Method and device for treating chlorosilane tail gas

A technology for tail gas treatment and chlorosilane, applied in the direction of halosilane, separation methods, chemical instruments and methods, etc., can solve environmental pollution, the production cost of polysilicon enterprises is not competitive, increase the consumption of raw silicon powder and liquid chlorine, etc. , to achieve the effect of less investment, improving the utilization rate of water resources and reducing water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

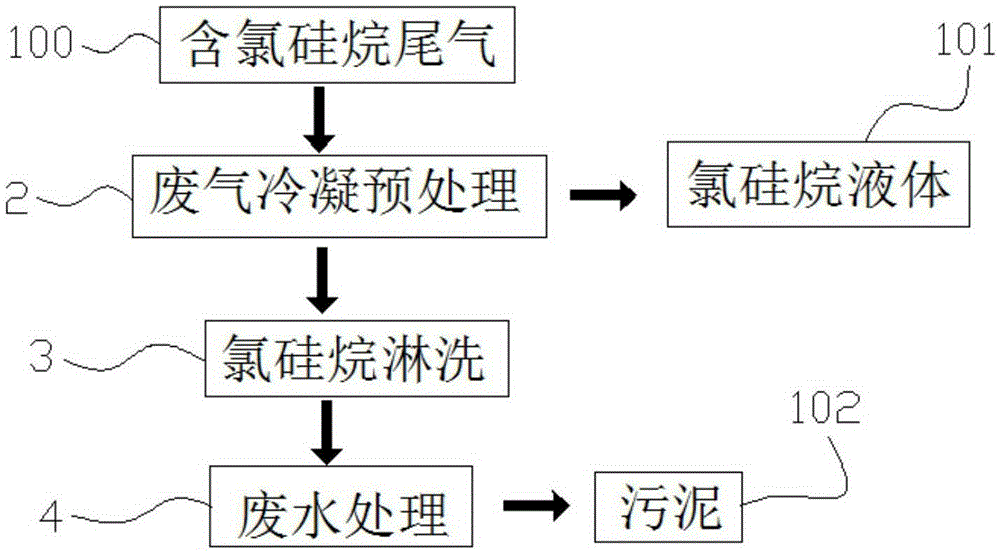

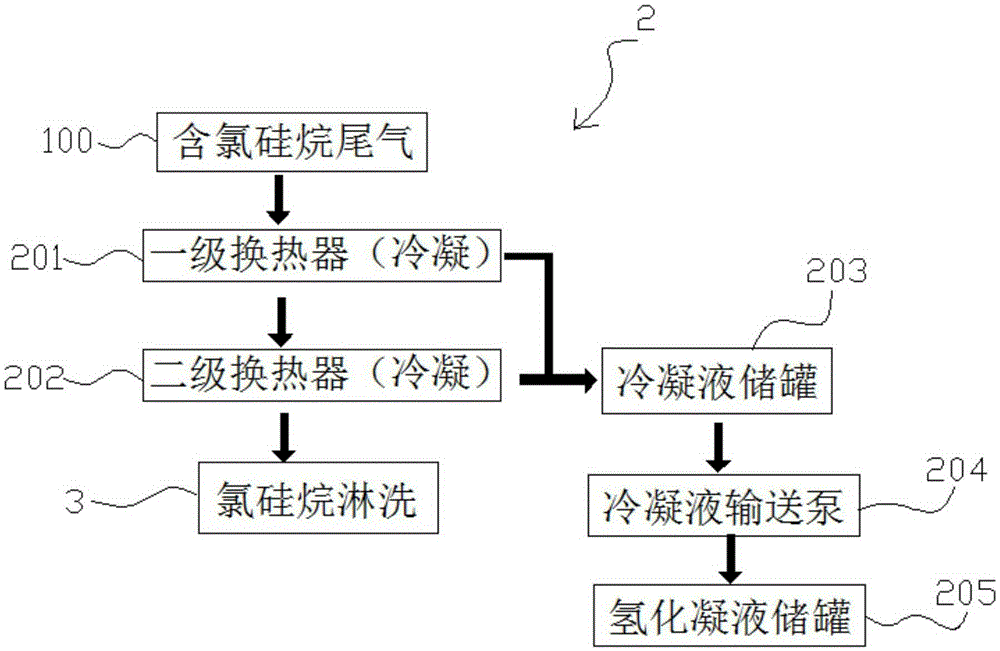

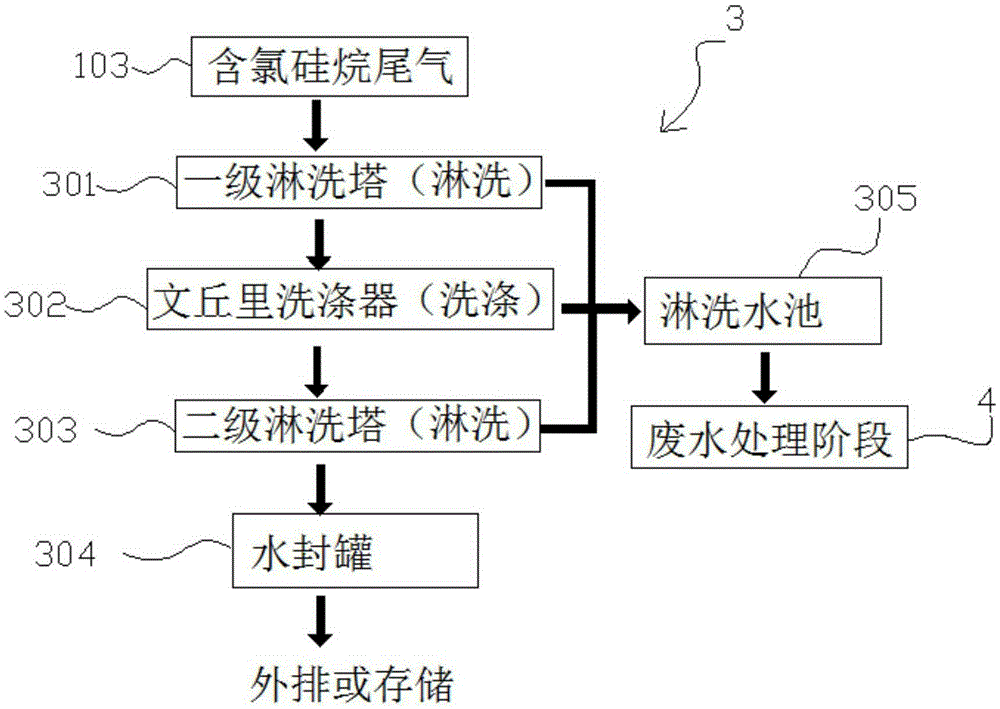

[0032] Such as figure 1 Shown is the main process flow of the present invention-a method for treating chlorosilane tail gas. The treated chlorosilane tail gas is the tail gas containing a large amount of silicon tetrachloride, trichlorosilane and polysilane produced in the polysilicon reduction process section. ;The tail gas treatment capacity of the whole tail gas can reach 8000Nm3 / h, the chlorosilane contained in the tail gas is 1250kg / h, and the others are non-condensable gases. The treatment process includes the following steps: the tail gas 100 containing chlorosilanes passes through 1) waste gas condensation pretreatment stage 2, the temperature of the chlorosilane gases contained in the waste gas is reduced below the boiling point, so that most of the chlorosilane gases in the tail gas are transformed from gaseous state The chlorosilane liquid 101 in liquid state is stored for later use; the remaining uncondensed tail gas and other non-condensable gases are processed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com