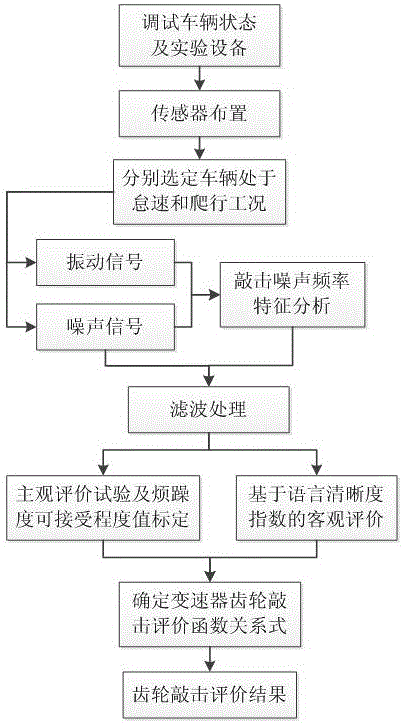

Transmission gear knocking testing and noise quality analyzing method

A transmission gear and analysis method technology, applied in the direction of measuring ultrasonic/sonic/infrasonic waves, instruments, measuring devices, etc., can solve the driver's restlessness, consume a lot of manpower and material resources, and fail to give a clear objective of gear knocking noise Evaluate parameters and other issues to achieve the effect of shortening the experimental cycle and reducing the cost of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

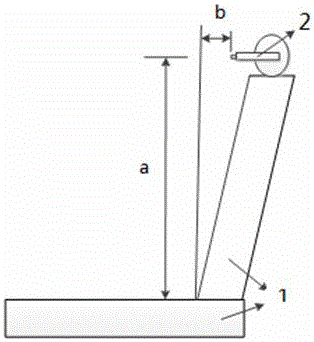

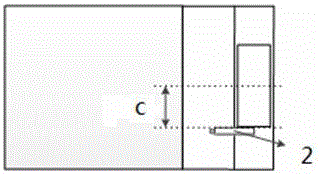

[0027] (1) Adjust the state of the experimental vehicle and prepare the data testing and collection equipment used, and arrange the vibration acceleration sensor and microphone: the layout of the microphone at the driver's ear is as follows: figure 2 As shown in , the spatial arrangement position of the microphone is required in the figure; the vibration acceleration sensor on the transmission case and the nearby microphone are as follows: Figure 4 As shown in , the vibration acceleration sensors are respectively arranged on the bearing seat of the transmission drive shaft and the shell surface in the axial middle of the transmission. The principle is to choose a large and flat shell surface to facilitate pasting the acceleration sensor. The microphone near the transmission is arranged on The distance is 30±2cm and is directly opposite to the spatial position of the vibration acceleration sensor on the surface of the transmission axial middle casing. Among them, the vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com