Crystallizer casting powder for high-aluminum steel continuous casting

A technology for mold slag and high-aluminum steel, which is applied in the field of slab continuous casting production of high-alumina steel ([Al]=0.5% to 3.5%), to prevent slag coiling, well control heat transfer characteristics, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The mold flux for continuous casting of high-alumina steel of the present invention will be further described below in combination with specific examples.

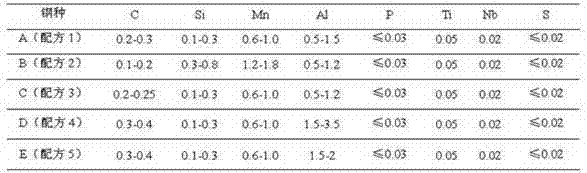

[0048] Table 1 lists the weight percentages of typical chemical components of five examples produced according to the mold powder for continuous casting of high aluminum steel and its manufacturing method of the present invention, and the balance is unavoidable impurities.

[0049] Table 2 lists the weight ratios of mold flux premelting raw materials in five examples.

[0050] Table 3 lists some important properties corresponding to the mold fluxes of the five examples.

[0051] Table 4 lists the typical components of the mold fluxes of the five embodiments corresponding to the cast steel types.

[0052]

[0053] Table 1 Typical chemical composition of continuous casting mold flux (weight percent, %)

[0054]

[0055] Table 2 Weight ratio of premelted raw materials for continuous casting mold flux

[0056] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com