Ethylene oligomerization continuous reaction method

An ethylene oligomerization and reaction technology, applied in chemical instruments and methods, hydrocarbons, organic compounds/hydrides/coordination complex catalysts, etc. Harsh process conditions and other problems, to achieve the effect of high selectivity, good repeatability, and overcoming technical bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

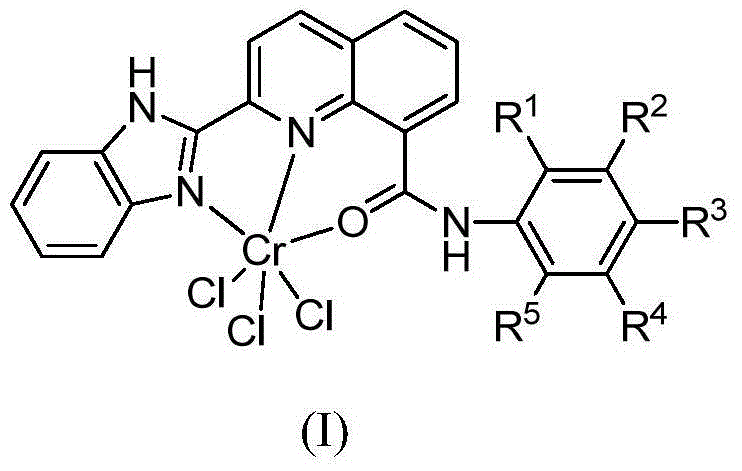

[0026] 1. Synthesis of 2-(1H-2-benzoimidazolyl)-8-acetyl-2’,6’-dimethylanilinoquinoline chromium(III) chloride as the main catalyst

[0027] According to the preparation method reported in literature (Organometallics2011,30,3001–3009), 2-(1H-2-benzimidazolyl)-8-acetyl-2',6'-dimethylanilinoquinoline chloride was prepared Chromium (III) complexes.

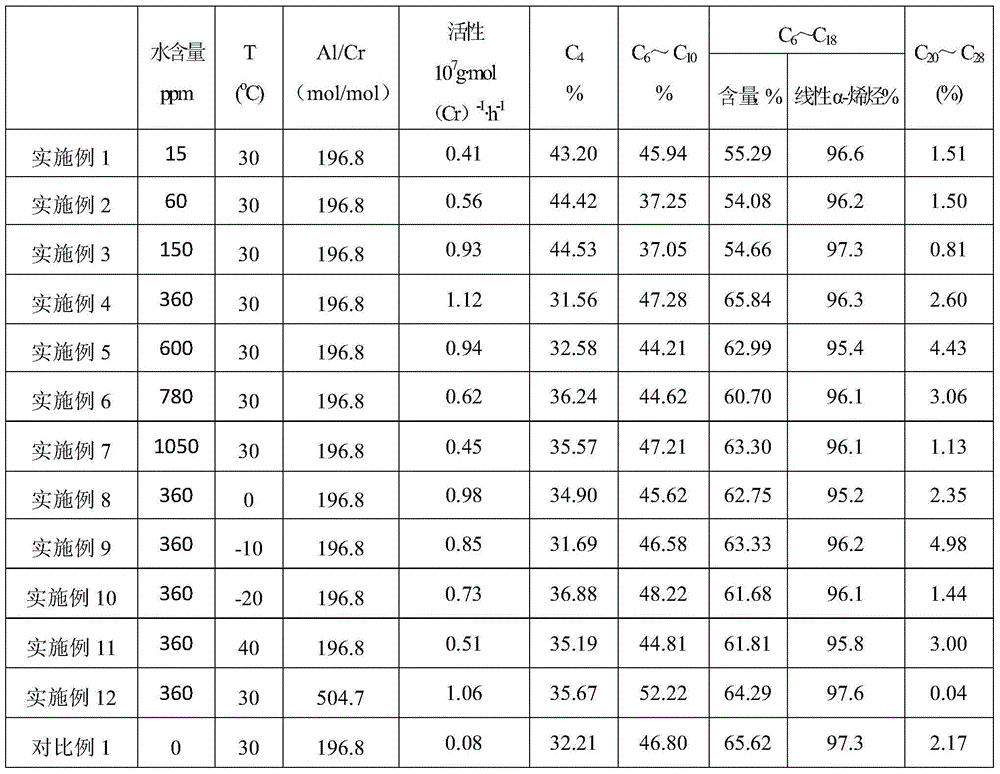

[0028] 2. The continuous reaction of ethylene oligomerization specifically comprises the following steps: (1) in a 100ml continuous reaction device, aqueous ethylene, solvent xylene, main catalyst solution (concentration is 2.5 μ mol / ml, solvent is xylene) and cocatalyst solution (concentration is 715 μ mol / ml, and solvent is xylene) enters reactor respectively, and flow rate is respectively 80g / h, 168.26g / h, 3.40g / h and 2.34g / h, and Al / Cr is 196.8 in the reaction system, keeps at The residence time of the reaction material in the reactor is 30min; (2) the reaction pressure is 1MPa and the reaction temperature is 30°C, wherein, taki...

Embodiment 2

[0030] Same as Example 1, the difference is that the mass content of water is 60ppm. See Table 1 for the data.

Embodiment 3

[0032] Same as Example 1, the difference is that the mass content of water is 150ppm. See Table 1 for the data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com