Multifunctional pressure chemical degreasing sewage purification equipment

A kind of purification equipment and pressure-type technology, which is applied in the direction of chemical instruments and methods, filtration separation, filtration circuit, etc., can solve the problems of unsatisfactory treatment effect, small footprint, large footprint, etc., to achieve high cost performance and save floor space The effect of land area and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

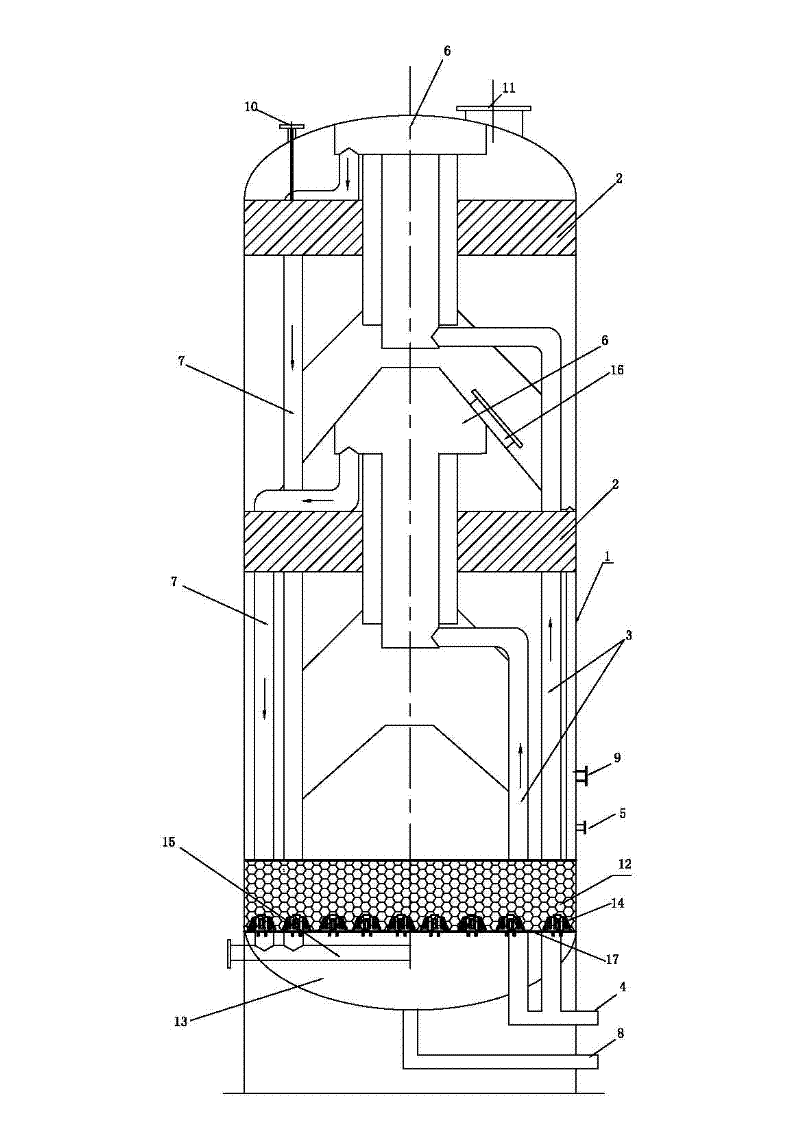

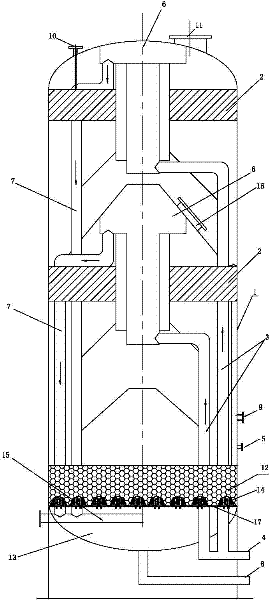

[0021] Such as figure 1 shown.

[0022] A multifunctional pressure-type chemical degreasing sewage purification equipment, which includes a housing 1, an automatic air release valve 10 and manholes 11, 16 for maintenance are installed on the upper part of the housing 1, and the housing 1 is provided with at least two Two independent sedimentation areas 2, the sedimentation area 2 can adopt the commonly used PVC inclined pipe packing structure or shallow filter material type structure in the existing sewage treatment, the sewage in the sewage water inlet pipe 3 directly enters the sedimentation area 2, each sedimentation The sewage inlet pipes 3 in the area are all connected to the high-pressure sewage pipe 4, and the sewage inlet pipe 3 is provided with a dosing port 9, and the sewage directly reacts with the medicine during the rising process, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com