Patents

Literature

93 results about "Calcium chlorate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium chlorate is the calcium salt of chloric acid, with the chemical formula Ca(ClO₃)₂. Like other chlorates, it is a strong oxidizer.

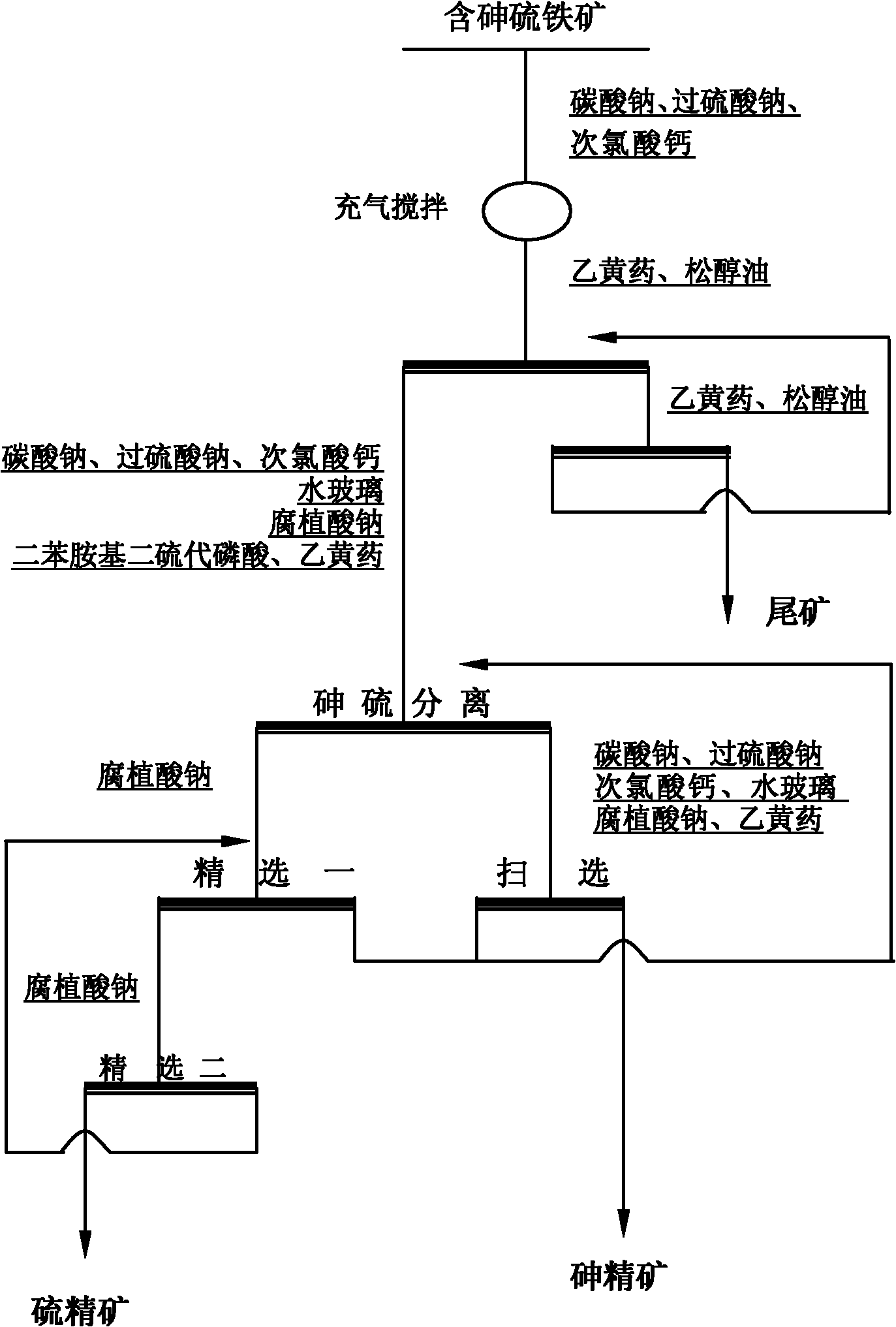

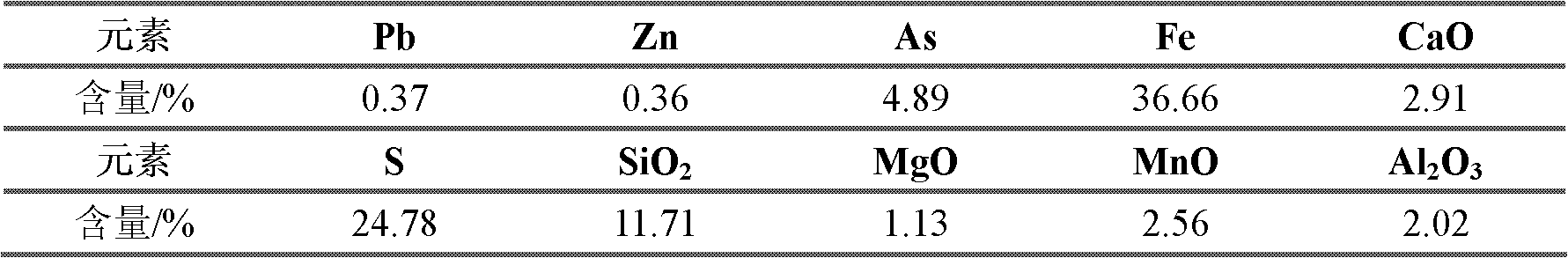

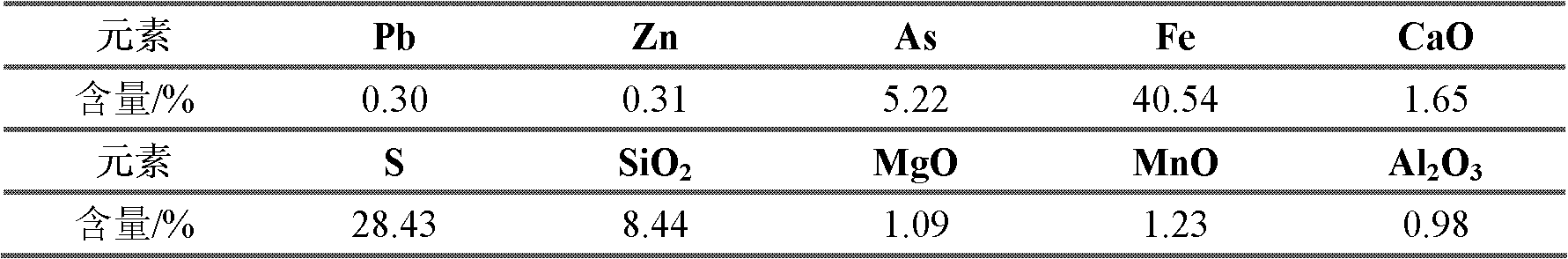

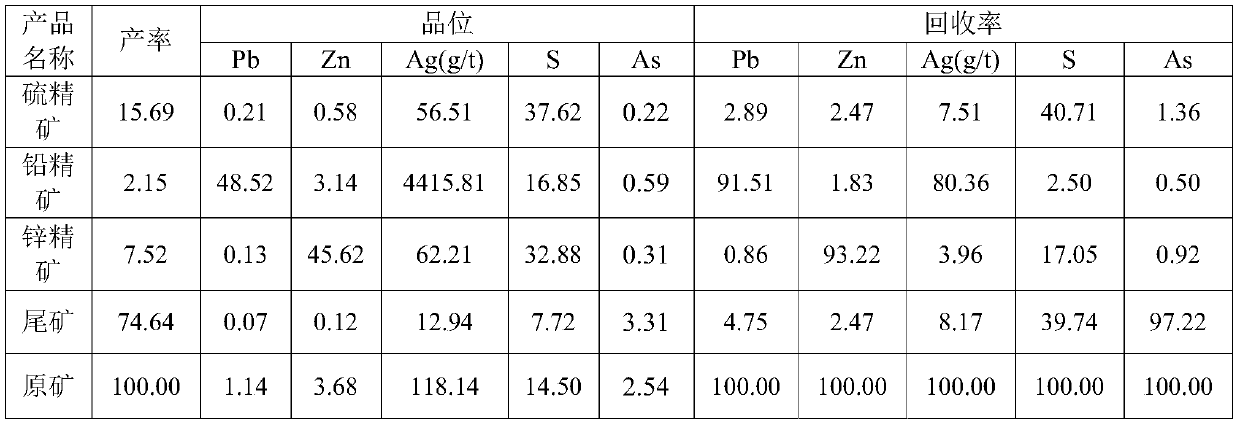

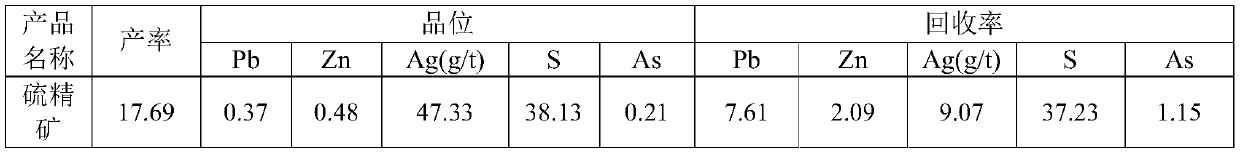

Floatation separation method for pyrites from arsenopyrites

InactiveCN101844108AIncrease oxygen contentElectrochemical conditions for stable flotationFlotationMineral flotationElectrochemistry

The invention aims at floatation separation of arsenic from sulfur in arsenic-containing pyrites. The floatation separation comprises the following steps of: adjusting an ore pulp to keep the pH value of the pulp between 9 and 10; adjusting the potential of the ore pulp to between 350 and 380 millivolts by adding oxidant medicaments of sodium persulfate and calcium hypochlorite; introducing air to increase oxygen content in the ore pulp; and stabilize electrochemical conditions of mineral floatation. During the floatation separation of the pyrites from the arsenopyrites, the potential of the ore pulp is stabilized by adding the oxidant medicaments of sodium persulfate and calcium hypochlorite; the arsenopyrite is suppressed by using a new collector of dianilino dithiophosphoric acid, and regulators of sodium silicate and sodium humate according to a principle of an electrochemical floatation process to make the pyrites such as arsenopyrites, iron pyrites, pyrrhotites and the like acted with a medicament selectively in the subsequent floatation process; and the floatation separation of the pyrites from the arsenopyrites is performed so as to form a sulfur concentrate with low arsenic content.

Owner:CENT SOUTH UNIV +1

Calcium hypochlorite composition

Calcium hypochlorite compositions that are classified as a Packing Group III Division 5.1 oxidizer material or as a non-Division 5.1 oxidizer material are described. In one embodiment, the compositions comprise an admixture of particulate calcium hypochlorite and particulate metaboric acid. The calcium hypochlorite is present in the composition in an amount and is of a concentration such that the composition would be classified as a Packing Group II Division 5.1 oxidizer in the absence of said particulate metaboric acid. Other embodiments described are solid shaped articles, e.g., tablets, comprising the described calcium hypochlorite-metaboric acid composition.

Owner:AXIALL OHIO

Air smell removing disinfectant

The invention belongs to the field of disinfection supplies, and relates to an air smell removing disinfectant. The air smell removing disinfectant comprises a solid part and a liquid part; the solid part comprises the following components in percentage by weight: 1 to 78 percent of sodium chlorite, 0.01 to 50 percent of potassium chlorite, 2 to 85 percent of sodium chlorate, 1 to 69 percent of calcium chlorite, 0 to 80 percent of calcium chlorate, 0.1 to 85 percent of potassium chlorate, and 1 to 90 percent of sodium hypochlorite; the liquid part comprises the following components in percentage by concentration: 0.1 to 36.3 percent of hydrochloric acid, 0 to 2 percent of copper sulfate, 0 to 15 percent of aluminum potassium sulfate, and the balance of distilled water; and the solid part and the liquid part are mixed in a mass-volume ratio of 1: (1.5-20) in use to release smell removing disinfection gas. The air smell removing disinfectant can quickly and efficiently achieve a smell removing disinfection effect; and after the disinfectant is used, the disinfectant is environment-friendly and safe, does not have residue or stimulation to the human body, and does not harm the body.

Owner:深圳市元煜之生物科技有限公司

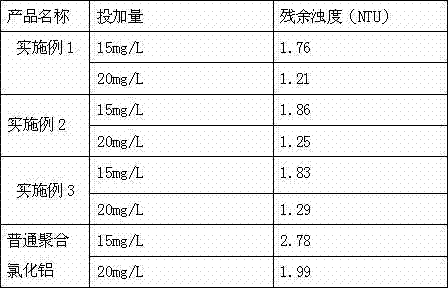

Special poly aluminum chloride for municipal water supply and preparation method of poly aluminum chloride

InactiveCN104709990AImprove water qualityHigh removal rateWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateSodium aluminate

The invention relates to an agent for water supply treatment, in particular to special poly aluminum chloride for municipal water supply and a preparation method of poly aluminum chloride. Poly aluminum chloride mainly solves the technical problems that calcium oxide in calcium aluminate powder carries out acid-base neutralization reaction to certainly influence dissolving of aluminum oxide in calcium powder, detection and adjustment are required constantly in a production process, and a gel phenomenon easily appears in the prior art. The method comprises the steps of adding an aluminum-containing raw material in hydrochloric acid, stirring for sufficient reaction to form poly aluminum chloride liquid, adding calcium chlorate powder or sodium aluminate into the poly aluminum chloride liquid in a stirring tank for sufficient reaction, immediately adding water to cool and dilute after the reaction, and finally obtaining special poly aluminum chloride for the municipal water supply.

Owner:杭州萧山三江净水剂有限公司

Mine use hole packer hole packing material

ActiveCN104479650AGood sealing tightnessRapid expansion and solidificationDrilling compositionSealing/packingCalcium silicateCoal

The invention discloses a mine use hole packer hole packing material which is composed of the following components by weight: 0.5-0.8 part of calcium hydroxide, 0.5-1.5 parts of sodium chloride, 1-2.5 parts of sodium thiosulfate, 0.1-0.4 part of Nekal BX, 1-5 parts of calcium silicate, 0.2-0.4 part of water reducing agent JN, 00.3-0.7 parts of ammonium chloride, 0.001-0.006 part of aluminum hydroxide, 0.001-0.006 part of calcium chlorate, 80-90 parts of iron powder, 1.2-1.5 parts of calcium carbonate and 0.05 to 0.20 part of magnesium hydrate. The mine use hole packer hole packing material realizes the rapid expansion solidification, the tine is improved from 30 minutes in the prior art to 10 minutes, gas drainage-suction borehole sealing tightness is good, water exploration can be quickly realized by water exploration borehole and sealing, in pressure measuring borehole and sealing, pressure measuring can be realized in 24h, operation is simple, use is convenient, the labor intensity is reduced, work efficiency is improved, and the mine use hole packer hole packing material is suitable for hole sealing of various borehole under coal mine wells.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

Sullage oxidized coagulated decolorizing process technique

ActiveCN101139145AAchieve removalAchieve decolorizationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationTherapeutic effectReaction speed

The present invention relates to a sewage oxidation coagulation decolorizing treatment technics. The sewage firstly enters an oxidation decoloring section. Added in An oxidant, the sewage enters a mixed coagulation reactor after the oxidation reaction lasting for 1 to 180 minutes; a coagulant PAC is added in the mixed coagulation reactor and after the fully mixed coagulation reacting, a flocculating agent PAM is added in; after fully reacting, the sewage enters a solid-liquor separator and the clear solution after separating solid from liquor is discharged through the solid-liquor separator. The oxidant is an oxidant of sodium hypochlorite, or calcium hypochlorite or peroxide or any combination of the three; the quantities added to are respectively that the sodium hypochlorite and the calcium hypochlorite are respectively 50 to 20000 PPM, and the peroxide is 0 to 10000 PPM. The quantities of the added coagulant PAC and the flocculating agent PAM are respectively that the PAC is 0 to 2000PPM and the PAM is 0 to 20 PPM. The present invention has the advantages of good treatment effect, innocuity of reaction products, no need of secondary treatment and good operation performance. The present invention has a quicker reaction speed under a normal temperature and is convenient to match and join with the front and back treatment technics.

Owner:山东环发科技开发有限公司

Method for treating wastewater containing hypochlorite

InactiveCN105502609AInhibit hydrolysisLong shelf lifeWater contaminantsWater/sewage treatment by flocculation/precipitationExhaust gasCalcium hypochlorite

The invention relates to a method for treating wastewater containing hypochlorite, and belongs to the technical field of wastewater treatment. In the method, after pickle liquor and wastewater containing hypochlorite are mixed, a polymeric ferric salt solution is prepared. According to the method for treating wastewater containing hypochlorite by use of the polymeric ferric salt solution, provided by the invention, the pickle liquor treatment and the treatment of the wastewater containing hypochlorite are combined to generate the polymeric ferric salt solution through a reaction, chlorine gas generated through the reaction is absorbed through tail gas to generate calcium hypochlorite or sodium hypochlorite to be recycled, or the chlorine gas is collected and recycled after being treated through a gas cleaning device.

Owner:郑宏伟

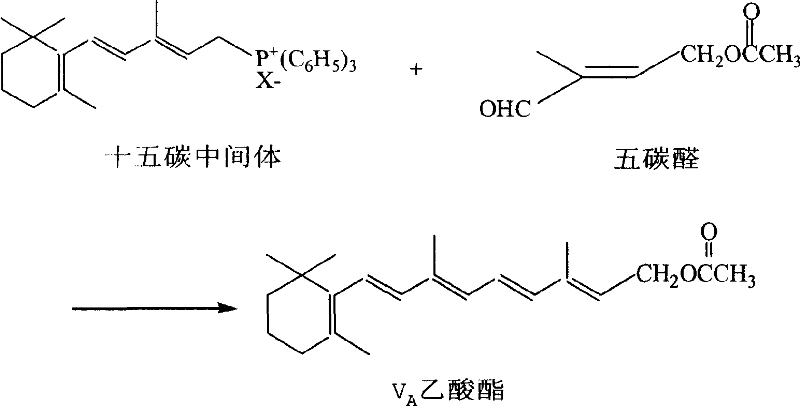

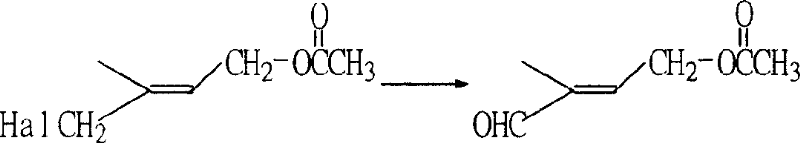

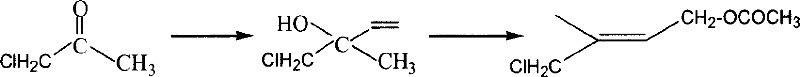

Preparation method of 1-chlorin -2-methyl -4-acetoxy-2- butylene

InactiveCN101041619AIncrease contentHigh yieldOrganic compound preparationCarboxylic acid esters preparationAcetic acidAcetic anhydride

The invention discloses a making method of 1-chlorine-2-methyl-4-acetoxy-2-butene, which comprises the following steps: adopting isoprene as raw material; adding calcium hypochlorite solid and acetic acid as pH value adjuster to do chlorohydrin reaction; obtaining the additional product of 1, 2 position and 1, 4 position; reacting the additional product and acetic anhydride catalyzed by acid to produce the product; making the reacting system mild with little heteroion; improving the content and receiving rate of product.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY +1

Removable Coating and Application Method

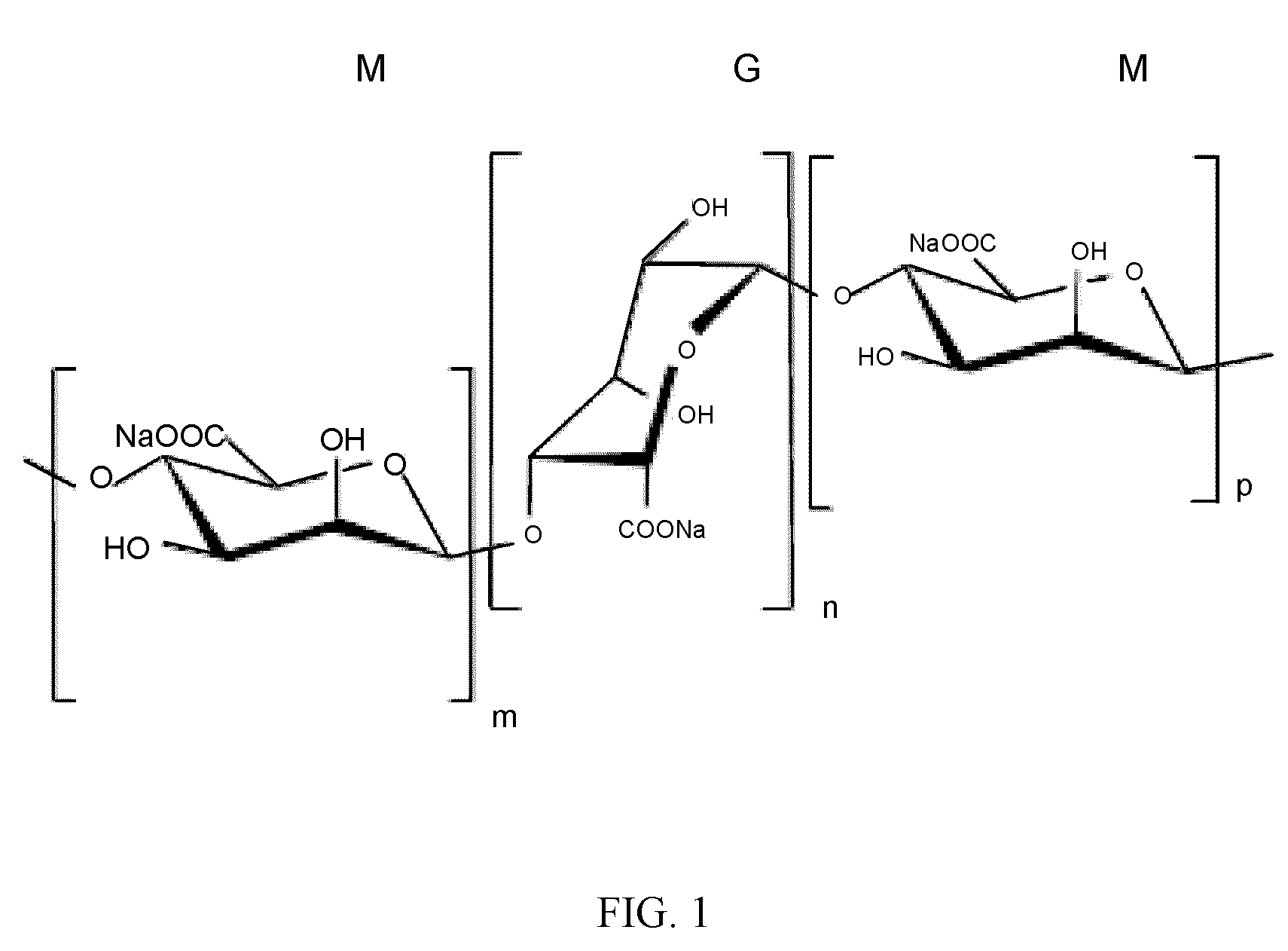

ActiveUS20090053497A1Liquid surface applicatorsDetergent mixture composition preparationCoating systemCarbonate

A removable, colored X-alginate coating composition for a surface includes an aqueous solution of sodium alginate including a colorant and an aqueous solution containing divalent cations. In various aspects, the aqueous solution containing divalent cations includes, but is not limited to, calcium chloride, calcium chlorate, calcium carbonate, magnesium chloride, magnesium chlorate, or magnesium carbonate. The applied coating composition is advantageously in the form of a thin film coating. The thin film may have a thickness about equal to or greater than 10 nanometers and may include more than a single layer; for example, two mono-layers, but not limited as such. Any one of the plurality of monolayers may have a thickness about equal to or greater than five nanometers. Advantageously, the X-alginate coating composition according to the embodiments of the invention is substantially removable from the application surface on-demand upon the application of a suitable chelator. According to an advantageous embodiment, the coating composition is essentially non-toxic and bio-degradable. A reversible, colored X-alginate coating system includes a colored X-alginate coating composition and a colored X-alginate coating composition remover. The remover may be a chelator such as, but not limited to, disodium ethylenediamine tetraacetate (EDTA), ethylene glycol tetraacetic acid (EGTA), or sodium citrate. A method for reversibly coloring a surface includes applying an aqueous solution of sodium alginate including a colorant onto the surface and applying an aqueous solution containing divalent ions onto the surface, wherein the solutions are in mutual contact on the surface. Water may subsequently be applied to the coated surface as a final washing step.

Owner:CORNELL UNIVERSITY

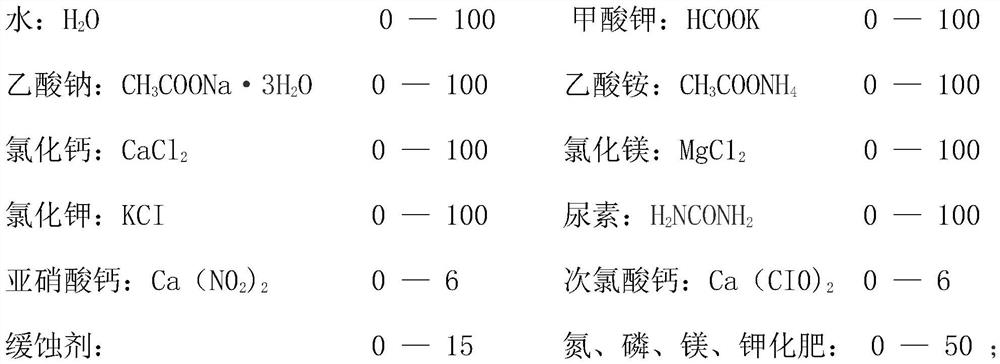

Snow melting agent

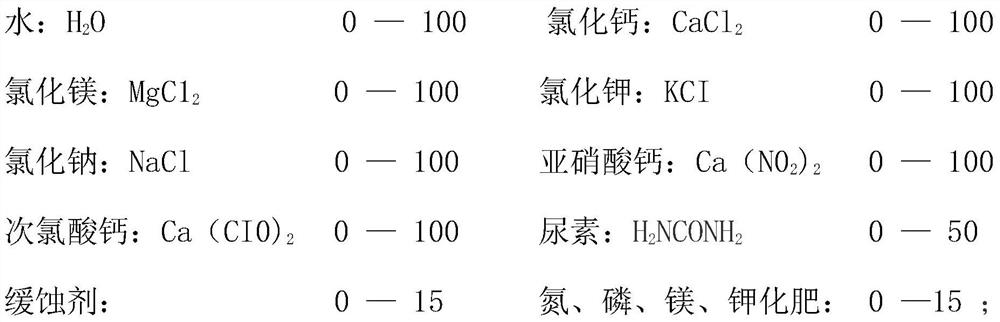

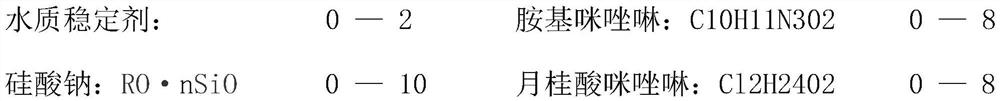

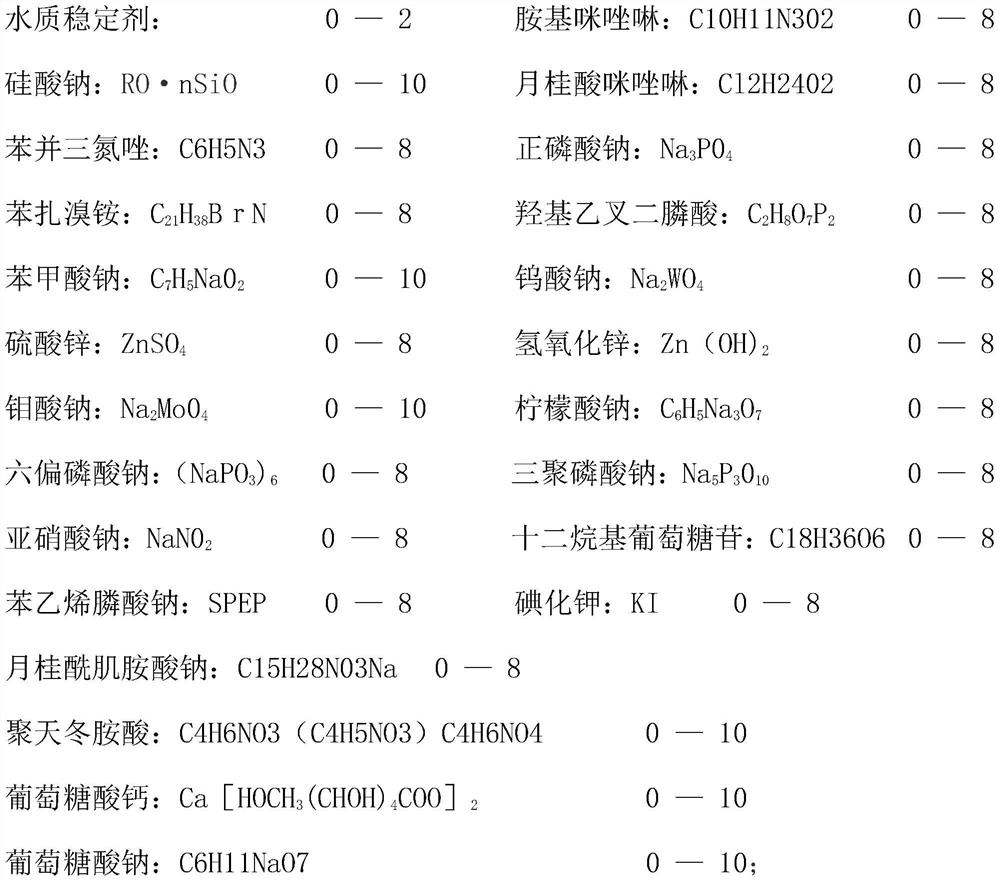

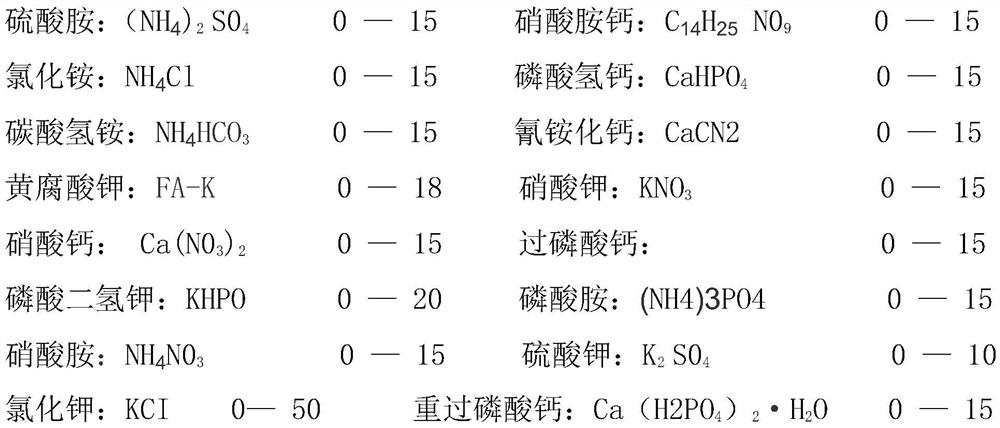

InactiveCN111748319APromote environmental protectionFast ice and snow removalCalcareous fertilisersMagnesium fertilisersSODIUM METAPHOSPHATESodium phosphates

The invention discloses a snow melting agent, and belongs to the technical field of composite salt. Water and one, two, three, four, or five of calcium chloride, magnesium chloride, potassium chloride, sodium chloride, calcium nitrite, calcium hypochlorite, and urea chemical raw materials, a a water quality stabilizer, one, two, three, four, or five of sodium citrate, sodium hexametaphosphate, sodium gluconate, polyaspartic acid and other chemical materials as a corrosion inhibitor, one, two, three, four, or five of chemical fertilizers for promoting plant growth, potassium fulvate for improving a soil aggregate structure, and sodium chloride and activator urea for alleviating pavement thermal shock are used for forming the snow melting agent according to respective attributes. The snow melting speed is high, the use amount is small, and the effect is good; both solid and liquid exist and the snow melting agent can be used at the temperature of over 35 DEG C; corrosion to metal and concrete can be effectively reduced; the plant growth is promoted; the snow melting agent has functions of bleaching, sterilization, disinfection, skid resistance, road surface cleaning and the like on water obtained after ice and snow melting; the snow melting agent, is suitable for mechanical throwing or spraying operation.

Owner:杨毅男

Method for treating sewage generated during fluorescent penetrant testing

InactiveCN103553234AEasy to handleEasy to transportSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentFluorescenceSewage

The invention belongs to an environment engineering technology and relates to an improved method for treating sewage generated during fluorescent penetrant testing. The method is characterized by comprising the following treatment steps: adding a water treatment flocculant into sewage; adding calcium hypochlorite into the sewage; treating the filtered precipitate. The invention provides a sewage treatment method through which the sewage generated during fluorescent penetrant testing can be effectively treated and the precipitate can be dehydrated into solids, and the environment-friendly requirements are met. Meanwhile, the precipitate is convenient to transport and treat.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for improving metallurgical performance of sintered ore

The invention relates to a method for improving metallurgical performance of sintered ore. The method comprises the following steps: performing first-time uniform mixing and second-time mixing pelleting on sintering raw materials and fuel to form a sintering mixed material, wherein calcium chlorate is added in the sintering mixed material during first-time uniform mixing and second-time mixing pelleting to obtain a sintering mixed material A, a sintering mixed material B and a sintering mixed material C, and the calcium chlorate is added in a form of a saturated solution; and taking the sintering mixed material A as a bottom layer sintering material, taking the sintering mixed material B as a middle layer sintering material, taking the sintering mixed material C as an upper layer sinteringmaterial, igniting and drafting after adding all the three sintering mixed materials to perform sintering to obtain a finished product sintered ore. The calcium chlorate is added in the sintering mixed material, the calcium chlorate is heated and decomposed to release oxygen, so that the content of oxygen in the sintering material layer can be increased, the proportion of calcium ferrite in the sintered ore is increased, and the reducing property and the softening-melting and dropping property of the sintered ore are improved; meanwhile, the formed calcium chlorate is attached to the sinteredore uniformly, so that the low-temperature reducing pulverability of the sintered ore is improved.

Owner:ANGANG STEEL CO LTD

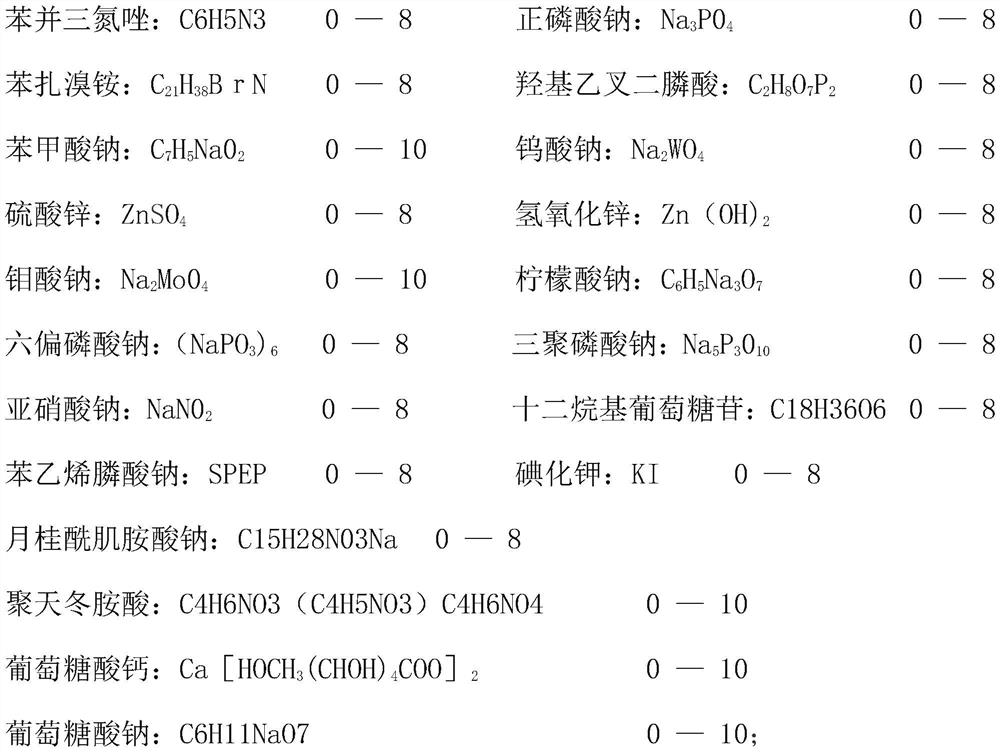

Treatment method of high-concentration phosphorus-containing wastewater

InactiveCN109879470APromote decompositionIncrease the content of free oxygenWater contaminantsWaste water treatment from metallurgical processCalcium hydroxideWastewater

The invention discloses a treatment method of high-concentration phosphorus-containing wastewater. The method comprises the following steps: enabling the wastewater to flow into a first sedimentationtank, adding calcium hydroxide and calcium chloride, adjusting the pH value to 8.5-12.0, recovering calcium phosphate precipitate, enabling the supernatant to automatically flow into an oxidation tank, and sequentially adding calcium hypochlorite and calcium hydroxide-nickel oxyhydroxide into the oxidation tank for full reaction; then, allowing the wastewater to automatically flow into a coagulating tank in which polyacrylamide is added and a second sedimentation tank for coagulating sedimentation, and discharging the supernatant into an adjusting tank and detecting whether to reach the standard or not; and allowing the precipitate to flow back to the oxidation tank. According to the method provided by the invention, orthophosphate is firstly removed by utilizing calcium chloride and calcium hydroxide, then hypochlorous acid is accelerated to be converted into free oxygen by utilizing calcium hydroxide-nickel oxyhydroxide to accelerate the reaction between the free oxygen and complex phosphorus or organic phosphorus, and the generated orthophosphate is quickly combined by utilizing excessive calcium ions to form calcium phosphate precipitate. And finally, comprehensive removal of phosphorus is realized, and the wastewater treatment cost is reduced.

Owner:文树龙

Air smell removing disinfectant

The invention belongs to the field of disinfection supplies, and relates to an air smell removing disinfectant. The air smell removing disinfectant comprises a solid part and a liquid part; the solid part comprises the following components in percentage by weight: 1 to 78 percent of sodium chlorite, 0.01 to 50 percent of potassium chlorite, 2 to 85 percent of sodium chlorate, 1 to 69 percent of calcium chlorite, 0 to 80 percent of calcium chlorate, 0.1 to 85 percent of potassium chlorate, and 1 to 90 percent of sodium hypochlorite; the liquid part comprises the following components in percentage by concentration: 0.1 to 36.3 percent of hydrochloric acid, 0 to 2 percent of copper sulfate, 0 to 15 percent of aluminum potassium sulfate, and the balance of distilled water; and the solid part and the liquid part are mixed in a mass-volume ratio of 1: (1.5-20) in use to release smell removing disinfection gas. The air smell removing disinfectant can quickly and efficiently achieve a smell removing disinfection effect; and after the disinfectant is used, the disinfectant is environment-friendly and safe, does not have residue or stimulation to the human body, and does not harm the body.

Owner:深圳市元煜之生物科技有限公司

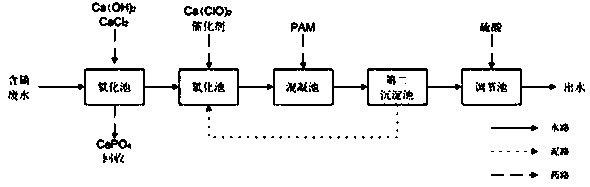

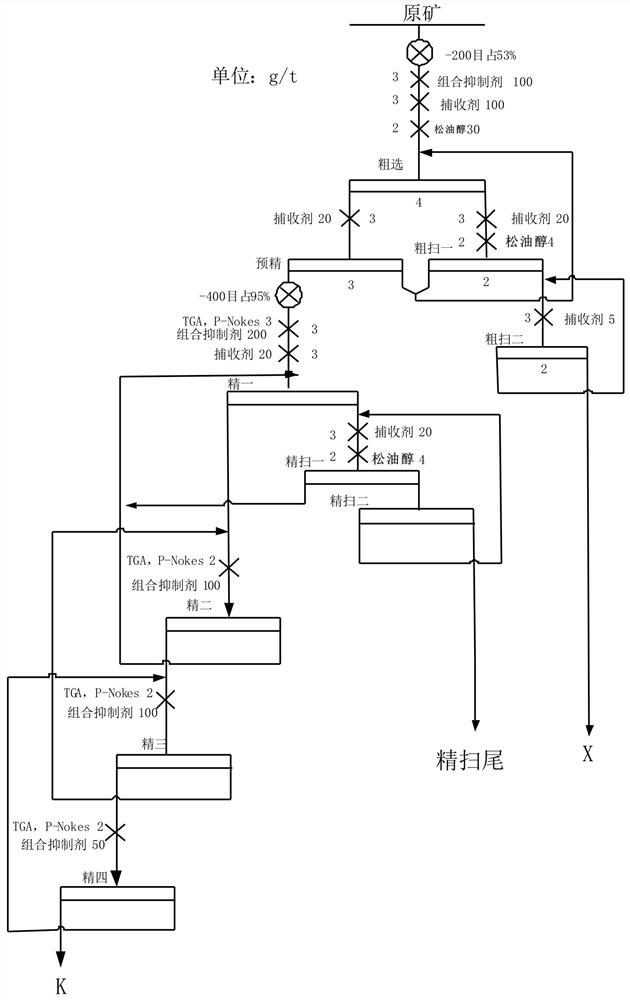

Toxic sand combined inhibitor and high-sulfur high-arsenic lead-zinc-silver ore beneficiation method

InactiveCN111250270AEfficient separationEfficient recyclingFlotationWet separationCalcium hypochloriteMagnetic separation

The invention discloses a toxic sand combined inhibitor and a high-sulfur high-arsenic lead-zinc-silver ore beneficiation method, the toxic sand combined inhibitor is formed by mixing lime, calcium hypochlorite and sodium humate, and the mass ratio of the lime to the calcium hypochlorite to the sodium humate is (4.0-8.0): (2.0-4.0): (1.0-2.0). The lead-zinc-silver ore beneficiation method comprises the following steps that a toxic sand combined inhibitor is added into raw ore pulp for lead roughing, and lead roughing concentrate and lead roughing tailings are obtained; lead scavenging is conducted on the lead roughing tailings at least once, and lead scavenging tailings are obtained; the lead roughing concentrate is subjected to at least one time of lead concentration, and lead concentrateis obtained; magnetic separation is carried out on the lead scavenging tailings to obtain magnetic separation tailings; concentrating and dehydrating are carried out on the magnetic separation tailings to obtain concentrated ore pulp, and the toxic sand combined inhibitor is added into the concentrated ore pulp for zinc flotation to obtain zinc concentrate. The method can effectively separate thelead-zinc-silver minerals from pyrrhotite and poisonous sand, and is simple, easy to implement, efficient and environmentally friendly.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Calcium hypochlorite compositions

Described are compositions containing a mixture of (a) particulate calcium hypochlorite and (b) an amount of aluminum hydroxide that is sufficient to increase the UN-burn time of the composition by a factor of at least 2.5 compared to that of the calcium hypochlorite, the composition having an available chlorine content of at least 35 weight percent. Further described are solid compositions of (a) granular calcium hypochlorite having a UN Packing Group oxidizer classification of II, and (b) an amount of aluminum hydroxide such that the composition is classified as a Packing Group III Division 5.1 oxidizer or as a non-Division 5.1 oxidizer, the composition having an available chlorine content of at least 40 weight percent. Further described are formed articles prepared from the above-described compositions.

Owner:AXIALL OHIO

Method of removing chlorine gas out of industrial tail gas by using lime milk and catalyst thereof

ActiveCN106731566AReduce generationReduce the impactPhysical/chemical process catalystsDispersed particle separationCalcium hypochloriteHypochlorous acid

The invention belongs to the technical field of chlorine gas adsorption and in particular relates to a method of removing chlorine gas out of industrial tail gas by using lime milk and a catalyst thereof. In order to solve the problems that an absorption end point by an existing lime milk method which absorb chlorine gas cannot be achieved as a result of generation of calcium hypochlorite, and equipment is corroded and the like, the invention provides the method of removing chlorine gas in industrial tail gas by lime milk, wherein a mixed contact catalyst is added when the lime milk absorbs chlorine gas, and the mixed contact catalyst is a mixture of nickel chloride and ferric trichloride. According to the method provided by the invention, by adding the catalyst to reduce generation of calcium hypochlorite and accelerate newly generated calcium hypochlorite to decompose, the concentration of calcium hypochlorite in the lime milk is 1.0% or below, so that smooth production of absorbing chlorine gas by the lime milk is guaranteed, the absorptive amount is great, the service life of the equipment is also prolonged, and the production cost is lowered; meanwhile, the influence of chlorine gas generated by decomposing calcium hypochlorite on physical health of staff can be also reduced; therefore, the method has obvious economical and social benefits.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

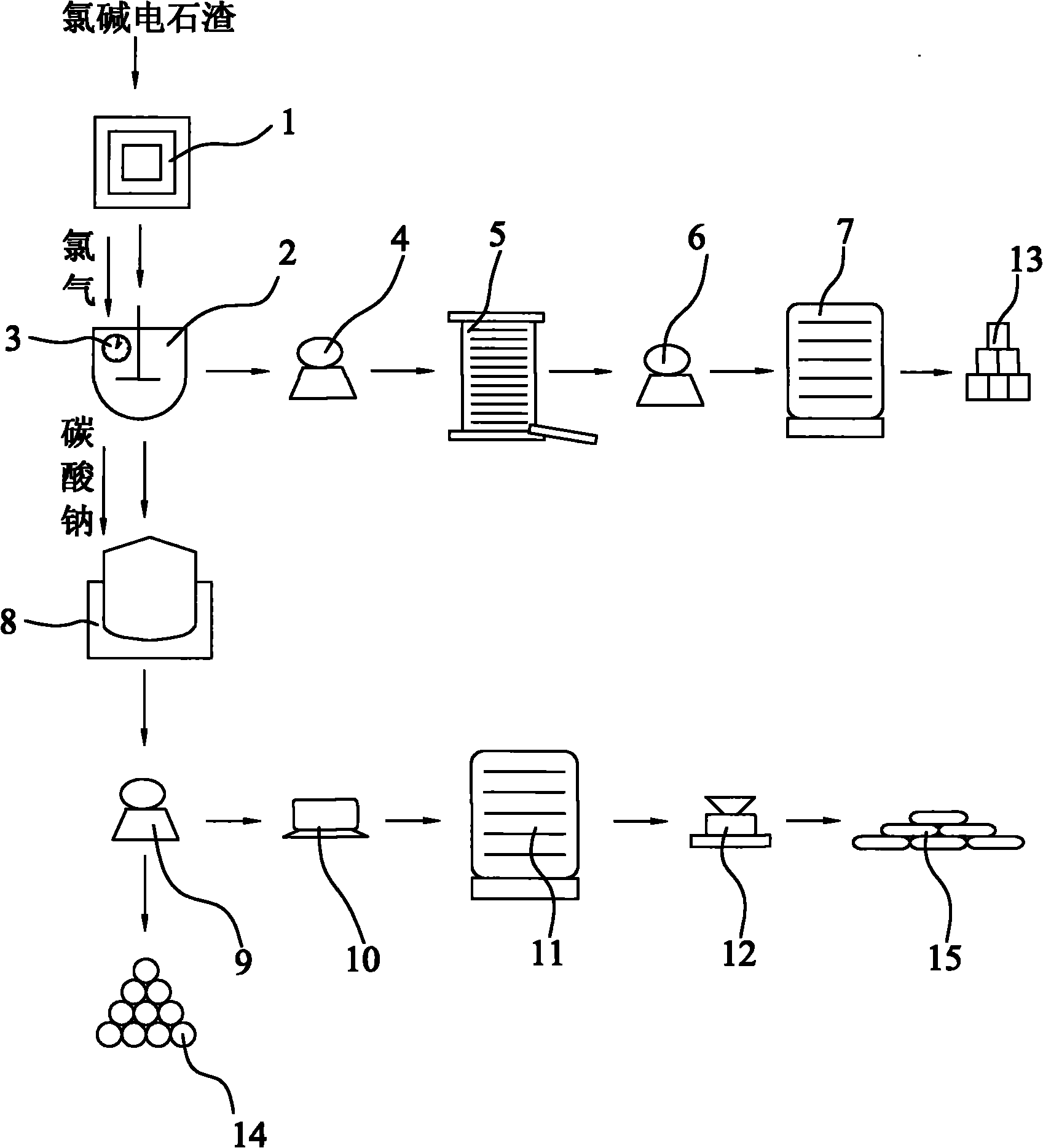

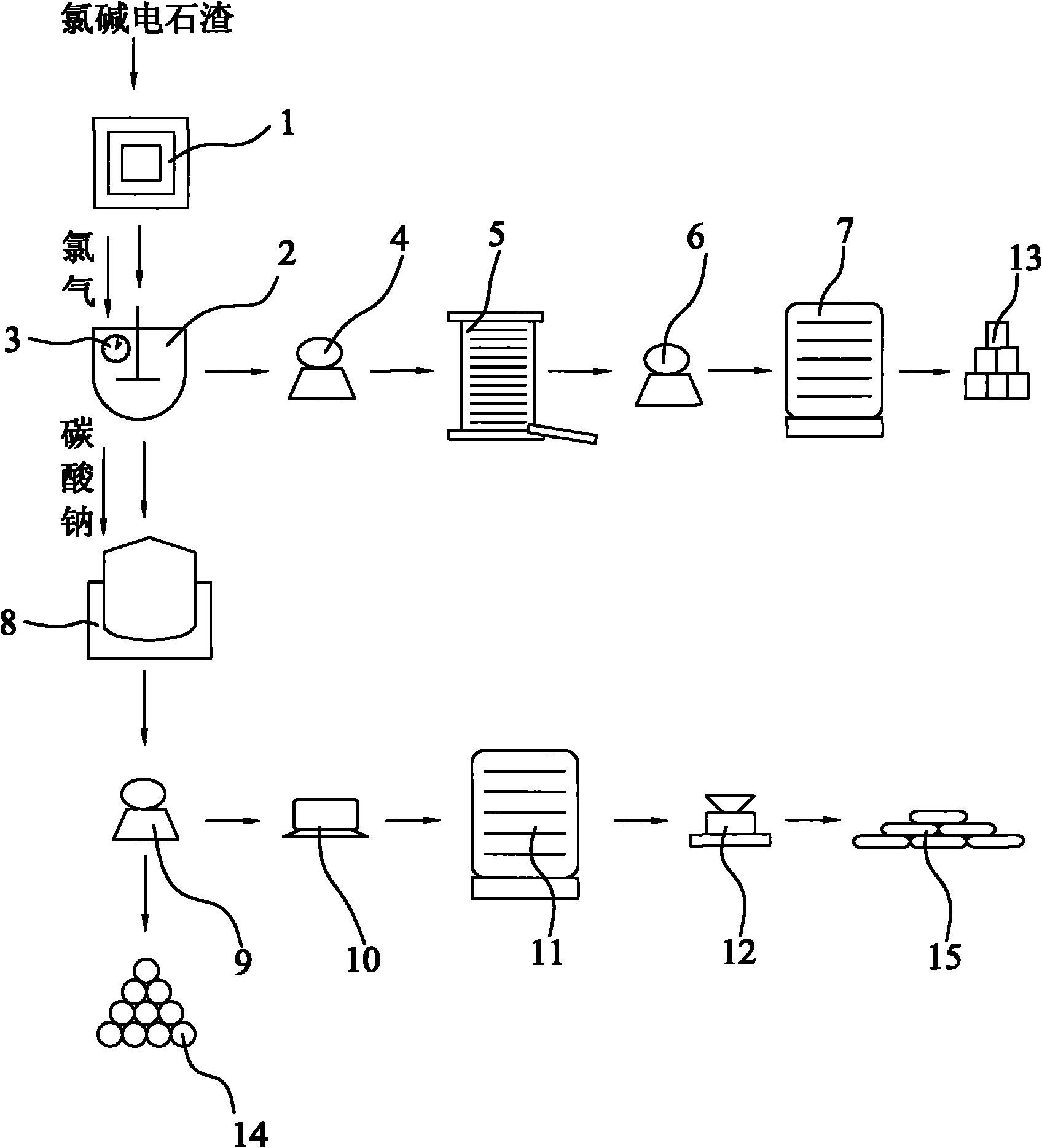

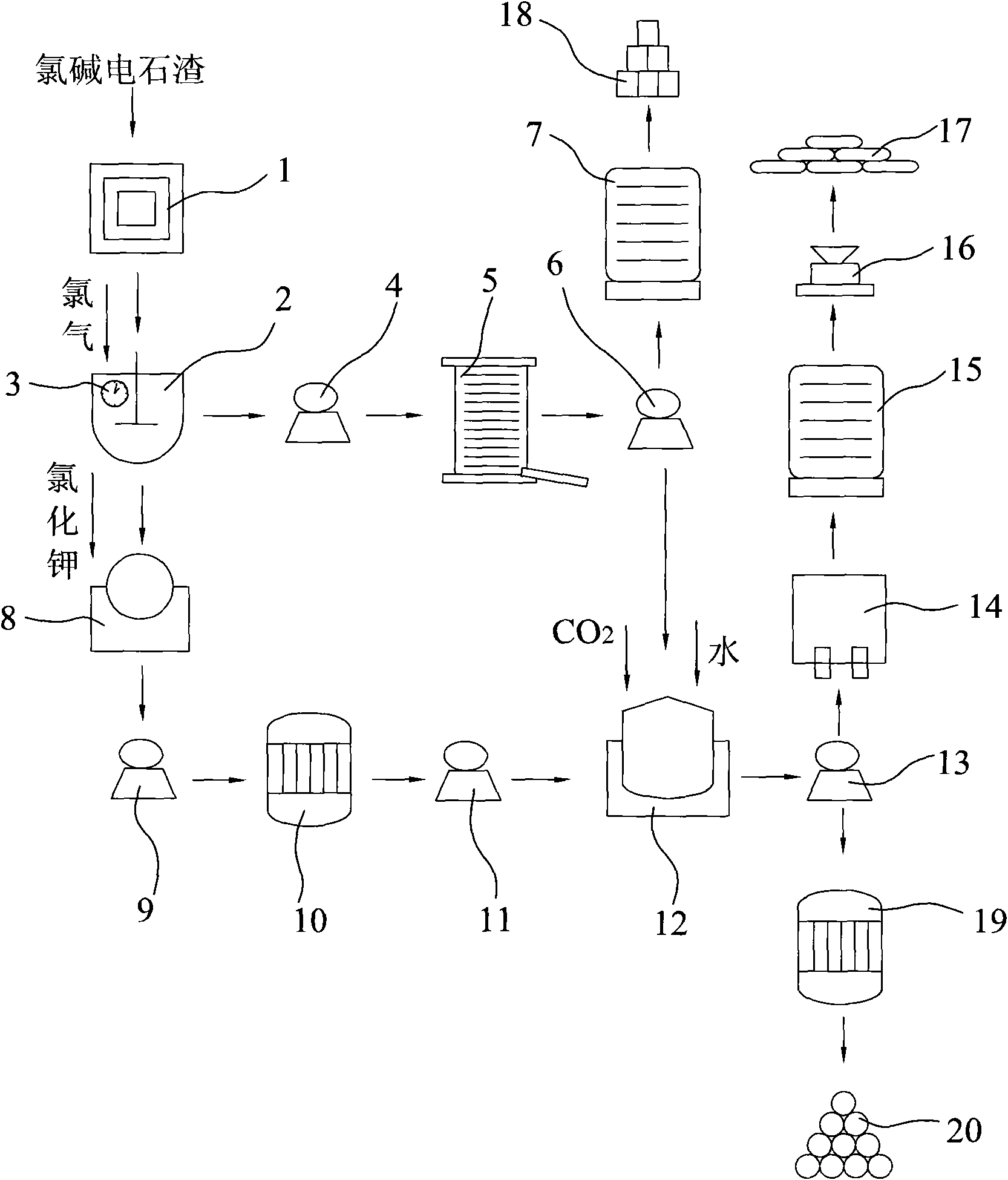

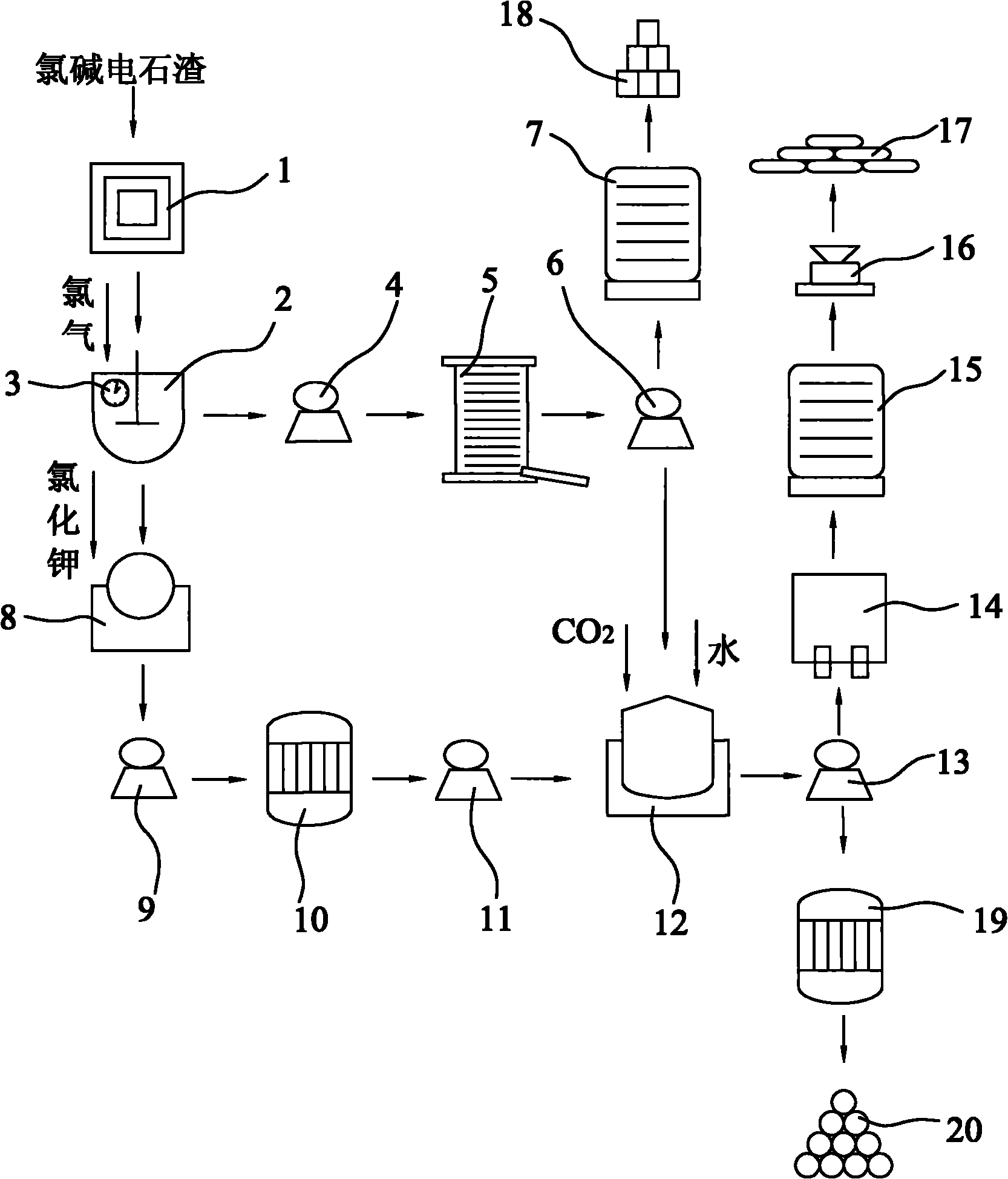

Method for co-production of light calcium carbonate and ammonium chloride in preparation of potassium chlorate by carbide slag

InactiveCN101823695AEasy to operateLess investmentChloratesCalcium/strontium/barium carbonatesSlagDecomposition

The invention discloses a method for co-production of light calcium carbonate and ammonium chloride in the preparation of potassium chlorate by carbide slag. In the method, calcium hydroxide in chlor-alkali carbide slag reacts with chlorine gas to produce reaction products with calcium chlorate and calcium chloride; the reaction products are filtered to remove impurities, solid calcium chlorate can be separated out through settlement under the reduced temperature, and then solid calcium chlorate and calcium chloride filtrate can be obtained through filtration again; the reaction products with the calcium chlorate and the calcium chloride can also react with potassium chloride for double decomposition to produce mixed solution of potassium chlorate and calcium chloride; the mixed solution is filtered to remove impurities, potassium chlorate crystals can be separated out through distillation under the reduced pressure, and potassium chlorate crystals and calcium chloride solution can be obtained through filtration again; and then the calcium chloride solution after being treated with a surfactant react with carbon dioxide and ammonia in a carbonation tower for carbonation, thereby obtaining the light calcium carbonate and ammonium chloride.

Owner:汪晋强

Concrete waterproof additive

The invention belongs to the technical field of concrete waterproof additives, and particularly relates to a concrete waterproof additive. The concrete waterproof additive is prepared from the following components in parts by mass: 100-200 parts of silica fume, 50-100 parts of sodium methylsilanolate, 20-50 parts of triethoxysilane, 20 -40 parts of organic silicon water aqua, 100-200 parts of calcium carbonate, 10-20 parts of expanding agent, 10-20 parts of cross-linking agent, 20-50 parts of volcanic ash, 50-100 parts of ferric chloride and 10-20 parts of a water reducing agent. The double-expansion-source expanding agent based on the sulfate-series expanding agent and the magnesium oxide-series expanding agent is arranged, and the cracks appearing on the outer wall of the cement caused by the fact that monosulfate is used as an additive and easily reacts with calcium hydroxide and hydrated calcium chlorate in cement to generate hydrated calcium sulphoaluminate can be reduced so the compactness of concrete is improved, and the formed liquid siliceous compacting agent can preliminarily compact concrete gaps without influencing the use of the expanding agent.

Owner:苏州万众建筑材料有限公司

Method for producing calcium chlorate and co-producing fine calcium carbonate and sodium chloride by using carbide slag

InactiveCN102101652AEasy to operateLess investmentCalcium/strontium/barium carbonatesChloratesSlagSurface-active agents

The invention discloses a method for producing calcium chlorate and co-producing fine calcium carbonate and sodium chloride by using carbide slag, comprising the following steps of: generating a reaction product containing the calcium chlorate and calcium chloride by reacting calcium hydroxide contained in chlor-alkali carbide slag with chlorine; filtering and decontaminating the reaction product, reducing temperature, subsiding, and then separating out a calcium chlorate solid; then filtering to obtain the calcium chlorate solid and calcium chloride filter liquor; treating the calcium chloride filter liquor by using a surface active agent, and then reacting with sodium carbonate in a corrosion-resisting reactor to obtain a calcium carbonate sediment and sodium chloride mixed solution; and filtering and separating the calcium carbonate and the sodium chloride.

Owner:汪晋强

Ice and snow quick-melting agent

InactiveCN111763497AReduce corrosionHas anti-rustSuperphosphatesOther chemical processesSODIUM METAPHOSPHATESodium acetate

Owner:杨毅男

Method for producing potassium chlorate and co-producing superfine calcium carbonate and ammonium chloride by utilizing carbide slag

InactiveCN102086026AEasy to operateLess investmentChloratesCalcium/strontium/barium carbonatesSlagDecomposition

The invention discloses a method for producing potassium chlorate and co-producing superfine calcium carbonate and ammonium chloride by utilizing carbide slag, which comprises the following steps of: reacting calcium hydroxide in chlor-alkali carbide slag with chlorine to generate a reaction product containing calcium chlorate and calcium chloride; filtering the reaction product to remove impurities, cooling and precipitating to separate out solid calcium chlorate, and filtering to obtain the solid calcium chlorate and calcium chloride filtrate; performing a double decomposition reaction of the reaction product containing the calcium chlorate and the calcium chloride and potassium chloride to generate mixed solution of the potassium chlorate and calcium chloride; filtering the mixed solution to remove impurities, distilling under reduced pressure, separating out potassium chlorate crystals, and filtering to obtain the potassium chlorate crystals and solution of calcium chloride; and treating the solution of calcium chloride by using a surfactant, and carburizing carbon dioxide and ammonia water in a carbonizer to obtain lightweight calcium carbonate and ammonium chloride.

Owner:汪晋强

Calcium hypochlorite composition

Calcium hypochlorite compositions that are classified as a Packing Group III Division 5.1 oxidizer material or as a non-Division 5.1 oxidizer material are described. In one embodiment, the compositions comprise an admixture of particulate calcium hypochlorite and particulate metaboric acid. The calcium hypochlorite is present in the composition in an amount and is of a concentration such that the composition would be classified as a Packing Group II Division 5.1 oxidizer in the absence of said particulate metaboric acid. Other embodiments described are solid shaped articles, e.g., tablets, comprising the described calcium hypochlorite-metaboric acid composition.

Owner:AXIALL OHIO

Modified macroporous adsorption resin, and preparation method and application thereof

ActiveCN113231046AAchieve hydrophilic modificationSimple post-processingOther chemical processesSolid sorbent liquid separationPotassium hypochloriteDouble bond

The invention relates to a modified macroporous adsorption resin, and a preparation method and application thereof. The preparation method of the modified macroporous adsorption resin comprises the following steps: obtaining macroporous adsorption resin, wherein the surface of the macroporous adsorption resin contains double bonds; and mixing water, an oxidizing agent and the macroporous adsorption resin, and carrying out one-step oxidation reaction to oxidize the double bonds into hydroxyl groups, wherein the oxidizing agent is a combination of sulfuric acid and peracetic acid, or pypocholoride, periodate, or a combination of hydrogen peroxide and peracetic acid, the pypocholoride is at least one of sodium hypochlorite, potassium hypochlorite and calcium hypochlorite, and the periodate is at least one of sodium periodate and potassium periodate. According to the preparation method of the modified macroporous adsorption resin, hydrophilic modification of the macroporous adsorption resin can be achieved through one-step reaction, no organic solvent is needed, and the preparation method is environmentally friendly, few in reaction by-products, easy to clean and high in safety to human bodies.

Owner:GUANGZHOU KONCEN BIOSCI

Magnesium alloy surface chromium-free composite passivation solution

InactiveCN104342678AImprove corrosion resistanceImprove efficiencyMetallic material coating processesChromium freePhosphate

The present invention discloses a magnesium alloy surface chromium-free composite passivation solution, which comprises 12-14 g / L of sodium molybdate, 6-8 g / L of manganese dihydrogen phosphate, 4-6 g / L of calcium dihydrogen phosphate, 14-16 g / L of zinc oxide, 26-28 g / L of 85% phosphoric acid, 6-8 g / L of sodium nitrate, 2-4 g / L of calcium chlorate, 2-4 g / L of boric acid, 1-3 g / L of strontium chloride, 2-4 g / L of potassium peroxide, 0.3-0.5 g / L of OP-10, and the balance of deionized water.

Owner:WUXI SHITANGWAN IND PARK DEV CONSTR

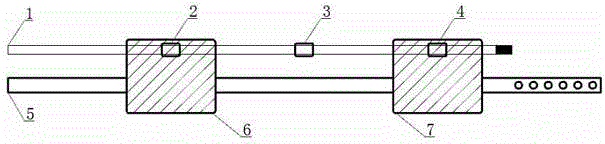

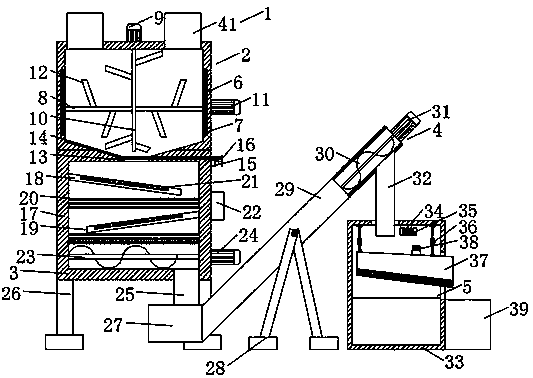

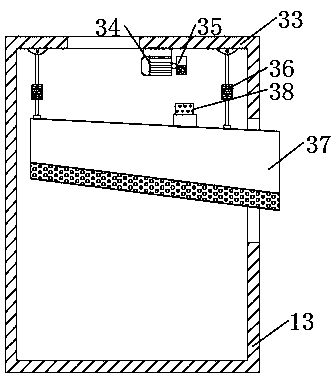

Drying device for production of calcium hypochlorite

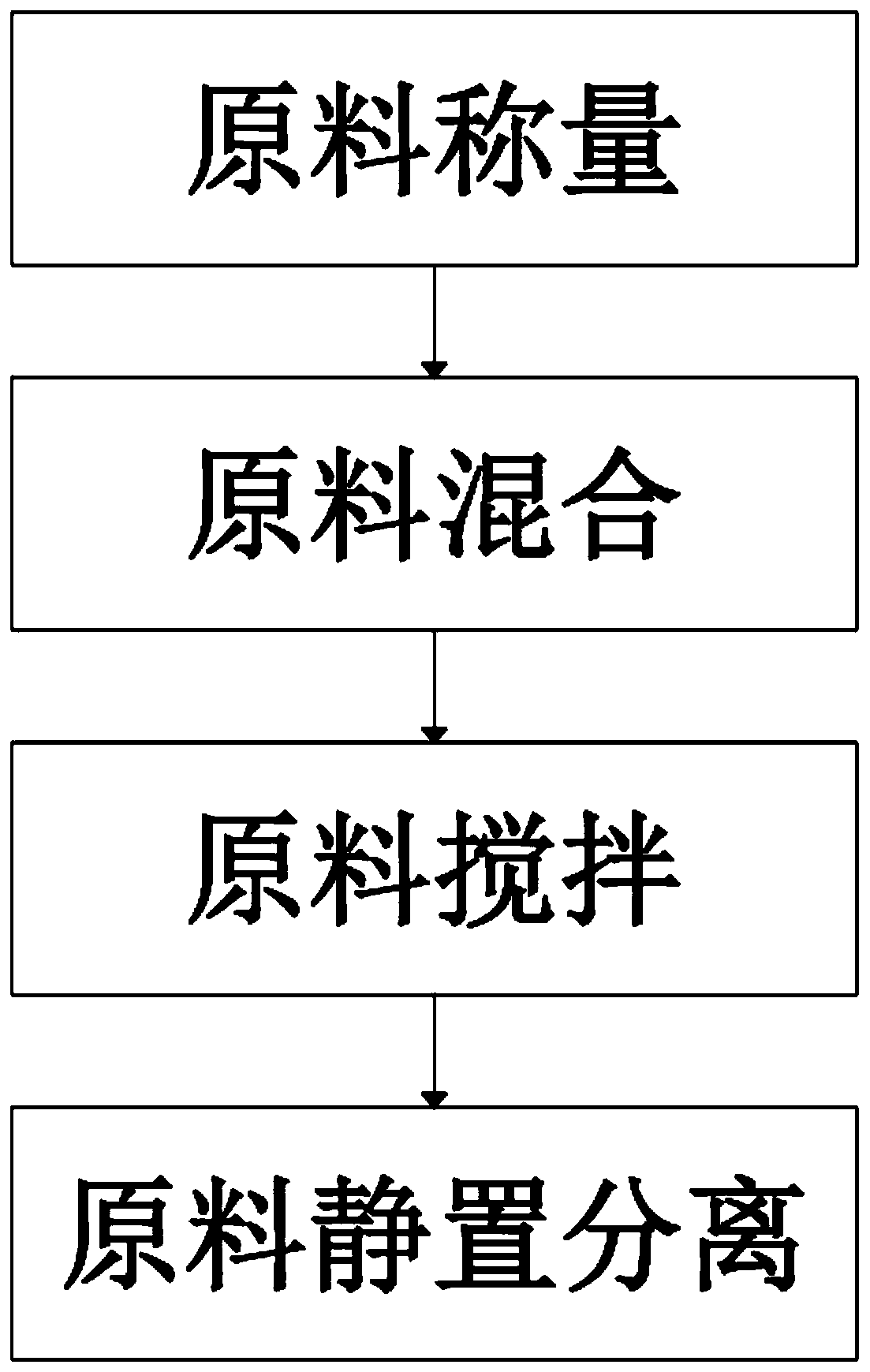

The invention discloses a drying device for production of calcium hypochlorite. The drying device comprises a drying device body, wherein the drying device body consists of a stirring mechanism, a drying mechanism, a conveying mechanism and a screening mechanism; the drying mechanism is fixedly connected to the bottom of the stirring mechanism; the conveying mechanism is connected to the bottom ofthe drying mechanism; and the screening mechanism is arranged below the conveying mechanism. The drying device is compact in structure; as the stirring mechanism is arranged, raw materials are mixedmore thoroughly and uniformly; as the drying mechanism is arranged, the heating time is prolonged by a first spreading plate and a second spreading plate to ensure that the materials are heated more uniformly, and accordingly, the drying uniformity can be guaranteed; as the screening mechanism is arranged, the dried materials with different particle sizes can be screened to ensure a consistent particle size of the materials; the production efficiency of calcium hypochlorite is guaranteed; and the product quality of calcium hypochlorite is improved.

Owner:德州凯密迪化工有限公司

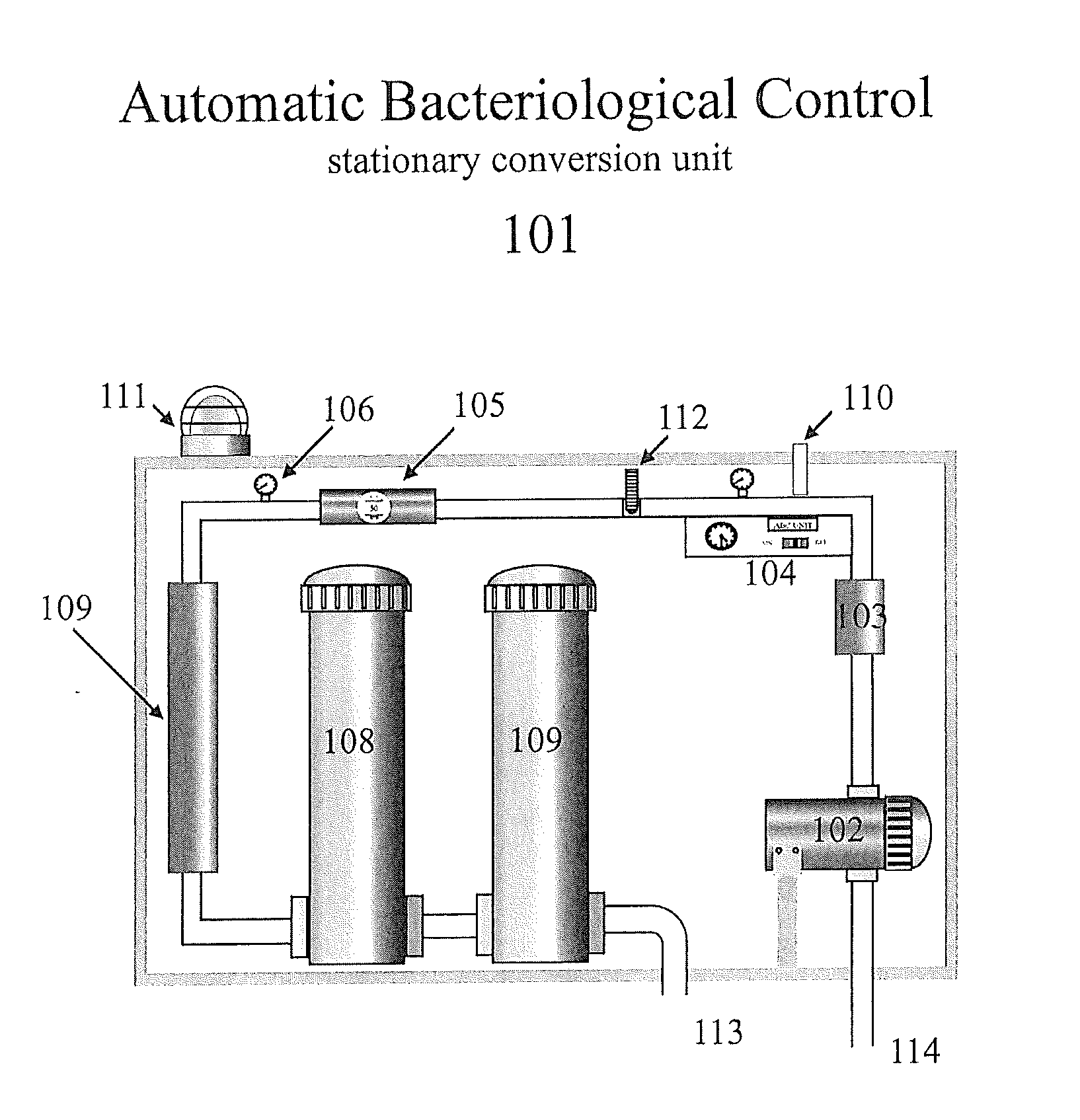

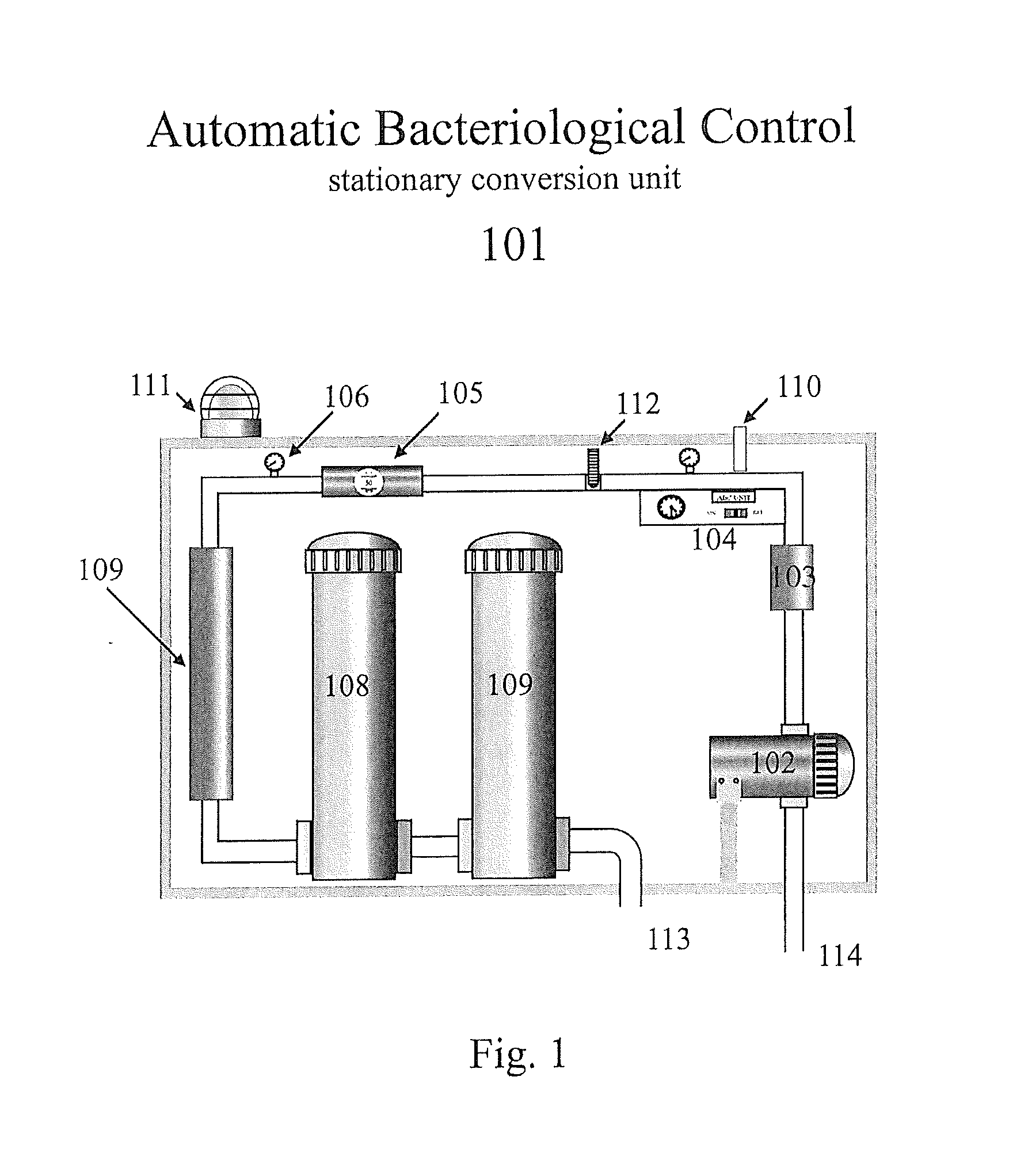

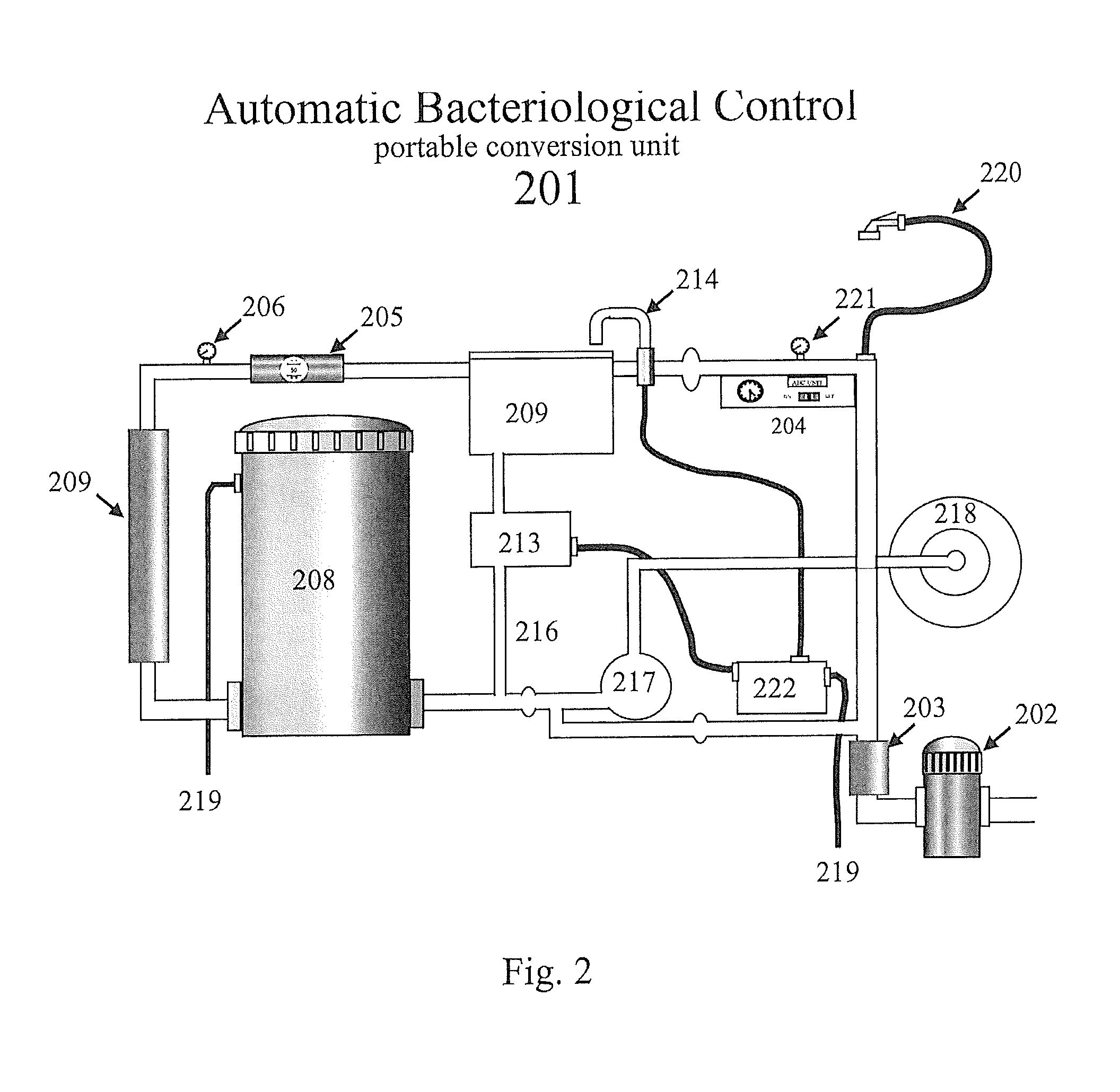

System and method for treatment of water systems

ActiveUS20130306567A1Reduce environmental risksUse minimizedWater treatment parameter controlSpecific water treatment objectivesWater treatment systemSodium chlorate

A water treatment system for producing a sodium hypochlorite solution to control bacteria levels in well water containing: a pH adjuster; a container containing solid calcium hypochlorite for producing a calcium hypochlorite solution; and a container containing solid sodium carbonate for producing the sodium hypochlorite solution and a method of controlling bacteria levels in well water by using intermittent injections of a sodium hypochlorite solution with alternating pH values.

Owner:AQUIFER MAINTENANCE & PERFORMANCE SYST

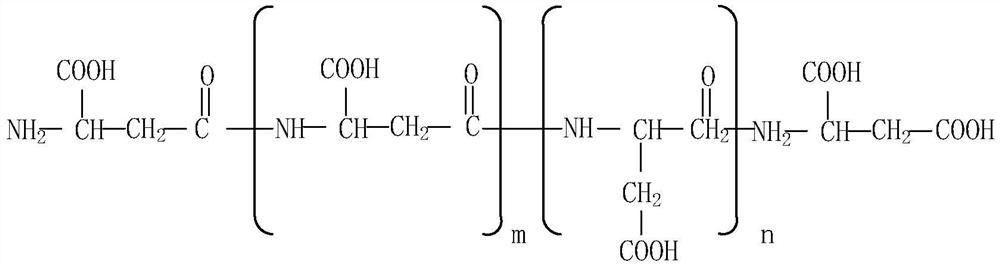

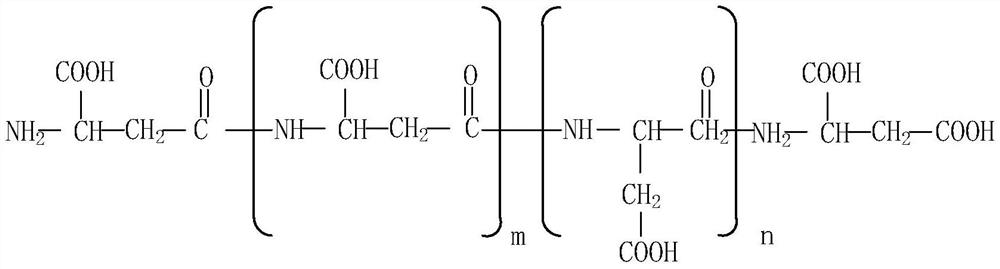

Combined inhibitor for separating pyrite from complex molybdenite and separation method thereof

PendingCN114471958AOvercoming the problem of recovery rate impactImprove space utilizationFlotationCalcium hypochloriteNuclear chemistry

The invention discloses a combined inhibitor for separating pyrite from complex molybdenite and a separation method of the combined inhibitor, and relates to the technical field of mineral processing, the combined inhibitor comprises polyaspartic acid, calcium hypochlorite and sodium humate according to the mass ratio of (1-3): (3-6): (3-6); the combined inhibitor is added by respectively preparing the components into aqueous solutions, wherein the mass concentration of the polyaspartic acid aqueous solution is 0.5-1.0%; the mass concentration of the calcium hypochlorite aqueous solution is 3.0-6.0%; the mass concentration of the sodium humate aqueous solution is 3.0-6.0%; the adding mass ratio of the three aqueous solutions is (2-3): 1: 1; the combined inhibitor is applied to the ore grinding and flotation process, efficient separation of molybdenite and pyrite is achieved, and the problems that a traditional lime method influences the recovery rate of molybdenite and a cyanide method has huge harm to the ecological environment are solved.

Owner:金堆城钼业汝阳有限责任公司

Thallium ion treating agent and thallium-containing wastewater treating method

InactiveCN106946311AAchieving processing powerReasonable formulaWater contaminantsWater/sewage treatment by neutralisationFiltrationCalcium hypochlorite

The invention relates to a thallium ion treating agent. The thallium ion treating agent is prepared from the following raw materials in percentage by mass: 8 to 22% of zinc sulfate, 13 to 28% of magnesium sulfate, 7 to 22% of polyaluminum chloride, 18 to 32% of calcium hypochlorite, 2 to 17% of sodium hydroxide, 16 to 31% of calcium oxide, 7 to 25% of activated carbon and 10 to 28% of ferrous sulfate. The invention further relates to a thallium-containing wastewater treating method, and the treating method comprises the following steps: (1) preparing tap water and the thallium ion treating agent into a medical solution for future use; (2) adding the prepared medical solution into thallium-containing wastewater to react; and (3) after completing reaction, carrying out precipitation or filtration treatment to wastewater subjected to reaction. The thallium ion treating agent provided by the invention can be prepared for use in advance; the preparation method and application method are simple; the reaction is easy to control; and the thallium ion treating agent has the advantages that the treatment efficiency is high, and the cost is low.

Owner:韶关市雅鲁环保实业有限公司

Method for directly producing polymeric aluminium chloride additive by employing calcium hypochlorite powder

InactiveCN101200301AReduce pollutionReduce labor intensityAluminium chloridesWater/sewage treatment by flocculation/precipitationAluminium chlorideHeating time

The invention relates to a method of utilizing calcium chlorate powder to directly produce aluminum chloride treatment agent in sewage treatment agent production field. 1. 10 weight water is added, steam is heated at not below 60 DEG C, heating time is 0.5-1.5h, 10 weigh hydrochloric acid is added, and the steam is closed; 2. 4-4.5 weight calcium aluminate powders are added slowly, simultaneously 5 weight water is added, reaction time is 0.5-1.5h; 3. 6 weigh hydrochloric acid is added, the steam is opened for warming up, the temperature is kept at 100-102 DEG C, reaction time is 7-8h, finally PH value is controlled at 2.5-2.7, baume degree is controlled at 27-28. The process of the invention uses single raw materials for production, the reaction time of the process is 2h less than that of prior process, so as to lower labor intensity of staff, reduce environmental pollution, thereby facilitating sewage treatment effect and improving labor intensity and environment.

Owner:HUATAI GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com