Ultrafiltration membrane for wastewater treatment and preparation method thereof

A wastewater treatment and ultrafiltration membrane technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problem of poor chemical corrosion resistance and poor hydrophilicity of ultrafiltration membranes , ultrafiltration membrane toughness and other issues, to achieve high adsorption capacity, high selectivity, enhanced intermolecular force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

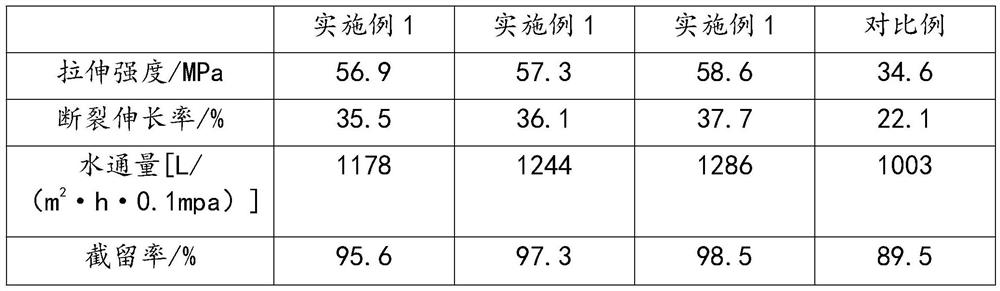

Embodiment 1

[0033] This embodiment is an ultrafiltration membrane used for wastewater treatment, which is prepared from the following components in parts by weight:

[0034]20 parts of chlorinated polyvinyl chloride, 2 parts of modified polyacrylonitrile, 10 parts of polyethylene glycol, 1 part of polyoxyethylene fatty alcohol ether, 40 parts of dimethylformamide;

[0035] The ultrafiltration membrane used for wastewater treatment is prepared by the following steps:

[0036] Step 1: Put chlorinated polyvinyl chloride, modified polyacrylonitrile, and polyethylene glycol into dimethylformamide, stir and mix at a temperature of 50°C and a speed of 50r / min, and mix evenly. Vacuum defoaming to obtain raw material liquid;

[0037] Step 2: Spin the raw material solution through a spinning machine to obtain a fiber film, immerse the fiber film in a 30°C deionized water coagulation bath, and then stretch the solidified fiber film to 1.5 times the original length to obtain a fiber super membrane;...

Embodiment 2

[0048] This embodiment is an ultrafiltration membrane used for wastewater treatment, which is prepared from the following components in parts by weight:

[0049] 30 parts of chlorinated polyvinyl chloride, 4 parts of modified polyacrylonitrile, 15 parts of polyethylene glycol, 2 parts of polyoxyethylene fatty alcohol ether, 50 parts of dimethylformamide;

[0050] The ultrafiltration membrane used for wastewater treatment is prepared by the following steps:

[0051] Step 1: Put chlorinated polyvinyl chloride, modified polyacrylonitrile, and polyethylene glycol into dimethylformamide, stir and mix at a temperature of 75°C and a speed of 125r / min, and mix evenly. Vacuum defoaming to obtain raw material liquid;

[0052] Step 2: Spin the raw material solution through a spinning machine to obtain a fiber film, immerse the fiber film in a 45°C deionized water coagulation bath, and then stretch the solidified fiber film to 1.8 times the original length to obtain a fiber super membra...

Embodiment 3

[0063] This embodiment is an ultrafiltration membrane used for wastewater treatment, which is prepared from the following components in parts by weight:

[0064] 40 parts of chlorinated polyvinyl chloride, 5 parts of modified polyacrylonitrile, 20 parts of polyethylene glycol, 3 parts of polyoxyethylene fatty alcohol ether, 60 parts of dimethylformamide;

[0065] The ultrafiltration membrane used for wastewater treatment is prepared by the following steps:

[0066] Step 1: Put chlorinated polyvinyl chloride, modified polyacrylonitrile, and polyethylene glycol into dimethylformamide, stir and mix at a temperature of 100°C and a rotation speed of 200r / min, and mix evenly. Vacuum defoaming to obtain raw material liquid;

[0067] Step 2: Spin the raw material solution through a spinning machine to obtain a fiber film, immerse the fiber film in a 60°C deionized water coagulation bath, and then stretch the solidified fiber film to twice the original length to obtain a fiber super ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com