Treatment method of high-concentration phosphorus-containing wastewater

A treatment method and high-concentration technology, applied in metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of slow reaction, incomplete network breaking, large amount of waste residue, etc. Easy to operate, eliminates the need to deal with sediments, and has the effect of low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

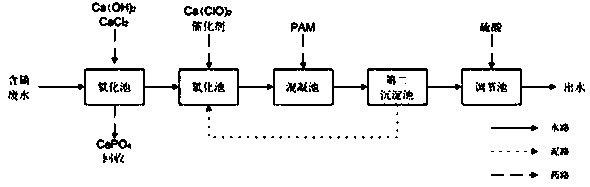

Image

Examples

Embodiment 1

[0037] Taking high-concentration phosphorus-containing wastewater from a factory in Zhongshan as the treatment object, the total phosphorus of the raw water quality is 790.58mg / L, the pH is 3.0, and the chemical oxygen demand COD is 897.36mg / L.

[0038] Add the raw water of electroplating wastewater to the first sedimentation tank, add sodium hydroxide to adjust the pH to 8.5, and carry out the reaction for 4 hours to remove most of the orthophosphate. The wastewater flows into the oxidation tank by itself, and 0.6 kg per ton of wastewater is added to the oxidation tank. The amount of calcium hypochlorite was added, 0.2 kg of catalyst was added to each liter of waste water, and the reaction was carried out for 4 hours; after the reaction, the mixed liquid flowed into the coagulation tank, 3g of PAM was added to each ton of waste water for coagulation, and then the mixer was started to stir, and the waste water was coagulated The residence time in the tank is 15min (the fast mix...

Embodiment 2

[0040] Taking high-concentration phosphorus-containing wastewater from a factory in Zhuhai as the treatment object, the total phosphorus in the raw water quality is 1430.58mg / L, and the pH is 2.7.

[0041] Add the phosphorus-containing wastewater raw water to the first sedimentation tank, add sodium hydroxide to adjust the pH to 12, and carry out the reaction for 4 hours. The wastewater flows into the oxidation tank by itself, and calcium hypochlorite is added in an amount of 1.2 kg per ton of wastewater in the oxidation tank. , add 0.5kg of catalyst per ton of wastewater, and react for 4 hours; after the reaction, the mixed solution flows into the coagulation tank, and 10g of PAM is added to each ton of wastewater for coagulation, and then the mixer is started to stir, and the retention time of wastewater in the coagulation tank The time is 15min (the fast mixing tank stays for 5min, the speed is 300r / min; the slow mixing tank stays for 10min, the speed is 300r / min); the effluen...

Embodiment 3

[0043] Taking high-concentration phosphorus-containing wastewater from a factory in Zhuhai as the treatment object, the total phosphorus of the raw water quality is 958.5mg / L, the pH is 3.1, and the COD is 238.16mg / L.

[0044] Add the raw water of the electroplating wastewater into the first sedimentation tank, add sodium hydroxide to adjust the pH to 9.8, and carry out the reaction for 4 hours. The supernatant of the wastewater flows into the oxidation tank by itself, and in the oxidation tank, add 0.8 kg per ton of waste water to add once Calcium chlorate, add 0.5mol of catalyst per ton of waste water, and react for 4 hours; after the reaction, the mixed solution flows into the coagulation tank, and 7gPAM is added to each ton of waste water for coagulation, and then the mixer is started to stir, and the waste water is in the coagulation tank The residence time in the tank is 15 minutes (the fast mixing tank stays for 5 minutes, and the rotation speed is 300r / min; the slow mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com