High-efficiency decolorization and recycling method of printing wastewater

A technology for printing wastewater and decolorization, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sewage treatment, etc., can solve the problems of complex treatment process, complex equipment, high treatment cost, etc., achieve low cost, avoid discharge, reduce the effect of pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

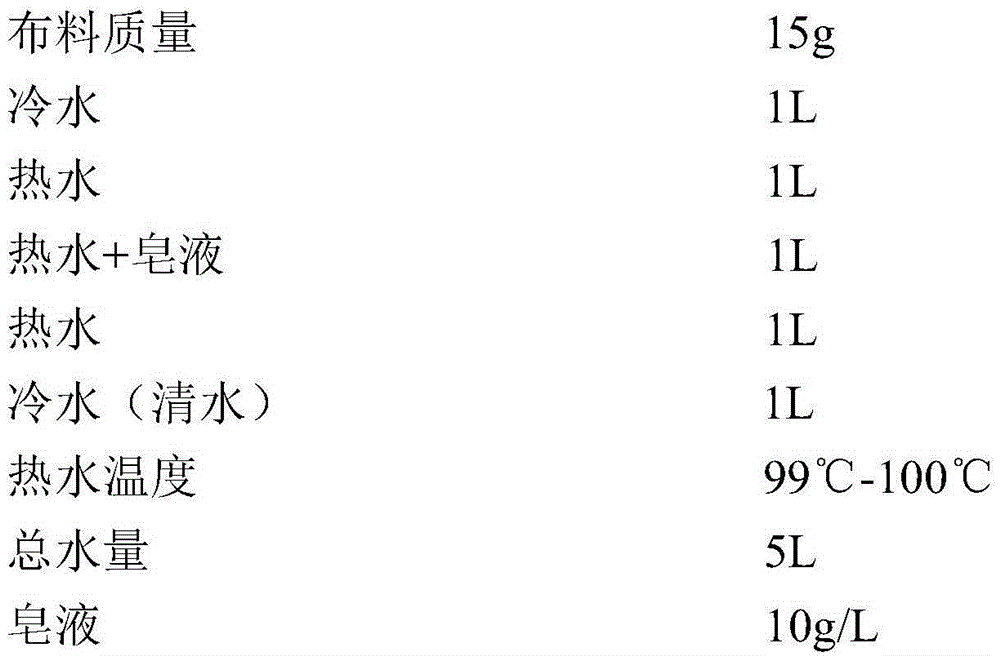

Image

Examples

Embodiment 1

[0034] A high-efficiency decolorization and reuse method for printing waste water, comprising the following steps:

[0035] Collect 3000mL of printing waste water in the reactor, slowly add sulfuric acid to adjust the pH value of the waste water to 3-4;

[0036] Mix tributyl phosphate and aviation kerosene uniformly at a volume ratio of 2:8 to obtain a decolorizing solution;

[0037] Take 100ml of the decolorizing solution and add it to the printing waste water adjusted to pH for decolorization treatment. After reacting for 30 minutes, let it stand for 30 minutes to obtain the loaded decolorizing solution of the upper layer and the reused water of the lower layer.

[0038] It can be observed that the recycled water in the lower layer is nearly colorless, and the decolorization rate reaches 99%.

[0039] Add 18ml of sodium hydroxide solution with a mass concentration of 20% to the loaded decolorizing solution on the upper layer, and react for 30 minutes. The dye loaded in the ...

Embodiment 2

[0048] A high-efficiency decolorization and reuse method for printing waste water, comprising the following steps:

[0049] Collect 3000mL of printing waste water in the reactor, slowly add sulfuric acid to adjust the pH value of the waste water to 3-4;

[0050] Mix trioctyl phosphate and aviation kerosene in a volume ratio of 3:7 to obtain a decolorizing solution;

[0051] Take 80ml of the decolorizing solution and add it to the printing waste water with adjusted pH for decolorization treatment. After reacting for 35 minutes, let it stand for 35 minutes to obtain the loaded decolorizing solution of the upper layer and the reused water of the lower layer.

[0052] It can be observed that the recycled water in the lower layer is nearly colorless, and the decolorization rate reaches 99%.

[0053] Add 20ml of potassium hydroxide solution with a mass concentration of 15% to the loaded decolorizing solution on the upper layer. After reacting for 20 minutes, the dye loaded in the dec...

Embodiment 3

[0057] A high-efficiency decolorization and reuse method for printing waste water, comprising the following steps:

[0058] Collect 3000mL of printing waste water in the reactor, slowly add sulfuric acid to adjust the pH value of the waste water to 3-4;

[0059] Mix trioctylphosphine and sulfonated kerosene uniformly at a volume ratio of 4:6 to obtain a decolorizing solution;

[0060] Take 100ml of the decolorizing solution and add it into the printing waste water with adjusted pH for decolorization treatment. After reacting for 60 minutes, let it stand for 60 minutes to obtain the loaded decolorizing solution of the upper layer and the reused water of the lower layer.

[0061] It can be observed that the recycled water in the lower layer is nearly colorless, and the decolorization rate reaches 99%.

[0062] Add 15ml of sodium carbonate solution with a mass concentration of 10% to the loaded decolorizing solution on the upper layer. After reacting for 30 minutes, the dye load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com