Patents

Literature

40results about How to "Increase chlorine content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of chlorinated polyvinyl chloride resin

InactiveCN102936302AIncrease chlorine contentIncrease the chlorination temperatureChlorinated polyvinyl chlorideEthyl Chloride

The invention provides a method for suspension synthesis of chlorinated polyvinyl chloride (CPVC) resin from a hydrochloric acid aqueous solution. According to the method, polyvinyl chloride is taken as the raw material, no swelling agent is added, a chlorination medium is added and the chlorination temperature is enhanced so as to synthesize the CPVC resin. The method shortens the chlorination time, increases the chlorine content of CPVC, reduces the environmental pollution caused by swelling agent separation in post-treatment, and lowers the cost.

Owner:沈阳欧陆科技发展有限公司

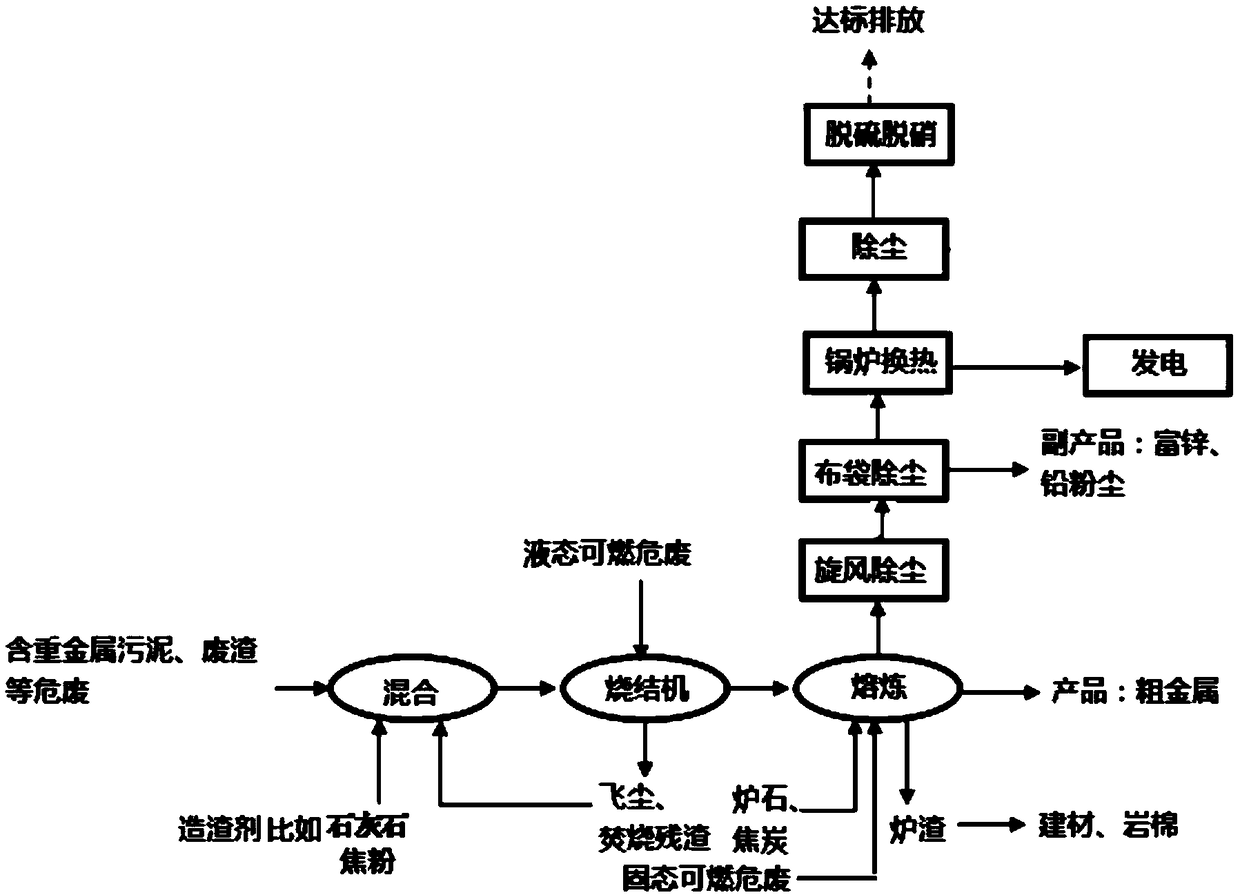

Method for treating hazardous wastes through cooperation of metallurgical furnace

ActiveCN109457113AAchieve reductionImplement resourcesProcess efficiency improvementSmelting processAlloy

The invention discloses a method for treating hazardous wastes through the cooperation of a metallurgical furnace. The method comprises the steps of sintering for agglomerating the hazardous wastes containing heavy metal, or condensing for agglomeratingthe hazardous wastes containing the heavy metal, and smelting the combustible hazardous wastes to form a finished product block so as to obtain analloy crude product containing the heavy metal. According to the method for treating the hazardous wastes through the cooperation of the metallurgical furnace provided by the invention, the hazardouswastes containing the heavy metal are treated through a melting furnace, valuable metal in the hazardous wastes containing the heavy metal is recycled, meanwhile, organic matters inthe combustible hazardous wastes are decomposed by high temperature of the melting furnace, and heat values in the organic matters are utilized, so that inthe smelting process of the hazardous wastes containing the heavy metal, the harmful element of the combustible hazardous wastes, and fly ash used as a first slag former or furnace slags produced by residue incineration is reduced to be below 0.1 percent, the wastes can be directly used as building materials and used for preparing rock wool and the like, and the metal recovery rate reaches to more than 90 percent.

Owner:唐山市丰润区明营再生资源有限公司

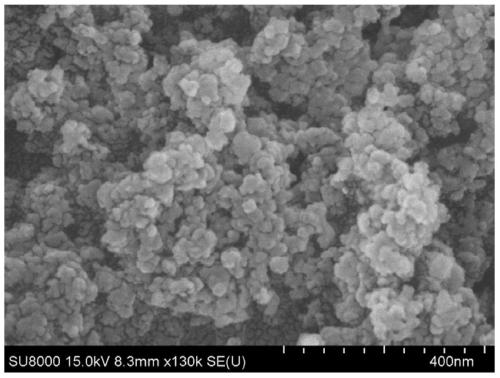

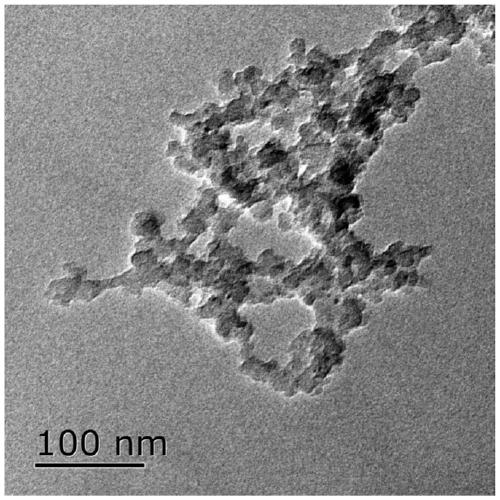

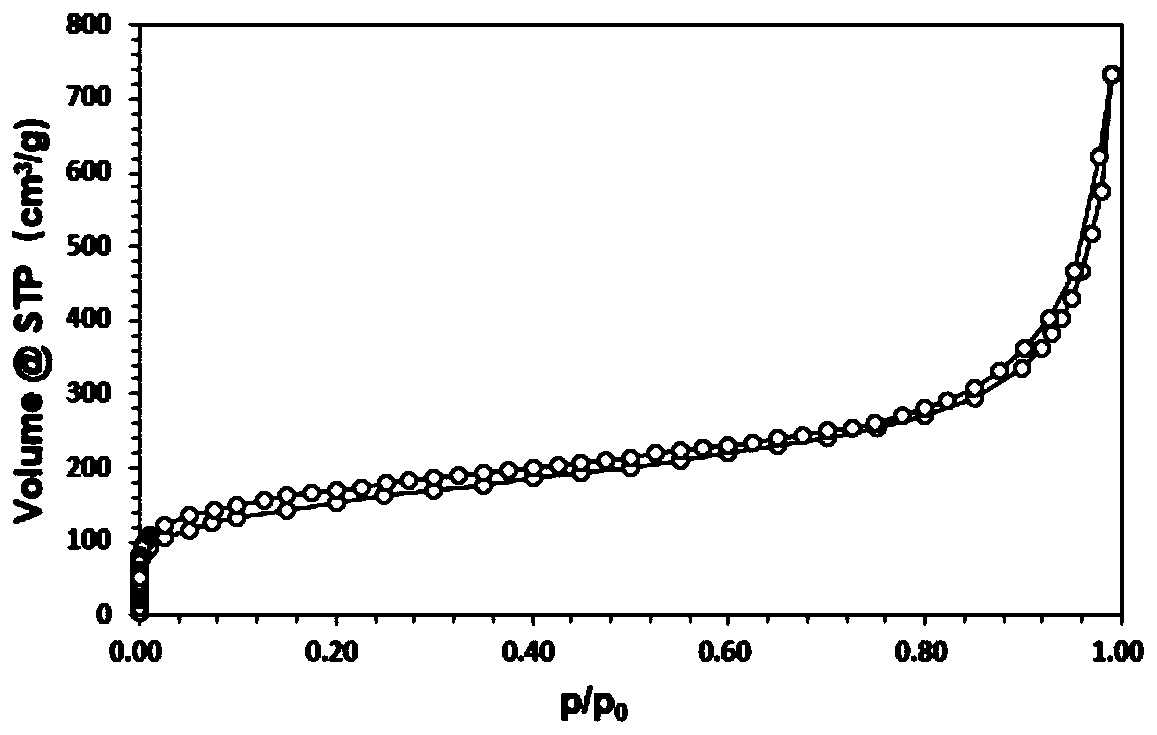

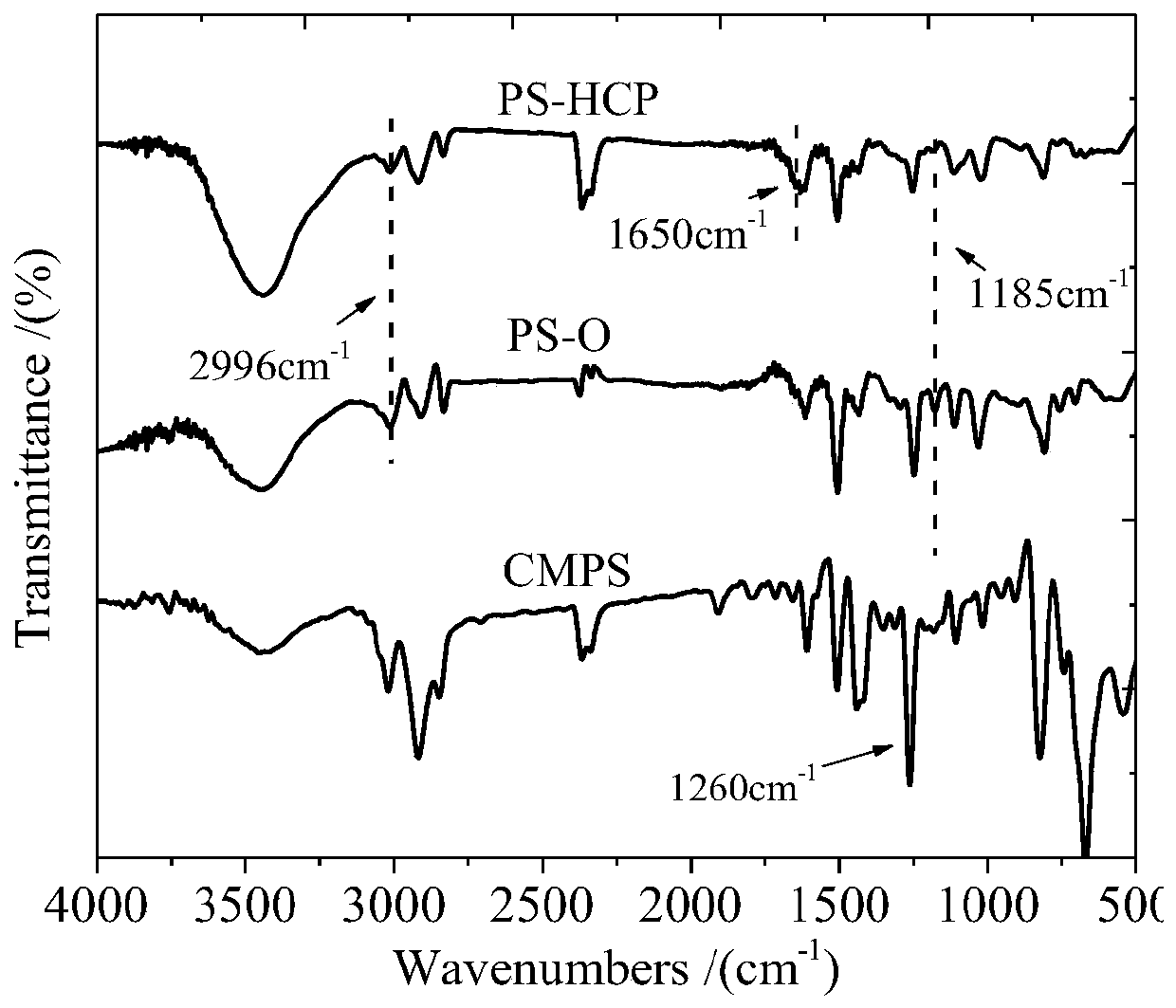

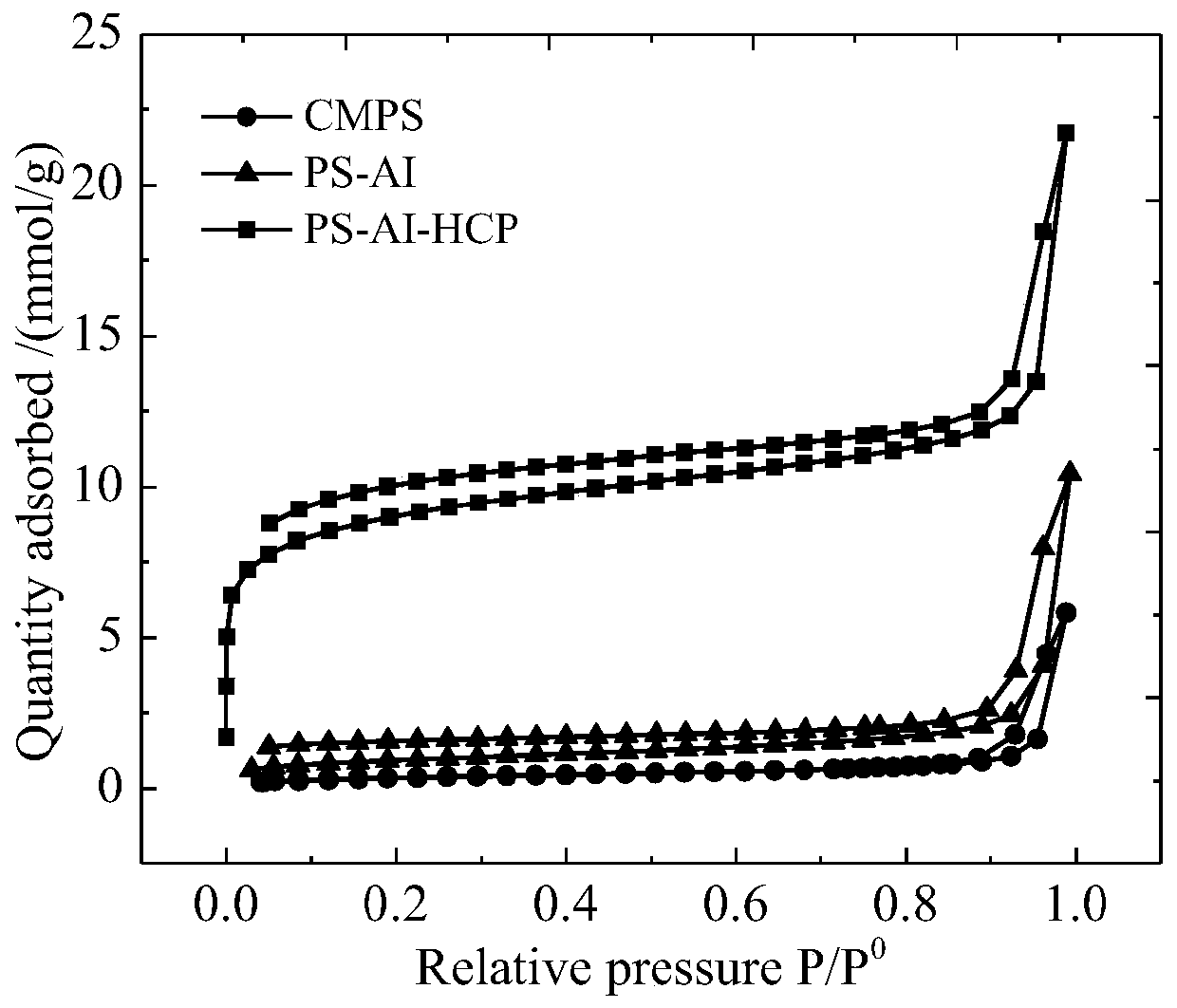

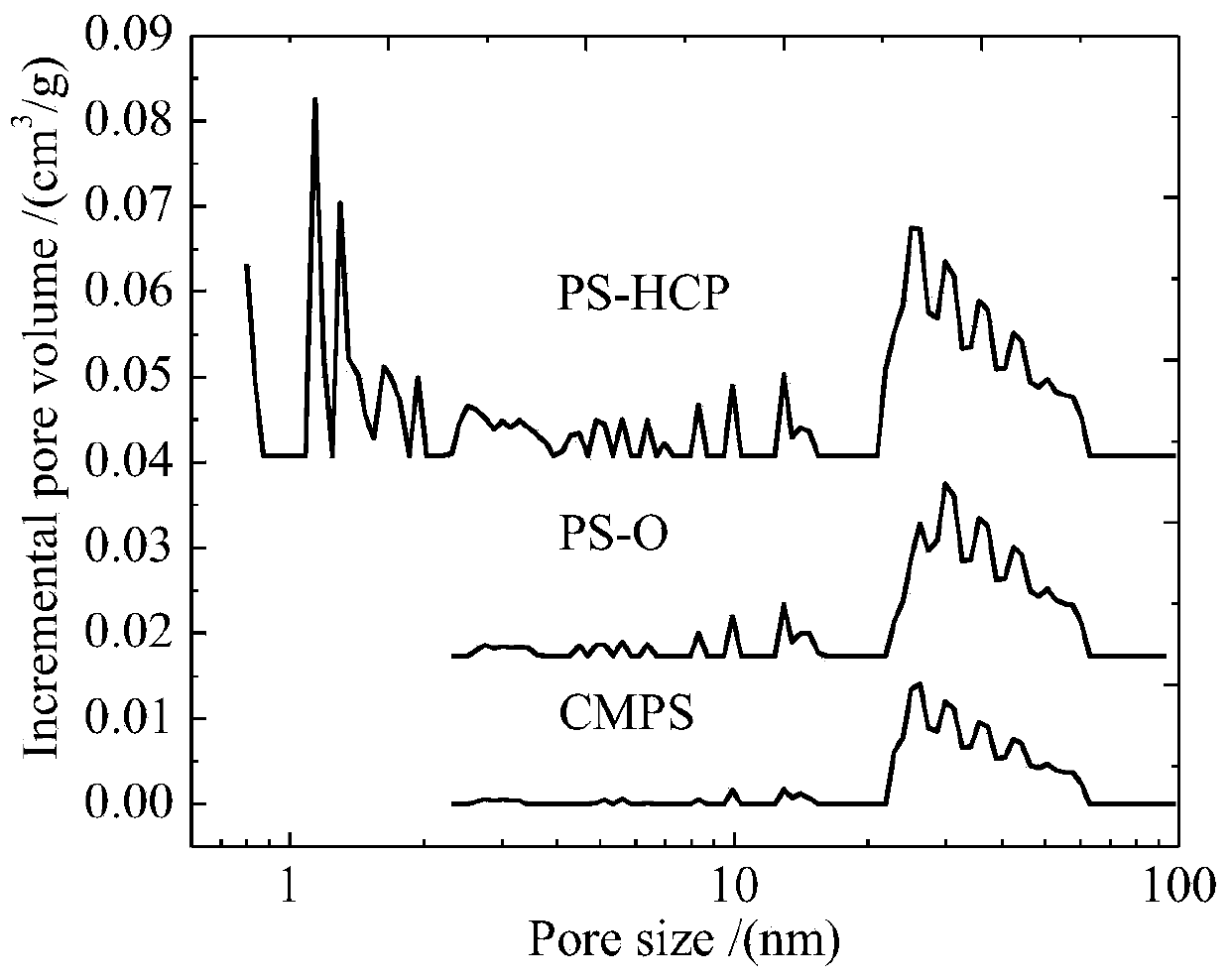

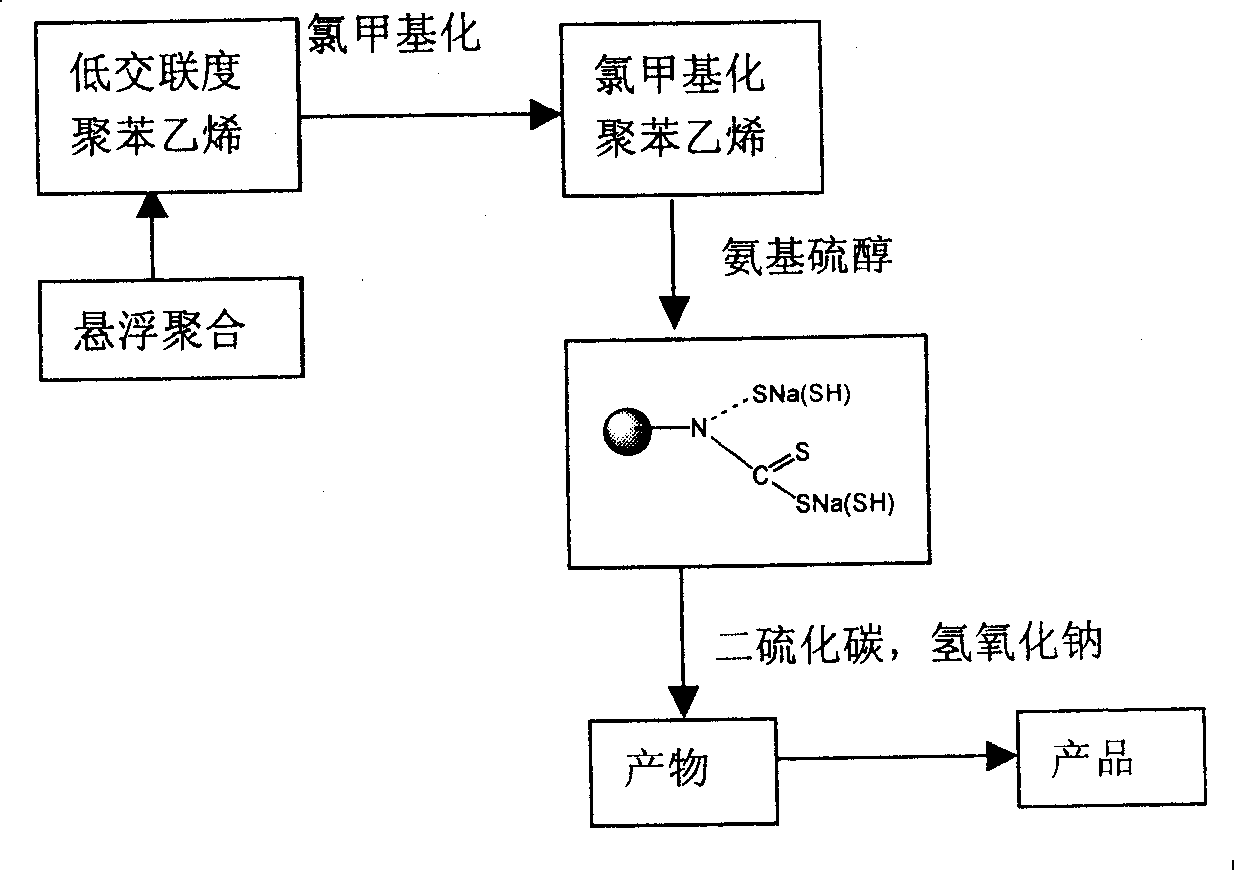

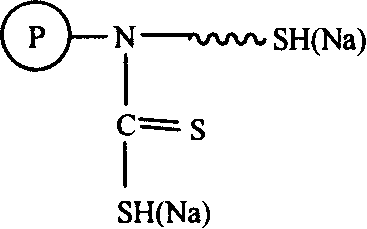

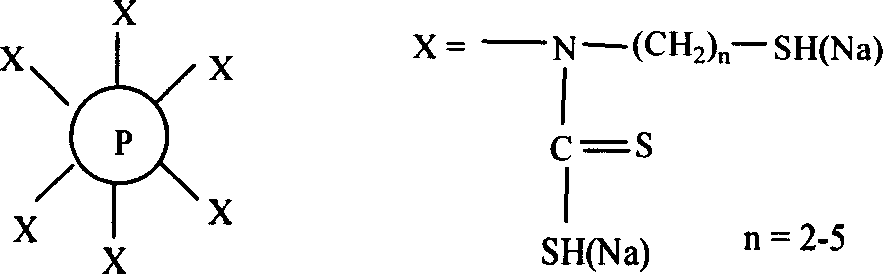

Crosslinked polystyrene adsorbent, and preparation method and application thereof

ActiveCN109701505AIncrease chlorine contentLewis is highly alkalineOther chemical processesWater contaminantsSorbentCarbon Chloride

The invention provides a crosslinked polystyrene adsorbent, and a preparation method and an application thereof. The crosslinked polystyrene adsorbent through a Friedel-Crafts alkylation reaction of 1-10 parts by weight of waste foam, 200-320 parts by weight of carbon tetrachloride and 10 parts by weight of anhydrous aluminum trichloride. The waste foam and carbon tetrachloride are used as raw materials, and undergo the Friedel-Crafts alkylation reaction under the catalysis action of anhydrous aluminum trichloride, and the carbon tetrachloride and the polystyrene linear molecules of the wastefoam are crosslinked to form a three-dimensional network structure, so the crosslinked polystyrene adsorbent has a high chlorine content and a strong Lewis base property, and can be strong chemicallyreacted with phenolic pollutants with Bronsted acidity in water, thereby the adsorbent has a high sewage dephenolization efficiency, and the dephenolization rate can reach 90% or above.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

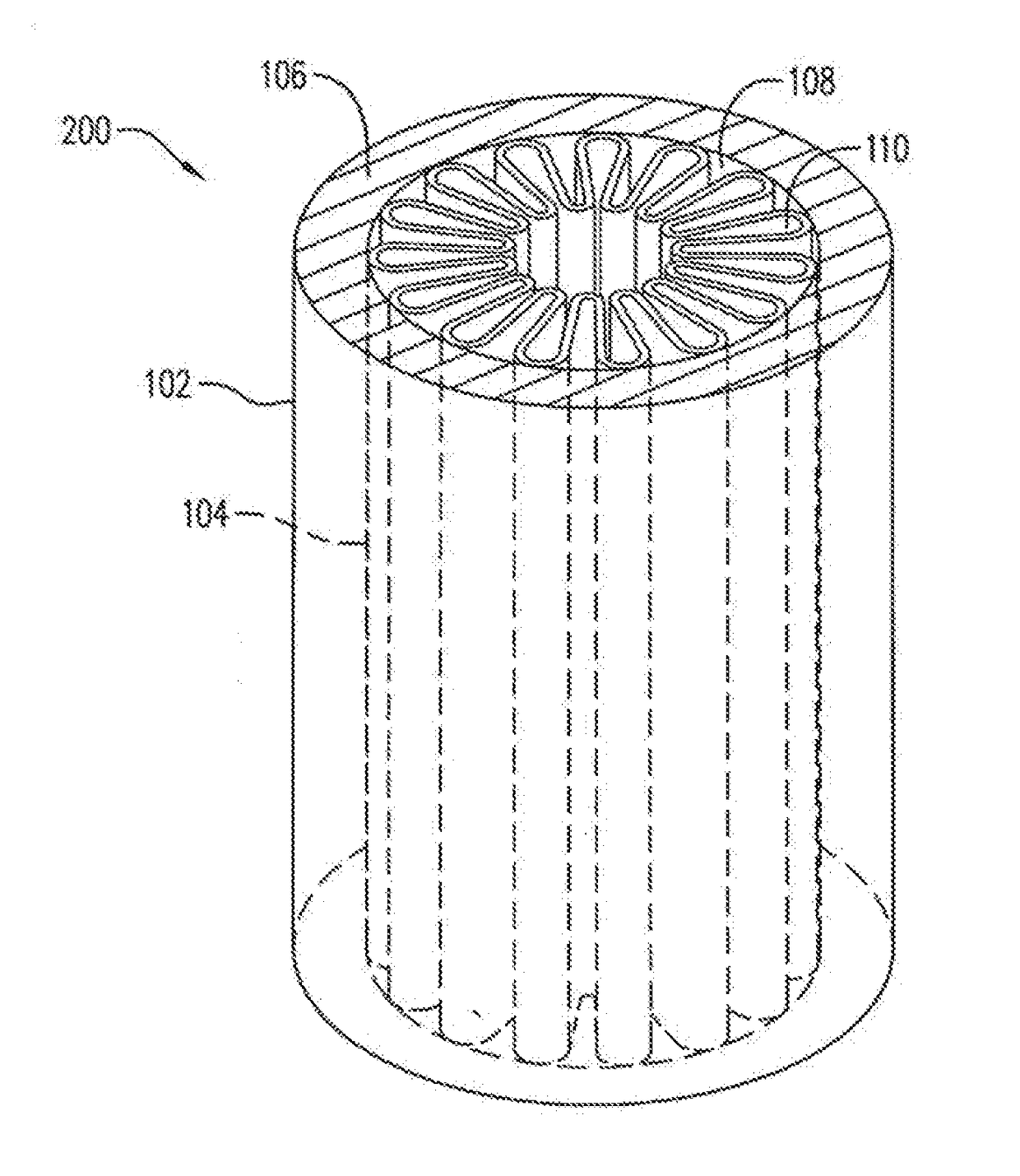

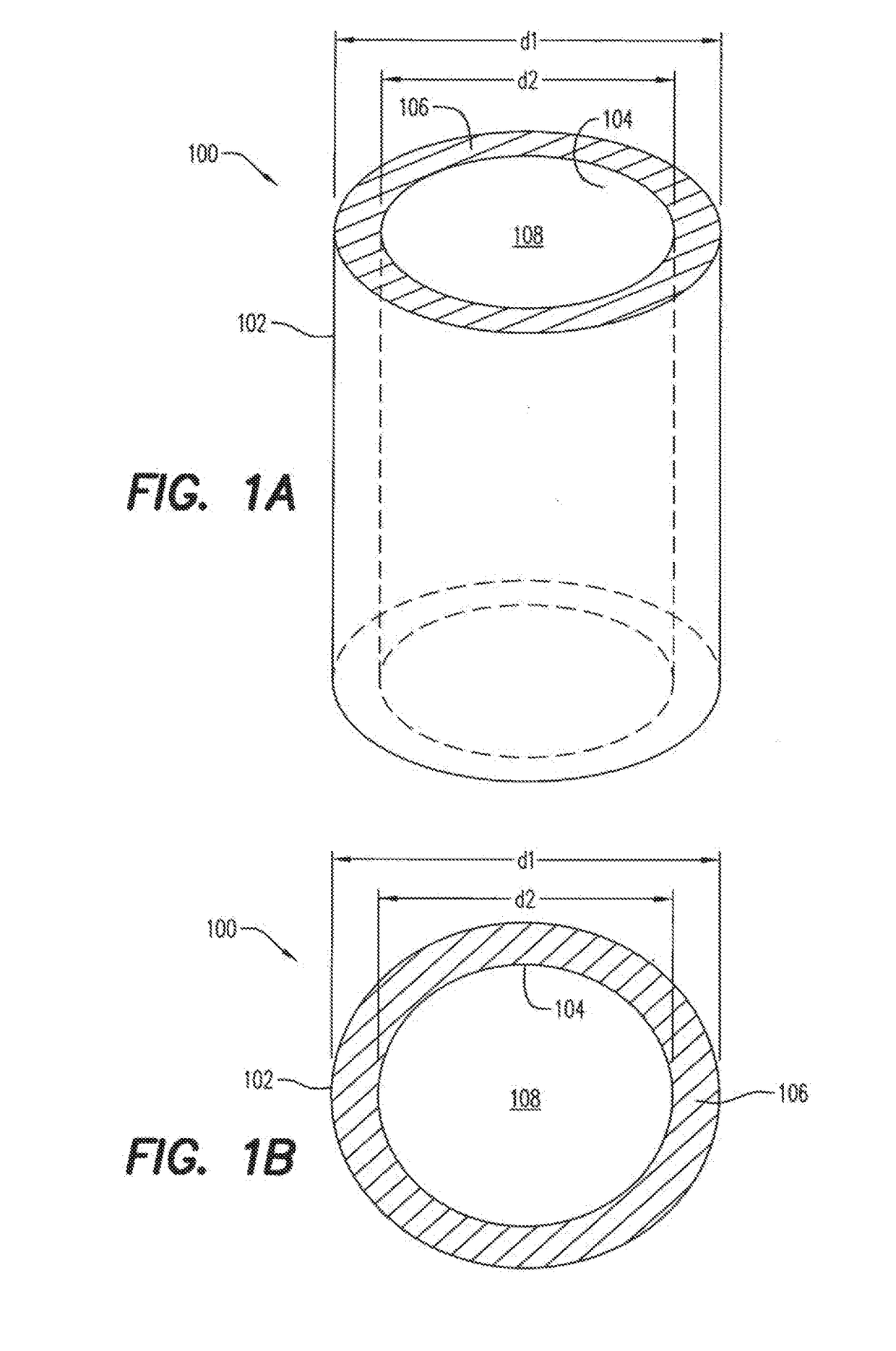

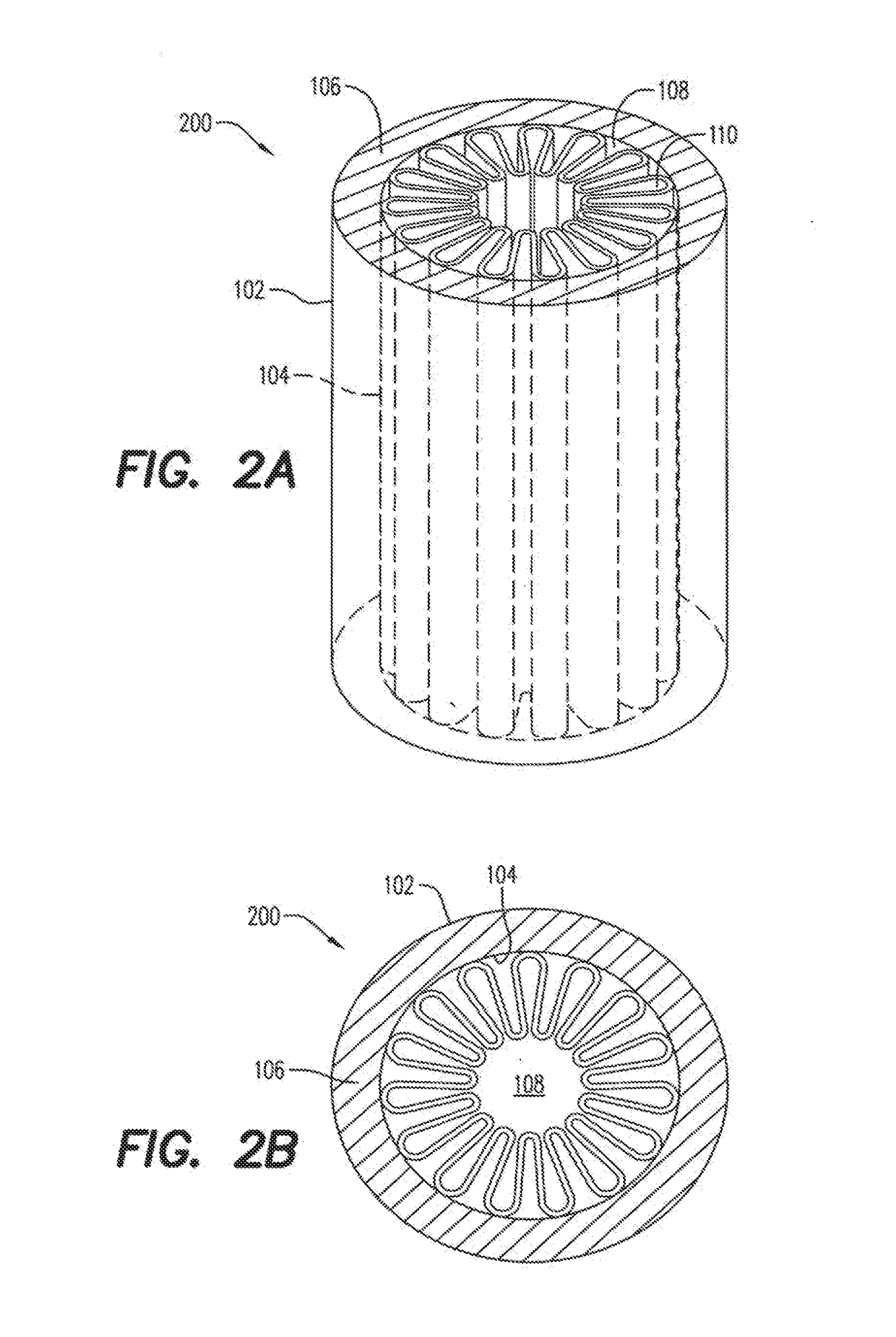

Fluid purification media and systems and methods of using same

InactiveUS20180099878A1Increase chlorine contentLower overall pressure dropIon-exchange process apparatusOther chemical processesChemistryHigh density

A fluid purification system capable of removing lead from significant volumes of fluids also containing at least one of TOC and TTHM under low pressure conditions and at reasonable flow rates is provided. The system comprises a first fluid purification media comprising a rigid porous purification block. The rigid purification block includes a longitudinal first surface; a longitudinal second surface disposed inside the longitudinal first surface; and a porous high density polymer disposed between the longitudinal first surface and the longitudinal second surface. The system further includes a second fluid purification media, comprising a fibrous, nonwoven fabric disposed adjacent to the first surface of the first fluid purification media, the second surface of the first purification media, or both.

Owner:KINETICO

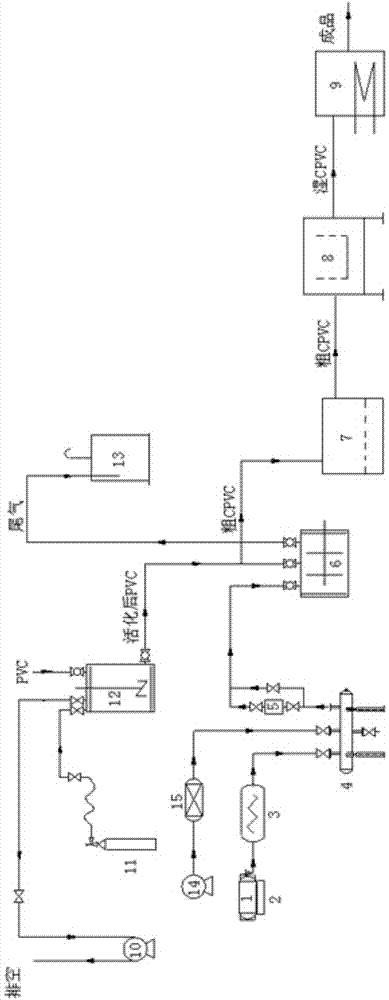

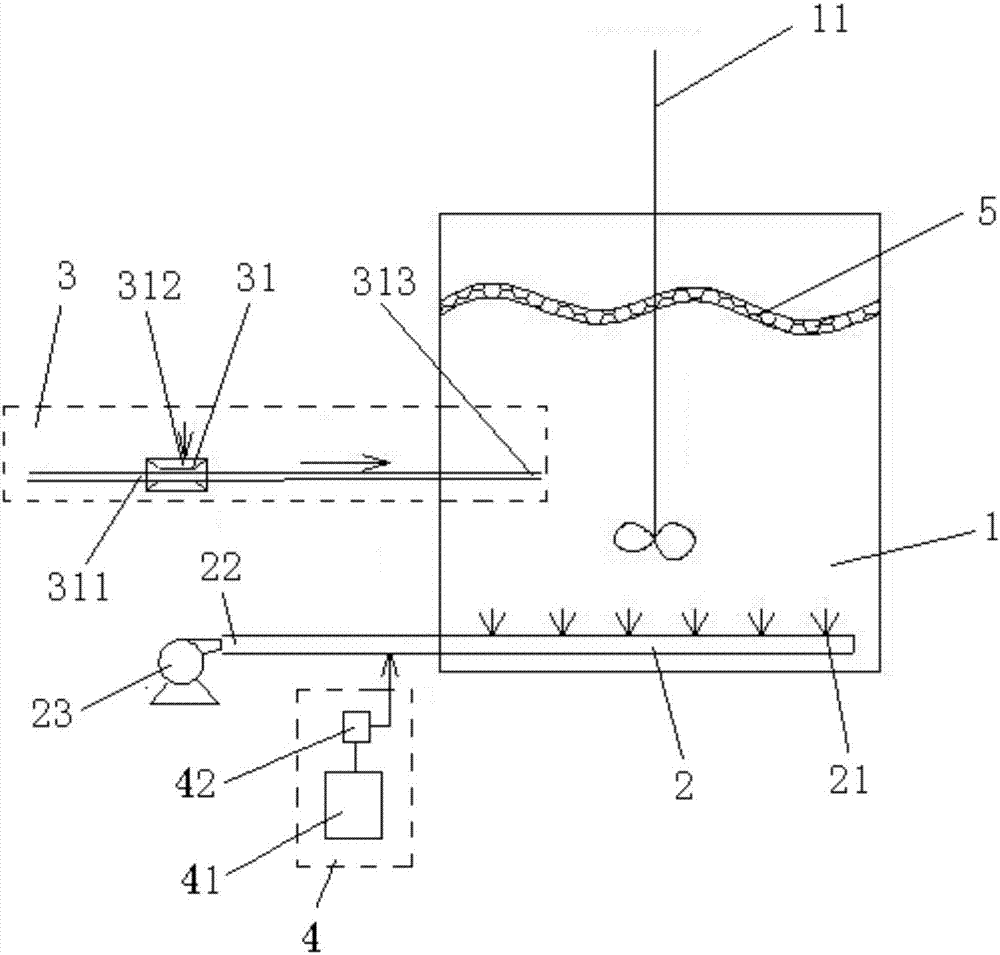

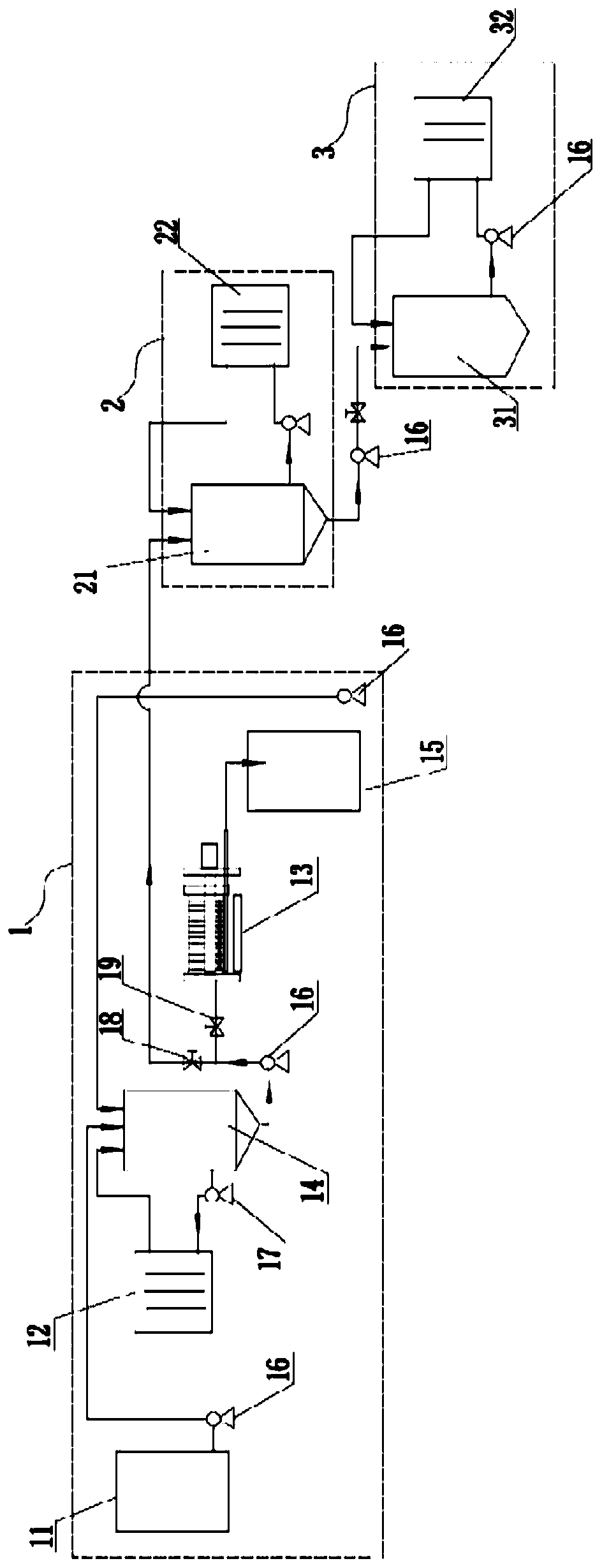

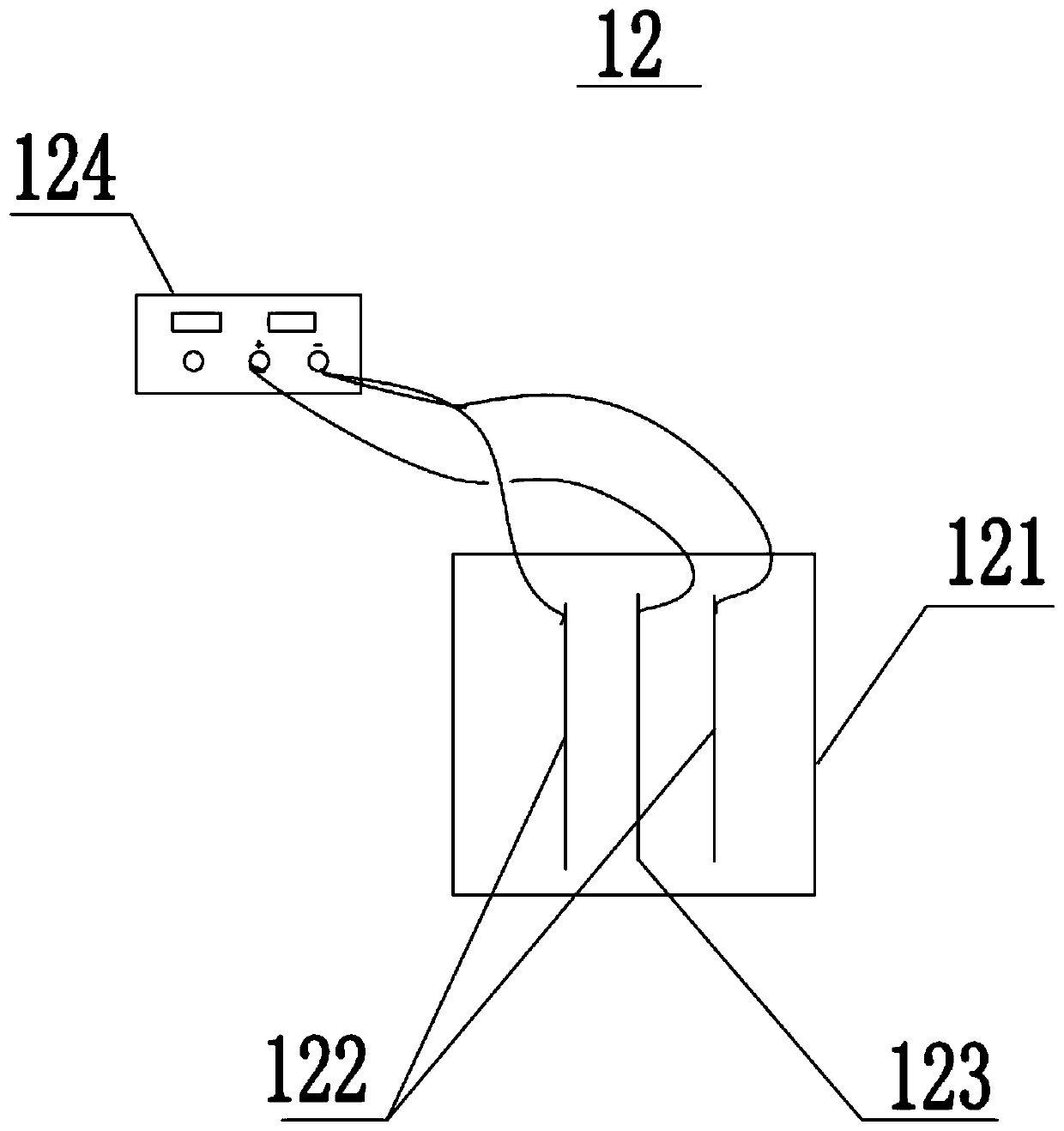

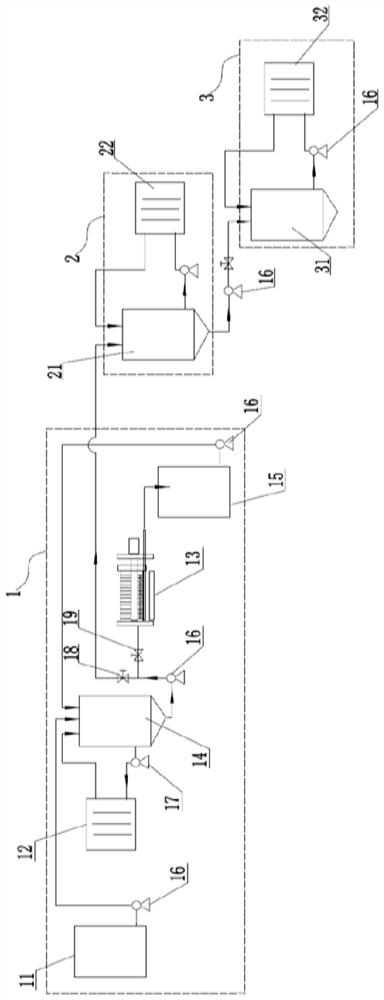

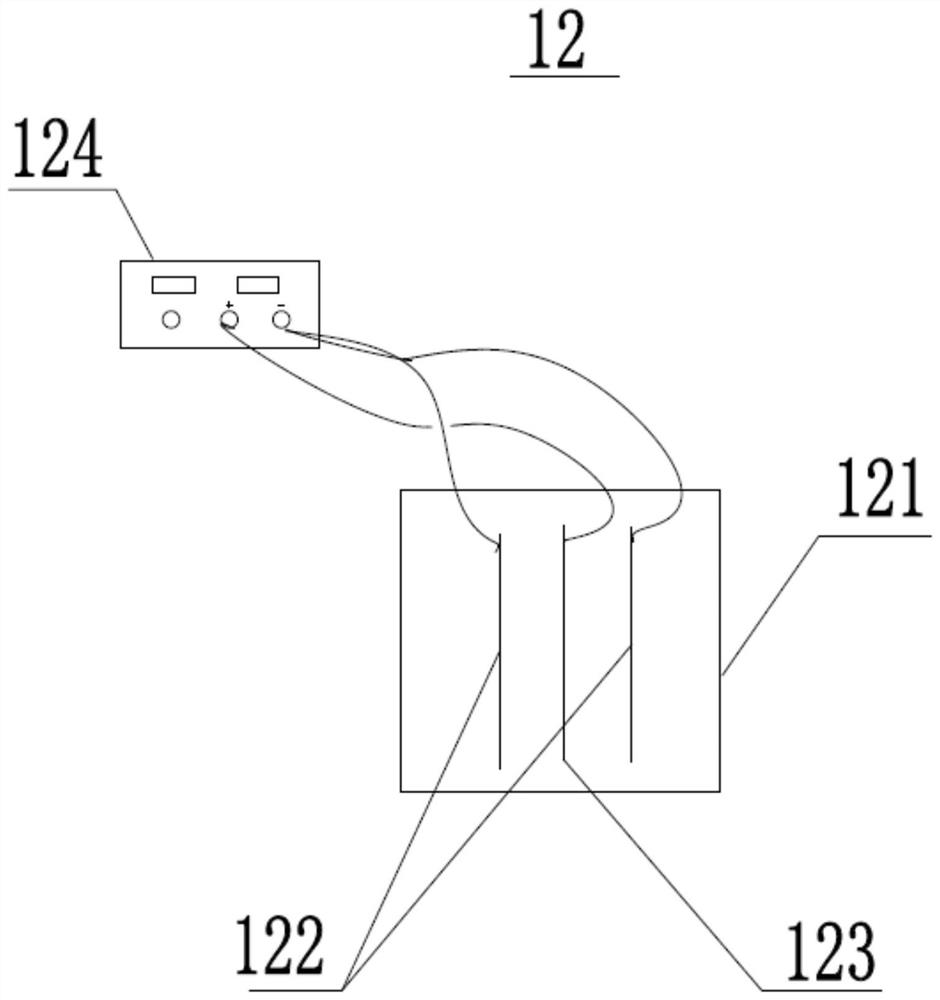

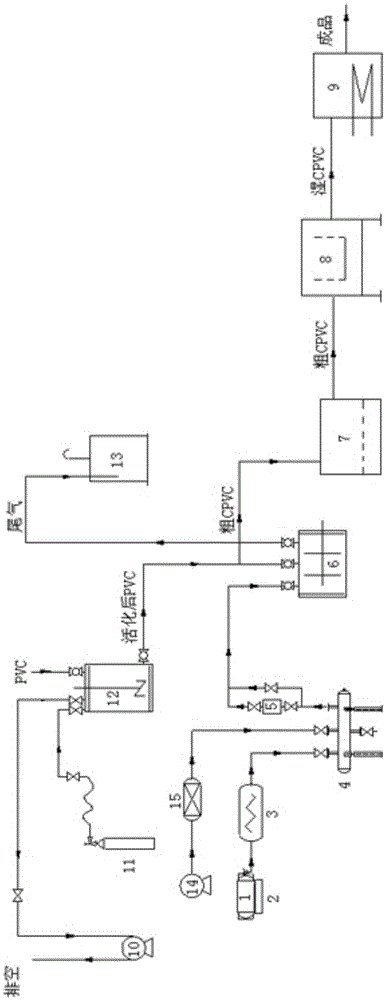

Reaction system and method for intermittent production of chlorinated polyvinyl chloride

The invention discloses a reaction system and method for intermittent production of chlorinated polyvinyl chloride. The reaction system mainly comprises a liquid chlorine vaporizer, a chlorine buffer tank, an activation reactor and a chlorination reactor, wherein the chlorine buffer tank is connected between the liquid chlorine vaporizer and the chlorination reactor, and the activation reactor is connected to the chlorination reactor. The reaction system disclosed by the invention is suitable for gas-solid phase chlorination reaction of polyvinyl chloride and other powder, can be singly used as a chlorination reaction system, can be used together with other chlorination systems, and has very good using flexibility. The reaction system and method for the intermittent production of chlorinated polyvinyl chloride are low in cost, high in product quality, easy in operation control and high in energy source utilization ratio, reduce the production cost, and can improve the chlorine content in chlorinated polyvinyl chloride to be more than 65%.

Owner:中国平煤神马控股集团有限公司

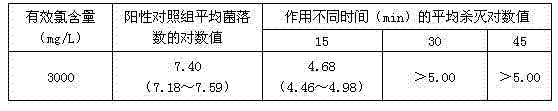

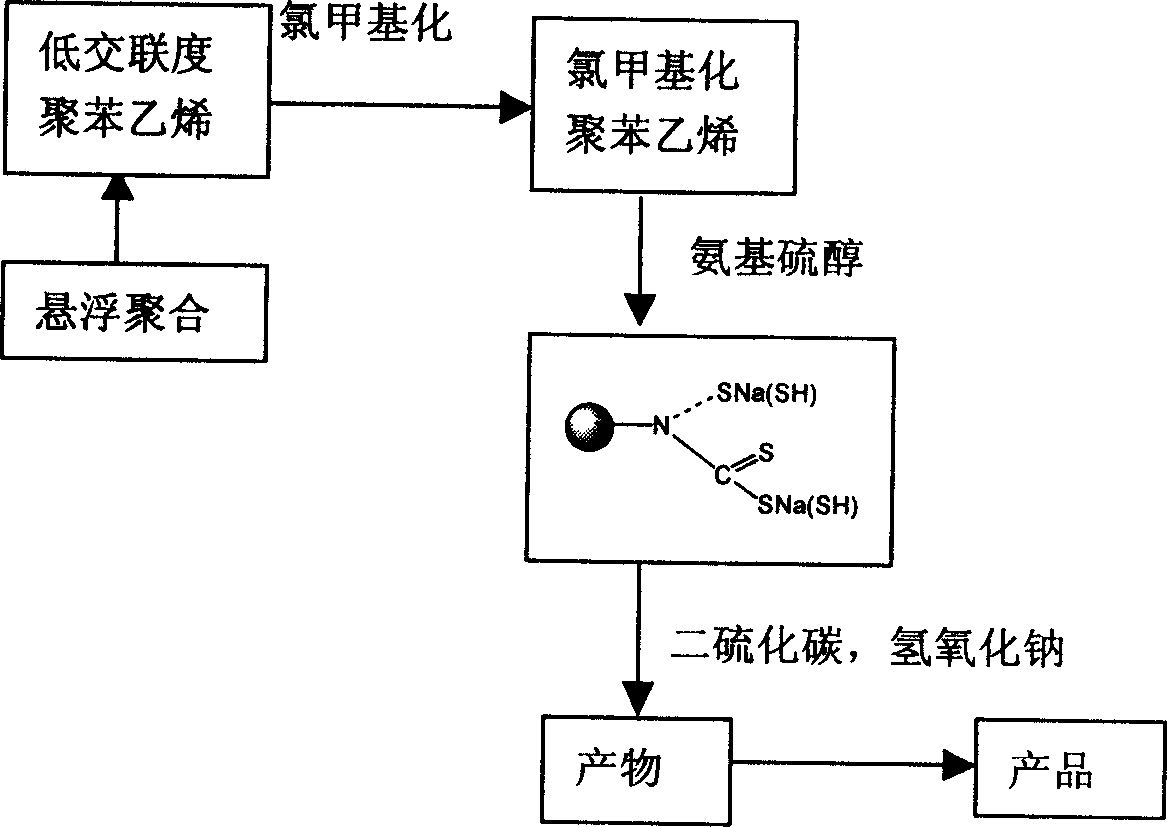

Trichloroiminocyanuric acid effervescent tablet and preparation method thereof

InactiveCN102396465AIncrease chlorine contentIncreased chlorine content is higher,BiocideFungicidesLarge particlePolyvinylpyrrolidone

The invention discloses a trichloroisocyanuric acid effervescent tablet and a preparation method thereof. The trichloroisocyanuric acid effervescent tablet comprises raw materials of, by weight, 46-50% of trichloroisocyanuric acid, 18-23% of cyanuric acid, 14-17% of cyanuric acid, 2-5% of boric acid, 5-8% of sodium benzoate, 1-2% of polyvinylpyrrolidone, 0.2% of sodium dodecyl sulfate, 1.5% of anhydrous citric acid and 0.3% of carboxymethylcellulose sodium. The preparation method comprises steps of: (1) raw material screening: sieving trichloroisocyanuric acid, sodium carbonate, cyanuric acid and boric acid, separating adhesive particles and removing large particles or hard block; (2) mixing well the raw materials; (3) crushing the materials; (4) placing sodium benzoate into a mixture to obtain a standby material; (5) granulating the standby material to obtain a granular standby material; (6) adding polyvinylpyrrolidone, sodium dodecyl sulfate, anhydrous citric acid and carboxymethylcellulose sodium into the standby material and mixing well for reservation; (7) compacting the materials to obtain the trichloroisocyanuric acid effervescent tablets.

Owner:山东大明消毒科技有限公司

Poly-alpha-olefin base oil and preparation method thereof

ActiveCN111019734AHigh oligomerization reactivityIncrease chlorine contentPhysical/chemical process catalystsHydrocarbonsPolyolefinPtru catalyst

The invention relates to a preparation method of poly-alpha-olefin base oil. The method comprises the following steps: S1, catalyzing an oligomerization reaction of an alpha-olefin mixture for 3-8 hours by using a Cr-AlCl3 / Al2O3 immobilized catalyst at a temperature of 50-120 DEG C under a pressure of 0.1-1.0 MPa and an alpha-olefin / solvent volume ratio of (1:0)-(1:1); and S2, after the reaction is stopped, filtering the catalyst, washing with distilled water, carrying out atmospheric distillation to remove the solvent, carrying out reduced pressure distillation to remove the unreacted alpha-olefin and part of the alpha-olefin dimer, and carrying out hydrogenation to obtain the poly-alpha-olefin base oil. The invention also relates to the poly-alpha-olefin base oil prepared by the method.The PAO base oil prepared by the method does not need to be mixed with low-viscosity PAO oil for PAO with a kinematic viscosity range of 30-40 mm<2> / s at 100 DEG C, so that the volatility of lubricating oil can be greatly reduced.

Owner:PETROCHINA CO LTD

Fast-speed lakh bleaching and antichlorating method

InactiveCN1778853ADoes not change or affect colorShorten bleaching timeNatural resin purificationShellacBleach

A fast bleaching and antichloration method with shellac is carried out by mixing shellac with soda and water, heating to 75í½95íÒC, dissolving into shellac alkaline solution with concentration<25%, filtering, keeping temperature between 75í½95íÒC, agitating for shellac alkaline solution by 50-90r / min speed, adding into chlorine-contained bleaching agent with chlorine content 15í½22wt%, agitating for 30-40mins to obtain bleaching glue, raising temperature to 85í½95íÒC, and agitating 3í½8mins by 50-90r / min speed to obtain dechloridized glue. Its advantages include long storage period, better product quality and shorter bleaching time.

Owner:李琳

Preparation process of chlorinated polyvinyl chloride resin

ActiveCN100569810CObserve the color change timeImprove heat stabilityChlorinated polyvinyl chlorideCentrifugation

The invention discloses a method for preparing chlorinated polyvinyl chloride resin. The invention adopts water or hydrochloric acid as the suspending medium, and polyvinyl chloride is suspended in the liquid phase with a solid content (wt) not higher than 30%. Control the chlorine flow rate and chlorination reaction temperature of the three stages of chlorination, and pass chlorine gas that does not exceed 20% of the theoretical chlorine content to make the chlorine content of the resin reach 66-70%. After acid filtration, neutralization, water washing, and centrifugation , drying, to obtain high heat-resistant stability suitable for the production of corrosion-resistant, high-temperature pipe resin.

Owner:SHANGHAI CHLOR ALKALI CHEM

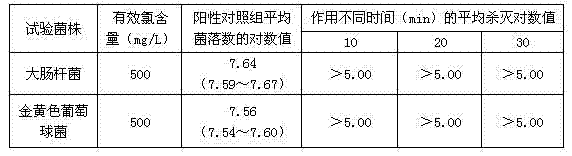

Ultrafiltration membrane for wastewater treatment and preparation method thereof

InactiveCN112108002AIncrease water fluxHigh retention rateMembranesUltrafiltrationUltrafiltrationPolythylene glycol

The invention discloses an ultrafiltration membrane for wastewater treatment and a preparation method of the ultrafiltration membrane. The ultrafiltration membrane is prepared from the following components: chlorinated polyvinyl chloride, modified polyacrylonitrile, polyethylene glycol, polyoxyethylene fatty alcohol ether and dimethylformamide. The ultrafiltration membrane is subjected to hydrophilic modification, so that the infiltration rate of the ultrafiltration membrane is high, the water flux of the ultrafiltration membrane is increased, and the rejection rate of the ultrafiltration membrane is increased; after the polyvinyl chloride is subjected to chlorination modification, the chlorine content of the material is improved, so that the molecular bond polarity of the material is increased, the intermolecular force is enhanced, the chemical stability is improved, and the mechanical property, the chemical corrosion resistance and the heat resistance of the material are greatly improved; polyacrylonitrile is modified, so that precious metal ions and rare metal ions have high adsorption capacity; and the ultrafiltration membrane is good in wastewater treatment effect, good in physical property and mechanical property and not prone to loss, and the wastewater treatment cost is reduced.

Owner:广德华东电子电路发展有限公司

Low-cost poly-alpha-olefin base oil and preparation method thereof

InactiveCN103374433AEasy to makeImmobilized reaction efficiency is highTreatment with hydrotreatment processesBase-materialsAlpha-olefinTert butyl

The invention discloses a low-cost PAO (poly-alpha-olefin) base oil and a preparation method thereof. The preparation method comprises the following steps: carrying out oligomerization reaction on raw materials isobutylene and C8-C12 alpha-olefins at 50-80 DEG C under the hydrogen partial pressure of 0.25-0.4 MPa and the reaction pressure of 0.5-1.0 MPa by using gamma-aluminum oxide (gamma-Al2O3)-supported nickel (II)-organic aluminum as a catalyst and tert-butyl chlorine as a cocatalyst, and carrying out after-treatment to obtain oligomers; and hydrogenizing the oligomers to obtain the PAO base oil. The C8-C12 alpha-olefin content in the obtained PAO base oil is 60-81 omega%, the number-average molecular weight of the base oil is less than 550, the molecular weight distribution is less than 15, the 100 DEG C kinematic viscosity is 8.8-28.0 mm<2> / s, the viscosity index is 121-147, the pour point is -38 to -52 DEG C, and the bromine number is less than 0.050 bromine g / 100g PAO.

Owner:上海泰强粘合剂有限公司 +1

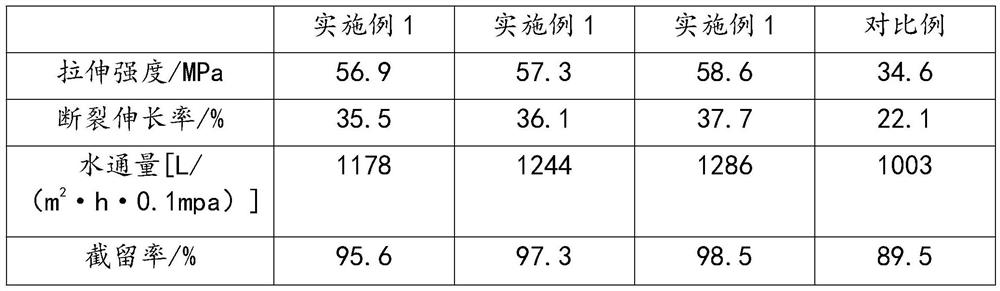

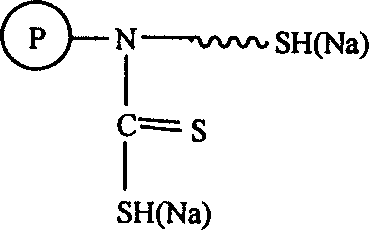

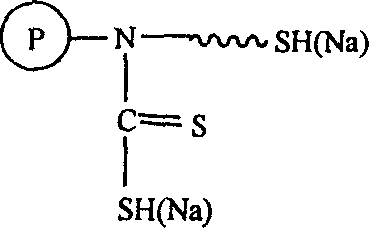

Novel high effective noble metal adsorbent and its preparing method

InactiveCN1683072ALarge degree of chloromethylationIncrease chlorine contentOther chemical processesProcess efficiency improvementChemistryPolystyrene

The present invention relates to the design and synthesis method of adsorbing resin, and by means of special polymerization method, small crosslinked polystyrene ball is made to possess proper geometric features and maximized function. By means of proper design, the synthesis steps are reduced, and functional radical contains special reactive functional groups capable of adsorbing noble metal. One functional molecule contains four adsorbing groups. The obtained adsorbent has excellent noble metal adsorbing performance and selectivity under different pH conditions, and may be used in the adsorption and recovery of noble metal in different fields.

Owner:SUZHOU UNIV

Method for preparing oxygen-enriched super-crosslinked resin based on Friedel-Crafts alkylation reaction and application of oxygen-enriched super-crosslinked resin

InactiveCN111073021AIncrease oxygen contentIncrease chlorine contentOther chemical processesWater contaminantsPolymer sciencePolystyrene

The invention relates to a method for preparing oxygen-enriched super-crosslinked resin based on a Friedel-Crafts alkylation reaction and application of the oxygen-enriched super-crosslinked resin, and the method for preparing the oxygen-enriched super-crosslinked resin based on the Friedel-Crafts alkylation reaction comprises the following steps: (1) swelling chloromethylated crosslinked polystyrene; (2) preparing oxygen-enriched precursor resin, namely carrying out a Friedel-Crafts reaction on the chloromethylated crosslinked polystyrene treated in the step (1) and oxygen-containing small molecules at 40-50 DEG C under the catalysis of a Lewis acid for a preset time; and (3) preparing the oxygen-enriched super-crosslinked resin, namely carrying out a Friedel-Crafts reaction on the oxygen-enriched precursor resin prepared in the step (2) and rigid small molecules at 80-90 DEG C for a preset time, and weaving the oxygen-enriched precursor resin skeleton. The oxygen-enriched super-crosslinked resin is easy to elute after adsorption, can be repeatedly used, has a good repeated use effect, can be widely applied to the fields of chemical analysis, drug separation and purification, environmental pollution treatment and the like, and has a great development prospect.

Owner:CENT SOUTH UNIV

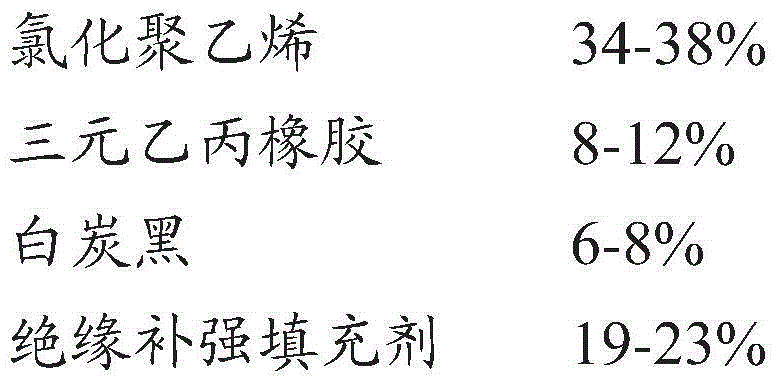

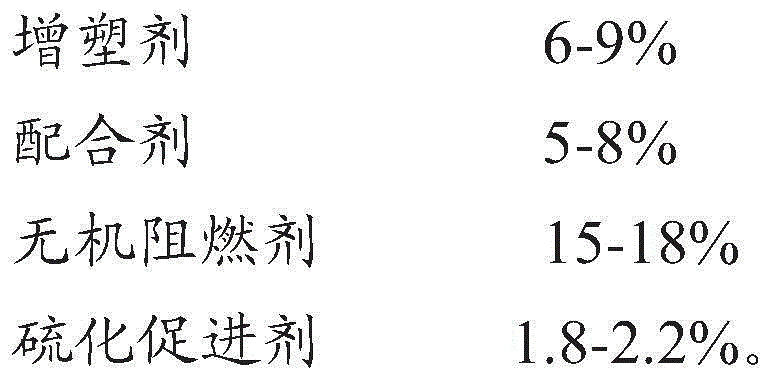

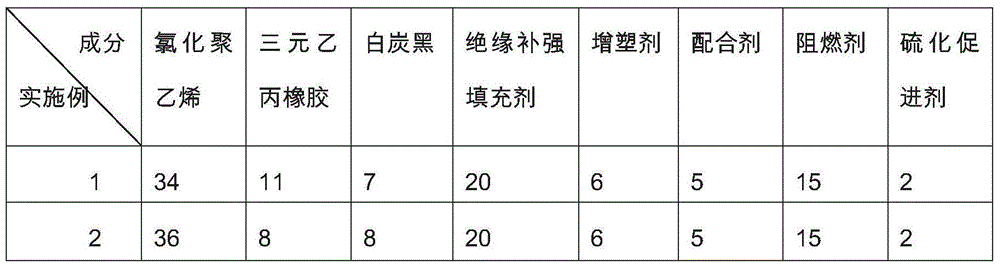

Special mixing rubber for insulating low-temperature-resistant wire core, and preparation method thereof

InactiveCN106467637AGood compatibilityMake up for low temperature resistanceRubber insulatorsPolymer scienceVulcanization

The invention discloses a special mixing rubber for an insulating low-temperature-resistant wire core, wherein the components comprise 34-38% of chlorinated polyethylene, 8-12% of ethylene propylene diene monomer, 6-8% of white carbon black, 19-23% of an insulating reinforcing filler, 6-9% of a plasticizer, 5-8% of other matching agents, 15-18% of a flame retardant agent, and 1.8-2.2% of a vulcanization accelerator. According to the present invention, the special mixing rubber has advantages of good low-temperature resistance, no embrittlement in a low temperature environment, good flame retardancy and high insulation resistance, and retains other good comprehensive performances.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

A method for separating and purifying desulfurized gypsum and a device for realizing the method

InactiveCN106315652BIncrease chlorine contentImprove resource utilizationCalcium/strontium/barium sulfatesFlotationFoaming agentPurification methods

The invention provides a separation and purification method of desulfurized gypsum and the implementation thereof to upgrade the quality of the desulfurized gypsum. The method is to add alcoholic foaming agent and hydrophobic collector into the desulfurized gypsum slurry in the stirring condition. The equipment for the implementation comprises the collector injection unit and the foaming agent injection unit. The outlet of the collector injection unit is connected to the desulfurized slurry pond; the outlet of the foaming agent injection unit is connected to the oxidized air transmission pipe. The invention applies the principle of dissolved air floating, combines the black gel debris and hydrophobic collector, and combines the hydrophobic base of the foam generated by the foaming agent and the hydrophobic base on the surface of the black gel debris, wherein the bubble takes the black debris to the liquid top layer to make the black debris detached from the desulfurized gypsum slurry. The removal rate of the black gel debris is higher than 90%, which guarantees the dehydration effects of the desulfurized gypsum slurry and enhances the purity and whiteness of the desulfurized gypsum and improves the quality of the desulfurized gypsum.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for preparing chlorinated maleic anhydride modified polyethylene material by using composite initiation system

The invention discloses a method for preparing a chlorinated maleic anhydride modified polyethylene material by using a composite initiation system. The method comprises the steps that first, polyethylene is dispersed in a reaction kettle containing an emulsifier, a dispersant and water, polyethylene is suspended under the condition of continuous stirring, and a peroxide-based composite initiatoris added; a certain amount of maleic anhydride is added at a certain temperature, cooling is performed after reaction for a period of time, and a certain amount of chlorine gas is introduced to continue the chlorination reaction; and finally, a chlorinated product is subjected to deacidification by washing, neutralization, dehydration and drying to obtain chlorinated maleic anhydride modified polyethylene. The composite initiation system is used for improving the production efficiency.

Owner:ZHEJIANG UNIV +1

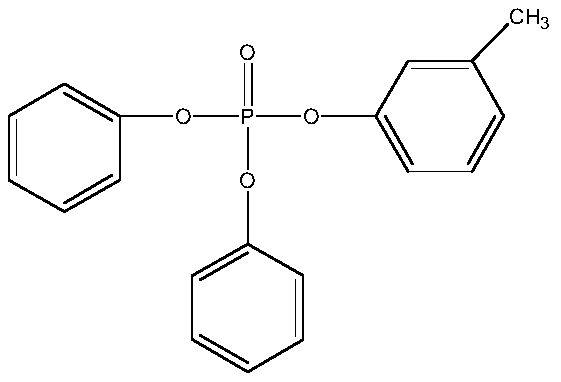

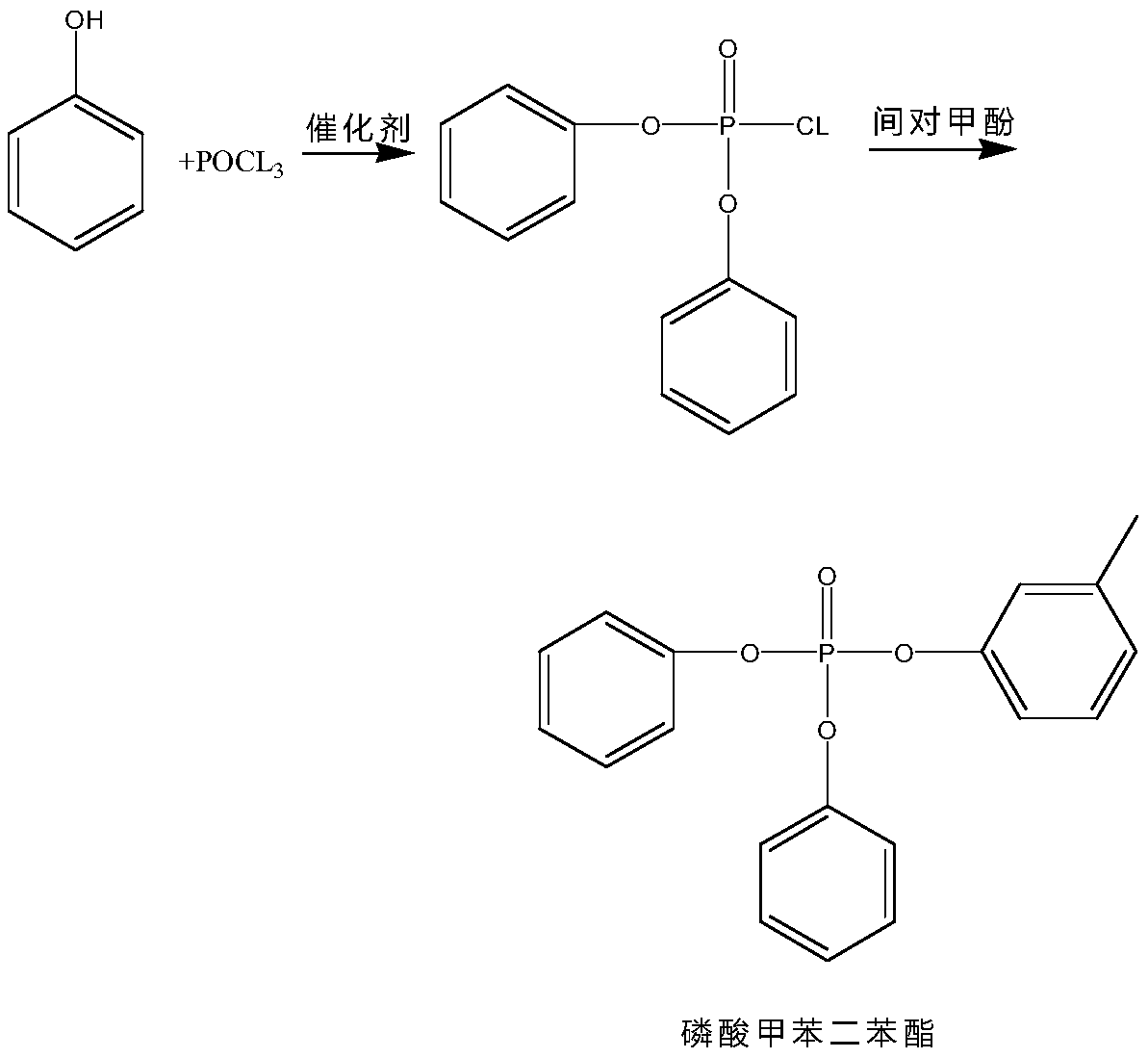

Preparation method of cresyl diphenyl phosphate

InactiveCN110423249ALess quantityOperational securityGroup 5/15 element organic compoundsDiphenyl phosphateCresol

The invention relates to a preparation method of cresyl diphenyl phosphate. The method includes the steps of: 1) esterification reaction: mixing phosphorus oxychloride with a catalyst, then adding phenol dropwise, and at the end of the reaction, conducting reduced pressure distillation to obtain diphenoxy phosphoryl chloride; 2) reduced pressure reaction: reacting the intermediate diphenoxy phosphoryl chloride obtain in step 1) with m, p-cresol under a reduced pressure, and removing the reacted hydrogen chloride gas to obtain a cresyl diphenyl phosphate crude product; and 3) refining: carryingout alkali washing, washing and reduced pressure distillation on the cresyl diphenyl phosphate crude product obtained in step 2) to obtain cresyl diphenyl phosphate. Phosphorus oxychloride and phenolare employed for reaction to prepare the diphenoxy phosphoryl chloride intermediate, the generated intermediate reacts with m, p-cresol to prepare the product, the synthetic route reduces the impurities phenyl xylylphosphate, tricresyl phosphate and triphenyl phosphate, thus improving the purity.

Owner:ZHEJIANG WANSHENG

Preparation method of polypropylene for preparation of chlorinated polypropylene with high chlorination rate

The invention relates to a preparation method of polypropylene for preparation of chlorinated polypropylene with a high chlorination rate, which comprises the following steps: adding 3-20mmol of aluminium alkyl hexane solution into 1000ml of straight-chain saturated paraffin or straight-chain saturated paraffin mixture; adding 0.1-0.5g of catalyst per ml of straight-chain saturated paraffin or mixture with straight-chain saturated paraffin; and adding 10-150mul of orthosilicate component per g of catalyst, adding 10-150mul of dicarboximide compound per g of catalyst and filling gas mixture of propylene and hydrogen. The catalyst is a Ziegler-Natta catalyst; the straight-chain saturated paraffin is hexane or octane; the straight-chain saturated paraffin mixture is mixture of nonane and decane; and the dicarboximide compound is 2, 2, 6, 6-4-methylpyridine. As to the polypropylene, the melt flow index is 20-50g / 10min, the isotacticity is 91-95 percent, the crystallinity is 40-54 percent and the bulk density is higher than 0.38g / cm3.

Owner:PETROCHINA CO LTD

Device and method for preparing calcium hypochlorite, calcium chlorate and calcium perchlorate

ActiveCN110129820ASolve the emission problemIncrease chlorine contentCellsChemical industryWater discharge

The invention relates to a device and method for preparing calcium hypochlorite, calcium chlorate and calcium perchlorate, relates to the technical field of chemical industry, and provides a device and method for resourceful treatment of wastewater. The device for preparing the calcium hypochlorite, the calcium chlorate and the calcium perchlorate comprises a first-stage electro-oxidation unit, asecond-stage electro-oxidation unit and a third-stage electro-oxidation unit, wherein different solutions are respectively electro-oxidized through the three stages of electro-oxidation units; the next stage of electro-oxidation unit is used for electro-oxidizing products of the previous stage of electro-oxidation unit to separately obtain a calcium hypochlorite solution, a calcium chlorate solution and a calcium perchlorate solution, and thus, a purpose of increasing the content of chlorine is achieved; and in addition, the calcium chloride raw materials in the invention are wide, and particularly, calcium chloride high-salt waste liquid generated in chemical production can be used as a raw material, so that resource utilization is further realized, and the problem of calcium chloride waste water discharge is solved.

Owner:SHANDONG RUIKE ENVIRONMENTAL TECH CO LTD

Calcium hypochlorite, calcium chlorate, calcium perchlorate preparation device and method

ActiveCN110129820BSolve the emission problemIncrease chlorine contentCellsCalcium perchlorateChemical industry

The invention relates to a device and method for preparing calcium hypochlorite, calcium chlorate and calcium perchlorate, relates to the technical field of chemical industry, and provides a device and method for resourceful treatment of wastewater. The device for preparing the calcium hypochlorite, the calcium chlorate and the calcium perchlorate comprises a first-stage electro-oxidation unit, asecond-stage electro-oxidation unit and a third-stage electro-oxidation unit, wherein different solutions are respectively electro-oxidized through the three stages of electro-oxidation units; the next stage of electro-oxidation unit is used for electro-oxidizing products of the previous stage of electro-oxidation unit to separately obtain a calcium hypochlorite solution, a calcium chlorate solution and a calcium perchlorate solution, and thus, a purpose of increasing the content of chlorine is achieved; and in addition, the calcium chloride raw materials in the invention are wide, and particularly, calcium chloride high-salt waste liquid generated in chemical production can be used as a raw material, so that resource utilization is further realized, and the problem of calcium chloride waste water discharge is solved.

Owner:SHANDONG RUIKE ENVIRONMENTAL TECH CO LTD

Preparation method of setting paraffin for polyurethane foam caulk

ActiveCN105733680BHigh viscosityIncrease chlorine contentPetroleum chemical modificationParaffin waxPolymer science

The invention discloses a method for producing shaping paraffin serving as polyurethane foam crack filler.The method comprises the following steps of adding heavy liquid wax and light liquid wax into a reaction kettle, and stirring the materials to be uniform, so that reaction materials are obtained; introducing chlorine into the reaction kettle, and controlling the reaction temperature; after the reaction materials react with the chlorine for a while, detecting the density and viscosity of chlorinated paraffin, and then blowing off hydrogen chloride gas; then detecting the acid value, and then adding compound heat stabilizer, so that the shaping paraffin is obtained.The method has the advantages that the produced shaping paraffin is high in chlorine content, as a result of increase of the chlorine content, the viscosity of the polyurethane foam crack filler can be increased accordingly, and thereby the phenomena that when the polyurethane foam crack filler is used under the condition of low temperature and low humidity, the completely dry speed is low, obtained foam is low in viscosity and thus cannot support a framework of the foaming volume, obtained foam is made to flow out and cannot expand in a space where gluing is predicted to be conducted are avoided.

Owner:SHIJIAZHUANG DONGXIANG CHEM CO LTD

A kind of polypropylene preparation method for preparing high chlorination rate chlorinated polypropylene

The present invention relates to a polypropylene preparation method for preparing chlorinated polypropylene with high chlorination rate; adding 3-20mmol alkyl aluminum hexane solution to 1000ml linear saturated alkane or linear saturated alkane mixture; adding 0.1- 0.5g catalyst / ml linear saturated alkanes or linear saturated alkanes mixture; 10-150μl orthosilicate compound / g catalyst, 10-150μl nitrogen-containing heterocyclic compound / g catalyst, feed propylene / hydrogen mixed gas; The catalyst is Ziegler-Natta catalyst; the linear saturated alkane is hexane or octane; the linear saturated alkane mixture is a mixture of nonane and decane; the nitrogen-containing heterocyclic compound is 2,2,6,6-tetramethyl Pyridine: The melt index of the polypropylene is 20-50g / 10min, the isotacticity is 91-95%, the crystallinity is 40-54%, and the bulk density is greater than 0.38g / cm3.

Owner:PETROCHINA CO LTD

Novel high effective noble metal adsorbent and its preparing method

InactiveCN100384528CLarge degree of chloromethylationIncrease chlorine contentOther chemical processesProcess efficiency improvementSynthesis methodsSorbent

The present invention relates to the design and synthesis method of adsorbing resin, and by means of special polymerization method, small crosslinked polystyrene ball is made to possess proper geometric features and maximized function. By means of proper design, the synthesis steps are reduced, and functional radical contains special reactive functional groups capable of adsorbing noble metal. One functional molecule contains four adsorbing groups. The obtained adsorbent has excellent noble metal adsorbing performance and selectivity under different pH conditions, and may be used in the adsorption and recovery of noble metal in different fields.

Owner:SUZHOU UNIV

A reaction system and method for batch production of chlorinated polyvinyl chloride

The invention discloses a reaction system and method for batch production of chlorinated polyvinyl chloride. The reaction system mainly includes a liquid chlorine vaporizer, a chlorine gas buffer tank, an activation reactor and a chlorination reactor. A chlorine buffer tank is connected, and an activation reactor is connected to the chlorination reactor. The reaction system of the present invention is not only suitable for the gas-solid phase chlorination reaction of polyvinyl chloride, but also suitable for the gas-solid phase chlorination reaction of other powders. It can not only be used as a chlorination reaction system alone, but also can be combined with other chlorination systems. Used together, it has good flexibility of use. The reaction system and method for intermittently producing chlorinated polyvinyl chloride of the present invention are low in cost, high in product quality, easy to control in operation, high in energy utilization rate, reduced in production cost, and can increase the chlorine content in chlorinated polyvinyl chloride to 65%. above.

Owner:中国平煤神马控股集团有限公司

A kind of polyalpha-olefin base oil and preparation method thereof

ActiveCN111019734BHigh oligomerization reactivityIncrease chlorine contentPhysical/chemical process catalystsHydrocarbonsPolyolefinPtru catalyst

The present invention relates to a method for preparing a poly-alpha-olefin base oil, comprising the following steps: S1, at a temperature of 50° C. to 120° C., a pressure of 0.1 to 1.0 MPa, and a volume ratio of alpha-olefin to solvent of 1:0 to 1:1 condition, with Cr-AlCl 3 / Al 2 O 3 The solid-supported catalyst catalyzes the oligomerization reaction of the α-olefin mixture for 3 to 8 hours; S2, after the reaction is stopped, the catalyst is filtered, washed with distilled water, the solvent is removed by atmospheric distillation, and the unreacted α-olefin and some α-olefin dimerization are removed by vacuum distillation After hydrogenation, polyα-olefin base oil is obtained. The present invention also relates to polyalpha-olefin base oils prepared by the above method. The PAO base oil prepared by this method needs a kinematic viscosity of 30-40mm at 100℃ 2 PAOs in the / s viscosity range do not need to be mixed with low-viscosity PAO oils, which can greatly reduce the volatility of lubricating oils.

Owner:PETROCHINA CO LTD

Chlorinated polystyrene and a preparing method thereof

InactiveCN106565868ASmall mechanical propertiesImprove flame retardant performanceHeat resistancePolystyrene

Chlorinated polystyrene and a preparing method thereof are provided. The chlorinated polystyrene and the method are characterized in that the method includes steps of (1) suspending and dispersing polystyrene powder into a water medium under stirring, and adding an emulsifier, a dispersant and an initiator, and (2) raising the temperature to 60-80 DEG C, feeding chlorine, reacting the materials, gradually controlling and raising the temperature to be 100-110 DEG C and reacting continuously, with the reaction time being 1-4 h; the temperature rising rate in the step (2) is 15-20 DEG C / h; a water-phase suspension process is adopted to perform chlorination on the polystyrene so that flame retardance and heat resistance can be improved; and addition of a flame retardant reducing mechanical properties of the polystyrene is avoided.

Owner:山东龙阳化工有限公司

A kind of preparation method of aqueous phase suspension method cpvc resin

ActiveCN106565872BAchieve chlorination terminationHigh efficiency in removing impuritiesChemical effectsChemistry

A preparation method of CPVC resin by a water-phase suspension method belongs to the field of a CPVC preparation technology. The preparation method is characterized in that ultrasonic wave at specific frequency is selected and has an effect of dispersing PVC resin. At this frequency of ultrasonic wave, it can be ensured that PVC resin is uniformly dispersed in an aqueous suspension system; and by utilization of energy effect and chemical effect of ultrasonic wave, deep chlorination and chlorination uniformity are guaranteed and structure defect of CPVC resin is reduced. The prepared CPVC resin has high chlorine content and ageing whiteness, good initial coloration, long dynamic thermal stable time, and good processing plasticizing performance.

Owner:CHINA PETROLEUM & CHEM CORP

Chlorinated butadiene rubber material, and preparation method and application thereof

PendingCN114044838AIncrease chlorine contentStrong intermolecular forcesSpecial tyresRubber materialPolymer science

The invention belongs to the technical field of high polymer materials, and particularly relates to a chlorinated butadiene rubber material, and a preparation method and application thereof. The chlorinated butadiene rubber material is prepared by a substitution reaction of butadiene rubber with chlorine, wherein the butadiene rubber contains 38%-46% of cis-1,4 butadiene rubber. The chlorine content of the chlorinated butadiene rubber material is 20-35%. The preparation method of the chlorinated butadiene rubber material is simple to operate and easy to control, the comprehensive performance of the finally obtained chlorinated butadiene rubber material is improved, and the chlorinated butadiene rubber material can be used for manufacturing truck tire treads and is large in usage amount and low in cost.

Owner:瑞易德新材料股份有限公司

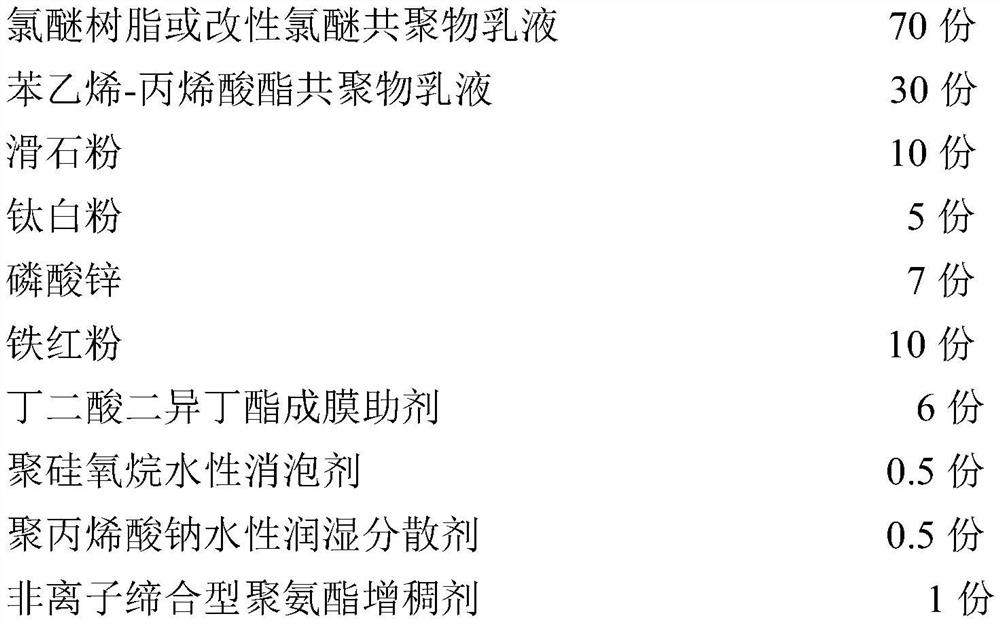

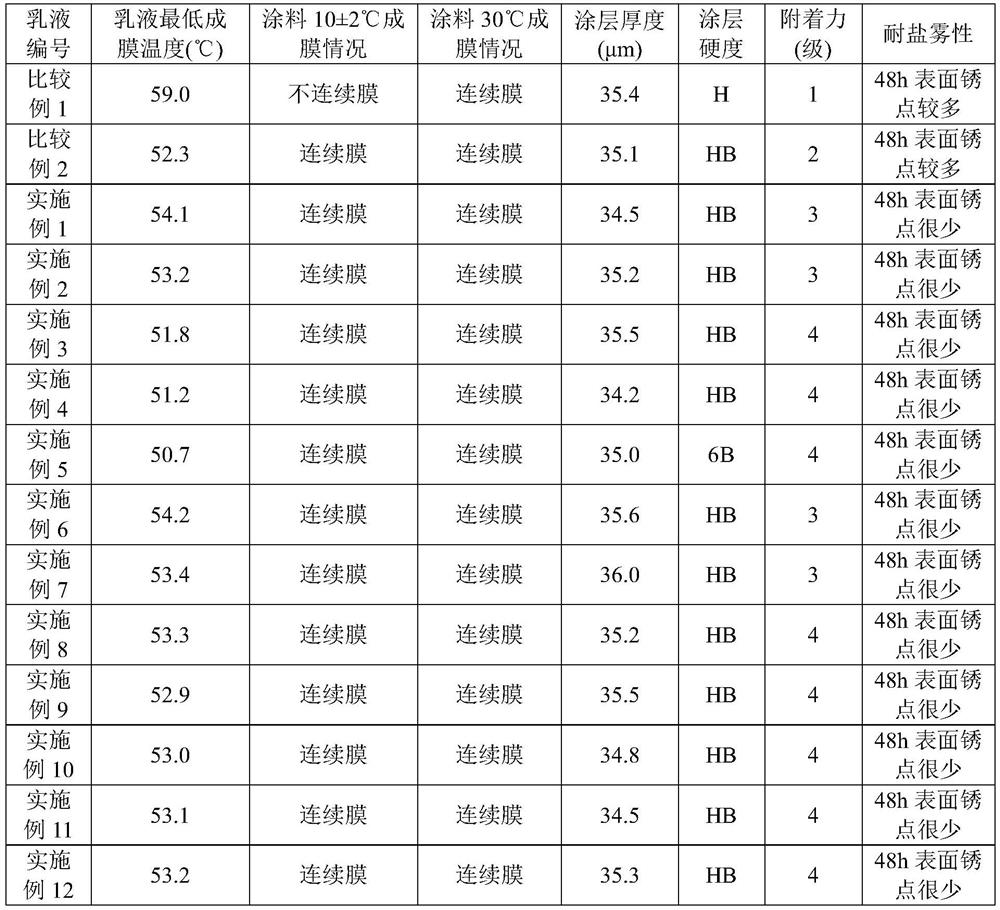

Vinyl chloride copolymer emulsion for water-based anticorrosion coating and its preparation method and application

InactiveCN111234084BLower glass transition temperatureIncrease chlorine contentAnti-corrosive paintsPolymer scienceAqueous solution

The invention discloses a vinyl chloride copolymer emulsion for water-based anticorrosion coatings and a preparation method thereof, comprising the steps of: adding deionized water, vinyl chloride, allyl chloride, isobutyl vinyl ether, maleic anhydride, Emulsifier and reducing agent, stir and heat up to 45-60°C, then continuously drop ammonium persulfate initiator aqueous solution to start polymerization, continuously add vinyl chloride during polymerization, control the speed of vinyl chloride addition, and maintain the pressure of the polymerization system ± 0.1 kg / cm 2 , continue to polymerize until the pressure of the system drops by 0.5-2.0kg / cm after adding vinyl chloride 2 When the temperature is lowered, the polymerization is terminated, unreacted monomers are removed, and a vinyl chloride copolymer emulsion is obtained. The present invention increases the chlorine content of the copolymer by introducing the addition amount of propylene chloride monomer and isobutyl vinyl ether, and at the same time introduces maleic anhydride, the caking monomer, so that the obtained vinyl chloride copolymer can be used to prepare the vinyl chloride copolymer with good anticorrosion effect and Adhesive water-based paint.

Owner:JIANGSU LISIDE NEW MATERIAL

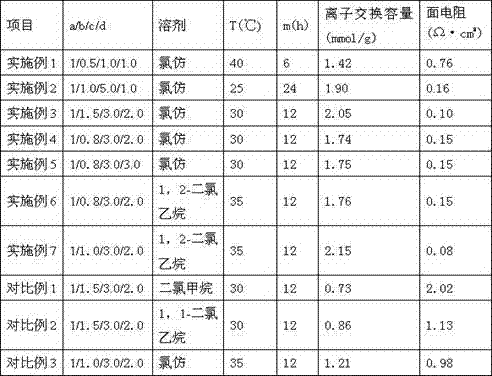

A modified tri-block copolymer electrolyte membrane and its preparation method

InactiveCN105169977BSuitable for mass productionEasy to useSemi-permeable membranesIon-exchange membranesSolid content

The invention provides a modified triblock copolymer electrolyte membrane and a preparation method thereof, belonging to the technical field of electrolyte. The modified triblock copolymer electrolyte membrane has a structure as shown in the specification, wherein in the formula, m, n and p are respectively integers from 50 to 3000, x is more than zero and smaller than or equal to m, and y is more than zero and smaller than or equal to n; T is monovalent anion. The preparation method comprises the following steps: adding modified triblock copolymer SEBS and excess trimethylamine and dimethylformamide into a reactor, wherein the solid content is 5-20wt%; stirring for reaction for 24 hours at 40 DEG C, then coating reaction liquid to a clean horizontal glass board to form a membrane naturally, evaporating the solvent at the temperature of 60 DEG C, and stripping the membrane, thus obtaining the modified triblock copolymer electrolyte membrane. According to the invention, the conventional route of chloromethylation is abandoned, and a chloroacetyl modification method is adopted, so that the membrane is relatively environmental-friendly and safe, and an ion exchange membrane with higher chlorine content, namely, higher ion exchange capacity, and excellent conductivity can be obtained.

Owner:NANYANG NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com