Patents

Literature

36results about How to "Change chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

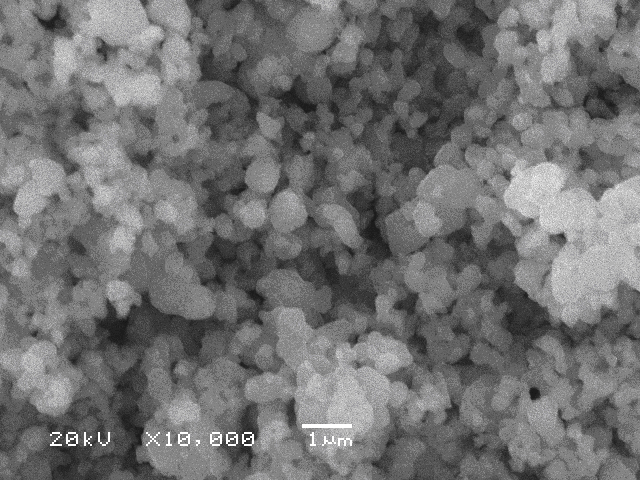

Super paramagnetic ferric oxide composite nanometre particle preparation method

InactiveCN1736881AReduce nucleationReduced growth rateNanostructure manufactureFerric oxidesSal ammoniacNanoparticle

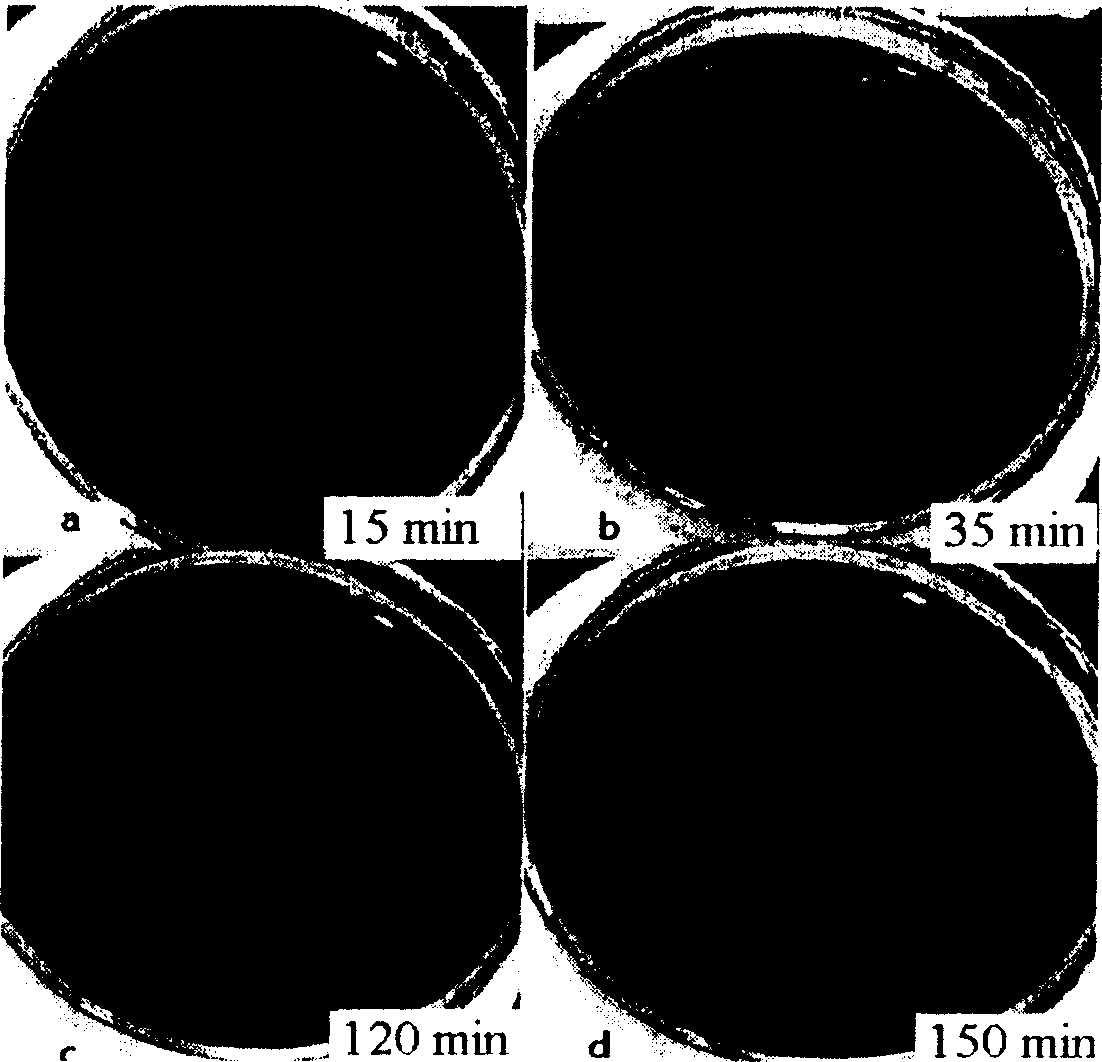

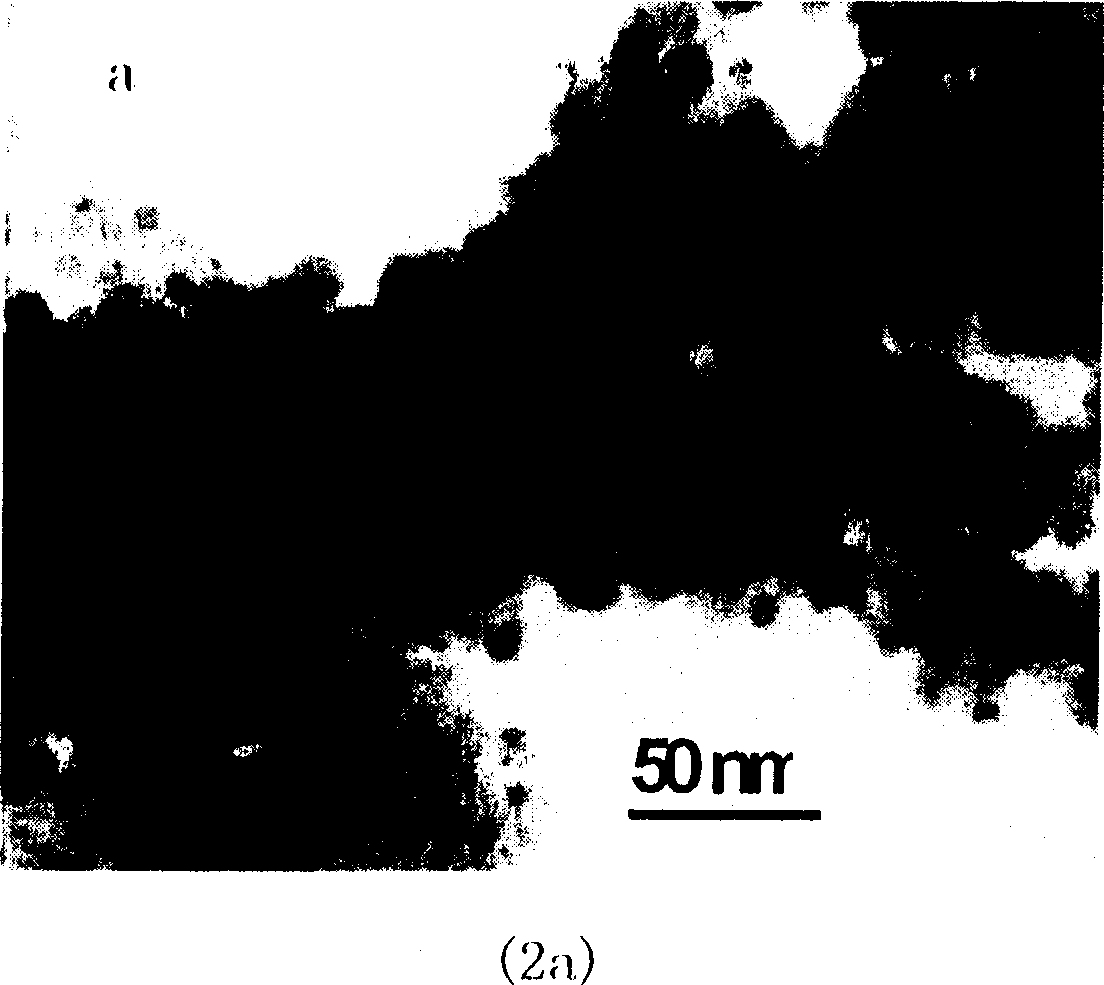

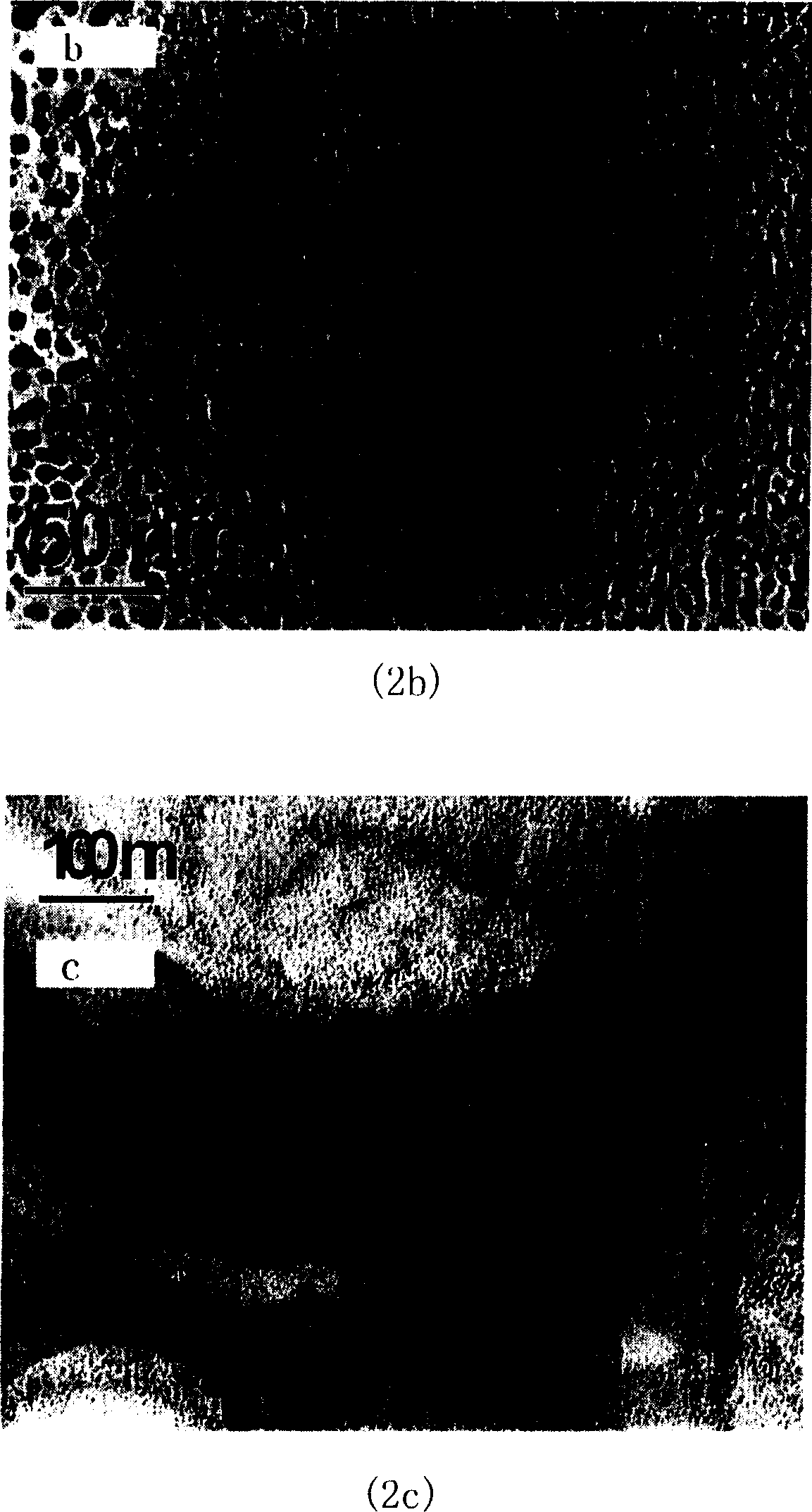

The invention discloses a preparation method for composite nano particcle of superparamagnetic ferric oxide. Wherein, adding ammonia and sodium citrate synchronously and speed controlled to make ions of Fe3+ and Fe2+ coprecipitate and form Fe3O4 nano particle with water-phase dispersion surface adsorbed by citric acid radical that can be substituted by multi chemical functional group on basic condition as crystal seed for sodium citrate-goden chloric acid reduction reaction and form SPION nano particle.

Owner:HUAZHONG UNIV OF SCI & TECH

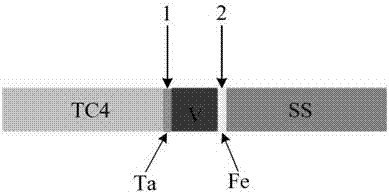

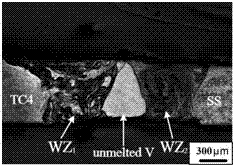

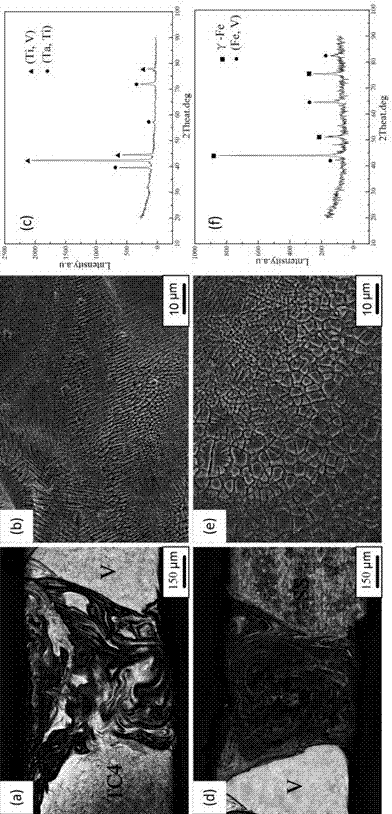

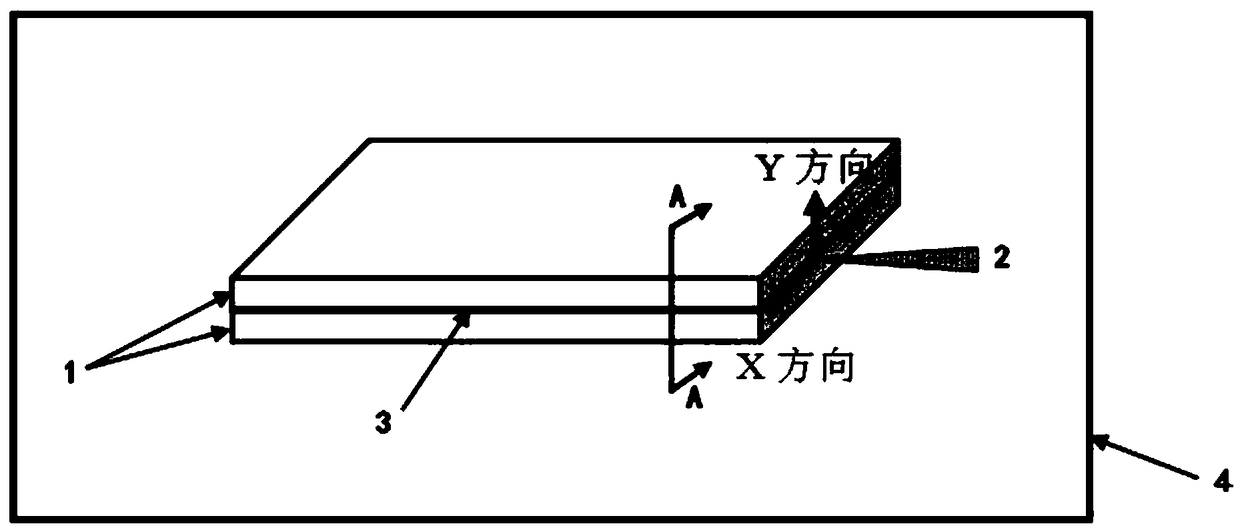

Laser welding method of titanium alloy-stainless steel dissimilar metal by adopting composite intermediate layer

ActiveCN107127454AEasy to shapeAvoid unfusedWelding/soldering/cutting articlesLaser beam welding apparatusOmegaTitanium alloy

The invention relates to a laser welding method of a titanium alloy-stainless steel dissimilar metal by adopting a composite intermediate layer, and belongs to the technical field of material welding (connection). According to the method, laser is adopted as a welding heat source, and a Ta / V / Fe composite layer is used as an intermediate layer material, so that formation of an omega brittle phase in a titanium alloy-vanadium welding line and an alpha brittle phase in a vanadium-stainless steel welding line can be controlled, the joint brittleness can be reduced, and the joint performance can be improved; by adopting the two welding, a high-quality high-efficiency welding joint which is made of a dissimilar metal material and contains a titanium alloy-vanadium welding line, an unmolten vanadium layer and a vanadium-stainless steel welding line can be obtained. The process comprises the steps of plate assembling and clamping, preload adjustment of a titanium alloy-intermediate layer-stainless steel contact face, and laser welding along the center line of a Ta intermediate layer and the center line of a Fe intermediate layer, so that connection of the titanium alloy-stainless steel dissimilar metal can be realized. The method has the advantages of stable welding process, attracted welding line formation, no welding defects including crack, pore, undercutting, uncomplete welding, incomplete fusion and the like, and good welding process performance.

Owner:JILIN UNIV

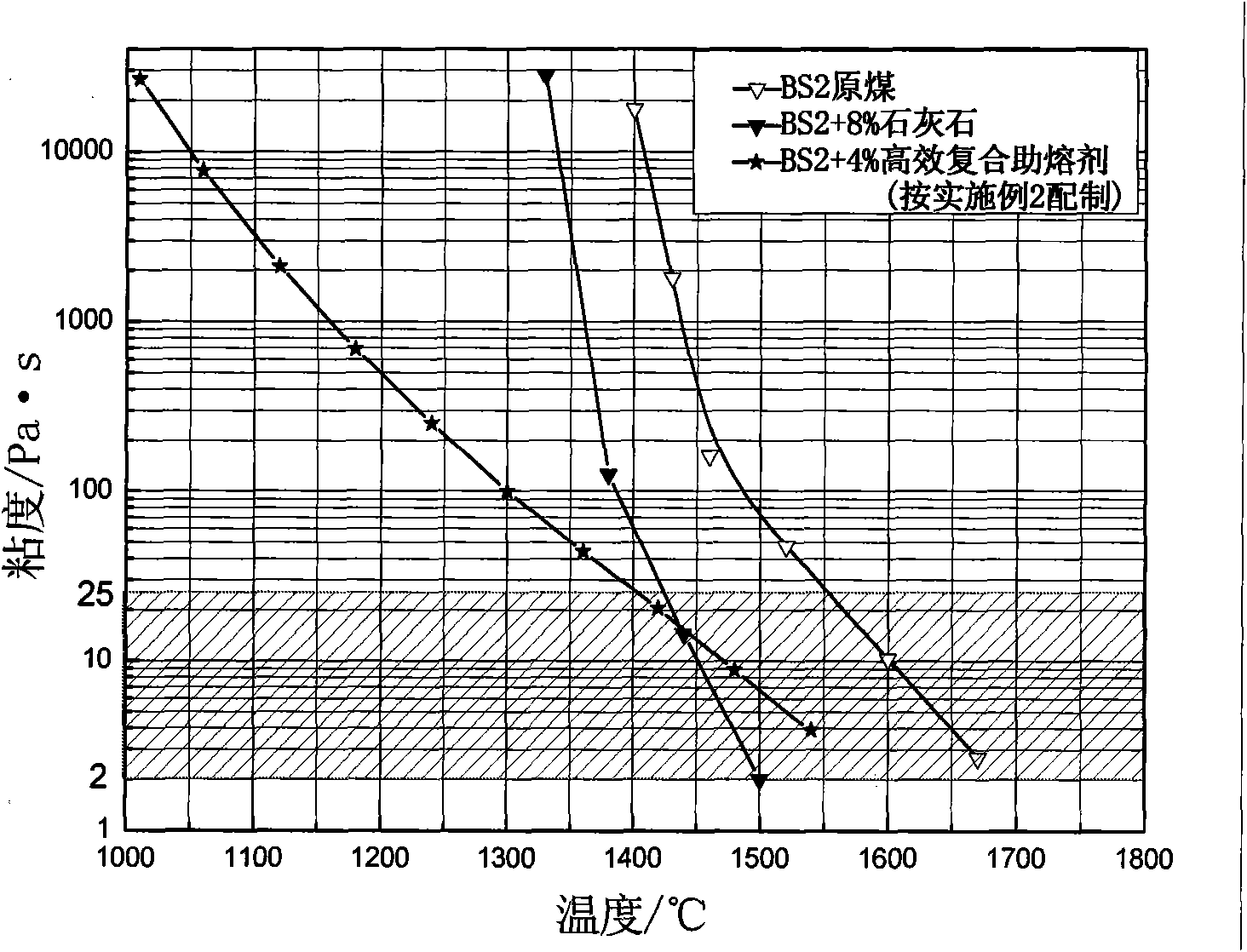

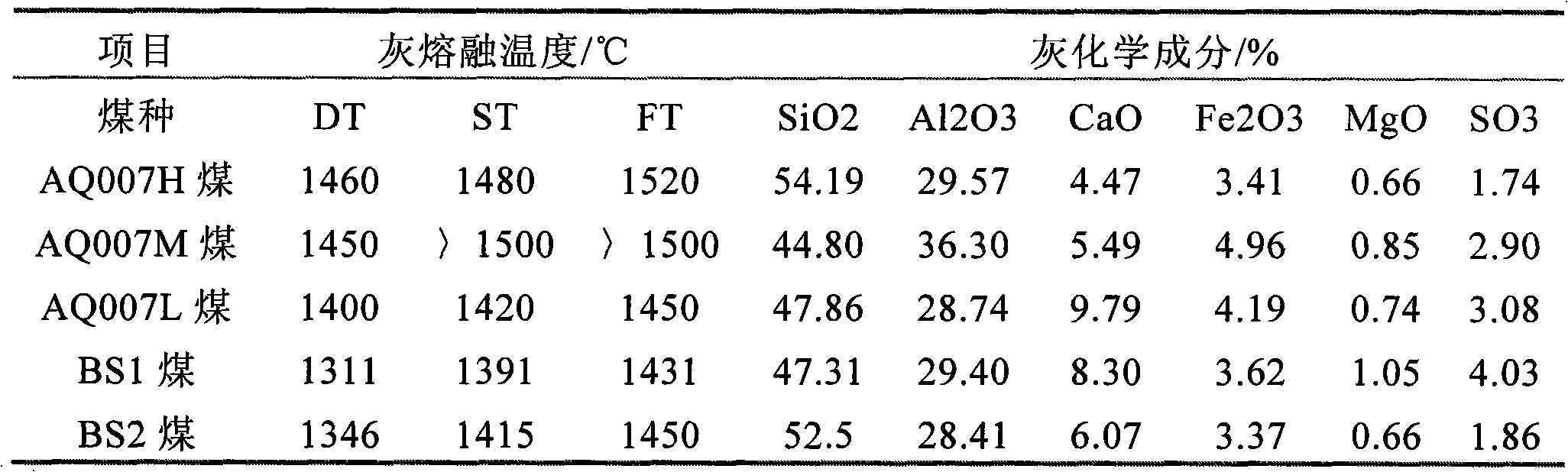

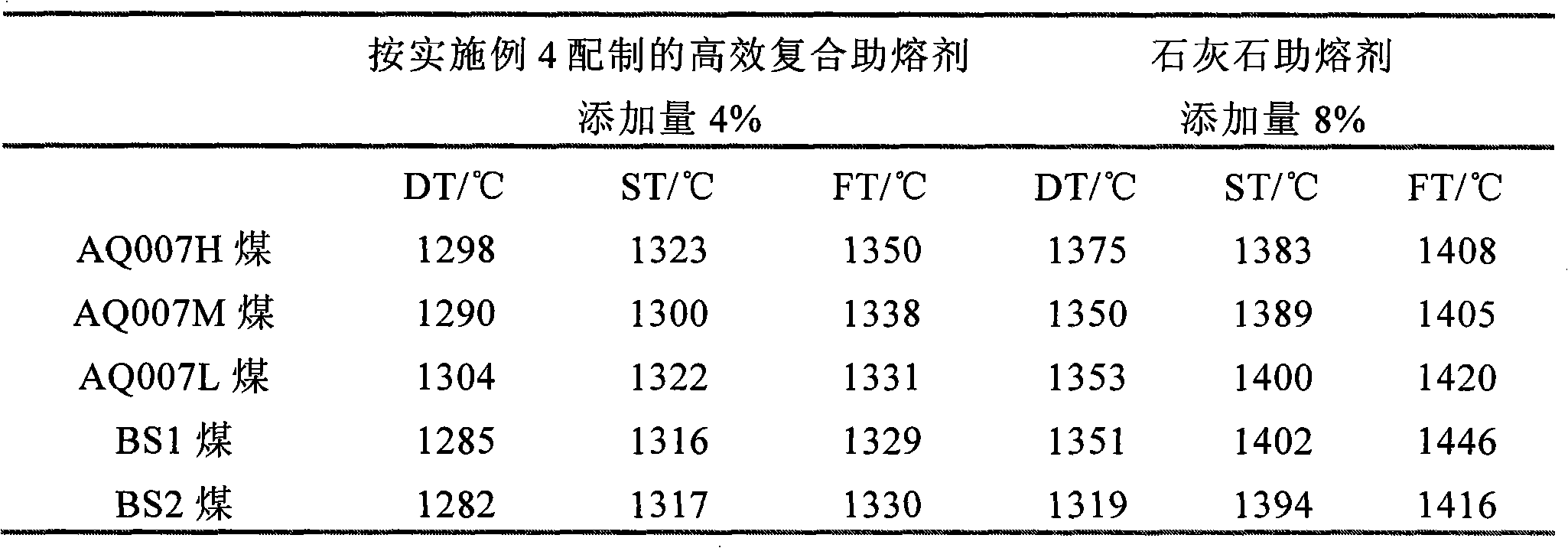

Efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag

The invention provides an efficient composite fluxing agent for improving melting characteristic of gasified pulverized coal slag. The efficient composite fluxing agent is compounded by two or more ore powders containing basic oxides. The efficient composite fluxing agent comprises the components by weight percentage of 12-30% of MgO and 3-30% of CaO. As for the coals at the mine field in the northern Anhui province, when the addition amount is 2-6%, the melting temperature of the pulverized coal can be reduced from 1500 DEG C to below 1400 DEG C, the viscosity of the pulverized coal can be ranged from 2 to 25 Pa*s, thus effectively improving the melting characteristic of the coals in the mine field in the northern Anhui province. The fluxing agent can be used for replacing lime stone fluxing agent and the addition amount is only half of that of the lime stone.

Owner:CHINA PETROLEUM & CHEM CORP +1

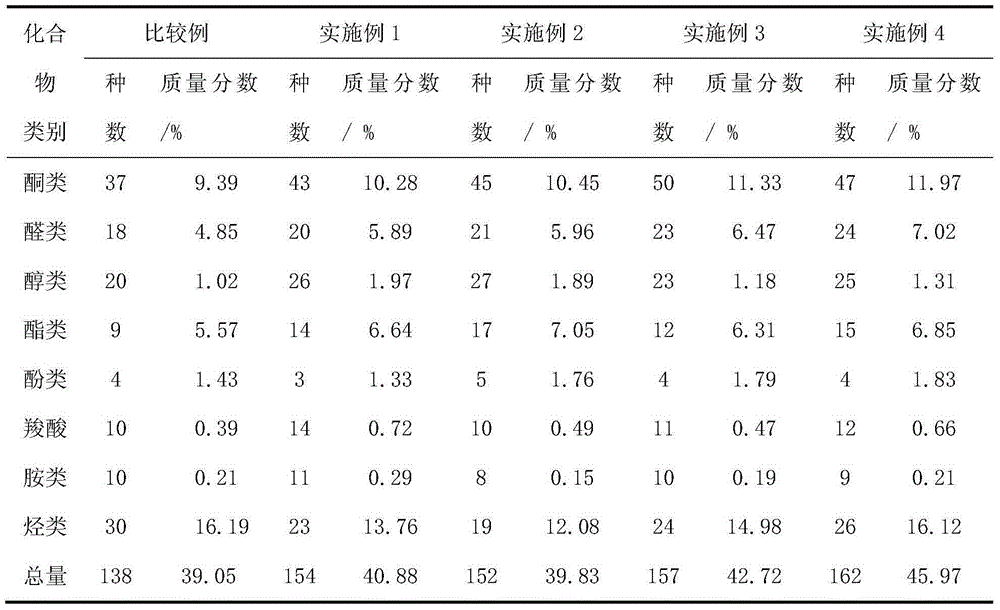

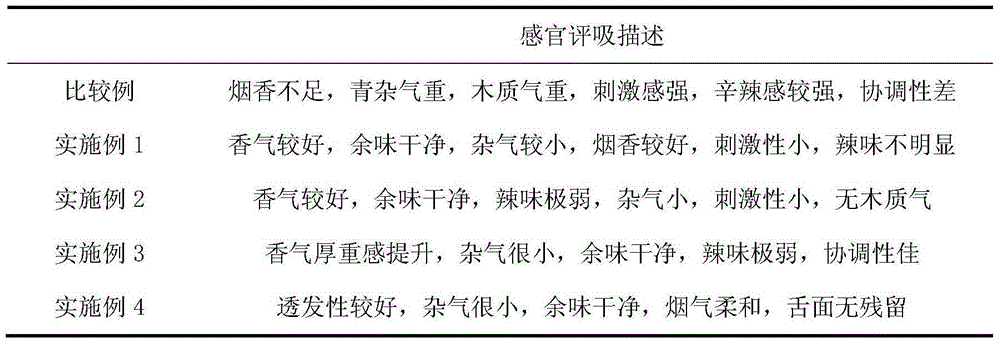

Method for preparing tobacco sheet through enzymolysis extraction-Maillard reaction composite technology

InactiveCN105077571AQuality improvementImprove extraction efficiencyTobacco treatmentMaillard reactionChemical composition

The invention discloses a method for preparing a tobacco sheet through an enzymolysis extraction-Maillard reaction composite technology. The method comprises the following specific steps: carrying out enzymolysis extraction simultaneously on tobacco powder in water, carrying out solid-liquid separation, concentrating the enzymolysis liquid, adding with reducing sugar and amino acid and carrying out Maillard reaction at 70 DEG C, uniformly coating paper base with the reaction liquid, drying, and shredding, and thus obtaining the tobacco sheet. With the adoption of the enzymolysis extraction-Maillard reaction composite technology, the advantages of the preparing process of the tobacco sheet through the paper-making process are exerted, meanwhile, the two technological means of the enzymolysis and the Maillard reaction are comprehensively utilized, so that the extraction efficiency of the tobacco aroma materials is improved, and moreover, the chemical components of tobacco are selectively changed, so that the purposes of aroma enhancement and harm reduction are achieved, and therefore, the method has the incomparable advantages.

Owner:CHINA TOBACCO GUANGXI IND +1

Method for comprehensive and safe utilization of domestic garbage incineration fly ash

ActiveCN110255901ASolve the technical bottleneck of difficult separationGood effectCeramic shaping apparatusCeramic materials productionResource utilizationExpanded clay aggregate

The invention relates to a method for comprehensive and safe utilization of domestic garbage incineration fly ash. The method has the characteristic of comprising the steps: mixing the domestic garbage incineration fly ash with a specific inorganic curing agent and water at a weight ratio of (1-10):1:1 so as to form a mixture, molding the mixture, curing the molded product at a certain temperature for a period of time, immersing the cured product in water at 5-100 DEG C for a certain period of time, putting the solid phase product in a plasma processing device after soaking, and performing melting or sintering at a high temperature of 1200-1500 DEG C so as to form a vitreous body or ceramsite. Through the method, the technical problem of difficult separation of a large amount of inorganic salts in the domestic garbage incineration fly ash is solved effectively, a feasible technical method is provided for resource utilization of the high value-added inorganic salts in the domestic garbage incineration fly ash, and a large amount of the inorganic salts in the domestic garbage incineration fly ash is removed, so that the effect and efficiency of fly ash treatment through plasma hot melt are improved significantly, and safe and reliable building materials obtained through resource utilization of the fly ash are obtained.

Owner:深圳市航天新材科技有限公司

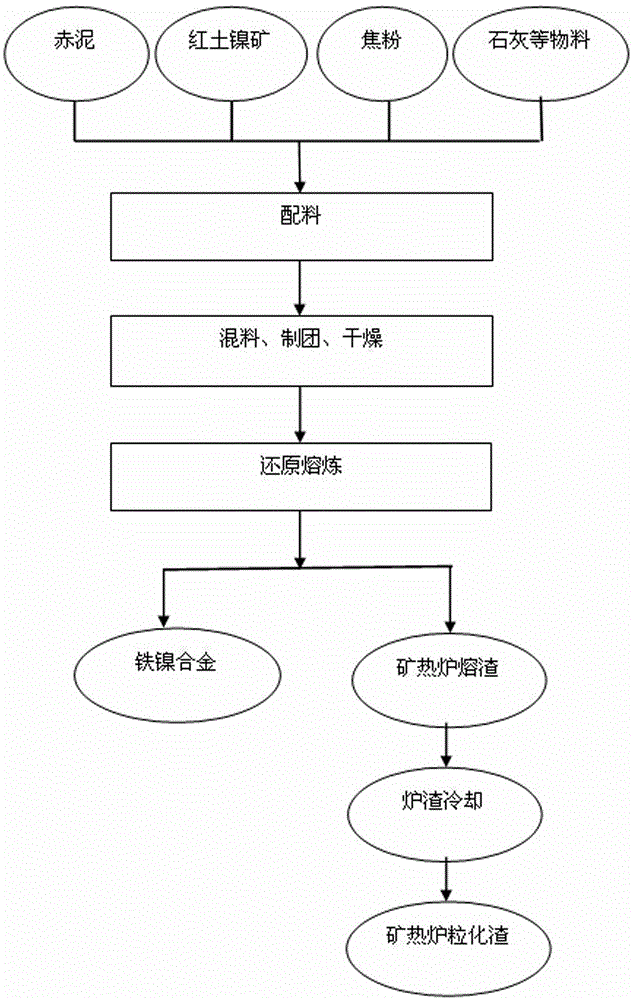

Method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore

ActiveCN106148699AHighlight substantive featuresSignificant progressProcess efficiency improvementRed mudResource utilization

The invention provides a method for preparing ferronickel byproduct active smelting electric furnace grain slag through red mud and nickel laterite ore. The method is characterized by comprising the following steps that 1, proportioning is carried out, specifically, raw materials include the red mud, the nickel laterite ore, coke powder and lime; and 2, reduction smelting of a smelting electric furnace is carried out, specifically, clusters formed through the raw materials prepared in the step 1 are conveyed into the smelting electric furnace for reduction smelting, slag and iron separation is completed through slag pre-making, melting and reduction, a furnace slag layer is formed, the furnace slag is discharged out of a slag opening regularly and subjected to water quenching or air-cooling pelletization, and the active smelting electric furnace grain slag is obtained. The smelting electric furnace grain slag prepared through the method can serve as a mixed material applied in the cement production process, the cement performance is improved, the variety and labels of cement products are adjusted, and the production cost is reduced; and meanwhile, the slag can be used for producing a concrete admixture independently or by being combined with other raw concrete admixture materials, and the resource utilization of the ferronickel byproduct active smelting electric furnace grain slag prepared through the red mud and the nickel laterite ore is effectively achieved.

Owner:GUANGXI UNIV

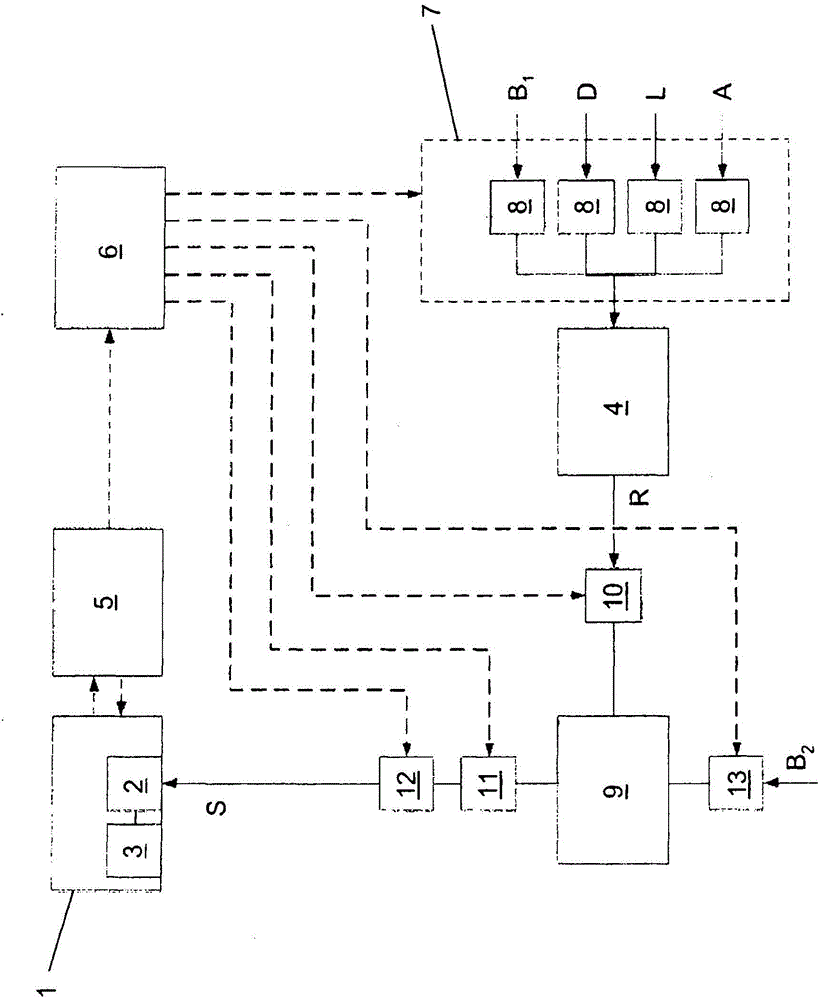

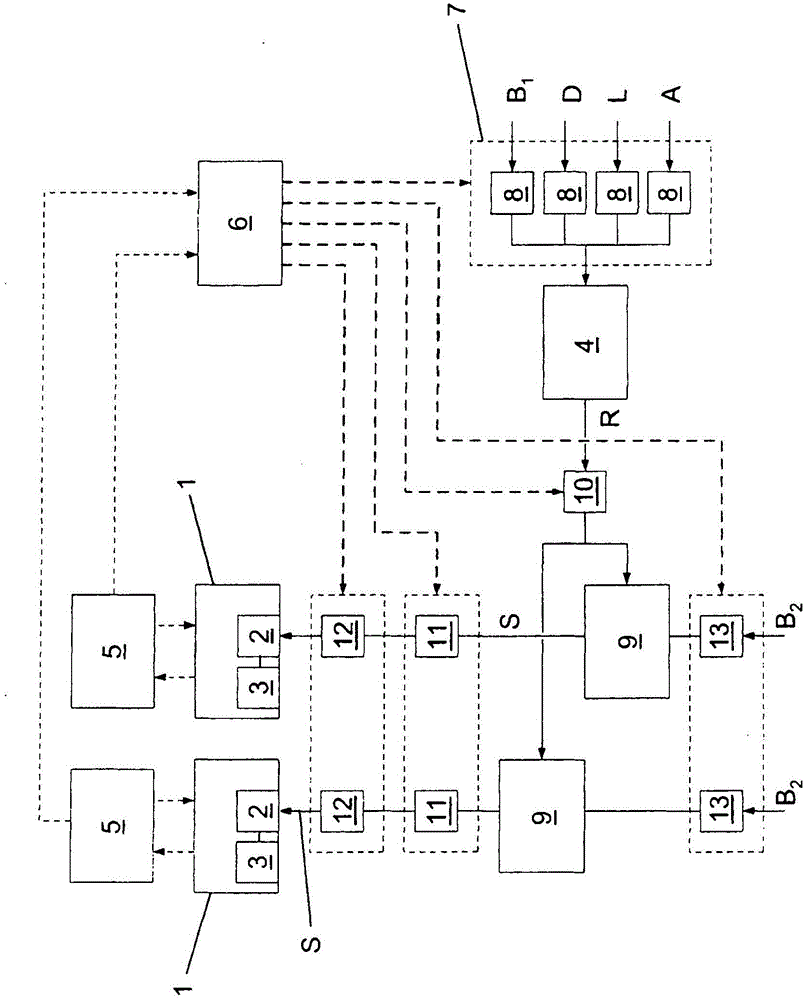

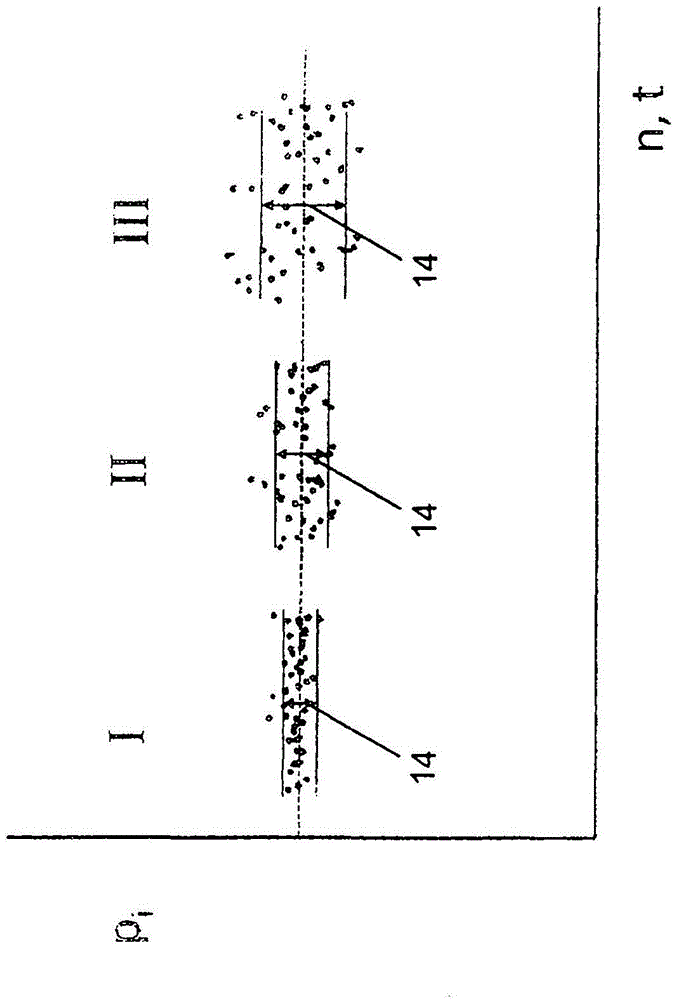

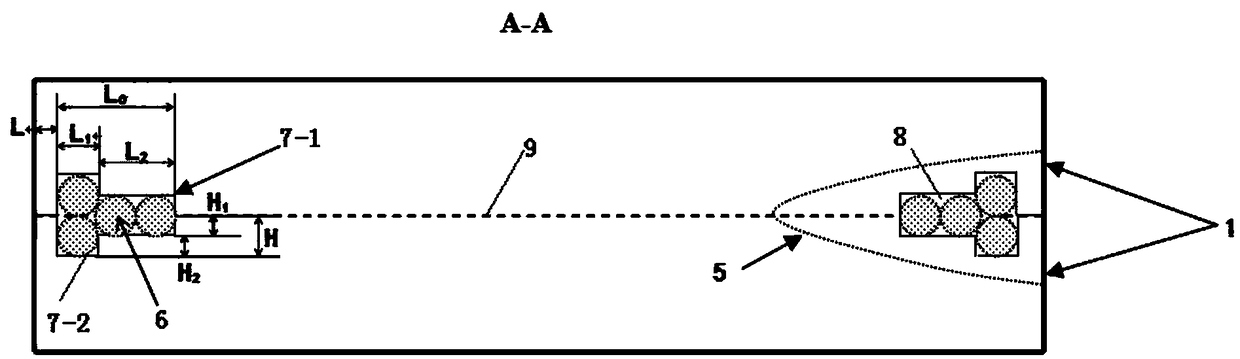

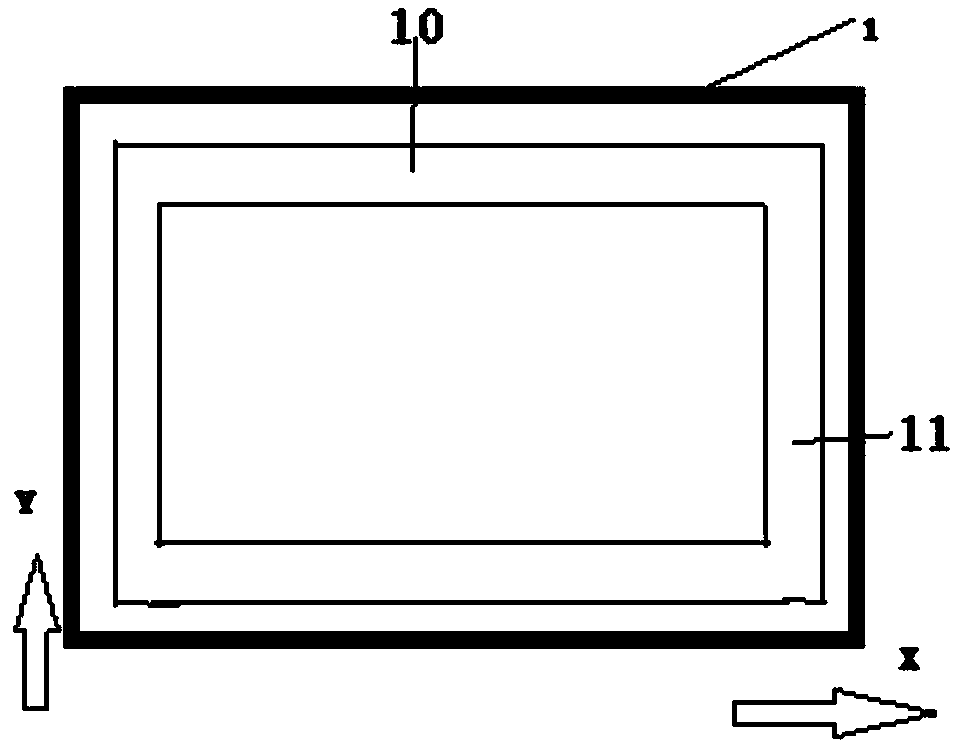

Method for operating at least one precombustion chamber-fired internal combustion engine

InactiveCN103958865AImprove combustion characteristicsBest chemical compositionElectrical controlInternal combustion piston enginesChemical compositionOtto cycle

The invention relates to a method for operating at least one precombustion chamber-fired internal combustion engine (1), in particular a stationary gas Otto cycle engine, having a pilot chamber (2) and a main combustion chamber (3) associated with the precombustion chamber (2), wherein a gas mixture is fed to the precombustion chamber (2) as flushing gas (S), wherein a synthesis gas (R) generated in a fuel reformer (4) and a fuel (B2) from a fuel source are fed to the flushing gas (S) and wherein a fuel (B1) and at least one further substance stream (D, L, A) are fed to the fuel reformer (4) for the reforming process, wherein at least one operating parameter of the at least one internal combustion engine is monitored, wherein in accordance with a change in the at least one operating parameter the chemical composition of the flushing gas (S); is modified by changing the mass stream of the at least one further substance stream (D, L, A).

Owner:GE JENBACHER

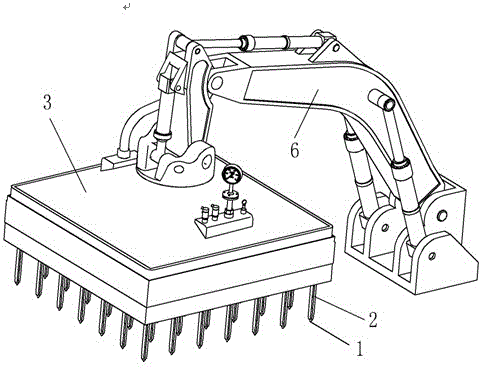

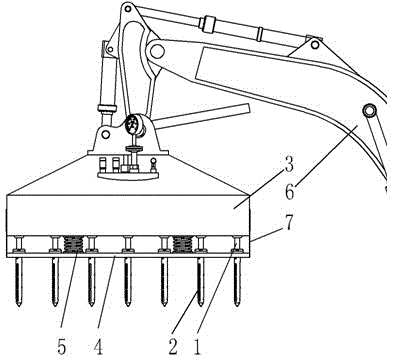

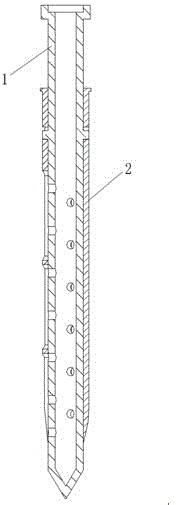

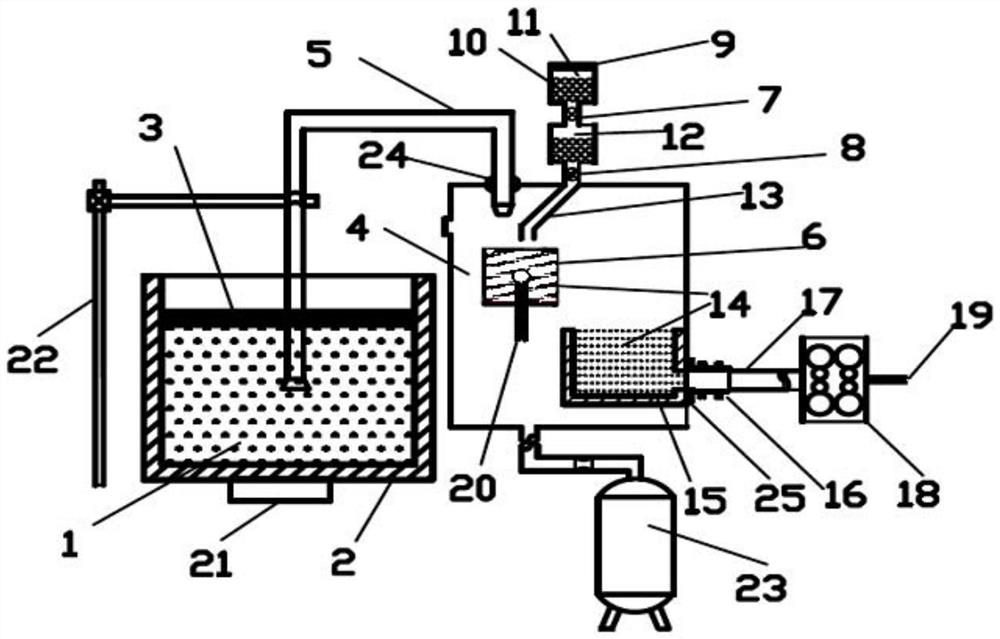

In situ heat injection treatment device of root nematodes in soil

The invention provides an in situ heat injection treatment device of root nematodes in soil. The in situ heat injection treatment device comprises a steam distribution chamber, a heat injection mechanism and a supporting plate, wherein the supporting plate is connected with the steam distribution chamber through an elastic mechanism, and the heat injection mechanism comprises a heat injection pipe and a protecting sleeve; the upper end of the heat injection pipe is fixedly connected to the bottom of the steam distribution chamber and is communicated with the inside of the steam distribution chamber, and the protecting sleeve is rotatably arranged on the supporting plate in situ; the protecting sleeve is sleeved on the heat injection pipe, and the two ends of the heat injection pipe extend out of the protecting sleeve; air outlets are distributed in the wall of the heat injection pipe and a pin shaft is arranged on the heat injection pipe, and air outlet slots are distributed in the wall of the protecting pipe and a spiral slot is arranged in the protecting pipe; the pin shaft in the heat injection pipe is positioned in the spiral slot, and the steam distribution chamber is a sealed container; and a steam inlet is arranged in the steam distribution chamber. The in situ heat injection treatment device provided by the invention has the advantages of simple structure, convenience in operation, low treatment cost and good effects, and effectively kills the root nematodes in soil though steam heat injection in situ.

Owner:孙腾腾

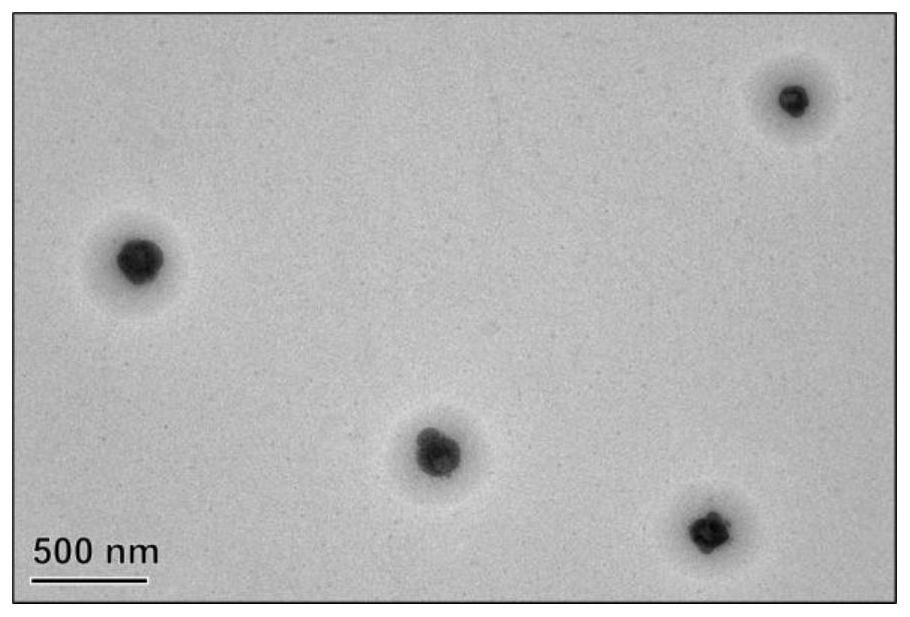

Amphiphobic fluorine-containing nanofluid as well as preparation method and application thereof

The invention relates to an amphiphobic fluorine-containing nanofluid as well as a preparation method and application thereof. The amphiphobic fluorine-containing nanofluid is composed of a nano core material and a polymer shell layer material, the surface of the nano core material is grafted with a coupling agent with double bonds, the polymer shell material is a fluorine-containing polymer, and the invention further provides a preparation method and application of the amphiphobic fluorine-containing nano fluid. The amphiphobic fluorine-containing nanofluid disclosed by the invention has extremely strong wetting reversal capability, can be used for transforming oil reservoirs, can convert the wettability of hydrophilic and oleophylic reservoirs into remarkable amphiphobic property, and effectively solves the liquid lock effect and Jamin effect caused by the wettability of the reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparation method and application of novel cigarette heating spice with smoke regulation and control function

PendingCN113528240AImprove suction qualityRich and full-bodiedTobacco preparationTobacco treatmentBiotechnologyUltrafiltration

The invention belongs to the technical field of heating cigarettes, and particularly relates to a preparation method and application of a novel heating cigarette spice with a smoke regulation and control function. The preparation method comprises the following steps: fermenting a mixed raw material of Zimbabwe flue-cured tobacco and tea leaves by using bacillus at 25-30 DEG C, taking out a fermentation substrate after 5-10 days of fermentation, and extracting the fermentation substrate by using an ethanol solution with the concentration of 60-80wt% to obtain a crude extract; and filtering the crude extract by using an ultrafiltration membrane with the molecular weight of 10,000-30,000 under the conditions of room temperature and operation pressure of 0.16-0.18 MPa to obtain the novel spice. Chemical components of tobacco leaves and tea leaves are changed by utilizing a microbial fermentation technology and a novel extraction and separation technology, and novel precursor-aroma substances are extracted and separated from the chemical components and are added into the heated cigarettes, so that the release amount of harmful substances in smoke of the heated cigarettes is effectively reduced, the smoking quality of the heated cigarettes is improved, and the smoke is rich and full; and miscellaneous gas and wood gas are covered, so that the taste is mellower.

Owner:CHINA TOBACCO YUNNAN IND

Chemical mechanical polishing solution for processing optical surface of Ge-As-Se chalcogenide glass

InactiveCN111040639AReduce the number of defectsDecrease the surface roughness valuePolishing compositions with abrasivesSodium bicarbonatePhosphate

The invention discloses a chemical mechanical polishing solution for processing an optical surface of Ge-As-Se chalcogenide glass. The chemical mechanical polishing solution comprises polishing powder, a chemical corrosion reagent, a pH reagent, a dispersing agent and deionized water, the polishing powder is selected from aluminum oxide, diamond powder and cerium oxide, the chemical corrosion reagent is an alkaline reagent or an oxidizing agent, the alkaline reagent is sodium hydroxide, sodium carbonate, sodium bicarbonate, cyclohexylamine, triethylamine or ethylenediamine, the oxidizing agentis one of hydrogen peroxide, potassium permanganate, ferric chloride and potassium ferrate, the pH reagent is used for ensuring the stable acid-base property of the polishing solution, the acid is selected from sulfuric acid, hydrochloric acid, oxalic acid, acetic acid and citric acid, the alkali is selected from sodium hydroxide, sodium carbonate, sodium bicarbonate, cyclohexylamine, triethylamine and ethylenediamine, and polyphosphate is selected as the dispersing agent and used for improving the dispersity of the polishing powder in turbid liquid. For chalcogenide glass with different components, only the concentration of the chemical corrosion reagent needs to be adjusted in a targeted mode, and universality is achieved.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

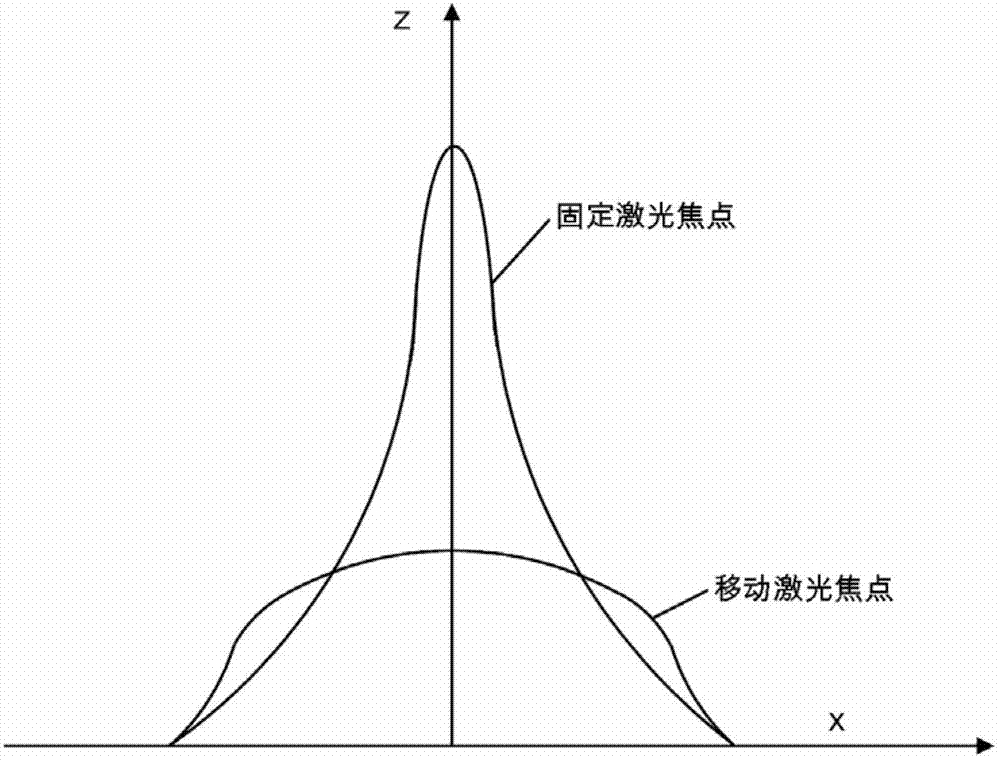

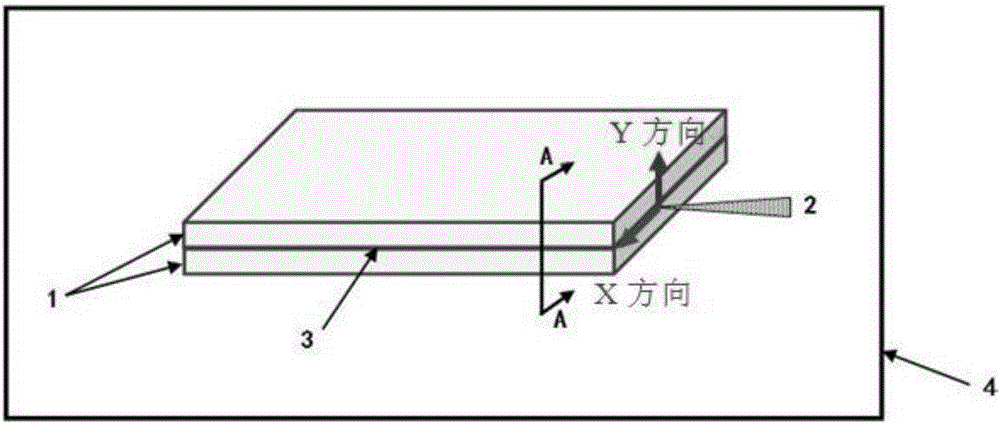

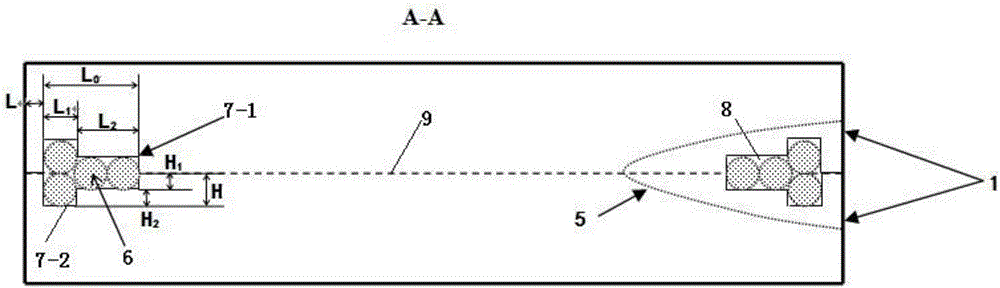

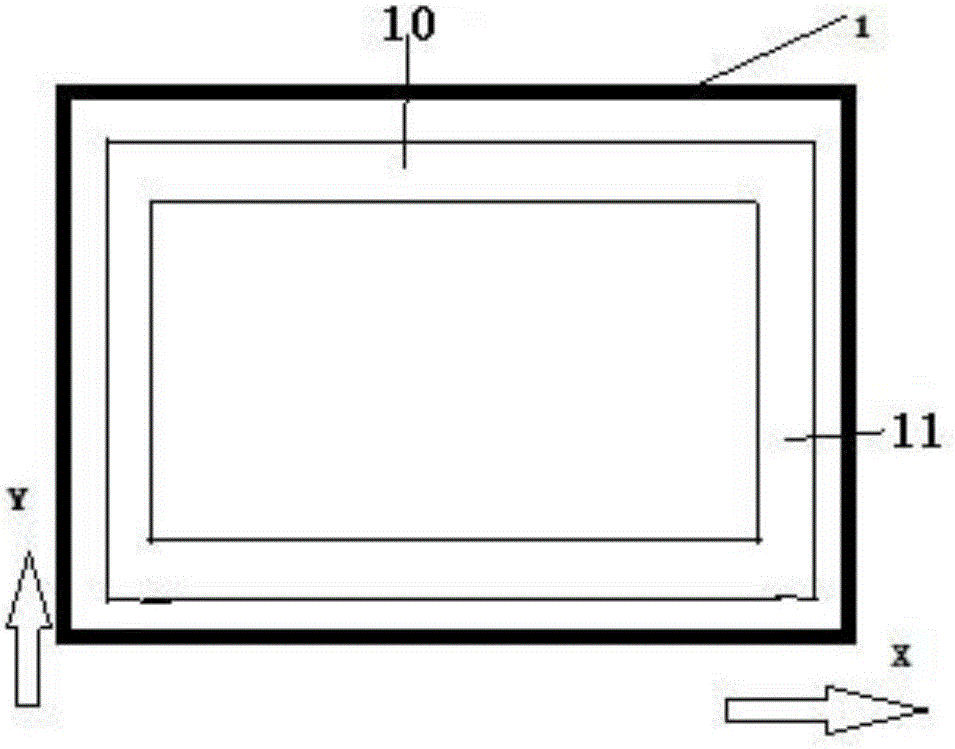

Mobile laser focus-induced pulse micro arc discharge method and application thereof

The invention discloses a mobile laser focus-induced pulse micro arc discharge method and application thereof. According to the method, a tool electrode and a workpiece are used to form an electrode pair; laser pulse is focused on the surface of the workpiece to form a high ionization zone; the tool electrode is induced to discharge towards the high ionization zone; and meanwhile, a laser focus point moves according to the preset frequency and path and a discharge point is induced by the high ionization zone to move along with the laser focus point, so that controllable and ordered motion of the discharge point is realized. According to the method, on the premise of ensuring the setting and distribution of the discharge position, the electric arc pressure is controlled by controlling the scanning area of the laser focus point, so that the relatively-flat workpiece surface is obtained under the same input energy, the later grinding amount is reduced and the effective strengthening depth is increased.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

A kind of pentaerythritol ester base oil and its synthetic method

ActiveCN105219480BChange chemical compositionHigh viscosityBase-materialsPtru catalystCarboxylic acid

The invention provides pentaerythritol ester base oil and a synthesis method thereof. The concrete synthesis method comprises the following steps of adding a catalyst A into pentaerythritol serving as a reaction raw material to carry out self-polymerization reaction to generate pentaerythritol rich in a dipolymer; adding fatty acid or arylcarboxylic acid into pentaerythritol rich in the dipolymer to carry out esterification reaction to obtain a crude product; and deacidifying and decolorizing the crude product to obtain the pentaerythritol ester base oil. The dipolymer of pentaerythritol ester and corresponding esters are introduced to a mixture, so that the viscosity and viscosity-temperature characteristics of the base oil are improved, and the condensation point of the base oil is reduced; and the obtained base oil is particularly suitable for the fields of aircraft engine lubricating oil, gear oil and the like.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Nano composite condom and making method thereof

InactiveCN1154454CChange chemical compositionNo cross infectionMale contraceptivesChemical compositionEmulsion

The present invention relates to a nano compound condom, Every condom contains a solid metal cation carrier material which is formed from (NaAg)2ZrPO4 or (NaNn)2ZrPO4 or (NaCu)2ZrPO4 or their mutually-combined product and whose microparticle size is below 0.1 micrometer and whose weight is 0.01-0.8 of that of emulsion. Its released metal cation can change the chemical composition of bacterial mechanism, and can break the acid protein on which the bacteria depend for existance, can kill AIDS vines and various VD pathogens, and can prevent cross-infection.

Owner:天津市亚马逊科技发展有限公司

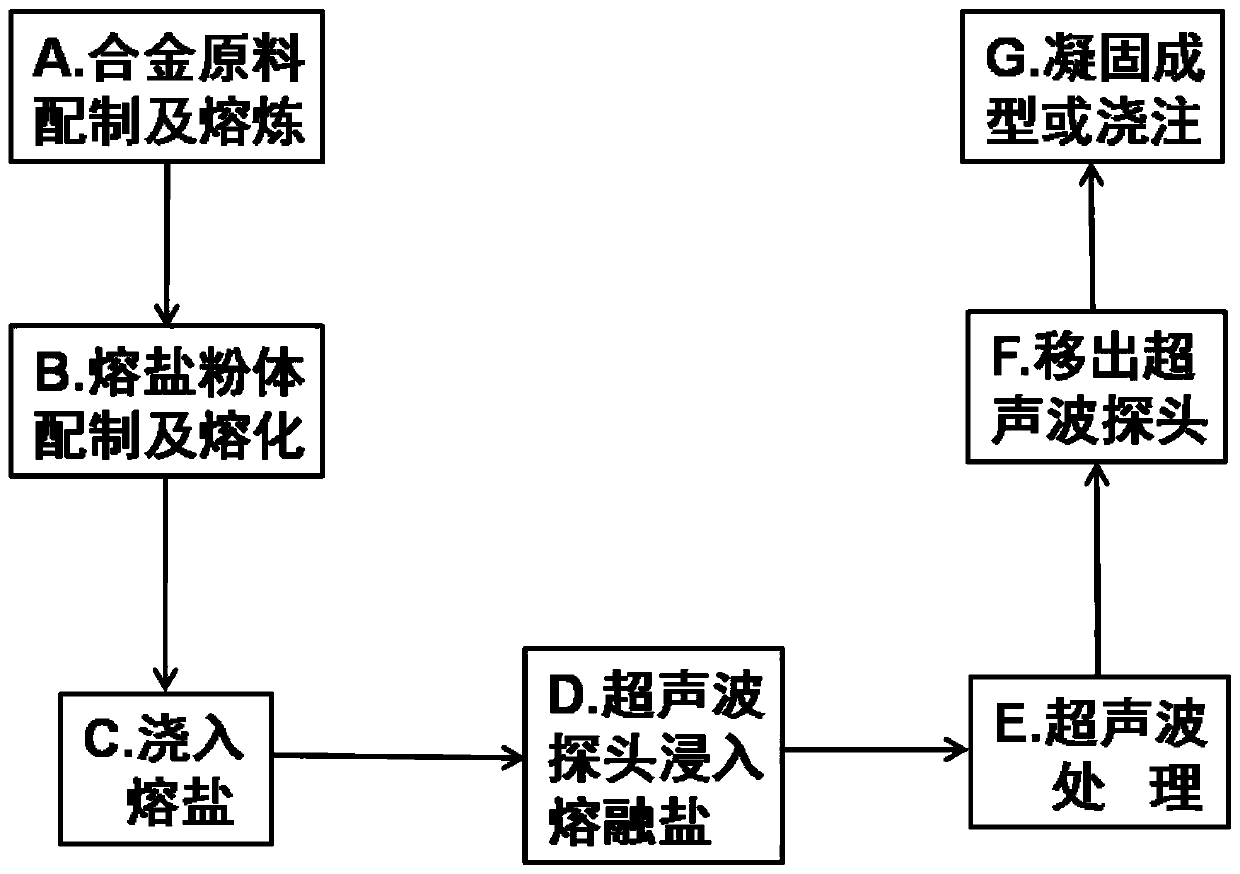

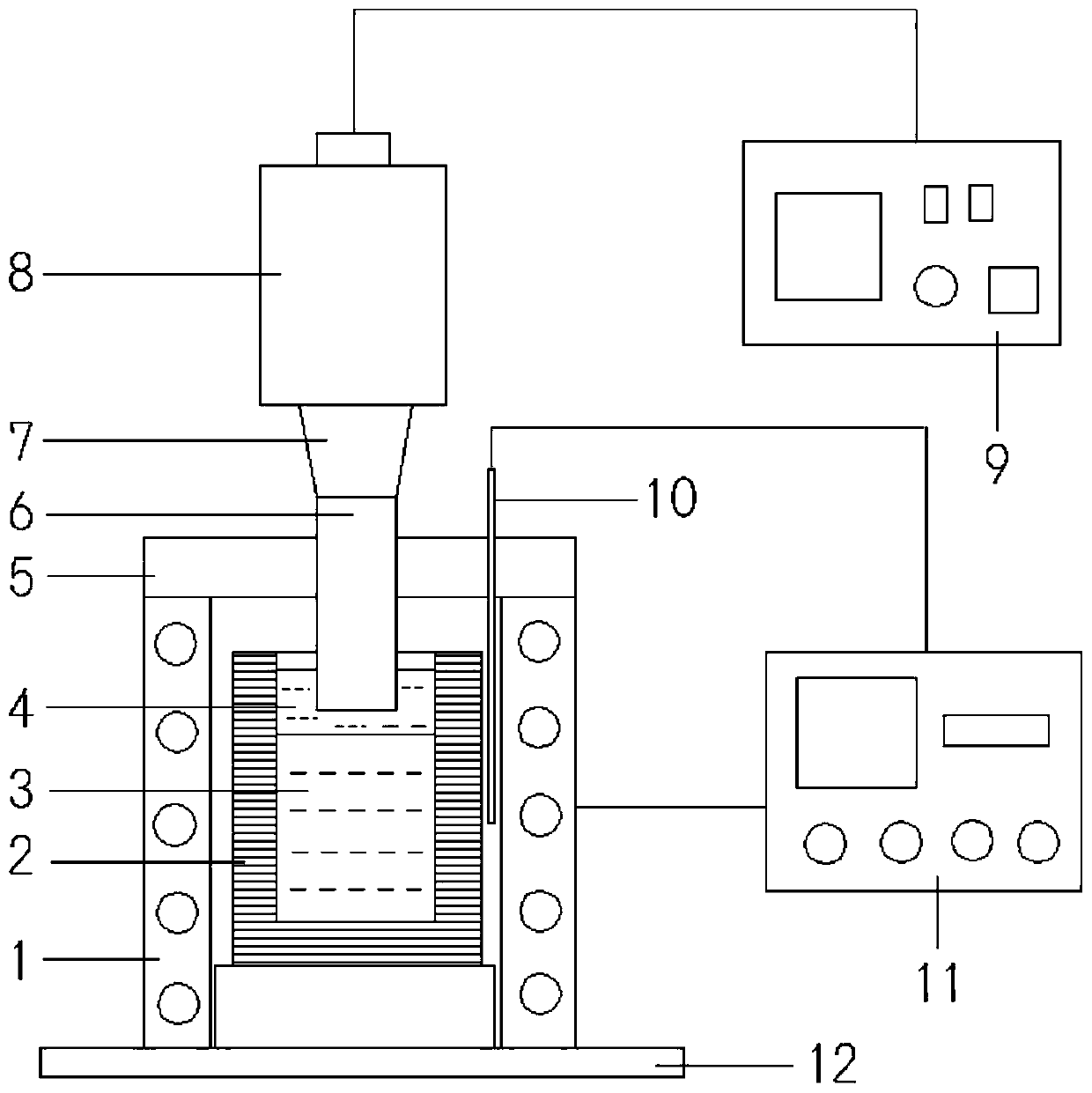

Method for protecting ultrasonic probe

ActiveCN109868371AGood processing effectEasy to operateProcess efficiency improvementCavitationChemical composition

The invention relates to the technical field of liquid processing of materials, in particular to a method for protecting an ultrasonic probe from damage and erosion while realizing indirect treatmentof a metal melt by propagating ultrasonic waves through mixed molten salt (or slag and a fluxing agent). The method comprises the following steps: A, alloy raw materials are prepared and smelted; B, molten salt powder is prepared and melted; C, the molten salt is poured; D, the ultrasonic probe is immersed in the molten salt; E, ultrasonic treatment is conducted; F, the ultrasonic probe is removed; and G, solidification forming or pouring is conducted. According to the technical scheme, the problems that in the prior art, an ordinary ultrasonic probe is very prone to cavitation thermal corrosion, the melt is polluted, the chemical compositions of the melt are changed, and the significance of ultrasonic treatment is lost; and the ultrasonic probe made of metal ceramic is excessively high incost and long in production cycle, is prone to being bumped and damaged, and needs to be fully preheated to avoid explosion due to the over-high temperature, and thus the ultrasonic probe has the requirements for care and cautiousness in operation to avoid damage are solved.

Owner:DALIAN JIAOTONG UNIVERSITY

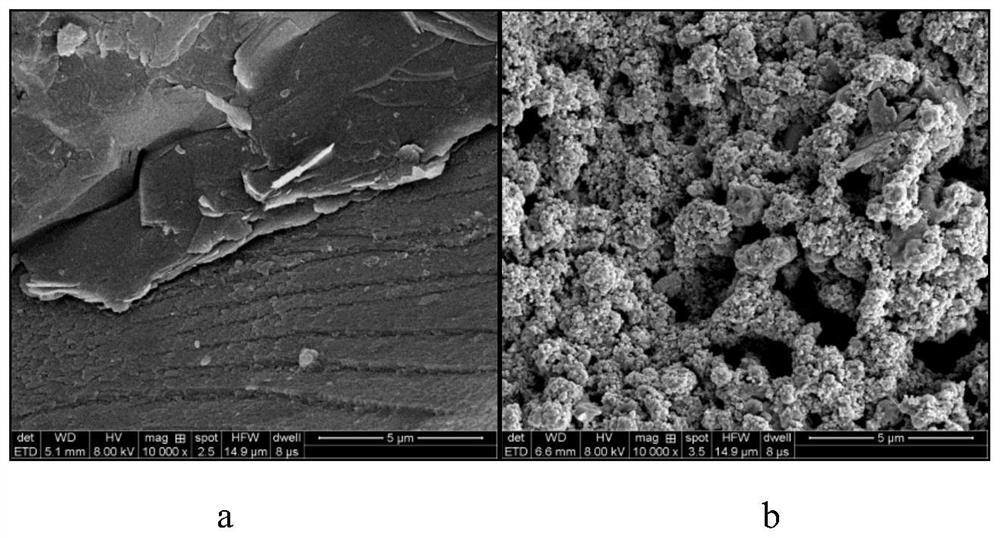

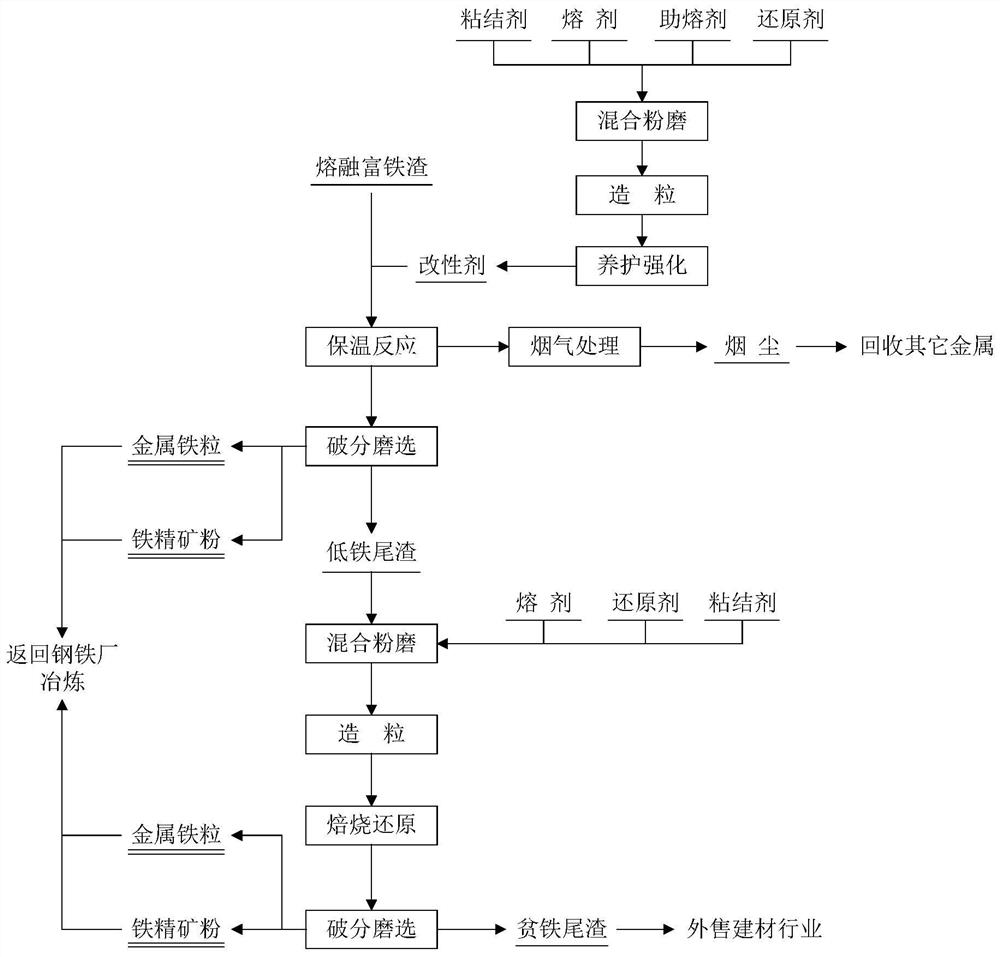

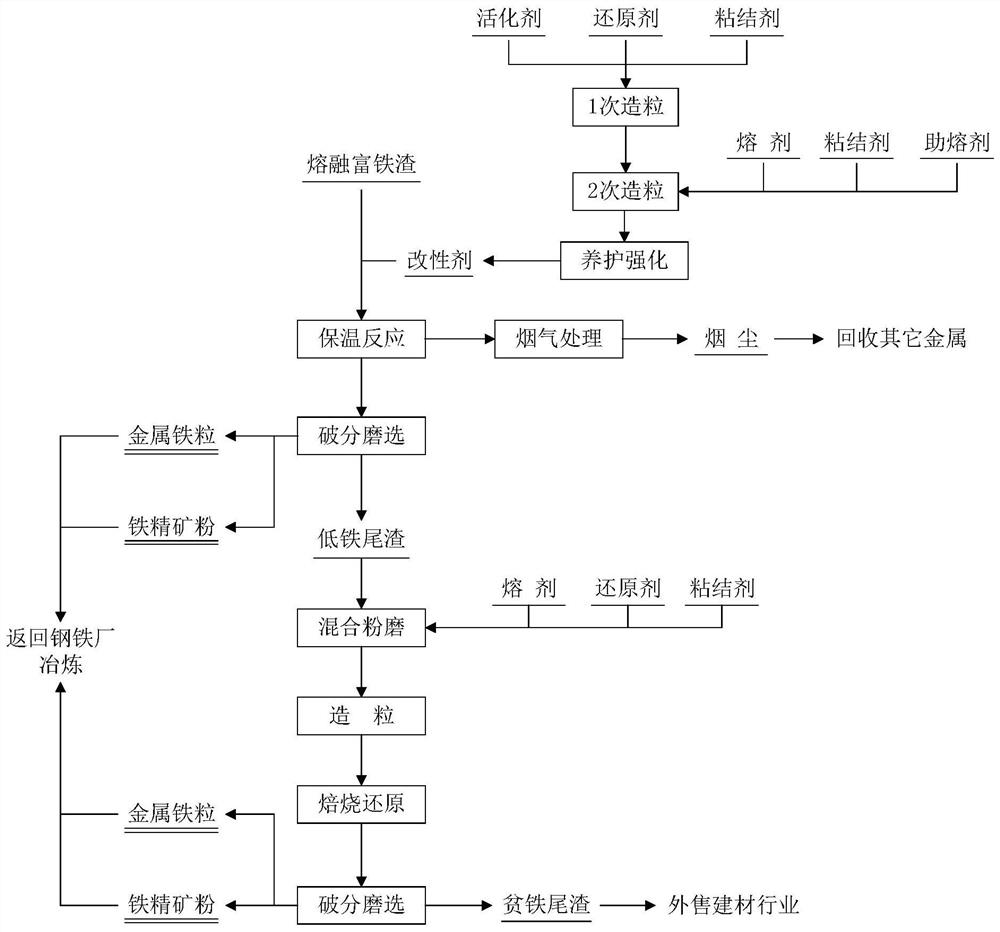

Slag modification reducer and preparation method thereof, and method for Fe recovery with slag waste heat

ActiveCN111763820AChange chemical compositionChange structureSolid waste managementSeparation technologyHeat conservation

The invention discloses a slag modification reducer. The slag modification reducer is shaped like spherical particles with a particle diameter of 10-30 mm and comprises 100 parts by weight of a fusionagent, 5-24 parts by weight of a reduction agent, 8-18 parts by weight of a binder and 0-10 parts by weight of a fluxing agent. The invention also discloses a method for Fe recovery with slag waste heat. The method comprises the following steps: (a) during a course when slag is discharged from a smelting furnace and poured into a heat-preservation container, the slag modification reducer is addedinto a slag flow, and a modified reduction reaction takes place; and (b) after the slag completes the reaction with the modification reducer, solid slag in the heat-preservation container is crushed,and metal Fe particles and / or Fe ore concentrate powder are obtained through magnetic separation. The method aims at the fact that the slag contains a lot of waste heat and residual Fe resources, directly conducts high-temperature waste heat modification of the slag, adjusts chemical components and a smelting temperature of the slag, reduces reduction potential energy of Fe oxides and then uses amiddle-low temperature roasting temperature and a grinding-separation technology to realize efficiency recovery of Fe in the slag.

Owner:CHINA ENFI ENGINEERING CORPORATION

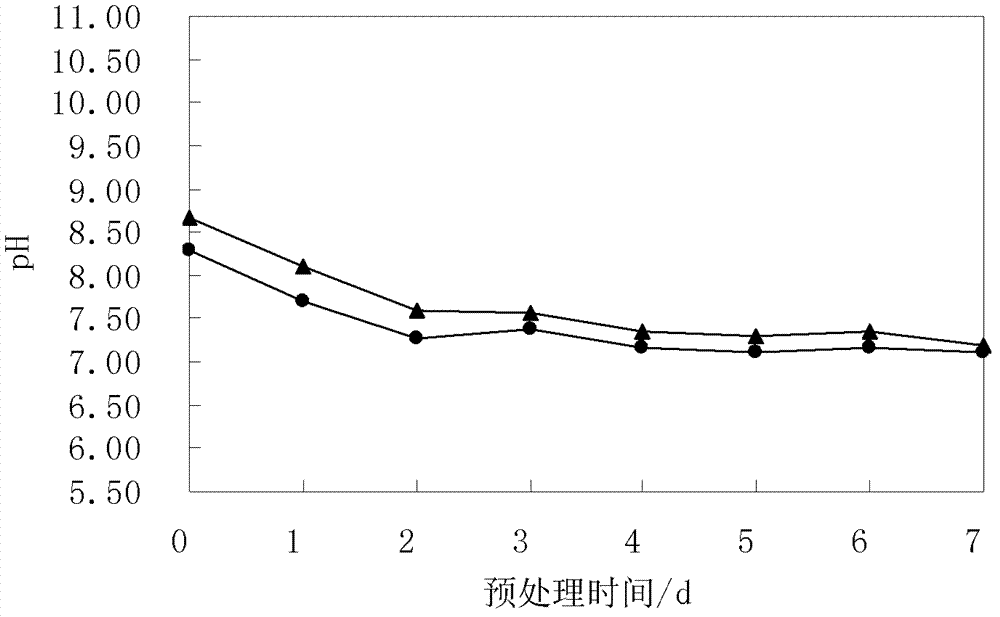

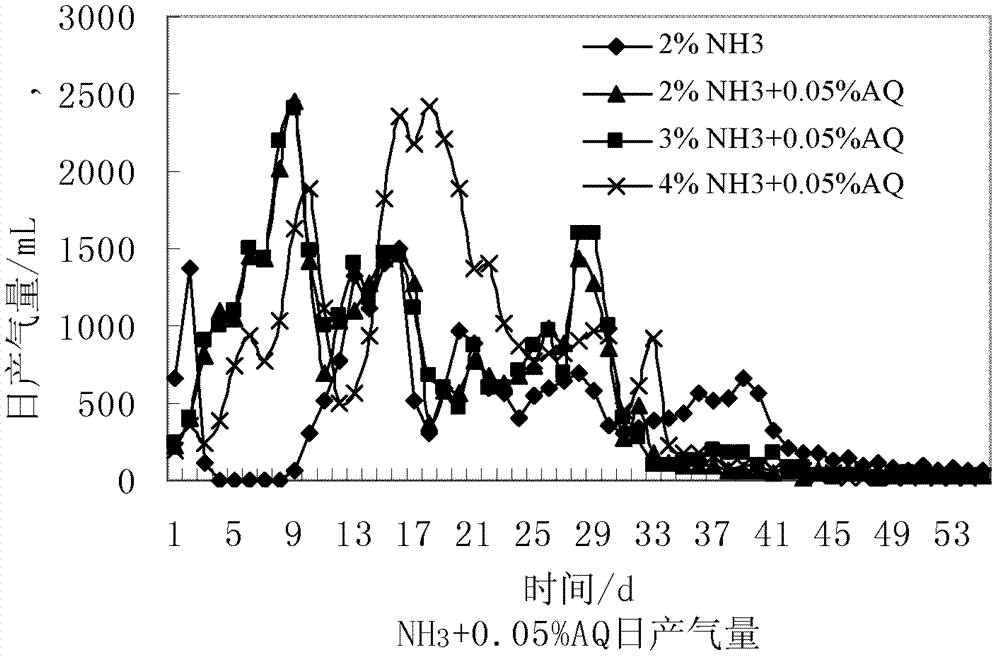

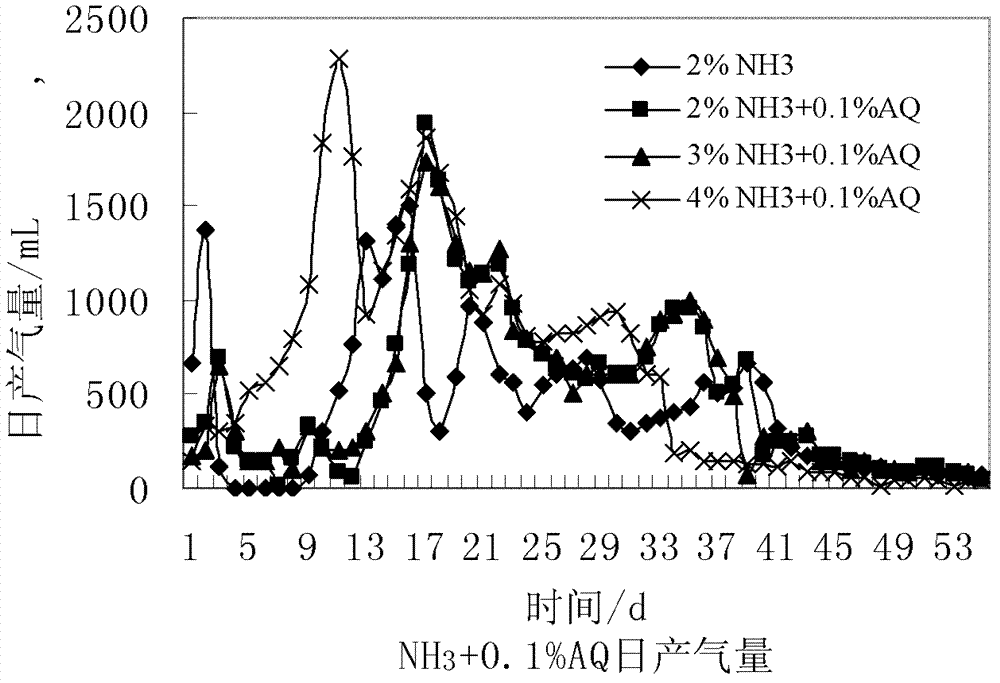

Method for increasing wheat straw anaerobic gas yield through pretreatment of catalysis-ammoniation on wheat straws in solid state at normal temperature

ActiveCN102604998BReduce preprocessing timeDamage structureWaste based fuelFermentationDry weightAmmonia

The invention discloses a method for increasing the wheat straw anaerobic gas yield through pretreatment of catalysis-ammoniation on wheat straws in a solid state at normal temperature. The method comprises the following steps of: mixing an ammonia-containing solution and anthraquinone, adding water of which the weight is less than 2.5 to 5.5 times the dry weight of the wheat straws into the mixture, and fully mixing the mixture and the crushed wheat straws, wherein the mixed wheat straws are still in a wet solid state; storing the mixture for 4 days in a sealed bag at normal temperature, allowing ammonia which carries the anthraquinone to gradually adhere to the surfaces of the wheat straws because the ammonia has volatility, wherein catalysis-ammoniation reaction is performed; and adding the pre-treated wheat straws, inoculation mud and a proper amount of water into an anaerobic digestion reactor to perform anaerobic digestion, wherein the whole anaerobic digestion process lasts for 25 to 35 days. Results show that the gas yield of the wheat straws pre-treated by the method is obviously increased. When the wheat straws pre-treated by the method are compared with the wheat straws pre-treated by ammoniation through only 2 percent of ammonia, the gas yield of unit TS of the wheat straws which are subjected to catalysis-ammoniation through the anthraquinone is 17 to 56.6 percent higher than that of the wheat straws which are not subjected to catalysis-ammoniation through the anthraquinone, the anaerobic digestion time is shortened by 41.42 percent, and the content of the efficient component methane in the biogas is improved by about 3 to 10 percent, so that the production efficiency of the anaerobic digestion reactor is improved.

Owner:BEIJING UNIV OF CHEM TECH

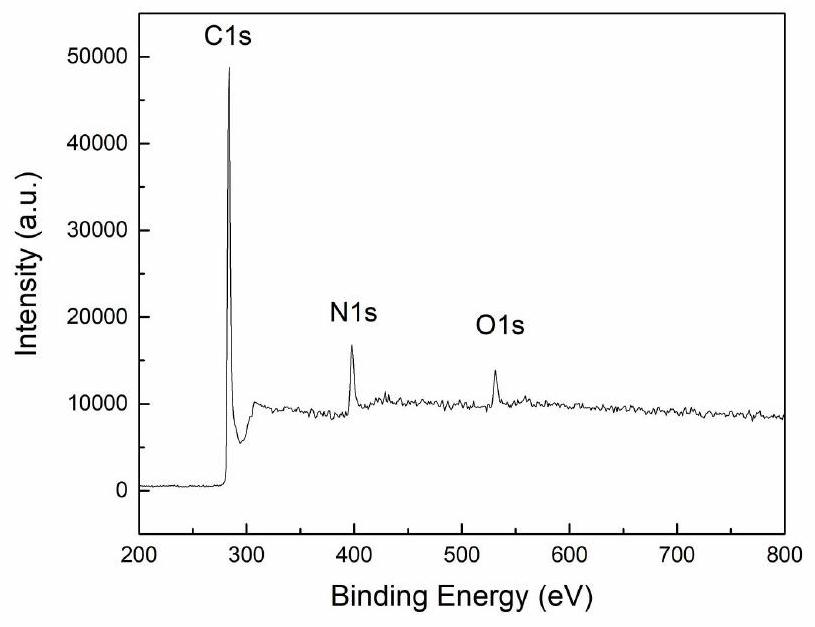

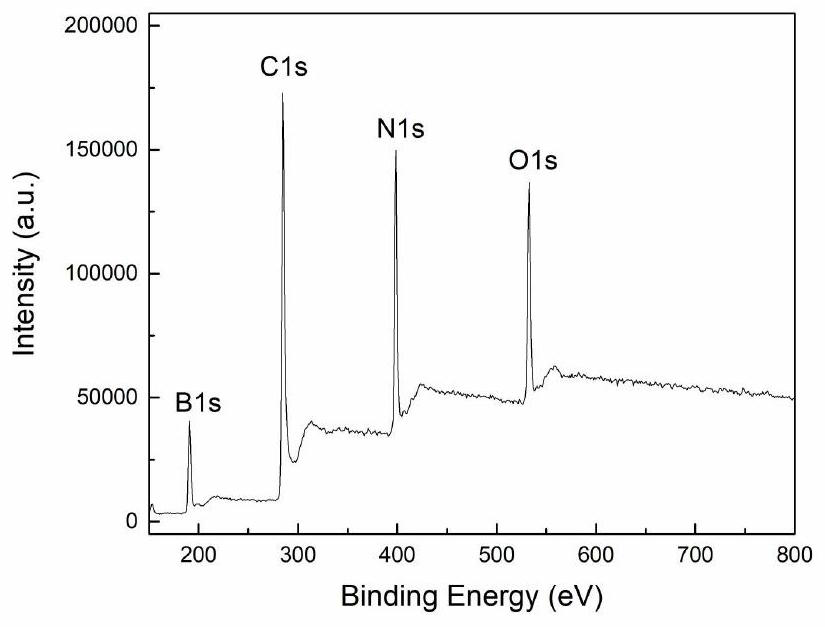

A kind of nano enzyme, preparation method and application thereof

ActiveCN111517318BImplement new applicationsGood dispersionPhysical/chemical process catalystsGraphiteCombinatorial chemistryEnzyme catalysis

The invention discloses a nanozyme, a preparation method and its application, and belongs to the technical field of nanozyme catalysis, and solves the problem that the original graphyne is not used in the field of simulated enzyme catalysis in the prior art, and the catalytic activity of the simulated enzyme of the original graphyne is low. . The material of the nanozyme of the present invention contains graphyne, and the preparation method of the nanozyme comprises: step 1, preparing graphyne oxide; step 2, modifying graphyne oxide to obtain nitrogen-doped graphyne nanozyme or boron-nitrogen doped graphyne nanozyme. The nanozyme of the invention has high catalytic performance and wide application range.

Owner:北京高能科迪科技有限公司

Welding stick embedding vacuum electron beam welding method

InactiveCN106513974AIncrease energy densityHigh penetrationElectron beam welding apparatusWelding/soldering/cutting articlesMolten bathHigh energy

The invention provides a welding stick embedding vacuum electron beam welding method. A low-carbon welding stick is embedded in an initial weldment, and two continuous casting sheet billets are stacked and welded together through an electron beam in the vacuum environment and then are used for subsequent steel rolling production. The low-carbon welding stick is embedded, chemical components of a molten bath can be finely adjusted, a peritectic reaction area is avoided, and welding crack sensitivity of base metal is reduced. Compared with self-fluxing vacuum electron beam welding, the beneficial effects of high-energy density, high penetration performance, the small welding deformation area, easy control, the high production efficiency and the like of self-fluxing vacuum electron beam welding can be kept, meanwhile, the assembling precision during butt welding can be obviously improved, welding line formation is improved, and the mechanical performance of connectors is improved. By means of the method, the problem that a self-fluxing vacuum electron beam welding method is adopted in crack sensitivity steel grade welding, welding cracks happen is solved, the application range of vacuum electron beam welding is greatly enlarged, the method is suitable for mass industrial production, and obvious economical and social benefits are achieved.

Owner:TIANJIN UNIV

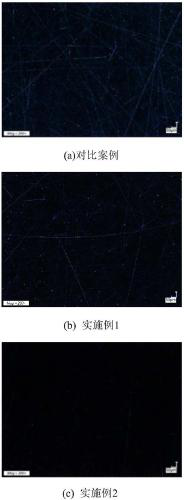

Composite membrane material and preparation method thereof

PendingCN114457580AReduce quality problemsHigh tensile strengthFibre typesSynthetic resin layered productsTextile fiberPolymer science

The invention relates to a composite membrane material and a preparation method thereof, and belongs to the technical field of building membrane materials. The material consists of a fabric containing UHMWPE (Ultra High Molecular Weight Polyethylene) fibers subjected to surface modification treatment, a macromolecular coupling agent and a thermoplastic resin adhesive film, the surface modification treatment method is a plasma treatment method or a corona treatment method. The preparation method comprises the following steps: carrying out surface modification treatment on UHMWPE (Ultra High Molecular Weight Polyethylene) fibers or a fabric only formed by the UHMWPE fibers, immersing in a polymer coupling agent emulsion, and drying; other textile fibers and the UHMWPE fibers are jointly woven into a fabric, and the fabric and the thermoplastic resin adhesive film are subjected to hot-pressing compounding. Or the fabric only formed by the UHMWPE fibers and the thermoplastic resin adhesive film are subjected to hot-pressing compounding. According to the method, the surface inertness and hydrophobicity of the UHMWPE fiber are improved, and the UHMWPE fiber is compounded with a thermoplastic resin adhesive film.

Owner:北京理工艾尔安全科技有限公司 +1

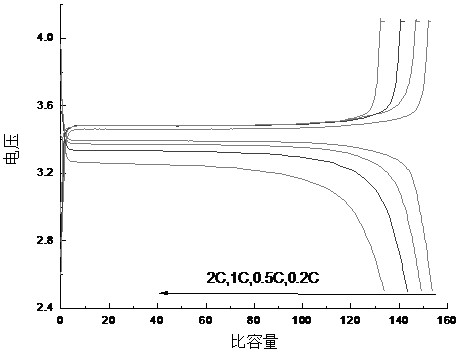

A method for directly repairing lithium iron phosphate waste powder by fire method to prepare battery-grade lithium iron phosphate

ActiveCN109256595BAvoid pollutionEasy to recyclePhosphatesCell electrodesLithium iron phosphateIron removal

Owner:ZHUZHOU SMELTER GRP

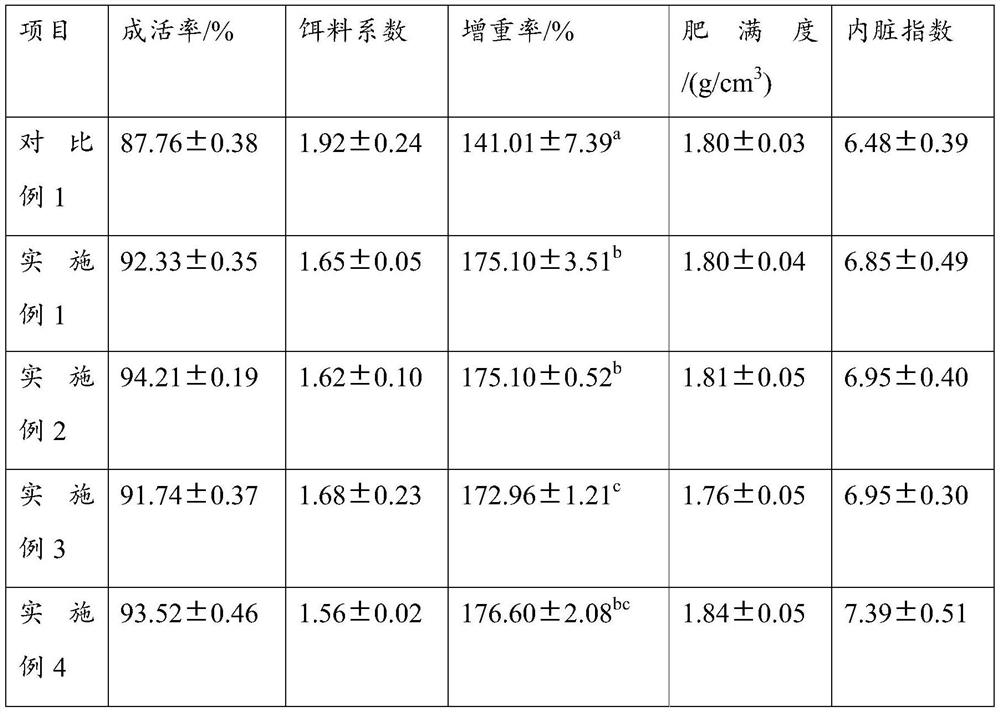

Preparation method and application of grass carp fermented soft particles based on lactobacillus

PendingCN114304440AChange chemical compositionAdd lessFood processingAnimal feeding stuffIntestinal microorganismsNutrition

The invention belongs to the technical field of aquaculture, and discloses a preparation method and application of lactobacillus-based grass carp fermented soft granules, the preparation method comprises the following steps: mixing and stirring probiotics, dendrobium nobile pulp and high fructose corn syrup, fermenting to obtain fermented dendrobium nobile, adding basic granules, and stirring to obtain a fermented mixture; and mixing the vinasse yeast culture and the fermentation mixture, adding photosynthetic bacteria, carrying out sunshine heating, and adding sodium carboxymethyl cellulose for bonding to obtain the grass carp fermented soft particles. According to the invention, basic feed components are firstly granulated, then vinasse yeast culture is added, and the vinasse yeast culture contains substances such as a culture medium and nutritive salt capable of providing nutrition for an organism, and also contains functional growth factors and substances with a function of enhancing immunity; and then through the combined action with bile acid in the basal feed, the abundance of specific types of intestinal microorganisms in the body is changed, and the addition amount of other substances, such as corn and wheat, can be reduced.

Owner:佛山市顺德区活宝源生物科技有限公司

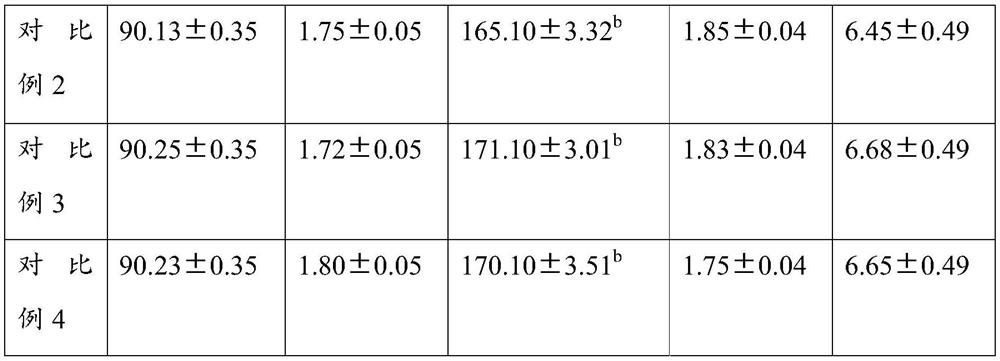

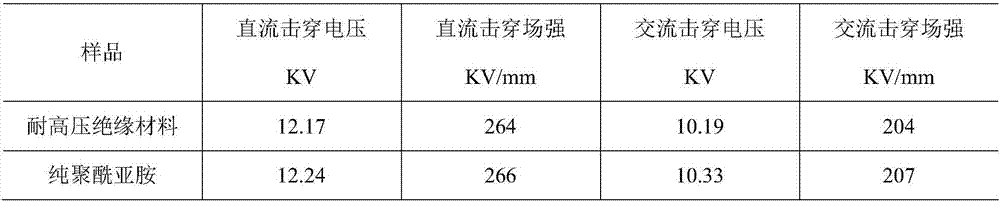

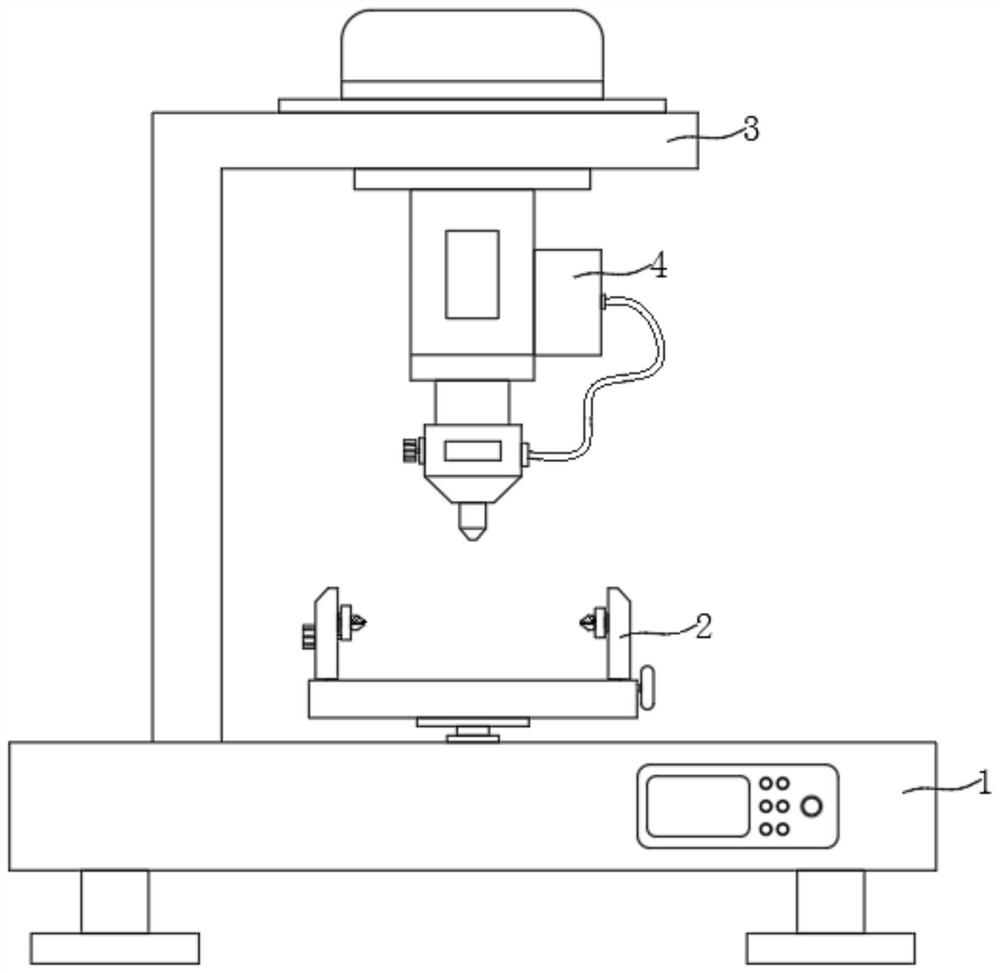

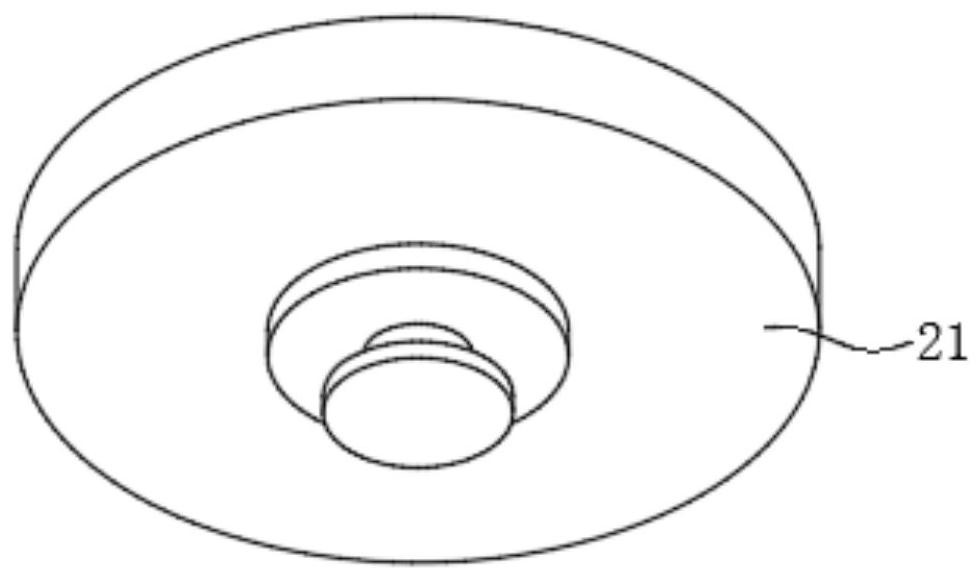

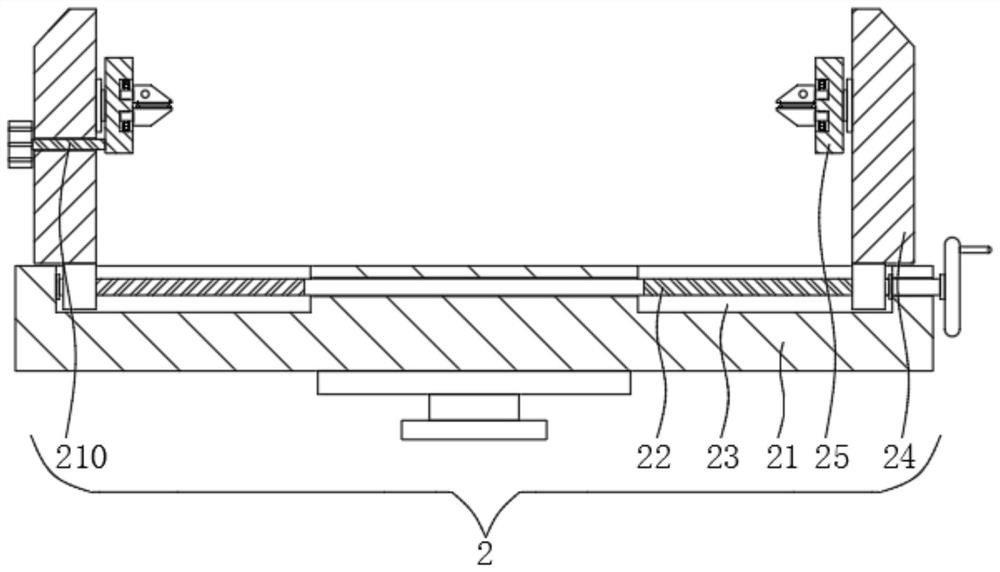

High-voltage-resistant insulation material and preparation method thereof

The invention relates to a high-voltage-resistant insulation material and a preparation method thereof, and belongs to the field of insulation material preparation. The high-voltage-resistant insulation material is mainly prepared from the following raw materials in parts by weight: 15 to 30 parts of trimellitic anhydride, 20 to 30 parts of 5-norbornene-2,3-dicarboxylic monomethylester, 30 to 70 parts of N-methyl pyrrolidone, 10 to 20 parts of xylene, 15 to 30 parts of N,N-dimethylacetamide, 5 to 10 parts of phenol, 20 to 100 parts of 4,4'-diphenylmethane diisocyanate, 0.5 to 10 parts of modified nanometer particles and 0.5 to 10 parts of modified fiber. The high-voltage-resistant insulation material has the advantages that the high-voltage-resistant performance is unchanged; the corona-resistant capability and the ablation-resistant capability are improved.

Owner:HARBIN UNIV OF SCI & TECH

A laser remanufacturing method for power lithium battery of heavy-duty equipment

ActiveCN113097581BReduce maintenance costsHigh strengthCell electrodesFinal product manufactureBattery cellLithium battery

The invention provides a laser remanufacturing method of a power lithium battery for heavy-duty equipment. The laser remanufacturing method of the lithium battery for heavy-duty equipment includes the following steps: S1. Place the damaged lithium battery for heavy-duty equipment in a battery dismantling device, so that the lithium battery casing is separated from the lithium battery body. The invention provides a laser remanufacturing method for power lithium batteries of heavy-duty equipment, which mainly uses laser surface alloying technology and laser cladding technology to respectively repair the bent pole plate and cracked pole plate, and repair the damaged pole plate, Complete the maintenance of the entire lithium battery, try to avoid direct replacement of new plates, make full use of the limited plates, and avoid waste of resources. For manufacturers who are used for many lifting assemblies at the same time, it greatly saves the maintenance of lithium batteries After repairing, a new surface alloy layer based on the original base material is formed, which greatly increases the overall strength of the plate.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

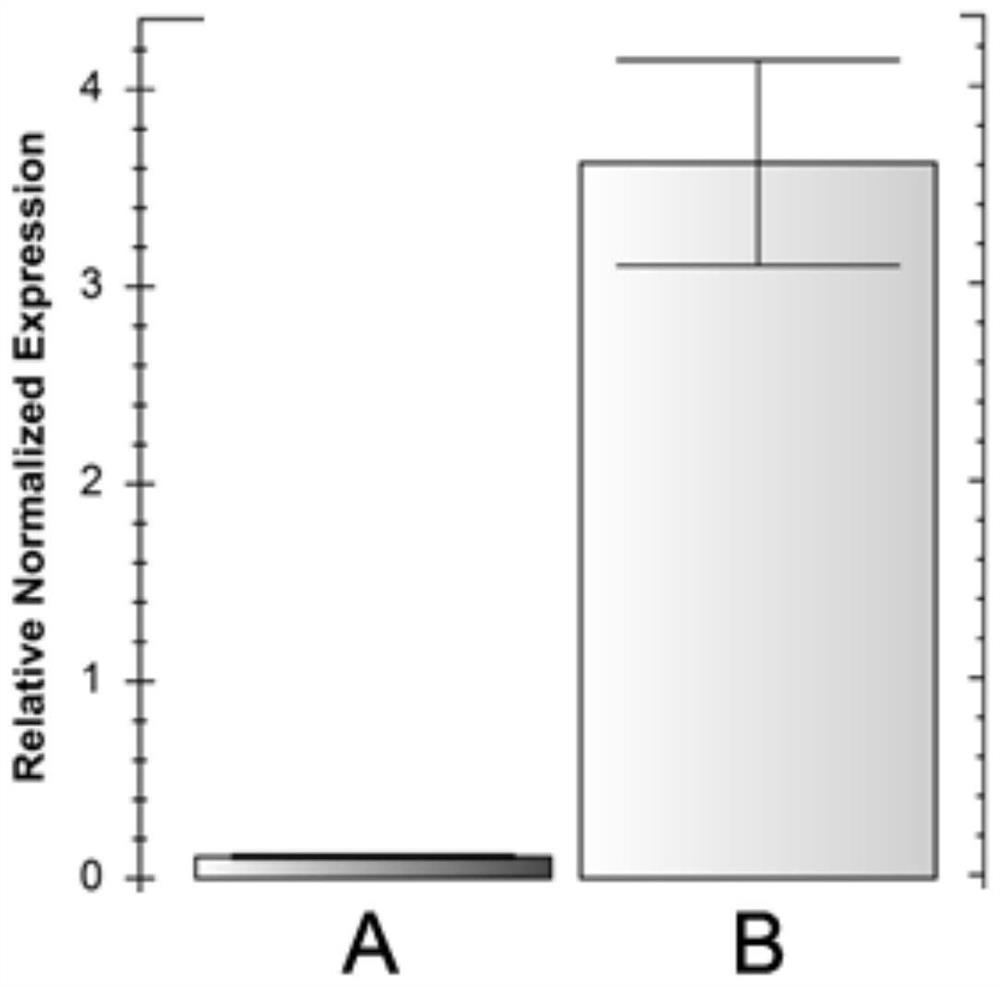

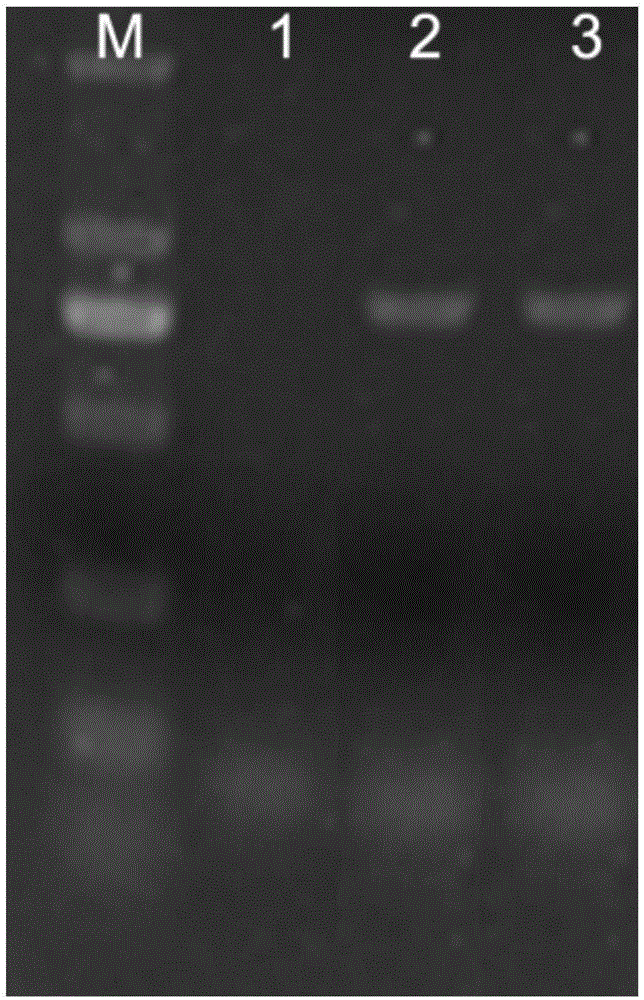

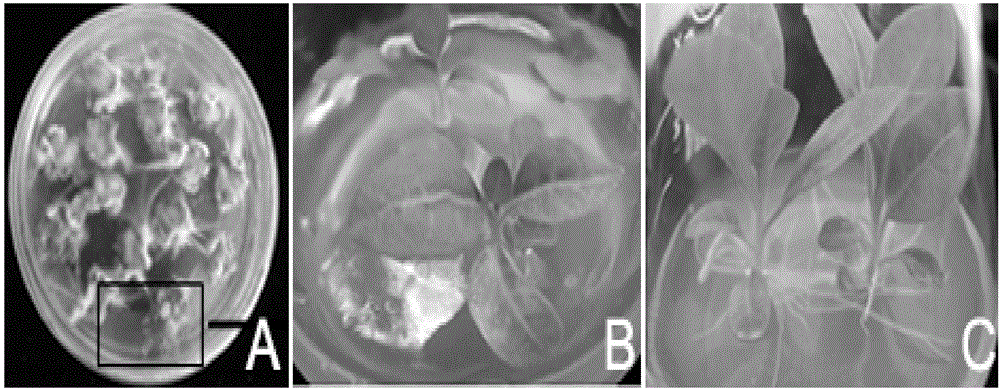

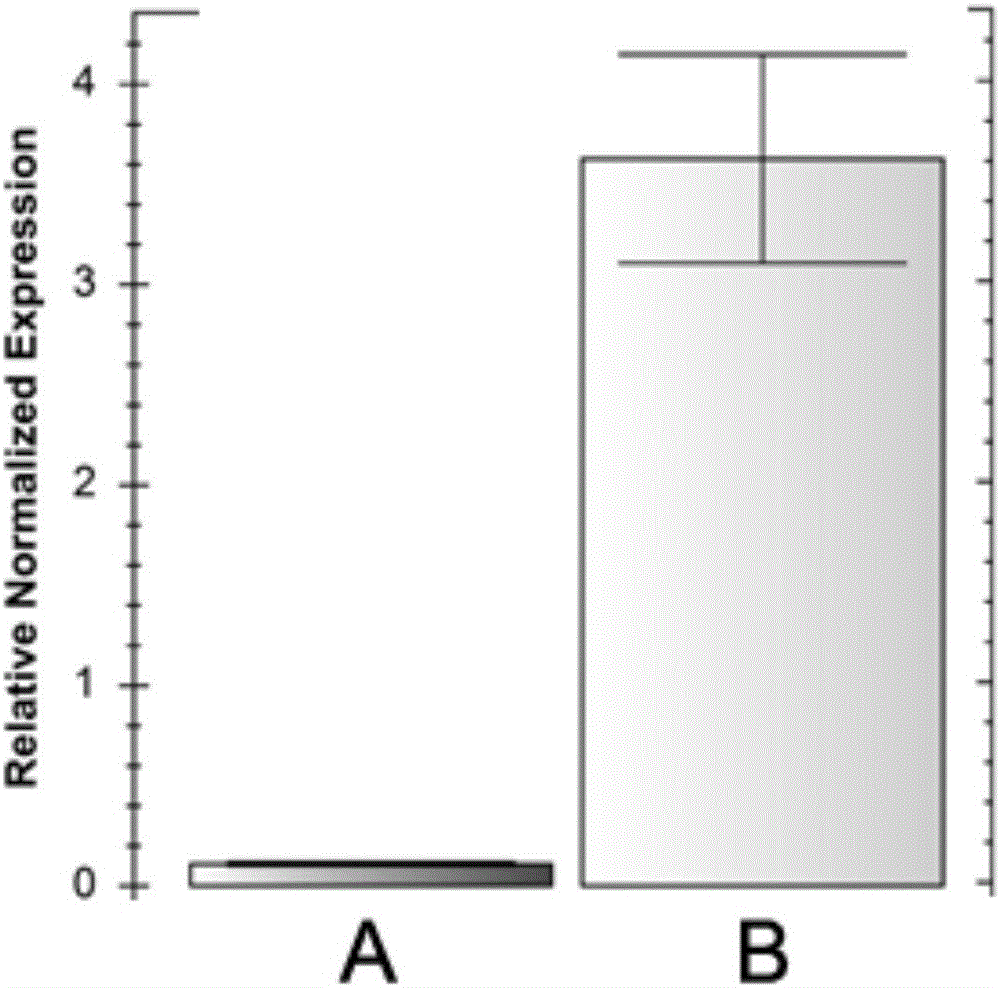

Application of Tobacco C2H2 Zinc Finger Protein Gene nt540

The invention discloses application of a tobacco C2H2-type zinc finger protein gene Nt540. A gene fragment with a nucleotide sequence shown as SEQ ID NO.1 is provided. The invention further discloses a recombinant vector comprising the gene fragment, a recombinant strain and application of the recombinant vector and the recombinant strain. Through transfer of the gene Nt540 and the recombinant strain, the tobacco quality is improved effectively, novel materials and novel approaches are provided for tobacco variety improvement, and accordingly such application has a promising application prospect.

Owner:GUIZHOU TOBACCO SCI RES INST +1

A Vacuum Electron Beam Welding Method of Pre-embedded Welding Wire

InactiveCN106513974BLow susceptibility to weld cracksImprove mechanical propertiesElectron beam welding apparatusWelding/soldering/cutting articlesButt weldingHigh energy

The invention provides a welding stick embedding vacuum electron beam welding method. A low-carbon welding stick is embedded in an initial weldment, and two continuous casting sheet billets are stacked and welded together through an electron beam in the vacuum environment and then are used for subsequent steel rolling production. The low-carbon welding stick is embedded, chemical components of a molten bath can be finely adjusted, a peritectic reaction area is avoided, and welding crack sensitivity of base metal is reduced. Compared with self-fluxing vacuum electron beam welding, the beneficial effects of high-energy density, high penetration performance, the small welding deformation area, easy control, the high production efficiency and the like of self-fluxing vacuum electron beam welding can be kept, meanwhile, the assembling precision during butt welding can be obviously improved, welding line formation is improved, and the mechanical performance of connectors is improved. By means of the method, the problem that a self-fluxing vacuum electron beam welding method is adopted in crack sensitivity steel grade welding, welding cracks happen is solved, the application range of vacuum electron beam welding is greatly enlarged, the method is suitable for mass industrial production, and obvious economical and social benefits are achieved.

Owner:TIANJIN UNIV

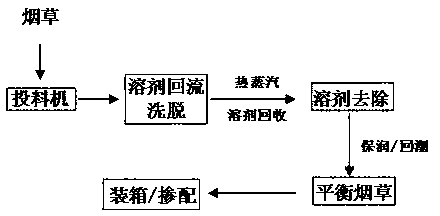

Technology for reducing harmful ingredients in smoke

The invention relates to a technology for reducing harmful ingredients in smoke. The technology comprises processes as follows: step one, backflow elution of tobacco: a used solvent is normal hexane or 95% ethanol, and the tobacco is subjected to backflow elution for 10-60 minutes; step two, solvent recovery: the solvent on the tobacco is removed by using superheated steam; and step three, tobacco structure repairing: glycerin or propylene glycol is mixed with water or ethyl alcohol to prepare a repairing solution, the use amount of glycerin or propylene glycol is 1%-15% of tobacco in percentage by weight, and the repairing solution is uniformly sprayed on the tobacco for repairing for 2-72 hours. According to a cigarette prepared by tobacco treated by the technology, the harmful ingredients in the smoke can be remarkably reduced, and the safety of the cigarette is guaranteed.

Owner:YUNNAN RES INST OF TOBACCO SCI

Application of tobacco C2H2-type zinc finger protein gene Nt540

The invention discloses application of a tobacco C2H2-type zinc finger protein gene Nt540. A gene fragment with a nucleotide sequence shown as SEQ ID NO.1 is provided. The invention further discloses a recombinant vector comprising the gene fragment, a recombinant strain and application of the recombinant vector and the recombinant strain. Through transfer of the gene Nt540 and the recombinant strain, the tobacco quality is improved effectively, novel materials and novel approaches are provided for tobacco variety improvement, and accordingly such application has a promising application prospect.

Owner:GUIZHOU TOBACCO SCI RES INST +1

Pills capable of strengthening muscles and bones and increasing height and preparing method and application thereof

InactiveCN109731050ADysplasiaHave a curative effectHeavy metal active ingredientsMetabolism disorderDiseaseMYRRH TINCTURE

The invention relates to the technical field of traditional Chinese medicine and health-care products, in particular to pills capable of strengthening muscles and bones and increasing height and a preparing method and application thereof. The pills capable of strengthening muscles and bones and increasing height are prepared from prepared rhizome of rehmannia, fructus lycii, myrrh, cortex acanthopanacis, frankincense, radix morindae officinalis, cortex lycii radicis, radix dipsaci, cortex eucommiae, rhizoma drynariae, cornua cervi pantotrichum, radix achyranthis bidentatae, flowers carthami, white poria and native copper. According to the pills capable of strengthening muscles and bones and increasing height, main medicine and subsidiary medicine are combined, and child retardation of walking, dysplasia, weakness and inability, and limitation to muscle and bone stretching and other congenital diseases caused by bad factors, undernutrition or acquired susceptibility to diseases can be effectively treated.

Owner:朱彤

A kind of rare earth aluminum alloy production device for metallurgy

ActiveCN110777274BPrevent oxidationChange chemical compositionMetal rolling arrangementsRare-earth elementVacuum chamber

The invention discloses a rare-earth aluminum alloy production device for metallurgy, which comprises an aluminum bag and a vacuum chamber connected in sequence, wherein the aluminum liquid is stored in the aluminum bag, the guide tube is connected to the aluminum liquid and the vacuum chamber, and electromagnetic induction heating is arranged in the vacuum chamber For the container, there is a feeding bin for rare earth bulk materials above the vacuum chamber, and a continuous casting buffer container is provided at the outlet of the electromagnetic induction heating container in the vacuum chamber, and the continuous casting buffer container is connected with the continuous casting machine and the rolling unit outside the vacuum chamber in turn. The invention realizes the feeding of the aluminum element and the rare earth element in a vacuum environment, and solves the phenomenon that the aluminum element and the rare earth element are easy to absorb gas and oxidize. The rare earth wire produced by the device has the characteristics of easy storage and strong process adaptability.

Owner:山东钢铁集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com