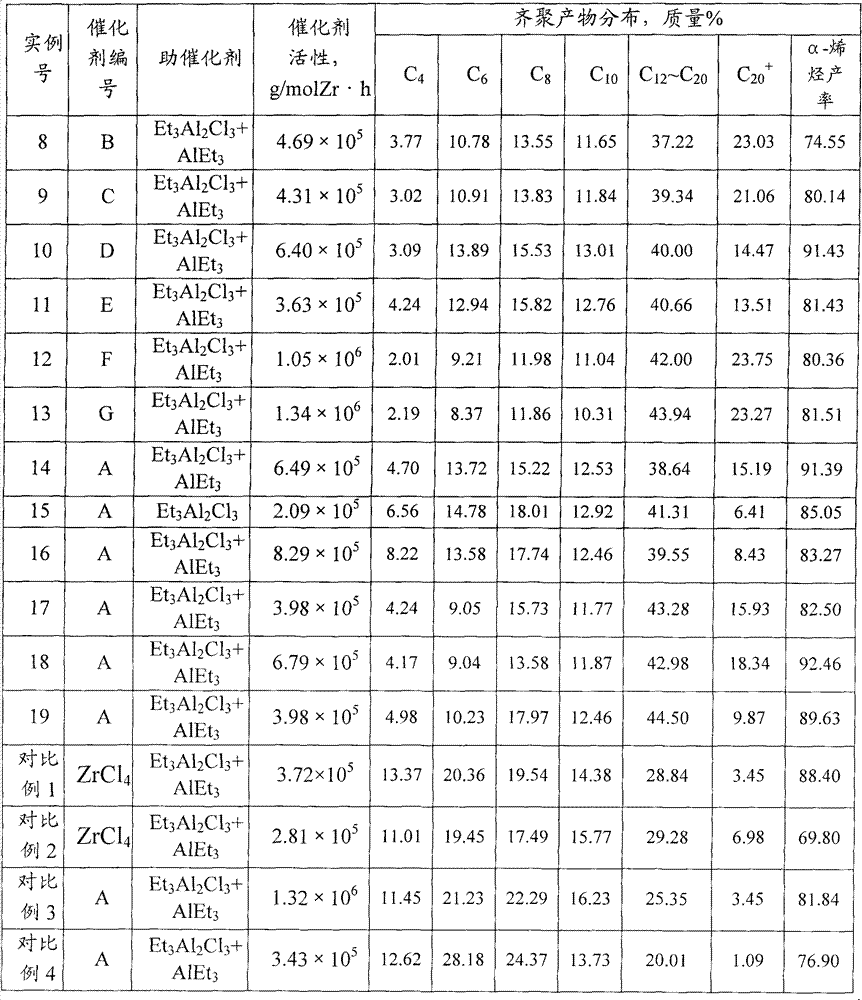

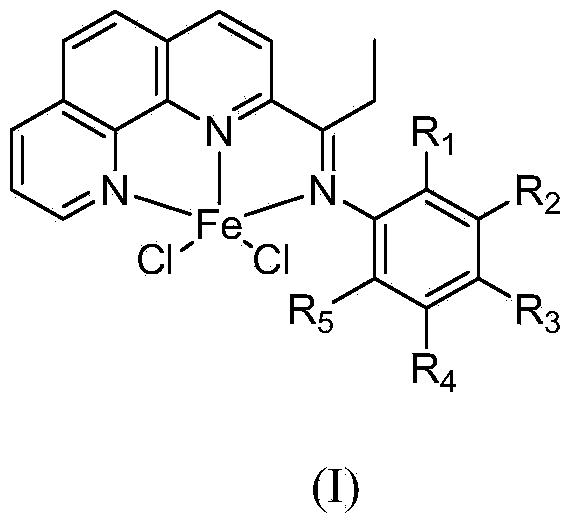

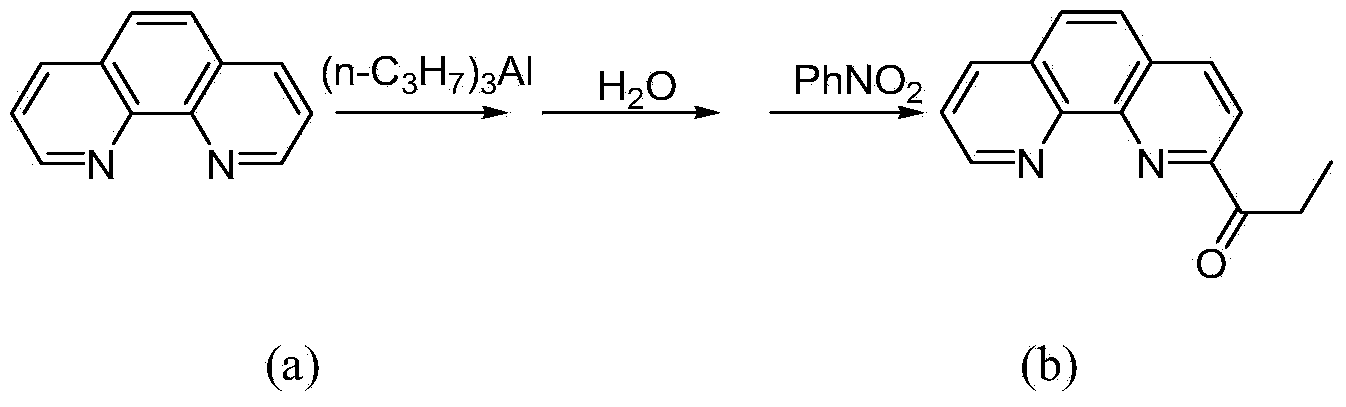

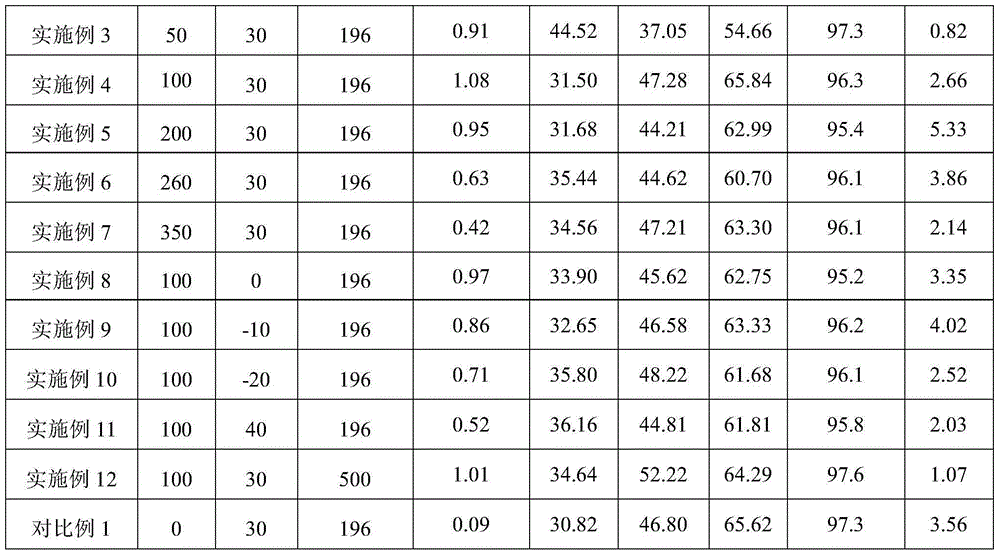

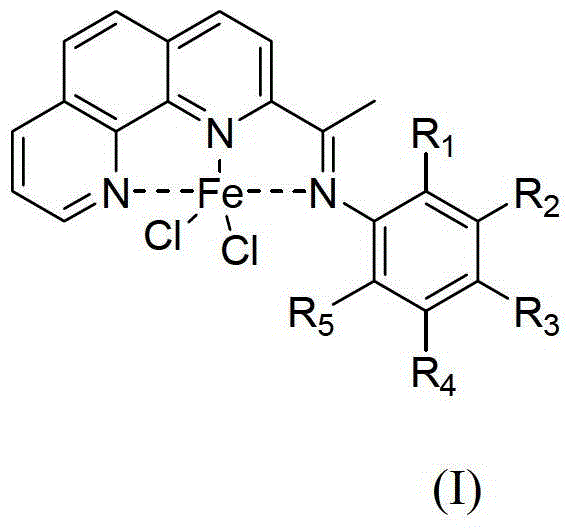

Catalyst composition for ethylene oligomerization and application thereof

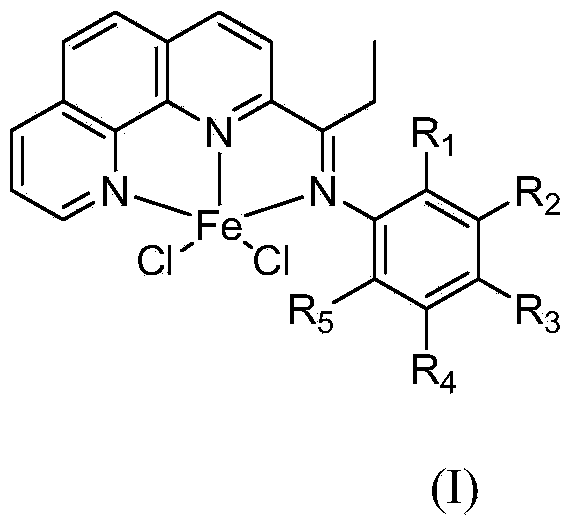

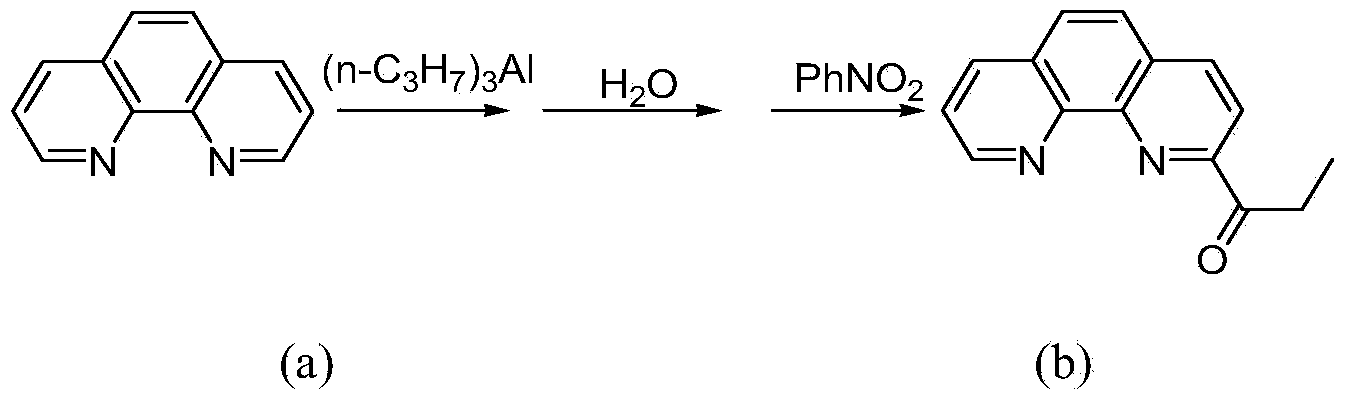

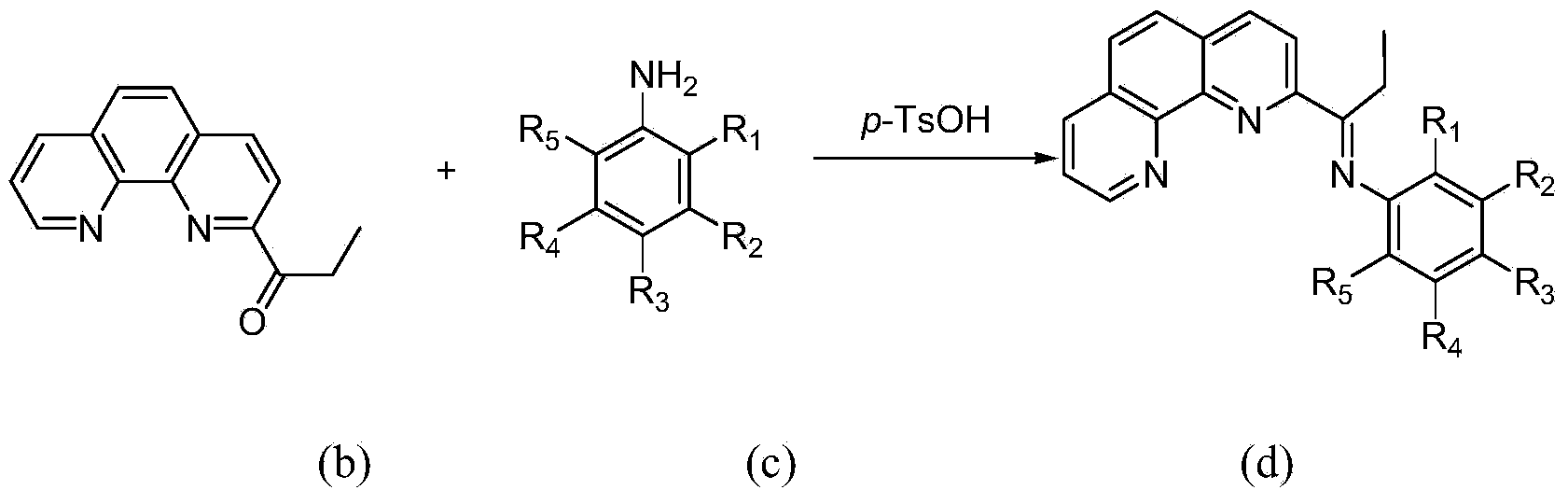

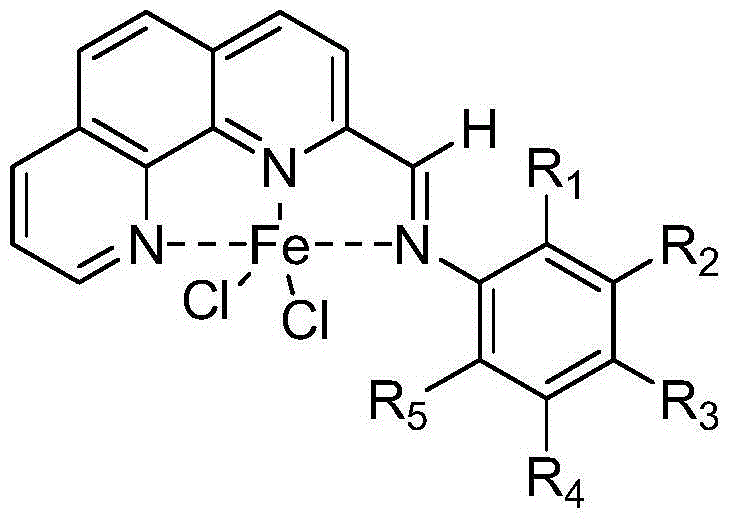

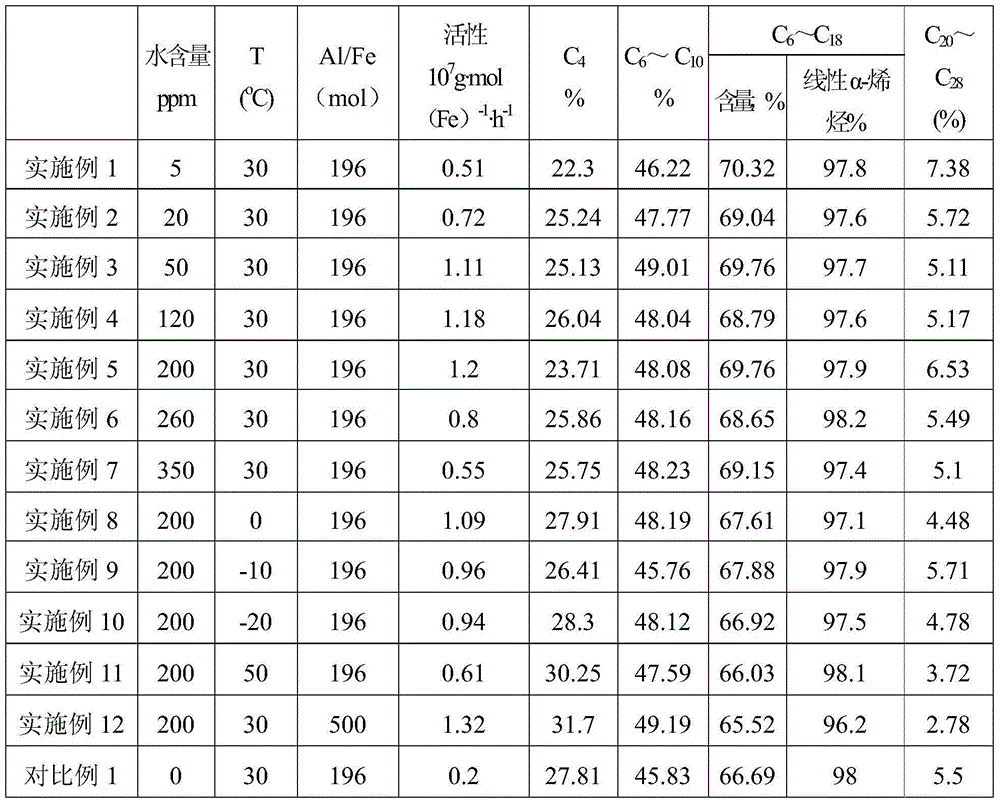

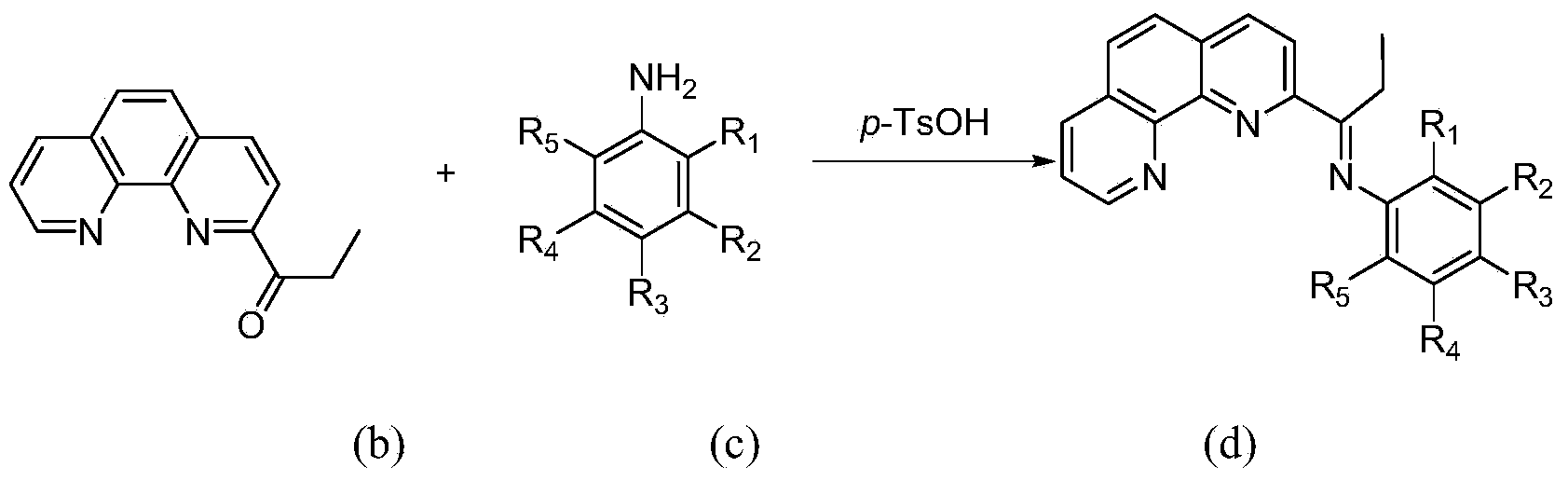

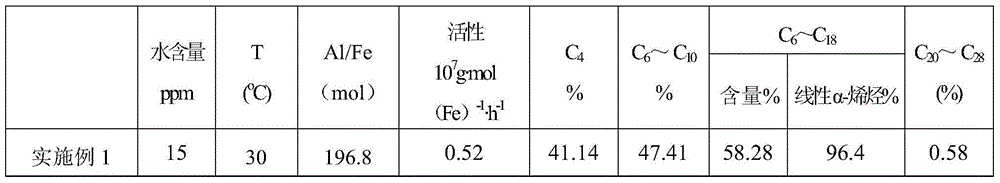

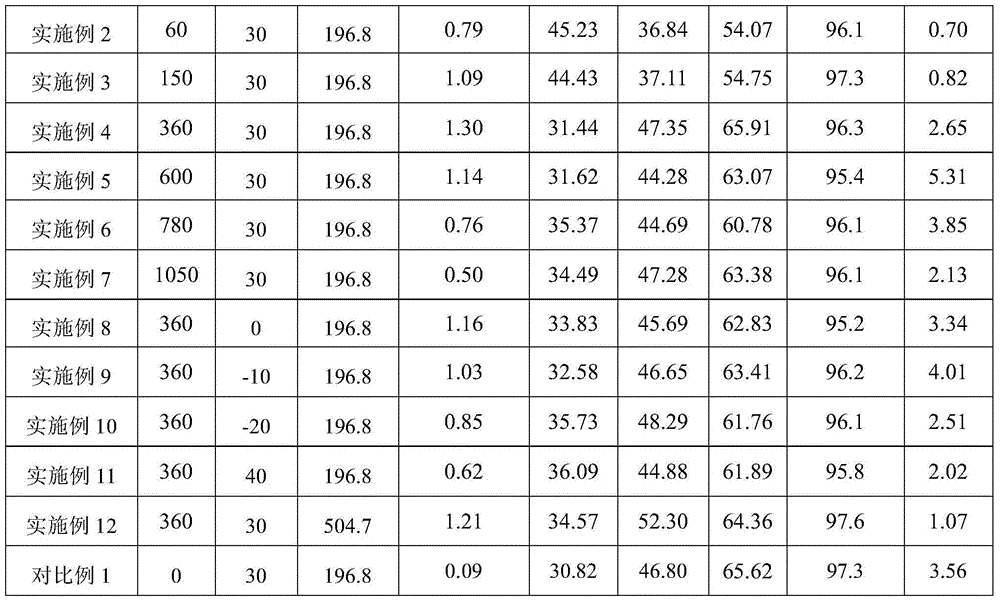

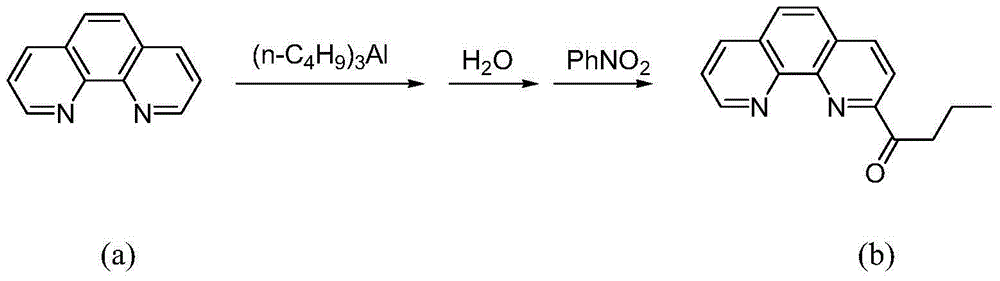

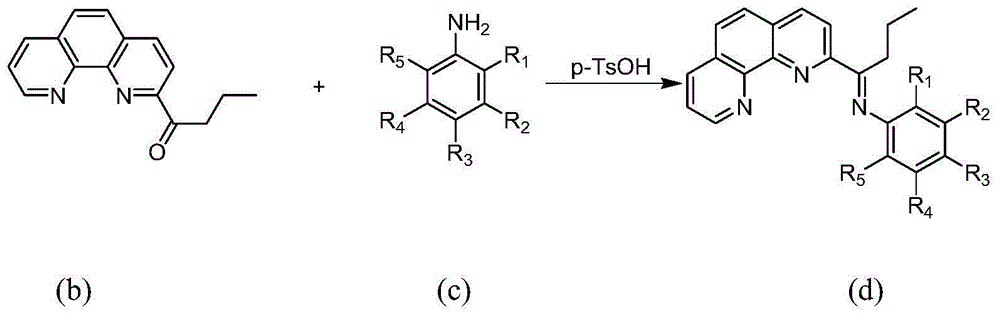

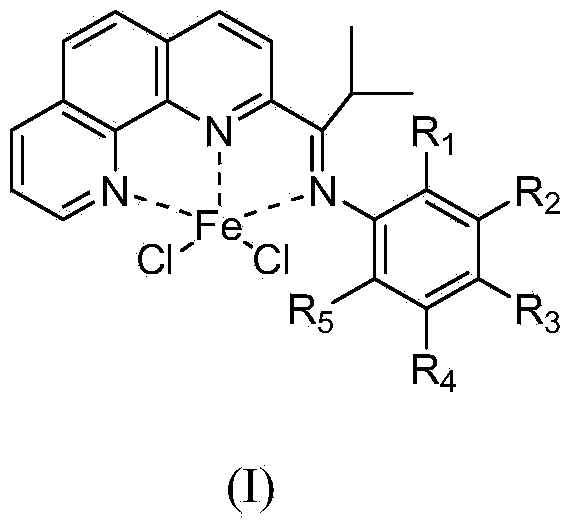

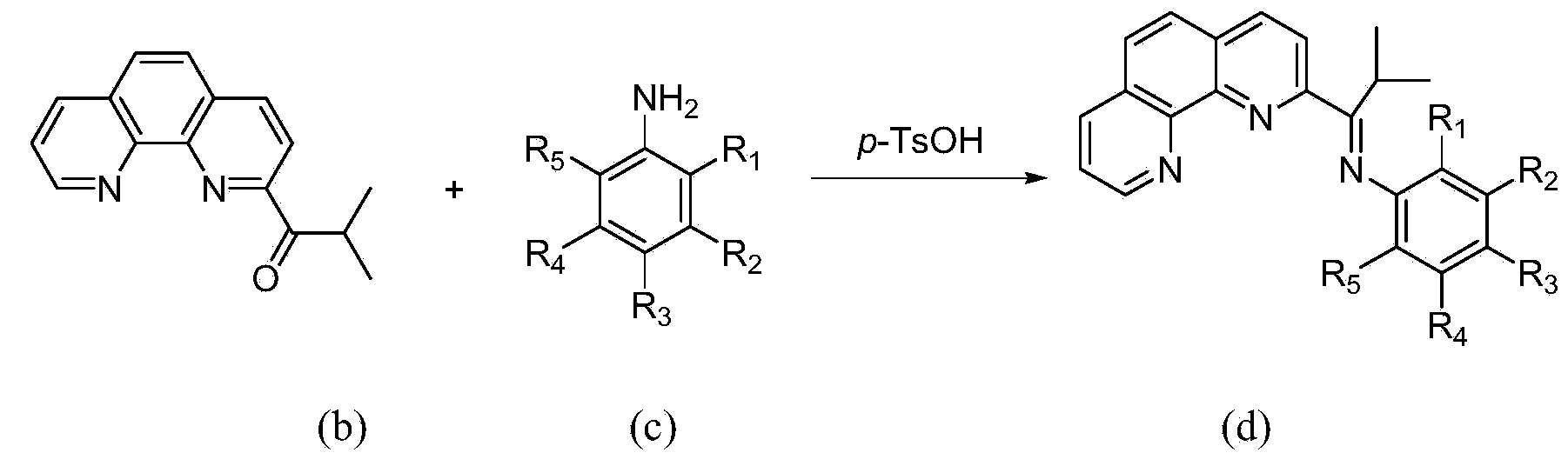

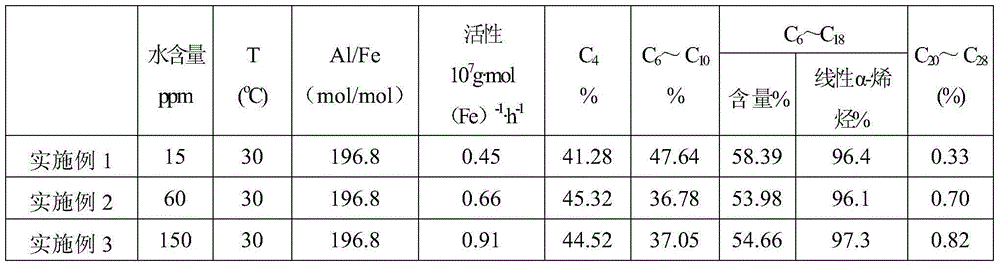

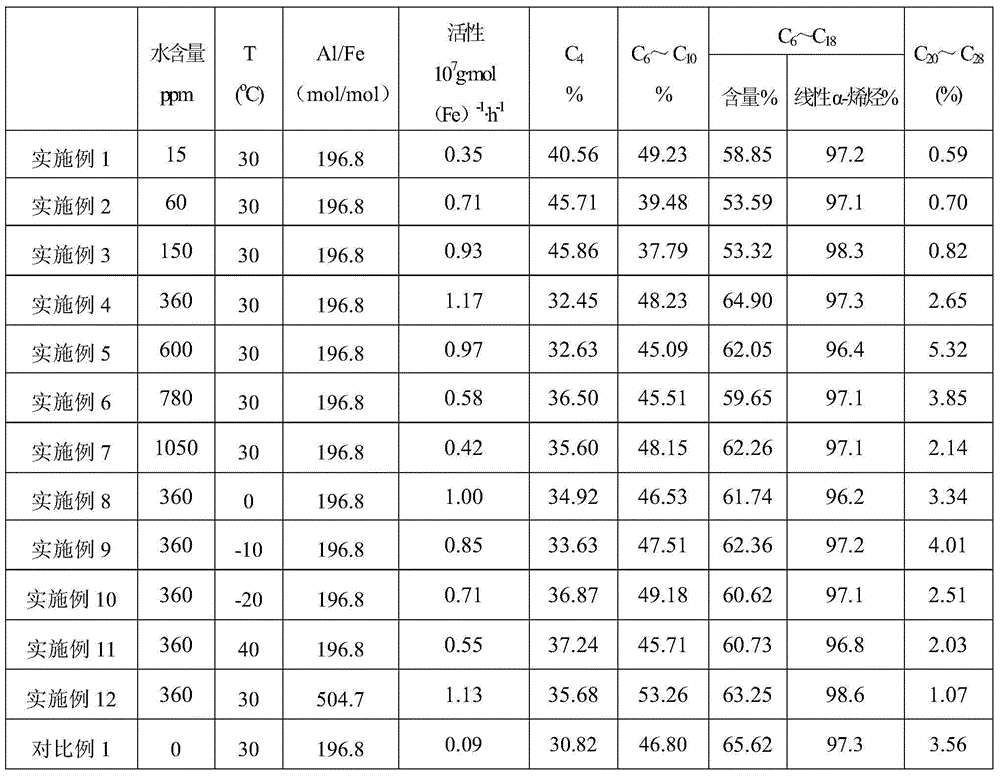

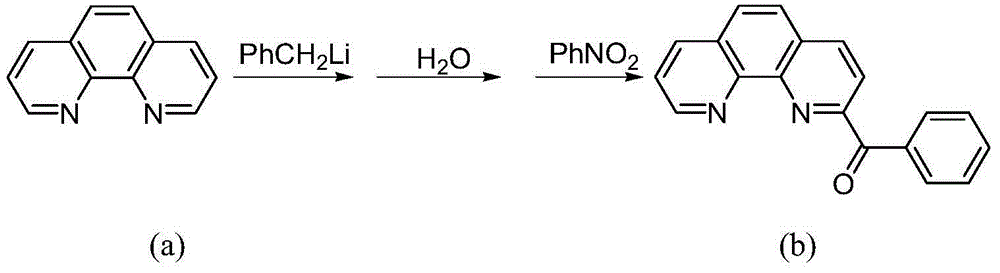

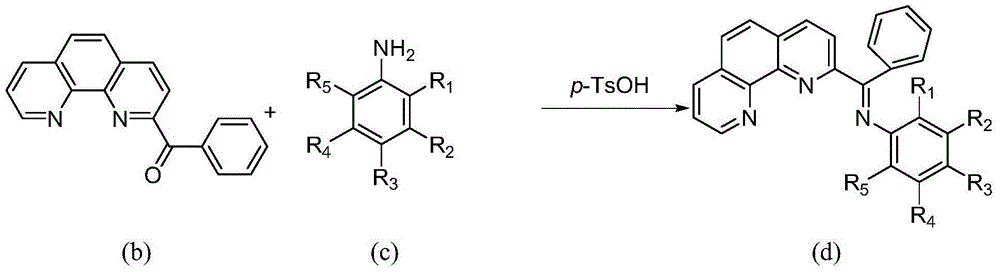

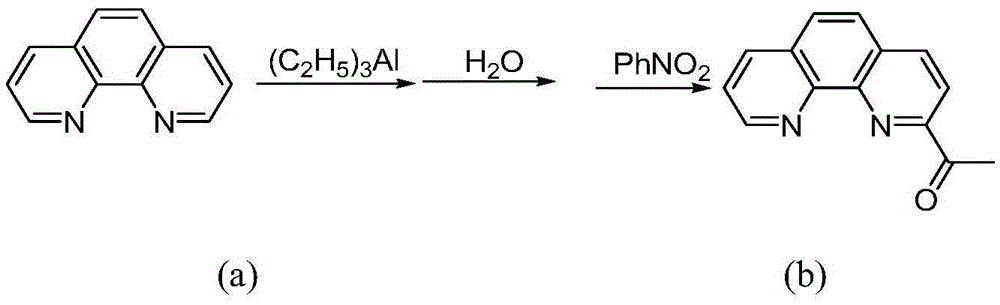

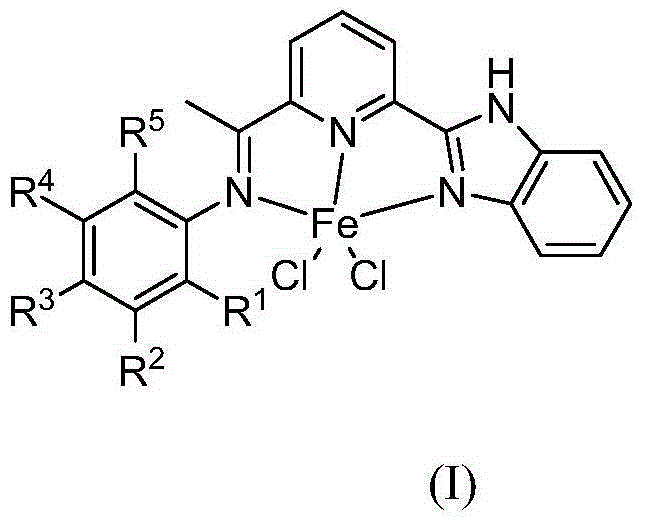

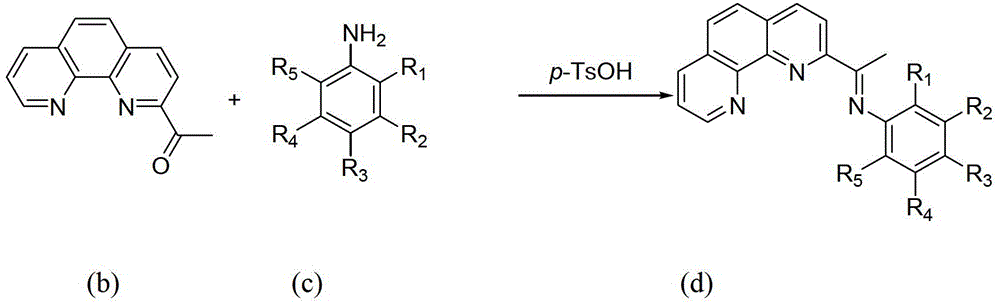

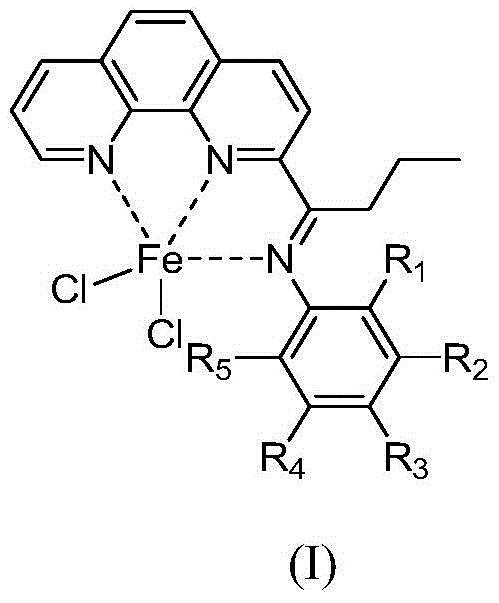

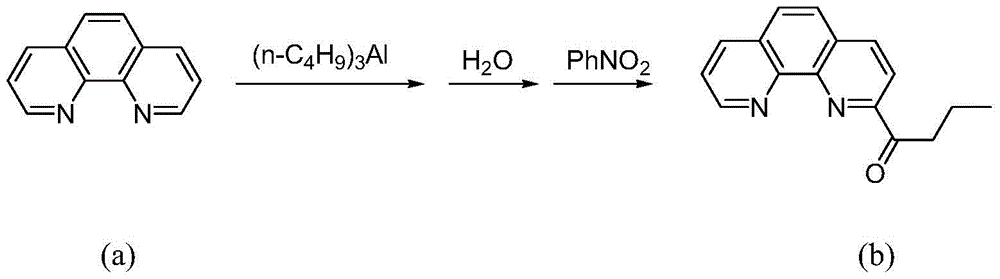

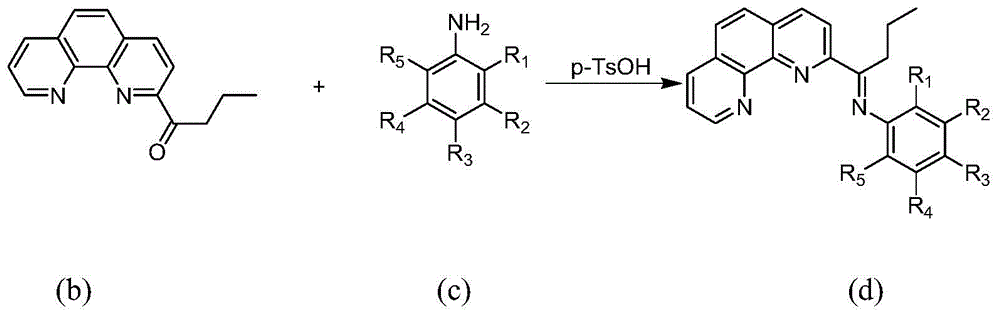

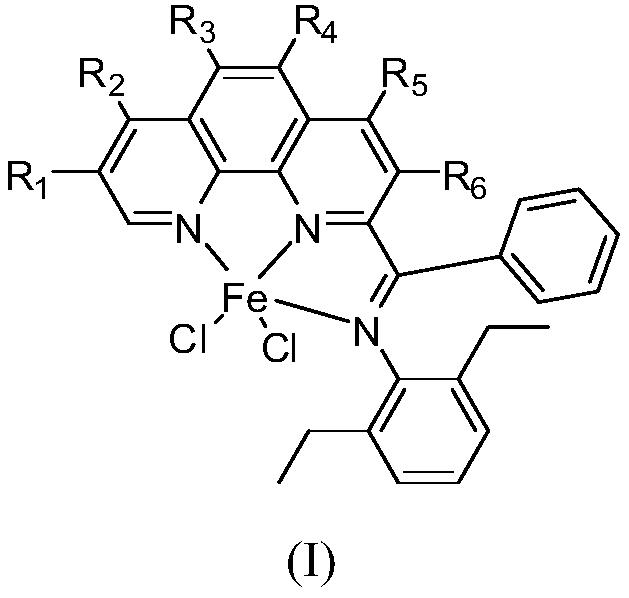

ActiveCN104107723AHigh ethylene oligomerization reactivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsOrganic solventHydrogen

The invention discloses a catalyst composition for ethylene oligomerization. The catalyst composition comprises chlorinated-2-n-propiono-1,10-phenanthroline amine iron (II) which is shown in a formula (I) as described in the specification and is used as a main catalyst, an aluminum-containing cocatalyst, water and an organic solvent. In the formula (I), R1 to R5 are independently selected from the group consisting of hydrogen, C1-6 alkyl groups, halogen, C1-6 alkoxy groups and a nitro group. According to the invention, the catalyst composition consisting of the complex main catalyst as shown in the formula (I), the aluminum-containing cocatalyst, water and the organic solvent is adopted for ethylene oligomerization, so high oligomerization reaction activity and high selectivity of alpha-olefin are obtained, and rapid initiation, stable operation and good repeatability of oligomerization are realized; even under the condition of a low aluminum / iron ratio, good oligomerization reaction activity is maintained, so technical biases of the skilled in the art are overcome and unexpected technical effects are obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

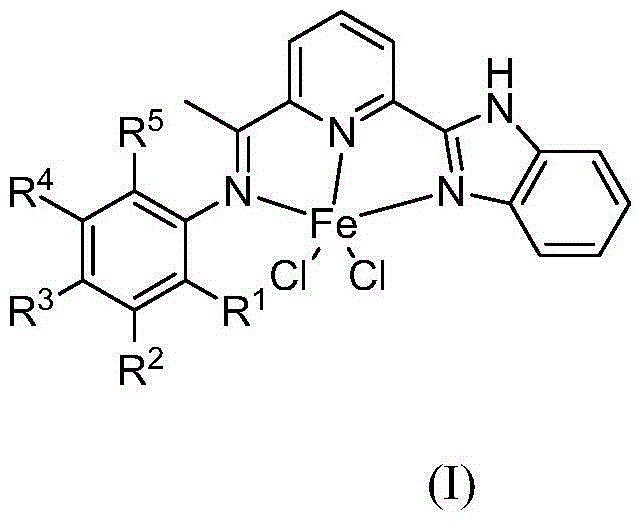

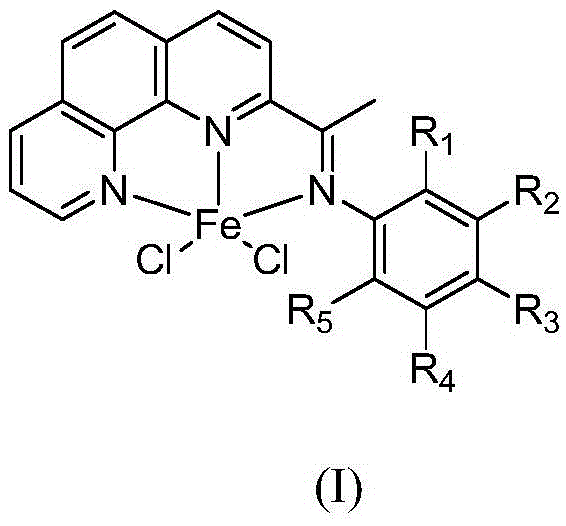

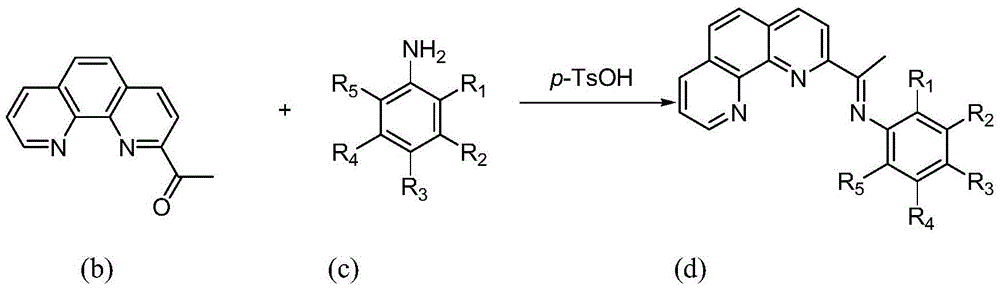

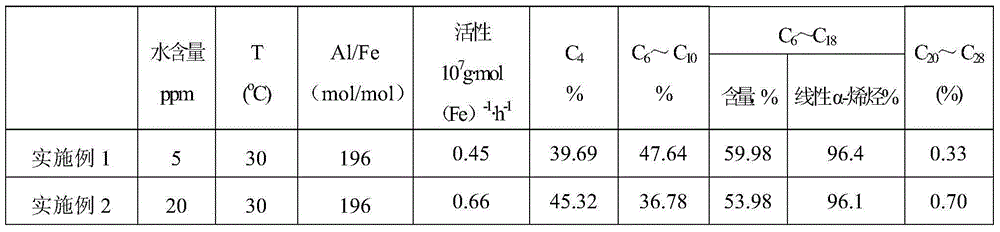

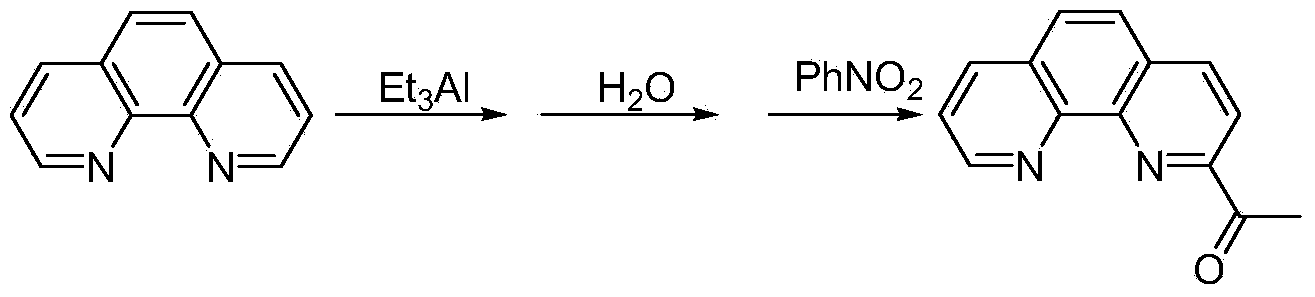

Catalyst composition for ethylene oligomerization and ethylene oligomerization method

ActiveCN104415789AHigh oligomerization reactivityTriggered quicklyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAluminiumCoordination complex

The invention provides a catalyst composition for ethylene oligomerization, which comprises a main catalyst of chlorinated 2-formyl-1,10-phenanthroline aminal iron (II) complex as shown in formula I, an aluminium-containing cocatalyst, water, and an organic solvent. When the catalyst composition of the invention is used in ethylene oligomerization reaction process, the catalyst compoeition has very high oligomerization reactivity, the selectivity for alpha-olefins is high, and the oligomerization reaction is rapid in initiation, stable in operation, and good in repeatability; even if the aluminium / iron ratio is low, the oligomerization reactivity is very good, so the cost of the ethylene oligomerization is greatly reduced, and the catalyst composition is strong in practicality, and wide in industrialization prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-cost poly-alpha-olefin base oil and preparation method thereof

InactiveCN103374433AEasy to makeImmobilized reaction efficiency is highTreatment with hydrotreatment processesBase-materialsAlpha-olefinTert butyl

The invention discloses a low-cost PAO (poly-alpha-olefin) base oil and a preparation method thereof. The preparation method comprises the following steps: carrying out oligomerization reaction on raw materials isobutylene and C8-C12 alpha-olefins at 50-80 DEG C under the hydrogen partial pressure of 0.25-0.4 MPa and the reaction pressure of 0.5-1.0 MPa by using gamma-aluminum oxide (gamma-Al2O3)-supported nickel (II)-organic aluminum as a catalyst and tert-butyl chlorine as a cocatalyst, and carrying out after-treatment to obtain oligomers; and hydrogenizing the oligomers to obtain the PAO base oil. The C8-C12 alpha-olefin content in the obtained PAO base oil is 60-81 omega%, the number-average molecular weight of the base oil is less than 550, the molecular weight distribution is less than 15, the 100 DEG C kinematic viscosity is 8.8-28.0 mm<2> / s, the viscosity index is 121-147, the pour point is -38 to -52 DEG C, and the bromine number is less than 0.050 bromine g / 100g PAO.

Owner:上海泰强粘合剂有限公司 +1

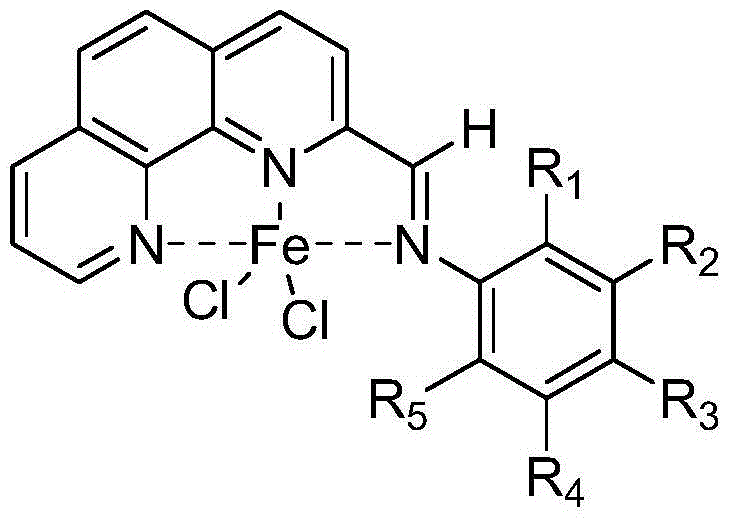

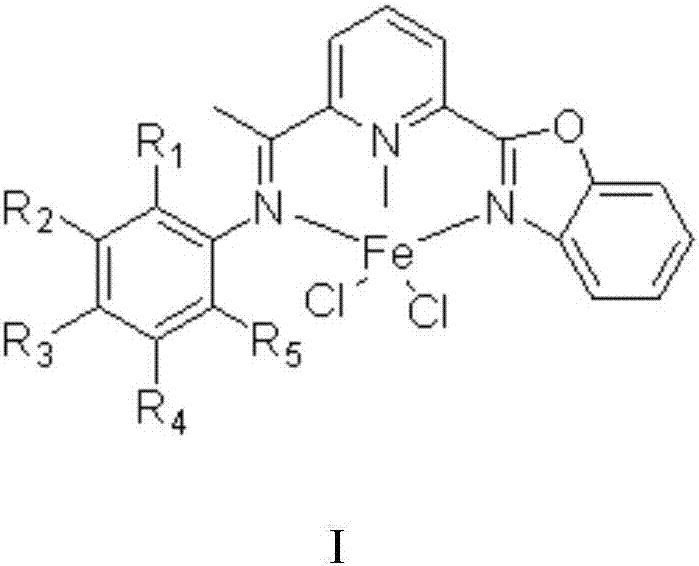

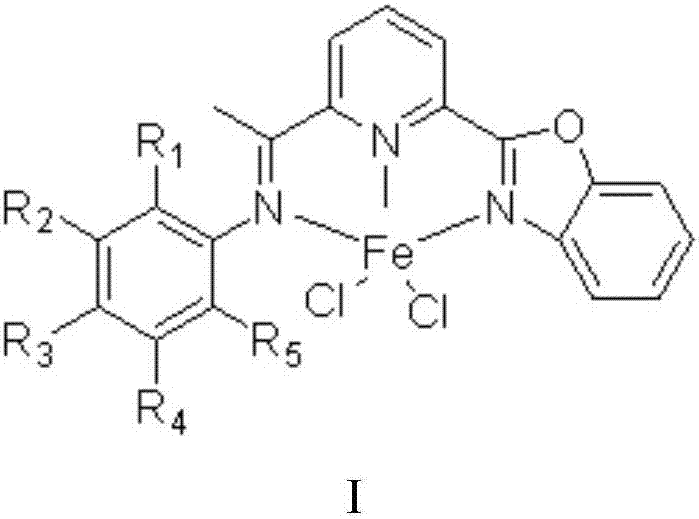

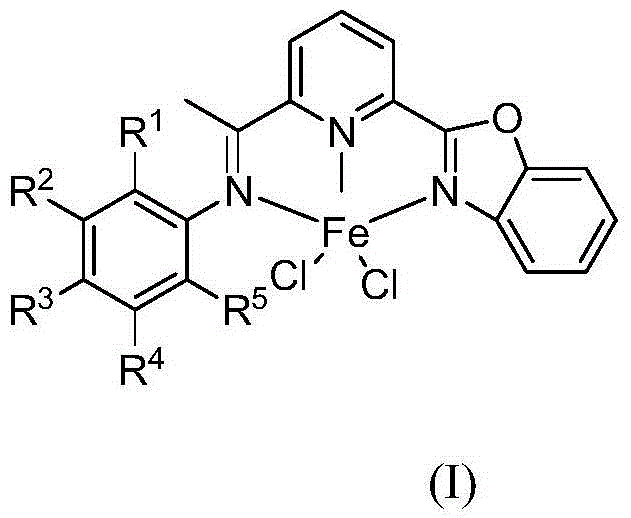

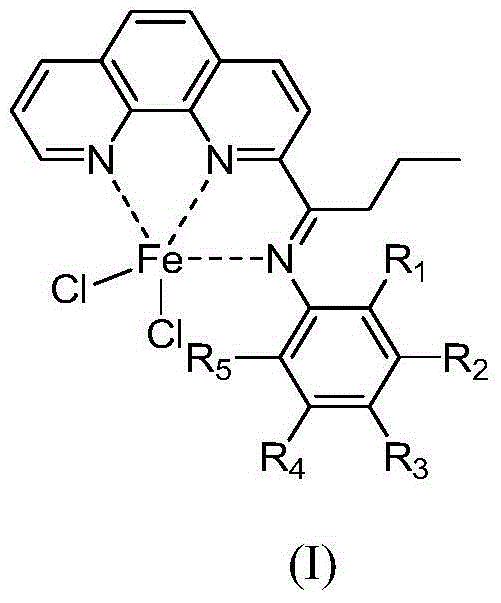

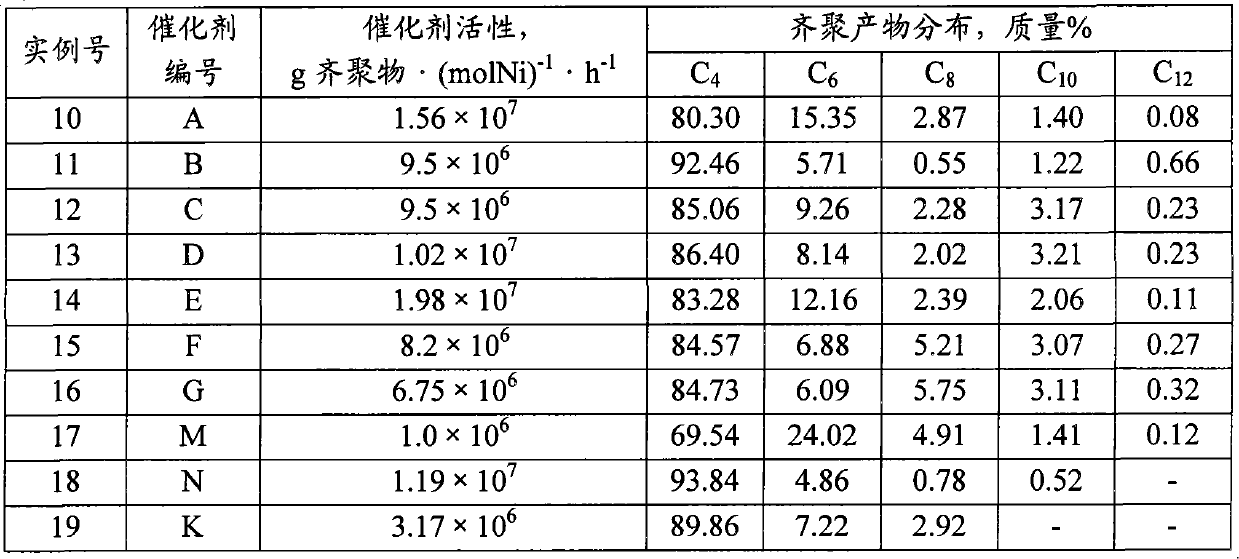

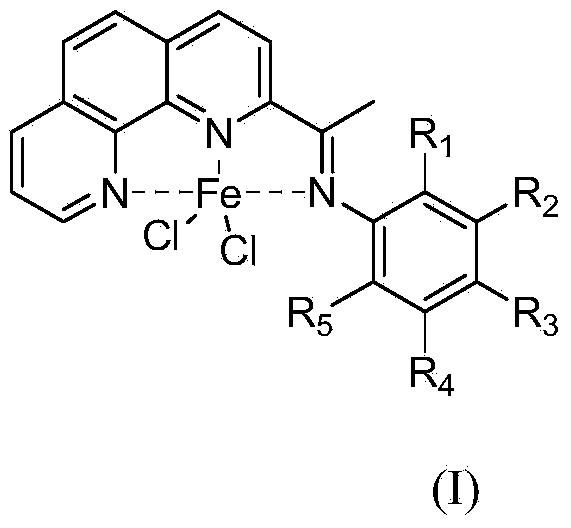

Ethylene oligomerization catalyst composition and application thereof

ActiveCN107282123ARapid responseImprove responseOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsBenzoxazoleChloride

The invention relates to an ethylene oligomerization catalyst composition which comprises a chloride 2-benzoxazolyl-6-acetyl condensed amino ferrite (II) complex shown in formula I, an aluminum-containing promoter and tert-butyl hydroperoxide. The invention further provides an ethylene oligomerization method. The ethylene oligomerization catalyst composition provided by the invention is applied to ethylene oligomerization, and is high in reaction activity at low temperature in the presence of low Al / Fe, that is, the reaction activity is up to 1.62*10<7>g.mol (Fe)<1>.h<1>.

Owner:CHINA PETROLEUM & CHEM CORP +1

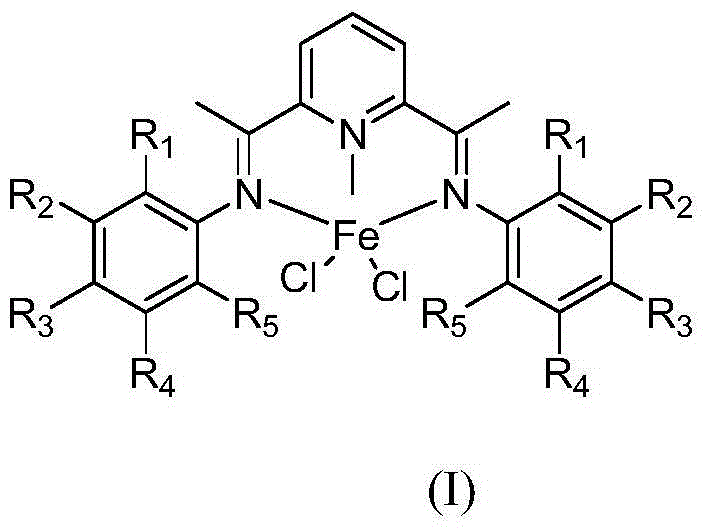

Ethene oligomerization continuous reaction method

ActiveCN105566038AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventAlpha-olefin

The invention discloses an ethene oligomerization continuous reaction method. The method comprises that a main catalyst 2, 6-diacetylpyridine(anil)FeCl2 shown in the formula (I), an aluminum-containing cocatalyst and an organic solvent are added into aqueous ethene as a raw material. The catalyst is used for an ethene oligomerization reaction process, has very high oligomerization reaction activity and high alpha-ethene selectivity, realizes fast oligomerization reaction initiation, stable reaction process and good repeatability and still has very good oligomerization reaction activity at a low aluminum / iron ratio. The ethene oligomerization continuous reaction method overcomes technology biases of the technicist in the field, produces unforeseeable technical effects, realizes good balance of catalysis effects and a cost, greatly reduces an ethene oligomerization reaction cost and has good practicality and a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene oligomerization catalyst and preparation method

ActiveCN101816951BHigh yieldReduce contentOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAlpha-olefin

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene oligomerization method

ActiveCN104109064AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsSolventHalogen

The invention discloses an ethylene oligomerization method. Ethylene is subjected to oligomerization in a reaction system consisting of n-propiono-substituted-1,10-phenanthroline amine iron (II) which is shown in a formula (I) as described in the specification and is used as a main catalyst, an aluminum-containing cocatalyst, water and an organic solvent. The solvent is alpha-olefin of Cn (n is greater than 4 and no less than 10). In the formula (I), R1 to R5 are independently selected from the group consisting of hydrogen, C1-C6 alkyl groups, halogen, C1-C6 alkoxy groups and a nitro group. The method overcomes technical biases, optimizes ethylene oligomerization process, has high oligomerization activity, enables rapid initiation, stable operation, low toxicity and environmental protection of the ethylene oligomerization process to be realized, allows good balance to be reached between a catalytic effect and cost and has good practicality; moreover, the method enables cost for ethylene oligomerization to be greatly decreased and has wide industrial prospects in overall consideration of the catalytic effect and production cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

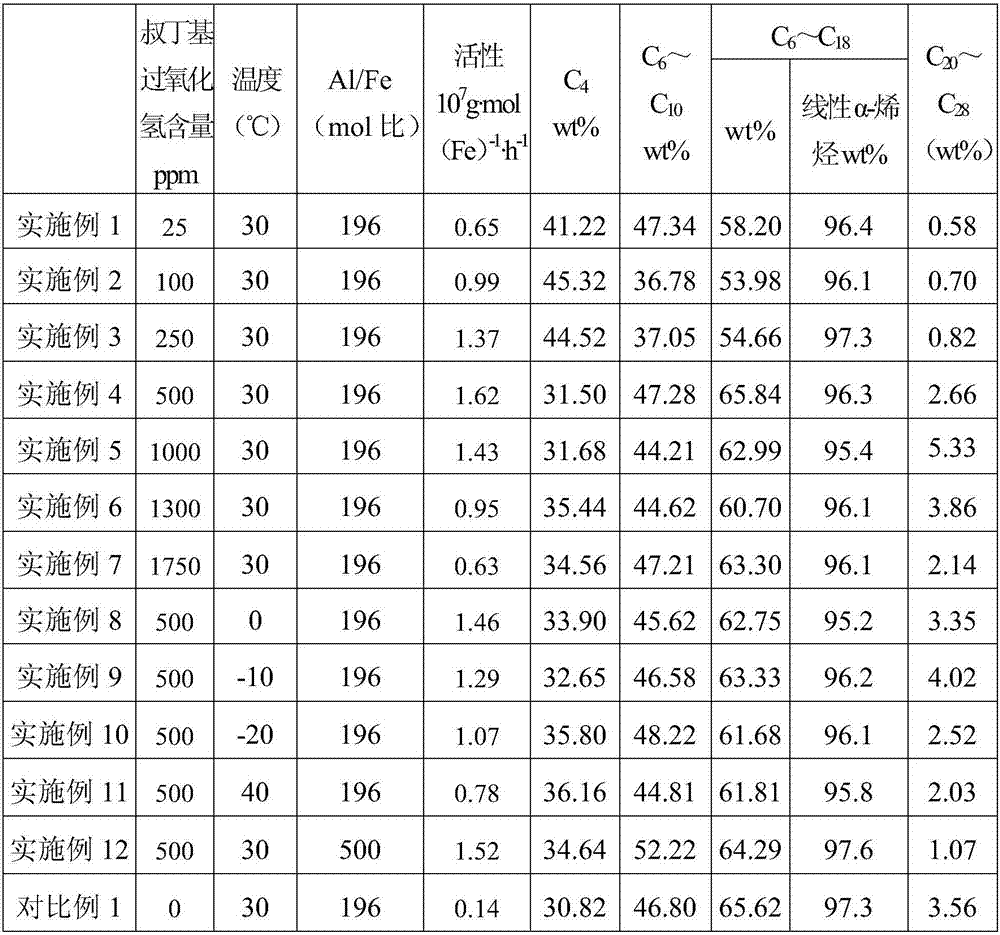

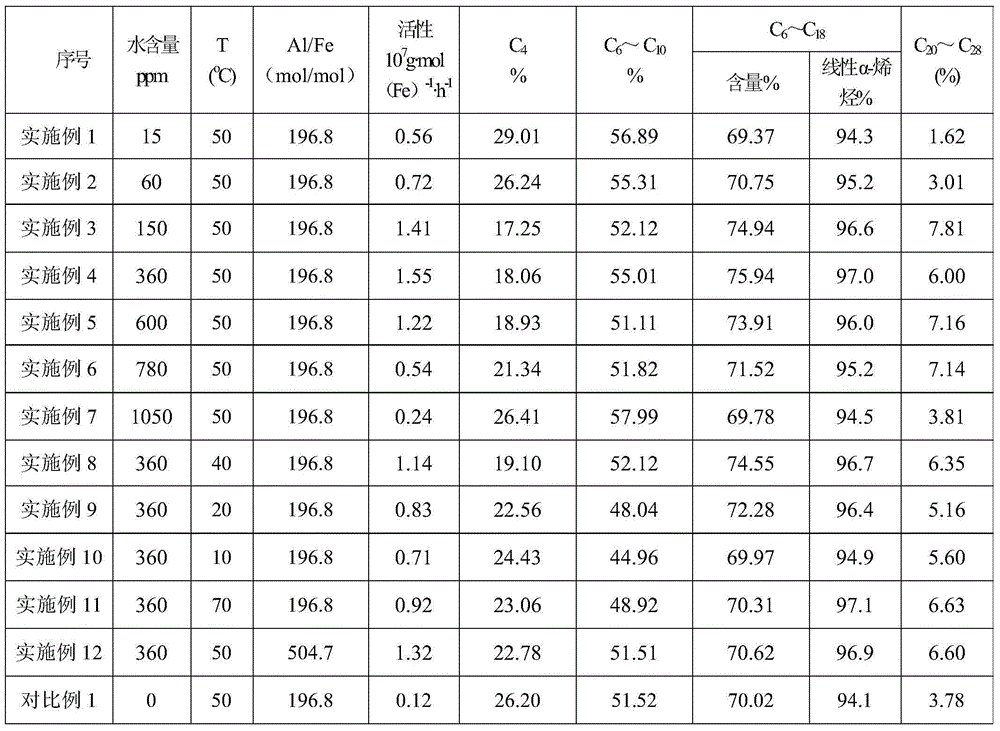

Ethene oligomerization continuous reaction method

ActiveCN105566025AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsBenzoxazoleOrganic solvent

The invention discloses an ethene oligomerization continuous reaction method. The method comprises that a main catalyst 2-benzoxazolyl-6-acetyl(anil)FeCl2 shown in the formula (I), an aluminum-containing cocatalyst and an organic solvent are added into aqueous ethene as a raw material. The catalyst is used for an ethene oligomerization reaction process, has very high oligomerization reaction activity and high alpha-ethene selectivity, realizes fast oligomerization reaction initiation, stable reaction process and good repeatability and still has very good oligomerization reaction activity at a low aluminum / iron ratio. The ethene oligomerization continuous reaction method overcomes technology biases of the technicist in the field, produces unforeseeable technical effects, realizes good balance of catalysis effects and a cost, greatly reduces an ethene oligomerization reaction cost and has good practicality and a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

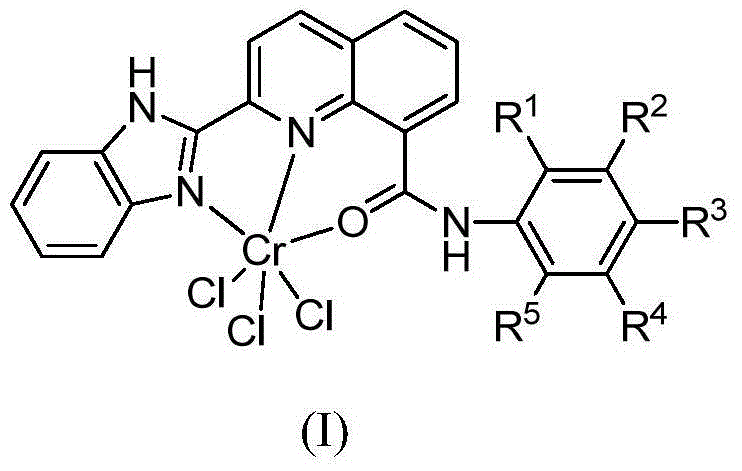

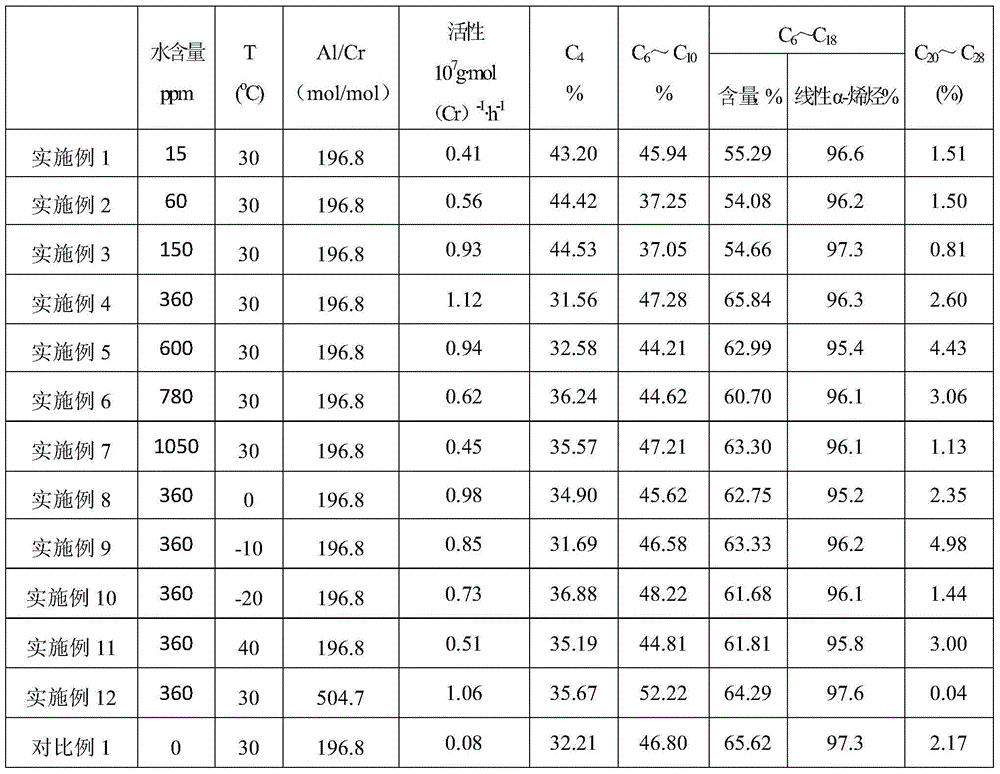

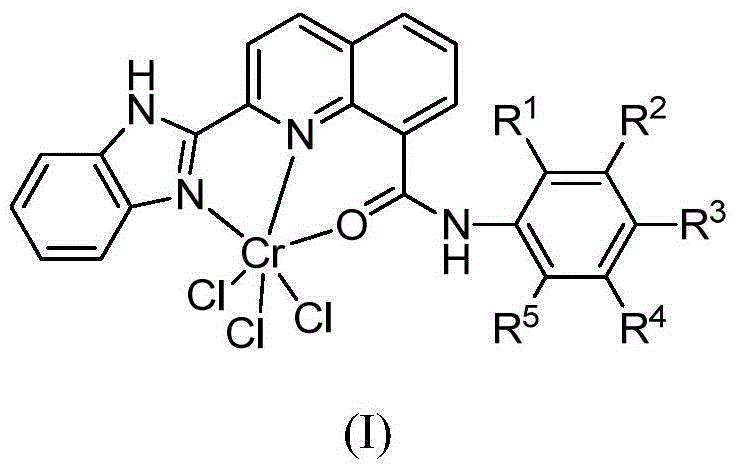

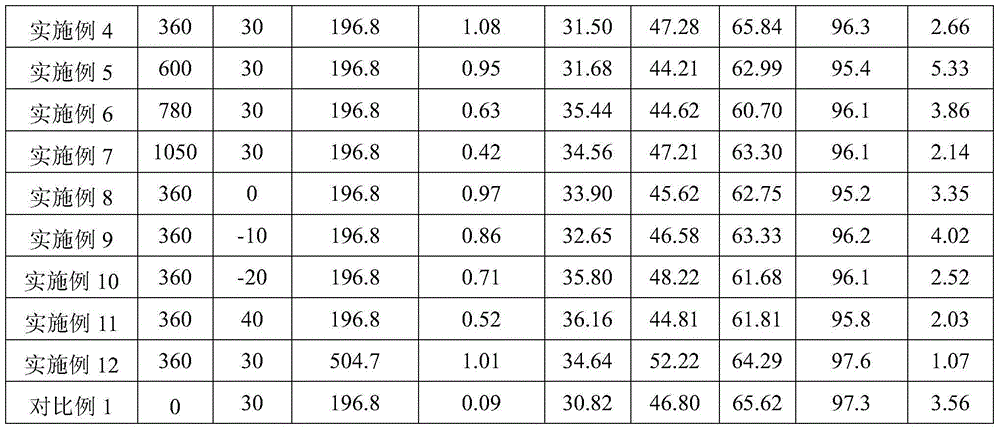

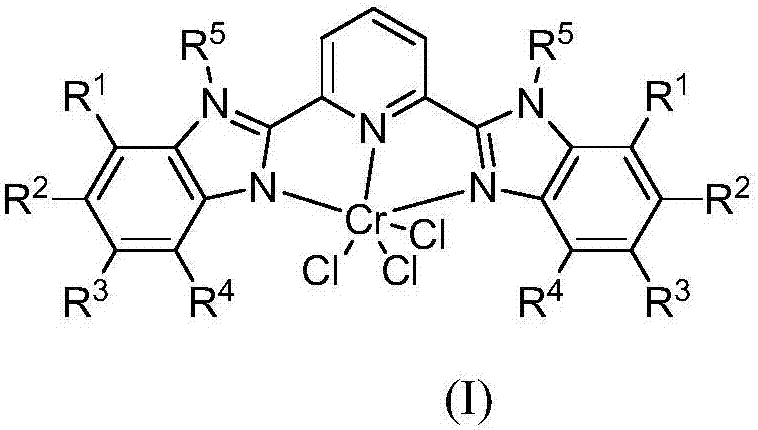

Ethylene oligomerization continuous reaction method

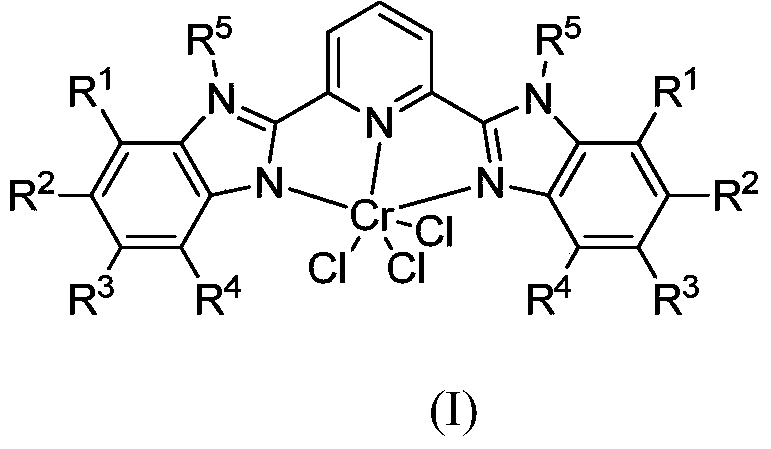

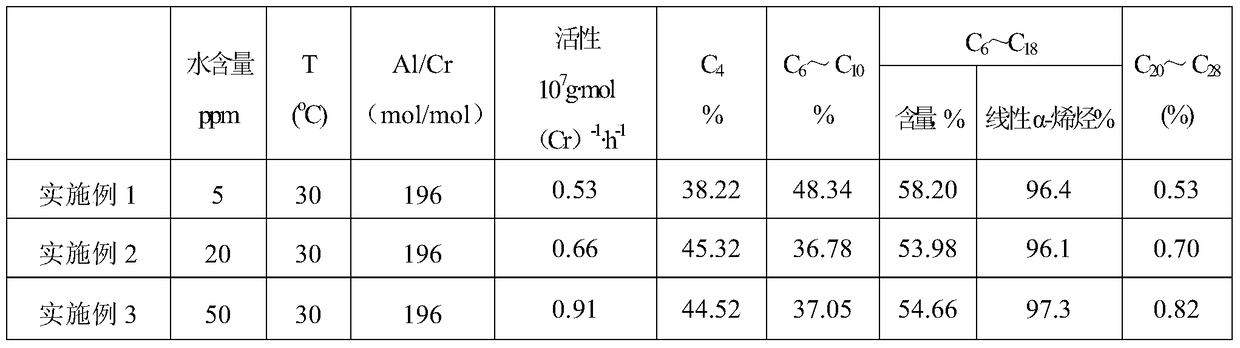

ActiveCN105566041AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventCatalytic effect

The invention discloses an ethylene oligomerization reaction method; with adopting of water-containing ethylene as a raw material, and under the action of a main catalyst chloro-2-(1H-2-benzoimidazole)-8-acetanilide quinoline chromium (III) complex represented by the formula (I), an aluminum-containing co-catalyst and an organic solvent, an ethylene oligomerization reaction is performed; according to the method, the method is used for the ethylene oligomerization reaction process, the oligomerization reaction activity is high, the selectivity of alpha-olefin is high, the oligomerization reaction is fast to initiate, the operation is smooth and steady, and the repeatability is good; even when the aluminum / chromium ratio is low, the catalyst still has good oligomerization reaction activity; therefore, the technical prejudice of technical personnel in the field is overcome, unexpected technical effects are obtained, and the catalytic effect and cost are better balanced, so that the cost of the ethylene oligomerization reaction is significantly decreased, the practicality is high, and the prospects for industrialization are broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oligomerization method of ethylene

ActiveCN104628502AHigh selectivityEliminate pollutionHydrocarbonsHydrocarbon preparationCarbon numberHalogen

The invention discloses an oligomerization method of ethylene. The ethylene carries out oligomerization reactions in a reaction system composed of a main catalyst, an aluminum-containing co-catalyst, water and an organic solvent; wherein the main catalyst is chlorinated 2-n-butyryl-1,10-phenanthroline amine-Fe (II) represented by the formula (I), the organic solvent is alpha-alkene with n carbons (4<n<=10), and in the formula (I), and the R1, R2, R3, R4, and R5 individually represent a hydrogen atom, an alkyl group with a carbon number of 1 to 6, a halogen atom, an alkyloxy group with a carbon number of 1 to 6, or a nitro group. The provided oligomerization method overcomes the technical bias, and optimizes the oligomerization technology. In the provided method, the oligomerization activity is high, thus the ethylene oligomerization reactions can be triggered rapidly, the operation of the technology is stable, the method is environment-friendly, the toxicity is greatly reduced, the catalytic effect and cost are well balanced, the provided method is very practical and greatly reduces the ethylene oligomerization cost, the catalytic effect and production cost are taken into account as a whole, and the industrialization prospect of the oligomerization method is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

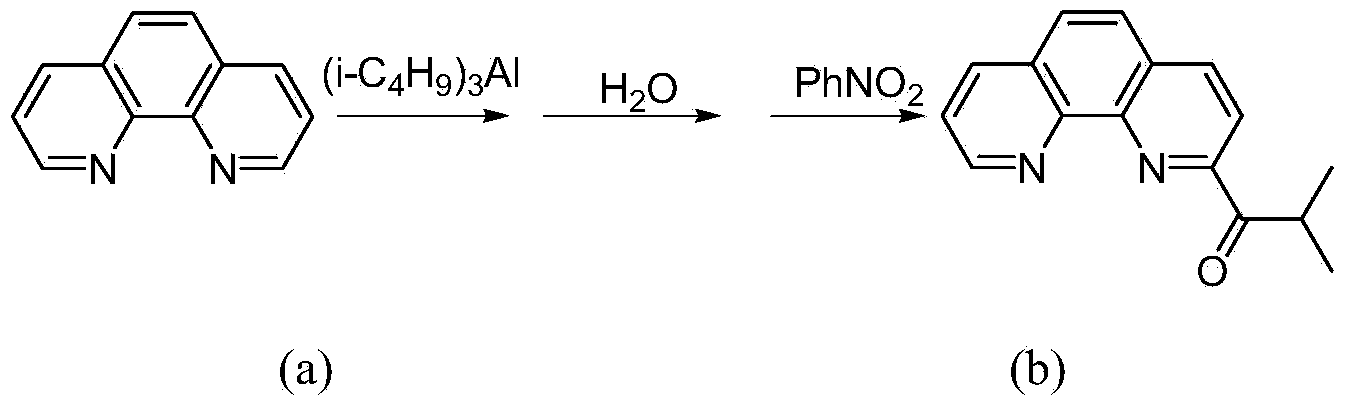

Catalyst composition for ethylene oligomerization and application thereof

ActiveCN104107724AHigh selectivityHigh ethylene oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsHydrogenOrganic solvent

The invention discloses a catalyst composition for ethylene oligomerization. The catalyst composition comprises chlorinated-2-isobutyryl-1,10-phenanthroline amine iron (II) which is shown in a formula (I) as described in the specification and is used as a main catalyst, an aluminum-containing cocatalyst, water and an organic solvent. In the formula (I), R1 to R5 are independently selected from the group consisting of hydrogen, C1-C6 alkyl groups, halogen, C1-C6 alkoxy groups and a nitro group. With the oligomerization catalyst composition and method provided by the invention for ethylene oligomerization, technical biases are overcome, ethylene oligomerization process is optimized, high oligomerization activity is obtained, the application amount of the cocatalyst is small, rapid initiation and stable operation of ethylene oligomerization process are realized, good balance is reached between a catalytic effect and cost, good practicality is obtained, and cost for ethylene oligomerization is greatly decreased; in overall consideration of the catalytic effect and production cost, the catalyst has wide industrial prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Load-type olefin oligomerization catalyst and preparation method thereof

ActiveCN101618344AHigh oligomerization reactivityCarbon number distribution is wideOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAcetic acidHydrogen

The invention discloses a load-type olefin oligomerization catalyst, which comprises a complex loaded on a medium-pore aluminum silica material and having an expression shown as formula (I). The catalyst contains 0.1 to 5.0 mass percent of nickel; in the formula (I), R is selected from hydrogen, alkyl of C1 to C12, alkoxy or nitryl of C1 to C6, X is halogen or acetate moiety, and n is 1 or 2; the medium-pore aluminum silica material has a pseudo-boehmite phase structure, and comprises the anhydrous chemical composition based on the mass of oxide of (0-0.3)Na2O.(40-90)Al2O3.(10-60)SiO2, the specific surface area of the medium-pore aluminum silica material is between 200 and 400m<2> / g, the pore volume is between 0.5 and 2.0 ml / g, the average aperture is between 8 and 20nm and the most probable aperture is between 5 and 15nm. The catalyst is used for olefin oligomerization and has higher reaction activity; and oligomerization products have wider distribution range without generating polymers.

Owner:CHINA PETROLEUM & CHEM CORP +1

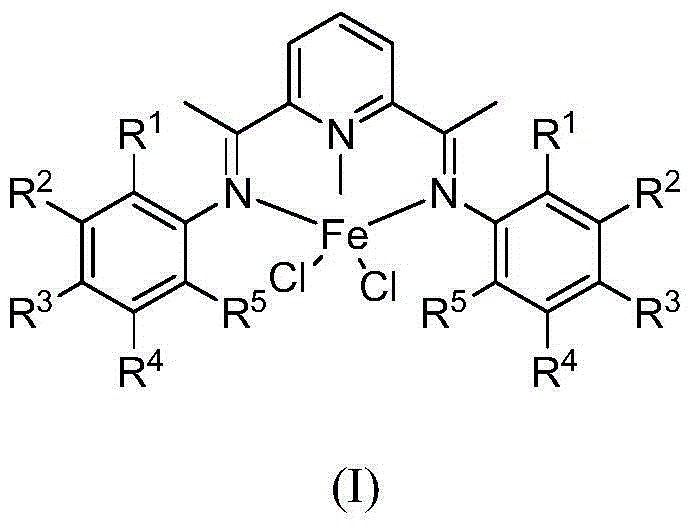

Ethene oligomerization continuous reaction method

ActiveCN105566040AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventAlpha-olefin

The invention discloses an ethene oligomerization continuous reaction method. The method comprises that a main catalyst 2-acetyl-6-(1H-benzimidazolyl)(anil)FeCl2 shown in the formula (I), an aluminum-containing cocatalyst and an organic solvent are added into aqueous ethene as a raw material. The catalyst is used for an ethene oligomerization reaction process, has very high oligomerization reaction activity and high alpha-ethene selectivity, realizes fast oligomerization reaction initiation, stable reaction process and good repeatability and still has very good oligomerization reaction activity at a low aluminum / iron ratio. The ethene oligomerization continuous reaction method overcomes technology biases of the technicist in the field, produces unforeseeable technical effects, realizes good balance of catalysis effects and a cost, greatly reduces an ethene oligomerization reaction cost and has good practicality and a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethene oligomerization continuous reaction method

ActiveCN105566039AHigh oligomerization reactivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsAluminiumOrganic solvent

The invention discloses an ethene oligomerization continuous reaction method. The method comprises that a main catalyst 2, 8-diacetylquinoline(anil)FeCl2 shown in the formula (I), an aluminum-containing cocatalyst and an organic solvent are added into aqueous ethene as a raw material. The catalyst is used for an ethene oligomerization reaction process, has very high oligomerization reaction activity and high alpha-ethene selectivity, realizes fast oligomerization reaction initiation, stable reaction process and good repeatability and still has very good oligomerization reaction activity at a low aluminum / iron ratio. The ethene oligomerization continuous reaction method overcomes technology biases of the technicist in the field, produces unforeseeable technical effects, realizes good balance of catalysis effects and a cost, greatly reduces an ethene oligomerization reaction cost and has good practicality and a wide industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene oligomerization method

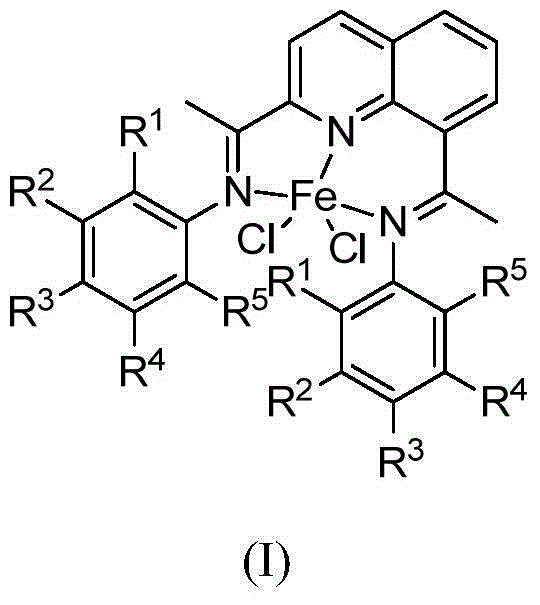

ActiveCN104628503AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsHydrogenHalogen

The present invention discloses an ethylene oligomerization method, which comprises that ethylene is subjected to an oligomerization reaction in a reaction system containing an iron 2-benzoyl-1,10-phenanthroline polyamine chloride coordination compound main catalyst represented by a formula (I), an aluminum-containing cocatalyst, water and an organic solvent, wherein the organic solvent is alpha-olefin of Cn (n is more than 4 and is less than or equal to 10), and in the formula, R1-R5 are respectively and independently selected from hydrogen, C1-C6 alkyl, halogen, C1-C6 alkoxy and nitro. According to the present invention, the technical prejudice is overcome, and the oligomerization reaction process is optimized, such that the oligomerization activity is high, the ethylene oligomerization reaction process has characteristics of rapid initiation, stable operation, low toxicity, environmental protection, good catalysis effect and cost balancing, and strong practicality, the ethylene oligomerization reaction cost is substantially reduced, the catalytic effect and the production cost are comprehensively considered, and the industrial prospect is broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of ethylene oligomerization

ActiveCN104418690BHigh selectivityEliminate pollutionHydrocarbonsBulk chemical productionHalogenHydrogen

Owner:CHINA PETROLEUM & CHEM CORP +1

Load-type olefin oligomerization catalyst and preparation method thereof

ActiveCN101618344BHigh oligomerization reactivityCarbon number distribution is wideOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsCoordination complexPolymer

Owner:CHINA PETROLEUM & CHEM CORP +1

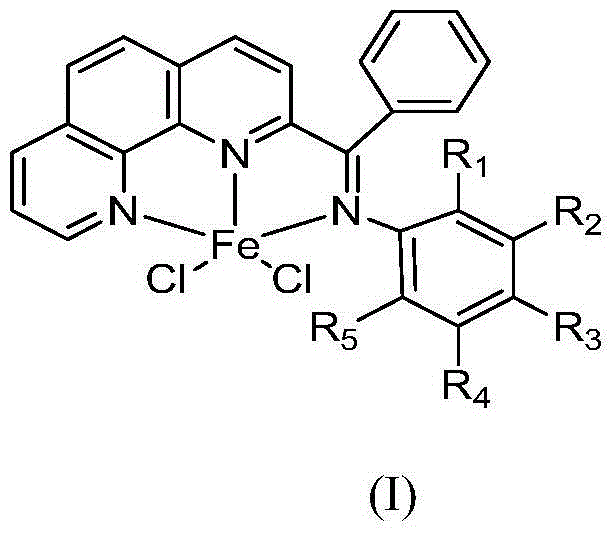

Catalyst composition used for ethylene oligomerization, and application thereof

ActiveCN105562085AHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventAlpha-olefin

The invention discloses a catalyst composition used for an ethylene oligomerization reaction technology. The composition comprises a main catalyst 2-acetyl-6-(1H-2-benzoxazolyl)aminochloro iron (II) complex represented by formula (I), an aluminum-containing cocatalyst, water and an organic solvent. The catalyst composition prepared in the invention is used in the ethylene oligomerization reaction technology, has the advantages of very high oligomerization reaction activity, high selectivity of alpha-olefin, rapid initiation of the oligomerization reaction, stable running and good repeatability, still has very good oligomerization reaction activity even if the aluminum / iron ratio is low, so the technical prejudice of technical personnel in the field is overcome, an unexpected technical effect is achieved, and the catalysis effect and the cost are well balanced, thereby the ethylene oligomerization reaction cost is greatly reduced, the practicality is strong, and the industrial prospect is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of catalyst composition for ethylene oligomerization

ActiveCN104338557BHigh ethylene oligomerization reactivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventPhenanthroline

The invention discloses a catalyst composition for an ethylene oligomerization reaction technology. The catalyst composition comprises a main catalyst, chlorination 2-acetyl-1,10-phenanthroline amine iron (II) complex, an aluminiferous promoter, water and an organic solvent. According to the invention, the catalyst composition is adopted for the ethylene oligomerization reaction technology, and has very high oligomerization reaction activity; alpha-olefin is high in selectivity, and the oligomerization reaction is triggered rapidly, runs stably and is good in repeatability; even though the aluminum / ferrum ratio is low, the catalyst composition still has very good oligomerization reaction activity, so that the technical prejudice of technicians in the field is overcome, unexpected technical effects are obtained, and the catalytic effect and cost are balanced well; therefore, the cost of the oligomerization reaction is lowered greatly, and the catalyst composition is high in practicability, and has wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst composition for ethylene oligomerization and application thereof

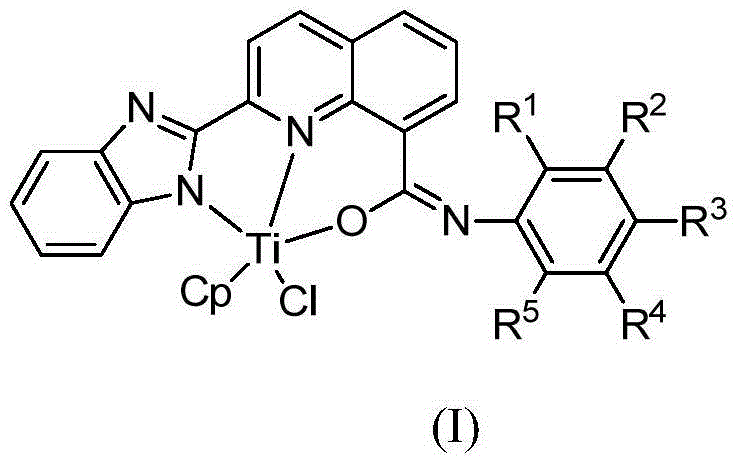

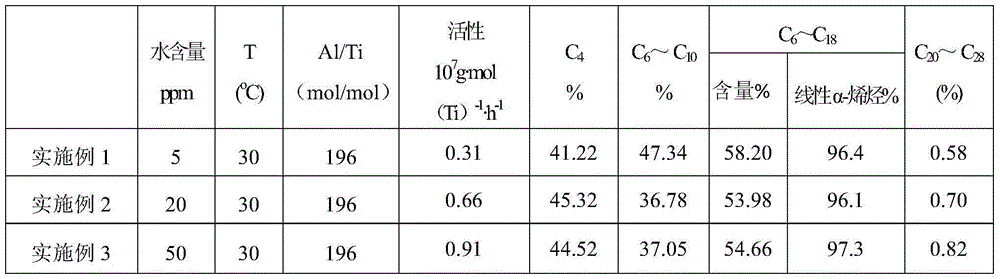

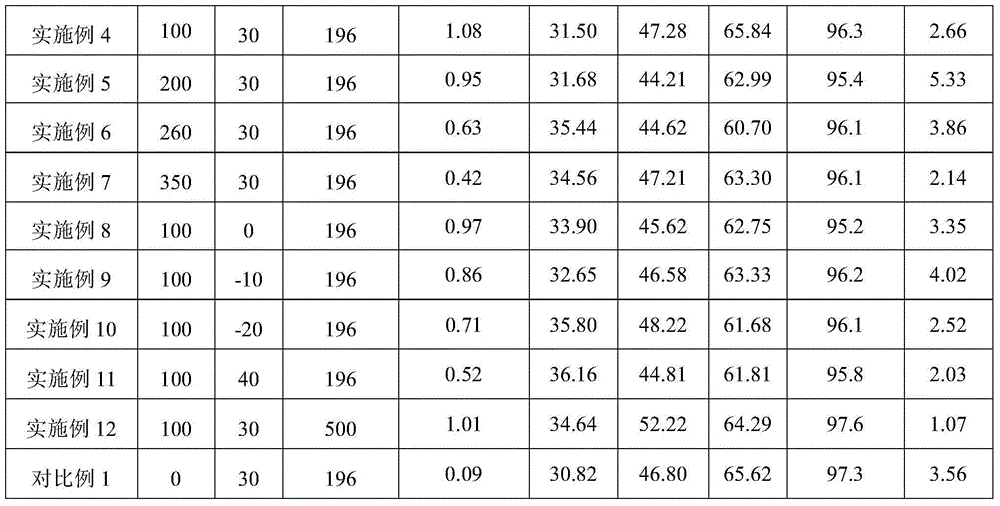

ActiveCN105562087AHigh oligomerization reactivityHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsQuinolineAluminium

The invention discloses a catalyst composition for ethylene oligomerization. The catalyst composition comprises a main catalyst (cyclopentadienyl) titanium chlorinated 2-(2-benzimidazolyl)-8-acetanilide quinoline complex as shown in a formula (I) which is described in the specification, an aluminum-containing cocatalyst, water and an organic solvent. The catalyst composition has high oligomerization reaction activity and high alpha-alkene selectivity when applied to ethylene oligomerization, and oligomerization reaction is rapidly initiated, runs stably and has good repeatability; even under the condition of a low aluminum / titanium ratio, good oligomerization reaction activity is maintained; thus, technical biases of the skilled in the art are overcome, unexpected technical effects are obtained, catalysis effect and cost are better balanced, cost for ethylene oligomerization is greatly reduced and the catalyst has good practicality and wide industrialization prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method of ethylene oligomerization

ActiveCN104628502BHigh selectivityEliminate pollutionHydrocarbonsHydrocarbon preparationCarbon numberOrganic solvent

The invention discloses an oligomerization method of ethylene. The ethylene carries out oligomerization reactions in a reaction system composed of a main catalyst, an aluminum-containing co-catalyst, water and an organic solvent; wherein the main catalyst is chlorinated 2-n-butyryl-1,10-phenanthroline amine-Fe (II) represented by the formula (I), the organic solvent is alpha-alkene with n carbons (4<n<=10), and in the formula (I), and the R1, R2, R3, R4, and R5 individually represent a hydrogen atom, an alkyl group with a carbon number of 1 to 6, a halogen atom, an alkyloxy group with a carbon number of 1 to 6, or a nitro group. The provided oligomerization method overcomes the technical bias, and optimizes the oligomerization technology. In the provided method, the oligomerization activity is high, thus the ethylene oligomerization reactions can be triggered rapidly, the operation of the technology is stable, the method is environment-friendly, the toxicity is greatly reduced, the catalytic effect and cost are well balanced, the provided method is very practical and greatly reduces the ethylene oligomerization cost, the catalytic effect and production cost are taken into account as a whole, and the industrialization prospect of the oligomerization method is wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst composition for ethylene oligomerization and application thereof

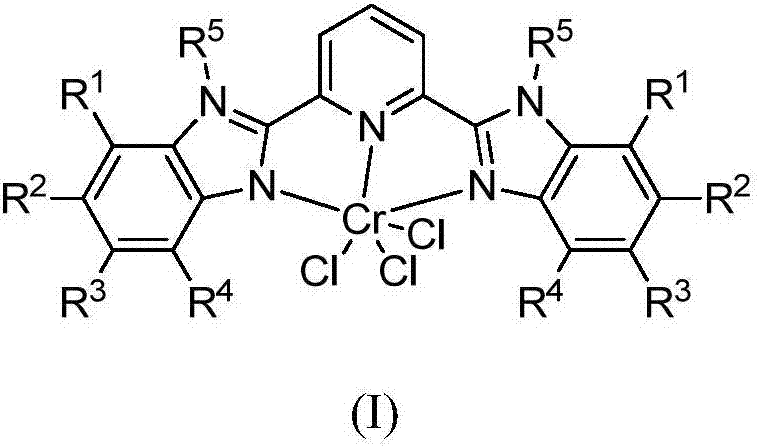

ActiveCN105478166BHigh selectivityHigh oligomerization reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsOrganic solventPyridine

The invention discloses a catalyst composition for an ethylene oligomerization reaction process. The catalyst composition contains a main catalyst represented by a formula I shown in the description, i.e., a chlorinated 2,6-di(2-benzimidazoyl)pyridine chromium (III) complex, an aluminiferous cocatalyst, water and an organic solvent. According to the catalyst composition, the catalyst composition disclosed by the invention is applied to the ethylene oligomerization reaction process and has very high oligomerization reaction activity and high alpha-olefin selectivity, and the oligomerization reaction is high in initiating speed, stable in operation and good in repeatability; even if the Al / Cr ratio is low, the catalyst composition has very good oligomerization reaction activity; and thus, the technical prejudice of those skilled in the art are overcome, an unexpected technical effect is achieved, and the catalysis effect and the cost are better balanced, so that the cost of ethylene oligomerization reaction is reduced greatly, the practicability is high, and the industrialization prospect is broad.

Owner:CHINA PETROLEUM & CHEM CORP +1

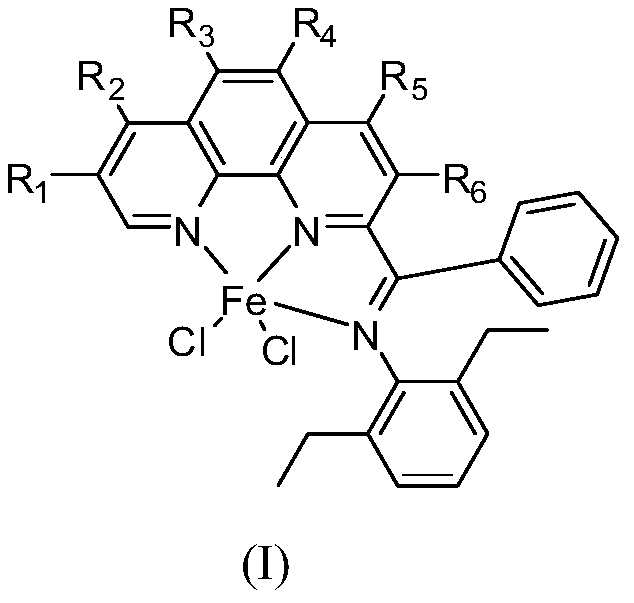

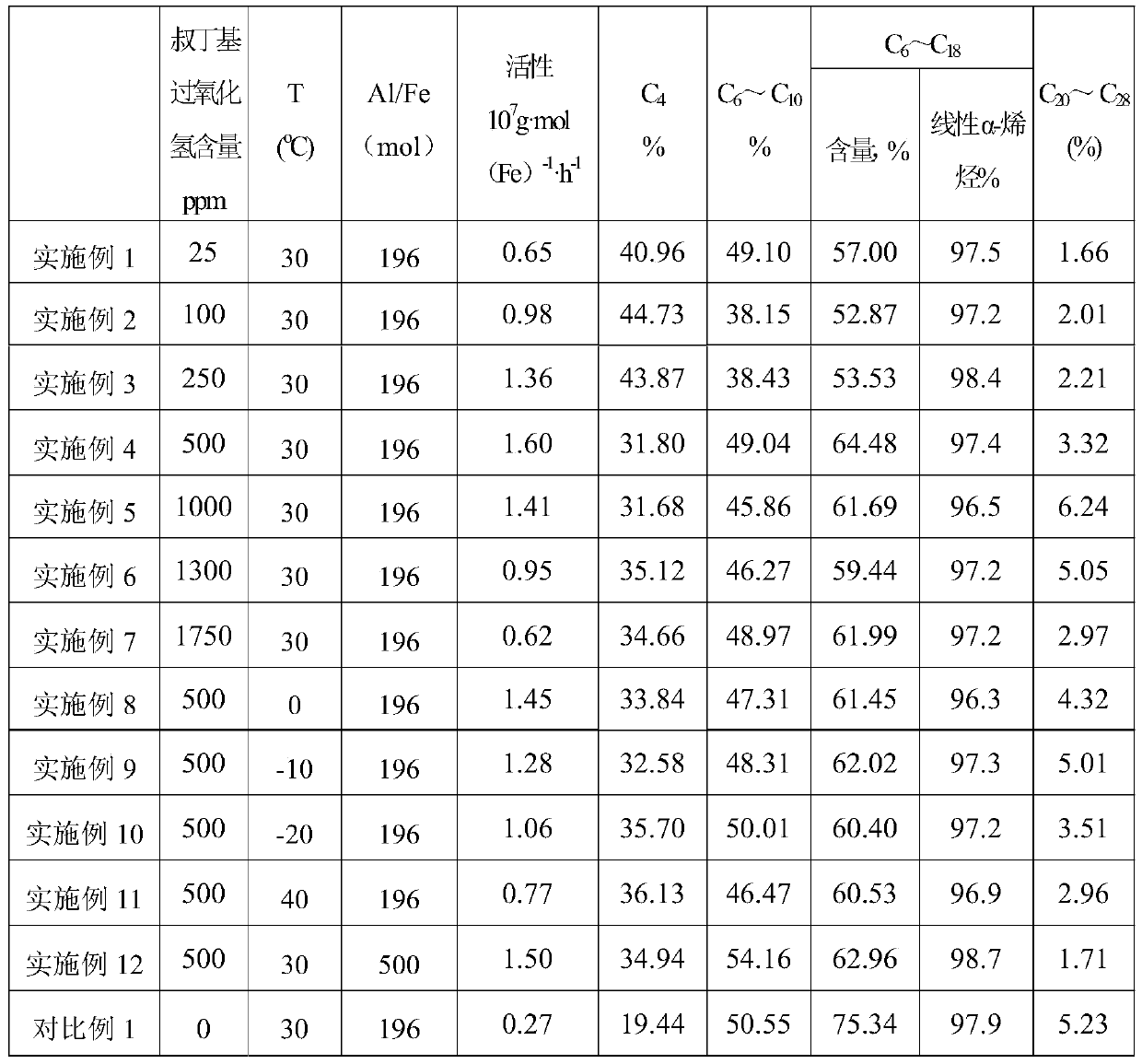

Catalyst composition and application for ethylene oligomerization

ActiveCN107282115BOligomerization costs dropPracticalOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPtru catalystPhenanthroline

The invention discloses a catalyst composition for an ethylene oligomerization reaction technology and an application of the catalyst composition. The composition comprises a main catalyst, namely a chlorination substituted-2-benzoyl-1,10-phenanthroline poly-2,6-diethylaniline ferrum (II) complex shown as formula (I) as shown in the specification, an aluminiferous promoter and tert-butyl hydroperoxide. When the catalyst composition is used for the ethylene oligomerization reaction technology, the catalyst composition has very high oligomerization reactivity and high alpha-olefin selectivity; an oligomerization reaction is initiated rapidly, runs steadily, and is good in repeatability; even at a low aluminum / ferrum ratio, the catalyst composition has very good oligomerization reactivity; technical prejudice of those skilled in the art is overcome; unexpected technical effects are obtained; a catalytical effect and cost are balanced better; the cost of the ethylene oligomerization reaction is greatly lowered; and the catalyst composition has strong practicability and wide industrialization prospects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ethylene oligomerization method

ActiveCN104341260AHigh selectivityHigh oligomerization reactivityHydrocarbonsBulk chemical productionOrganic solventPhenanthroline

The invention discloses an ethylene oligomerization method. The method comprises the following steps: performing oligomerization reaction on ethylene in a reaction system which comprises a chloridized 2-acetyl-1,10-phenanthroline amine iron (II) complex main catalyst shown by a formula (I) in the specification, an aluminum-containing promoter, water and an organic solvent. According to the method disclosed by the invention, ethylene oligomerization reaction has relatively high oligomerization reaction activity and high alpha-olefin selectivity, and still has relatively good oligomerization reaction activity even under the condition of low Al / Fe ratio; and in addition, even the oligomerization reaction is performed at relatively low temperature, the relatively high oligomerization reaction activity can still be achieved. Moreover, in an oligomerization reaction process, the ethylene oligomerization method disclosed by the invention is rapid in reaction initiation, stable in operation and good in repeatability, and thus the technical biases of those skilled in the art can be overcome, unexpected technical effects can be achieved, and wide industrial prospects can be provided.

Owner:CHINA PETROLEUM & CHEM CORP +1

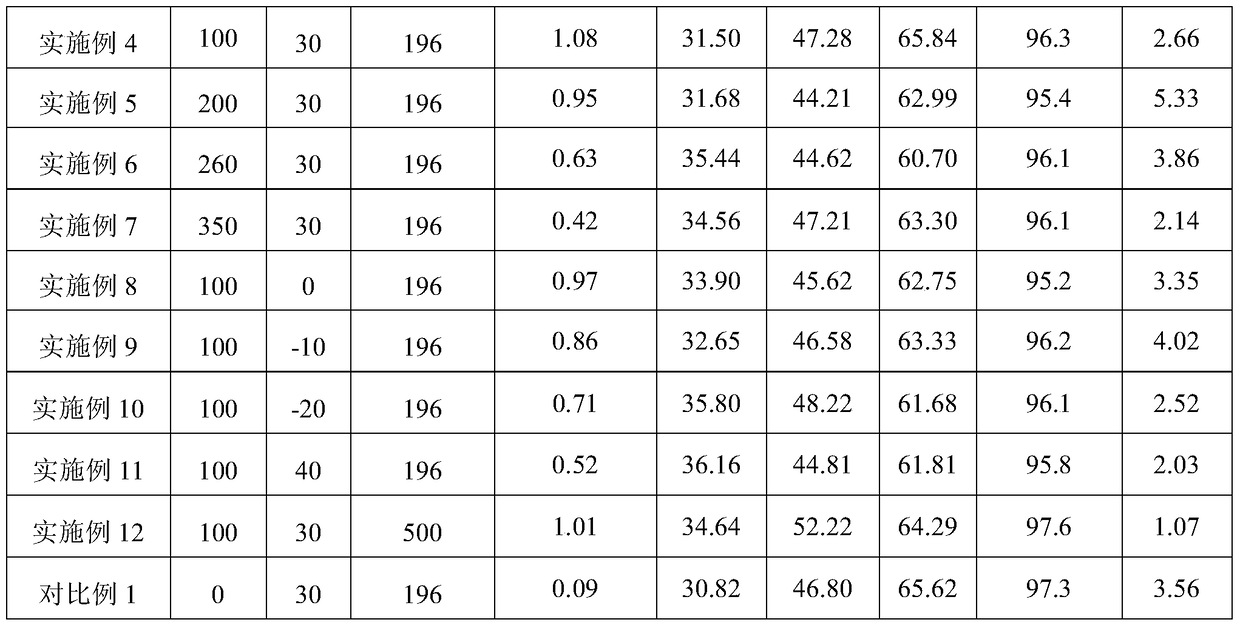

Ethylene oligomerization catalyst composition and oligomerization method

ActiveCN107282118AOligomerization costs dropPracticalOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPyridineAlpha-olefin

The invention discloses a catalyst composition for an ethylene oligomerization reaction process. The catalyst composition comprises a main catalyst shown in formula I, namely a 2,6-di(2-benzimidazolyl) pyridine chromium (III) complex, an aluminum-containing promoter and tert-butyl hydroperoxide. The catalyst composition disclosed by the invention is applied to the ethylene oligomerization reaction process, is very high in oligomerization reaction activity, high in alpha-olefin selectivity, is rapid in oligomerization reaction initialization speed, stable in operation and good in repeatability, and is still very good in oligomerization reaction activity even in a low aluminum / chromium ratio, so that technical prejudice of operators of the field is overcome, unforeseeable technical effects are achieved, catalysis effects and cost are relatively well balanced, the ethylene oligomerization reaction cost is greatly reduced, and the catalyst composition is good in practicability and wide in industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com