Super paramagnetic ferric oxide composite nanometre particle preparation method

A technology of superparamagnetic iron oxide and composite nanoparticles, which is applied in the direction of iron oxide, nanostructure manufacturing, iron oxide/iron hydroxide, etc., can solve problems such as difficulty, reduce yield, simplify process steps, and promote production Nuclear and outgrowth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

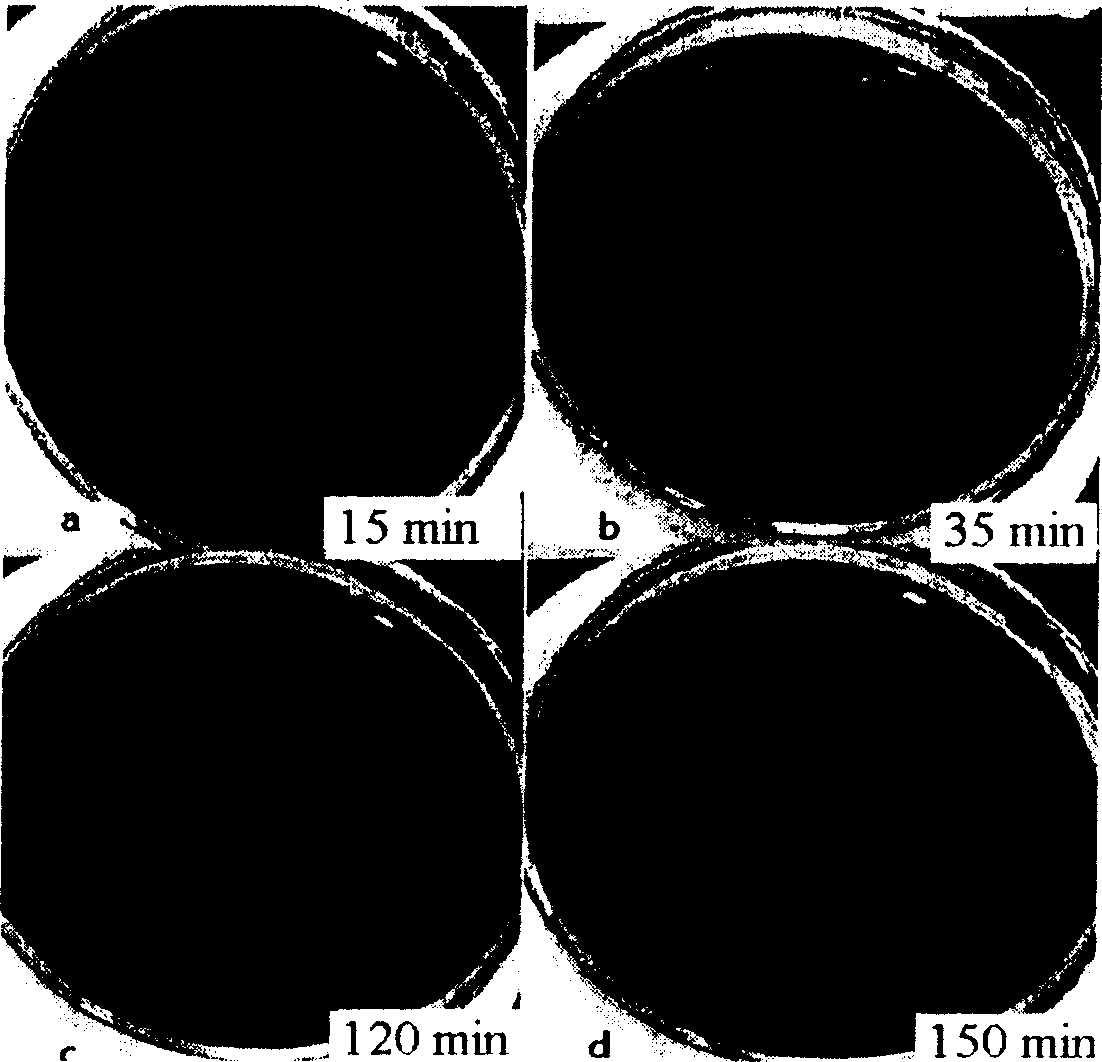

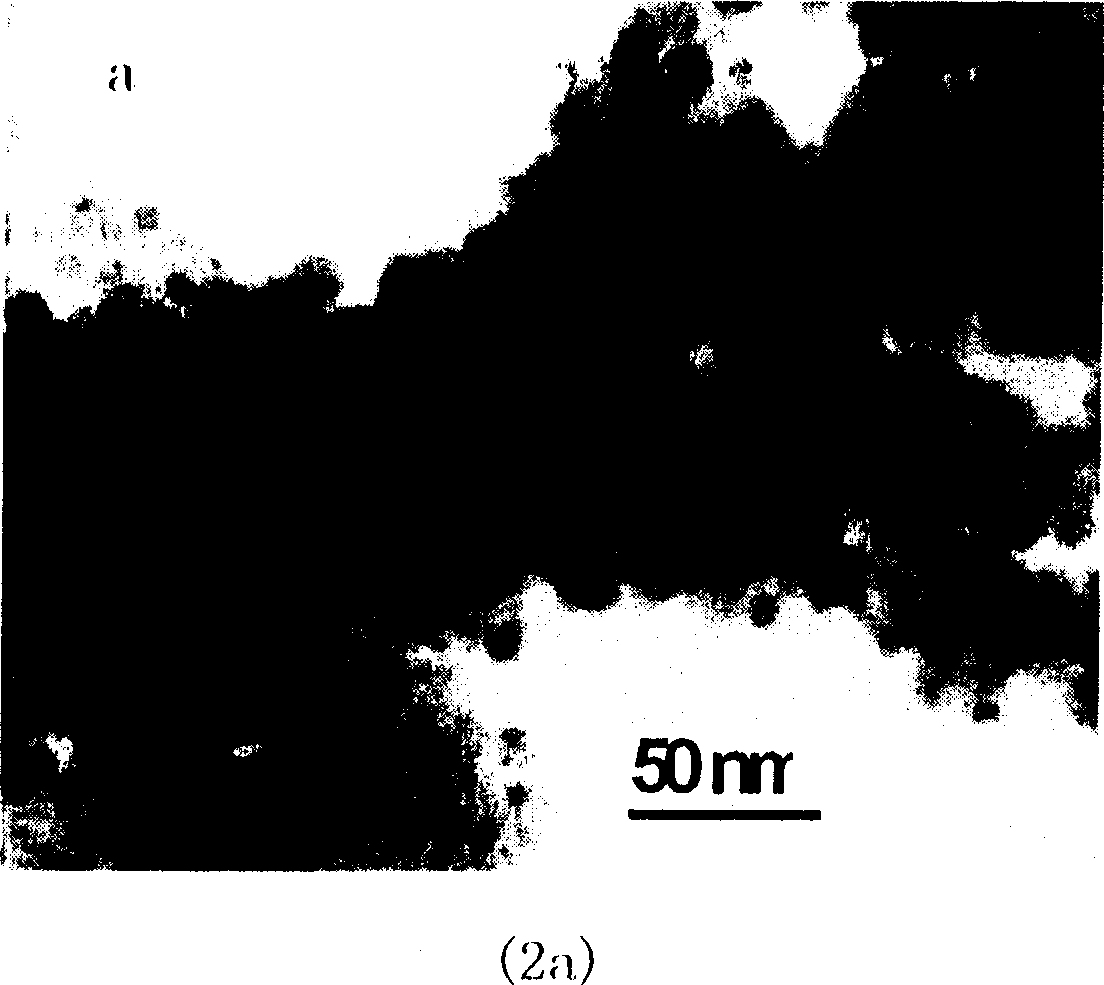

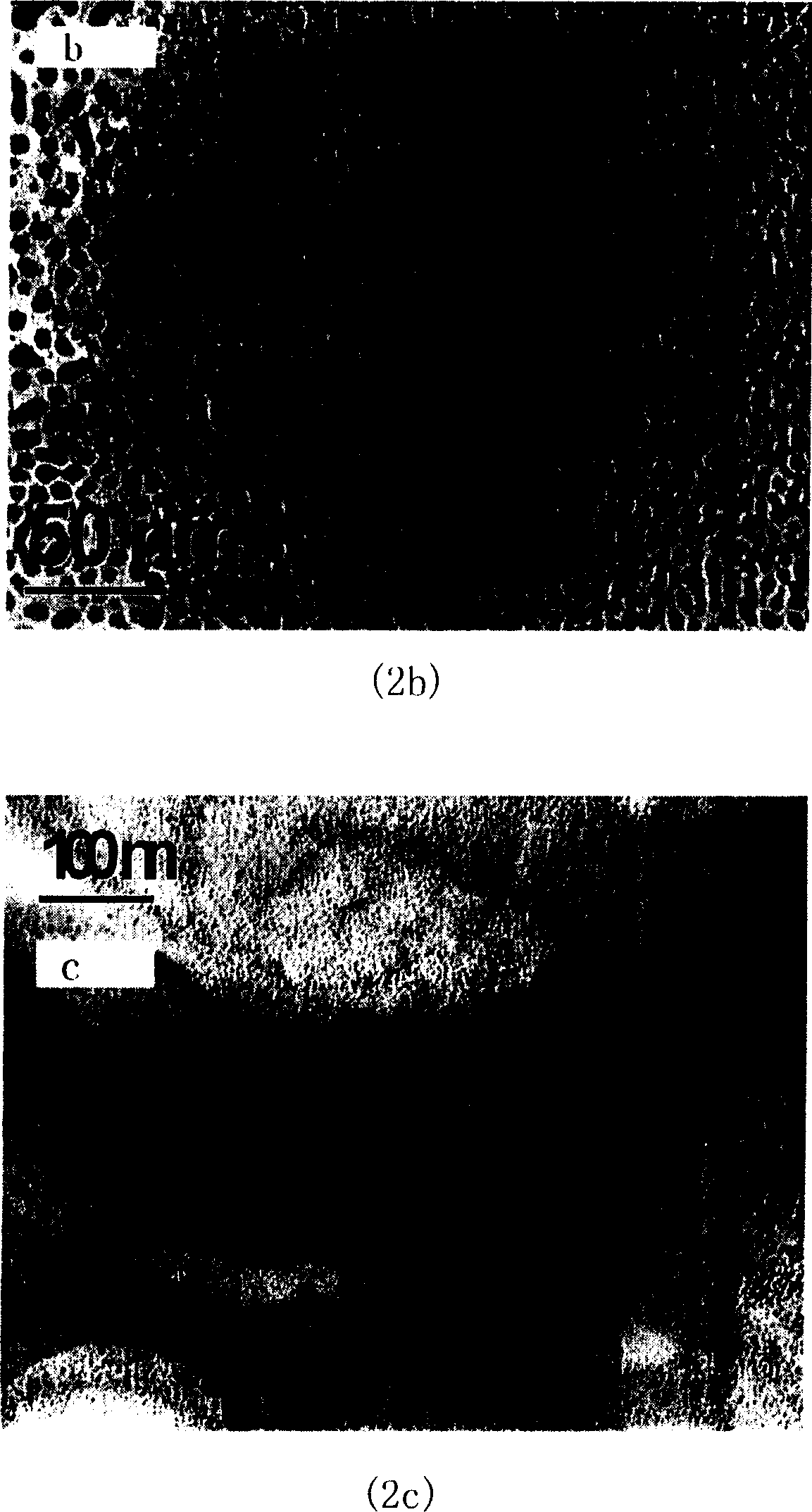

[0042] 1.1. Add 4.64 g of FeCl 3 ·6H 2 O (17mmol) and 1.70 g FeCl 2 4H 2 O (8.5mmol) dissolved in 250ml deoxygenated deionized water (18.2MΩ·cm -1 ), put it into a 500ml three-necked round-bottom reaction flask equipped with a mechanical stirring rod, and be protected by a nitrogen atmosphere; the concentration of 100ml of ammonia water 100ml of 1MOL / L and the deionized water preparation of deoxidation is the sodium citrate of 1MOL / L After mixing 19ml of the solution, drop it into the rapidly stirred iron and ferrous salt solution at a rate of 4ml / min; the color of the solution gradually turns brown, and finally dark black; after the addition of the mixed solution is completed, the stirring reaction continues for more than 30 minutes; During the whole reaction process, the temperature is always controlled at about 50°C; the obtained superparamagnetic iron oxide nanoparticle ferrofluid is quickly moved into a container and sealed for storage;

[0043] 1.2. Add 200ml of sodi...

Embodiment 2

[0045] 2.1. Add 3.712 grams of FeCl 3 ·6H 2 O (13.6 mmol) and 1.368 g FeCl 2 4H 2 After O (6.8mmol) was dissolved in 50ml deoxygenated deionized water, put it into a 100ml three-necked round-bottomed reaction bottle equipped with a mechanical stirring bar, and be protected by a nitrogen atmosphere; prepare 67ml of ammonia water with a concentration of 3MOL / L and deoxidized deionized water After mixing 5.1ml of sodium citrate solution with a concentration of 3MOL / L, drop it into the rapidly stirred iron and ferrous salt solution at a rate of 2ml / min; the color of the solution gradually turns brown, and finally dark black; the mixture is added dropwise After completion, the stirring reaction continued for more than 30 minutes; during the entire reaction process, the temperature was always controlled at about 80°C; the obtained superparamagnetic iron oxide nanoparticle ferrofluid was quickly moved into a container and sealed for storage;

[0046] 2.2. Add 100ml concentration t...

Embodiment 3

[0048] 3.1. Add 2.784 g of FeCl 3 ·6H 2 O (10.2 mmol) and 1.02 g FeCl 2 4H 2 After O (5.1mmol) was dissolved in 200ml deoxidized deionized water, put it into a 500ml three-necked round-bottom reaction flask equipped with a mechanical stirring bar, and be protected by a nitrogen atmosphere; After mixing 20ml of sodium citrate solution with a concentration of 0.5MOL / L prepared by nanopure water, drop it into the rapidly stirred iron and ferrous salt solution at a rate of 5ml / min; the color of the solution gradually becomes dark black; the mixed droplet After the addition is complete, the stirring reaction continues for more than 30 minutes; during the entire reaction process, the temperature is always controlled at about 40°C; the obtained superparamagnetic iron oxide nanoparticle magnetic fluid is quickly moved into a container and sealed for storage;

[0049] 3.2. Add 250ml of sodium citrate solution with a concentration of 4.85mMOL / L to a 500ml three-necked round-bottomed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com