Method for treating low-temperature oily wastewater with strong oxidant

A technology for strong oxidants and oily sewage, applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. Flushing workload and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

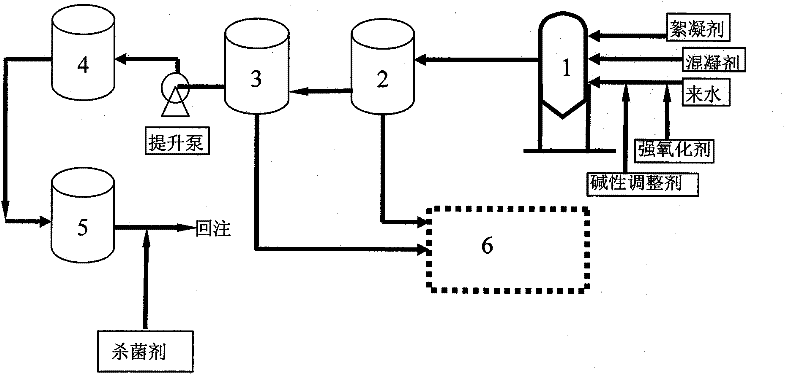

Method used

Image

Examples

Embodiment Construction

[0008] Take the sewage before treatment from the sewage station on site, accurately measure 2000ml water samples and put them in a 2000ml beaker, and add various sewage treatment chemicals according to the experimental requirements under stirring at a speed of 150r / min. After completing the above operations, continue to stir at 150r / min for 1min, then stir at 35r / min for 3min, and let it stand for 15min. Take the upper layer of water, sand filter it, and put it in a beaker to analyze various indicators.

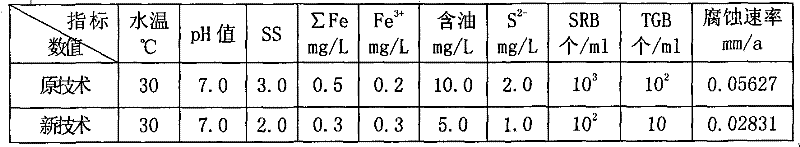

[0009] Table 2 Different methods of treating low temperature oily sewage water quality (oxidant content 25mg / L)

[0010]

[0011] It can be seen from Table 2 that after improving the technology of low-temperature oily sewage, Fe, S 2- , SRB, TGB and other indicators are better than the traditional technology, indicating that the improved technology can weaken the impact of temperature drop on water quality, and reach the A2 standard of SY / T5329-94 "Recommended indicators a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com