Patents

Literature

108results about How to "Achieve decolorization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for treating livestock and poultry breeding sewage entering Lake Taihu

ActiveCN104671615AEasy to handleLow costMultistage water/sewage treatmentAnaerobic aerobicFlocculation

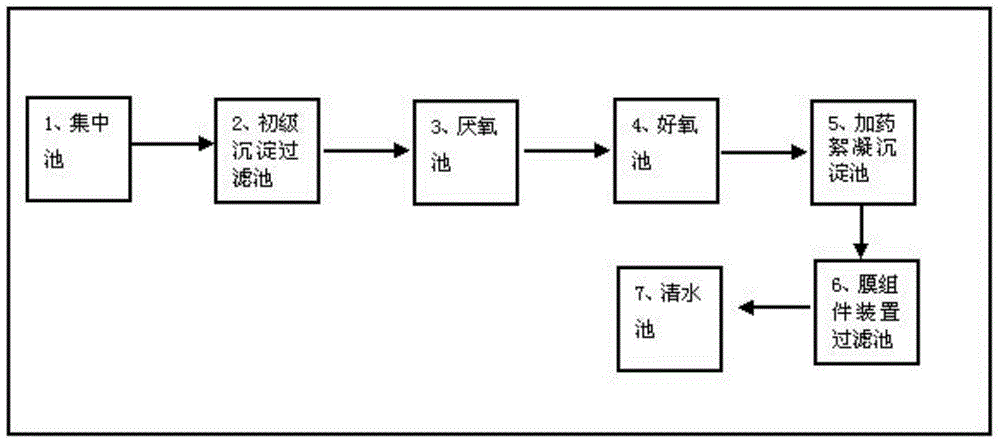

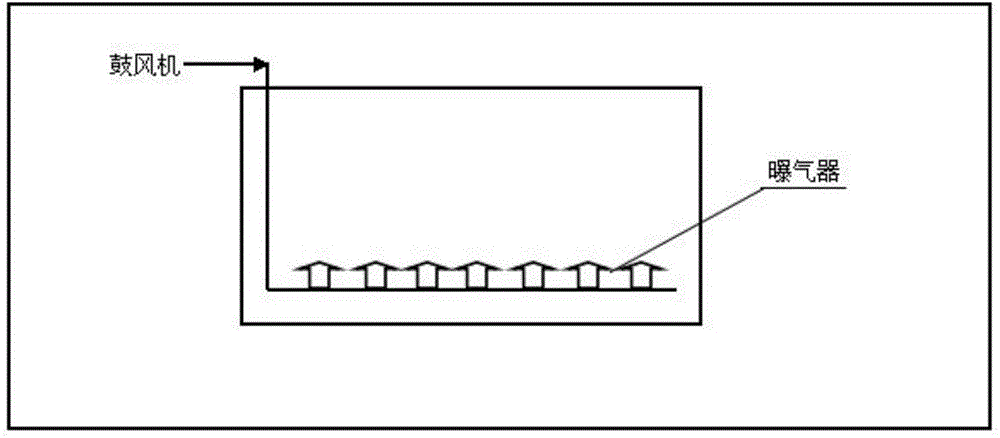

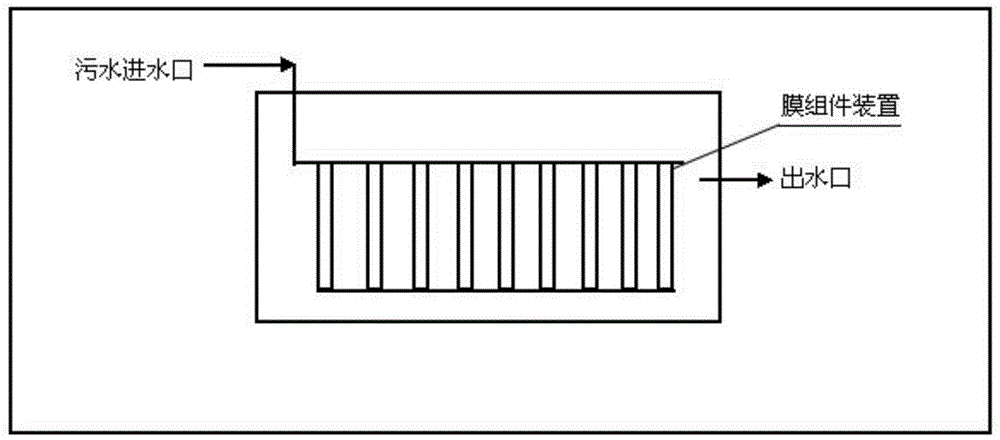

The invention relates to a process for treating livestock and poultry breeding sewage entering the Lake Taihu. According to the designed and adopted treating process, the technology that primary precipitation and filtration, anaerobic-aerobic biochemical treatment, dosing flocculation and coagulation reactions and membrane module filtration are combined is mainly used, and a material method for adding a compound water treatment agent is adopted, so that efficient denitrification, dephosphorization and COD reduction functions are realized; meanwhile, the process has good decoloration and sterilization effects. According to the process, the operation cost and the management cost are low, the sewage treatment effect is good, and treated livestock and poultry breeding sewage can reach the state-specified first-class discharge standard for sewage treatment in Lake Taihu regions.

Owner:JIANGSU LONG LEAPING ENG DESIGN

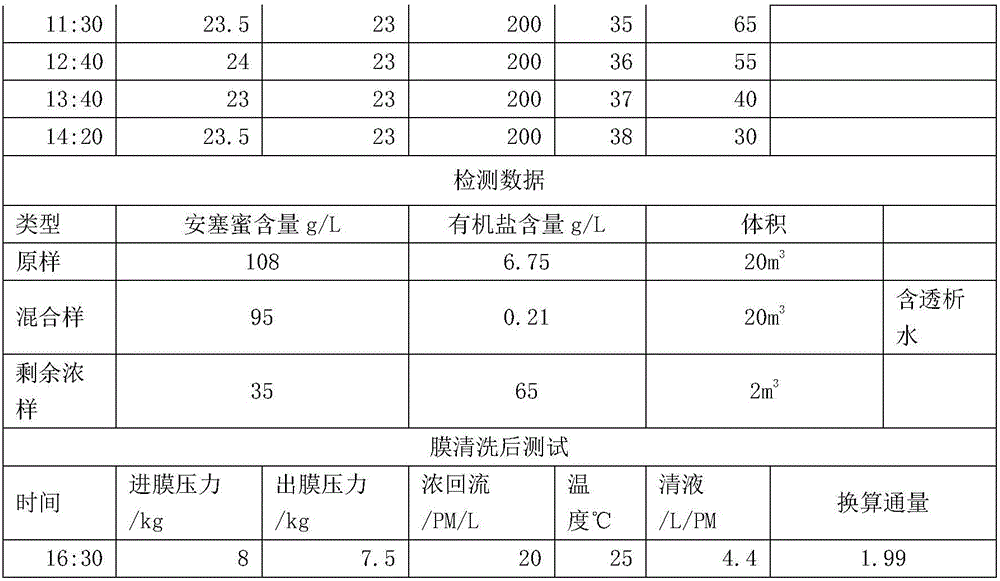

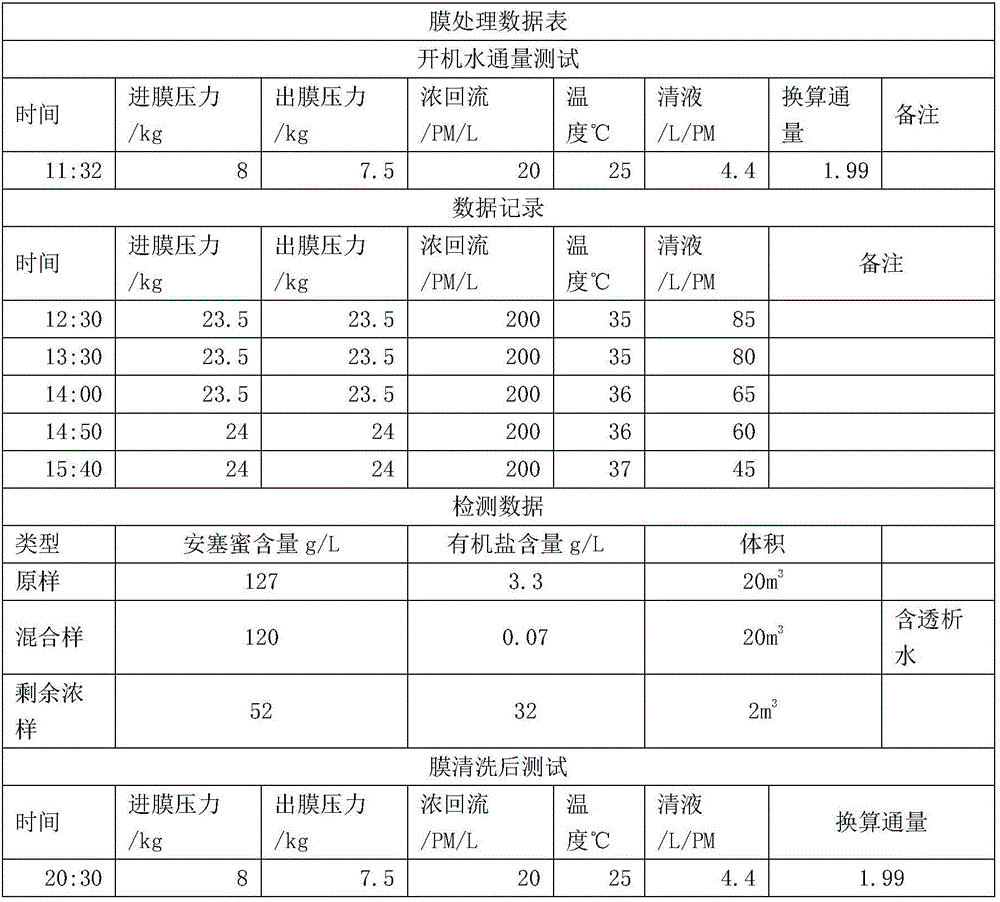

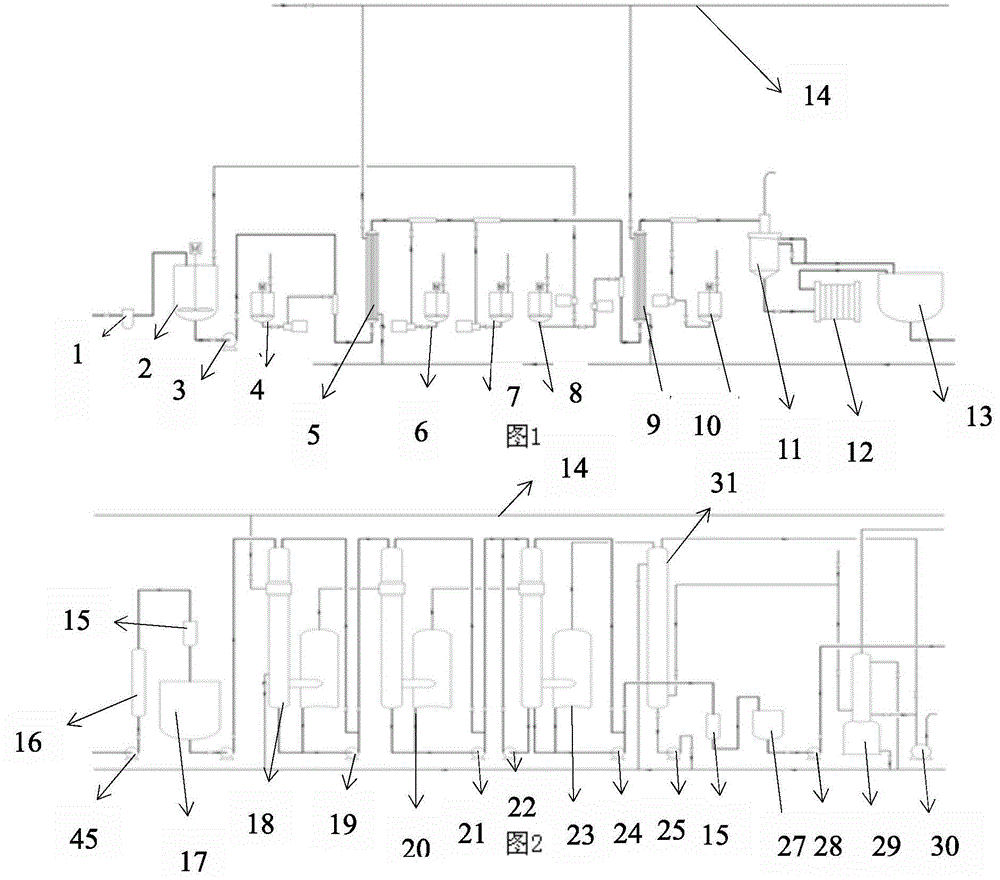

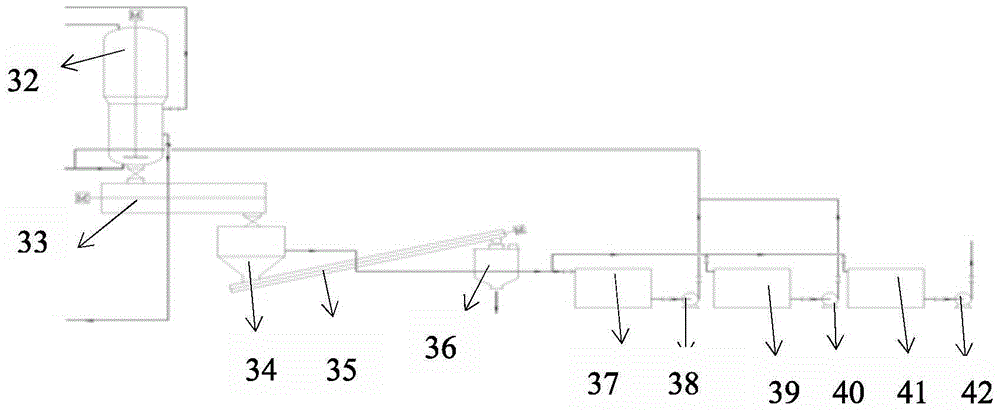

Method for equivalent dialysis through directly adopting membrane treatment

InactiveCN106262665AReduce energy consumptionReduce removal rateSemi-permeable membranesFood membrane processLiquid wasteLiquid storage tank

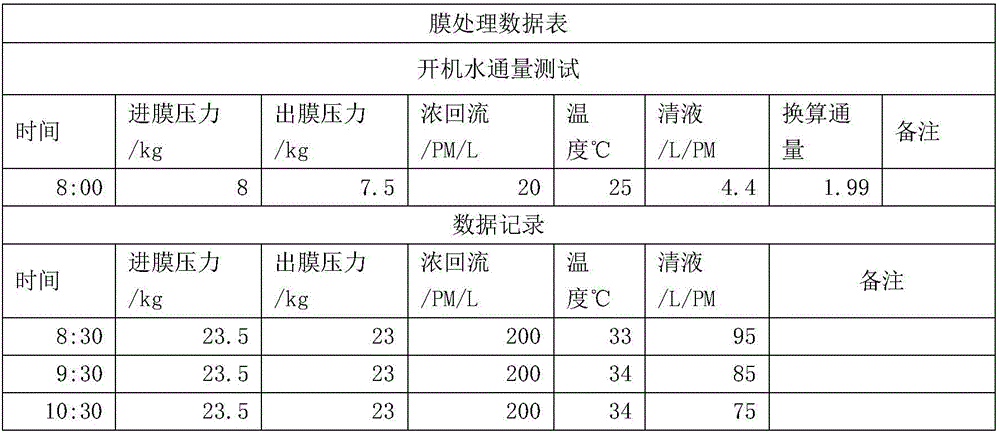

The invention discloses a method for equivalent dialysis through directly adopting membrane treatment. The method comprises the following steps: S1: storing the filtrate of Acesulfame in a filtrate storage tank, which is taken as a stock solution; S2: adopting a hot water circulation system to increase the temperature of the stock solution in the filtrate storage tank, setting membrane ingress pressure and membrane egress pressure simultaneously, and through transmission and concentration of an organic membrane, allowing a clear membrane liquid to flow to a clear membrane liquid storage tank for recycle; S3: when the clear membrane liquid flux in the clear membrane liquid storage tank drops to 20-60L / PM, using the same amount of water to dialyze, and dialyzing the Acesulfame out and recycling; S4: discharging the residual liquid in a circulation tank to a liquid waste disposing center directly so as to have liquid waste disposal; and S5: washing and detecting membrane equipment. The method disclosed by the invention adopts the hot water circulation system for heating and omits the concentration treating and recycling process, so that the energy consumption is saved, the concentration temperature is low, the material is difficult to break down, the purposes of liquid decoloration and organic salt treatment are realized, the product obtained can be recycled directly, and the equipment has a simple structure and a low treatment cost.

Owner:ANHUI WEIDUO FOOD INGREDIENTS CO LTD

Method for producing high-quality inulin by using jerusalem artichoke as raw material

The invention relates to a producing method of the qualified inulin, specifically a systemic method for producing qualified inulin having the chicory as material, comprising having fresh / dry chicory tuberous root as material, flaying, soaking, slicing up, extracting in hot water, flocculated depositing, decompressure filtration, desalination by ion exchange column, decoloring by ion exchange column, decompressure concentration, finally spray drying or freeze drying to produce the inulin. The invention is a producing craft for extracting the qualified inulin from plants with a physical chemistry means and has a good product quality, a high safety, a relative simple producing craft.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cane sugar manufacture production system

InactiveCN103981291ALow investment costReduce manufacturing costSucrose extractionSugar juice boiling/evaporationIndustrial equipmentSettling basin

The invention discloses a cane sugar manufacture production system. The production system is characterized by comprising a cleaning system, a discoloring system, an evaporation system, a sugar boiling system and a purging and drying system; the system device comprises a pipeline filter, a mixed juice tank, a mixed juice pump, a static mixer, a heater, a rapid settling basin, a dosing storage tank, a filter press, a falling film evaporator, a condenser, a discoloring column, a bag filter, a sugar boiling crystallizing tank, a syrup tank, a help-crystallization box, a purging box, a conveyor, a drying machine, a gas-liquid separator, a honey jar, a clear juice pump, a syrup pump, a circulating pump and a vacuum pump. According to the cane sugar manufacture production system, a stove drying system and a carbonation system in the original sugar refining design are canceled, a novel process is adopted, novel industrial equipment is introduced, and the system can serve as a scientific research platform for performing a novel cane sugar manufacture process or an industrial production line for producing raw sugar, primary white granulated sugar, high-grade sugar and refined sugar.

Owner:GUANGXI UNIV +1

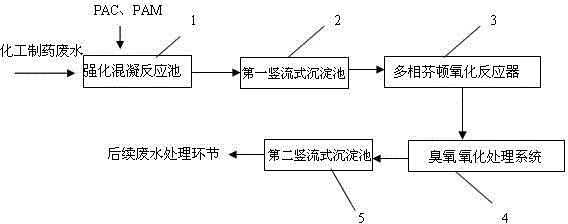

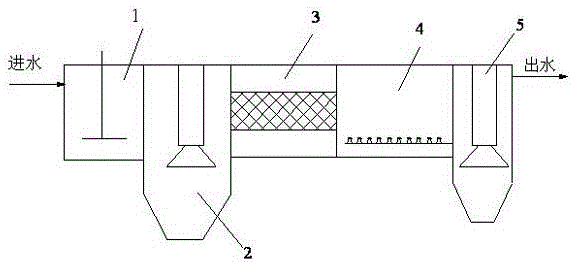

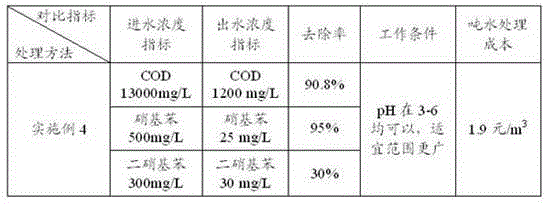

Chemical pharmaceutical wastewater pretreatment enhancement device and enhancement treatment method thereof

ActiveCN104355446AWide pH rangeOxidation reaction rate is fastWater treatment compoundsMultistage water/sewage treatmentPtru catalystEnvironmental engineering

The invention discloses a chemical pharmaceutical wastewater pretreatment enhancement device. The device comprises an enhanced coagulation reaction basin, a first vertical sedimentation basin, a multiphase Fenton oxidation reactor, an ozone oxidation treatment system and a second vertical sedimentation basin which are orderly communicated; and meanwhile, the invention discloses an enhancement treatment method of the device. In comparison with the traditional homogeneous phase Fenton method, the multiphase Fenton oxidation method is wider in suitable pH value, and faster in oxidation rate and better in degradation effect, and can provide catalyst iron ion for the ozone at the same time; the ozone has strong oxidation degradation effect on the organic pollutants in the water, and is capable of converting the complex organic pollutants into simple organics to realize the functions of decoloring, deodorizing, reducing COD and improving biodegradability, and the ozone has the advantages of being fast in speed, good in effect, free from secondary pollution, capable of producing in place and easily obtaining raw materials when reacting with the organic pollutants; and the multiphase Fenton oxidation method and the ozone oxidation form the organic coupling so as to effectively enhance the pretreatment effect of the chemical pharmaceutical wastewater.

Owner:TAIZHOU UNIV

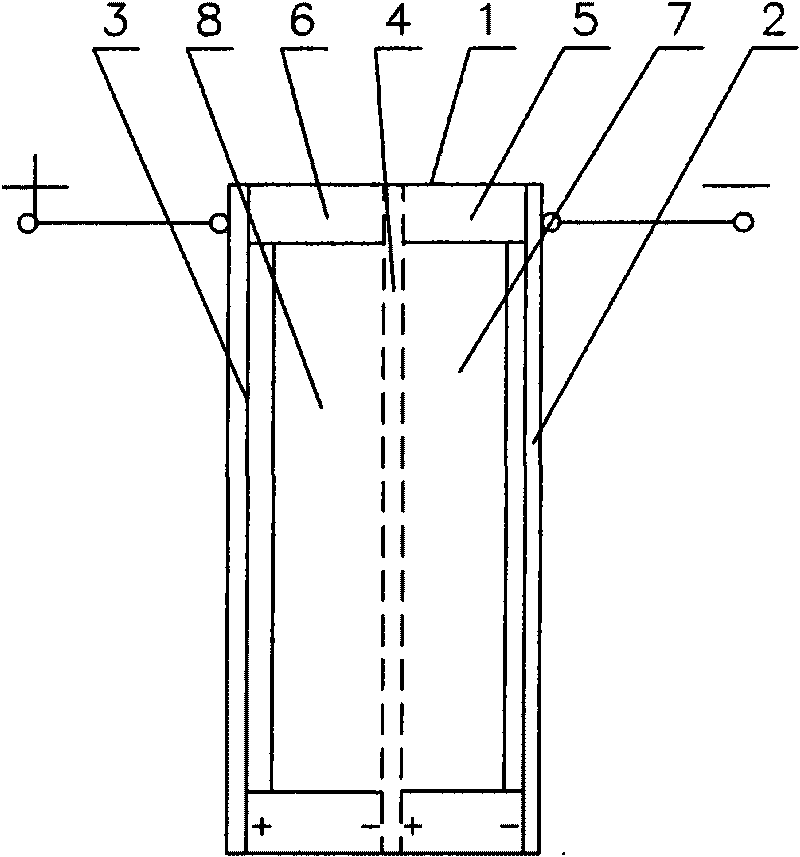

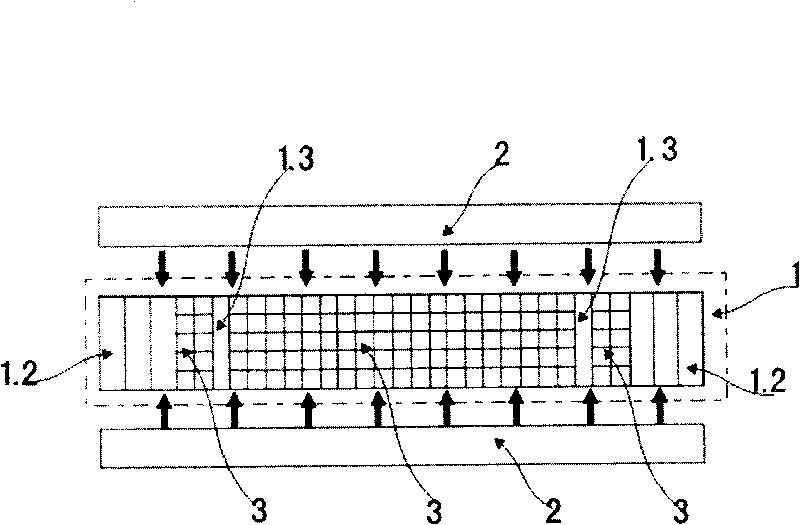

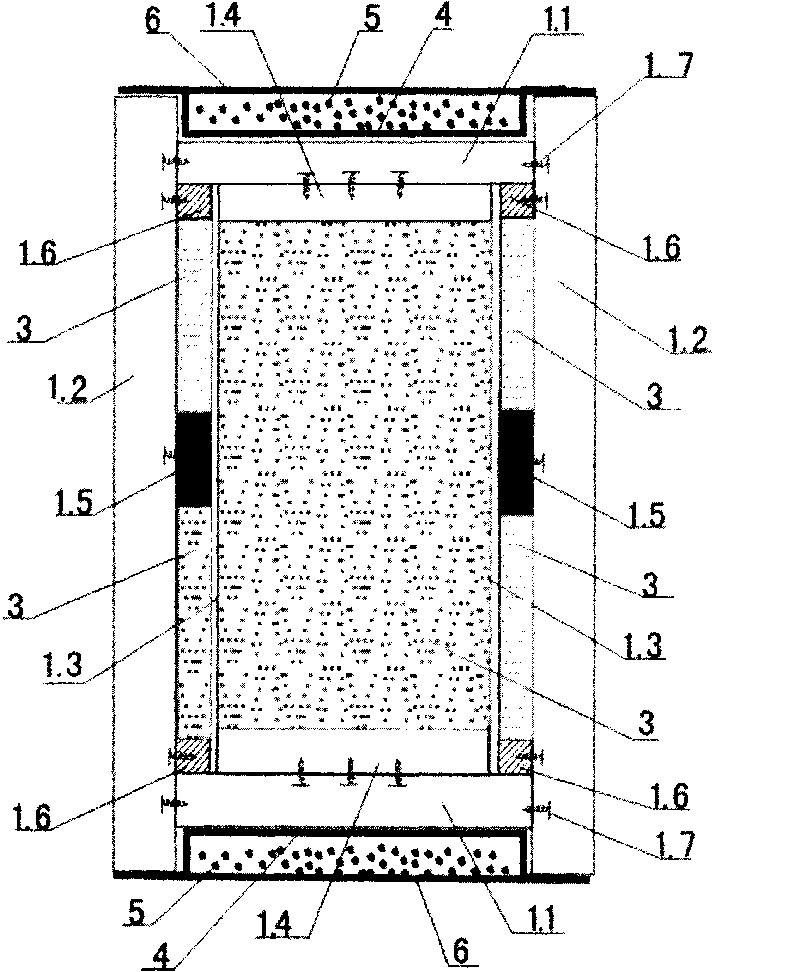

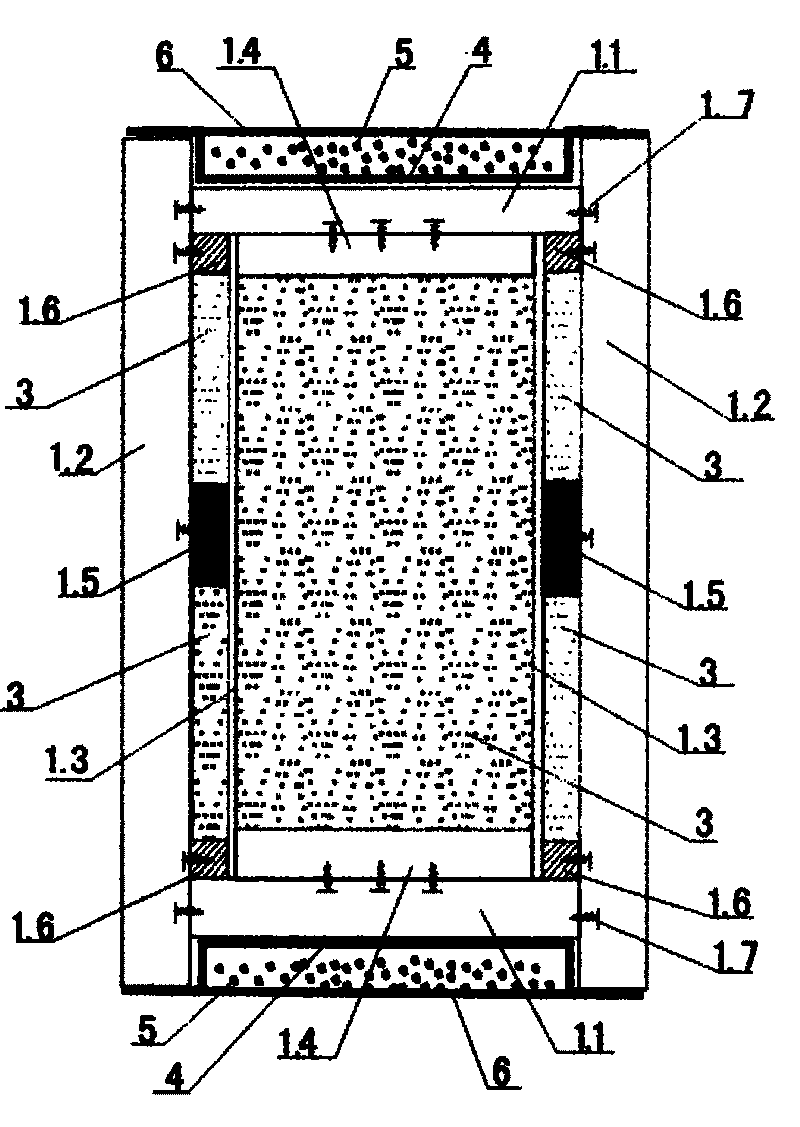

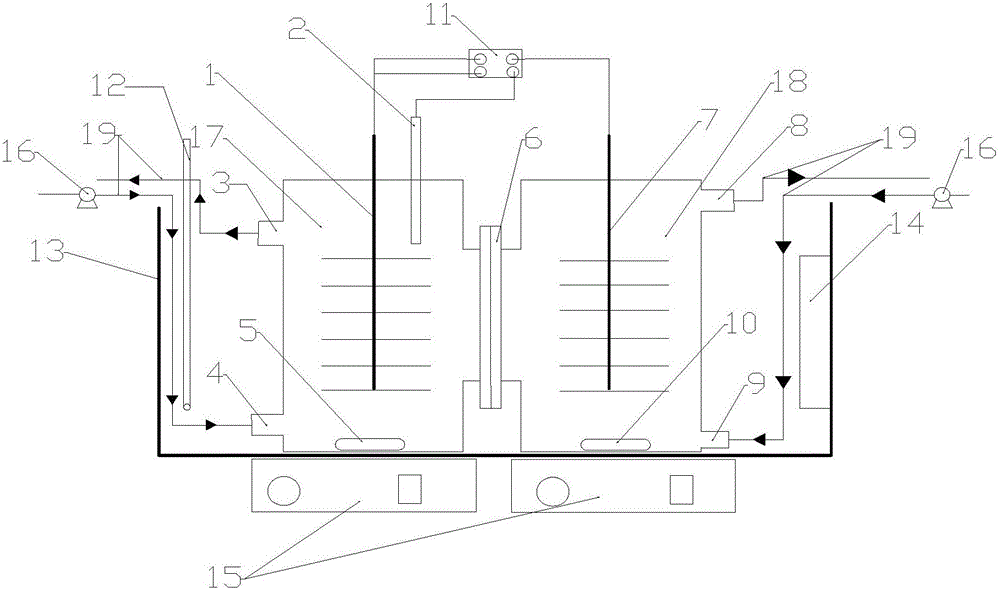

Bipolar membrane dual-liquid flow type hydroxyl radical generator

InactiveCN101748418ALow costEasy to manufactureCellsChemical industryHigh concentrationSemiconductor electrode

The invention relates to a bipolar membrane dual-liquid flow type hydroxyl radical generator, belonging to the technical field of electrochemistry electrolytic oxidation. The bipolar membrane dual-liquid flow type hydroxyl radical generator is composed of a cathode, an anode and a bipolar membrane located between the cathode and the anode. A cathode liquid chamber is formed between the bipolar membrane and the cathode; an anode liquid chamber is formed between the bipolar membrane and the anode; both the cathode and the anode adopt a single face electrode with a panel structure; and the cathode, the anode and the bipolar membrane are parallel to each other. The invention ensures that high-concentration hydroxyl radical strong oxidant solution can be generated by very low voltage and very high electricity efficiency, the effects of water sterilization, disinfection, decoloration, deodorization, and the like are superior to that of ozone, chlorine and other oxidants, has no toxicity, residue and secondary pollution. The invention has a plurality of innovations that bipolar membrane energy-saving dissociation molecules are inserted between electrolytic cells to supply OH to produce .HO, lead-free tin oxide semiconductor electrode is supplied for a cavity (h+) without lead to pollute water body, and a dual-liquid stream structure is used so that the concentration of .HO is never saturated.

Owner:薛廷芳

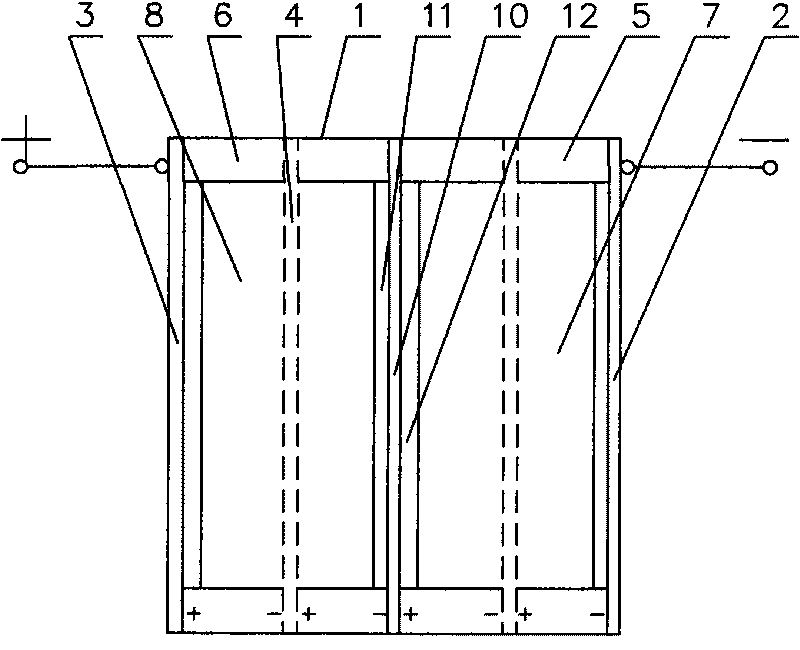

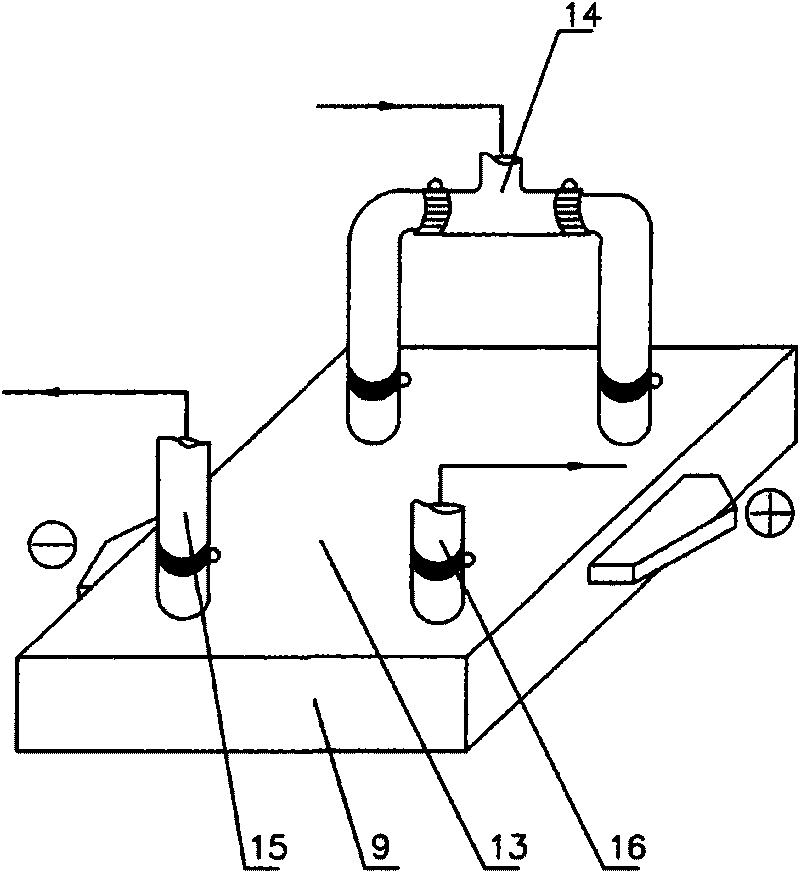

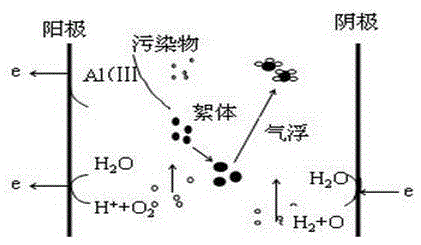

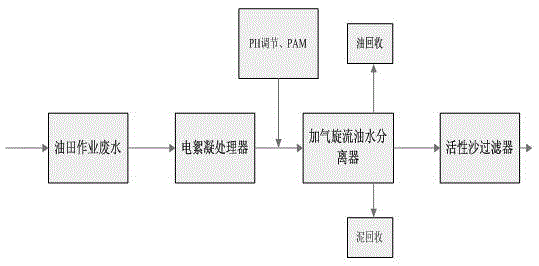

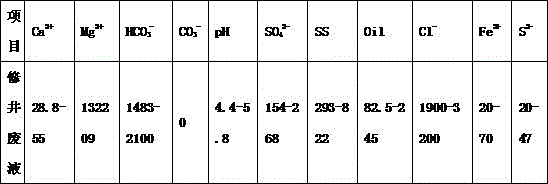

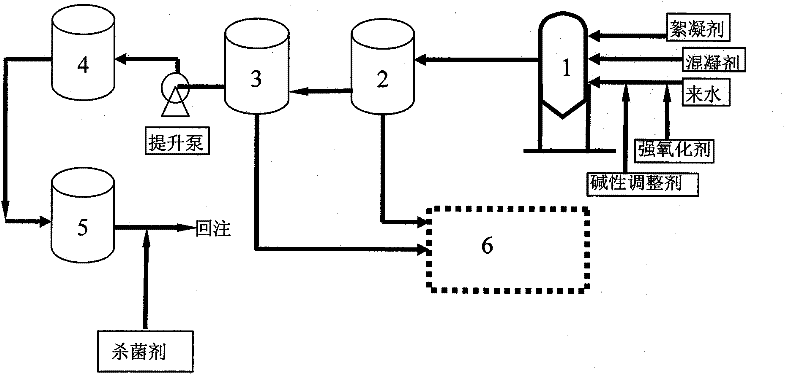

Electrocoagulation treatment method of wastewater from oil-field work

InactiveCN105461121AImprove oxidation capacityAchieve decolorizationWaste water treatment from quariesWater/sewage treatment by centrifugal separationLiquid wasteElectrolysis

The invention belongs to the technical field of oil-field wastewater treatment and specifically relates to an electrocoagulation treatment method of wastewater from oil-field work. The method comprises the following steps: (1) carrying out oil separation and settlement treatment on wastewater from oil-field work by an oil removal device; (2) carrying out static settling, and pumping an intermediate-layer clear liquid in the wastewater through a lift pump into an electrocoagulation treatment device to react and carry out low-pressure pulse electrocoagulation treatment, wherein DC power control output current density is 1-50 mA / cm<2>, polar plate spacing is 0.5-4 cm, and electrolysis time is 1-15 min; (3) adjusting pH to 6-7 by adding NaOH, and entering a swirl-flow oil-water separator with three separator outlets for respectively outputting effluent, dross and sump oil; and (4) filtering the effluent by an active sand filter such that the effluent finally reaches the standard. The method is simple to operate and is economic and efficient.

Owner:KARAMAY SANDA NEW TECH

Sullage oxidized coagulated decolorizing process technique

ActiveCN101139145AAchieve removalAchieve decolorizationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationTherapeutic effectReaction speed

The present invention relates to a sewage oxidation coagulation decolorizing treatment technics. The sewage firstly enters an oxidation decoloring section. Added in An oxidant, the sewage enters a mixed coagulation reactor after the oxidation reaction lasting for 1 to 180 minutes; a coagulant PAC is added in the mixed coagulation reactor and after the fully mixed coagulation reacting, a flocculating agent PAM is added in; after fully reacting, the sewage enters a solid-liquor separator and the clear solution after separating solid from liquor is discharged through the solid-liquor separator. The oxidant is an oxidant of sodium hypochlorite, or calcium hypochlorite or peroxide or any combination of the three; the quantities added to are respectively that the sodium hypochlorite and the calcium hypochlorite are respectively 50 to 20000 PPM, and the peroxide is 0 to 10000 PPM. The quantities of the added coagulant PAC and the flocculating agent PAM are respectively that the PAC is 0 to 2000PPM and the PAM is 0 to 20 PPM. The present invention has the advantages of good treatment effect, innocuity of reaction products, no need of secondary treatment and good operation performance. The present invention has a quicker reaction speed under a normal temperature and is convenient to match and join with the front and back treatment technics.

Owner:山东环发科技开发有限公司

Collagen and its preparing process

InactiveCN1683550AImprove hydrolysis yieldAdd flavorFermentationBulk chemical productionOil and greaseForeign matter

The present invention relates to collagen and its preparation process. The preparation process includes eliminating foreign matter and scale from fish skin, washing, chopping in meat chopper, adding deionized water and heating inside a container, hydrolyzing with hydrolyzing proteinase, secondary hydrolyzing with flavoring hydrolase, heating to inactivate, letting stand to laminate, eliminating upper oil and grease layer, filtering the hydrolyze, defatting in a supercritical CO2 equipment, microfiltering to obtain filtrate, and spray drying to obtain collagen powder. The collagen powder has high solubility, high yield and good taste. The collagen may be used widely in food, cosmetics, medical supplementary material, enzyme and bioactive matter carrier, etc.

Owner:青岛博恩生物科技有限公司

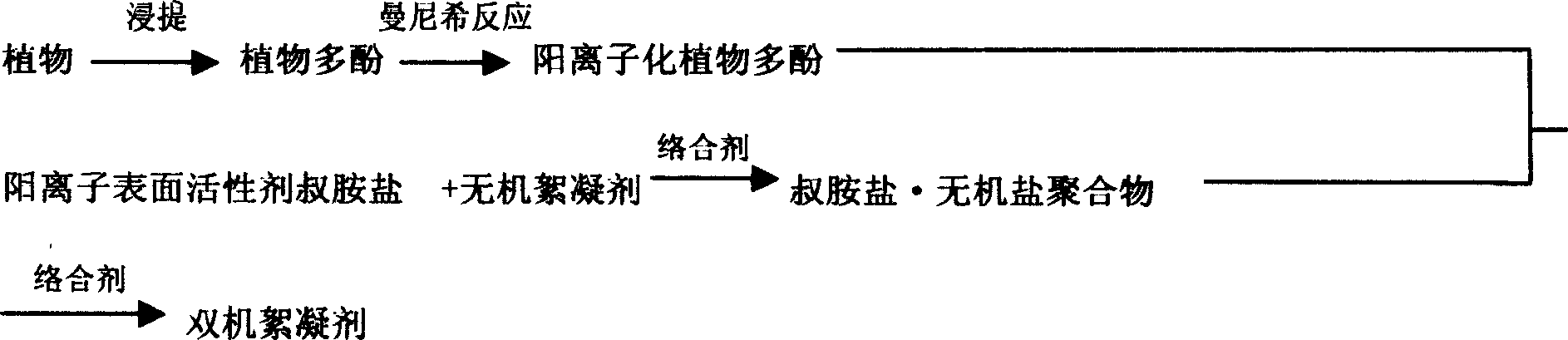

Double-machine flocculant

InactiveCN1460648AReduce processing costsReduce dosageWater/sewage treatment by flocculation/precipitationIron sulfateAluminium sulfate

The present invention relates to a water treatment agent, and is a network polymer which is formed from structure unit formed from plant polyphenol modified by Mannich reaction and structure unit formed by polymerization of tertiary ammonium salt and inorganic flocculant or structure unit formed by polymerization of quaternary ammonium salt and inorganic flocculant and whose molecular weight is 700000-25000000, in which the plant polyphenal is condensate polyphenol and complex polyhenol, the inorganic flocculant is any one of magnesium silicate, ferrous sulfate, aluminium sulfate, iron trichloride, polyiron and aluminium-containing iron sulfate.

Owner:ZIGONG QIANYE ENVIRONMENTAL PROTECTION IND

Method for preparing functional grease and active protein powder from abelmoschus manilhot

ActiveCN104342282AProtect nutritionHigh activityProtein composition from vegetable seedsFatty-oils/fats refiningDistillationActive protein

The invention provides a method for preparing functional grease and active protein powder from abelmoschus manilhot. The method comprises the following steps: washing abelmoschus manilhot seeds, drying, peeling, and pressing the seeds into a mould; subjecting the seed mould to a sub-critical extraction treatment, separating the solid-liquid phases after the extraction to obtain solid wet meal and a mixed solution; subjecting the mixed solution to an evaporation treatment to remove the extractant to obtain a grease solution; further subjecting the grease solution to molecular steaming refinement to obtain functional grease with an acid value of 0.21 to 0.23 mg / g; removing residual solvent on the solid wet meal which is separated out after the extraction, drying the meal at a low temperature, grinding, and sieving with a 60-mesh sieve so as to obtain the active protein powder. The provided method omits the tedious processes in the conventional grease refining technology such as deacidification, decoloring, and deodorizing through various chemical or physical processes, and has the advantages of short process procedure and high efficiency. The refined oil acid value is 0.21 to 0.23 mg / g after molecular distillation, and reaches the national A-grade edible oil standard. Furthermore, the obtained active protein powder is not processed at a high temperature, and is not modified, so the active protein powder is a high quality raw material for preparing foods with a high protein content.

Owner:台建祥 +5

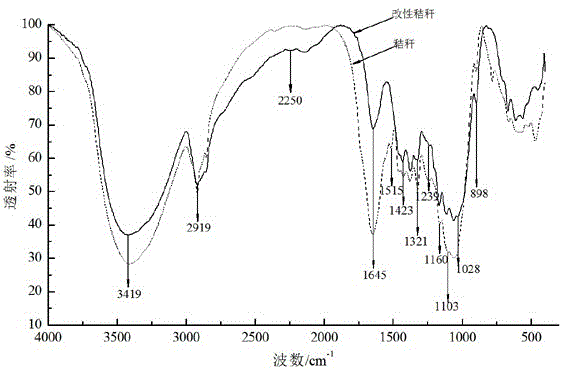

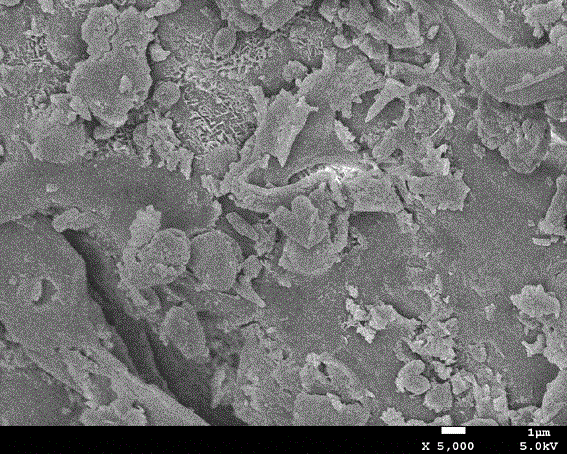

A method of treating dye wastewater by using modified straw

InactiveCN104310559BImprove cohesionStrong decolorization abilityWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationDyeing wastewaterPre treatment

The invention belongs to the technical field of water treatment in water pollution prevention and control, and relates to the treatment of dye wastewater, in particular to a method for treating dye wastewater by utilizing modified straws. The method comprises the following steps of performing straw modification by virtue of a two-step method, namely pre-treating rice straws by virtue of sodium hydroxide, and performing modification reaction on the pre-treated rice straws and tetradecyl trimethyl ammonium chloride; removing orange yellow II, methylene blue and eriochrome black T dyes from a water body to finally realize the treatment of the dye wastewater by virtue of the modified straws. The modified rice straws and tetradecyl trimethyl ammonium chloride are subjected to mixed reaction according to a mass ratio of 1:1 to 1:1.5; the content of sodium hydroxide is 10 to 30 mass percent. According to the technical scheme, the good coagulation effects, high decolorization capability and convenience in use are achieved, and the cost is lowered; agricultural straws can be recycled, and meanwhile, the dye wastewater can be decolored.

Owner:SICHUAN AGRI UNIV

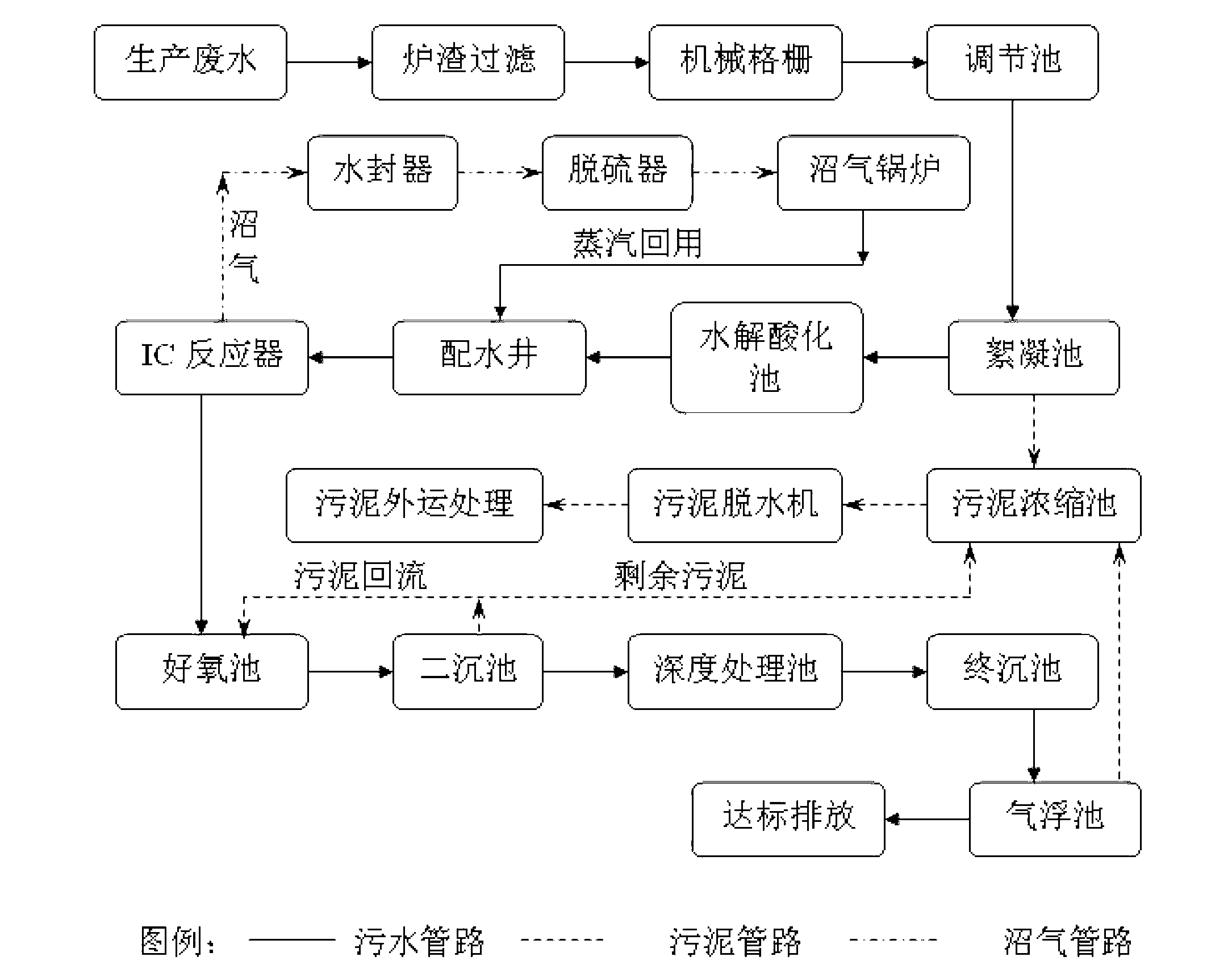

Treatment method of xylose production wastewater

ActiveCN103011506ARaise the pHLow running costMultistage water/sewage treatmentNature of treatment waterFlocculationSlag

The invention discloses a treatment method of xylose production wastewater. The treatment method comprises the following steps of: (1) filtering and absorbing the xylose production wastewater by using furnace slag, then adding the xylose production wastewater subjected to filtration and adsorption into an adjustment pool through mechanical grids, and subsequently adding the xylose production wastewater into a flocculation basin, and adding supernatant liquor into a hydrolysis acidification pool; (2) after the supernatant liquor enters into the hydrolysis acidification pool, finishing hydrolysis acidification; (3) after finishing the hydrolysis acidification, adding the supernatant liquor into a distribution well, then, feeding the supernatant liquor into an IC reactor, and feeding the supernatant liquor into an aerobic pool; (4) adding the wastewater into the aerobic pool; (5) after the wastewater is treated by the aerobic pool, adding the wastewater into a secondary sedimentation tank; (6) after the wastewater is treated by the secondary sedimentation tank, adding the wastewater into an advanced treatment tank; and (7) after the wastewater is treated by the advanced treatment tank, adding the wastewater into a final sedimentation tank, and adding the wastewater into an air floatation tank, so that the treated wastewater can reach 'first stage' standard In Integrated Wastewater Discharge Standard of the People's Republic of China (GB8978-1996) and can be discharged.

Owner:四平绿健生物技术有限公司

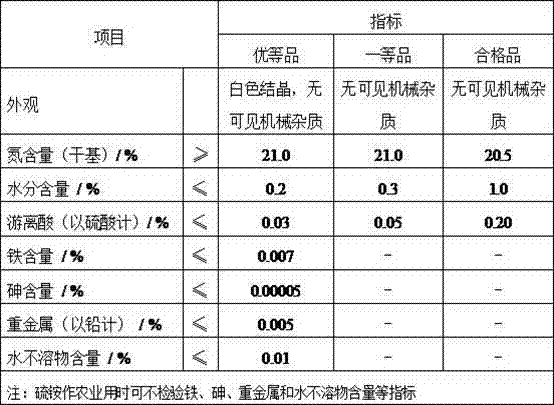

Method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization

InactiveCN103496715AImprove color levelReduced growth rateAmmonium sulfatesActivated carbonCrystal habit

The invention particularly relates to a method for producing industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization. According to the technical scheme, the method comprises the steps that the pH value of a coked coarse ammonium sulfate aqueous solution is adjusted through NaOH, activated carbon is further added, and the aqueous solution is filtered, so that a coked coarse ammonium sulfate crystallization mother solution is obtained; an acidity adjusting agent, a crystal habit modification agent and seed crystals are added to the mother solution, crystal is cultivated, and therefore suspended turbid crystal mush is prepared; finally, eluent is added to suspended turbid crystal mush flow, dilution crystallization is conducted, ammonium sulfate crystals are prepared through filtration and drying, the particle size distribution of a crystal product is concentrated, the surface is smooth, the purity is high, the liquidity is good, and the standard of an industrial grade superior product can be met. The particle size and the addition quantity of the seed crystals are changed so that the average particle size and the particle size distribution of the ammonium sulfate crystal product can be adjusted and controlled in the process of crystallization. The method for producing the industrial grade superior ammonium sulfate through coked coarse ammonium sulfate dilution crystallization has the advantages that the production cost is low, the production cycle is short, the average particle size is controllable, the particle size distribution is concentrated, one-way crystallization yield is high (no less than 95%), and the quality of the product is high.

Owner:WUHAN UNIV OF SCI & TECH

Method for printing and dyeing wastewater purification treatment in different steps

InactiveCN108467156AAchieve decolorizationIncrease profitWater/sewage treatment by irradiationWater contaminantsMicrofiltration membraneCatalytic oxidation

The invention discloses a method for printing and dyeing wastewater purification treatment in different steps. The method comprises the following steps: I, filtering with multiple mediums; II, performing visible light catalytic oxidation; III, filtering with a micro-filtration membrane; IV, filtering with an amphoteric ion-exchange resin. By adopting the treatment method disclosed by the invention, sewage can be purified step by step, that is, the sewage is treated with processes of grids, coagulating sedimentation, anaerobic hydrolysis and aerobic aeration tanks, and printing and dyeing wastewater effluent is fed through a multi-medium filtering layer from top to bottom; large-size garbage is firstly removed through the grids, further through coagulating sedimentation, impurities which can be relatively easily settled down are removed, meanwhile, decoloring is achieved, and further purification is carried out through the multi-medium filtering layer, so that the method has the advantages of high efficiency and environment protection.

Owner:许欠欠

Production process of medlar essential oil and edible meal powder

InactiveCN104774690AImprove digestion utilizationIncreased main fragrance ingredientsEssential-oils/perfumesFood preparationMeal powderOil and grease

The present invention provides a production process of medlar essential oil and edible meal powder. The production process comprises: pressing medlar or seed thereof into a billet, carrying out subcritical extraction, carrying out solid-liquid separation after the extraction to obtain a solid wet meal and a mixed solution, carrying out desorption evaporation on the mixed solution to remove the extractant so as to obtain the crude oil, further carrying out molecular distillation refining on the crude oil to obtain the medlar functional essential oil, completely removing the residual solvent from the solid wet meal, carrying out low-temperature drying, puffing, milling, and powder making, and screening with a 100-180 mesh sieve so as to obtain the medlar edible meal powder. With the method of the present invention, the complex processes that the chemical and physical methods are used to perform deacidification, decolorizing, deodorization and the like in the traditional grease refining are eliminated, the process is short, the efficiency is high, the acid value of the essential oil after the molecule distillation is 0.21-0.23 mg / g, and the essential oil meets the national grade-one edible oil standard. In addition, the oil-extracted meal powder obtained through the method of the present invention still contains all the nutrition and active components and pharmacological functions of the medlar or seeds excluding the oil, and is the high-quality additive for preparing the food or health product.

Owner:台建祥 +5

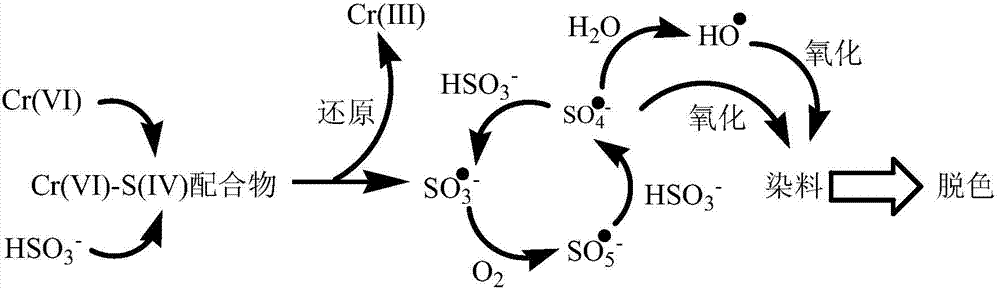

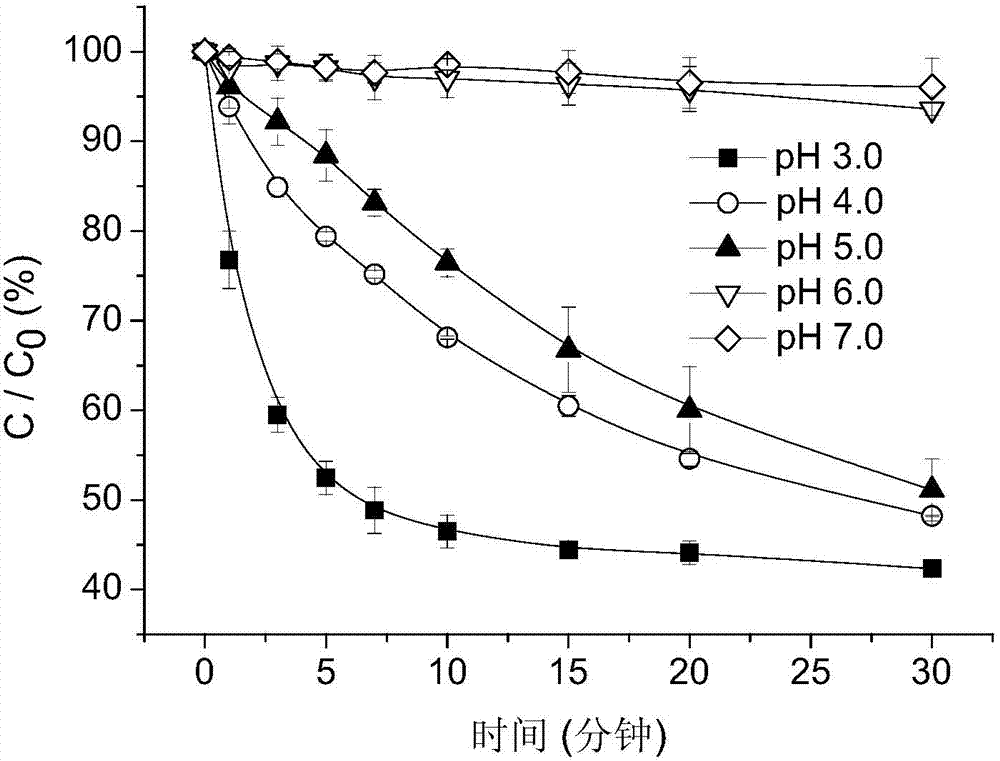

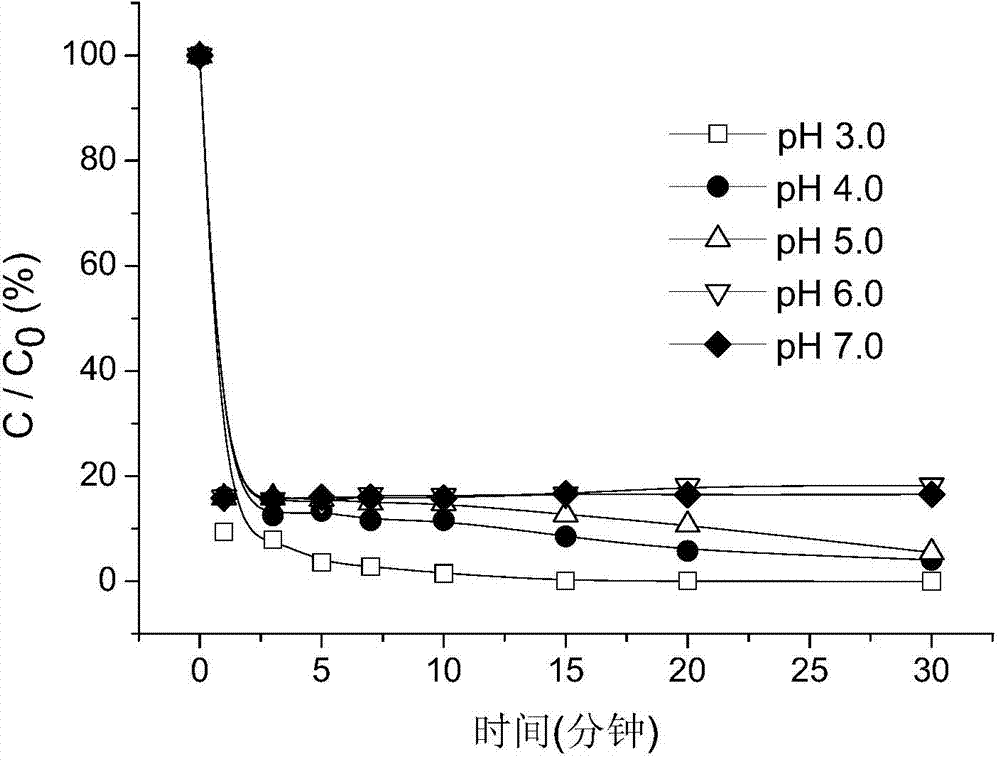

Method for simultaneously treating hexavalent chrome wastewater and organic dye wastewater

InactiveCN104709996AMild reaction conditionsIncrease reaction rateWater contaminantsWater/sewage treatment by neutralisationOrganic dyeWastewater

The invention discloses a method for simultaneously treating hexavalent chrome wastewater and organic dye wastewater. The preparation method comprises the following steps: adding sulfite and hexavalent chrome wastewater into organic dye wastewater, regulating the pH value to 3-7, and stirring or aerating until the organic dyes are decolorized or the hexavalent chrome is completely reduced. In the reaction, the complex formed by the hexavalent chrome and sulfurous acid generates intramolecular electron transfer, so that the hexavalent chrome is reduced into trivalent chrome, and the sulfuric acid free radical and hydroxy free radical are simultaneously generated to initiate the oxidizing decolorization on the coexisting dyes. The concentration of the sulfite is 1.9-35.0 times of that of the dyes, the concentration of the hexavalent chrome is 0.5-7.9 times of that of the dyes, and the pH value is 3-7. The hexavalent chrome is reduced into the lower-toxicity trivalent chrome during dye decolorization without adding any other catalyst or oxidizer; and thus, the method is simple to operate and is quick and efficient. Therefore, the method has very wide application prospects.

Owner:WUHAN UNIV

Ecological aluminium oxide melamine wood door and preparation method thereof

InactiveCN101733807AAdequate gluing propertiesEnough durabilityWood working apparatusPolystyreneEngineering

The invention discloses an ecological aluminium oxide melamine wood door, which is formed by an interlayer door frame and decorating plates which are pressed on the front and rear sides of the interlayer door frame. The ecological aluminium oxide melamine wood door is characterized in that: the decorating plates adopt melamine plates; an anti-wear agent prepared from aluminium oxide is laminated on the sides of the melamine plates; and the front and rear sides of the interlayer door frame are coated with polystyrene foams and then the melamine plates are pressed on the two sides by a hot press or a cold press. The ecological aluminium oxide melamine wood door and the preparation method thereof can not only solve the problem of wasting timber resources and simplify the production process, but also overcome the shortcoming of complicated process of the production method. The product cost is greatly reduced and the production cycle is shortened.

Owner:成都市科创巴赛科技有限公司

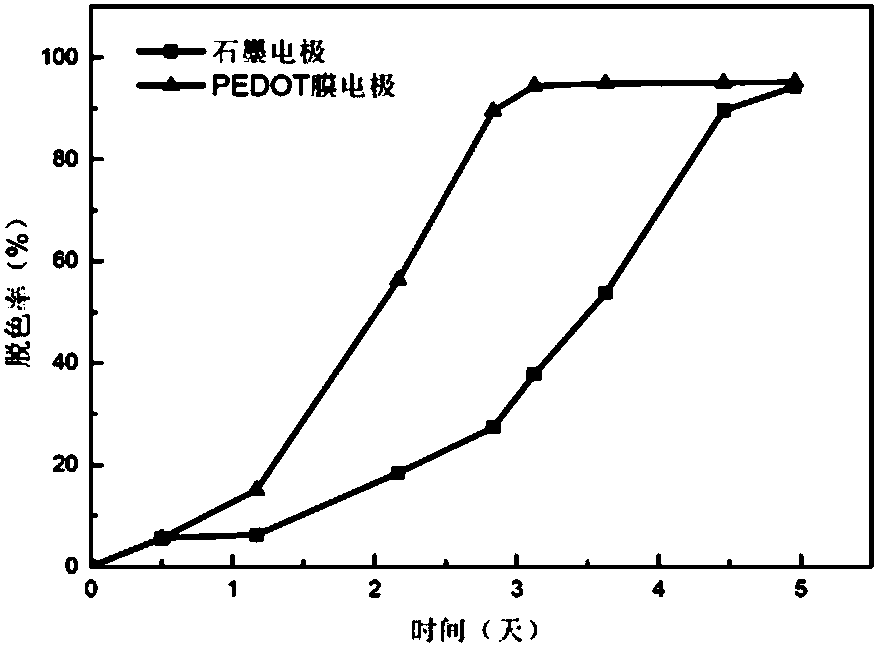

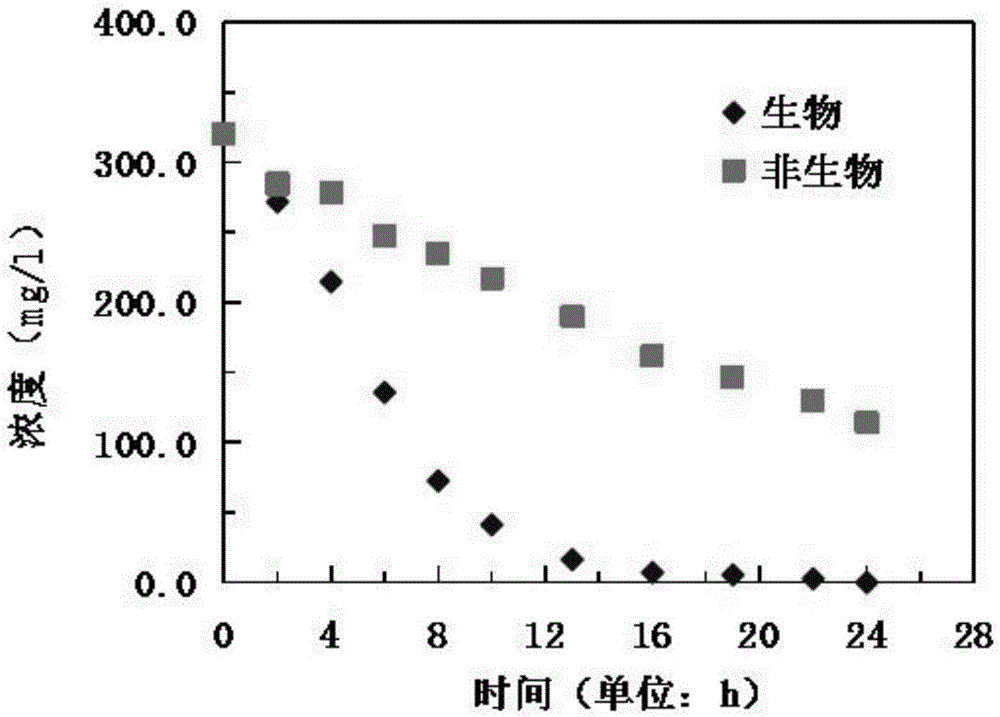

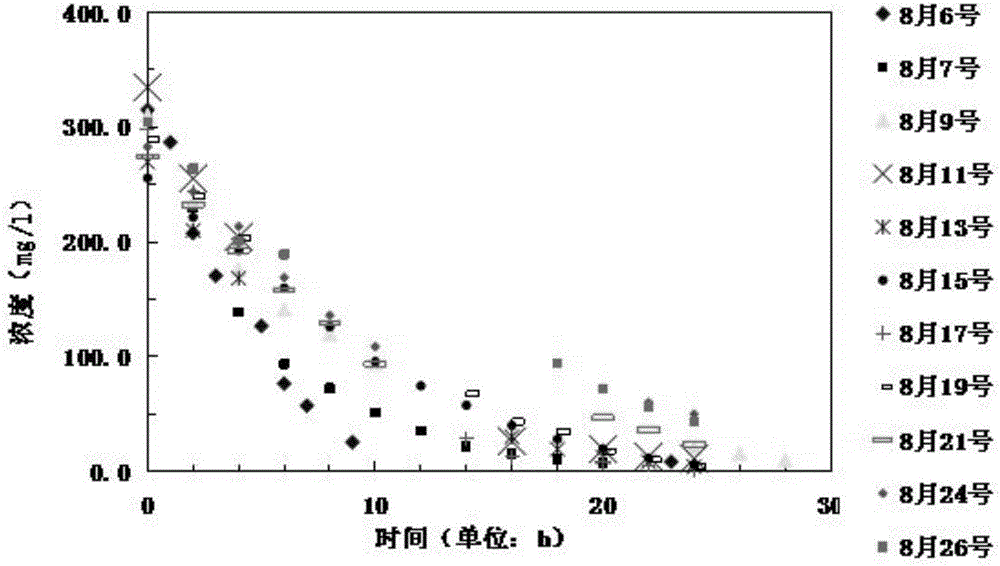

MFC (microbial fuel cell) decolorization method based on PEDOT membrane electrode

InactiveCN108328745AIncrease electricity productionGood decolorization effectCell electrodesWater contaminantsMicrobial fuel cellElectricity

The invention provides an MFC (microbial fuel cell) decolorization method based on a PEDOT membrane electrode and relates to MFCs. The PEDOT membrane electrode is obtained by modifying surface of an electrode base material with a PEDOT membrane; an MFC reactor is assembled preliminarily, the parts for preliminary assembly comprise a cathode chamber, an anode chamber, a separator, a sealing washer,a fixing clamp and an external resistor, and the separator is located between the anode chamber and the cathode chamber and fixed by the fixing clamp; an anolyte and a catholyte are added to the anode chamber and the cathode chamber of the MFC respectively; the electrode taken as an anode and a cathode is placed into the anode chamber and the cathode chamber of the MFC reactor, and the anode andthe cathode are connected with the external resistor; a decolorization medium in the anode chamber is inoculated with a decolorized electricigens; after inoculation, an anaerobic gas is introduced, air in the MFC reactor is discharged, and the MFC enters an operation state; electrogenesis curve, changing with time, of the MFC is recorded by measuring voltages at two ends of the external resistor;the anolyte is sampled regularly, and dye decolorization speed is calculated by measuring dye concentration of the anolyte.

Owner:XIAMEN UNIV

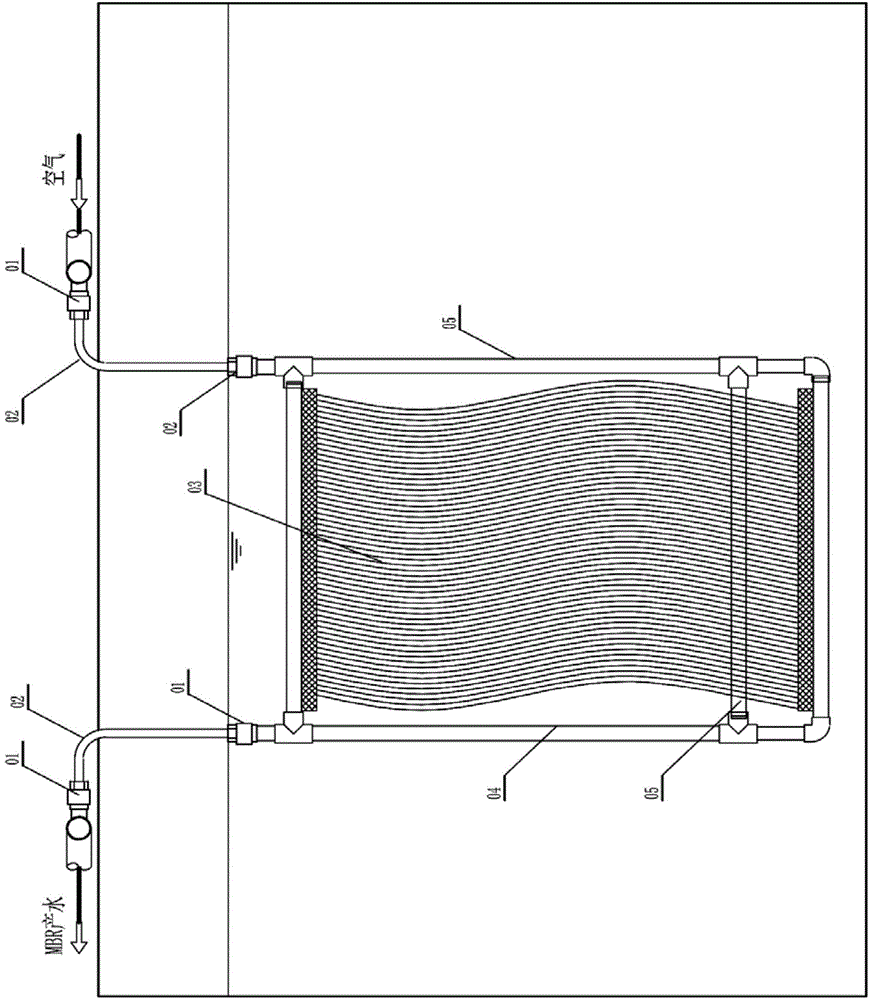

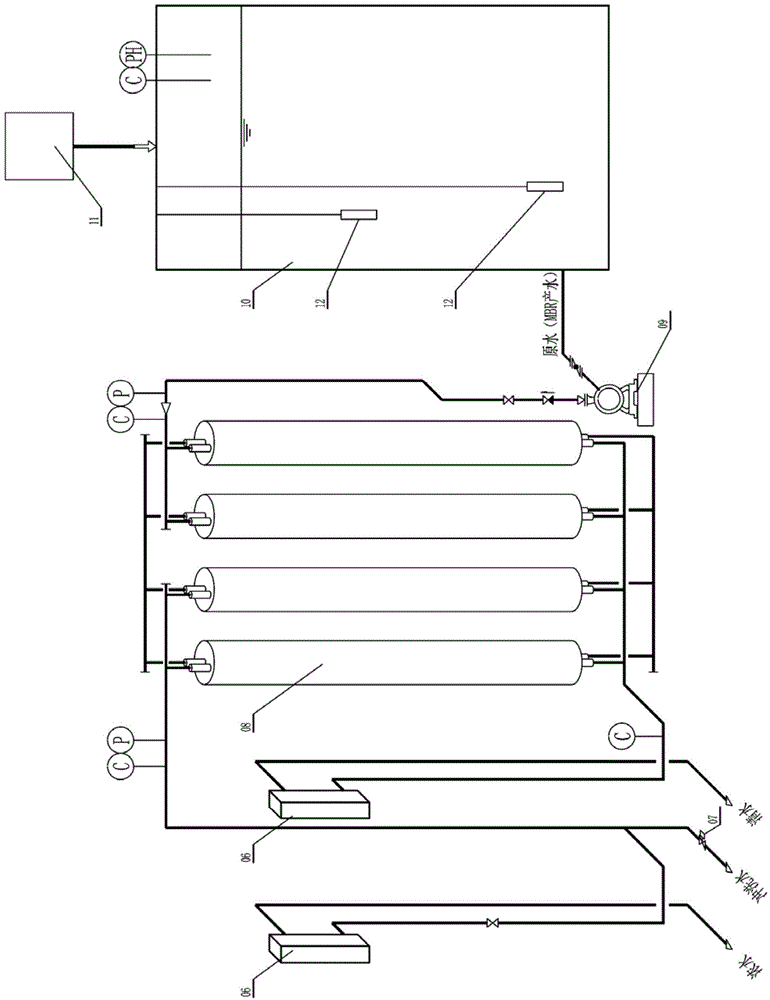

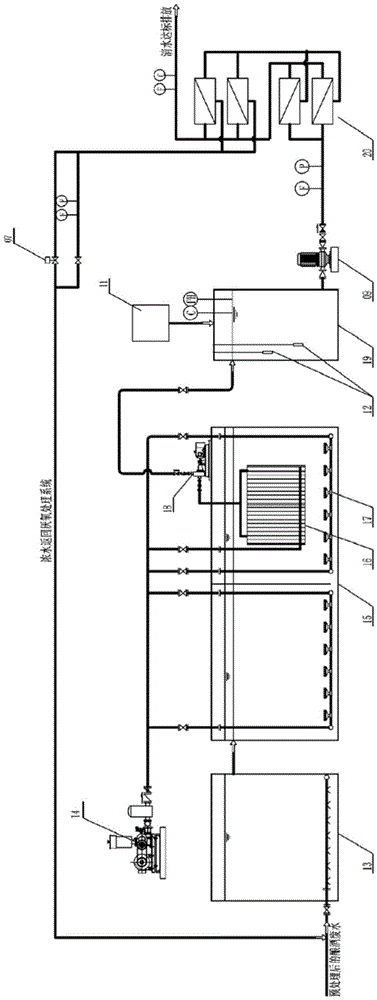

Efficient decolorization process for wastewater generated by brewing of white spirit

ActiveCN104086046ALow water turbidityChroma hasMultistage water/sewage treatmentWaste water treatment from food industryActivated sludgeFiltration

The invention relates to an efficient decolorization process for a wastewater generated by brewing of white spirit. The process comprises the following steps: a brewing wastewater enters into an anaerobic tank after pretreatment, most of organic matters and a part of chromaticity are removed under the action of anaerobic microorganisms, and then enters an aerobic tank to further carry out oxygenolysis; a mixed liquor of the aerobic tank enters into a membrane bioreactor to carry out solid-liquid separation; suspending activated sludge in the mixed liquor is intercepted, so as to obtain clear water of which the turbidity is smaller than 1NTU; and finally membrane separation is carried out through a nanofiltration membrane or ultrafiltration membrane filter device, wherein the chromaticity of the clear water after membrane separation is 2-4 times, and superior to the 20-fold limiting value specified by the national standard GB27631-2011 table 3; and concentrated water after membrane filtration returns to an anaerobic and aerobic membrane bio-reactor (MBR) biological treatment system to continue to process. The decolorization process adopted by the invention can be designed in a modularized manner, is less in floor area, low in operating cost, and convenient to be accessed into the existing wastewater biological treatment system, and has important significance on upgrading and reconstruction of the existing white spirit wastewater treatment.

Owner:桂润环境科技股份有限公司

Method for regenerating and extracting waste mineral oil by filling nitrogen extracting

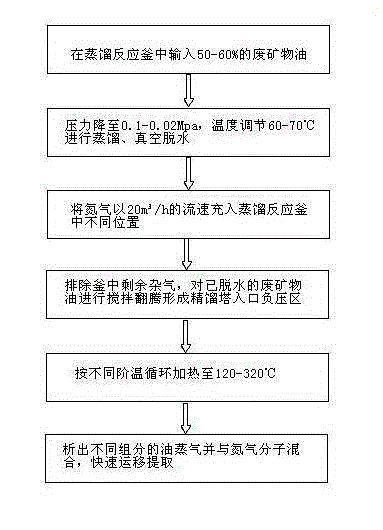

InactiveCN103146423ALower boiling temperatureBoiling temperature achievedTreatment with plural serial refining stagesLubricant compositionDistillationNitrogen gas

The invention discloses a method for regenerating and extracting waste mineral oil by filling nitrogen. The method comprises the following steps of: (1) delivering waste mineral oil into a distillation reactor, distilling at reduced pressure after reducing the pressure to -0.1MPa to -0.02Mpa, and dehydrating in vacuum; (2) filling nitrogen into different parts of the distillation reactor, removing other residual miscellaneous gases in the space of the distillation reactor, stirring the dehydrated waste mineral oil, and forming a negative-pressure zone at the inlet of a rectification tower; and (3) circularly heating the stirred waste mineral oil to 120-320 DEG C according to different thermophases, separating out oil steam with different components, mixing the oil steam with nitrogen molecules, transporting quickly, and extracting. The method effectively solves the problems of low regeneration yield of the waste mineral oil, low extraction efficiency and environment pollution.

Owner:佛山市和挚承环保科技有限公司

Dyeing wastewater treatment device and method for treating wastewater by using device

InactiveCN105948221AAchieve decolorizationAchieving processing powerTreatment by combined electrochemical biological processesWaste water treatment from textile industryActivated sludgeChemical oxygen demand

The invention belongs to the field of wastewater treatment, and discloses a dyeing wastewater treatment device and a method for treating wastewater by using the device. The dyeing wastewater treatment device comprises a cathode chamber, an anode chamber, an ion exchange membrane and a power source. The method comprises the following steps: a double-chamber microbial electrolytic bath is established, activated sludge is inoculated in the cathode chamber, and dyeing wastewater is introduced, so that microbes are domesticated and reproduced; an external power supply is used for providing different external voltages, and the cathode potential is controlled, thereby promoting the cathode to form the specific microbial film with favorable electrochemical activity; after the pH value, hydraulic retention time, COD (chemical oxygen demand) concentration of influent water and other parameters of the wastewater are regulated, the dyeing wastewater is decolorized and degraded in the cathode chamber of the reactor, and is finally discharged out of the cathode chamber, wherein the azo dye decolorization rate reaches 90% or above.

Owner:ANHUI NORMAL UNIV

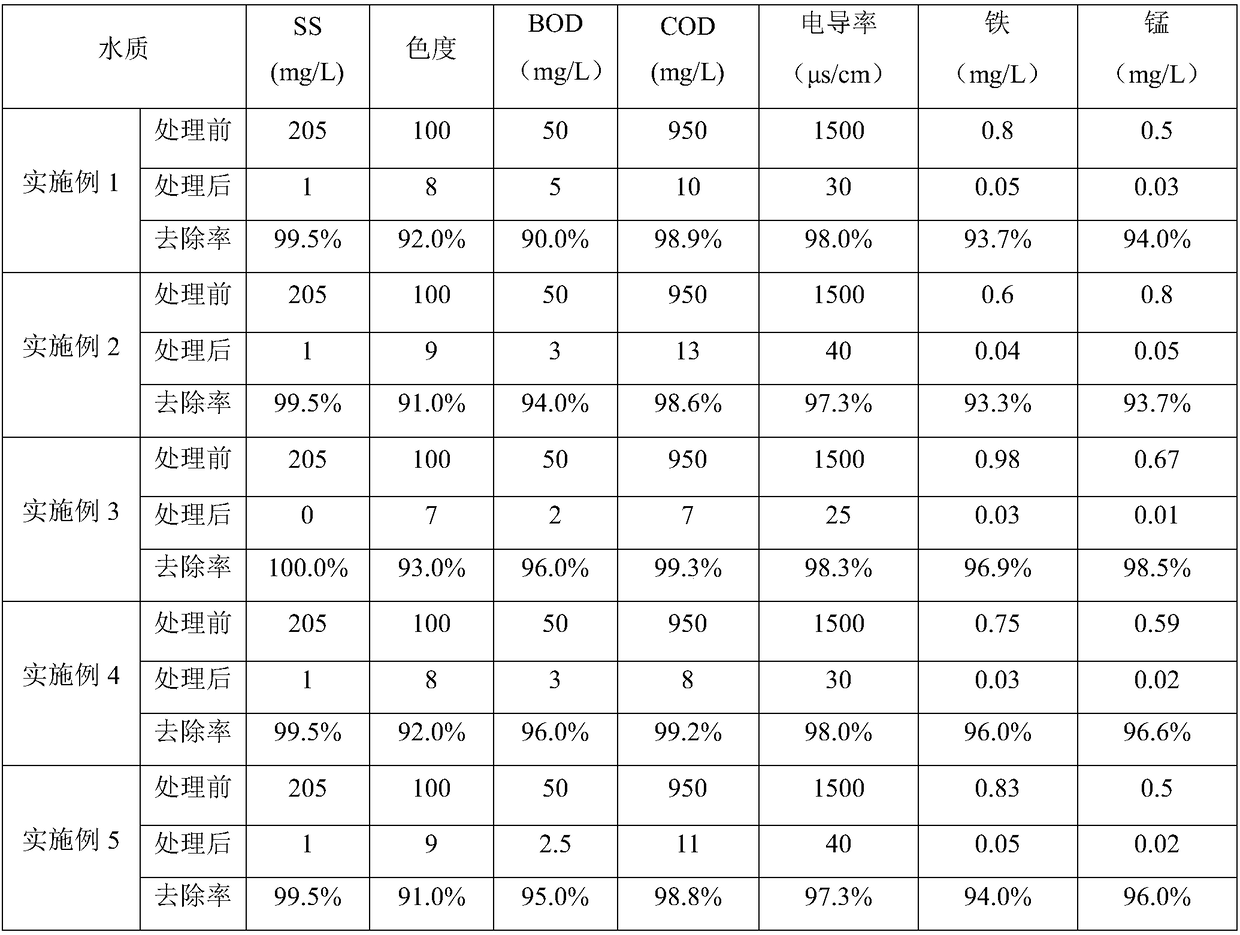

Treatment method of processing wastewater of jade

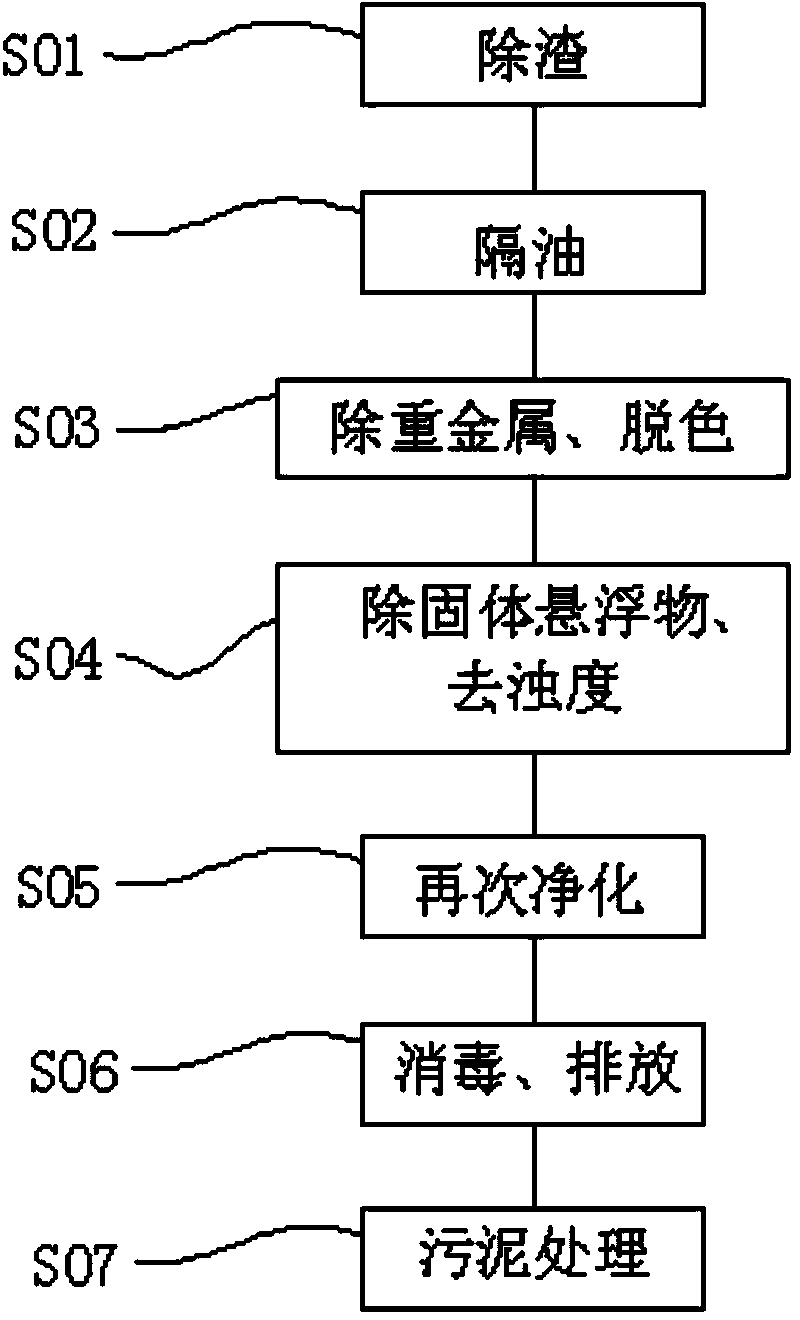

ActiveCN104193041AImprove heavy metal removal rate and decolorization rateImprove separation rateSludge treatment by de-watering/drying/thickeningMultistage water/sewage treatmentTotal phosphorusEnvironmental chemistry

The invention relates to a treatment method of processing wastewater of jade. The treatment method at least comprises the following steps: S01 deslagging, S02 oil separating, S03 heavy metal removal, and decoloration, S04 solid suspended matter and turbidity removal, S05 re-purifying, S06 disinfecting and discharging, and S07 sludge treating. The treatment method has the excellent effects that an oil and water separation rate is increased, and an oil removal rate is greater than 90% by an air floatation mode via an air floatation oil separation tank; with the adoption of a pipeline coagulation technology, removal of heavy metals and the decoloration are realized, a removal rate of the heavy metals is greater than 90%, and a decoloration rate is greater than 98%; matter-liquid separation is realized by a spiral-flow filter membrane purification can, a removal rate of solid suspended matters is greater than 99%, and an improvement rate of turbidity is greater than 98%; and with the adoption of an integral bioreactor, COD (Chemical Oxygen Demand), ammonia nitrogen and total phosphorus in the processing and production wastewater of the jade reach level I of the national rural drainage standard.

Owner:王新军

Grease decoloring method

ActiveCN102994225AHigh temperature time is shortHigh product yieldFatty-oils/fats refiningChemistryOil and grease

The invention discloses a grease decoloring method, belonging to the technical field of refining grease and used for solving the problems in grease decoloring that high temperature time is long, the product yield is low, and auxiliaries are in need and sewage is discharged. The grease decoloring method comprises the steps: increasing temperature of raw material oil to 150-170 DEG C through a heat exchanger, then sending the raw material oil into a molecular still, and evenly distributing on an evaporative surface with temperature of 190-245 DEG C through a distributor, wherein the vacuum degree ranges from 5Pa to 40 Pa; cooling light component pigment to 35-42 DEG C through a built-in condenser, wherein the cooled light component pigment flows in a light component collection tank and heavy components directly enter a heavy component collection tank; increasing the temperature of the heavy components to 230-260 DEG C through the heat exchanger, sending the heavy components to the molecular still, evenly distributing the material on the evaporative surface with temperature of 300-320 DEG C through the distributor under the vacuum degree of 0.1-5Pa, cooling light components to 35-42 DEG C through the built-in condenser, wherein the cooled light components flow in a decolored oil collection tank and the heavy components directly enter the heavy component collection tank. The grease decoloring method can be widely applied to the edible, cosmetic and fine chemical engineering fields.

Owner:陈汉卿

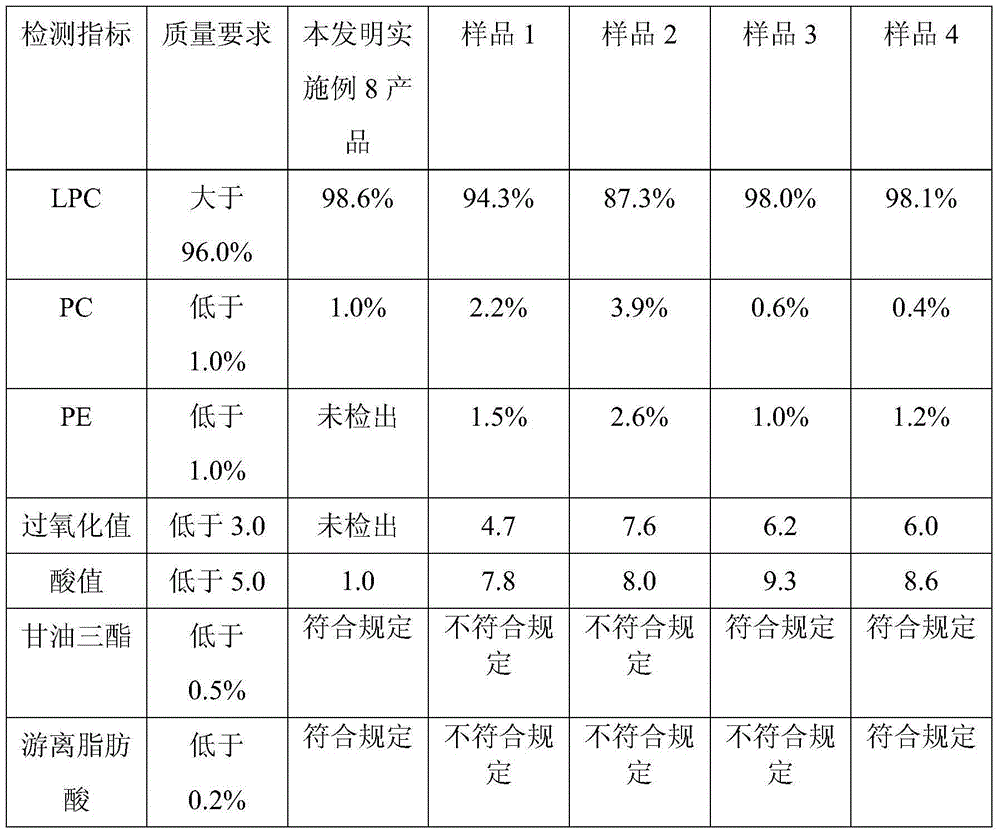

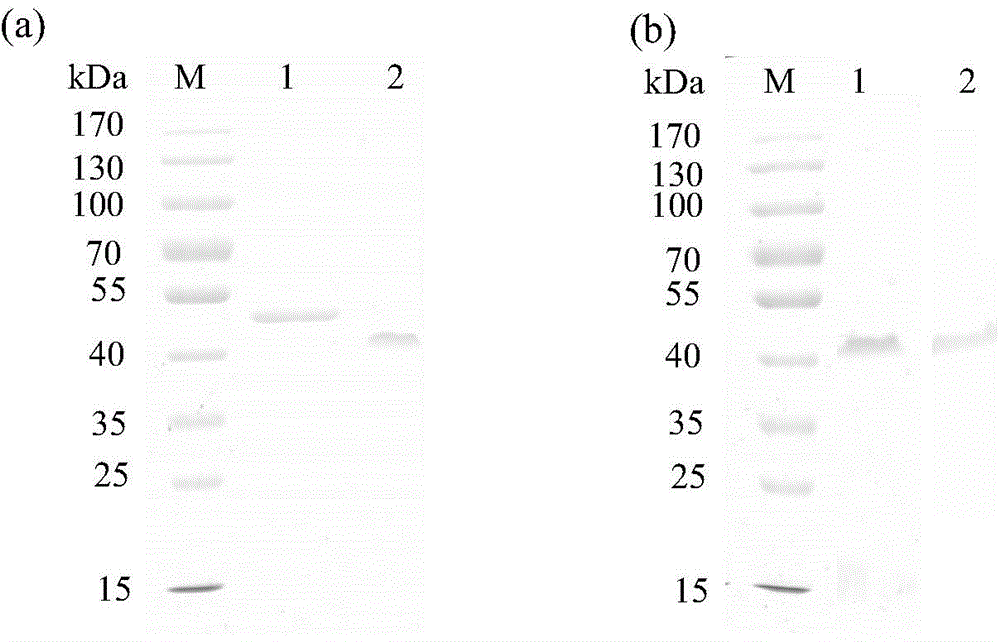

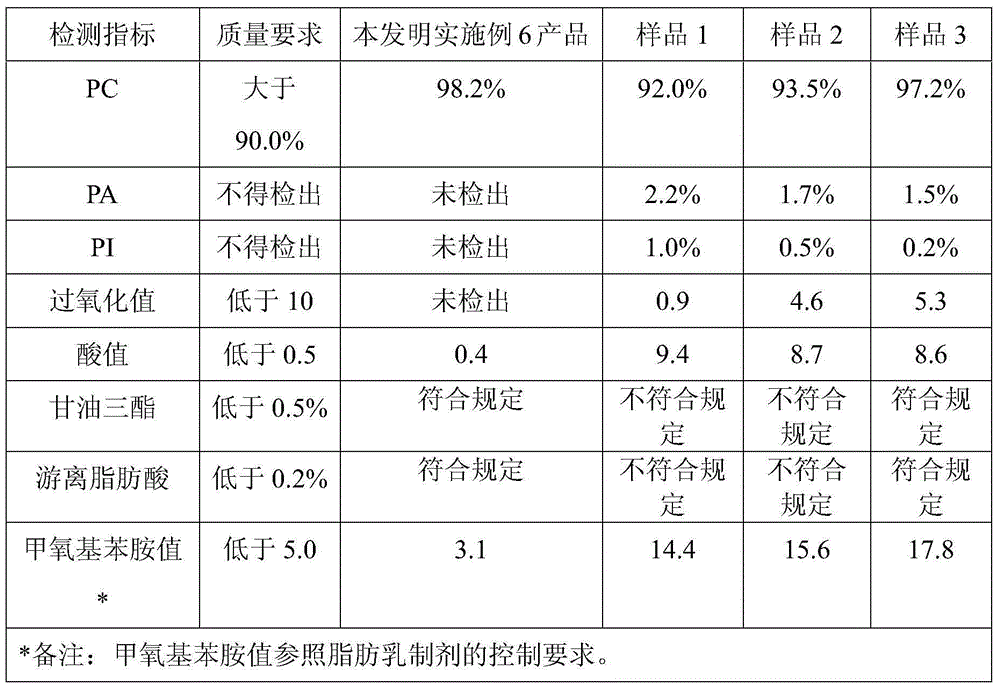

Preparation method of natural LPC (lysophosphatidylcholine)

ActiveCN104558021ALower impurity limitAchieve decolorizationPhosphatide foodstuff compositionsSolventPeroxide value

The invention discloses a preparation method of natural LPC (lysophosphatidylcholine). The method comprises steps as follows: a phospholipid coming from soybeans or yolks is taken as a raw material, elution is performed twice with a ternary mixed solvent consisting of a polyhalogenated alkane, low-carbon alcohol and water through column chromatography, drying is performed, and the natural LPC product is obtained. The product obtained with the method is high in LPC content (98.0-99.9% with HPLC (high performance liquid chromatography)), low in impurity content (the phosphatidylcholine content is lower than 1.0%, the phosphatidyl ethanolamine content is lower than 1.0%, the free fatty acid content is lower than 0.2%, and the triglyceride content is lower than 0.2%) and low in oxidative index (the acid value is lower than 1.0, the peroxide value is lower than 1.0, and the anisidine value is lower than 5.0) and meets the quality requirement of the medical phospholipid.

Owner:GUANGZHOU HANFANG PHARMA

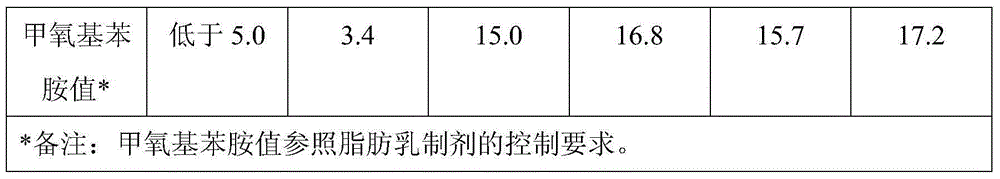

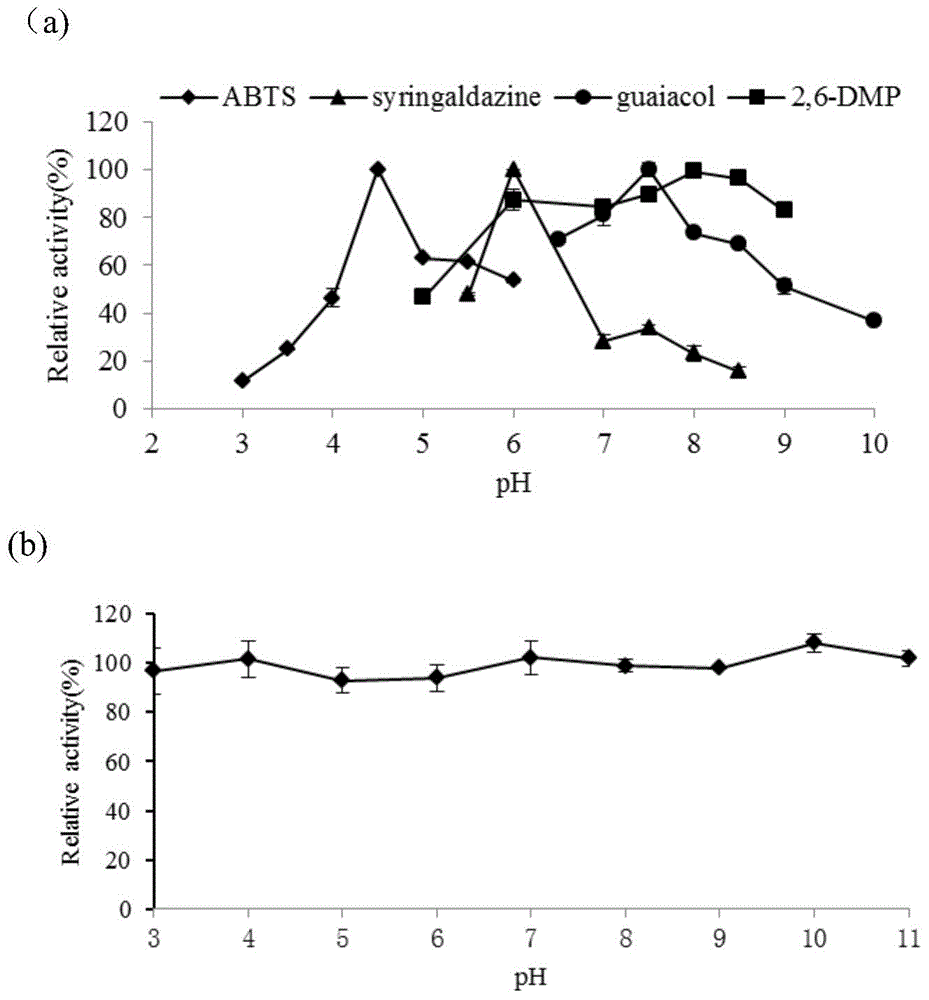

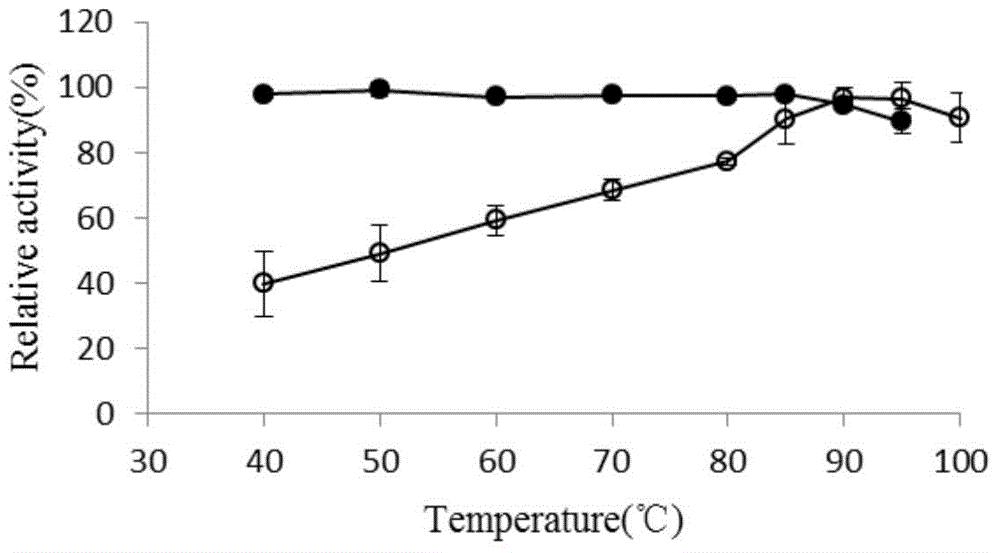

Thermus thermophilus laccase (benzenediol: oxygen oxidoreductases), engineering bacteria, recombinant laccase and use of recombinant laccase

ActiveCN104004721AHas laccase activityGood heat and alkali resistanceFungiMicroorganism based processesPichia pastorisOxidoreductase

The invention discloses a thermus thermophilus laccase (benzenediol: oxygen oxidoreductases), engineering bacteria, a recombinant laccase and a use of the recombinant laccase. The thermus thermophilus laccase has an amino acid sequence shown in the formula of Seq No.2. The DNA sequence for coding the above laccase is shown in the formula of Seq No.1. The DNA can be used in construction of a Pichia pastoris expression system. Through expression vector pHKFA1-lacTT linearization and then Pichia pastoris conversion by the expression vector, recombinant Pichia pastoris engineering bacteria are obtained. The recombinant laccase is obtained by fermentation of the recombinant Pichia pastoris engineering bacteria. The recombinant laccase has laccase activity and high temperature resistance, can be used in dye decoloring and especially in azo dye and anthraquinone dye decoloring, and has a decolourization ratio of 100%.

Owner:SOUTH CHINA UNIV OF TECH

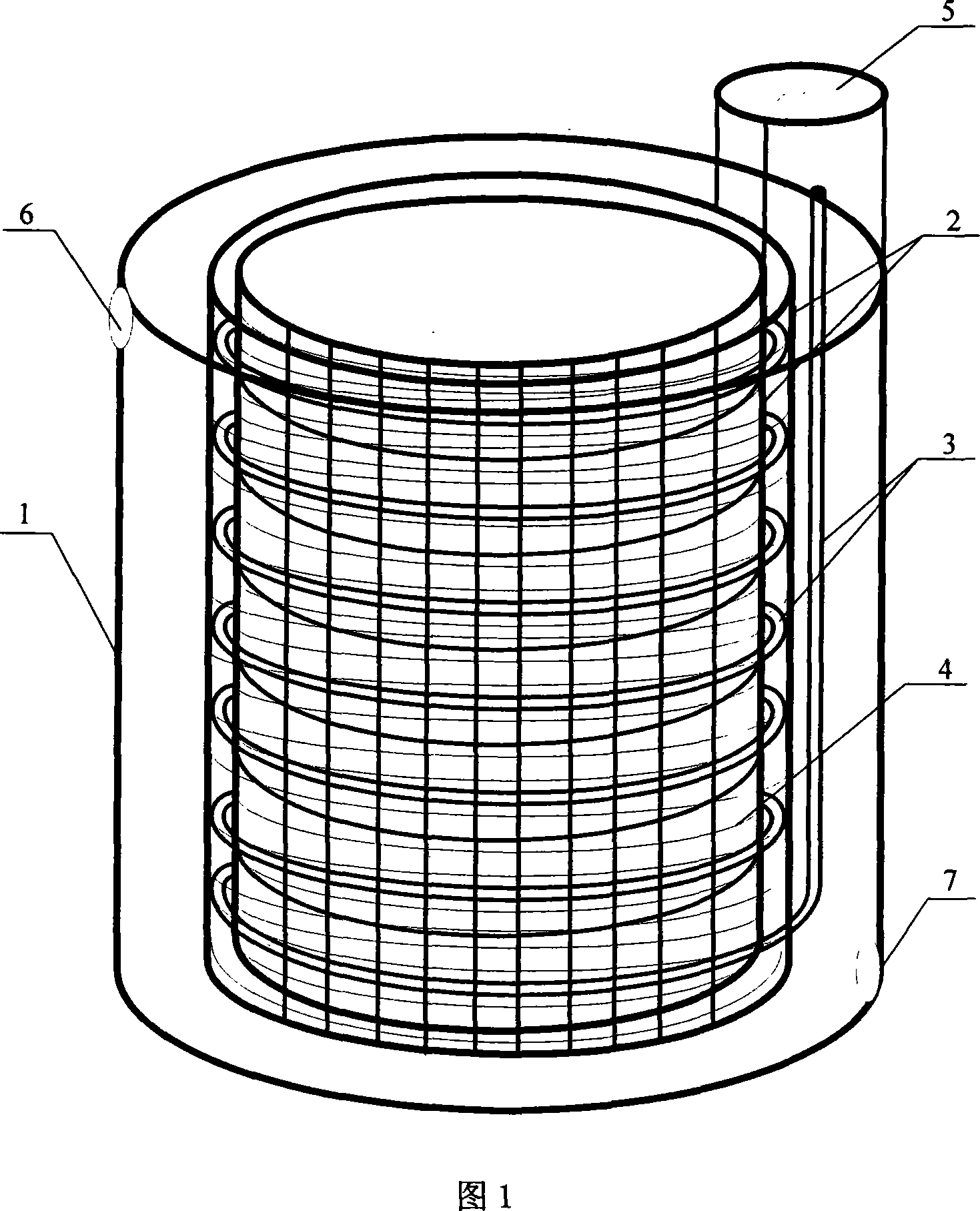

Light catalyzed water treatment equipment of 3D fiber layer of titanium dioxide

InactiveCN101049992AIncrease profitHigh activityWater/sewage treatment by irradiationEnergy based wastewater treatmentSewageWater treatment

This invention discloses a three-dimensional TiO2 fiber layer photocatalytic water purifier. The water purifier utilizes TiO2 fibers as the photocatalyst, and optical fibers as the light guiding medium. The optical fibers can guide sunlight into the water purifier, where sunlight acts as the activating source of TiO2 fibers so that wastewater and catalyst react under sunlight activation to remove impurities. The water purifier comprises an organic glass outer cylinder, with a water inlet at the bottom of one side, and a water outlet at the top of the other side. At least two sleeved aluminum mesh cylinders with the same height and different diameters are set in the organic glass outer cylinder, and the interlayer in between is composed of optical fiber beam and three-dimensional TiO2 fiber layer. A light focusing device is set at the top of the outer surface of the organic glass outer cylinder.

Owner:SHANDONG UNIV

Preparation method for polyene phosphatidyl choline for injection

ActiveCN104592292AReduce overdependenceLarge amount of processingPhosphatide foodstuff compositionsSolventPeroxide value

The invention discloses a preparation method for polyene phosphatidyl choline for injection. The preparation method comprises the following steps: dissolving with a proper solvent by taking soyabean lecithin as a raw material, performing elution twice with a ternary mixed solvent consisting of multi-halogenated hydrocarbon, low carbon alcohol and water through column chromatography, and drying to obtain a product polyene phosphatidyl choline. The product obtained by the preparation method disclosed by the invention is high in phosphatidylcholine content (98.0%-99.9%, HPLC (high performance liquid chromatography) process), low in impurity content (less than 1.0% of lysophosphatidyl choline, less than 0.5% of phosphatidyl inositol, less than 0.5% of phosphatidyl ethanolamine, less than 0.2% of free fatty acid and less than 0.2% of triglyceride), and low in oxidative index (an acid value lower than 0.5, a peroxide value lower than 1.0 and methoxy phenylamine value lower than 5.0), so that the product quality reaches the quality standards of polyene phosphatidyl choline for injection.

Owner:GUANGZHOU HANFANG PHARMA

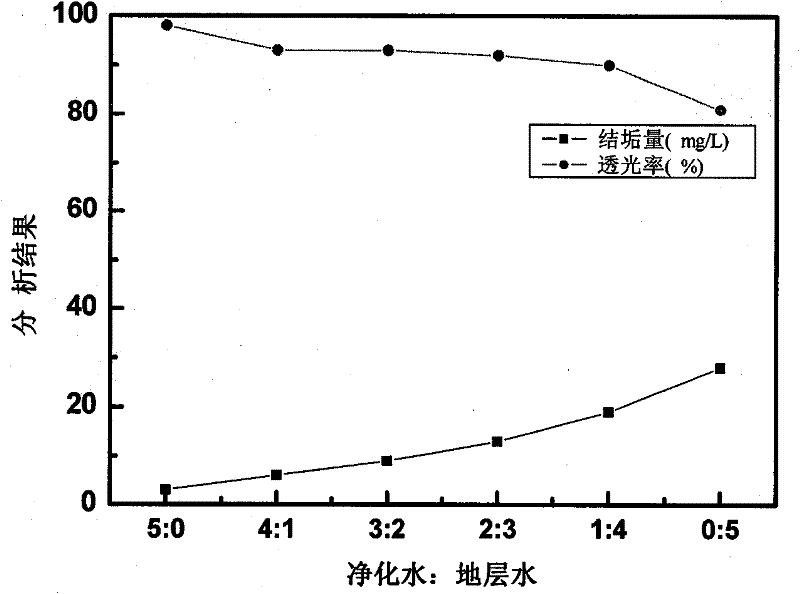

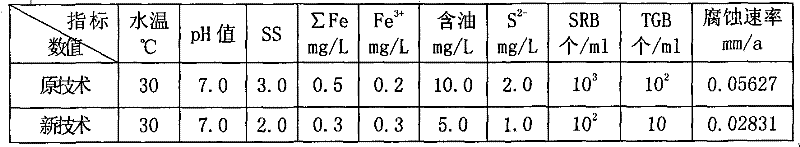

Method for treating low-temperature oily wastewater with strong oxidant

InactiveCN102442737ARaise the pHReduce difficultyMultistage water/sewage treatmentWater/sewage treatment by oxidationSewageTreated water

Belonging to the technical field of new materials, the invention relates to a method for treating low-temperature oily wastewater with a strong oxidant. Directed at the actual situations of low temperature, high viscosity and great treatment difficulty in the oily wastewater of oil fields at a later development stage, the invention puts forward a new technology for treating low-temperature oily wastewater. By adding chemical agents that are different from agents used in conventional wastewater treatment, as well as changing original water treatment processes, the method of the invention makes the treated water completely satisfy the requirements of injection water, and simultaneously can obtain enormous economic and environmental benefits.

Owner:张振飞

High-efficiency decolorization and recycling method of printing wastewater

ActiveCN105084436AImprove water resource utilizationLow costWater/sewage treatmentWaste water treatment from textile industryUtilization factorWater resources

The invention discloses a high-efficiency decolorization and recycling method of printing wastewater, which comprises the following steps: mixing a reactant and a diluter in a volume ratio of (2-4):(6-8) to obtain a decolorization solution; regulating the pH value of the printing wastewater to 3-4; and mixing the decolorization solution and printing wastewater to carry out decolorization treatment, and stratifying to obtain the loaded decolorization solution and recycled water. The method can quickly implement decolorization on the wastewater, and the decolorization rate can reach 99%. The decolorized printing wastewater can be directly recycled for the water washing technique, thereby enhancing the water resource utilization ratio.

Owner:BEIJING HUIYU LEBANG ENVIRONMENT PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com