Catalyst composition for ethylene oligomerization and application thereof

A technology for ethylene oligomerization and catalysts, which is applied in the direction of hydrocarbons, hydrocarbons, physical/chemical process catalysts, etc., can solve the problems of poor repeatability of oligomerization process reactions, harsh process requirements, and high production costs, etc., to achieve The effect of high selectivity, good repeatability and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

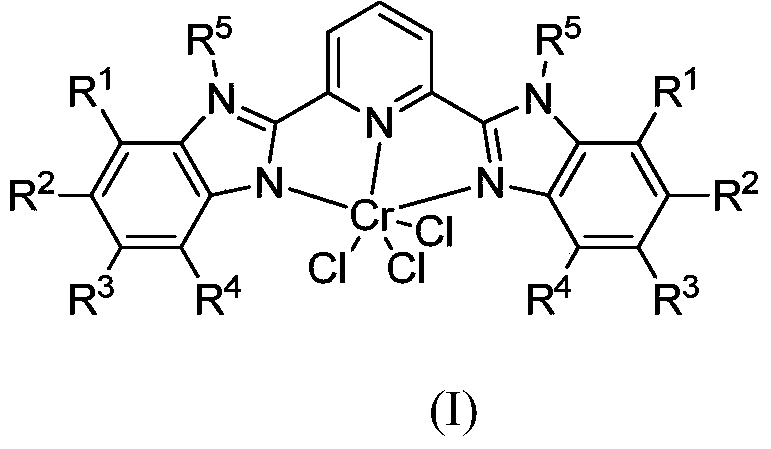

[0029] 1. Catalyst synthesis of chlorinated 2,6-bis(2-benzimidazolyl)pyridine chromium(III) complexes

[0030] According to the preparation method reported in literature (Organometallics.2006, 25, 1961-1969), 2,6-bis(2-benzimidazolyl)pyridine chromium(III) chloride complex was prepared.

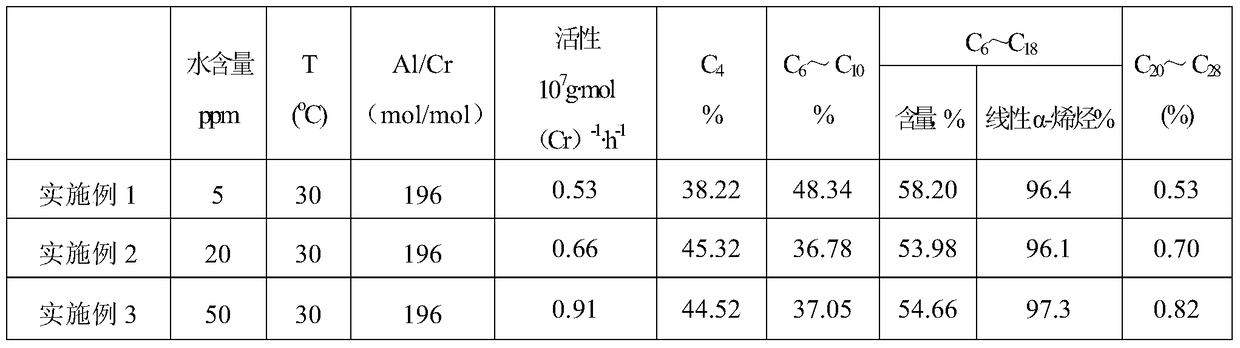

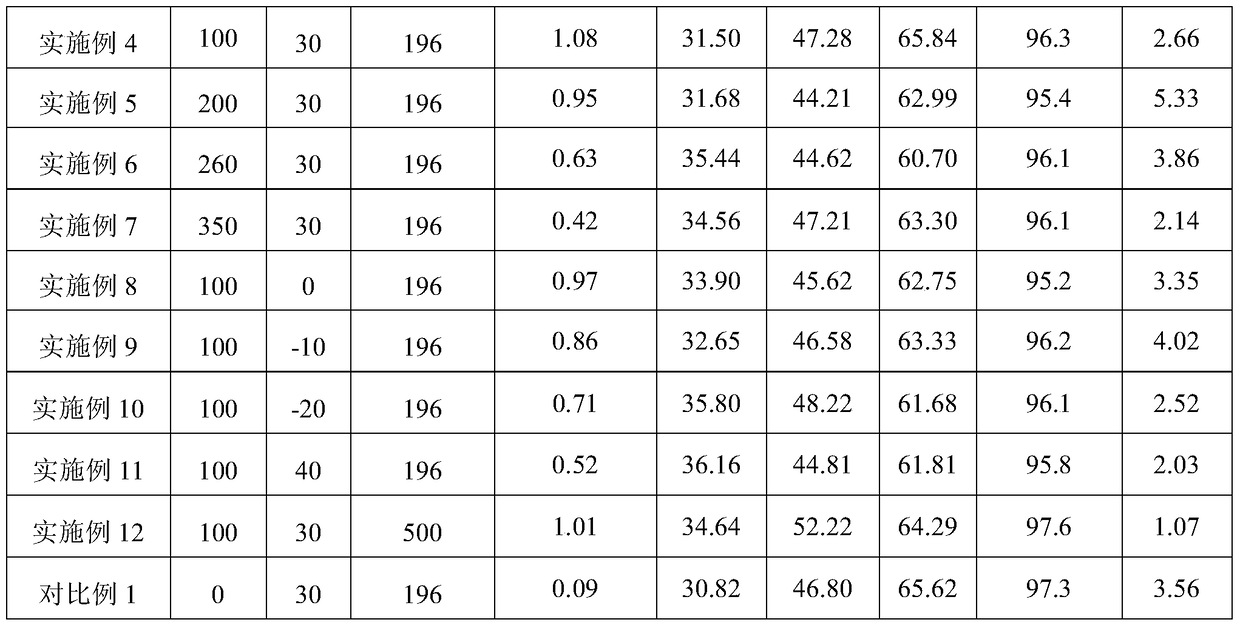

[0031] 2. Ethylene oligomerization reaction, which specifically includes the following steps: (1) replace the reaction system by high temperature drying, vacuum replacement and other operations to ensure that there is no water and oxygen in the reaction system; (2) use ethylene to replace the reaction system, Make the reaction system in an ethylene environment; (3) add water and toluene solvent in the reaction kettle, add 1.37ml triethylaluminum toluene solution (concentration is 715 μ mol / ml), add 2ml 2,6-di(2-benzene After the toluene solution (concentration is 2.5 μ mol / ml) of imidazolyl) pyridine chromium (III) complex, make the composition total amount be 100ml, wherein, take the weight ...

Embodiment 2

[0033] Same as Example 1, the difference is that the weight content of water is 20ppm. See Table 1 for the data.

Embodiment 3

[0035] Same as Example 1, the difference is that the weight content of water is 50ppm. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com