Load-type olefin oligomerization catalyst and preparation method thereof

A catalyst, supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as catalytic activity and selectivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

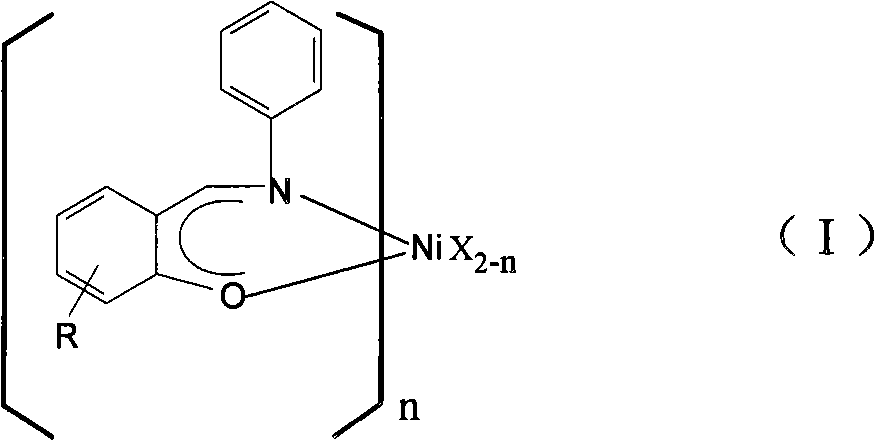

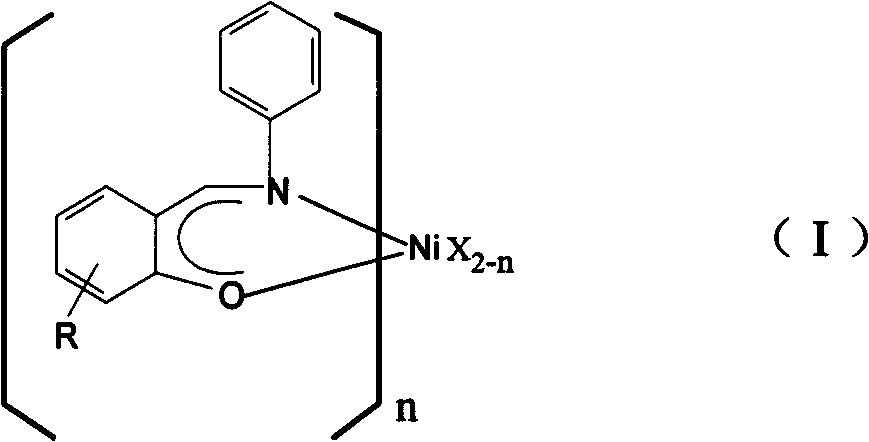

[0018] The preparation method of supported olefin oligomerization catalyst of the present invention, comprises the steps:

[0019] (1) After roasting the mesoporous silicon-alumina material, add aromatic hydrocarbons or halogenated alkanes to fully stir,

[0020] (2) Add the aromatic hydrocarbon or halogenated alkane solution of the complex described in formula (I) to the material after the stirring treatment in step (1) to continue the stirring reaction, collect the solid matter and then dry it.

[0021] In the method, step (1) is to process the carrier, the calcination temperature of the mesoporous silicon-aluminum material is preferably 200-800° C., and the stirring temperature after adding aromatic hydrocarbons or halogenated alkanes to the mesoporous silicon-alumina material is 0-120°C, preferably 20-60°C, the mass ratio of the added aromatic hydrocarbon or halogenated alkane to the carrier is 10-50:1, preferably 15-40:1.

[0022] The step (2) of the method is the loadin...

example 1

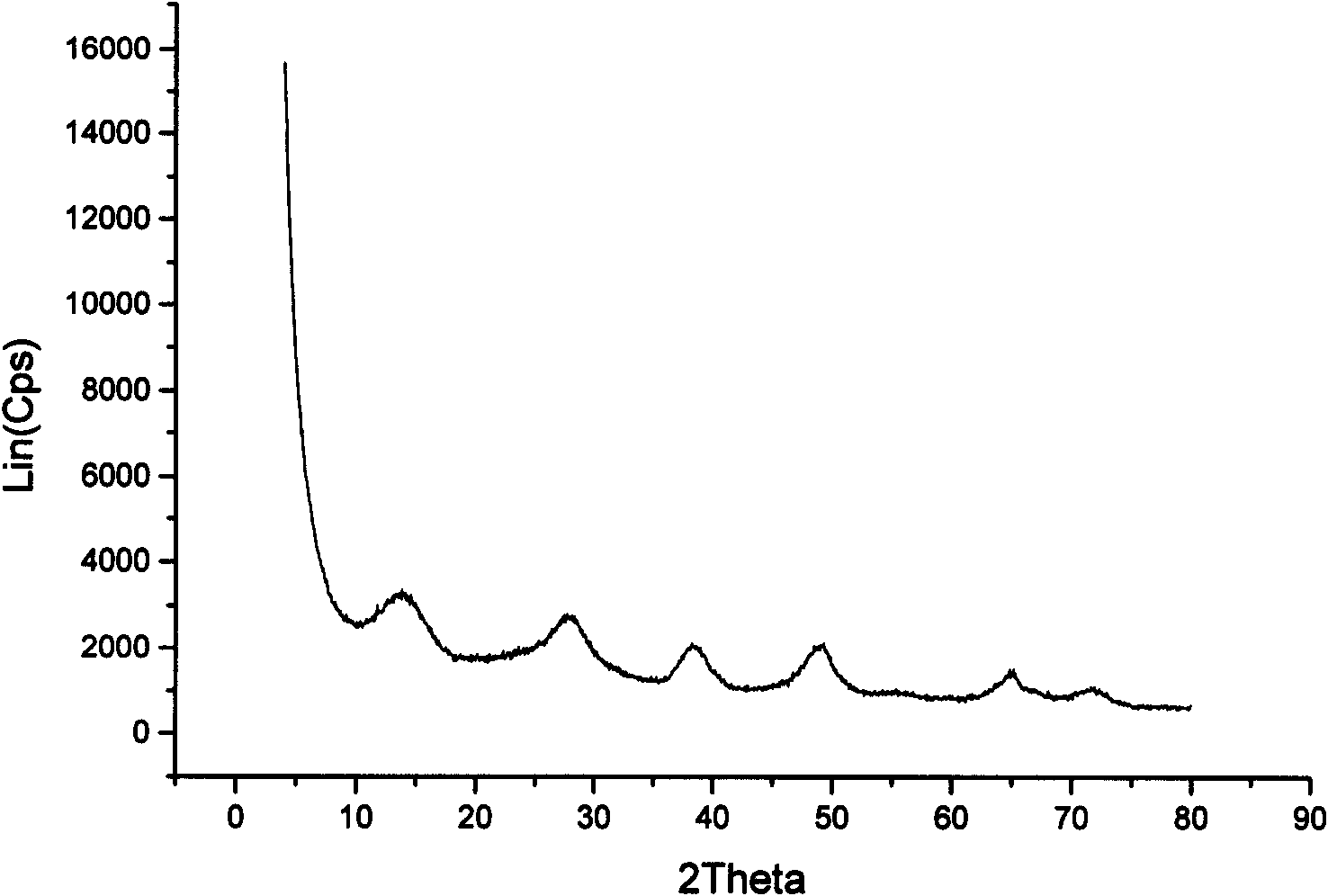

[0030] Preparation of mesoporous silica-alumina materials.

[0031] Take 100ml concentration as 90gAl 2 o 3 / L Al 2 (SO 4 ) 3 The solution was placed in a beaker, and ammonia water was added dropwise under stirring until the pH value of the system was 8, and the neutralization gelling temperature was 55°C. Add 50ml content of 60gSiO under stirring condition 2 / L of water glass, heated to 80°C for 4 hours; use NH 4 Cl solution according to precipitate (dry basis): ammonium salt: H 2 With a mass ratio of O=1:0.8:15, the silicon-aluminum precipitate was ion-exchanged at 60° C. to remove sodium ions therein. The exchange was repeated twice, each time for 0.5 hours, washed with water, filtered after each exchange, and then dried at 120°C for 15 hours to obtain a mesoporous silica-alumina material with a chemical composition of 0.035Na 2 O·75.5Al 2 o 3 24.4SiO2 2 , the specific surface area is 378m 2 / g, the pore volume is 1.21ml / g, the average pore diameter is 10.55nm, t...

example 2

[0033] Preparation of the complexes described in the present invention.

[0034] Add 0.15 mol of salicylaldehyde and 0.15 mol of aniline into the reactor, add 100 ml of absolute ethanol and reflux at 80°C for 4 hours, cool down to 0°C, precipitate crystals, and filter. The obtained solid was recrystallized with 100 ml of absolute ethanol, and dried under reduced pressure at 25° C. for 2 hours to obtain yellow needle-like crystals, which were salicylaldehyde aniline.

[0035] 1 gram (0.004 mol) of nickel acetate tetrahydrate is added in 120 milliliters of dehydrated alcohol, stir, after the solid dissolves completely, add the salicylaldehyde aniline ligand of 1.58 gram (0.008 mol), stir 12 hours, have A large number of green solids precipitated, filtered, and washed the filter cake with 30 ml of hexane for 3 times, and dried the filter cake at 60°C for 6 hours under reduced pressure to obtain grass green solid powder, which was bis(salicylaldehyde aniline) nickel complex , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com