High-COD phenol-containing sewage treatment method

A sewage treatment method and phenolic technology, which is applied in the field of high COD and phenolic sewage treatment, can solve the problems of excessive COD, unsolvable, strong toxicity, etc., and achieve the effects of reducing treatment load, reducing chroma, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

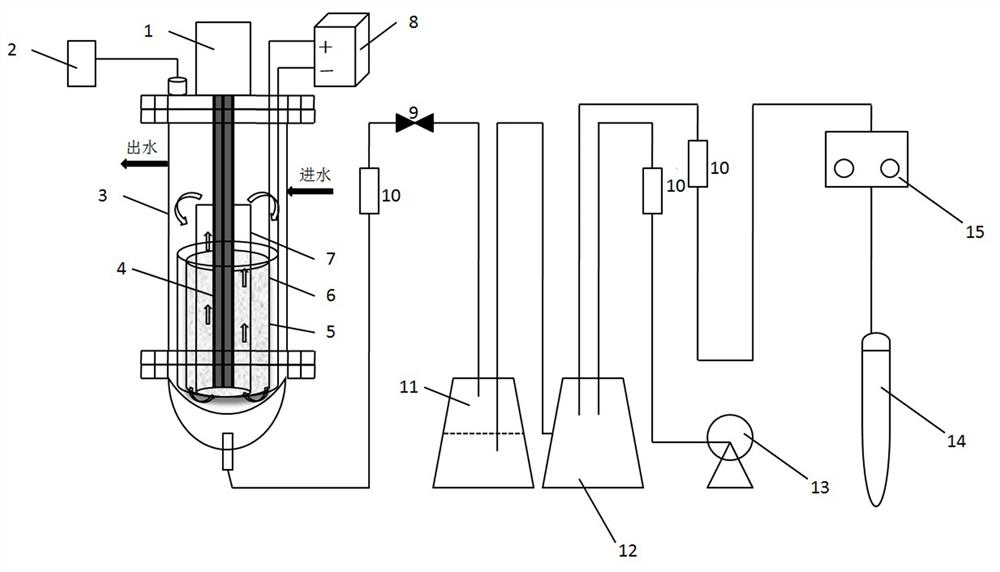

Image

Examples

Embodiment 1

[0033] A kind of high COD contains phenolic sewage treatment method, comprises the following steps:

[0034] Step 1. Phenol stripping: Pass the high-COD phenolic sewage into the regulating tank for water quality and water adjustment, remove impurities and suspended solids, and then enter the phenol stripping reactor. The stripping treatment pressure is 0.6MPa, temperature 95°C, blow-off time 4h, collect the separated phenols through the collector, and recycle them. The content of phenols is 27mg / L by sampling at the water outlet, and the removal rate is 87.4%;

[0035] Step 2. Enhanced coagulation: Pass the effluent from the phenol stripping reactor into the enhanced coagulation tank, add composite flocculant, pre-stir at 200r / min for 20s, then stir rapidly at 400r / min for 2min, and then adjust the speed to 50r / min Stir at a slow speed for 10 minutes, stop stirring, and let stand for 15 minutes, then discharge the coagulated sewage to the advection sedimentation tank, let it s...

Embodiment 2

[0043] A kind of high COD contains phenolic sewage treatment method, comprises the following steps:

[0044] Step 1. Phenol stripping: Pass the high COD phenolic sewage into the regulating tank to adjust the water quality and water quantity, remove impurities and suspended solids, and then enter the phenol stripping reactor. The stripping treatment pressure is 0.7MPa, temperature 96°C, blow-off time 3.5h, collect the separated phenols through the collector, and recycle them. The content of phenols in the water outlet is 22mg / L, and the removal rate is 89.7%;

[0045] Step 2. Enhanced coagulation: Pass the effluent from the phenol stripping reactor into the enhanced coagulation tank, add a composite flocculant, pre-stir at 200r / min for 40s, then stir rapidly at 400r / min for 3min, and then adjust the speed to 50r / min Stir at a slow speed for 15 minutes, stop stirring, and let it stand for 25 minutes, then discharge the coagulated sewage to the advection sedimentation tank, let i...

Embodiment 3

[0053] A kind of high COD contains phenolic sewage treatment method, comprises the following steps:

[0054] Step 1. Phenol stripping: Pass the high COD phenolic sewage into the regulating tank to adjust the water quality and water quantity, remove impurities and suspended solids, and then enter the phenol stripping reactor. The stripping treatment pressure is 0.5MPa, temperature 95°C, blow-off time 4h, collect the separated phenols through the collector, and recycle them. The content of phenols was 33mg / L by sampling at the water outlet, and the removal rate was 84.6%;

[0055] Step 2. Enhanced coagulation: Pass the effluent from the phenol stripping reactor into the enhanced coagulation tank, add a composite flocculant, pre-stir at 200r / min for 30s, then stir rapidly at 400r / min for 2min, and then adjust the speed to 50r / min Stir at a slow speed for 13 minutes, stop stirring, and let it stand for 20 minutes, then discharge the coagulated sewage to the advection sedimentation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com