Method for printing and dyeing wastewater purification treatment in different steps

A technology for printing and dyeing wastewater, purification and treatment, applied in water/sewage treatment, chemical instruments and methods, light water/sewage treatment, etc. High cost and other problems, to achieve the effect of increasing mechanical strength and stability, low price and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

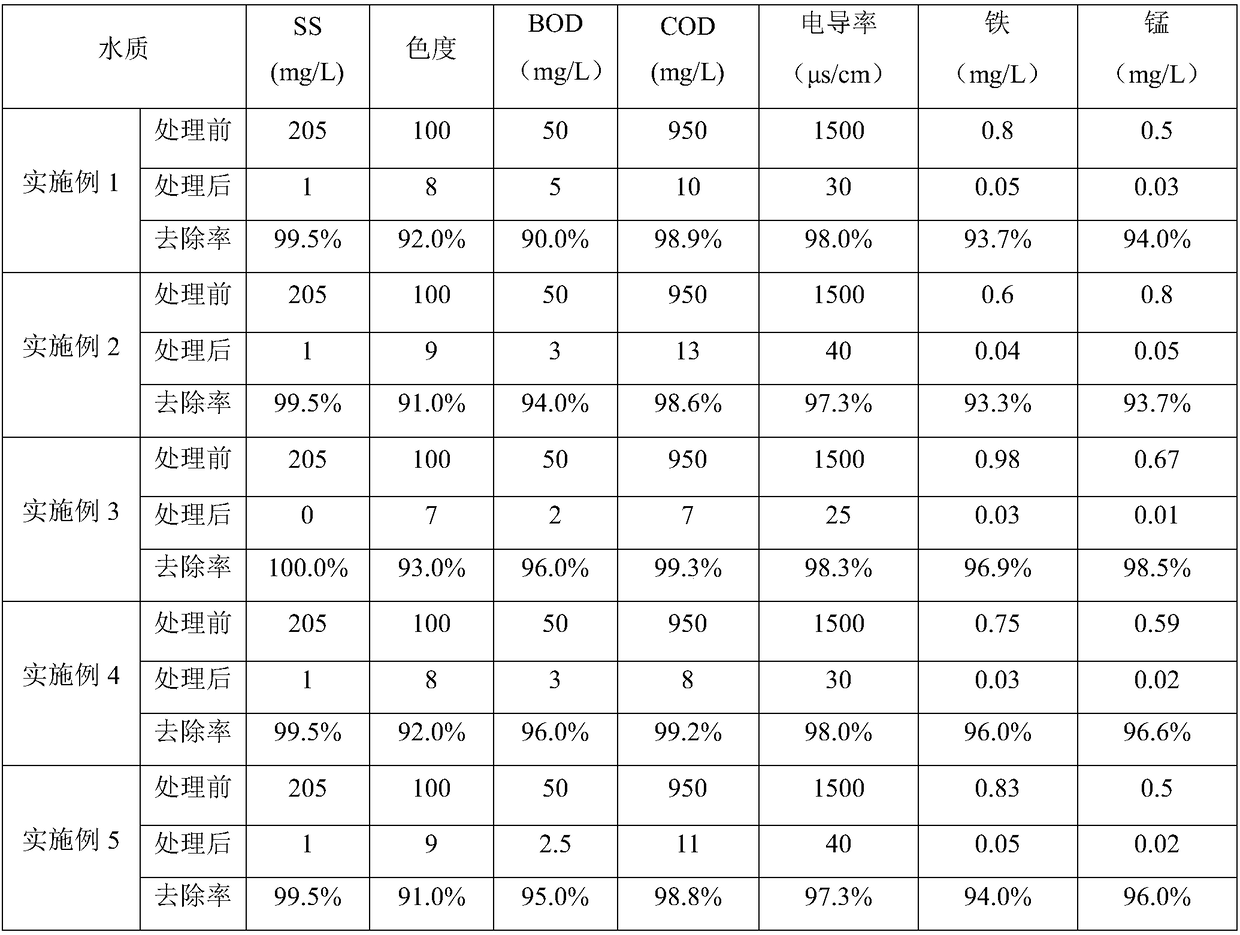

Examples

Embodiment 1

[0030] A method for step-by-step purification of printing and dyeing wastewater, the method comprising the steps of:

[0031] Step 1. Multi-media filtration: the effluent after the process of passing through the grille, adding coagulant for coagulation and sedimentation, anaerobic hydrolysis and aerobic aeration tank passes through the multi-media filter layer from top to bottom; the filter medium is: the upper layer is Anthracite, particle size 1mm, layer height 400mm, lower layer is quartz sand, particle size 0.5mm, layer height 800mm, flow velocity 8m / h; described coagulation precipitation step adds coagulant, and the composition of described coagulant is as follows: phenolic 6 parts of resin, 5 parts of nano zinc oxide, 4 parts of sodium lignosulfonate, 3 parts of carbon nanotube, 3 parts of activated carbon fiber, 3 parts of starch, 2 parts of organic montmorillonite, 2 parts of diatomite, pyrrhotite 2 parts, 2 parts of maghemite, 2 parts of ferromanganese permanent magne...

Embodiment 2

[0046] A method for step-by-step purification of printing and dyeing wastewater, the method comprising the steps of:

[0047] Step 1. Multi-media filtration: the effluent after the process of passing through the grille, adding coagulant for coagulation and sedimentation, anaerobic hydrolysis and aerobic aeration tank passes through the multi-media filter layer from top to bottom; the filter medium is: the upper layer is Anthracite, particle size 2mm, layer height 400mm, lower layer is quartz sand, particle size 1mm, layer height 800mm, flow rate 12m / h; described coagulation precipitation step adds coagulant, and the composition of described coagulant is as follows: phenolic resin 8 parts, 8 parts of nano zinc oxide, 8 parts of sodium lignosulfonate, 7 parts of carbon nanotubes, 6 parts of activated carbon fiber, 5 parts of starch, 5 parts of organic montmorillonite, 5 parts of diatomite, 3 parts of pyrrhotite 3 parts, 3 parts of maghemite, 3 parts of ferromanganese permanent m...

Embodiment 3

[0062] A method for step-by-step purification of printing and dyeing wastewater, the method comprising the steps of:

[0063] Step 1. Multi-media filtration: the effluent after passing through the grid, adding coagulant for coagulation and sedimentation, anaerobic hydrolysis and aerobic aeration tank process passes through the multi-media filtration layer from top to bottom. The filter medium is: the upper layer is anthracite, the particle size is 1.5 mm, and the layer height is 400 mm; the lower layer is quartz sand, the particle size is 0.7 mm, the layer height is 800 mm, and the flow rate is 10 m / h; The composition of the coagulant is as follows: 7 parts of phenolic resin, 6 parts of nano-zinc oxide, 6 parts of sodium lignosulfonate, 5 parts of carbon nanotubes, 4 parts of activated carbon fiber, 4 parts of starch, 3 parts of organic montmorillonite, diatomaceous earth 3 parts, 2.5 parts of pyrrhotite, 2.5 parts of maghemite, 2.5 parts of ferromanganese permanent magnetic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com