Light catalyzed water treatment equipment of 3D fiber layer of titanium dioxide

A water purification treatment device, titanium dioxide technology, applied in the direction of oxidized water/sewage treatment, light water/sewage treatment, energy wastewater treatment, etc., can solve the constraints of technology scale, industrialization development, low light utilization rate, reaction Slow speed and other problems, to achieve the effect of low cost, improved utilization rate, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

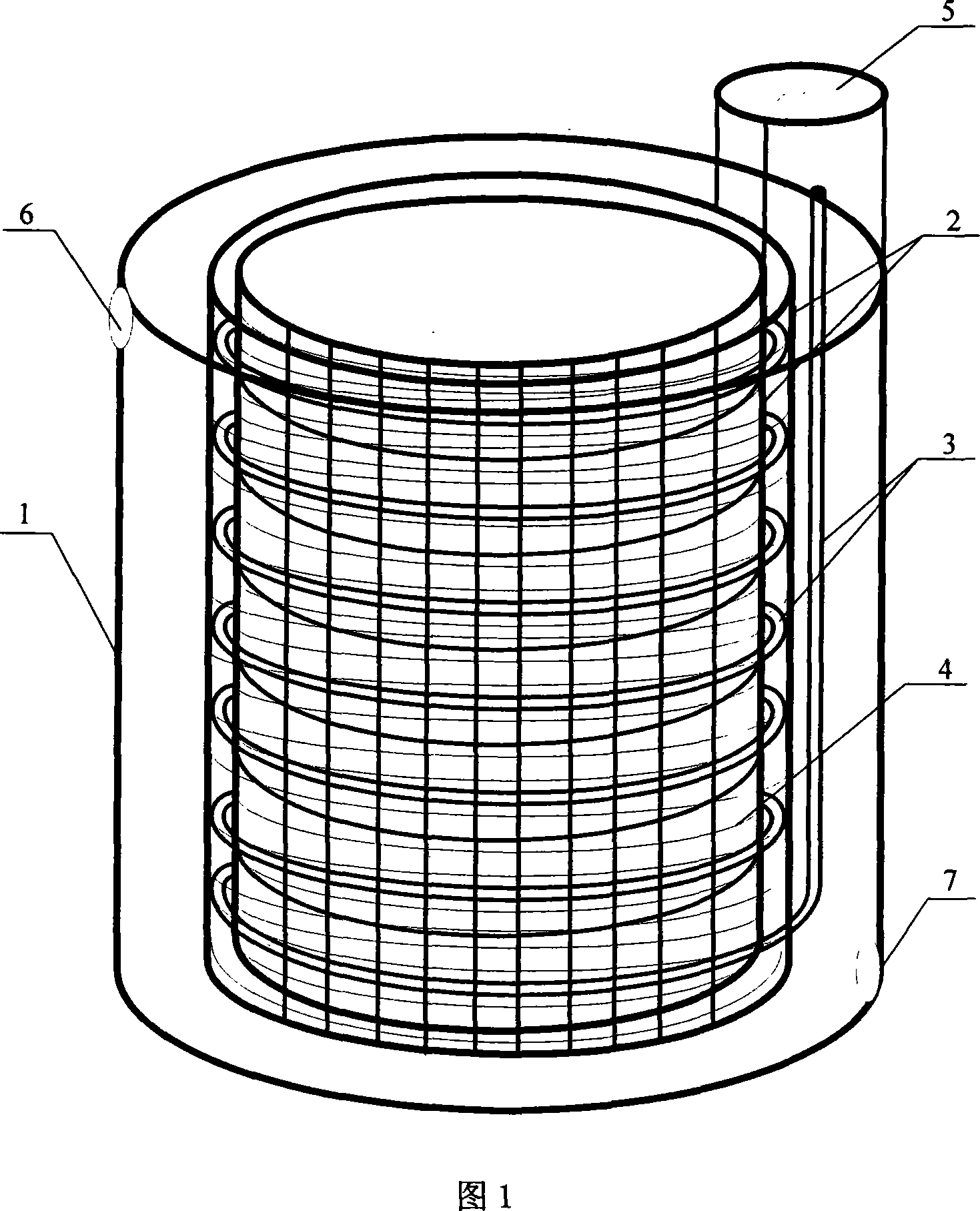

[0020] As shown in Figure 1: it includes a plexiglass cylinder 1, and two aluminum mesh cylinders 2 of the same height are installed in it, and the optical fiber bundle 3 and the three-dimensional titanium dioxide fiber are installed between the two aluminum mesh cylinders 2. The interlayer made of layer 4 composite.

[0021] Wherein 3 is divided into two parts, namely the helical part and the straight line part, at the tail end of the helix, the optical fiber is led along a straight line to the upper end surface of the plexiglass cylinder 1; the manufacturing method of the three-dimensional titanium dioxide fiber layer 4 is: Pour the spinning solution of titanium dioxide precursor into the centrifuge tube, and the centrifuge tube is fixed on the rotating mold, and the rotating mold is turned on at a speed of 6000r / min, so that it is translated and move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com