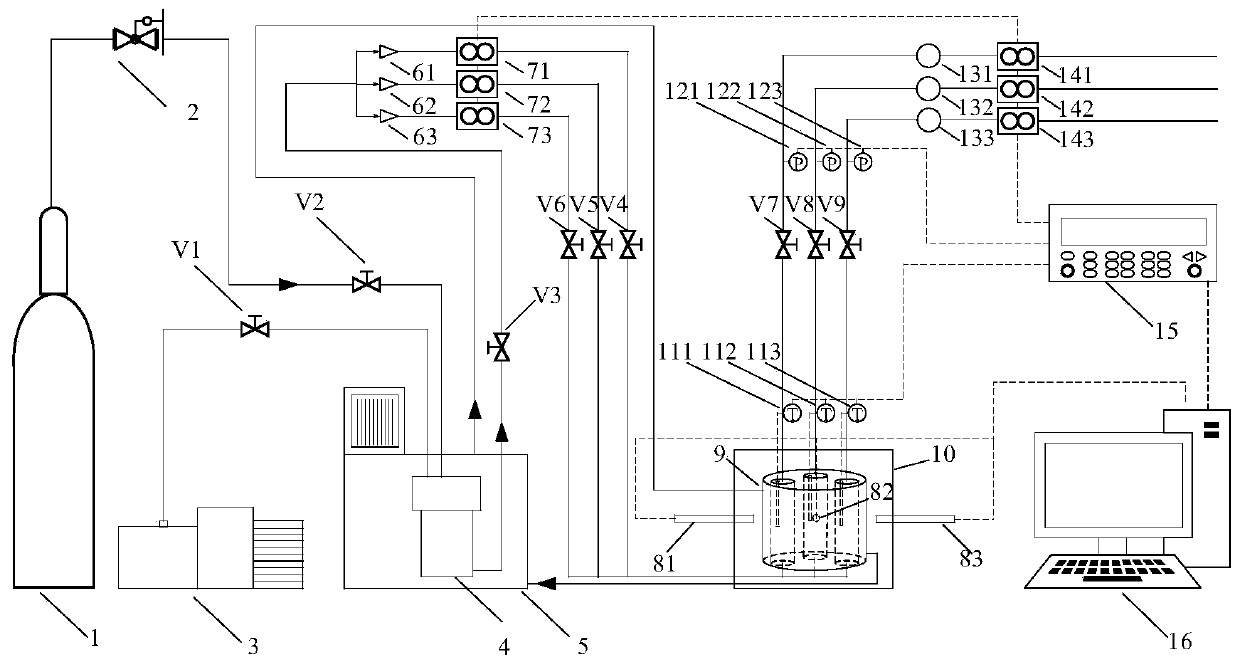

Device and method capable of achieving synchronous mesoscopic observation of formation and decomposition of gas hydrates

A gas hydrate and gas technology, applied in the direction of measuring devices, analyzing materials, material analysis through optical means, etc. Visualization and other issues to achieve the effect of shortening the experimental cycle and the reliability of observation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

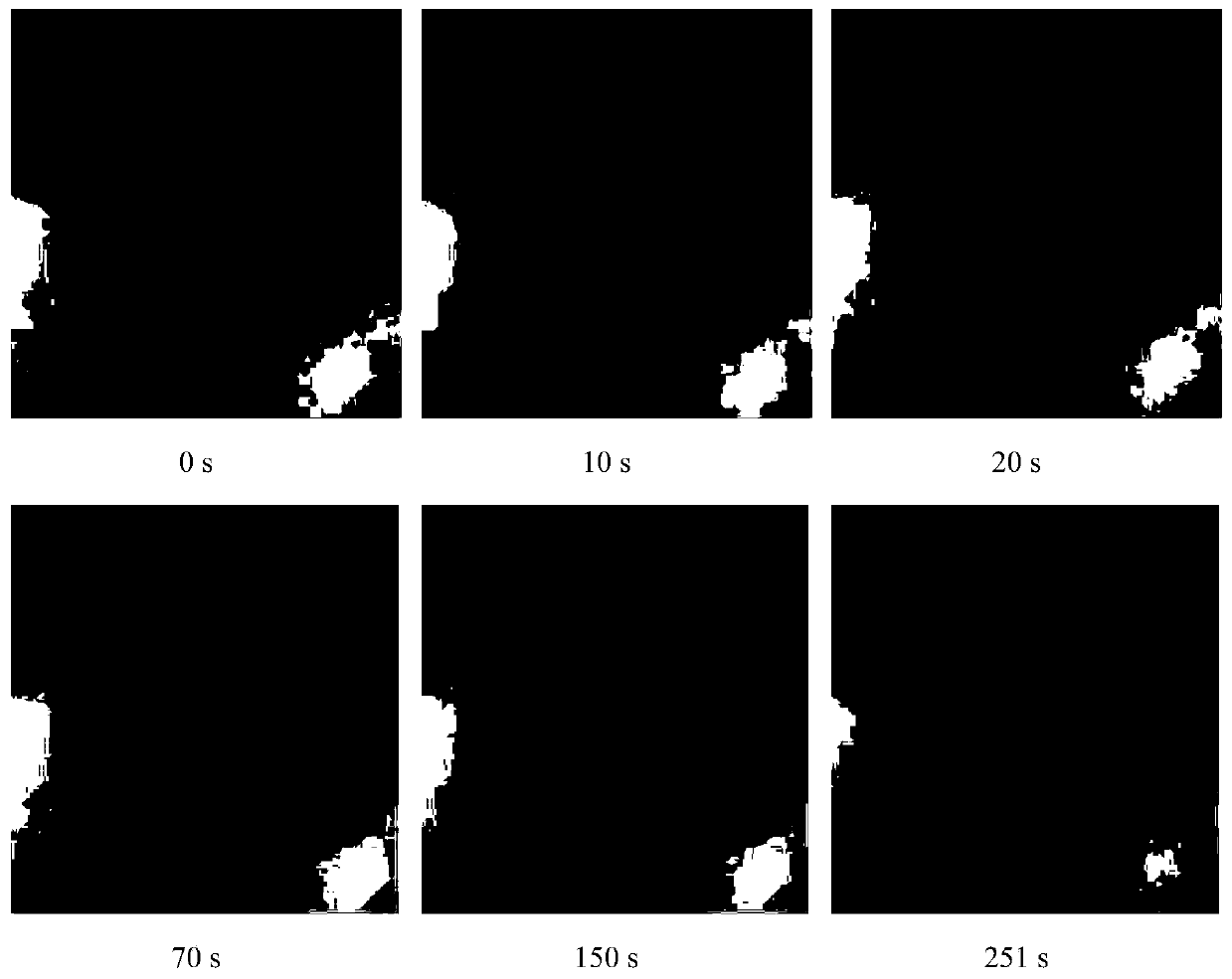

Examples

Embodiment 1

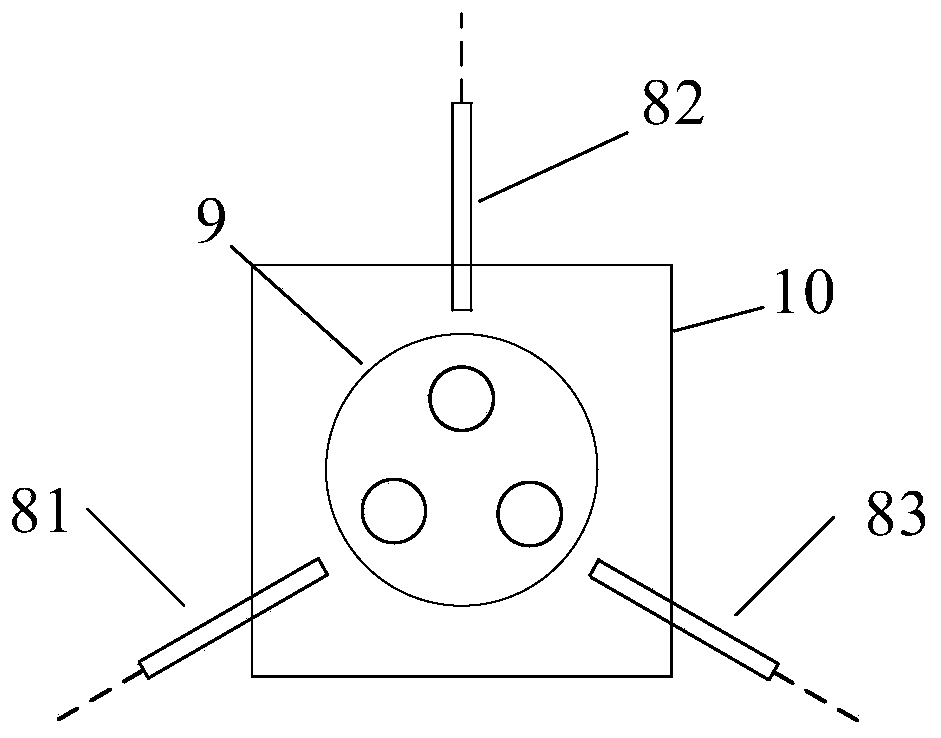

[0045] A method for synchronous mesoscopic observation of gas hydrate formation and decomposition based on the device, comprising steps:

[0046] (1) Fill the same porous medium into three sapphire cylinders respectively, add 3.5 wt% NaCl solution to simulate seawater to 100% saturation, and seal the reactor;

[0047] (2) Open the valves V2 and V3 in the device, open the valve V1 and then turn on the vacuum pump for 3 minutes;

[0048] (3) Close the stop valve V1, turn off the vacuum pump, then close the valve V3, open the main valve of the gas cylinder and open the pressure reducing valve V2, fill the gas storage tank with methane gas to 14 MPa, and then close the valve V2 and the pressure reducing valve 2 in turn and cylinder main valve;

[0049] (4) Open the valve V3, then open the branch valves V4, V5, and V6 respectively, open the secondary pressure reducing valves 61, 62, and 63 until the pressure is 0.05 MPa, and fill a small amount of methane gas into the high-pressur...

Embodiment 2

[0054] A method for synchronous mesoscopic observation of gas hydrate formation and decomposition in porous media based on the device, comprising steps:

[0055] (1) Fill the three sapphire cylinders with different porous media (or thermal mass enhancement materials), add SDS solution to 100% saturation, and seal the reactor;

[0056] (2) Open the valves V2 and V3 in the device, open the valve V1 and then turn on the vacuum pump for 3 minutes;

[0057] (3) Close the stop valve V1, turn off the vacuum pump, then close the valve V3, open the main valve of the gas cylinder and open the pressure reducing valve V2, fill the gas storage tank with methane gas to 14 MPa, and then close the valve V2 and the pressure reducing valve 2 in turn and cylinder main valve;

[0058] (4) Open the valve V3, then open the branch valves V4, V5, and V6 respectively, open the secondary pressure reducing valves 61, 62, and 63 until the pressure is 0.05 MPa, and fill a small amount of methane gas into...

Embodiment 3

[0063] A method for synchronous mesoscopic observation of gas hydrate formation and decomposition in porous media based on the device, comprising steps:

[0064] (1) Fill the same porous medium into three sapphire cylinders respectively, add 3.5 wt% NaCl solution to simulate seawater to 100% saturation, and seal the reactor;

[0065] (2) Open the valves V2 and V3 in the device, open the valve V1 and then turn on the vacuum pump for 3 minutes;

[0066] (3) Close the stop valve V1, turn off the vacuum pump, then close the valve V3, open the main valve of the gas cylinder and open the pressure reducing valve V2, fill the gas storage tank with methane gas to 14 MPa, and then close the valve V2 and the pressure reducing valve 2 in turn and cylinder main valve;

[0067] (4) Open the valve V3, then open the branch valves V4, V5, and V6 respectively, open the secondary pressure reducing valves 61, 62, and 63 until the pressure is 0.05 MPa, and fill a small amount of methane gas into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com