Efficient decolorization process for wastewater generated by brewing of white spirit

A technology for treating process and waste water, which is applied in the field of high-efficiency decolorization and removal of organic matter. It can solve the problems of insufficient decolorization effect, difficult engineering application, and high cost, so as to prolong the biodegradation time, ensure complete decomposition, prolong The effect of dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0024] Treated water volume: 1m 3 / h

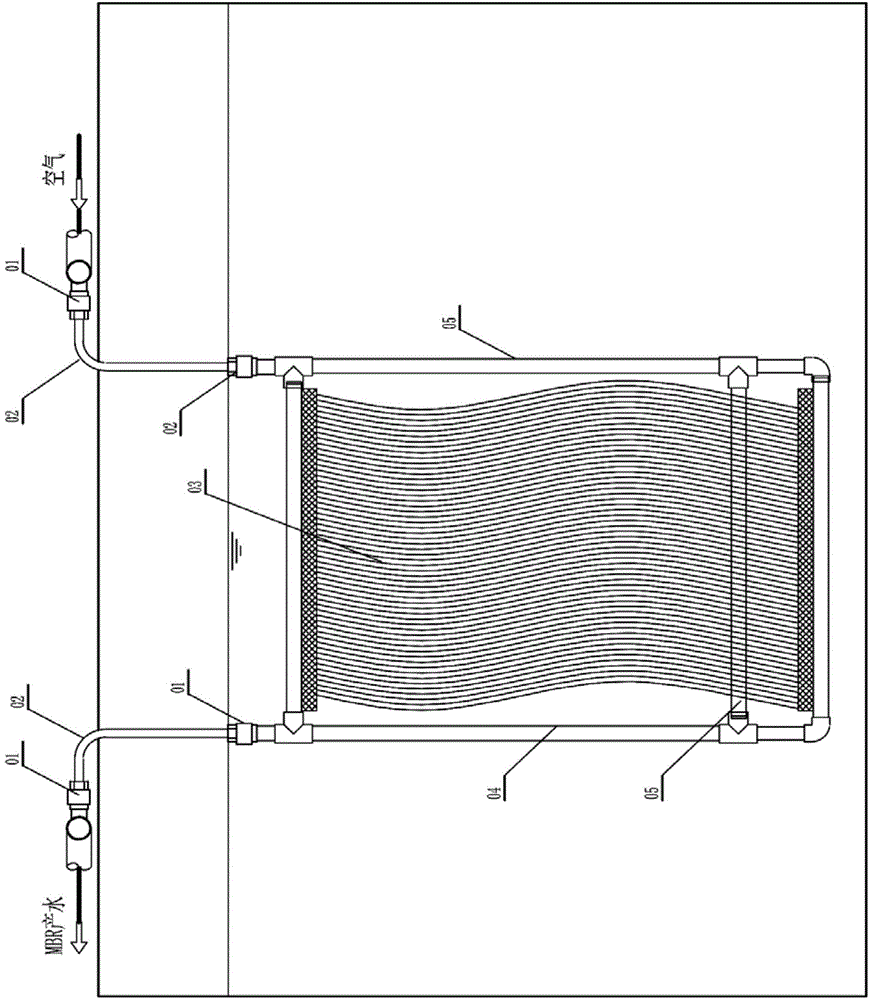

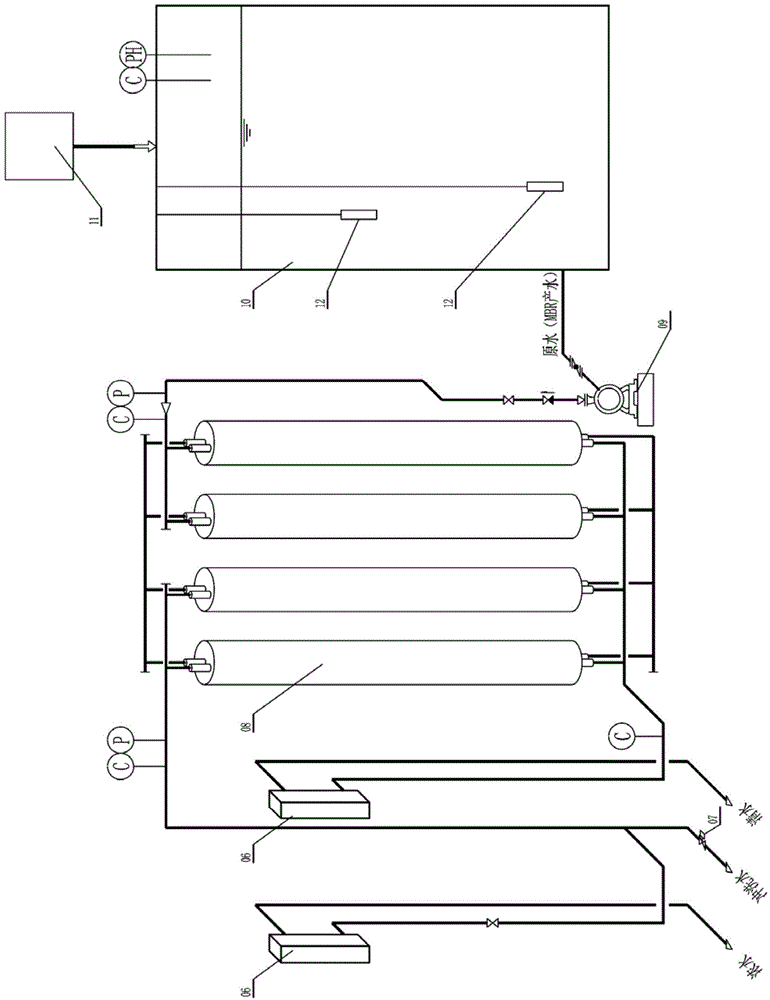

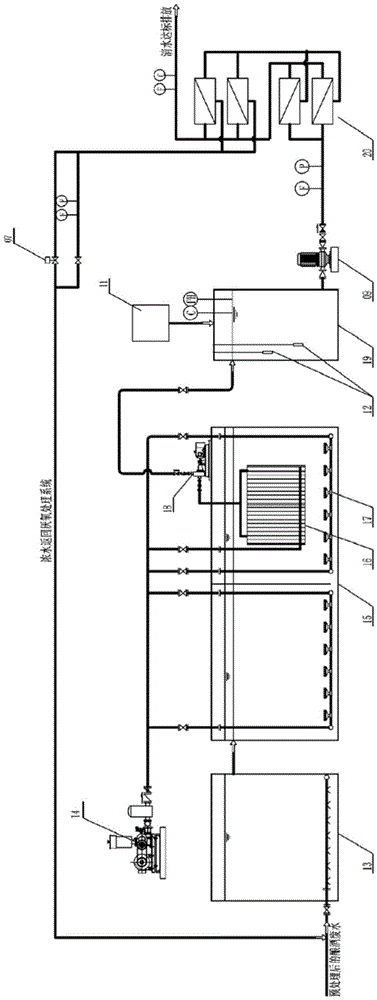

[0025] The brewing wastewater enters the anaerobic tank after pretreatment such as screening, slag removal and pH adjustment. After anaerobic treatment, most of the organic matter and part of the color are removed, and then enters the aerobic tank for aerobic decomposition. An MBR device is installed at the end of the aerobic tank, and the MBR device is connected to a self-priming pump. The activated sludge in the mixed solution of the aerobic tank is intercepted by the MBR membrane, and the clear water passing through the MBR is sucked into the storage tank by the self-priming pump, and then passed through the booster pump. It is sent to the nanofiltration membrane filtration device for membrane separation, in which particles above 0.5-5 nanometers, including color components and other particles, are intercepted by the nanofiltration membrane to form concentrated water and then returned to the anaerobic pool for further processing; The ...

Embodiment 1

[0026] The device used in Embodiment 1: the installed power is 1.0KW, and the components of the device are shown in Table 1. The schematic diagram of the connection structure of each part of the device is shown in image 3 shown.

[0027] Table 1: MBR+NF device

[0028]

[0029] The treatment effect of Example 1 on wastewater is shown in Table 2.

[0030] Table 2: Decolorization effect of MBR+NF

[0031] water sample

pH

COD Cr (mg / l)

Chroma (dilution factor)

6.60

2467

128

7.40

276

64

MBR outlet

7.60

161.7

32

7.50

59.2

2

[0032] The process of Example 1 is compared with the conventional waste water treatment process, and the obtained results are shown in Table 3.

[0033] Table 3: Comparative test decolorization effect

[0034]

Embodiment example 2

[0036] Treated water volume: 1m 3 / h

[0037] The brewing wastewater enters the anaerobic tank after pretreatment such as screening, slag removal and pH adjustment. After anaerobic treatment, most of the organic matter and part of the color are removed, and then enters the aerobic tank for aerobic decomposition. An MBR device is installed at the end of the aerobic tank, and the MBR device is connected to a self-priming pump. The activated sludge in the mixed solution of the aerobic tank is intercepted by the MBR membrane, and the clear water passing through the MBR is sucked into the storage tank by the self-priming pump, and then passed through the booster pump. It is sent to the ultrafiltration membrane filtration device for membrane separation, in which particles above 0.5-5 nanometers, including color components and other particles, are intercepted by the ultrafiltration membrane to form concentrated water and then returned to the anaerobic pool for further processing; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com