Patents

Literature

406results about How to "Reduced growth rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methods for the identification, assessment, and treatment of patients with cancer therapy

ActiveUS20060281122A1Reduced growth rateEliminate ineffective or inappropriate therapeutic agentsMechanical/radiation/invasive therapiesMicrobiological testing/measurementAbnormal tissue growthRegimen

The present invention is directed to the identification of predictive markers that can be used to determine whether patients with cancer are clinically responsive or non-responsive to a therapeutic regimen prior to treatment. In particular, the present invention is directed to the use of certain individual and / or combinations of predictive markers, wherein the expression of the predictive markers correlates with responsiveness or non-responsiveness to a therapeutic regimen. Thus, by examining the expression levels of individual predictive markers and / or predictive markers comprising a marker set, it is possible to determine whether a therapeutic agent, or combination of agents, will be most likely to reduce the growth rate of tumors in a clinical setting.

Owner:MILLENNIUM PHARMA INC

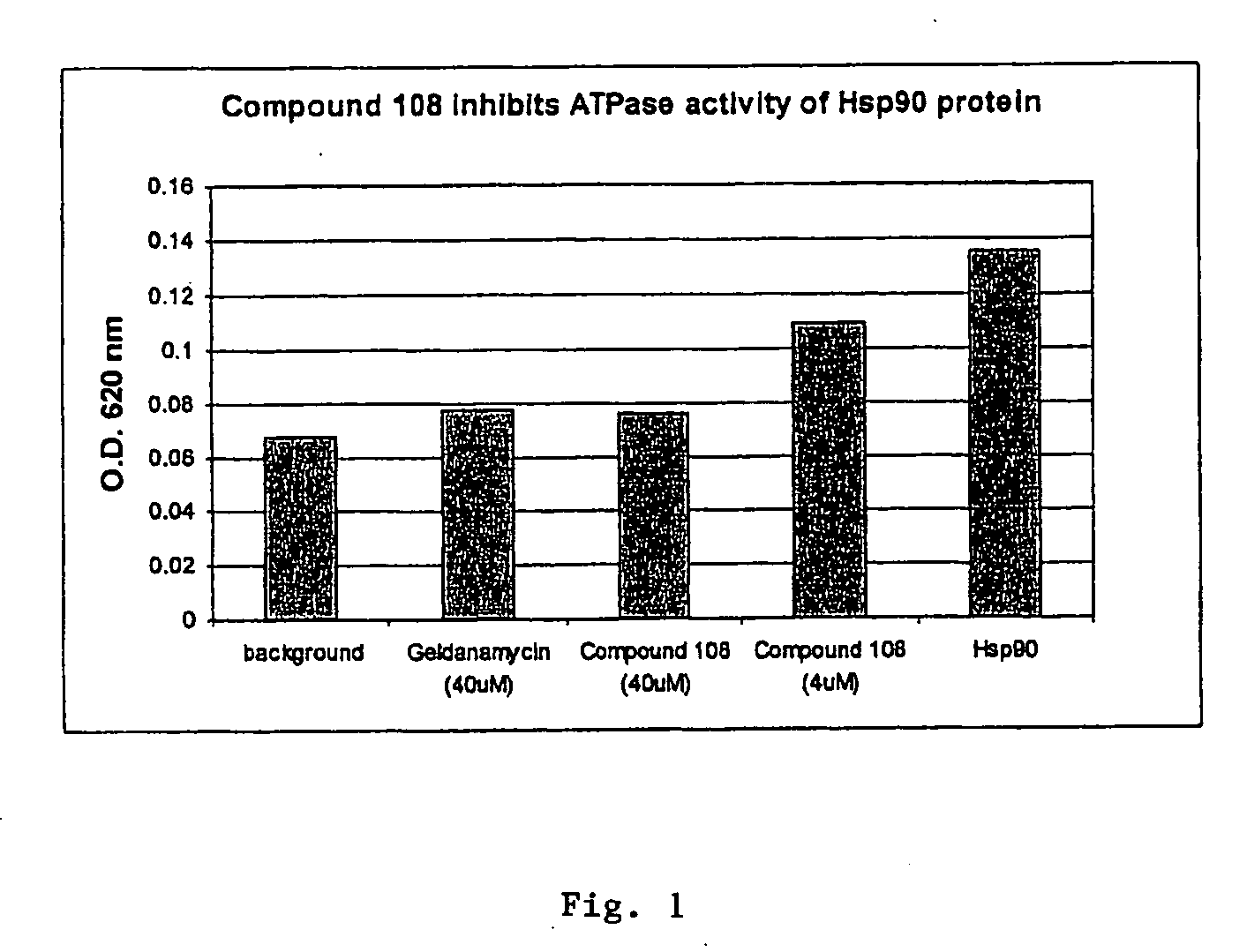

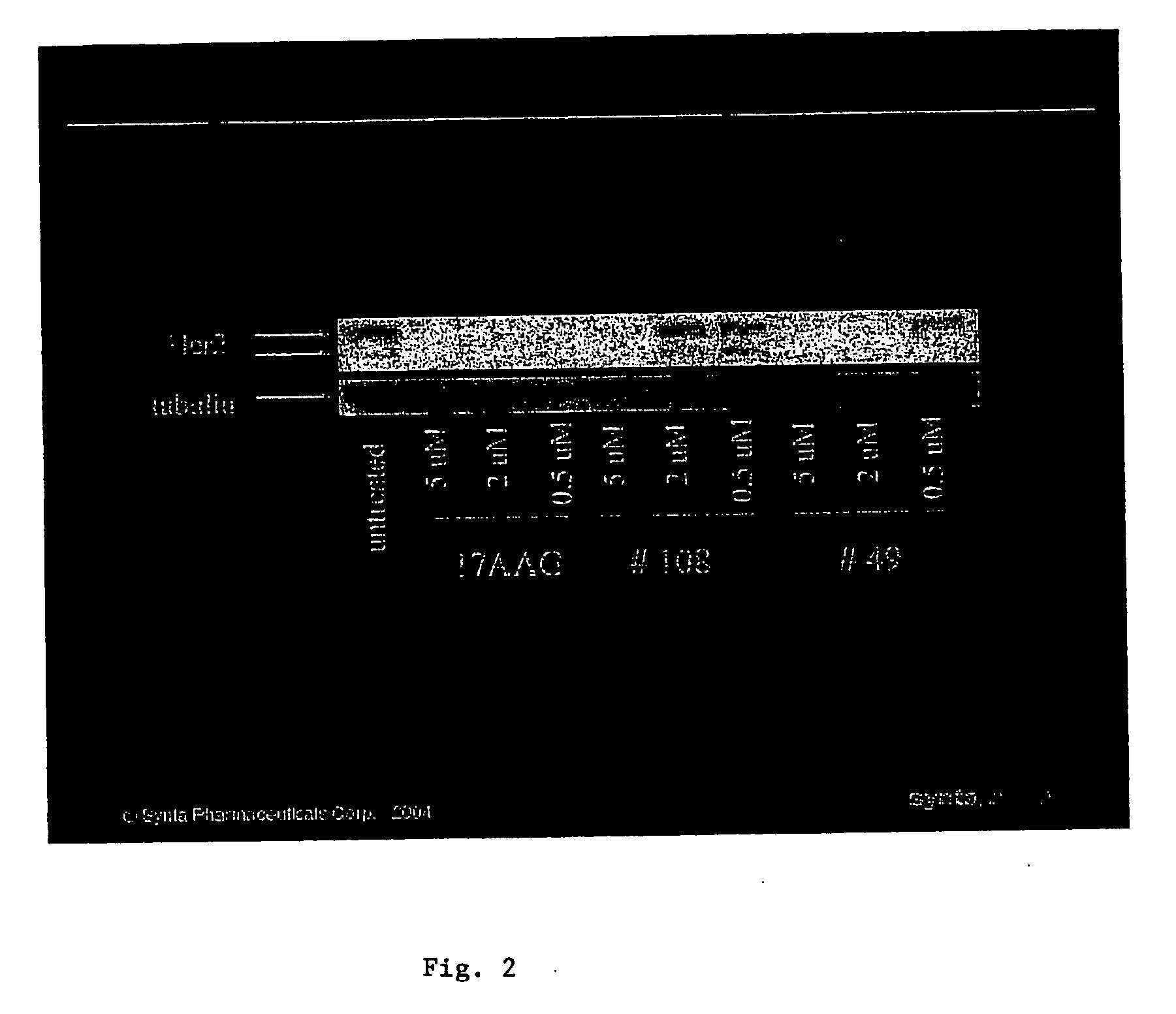

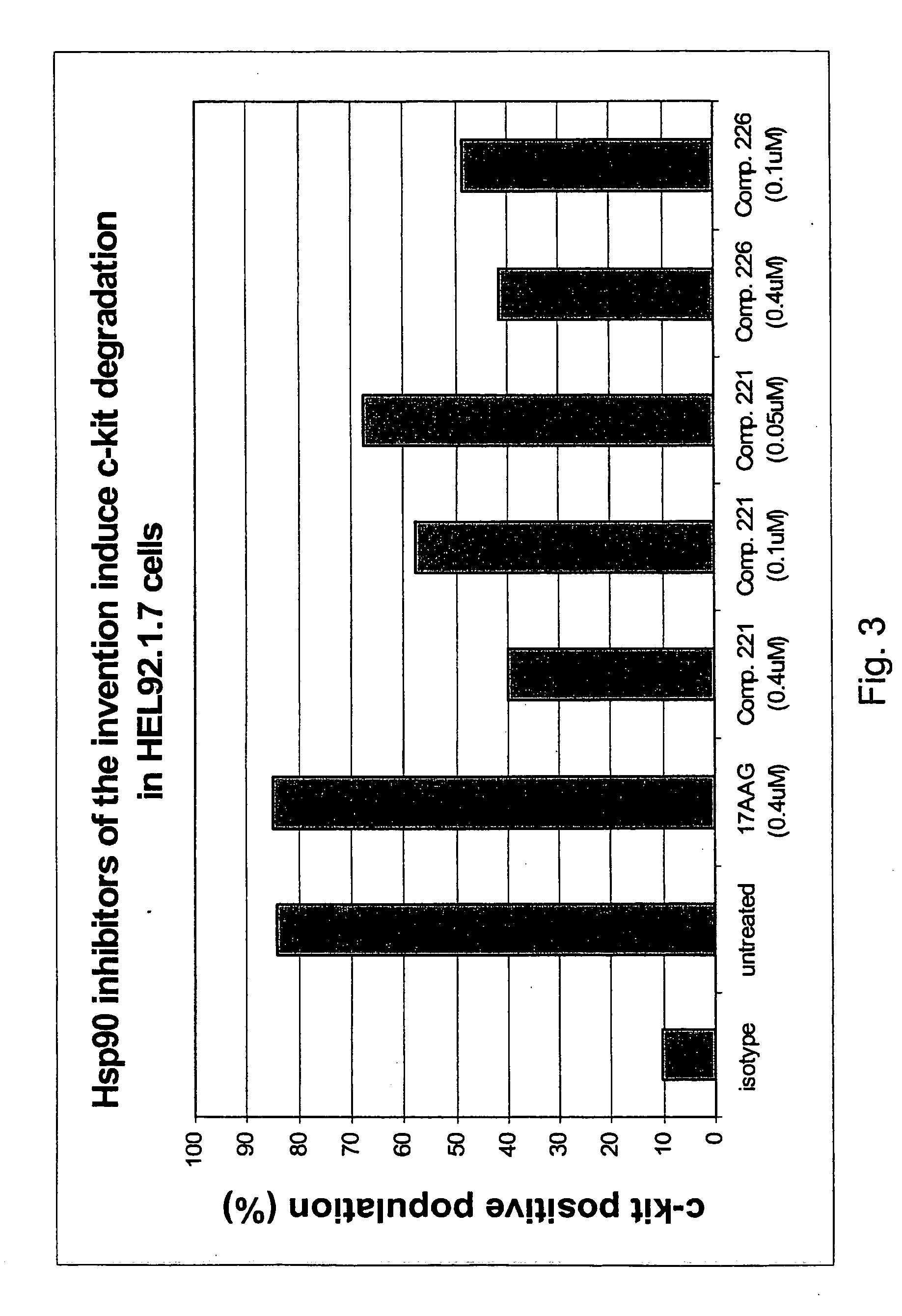

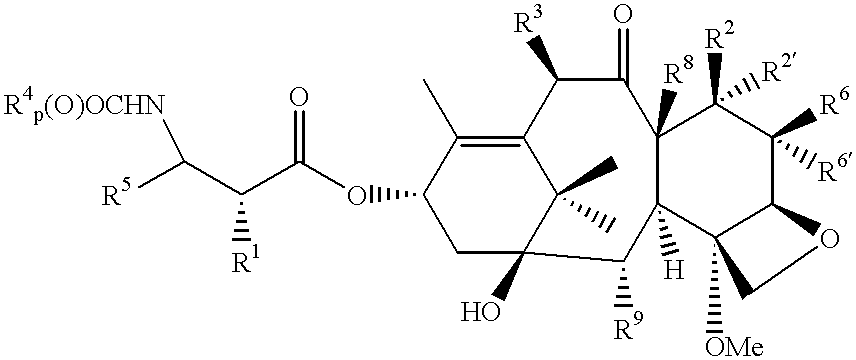

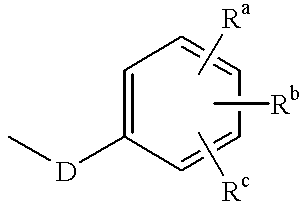

Triazole compounds that modulate Hsp90 activity

ActiveUS20060167070A1Reduced growth rateInhibit tumor growthBiocideOrganic chemistryTriazole antifungalsHSP90 Heat-Shock Proteins

The present invention relates to substituted triazole compounds and compositions comprising substituted triazole compounds. The invention further relates to methods of inhibiting the activity of Hsp90 in a subject in need thereof and methods for preventing or treating hyperproliferative disorders, such as cancer, in a subject in need thereof comprising administering to the subject a substituted triazole compound of the invention, or a composition comprising such a compound.

Owner:SYNTA PHARMA CORP

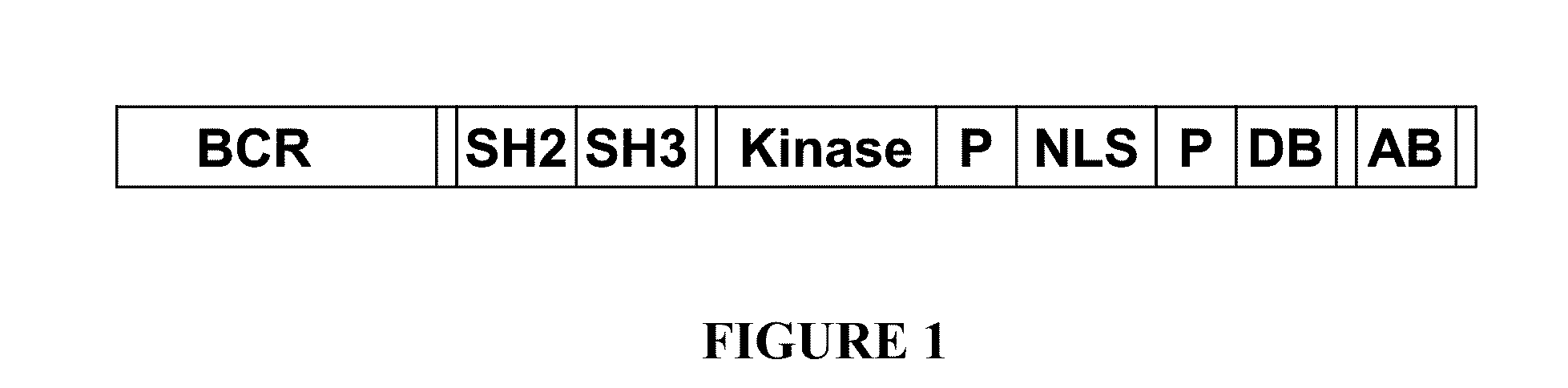

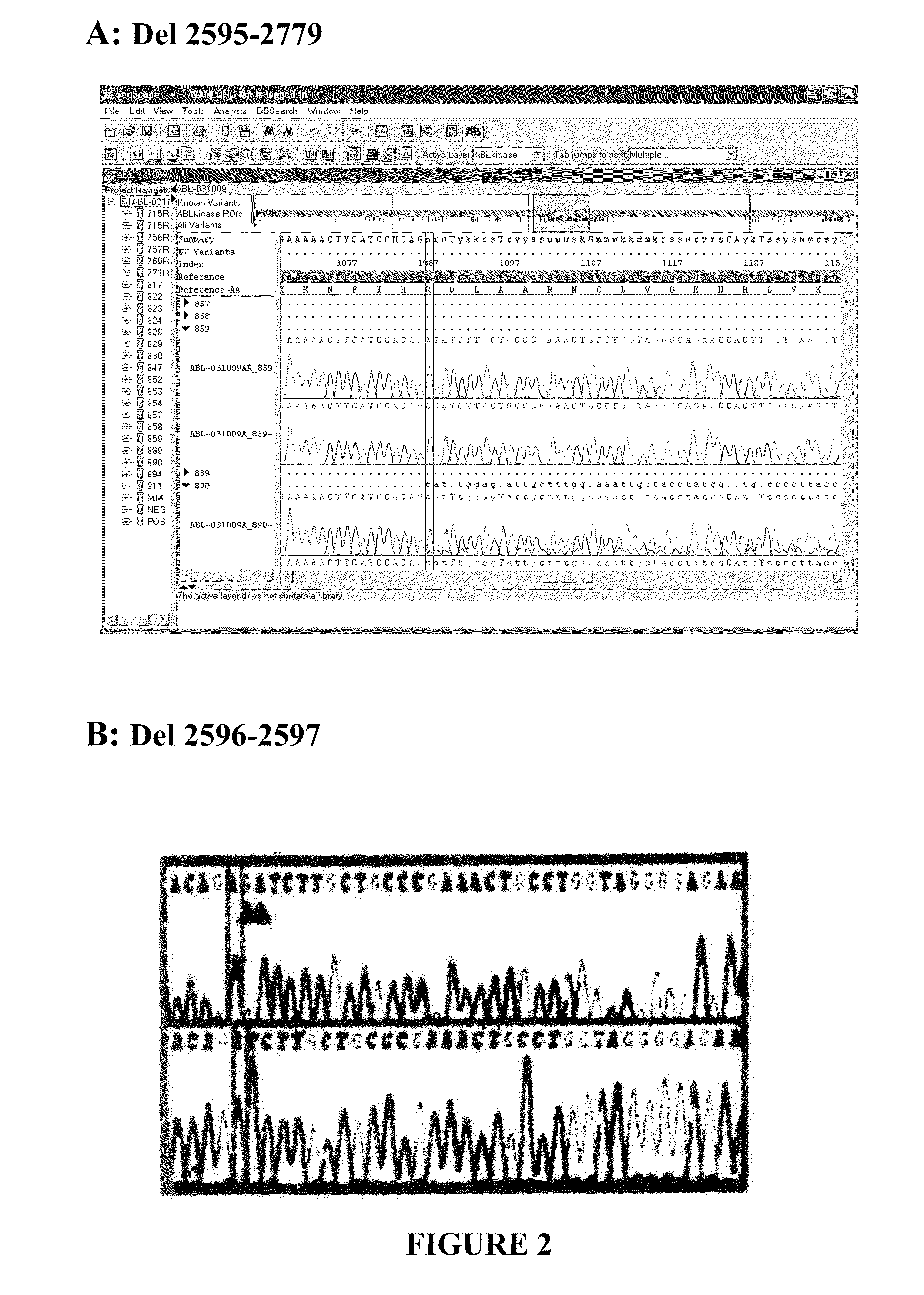

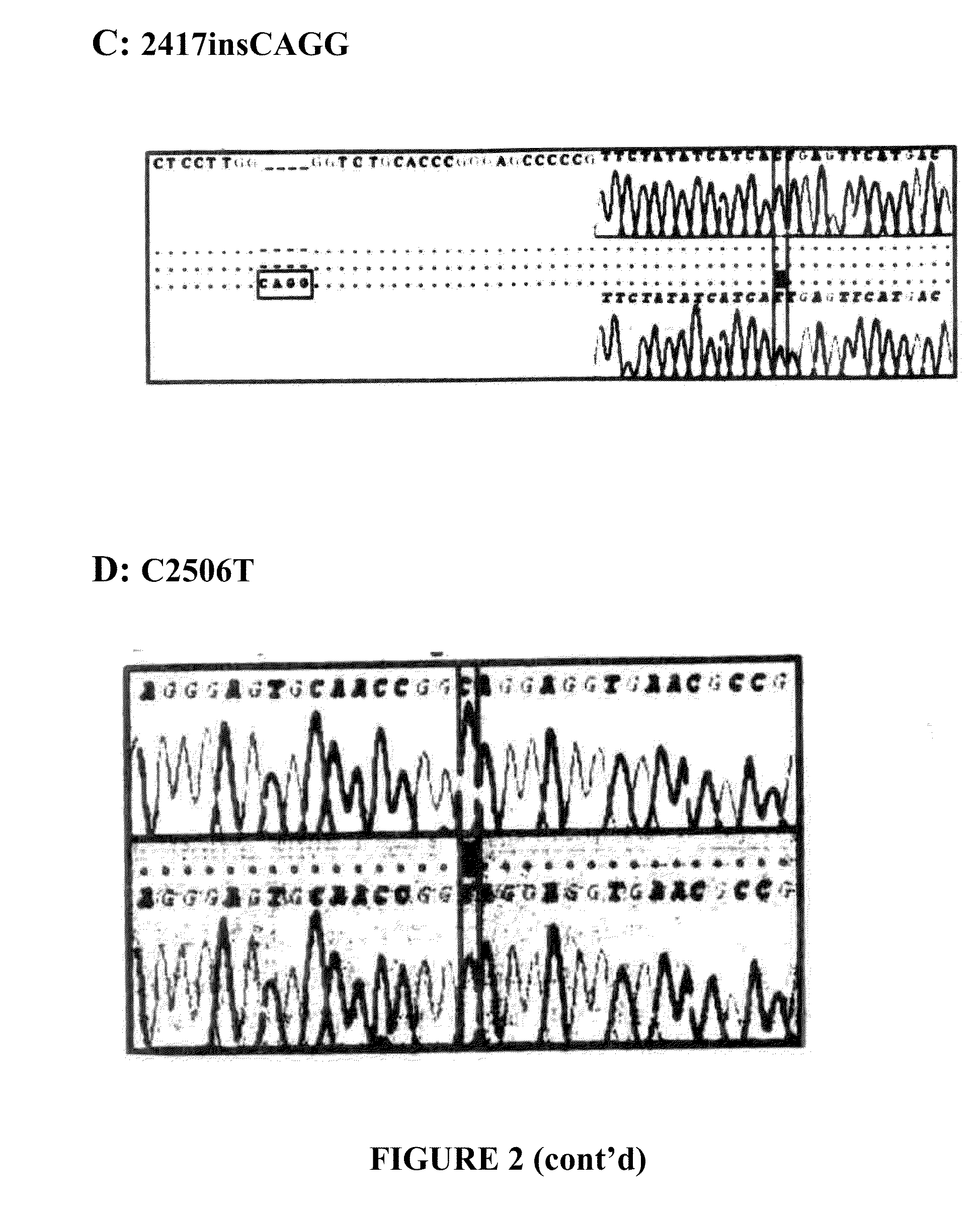

Bcr-abl truncation mutations

ActiveUS20110072889A1Good effectReduced growth rateMicrobiological testing/measurementFlow propertiesGene productTyrosine-kinase inhibitor

Truncation variants of BCR-ABL mRNA that produces BCR-ABL proteins with a truncated C-terminus and its role in resistance to treatment with kinase inhibitors is described. Vectors for expressing the truncated gene products are described as well as recombinant cells that express the truncated gene products from cDNA constructs. Also provided are methods compositions and kits for detecting the BCR-ABL truncation variants. Also provided are methods for determining the prognosis of a patient diagnosed as having myeloproliferative disease, and methods for predicting the likelihood for resistance to a treatment with tyrosine kinase inhibitor in a patient diagnosed as having myeloproliferative disease. Additionally, methods for screening BCR-ABL tyrosine kinase domain inhibitors which rely on the recombinant cells are also disclosed.

Owner:QUEST DIAGNOSTICS INVESTMENTS INC

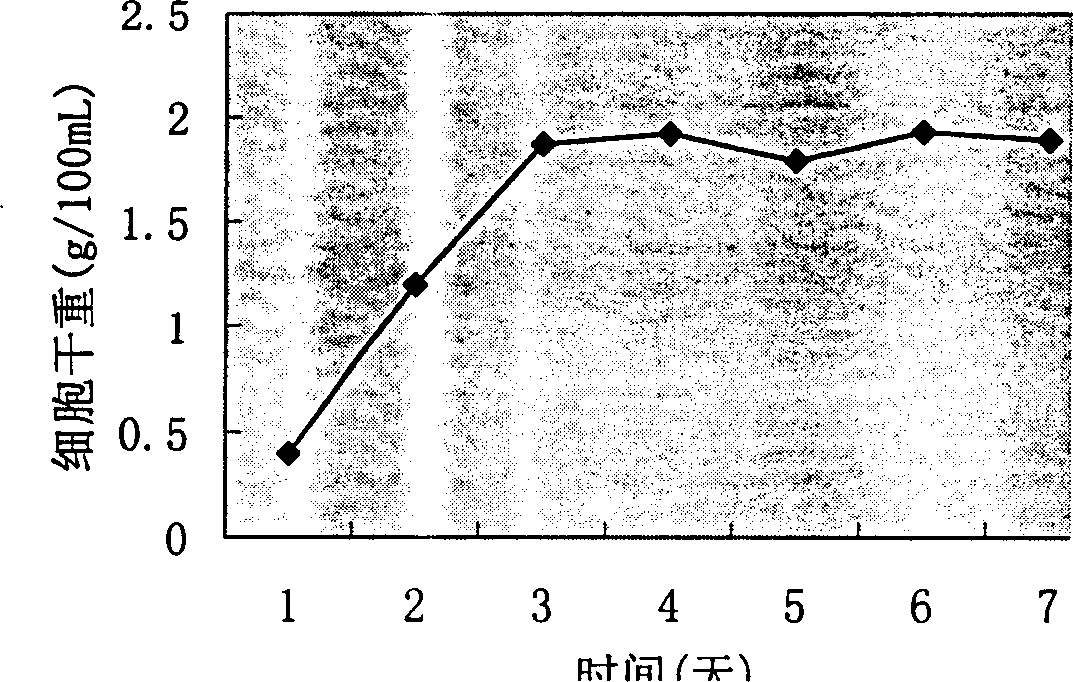

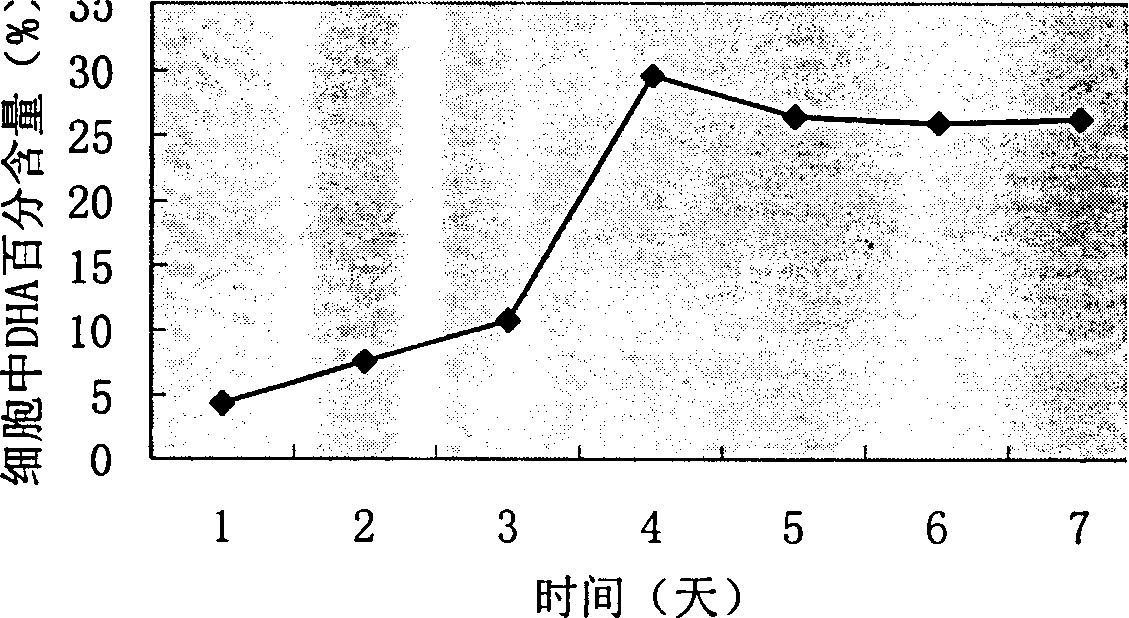

Industrial use of marine fungus fission chytrid OUC88

The present invention relates to the industrial application of ocean fission chytrid OUC88. The ocean fission chytrid OUC88 has capacity of generating rich docosahexaenoic acid (DHA), and has the preservation number of CGMCC No. 1240. The ocean fission chytrid OUC88 is new strain obtain with fission chytrid SR21 as originating strain and through chemical induction mutation and physical induction mutation. Through optimizing culture condition and replenishing carbon source in later culture stage, the present invention has dry cell weight reaching 25 g / L and DHA product up to 8.27 g / L. The thallus may be used as the additive for bread, mild product and other food products, especially baby's milk powder and can promote body's growth. The present invention has simple thallus fermenting process, high bioavailability, high yield of destination product and low cost.

Owner:OCEAN UNIV OF CHINA

Super paramagnetic ferric oxide composite nanometre particle preparation method

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

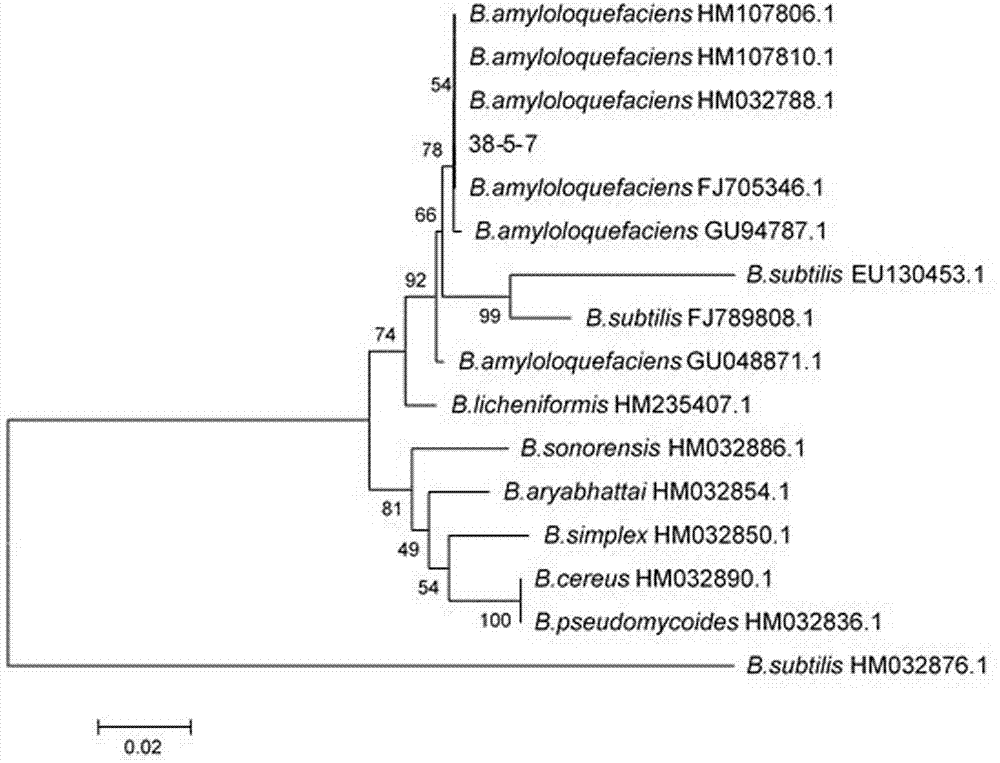

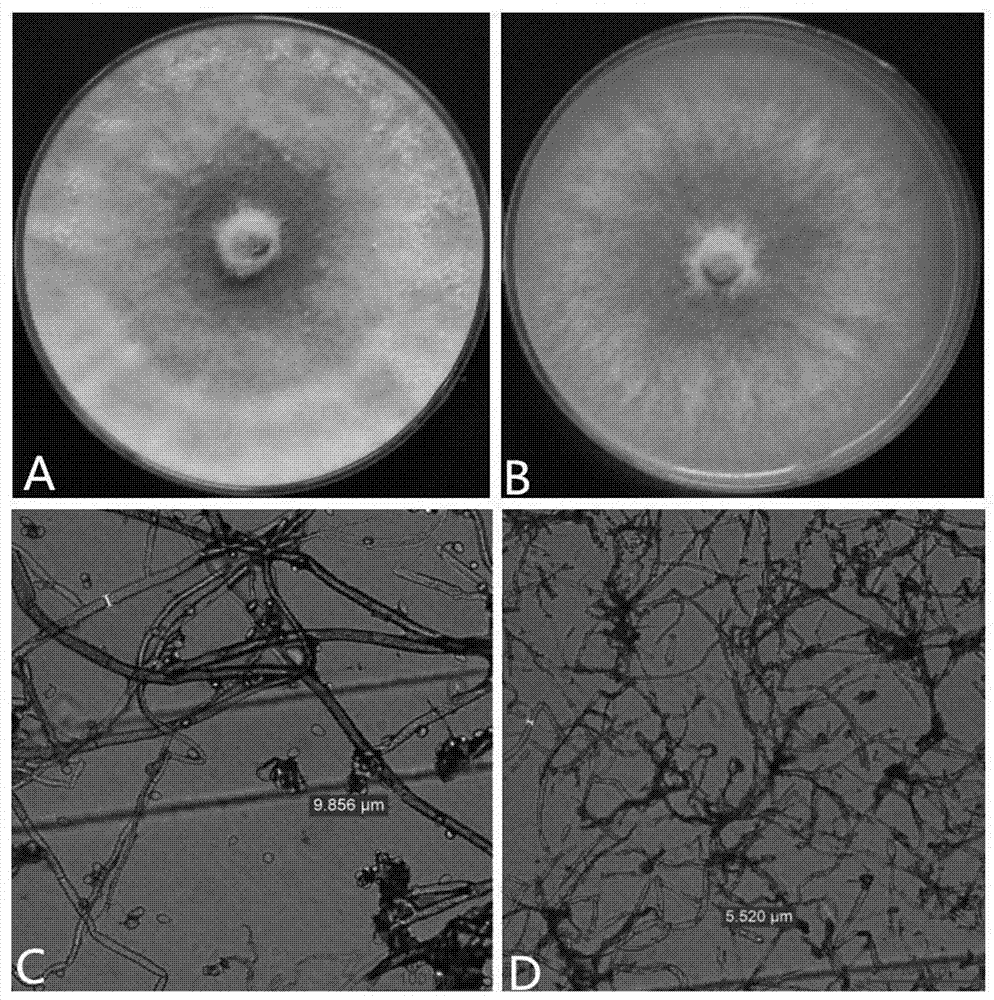

Bacillus amyloliquefaciense BA-KA3 and application thereof

ActiveCN104762223AGood control effectImprove germination rateBiocidePlant growth regulatorsBiotechnologySclerotinia

The invention relates to a Bacillus amyloliquefaciense BA-KA3 and application thereof. The Bacillus amyloliquefaciense BA-KA3 is preserved in China General Microbiological Culture Collection Center on October 23, 2013, and has preservation No. CGMCC8342; its on tomato gray mold germs has obviously of antagonistic anti-role, on wheat scab bacteria. The Bacillus amyloliquefaciense BA-KA3 has obvious antagonistic effect on Fusarium graminearum, Rhizoctonia cerealis, Alternaria alternata, Phytophthora capsici, Colletotrichum capsici, Cercospora personata, Alternaria alternate and Garlic sclerotinia disease, and can significantly improve plant growth indexes such as germination rate, and budding rate and root length of seeds,and especially applies to preparation of agricultural preparations for control of tomato diseases due to Botrytiscinerea invasion and has certain growth promotion effect.

Owner:BIOLOGY INST OF HEBEI ACAD OF SCI

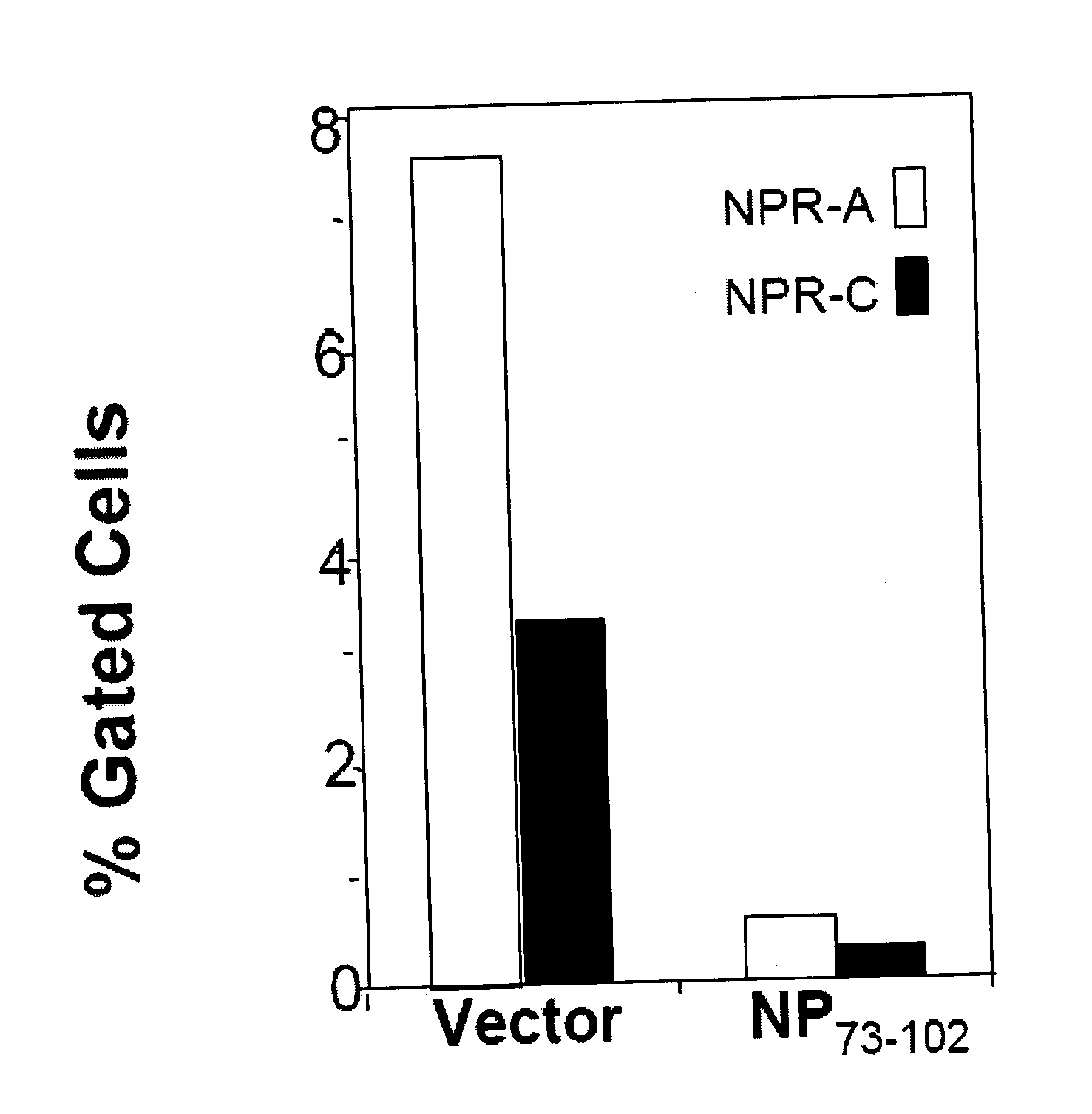

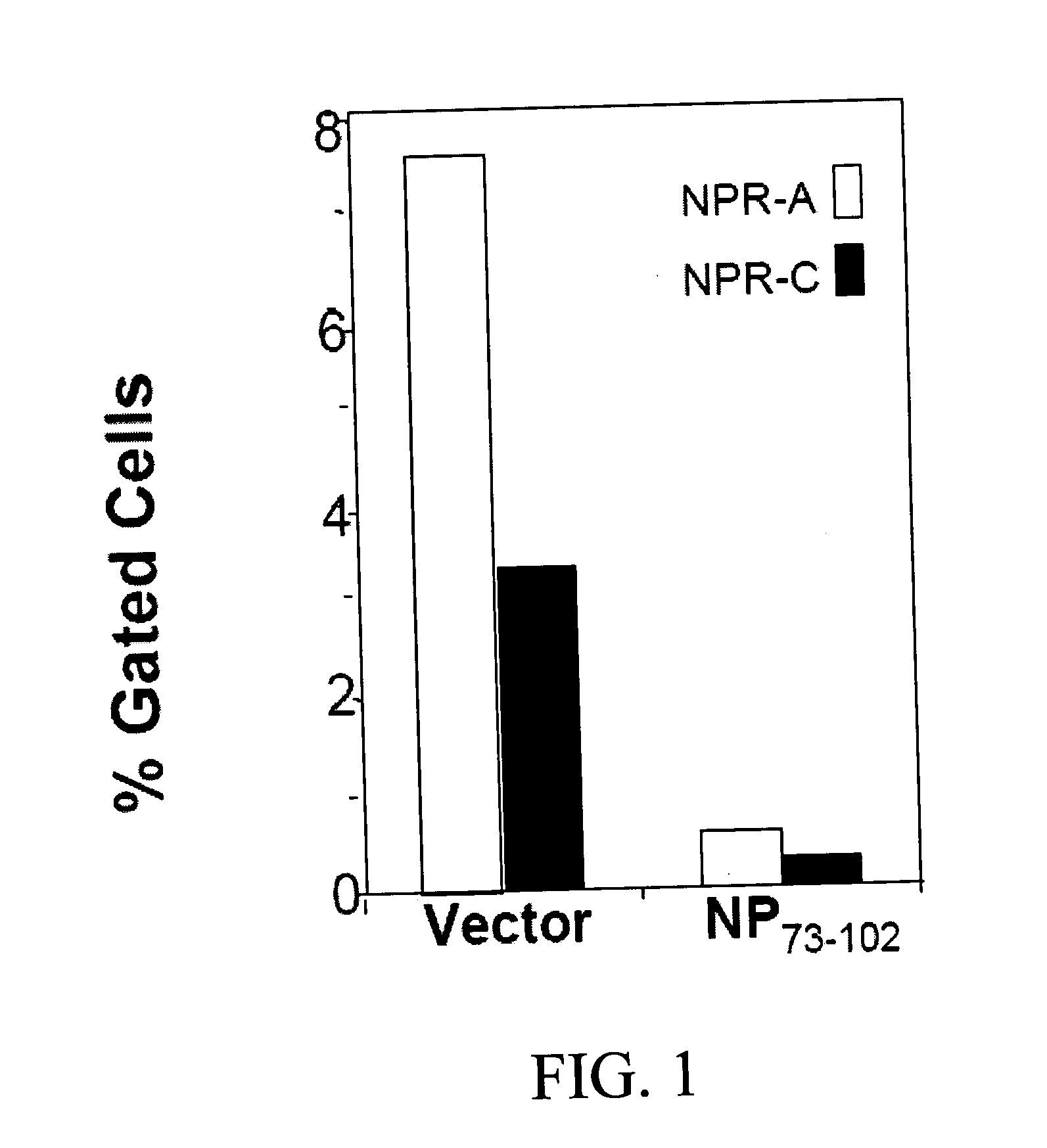

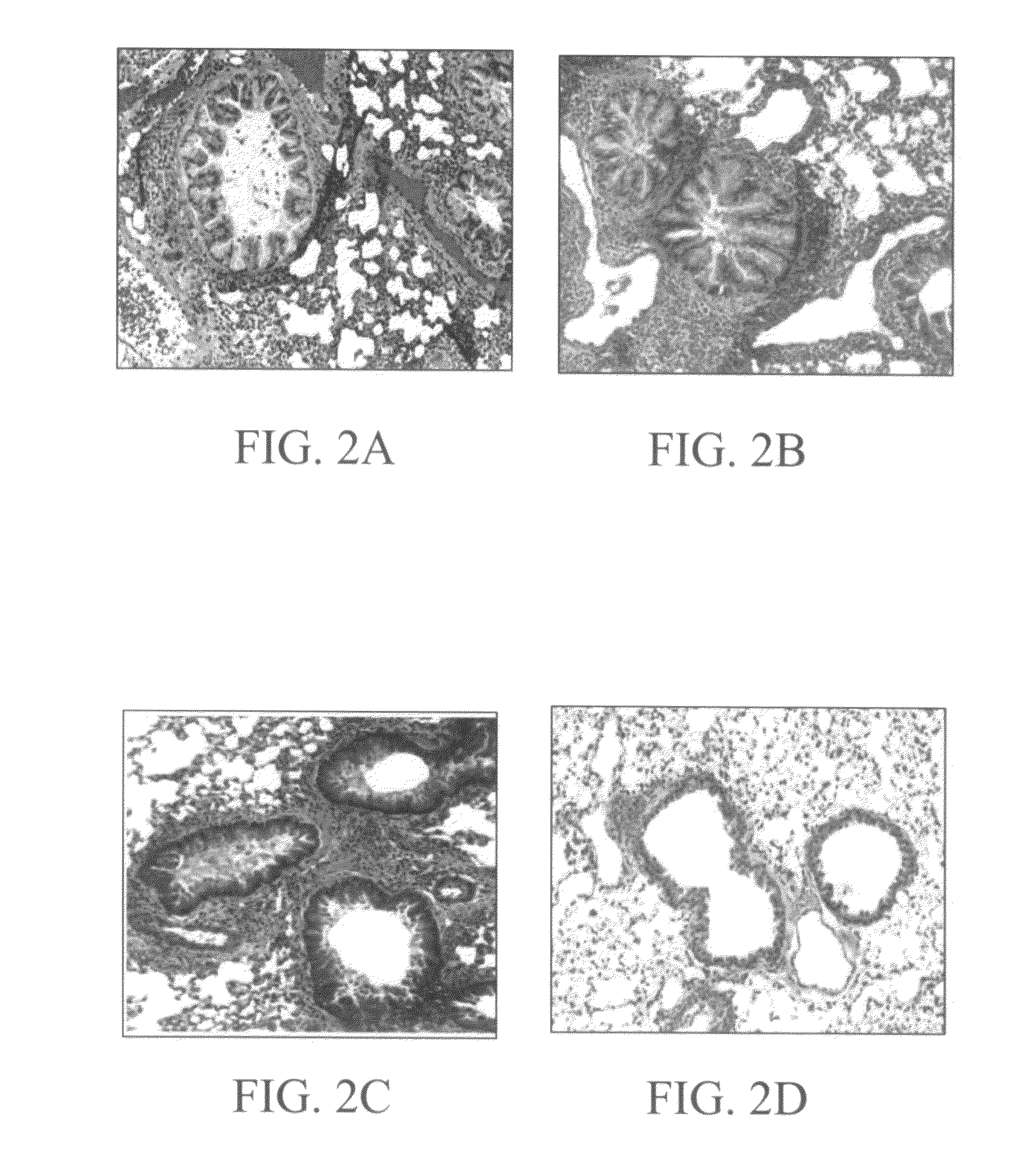

Methods and compositions for reducing activity of the atrial natriuretic peptide receptor and for treatment of diseases

InactiveUS20080214437A1Reduction in formation of tumorIncreased apoptosisCompounds screening/testingOrganic active ingredientsLipid formationDisease

Methods, compositions and devices are provided by the present invention for reducing activity of a natriuretic peptide receptor and other signals. Therapeutic treatments are provided by use of polynucleotides encoding a natriuretic peptide or by regulating the expression of natriuretic peptide receptor, such as NPRA and NPRC, or combinations of these therapies. Routes used for delivering polynucleotides encoding a natriuretic peptide, or, for example, siRNA that down regulates natriuretic peptide receptor include subcutaneous injection, oral gavage, transdermal and intranasal delivery routes. Compositions can include chitosan, chitosan derivatives, and chitosan derivative and a lipid. Transdermal delivery can use a transdermal cream. Intranasal delivery can use a dropper or an aspirator for delivery of a mist. Oral gavage delivers equivalent to oral delivery. Delivery permits cell and tissue specific targeting of gene therapies resulting in expression of a natriuretic peptide or down regulation of natriuretic peptide receptor. A variety of cancers, asthma and viral diseases can be treated therapeutically using the methods and compositions of the present invention.

Owner:MOHAPATRA SHYAM S +4

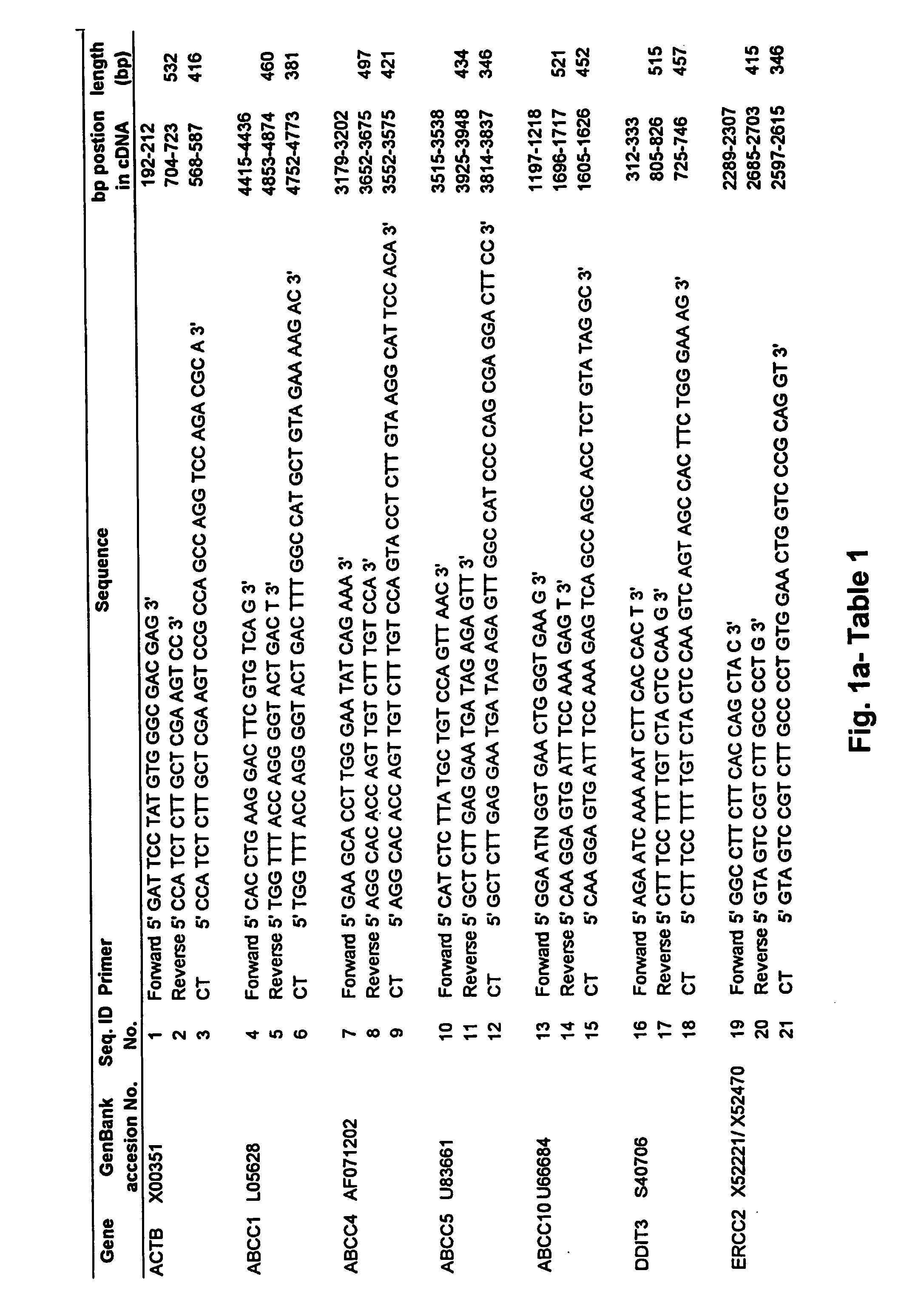

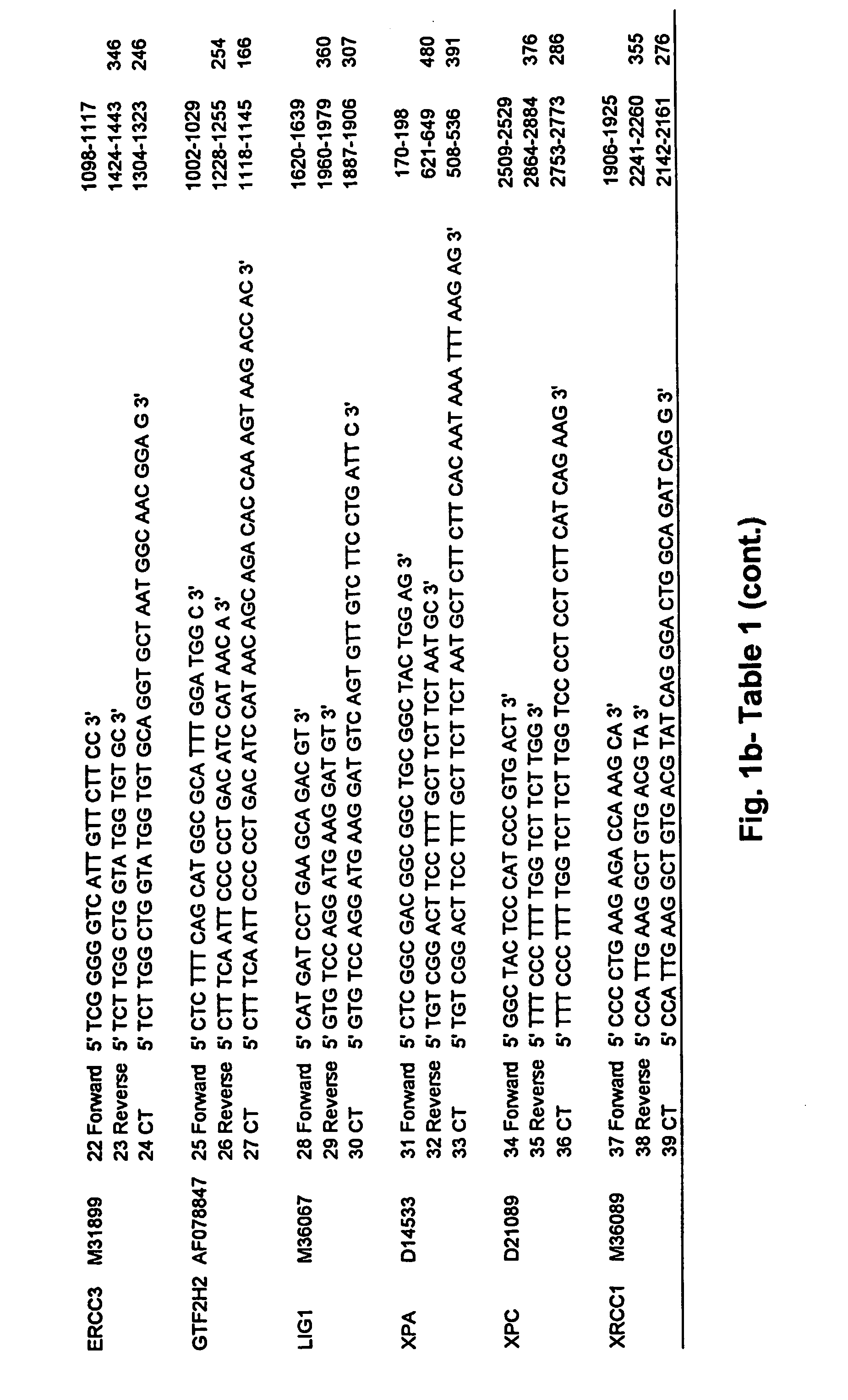

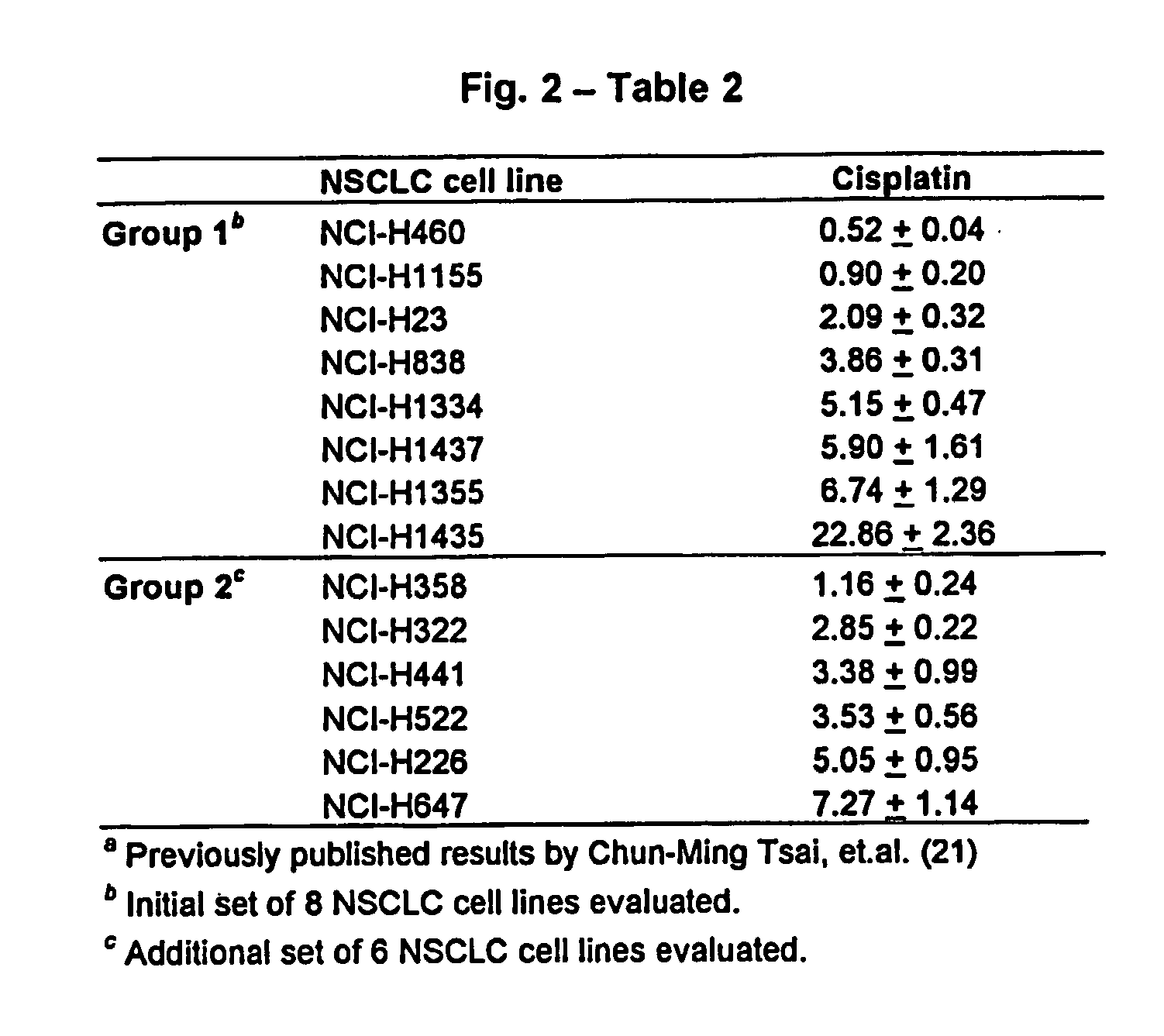

Method and compositions for the diagnosis and treatment of non-small cell lung cancer using gene expression profiles

ActiveUS20050260586A1Accurate diagnosisAccurately diagnose lung cancerMicrobiological testing/measurementFermentationDisease progressionBiology

The present invention identifies and quantifies changes in gene expression associated with non-small cell lung cancer NSCLC by examining gene expression in tissue from normal lung and diseased lung. The present invention also identifies and quantifies expression profiles which serve as useful diagnostic markers as well as markers that are useful to monitor disease states, disease progression, drug toxicity, drug efficacy and drug metabolism.

Owner:UNIVERSITY OF TOLEDO

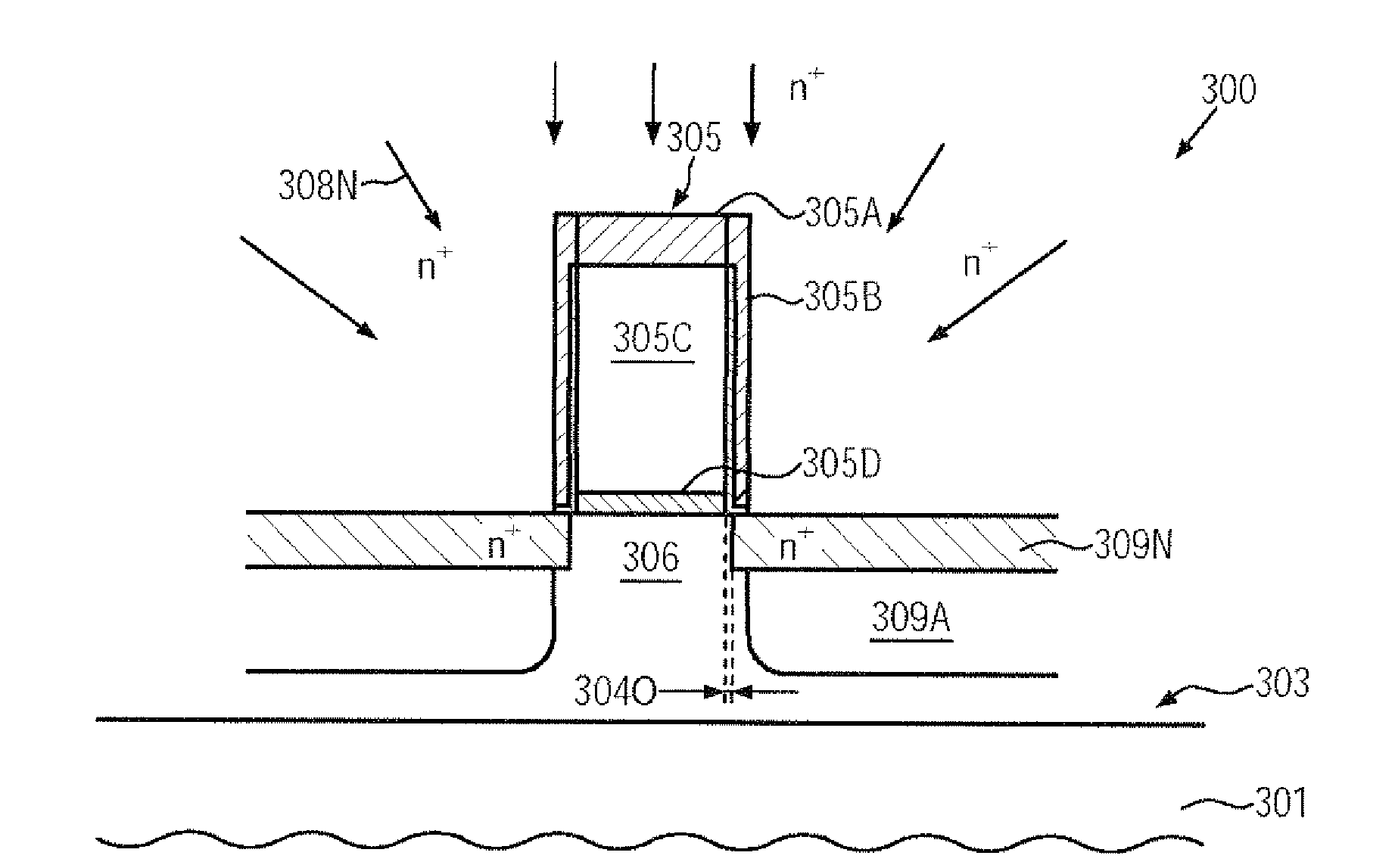

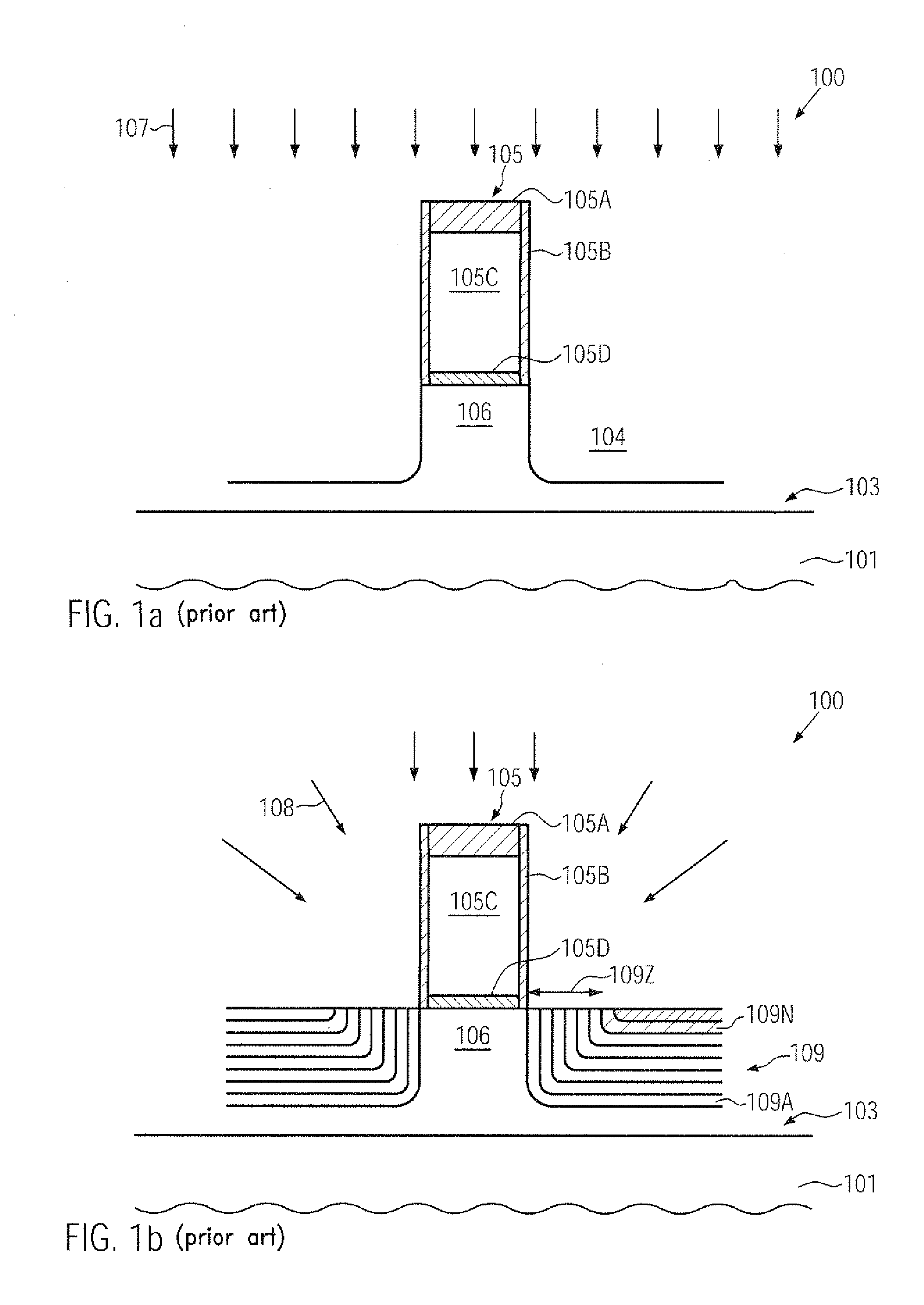

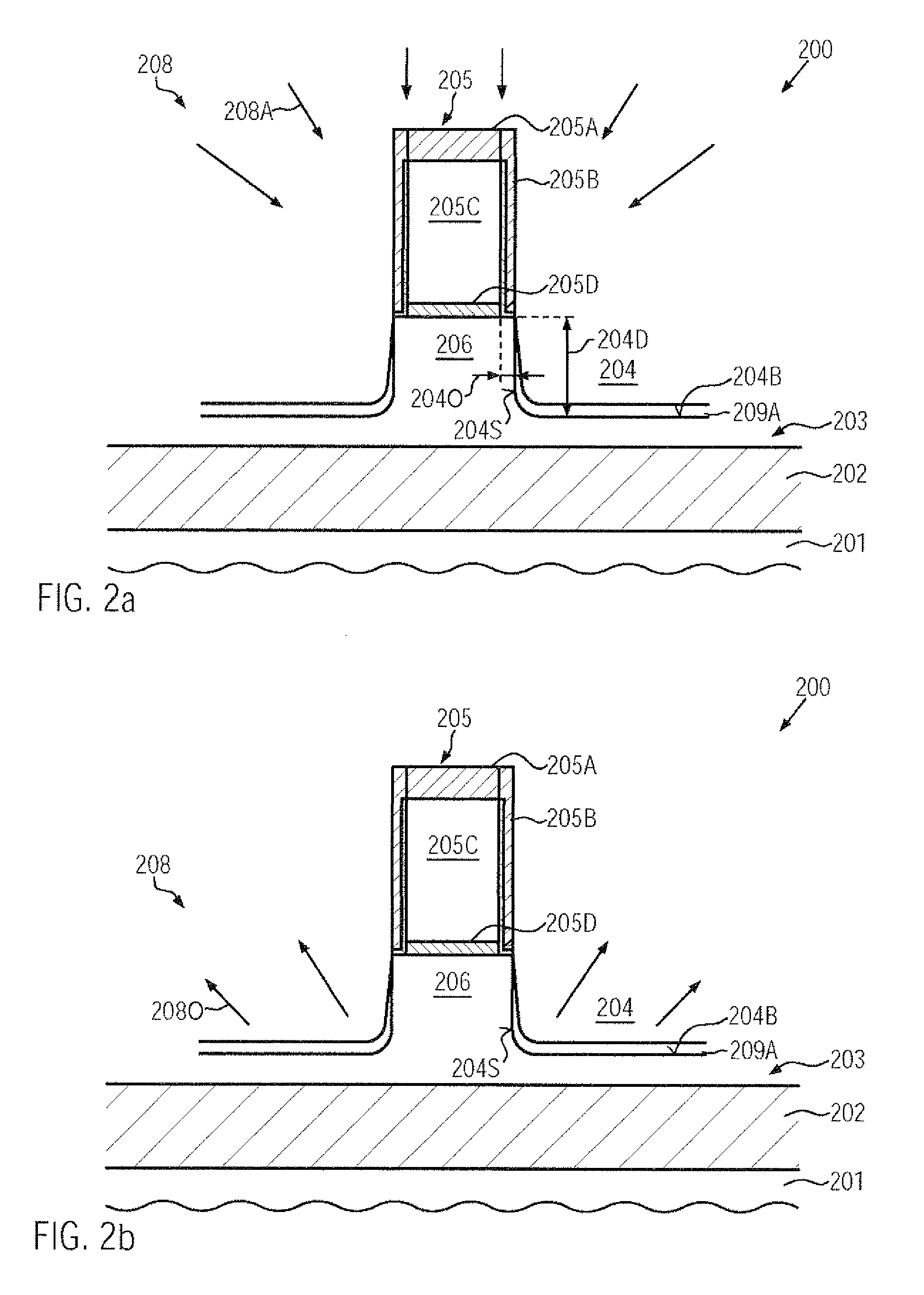

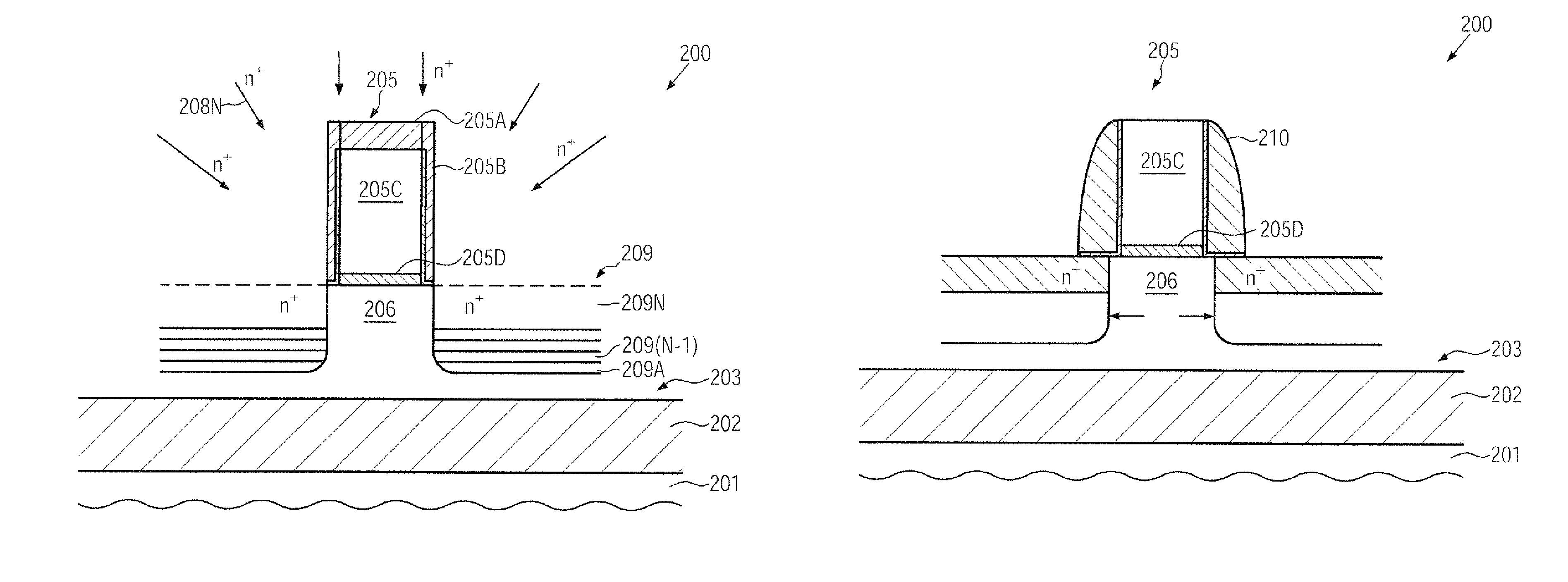

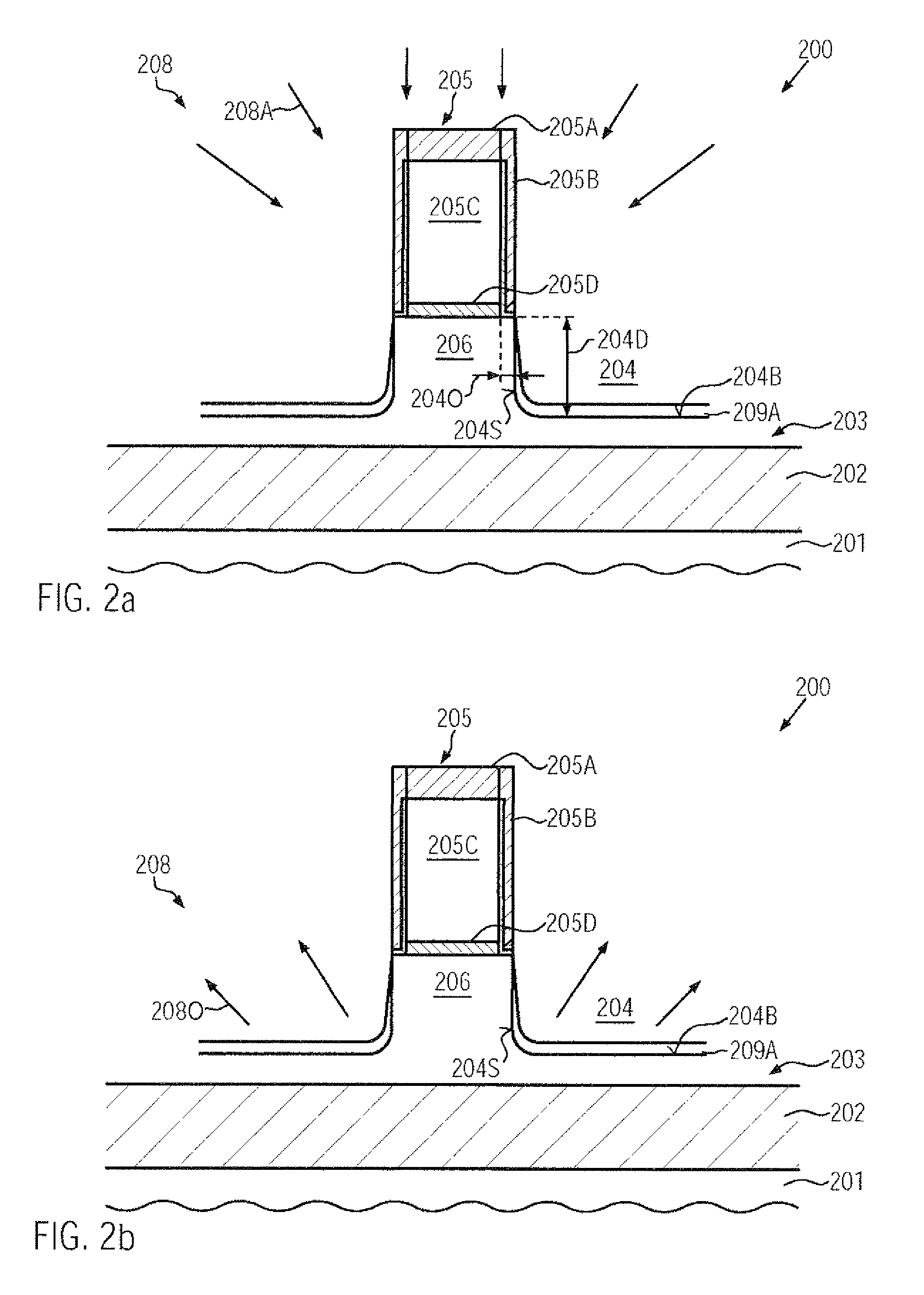

Shallow pn junction formed by in situ doping during selective growth of an embedded semiconductor alloy by a cyclic growth/etch deposition process

ActiveUS20100025779A1Increase strainImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingIn situ dopingUltra-high vacuum

A silicon / carbon alloy may be formed in drain and source regions, wherein another portion may be provided as an in situ doped material with a reduced offset with respect to the gate electrode material. For this purpose, in one illustrative embodiment, a cyclic epitaxial growth process including a plurality of growth / etch cycles may be used at low temperatures in an ultra-high vacuum ambient, thereby obtaining a substantially bottom to top fill behavior.

Owner:ADVANCED MICRO DEVICES INC

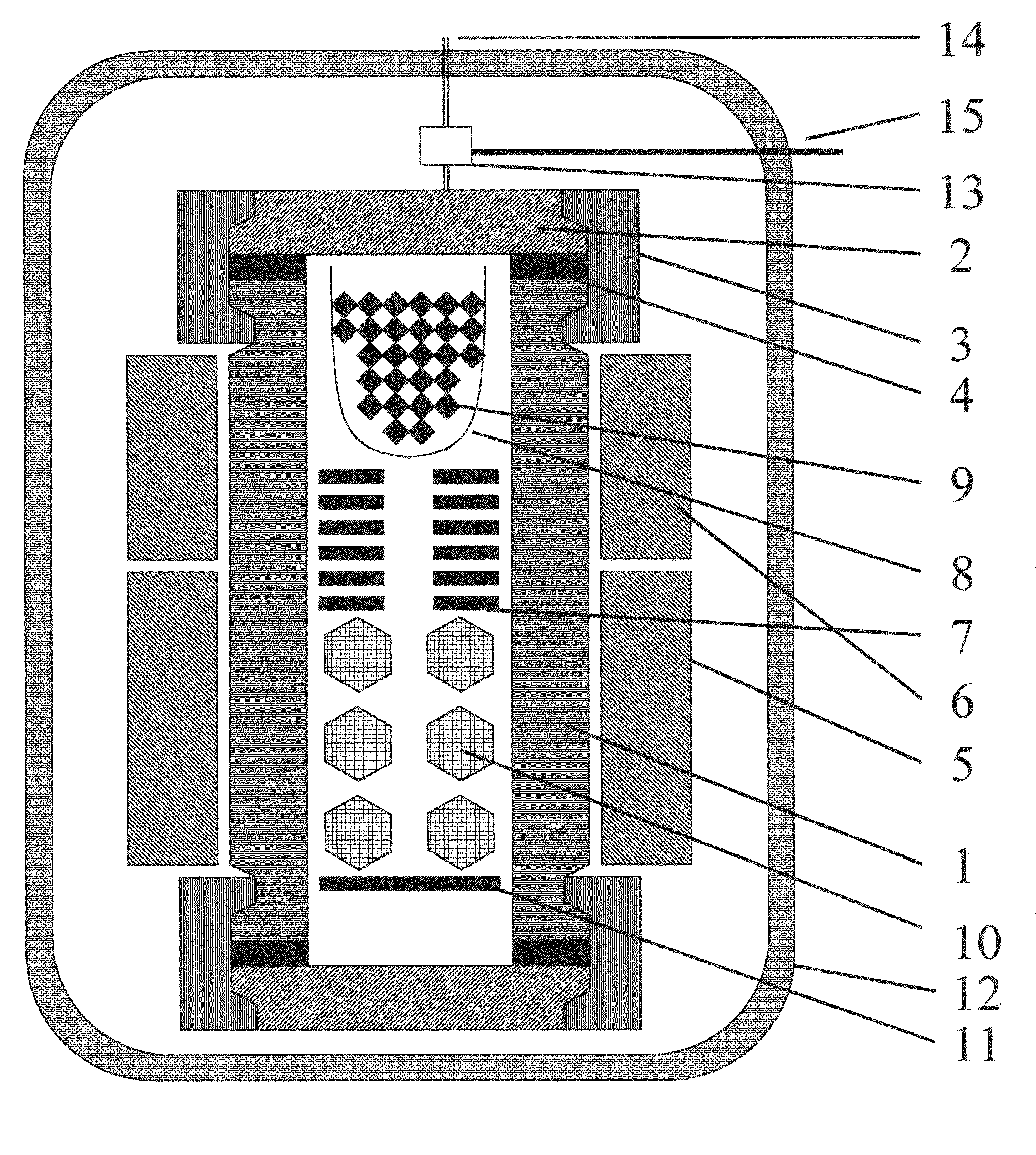

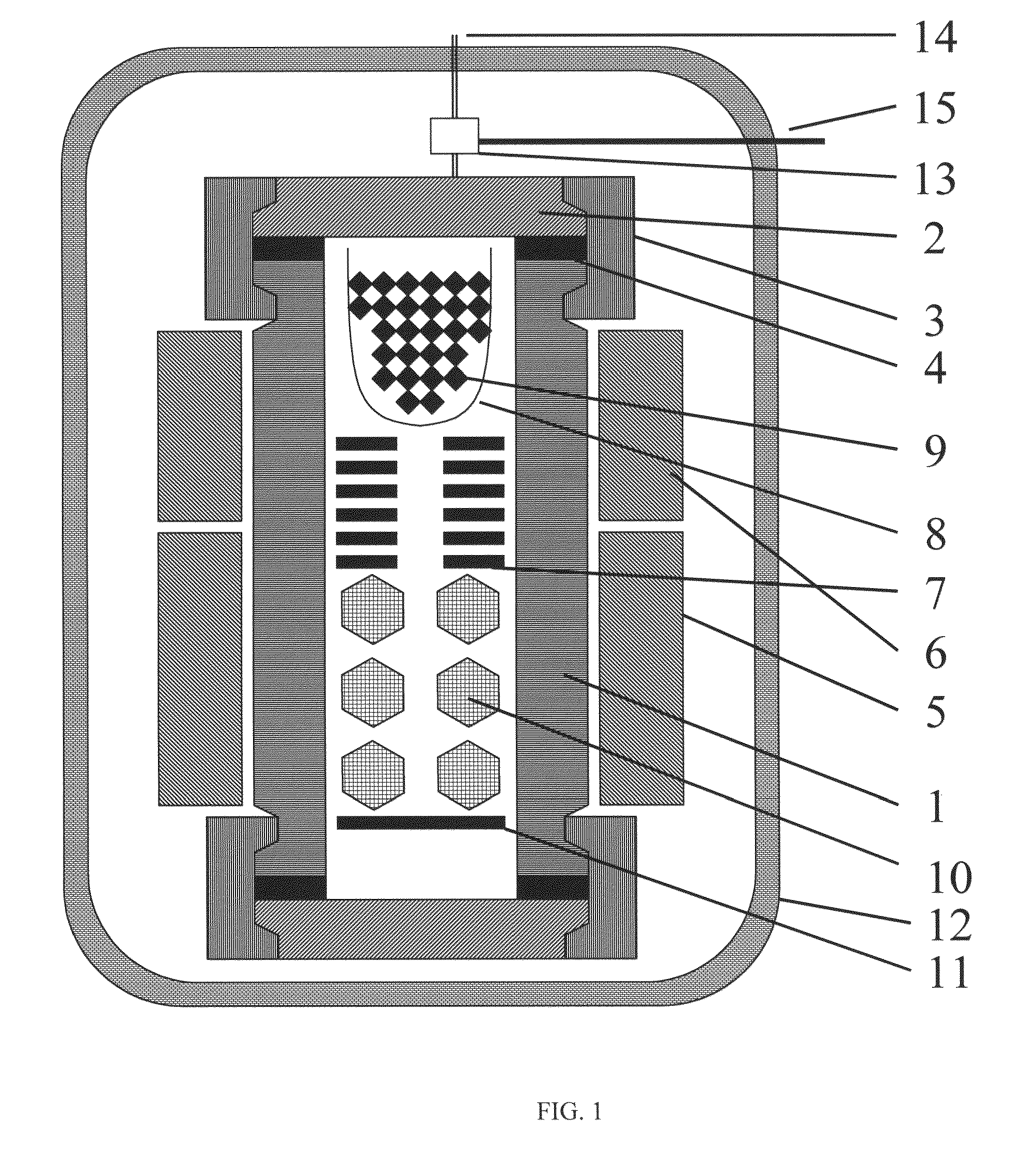

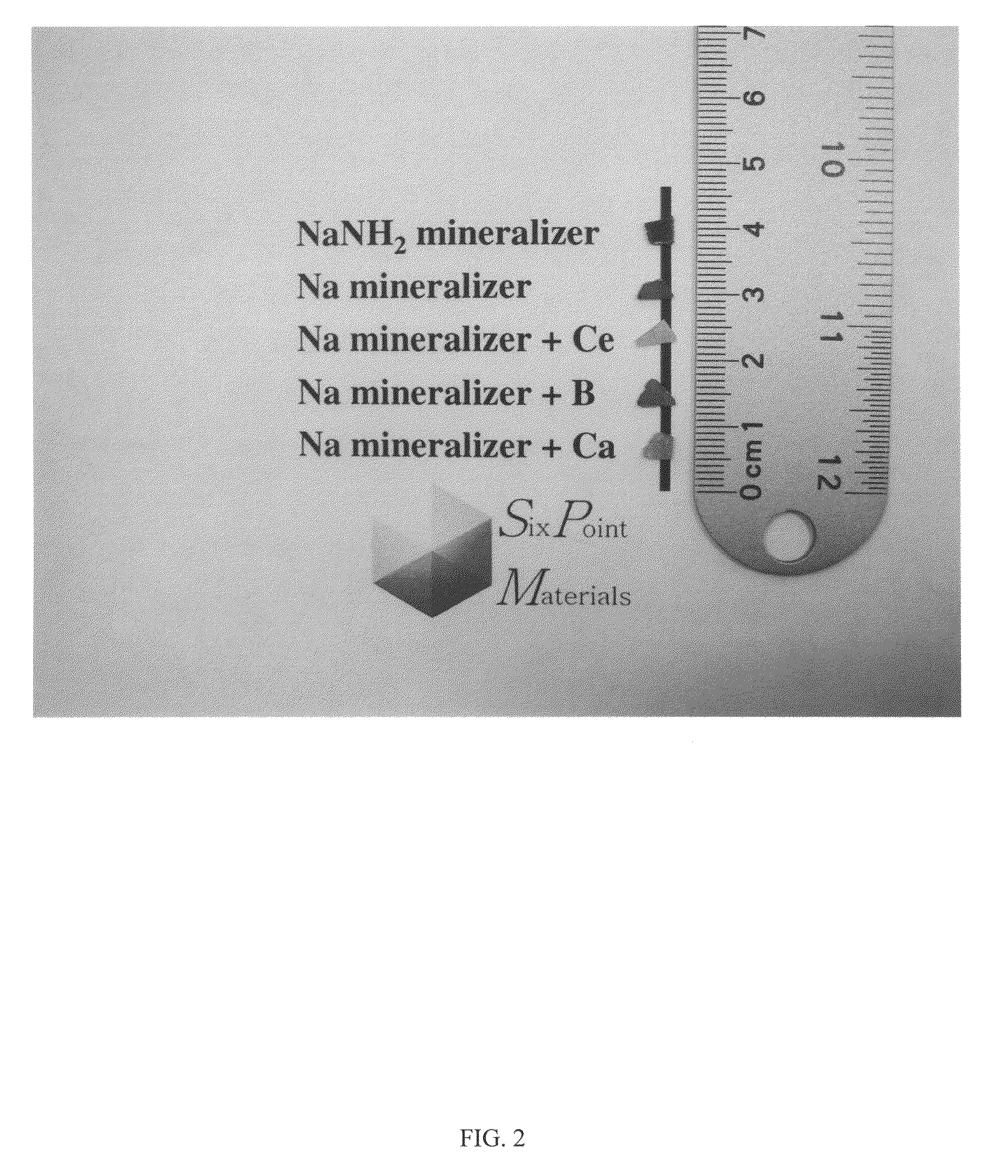

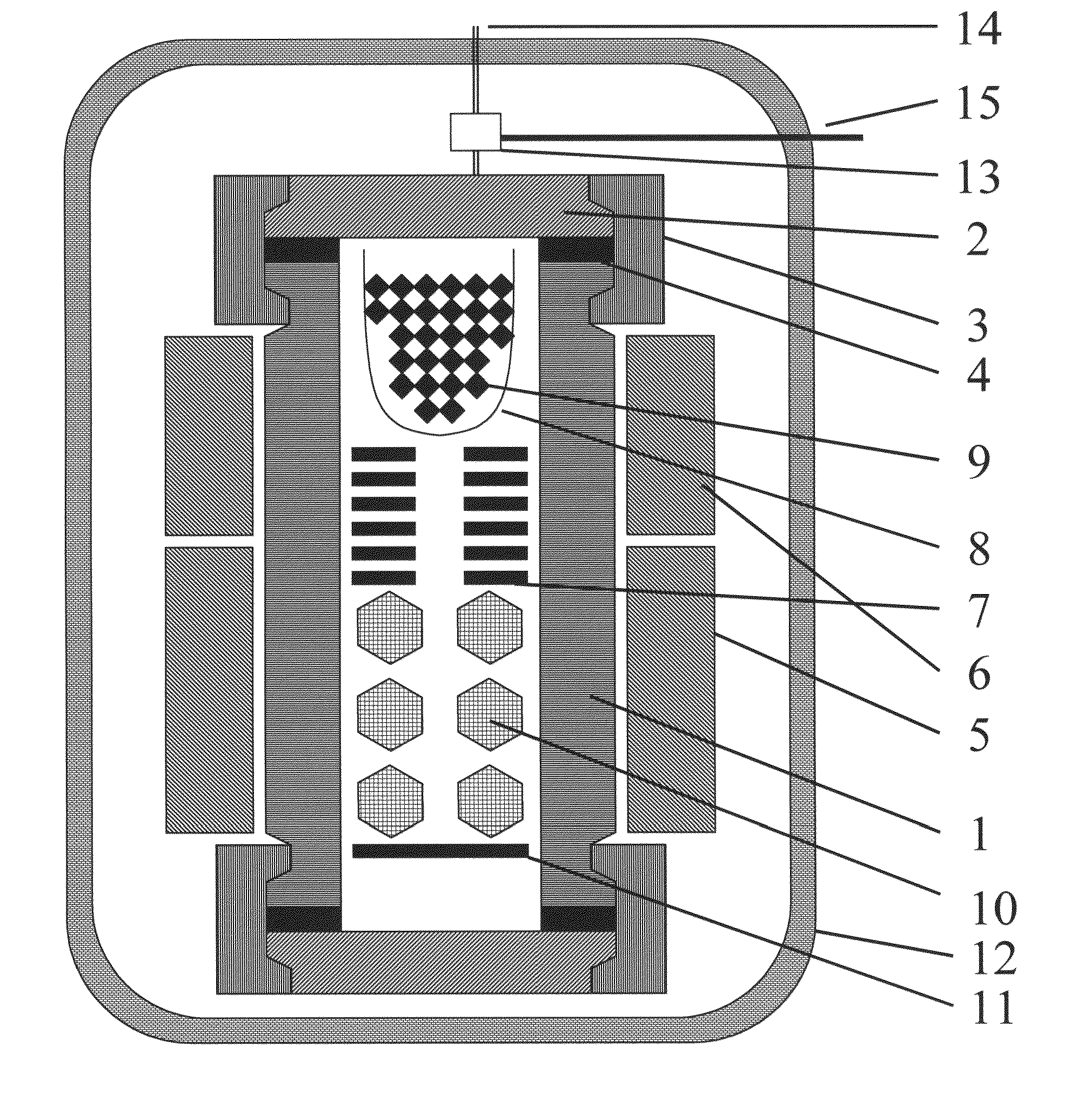

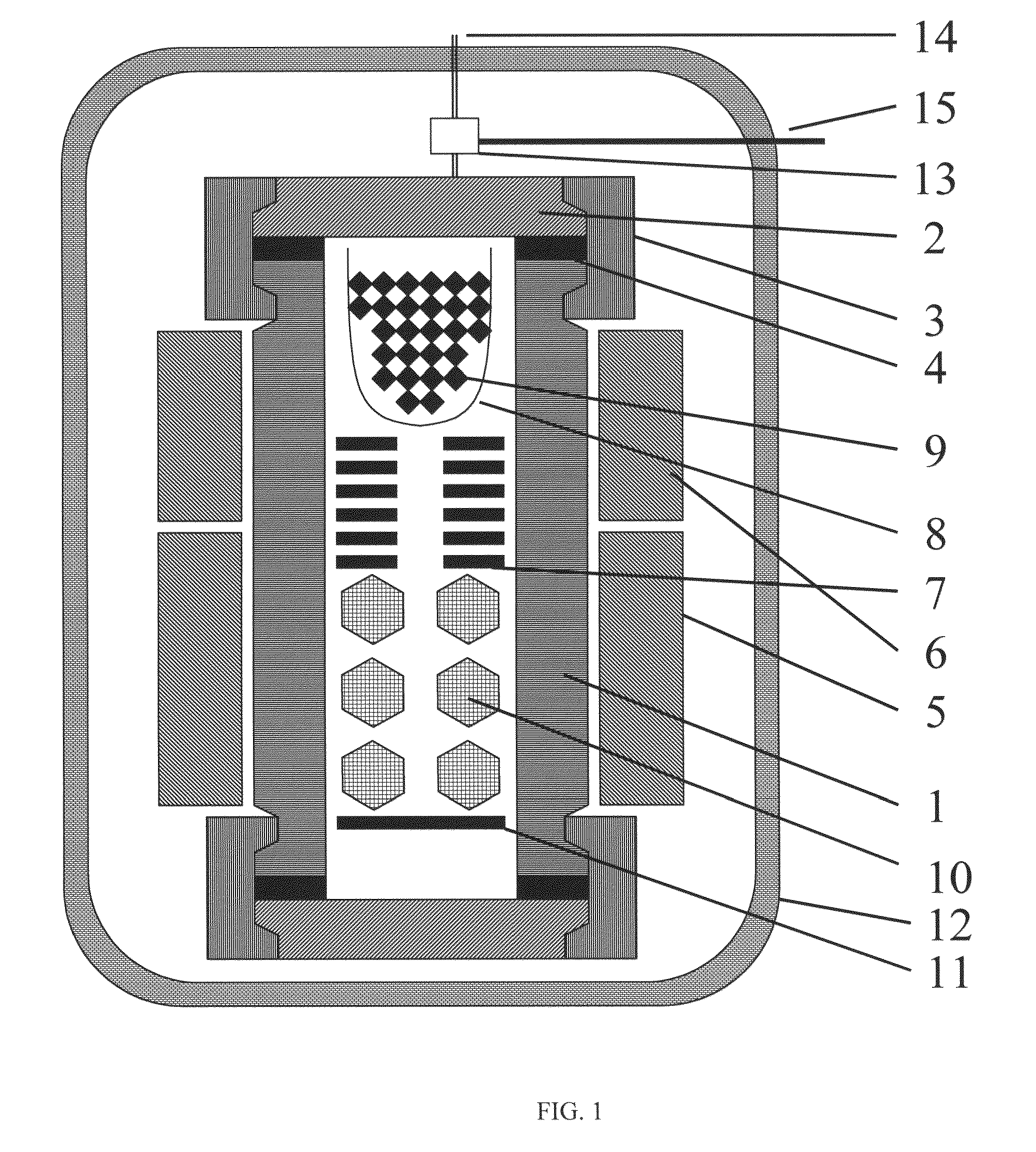

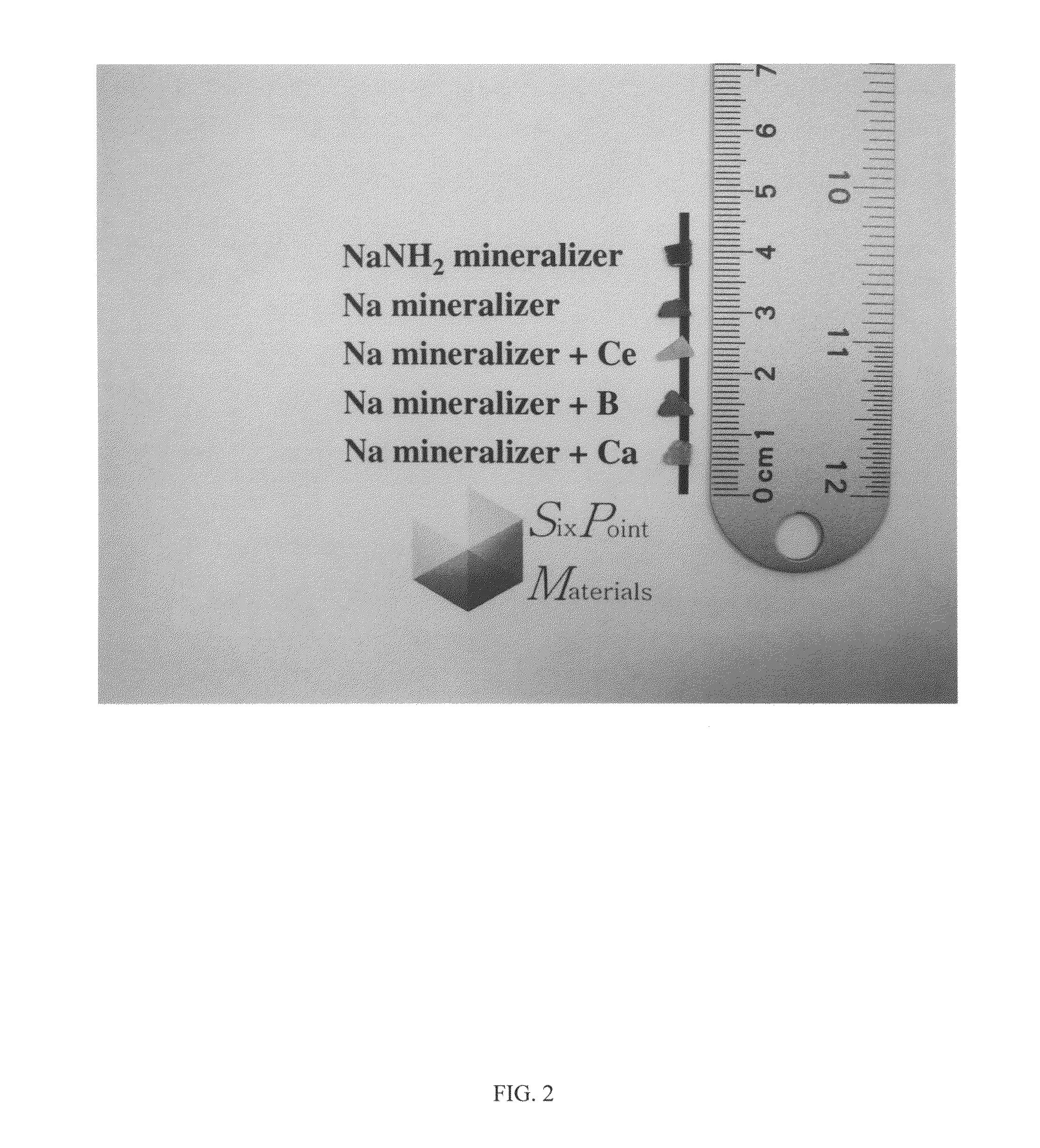

High-pressure vessel for growing group III nitride crystals and method of growing group III nitride crystals using high-pressure vessel and group III nitride crystal

ActiveUS20100068118A1Reducing parasitic depositionImprove structural qualityAfter-treatment apparatusPolycrystalline material growthOxygen contaminationEtching

The present invention discloses a high-pressure vessel of large size formed with a limited size of e.g. Ni—Cr based precipitation hardenable superalloy. The vessel may have multiple zones.For instance, the high-pressure vessel may be divided into at least three regions with flow-restricting devices and the crystallization region is set higher temperature than other regions. This structure helps to reliably seal both ends of the high-pressure vessel, and at the same time, may help to greatly reduce unfavorable precipitation of group III nitride at the bottom of the vessel.This invention also discloses novel procedures to grow crystals with improved purity, transparency and structural quality. Alkali metal-containing mineralizers are charged with minimum exposure to oxygen and moisture until the high-pressure vessel is filled with ammonia. Several methods to reduce oxygen contamination during the process steps are presented. Also, back etching of seed crystals and a new temperature ramping scheme to improve structural quality are disclosed.

Owner:SIXPOINT MATERIALS

Shallow PN junction formed by in situ doping during selective growth of an embedded semiconductor alloy by a cyclic growth/etch deposition process

ActiveUS8053273B2Increase strainImprove device performanceSolid-state devicesSemiconductor/solid-state device manufacturingIn situ dopingUltra-high vacuum

A silicon / carbon alloy may be formed in drain and source regions, wherein another portion may be provided as an in situ doped material with a reduced offset with respect to the gate electrode material. For this purpose, in one illustrative embodiment, a cyclic epitaxial growth process including a plurality of growth / etch cycles may be used at low temperatures in an ultra-high vacuum ambient, thereby obtaining a substantially bottom to top fill behavior.

Owner:ADVANCED MICRO DEVICES INC

Method of Regulating Hair Growth

InactiveUS20100016782A1Effectively regulateLimited abilityUltrasound therapyCosmetic preparationsEnergy deliveryEndocrinology

Method for regulating hair growth, comprising the steps of applying a composition to keratinous tissue comprising the hair in need of regulation, said composition comprising at least one PARP-1 inhibiting compound; and delivering energy to the keratinous tissue by means of an energy delivery device.

Owner:THE PROCTER & GAMBNE CO

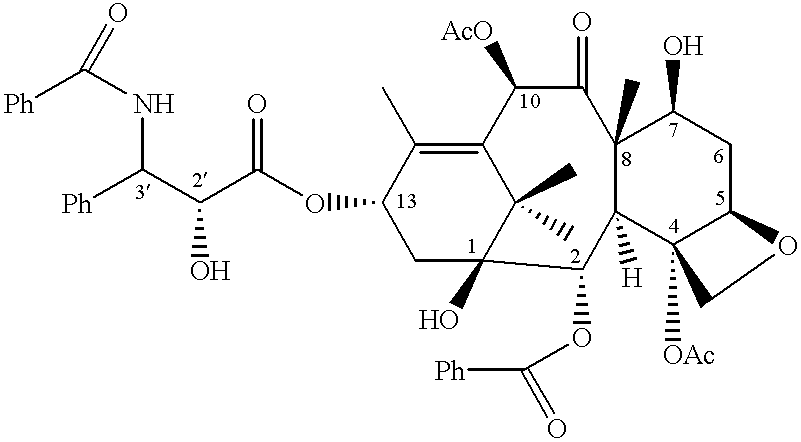

Methods and compositions for the identification, assessment, prevention and therapy of human cancers

InactiveUS20020051978A1Sure easyReduced growth rateMicrobiological testing/measurementDisease diagnosisHuman cancerCancer cell

The present invention is directed to the identification of markers that can be used to determine the sensitivity of cancer cells to a therapeutic agent. The present invention is also directed to the identification of therapeutic targets. Nucleic acid arrays were used to determine the level of expression of sequences (genes) found in 60 different solid tumor cancer cell lines selected from the NCI 60 cancer cell line series. Expression analysis was used to identify markers associated with sensitivity to certain chemotherapeutic agents.

Owner:MILLENNIUM PHARMA INC

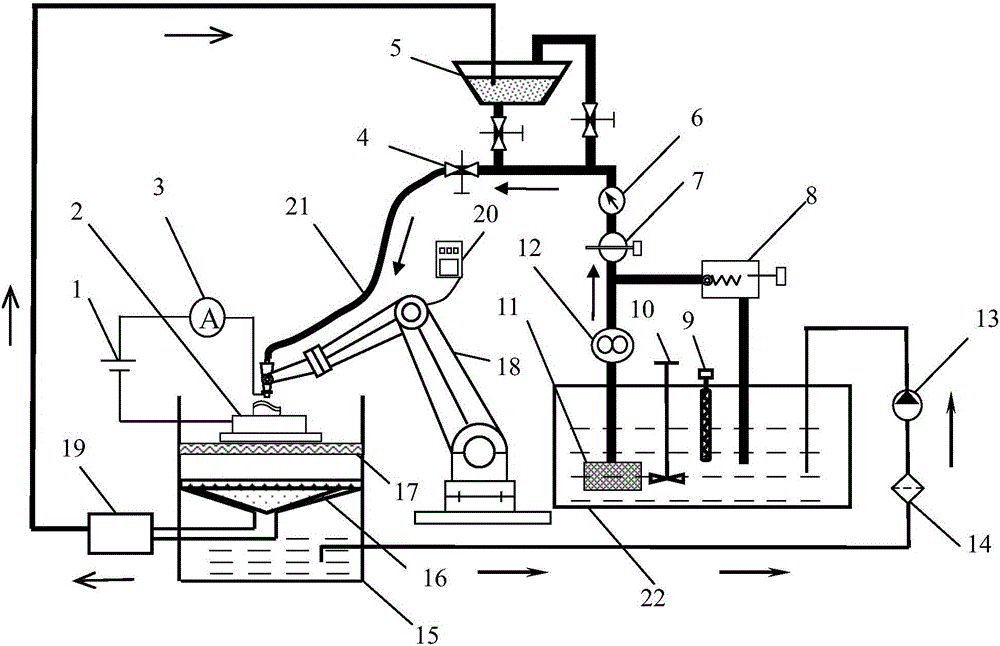

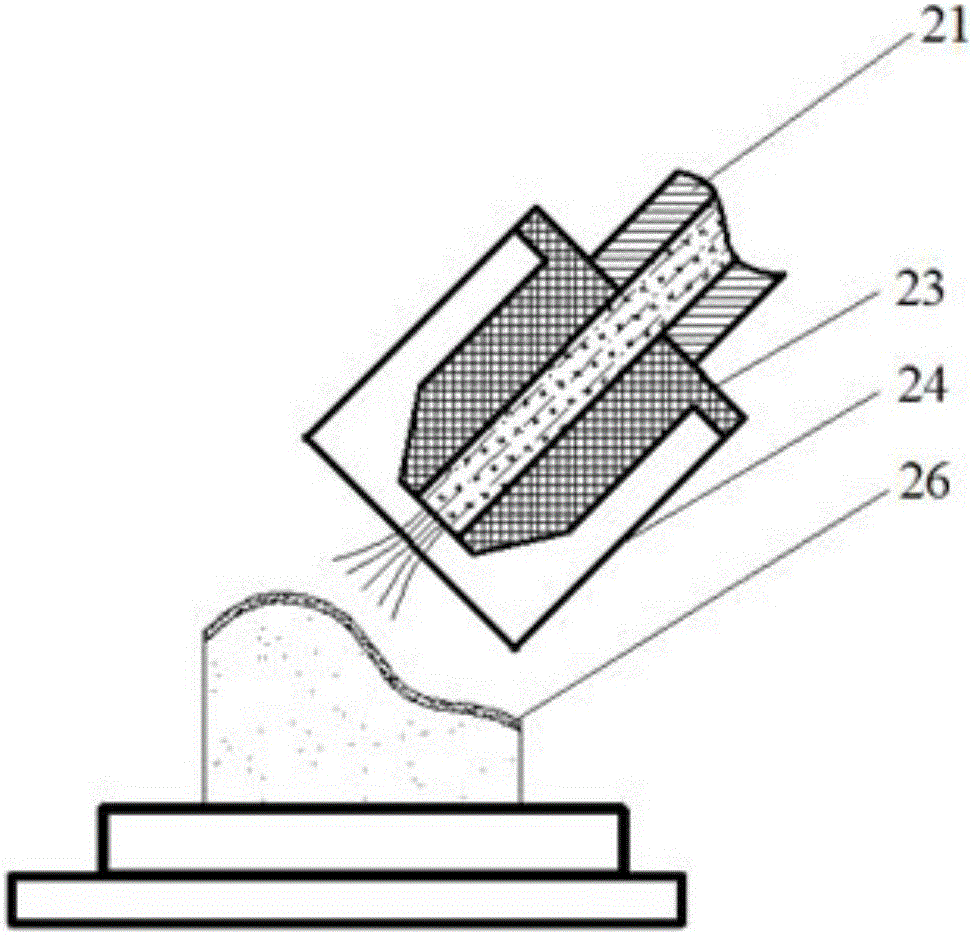

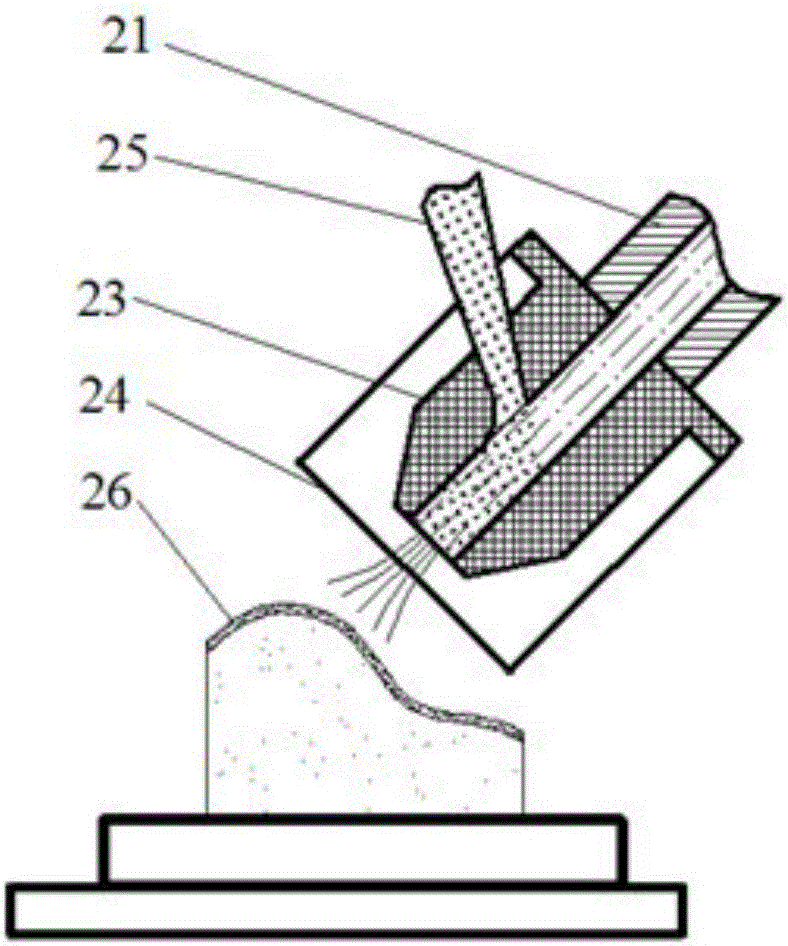

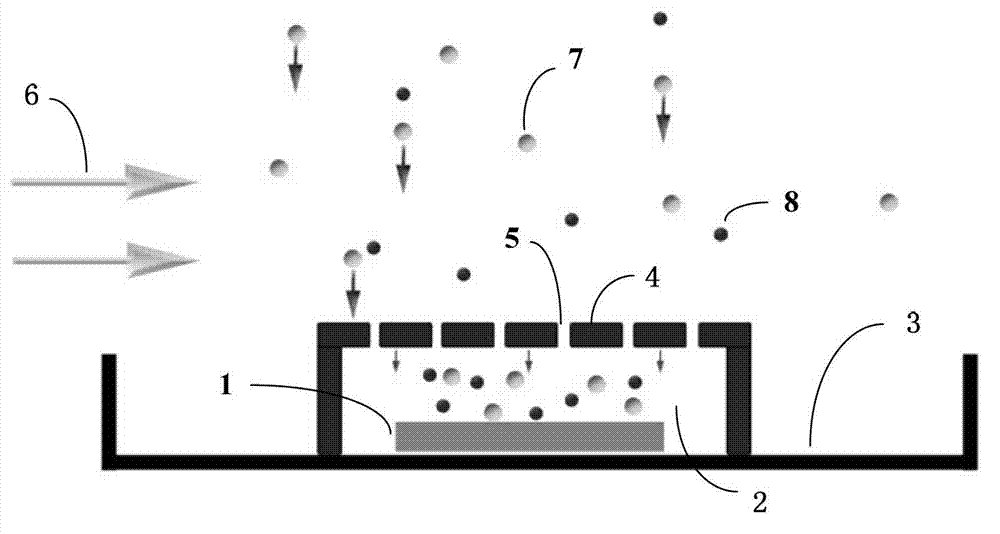

Three-dimensional surface shot peening jet electrodeposition manufacturing method and device

InactiveCN105951141ARemove in timeInhibit nodulationElectrolysis componentsElectrolytic coatingsNumerical controlImpurity

The invention provides a three-dimensional surface shot peening jet electrodeposition manufacturing method and device. According to the manufacturing method and device, a deposition solution and hard particles are mixed and deposit on a conductive substrate in a spraying manner, so that the rapid manufacturing technology of electrodeposition is realized, the growth rate of grains in the electrodeposition process is slowed down, the purpose of refining the grains is reached, and the quality of a deposition layer is dramatically improved; with combination of the shot peening strengthening technology and the electrodeposition technology, the defects of loose texture, pockmarks, pits and the like of the deposition layer caused by single electrodeposited cathode hydrogen evolution and impurity adhesion can be effectively overcome, and the hardness and the compactness of the deposition layer are improved; meanwhile, by introducing a five-axis linkage numerical control machining system, processing formation of a three-dimensional space can be realized, and the uniformity and the shape accuracy of the deposition layer are improved; and the technology can be widely applied to production of noble metal devices and parts in complex shapes and can also be used for surface rapid coat-plating, a strengthening technology and the like.

Owner:JIANGSU UNIV

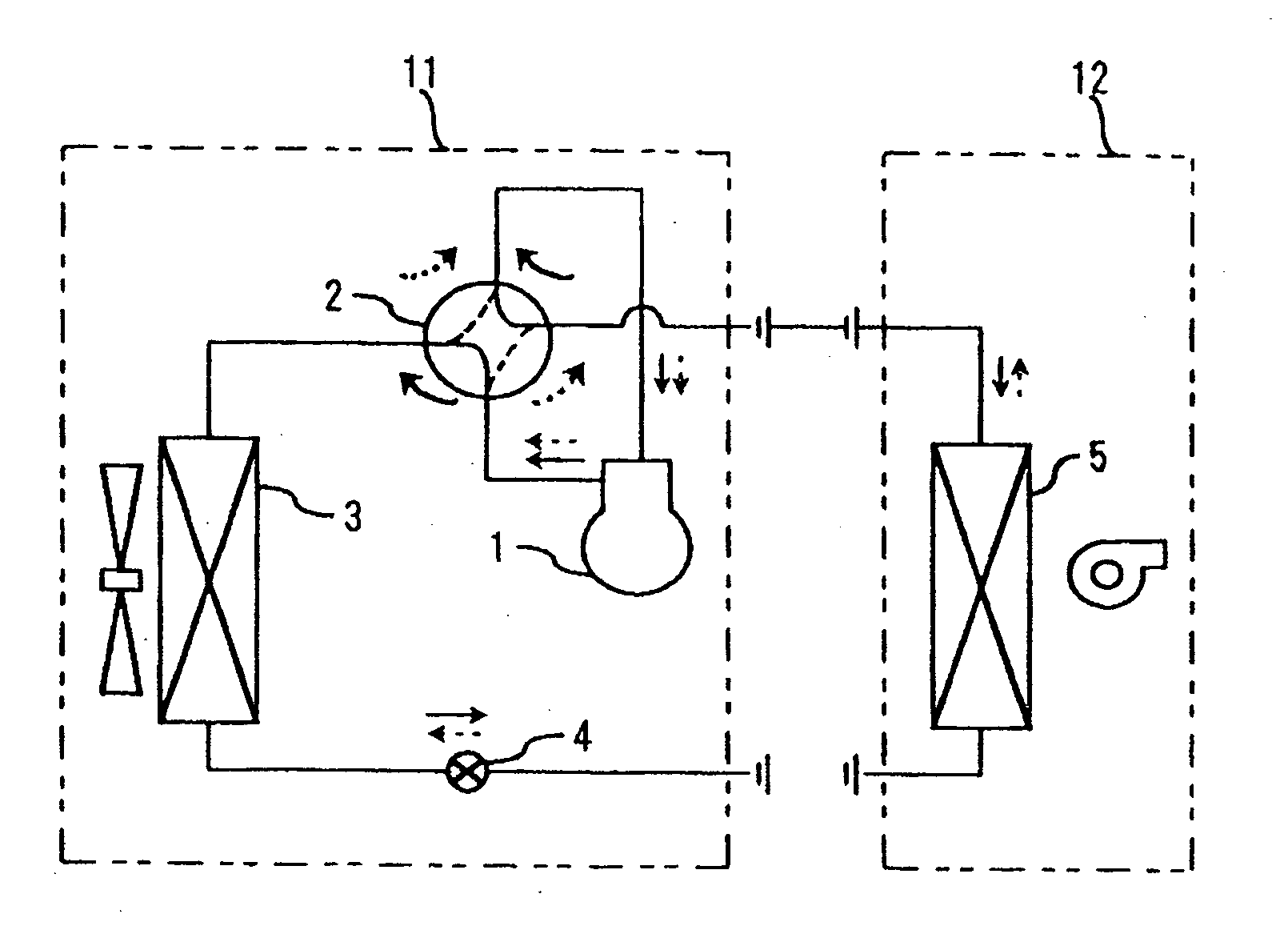

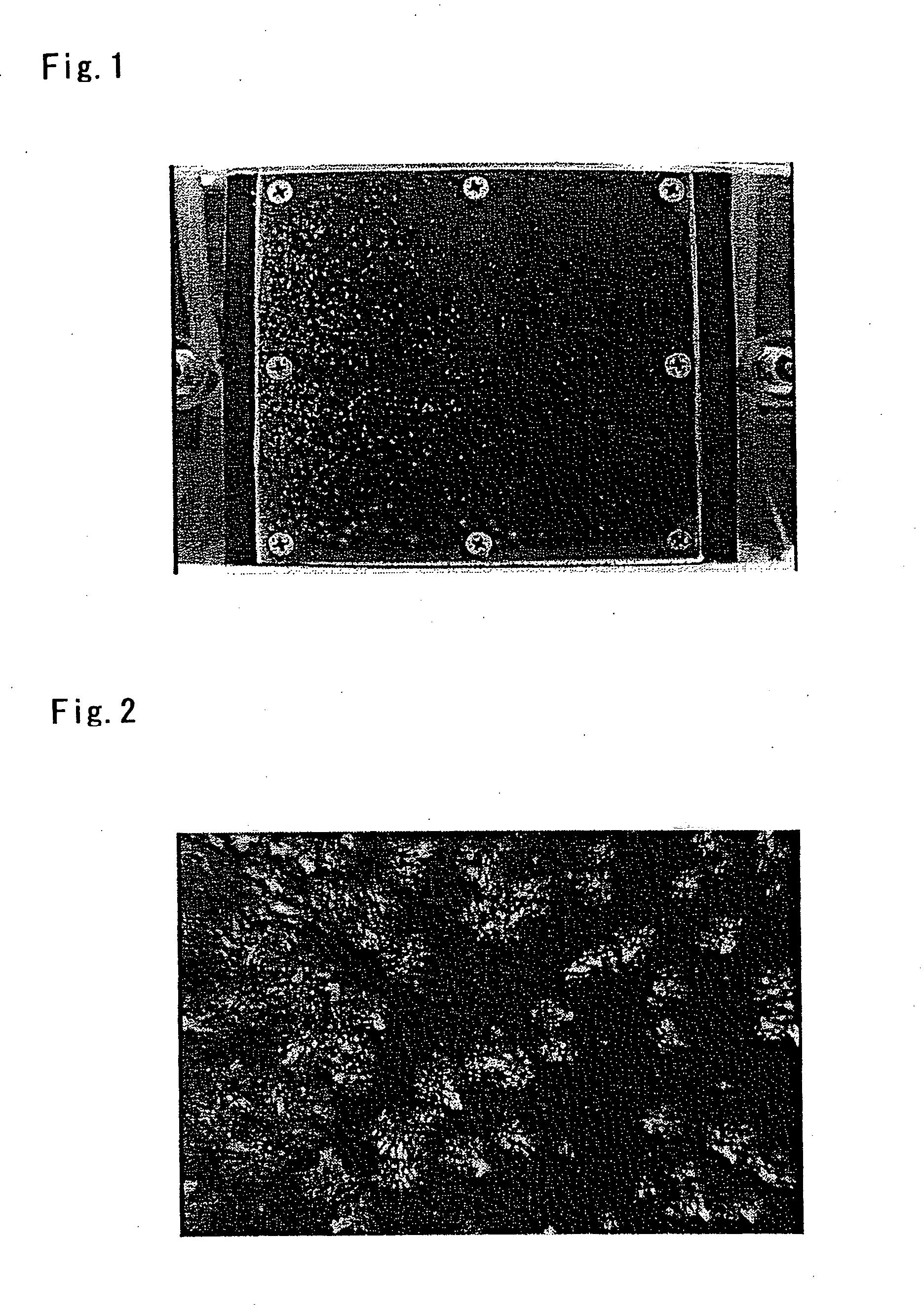

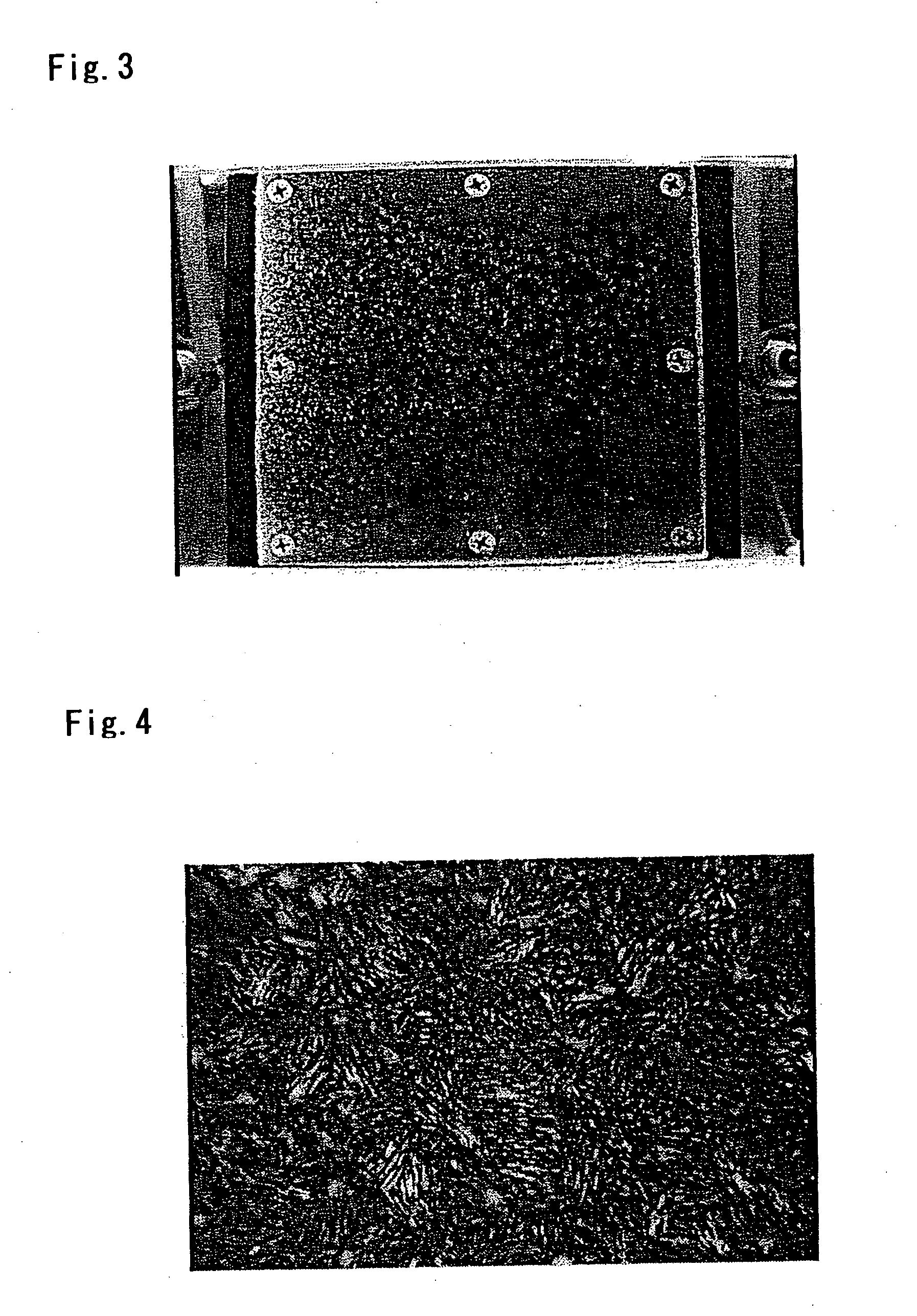

Heat exchanger for air and freezer device

InactiveUS20050257558A1Good effectReduction in heating comfortMaterial nanotechnologyCorrosion preventionFrostEngineering

Surface portions A with a low heat capacity and surface portions B to which frost or ice is poorly bound or attached are discretely distributed on the heat exchange surface. The surface portions A and the surface portions B have features by which, when heating the heat exchanger to which frost or ice is attached, frost or ice in contact with the surface portions A melts earlier than frost or ice in contact with the surface portions B, and at least a part of frost or ice attached to the surface portions B is made partially continuous with at least a part of frost or ice attached to the surface portions A and is thereby released from the surface portions B by its own weight. The heat exchanger having such a heat exchange surface is used as an evaporator of a refrigeration apparatus.

Owner:DAIKIN IND LTD

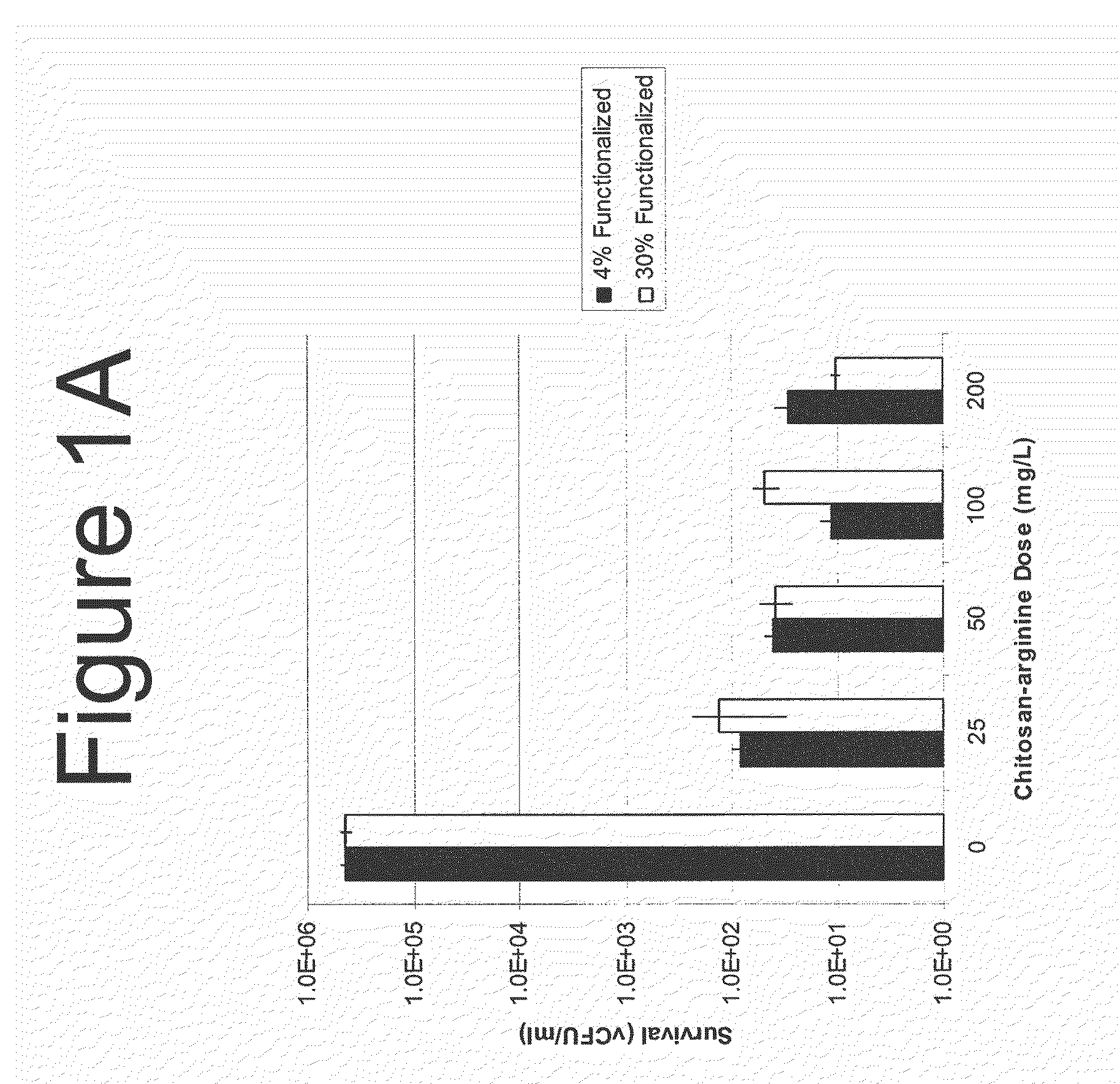

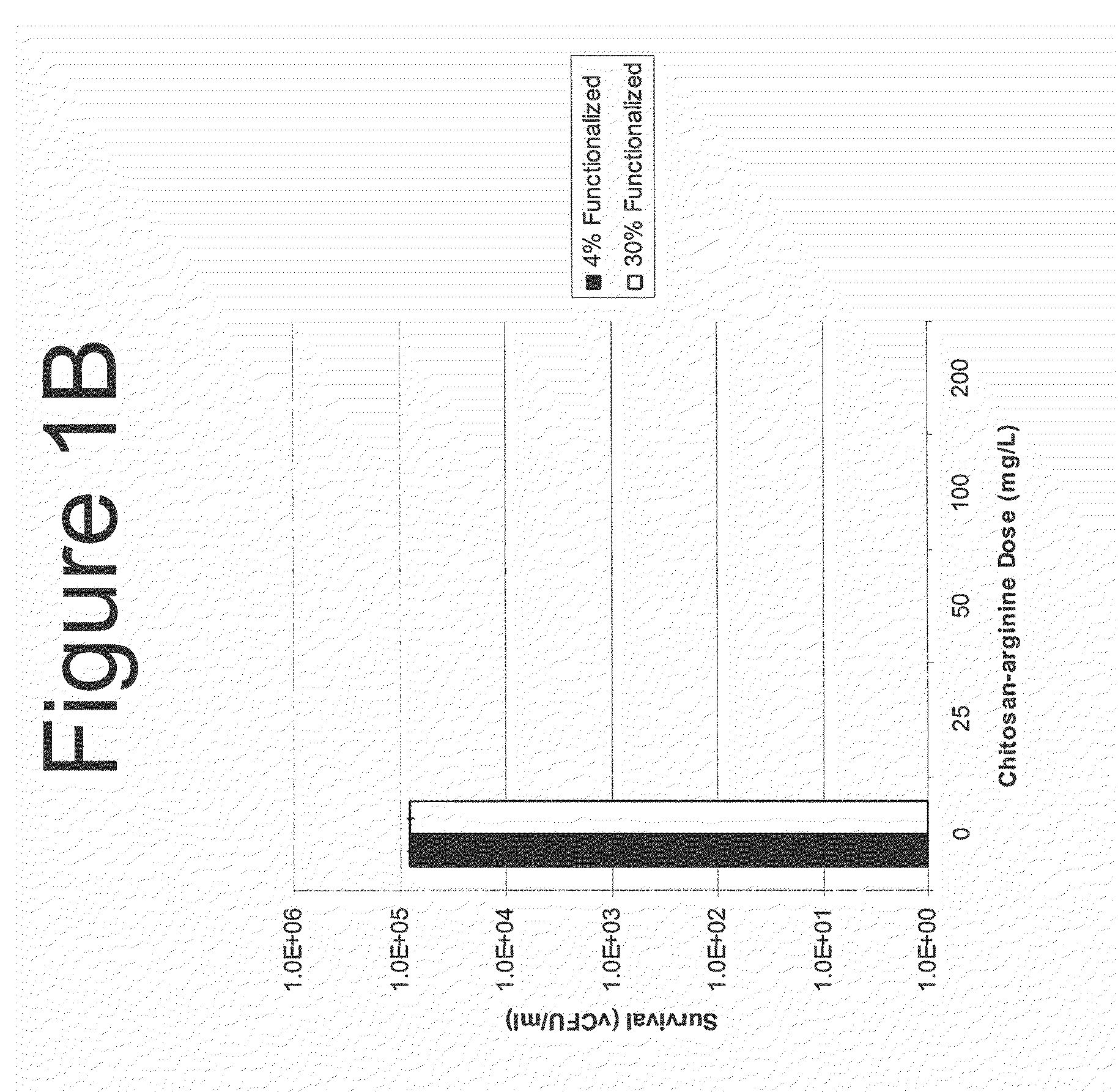

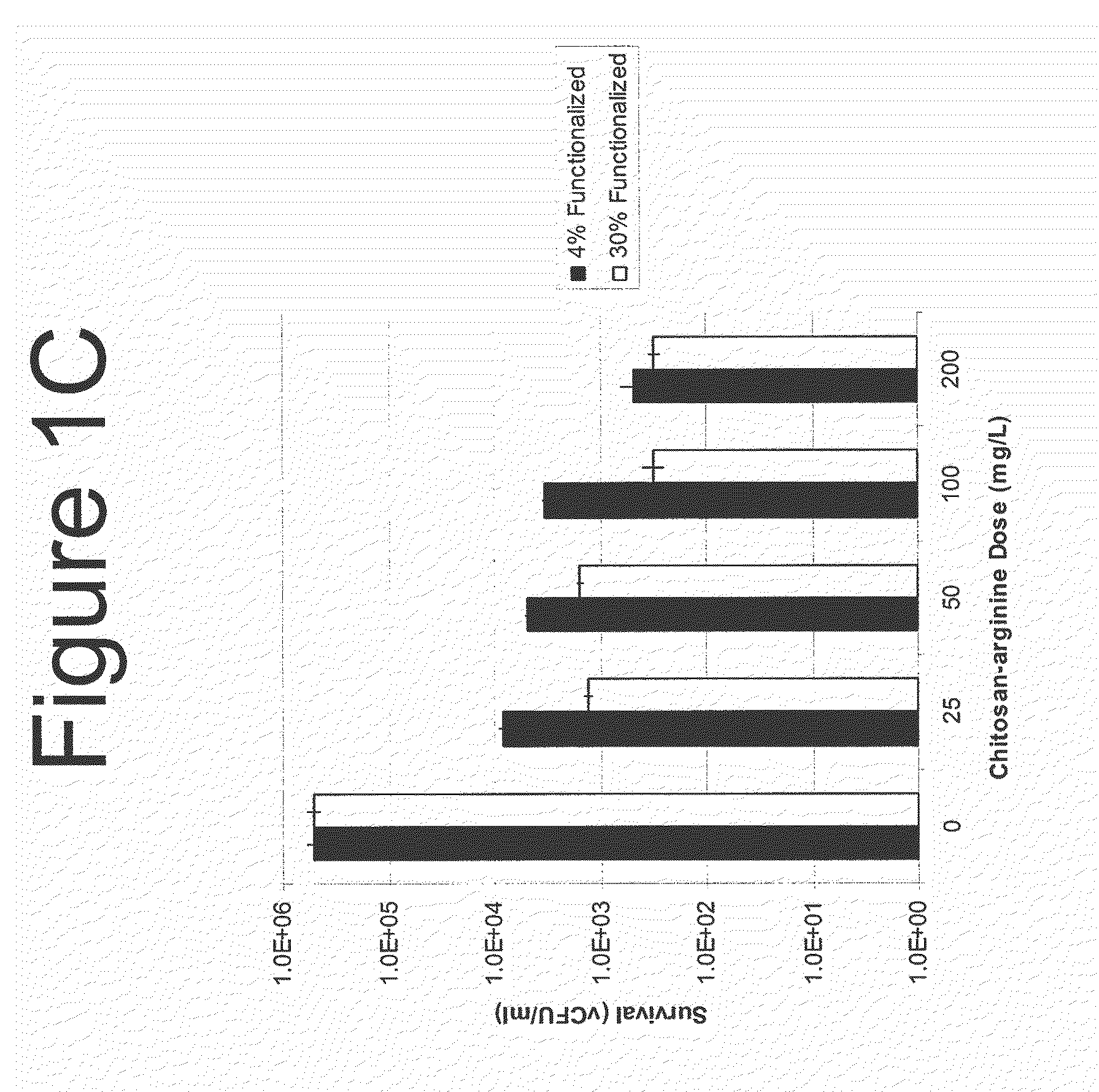

Methods and Compositions for the Prevention of and Treatment of Infections Utilizing Chitosan-Derivative Compounds

The present invention is directed to the treatment and prevention of nosocomial infections or MRSA infections utilizing soluble chitosan or chitosan derivative compounds. These chitosan-derivative compounds, e.g., chitosan-arginine and chitosan-acid amines, exhibit bactericidal activity against bacterial pathogens, e.g., drug resistant bacteria such as Methicillin-resistant Staphylococcus aureus (MRSA).

Owner:SYNEDGEN

Immunotoxin as a therapeutic agent and uses thereof

InactiveUS20040013691A1Improve anti-tumor effectStrong cytotoxicityOrganic active ingredientsBacterial antigen ingredientsDiseaseMechanism of action

The present invention further provides insight into the mechanism of action of immunotoxins in disease states such as hyperproliferative disease states. The present invention provides a novel method of treating diseases using immunotoxins and gene expression profiling to identify genes that are modulated by immunotoxin therapy.

Owner:RES DEVMENT FOUND

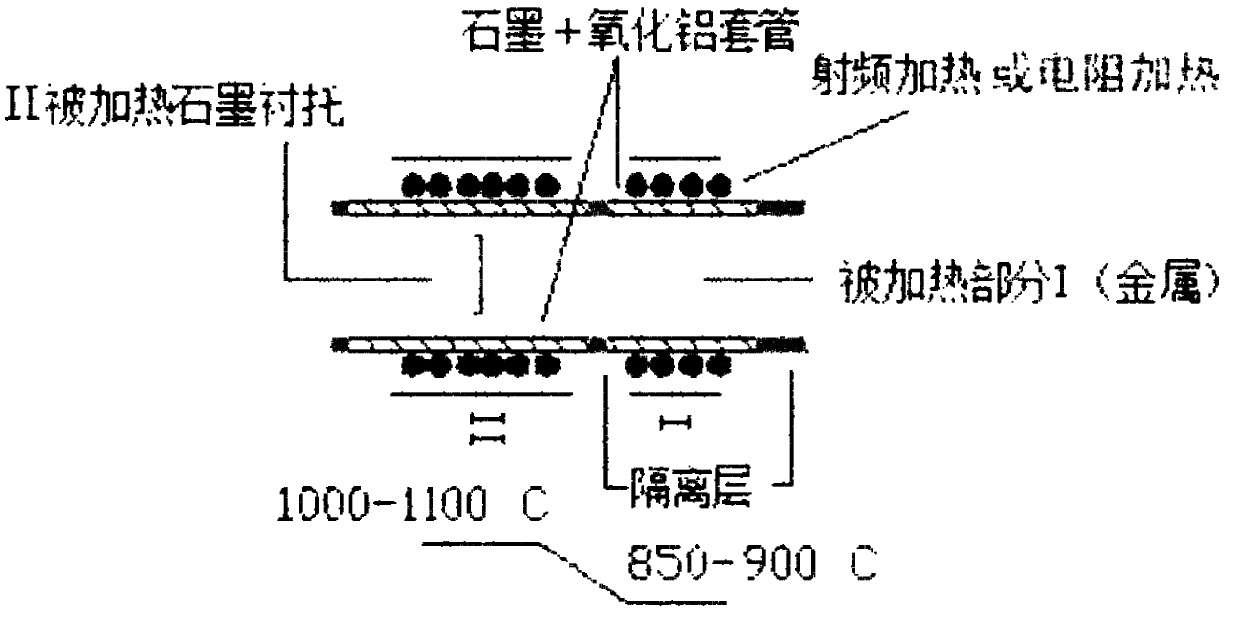

Method for preparing epitaxial graphene by thermal cracking silicon carbide

The invention relates to a method for preparing epitaxial graphene by thermal cracking silicon carbide, and belongs to the technical field of materials. According to the method improved based on method for preparing epitaxial graphene by argon assistant thermal cracking silicon carbide, in the process for preparing epitaxial graphene by argon assistant thermal cracking silicon carbide, a graphite cover (4) with a plurality air holes (5) covers a silicon carbide substrate (1) in an electric induction heating graphite boat, so that the disturbance of air flow and temperature is reduced, and graphene with a greater domain area can be obtained. Due to air holes (5), on the one hand, sublimation of Si is not affected, and on the other hand, the sublimating speed of Si is appropriately controlled to appropriately reduce the growing speed of graphene so as to better control growth thickness of graphene. The air holes (5) are consistent in aperture and uniformly distributed. The uniformity and the electronic mobility of graphene prepared are greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

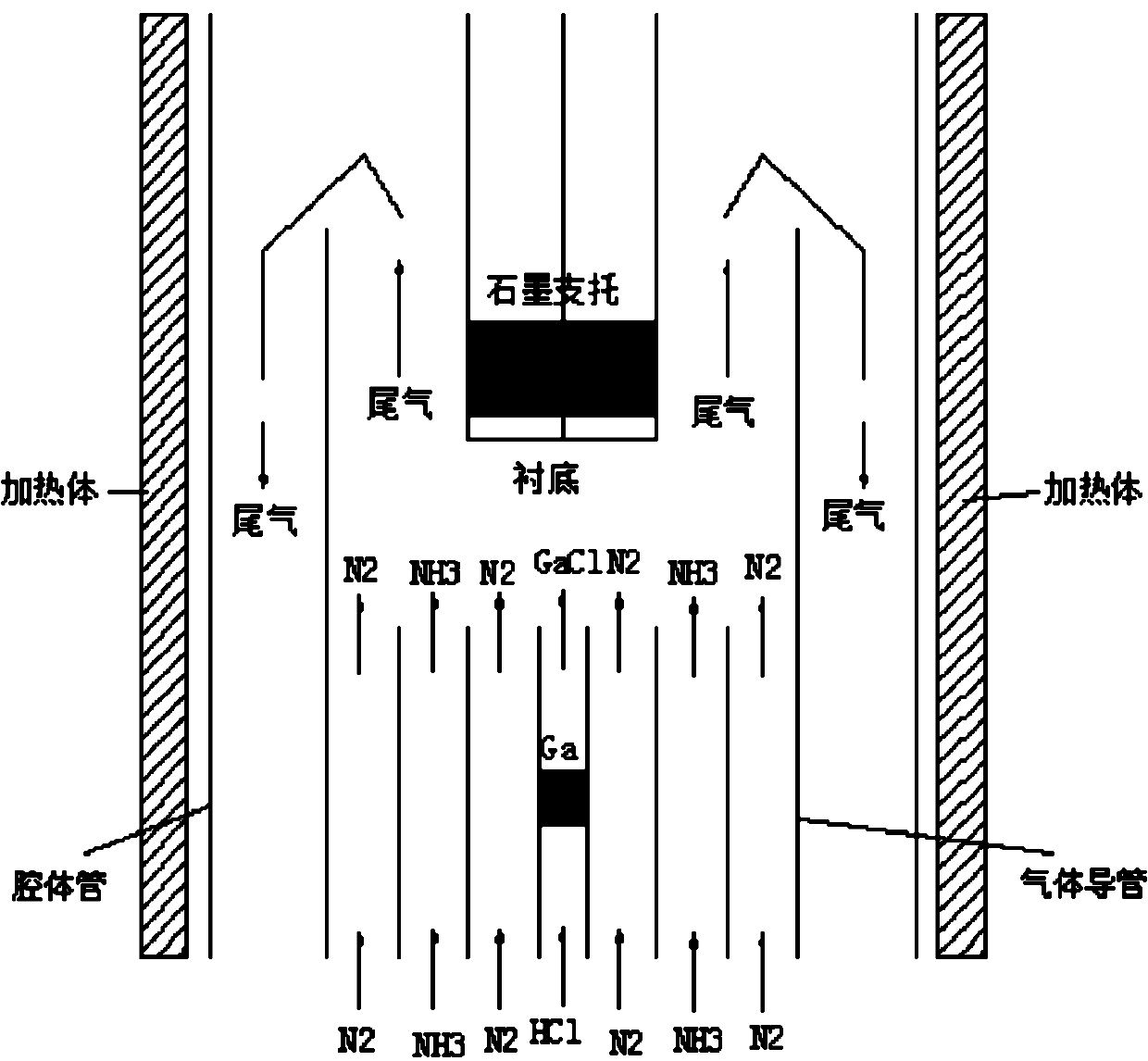

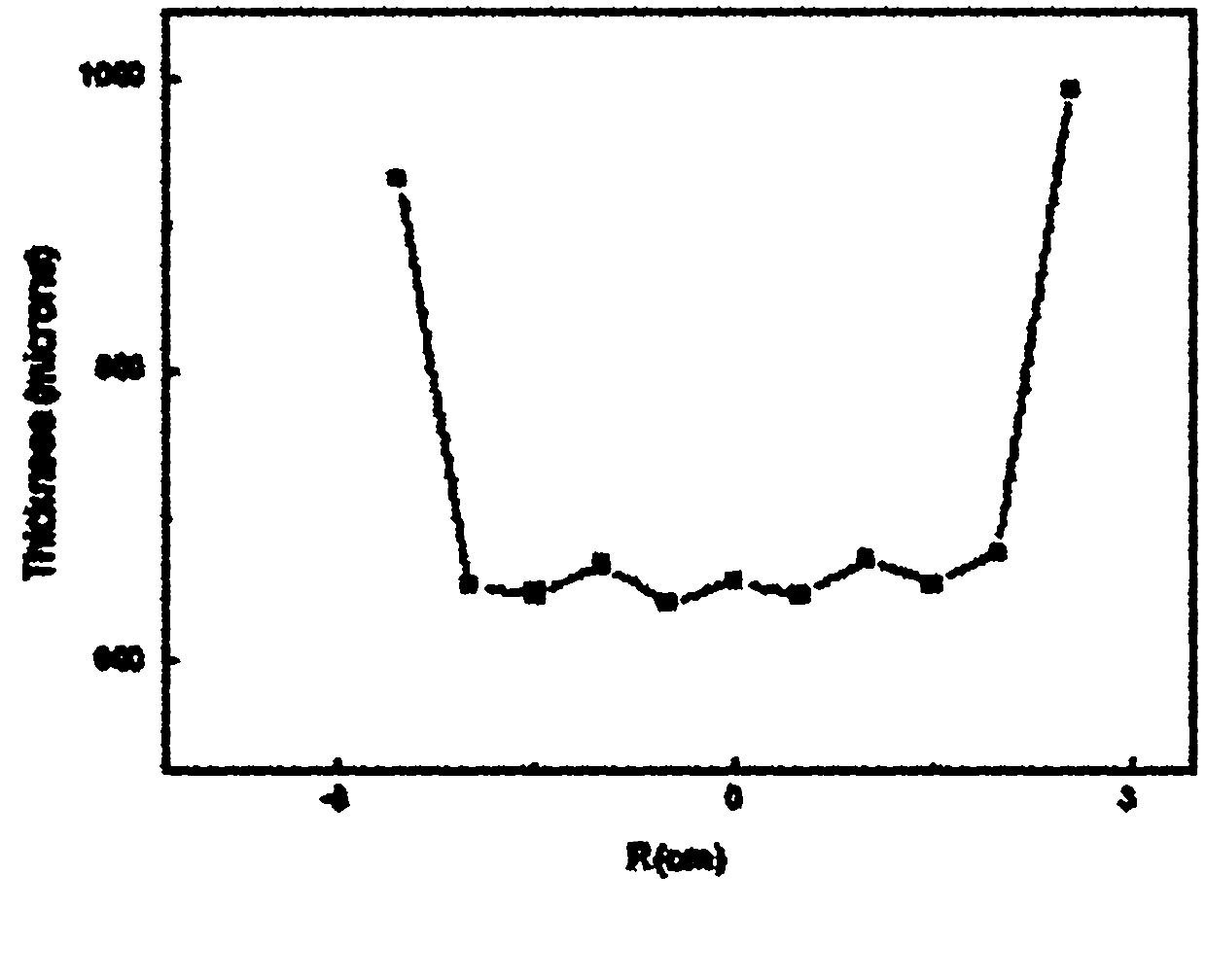

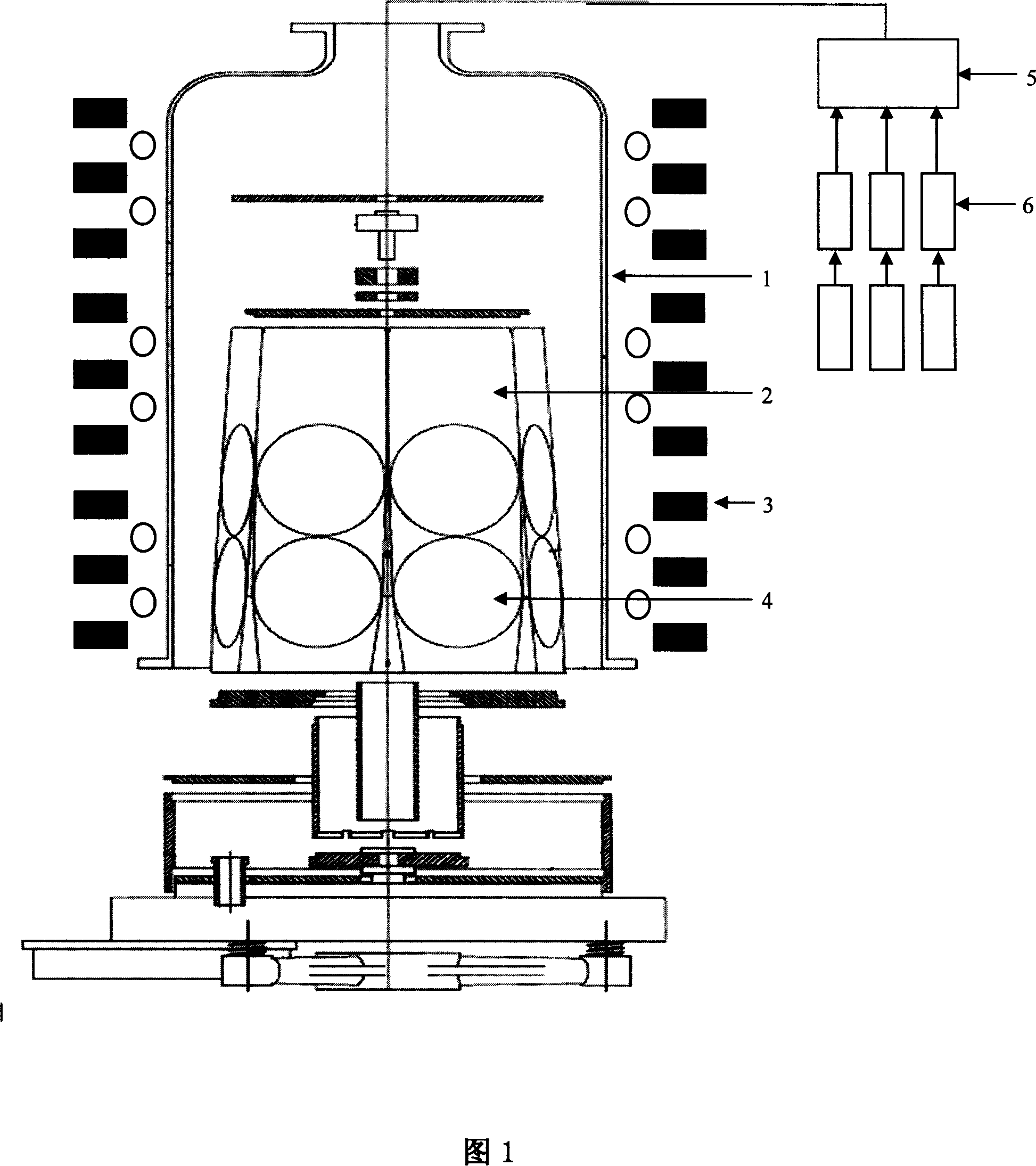

Vertical hydride vapor phase epitaxy growth system

ActiveCN102465333AAvoid transportAchieve growthPolycrystalline material growthFrom chemically reactive gasesSingle crystalGraphite

The invention relates to a vertical hydride vapor phase epitaxy growth system, which comprises a reaction chamber, a graphite support, epitaxy growth substrates and a heating system, wherein the graphite support is arranged in a growth region of the reaction chamber, and the reaction chamber is of a vertical structure; a plurality of epitaxy growth substrates are arranged above the graphite support or inversely arranged below the graphite support; a tail gas outlet is positioned at the lower part of the reaction chamber, wherein the reaction chamber is of an axial sleeve structure and is formed by sleeving a chamber pipe with a gas conduit, wherein the gas conduit is positioned at the inlet part of the chamber pipe, and a plurality of separating gas path structures are arranged inside the inlet part of the gas conduit and axially and uniformly distributed and are used for conveying a reaction gas to the epitaxy growth substrates of the growth region; and the outer conduit wall of the gas conduit extends to exceed the position of the graphite support. The vertical hydride vapor phase epitaxy growth system disclosed by the invention can be used for effectively preventing deposition and blockage caused by pre-reaction and reaction of tail gases, prolonging the sustained growing time of an HVPE (Hydride Vapor Phase Epitaxy) system and obtaining a GaN body single crystal material which cannot exist naturally and cannot grow by a conventional method.

Owner:NANJING UNIV

Manufacturing method for cilicon epitaxial wafer for 6'' VDMOS tube

ActiveCN101047122AGuaranteed uniformityImprove uniformitySemiconductor/solid-state device manufacturingHigh concentrationTower

The present invention relates to a preparation method of silicon epitaxial wafer for power VDMOS tube. Firstly, selection and usage of substrate are important, the selected substrate not only can meet the requirements for device, but also can meet the requirements for epitaxy. Its preparation method includes the following steps: selecting proper gas corrosion flow and gas corrosion time, reducing concentration of gas corrosion impurity in epitaxial reactor so as to reduce self-doping in epitaxial growth process; first layer epitaxial growth, on the substrate surface with high concentration utilizing lower temperature to grow a layer of purity epitaxial layer, encapsulating substrate surface and edge, controlling its growth temperature, growth rate and epitaxial time so as to make encapsulating layer obtain ideal effect, at the same time, selecting proper epitaxial condition to make the deformation of epitaxial wafer be minimum; and second layer epitaxial growth, utilizing tower temperature to grow a layer of epitaxial layer whose resistivity and thickness can meet requirements for device.

Owner:NANJING GUOSHENG ELECTRONICS

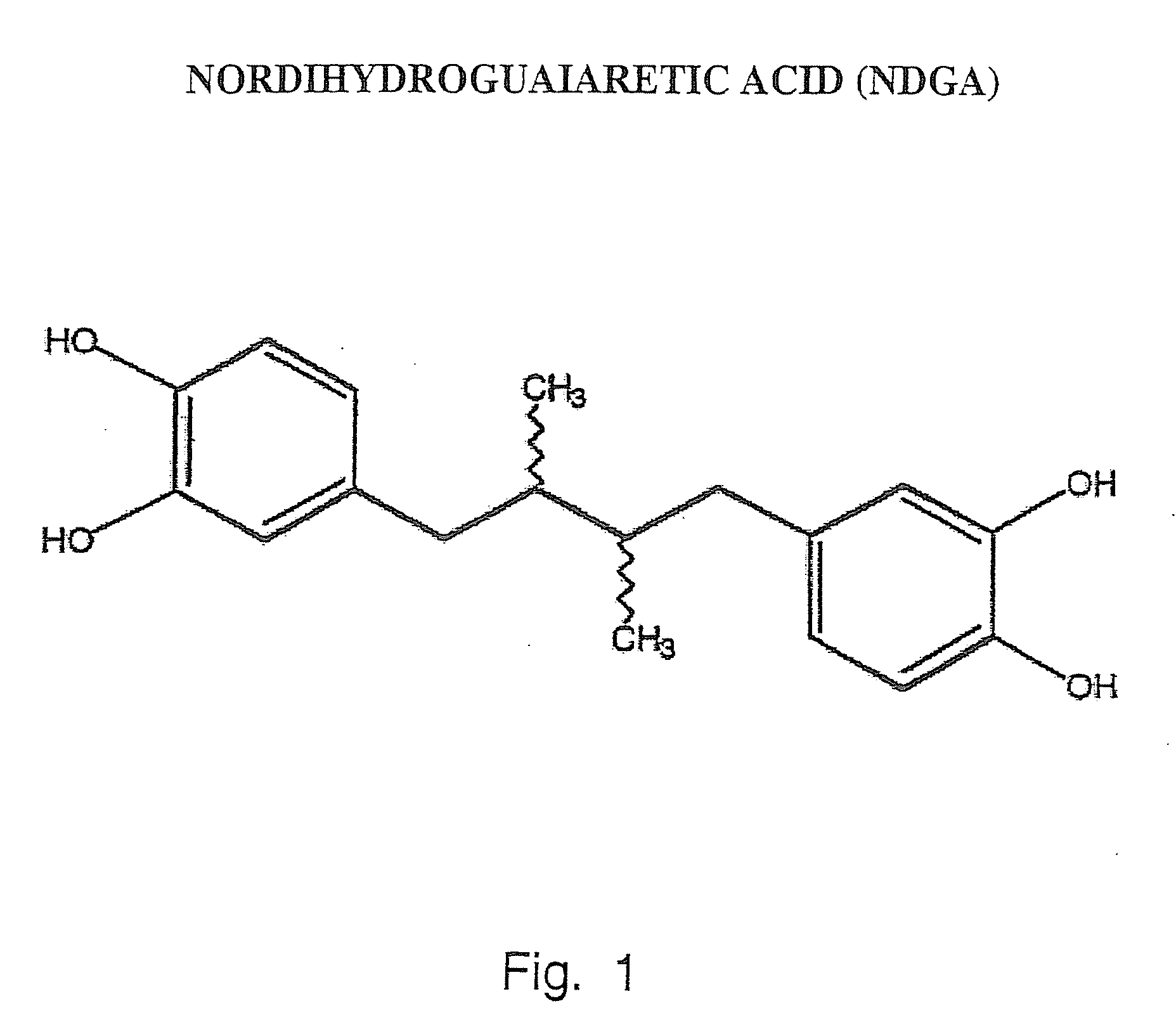

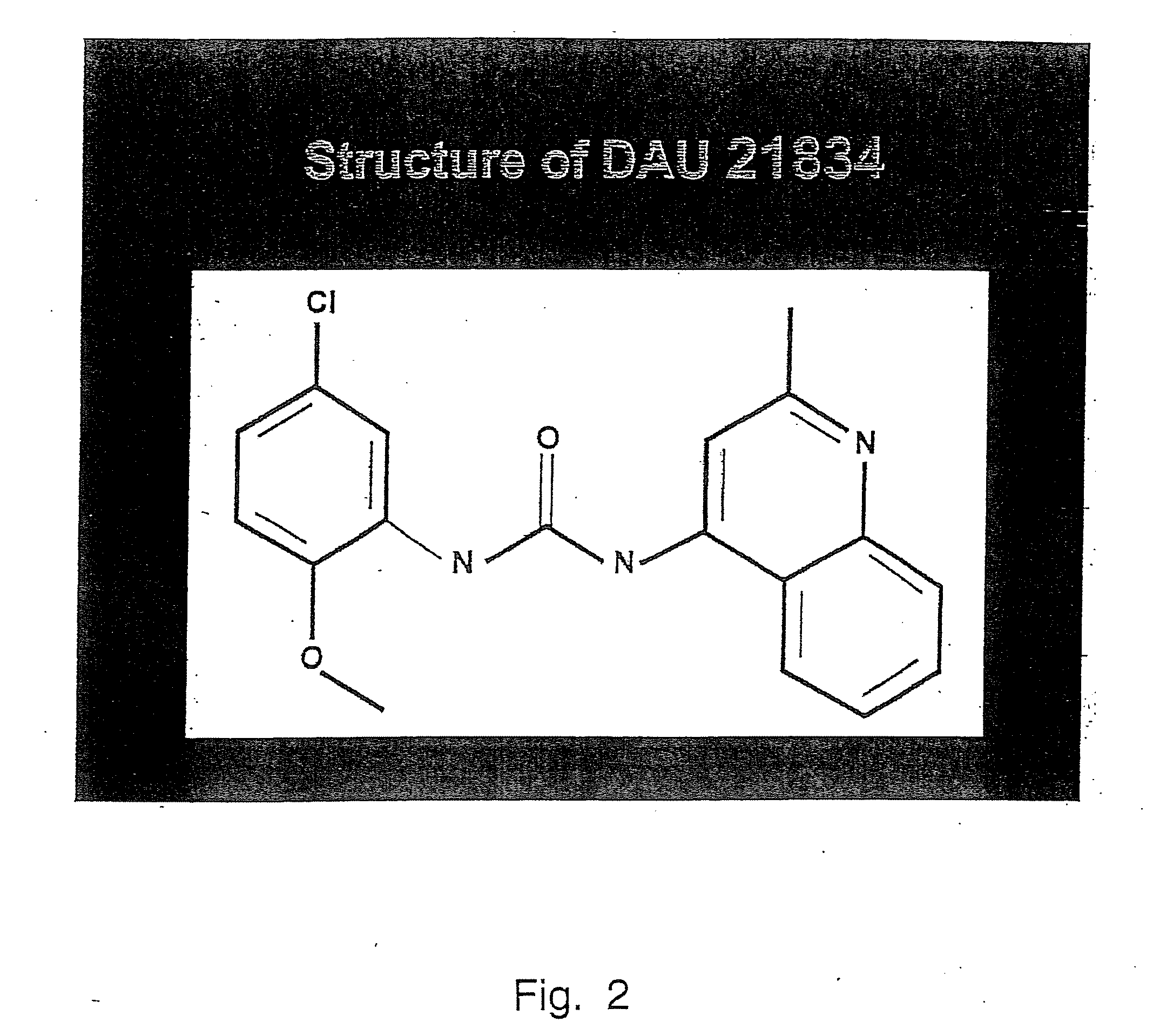

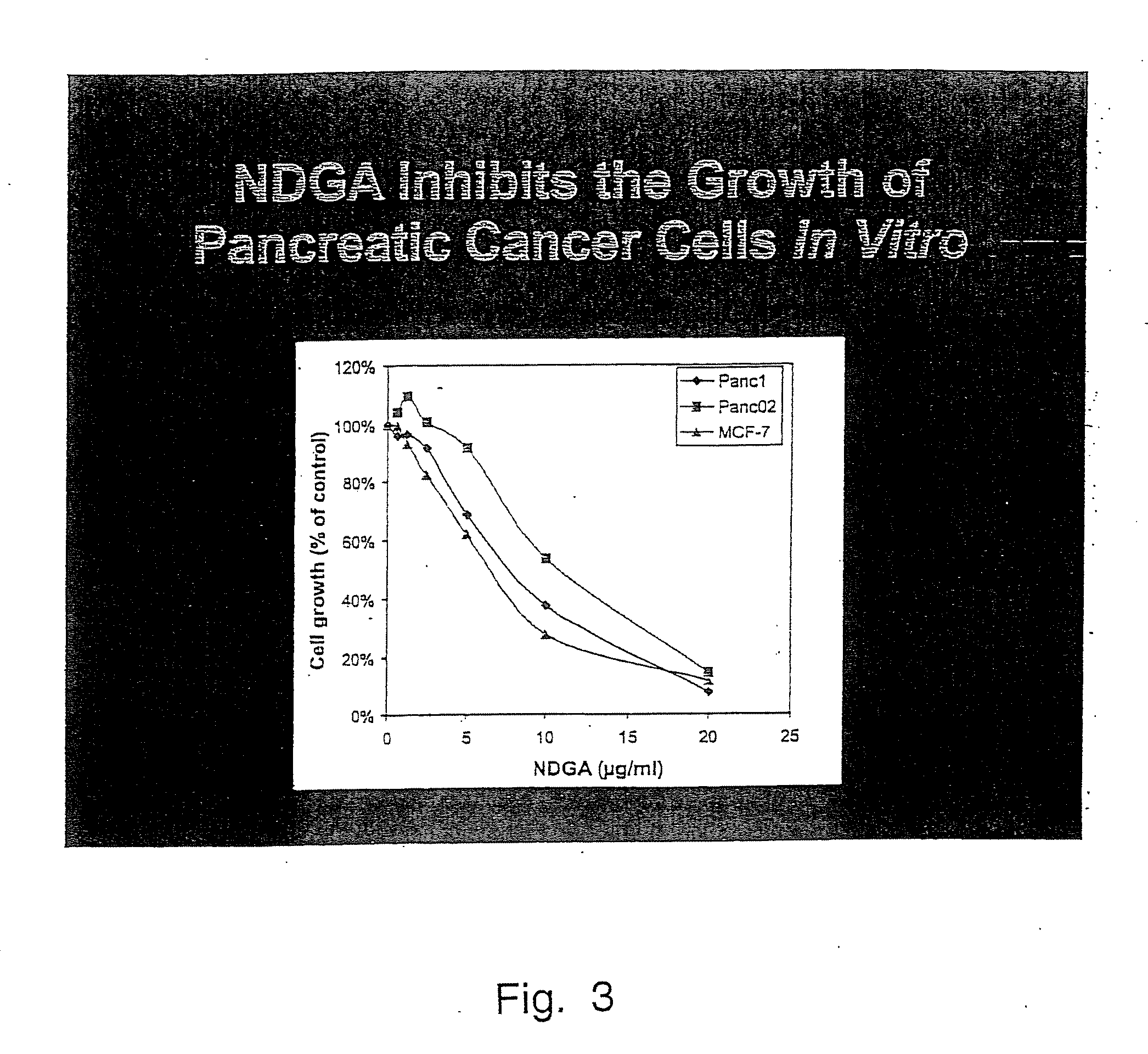

Tyrosine kinase receptor antagonists and methods of treatment for pancreatic and breast cancer

ActiveUS20070099847A1Eliminate side effectsGood effectBiocideCarbohydrate active ingredientsCancer cellGluconic acid

A method of treatment is disclosed whereby cancer cells are brought into contact with a formulation comprising an inhibitor of tyrosine kinase receptors. The formulation may be comprised of an injectable carrier and two or more tyrosine kinase receptor inhibitors which may be nordihydrogluaiaretic acid (NDGA) and doxyrubicine.

Owner:RGT UNIV OF CALIFORNIA

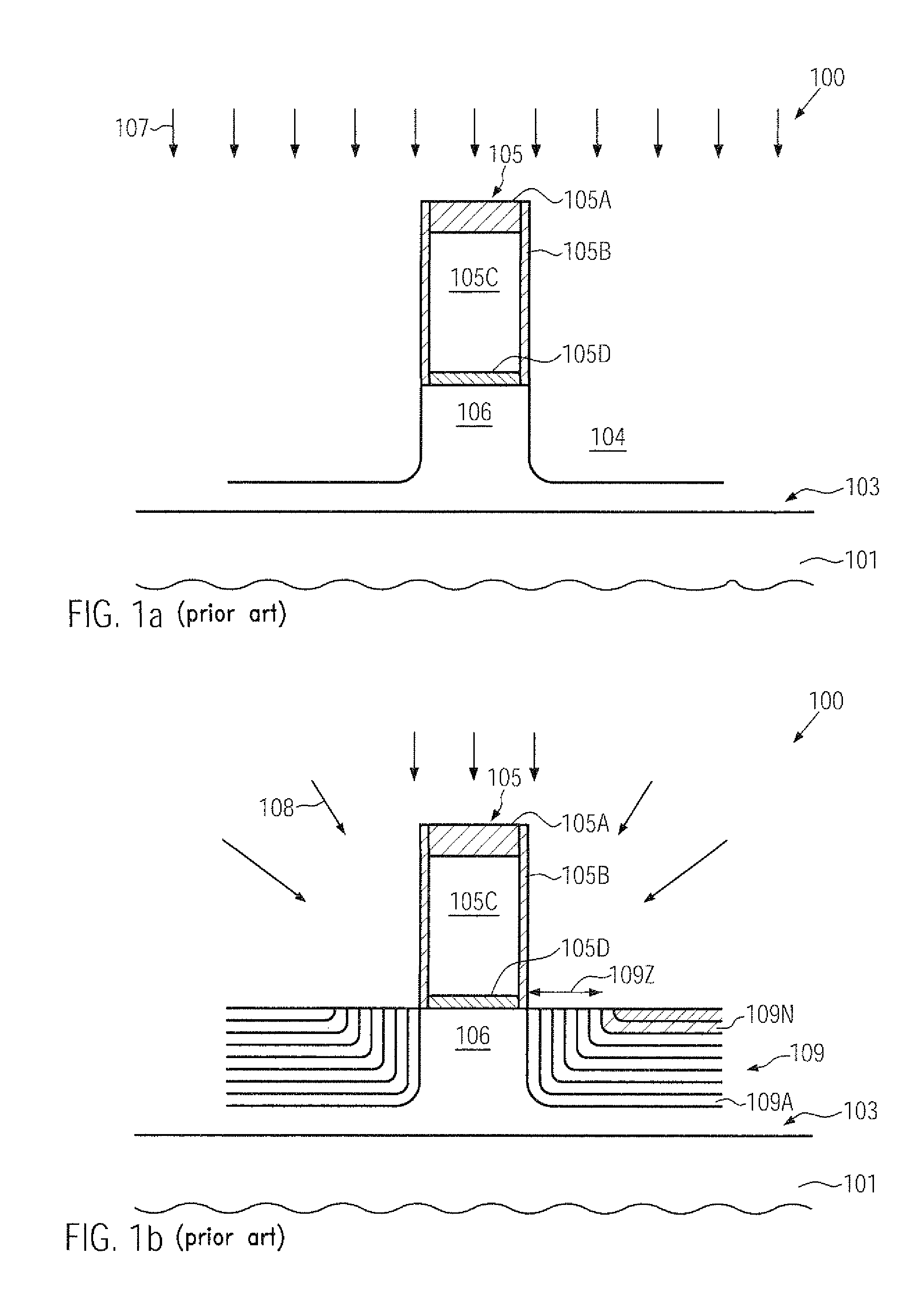

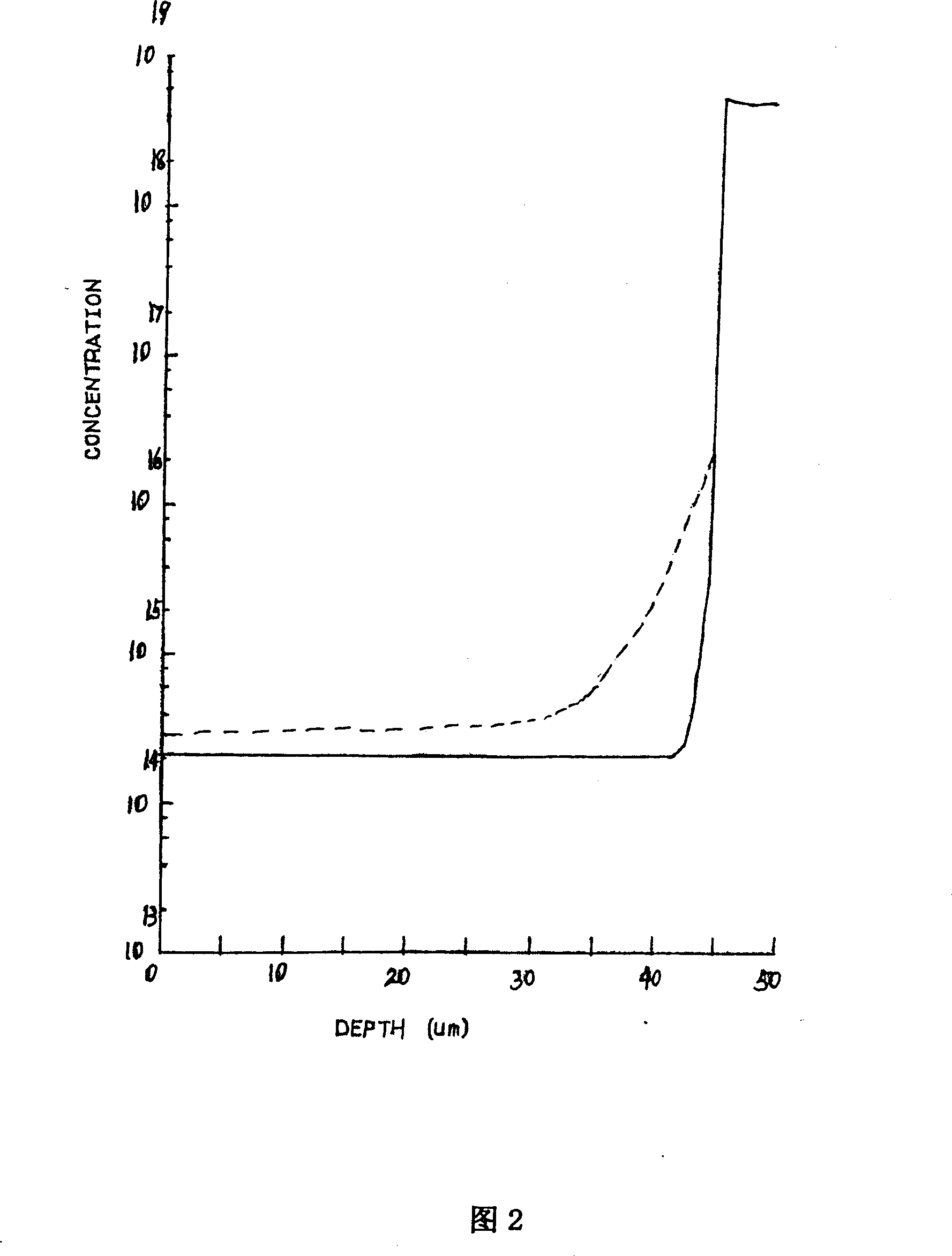

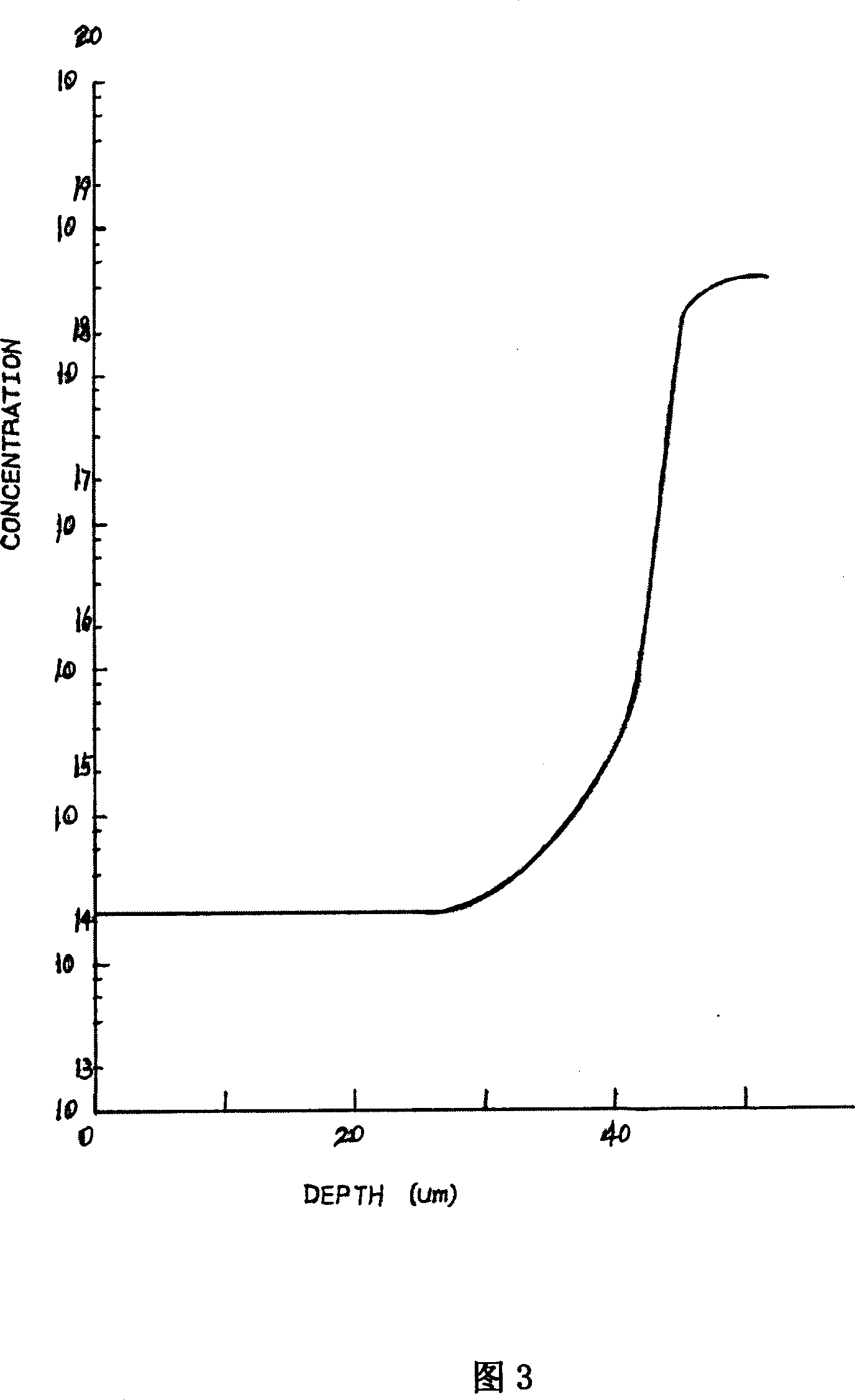

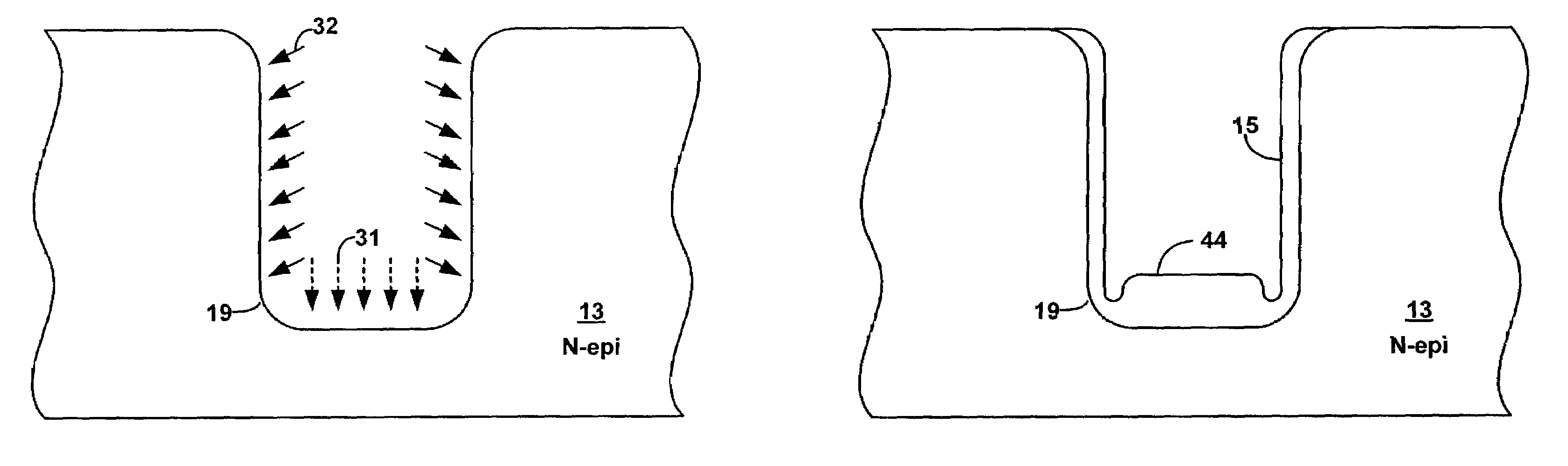

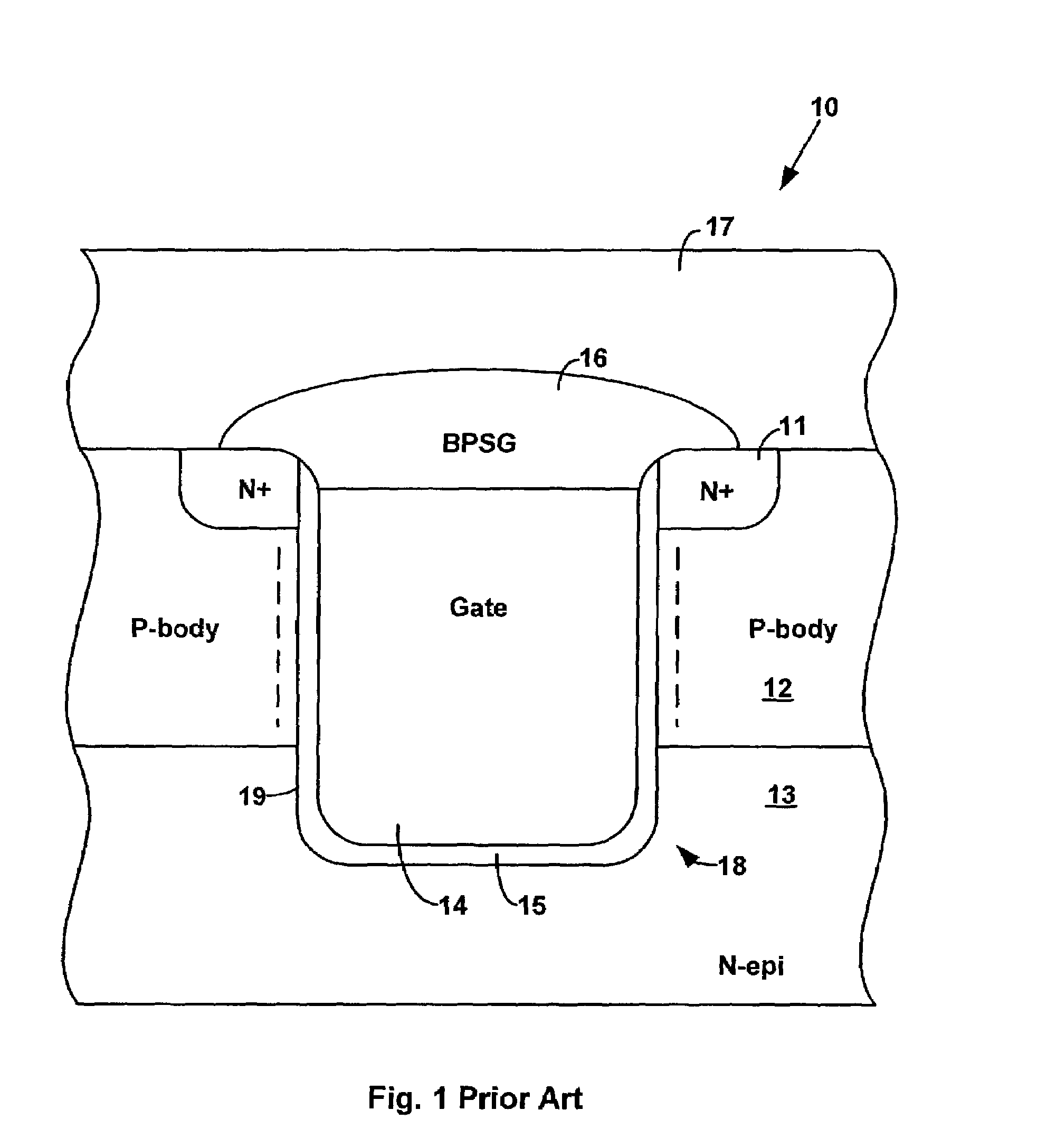

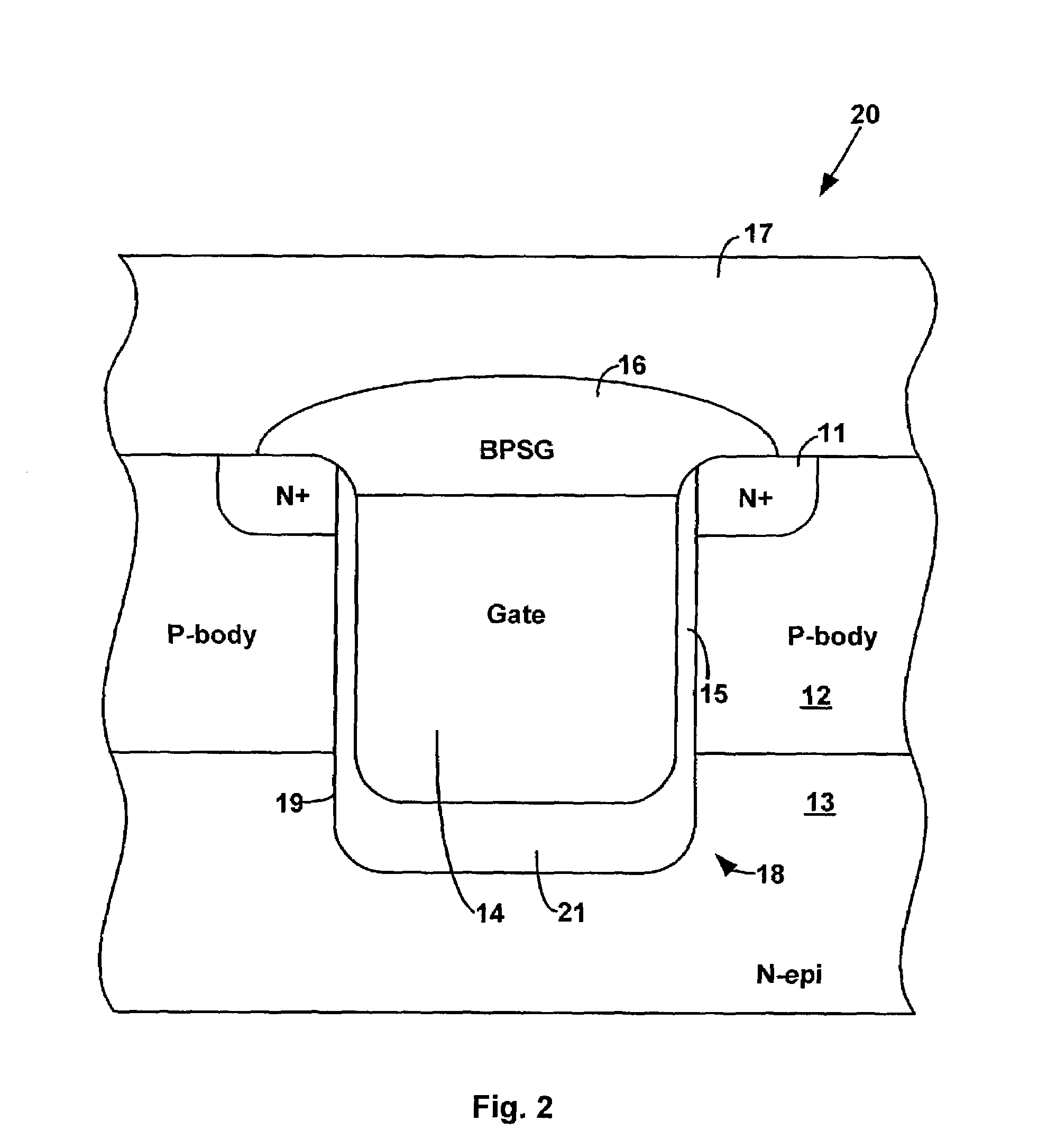

Self-aligned differential oxidation in trenches by ion implantation

InactiveUS7012005B2Increase insulating layer growth rateDecrease insulating layer growth rateSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetEngineering

In accordance with the present invention, a trench MOSFET is formed by creating a trench in a semiconductor substrate. A portion of either a side wall of the trench or the bottom of the trench is implanted with an implant species. An insulating layer is then grown overlying the bottom and side wall of the trench. The implant species is selected such that the insulating layer grows more quickly on the bottom of the trench than on the side wall of the trench, resulting in a thicker insulating layer in the bottom of the trench than on the trench side walls.

Owner:SILICONIX

High-pressure vessel for growing group III nitride crystals and method of growing group III nitride crystals using high-pressure vessel and group III nitride crystal

ActiveUS8236267B2Reduce depositionQuality improvementAfter-treatment apparatusPolycrystalline material growthOxygen contaminationEtching

Owner:SIXPOINT MATERIALS

Modulation of meiotic recombination

InactiveUS20040023388A1Inhibit cell proliferationReduced growth rateStable introduction of DNAFermentationFunctional activityMeiosis

The invention provides methods of modifying the level of expression or functional activity of factors such as enzymes or other catalytic proteins or structural proteins, alone or in concert, to modify the frequency of meiotic homologous recombination involving the exchange of genetic information between non-sister chromatids from homologous maternal and paternal chromosomes. The steps at which modulation may occur include: homologous chromosome pairing, double-strand break formation; resection; strand invasion; branch migration; and resolution. Methods of plant and animal breeding are also provided that utilize the modulation of meiotic homologous recombination.

Owner:AGRI & AGRI FOOD +1

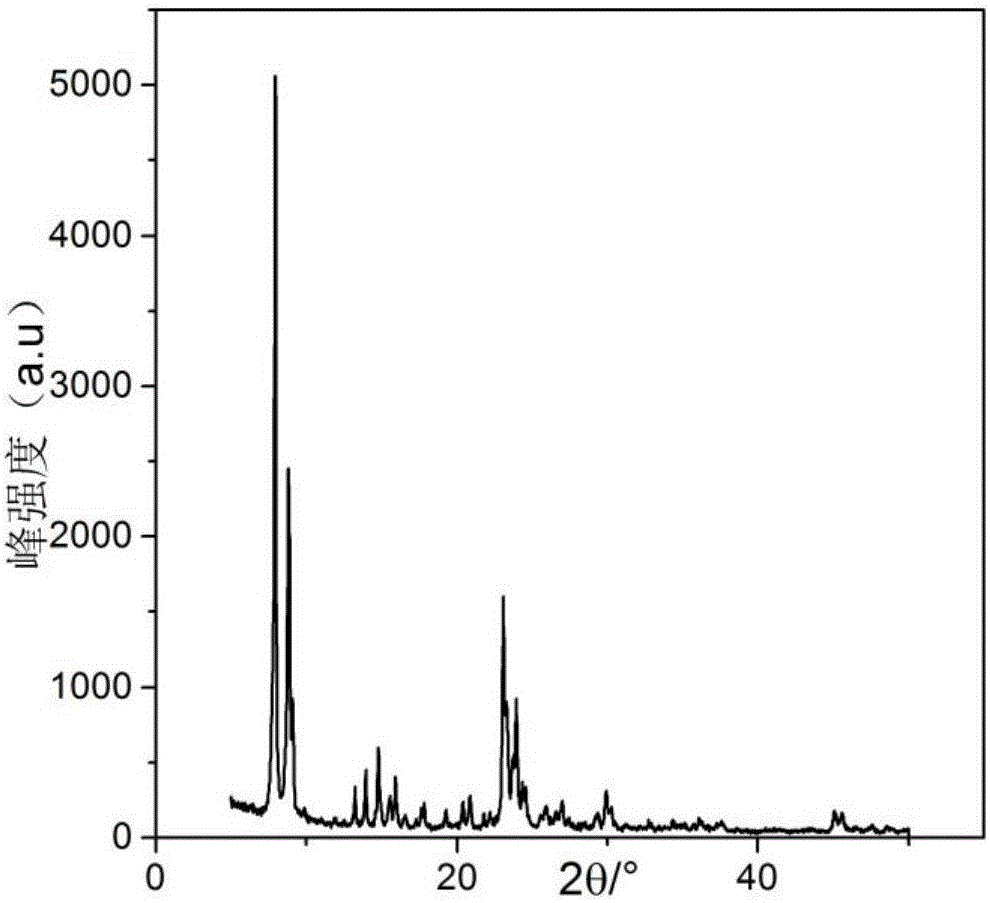

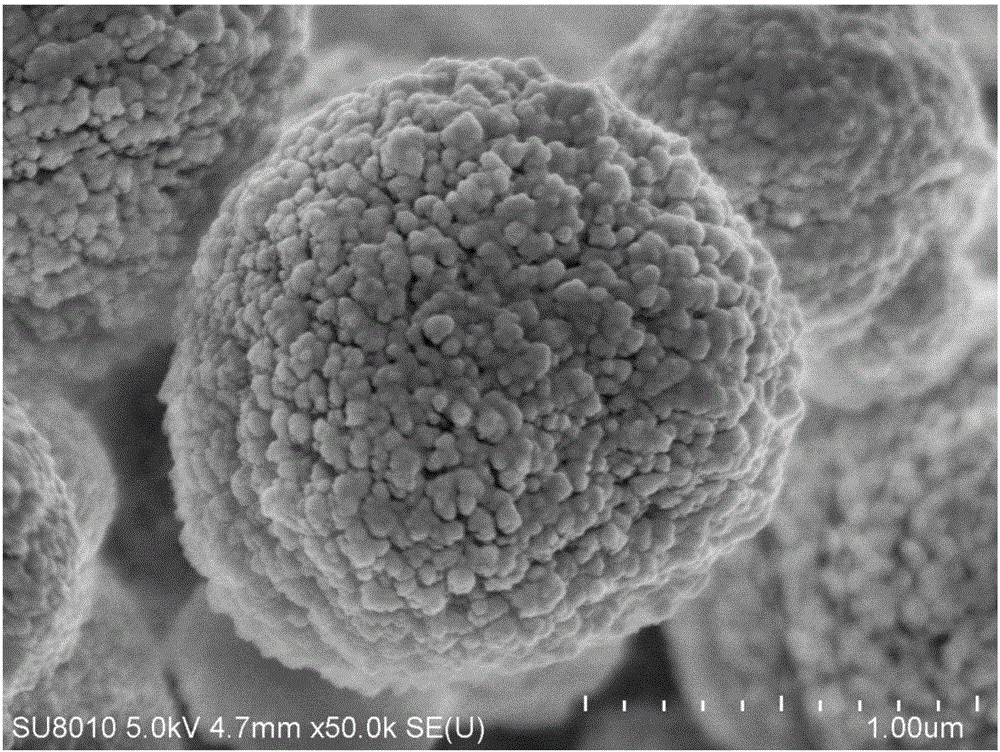

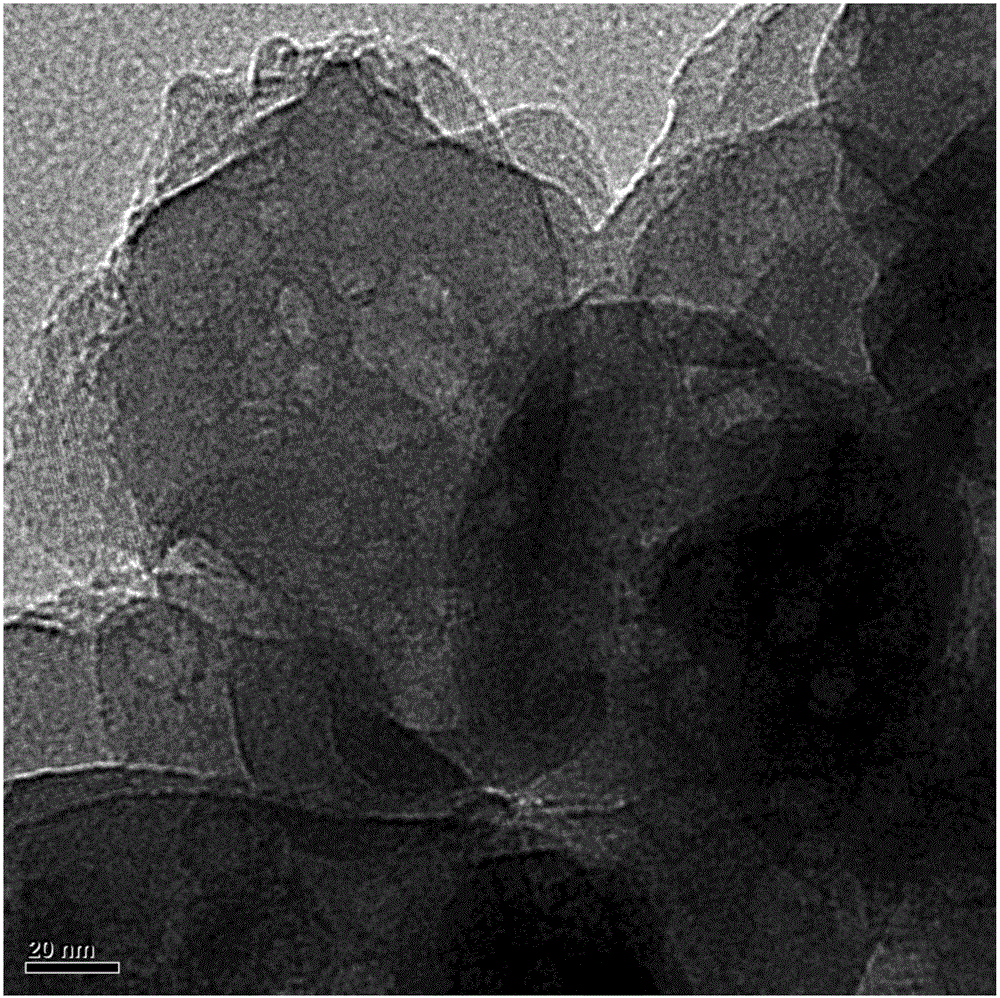

Multilevel structure ZSM-5 zeolite molecular sieve, as well as synthetic method and application thereof

ActiveCN106673008AImprove diffusion abilityHigh catalytic activityMolecular sieve catalystsOrganic compound preparationMolecular sieveSide reaction

The invention relates to a synthesized multilevel structure ZSM-5 zeolite molecular sieve with intracrystalline meso pores and intercrystalline meso pores, as well as a synthetic method and an application thereof. Except micropores of the zeolite structure, the multilevel structure ZSM-5 zeolite molecular sieve comprises the intracrystalline mesoporous and intercrystalline mesoporous structure, wherein primary nanometer crystal grain size is 40-500nm, and secondary accumulated particle size is 500nm-5[mu]m. The structure greatly improves diffusion performance and the catalyst activity of the molecular sieve, reduces possibility of generation of side reaction and carbon deposit, improves carbon accommodating capability of the molecular sieve catalyst, and prolongs life of the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

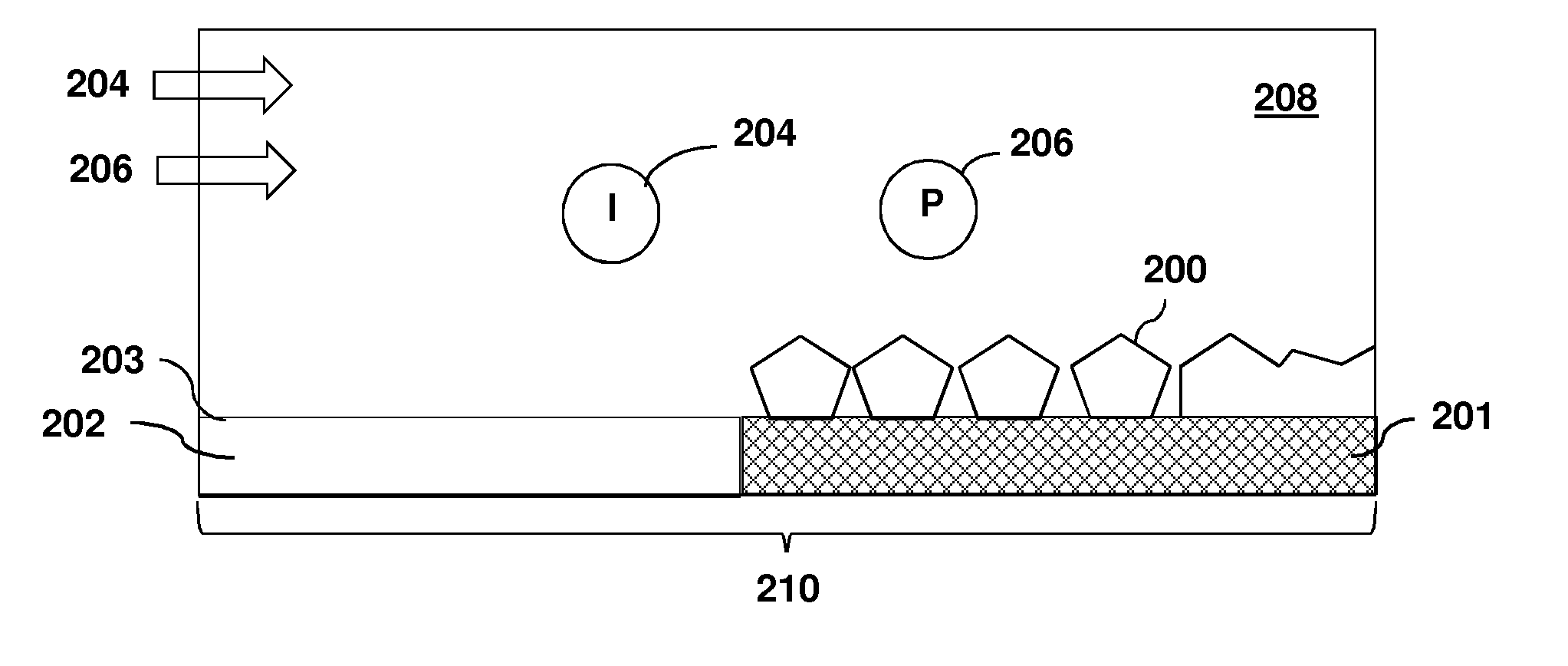

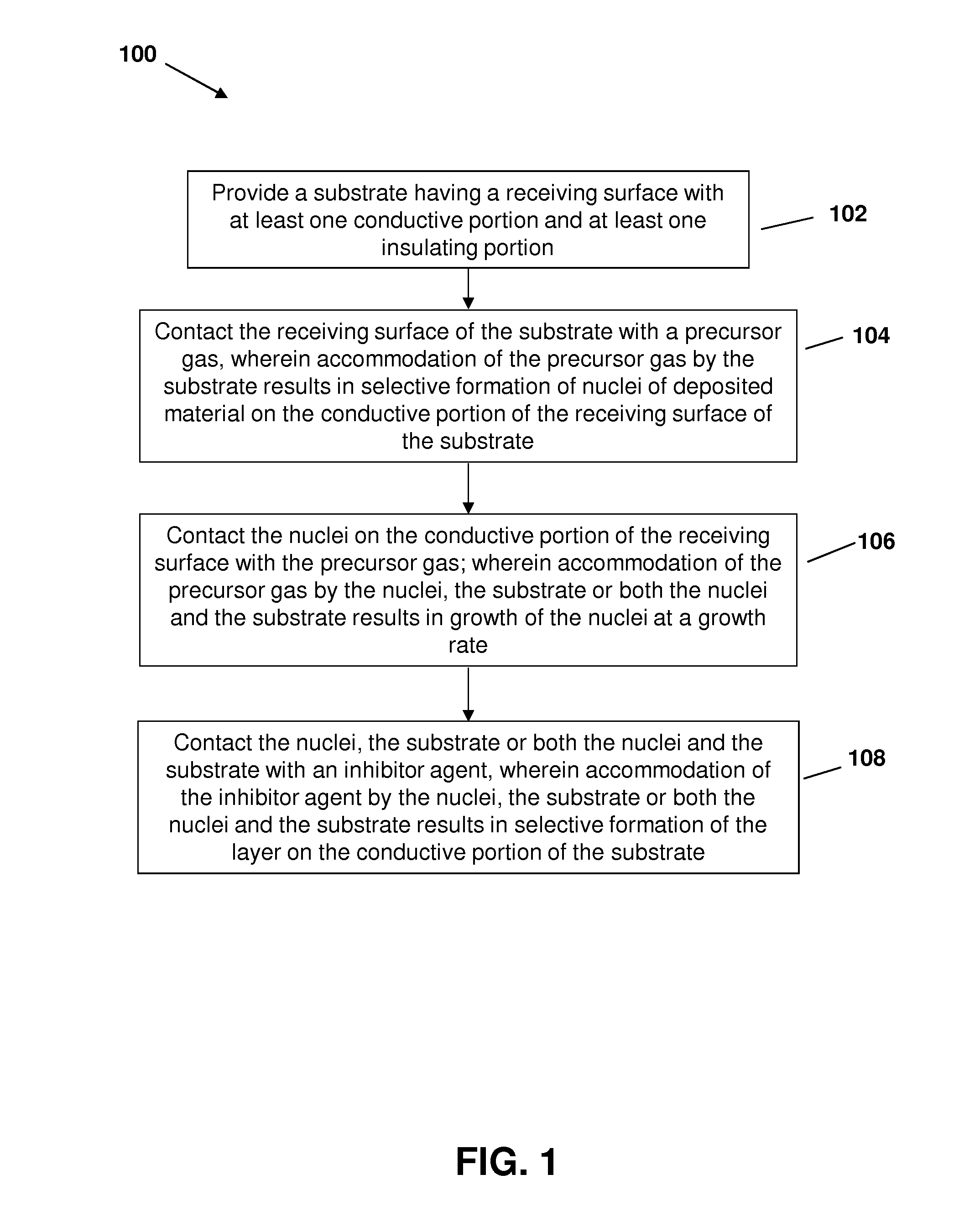

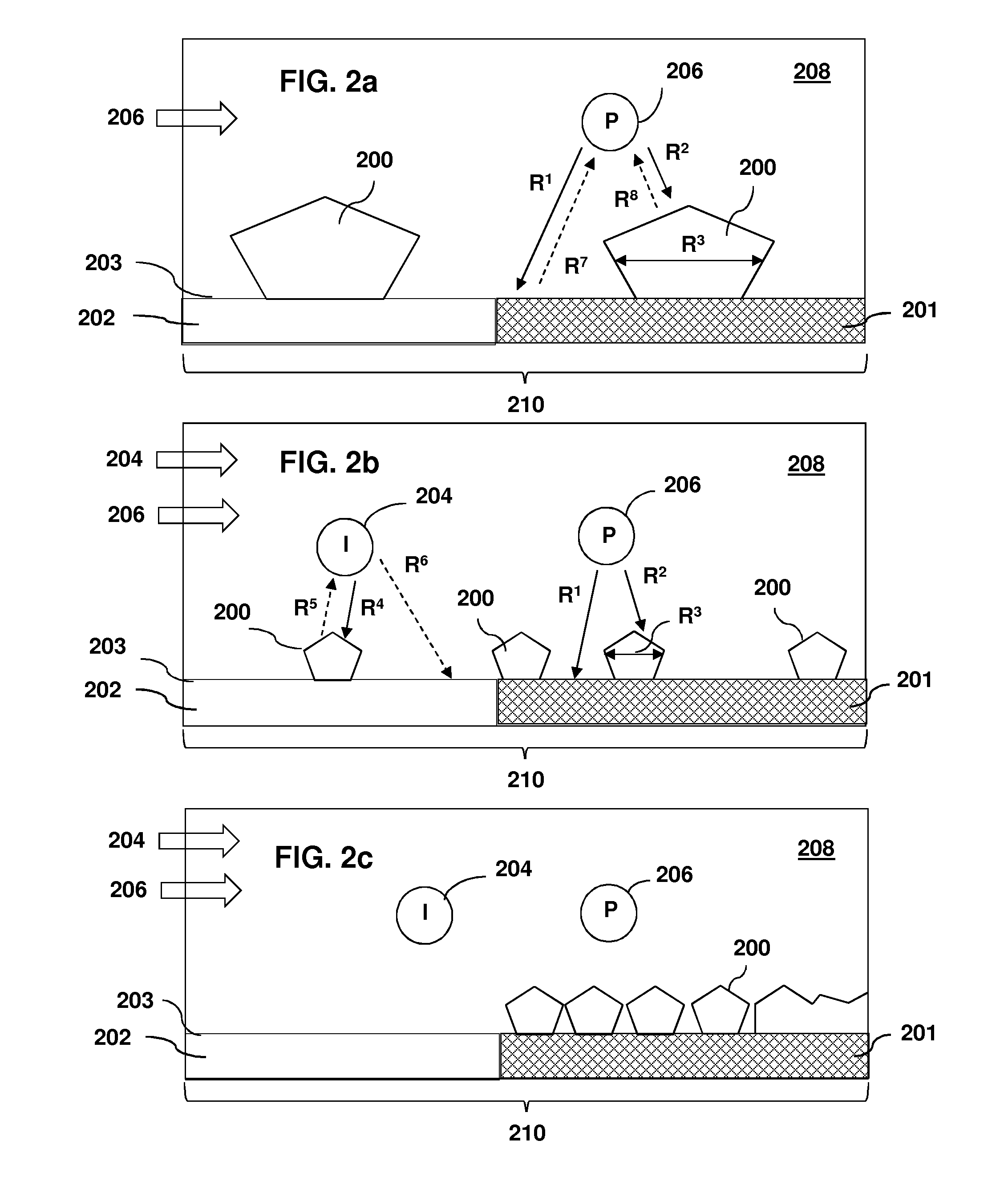

Use of an inhibitor molecule in chemical vapor deposition to afford deposition of copper on a metal substrate with no deposition on adjacent sio2 substrate

ActiveUS20160148839A1Reduced growth rateSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseCopper

Provided herein are methods for selectively forming layers of metal films on one portion of a substrate while leaving adjacent portions of the substrate uncoated. The methods provide for selectively depositing metal films on a conductive surface, such as ruthenium oxide, disposed on or near an insulating portion of the substrate, such as a silicon dioxide (SiO2) surface. The invention provides methods to simultaneously contact the substrate surface with both the precursor gas and the inhibitor agent leading to the selective formation of metal nuclei on the conductive portion of the substrate. In the methods described, nuclei are selectively formed by a disproportionation reaction occurring on the conductive portion of the substrate but not on the insulating portion of the substrate.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

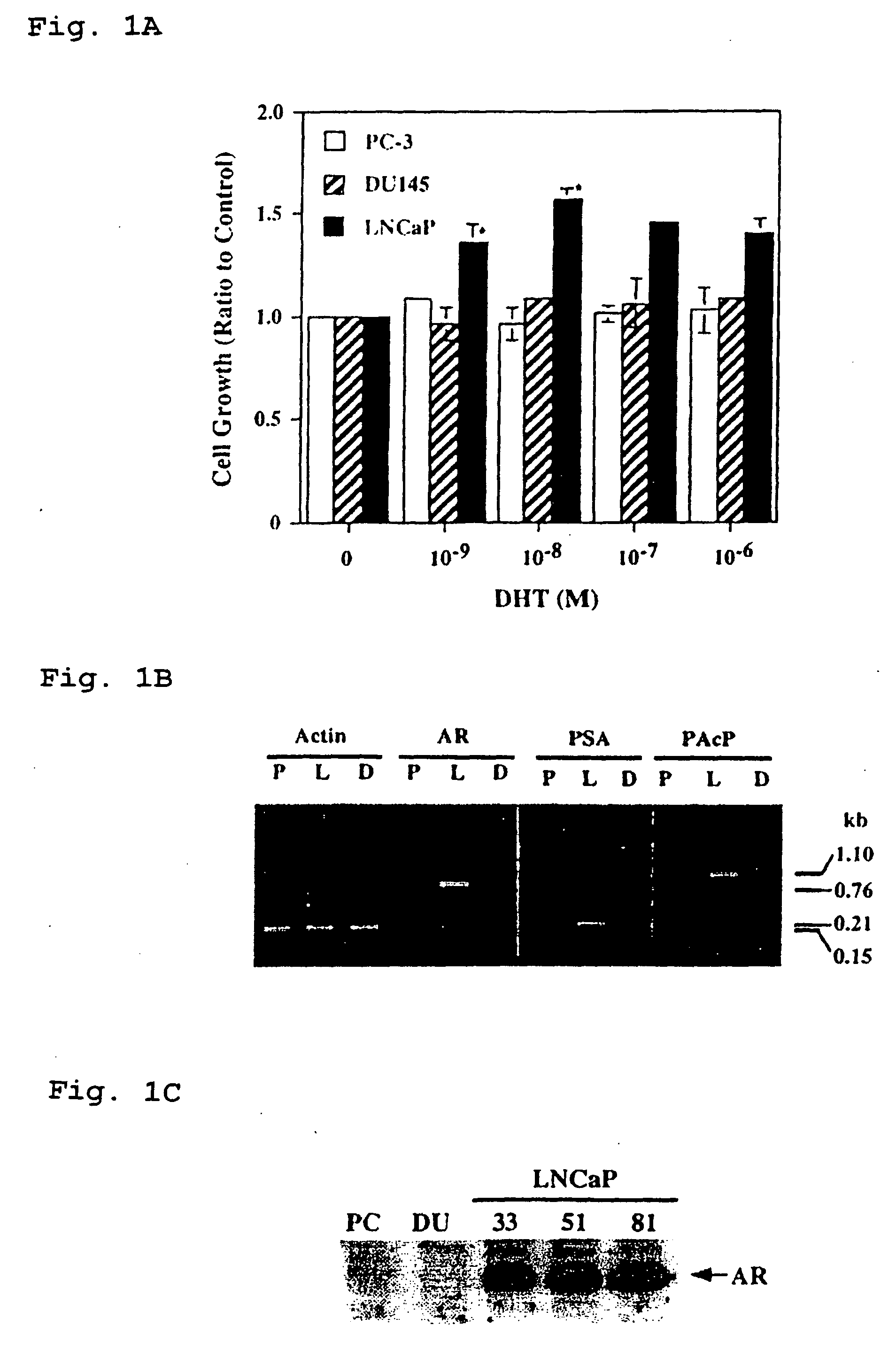

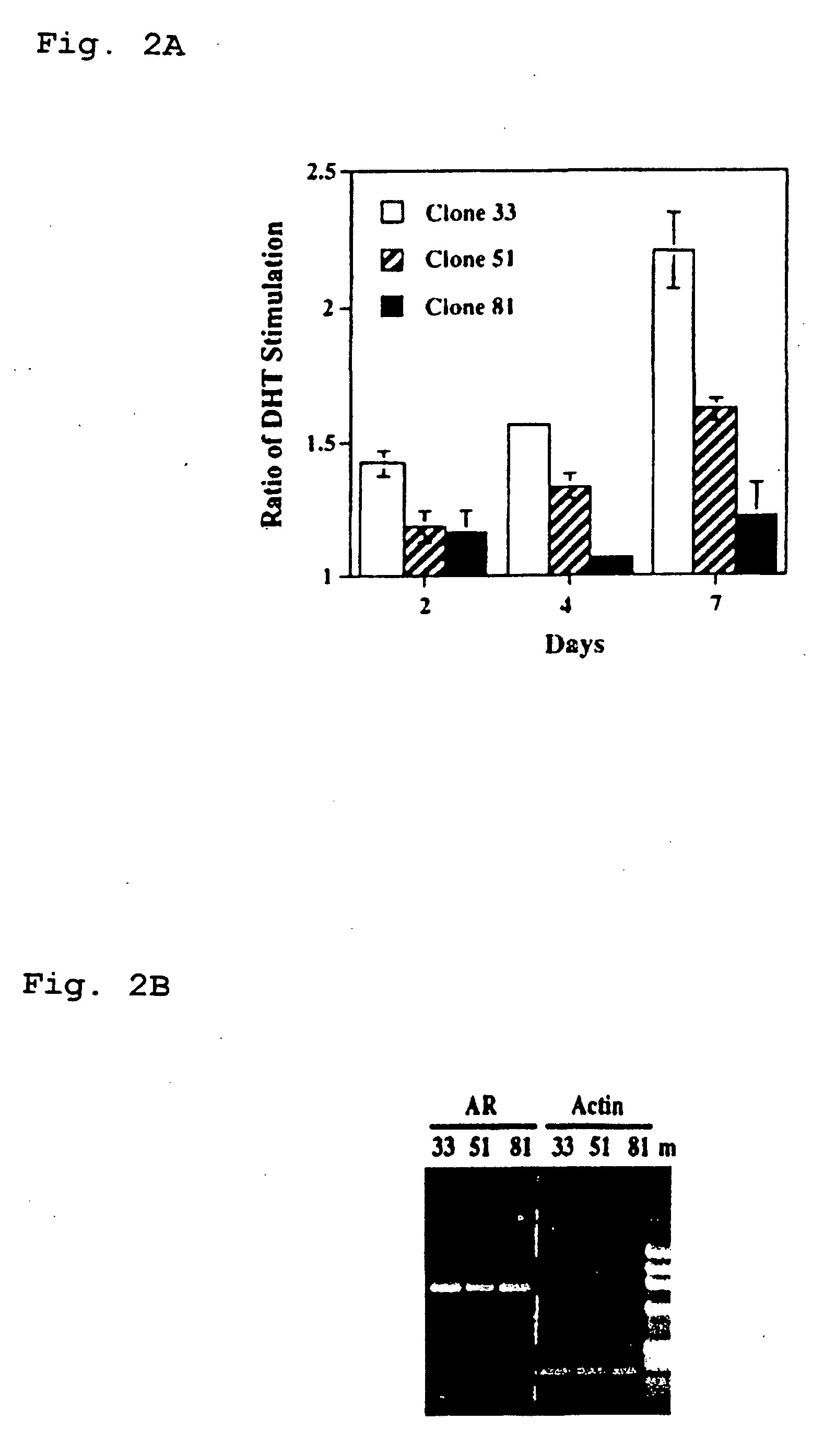

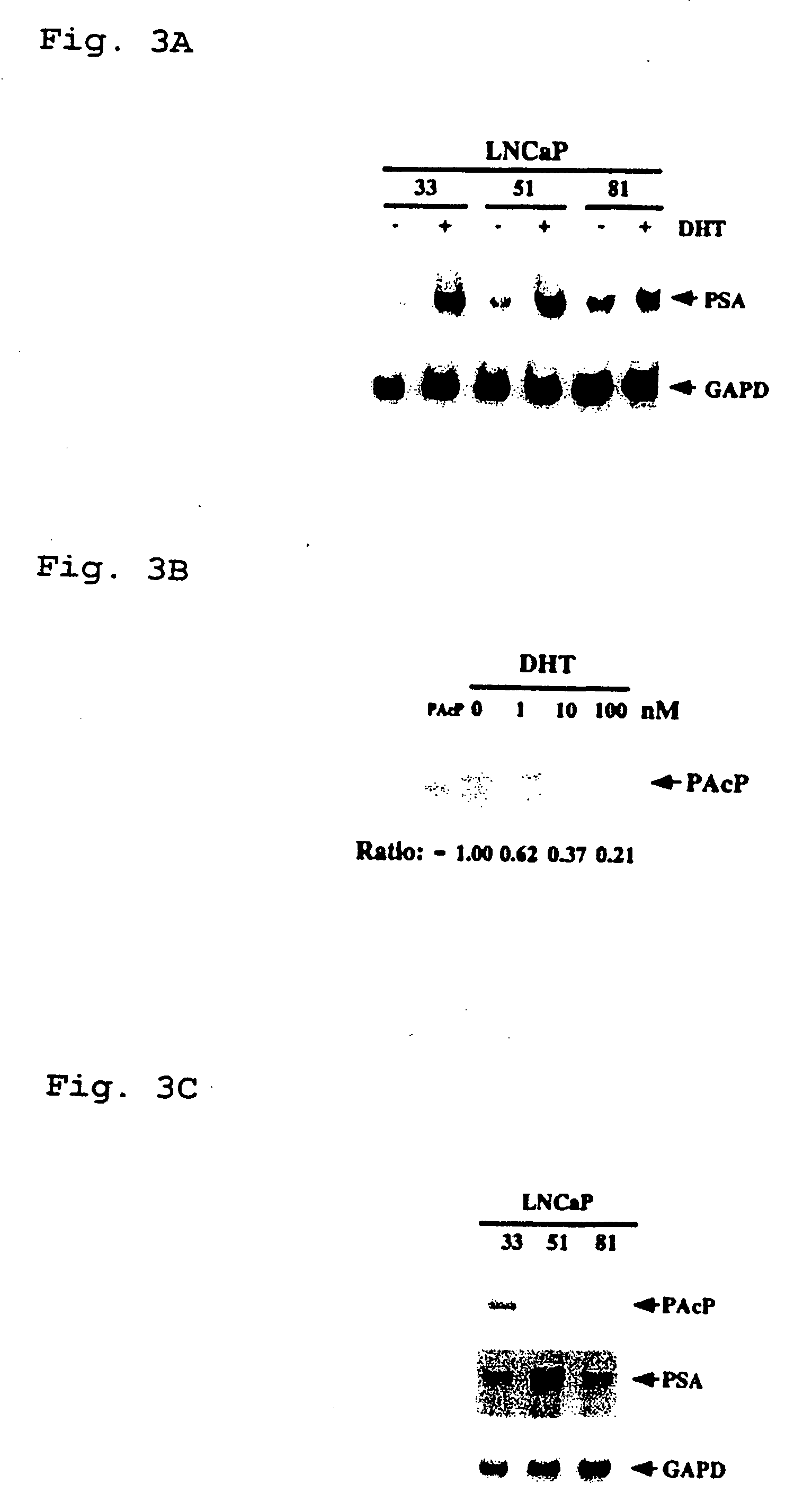

Therapeutic and diagnostic applications of prostatic acid phosphatase in prostate cancer

InactiveUS20060294615A1Good curative effectGood effectBiocideGenetic material ingredientsAndrogenMammal

Presented is a therapeutic method to treat prostate carcinomas in mammals comprising the administration of cellular PAcP protein. Also presented is a method to diagnose androgen-insensitive prostate carcinomas by determining the expression level of cellular PAcP in the prostate carcinomas, a decrease in expression being indicative of androgen-insensitivity. A promoter region that is specifically expressed in prostate tissue is presented, as is a xenograft animal model that mimics human prostate carcinomas in the expression of cellular PAcP.

Owner:BOARD OF RGT UNIV OF NEBRASKA

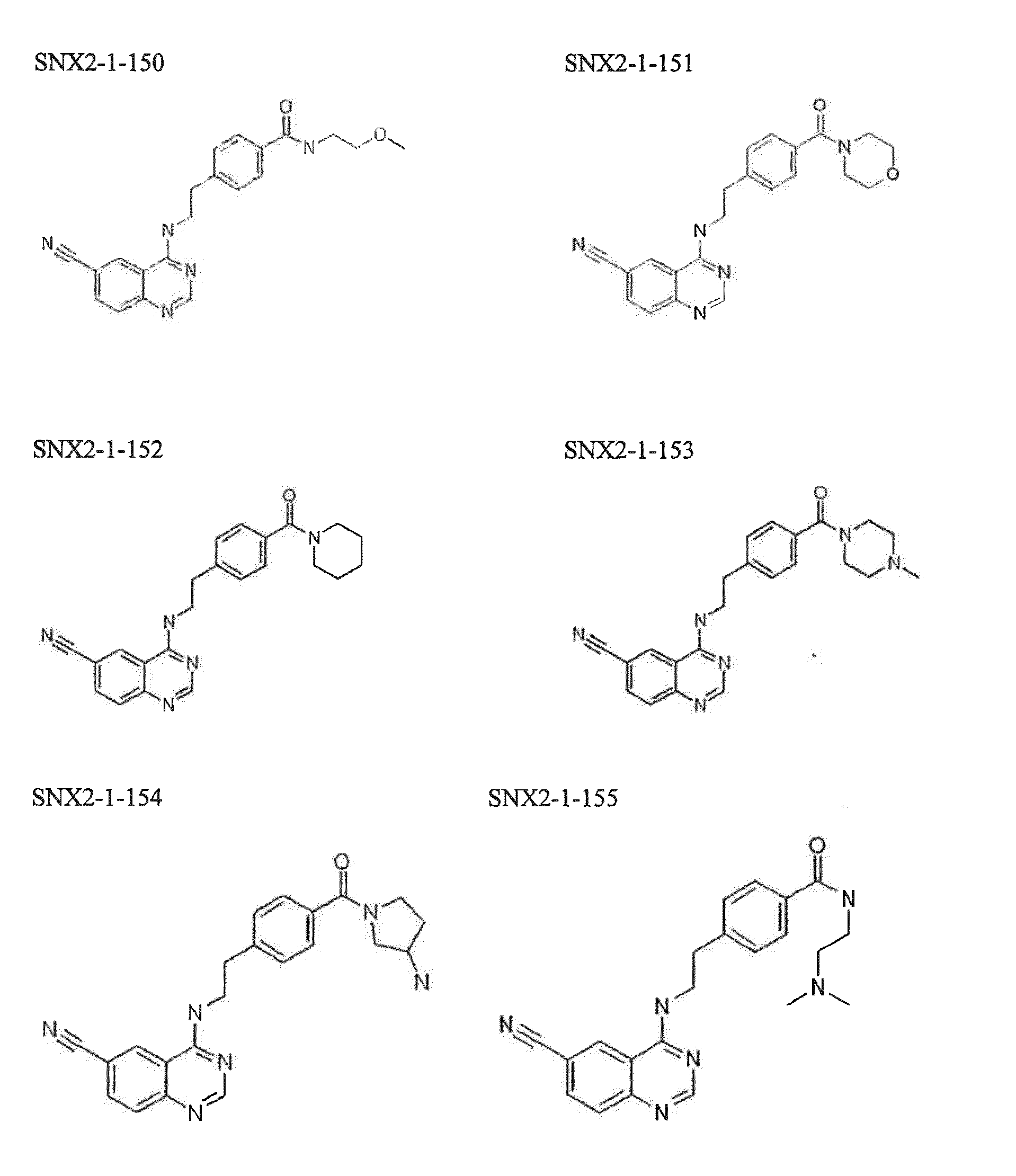

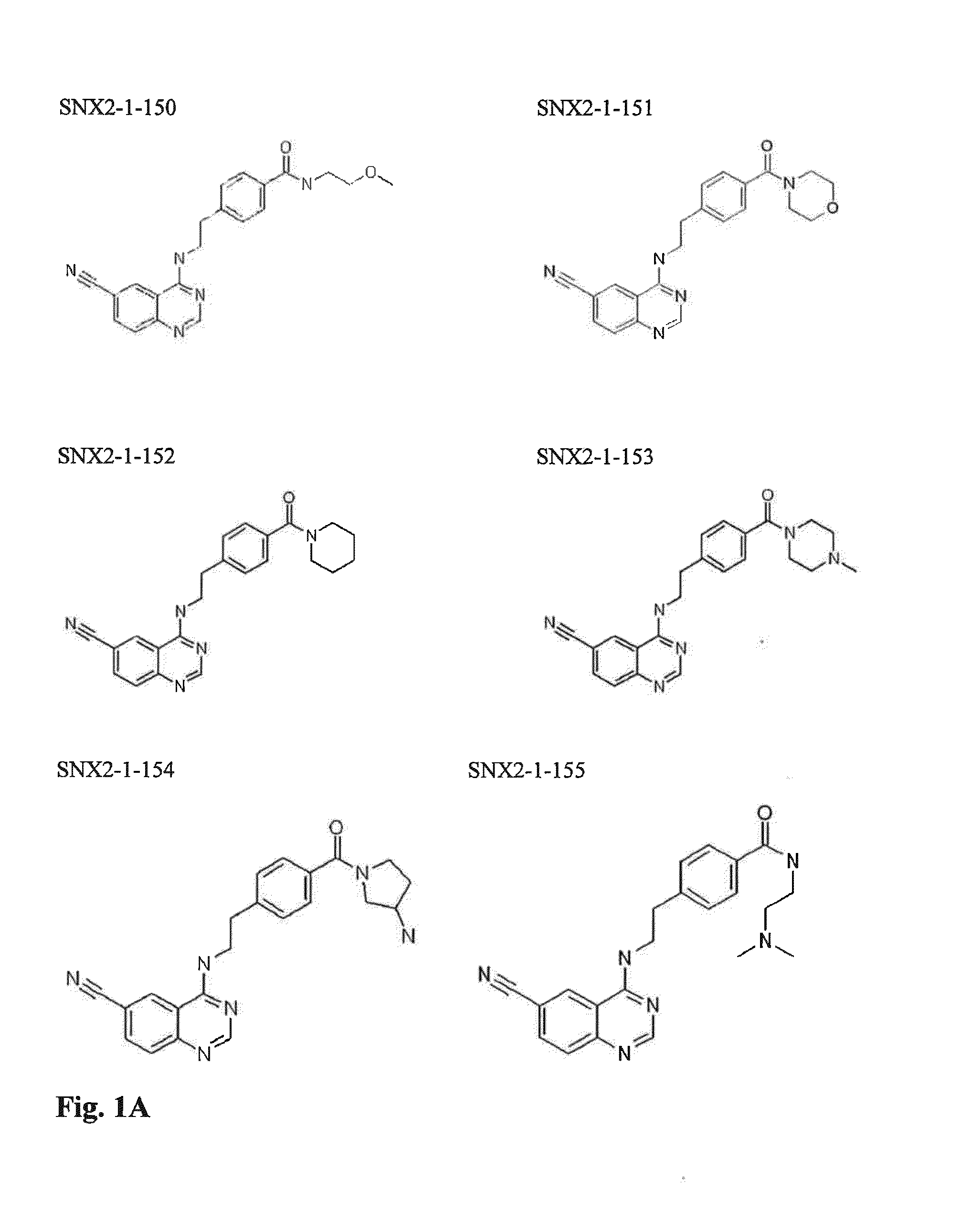

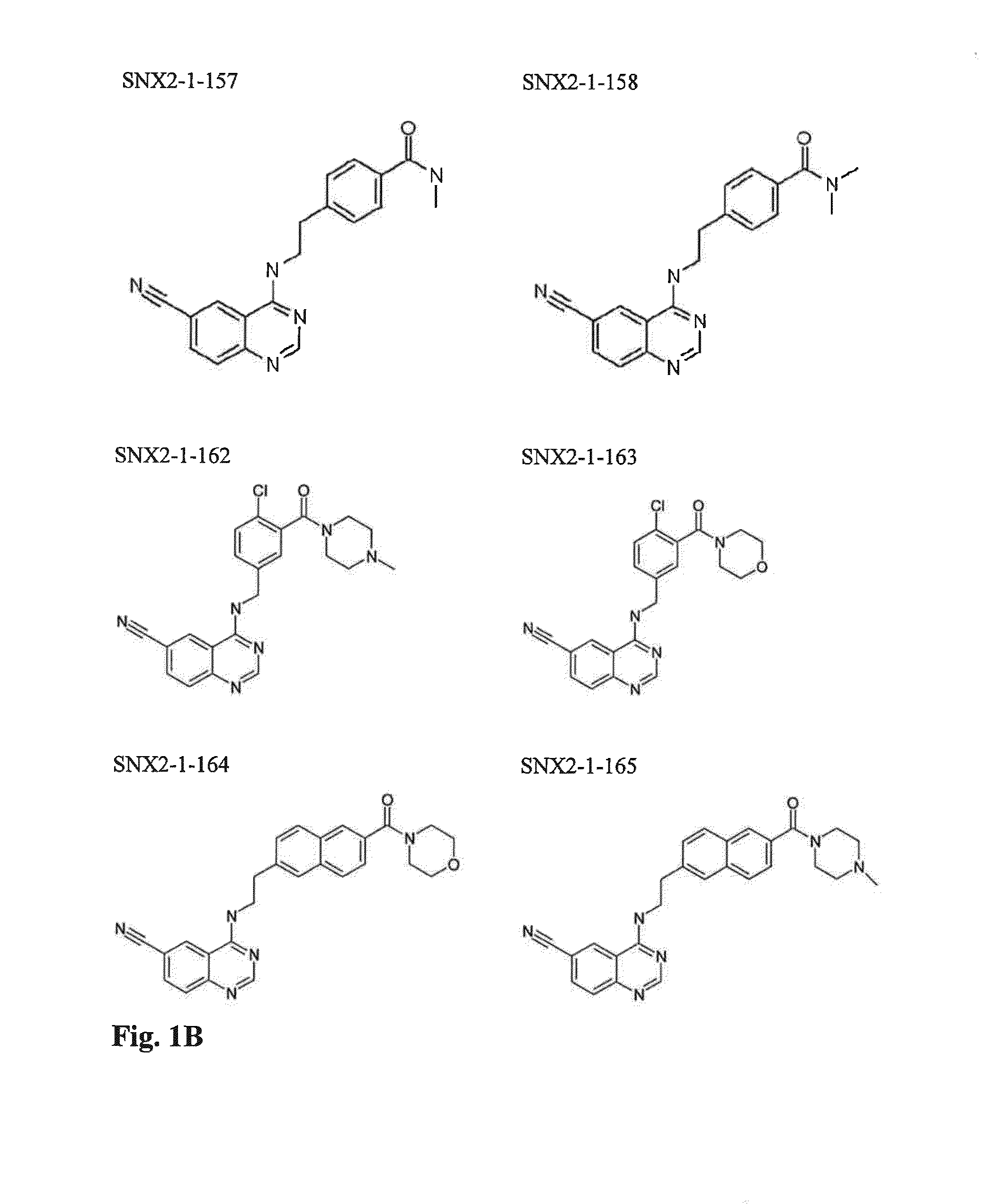

Cdk8-cdk19 selective inhibitors and their use in Anti-metastatic and chemopreventative methods for cancer

ActiveUS20140038958A1Improve impactPoor survivalOrganic active ingredientsBiocideDiseaseTumor recurrence

The invention relates to the compounds and methods for inhibiting the Cyclin-Dependent Kinase Inhibitor (CDKI) pathway. More particularly, the invention relates to compounds and methods for inhibiting the CDKI pathway for studies of and intervention in senescence-related and other CDKI-related diseases. The invention provides new compounds having improved solubility and / or potency, and methods for their use. In various aspects, the invention relates to the treatment of cancer. The invention provides methods for chemoprevention and prevention of tumor recurrence or metastasis. The invention further provides diagnostic techniques for treatment for certain cancer types. The invention utilizes specific inhibitors of CDK8 / 19 and / or measurement of CDK8 levels in a patient.

Owner:SENEX BIOTECHNOLOGY INC

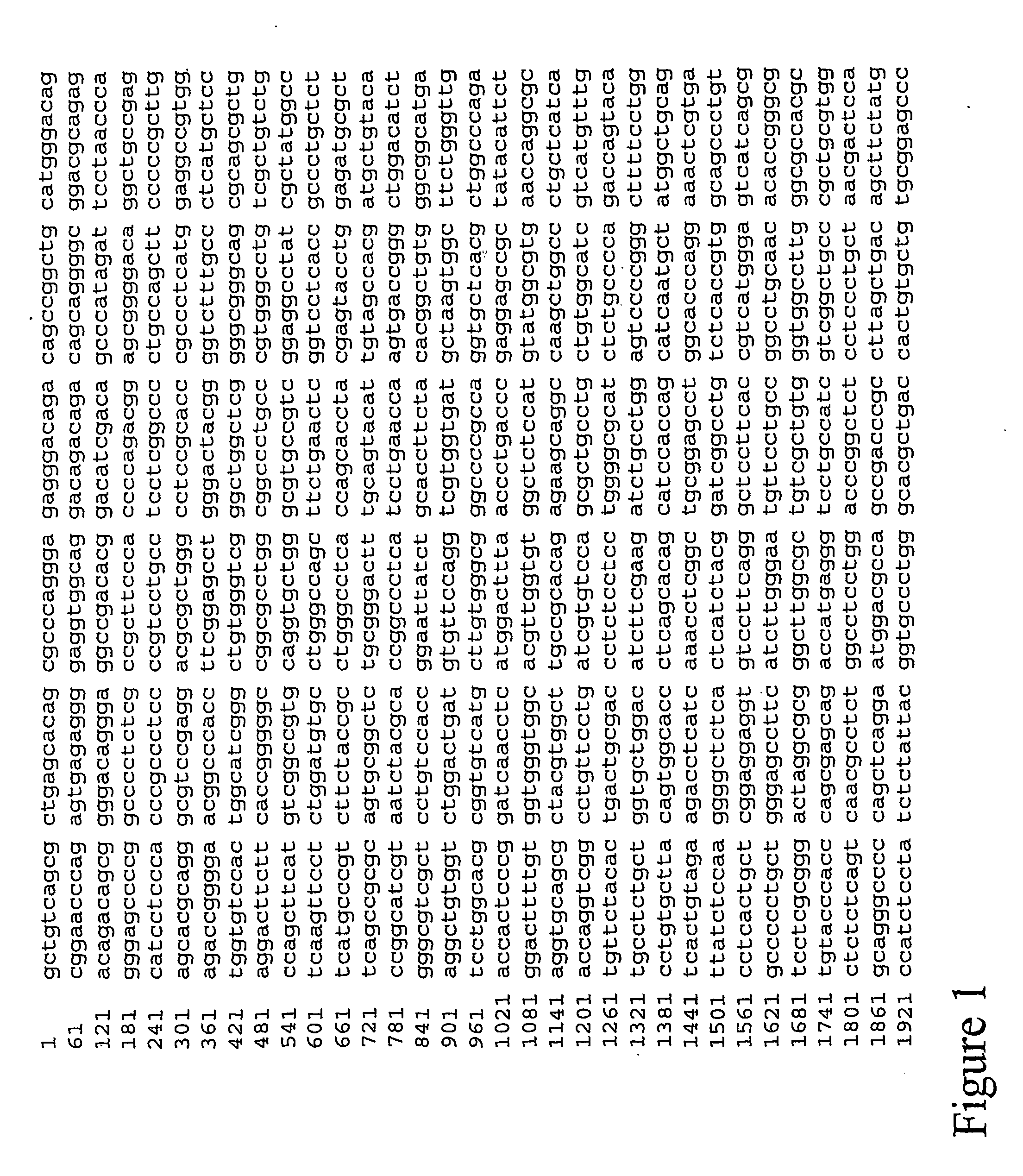

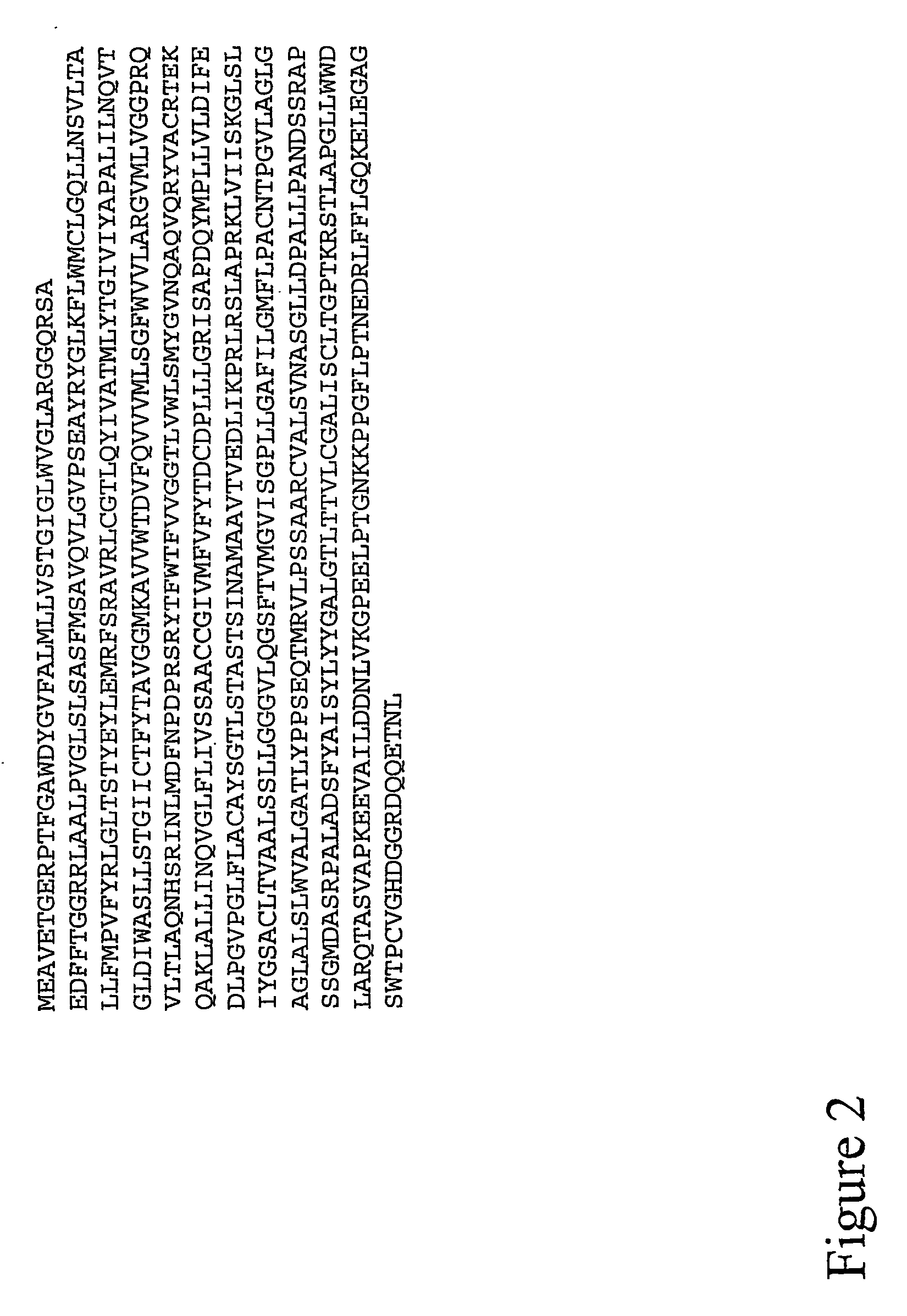

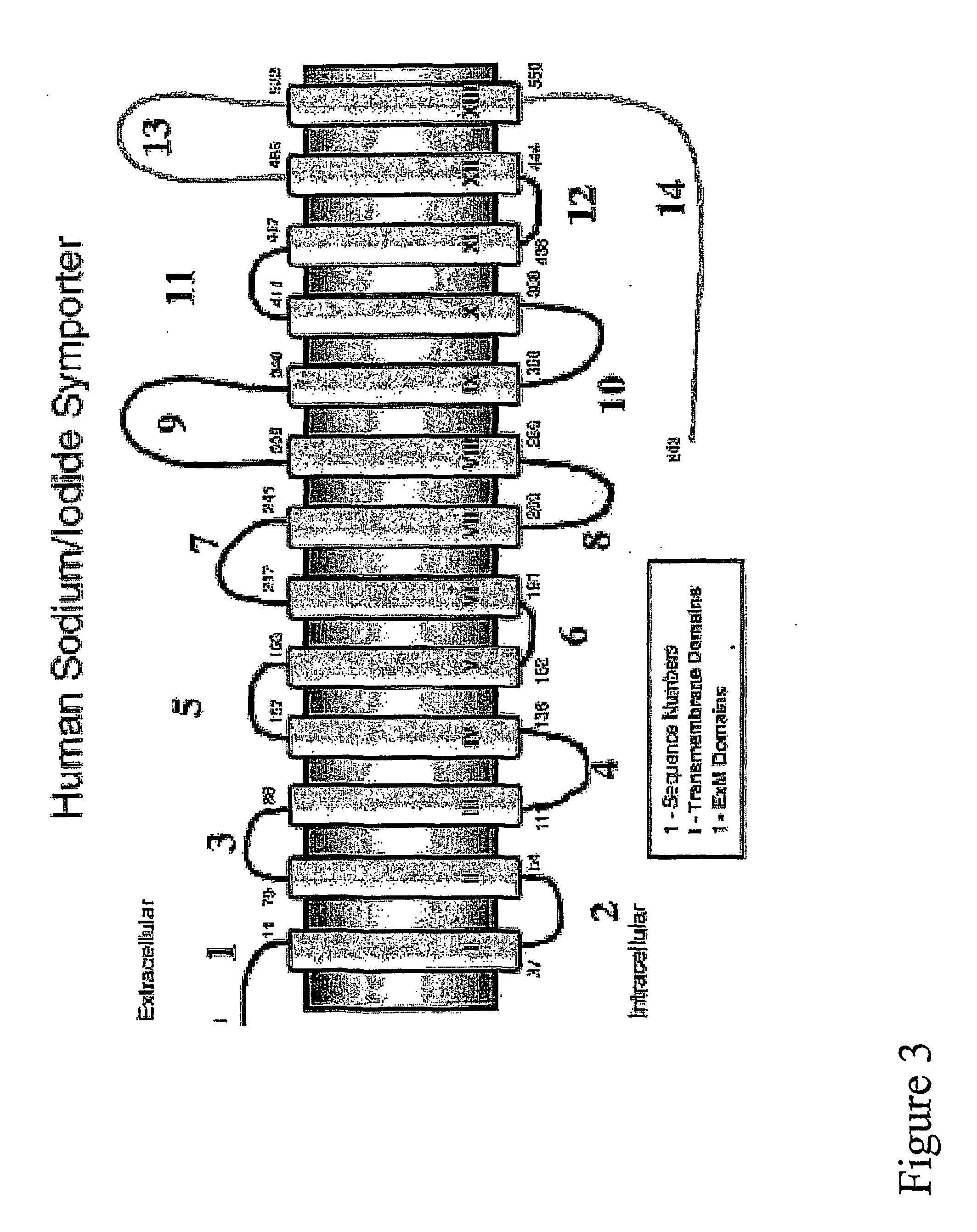

Modified sodium iodide symporter proteins and genes for imaging and cancer therapy

InactiveUS20060004191A1Increase concentrationReduced viabilityCell receptors/surface-antigens/surface-determinantsSugar derivativesCancer cellNucleotide

The invention provides modified sodium iodide symporter (NIS) proteins, and polynucleotides encoding modified NIS proteins. The modified NIS proteins have a net electrostatic charge more positive than that of corresponding wild-type NIS proteins. Expression of a modified NIS protein in a cell results in higher intracellular concentrations of NIS substrates as compared to equivalent expression of the corresponding wild-type NIS protein in a cell. The invention also provides methods for imaging cells or for therapy of cancer cells, using the modified NIS proteins to facilitate transport of NIS substrates into cells in the body of an individual. Uptake of NIS substrates suitable for either imaging or that have cytotoxic activity, into the cells of the individual that express modified NIS protein facilitate detection of the substrate (for imaging) or killing of the cancer cells (for therapy).

Owner:THE OHIO STATE UNIV RES FOUND

Industrial use of marine fungus fission chytrid OUC88

The present invention relates to the industrial application of ocean fission chytrid OUC88. The ocean fission chytrid OUC88 has capacity of generating rich docosahexaenoic acid (DHA), and has the preservation number of CGMCC No. 1240. The ocean fission chytrid OUC88 is new strain obtain with fission chytrid SR21 as originating strain and through chemical induction mutation and physical induction mutation. Through optimizing culture condition and replenishing carbon source in later culture stage, the present invention has dry cell weight reaching 25 g / L and DHA product up to 8.27 g / L. The thallus may be used as the additive for bread, mild product and other food products, especially baby's milk powder and can promote body's growth. The present invention has simple thallus fermenting process, high bioavailability, high yield of destination product and low cost.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com