Floatation separation method for pyrites from arsenopyrites

A technology for arsenopyrite and pyrite, which is applied in flotation, solid separation, etc., and can solve problems such as separation of sulfur and arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

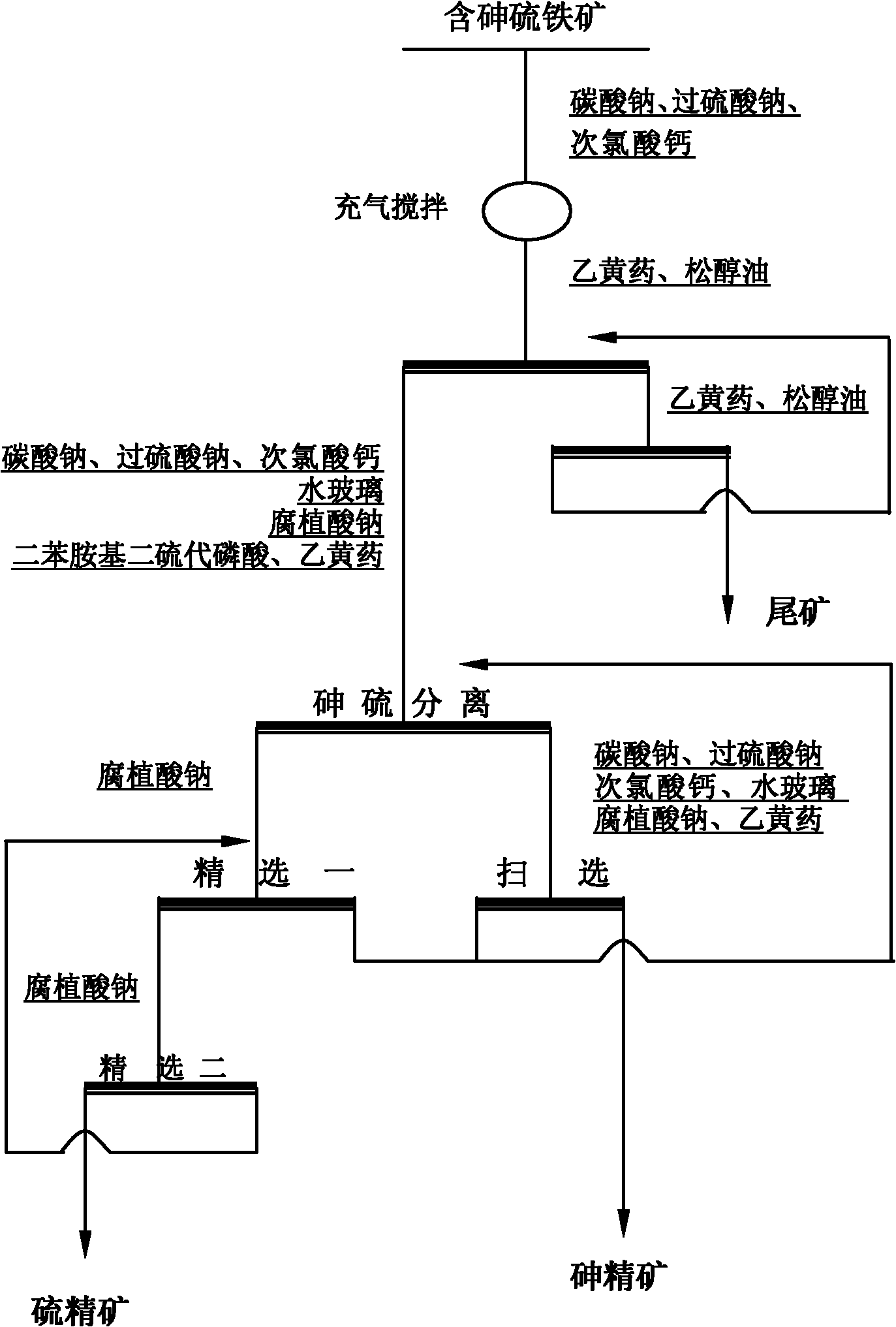

Image

Examples

Embodiment 1

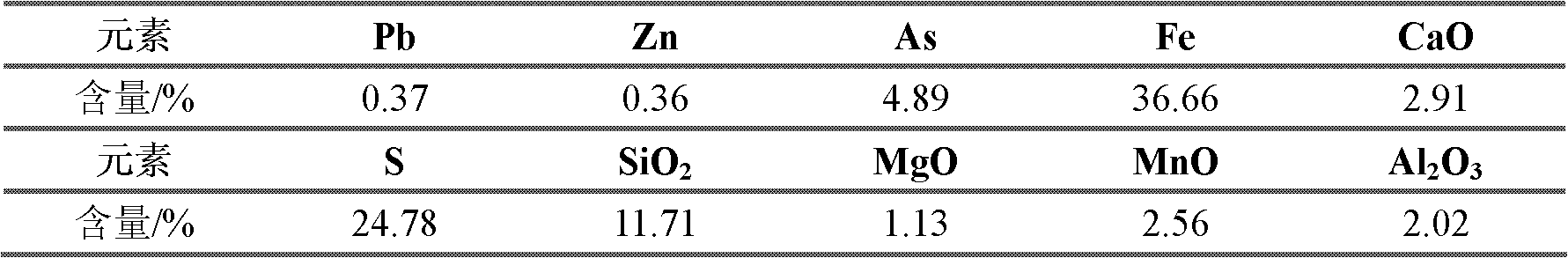

[0046] The pyrite of arsenic-containing pyrite after lead-zinc flotation in a lead-zinc sulfide ore in Mengzi, Yunnan Province, the sulfur is mainly distributed in pyrite and pyrrhotite, followed by arsenopyrite, and the arsenic-containing mineral is arsenopyrite. The results of the multi-element analysis of the raw ore are shown in Table 1.

[0047] Table 1 Multi-element analysis of raw ore

[0048]

[0049] use as figure 1 Shown technological process, concrete technological parameter is as follows:

[0050] 1) Adjustment of arsenic-containing pyrite pulp

[0051] In the mixing equipment, the solid-liquid ratio (mass ratio) is stirred and adjusted according to 3:1, the pH regulator sodium carbonate 1500g / t raw ore is added to keep the pH value at 9.0-9.3, and the pulp potential regulator sodium persulfate (Na 2 S 2 o 8 )500g / t raw ore, calcium hypochlorite (Ca(ClO) 2 ) 800g / t raw ore, adjust the pulp potential to 350-360mV relative to the hydrogen standard potential....

Embodiment 2

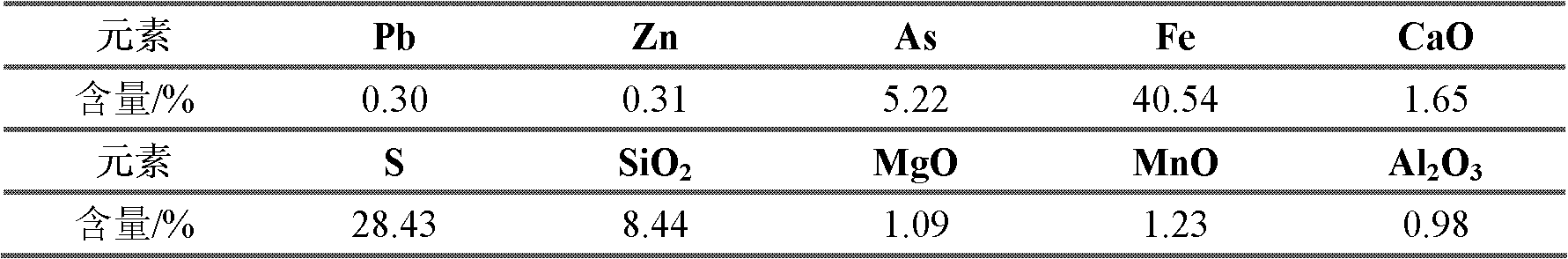

[0065] The pyrite of arsenic-containing pyrite after lead-zinc flotation in a lead-zinc sulfide ore in Wenshan, Yunnan. The sulfur is mainly distributed in the pyrite, and the arsenic-containing mineral is arsenopyrite. The results of the multi-element analysis of the raw ore are shown in Table 2.

[0066] Table 2 Multi-element analysis of raw ore

[0067]

[0068] use as figure 1 Shown technological process, concrete technological parameter is as follows:

[0069] 1) Adjustment of arsenic-containing pyrite pulp

[0070] For arsenic-containing pyrite, the solid-to-liquid ratio (mass ratio) in the mixing equipment is 3:1 for mixing and mixing, adding a pH regulator sodium carbonate 2000g / t raw ore to keep the pH value at 9.5-10, adding the slurry to adjust the potential sodium persulfate (Na 2 S 2 o 8 )800g / t raw ore, calcium hypochlorite (Ca(ClO) 2 ) 1000g / t raw ore, adjust the slurry potential to 360-380mV relative to the hydrogen standard potential. Air is fed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com